Microwave equipment capable of continuously smelting metal powder

A metal smelting and microwave technology, which is applied in the field of industrial furnaces, can solve the problems of complex sealing mechanism, power supply equipment, high cooling system requirements, and inconvenient maintenance, so as to reduce the strong mutual coupling of microwave sources, reduce power supply equipment requirements, and improve metal The effect of recovery

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

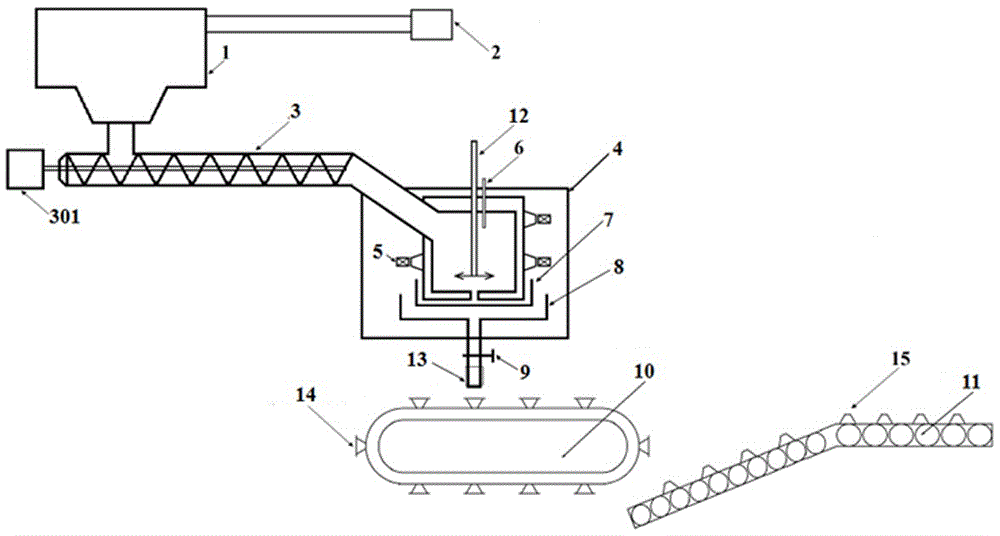

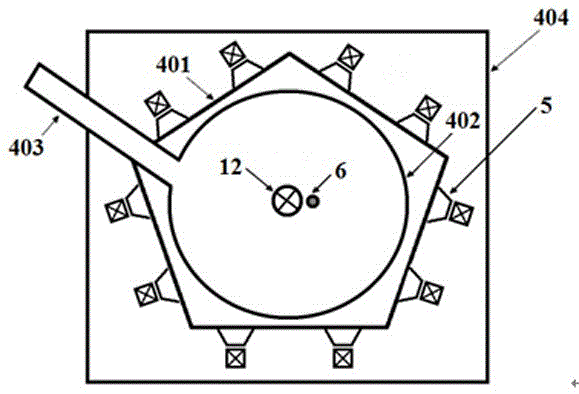

[0040] First, tin powder is loaded into the loading bin 1, and N is filled into the loading bin 1 through the atmosphere protection system. 2 Then by the continuous screw feeder 3, the tin powder in the loading bin 1 is constantly sent to the microwave cavity 401 of the microwave melting furnace 4 with the feeding speed of 20rpm; The generator 8 emits microwave energy with a total power of 10kW to heat and fully melt, and at the same time, the molten metal is stirred by the stirrer 12 at a stirring speed of 40rpm; finally, the metal tin liquid with a smelting time of 5 minutes flows naturally into the casting through the overflow tank 7 trough 8, and injected into the ingot mold 14 of the continuous ingot casting machine 10 through the sprue to realize the continuous casting of tin metal ingots, and the tin metal ingots are transported by the ingot casting machine 10 along with the ingot mold 14 and dropped into the conveyor belt 16 to send out after cooling . The slag rate o...

Embodiment 2

[0042] The process is as in Example 1, using tin powder as the smelting material, adopting the process of charging, filling with Ar protection, feeding and other processes according to the present invention, heating and smelting with a microwave with a total power of 20kW, the feeding speed is 40rpm, the stirring speed is 60rpm, and the smelting The time is 5 minutes, there is a small amount of inclusions in the ingot, the melting effect is good, and the slag removal rate is only 3.78%.

Embodiment 3

[0044] The process is as in Example 1, using tin powder as the smelting material, adopting the process of charging, inflating protection, feeding and other processes according to the present invention, using microwave heating and melting with a total power of 30kW, the feeding speed is 40rpm, the stirring speed is 60rpm, and the melting time is 7min, there is no intermixture in the ingot, the melting effect is good, and the slag yield is only 2.13%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com