Stainless steel water tank for nuclear power station and welding method

A stainless steel and nuclear power plant technology, applied in the field of nuclear power plant construction, can solve the problems such as the inability to guarantee the welding schedule, the poor appearance of the welding seam surface, and the difficulty in ensuring the continuity of the welding process. The effect of solving the problem of welding defects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

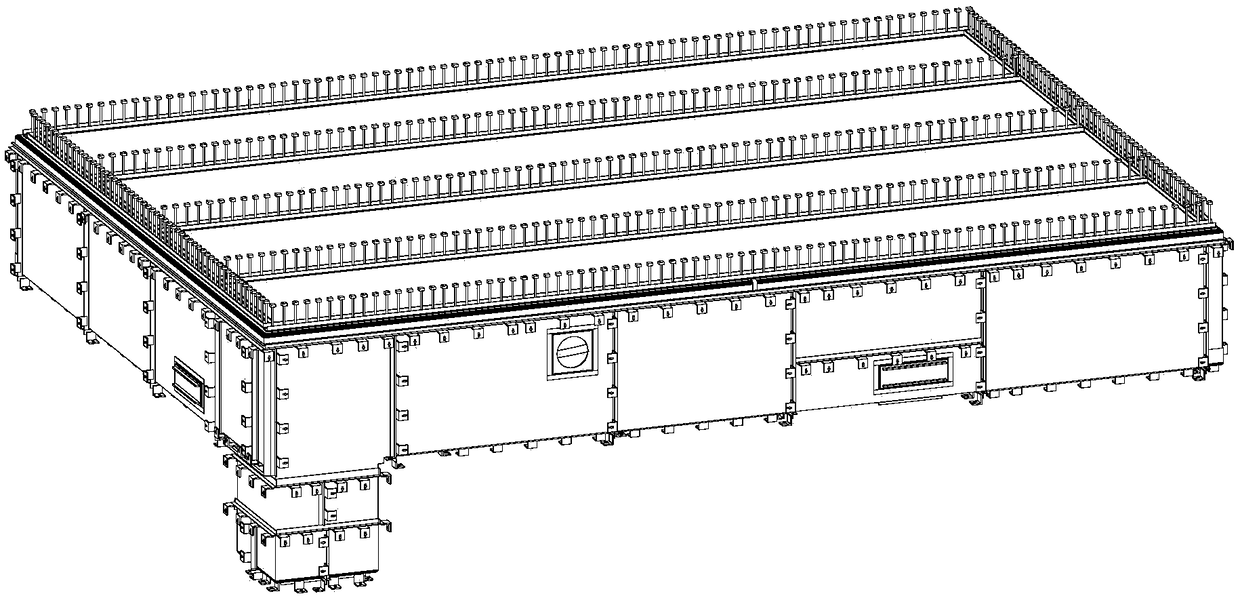

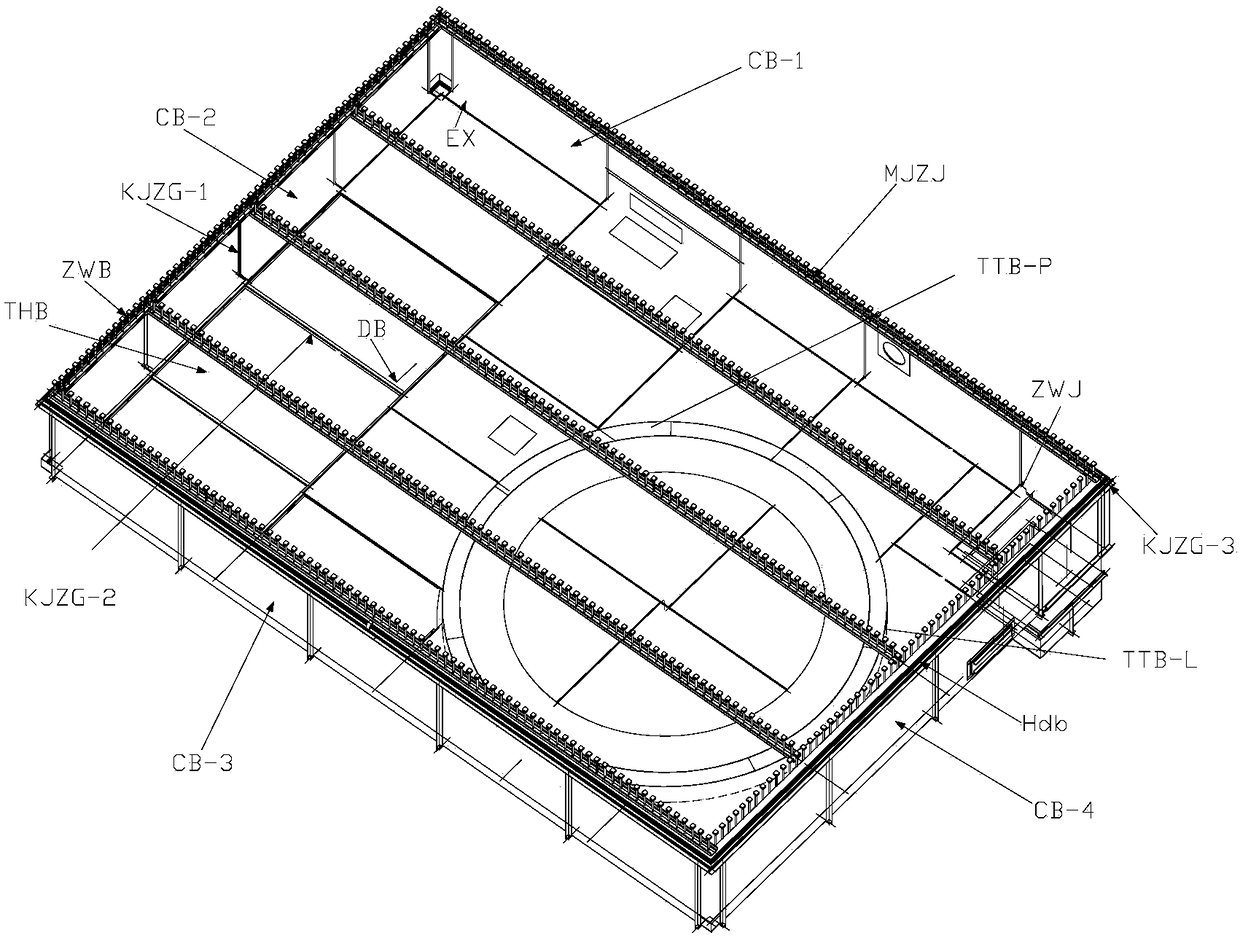

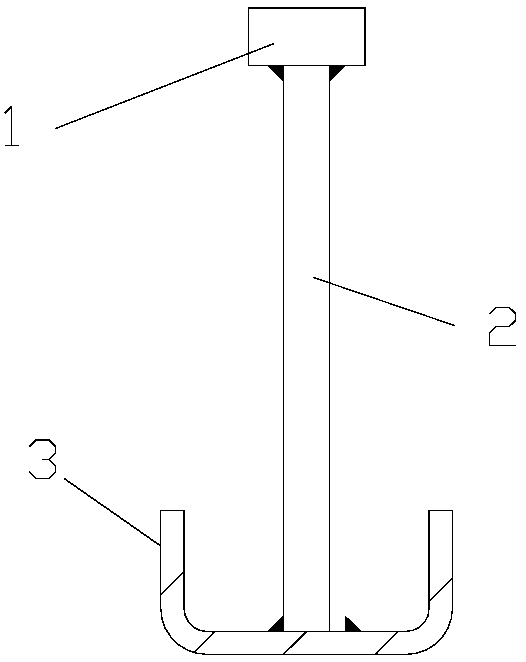

[0052] In this embodiment, the basic structure of the nuclear power plant stainless steel pool assembled and welded by means of MIG semi-automatic welding is as follows: figure 1 , figure 2 As shown, including joints to form a rectangular stainless steel pool bottom DB (3mm stainless steel plate), side walls CB-1, CB-2, CB-3, CB-4 (3mm stainless steel plate) and top ceiling THB (4mm stainless steel plate) cladding panels. The cladding of the adjacent bottom plate DB is welded through the bottom frame angle steel KJZG-2, and the outer edges of the cladding panels around the bottom plate DB and the bottom edges of the lower cladding panels EX of each side wall CB-1, CB-2, CB-3, and CB-4 pass through the bottom frame angle steel KJZG-2 welding, the side wall adjacent to the cladding panel is welded through the side frame angle steel KJZG-1, and the adjacent ceiling THB is welded through the anchor bar assembly MJZJ ( Figure 4 ), the end of the ceiling THBD and the side wall p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| yield strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com