Press type automatic tin supply electric soldering iron

An electric soldering iron, automatic technology, applied in the electronic field, can solve the problems of low welding operation efficiency, inconvenient welding operation, long time consumption, etc., achieve the effect of automatic supply and control of welding flow, simple and convenient operation, and improve welding efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

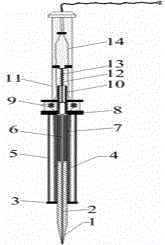

[0024] Below in conjunction with accompanying drawing technical scheme of the present invention is described further as follows:

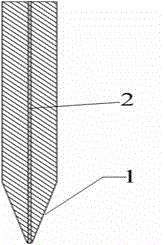

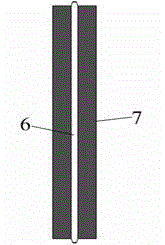

[0025] Such as figure 1As shown, a touch-pressure automatic tin supply soldering iron includes a soldering iron head (1), a heating device (5), a tin melting device (7), a pressure piston (10) and a handle device (11), and the soldering iron The head (1), the tin melting device (7) and the pressure piston (10) are combined together. The inner cavity of the three is connected and does not contact with the outside air, forming a closed inner cavity. Under certain circumstances, it can ensure that the liquid tin in the tin cavity does not fall. The soldering iron tip (1) has a tin-holding cavity (2) inside, the tin-holding cavity (2) is designed with a diameter of 0.5 mm, and is mainly used to accommodate solder liquid, and the tip of the soldering iron tip (1) has a tin-holding cavity The cavity (2) has the same pores through which solder liq...

Embodiment 2

[0032] For a better understanding of the present invention, the method of using the electric soldering iron of the present invention will be further described below in conjunction with the examples:

[0033] During specific use, when the power is plugged in, the two copper sheets (9) drawn out by the wires at the bottom of the handle device (11) are heated, and then transfer the heat to the two copper sheets (9) led out by the inner wires of the heating device (5). ), heating the heat transfer cylinder (4) wound with resistance wire through the wire (14) to transfer heat to the soldering iron tip (1) and the tin melting device (7), and melt the solder inside the tin melting cavity (6) from solid to liquid , and at the same time make the temperature of the soldering iron tip (1) reach the working temperature. Then gently touch the tip of the soldering iron tip (this process is completed within about 2-3 seconds), thereby pushing the combination of the soldering iron tip (1), th...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com