Agricultural machine for producing edible powder

A kind of agricultural machinery and powder technology, which is applied in the field of agricultural machinery for edible powder production, can solve the problems of difficulty in ensuring the accuracy of feeding volume, high labor intensity of staff, and improvement of processing efficiency, so as to shorten the processing cycle, humanize the design, The effect of cohesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0055] Such as figure 1 As shown, this embodiment discloses a cornmeal production and processing system, which includes a corn cob processing device, a corn kernel crushing device, a powder mixing device, and a powder running device in sequence from front to back according to the technological process.

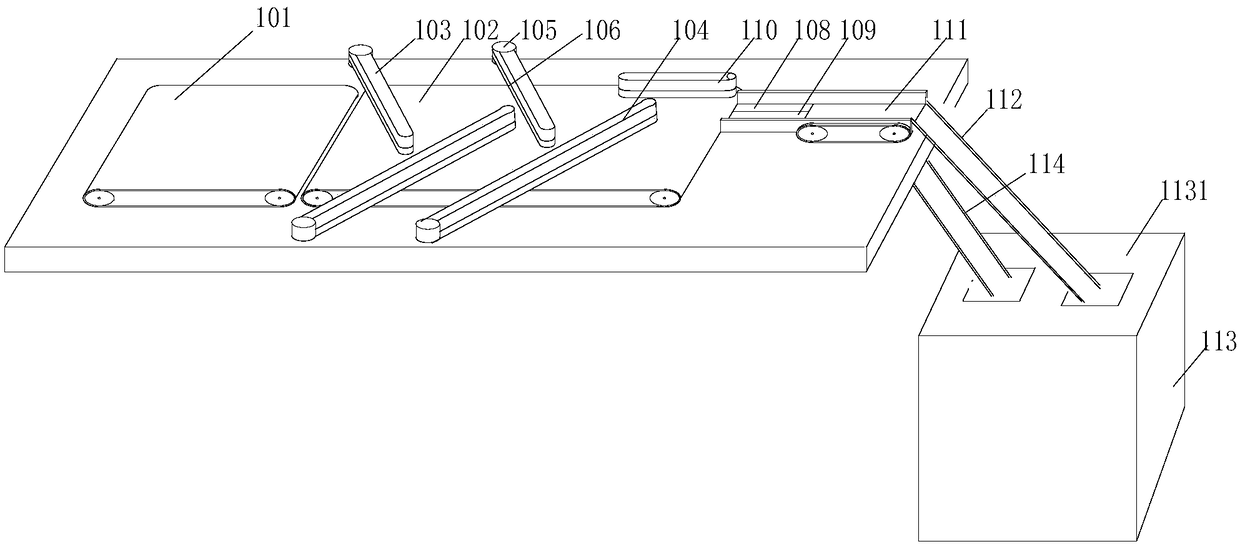

[0056] Such as figure 2 As shown, the corn cob processing device includes a feeding unit and a processing unit; the feeding unit includes a steering mechanism and a lane separation mechanism; the steering mechanism is used to transport corn cobs, and during the transmission process, the corn cobs are turned over until the axial direction of the corn cobs is consistent with the transmission direction ; The lane-dividing mechanism is connected end to end with the steering mechanism, and the lane-dividing mechanism is used to divide the corn cobs into upper and lower paths, and send them downward into the processing unit.

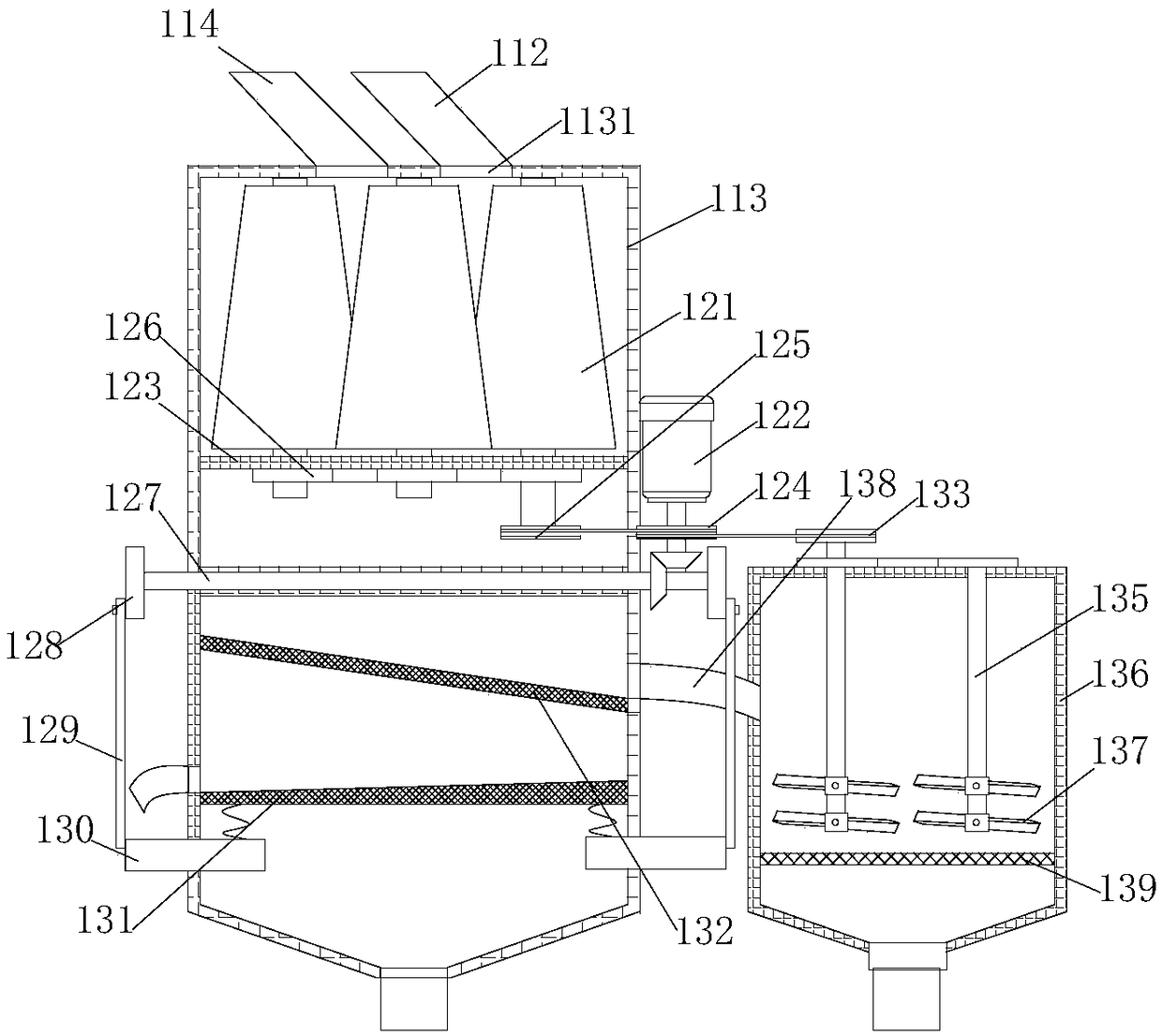

[0057] Such as image 3 As shown, the processing unit...

Embodiment 2

[0067] Such as figure 2 As shown, the difference between this embodiment and the above-mentioned embodiments is that the steering mechanism includes a first conveyor belt 102, at least two pairs of guide assemblies, and a third guide member 110; the guide assemblies are arranged horizontally along the conveying direction of the first conveyor belt 102, each Each guide assembly includes a first guide 103 and a second guide 104, the front end of the first guide 103 and the front end of the second guide 104 are respectively arranged on both sides of the first conveyor belt 102, the rear of the first guide 103 end and the rear end of the second guide 104 are all arranged above the first conveyor belt 102, the rear end of the second guide 104 is close to the rear end of the first conveyor 102 relative to the rear end of the first guide 103, and the first guide 103 and the second guide 104 are formed with an opening for the passage of corn cobs; the front end of the third guide 110...

Embodiment 3

[0070] Such as figure 2 As shown, the difference between this embodiment and the above-mentioned embodiments is that the front side of the first conveyor belt 102 is provided with a second conveyor belt 101 or a feeding plate that is inclined and the rear end is close to the working surface of the first conveyor belt 102; the first guide 103 , the second guide 104 and the third guide 110 are plate-like structures, the lower ends of the first guide 103, the second guide 104 and the third guide 110 are all rotatably connected with guide belts 106, and guided by the guide motor 105 Driven to rotate, the working surface of the guide belt 106 is perpendicular to the working surface of the first conveyor belt 102 .

[0071] Before processing, the corn cobs can be placed on the second conveyor belt 101 or the feeding plate, and the corn cobs can slowly move towards the first conveyor belt 102, and this design can control the feeding speed at the source. The first guide 103, the sec...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com