Patents

Literature

1168results about "Soldering iron" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

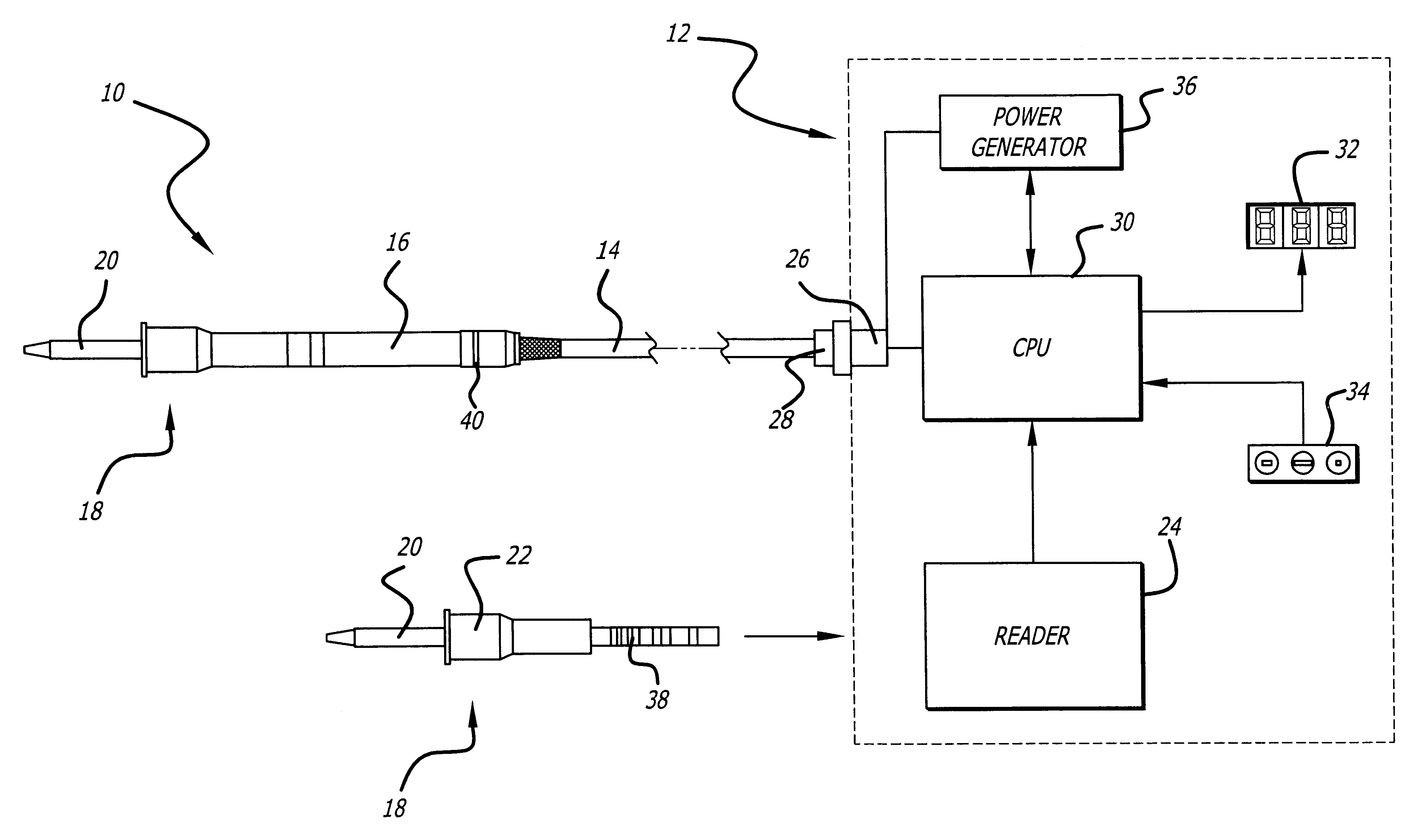

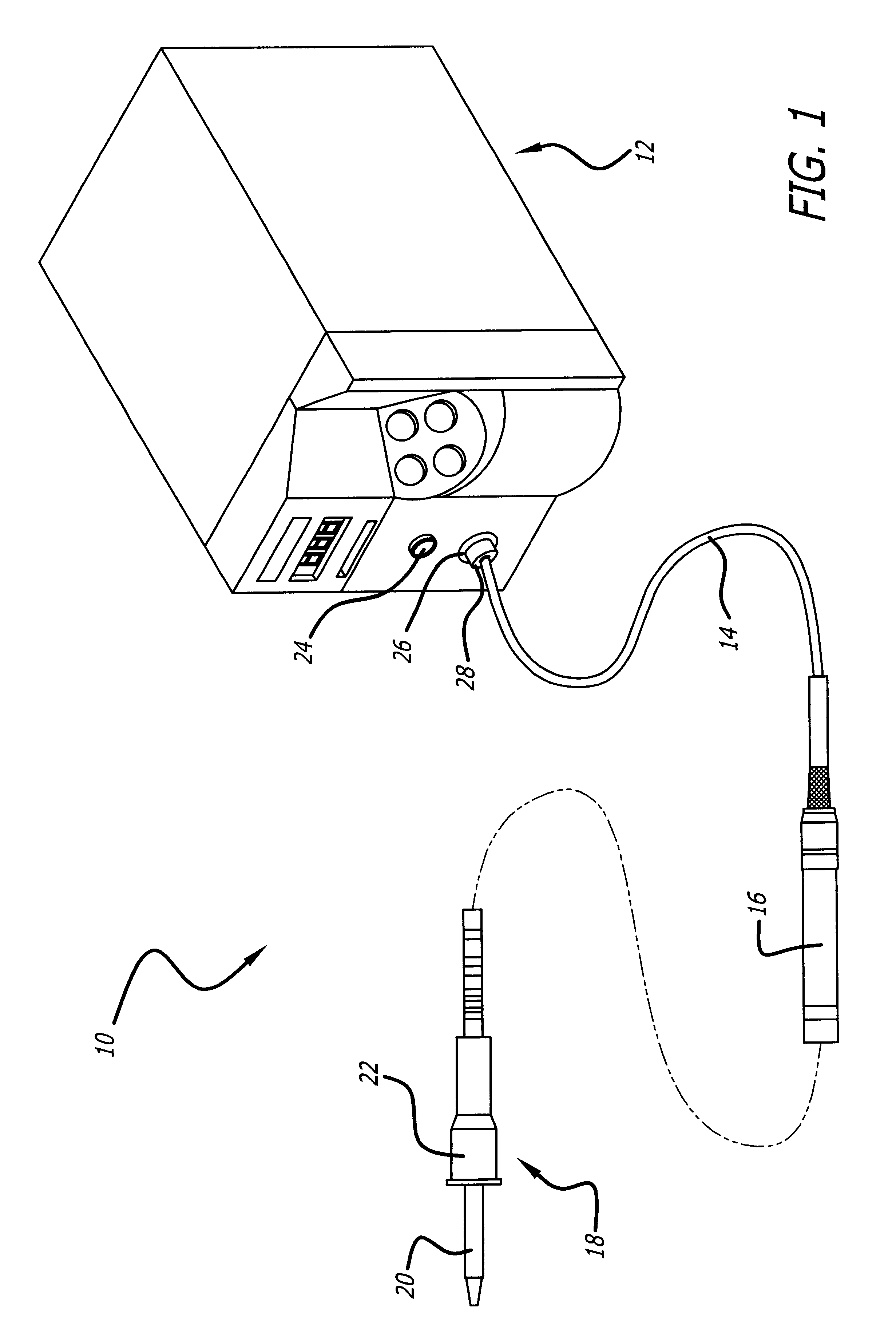

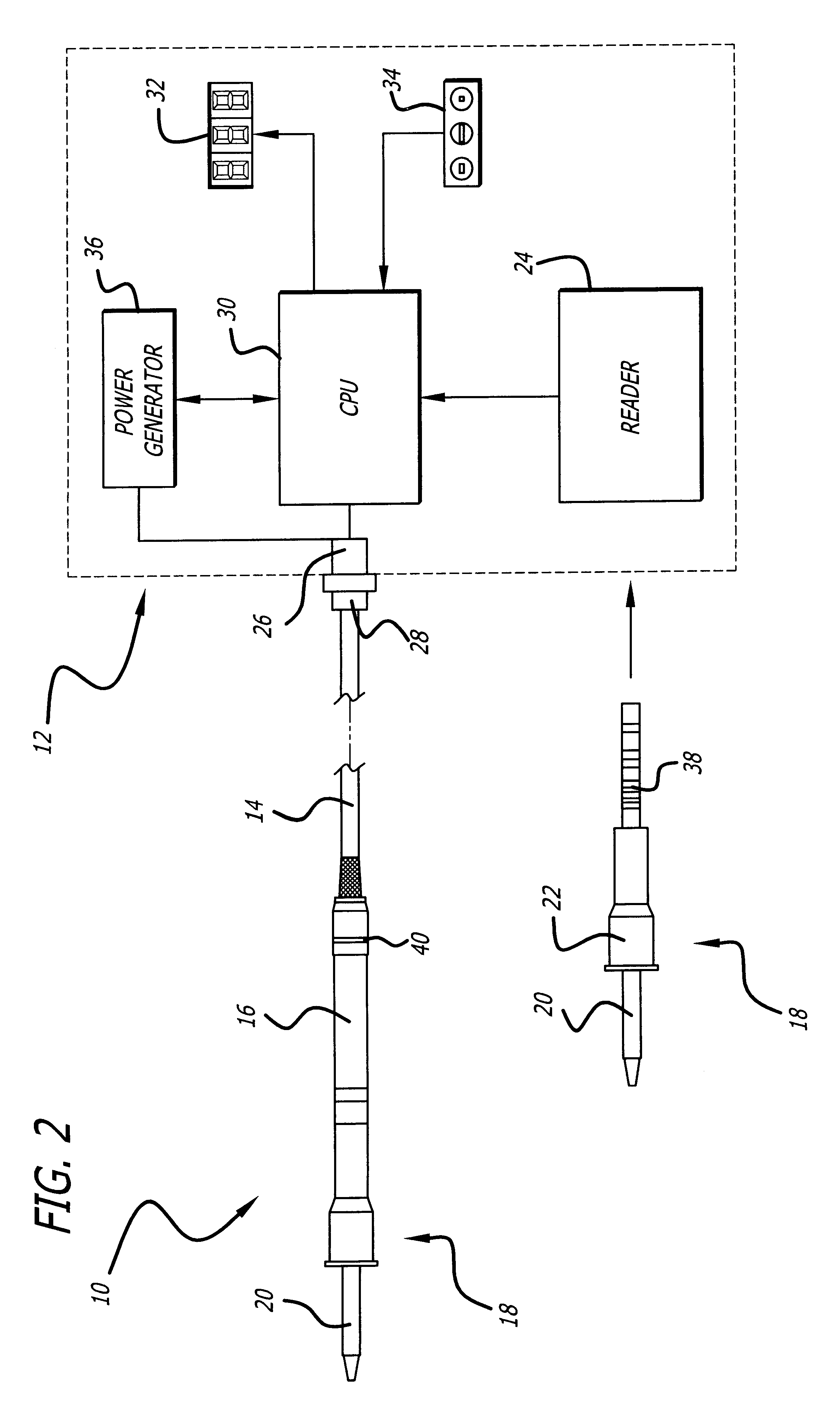

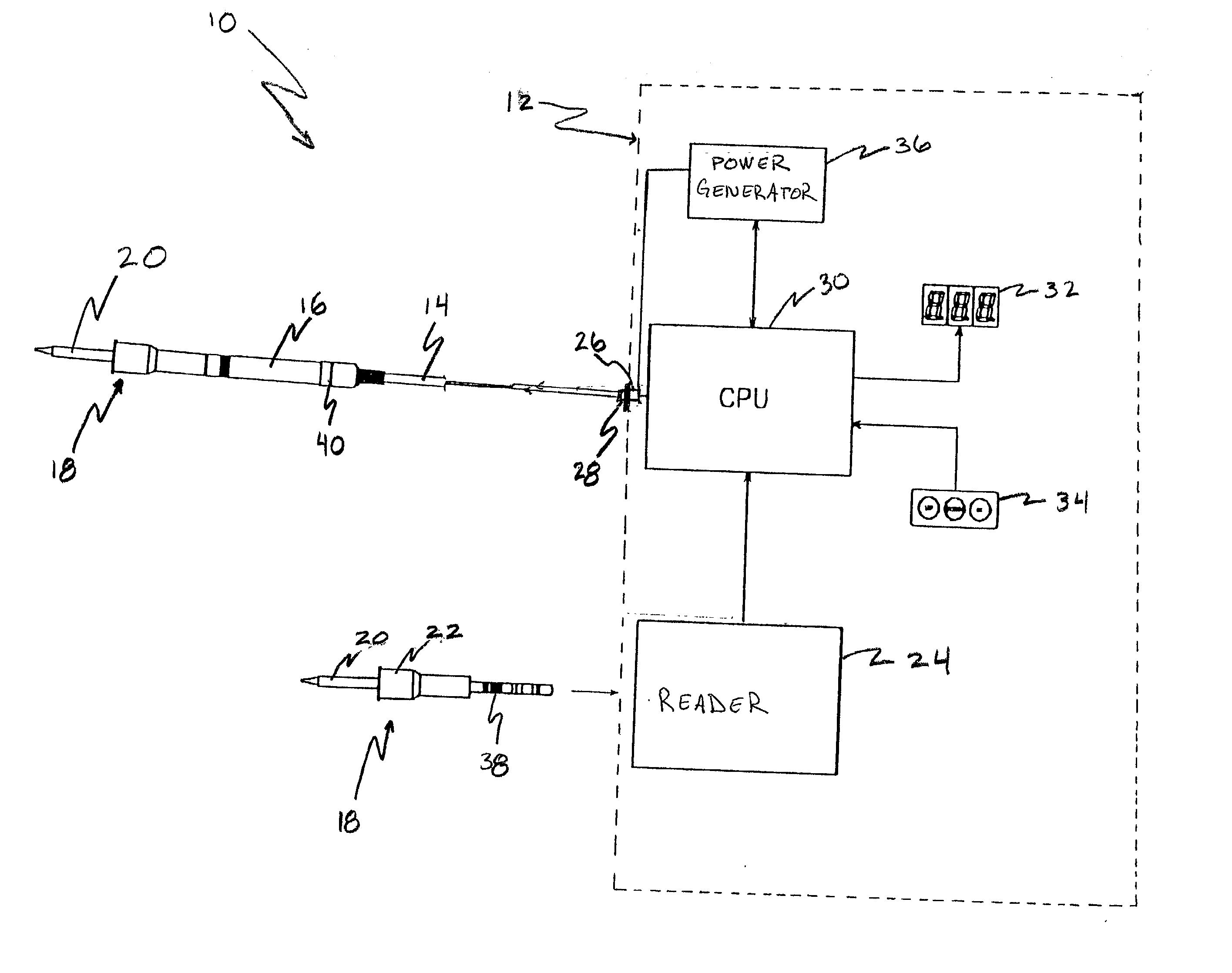

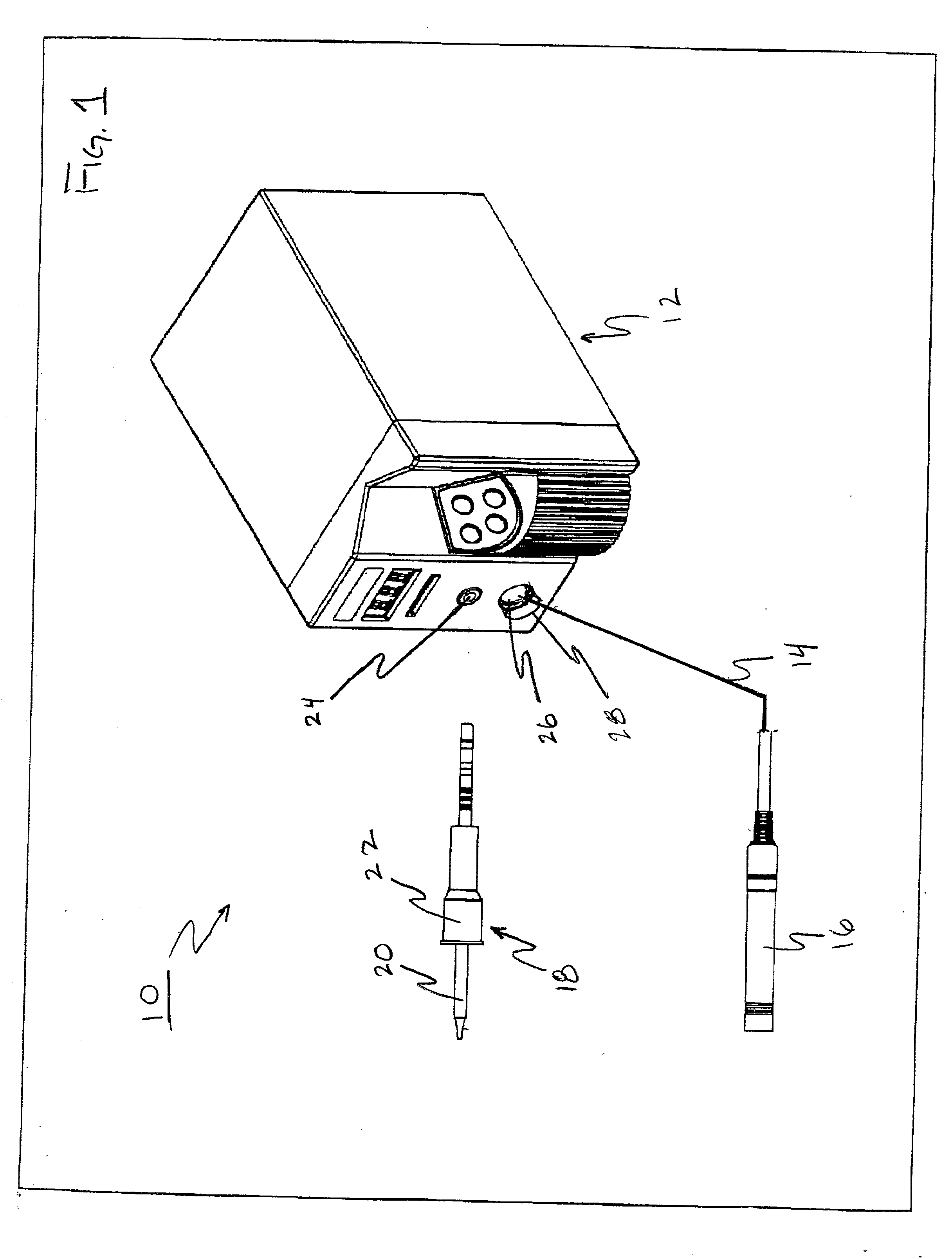

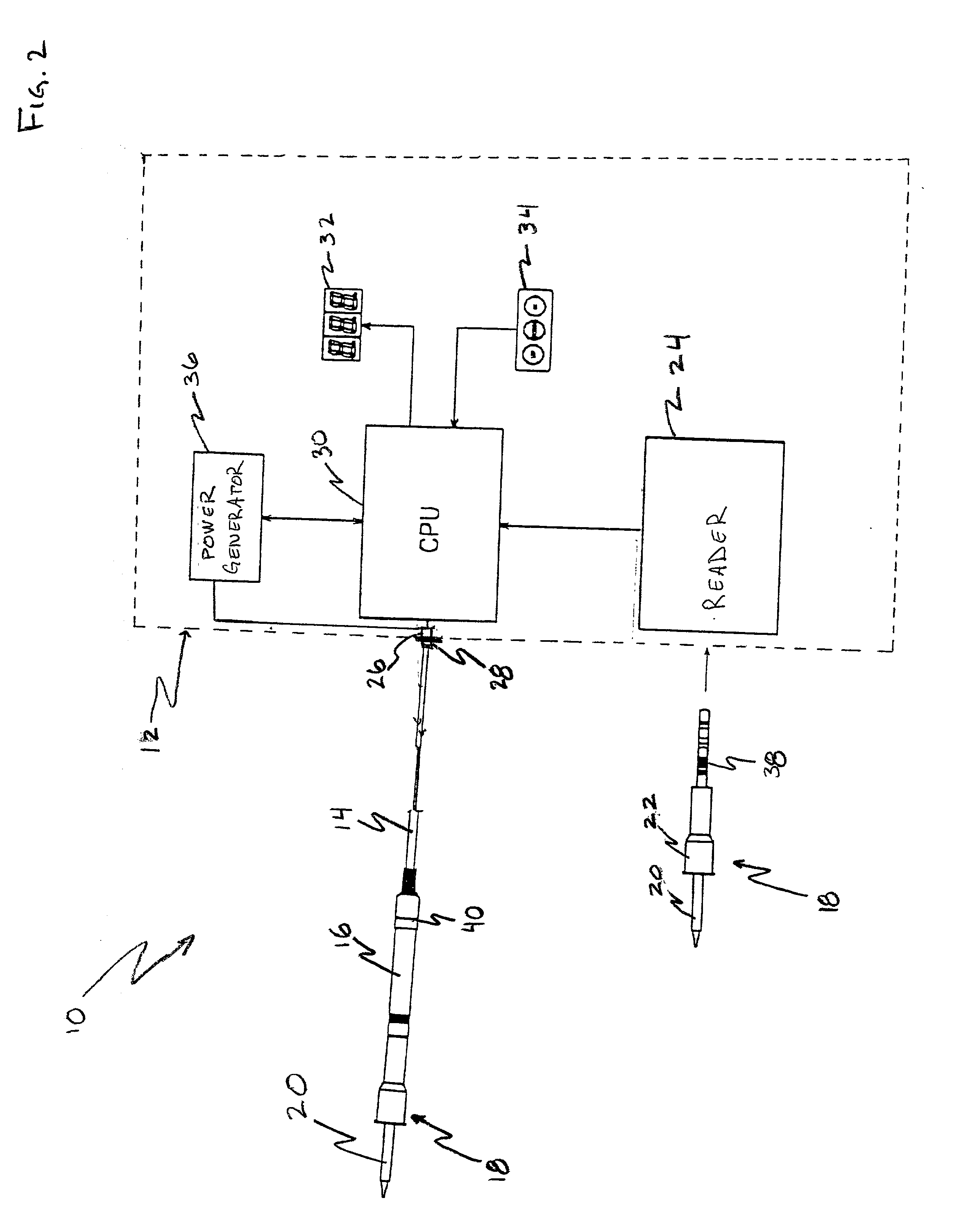

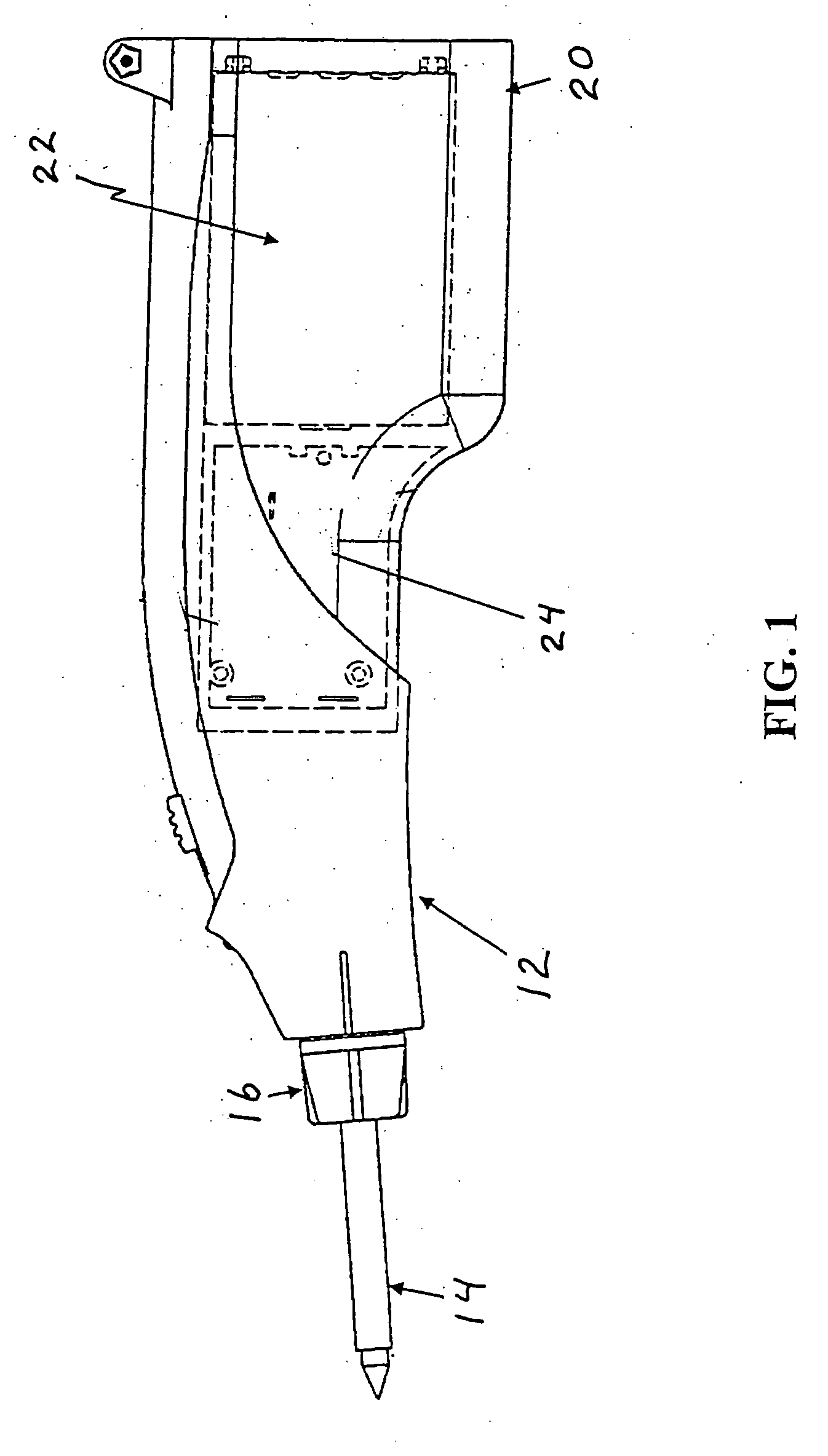

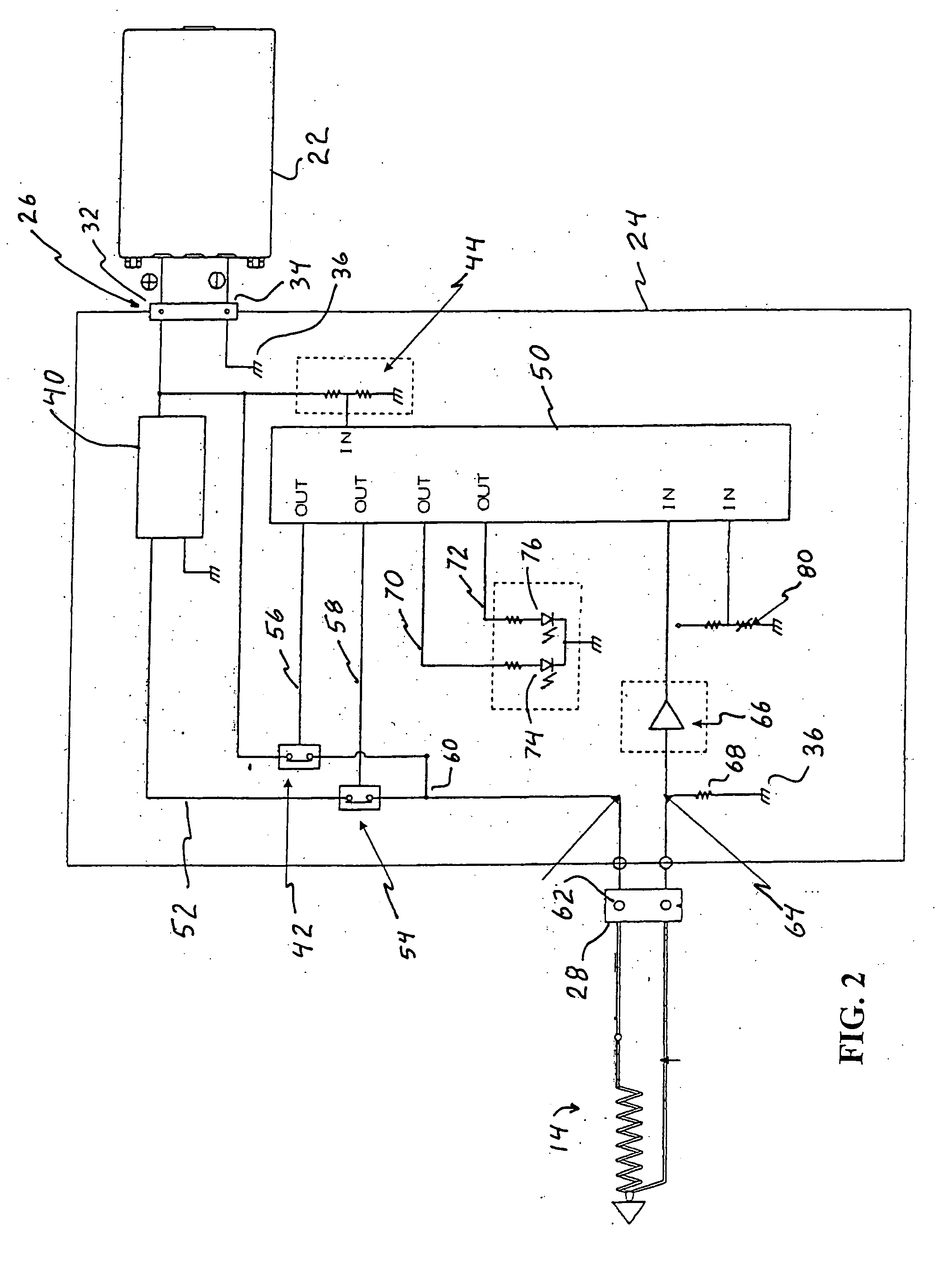

Automated soldering system

An automated soldering system with an intelligent power supply that can automatically configure the power output to interchangeable soldering cartridges, where the soldering cartridges include readable information to allow the power supply to properly power the cartridge to achieve a desired, entered operating temperature. The system includes a cartridge with an identifier that contains information particular to that cartridge, a reader able to read that information, and an indicator positioned on a connector into which the cartridge is inserted.

Owner:HAKKO CO LTD

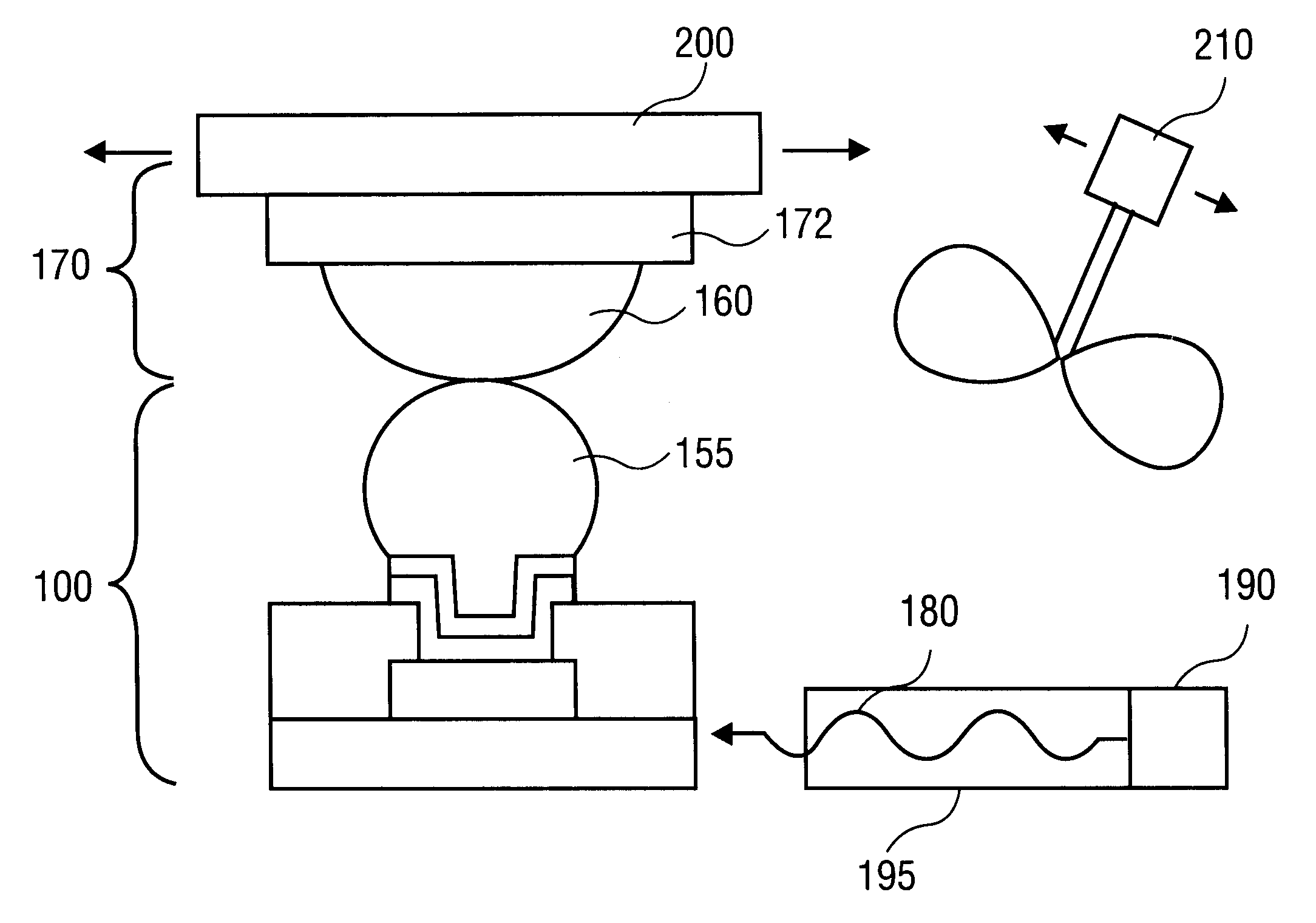

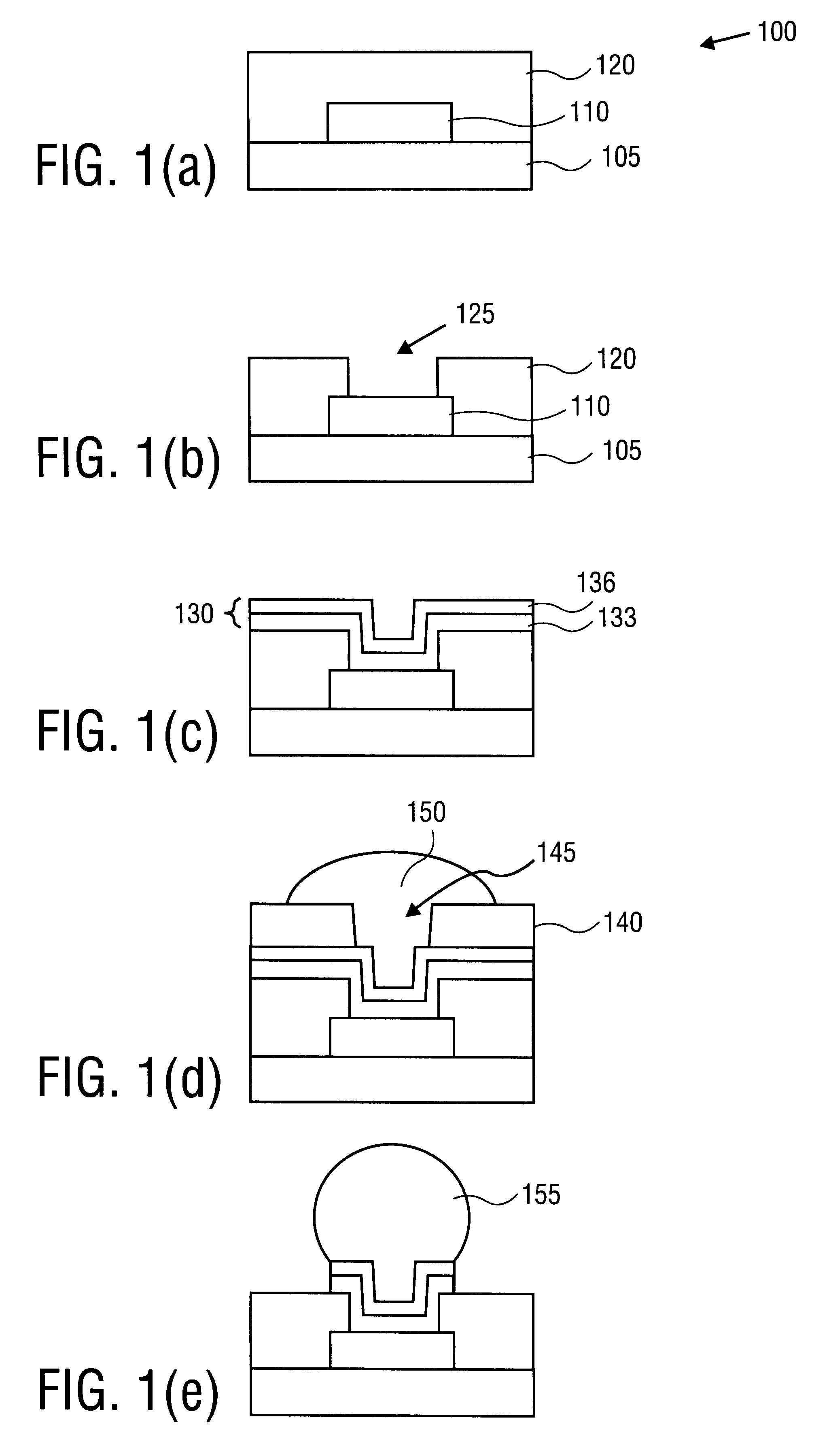

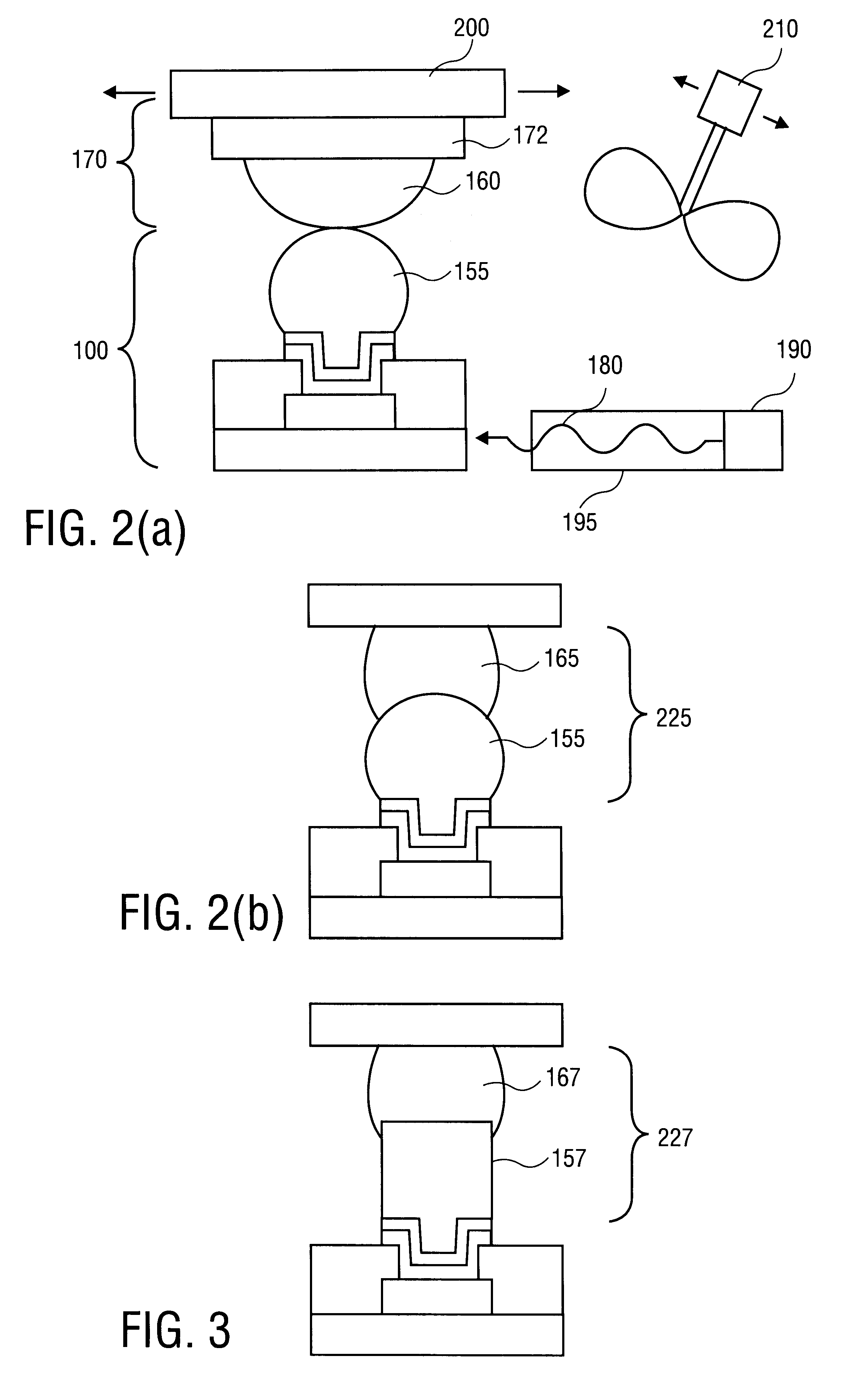

Solder reflow with microwave energy

The present invention includes a mechanical joint between a die and a substrate that is reflowed by microwave energy and a method of forming such a mechanical joint by printing a solder over a substrate, placing the solder in contact with a bump over a die, reflowing the solder with microwave energy, and forming a mechanical joint from the solder and the bump.

Owner:INTEL CORP

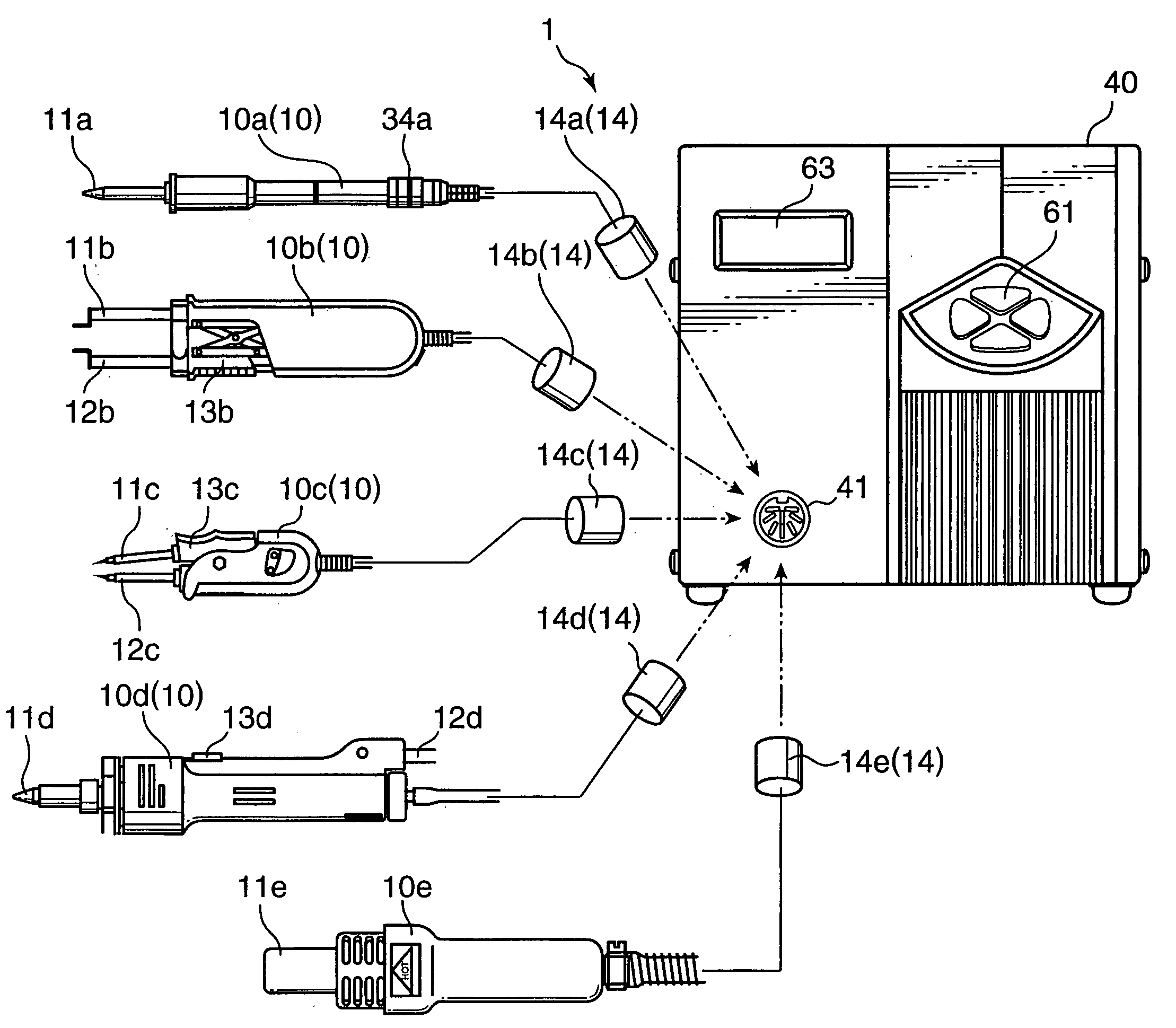

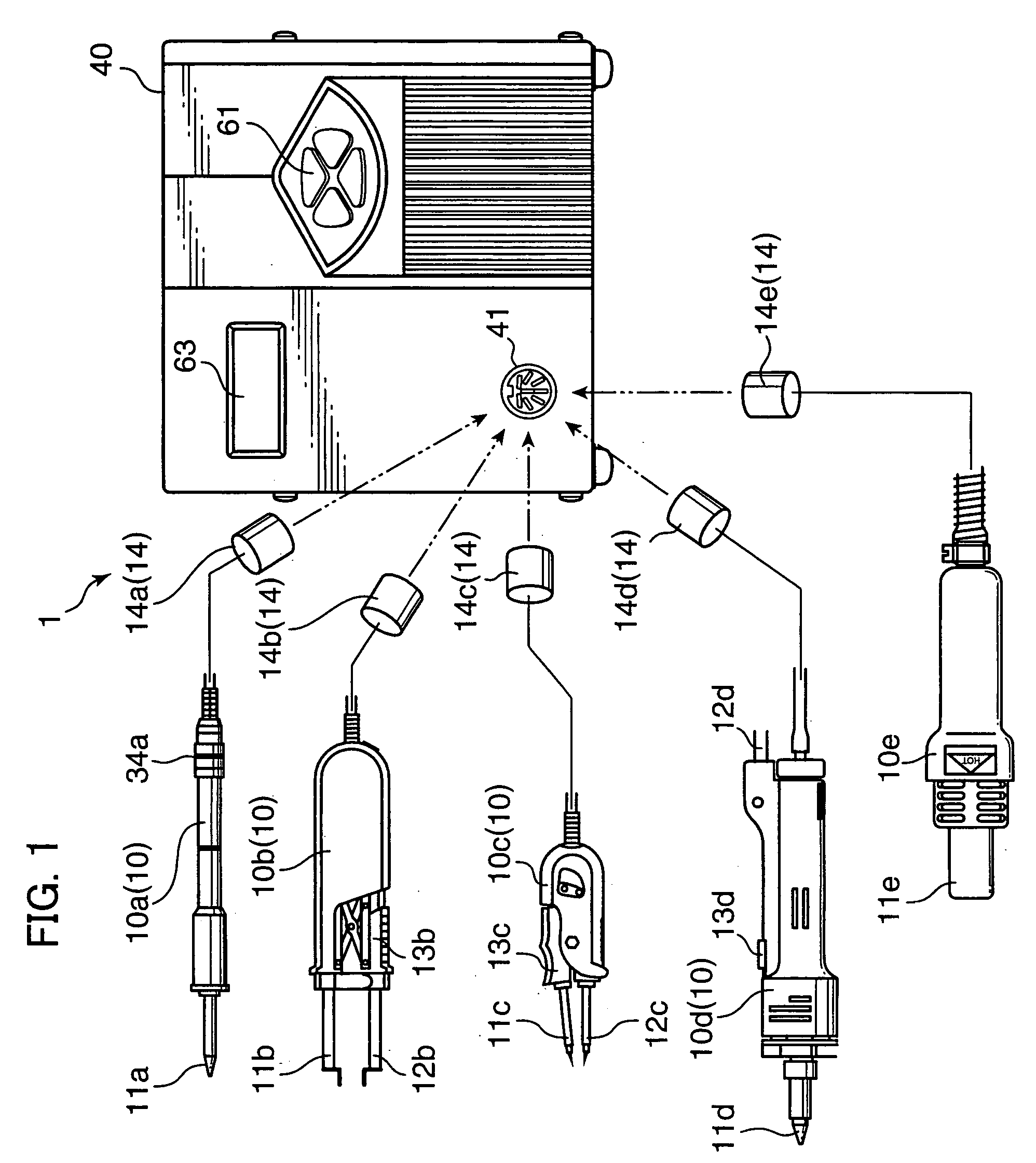

Temperature control system for solder handling devices and method for temperature control for those devices

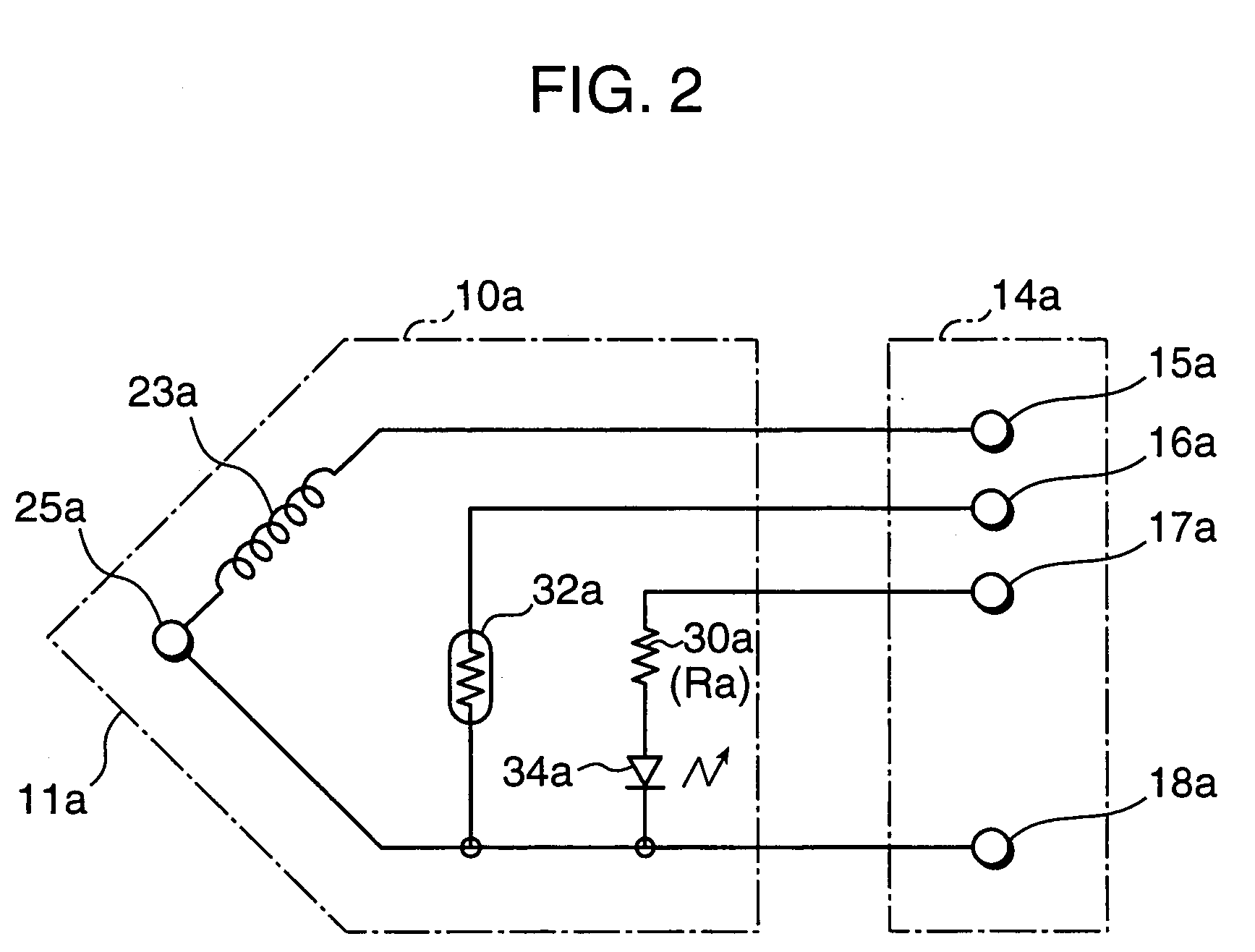

InactiveUS20050121495A1Improve accuracyImprove reliabilityAutomatic control devicesPrecision positioning equipmentTemperature controlElectrical resistance and conductance

In a temperature control system for controlling a heating member or means of a solder handling device, a plurality of solder handling devices such as soldering iron, a heater tweezer, a solder sucker and a hot air blower are selectively coupled with a temperature controller which in turn identify the solder handling device connected thereto and controls temperature of the heater of the connected device with temperature control characteristic suitable for the device. Each solder handling device may have a resistor of which resistance value represents the type of the device so that the temperature controller identify the device by the resistance value.

Owner:HAKKO CO LTD

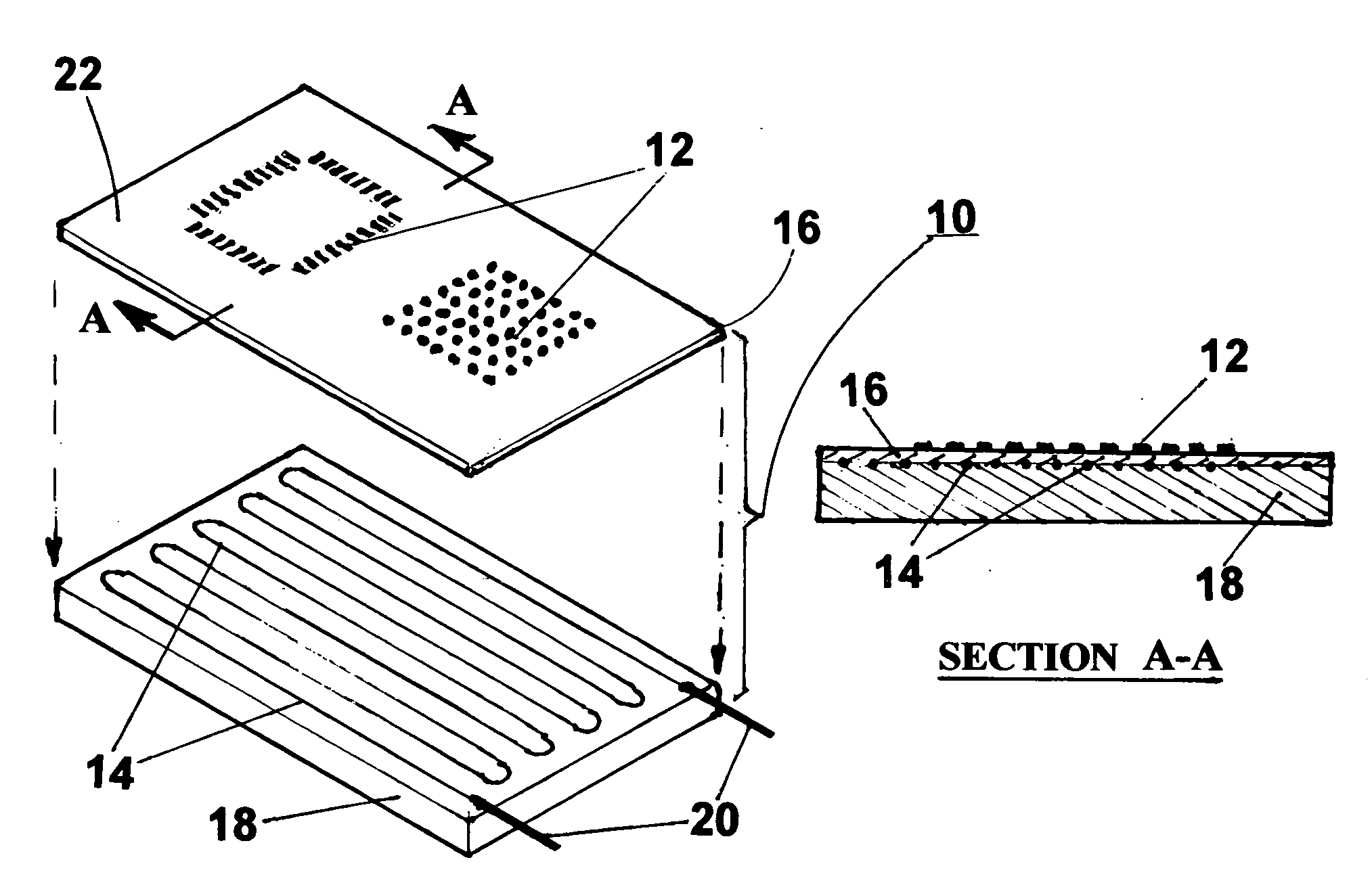

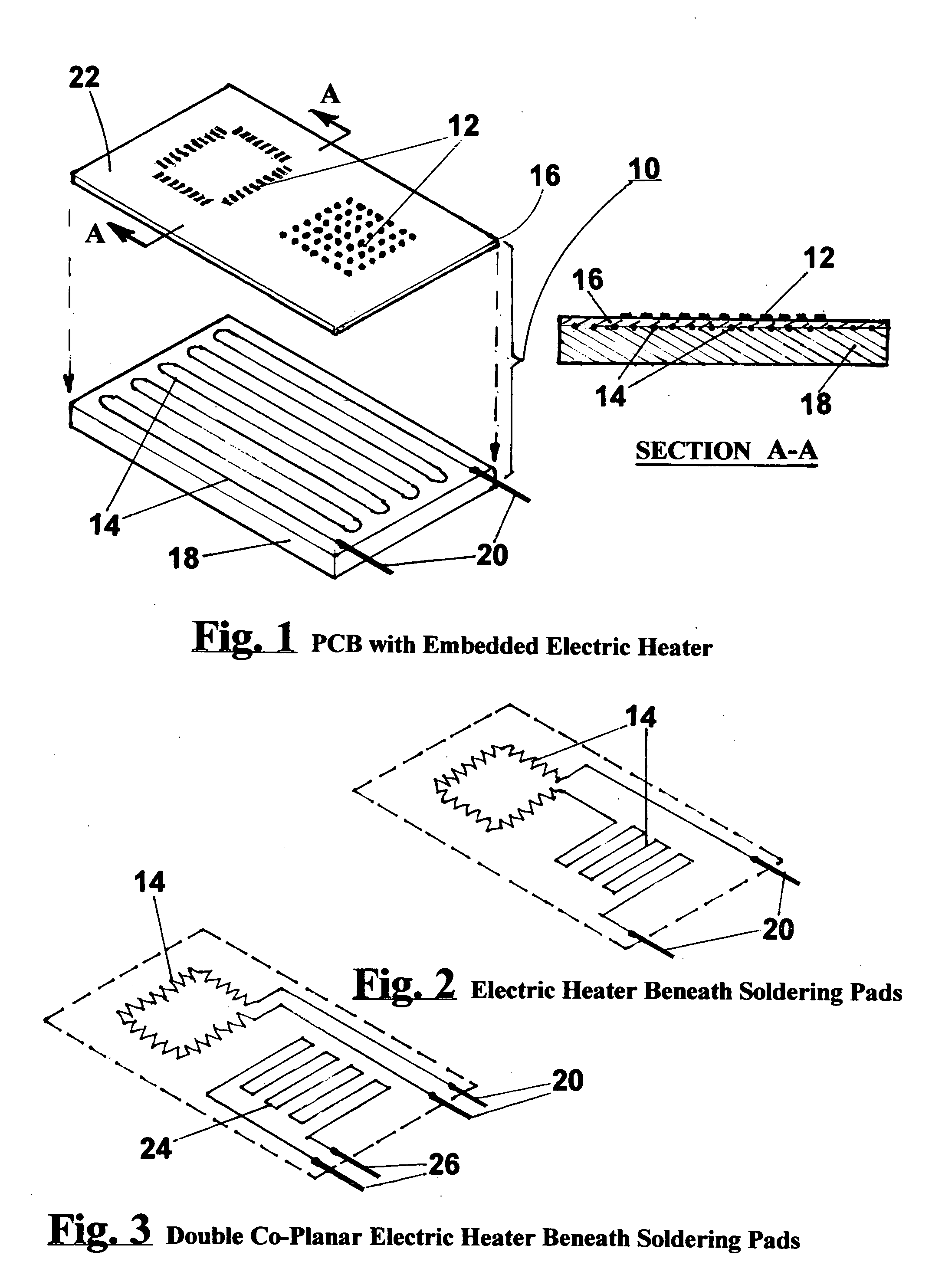

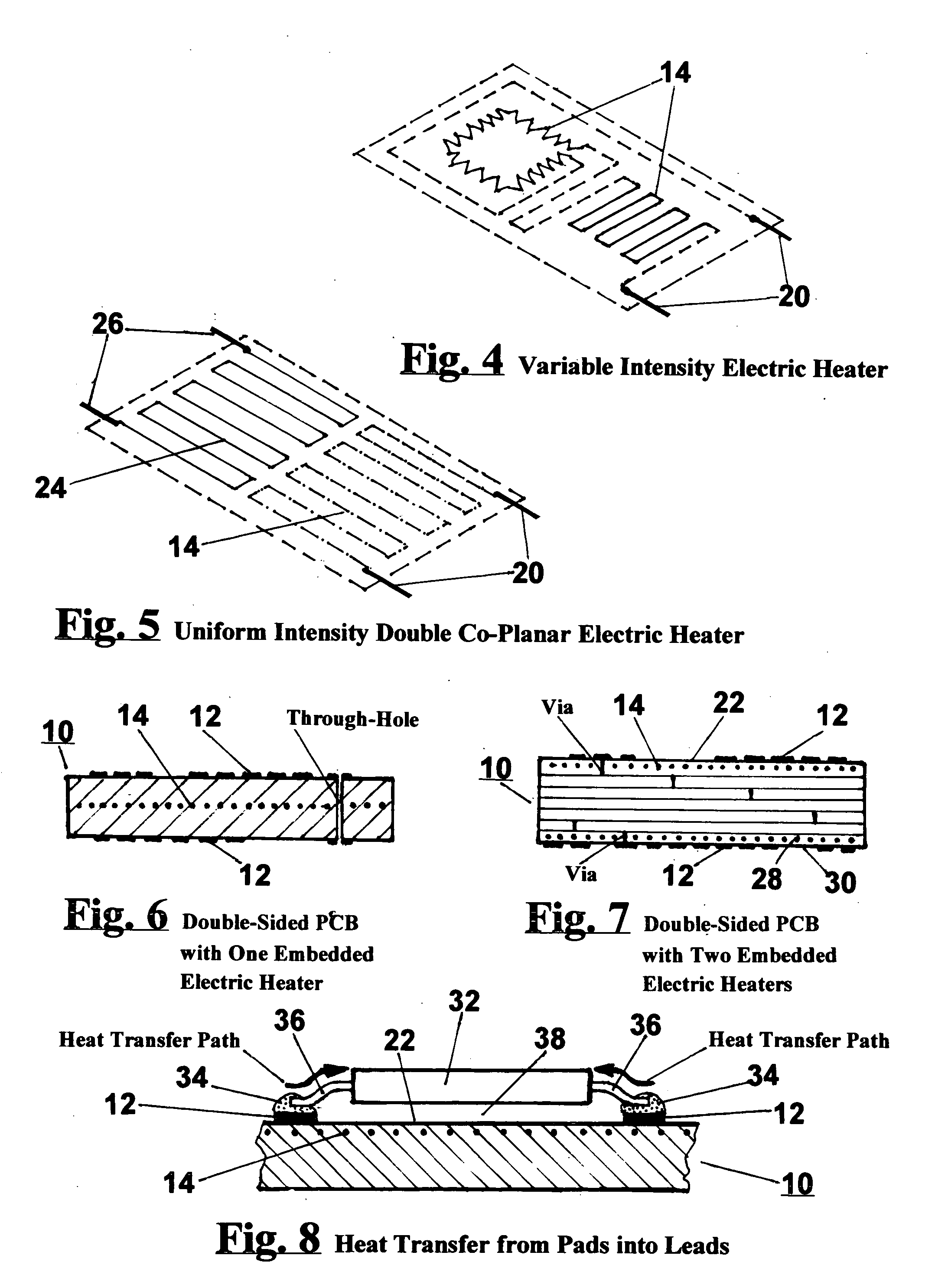

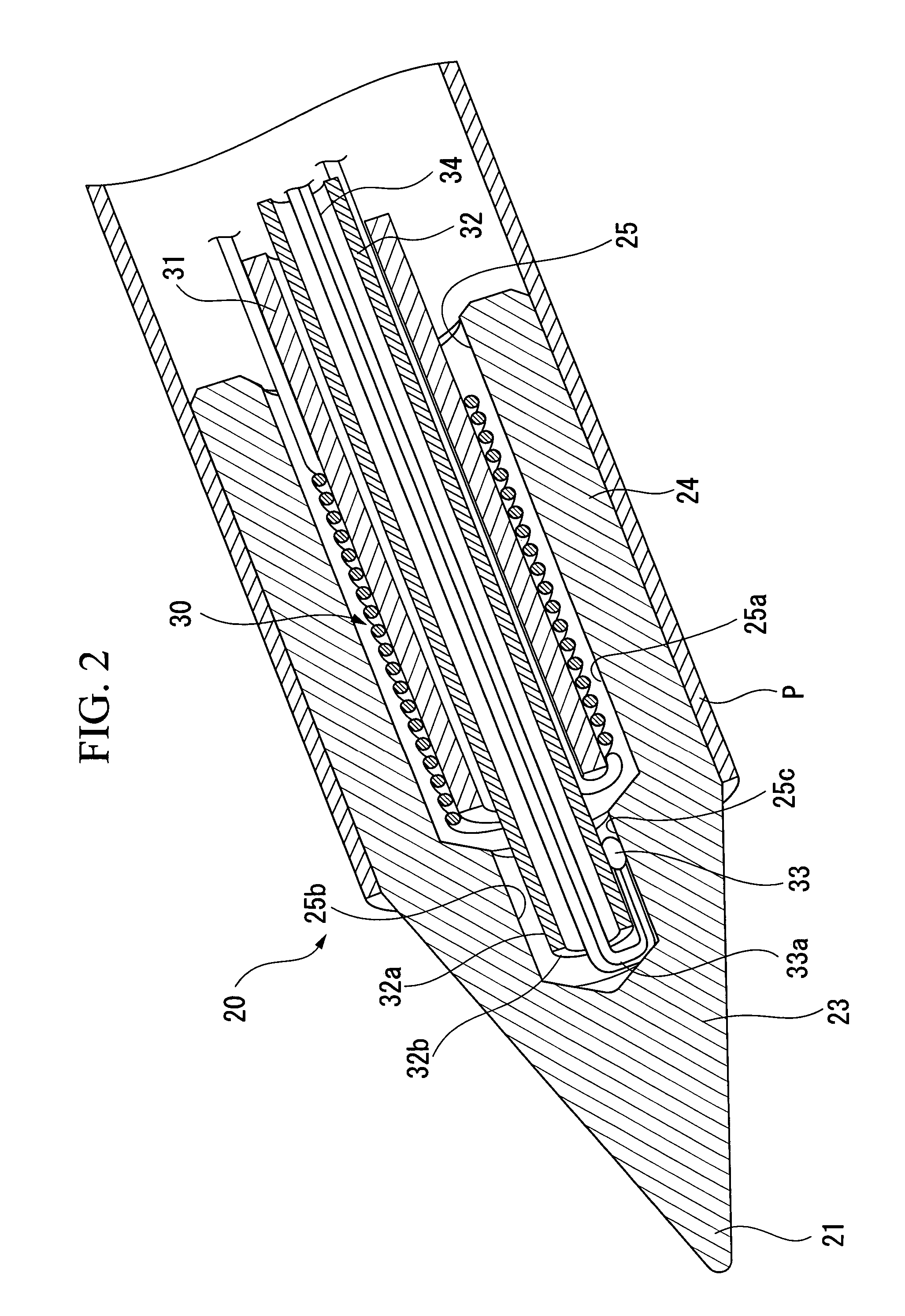

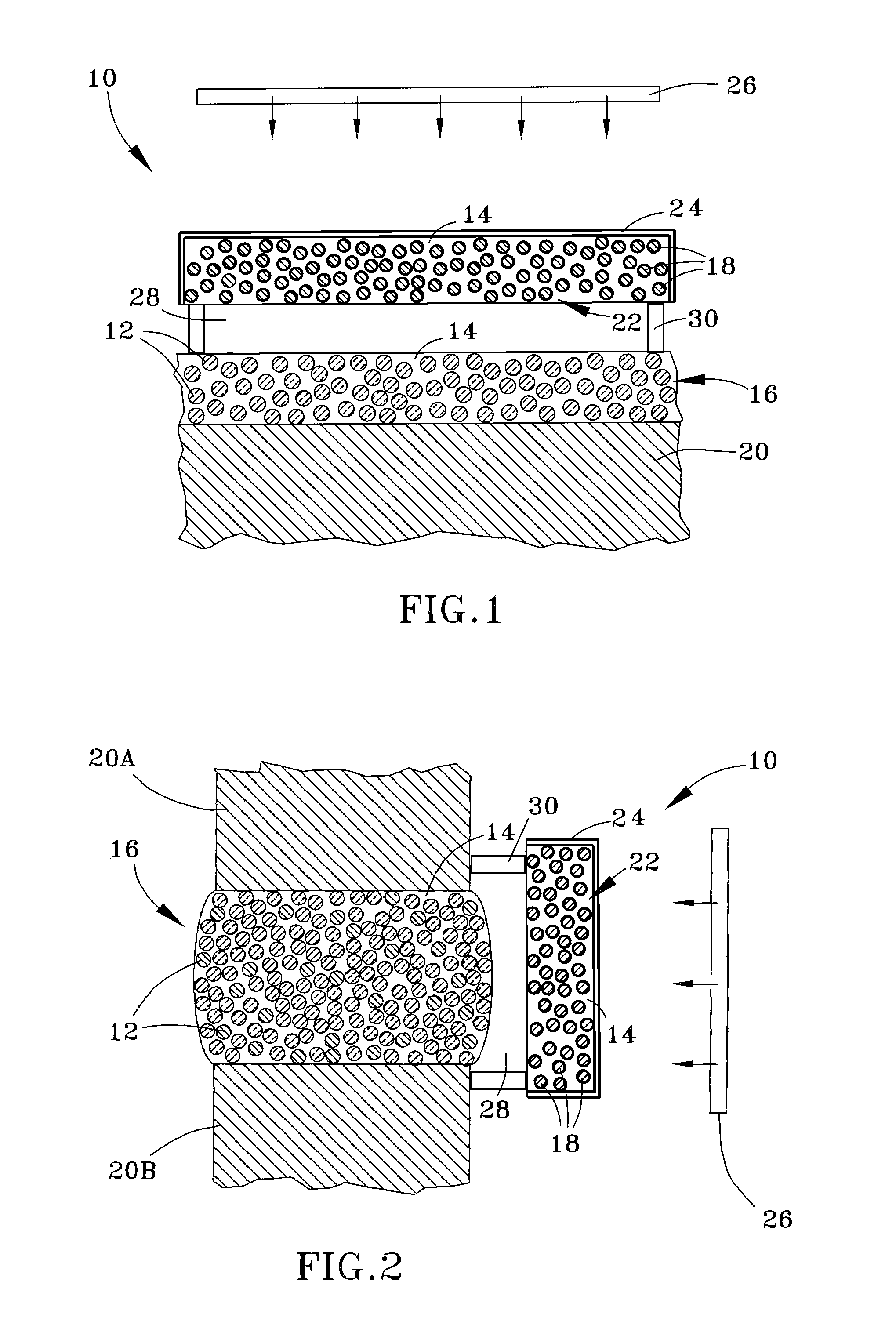

Self-reflowing printed circuit board and application methods

InactiveUS20060065431A1Reduce manufactured-product costLow temperature exposurePrinted circuit aspectsSolid-state devicesManufacturing cost reductionPrinted circuit board

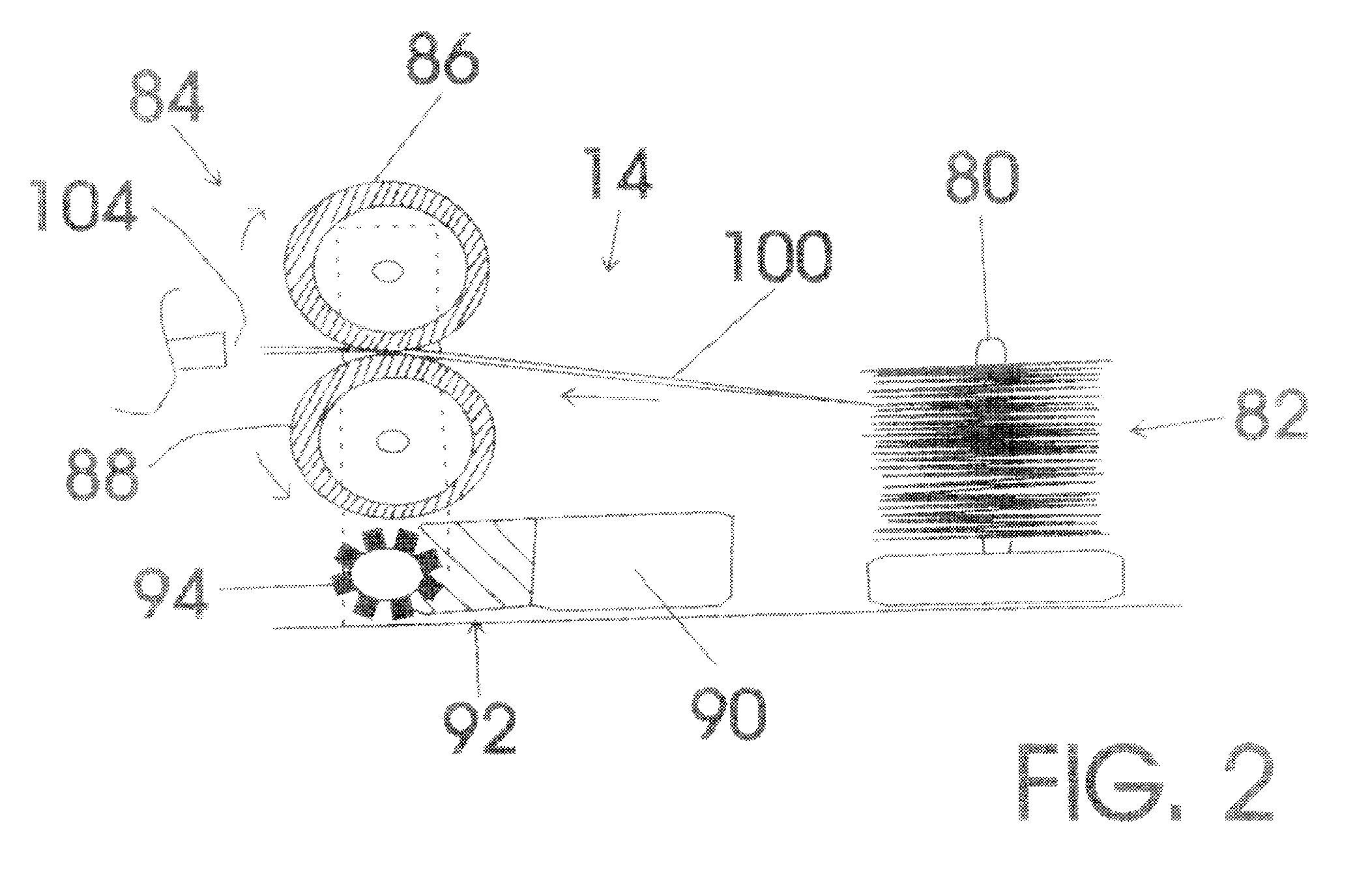

A novel printed circuit board (PCB) 10 that incorporates embedded into its substrate an electric heater 14 is disclosed. This electric heater 14 becomes the only source of heat for simultaneously soldering components to pads 12. The PCB 10 is the key element that permits to create apparatuses and implement processes for soldering PCB assemblies without utilizing a reflow oven. Compared against the prior art this invention requires less manufacturing equipment, reduces the manufacturing cost, reduces manufacturing energy consumption and improves the quality and reliability of soldered PCB assemblies.

Owner:TRUCCO HORACIO ANDRES

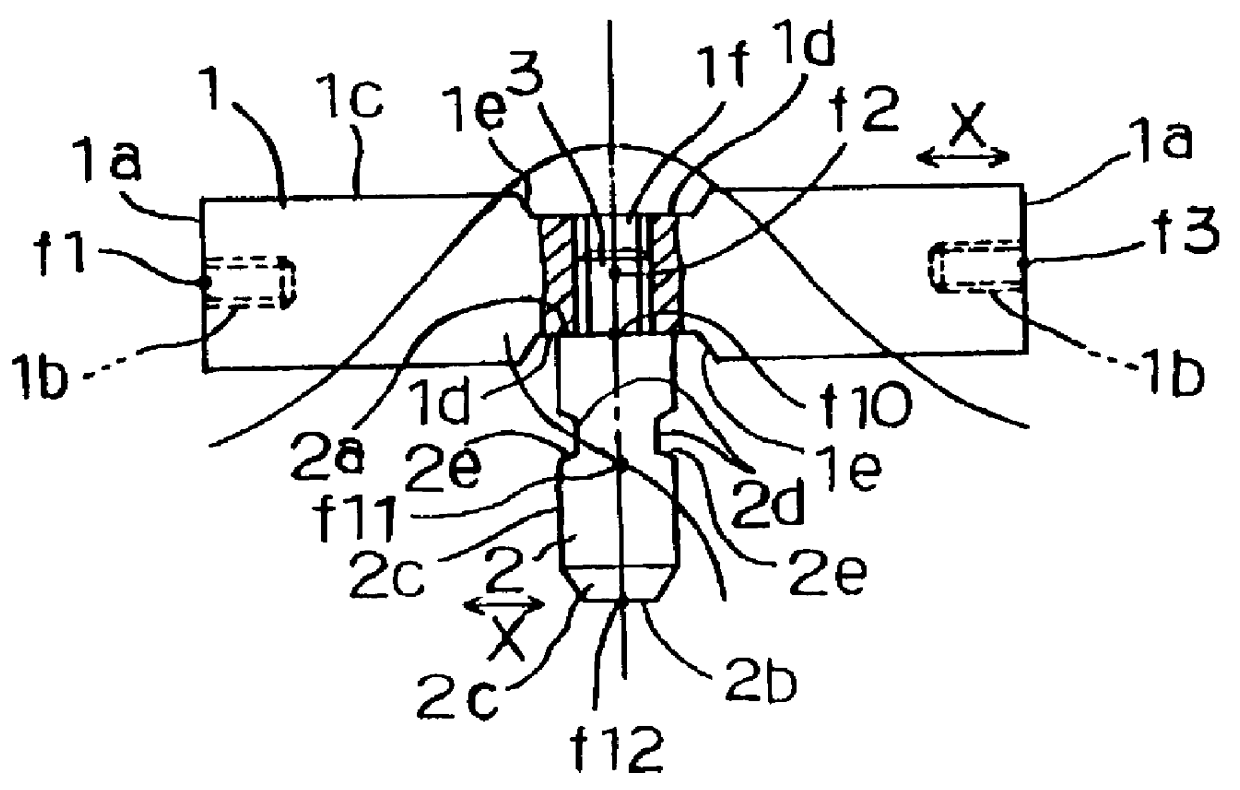

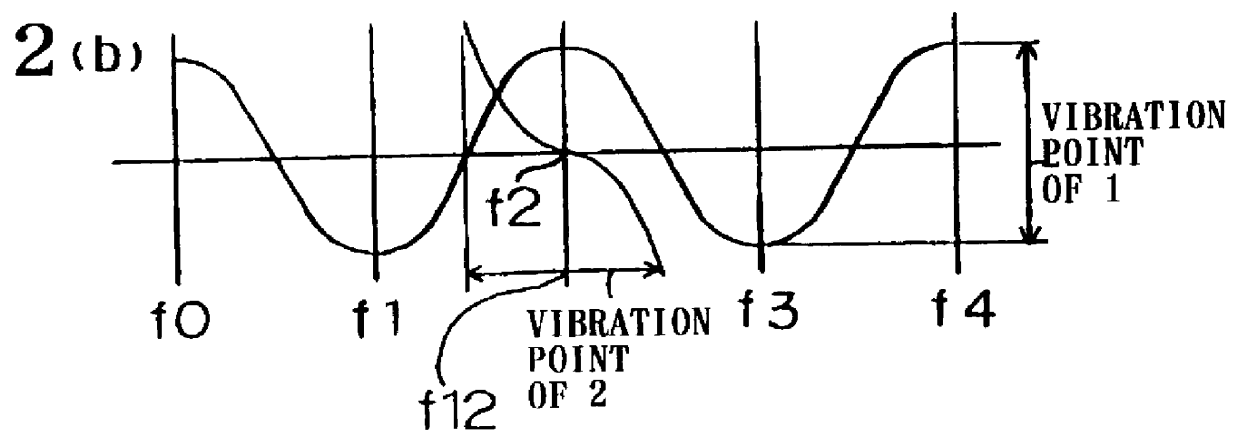

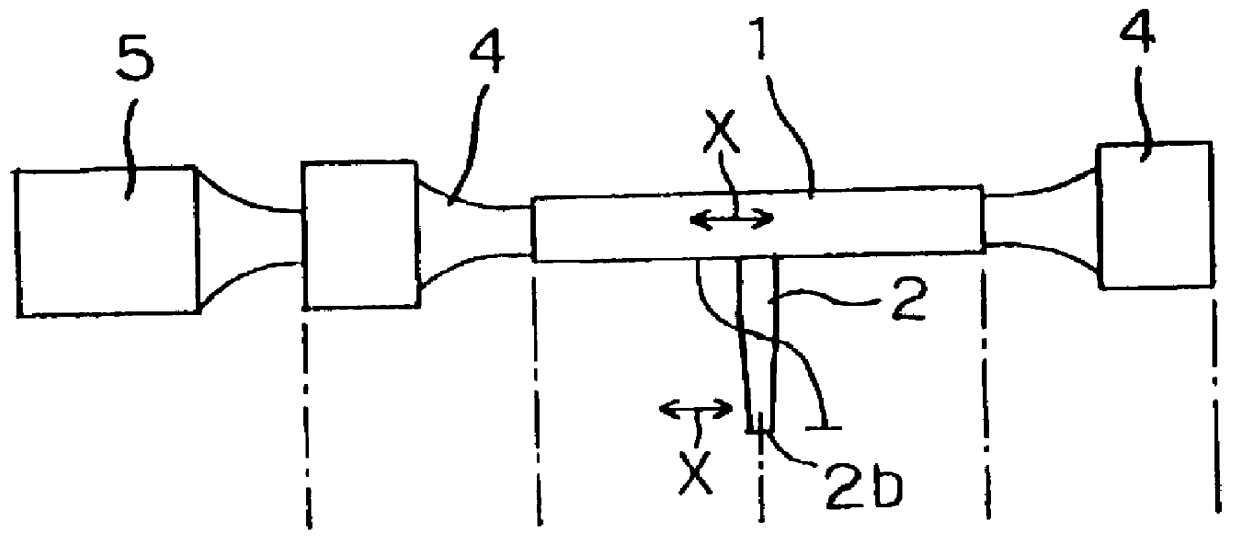

Ultrasonic vibration bonding resonator

InactiveUS6109502APiezoelectric/electrostriction/magnetostriction machinesWelding/cutting auxillary devicesResonanceUltrasonic vibration

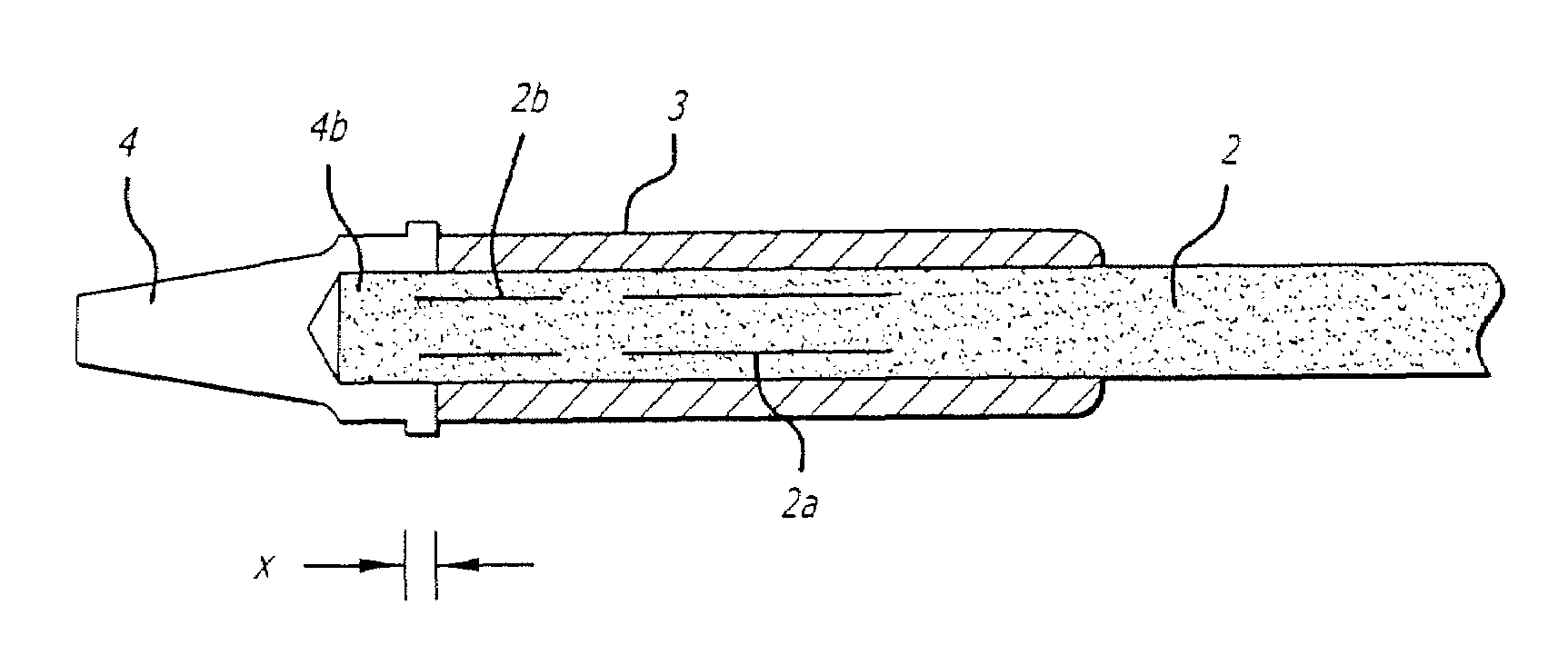

In order to realize effective and economical bonding operation even on workpiece whose inside is quite deep, a bonding tool, which has a length equivalent to a whole number of multiples of half the wavelength of the resonance frequency, is secured to an ultrasonic horn by a screw member which can advance or retreat in a direction perpendicular to the vibration direction indicated by an arrow X,thereby causing a front end surface of the bonding tool vibrate in the same direction as the vibration of the ultrasonic horn.

Owner:ULTEX CORP

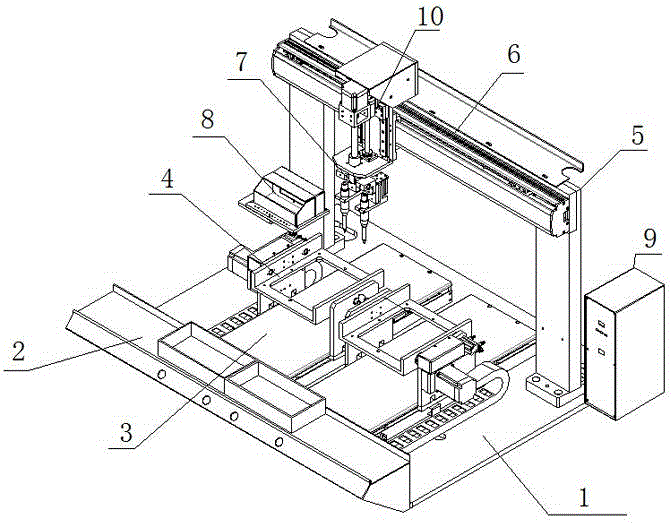

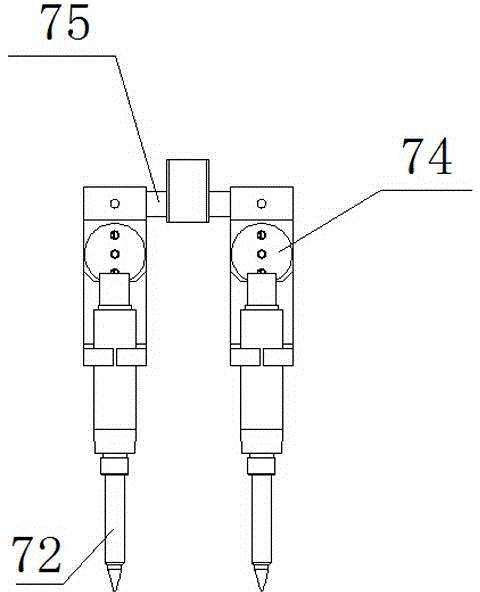

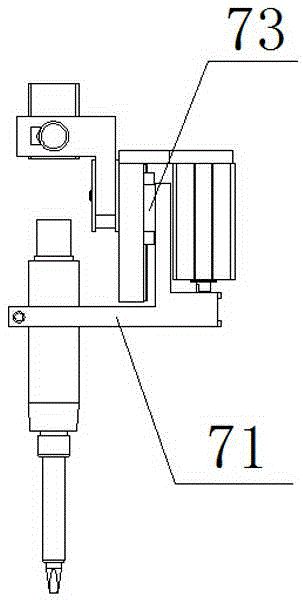

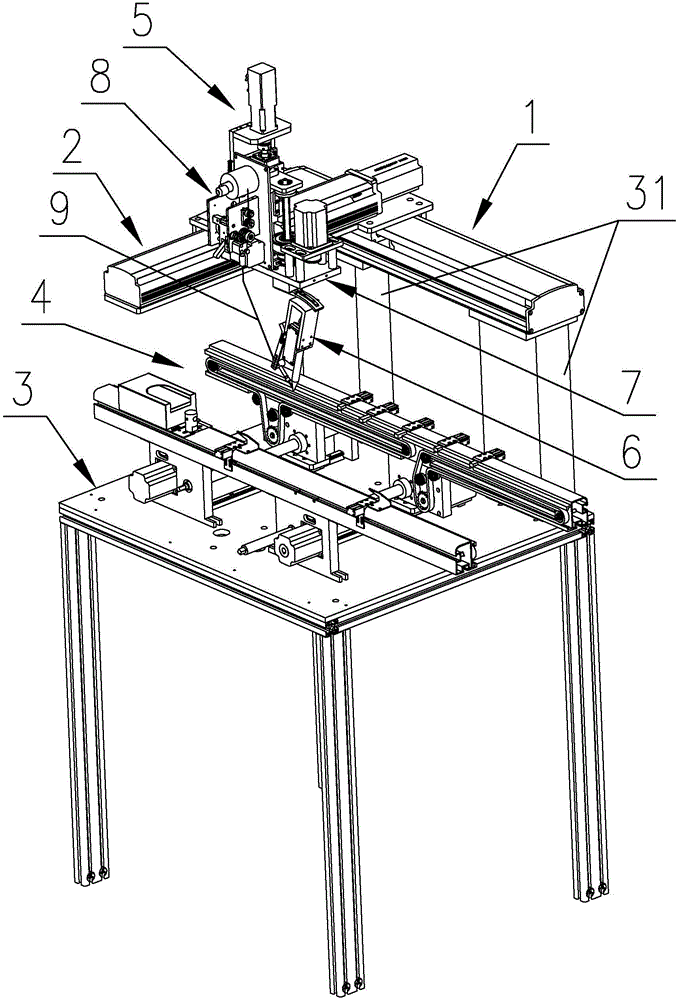

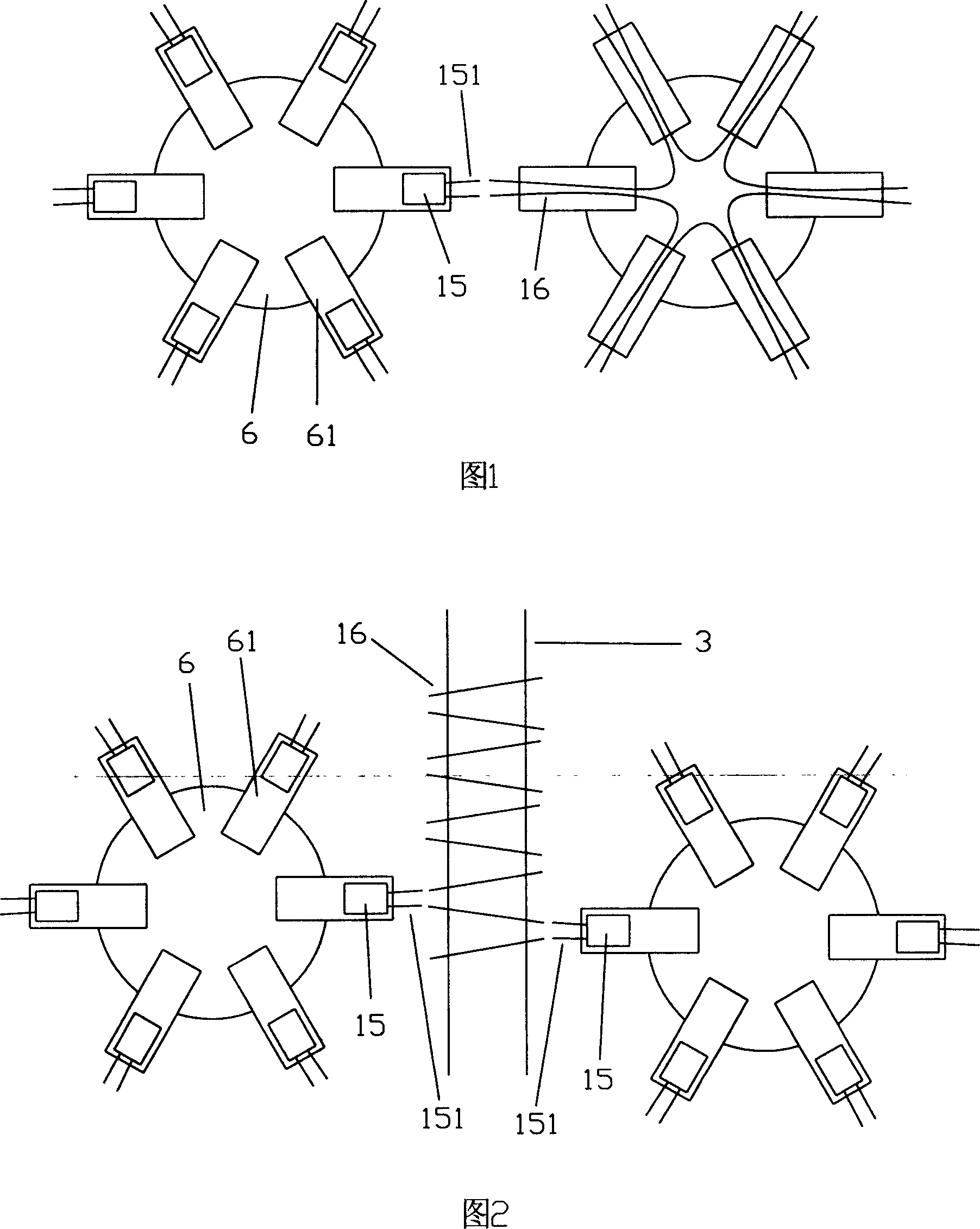

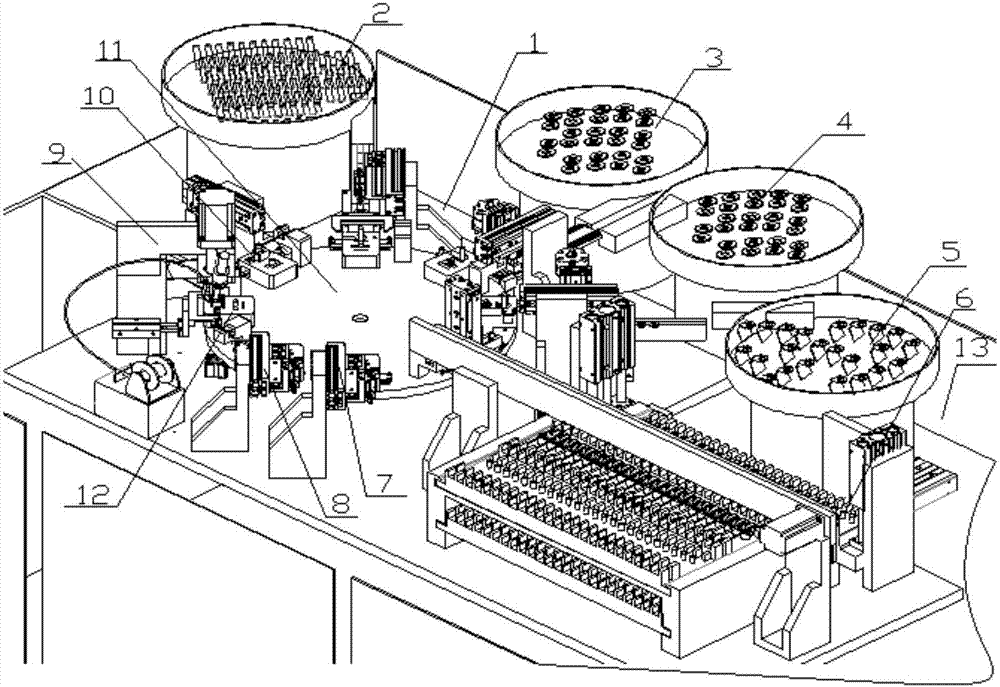

Multidirectional rotation working soldering tin machine capable of overturning jigs

ActiveCN104475900AImprove work efficiencyIncrease flexibilityHeating appliancesSoldering ironSlagTin

The invention relates to a multidirectional rotation working soldering tin machine capable of overturning jigs. The multidirectional rotation working soldering tin machine capable of overturning the jigs comprises a machine panel, a material station, Y-axis conveying mechanisms, overturning mechanisms, a welding bracket, an X-axis conveying mechanism, a multi-head independent control welding mechanism, a tin slag box, a welding station box, a soldering iron fixing block, a soldering iron, a sliding rail guide buffering assembly, a soldering iron left-and-right inclination angle regulating mechanism, a front-and-rear rotary regulating bracket and a soldering iron transfer cylinder. The multidirectional rotation working soldering tin machine capable of overturning the jigs can be used for determining to set the numbers of the overturning mechanisms and the Y-axis conveying mechanisms according to loading time and tin soldering time; by arranging more than one overturning mechanism paired with the Y-axis conveying mechanisms for use, a circuit board on which materials are loaded can be full-automatically overturned in a range of 180 degrees and the multi-head independent control welding mechanism can carry out non-stop tin soldering; the working efficiency is high; the working angle of the soldering iron in the random front-and-rear inclined direction can be regulated by the front-and-rear rotary regulating bracket; the working angle of the soldering iron in the random left-and-right inclined direction can be regulated by the soldering iron left-and-right inclination angle regulating mechanism; the multidirectional rotation working soldering tin machine capable of overturning the jigs has strong flexibility, has good effects and is low in cost.

Owner:DONGGUAN OKATA ELECTRONICS & TECH

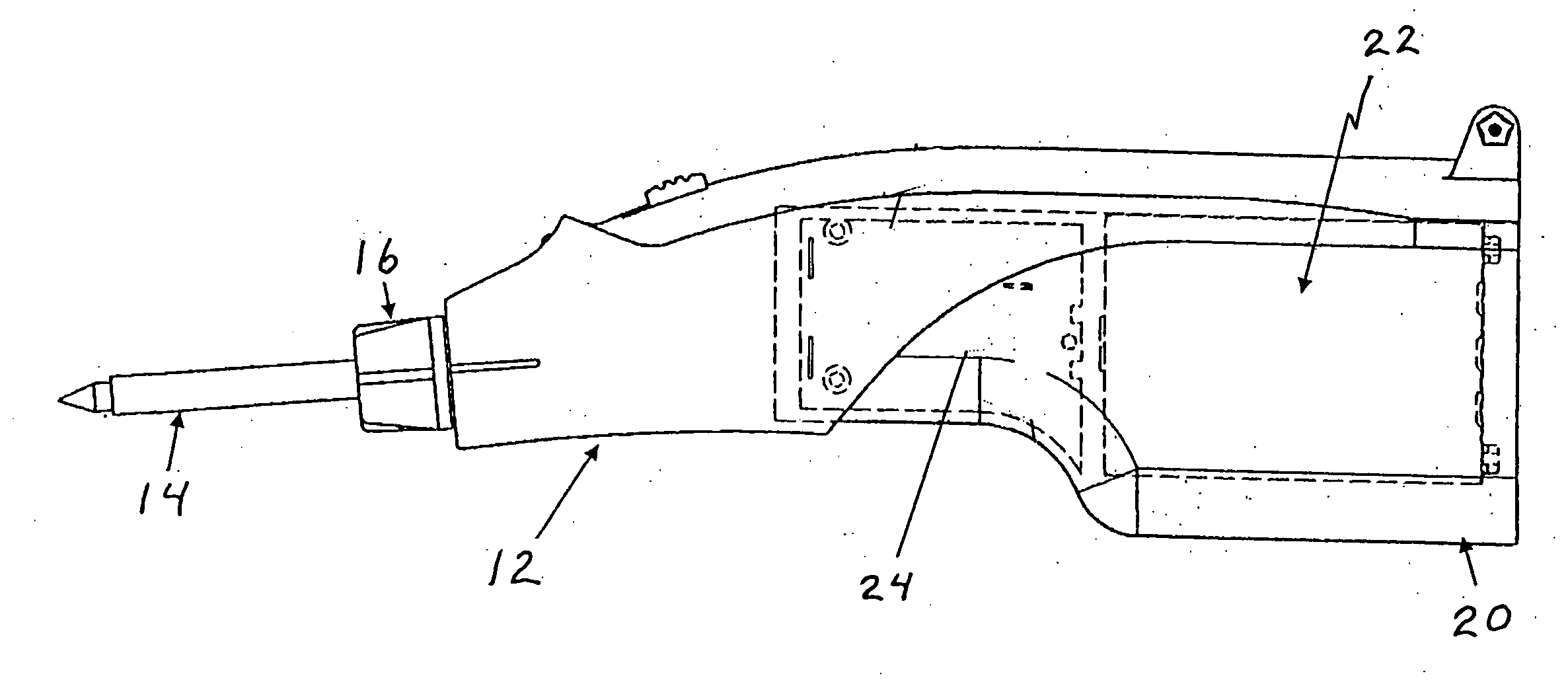

Self-feeding soldering device

A self feeding soldering device includes a soldering device; a solder feed mechanism carried on the soldering device; and a solder system controller in controlling connection with the soldering device and the solder feed mechanism. The solder feed mechanism allows the user to control the feed of solder wire onto the heated soldering tip of the soldering device or the area adjacent to the heated soldering tip to be soldered to free one hand of the user to secure the objects to be soldered.

Owner:MORRISON TERRY H

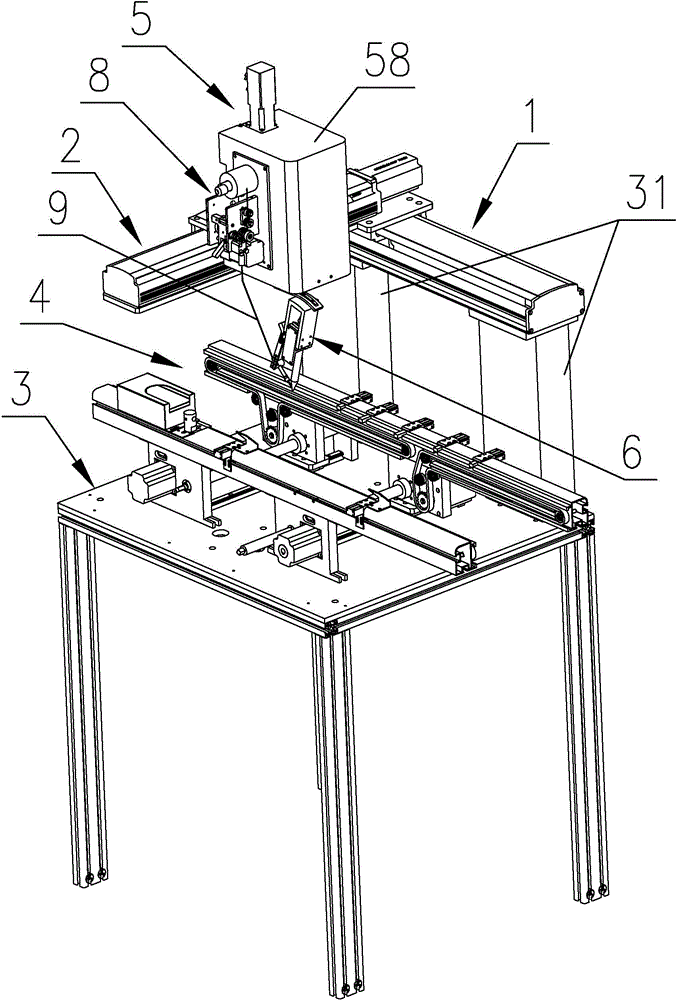

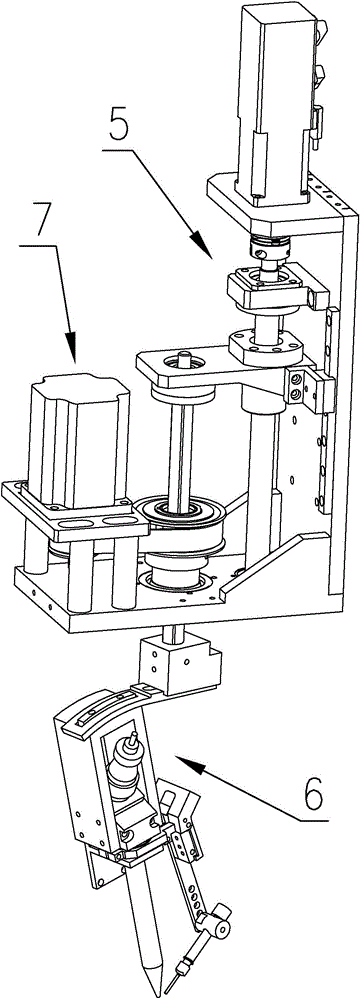

Cantilever type automatic tin soldering device

InactiveCN104625290AImprove efficiencyQuality improvementWelding/cutting auxillary devicesAuxillary welding devicesEngineeringAssembly line

The invention provides a cantilever type automatic tin soldering device. The device comprises an X-axis movement module, a Y-axis movement module, a rack and a product conveying assembly line, wherein the product conveying assembly line is installed on the rack, the X-axis movement module is installed on the rack through a supporting plate, and the Y-axis movement module is installed on the X-axis movement module. The device further comprises a Z-axis lifting module, an iron welding assembly, an iron welding assembly rotating device and a soldering tin supplying device, wherein the Z-axis lifting module is installed on the Y-axis movement module through a supporting frame, the iron welding assembly rotating device is installed on the supporting frame, the iron welding assembly is installed on the iron welding assembly rotating device, the solder wire supplying device is installed on the supporting frame, products to be subjected to tin soldering are fed into the product conveying assembly line and positioned, the iron welding assembly rotating device drives the iron welding assembly to rotate to an assigned angle, the soldering tin supplying device is used for conveying soldering tin to the iron welding assembly, and the X-axis movement module, the Y-axis movement module and the Z-axis lifting module are combined to drive the iron welding assembly to an assigned position for tin soldering.

Owner:东莞新友智能科技有限公司

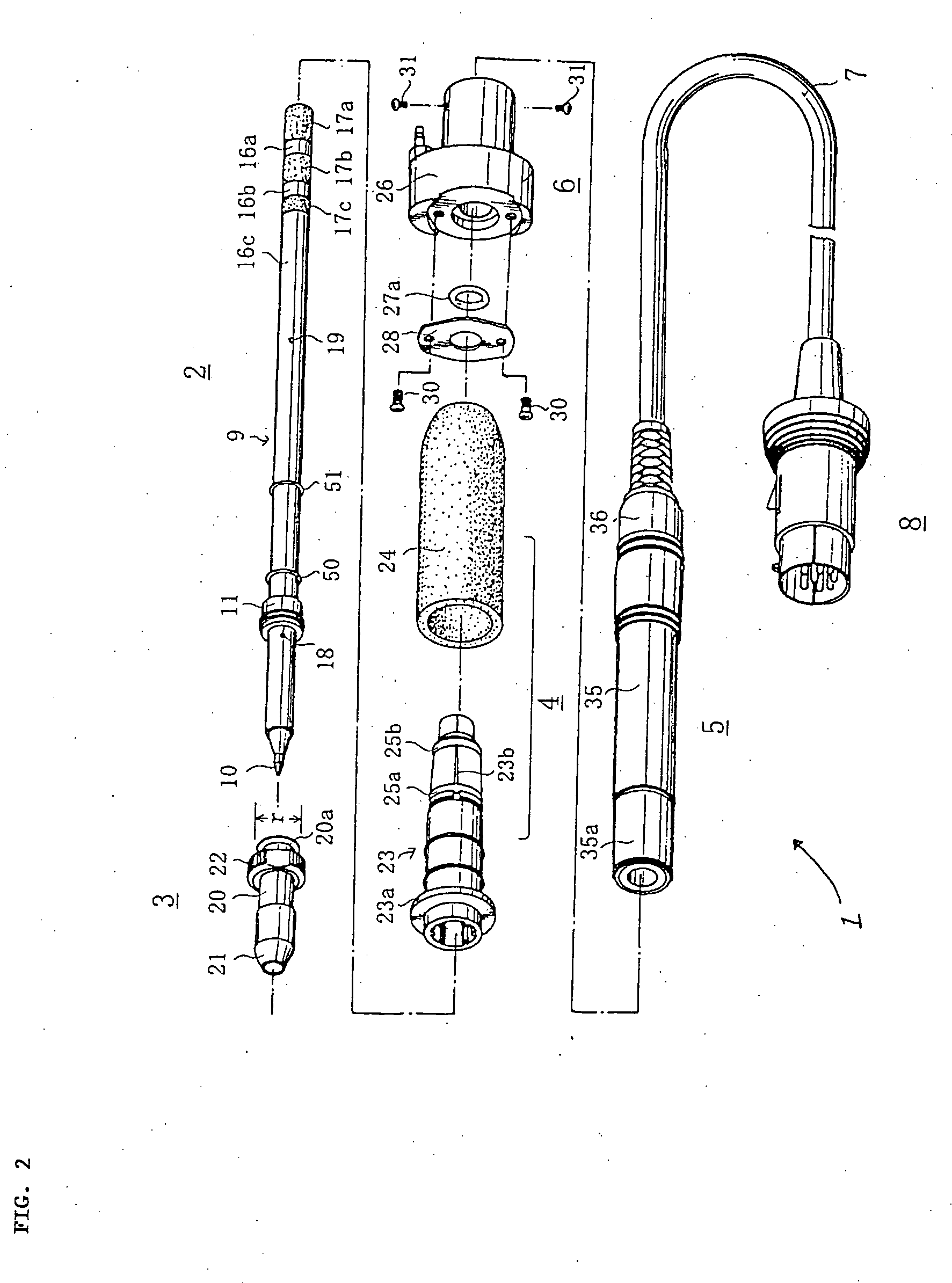

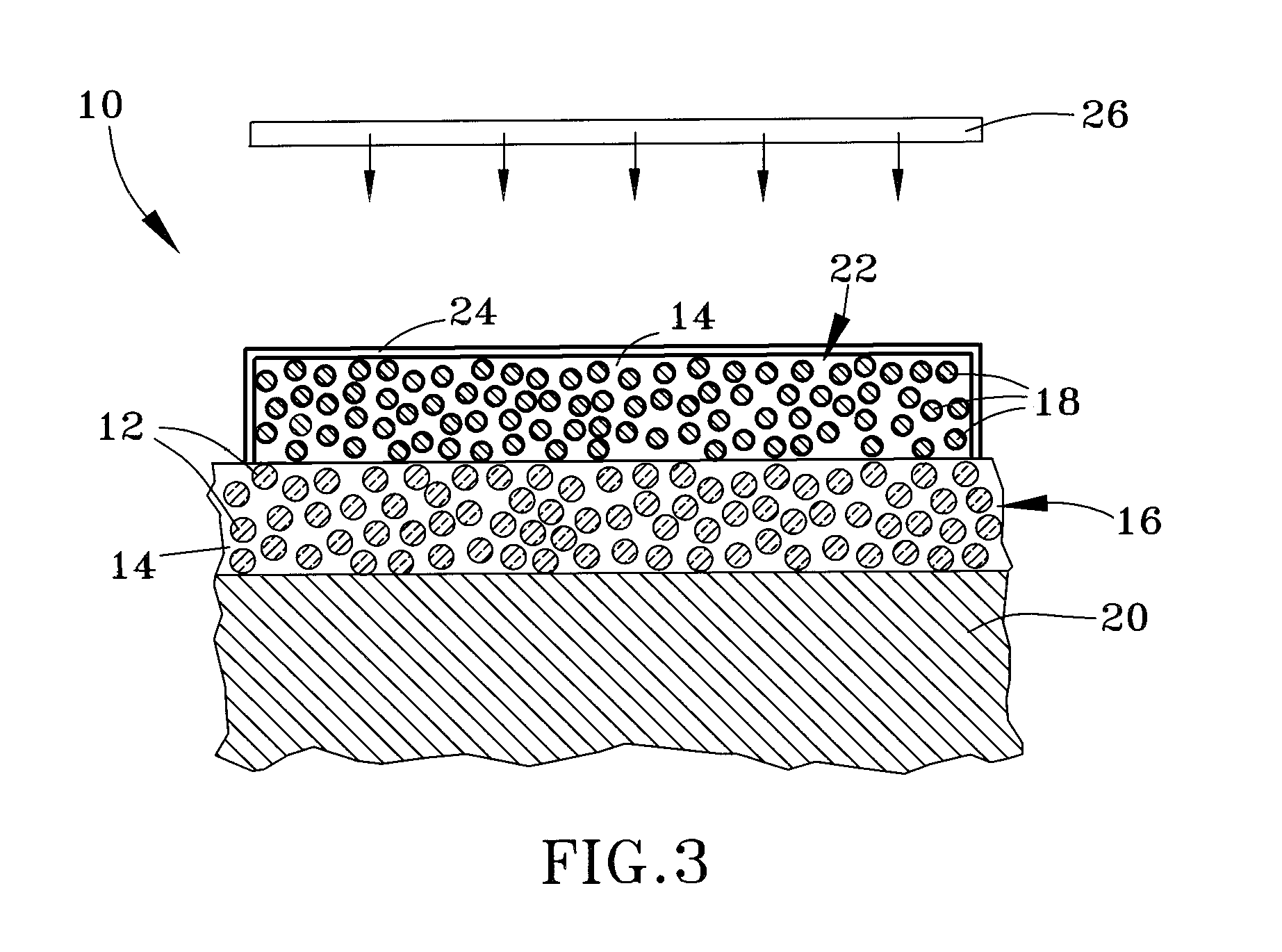

Replaceable soldering tip with sensor recess

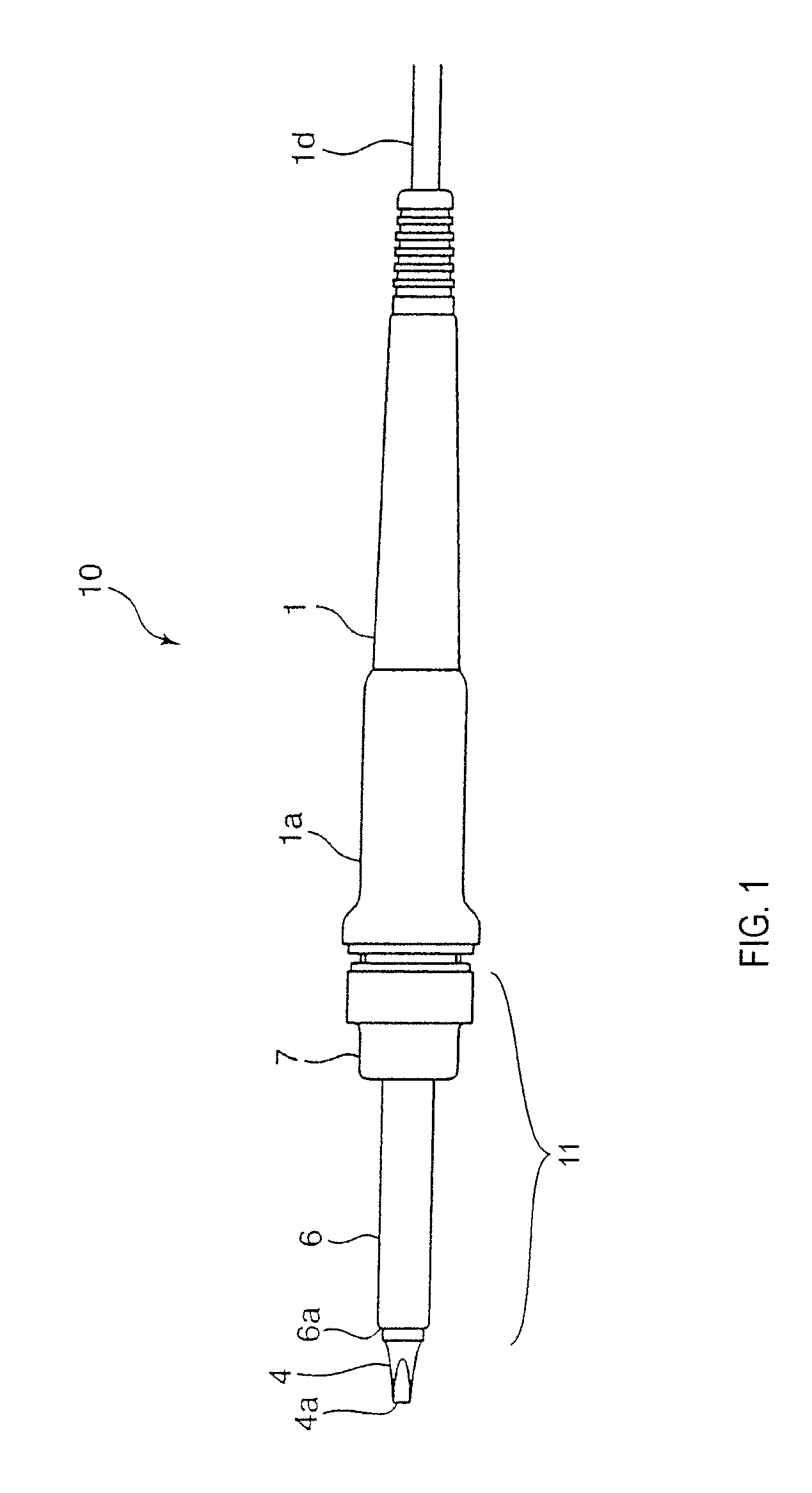

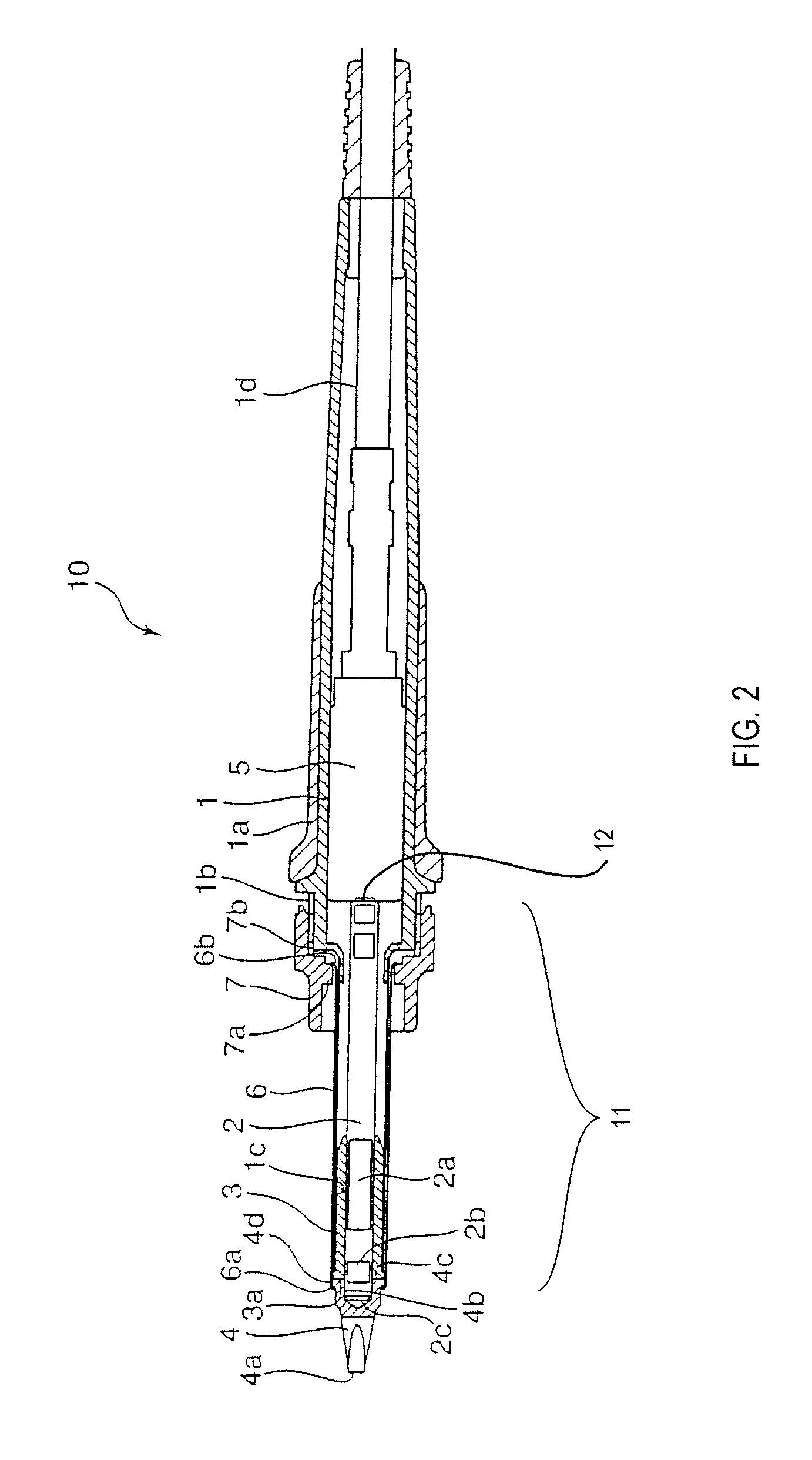

ActiveUS20040232132A1Easy to monitorHeating fastHeating element shapesHeating appliancesSolderingBiomedical engineering

A soldering or a desoldering tool includes a replaceable tip with a recess adapted to receive a portion of a temperature sensor to measure the temperature of the tip. Positioning the temperature sensor within the tip allows the temperature to be quickly measured so that the temperature near the tip may be more accurately monitored and controlled. The temperature sensor may be also integrated with the heater near the tip such that the temperature sensor is between the tip and the heater and near both of them so that the temperature of the tip is substantially that of the temperature of the heater. A sleeve may enclose the temperature sensor and the heater with a portion of the temperature sensor extending out from the foreward end of the sleeve. The replaceable tip may also have a bore adapted to receive a head protruding from the foreward end of the sleeve to couple the tip at a predetermined orientation with respect to the sleeve. The combination of bore and head allows the replaceable tip to be coupled with the sleeve in a consistent manner so that the temperature of the replacement tips can be measured accurately and dependably.

Owner:HAKKO CO LTD

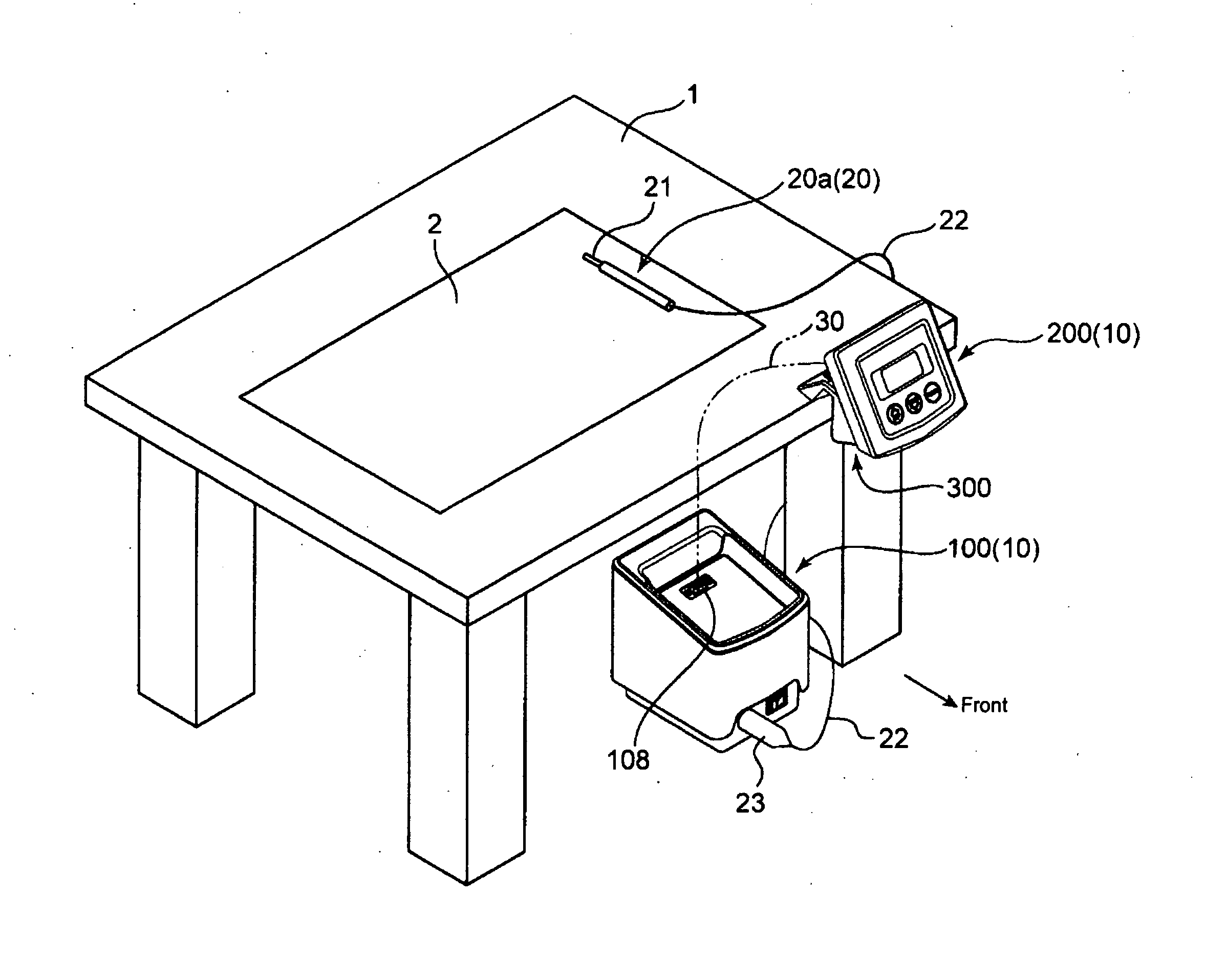

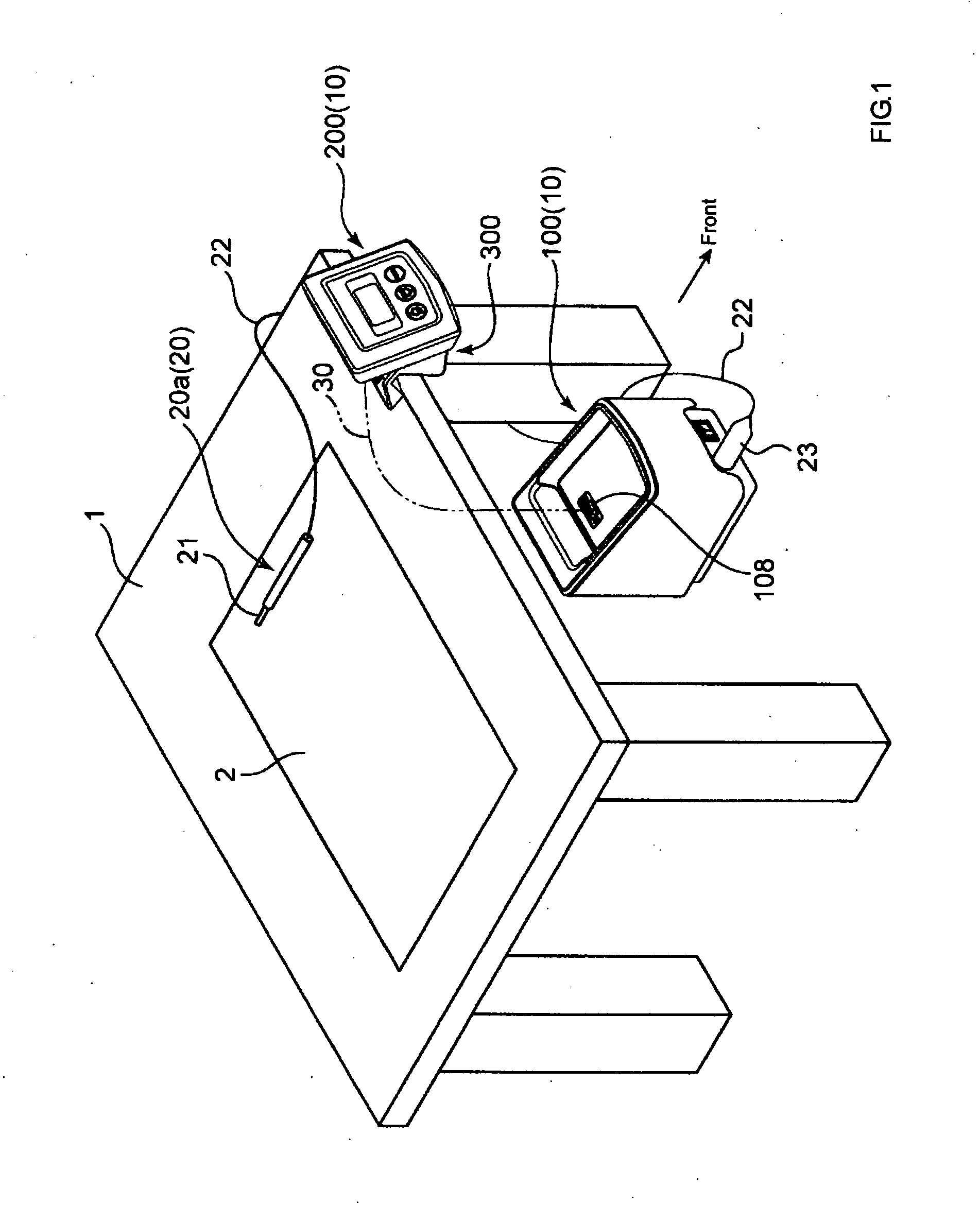

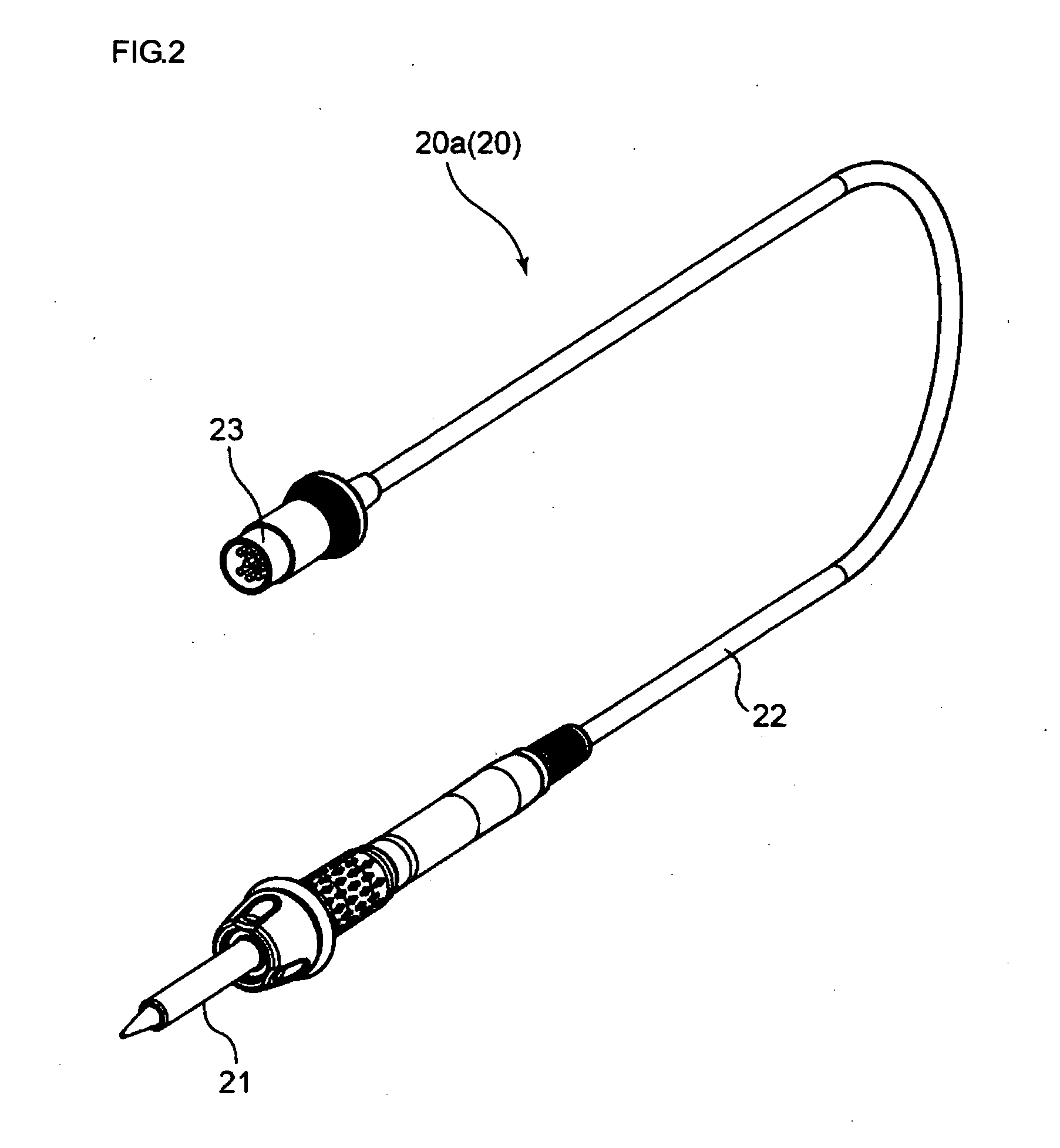

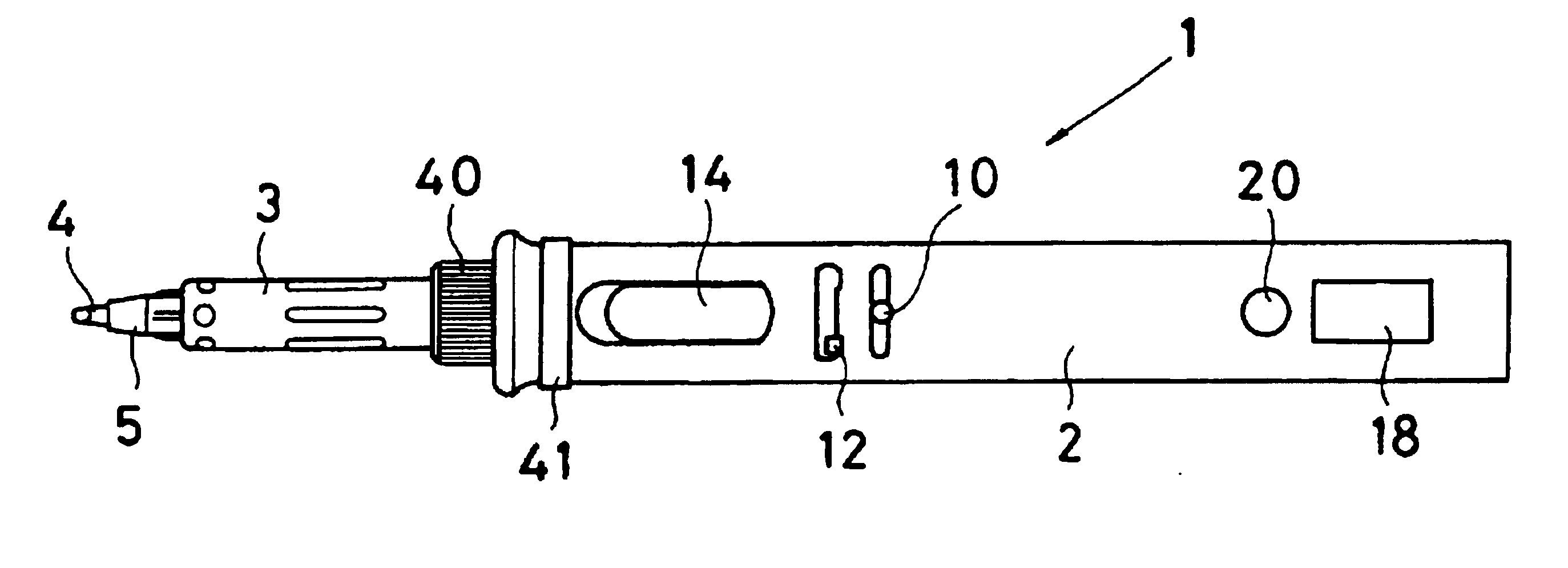

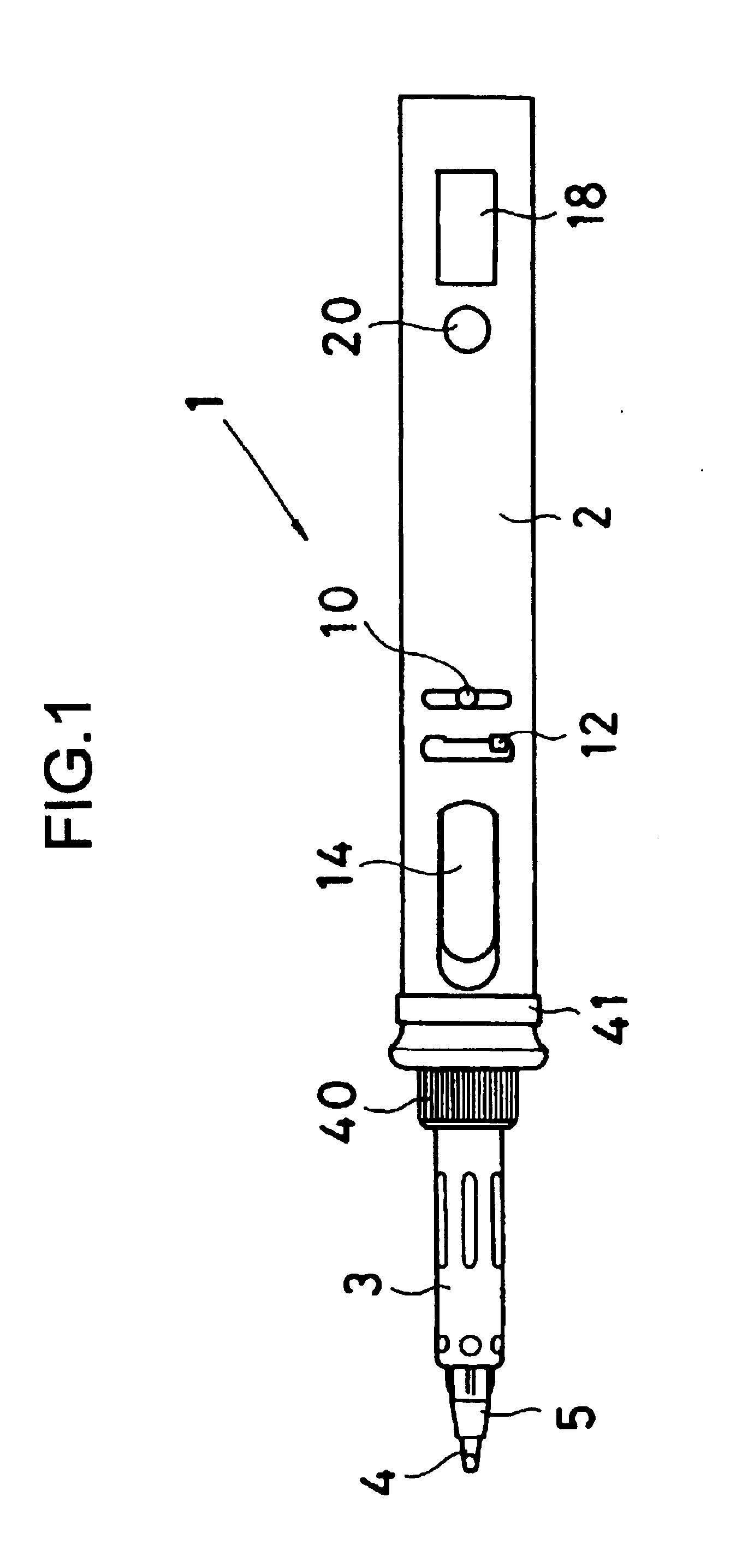

Soldering System Power Supply Unit, Control Unit, Administration Device, and Power Supply-and-Control Device

ActiveUS20150246404A1Improve convenienceSmall working areaComputer controlArc welding apparatusSolderingControl unit

The present invention is intended to ease the control and management of soldering devices, and enhance convenience. In accordance with the intention of the invention, a system includes a power supply unit having a connecting cable to be connected to soldering devices, a power supply portion supplying power to the soldering devices through the connecting cable, a power supply control portion to control the power supply from the power supply portion based on a temperature setting signal T(s) set in advance and a control unit that may be physically separated from the power supply unit but which inputs the temperature setting signal T(s) to the power supply control portion of the power supply unit.

Owner:HAKKO CO LTD

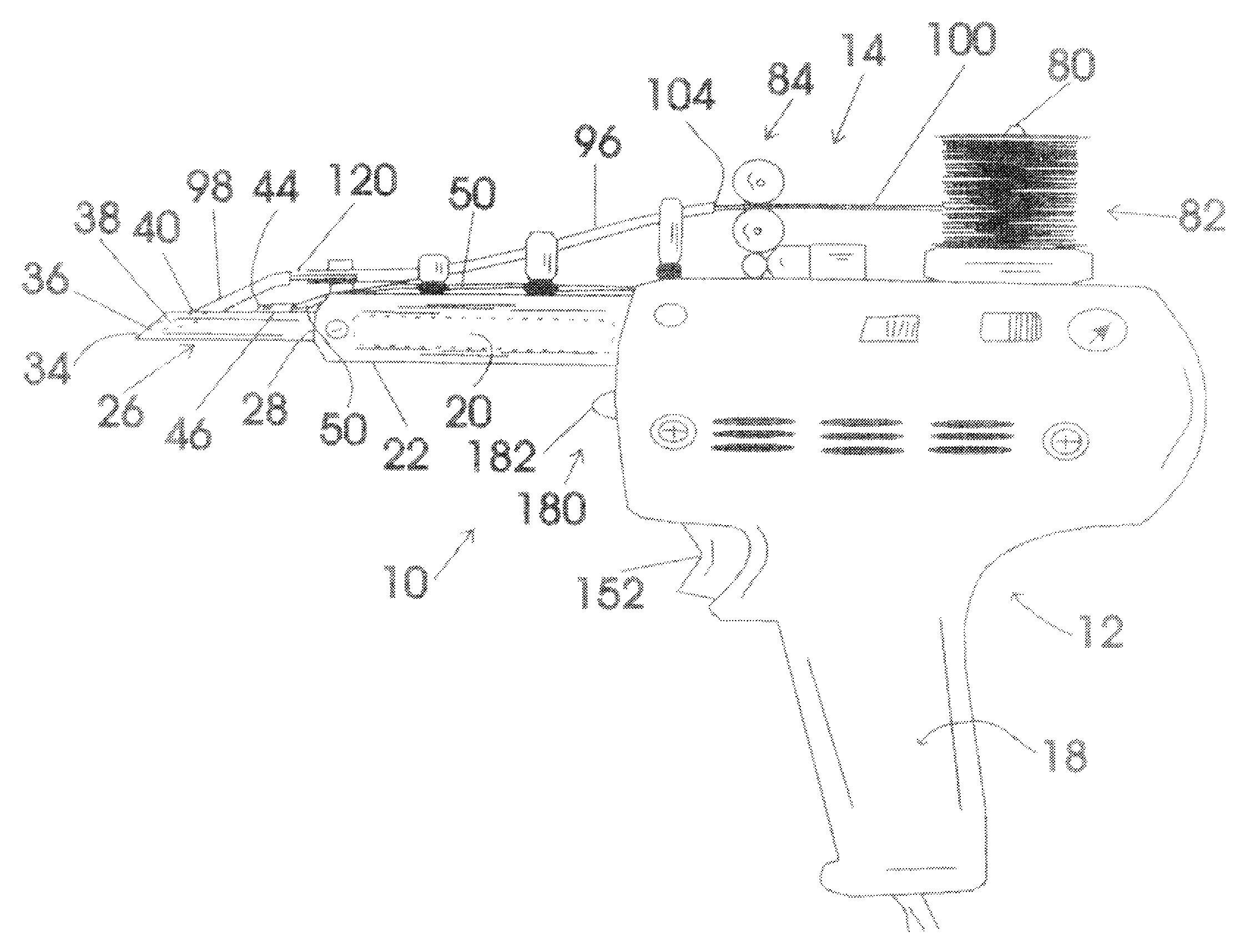

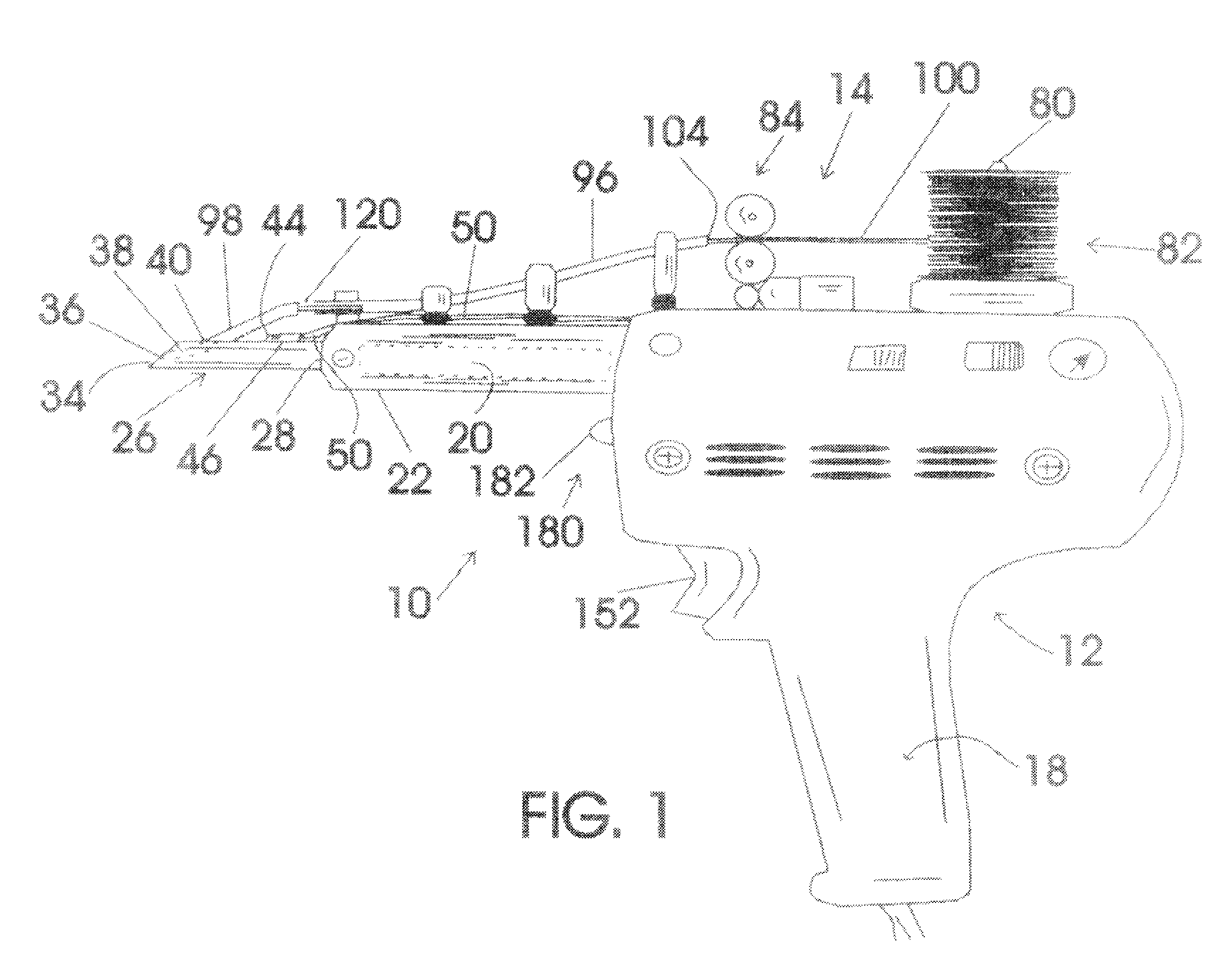

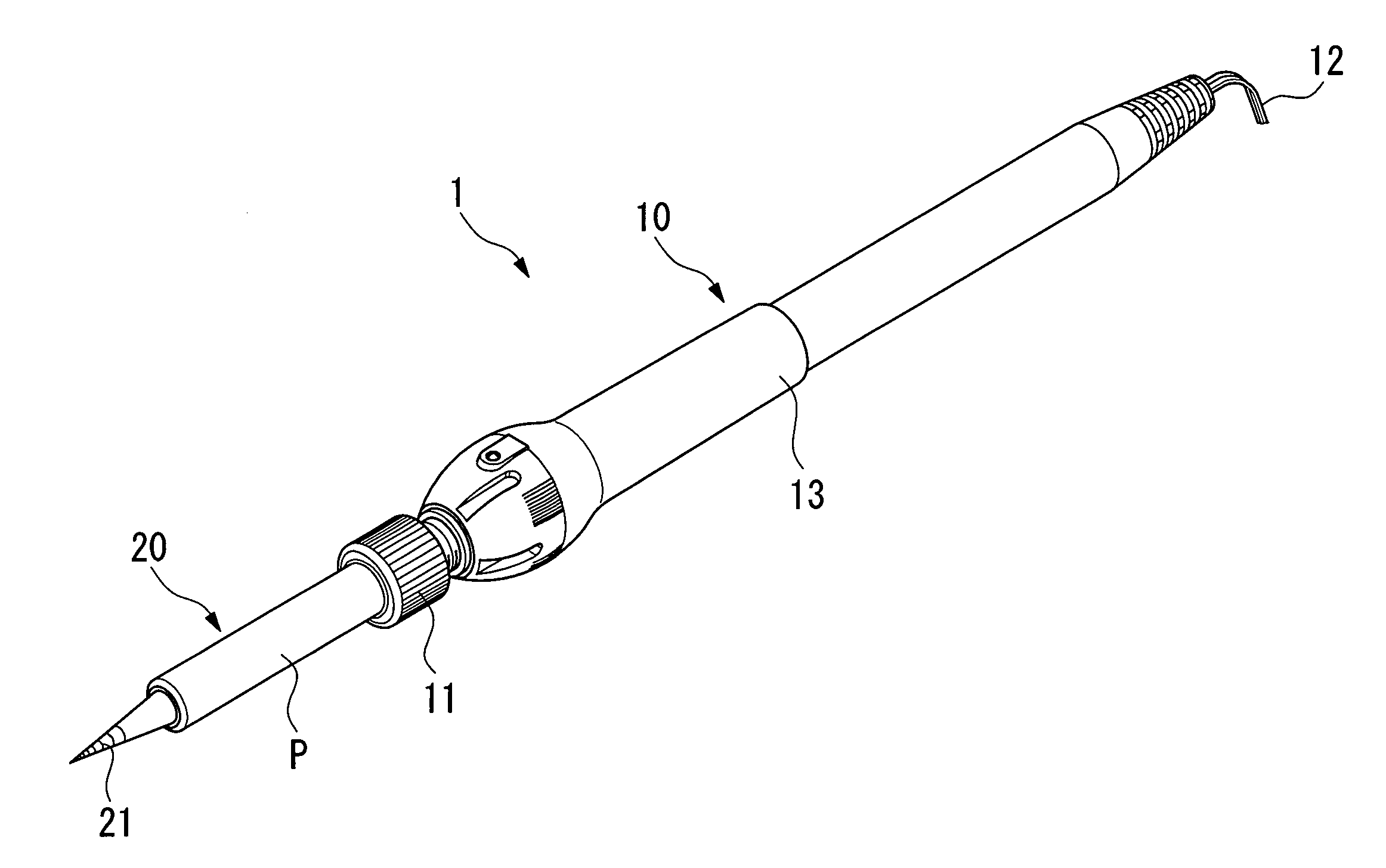

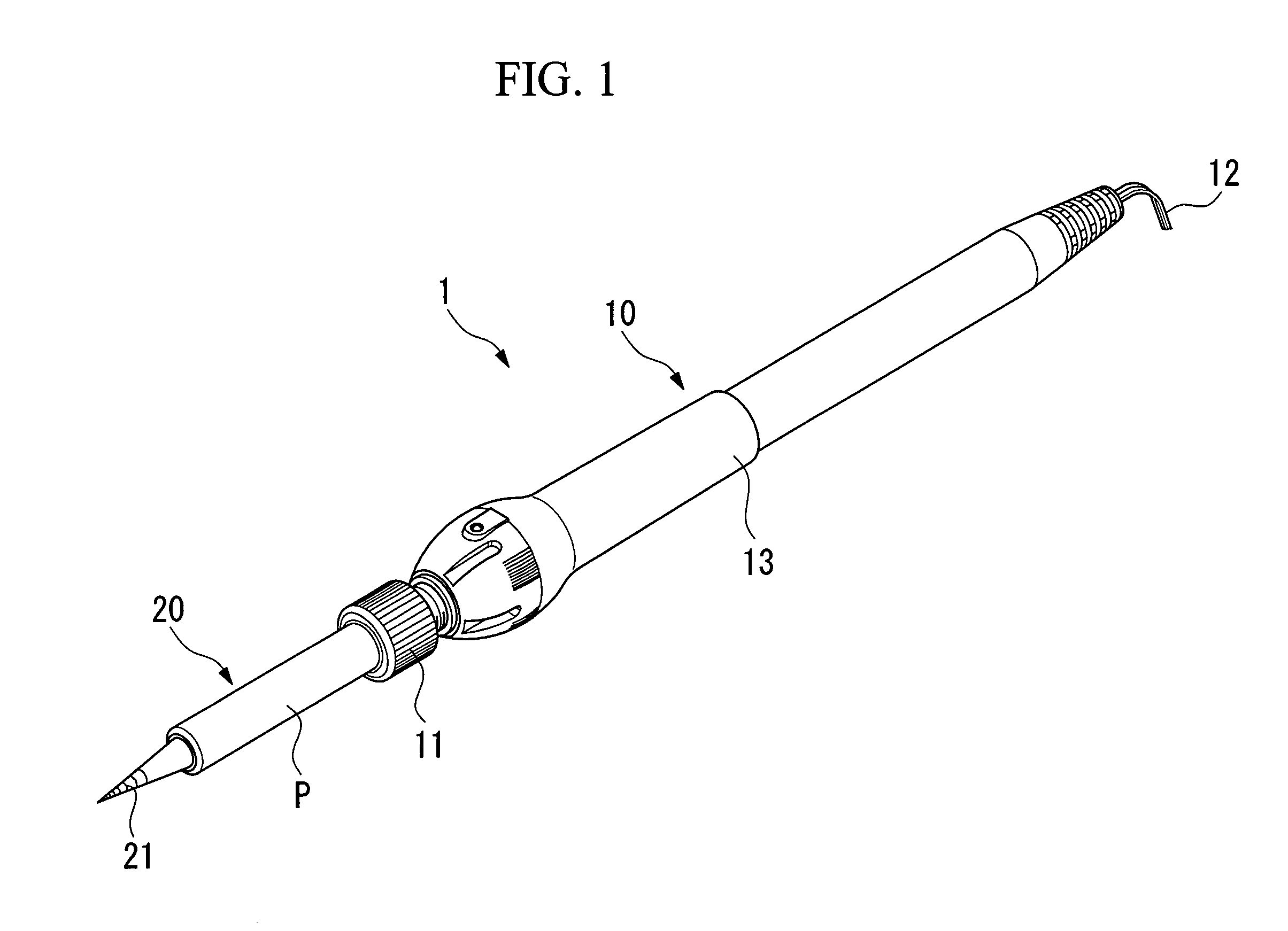

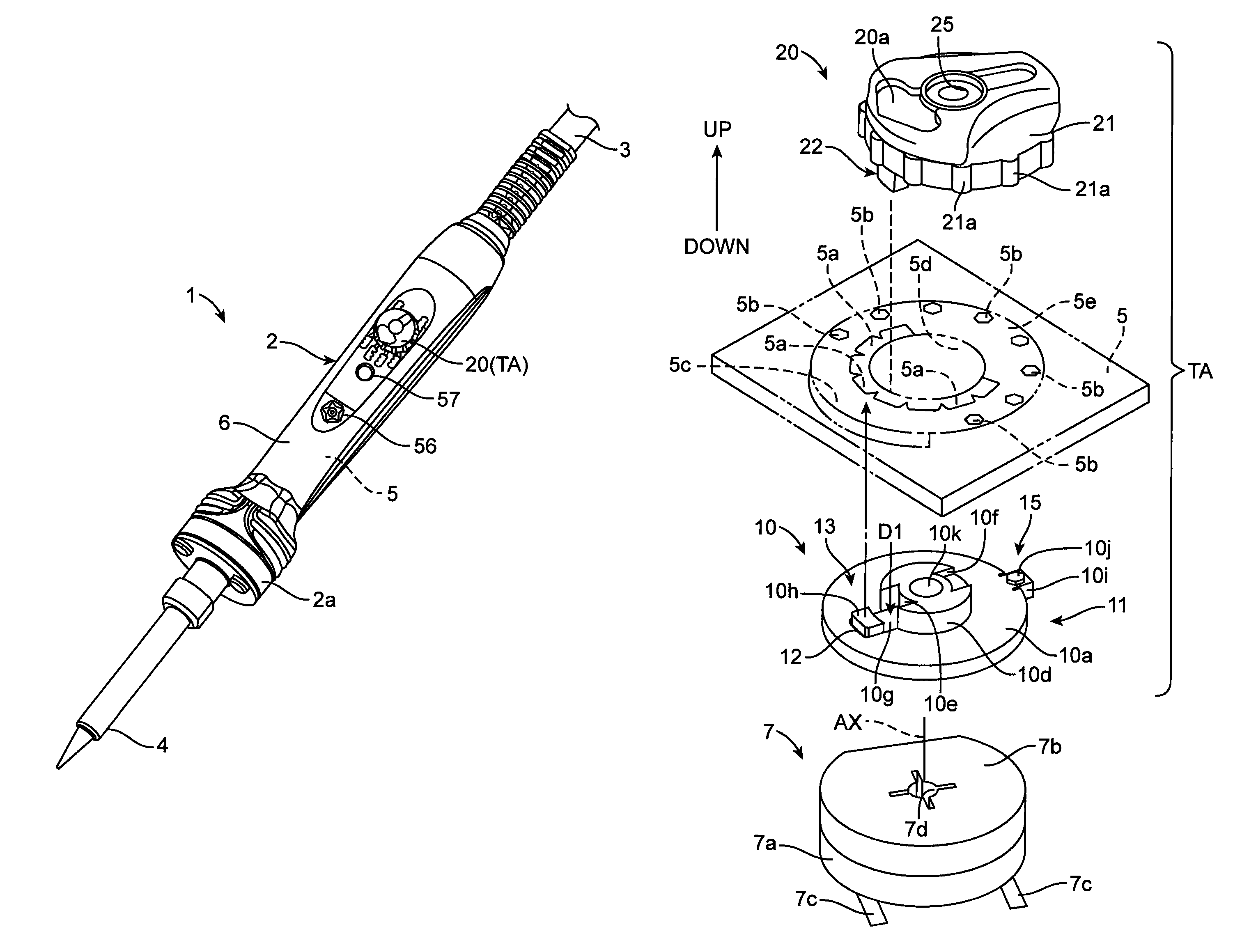

Automated soldering system

An automated soldering system with an intelligent power supply that can automatically configure the power output to interchangeable soldering cartridges, where the soldering cartridges include readable information to allow the power supply to properly power the cartridge to achieve a desired, entered operating temperature. The system includes a cartridge with an identifier that contains information particular to that cartridge, a reader able to read that information, and an indicator positioned on a connector into which the cartridge is inserted.

Owner:HAKKO CO LTD

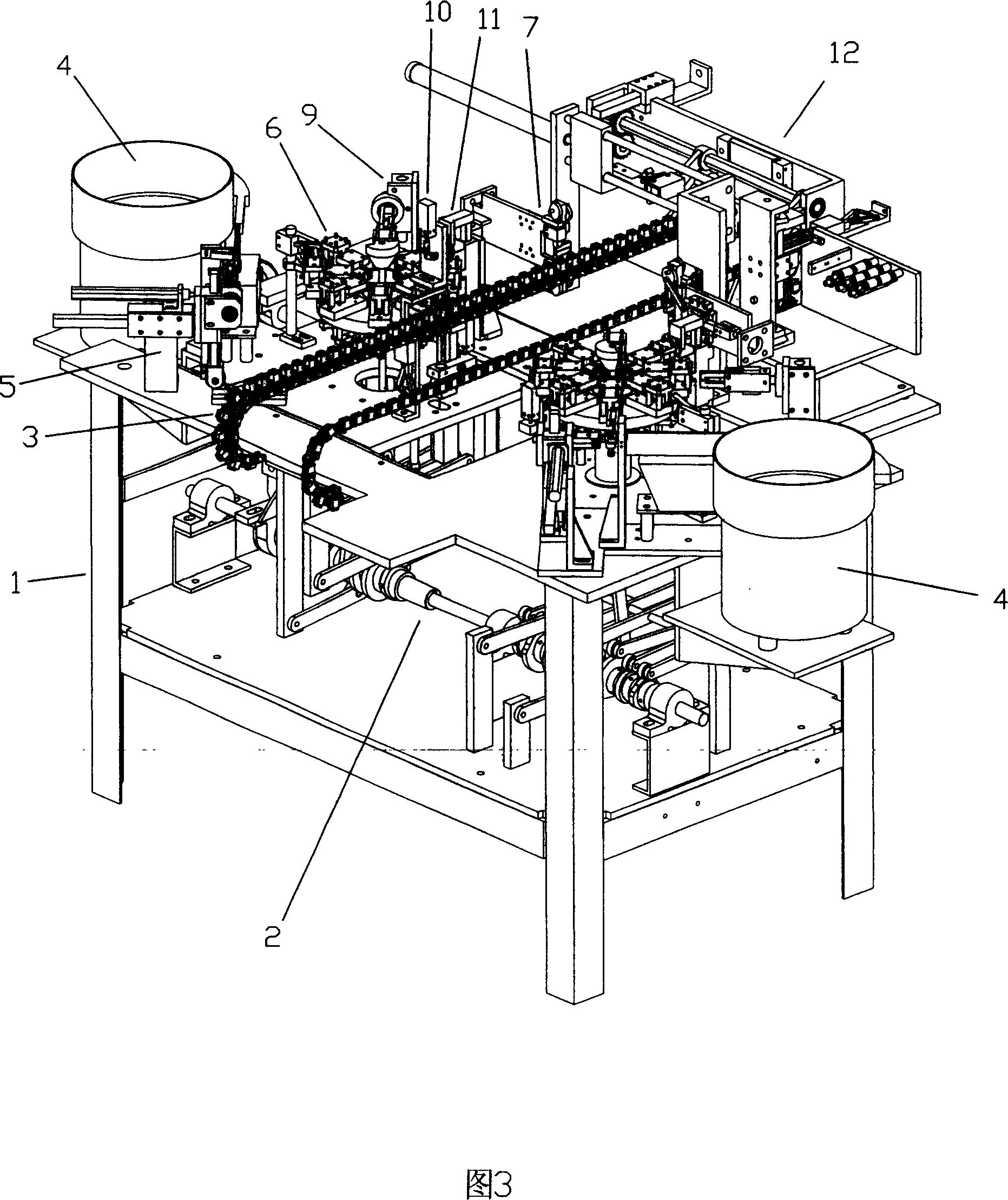

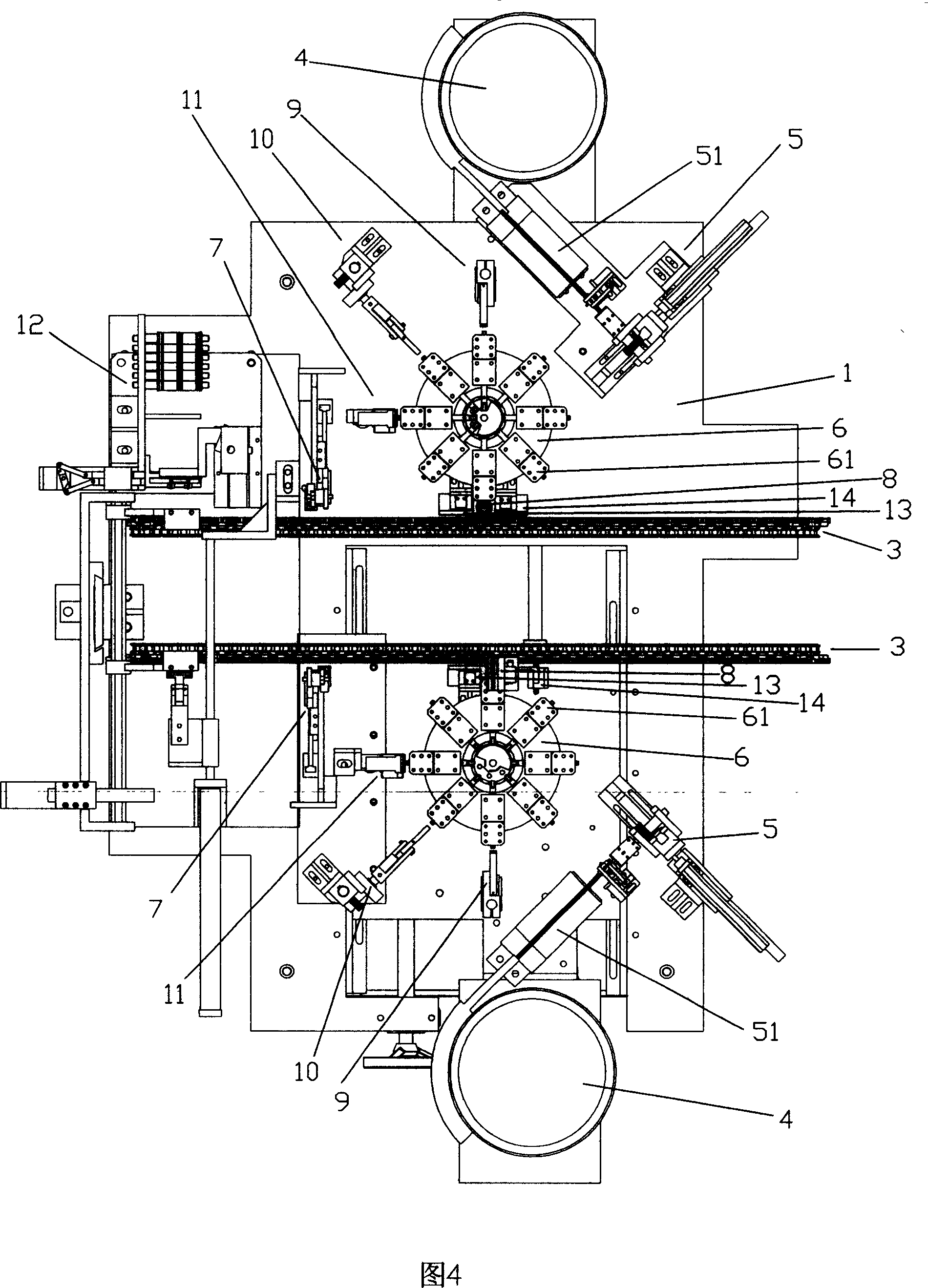

LED lamp pin welding method and equipment

InactiveCN101021298AIncrease productivityShort welding timeLine/current collector detailsPoint-like light sourceWire cuttingLED lamp

The present invention relates to a LED lamp pin welding equipment. It includes machine frame, transmission mechanism positioned under the machine frame, conveying chain positioned on the machine frame, vibration plate, LED-placing device, clamping device, stripping and wire-cutting device and welding device. It is characterized by that on the above-mentioned machine frame it has two vibration plates, two LED-placing devices, two clamping devices, two stripping and wire-cutting devices and two welding devices which are respectively positioned at two sides of conveying chain. Besides, said invention also provides the welding method matched with said LED lamp pin welding equipment.

Owner:HE SHAN NEO NEON LIGHTING DECORATION LTD

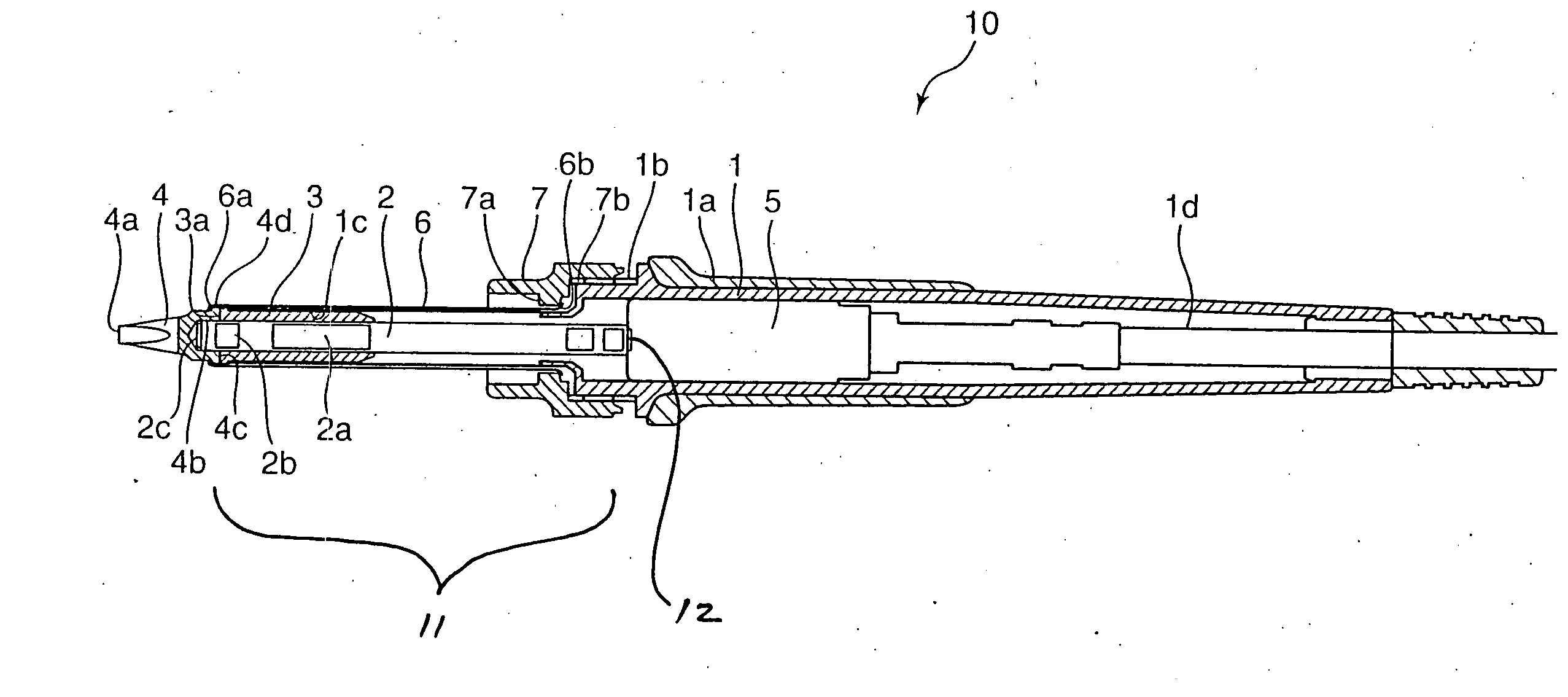

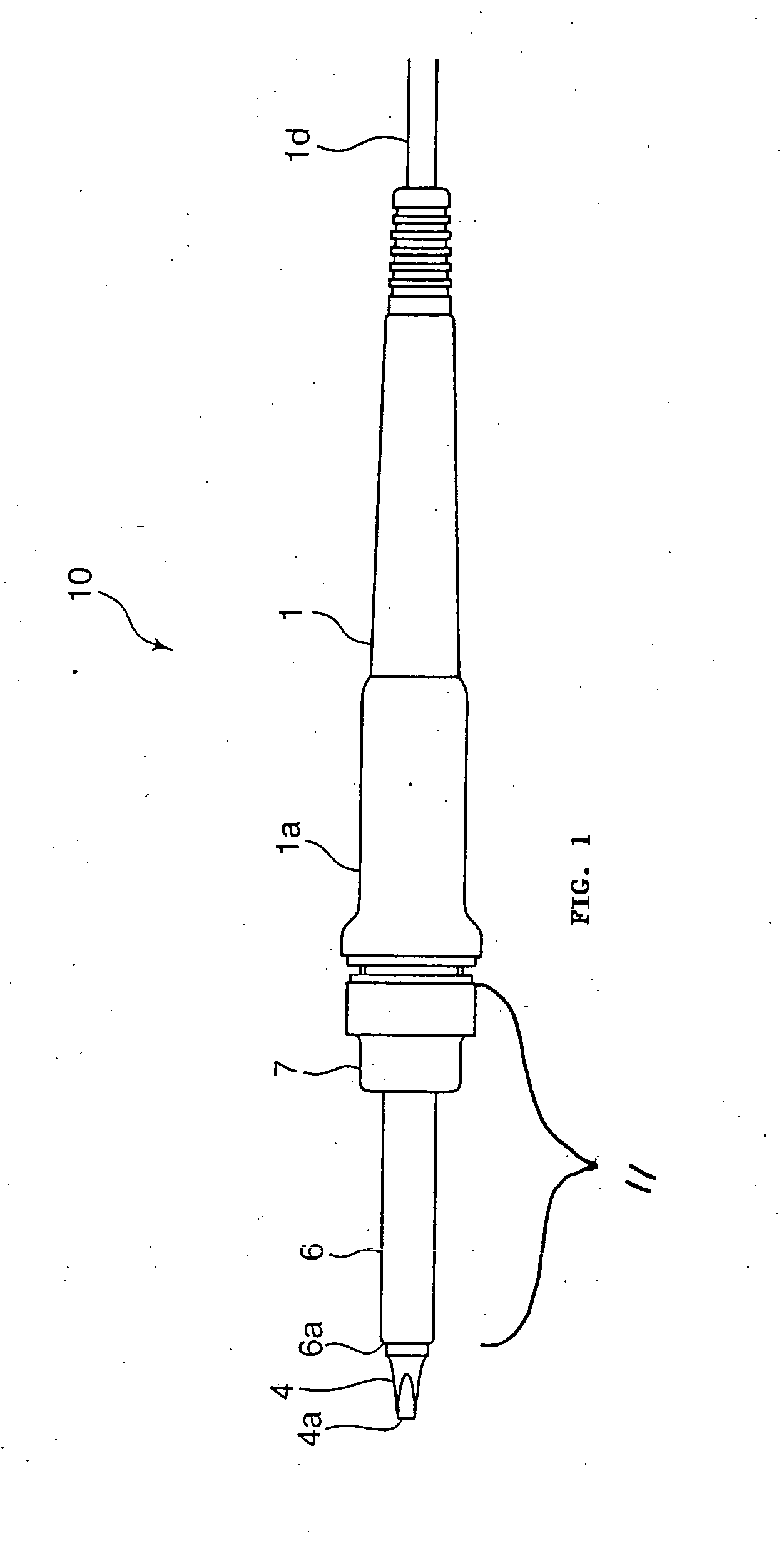

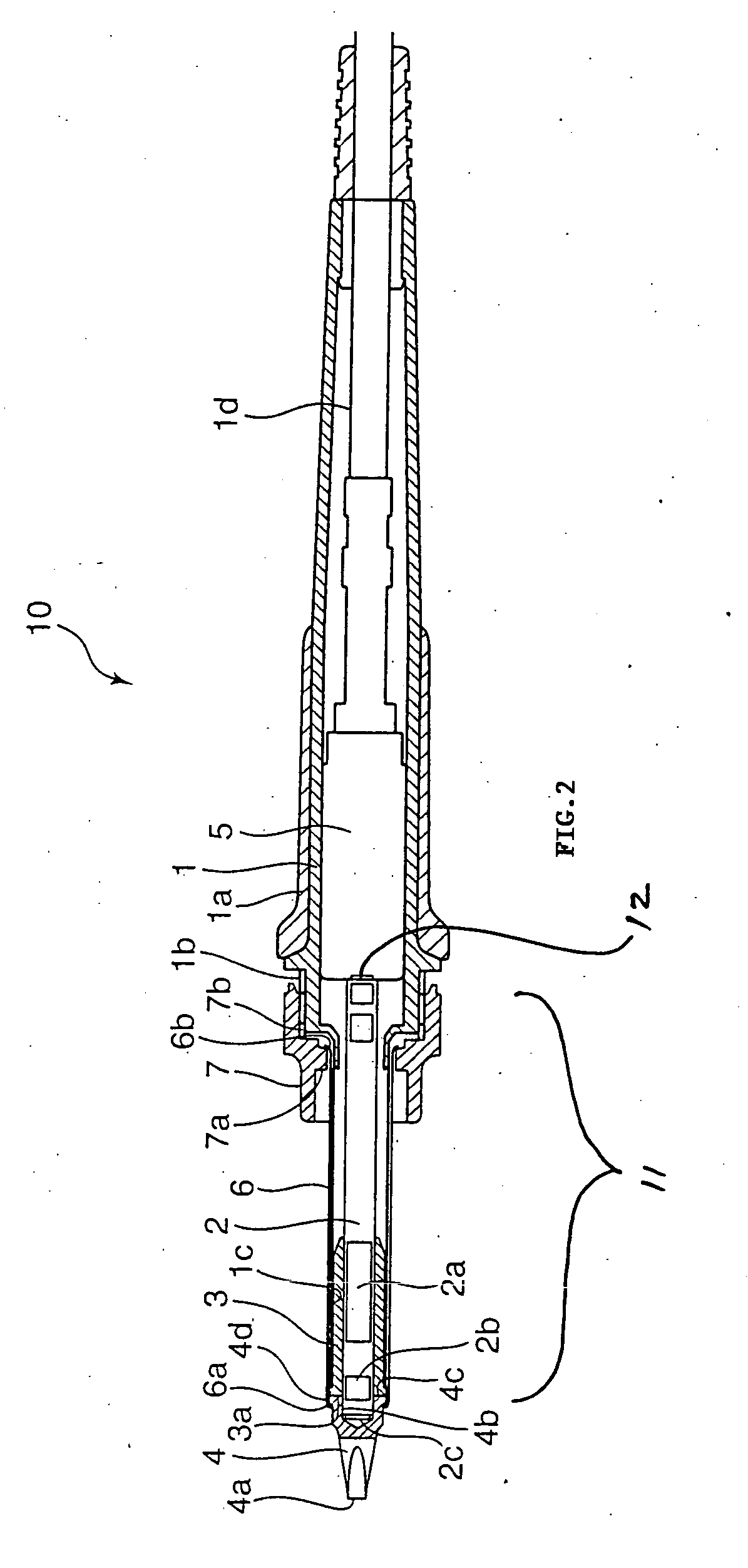

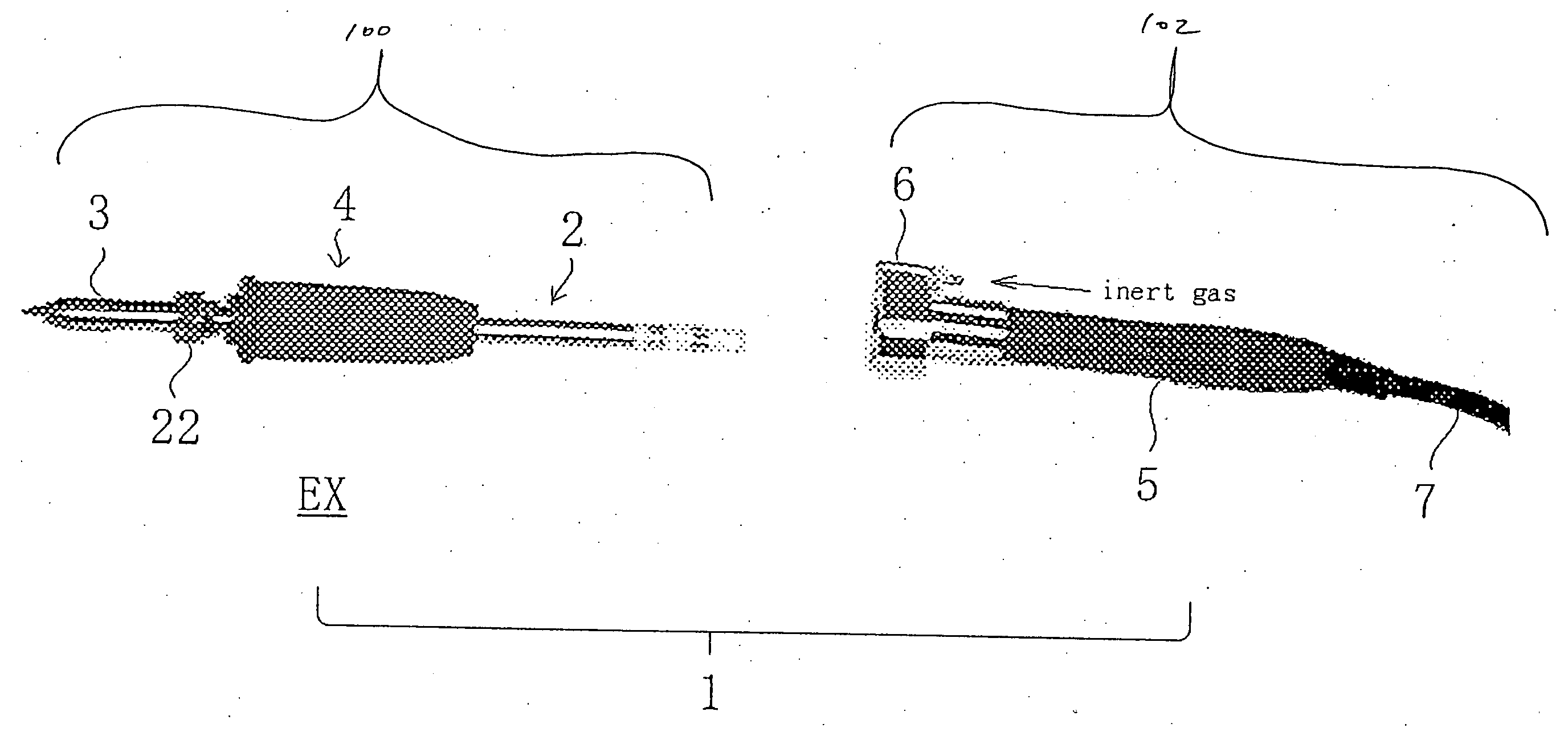

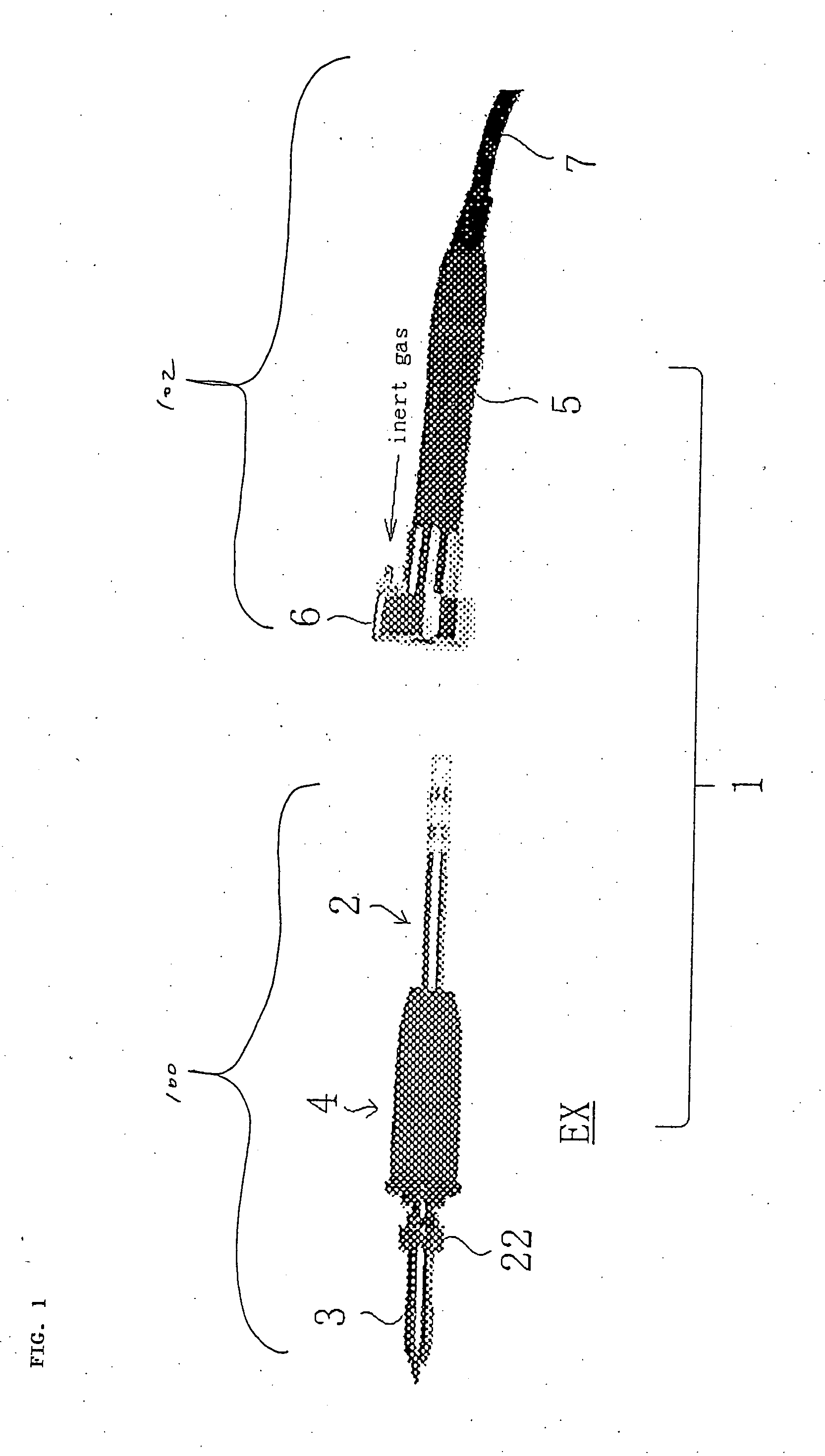

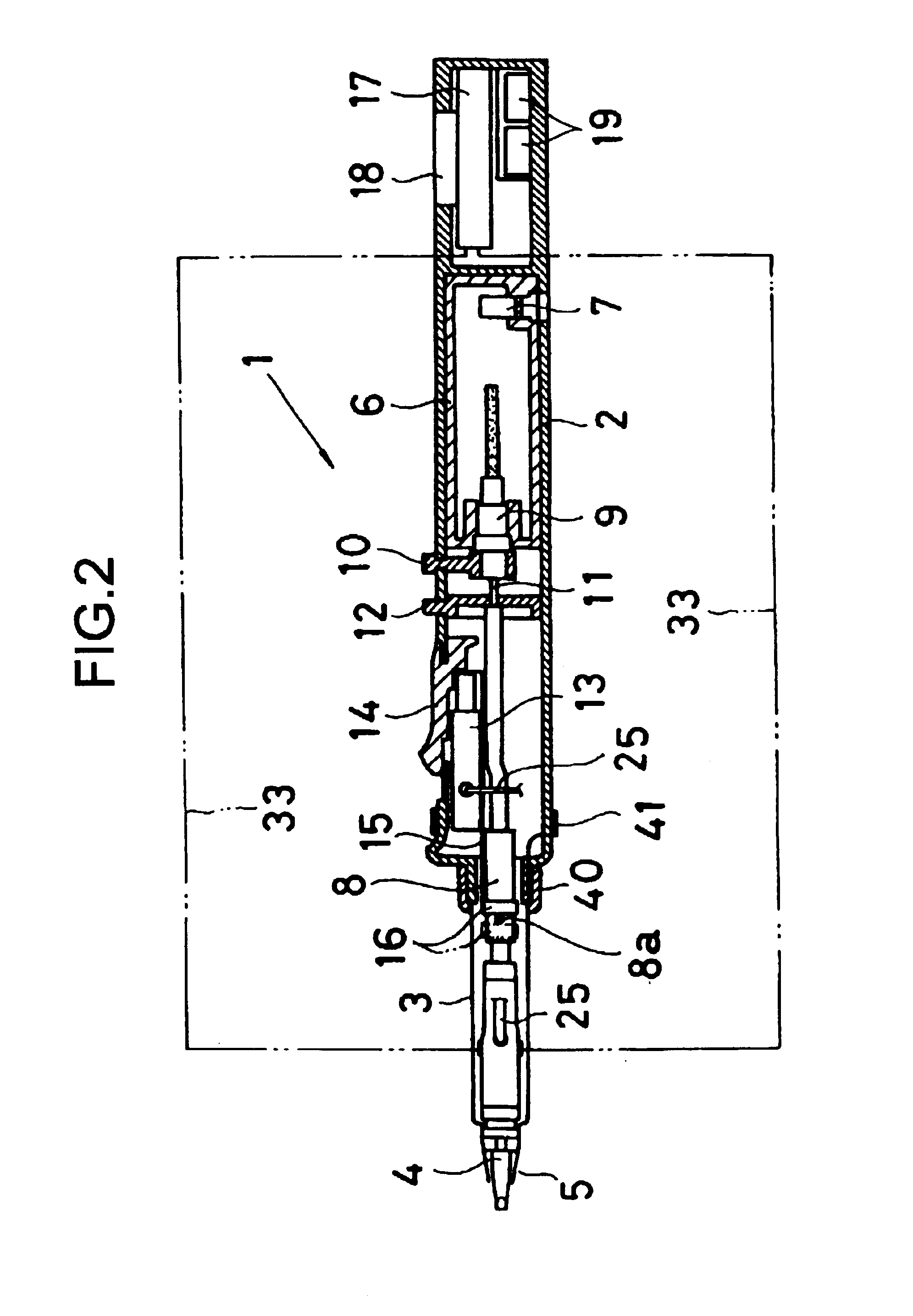

Cartridge-type soldering iron

ActiveUS20050092729A1Prevent oxidationGuaranteed to workHair dryingHeating element shapesEngineeringMechanical engineering

A soldering iron is configured to heat its tip and emit inert gas near the tip. This is accomplished by providing a heater cartridge having a heater pipe with a tip portion and a base portion. The heater pipe has a first hole in the tip portion and a second hole at the base portion. The heater pipe has a passage between the first and second holes so that gas can enter through the second hole and exit through the first hole. The heater cartridge has a grip handle between the tip and base portions of the heater pipe. The soldering iron has a handle base with a cavity adapted to receive the base portion of the heater pipe and at least a portion of the grip handle. The handle base is adapted to provide power and gas to the base portion of the heater pipe. The heater pipe transfers the power and gas from the base portion to the tip portion to heat the tip and emit gas near the tip. The cavity of the handle base is configured to substantially seal gaps between the grip handle and the handle base so that gas does not leak between the handle base and the grip handle.

Owner:HAKKO CO LTD

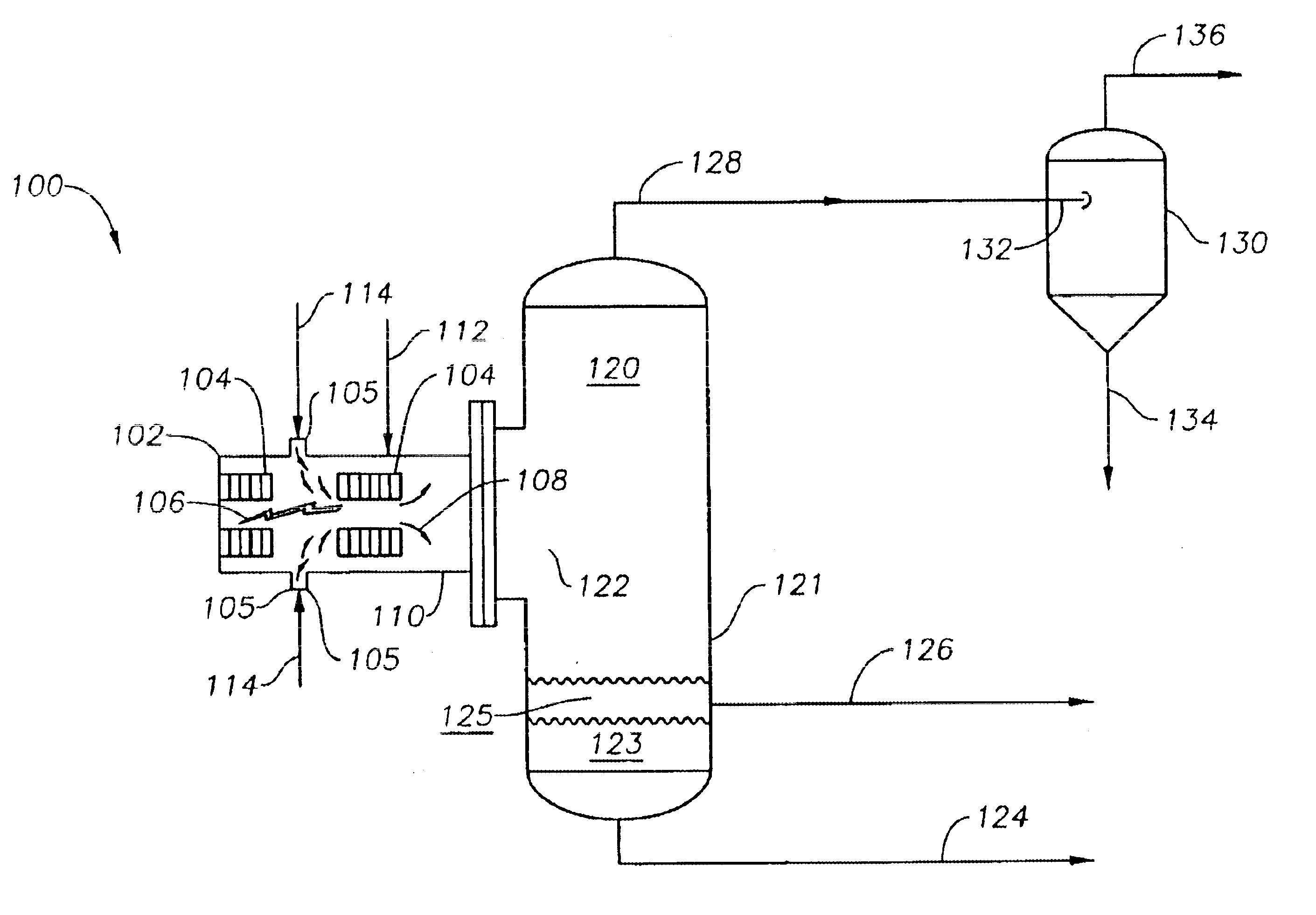

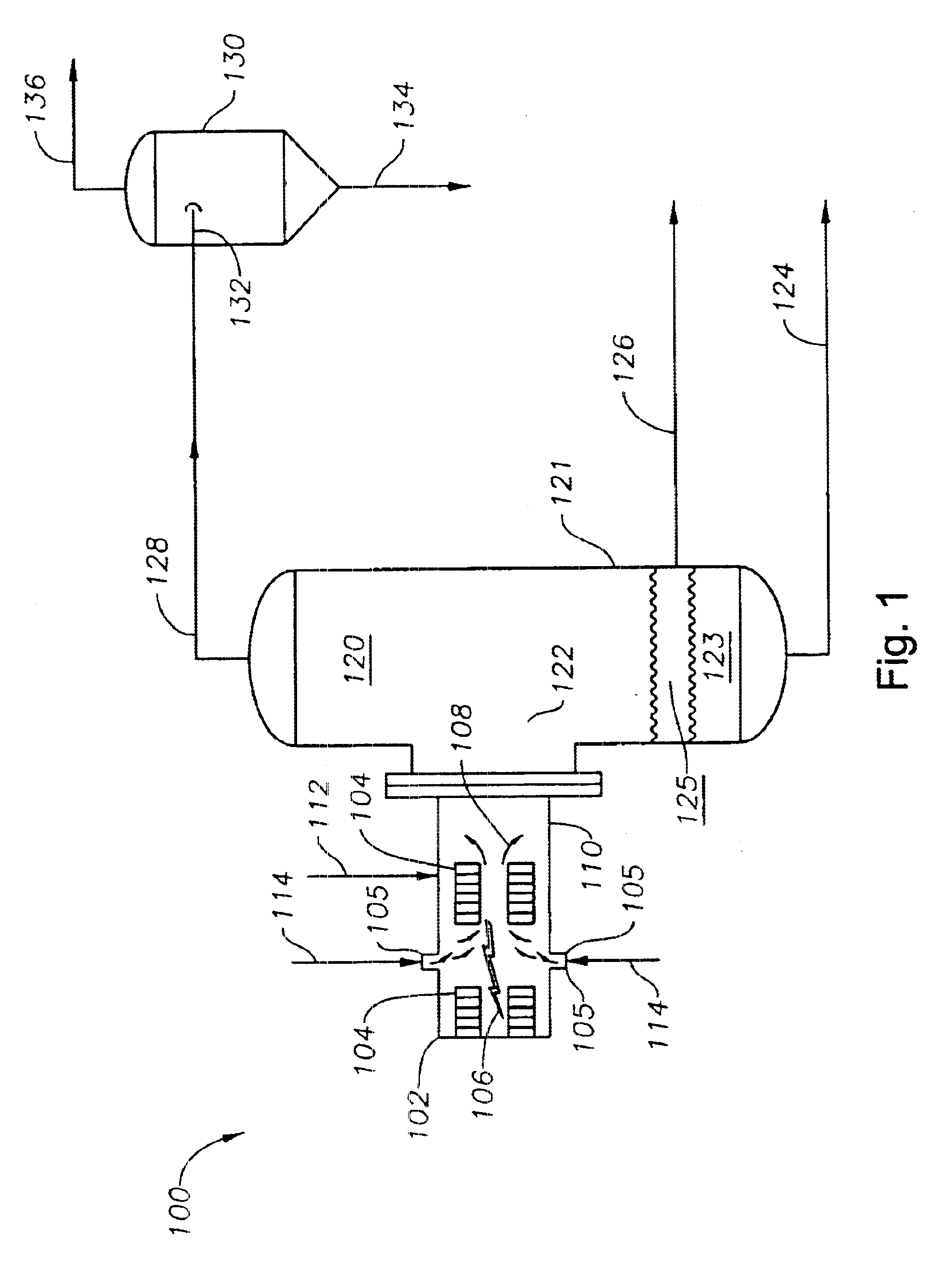

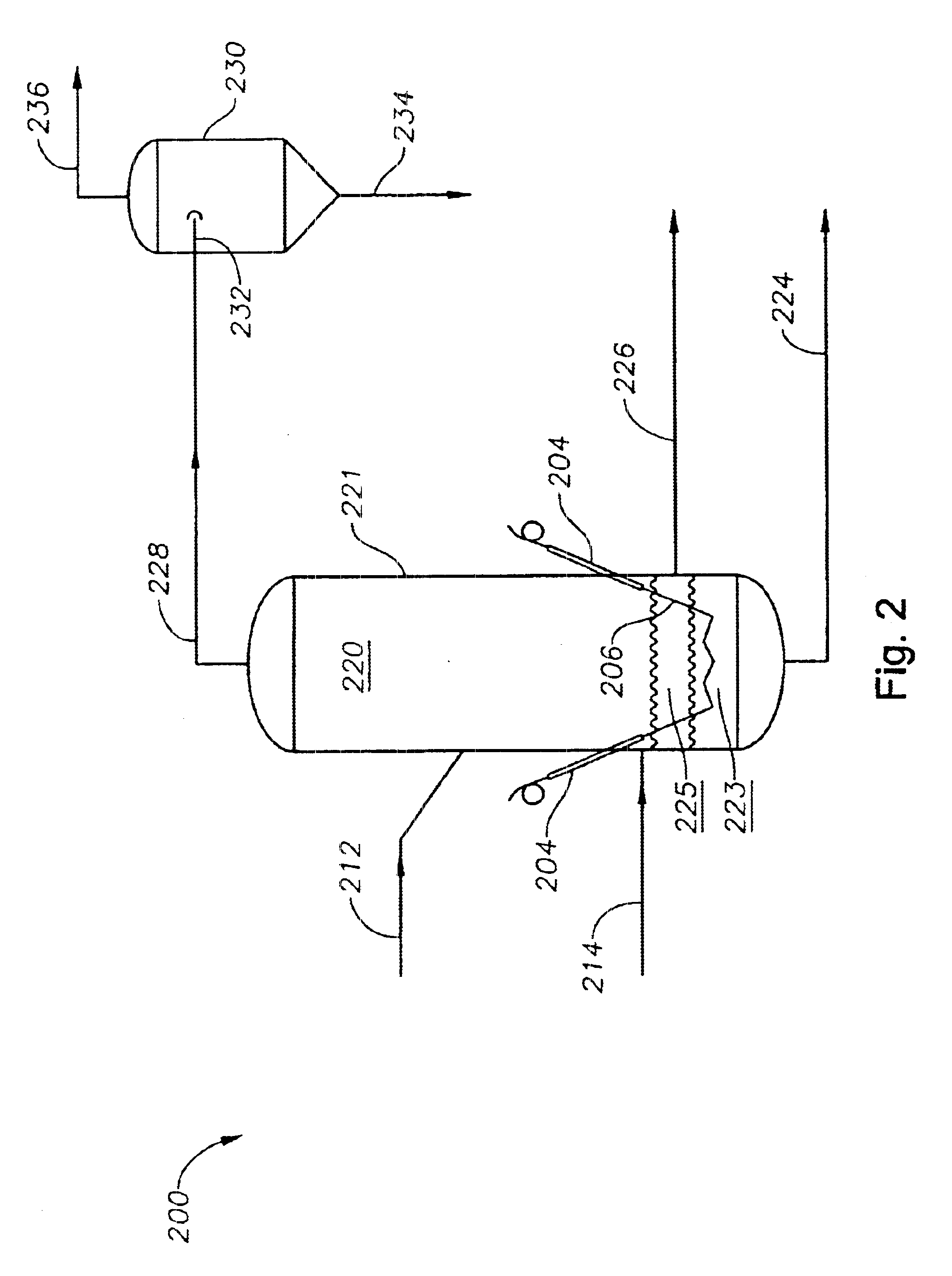

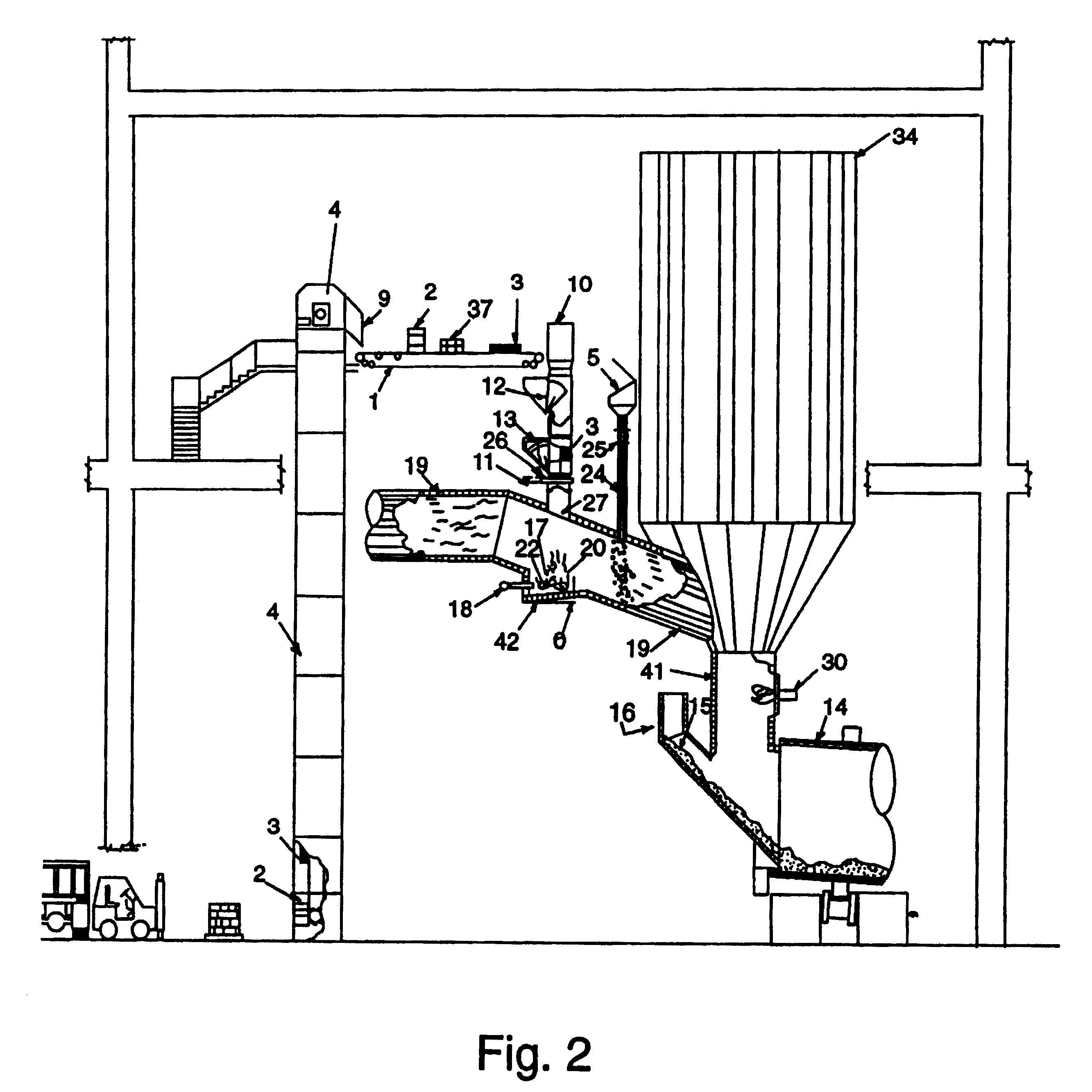

Method and apparatus for processing a waste product

A method and apparatus for processing a waste product and producing a synthesis gas is provided. The system includes a sealed, heated rotatable drum for preheating and preparing the waste material suitable for a plasma reactor, and processing the material in the reactor. The synthesis gas created by the reactor is used to preheat the waste material by circulating the hot synthesis gas around the drum. In an alternative embodiment, the hot synthesis gas flows through the drum to preheat the waste material and to clean the synthesis gas. Different methods of cooling and cleaning the synthesis gas are used. The system may comprise two plasma reactors in combination with a rotating desorber drum.

Owner:CLEAN HARBORS SAN LEON INC

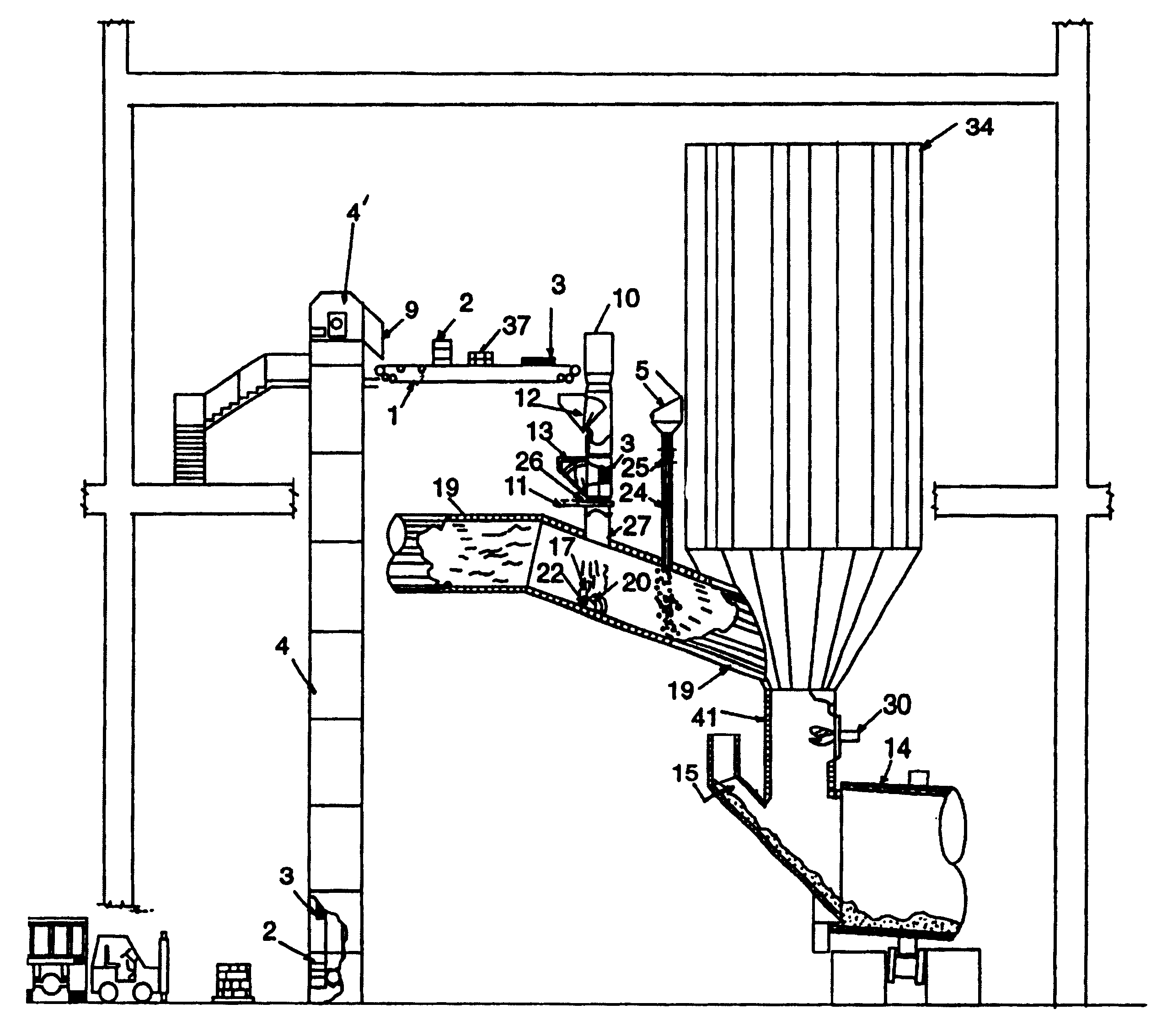

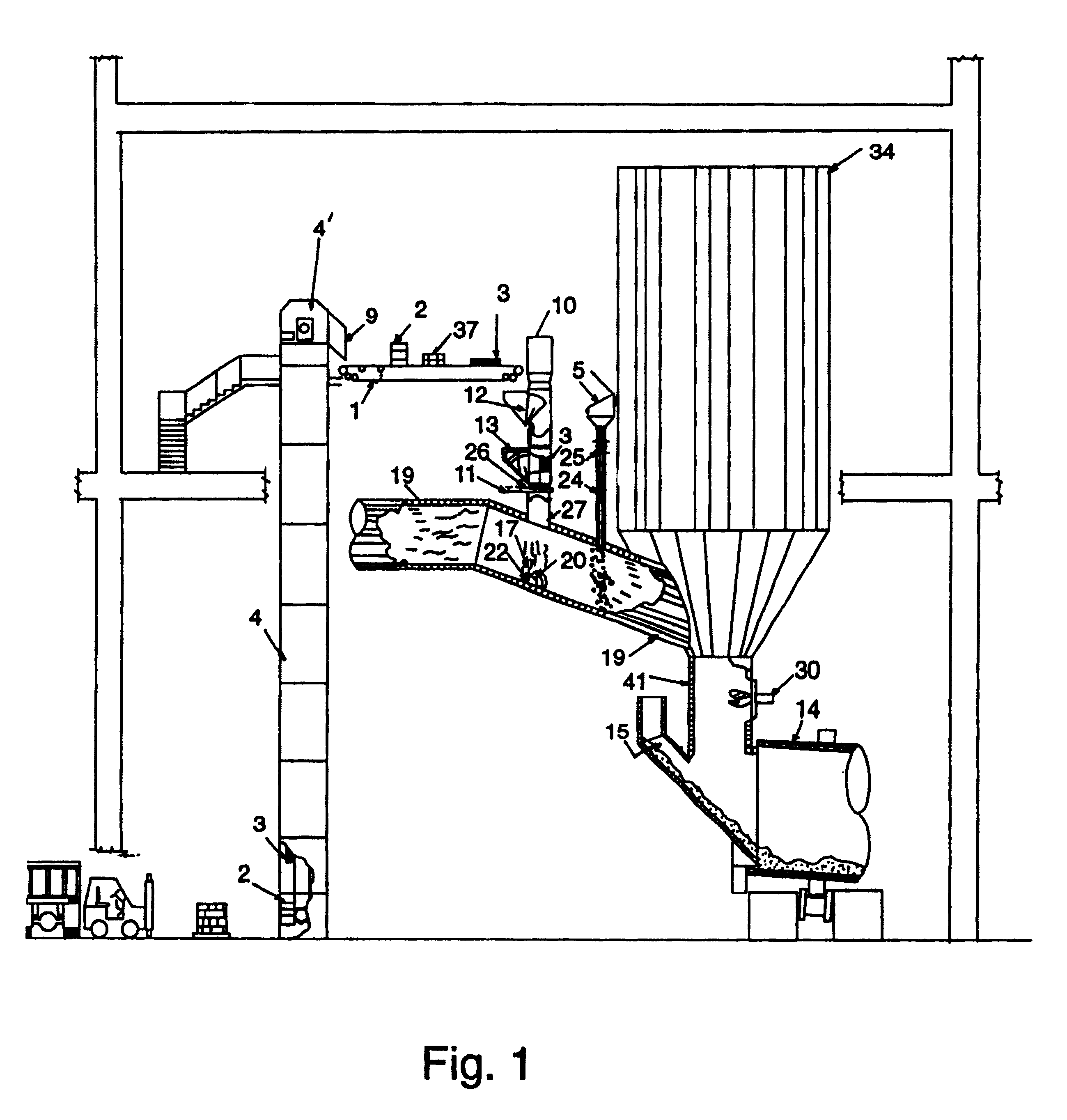

Method and apparatus for recovering energy from wastes by combustion in industrial furnaces

InactiveUS6470812B1Efficient energy recoveryEffective recoveryBranding equipmentMechanical apparatusWastewaterAtmospheric pollution

Method and apparatus to recover energy from waste by means of combustion of such waste in industrial furnaces, particularly of the rotary type, that has an external calciner, feeding such waste into the tertiary air duct of the calciner and burning the waste inside the duct itself, to efficiently make use of the energy produced by such combustion, as a contribution of the total cost of fuel necessary to operate the industrial furnace. The method and apparatus permit the elimination of hazardous wastes that are efficiently disassociated when burned sufficiently to produce effluents that are typically non-toxic, producing greatly reduced or even no atmospheric pollution nor environmental damage.

Owner:CEMEX DE C V

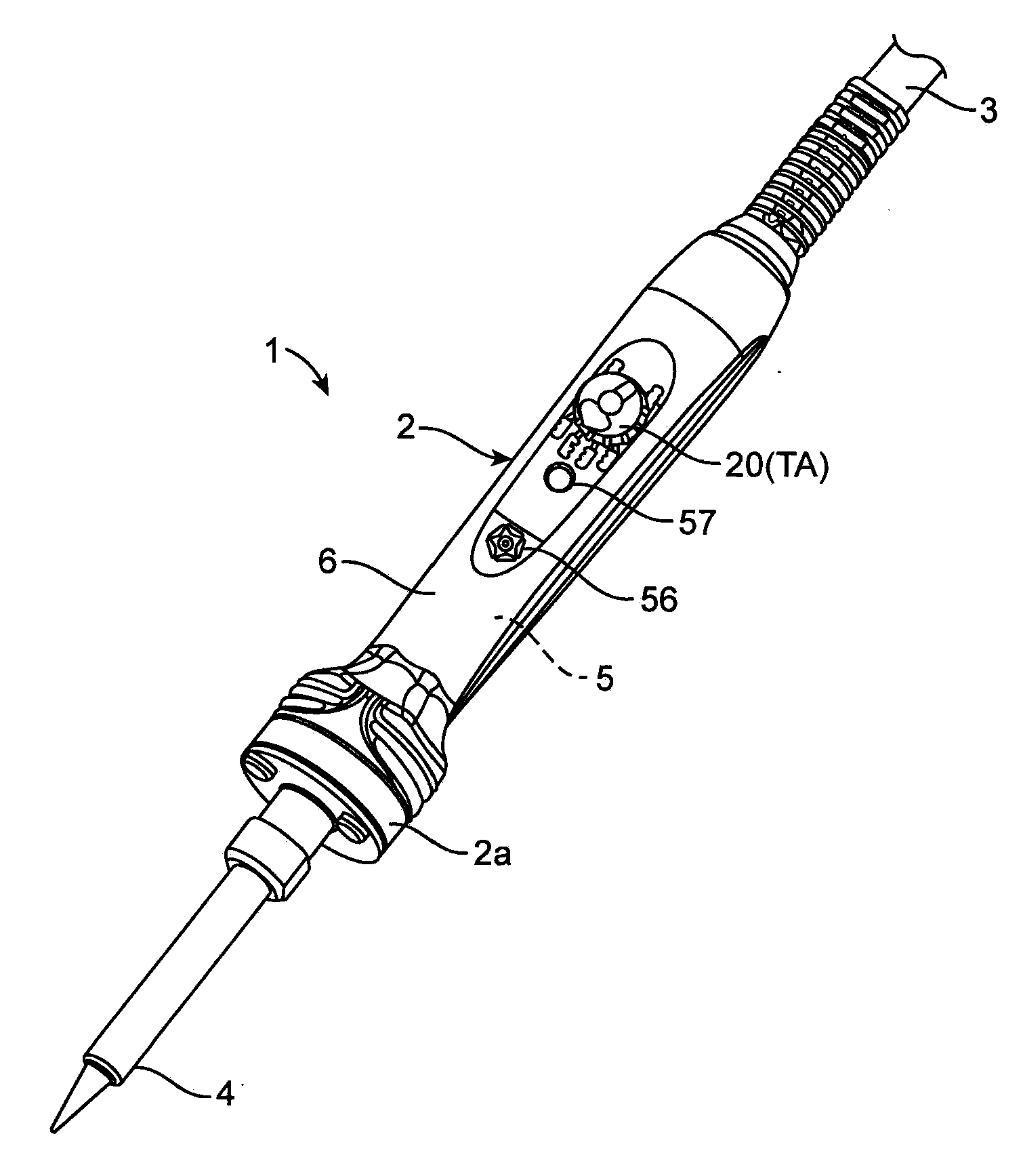

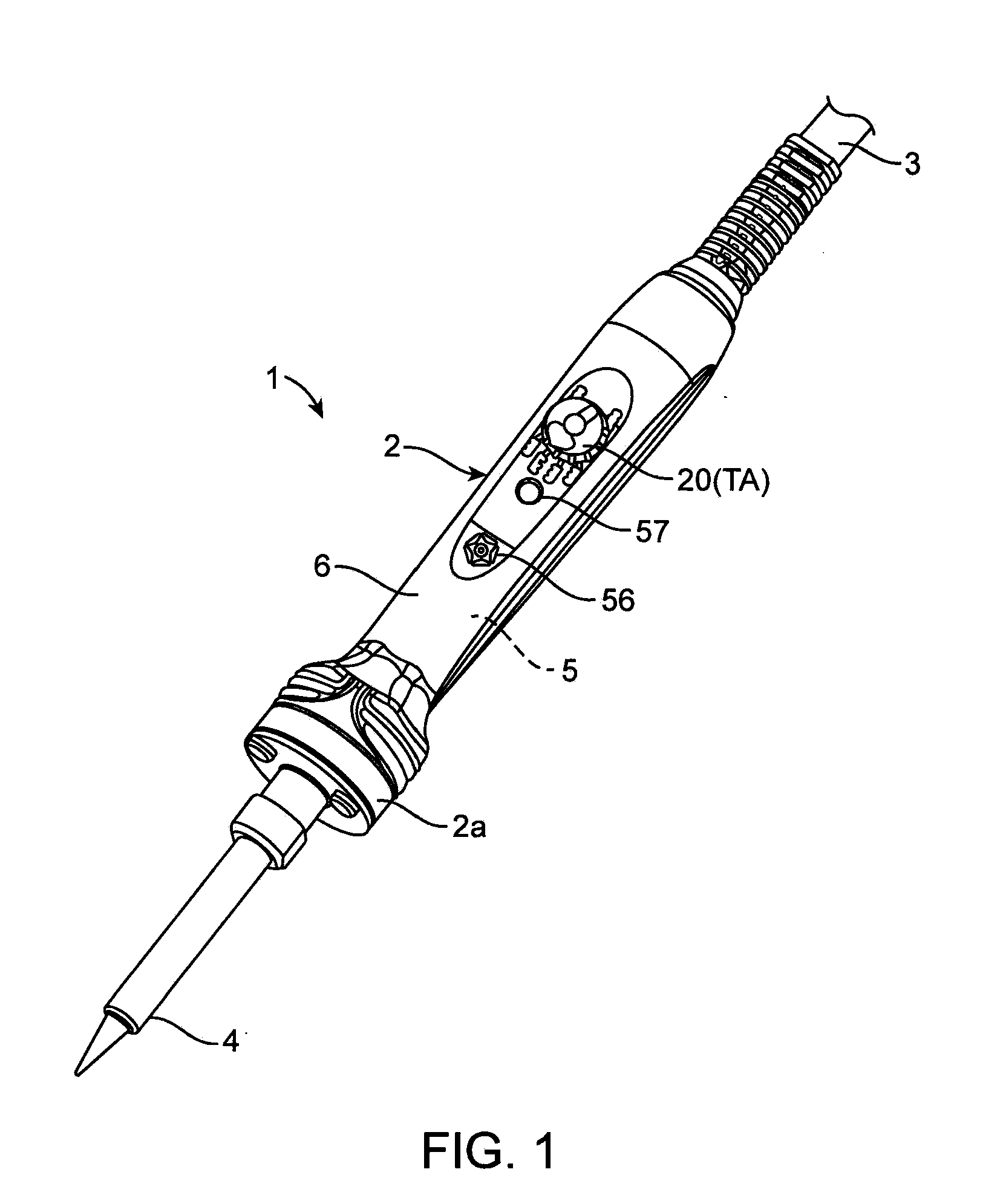

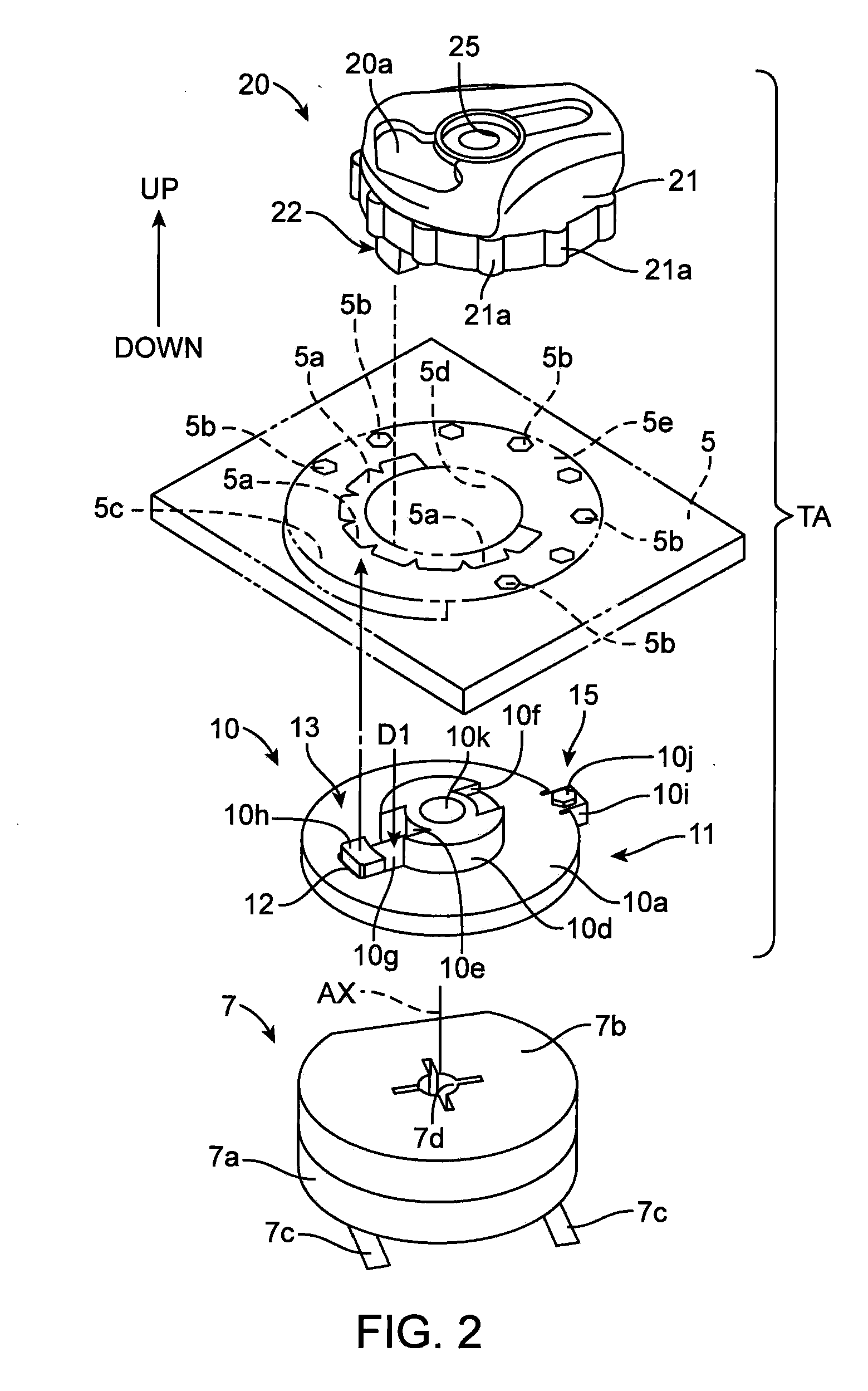

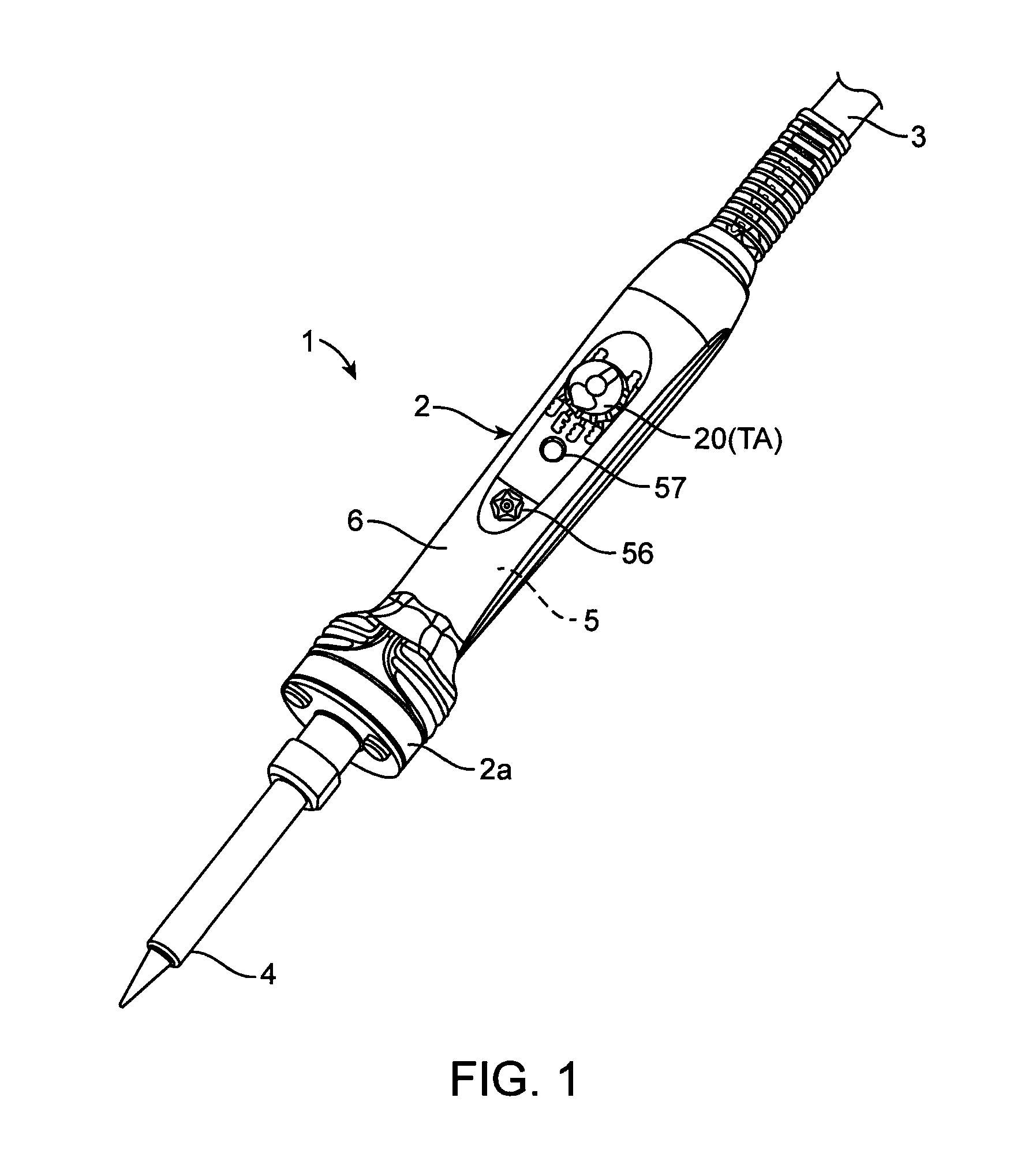

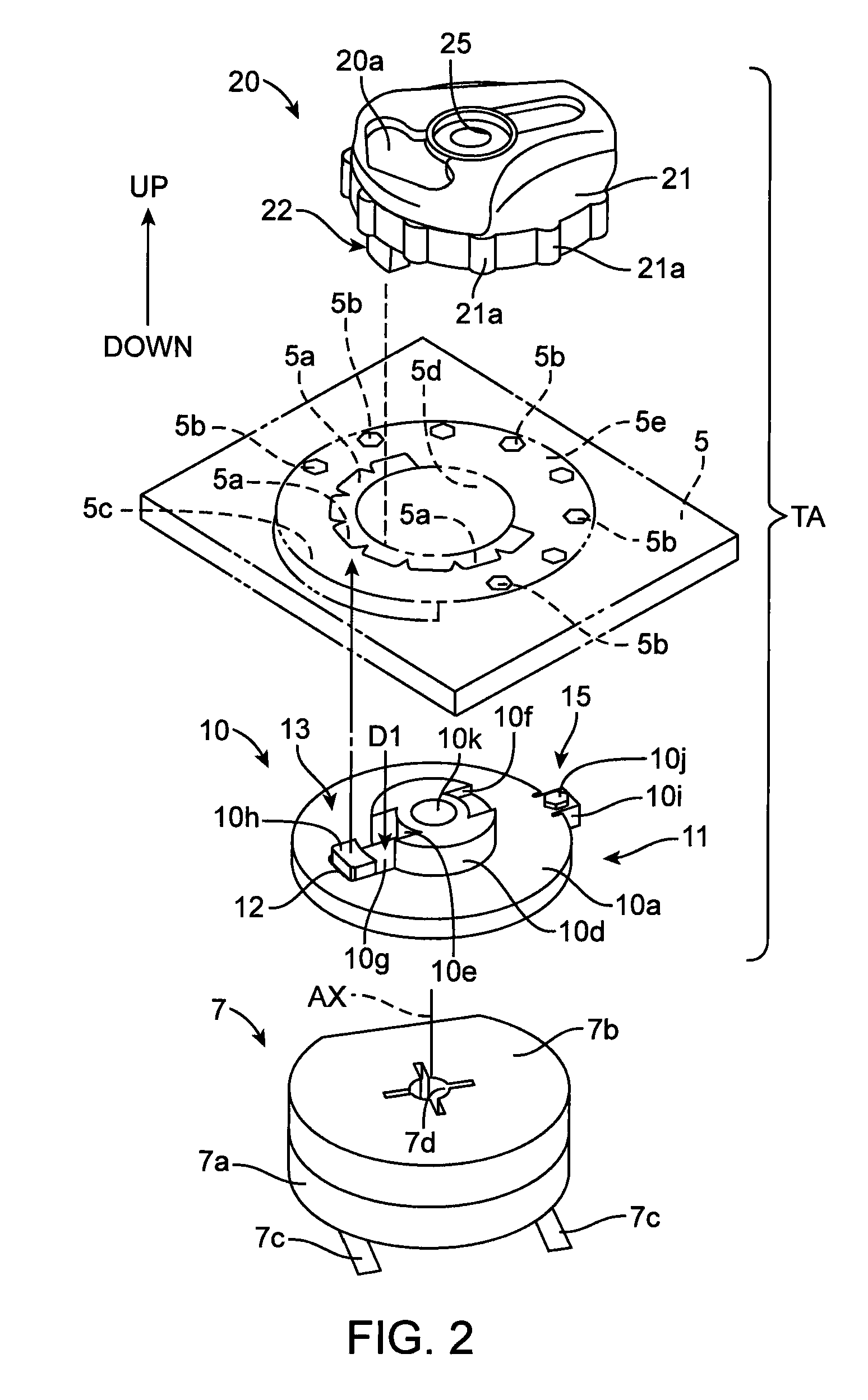

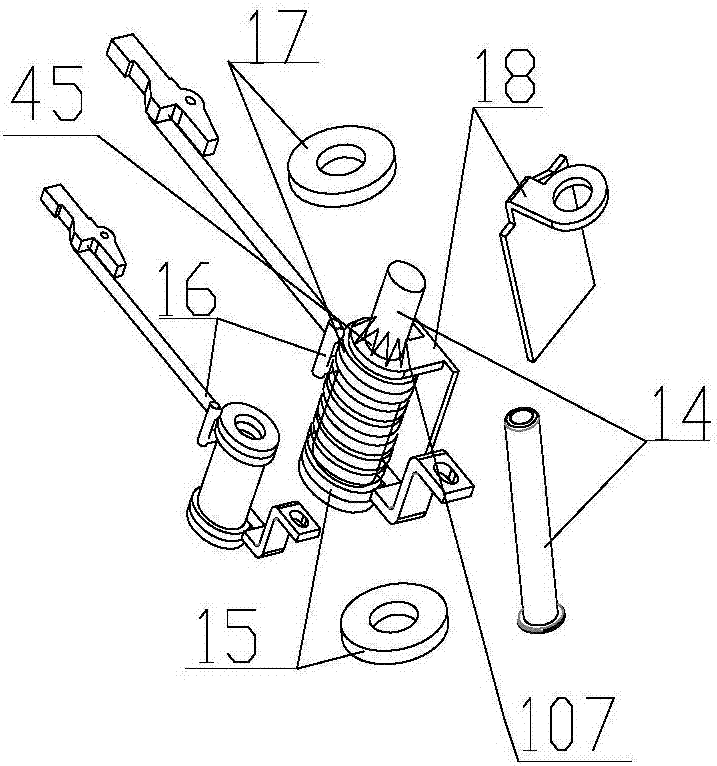

Solder Handling Assembly

ActiveUS20130105466A1Prevent rotationOhmic-resistance heating detailsSoldering ironEngineeringResistor

A solder handling assembly comprises a heating portion, a casing, a variable resistor, a connecting member coupled to the variable resistor, and an elastic-resilient member movable from a first state to a second state. The connecting member is rotatable relative to the casing and is configured to adjust a resistor value of the variable resistor when the connecting member is rotated relative to casing. When the elastic-resilient member is in the first state, the connecting member is prevented from rotating relative to the casing. When the elastic-resilient member is in the second state, the connecting member can be rotated relative to the casing.

Owner:HAKKO CO LTD

Soldering iron and method of manufacturing same

ActiveUS20060108345A1Heating fastIncrease heatHeating element shapesHeating appliancesBiomedical engineeringSoldering iron

A soldering iron provided with a soldering tip that melts solder at a distal end, having inside said soldering tip a substantially cylindrical insertion fit recess portion extending from a proximal end of the soldering tip to the distal end, opening at the proximal end, and a heater formed into a coil shape and whose surface is covered with an insulating oxide film being fittingly inserted into the insertion fit recess portion.

Owner:TAIYO ELECTRIC IND

Microwave brazing process and assemblies and materials therefor

A brazing process and assembly utilizing microwave radiation and a plasma generator that is heated by microwave radiation and generates a localized plasma capable of selectively heating and melting a braze alloy. The plasma generator contains a microwave-susceptible material that is susceptible to heating by microwave radiation, and a plasma-generating material capable of volatilizing and generating the plasma when the plasma generator is subjected to heating and microwave radiation. The brazing process includes applying a braze material to a surface of a substrate, positioning the plasma generator in proximity to the braze material, and then subjecting the plasma generator to microwave radiation to volatilize the plasma-generating material and generate a plasma that melts the braze alloy within the braze material.

Owner:GENERAL ELECTRIC CO

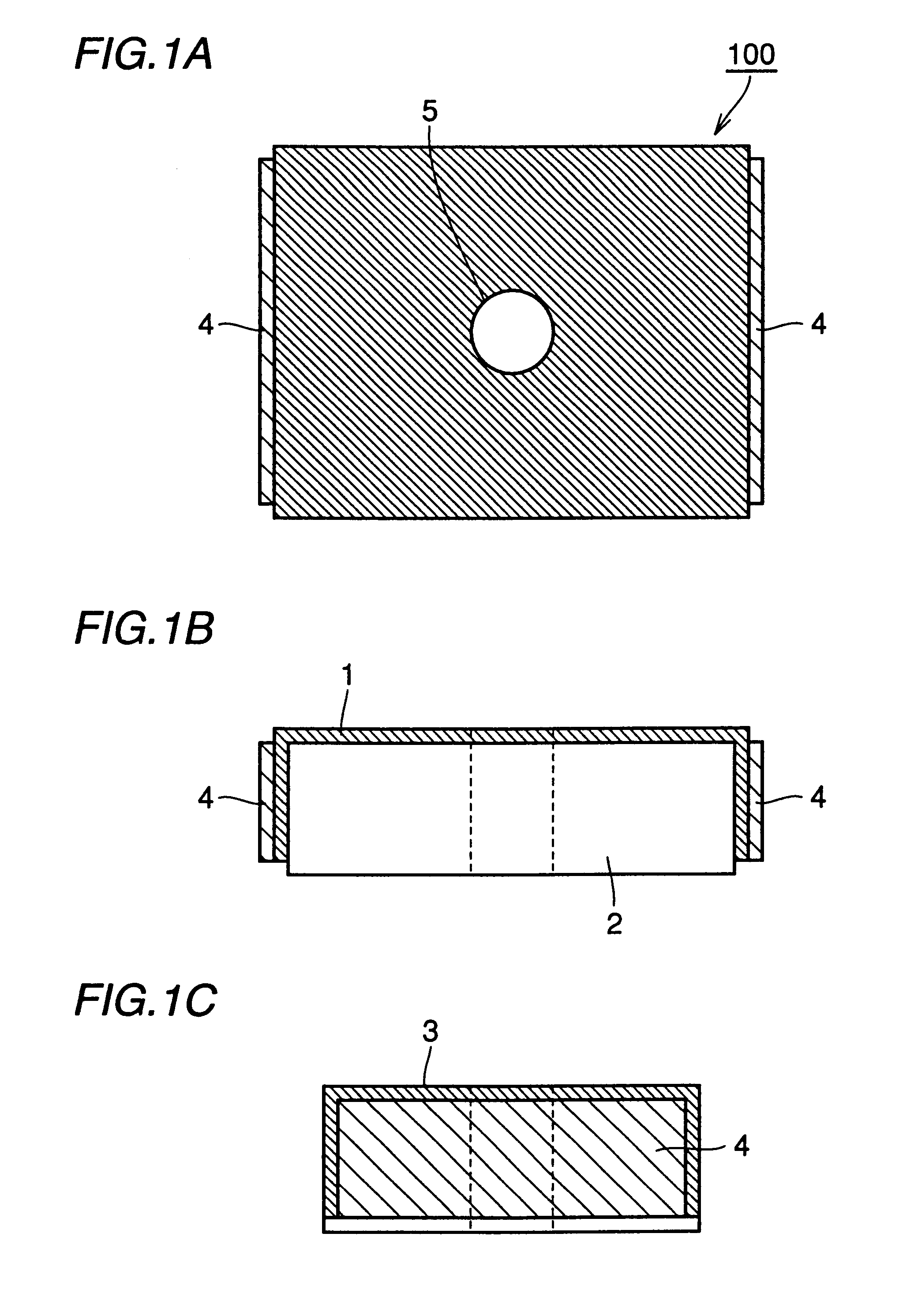

Soldering iron tip with metal particle sintered member connected to heat conducting core

ActiveUS7030339B2Increase plate thicknessExtended processing timeHeating element shapesSoldering bitsCeramic coatingHeat conducting

A soldering iron tip having a copper or copper alloy core and a metal particle sintered member connected to the core to transfer heat therefrom to form a working soldering tip. The sintered member can be manufactured by powder metallurgy from a base material (iron, nickel and / or cobalt particles) and an additive (silicon, copper, silver, tin, boron and / or carbon particles) where needed. The sintered member can be formed as a cap which is fitted onto the working tip with a silver paste sandwiched therebetween, a brazing filler metal ring is positioned between an abutment shoulder and the cap, flux applied to the joint and the cap brazed into place. A metal, cermet or ceramic coating sprayed on the outer surface of the core, except for the (masked) working tip end, is not wettable by solder. An Ag—Al—Cu alloy coating layer in the rearwardly-disposed cavity improves heat conduction from the heater therein.

Owner:HAKKO CO LTD

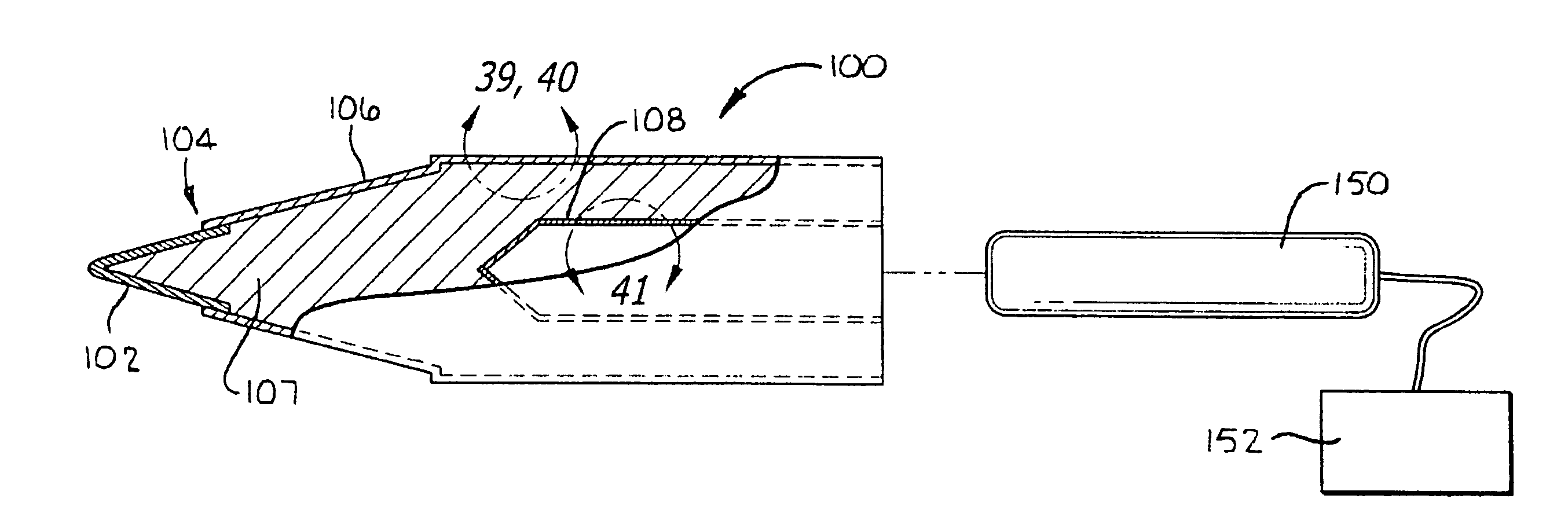

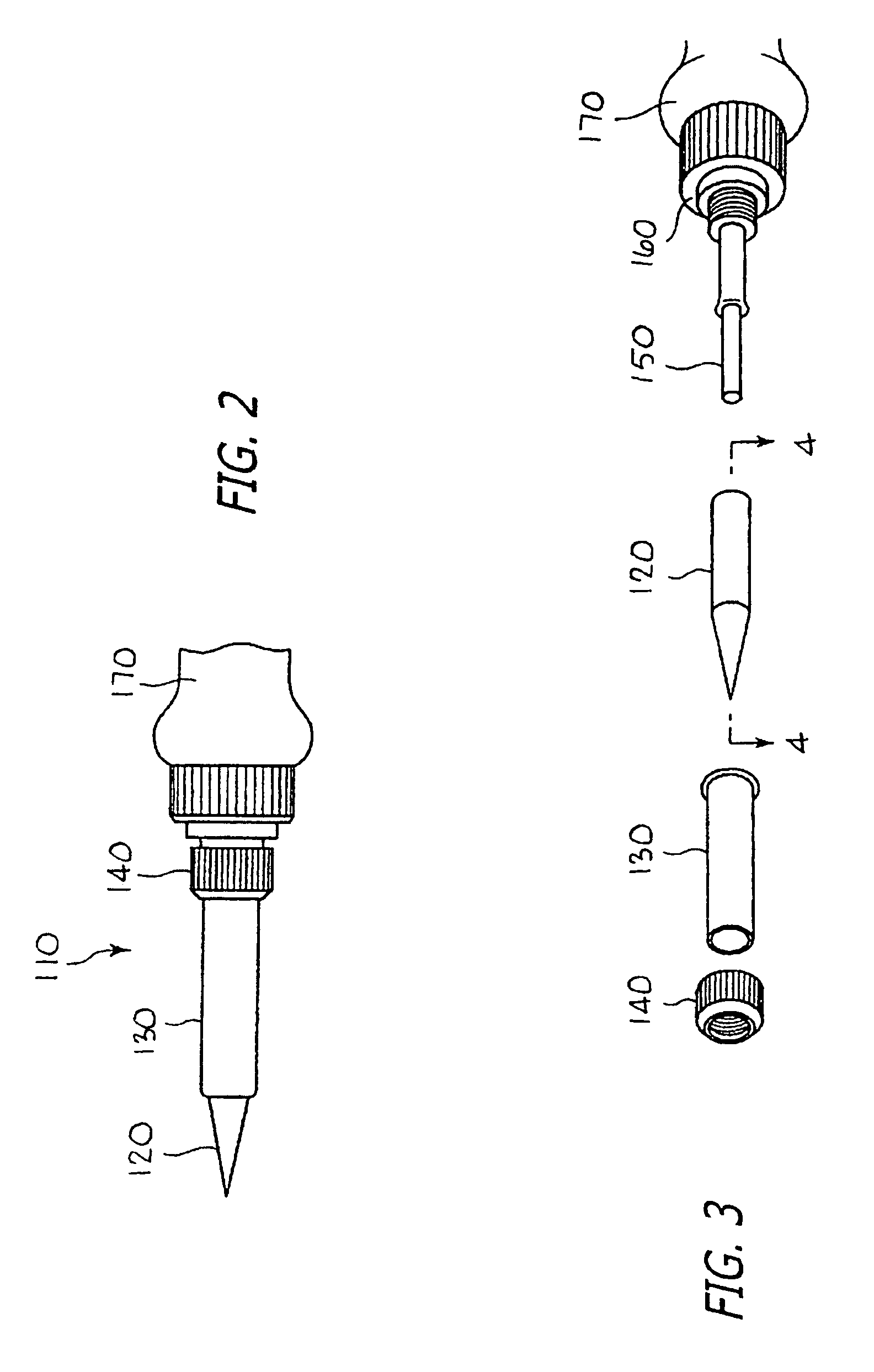

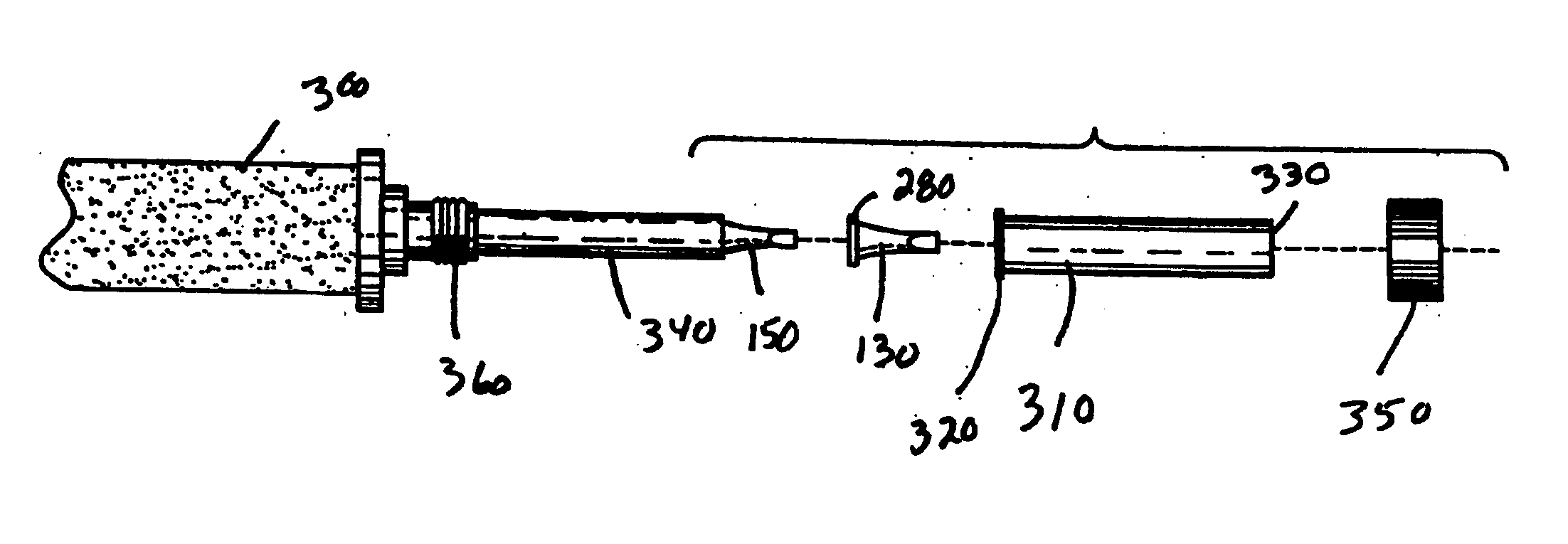

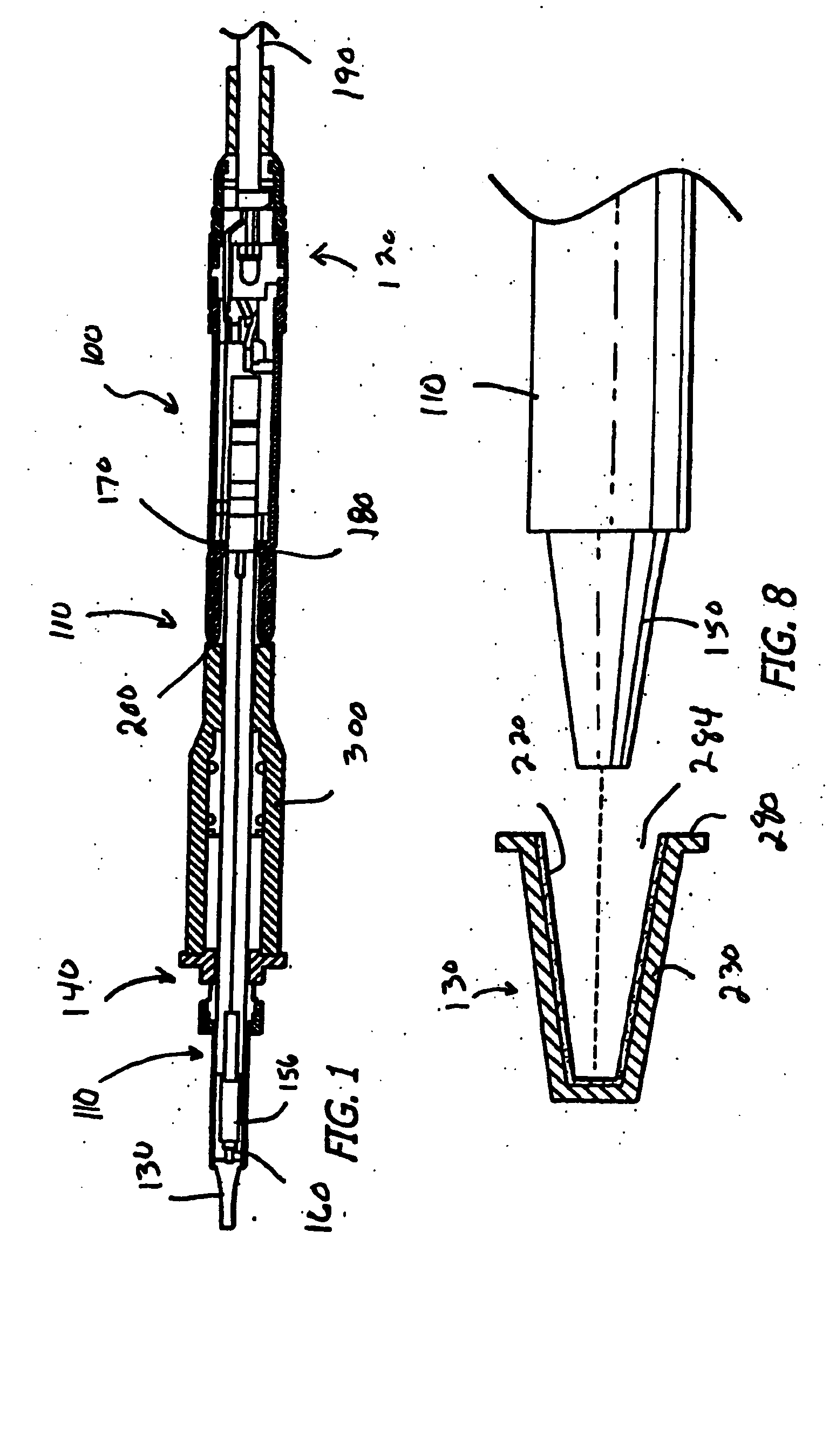

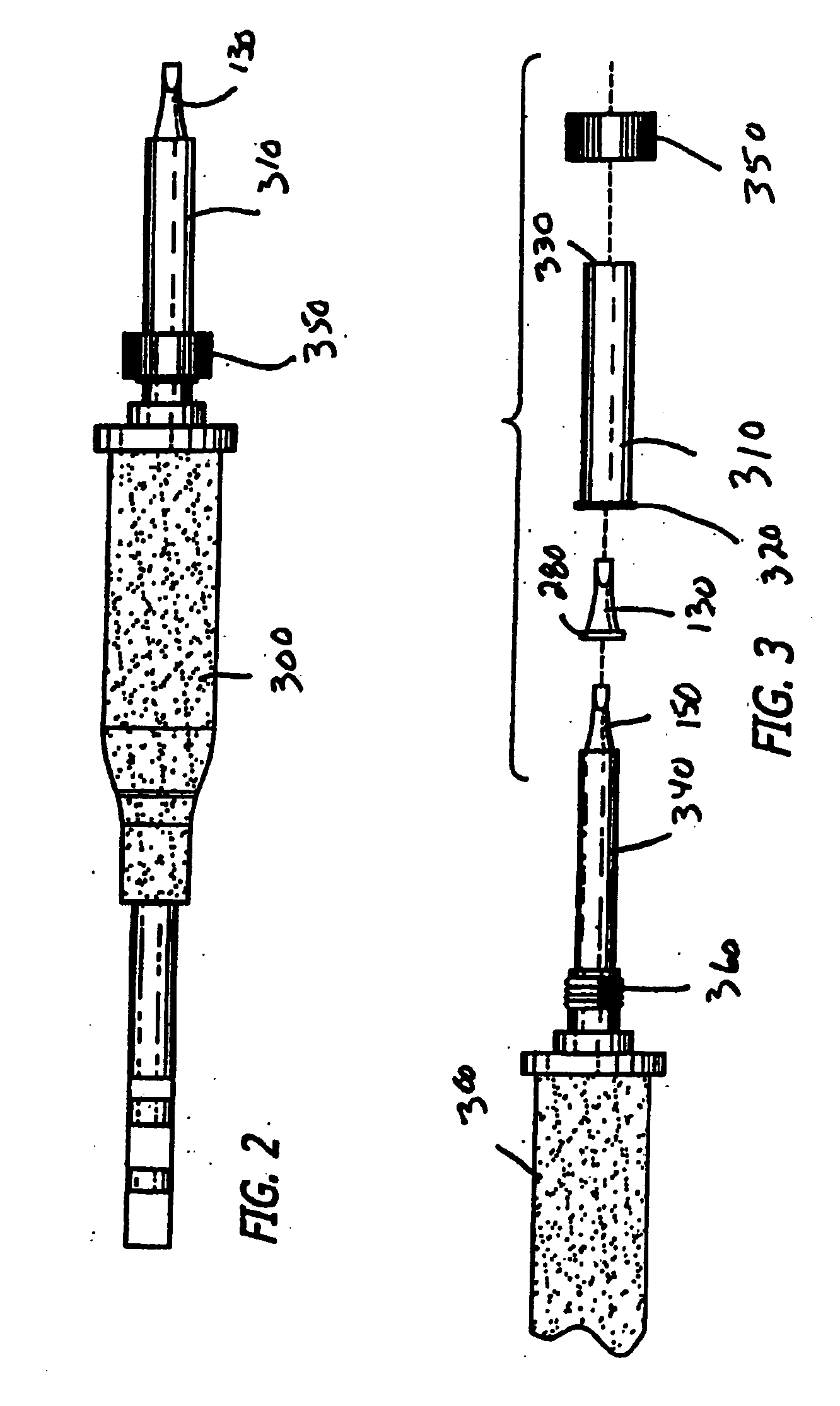

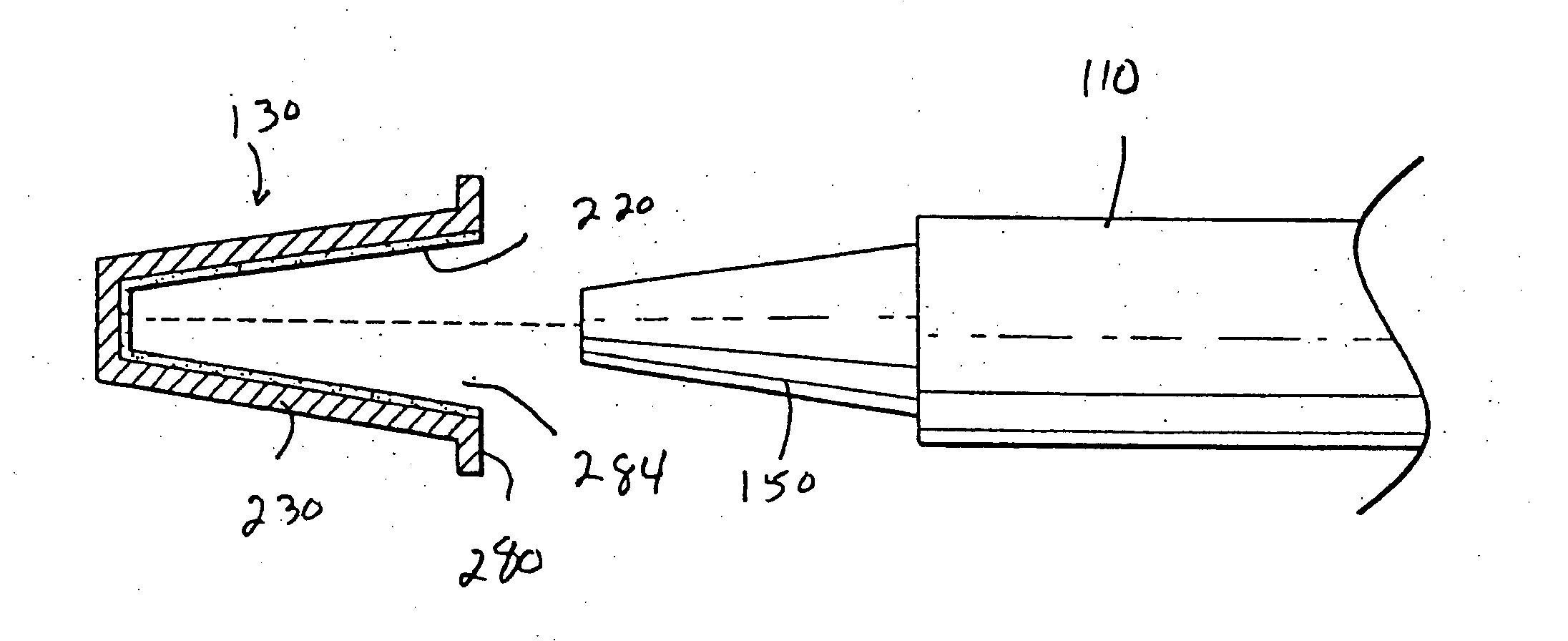

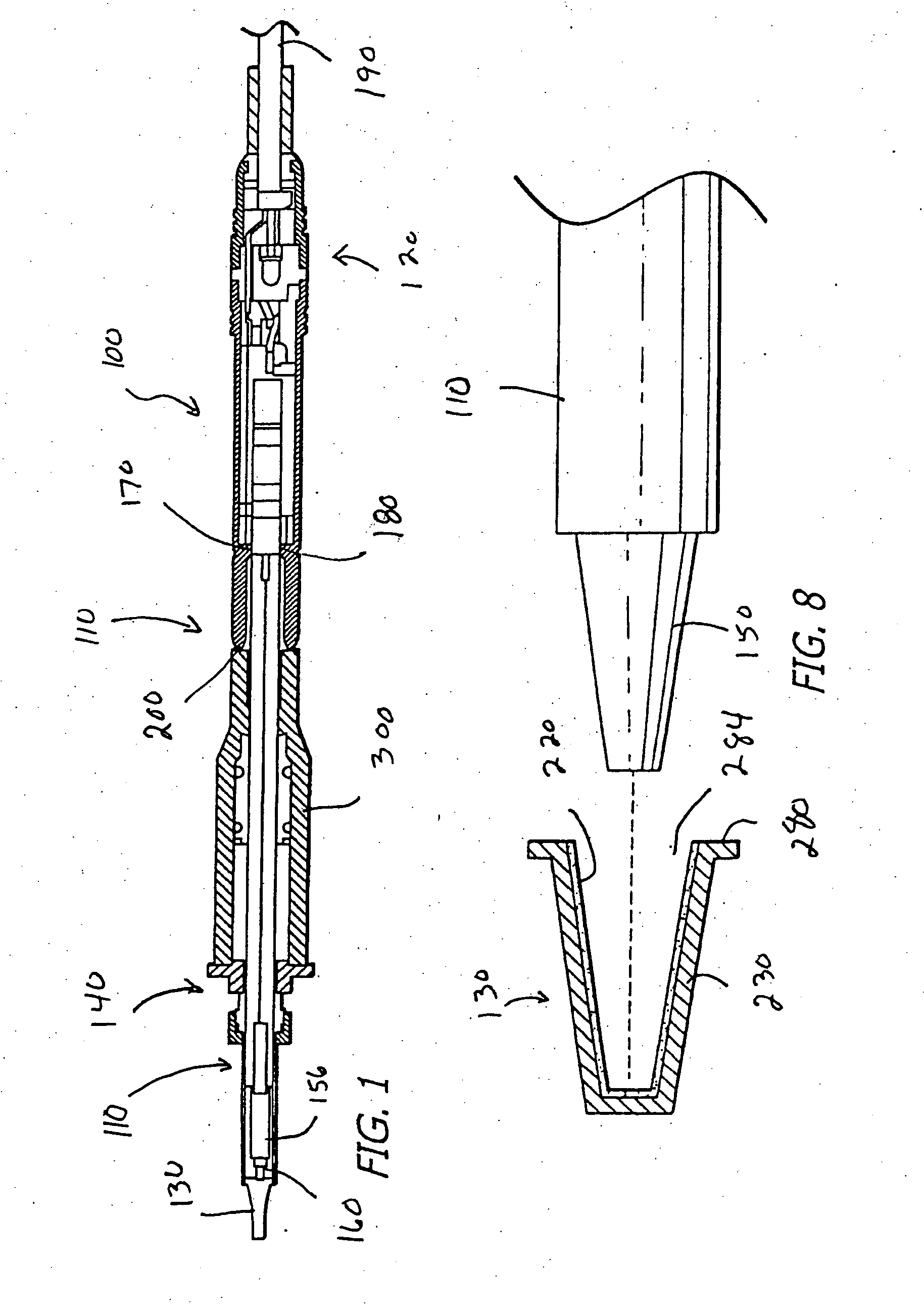

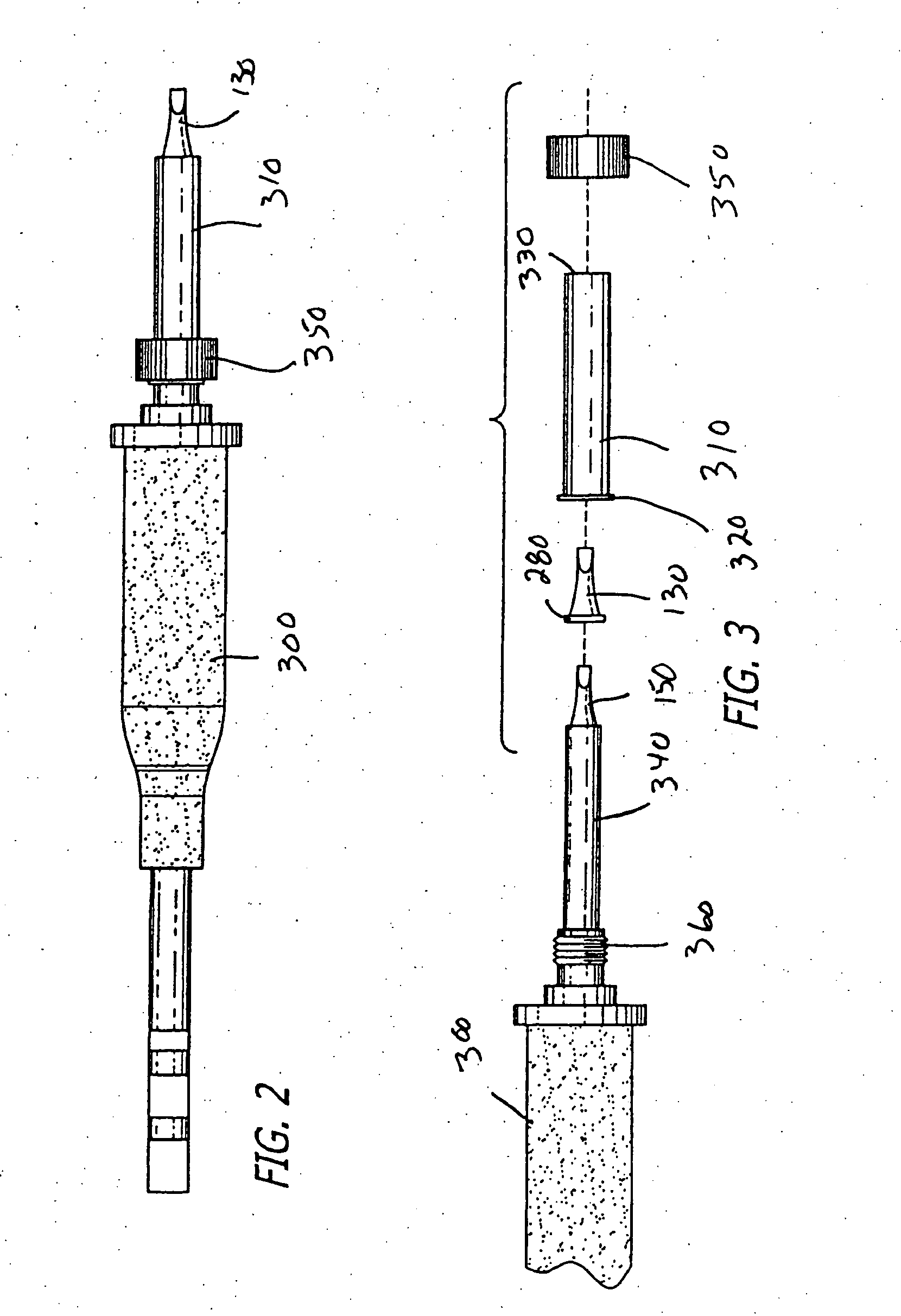

Soldering iron with replaceable tip

ActiveUS20060022018A1Improve thermal conductivityImprove the immunityHeating element shapesSoldering ironHeat conductingCoil spring

A soldering iron (and a desoldering iron) with a replaceable tip, which is releasably securable on the forward heat-conducting end of a soldering (or desoldering) iron heat assembly. The tip has a tapered heat conducting core in a tip cap. The face of the core can have a depression for mating engagement with a protrusion of the heat-conducting end. Also, the face can lie in the rear plane of the tip cap. An assembly which allows for the easy removal and application of a replacement tip can include a sleeve with tightening bolt, a coil spring sleeve, or a slotted compressible sleeve. The tip can thus be replaced after it has worn out, and the heat assembly unit need not be replaced until it has burnt out. Methods of manufacturing and using the tip are also disclosed.

Owner:HAKKO CO LTD

Soldering or desoldering iron

ActiveUS7679032B2Low costSecurely holdHeating element shapesHeating appliancesSolderingBiomedical engineering

Owner:HAKKO CO LTD

Control system for battery powered heating device

ActiveUS20060157466A1Temperature control using digital meansOhmic-resistance heating detailsControl systemElectricity delivery

A control system and method of controlling a battery powered heating device such as a soldering or desoldering tool that includes a control circuit to control the delivery of power to a cartridge heating tip and to cycle the power to the cartridge heating tip during times of no use so as to minimize the amount of power expended to maintain the device in a ready or usable state.

Owner:HAKKO CO LTD

Soldering tool

InactiveUS6874671B2Prevent oxidationExtend working lifeHeating appliancesCombustion using catalytic materialElectricityEngineering

A soldering iron capable of eliminating static charges accumulated on an operator or materials to be soldered simply without using no particular charge elimination device, the soldering iron comprising a combustion catalyst for complete combustion of a gas mixture of a fuel gas and air, a soldering iron tip heated by the combustion catalyst, a gas conduit for exhausting a combustion exhaust gas from the combustion catalyst along the outer circumference of the soldering iron tip toward the top end, and an electric conduction mechanism for electrically connecting an operator for conducting soldering and the soldering iron tip, fuel gas combustion products which are ionized and forming steams upon catalytic combustion contributing to charge elimination.

Owner:NAKAJIMA DOKOSHO CO LTD

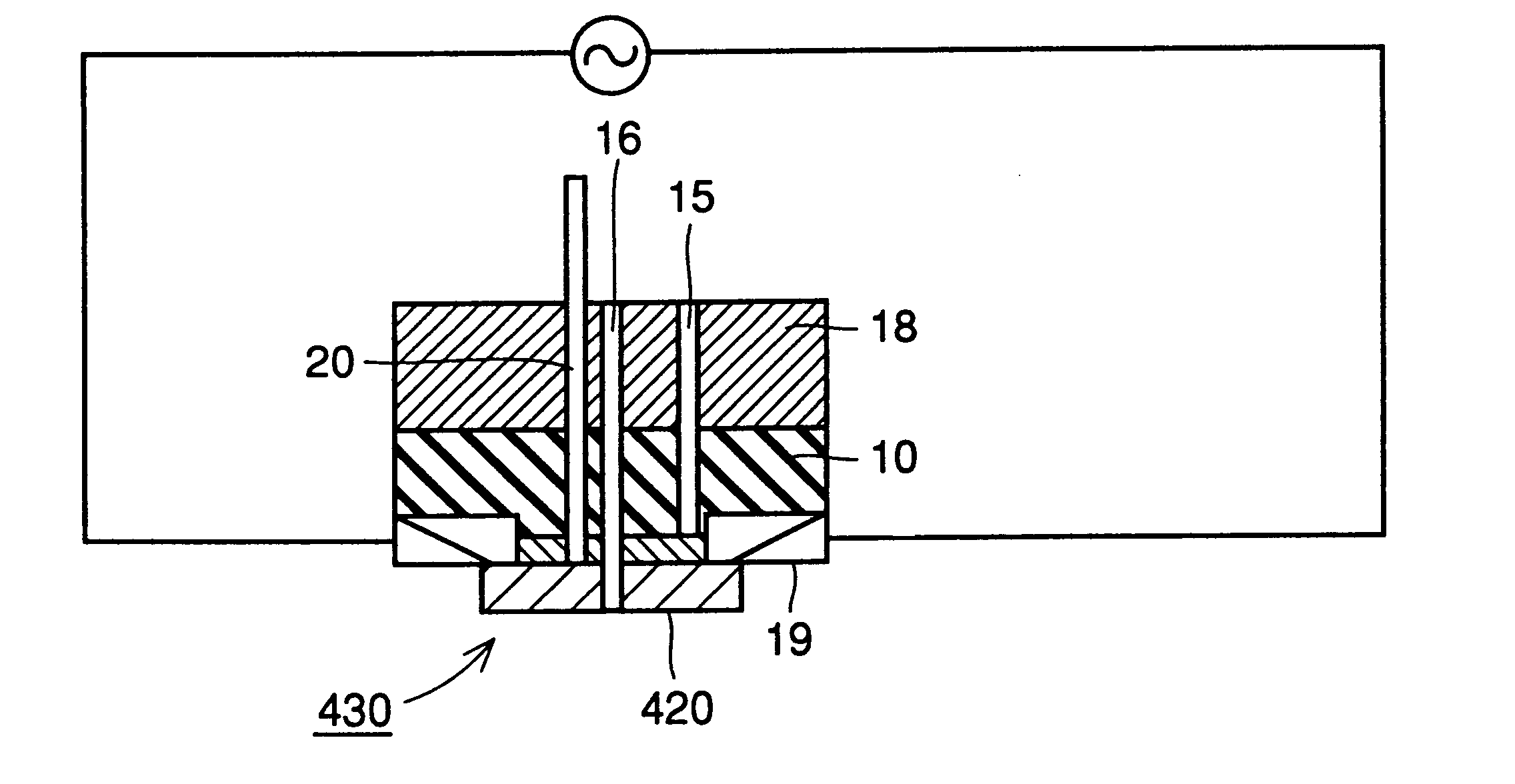

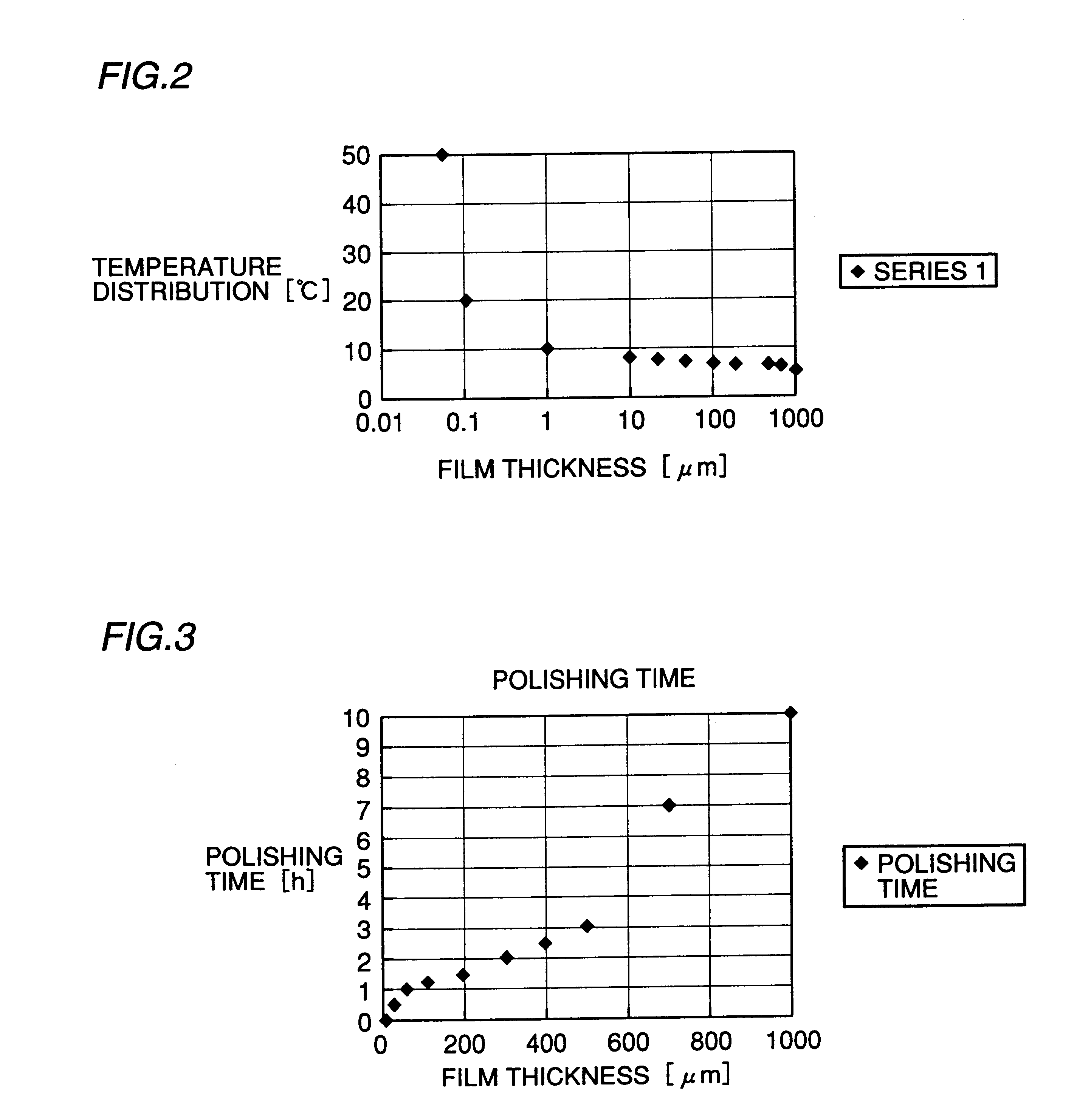

Tool tip and bonding tool comprising the tool tip and control method for the bonding tool

InactiveUS6270898B1High energyTemperature rise characteristic andDecorative surface effectsSemiconductor/solid-state device manufacturingElectrical resistance and conductanceMetallurgy

A conductive polycrystalline diamond film having specific resistance of at least 1x10-4 OMEGAcm and less than 1x103 OMEGAcm, whose film thickness is in the range of at least 0.1 mum and not more than 500 mum, is film-formed by vapor-phase synthesis on a surface employed for pressure bonding, a surface opposite to this surface or at least two side surfaces intersecting with these surfaces on a substrate of a bonding tool tip that is applicable for bonding and packaging a semiconductor chip.

Owner:SUMITOMO ELECTRIC IND LTD

Solder handling assembly

A solder handling assembly comprises a heating portion, a casing, a variable resistor, a connecting member coupled to the variable resistor, and an elastic-resilient member movable from a first state to a second state. The connecting member is rotatable relative to the casing and is configured to adjust a resistor value of the variable resistor when the connecting member is rotated relative to casing. When the elastic-resilient member is in the first state, the connecting member is prevented from rotating relative to the casing. When the elastic-resilient member is in the second state, the connecting member can be rotated relative to the casing.

Owner:HAKKO CO LTD

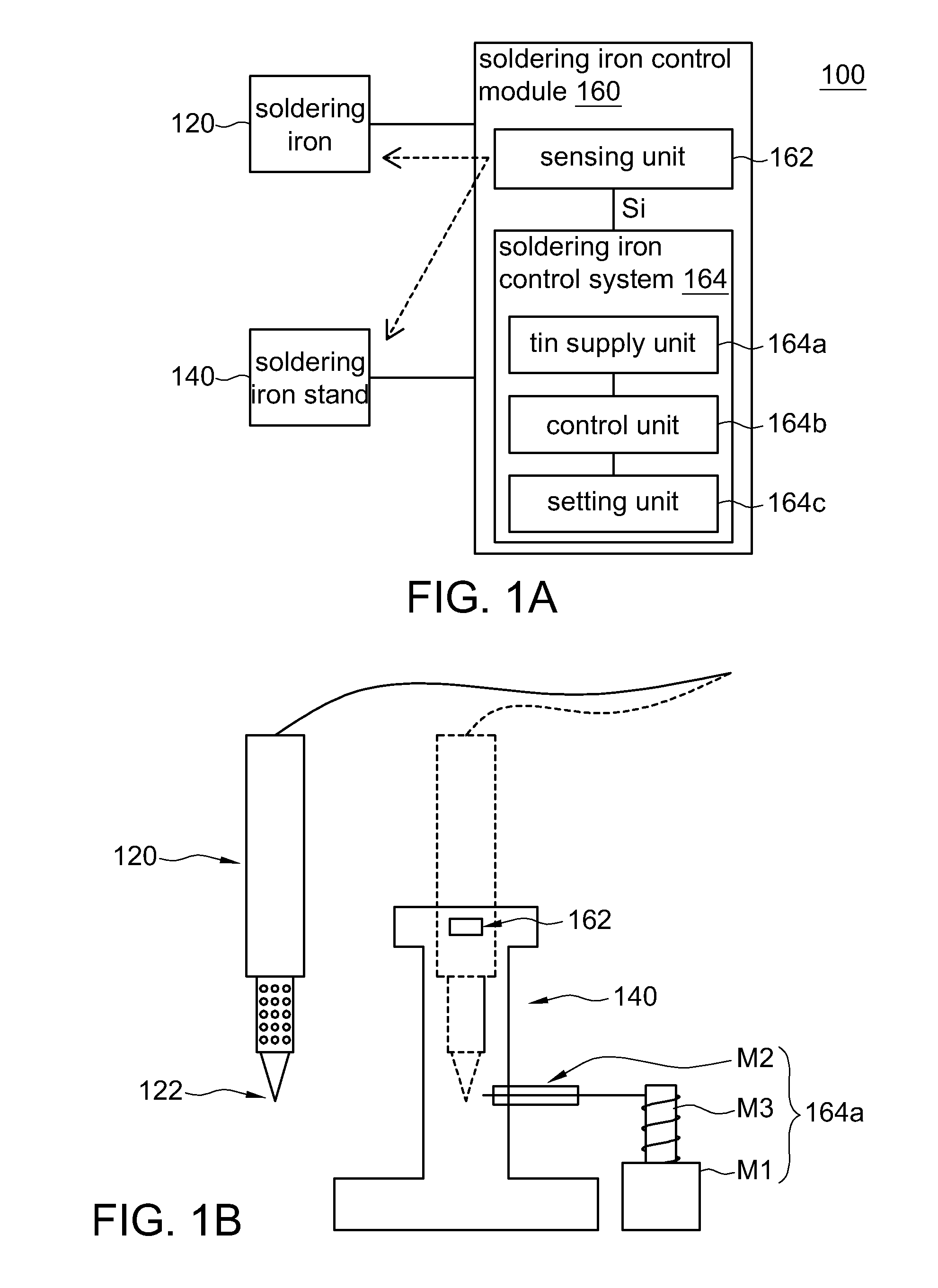

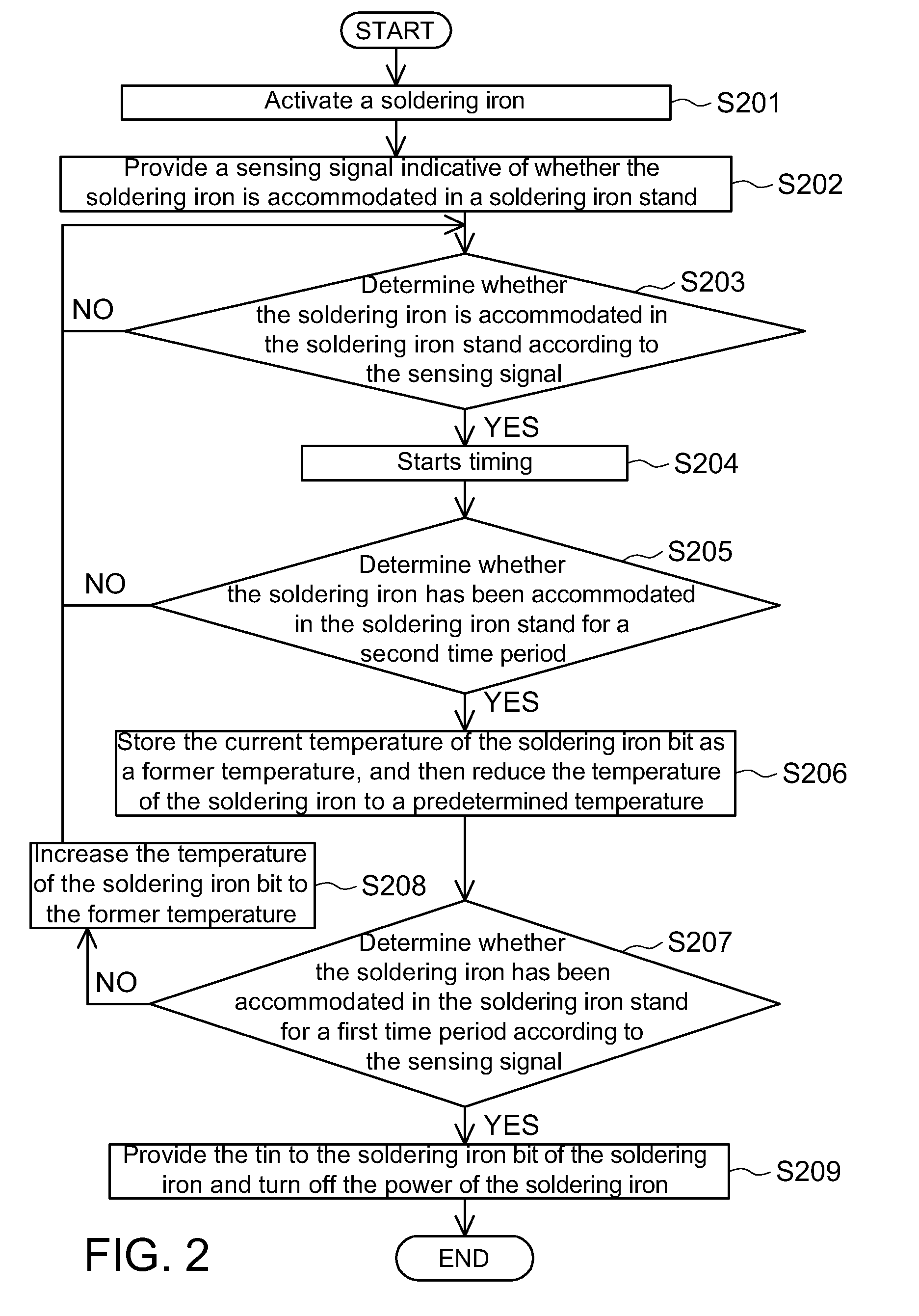

Soldering iron device, soldering iron control module and soldering control method thereof

InactiveUS20100084455A1Extend your lifeAutomatic control devicesPrecision positioning equipmentControl systemEngineering

A soldering iron control module applied to a soldering iron and a soldering iron stand is provided. The soldering iron stand accommodates the soldering iron which has a soldering iron bit. The soldering iron control module includes a sensing unit and a soldering iron control system. The sensing unit provides a sensing signal indicating whether the soldering iron is accommodated in the soldering iron stand. The soldering iron control system includes a tin supply unit and a control unit. The control unit determines whether the soldering iron has been accommodated in the soldering iron stand for a first time period according to the sensing signal. When the control unit determines that the soldering iron has been accommodated in the soldering iron stand for the first time period, the tin supply unit provides the tin to the soldering iron bit and the power of the soldering iron is turned off.

Owner:INVENTEC CORP

Press type automatic tin supply electric soldering iron

InactiveCN104526101AEasy to controlReal-time controlHeating appliancesSoldering ironInternal pressureElectronic industry

The invention relates to a press type automatic tin supply electric soldering iron which comprises a soldering iron head, a heating device, a tin melting device, a pressure piston and a handle device. The soldering iron head, the tin melting device and the pressure piston are combined together. Inner cavities of the soldering iron head, the tin melting device and the pressure piston are communicated and do not make contact with external air to form a closed inner cavity body. The heating device is mainly used for heating the soldering iron head and melting solid soldering tin in the tin melting cavity into molten tin. The tin melting cavity is mainly used for melting solid soldering tin. A inflator principle is adopted for the pressure piston, the internal pressure intensity can be changed by pushing a pressure rod, and therefore air flow is produced, and air is exhausted from an air outlet; the pressure rod is sleeved with a spring device which is used for making the electric soldering iron rapidly rotate back in a non-press state. The press type automatic tin supply electric soldering iron can be operated by one hand to control the amount of soldering tin, and can conduct automatic supply in real time and control the welding flow, effectively improve the welding efficiency in an electronic industry and save cost.

Owner:HUBEI UNIV OF TECH

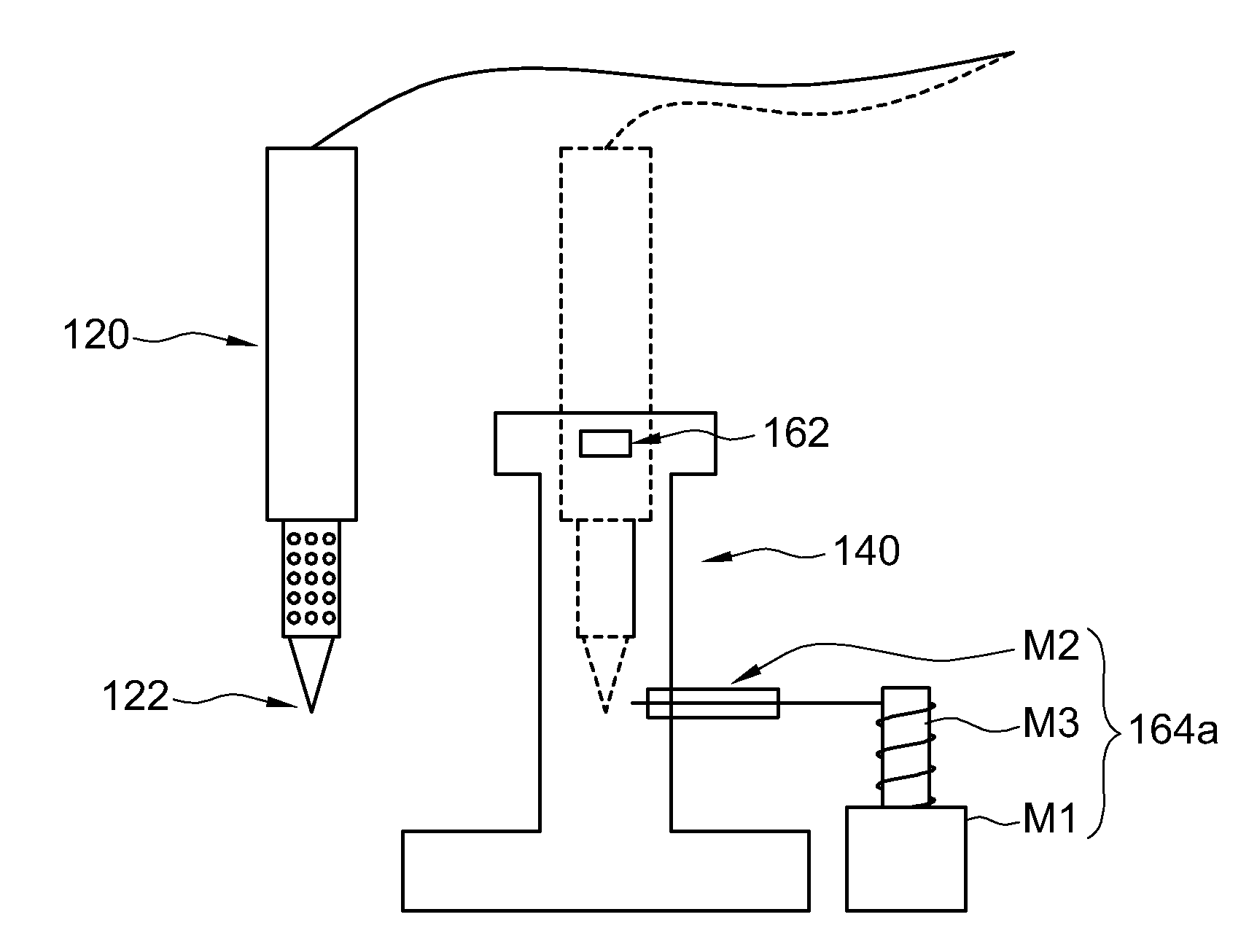

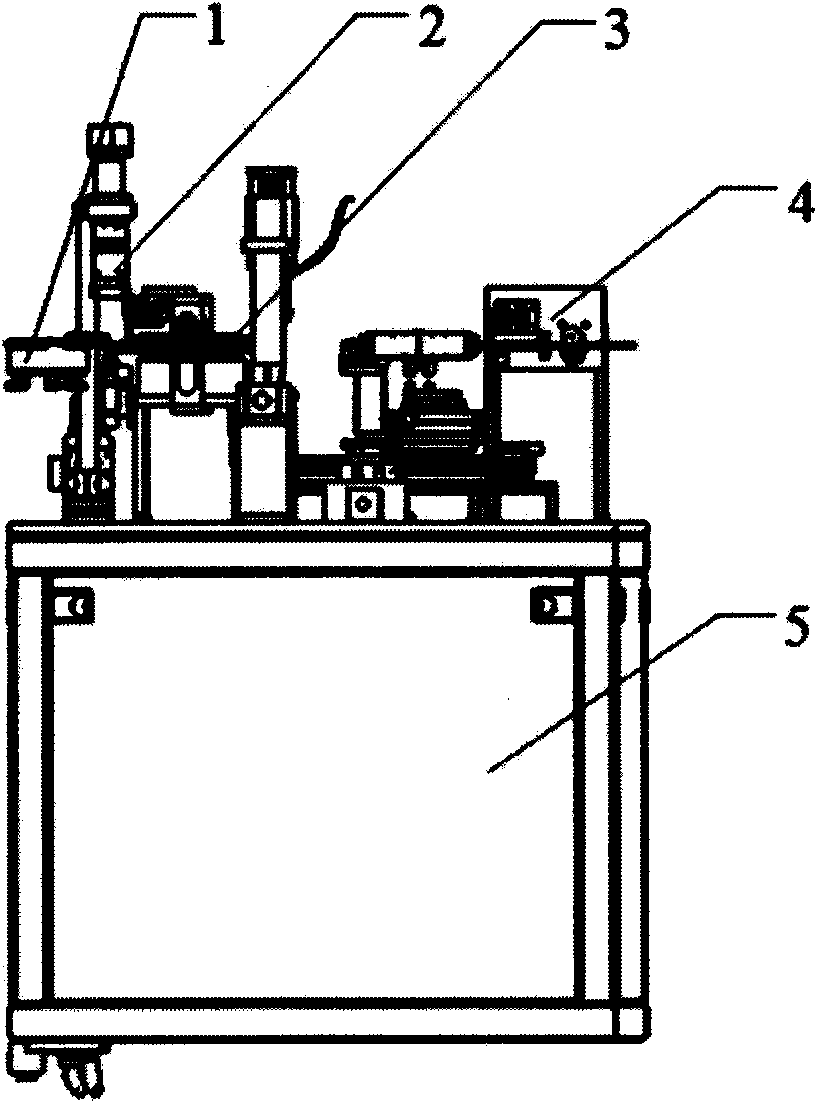

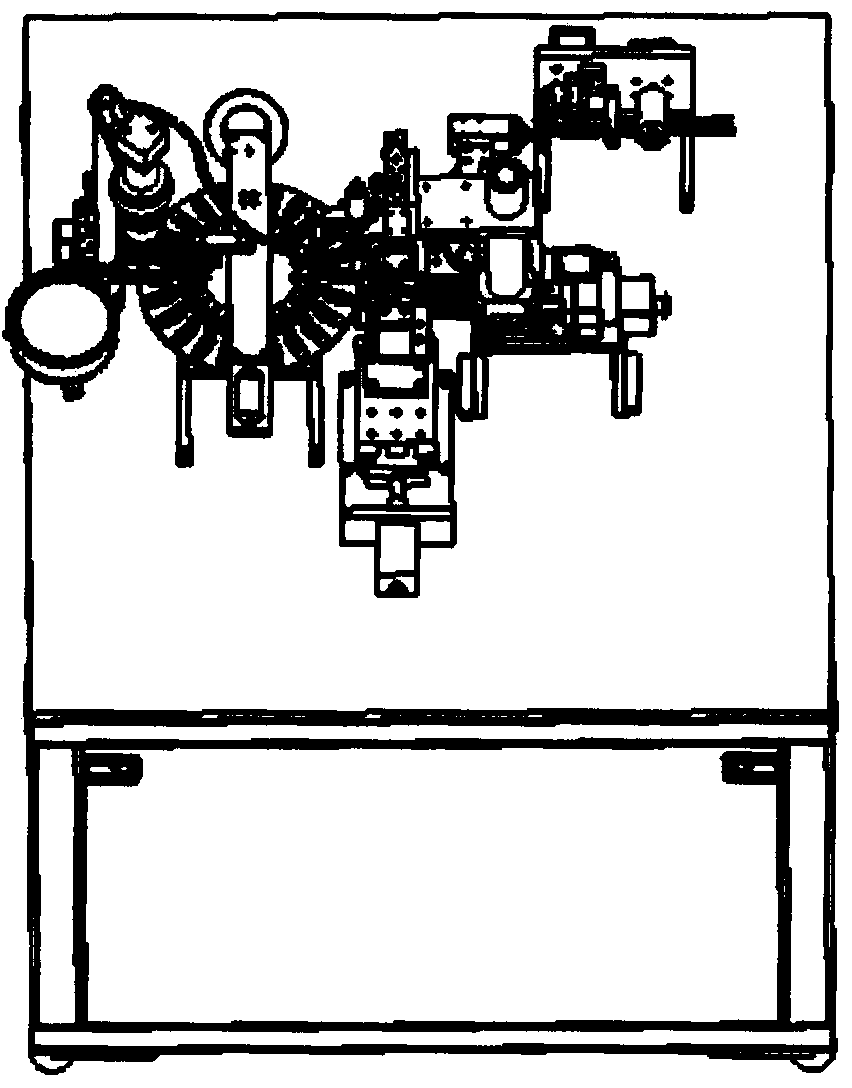

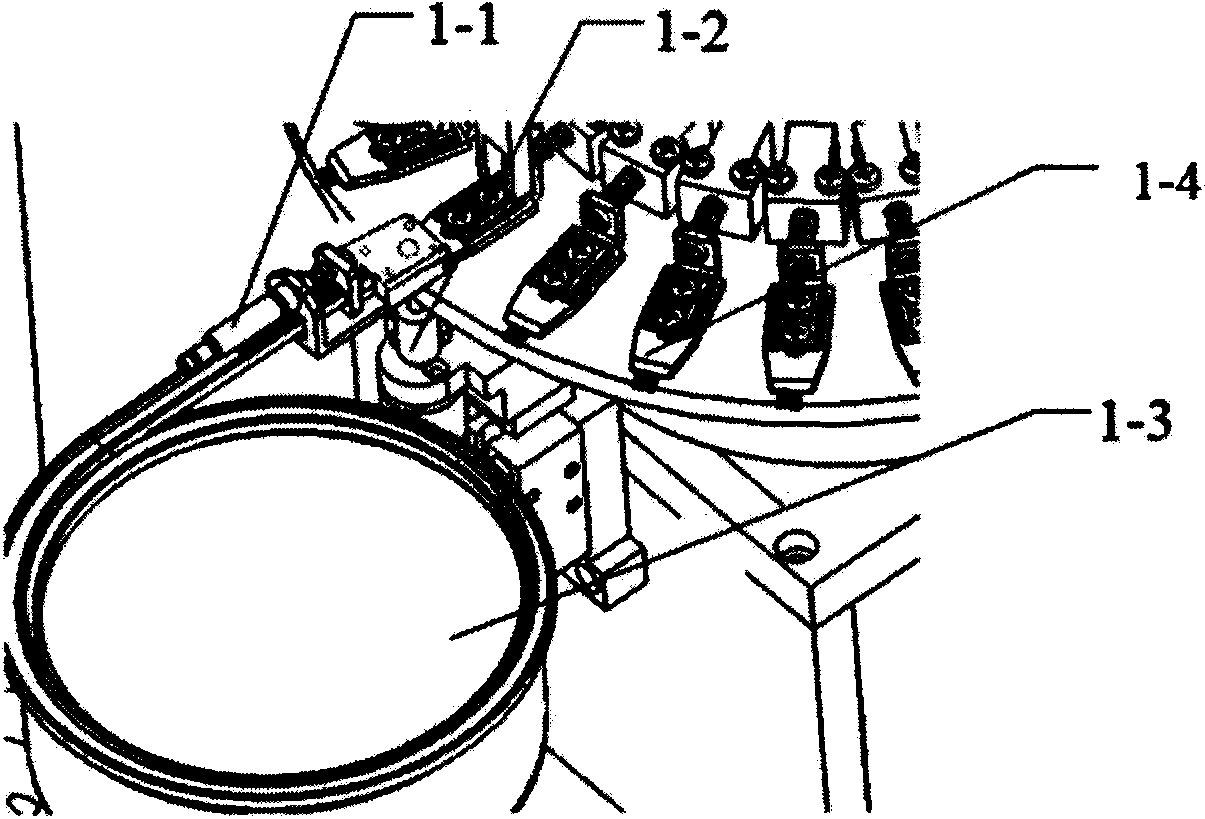

Microphone automated welding device and method

The invention discloses a Microphone automated welding device and method. The Microphone automated welding device comprises a vibration disk feeding module, an image acquisition module, a soldering operation module, a lead feeding module and an electrical control cabinet. The Microphone automated welding device integrates the functions of automatic identification of adjustment of a microphone welding bonding pad, automatic peeling and cutting-off of a lead, automatic welding, automatic sorting of microphones and automatic conveying of the lead. Therefore, the problems that microphone welding efficiency is not high and automated feeding and discharging cannot be achieved can be effectively solved.

Owner:SUZHOU DINA PRECISION EQUIP

Soldering iron with replaceable tip cap

InactiveUS20050011876A1Improve thermal conductivityImprove the immunityHeating element shapesSoldering bitsConductive pasteHeat conducting

A soldering iron (and a desoldering iron) with a replaceable tip cap are herein disclosed. The replaceable tip cap is fitted on the forward heat-conducting core end of a soldering (or desoldering) iron heat assembly. Conductive paste, powder or a low melting temperature material such as solder, can be sandwiched between the tip cap and the forward end to improve heat conductivity therebetween. An assembly which allows for the easy removal and application of a replacement tip cap can include a sleeve with tightening bolt, a coil spring sleeve, or a slotted compressible sleeve. The tip cap can thus be replaced after it has worn out, and the heat assembly unit need not be replaced until it has burnt out.

Owner:HAKKO CO LTD

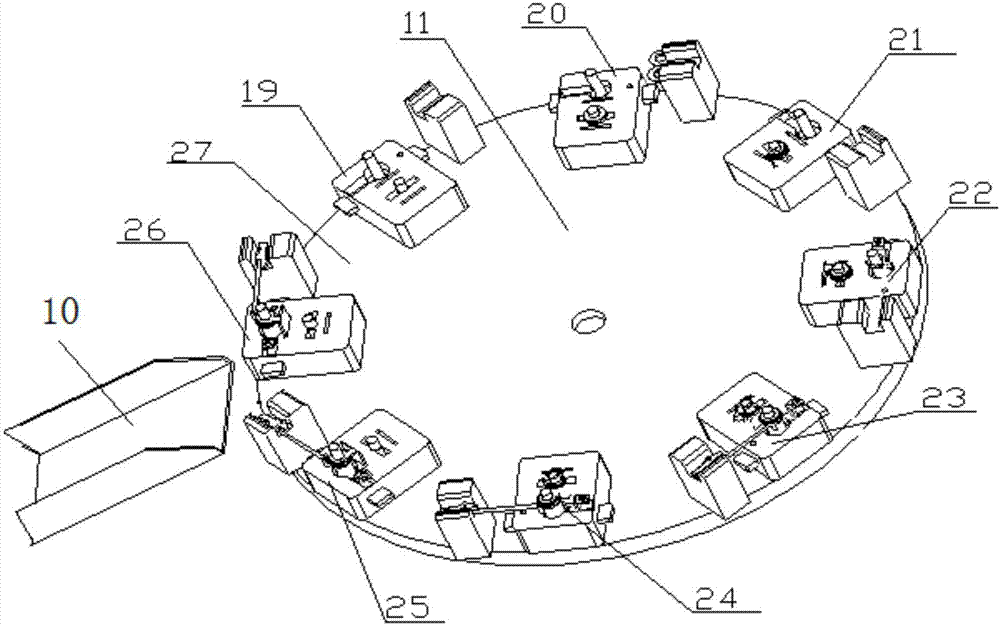

Low-voltage circuit breaker electromagnetic assembly welding system and method

ActiveCN107243682AEliminate weldsIncrease productivitySoldering ironWelding/soldering/cutting articlesLow voltage circuitsSoldering

The invention discloses a low-voltage circuit breaker electromagnetic assembly welding system. The system comprises a rotary disc assembly arranged on a machine frame; the rotary disc assembly comprises a rotary disc and eight fixture assemblies; the rotary disc is arranged on a horizontal table, the lower surface of the rotary disc is provided with a multi-station indexing mechanism, and rotary disc is provided with a transmission mechanism of its own; eight feeding and discharging mechanisms are sequentially arranged in the positions, surrounding the periphery of the rotary disc, of the horizontal table and the machine frame, specifically, the eight feeding and discharging mechanisms comprise the oil cup feeding mechanism, the lower gasket feeding mechanism, the upper gasket feeding mechanism, the magnet yoke feeding mechanism, the coil feeding mechanism, the upper gasket taking mechanism, the magnet yoke taking mechanism and the soldering mechanism, and the outer side of the soldering mechanism is provided with a finished product discharging outlet. All the mechanisms are connected with a central controller. The invention further discloses a full-automatic circuit breaker electromagnetic assembly welding method. According to the system and the method, the structure is compact, the full-automatic degree is high, and the finished product quality is good.

Owner:YUEQING YEDAO ELECTROMECHANICAL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com