Glass kiln raw material feeding system and feeding method thereof

A feeding system and glass raw material technology, applied in the feeding of melting furnaces, glass manufacturing equipment, manufacturing tools, etc., can solve the problems of unfavorable glass powder melting, affecting melting effect, affecting product quality, etc., to improve melting efficiency and quality , to ensure the effect of controlled and accurate feeding

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0020] The invention relates to a glass kiln raw material feeding system and a feeding method.

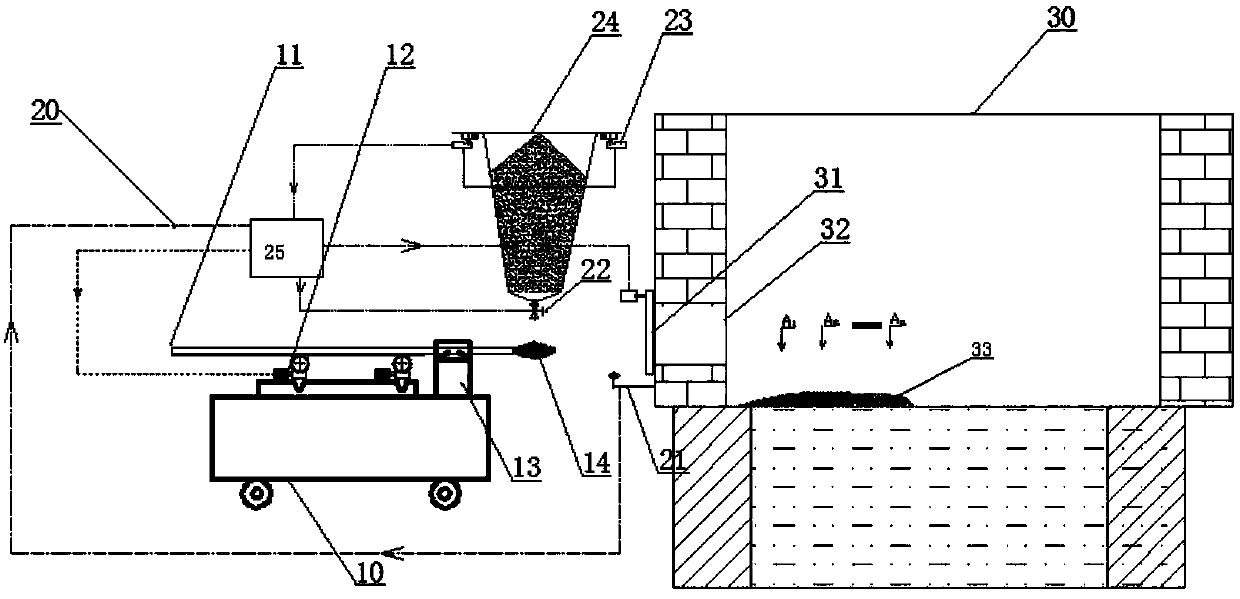

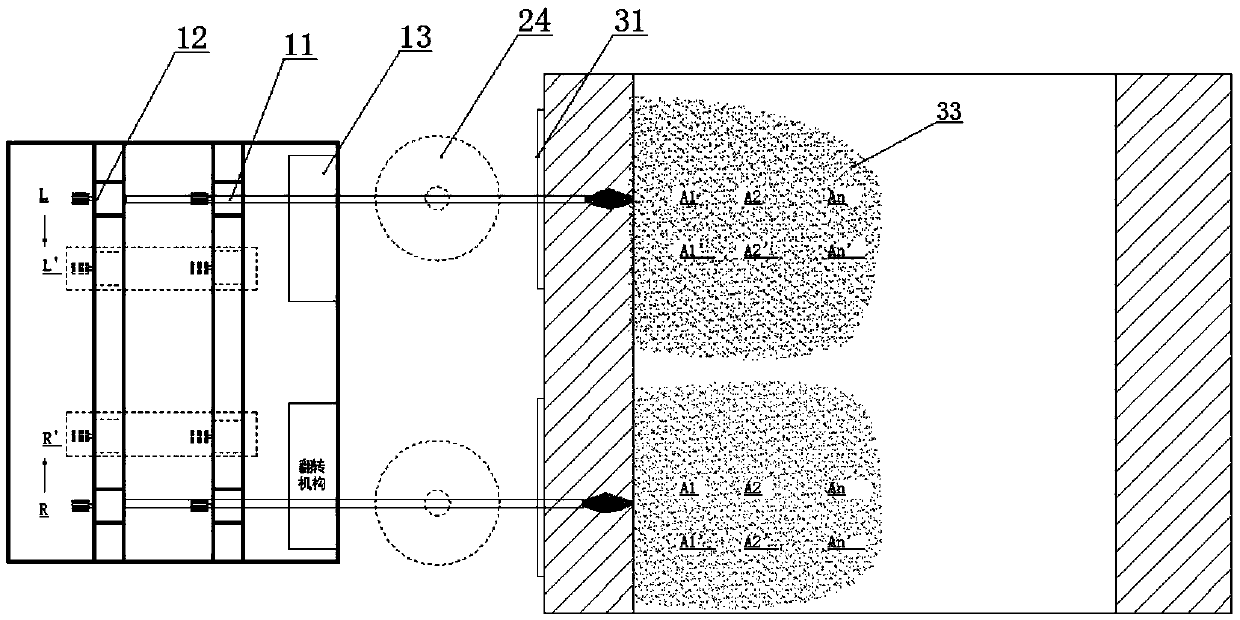

[0021] Such as figure 1 , 2 As shown, the feeding system includes a multi-station progressive shovel feeding device 10 , a control detection unit 20 and a pool furnace 30 .

[0022] Furthermore, the multi-station progressive shovel feeding device 10 includes: a feeding pusher rod 11 , a pusher mechanism 12 , a feeder rod turning mechanism 13 , and a shovel 14 .

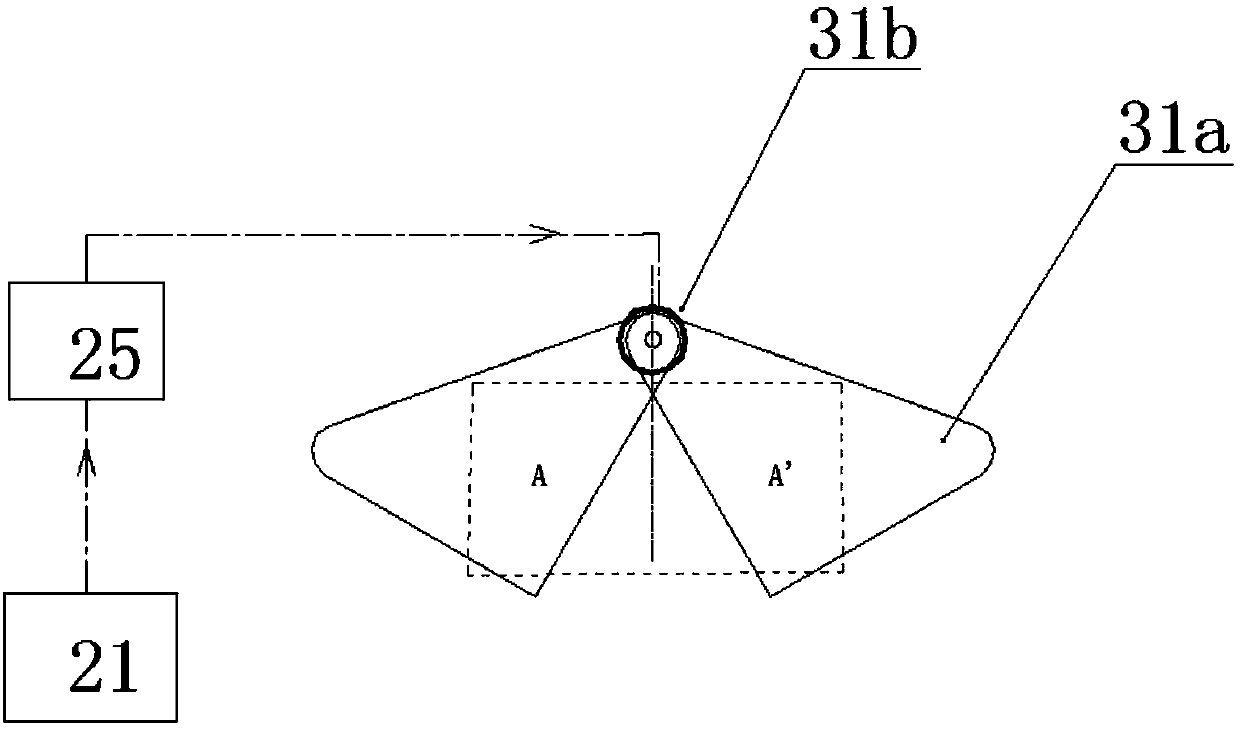

[0023] Furthermore, the control detection unit 20 includes a light detector 21 , a feeding valve 22 , a weighing sensor 23 , a feed bin 24 , and an operation controller 25 .

[0024] The feeding ports 32 of the pool furnace on the left and right sides respectively correspond to a multi-station progressive shovel feeding device 10, and the multi-station progressive shovel feeding device 10 pushes the shovels 14 in horizontal and vertical order through the propulsion mechanism 12, and each time they reach the pool At one...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com