Patents

Literature

99results about How to "Eliminate welds" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

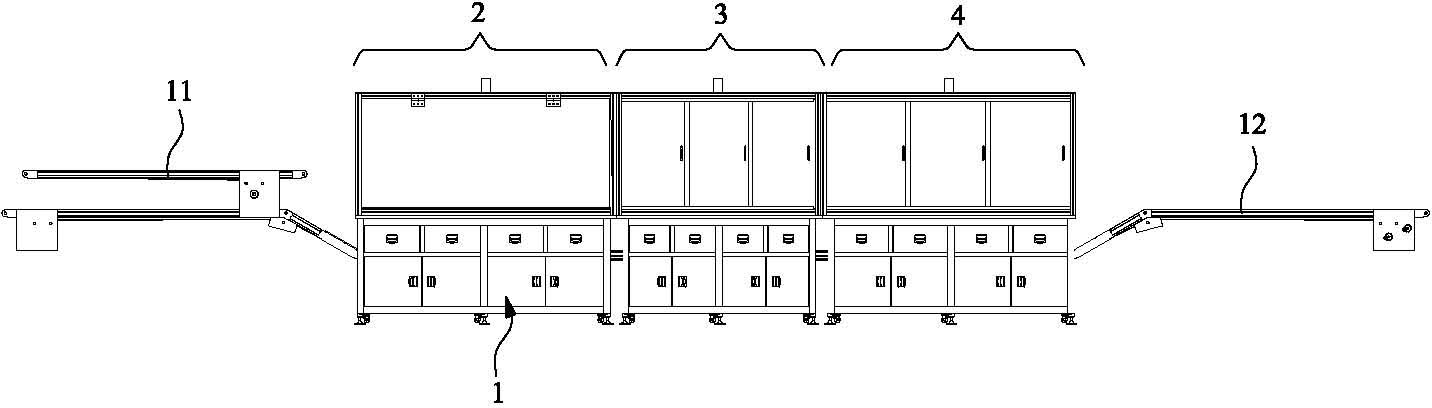

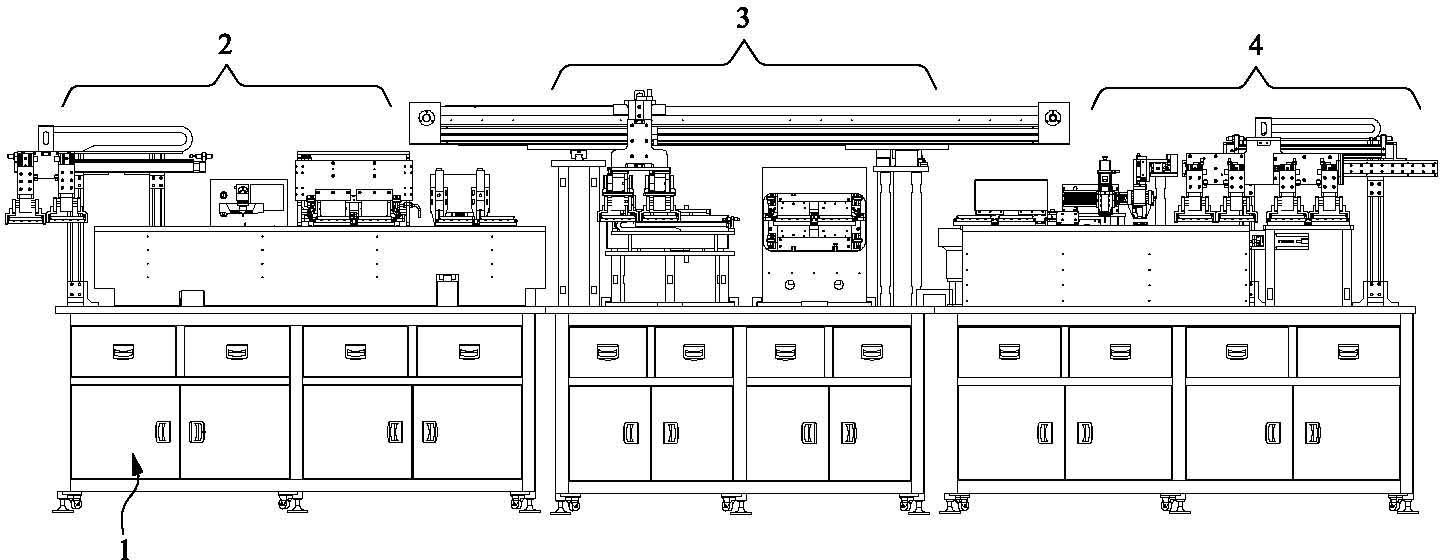

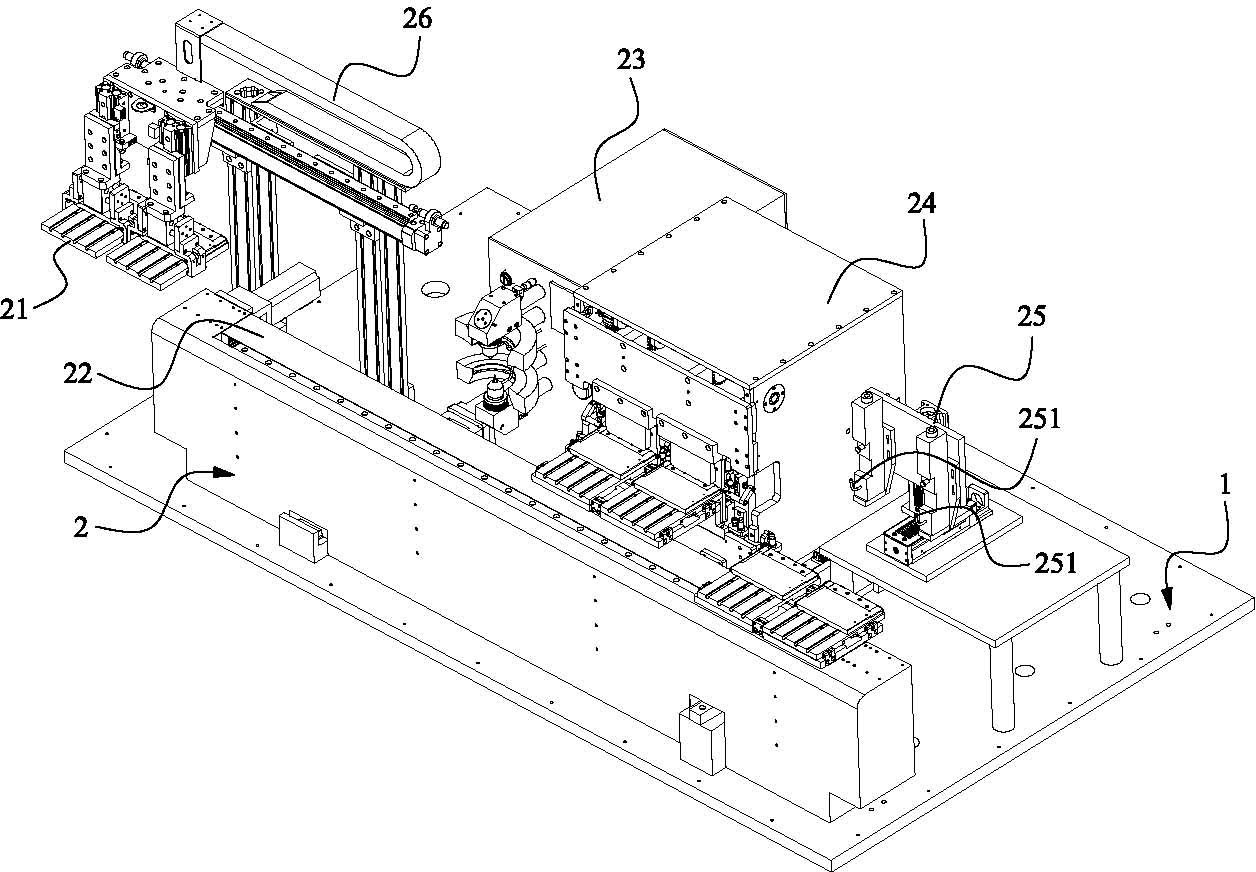

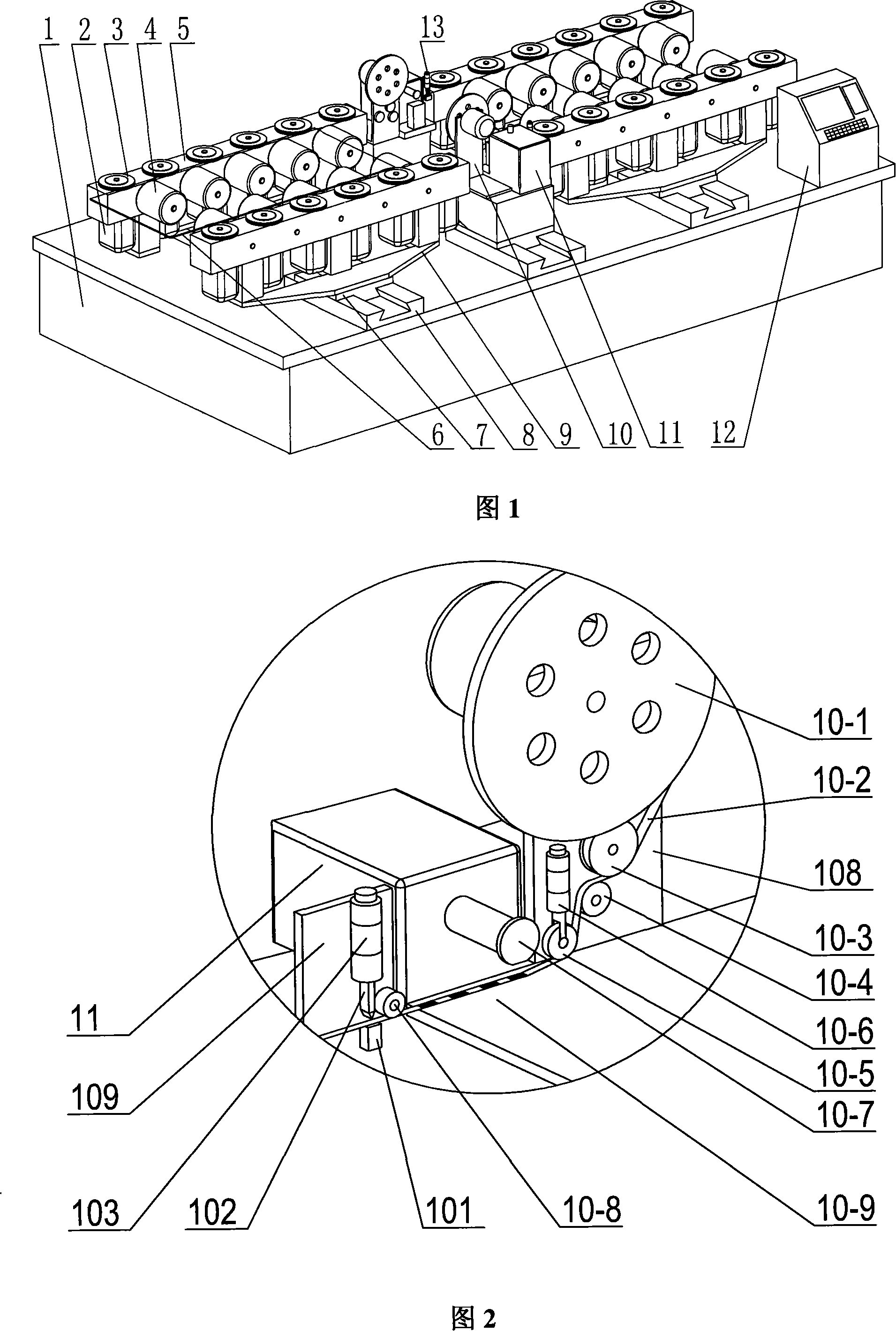

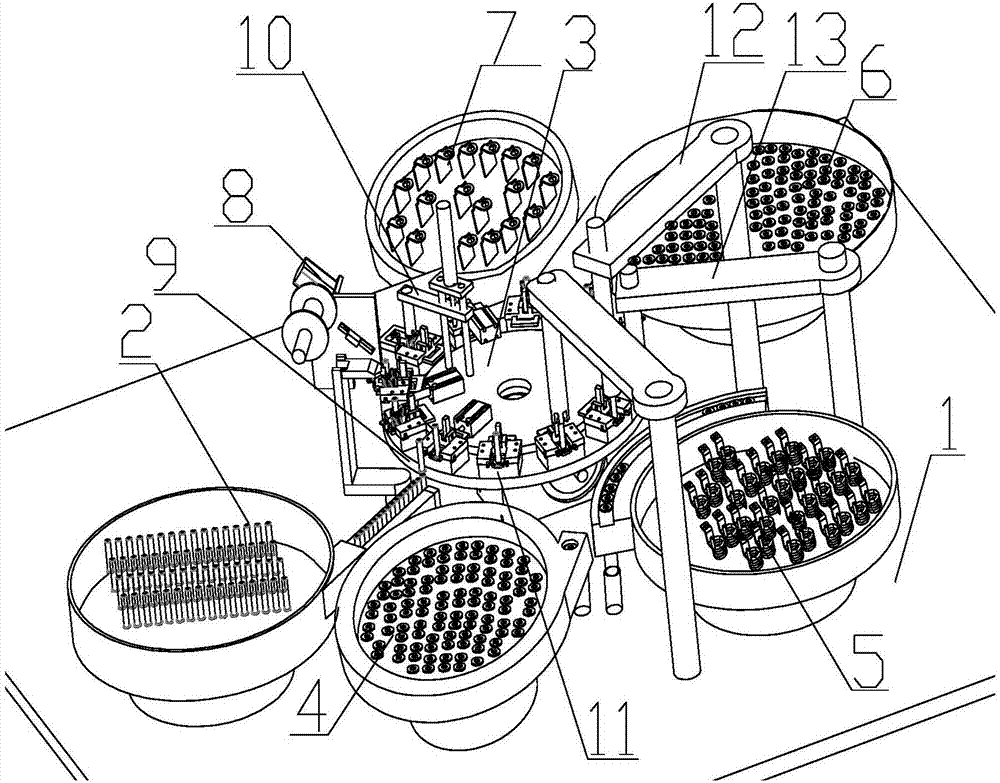

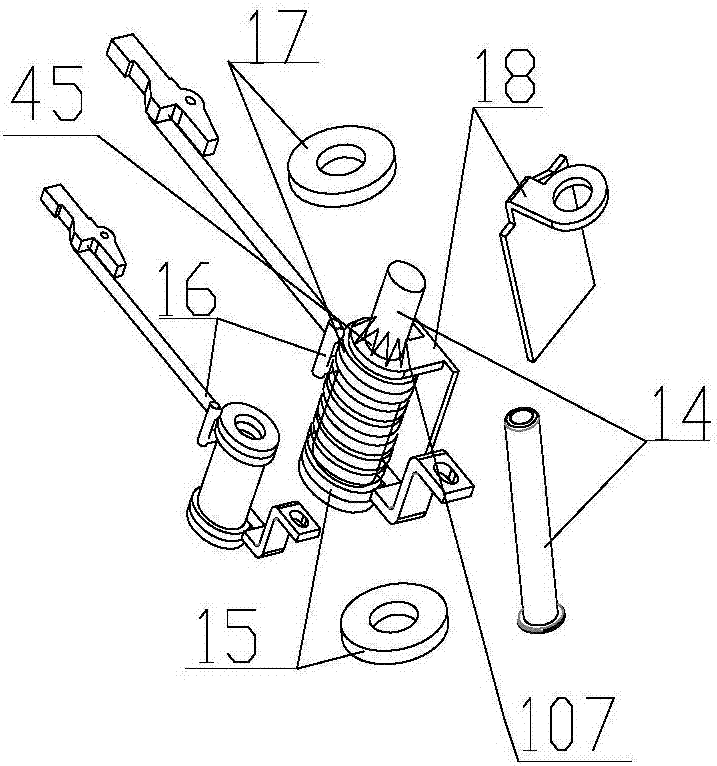

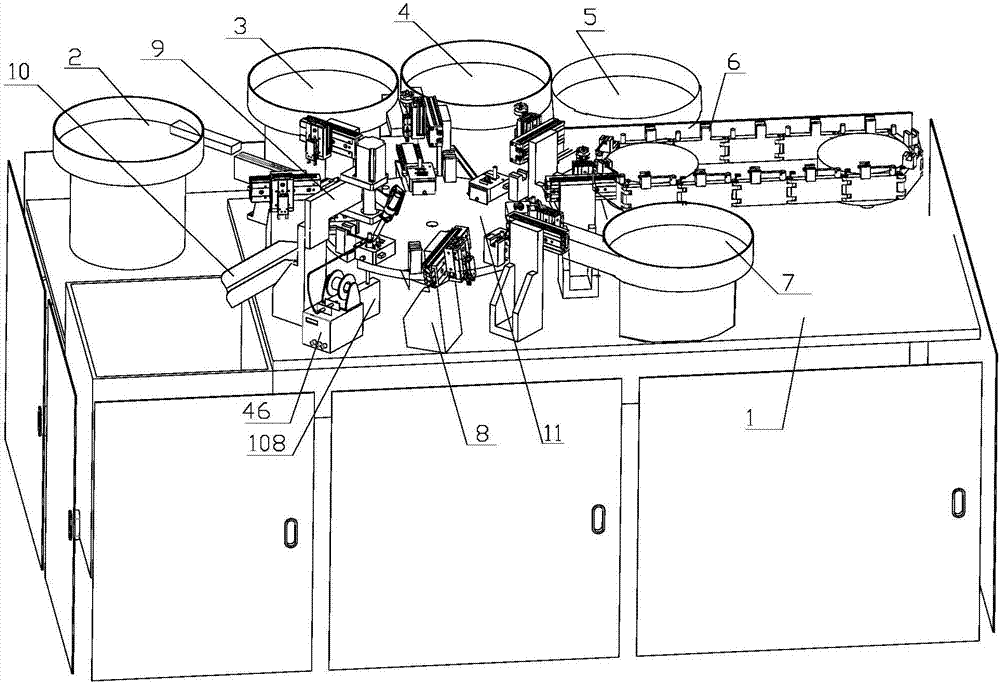

Automatic cable and connector processing, welding and assembling machine

InactiveCN102637988AEliminate weldsEliminate quality problemsLine/current collector detailsEconomic benefitsEngineering

The invention discloses an automatic cable and connector processing, welding and assembling machine, comprising a rack as well as a laser peeling module, an adhered tin trimming module and a plug welding module sequentially arranged on the rack, wherein the laser peeling module comprises a jig, a first transmission device, a laser device, a peeling device and a flux spraying device; the adhered tin trimming module comprises a clamping-jaw feeding device, a tin pot and a trimming device; and the plug welding module comprises a soldering device, a plugging device, a welding device and a clamping-jaw laying-off device. Therefore, the automatic machining on a cable is finished by virtue of the laser peeling module and the adhered tin trimming module, the laser peeling module, the adhered tin trimming module and the plug welding module are matched to weld and connect a connector and the cable together, and a core wire of the cable is kept to be straight in processes of processing and welding the core wire, so that the quality problems of insufficient soldering, leaving out of welding, short circuit and the like during the connection between the cable and the connector are eliminated, and the unmanned automatic processing, welding and assembling procedures are realized to effectively improve the production efficiency of products and to bring more economic benefits to enterprises.

Owner:DONGGUAN SANXIN PRECISION MACHINERY

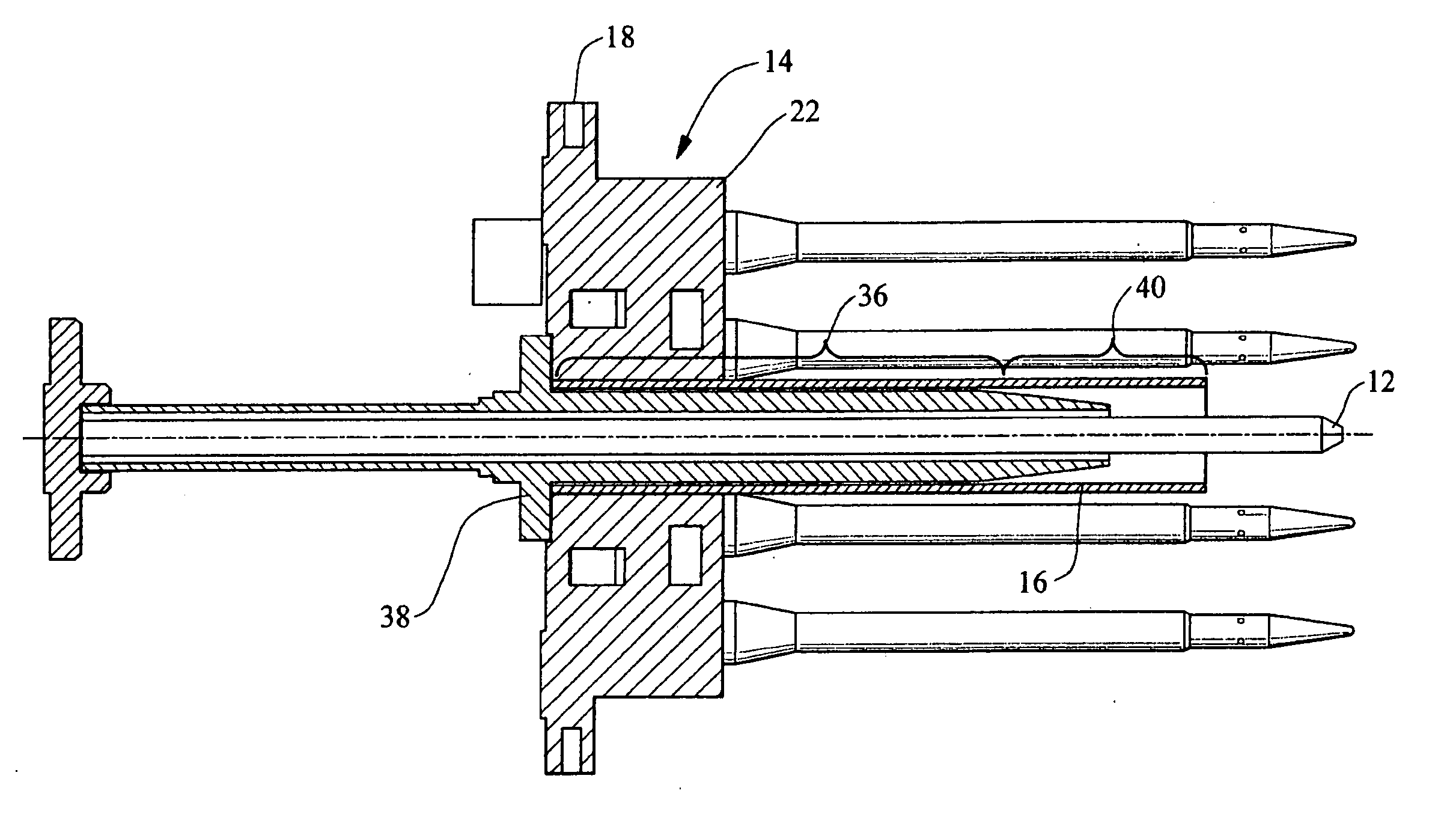

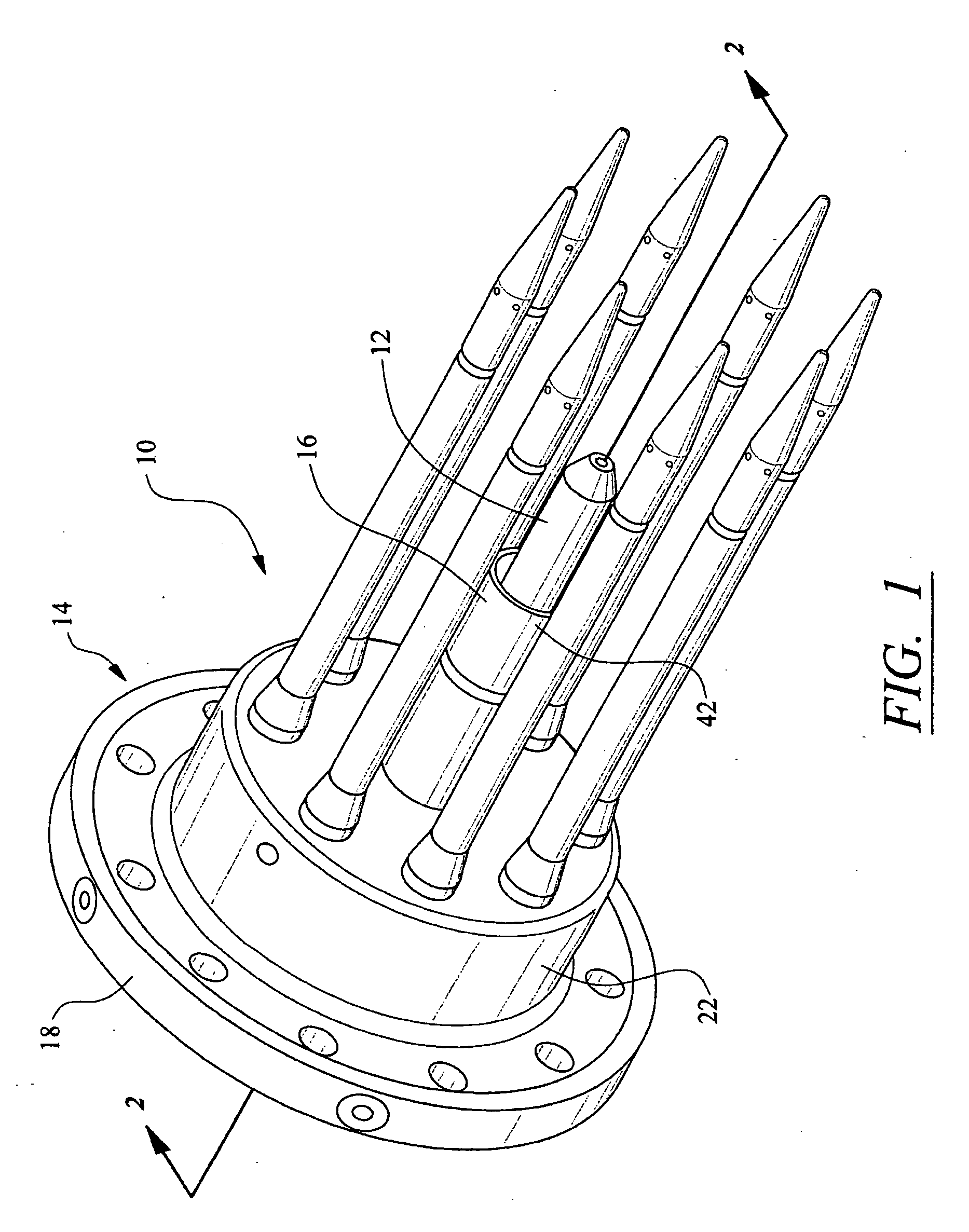

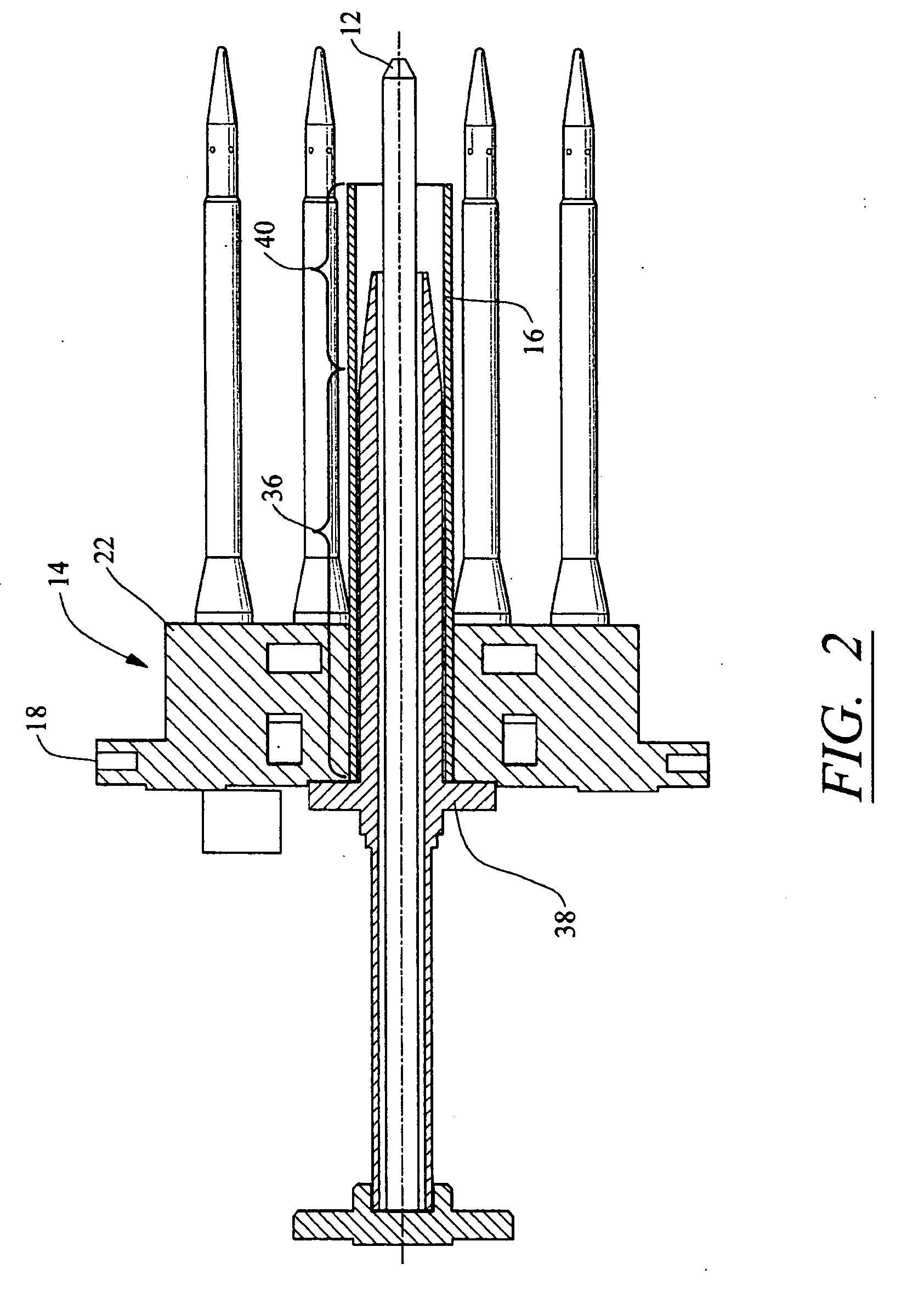

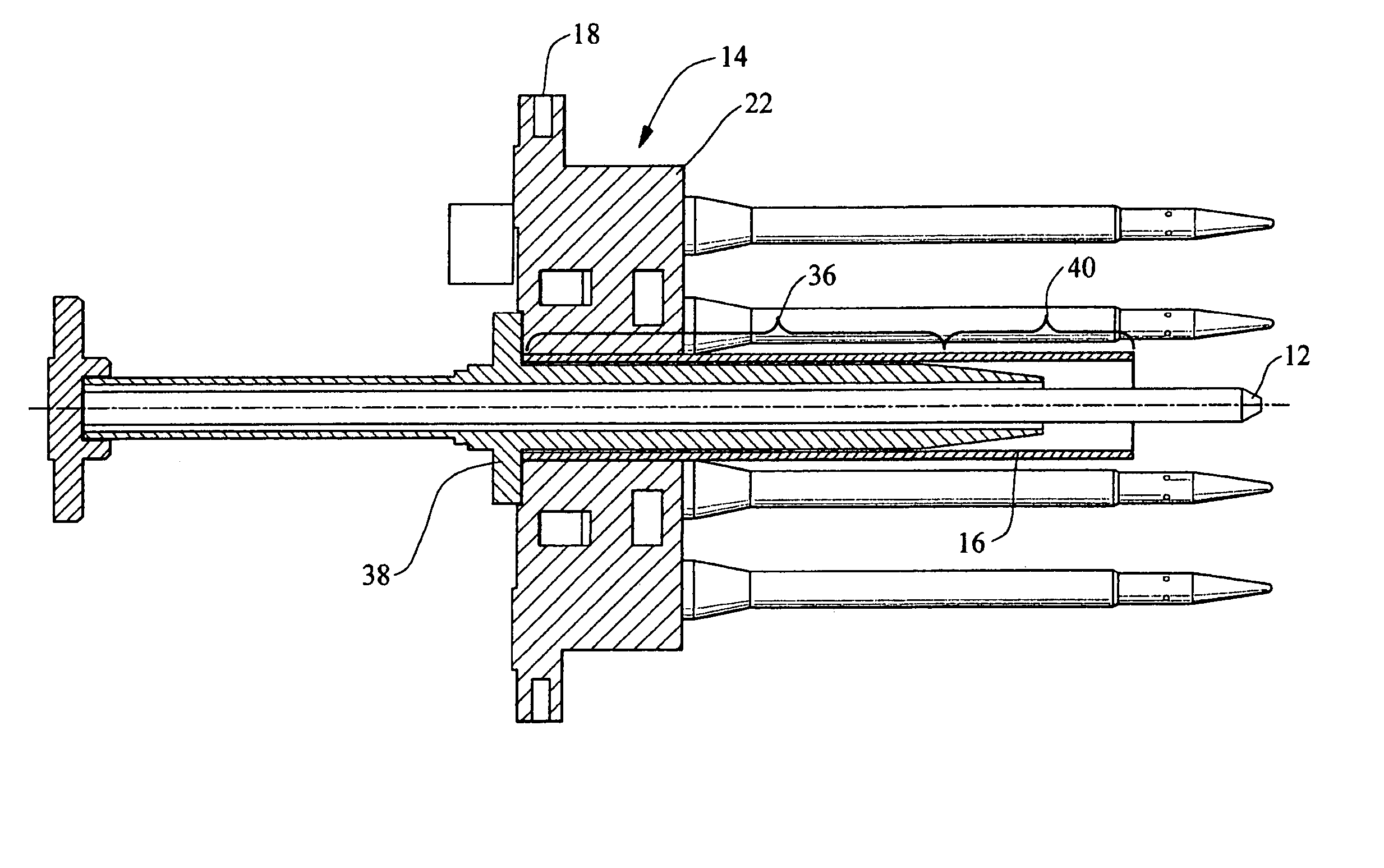

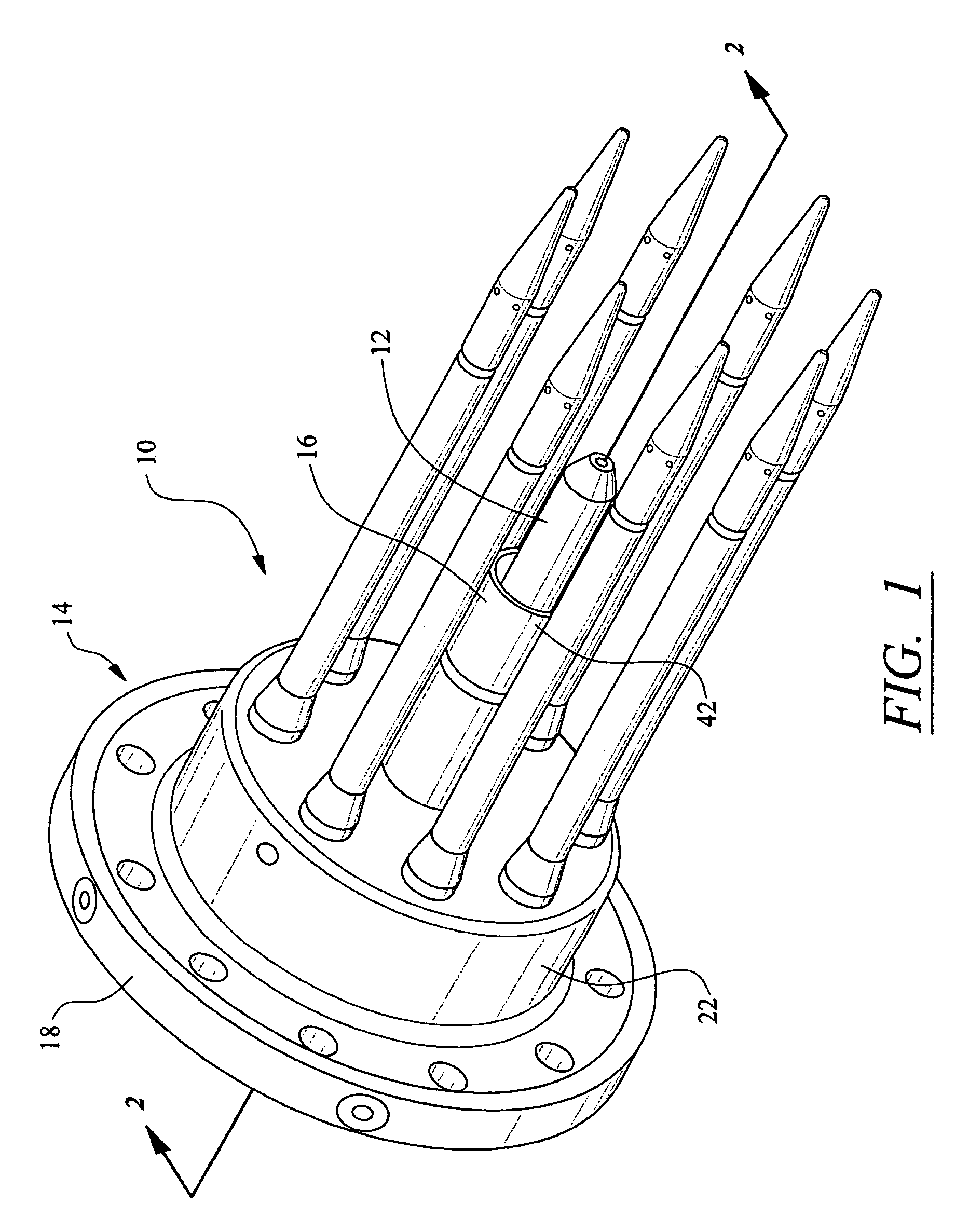

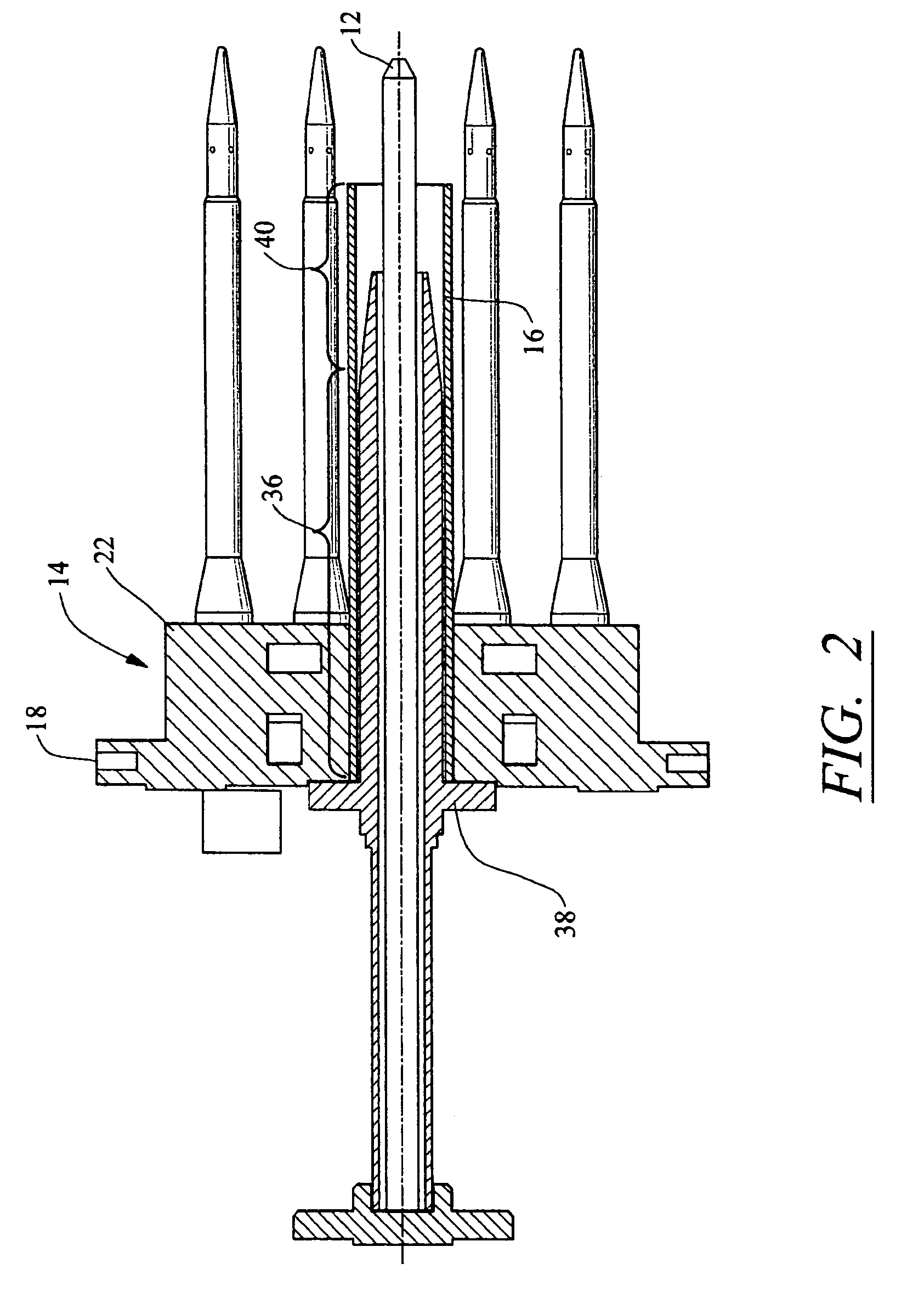

Support system for a pilot nozzle of a turbine engine

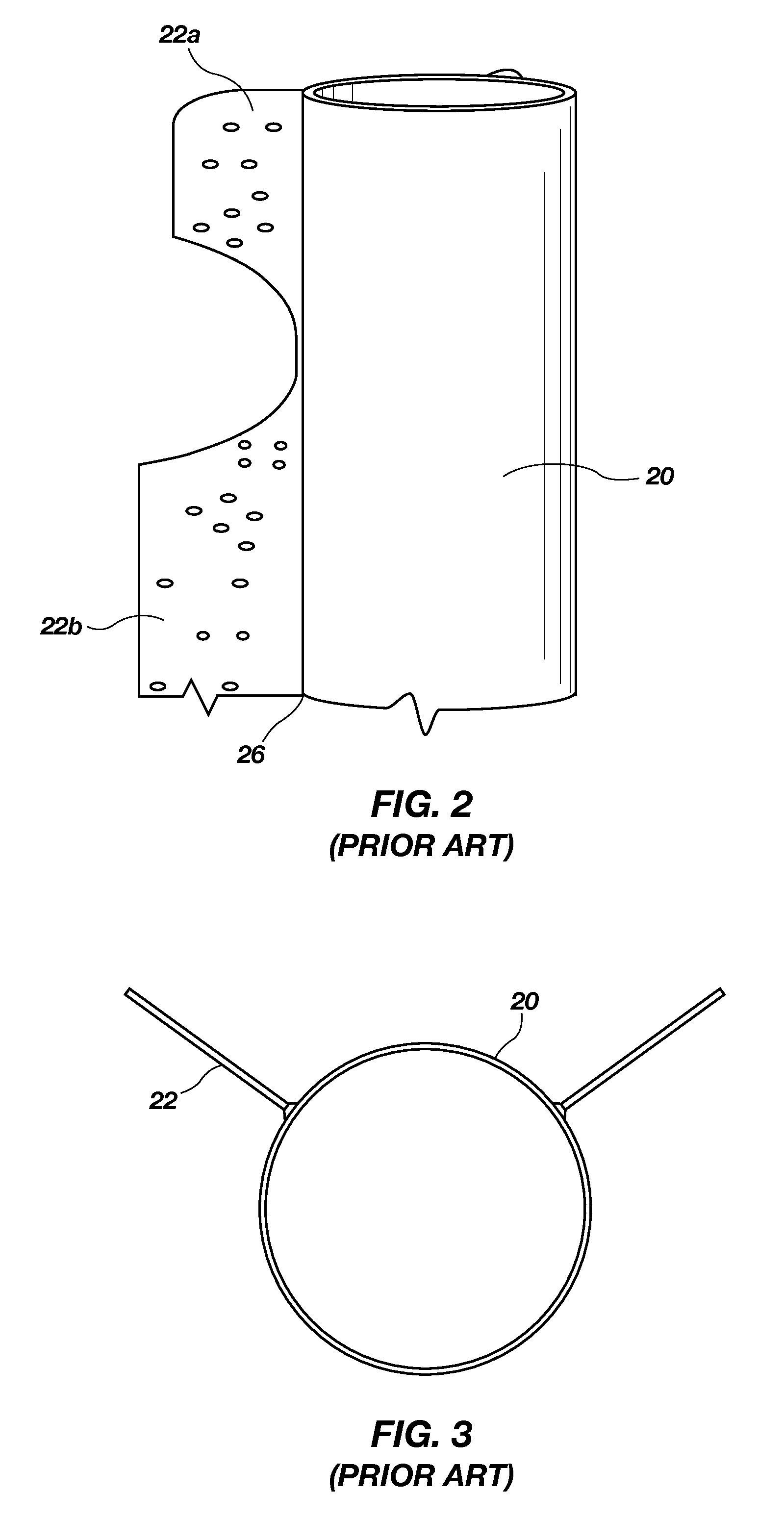

ActiveUS20060026966A1Raise the natural frequencyPrevent insertionContinuous combustion chamberTurbine/propulsion fuel supply systemsInterference fitSupporting system

An automatic recovery pilot nozzle support system for supporting a pilot nozzle in a fuel injection system of a turbine engine. The support system includes a sleeve extending from an orifice in a support housing, wherein the sleeve has a hollow opening for containing a pilot nozzle. The sleeve may increase the natural frequency of the pilot nozzle above an excitation zone, thereby limiting destructive vibrations. The sleeve may be attached to the support housing with an interference fit. The automatic recovery aspect of the support system enables the sleeve to maintain an interference fit with the support housing such that anytime the sleeve looses contact with the support housing, an insulative film of air forms between the sleeve and the support housing. The insulative film of air causes the temperature of the sleeve to increase, and the sleeve to expand and reform the interference fit with the support housing.

Owner:SIEMENS ENERGY INC

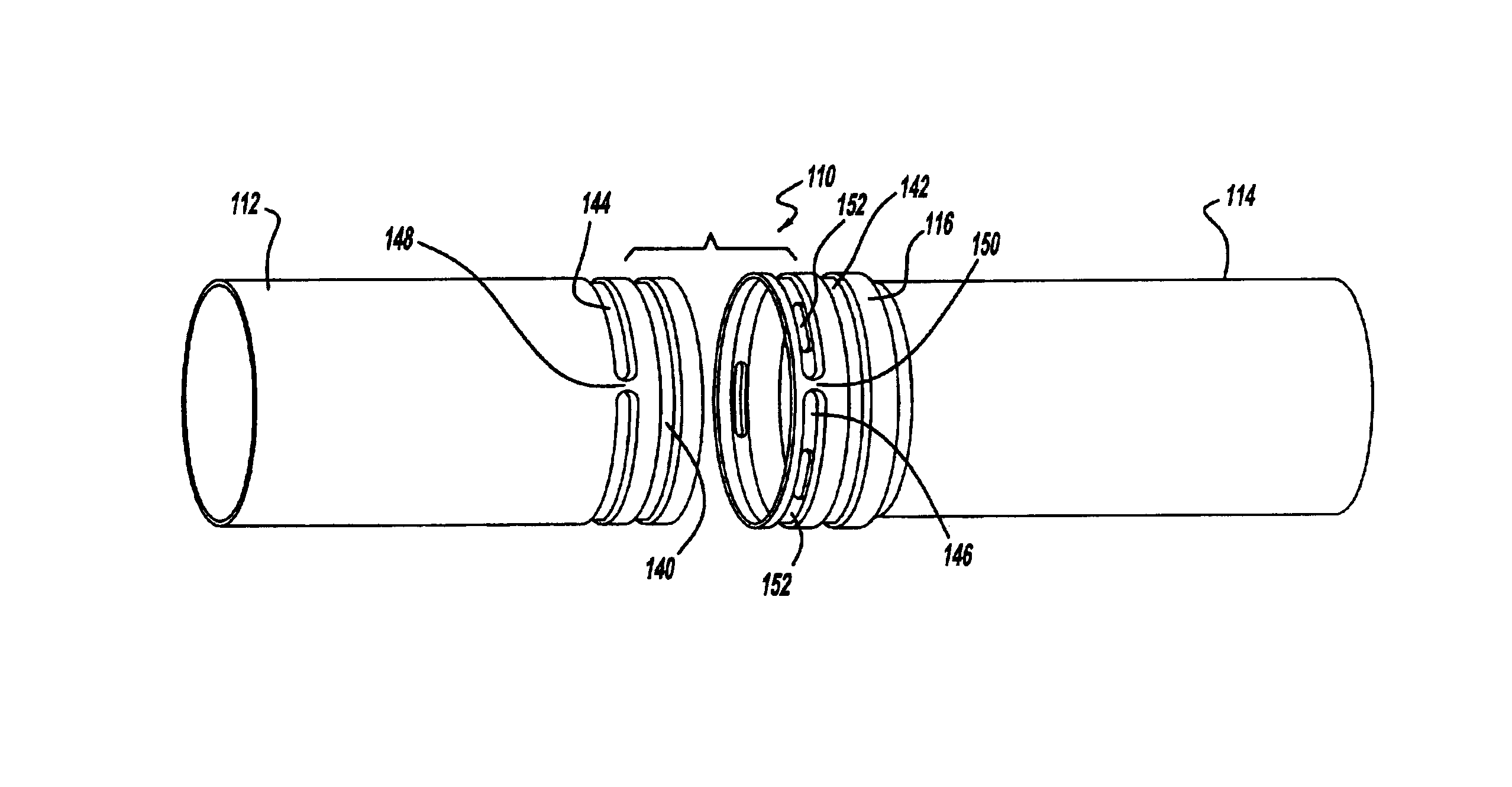

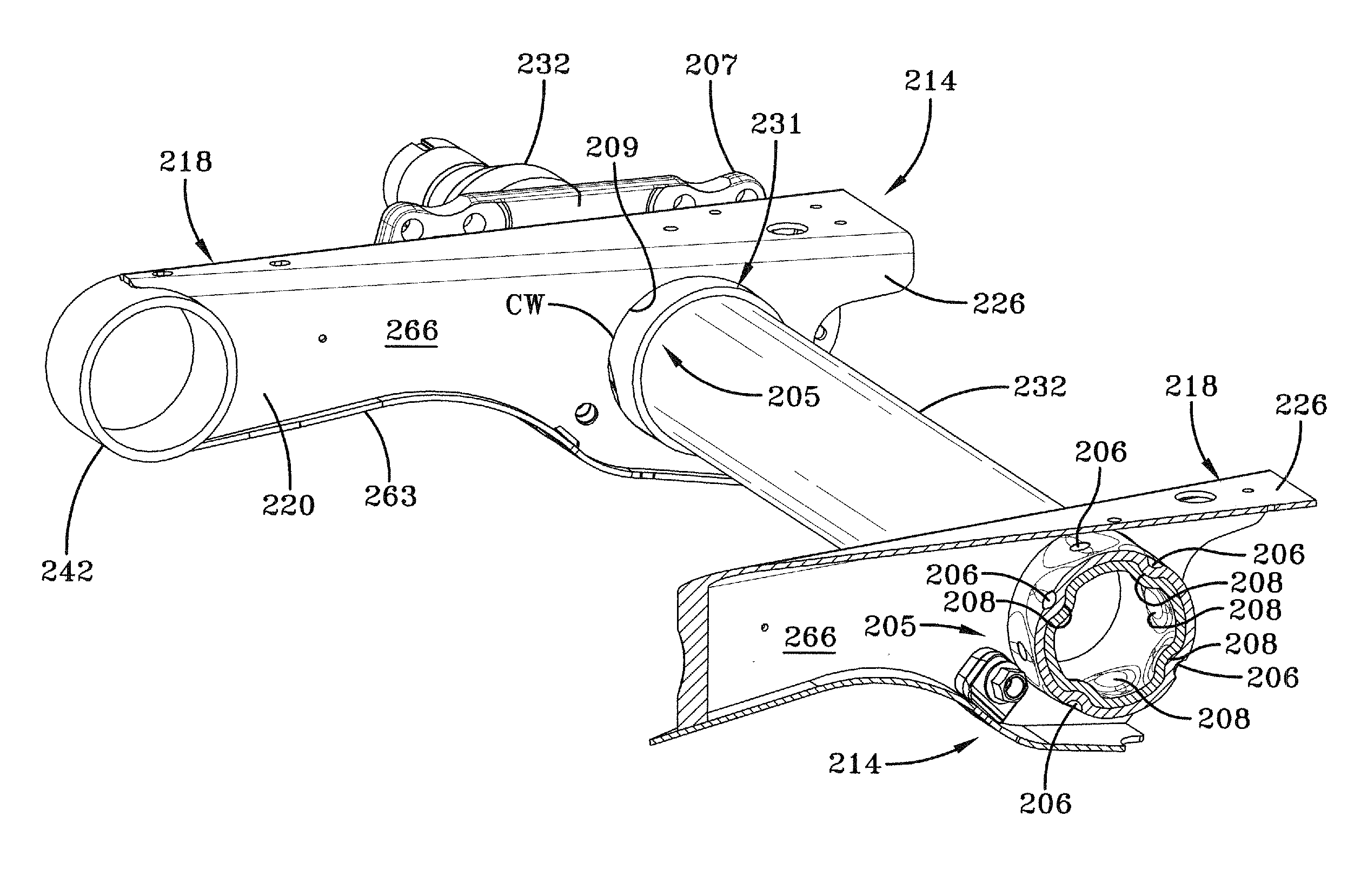

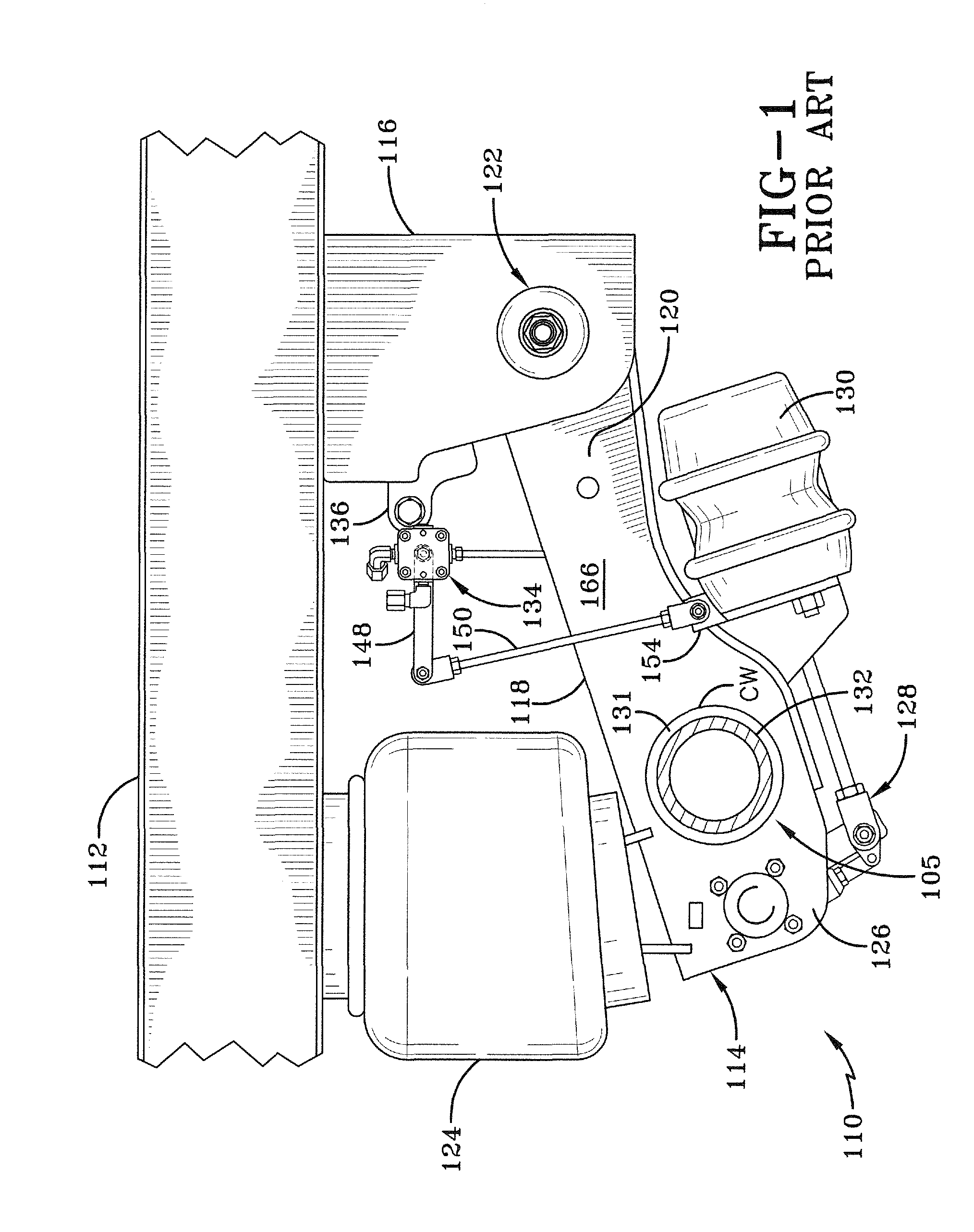

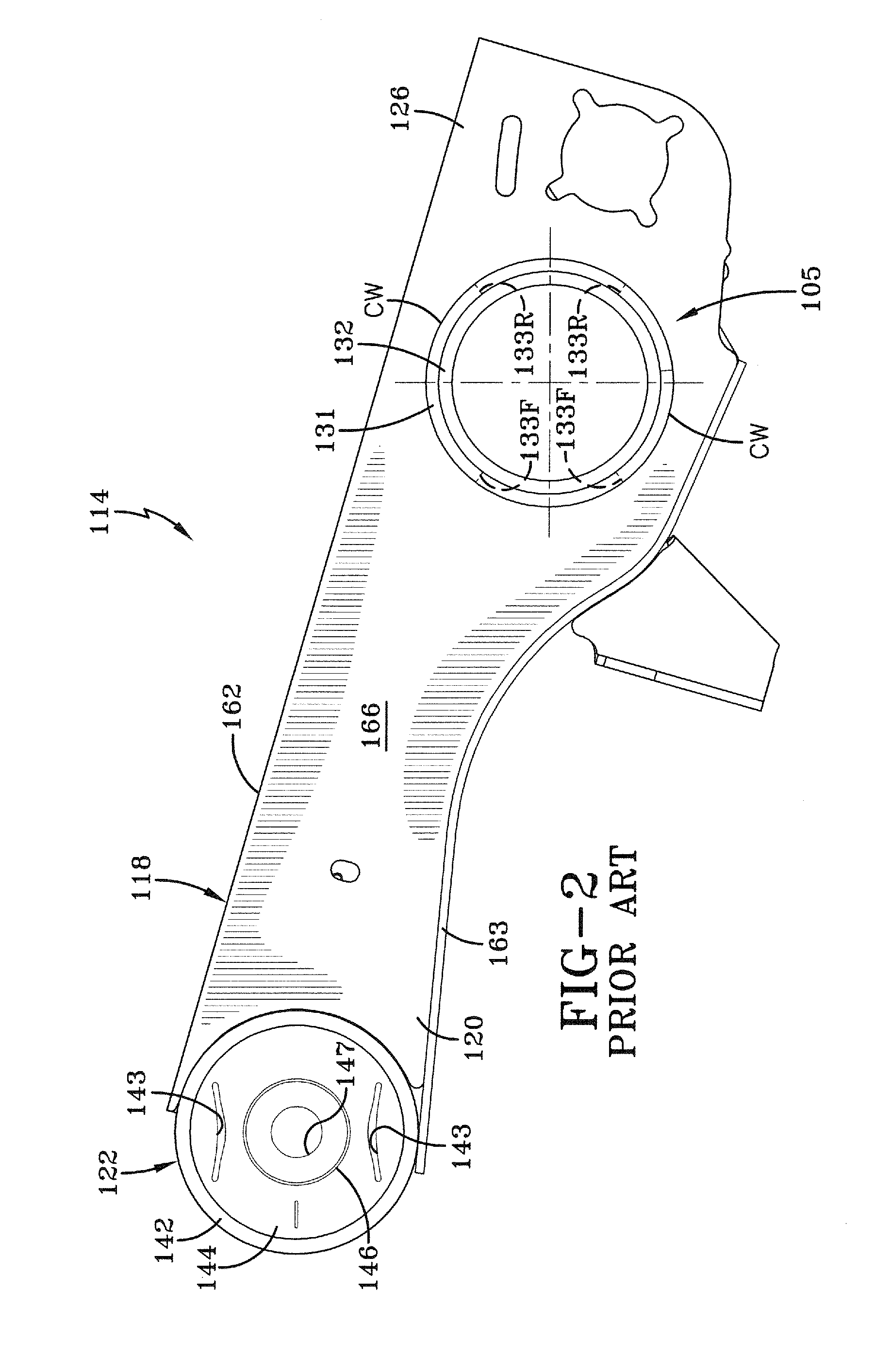

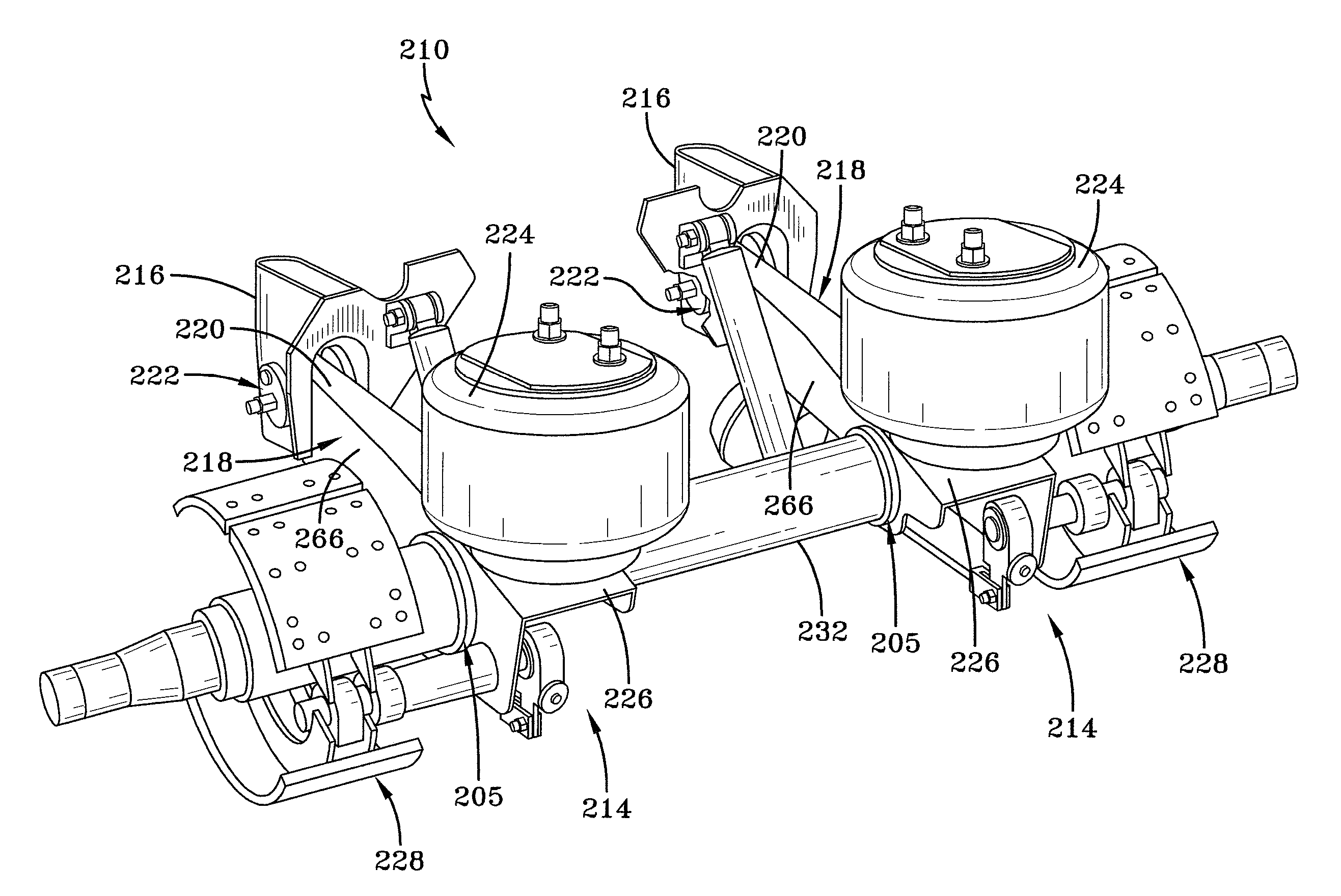

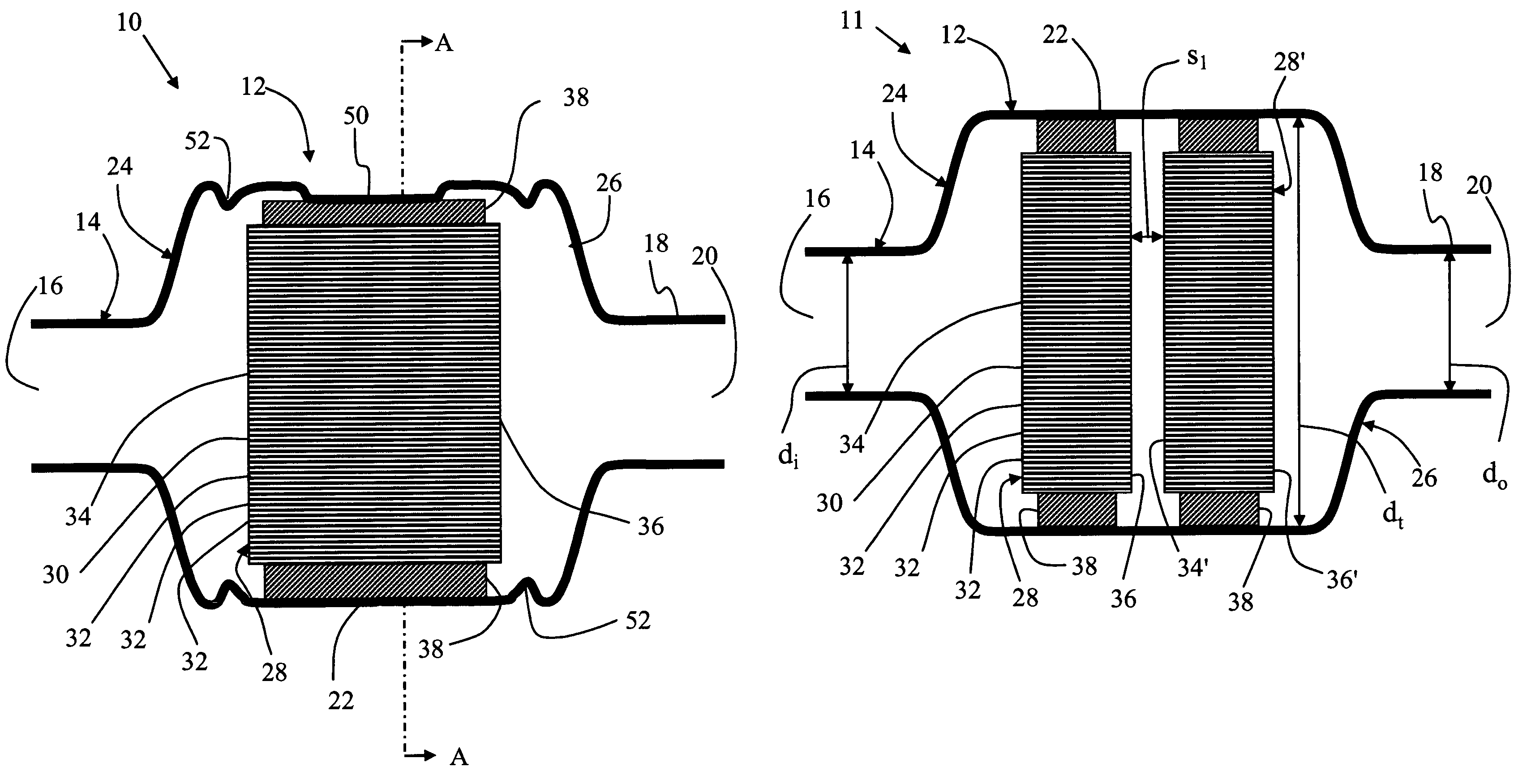

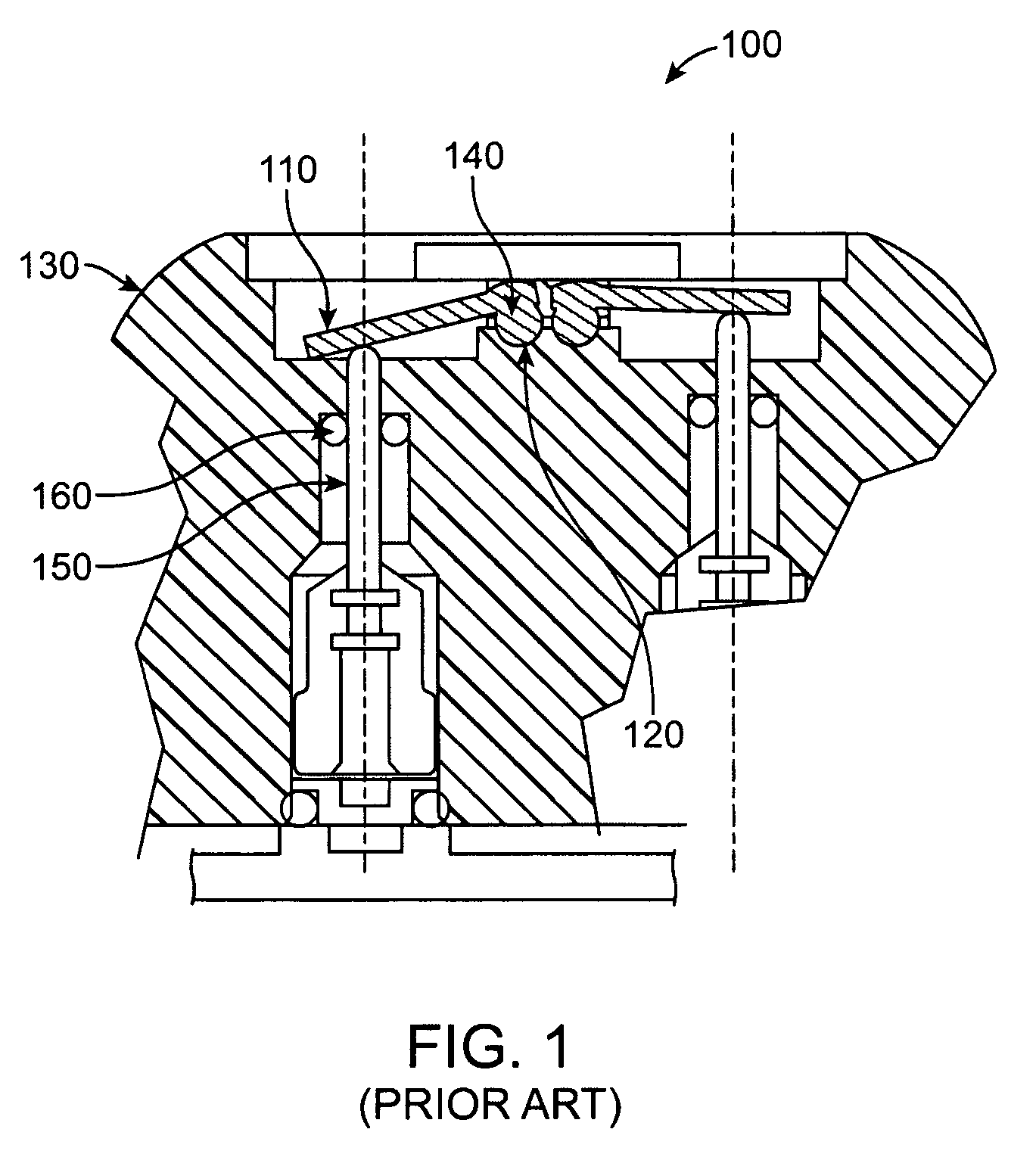

Heavy-duty axle-to-beam connection

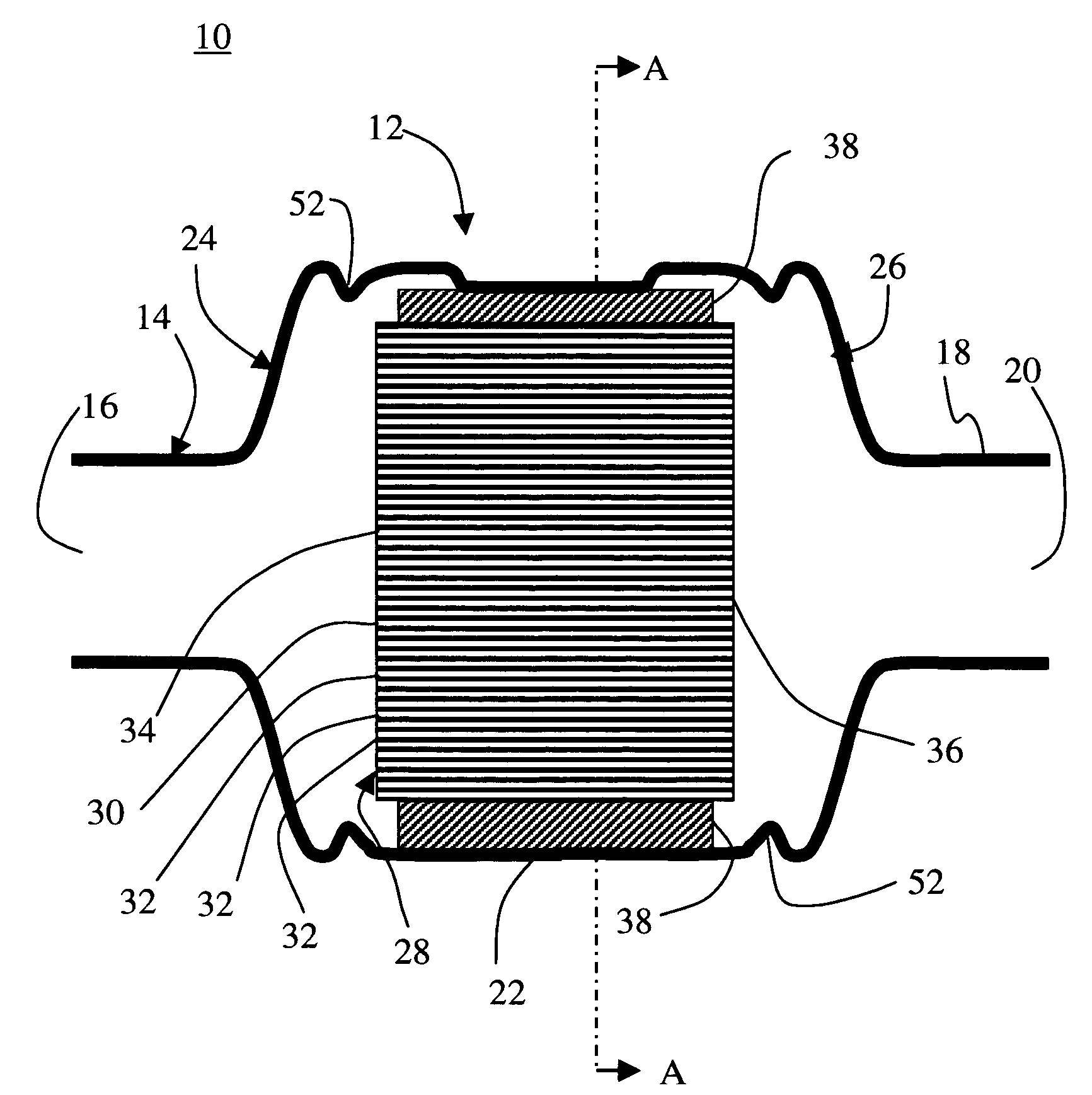

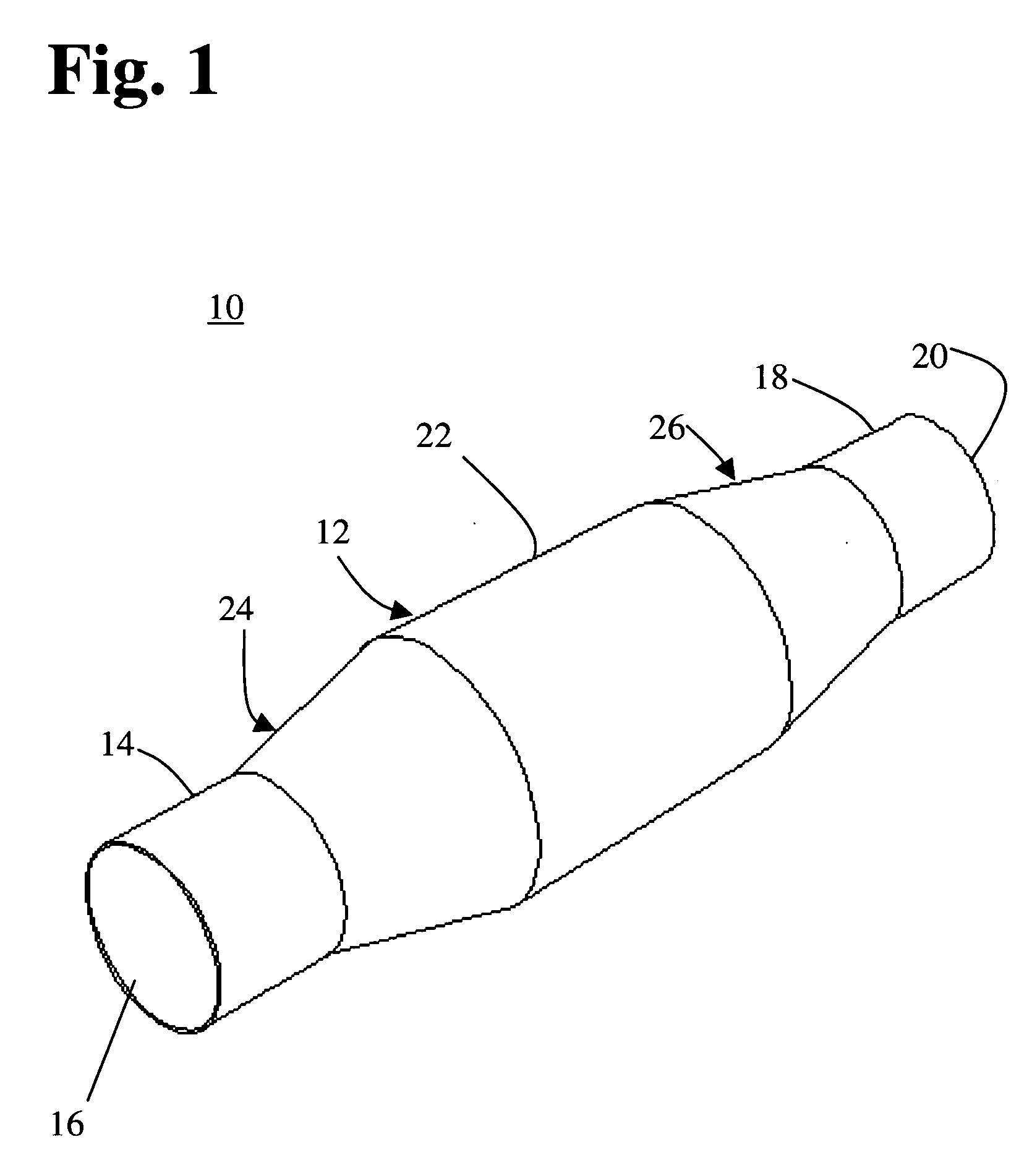

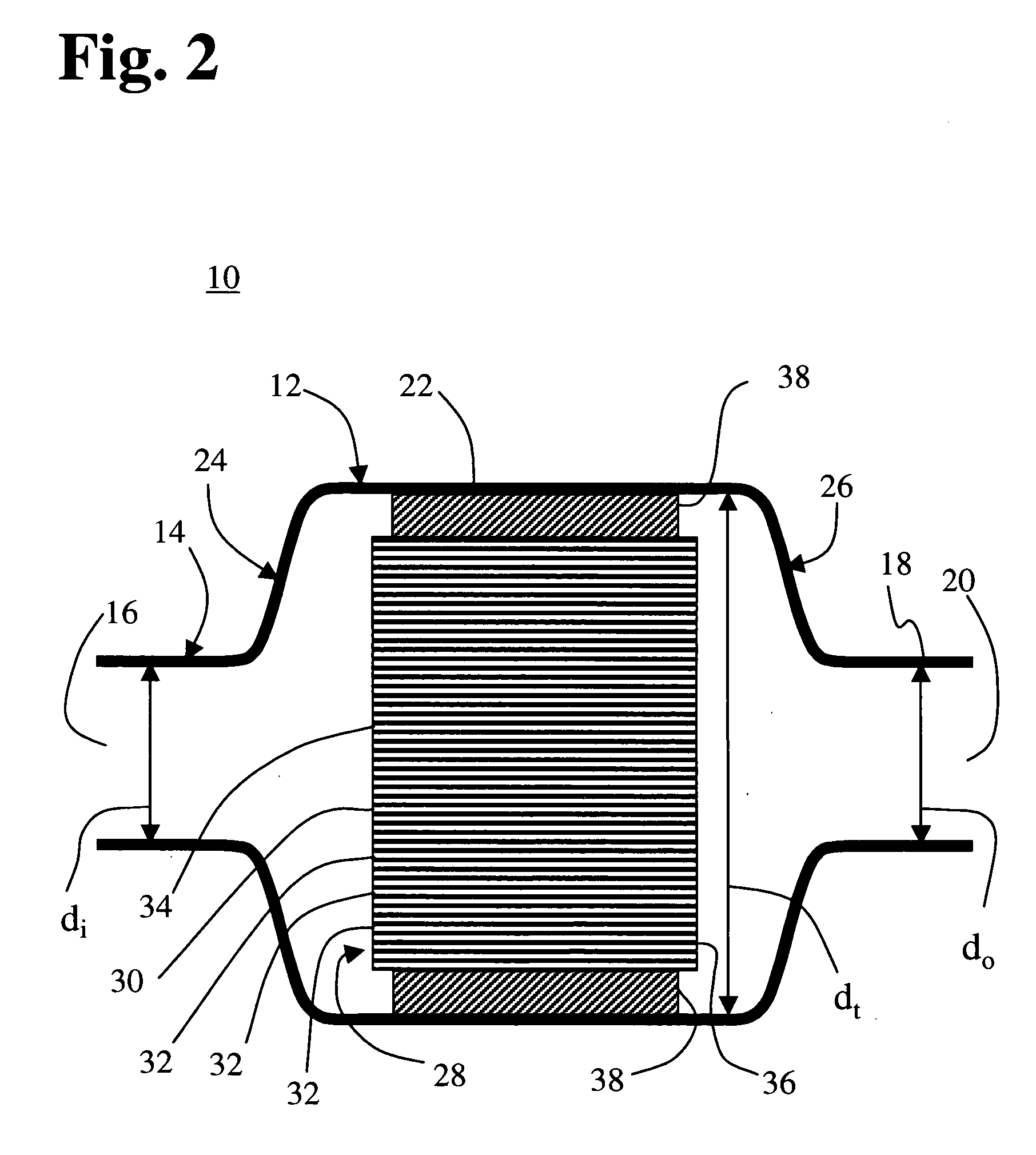

ActiveUS20120080862A1Eliminate weldsImproves life and durabilityLaminationLamination apparatusHeavy duty

An axle-to-beam connection for a vehicle axle / suspension system includes an axle having at least one depression formed therein. A sleeve is formed with at least one depression and disposed about the axle so that the axle depression and the sleeve depression matingly engage one another to form a mated pair of depressions. A method of forming the axle-to-beam connection includes providing an axle and disposing a sleeve about the axle. At least one mated pair of depressions is simultaneously formed in the axle and the sleeve. The sleeve is immovably mounted to a vehicle axle / suspension system.

Owner:HENDRICKSON USA L L C

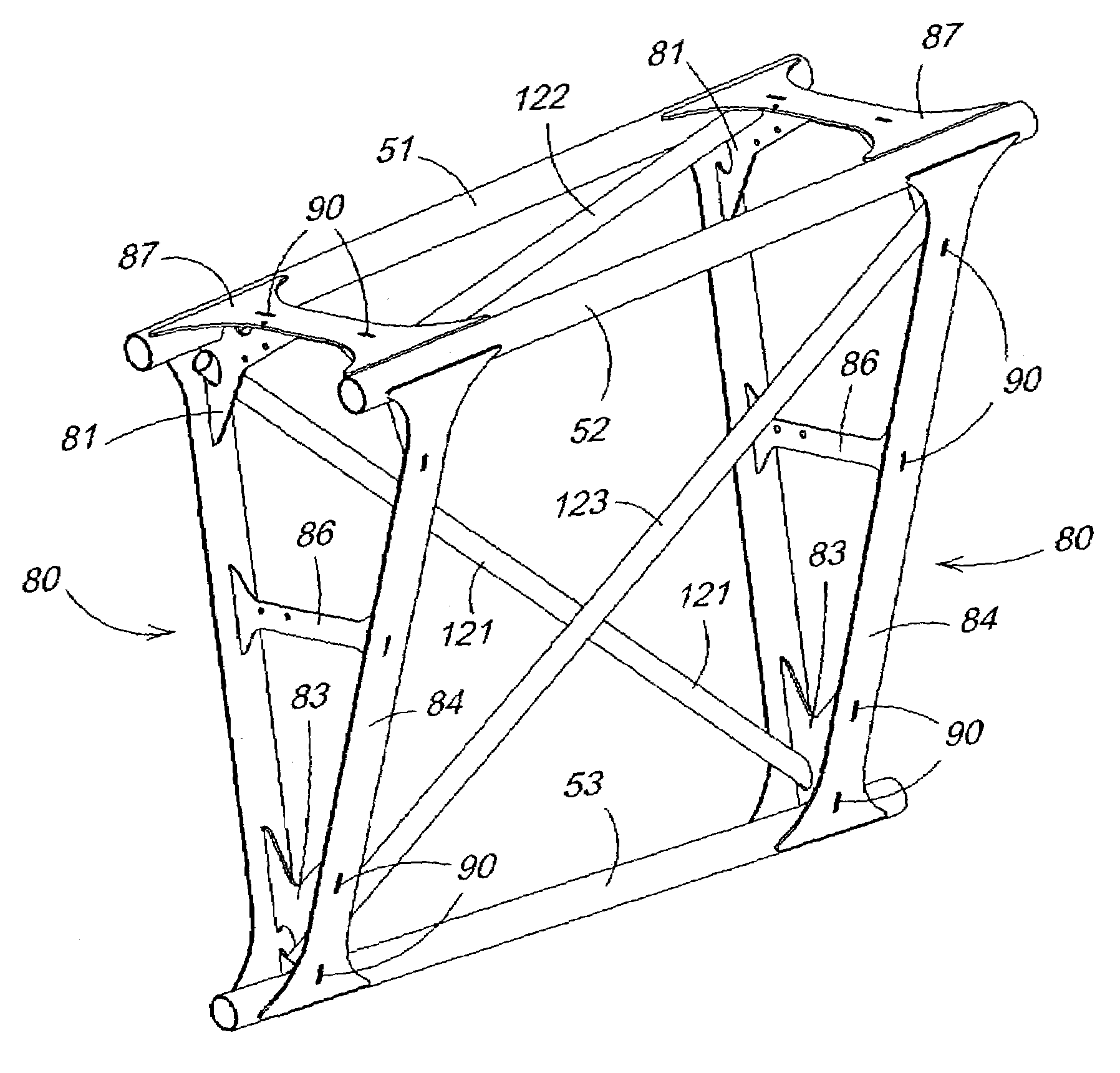

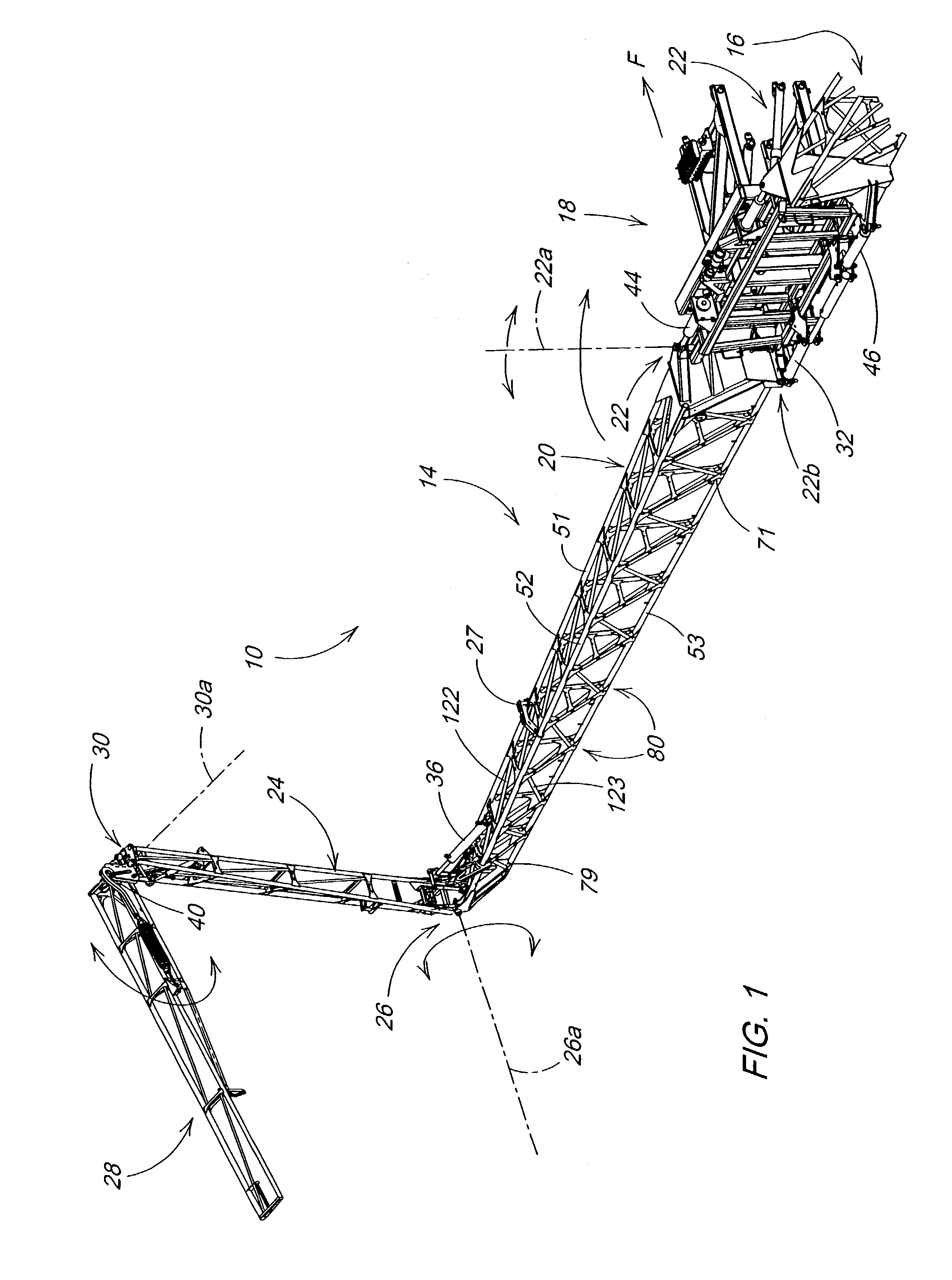

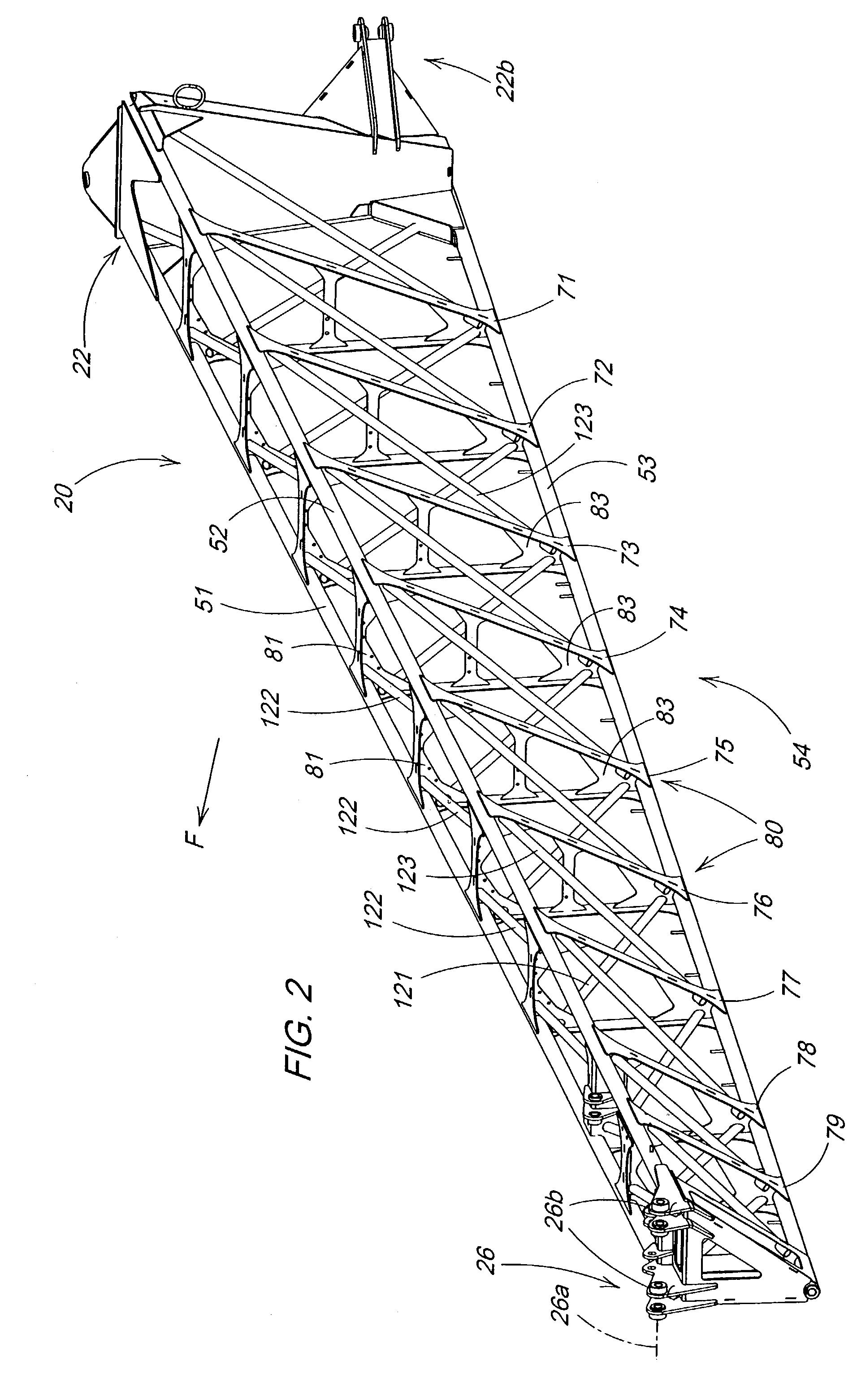

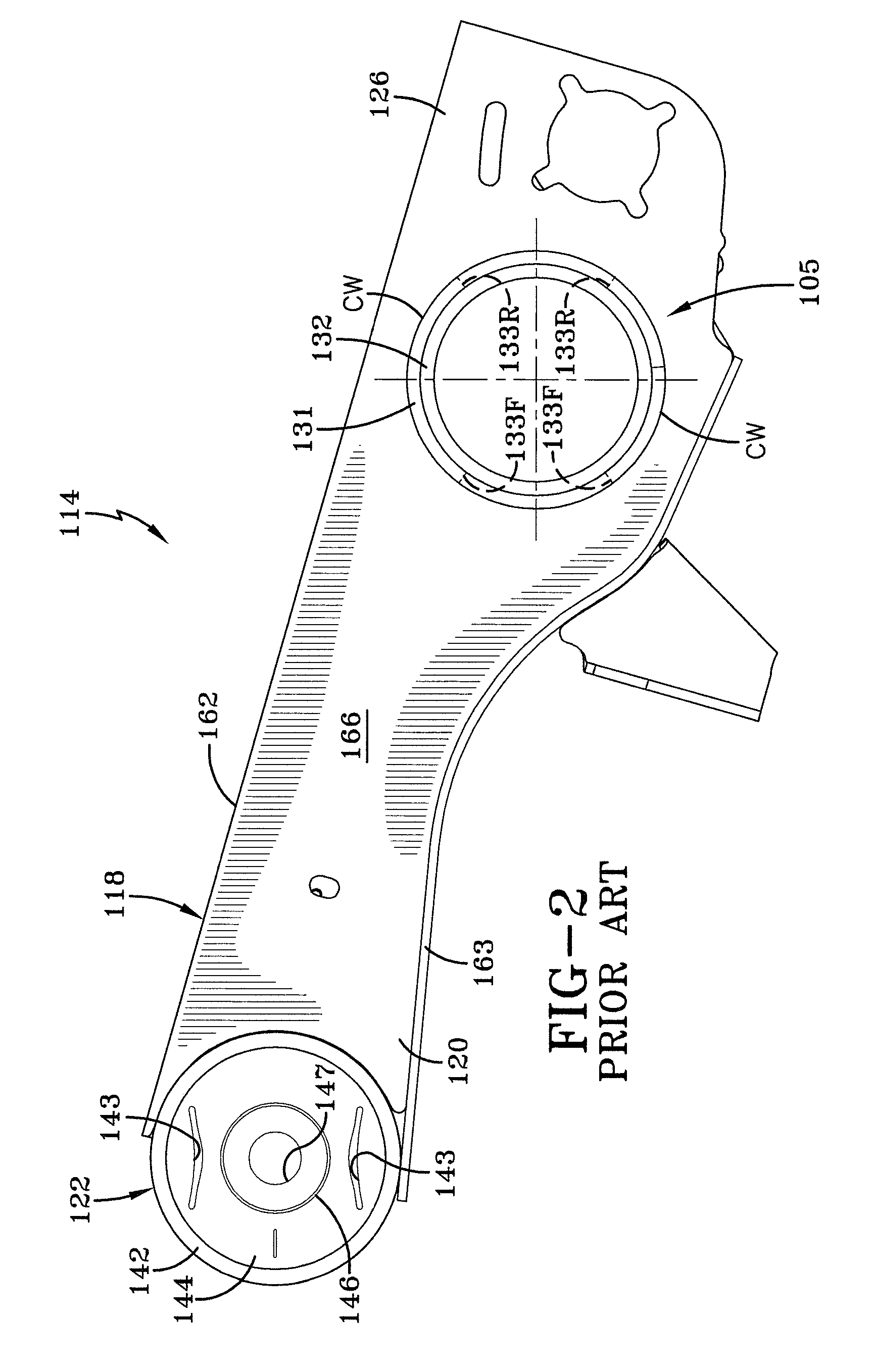

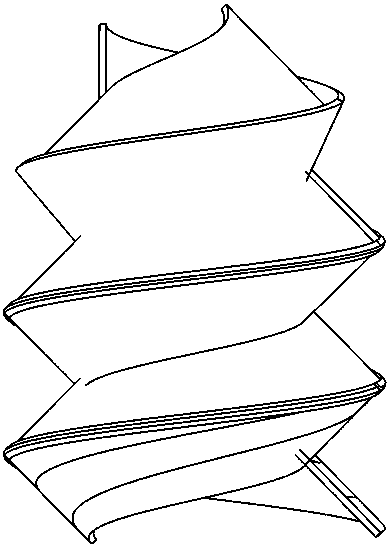

Agricultural boom structure

InactiveUS6966501B2Improved boom structureOvercome problemsSpray nozzlesTowersRight triangleEngineering

An easily manufactured large boom construction includes a plurality of main tube support sections fabricated from plate material of differing material thickness, grade and section dependent on load. The tube support sections include apertured areas which provide a preliminary snap-fit of the main tubes to significantly reduce need for additional fixturing. The opposite ends of diagonal tubes pass through apertures in the fabricated support sections for accurate tube location without complicated weld fixtures or precise tube length and cut end angle tolerances. The tubes are welded on opposite sides of the sections to eliminate need for tube-to-tube connections or connections wherein a cut end edge has to be precisely placed against a planar surface. An inverted right triangle boom cross section with wing over-top fold configuration ability provides strength, stiffness and infinite nozzle placement possibilities.

Owner:DEERE & CO

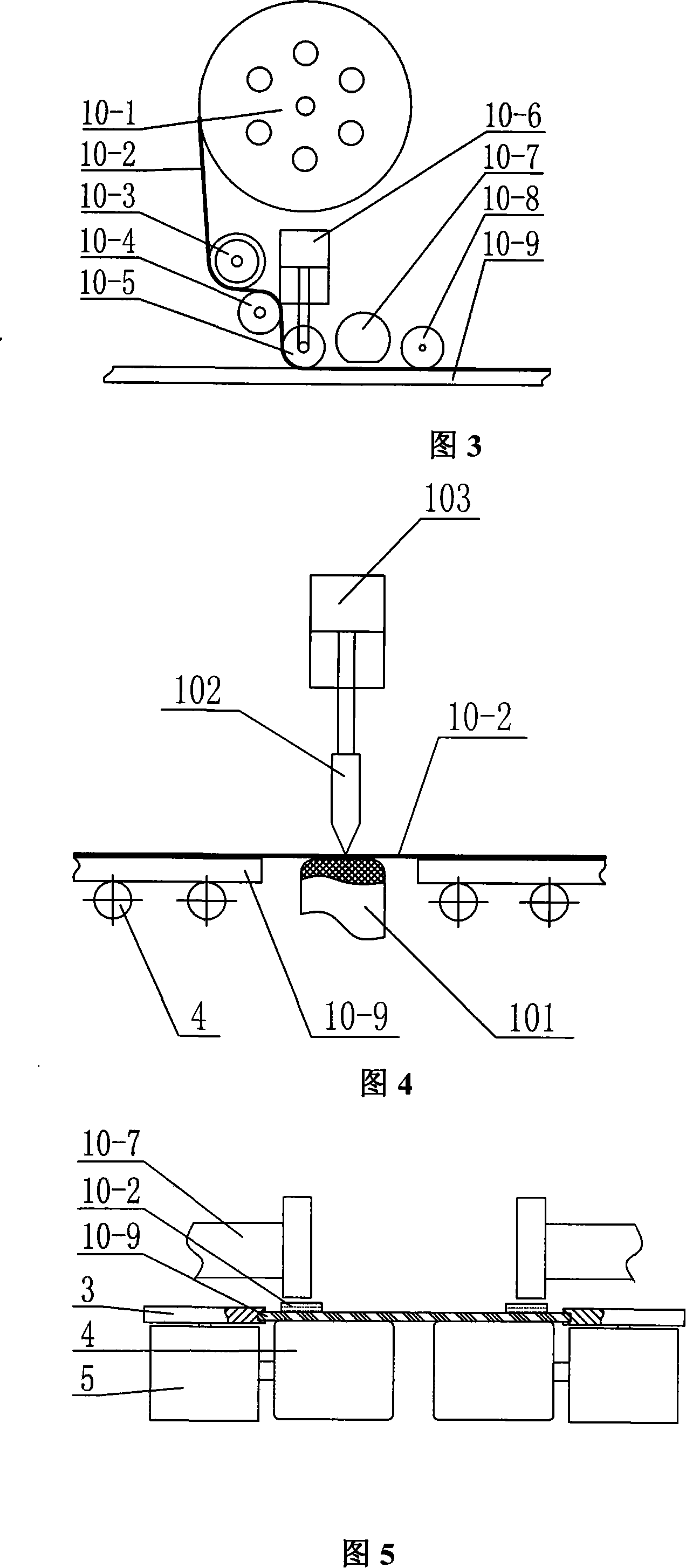

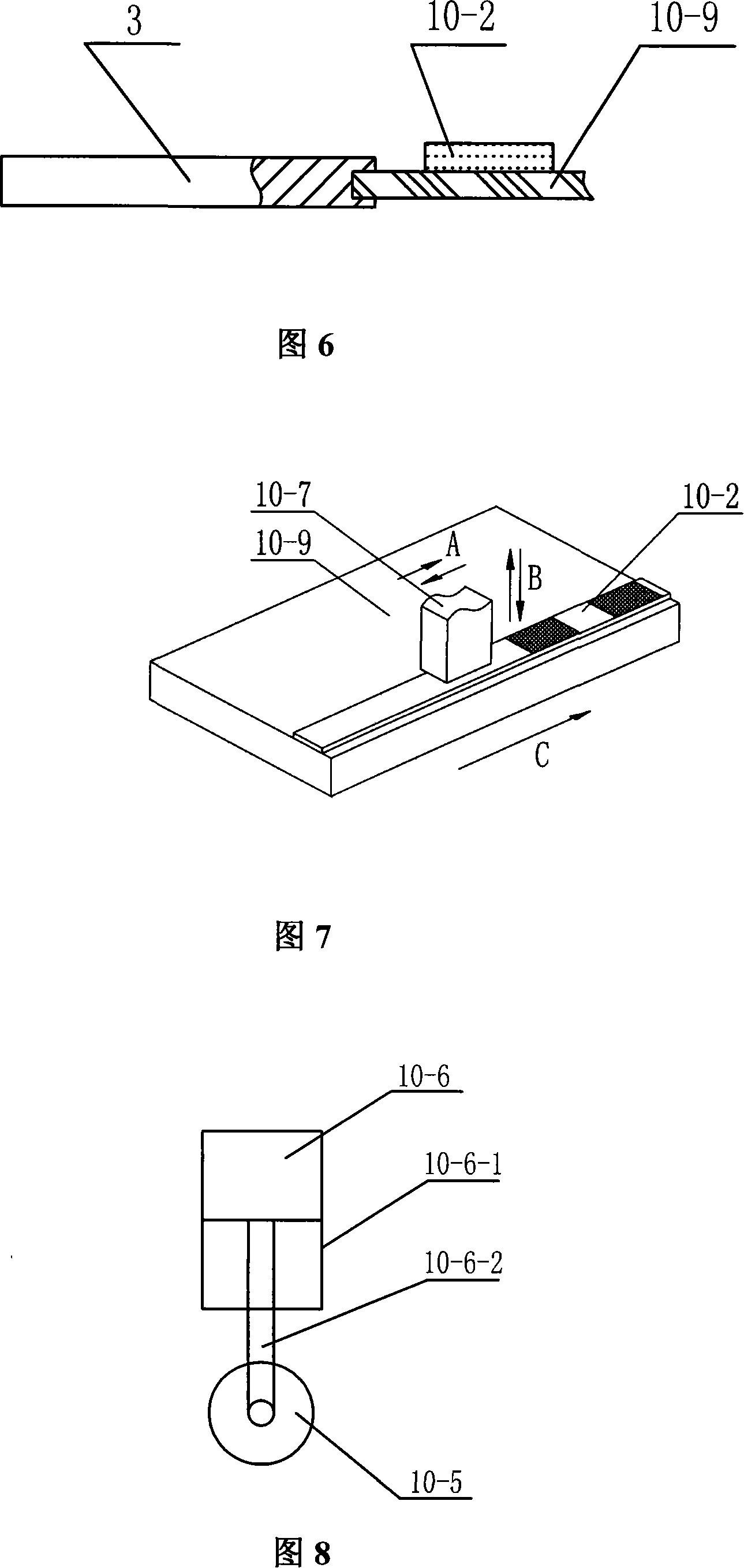

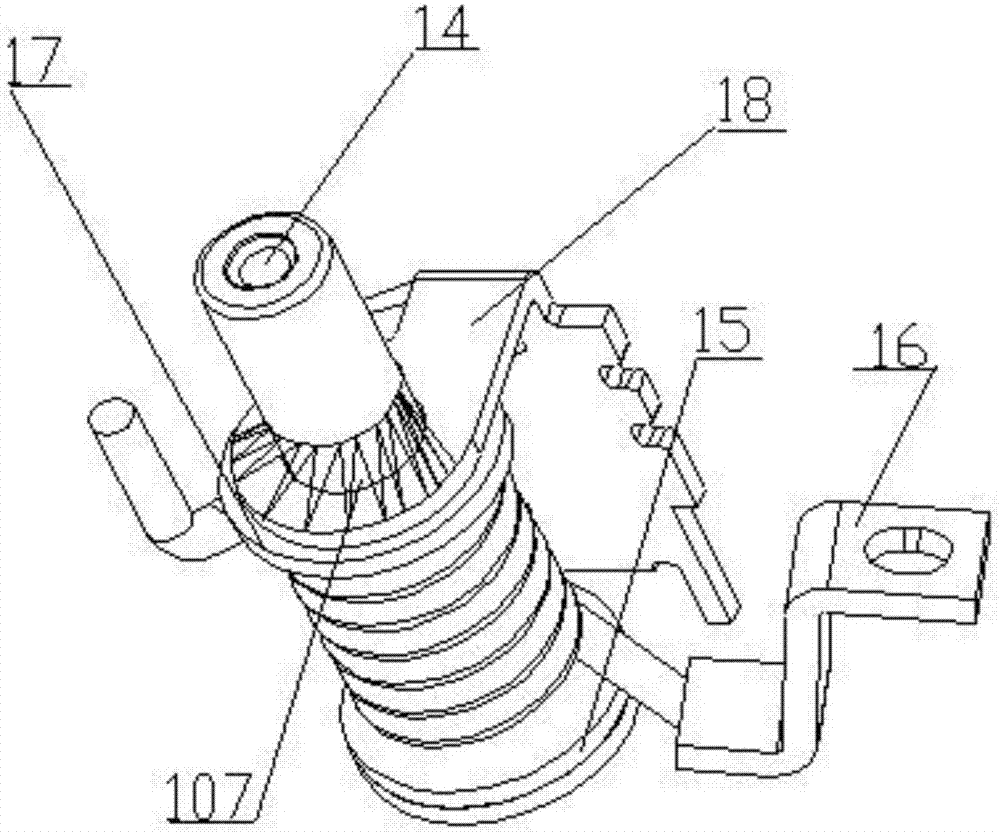

Ultrasonic soldering equipment for solar cell electrode

InactiveCN101110458ASatisfy the pressure line requirementsImprove efficiencyFinal product manufactureSemiconductor devicesElectrical batteryEngineering

The present invention discloses an automatic ultrasonic wave welding equipment for welding amorphous silicon solar cell electrode, which aims to improve current ultrasonic wave metal spot welding machine and add a mechanical wire pressing and take-up device and method to replace manual wire pressing and laying and is technically characterized in that a working table is composed of a feeding zone, a welding zone and a discharging zone. An electrode wire 10-2 is coiled on an uncoiling wheel 10-1 of the electrode wire pressing device 10. A guide wheel 10-3 and an extension-resistant tightening pulley 10-4 are arranged on a front slab bracket 108 below the uncoiling wheel 10-1. A corresponding ultrasonic wave welding head 10-7 is mounted between a coiling wheel 10-5 and a flattening wheel 10-8. The present invention is suitable for automatic welding of thin film solar cell electrode with glass or flexible material as substrate, thus ensuring high precision, nice appearance and equal distance between welding spots, improving welding efficiency and eliminating rosin joint.

Owner:李毅

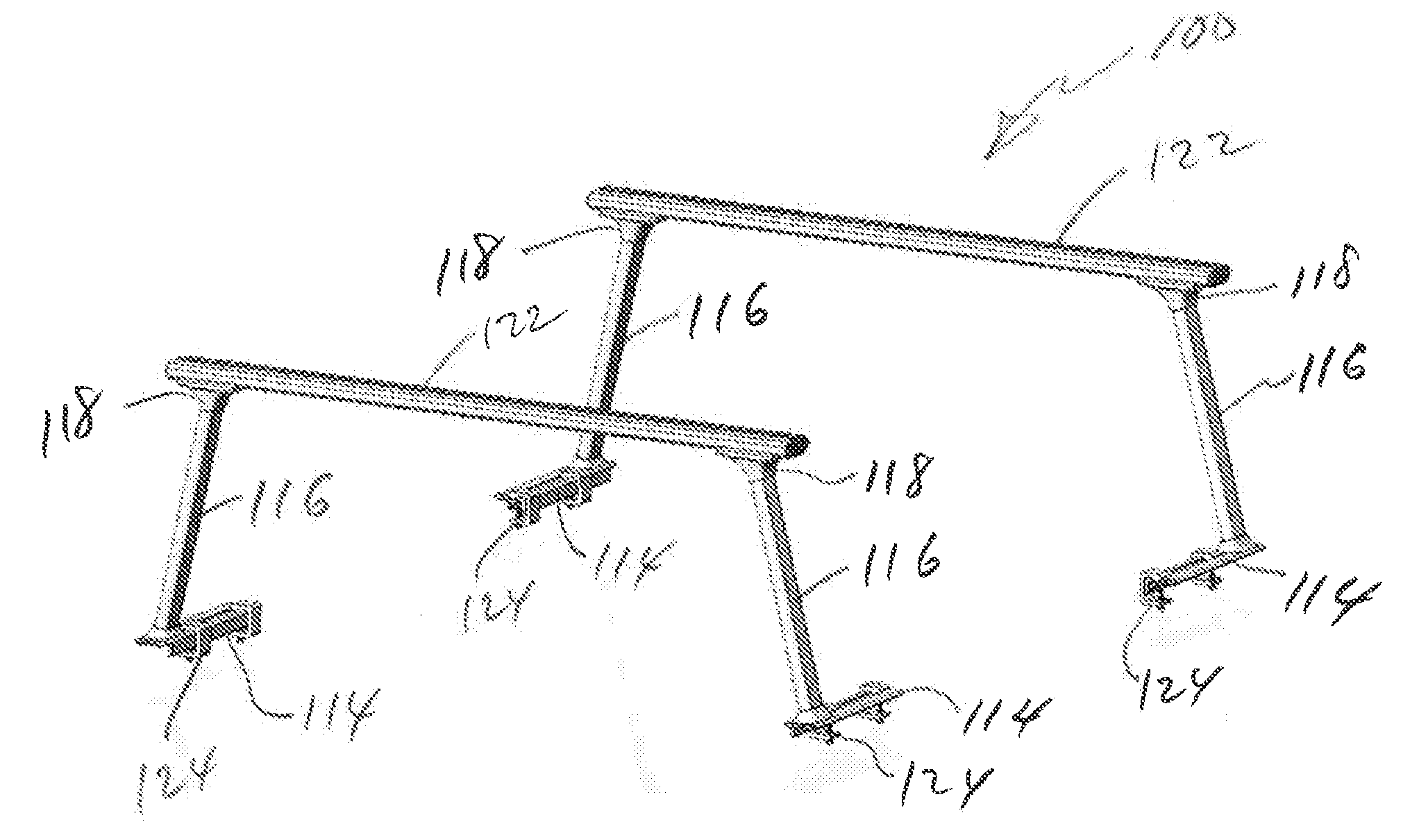

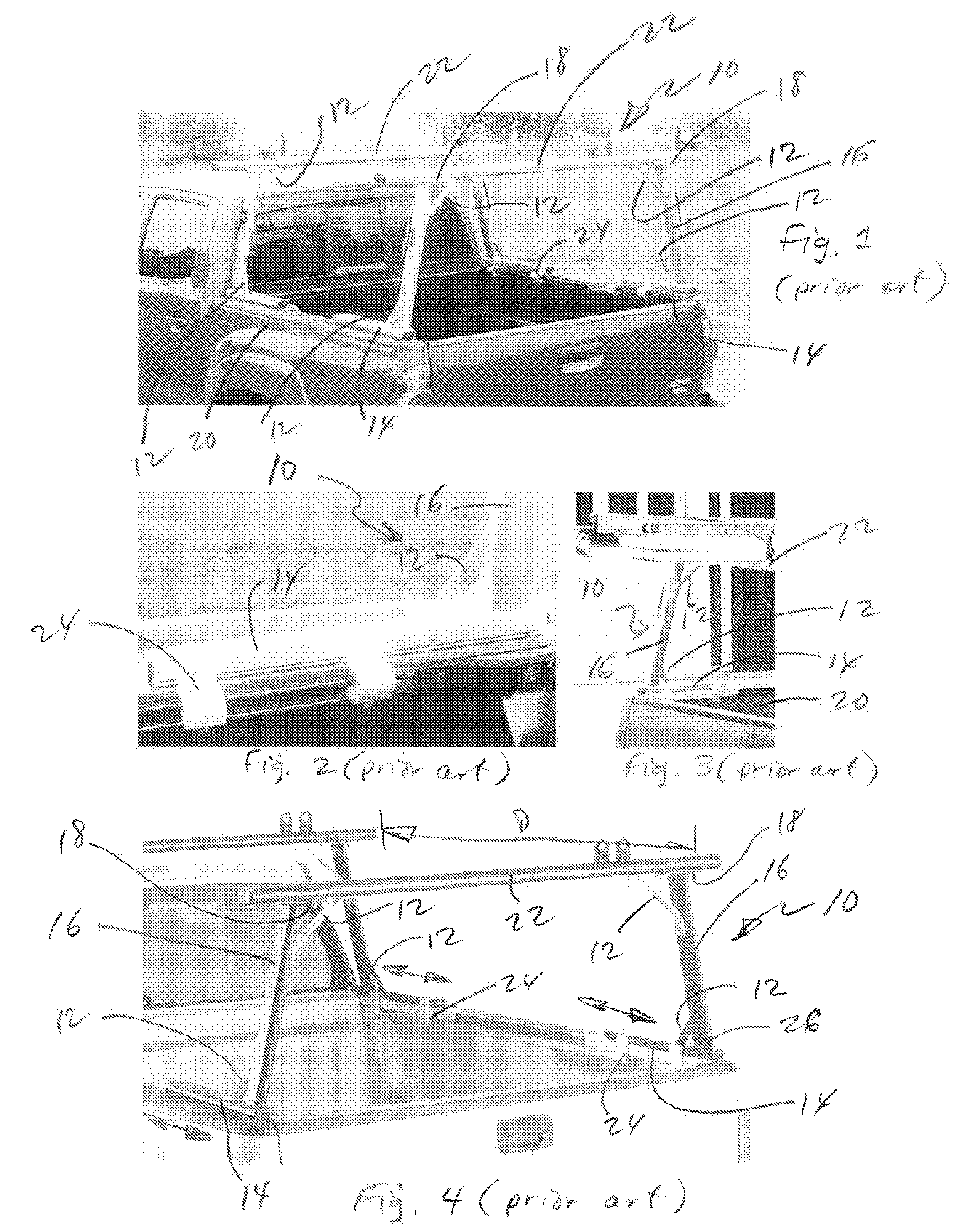

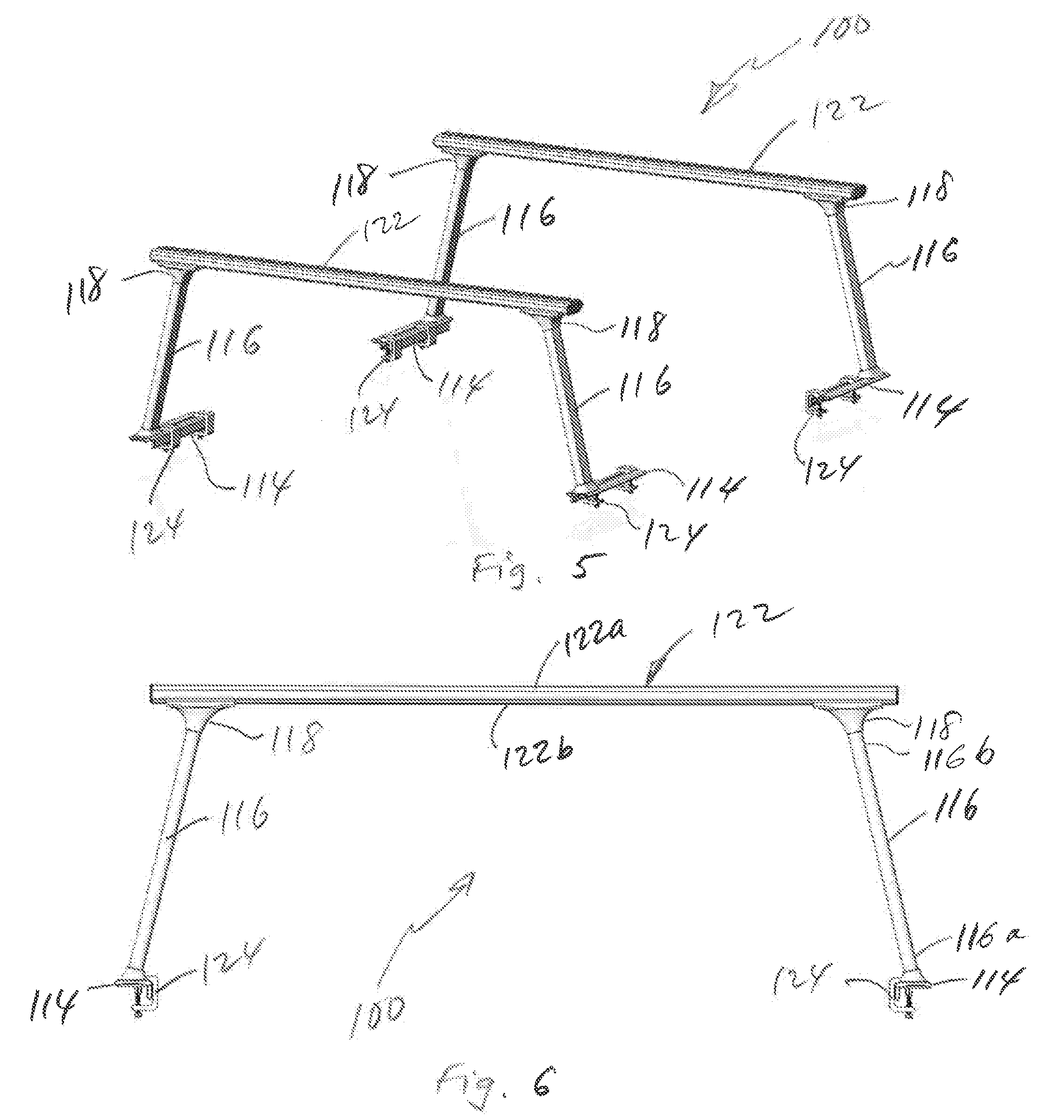

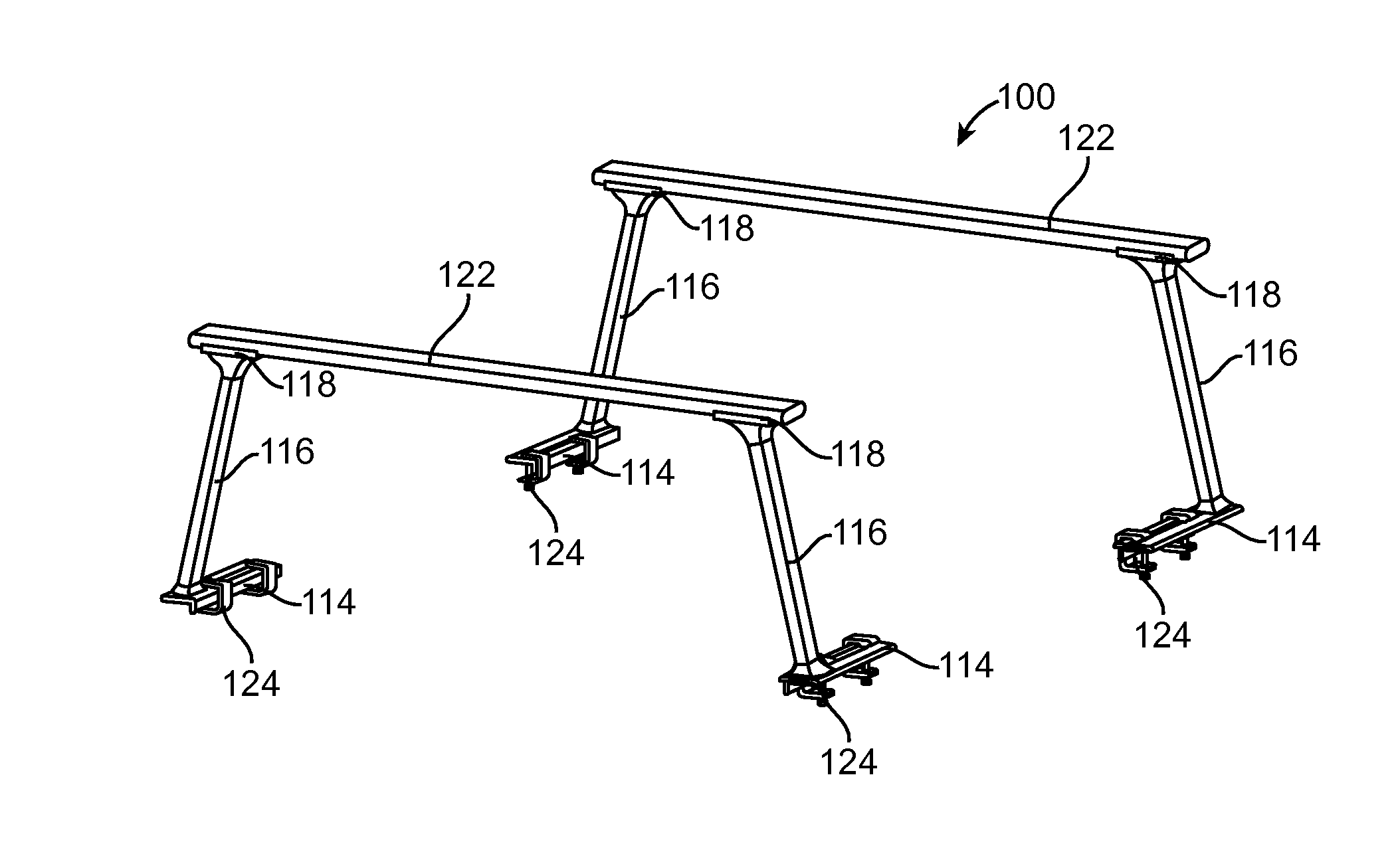

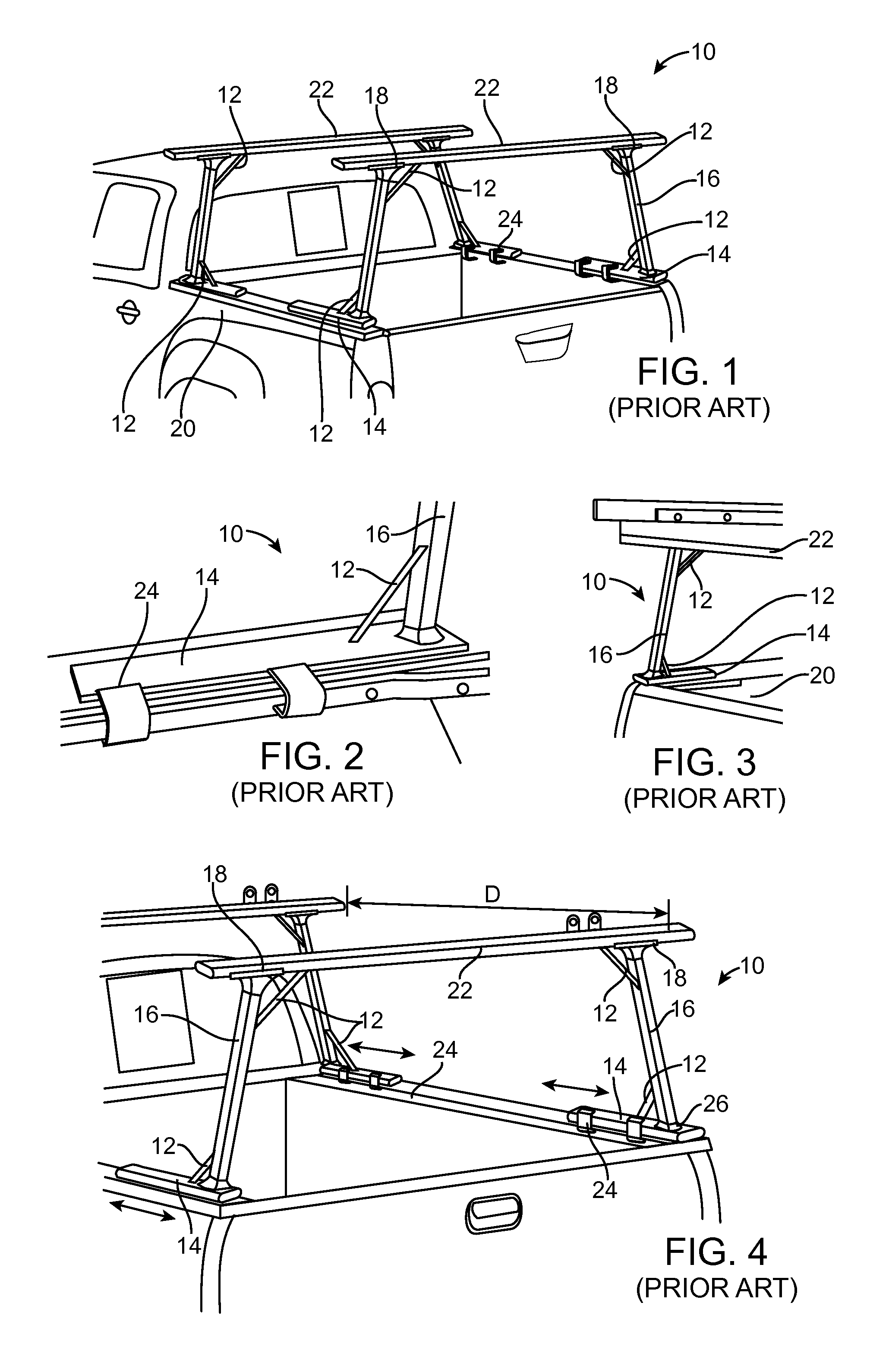

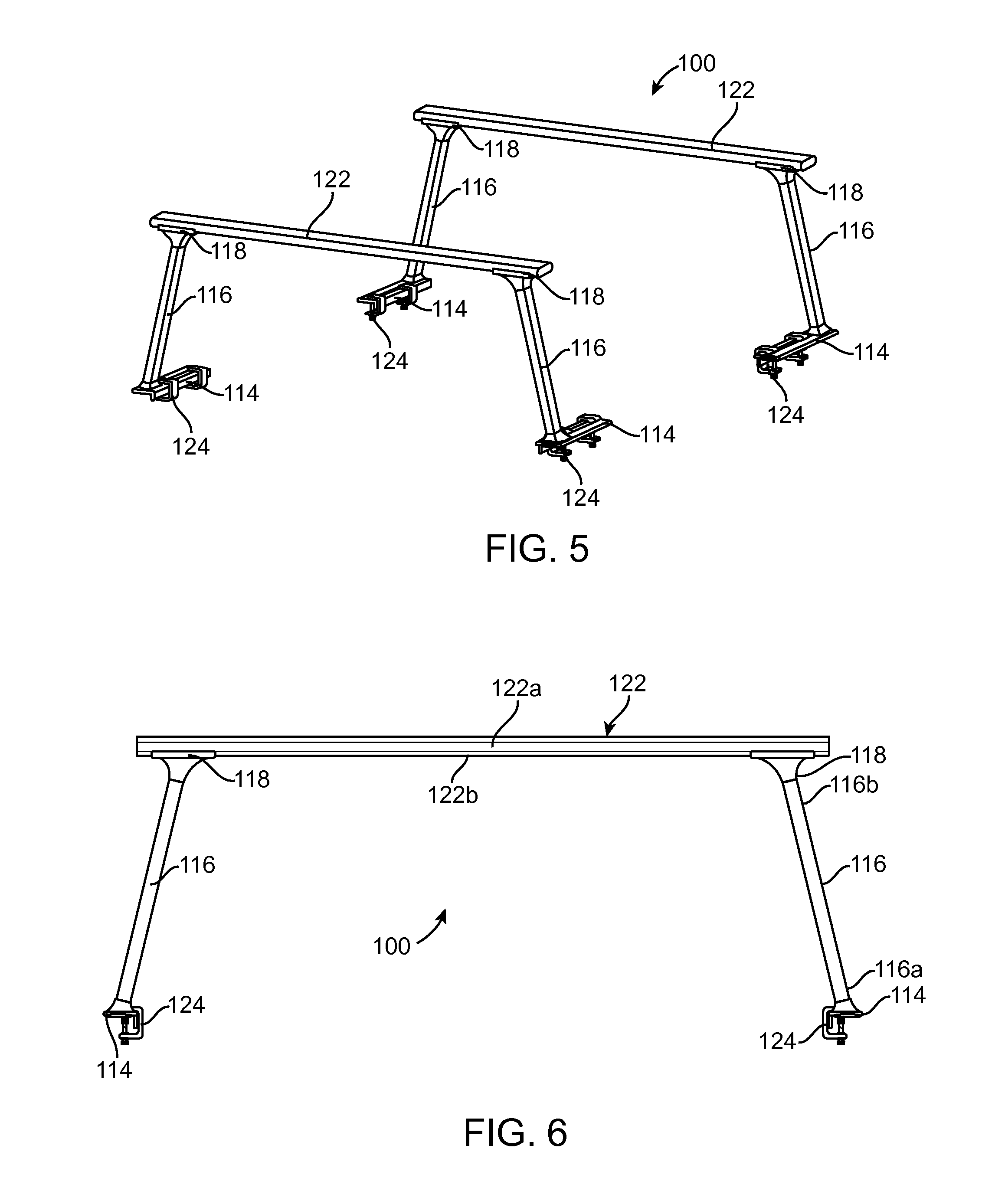

Modular rack system with gussetless joints

ActiveUS20100288808A1Overcome disadvantagesEliminate weldsPedestrian/occupant safety arrangementSupplementary fittingsGusset plateModularity

A modular rack system, for adjustably attaching equipment to a vehicle, includes a base mountable on a side wall of the vehicle. The rack system has a first wall that is disposed on and upwardly emanating from the top surface of the base that defines a lower seat. One end of a vertical member resides in the lower seat and is secured thereto. The other end of the vertical member resides in an upper seat defining by a downwardly depending wall from a saddle and is secured thereto. The first and second walls laterally stabilize the vertical member relative to the base and saddle to permit the base to be mounted to a side wall of a vehicle and a top rail to be secured to the saddle without the use of gussets or cross-braces.

Owner:THULE INC

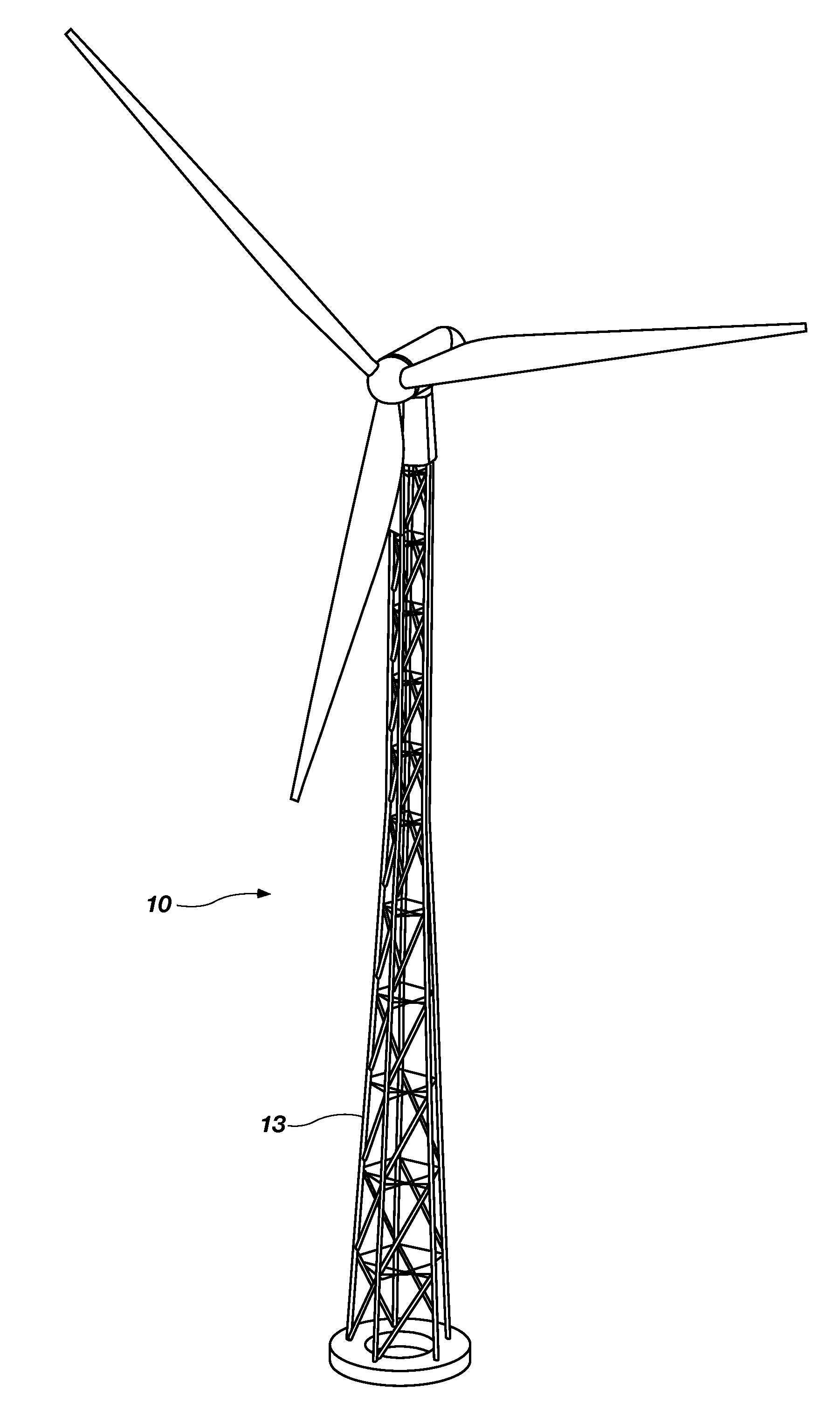

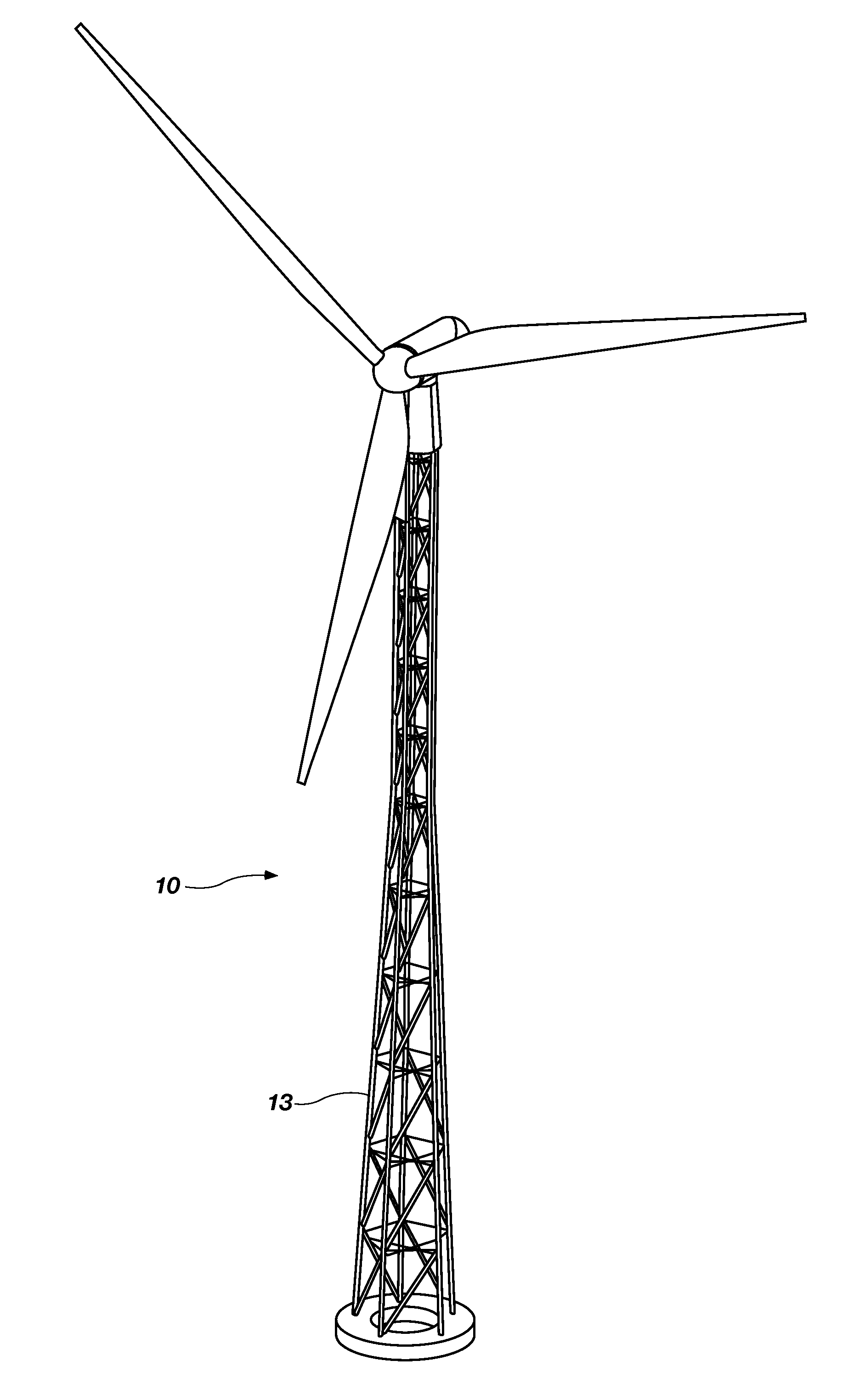

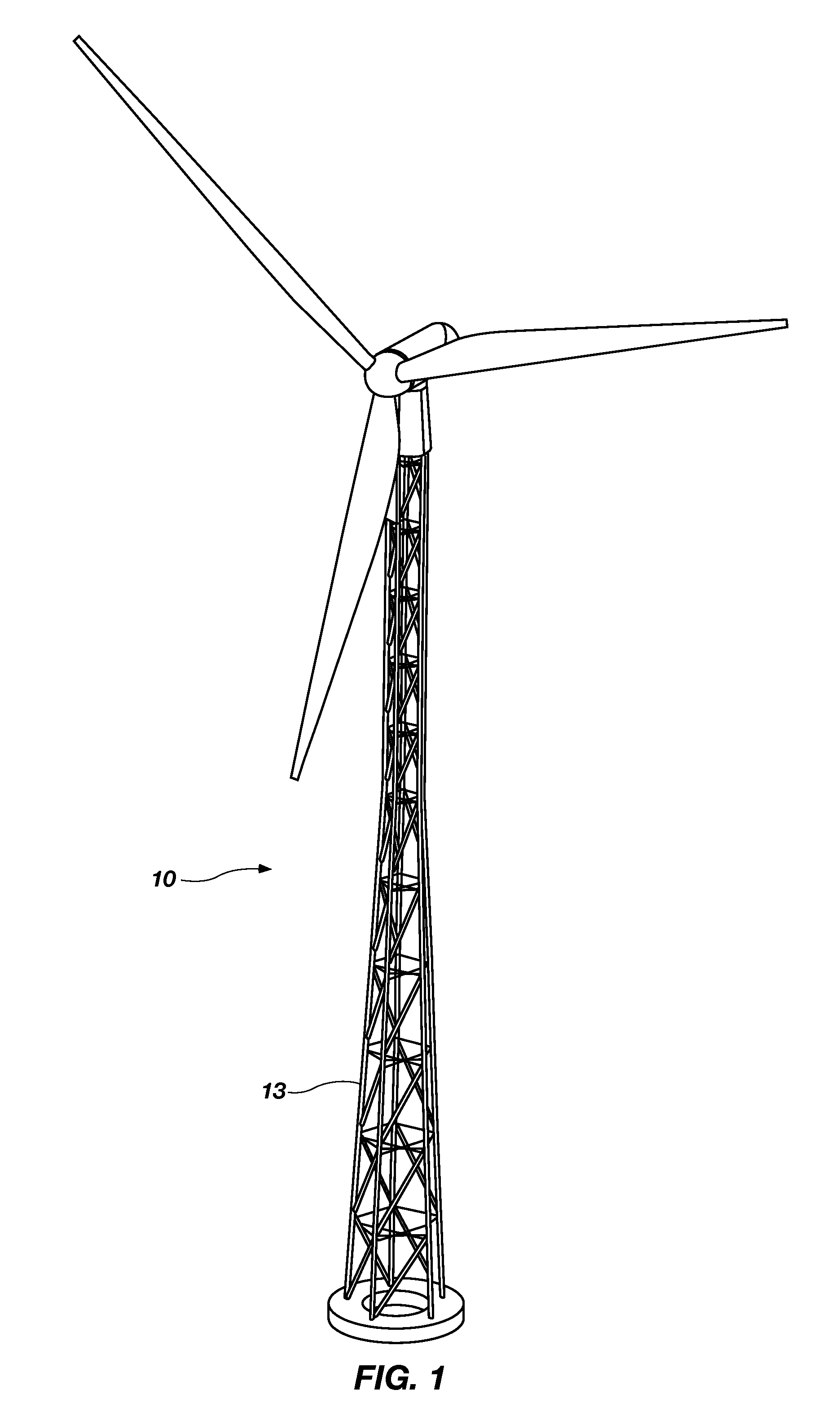

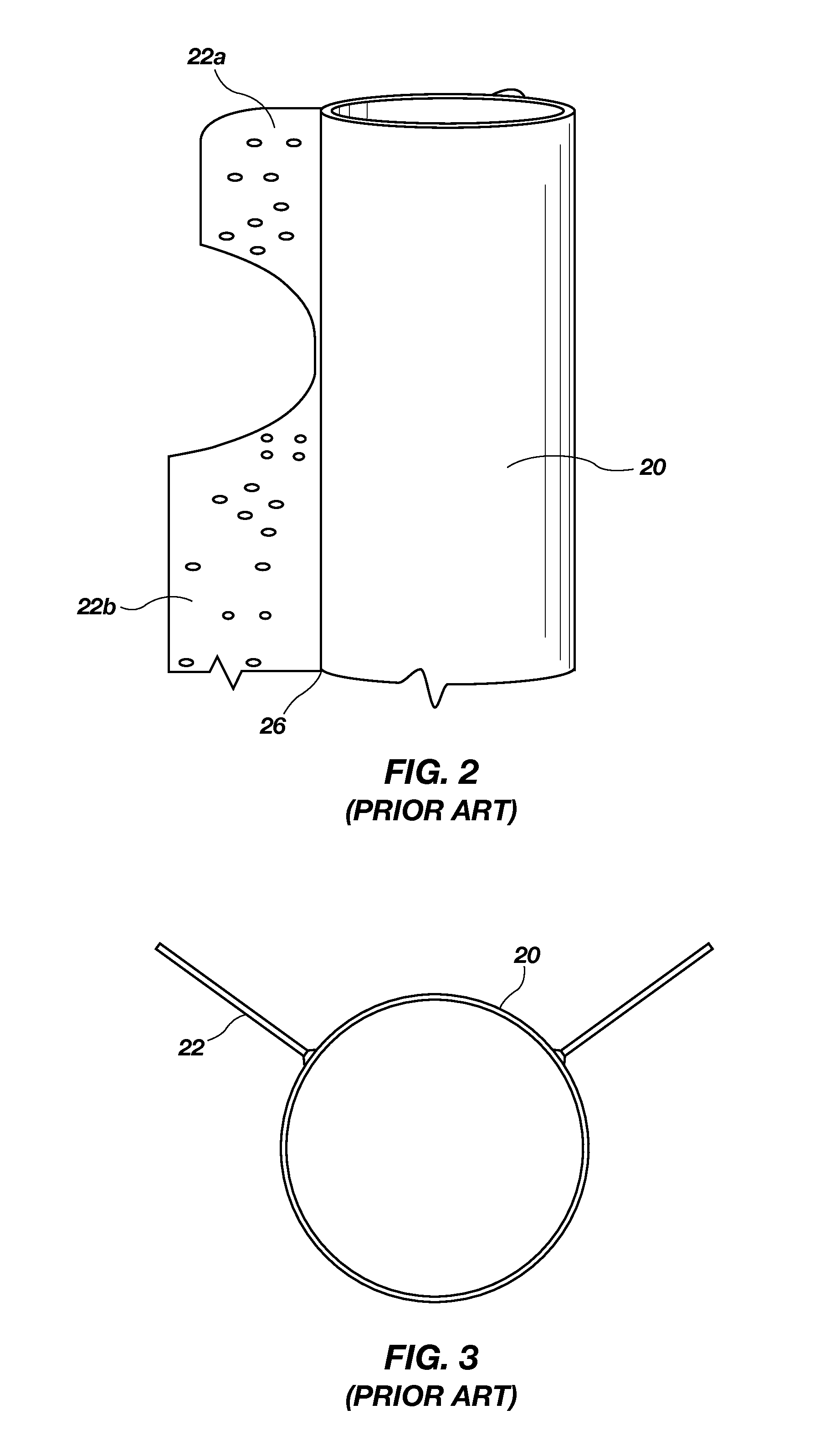

Structural shape for wind tower members

InactiveUS20100242406A1Increase weightWeigh it downWind motor supports/mountsMachines/enginesStructural componentStructural shapes

One of the major structural components in a space frame tower is the tower leg. A novel and nonobvious tower leg structure is provided which provides significant advantages and benefits over previously available structures.

Owner:GE WIND ENERGY

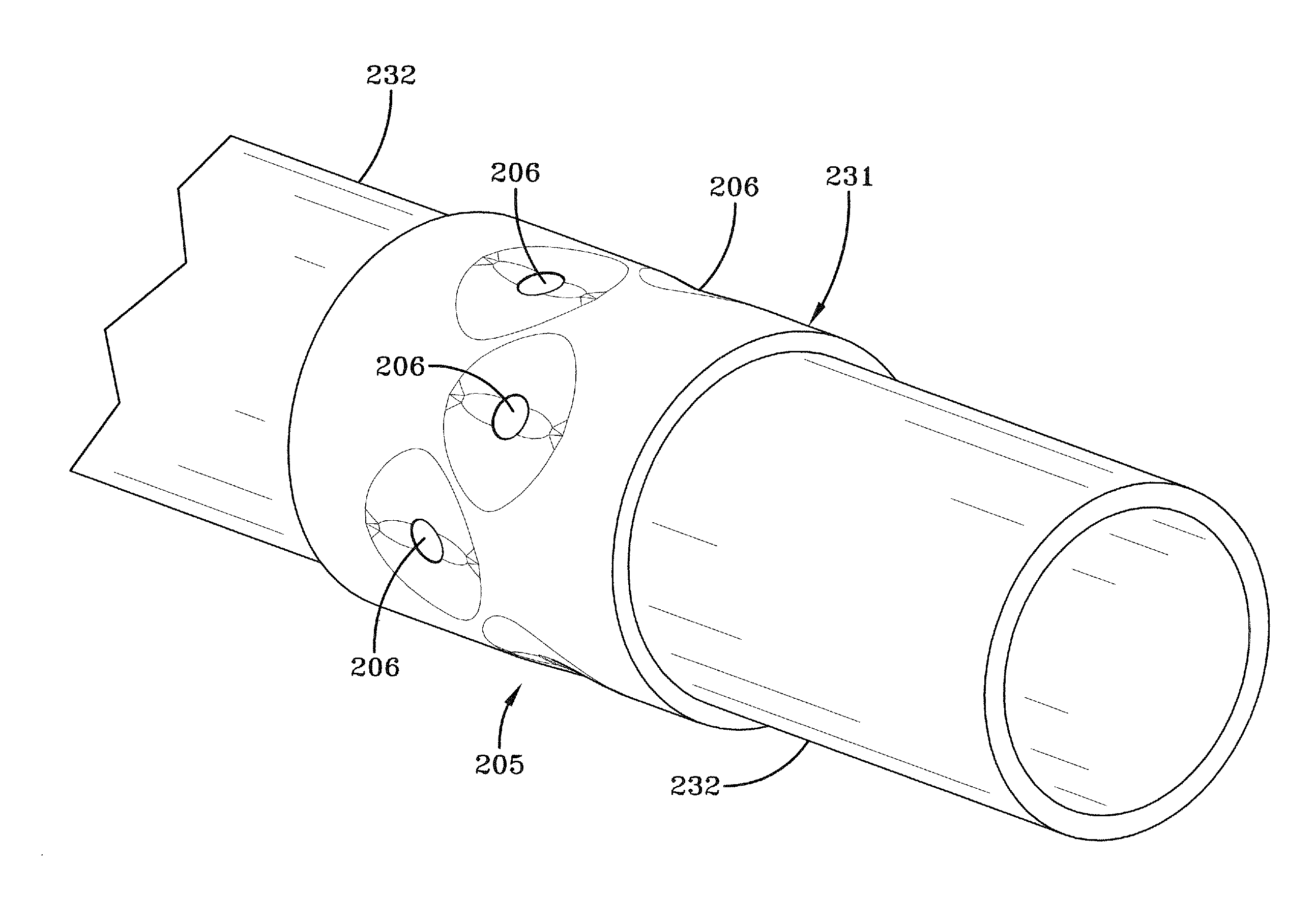

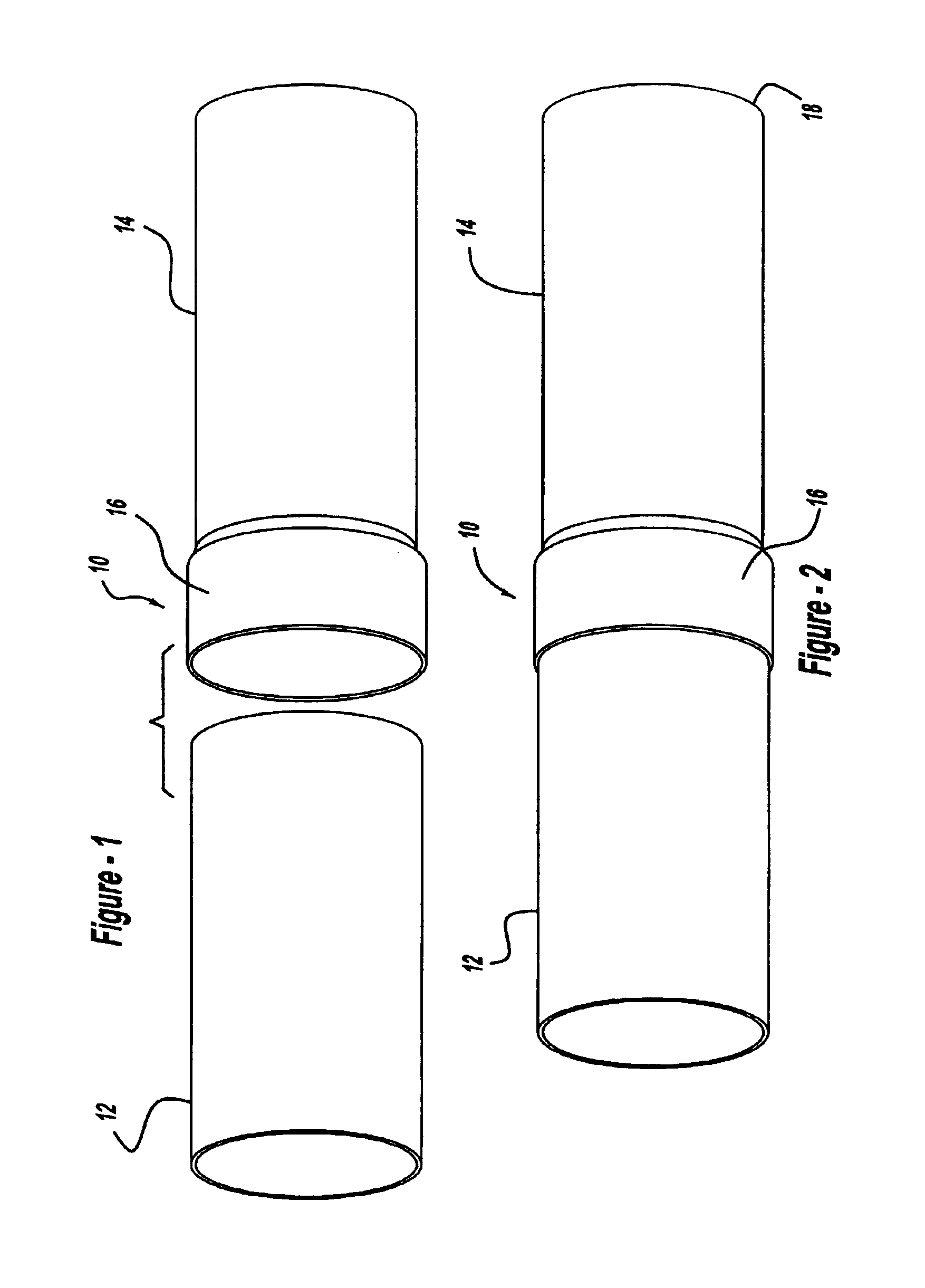

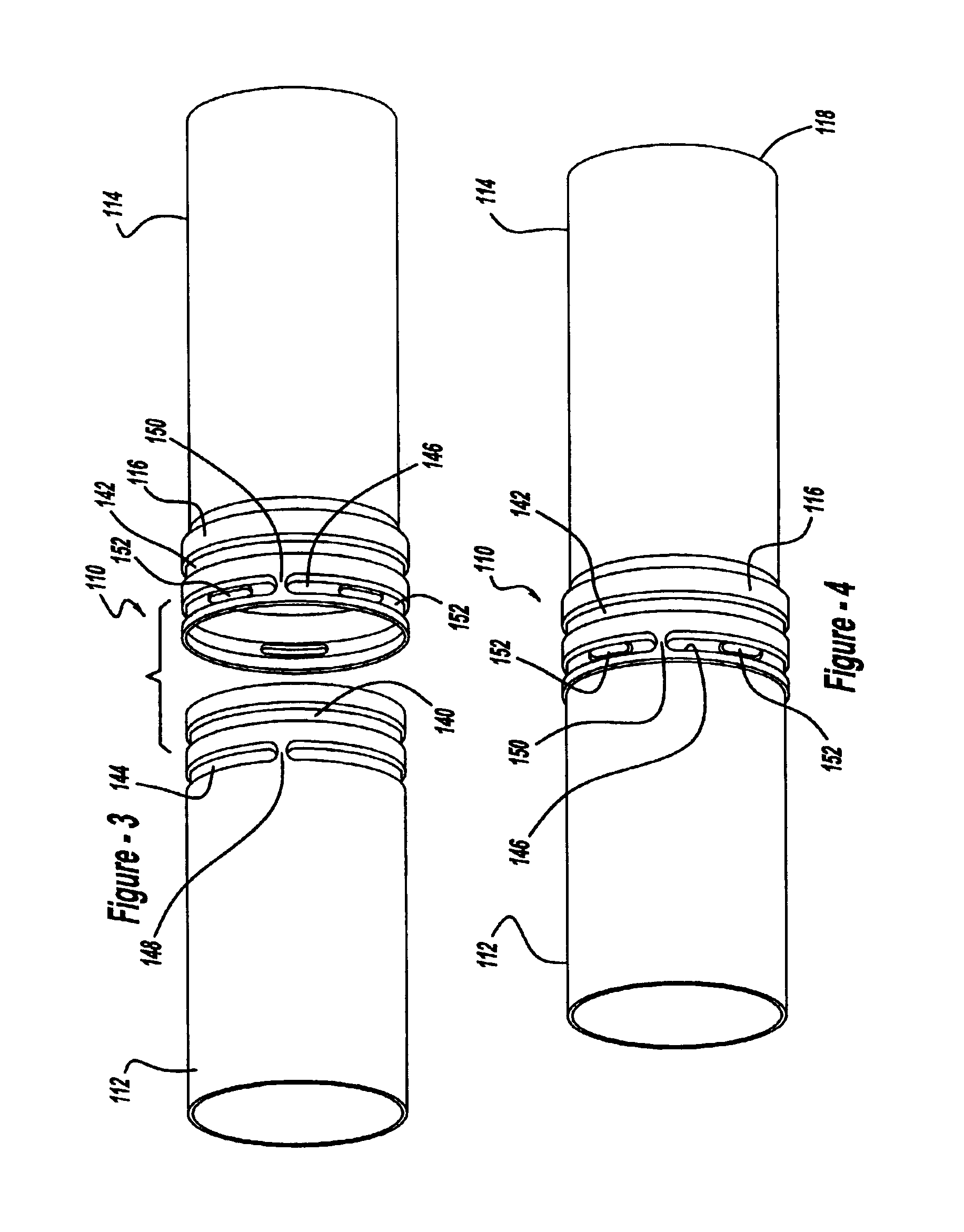

Method of joining tubular members

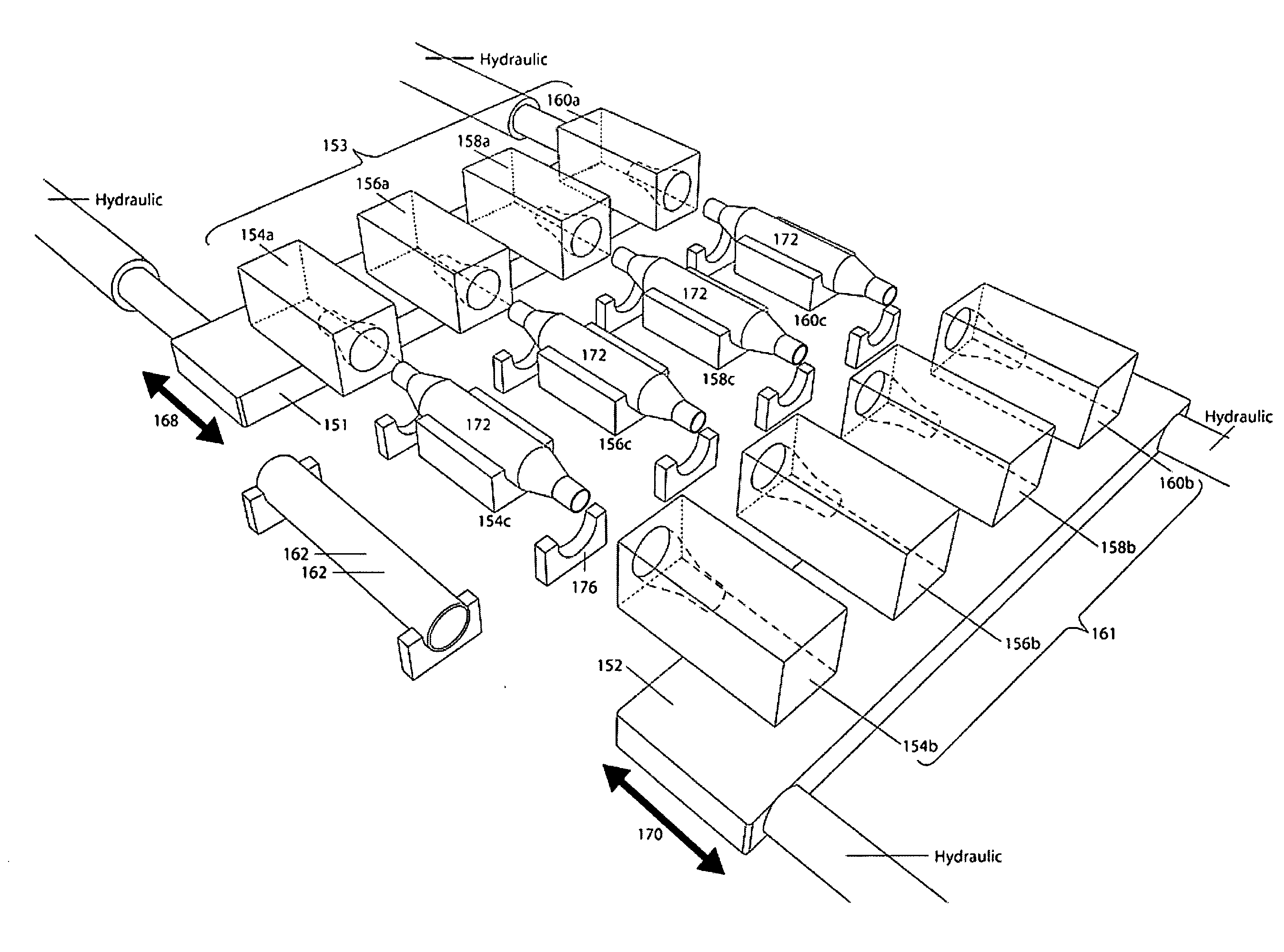

InactiveUS6922882B2Easy and fast assemblyEliminates joint corrosionMetal working apparatusEngineeringHydraulic pressure

A method of joining tubular members together includes the steps of providing an internal tubular member, providing an external tubular member, and heating the external tubular member and / or cooling the internal tubular member. The method also includes the steps of joining the internal tubular member and second tubular member together to form an overlap region of a joined tubular member, and positioning the joined tubular member between open die halves mating with one another to define a tubular cavity portion. The method includes the steps of progressively closing the die halves to progressively deform the joined tubular member within the tubular cavity portion. The method includes the steps of applying hydraulic pressure to expand and conform the joined tubular member to the tubular cavity portion. The method also includes the steps of separating the die halves and removing the expanded joined tubular member from the die.

Owner:GM GLOBAL TECH OPERATIONS LLC

Support system for a pilot nozzle of a turbine engine

ActiveUS7197877B2Raise the natural frequencyPrevent insertionTurbine/propulsion fuel supply systemsContinuous combustion chamberInterference fitSupporting system

An automatic recovery pilot nozzle support system for supporting a pilot nozzle in a fuel injection system of a turbine engine. The support system includes a sleeve extending from an orifice in a support housing, wherein the sleeve has a hollow opening for containing a pilot nozzle. The sleeve may increase the natural frequency of the pilot nozzle above an excitation zone, thereby limiting destructive vibrations. The sleeve may be attached to the support housing with an interference fit. The automatic recovery aspect of the support system enables the sleeve to maintain an interference fit with the support housing such that anytime the sleeve looses contact with the support housing, an insulative film of air forms between the sleeve and the support housing. The insulative film of air causes the temperature of the sleeve to increase, and the sleeve to expand and reform the interference fit with the support housing.

Owner:SIEMENS ENERGY INC

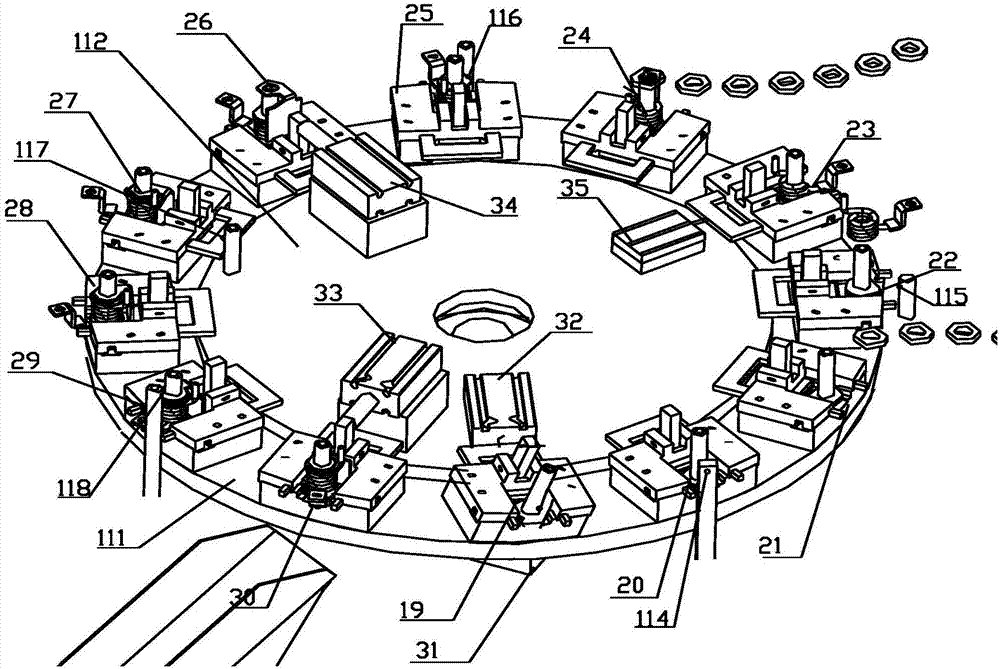

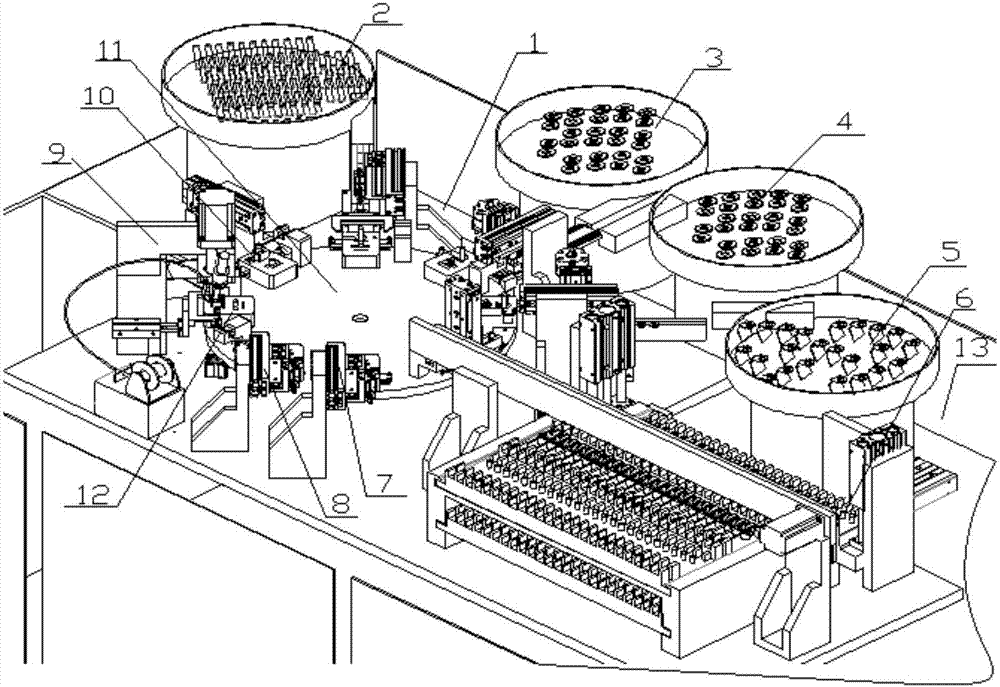

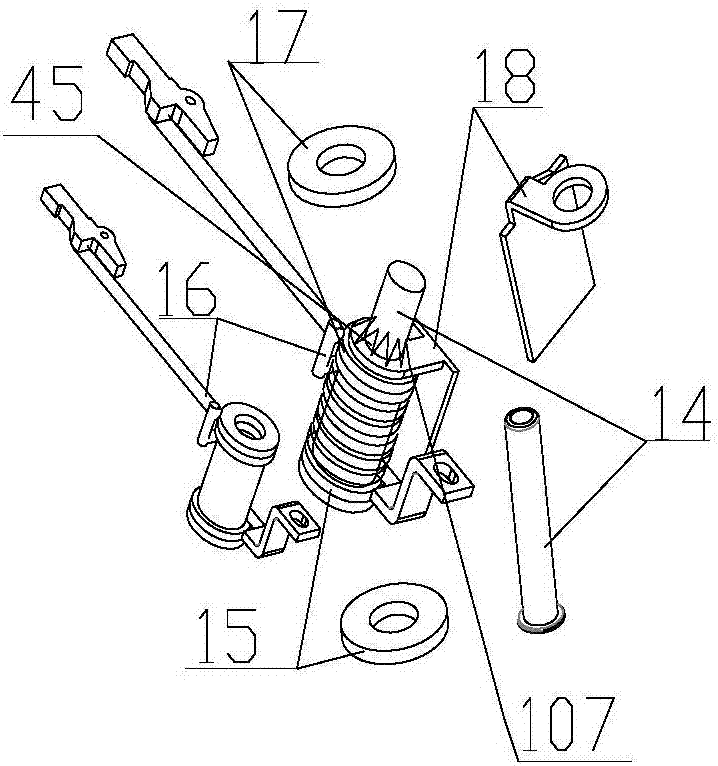

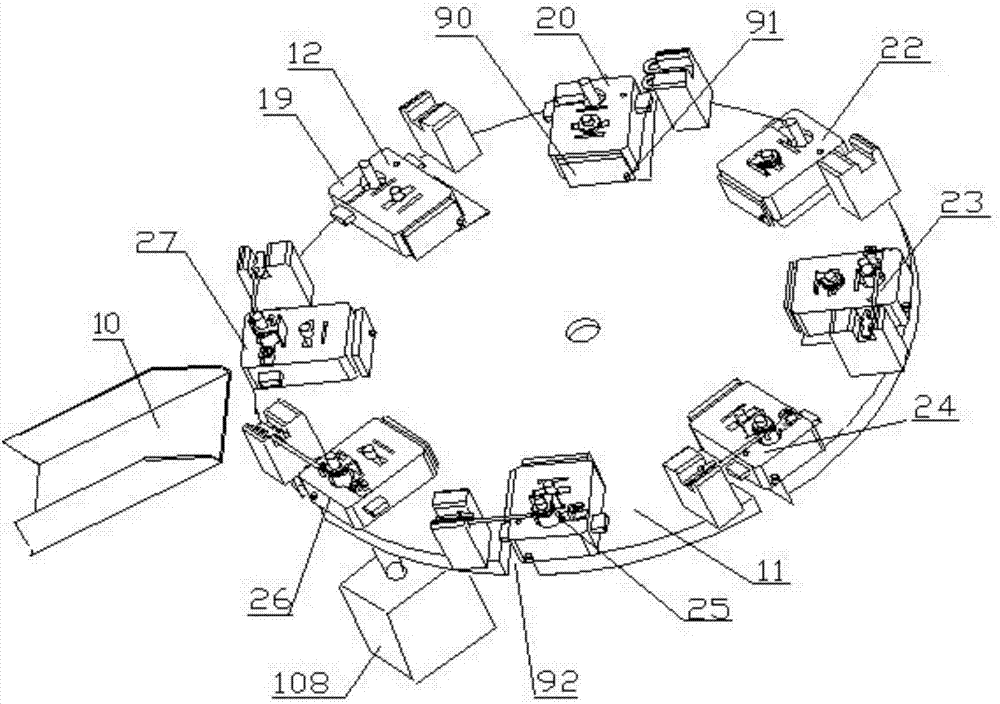

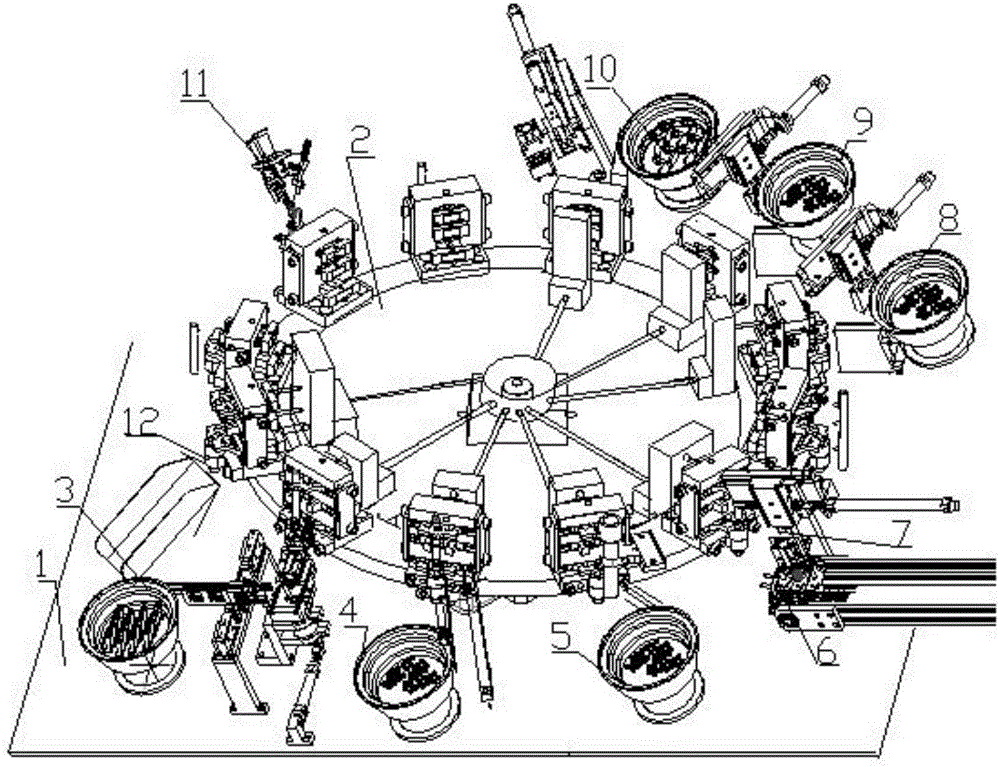

Full-automatic assembling-welding system for electric conduction assembly of low-voltage plastic-shell circuit breaker

ActiveCN107225304AEliminate weldsEliminate jammingMetal working apparatusSoldering auxillary devicesLow voltageCircuit breaker

The invention discloses a full-automatic assembling-welding system for an electric conduction assembly of a low-voltage plastic-shell circuit breaker. A rotating disc assembly is arranged on a horizontal table facet and comprises an inner disc and an outer rotating disc. The lower end of the inner disc is connected with a scale division mechanism. A first driving mechanism, a second driving mechanism, a third driving mechanism and a fourth driving mechanism are arranged on the upper surface, close to the outer edge, of the inner disc. Twelve clamp assemblies with the consistent structure are uniformly arranged on the outer rotating disc along the circumference. The twelve clamp assemblies are uniformly arranged as twelve rotating stations and are in one-to-one correspondence with feeding mechanisms, discharging mechanisms, a welding mechanism and a detector which surround the circumference of the rotating disc assembly. The structure is compact, the working efficiency is high, and the welding quality of a product is stable.

Owner:YUEQING YEDAO ELECTROMECHANICAL CO LTD

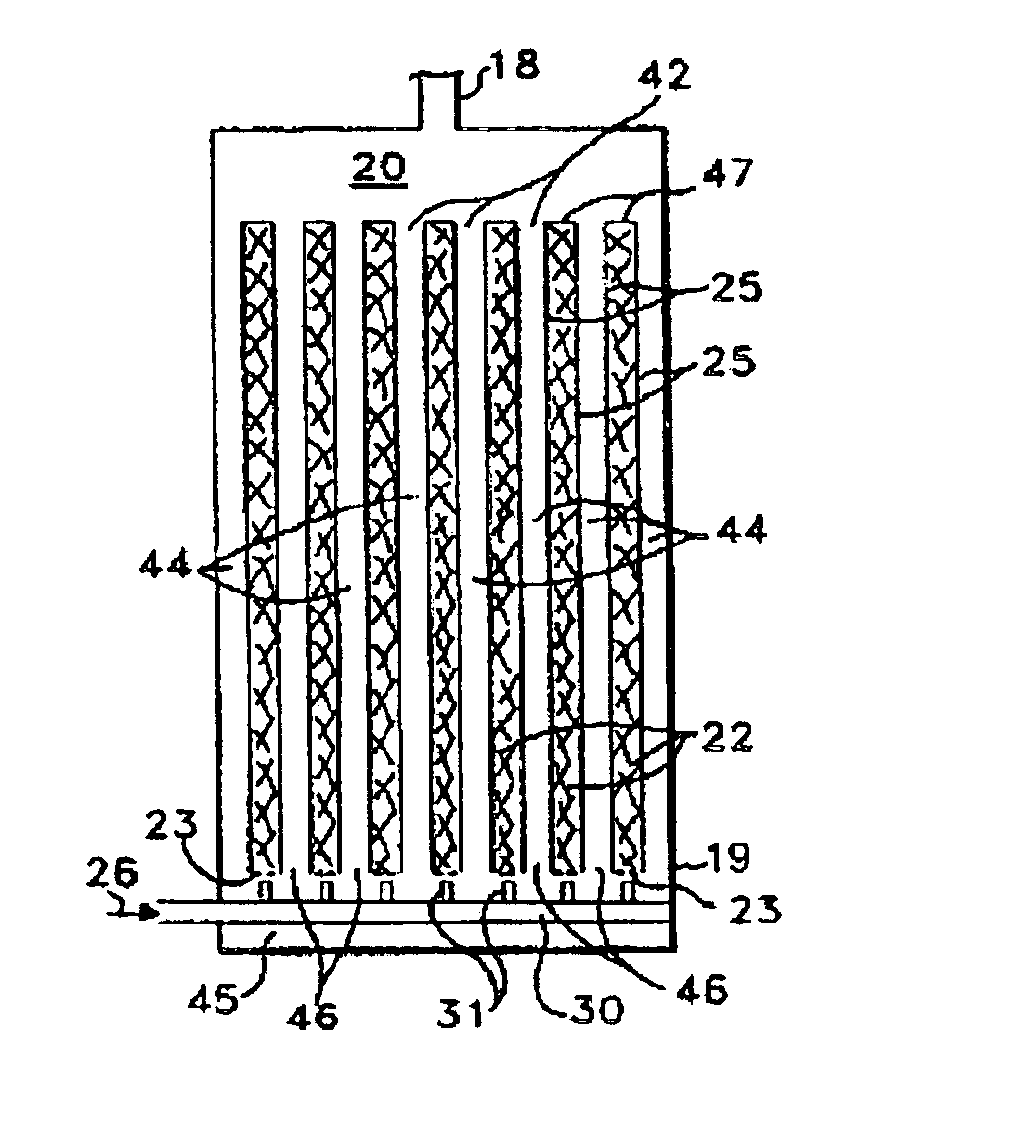

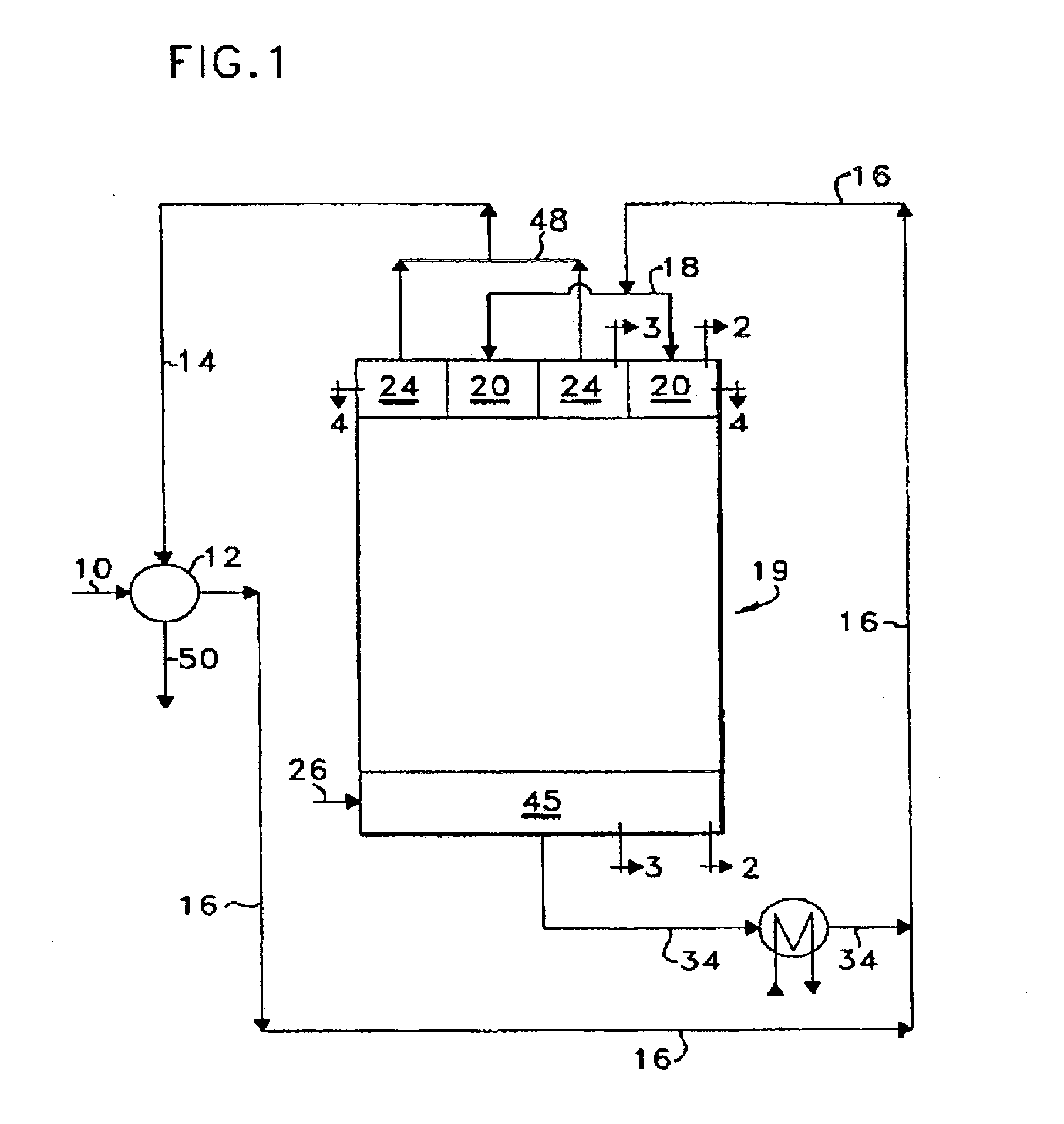

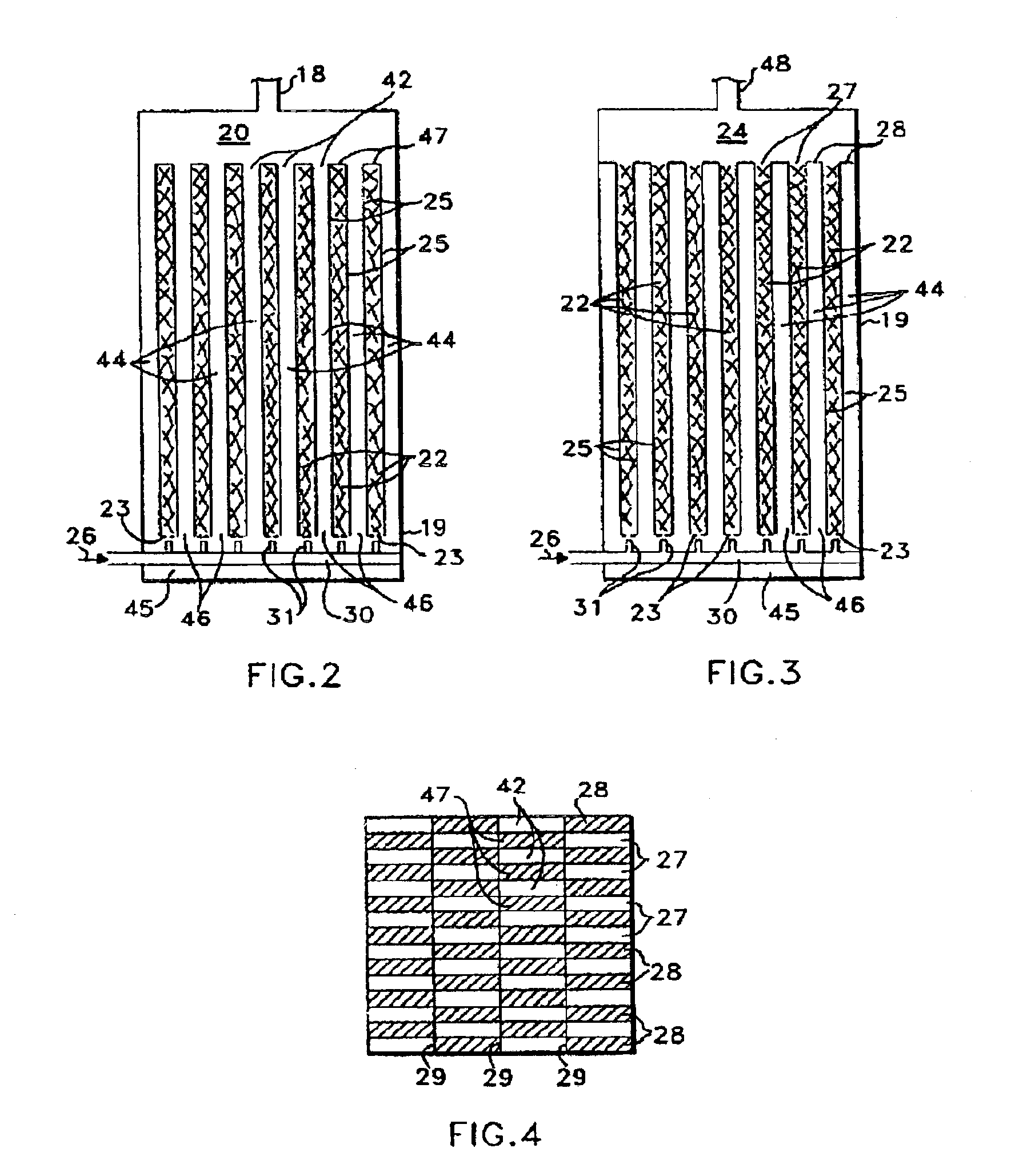

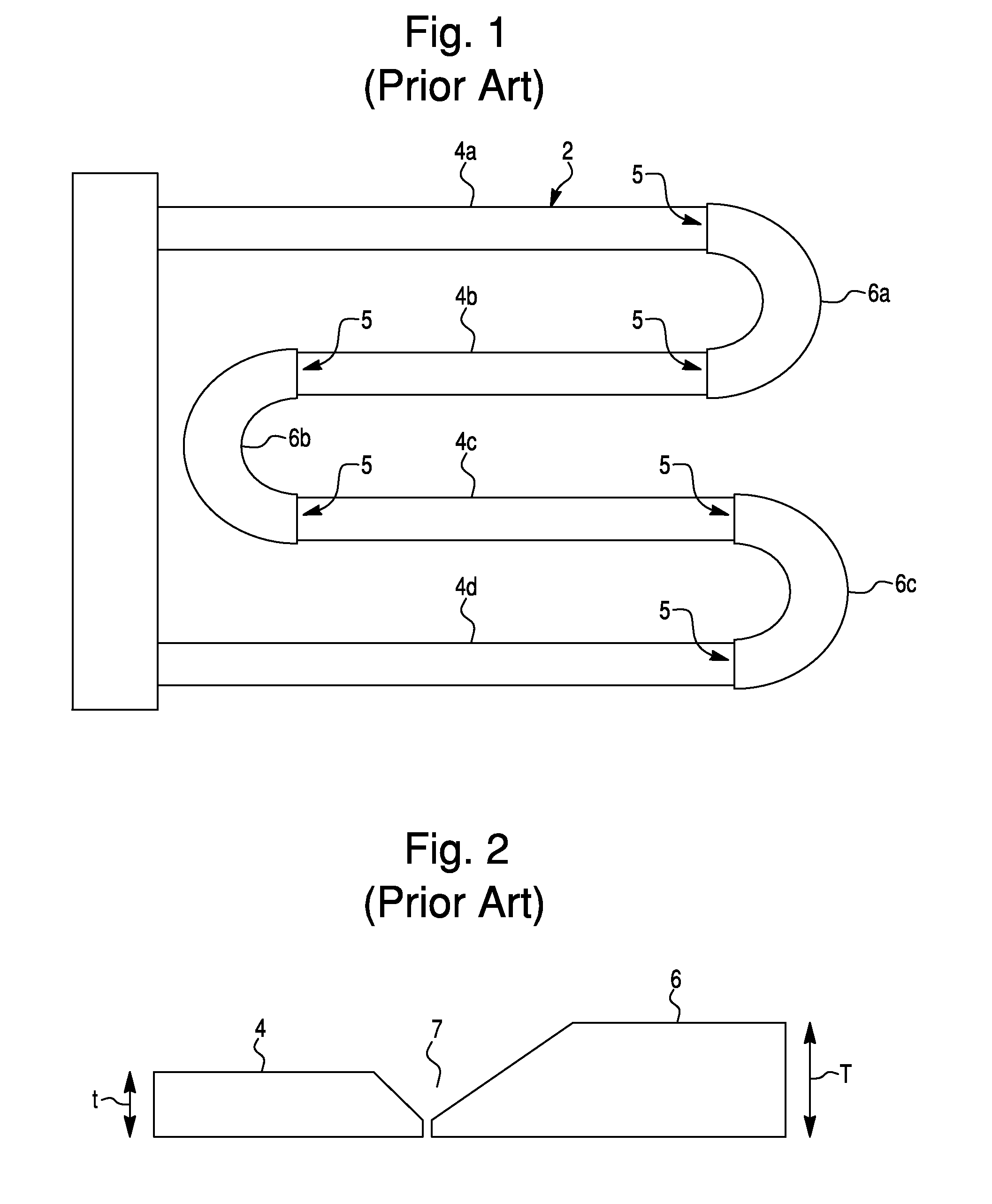

Apparatus using plate arrangement for exothermic reactions

InactiveUS6869578B1Easy transferEliminate weldsHydrogenPhysical/chemical process catalystsTemperature controlDiluent

A process and apparatus cools a heat exchange type reaction zone by passing the incoming reactants through heat exchange channels in heat exchange relationship with the reaction zone. The invention simplifies the operation and construction of the heat exchanging type reaction zone by directly communicating reaction channels that contain the reaction with the heating channels that heat reactant across an open manifold located at the end of the channels. Additional reactants, cooling fluids, or other diluents may enter the process directly through the manifold space to permit further temperature control of the reaction zone. The invention promotes better heat transfer efficiency than tube and shell heat transfer arrangements that have been used for similar purposes. The narrow channels are preferably defined by corrugated plates. The reaction channels will contain a catalyst for the promotion of the primary reaction.

Owner:UOP LLC

Low-voltage circuit breaker electromagnetic assembly welding system and method

ActiveCN107243682AEliminate weldsIncrease productivitySoldering ironWelding/soldering/cutting articlesLow voltage circuitsSoldering

The invention discloses a low-voltage circuit breaker electromagnetic assembly welding system. The system comprises a rotary disc assembly arranged on a machine frame; the rotary disc assembly comprises a rotary disc and eight fixture assemblies; the rotary disc is arranged on a horizontal table, the lower surface of the rotary disc is provided with a multi-station indexing mechanism, and rotary disc is provided with a transmission mechanism of its own; eight feeding and discharging mechanisms are sequentially arranged in the positions, surrounding the periphery of the rotary disc, of the horizontal table and the machine frame, specifically, the eight feeding and discharging mechanisms comprise the oil cup feeding mechanism, the lower gasket feeding mechanism, the upper gasket feeding mechanism, the magnet yoke feeding mechanism, the coil feeding mechanism, the upper gasket taking mechanism, the magnet yoke taking mechanism and the soldering mechanism, and the outer side of the soldering mechanism is provided with a finished product discharging outlet. All the mechanisms are connected with a central controller. The invention further discloses a full-automatic circuit breaker electromagnetic assembly welding method. According to the system and the method, the structure is compact, the full-automatic degree is high, and the finished product quality is good.

Owner:YUEQING YEDAO ELECTROMECHANICAL CO LTD

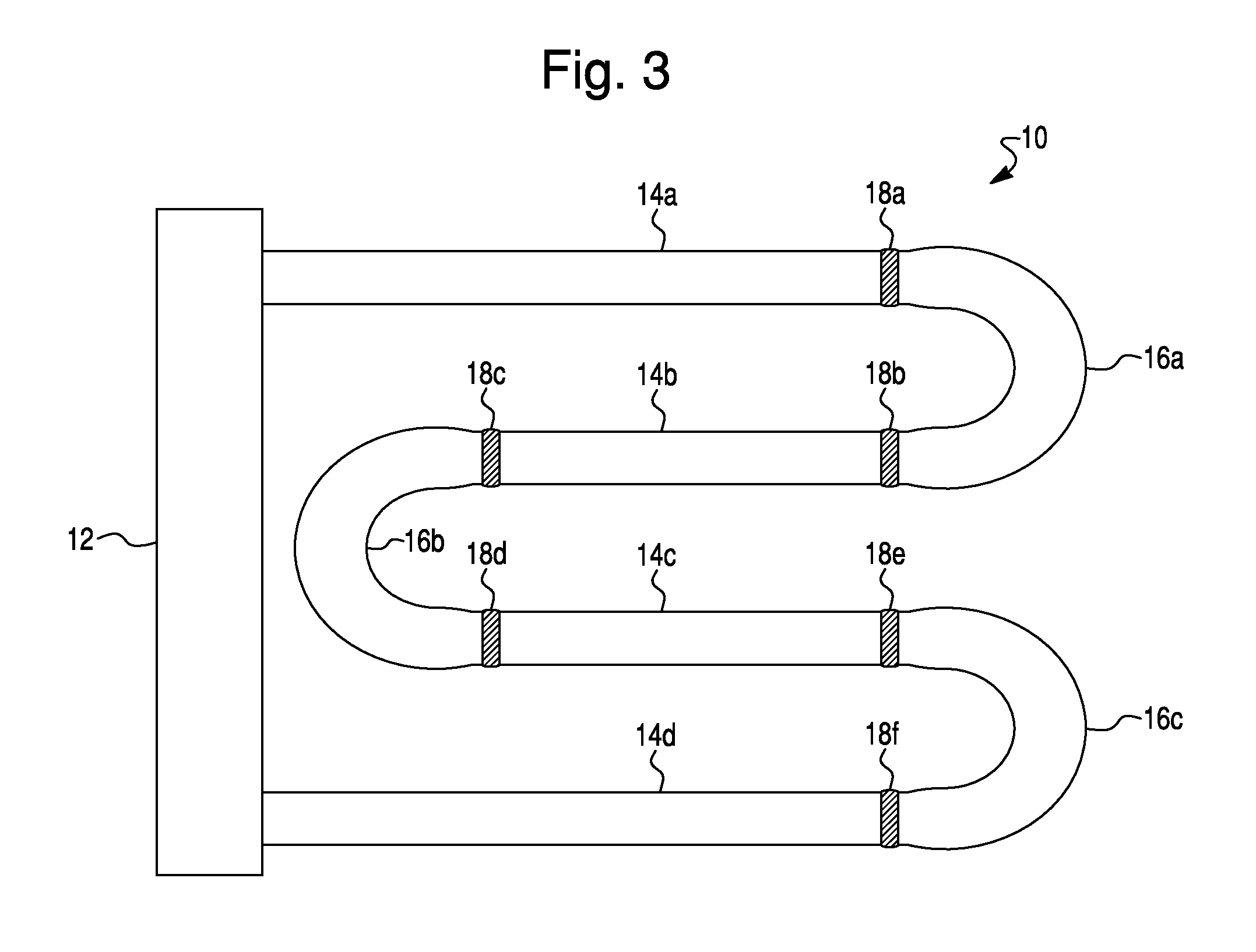

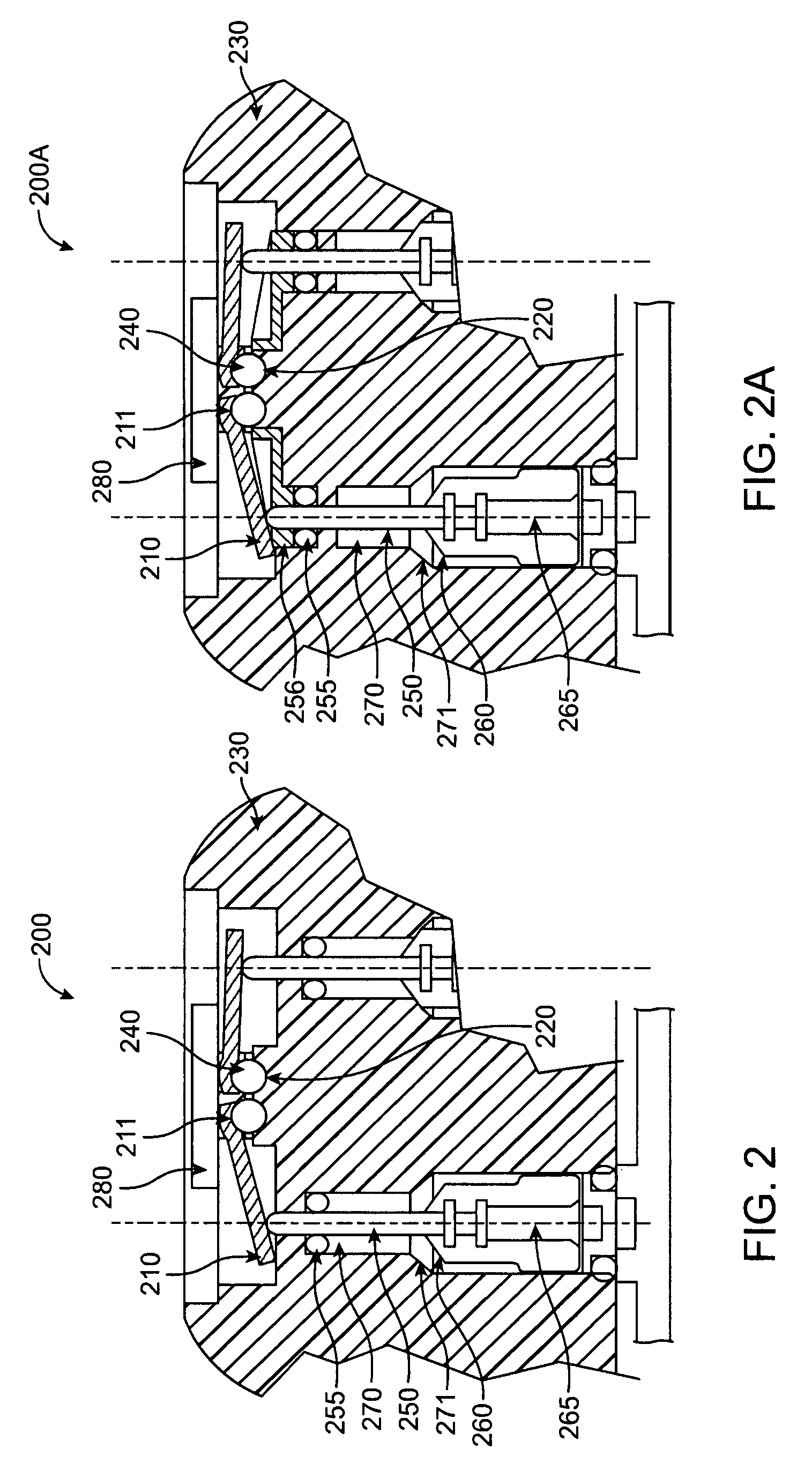

Heavy-duty axle-to-beam connection

ActiveUS8454040B2Eliminate weldsImproves life and durabilityLaminationLamination apparatusHeavy duty

An axle-to-beam connection for a vehicle axle / suspension system includes an axle having at least one depression formed therein. A sleeve is formed with at least one depression and disposed about the axle so that the axle depression and the sleeve depression matingly engage one another to form a mated pair of depressions. A method of forming the axle-to-beam connection includes providing an axle and disposing a sleeve about the axle. At least one mated pair of depressions is simultaneously formed in the axle and the sleeve. The sleeve is immovably mounted to a vehicle axle / suspension system.

Owner:HENDRICKSON USA L L C

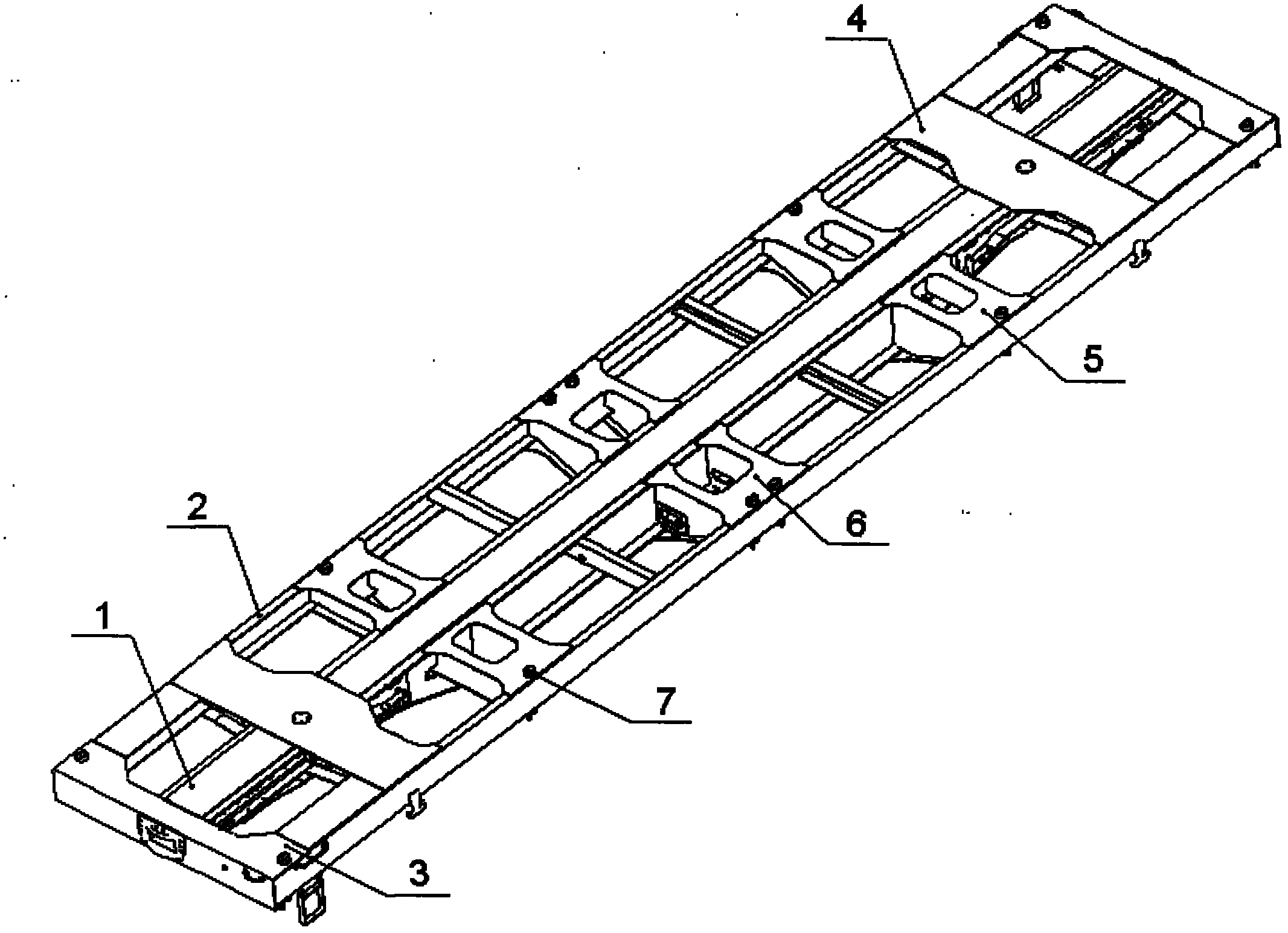

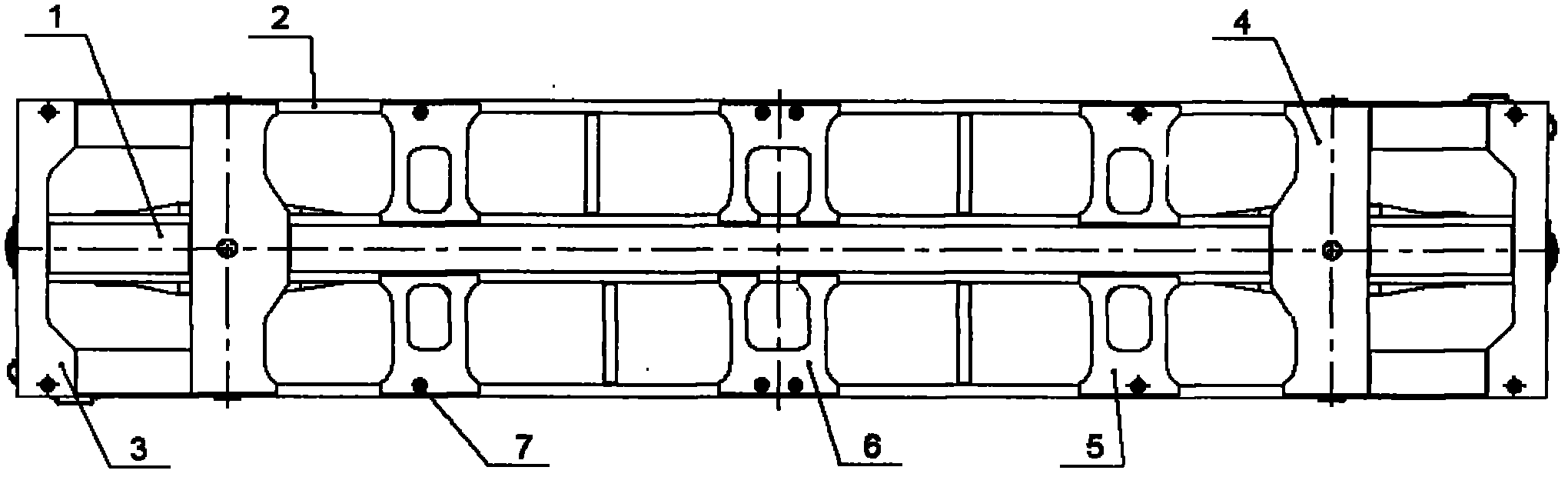

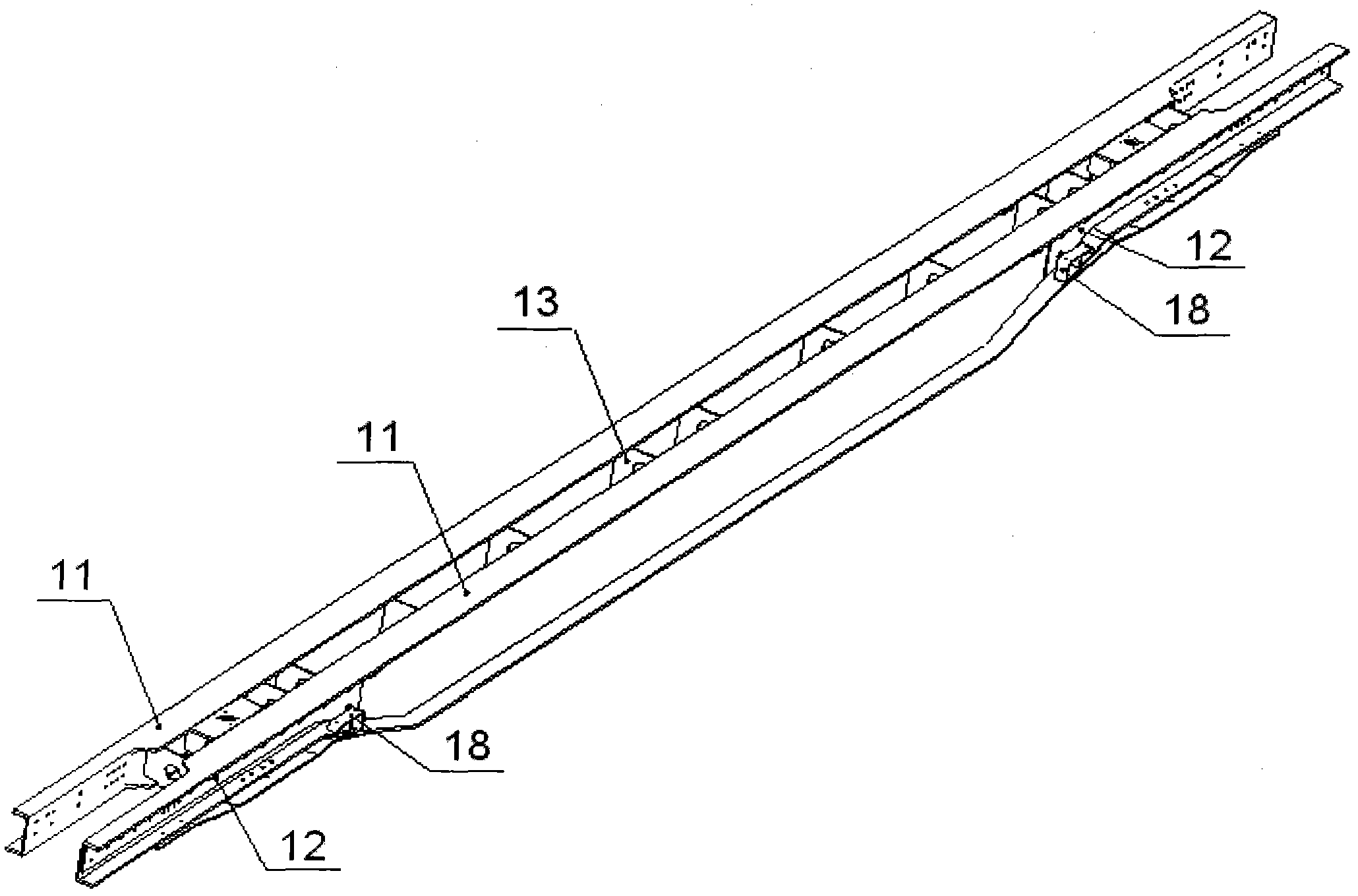

Load increasing container flat wagon body applicable to running on Thailand meter-gage railway

ActiveCN102079314AEven by forceQuality improvementUnderframesWagons/vansStress conditionsStructural engineering

The invention relates to a load increasing container flat wagon body applicable to running on a Thailand meter-gage railway. The load increasing container flat wagon body is characterized by comprising a middle beam assembly, two side beams, two end beam assemblies, two sleeper beam assemblies, four single-lock cross beam assemblies and two double-lock cross beam assemblies, wherein the two side beams are arranged in parallel on the left side and the right side of the middle beam assembly respectively and form a longitudinal beam of the body together with the middle beam assembly; the two end beam assemblies are arranged at the two ends of the longitudinal beam respectively and are transversely connected with the longitudinal beam respectively; the two sleeper beam assemblies are arranged on the longitudinal beam inside the two end beam assemblies respectively and are connected with the longitudinal beam respectively; and the four single-lock cross beam assemblies and the two double-lock cross beam assemblies are divided into a left group and a right group which are symmetrically arranged between the middle beam assembly and the side beams on the inner side of the sleeper beam assemblies respectively, and are transversely connected with the middle beam assembly and the side beams respectively. Through the load increasing container flat wagon body, the dynamic performance of a vehicle at the running speed of 100Km / h can be improved, the manufacturability can be improved, the hidden trouble in manufacturing quality can be reduced, the cross beams, the side beams and a locking device can be rationally arranged, the stressing condition of the body can be improved, and the service life of the vehicle can be prolonged.

Owner:CRRC QIQIHAR ROLLING CO LTD

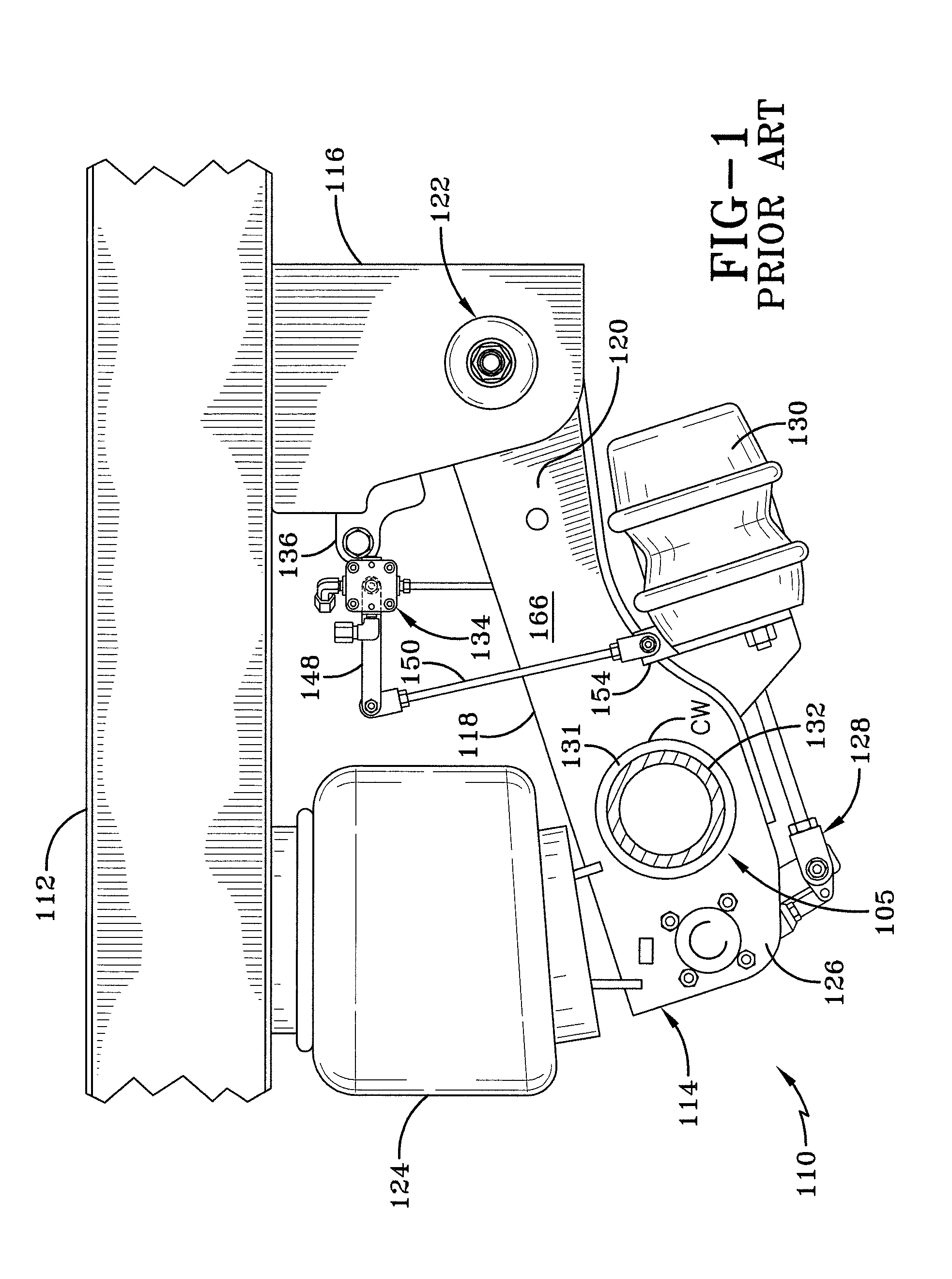

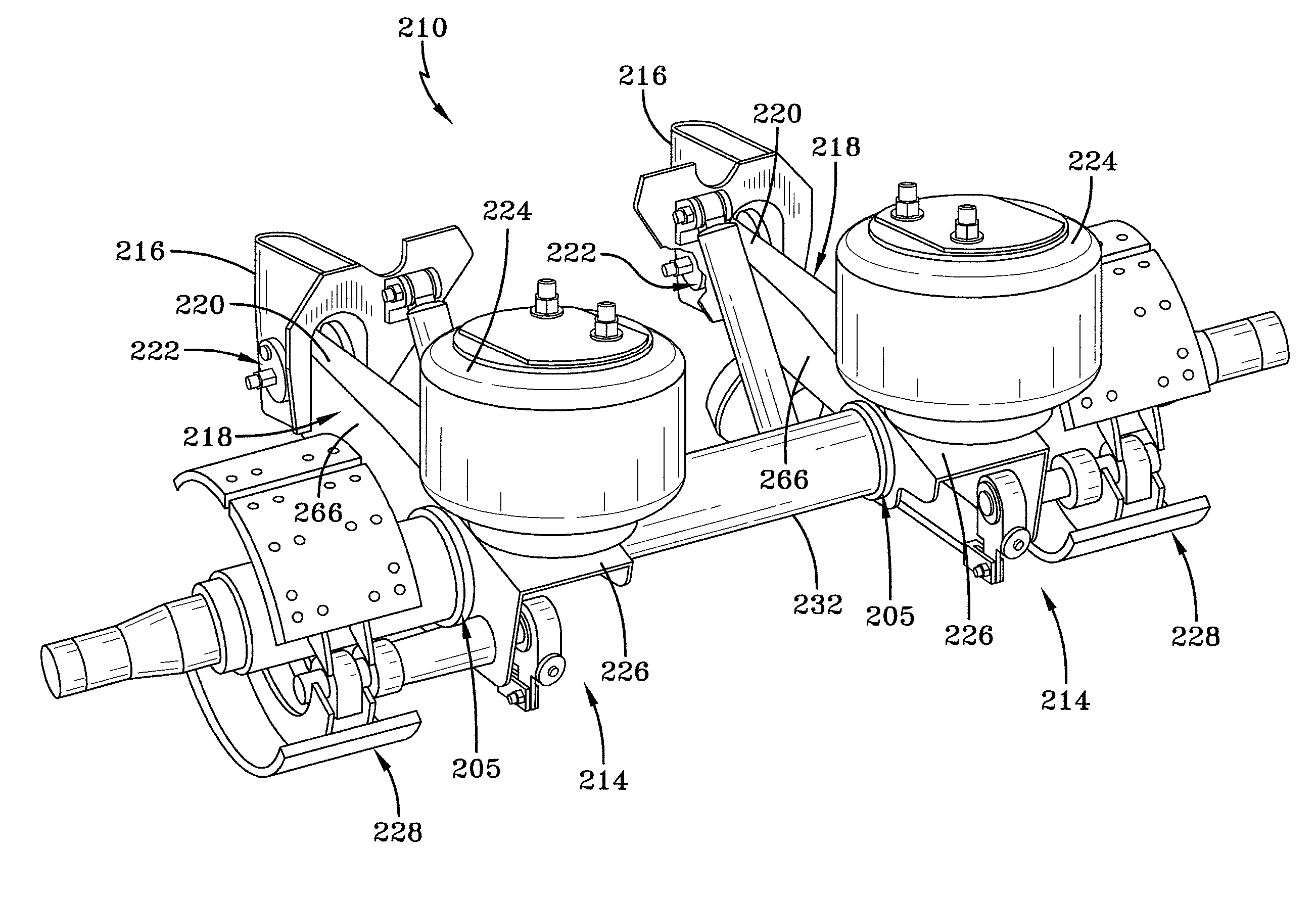

Heavy-duty vehicle axle-to-beam or crossbrace-to-beam connection

An axle-to-beam or crossbrace-to-beam connection for a vehicle axle / suspension system includes an axle or crossbrace having at least one depression formed therein. A sleeve is formed with at least one depression and disposed about the axle or crossbrace so that the axle or crossbrace depression and the sleeve depression matingly engage one another to form a mated pair of depressions. A method of forming the axle-to-beam or crossbrace-to-beam connection includes providing an axle or crossbrace and disposing a sleeve about the axle or crossbrace. At least one mated pair of depressions is simultaneously formed in the axle or crossbrace and the sleeve. The sleeve is immovably mounted to a vehicle axle / suspension system.

Owner:HENDRICKSON USA L L C

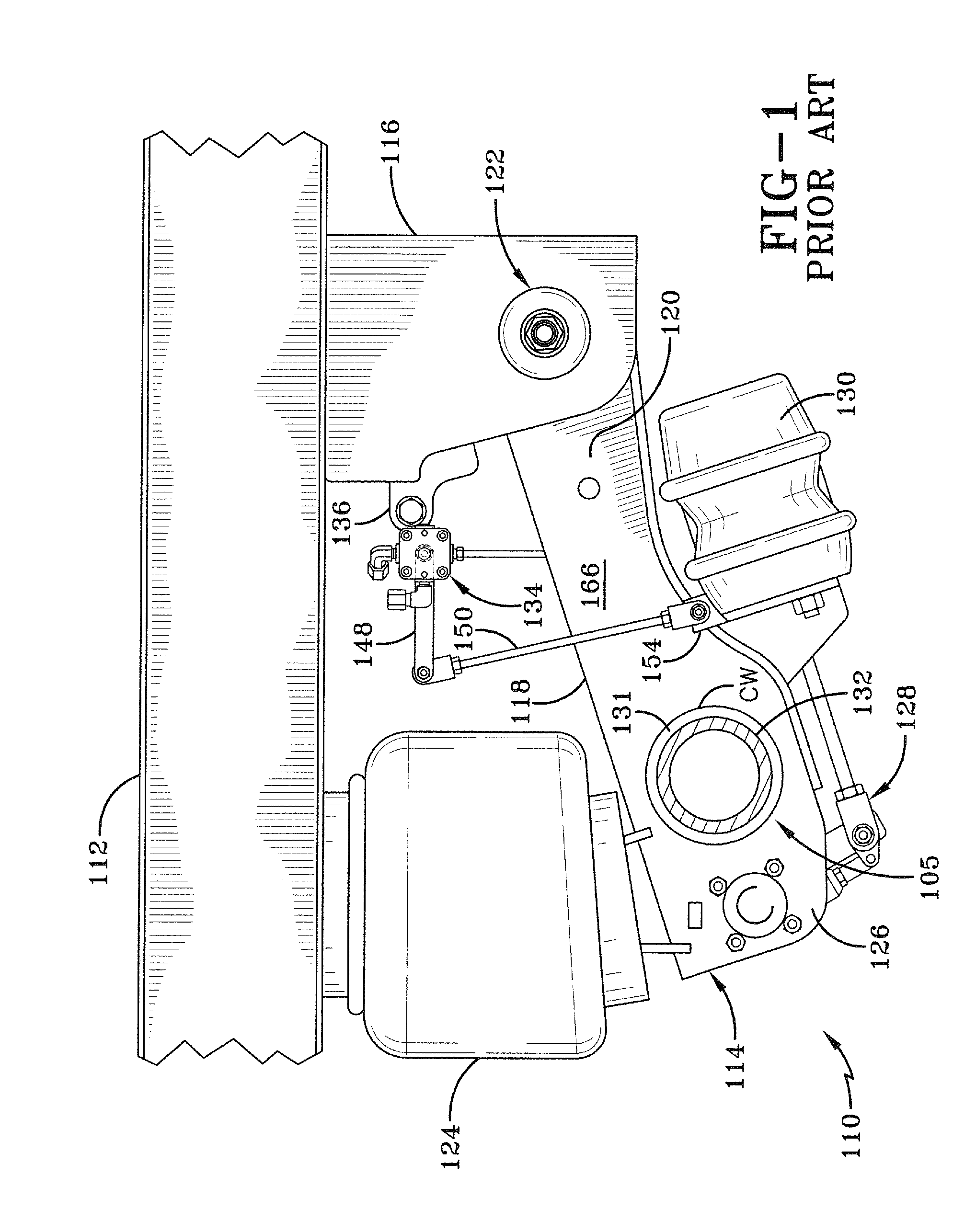

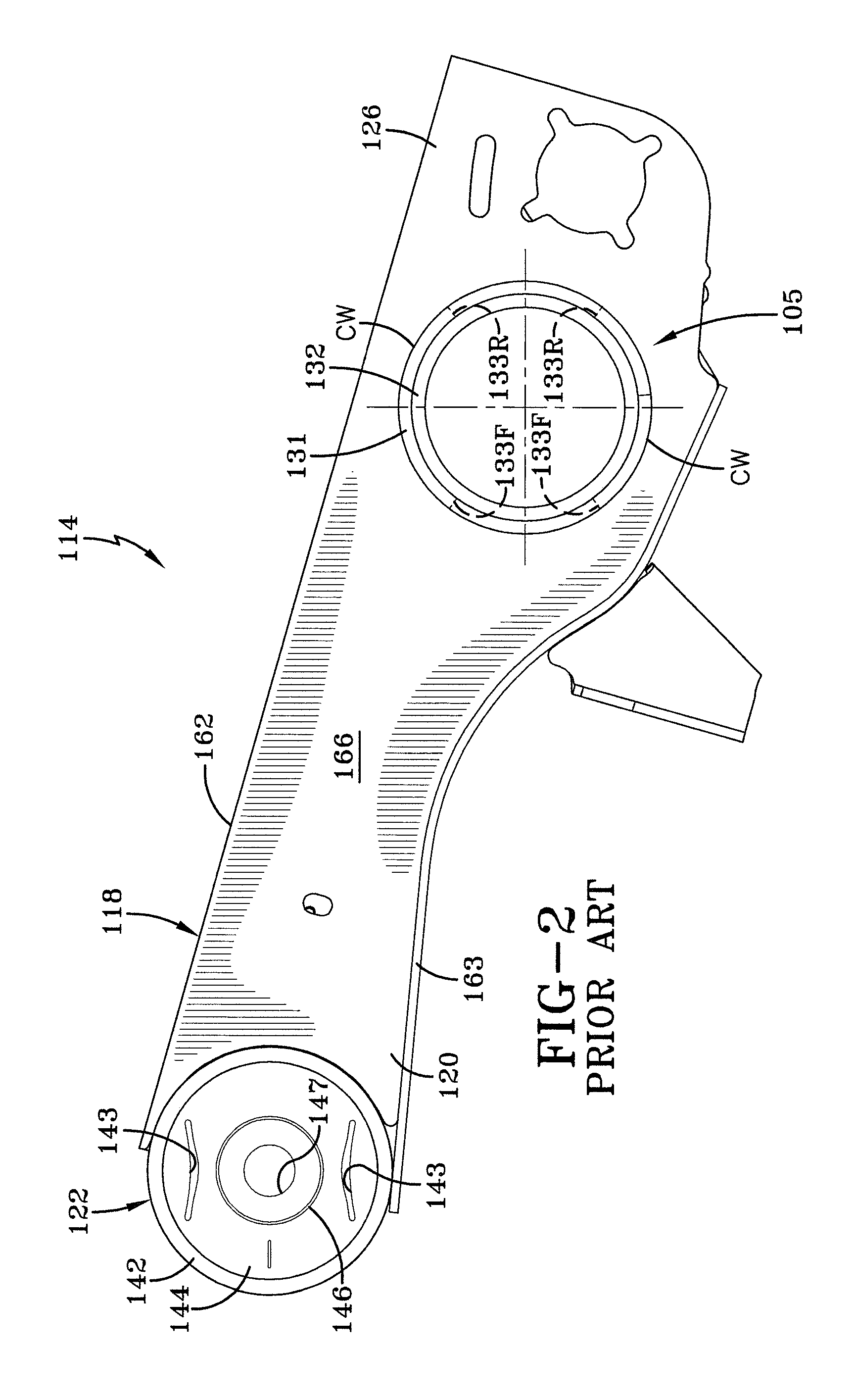

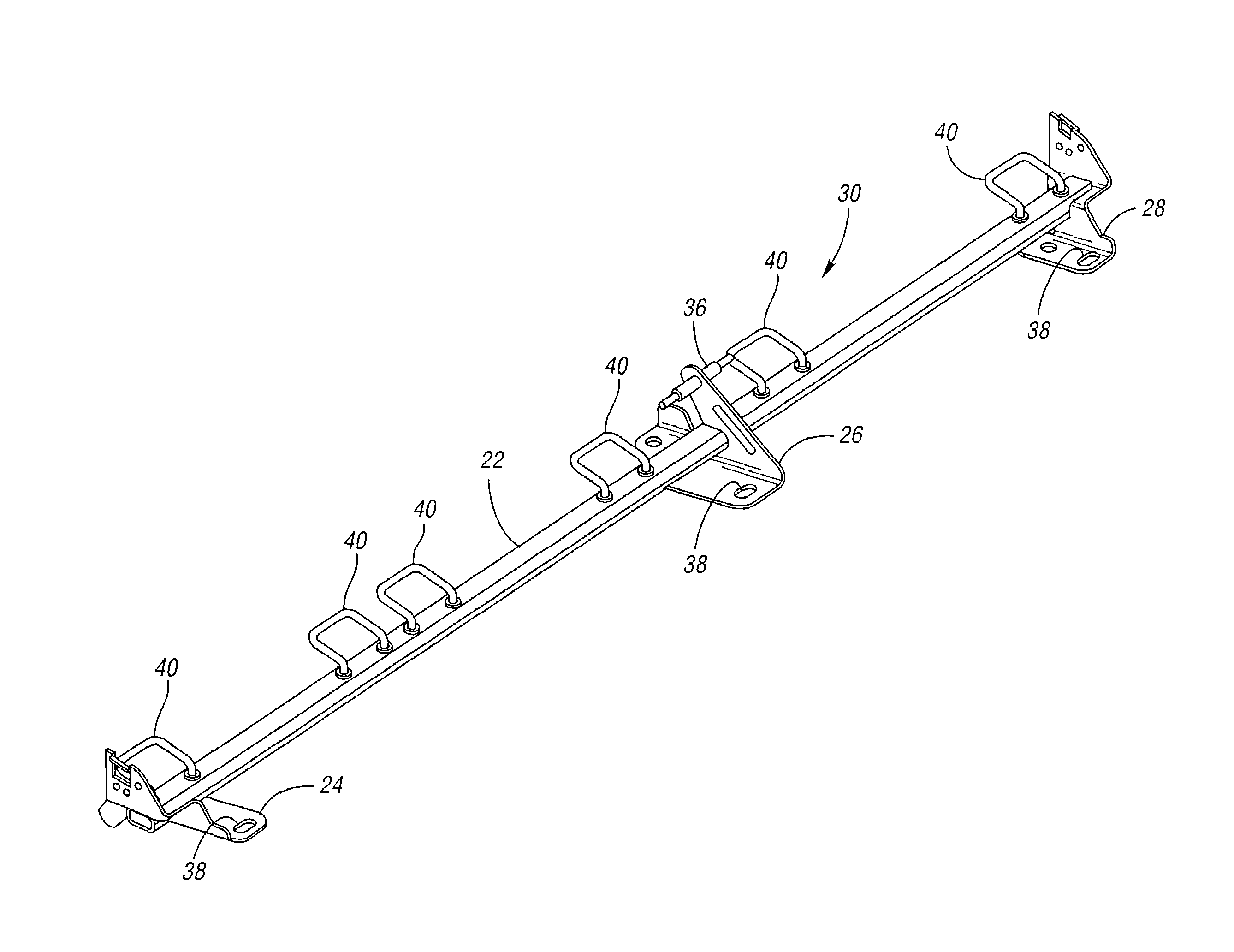

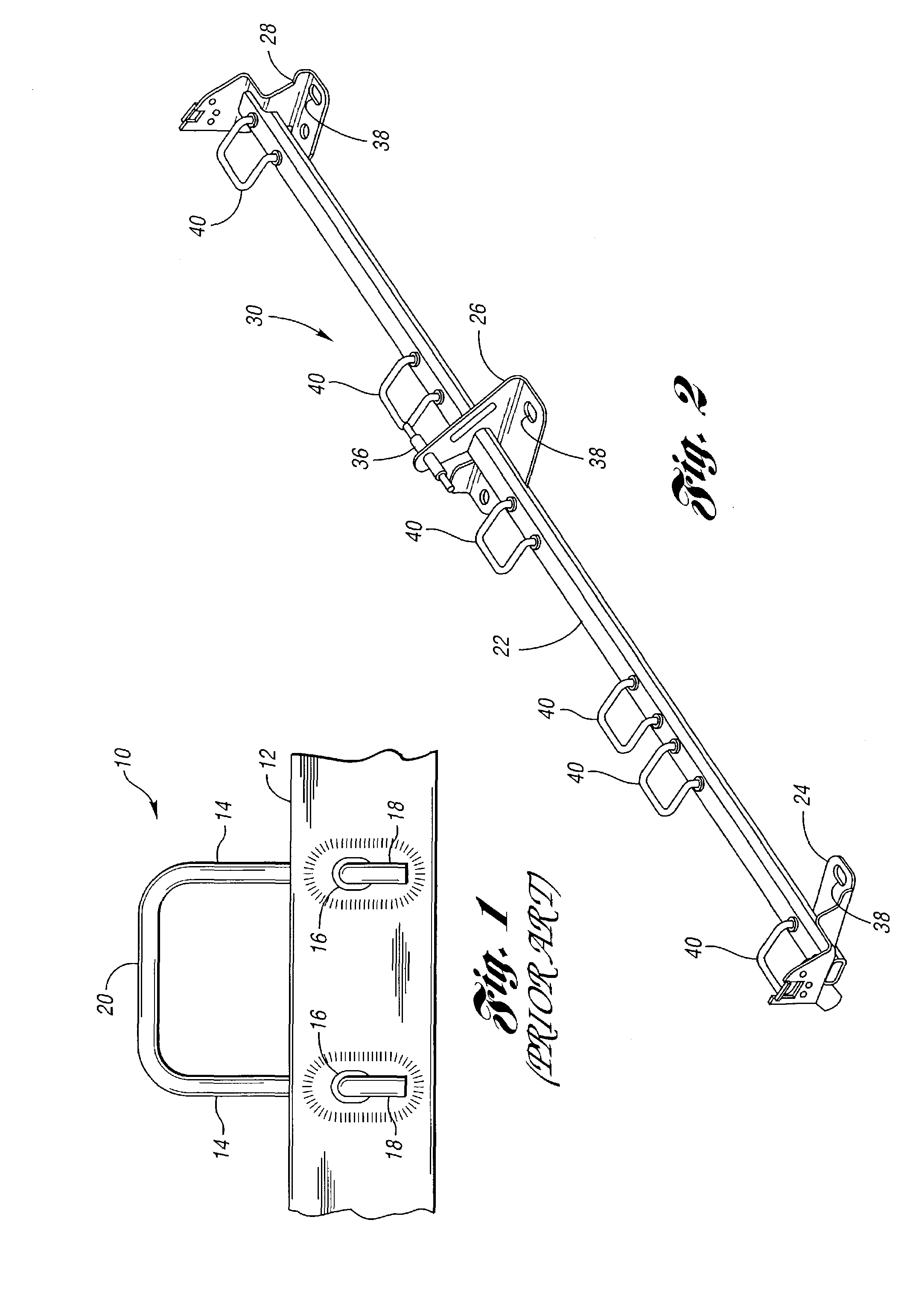

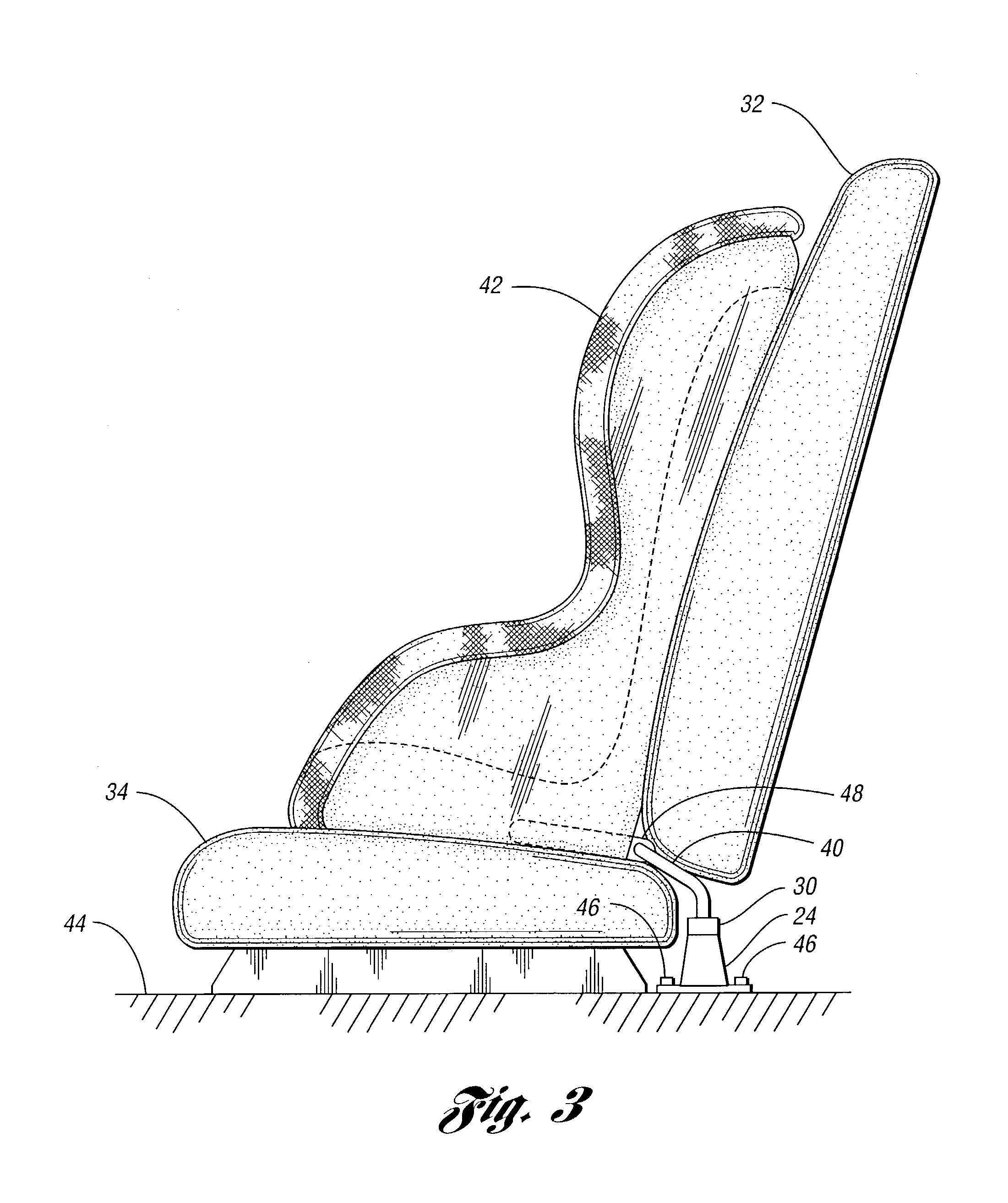

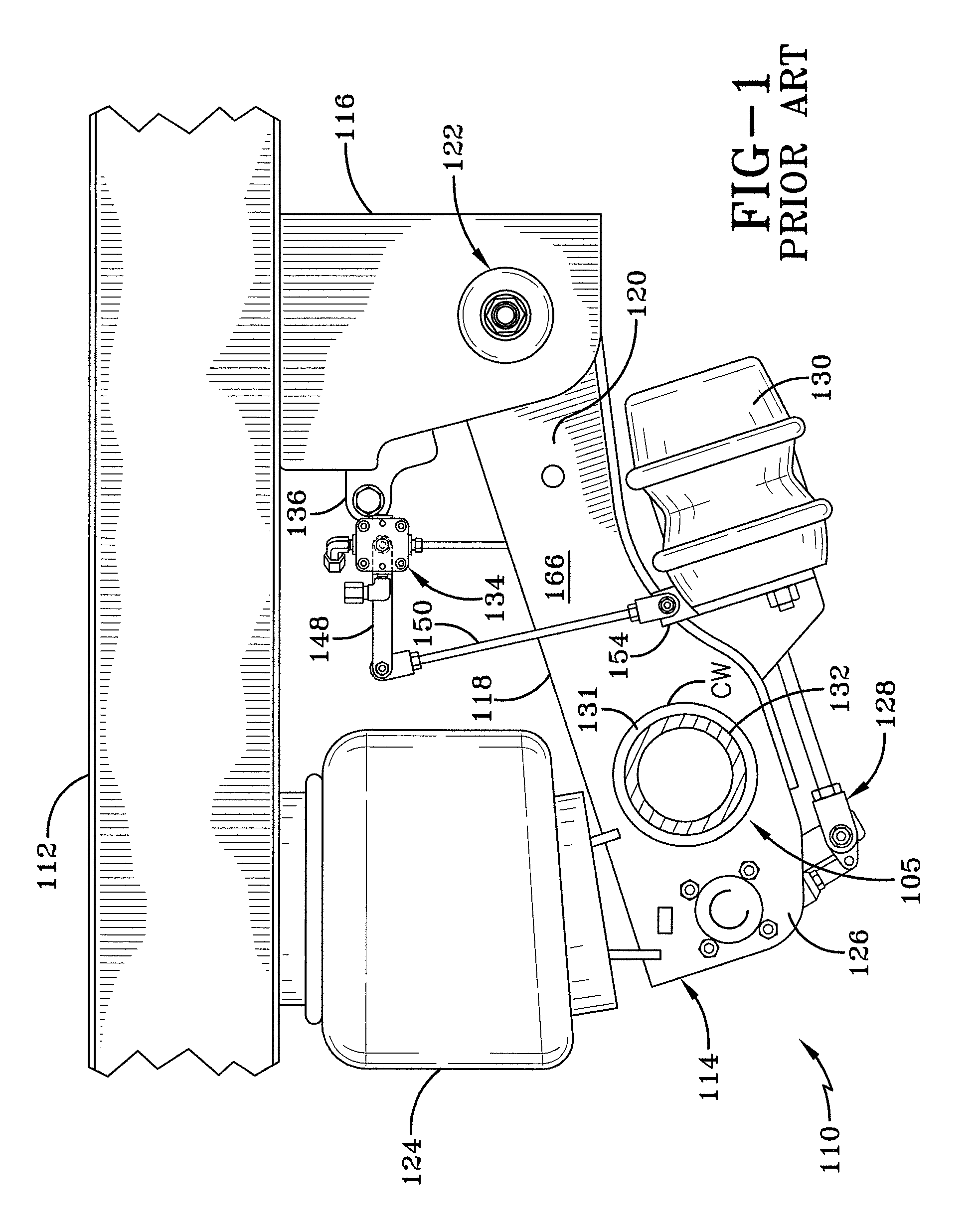

Restraint anchorage for a child restraint system

InactiveUS7131693B2Eliminate weldsImprove quality controlKids chairsStowing appliancesMobile vehicleChild restraint

A restraint anchorage for a child safety seat for an automotive vehicle having a cross member disposed behind the vehicle's seat. U-shaped latch wires are attached to the cross member. Collars are provided on the legs of the latch wires which engage one side of the cross members. The ends of the legs which protrude through holes provided in the cross member are peened over to form enlarged heads locking the latch wire to the cross member.

Owner:MAGNA CLOSURES INC

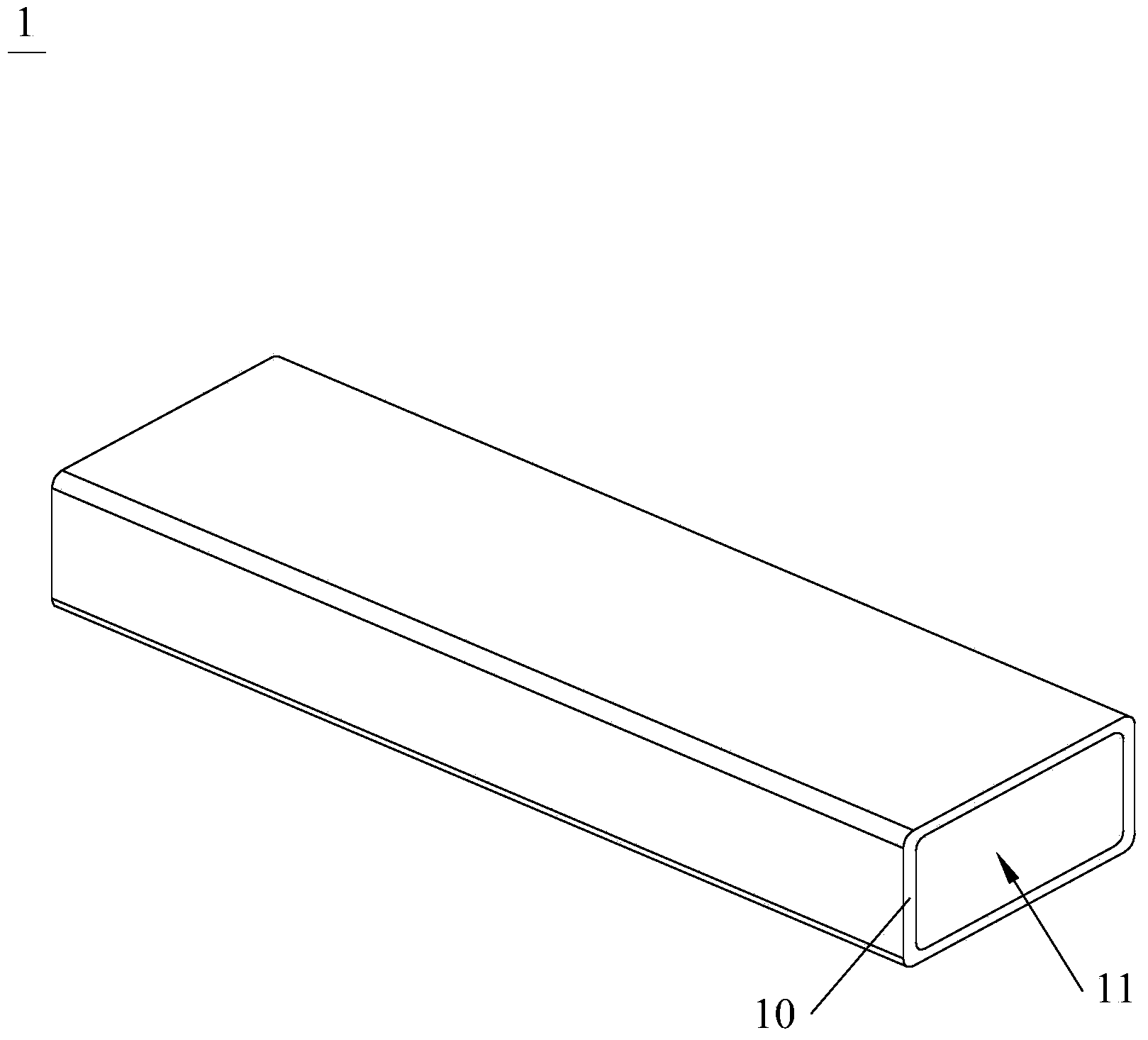

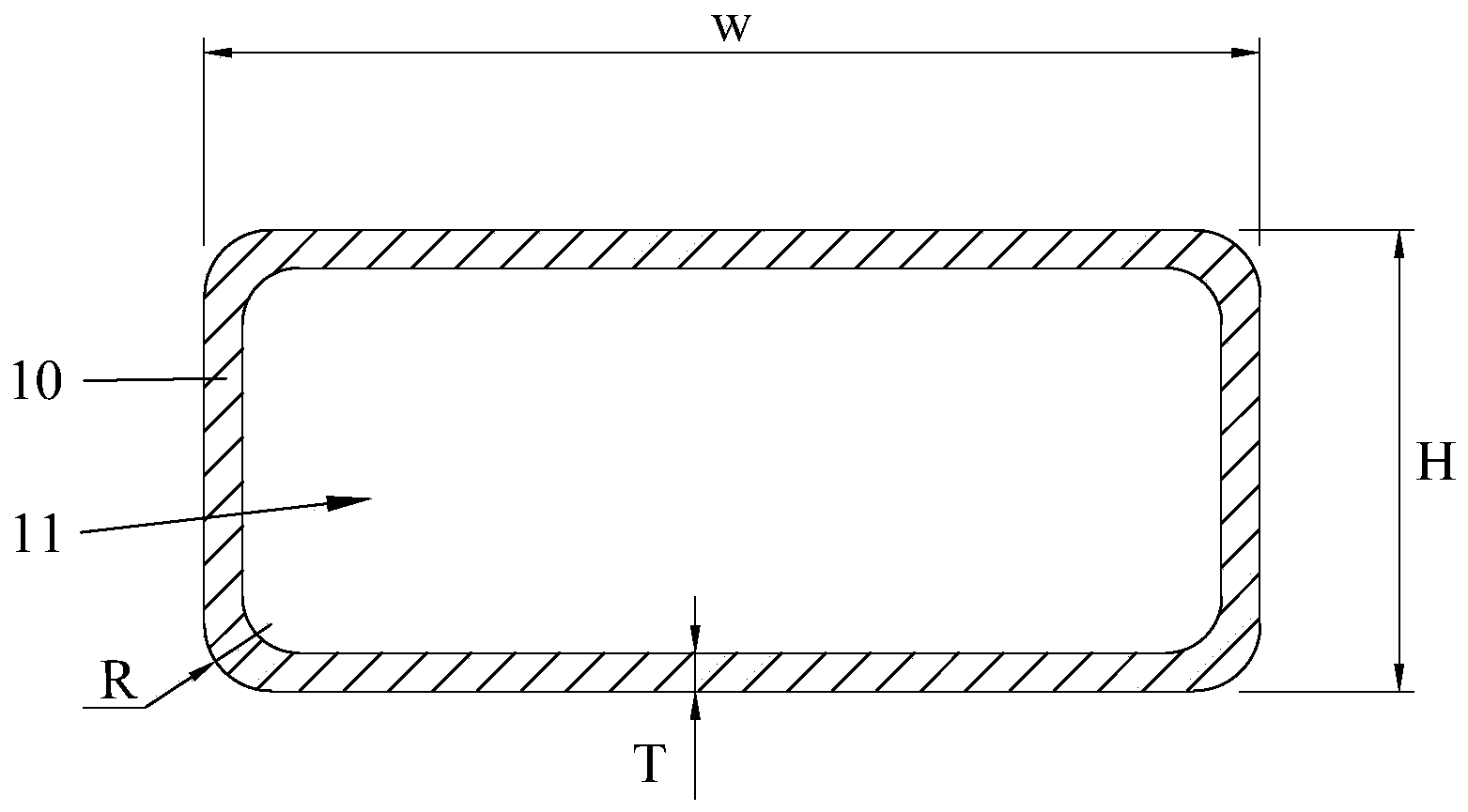

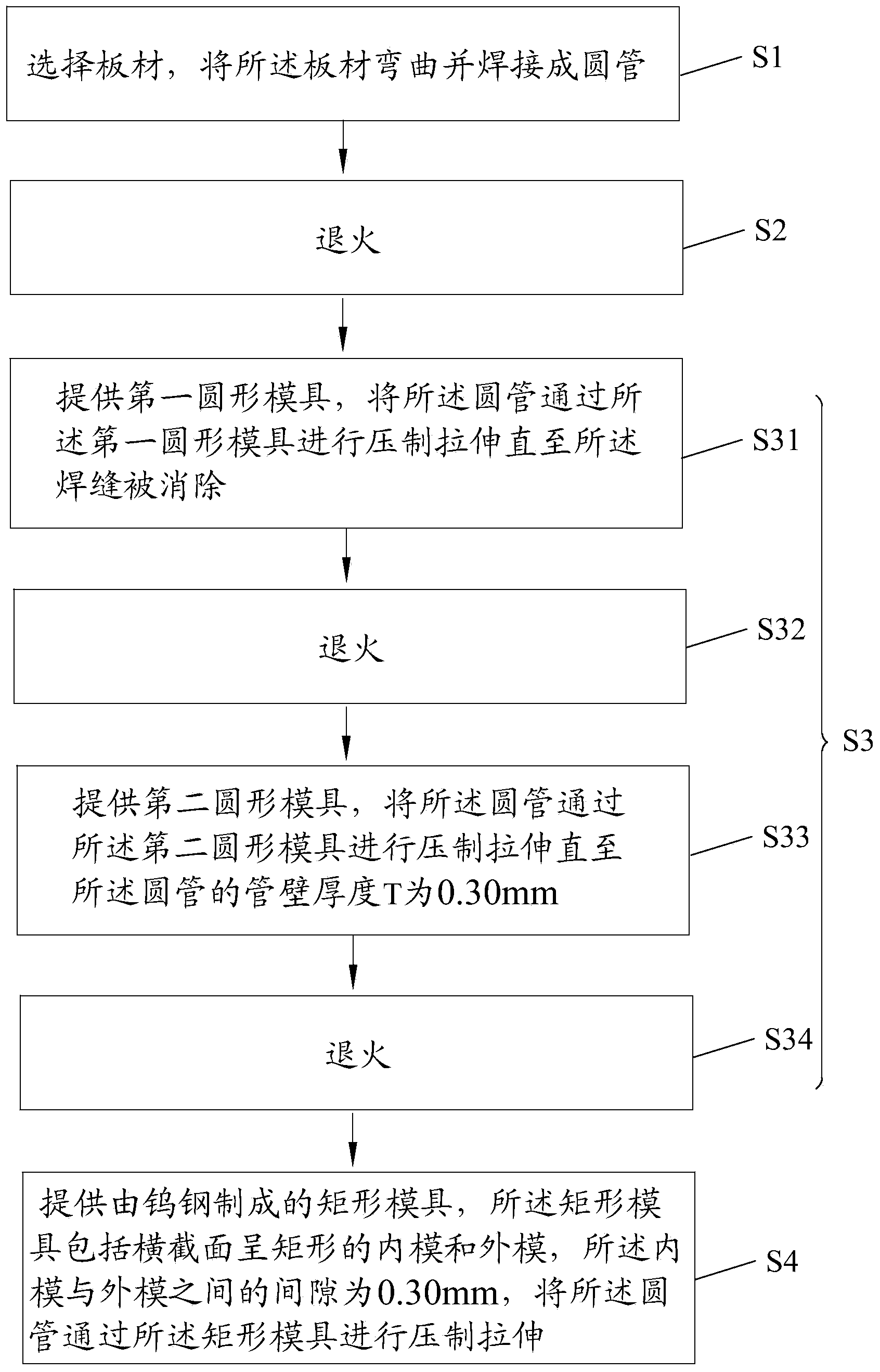

Rectangular pipe and production process thereof

InactiveCN103752644AEliminate weldsElongated constructional elementsCouplings bases/casesManufacturing engineeringSeries production

The invention discloses a rectangular pipe. The rectangular pipe comprises a pipe wall with the uniform thickness, wherein the pipe wall is defined in a closed mode to form an inner cavity; the outer contour of the rectangular pipe and the section of the inner cavity are rectangular; the thickness of the pipe wall is 0.30-0.35mm. According to the rectangular pipe, the size requirement of a universal serial bus (USB) interface on thickness is met, so that a seamless USB shell can be formed by using cutting and related processes. Correspondingly, the invention also discloses a production process for producing the rectangular pipe. According to the process, the rectangular pipes can be produced in batches.

Owner:陈皆得 +1

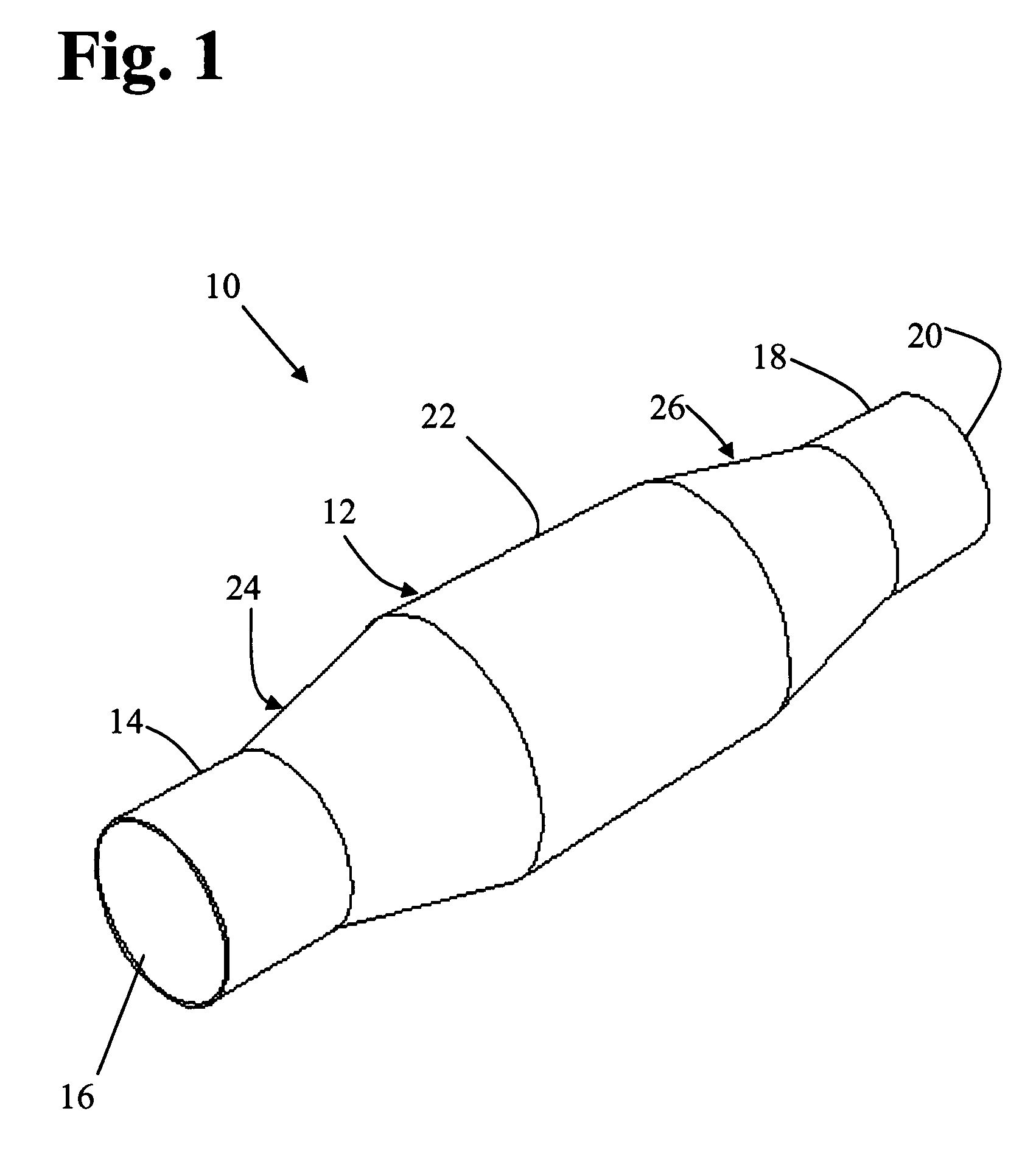

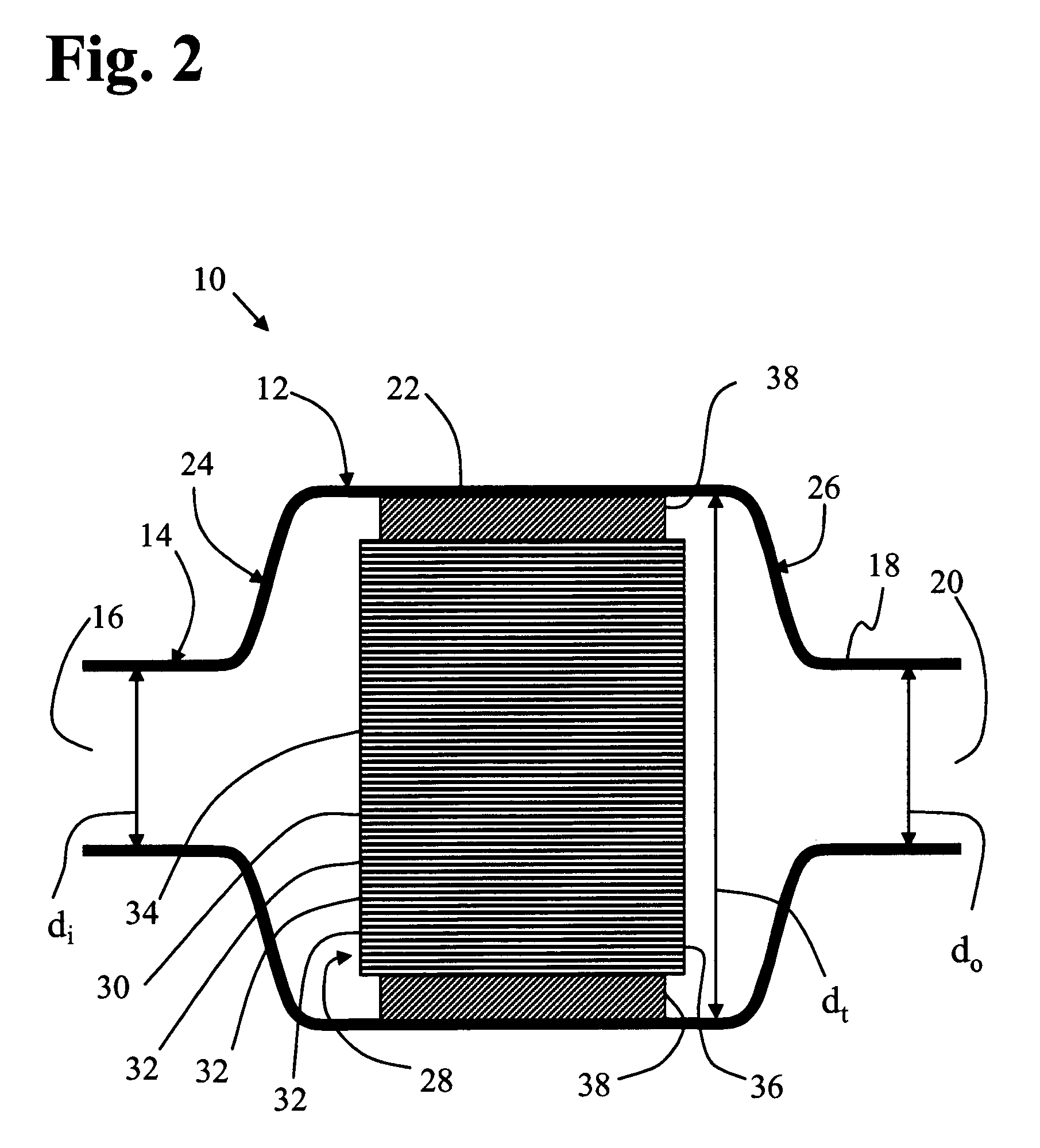

Automotive exhaust component and method of manufacture

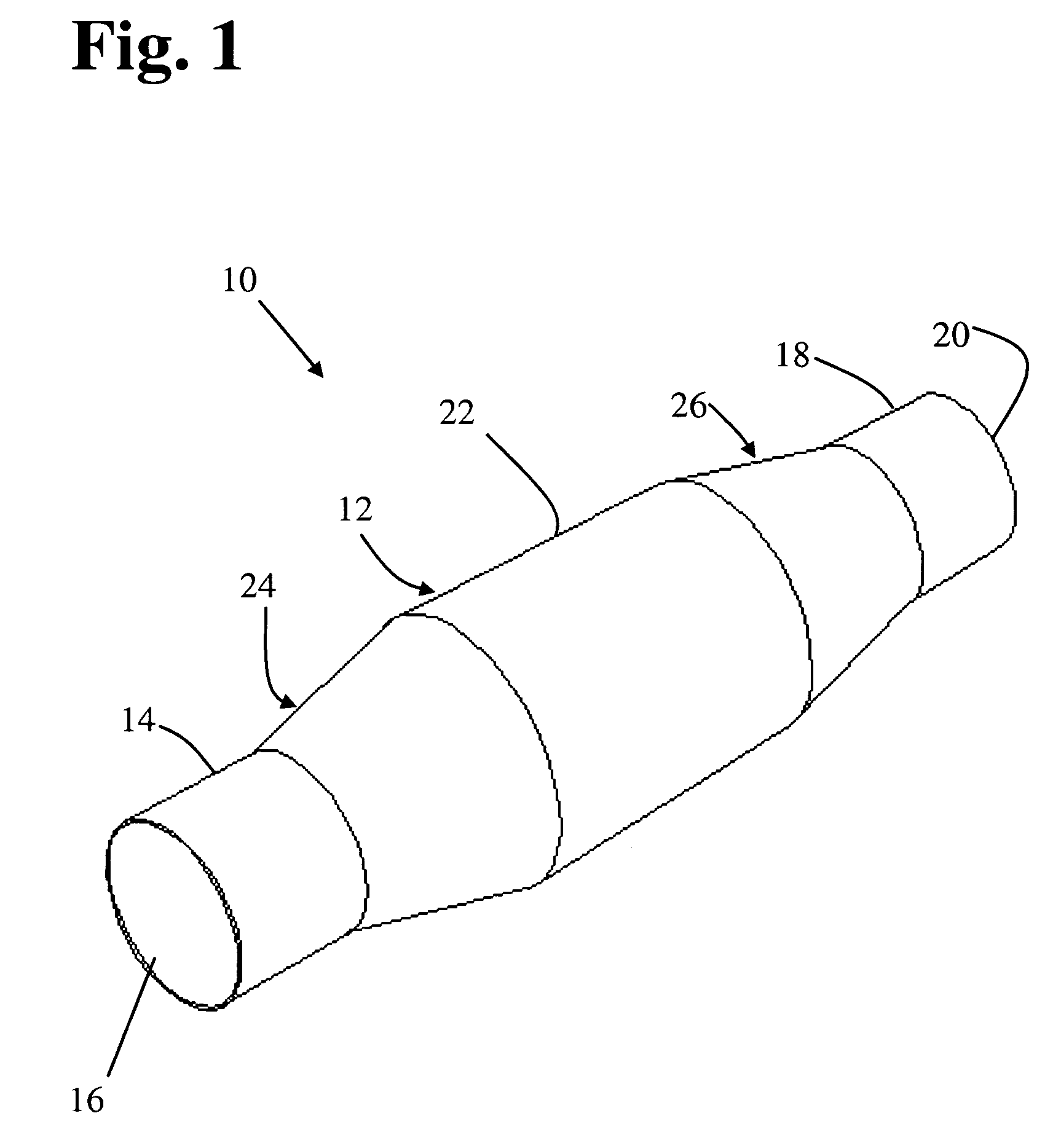

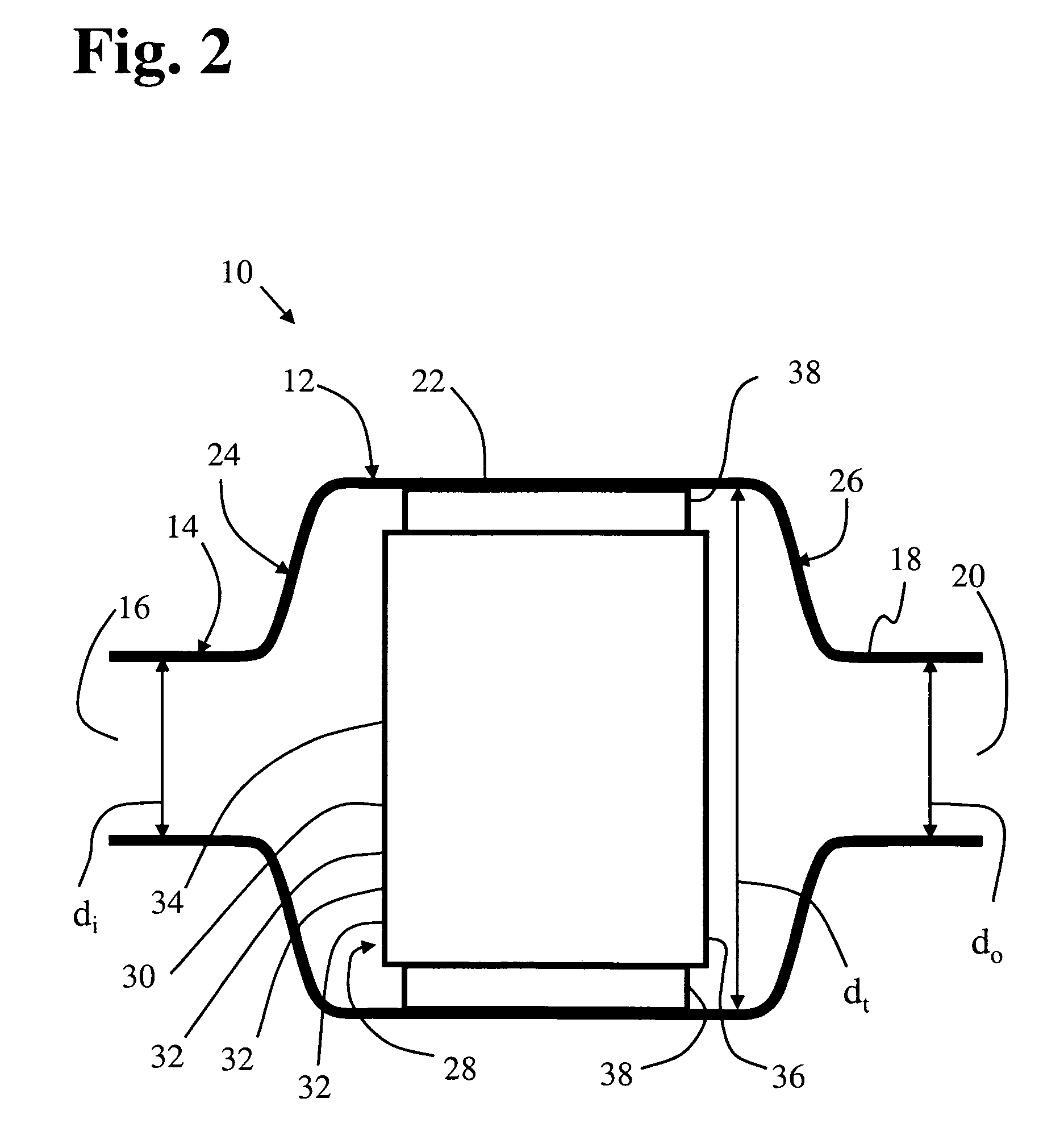

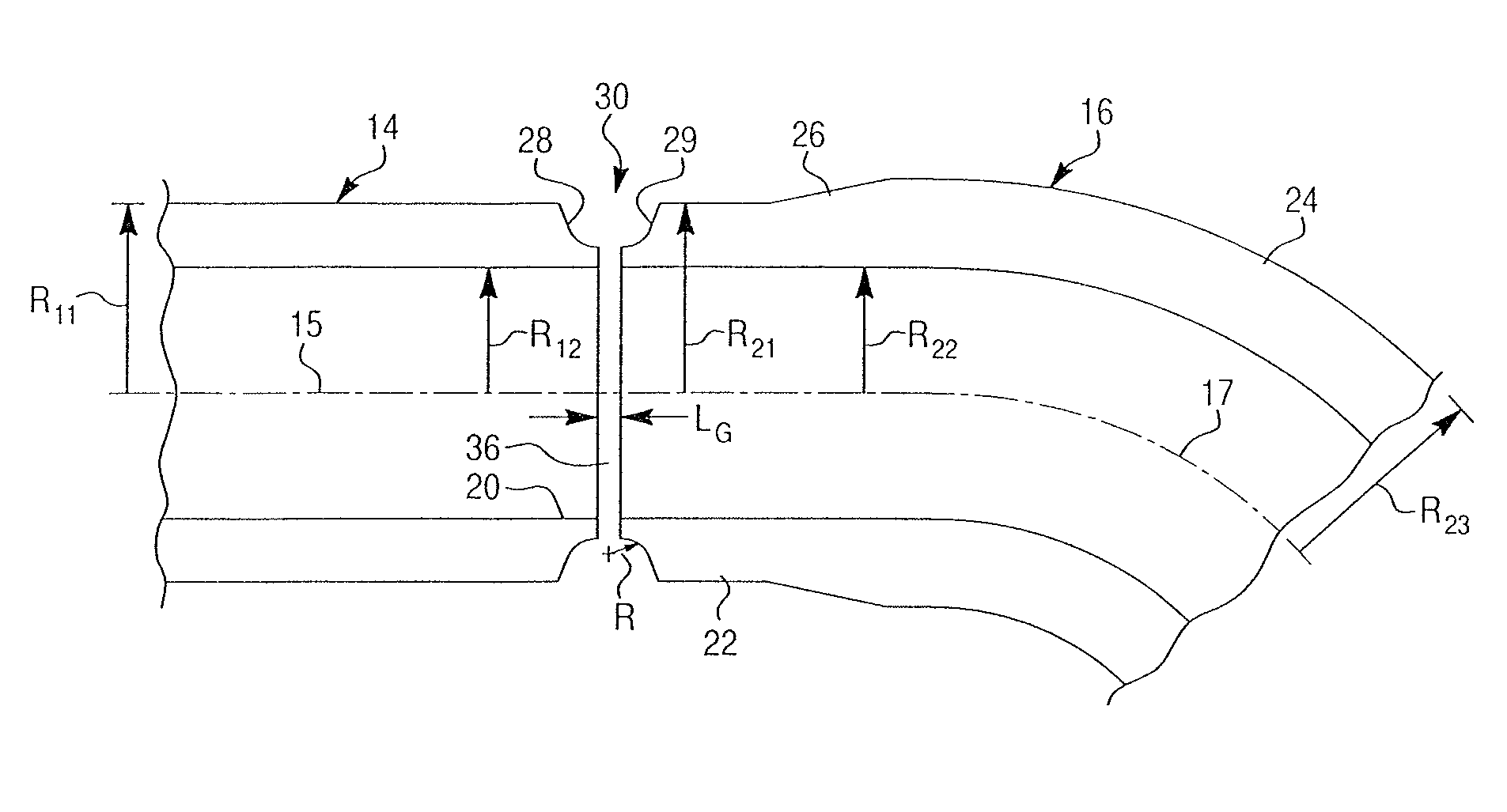

InactiveUS7252808B2Reduce the overall diameterMinimizationCombination devicesInternal combustion piston enginesProduct gasEngineering

A catalytic converter for an internal combustion engine exhaust system comprises a single-piece, seamless metal housing having tubulated gas inlet and outlet ports and a tubulated intermediate section with a plurality of cascaded catalytic element therein. The intermediate section is connected to the inlet port by an inlet transition section and to the outlet port by an outlet transition section. The inlet and outlet ports and the inlet and outlet transition sections are formed by swaging the ends of a seamless tube used to form the housing. Exhaust gas produced by operation of the engine passes into the converter and through the catalytic element. Noxious substances in the exhaust, including CO, NOx, and incompletely combusted hydrocarbons are converted to more benign substances through the action of the catalytic element, which is preferably a frangible ceramic honeycomb structure having a plurality of internal passages coated with a catalytically active substance. A swaging process is used to form tubulated ends on the converter. The tabulated ends minimize production of turbulence in the gas flow and allow the converter to be connected to the rest of the exhaust system by clamped, welded, or flanged joints. The one-piece, seamless construction of the converter is economical to produce and eliminates welding of housing components that tend to fail when subjected to corrosive exhaust gasses over a prolonged period of time.

Owner:EVOLUTION IND INC

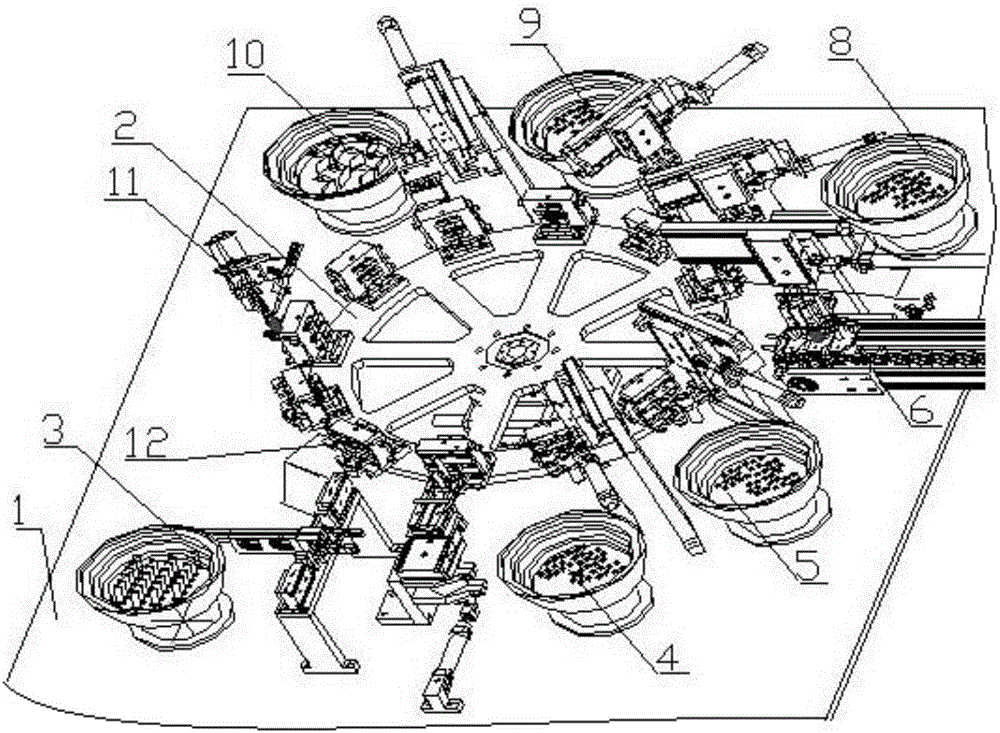

Full-automatic welding system and welding method of electromagnetic assembly of low-voltage circuit breaker

ActiveCN107414236AEliminate weldsIncrease productivitySolder feeding devicesSoldering auxillary devicesLow voltage circuitsEngineering

The invention discloses a full-automatic welding system of an electromagnetic assembly of a low-voltage circuit breaker. The system comprises a rotary disc arranged on a horizontal table top. Eight clamp assemblies are uniformly arranged along the circumference close to the outer edge of the rotary disc, and an indexing mechanism is arranged on the lower surface of the rotary disc; eight mechanisms are successively arranged around the periphery of rotary disc on the horizontal table top; the eight clamp assemblies are uniformly distributed as eight rotating stations which are successively an oil cup loading station, a lower gasket loading station, a magnet yoke loading and storing station, a coil loading station, an upper gasket loading station, a magnet yoke loading station, a tin solder station and a discharging station. A product taking mechanism is arranged on the outer side of the discharging station. The invention also discloses a welding method of the electromagnetic assembly of the low-voltage circuit breaker. The device and method disclosed by the invention are compact in structure, reliable to work and high in welding quality.

Owner:YUEQING YEDAO ELECTROMECHANICAL CO LTD

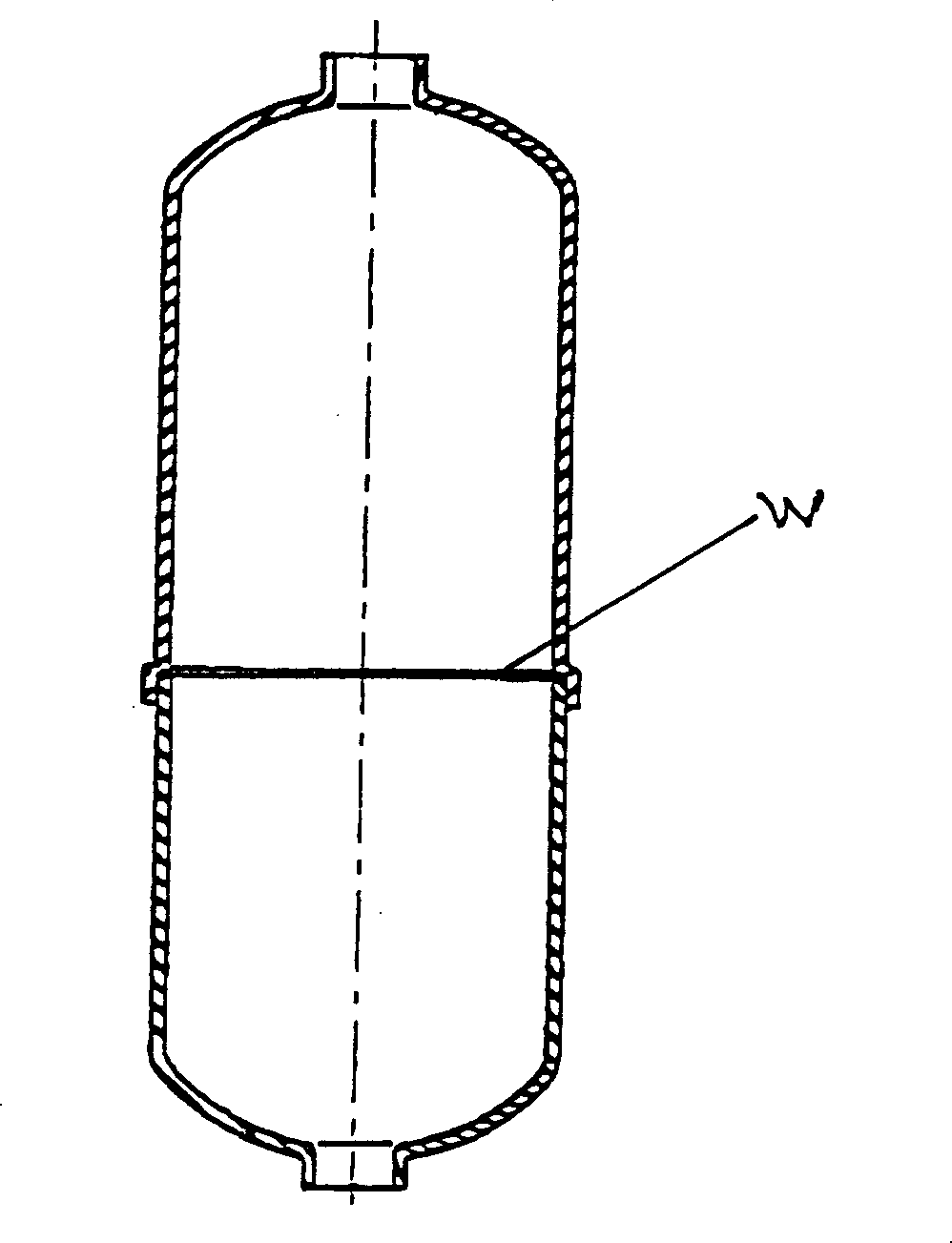

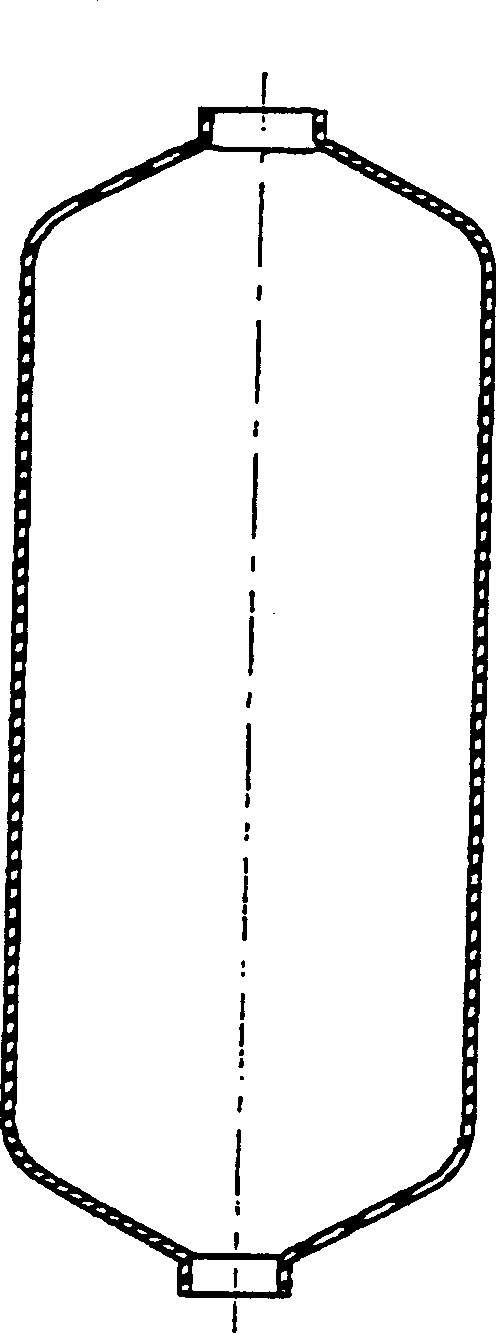

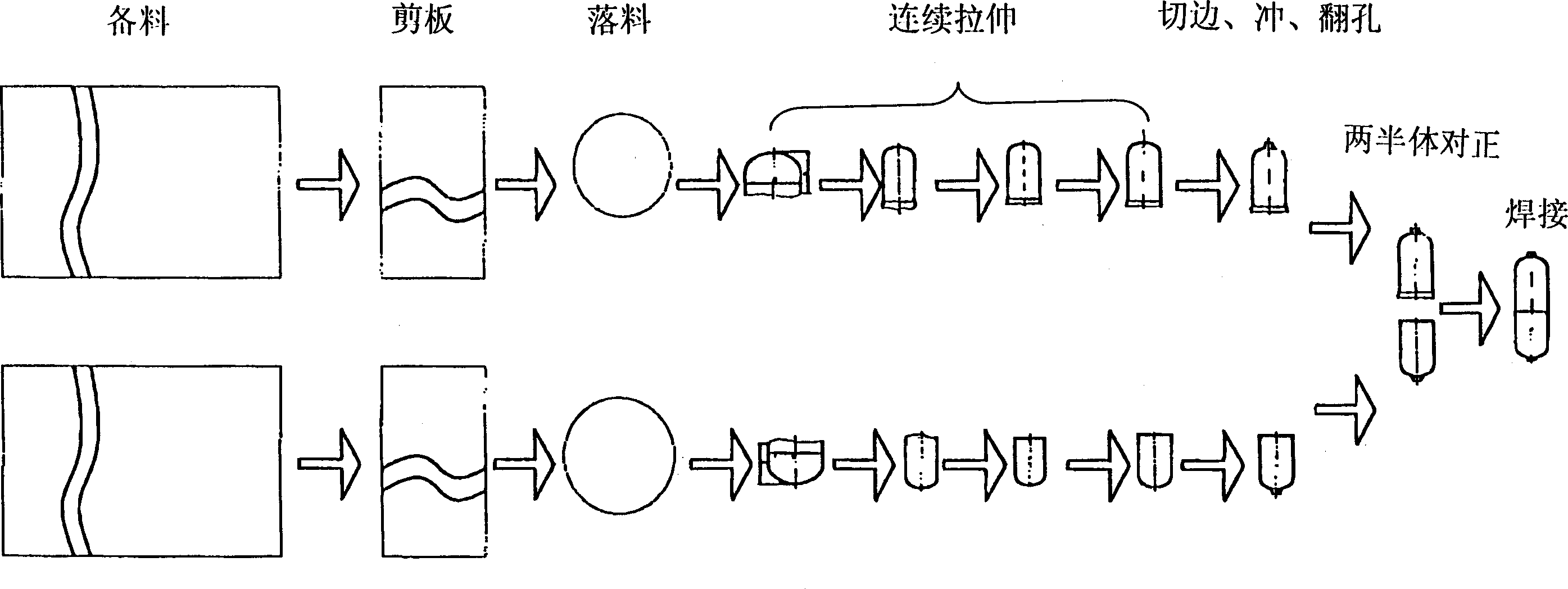

Method for forming steel liquid storage cylinder

InactiveCN1465453ALess coordinationImprove coordination efficiencyHollow articlesPlanishingWeld seam

The present invention discloses a forming method of liquid storage cylinder made of steel which is used in the refrigeration equipment, and is characterized by that it selects ST14 cold-drawn steel pipe as raw material, and its forming method includes the following steps: preparing raw material, cutting said ST14 cold-drawn steel pipe and stretch planishing by rotary extrusion machine tool so as to obtain the invented product without welded seam.

Owner:TAIZHOU JINFAN REFRIGERATION APPLIANCES

Automotive exhaust component and process of manufacture

InactiveUS20080209729A1Low production costEliminate weldsCombination devicesInternal combustion piston enginesProduct gasEngineering

A catalytic converter for an internal combustion engine exhaust system comprises a single-piece, seamless metal housing having tubulated gas inlet and outlet ports and a tubulated intermediate section with at least one catalytic element therein. The converter is manufactured by a multi-step swaging process carried out in a transfer press. The press has a plurality of swaging stations that include swaging die sets that provide a graduated series of swaging steps. The process is operated continuously, with one of the swaging steps being carried out in each station during each press stroke.

Owner:EVOLUTION IND INC

Nickel-base radiant tube and method for making the same

ActiveUS8733619B2Reduce impactReduce stress concentrationThermal non-catalytic crackingArc welding apparatusButt weldingStraight tube

Owner:ARCELORMITTAL INVESTIGACION Y DESARROLLO SL

Heavy-duty vehicle axle-to-beam or crossbrace-to-beam connection

Owner:HENDRICKSON USA L L C

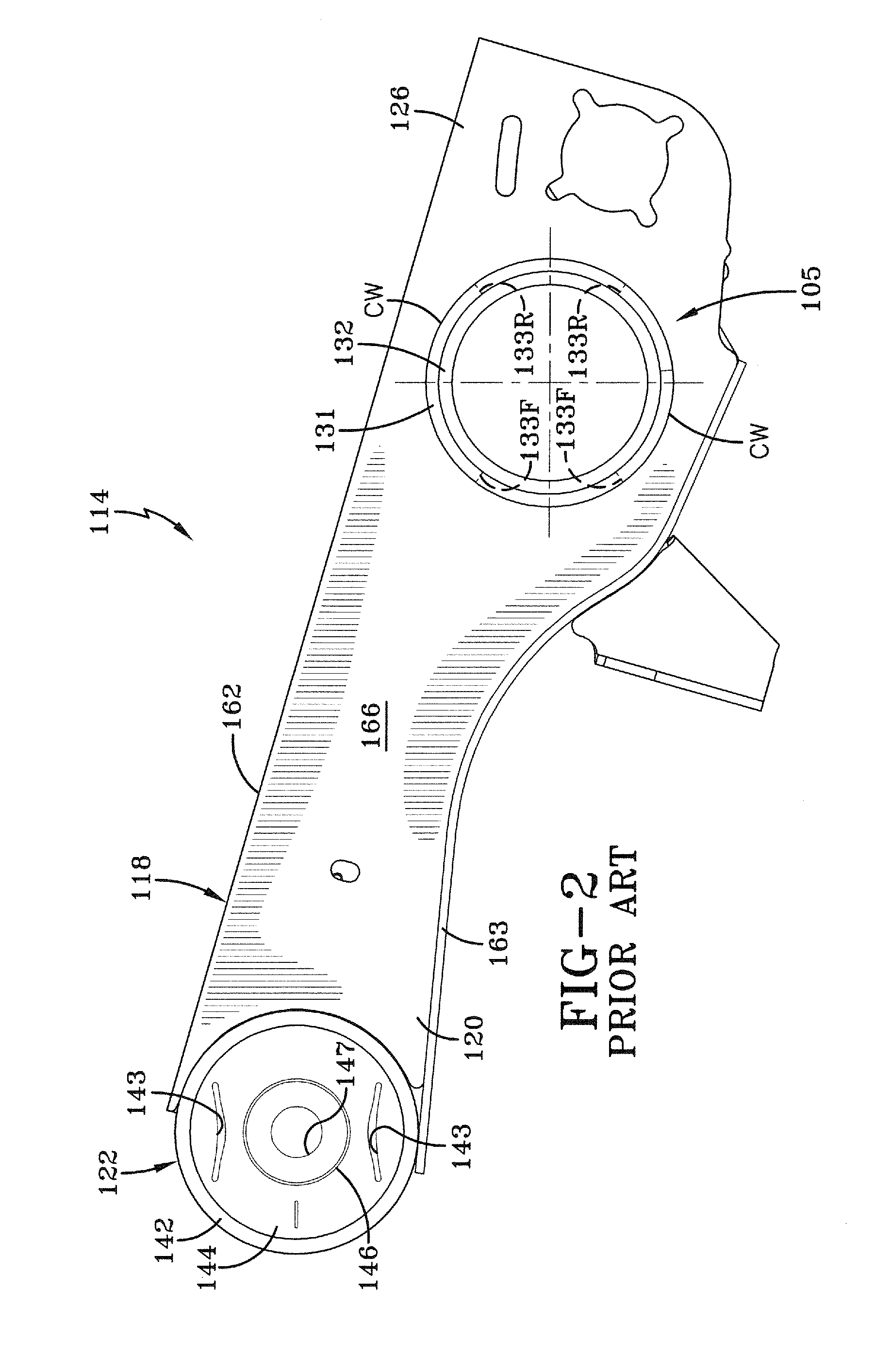

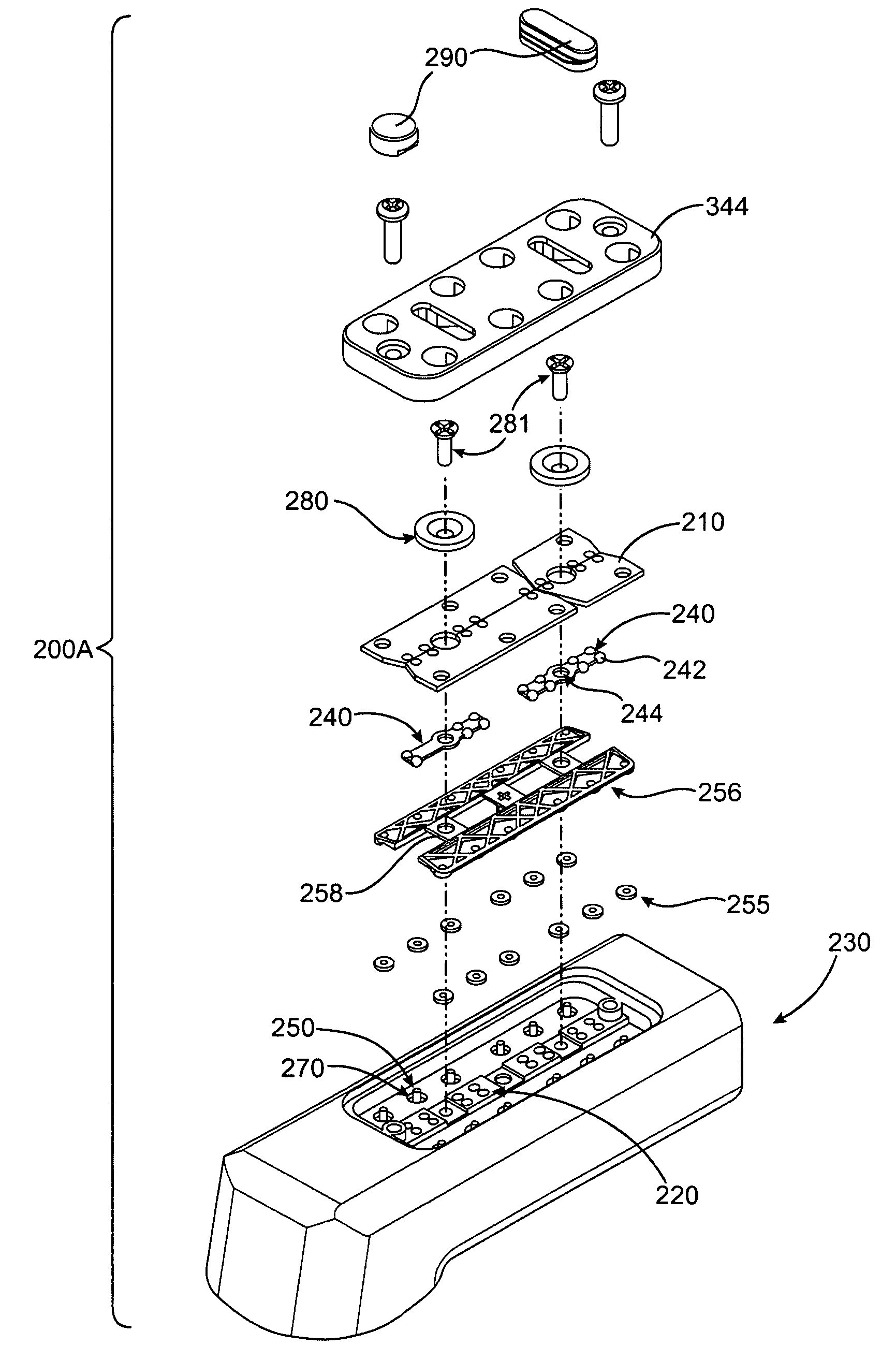

Beverage dispensing apparatus with butterfly plates and a molded O-ring retainer

ActiveUS8272536B2High retention rateEasy to replaceSpindle sealingsOperating means/releasing devices for valvesEnvironmental resistanceBall bearing

The present invention provides improved retention of O-rings and easier O-ring replacement by using an O-ring retainer in a bar gun. Furthermore, the assembly of the butterfly plates of the bar gun is improved by using molded ball bearing clusters that fit in recesses in the butterfly plates, thus eliminating the welding of the balls to the butterfly plates and the need to purchase such precise and intricately small balls. The O-ring retainer and molded ball bearing cluster are preferably made from bearing quality acetal plastic materials.

Owner:AUTOMATIC BAR CONTROLS

Automotive exhaust component and method of manufacture

InactiveUS20050271561A1Reduce the overall diameterMinimizationCombination devicesInternal combustion piston enginesHydrocotyle bowlesioidesHazardous substance

A catalytic converter for an internal combustion engine exhaust system comprises a single-piece, seamless metal housing having tubulated gas inlet and outlet ports and a tubulated intermediate section with a catalytic element therein. The intermediate section is connected to the inlet port by an inlet transition section and to the outlet port by an outlet transition section. The inlet and outlet ports and the inlet and outlet transition sections are formed by swaging the ends of a seamless tube used to form the housing. Exhaust gas produced by operation of the engine passes into the converter and through the catalytic element. Noxious substances in the exhaust, including CO, NOx, and incompletely combusted hydrocarbons are converted to more benign substances through the action of the catalytic element, which is preferably a frangible ceramic honeycomb structure having a plurality of internal passages coated with a catalytically active substance. A swaging process is used to form tubulated ends on the converter. The tabulated ends minimize production of turbulence in the gas flow and allow the converter to be connected to the rest of the exhaust system by clamped, welded, or flanged joints. The one-piece, seamless construction of the converter is economical to produce and eliminates welding of housing components that tend to fail when subjected to corrosive exhaust gasses over a prolonged period of time.

Owner:EVOLUTION IND INC

Structural shape for wind tower members

InactiveUS8910446B2Lose weightWeight increaseWind motor supports/mountsLoad-supporting elementsTowerSpace frame

One of the major structural components in a space frame tower is the tower leg. A novel and nonobvious tower leg structure is provided which provides significant advantages and benefits over previously available structures.

Owner:GE WIND ENERGY

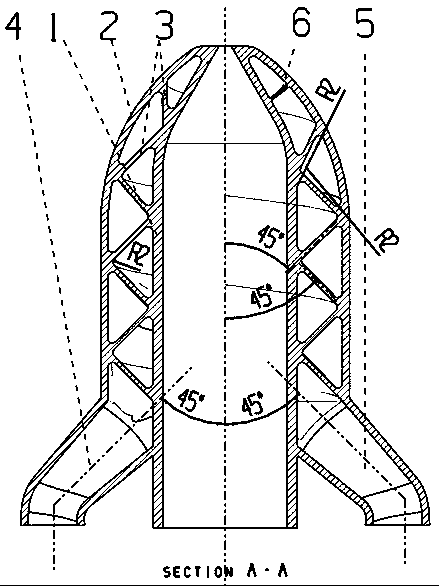

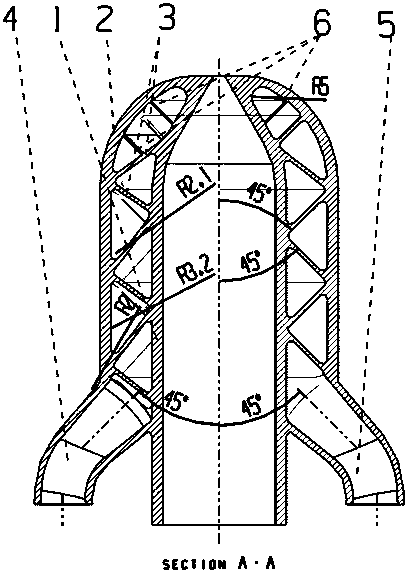

Novel coal gasification process burner jet nozzle

PendingCN109022043AImprove heat transfer efficiencyPlay a role in strengthening the structureGasification processes detailsGranular/pulverulent flues gasificationSpray nozzleSpherical shaped

The invention discloses a novel coal gasification process burner jet nozzle. The burner jet nozzle is of an integral single structure, and consists of five parts including an inner wall, an outer wall, a runner separation plate, a water inlet and a water outlet, wherein the runner separation plate connects the inner wall and the outer wall. The front part of the jet nozzle is in a spherical shape,an oval shape or a conic shape; the back part of the jet nozzle is in a cylindrical shape. The adjacent runner separation plate and the inner and outer walls form a triangular runner; the runner formed with the inside is a water inlet passage; the runner formed with the outer wall is a water outlet passage; a water inlet and outlet passage is communicated with a jet head. The jet nozzle is an integral structure; the runner separation plate realizes the complex functions of separating the runner, enhancing the structure and increasing the heat conduction area. The manufacturing work proceduresof the burner jet nozzle are simplified; the welding bead is eliminated; the burner heat radiation efficiency is improved; the service life of the burner can be effectively prolonged.

Owner:北京精益增材科技有限公司

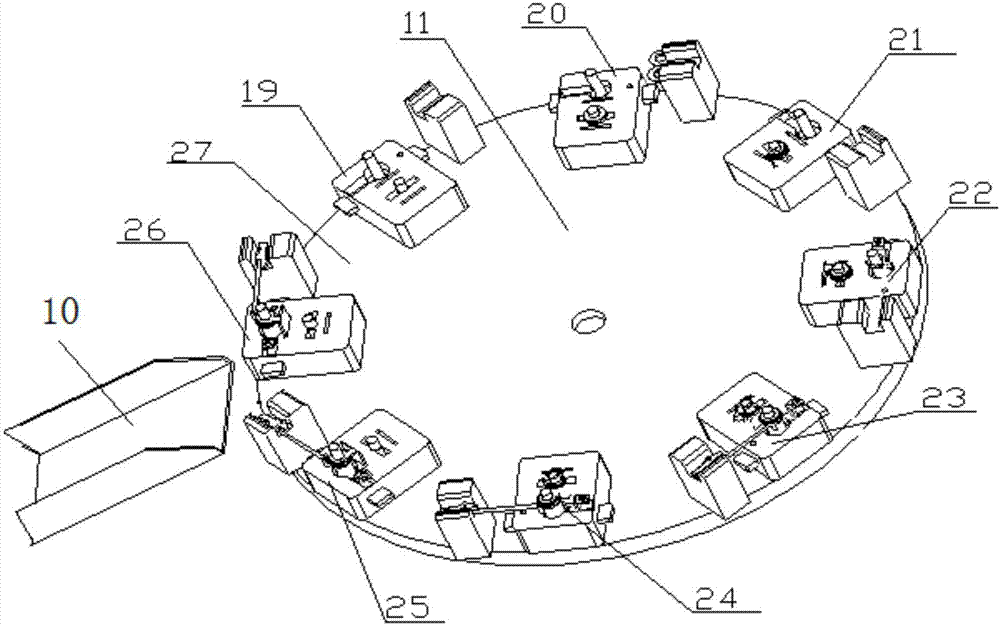

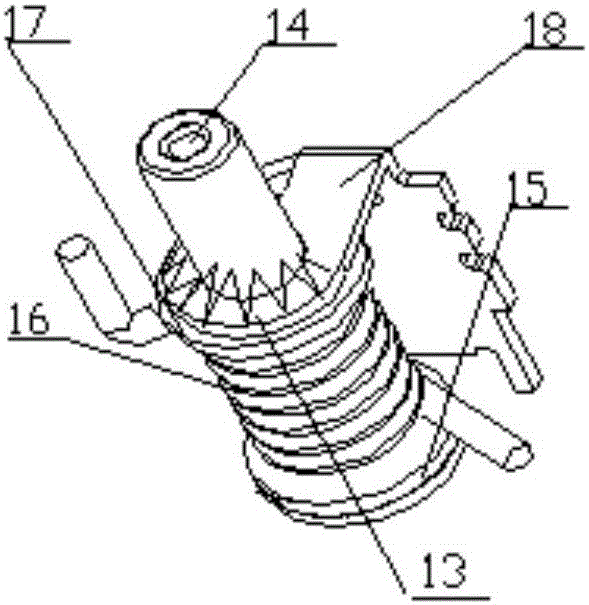

Automatic tin soldering mechanism of coil conductive assembly of low-voltage circuit breaker and welding system of coil conductive assembly of low-voltage circuit breaker

ActiveCN107433375AEliminate WeldingEliminate high failures and jamsMetal working apparatusSoldering auxillary devicesSolderingEngineering

The invention discloses an automatic tin soldering mechanism of a coil conductive assembly of a low-voltage circuit breaker and further discloses a welding system of the coil conductive assembly of the circuit breaker. The welding system of the coil conductive assembly of the circuit breaker comprises a rotating disk assembly. The rotating disk assembly is arranged on a horizontal tabletop. Nine feeding and discharging mechanisms and three detectors are sequentially arranged on the horizontal tabletop around the periphery of the rotating disk assembly. The rotating disk assembly comprises an inner disk and an outer rotating disk. Twelve stations are evenly arranged on the outer rotating disk and are close to the outer side in the circumference direction. The inner disk is provided with eight station starting mechanisms used for driving station clamps to be opened or closed in the circumferential direction. Each station starting mechanisms is connected with a station starting transmission mechanism through a connection rod. The twelve stations are each provided with a station clamp. The twelve station clamps are evenly arranged on the outer rotating disk and are close to the outer side of the outer rotating disk, and the twelve station clamps correspond to the nine feeding and discharging mechanisms surrounding the outer circumference of the rotating disk assembly in position. The welding system of the coil conductive assembly of the low-voltage circuit breaker is compact in structure, reliable in work and high in welding quality.

Owner:YUEQING YEDAO ELECTROMECHANICAL CO LTD

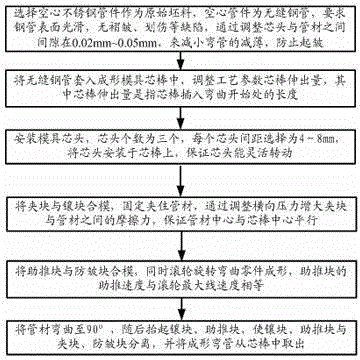

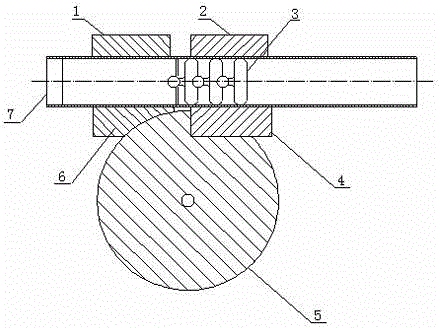

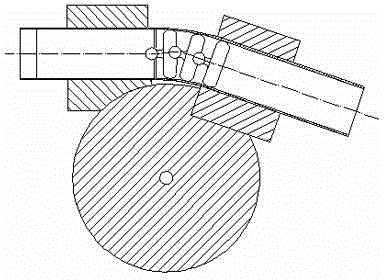

Method for forming ultra-thin stainless steel bend pipe

The invention relates to a method for forming an ultra-thin stainless steel bend pipe. The method comprises the following steps: selecting hollow stainless seamless steel pipe as raw blank, regulating the clearance between a core head and the pipe to reduce the thickness reduction of the bend pipe and prevent corrugation; sleeving the seamless steel pipe in a forming mold core rod, regulating the technology parameters such as mandrel extension; mounting three mold core heads on a mandrel, wherein the distance between the mold core heads is in the range of 4-8 mm and thus the core heads can flexibly rotate; combining a clamping block and an insert block and fixing and clamping the pipe, guaranteeing the center of the pipe paralleled to the center of the mandrel by regulating the transverse pressure and increasing the friction force between the clamping block and the pipe; combining a push aid block and an anti-corrugation block, allowing a roller to rotate, forming a bend part, wherein the push aid speed of the push aid block is equal to the maximum linear velocity of the roller; bending the pipe to 90 degrees, lifting up the insert block and the push aid block, separating the insert block and the push aid block from the clamping block and the anti-corrugation block, and taking the formed bend pipe from the mandrel.

Owner:SHANGHAI SPACE PRECISION MACHINERY RES INST

Modular rack system with gussetless joints

ActiveUS20140305979A1Eliminate weldsImprove the preparation effectPedestrian/occupant safety arrangementSupplementary fittingsGusset plateModularity

A modular rack system, for adjustably attaching equipment to a vehicle, includes a base mountable on a side wall of the vehicle. The rack system has a first wall that is disposed on and upwardly emanating from the top surface of the base that defines a lower seat. One end of a vertical member resides in the lower seat and is secured thereto. The other end of the vertical member resides in an upper seat defining by a downwardly depending wall from a saddle and is secured thereto. The first and second walls laterally stabilize the vertical member relative to the base and saddle to permit the base to be mounted to a side wall of a vehicle and a top rail to be secured to the saddle without the use of gussets or cross-braces.

Owner:THULE INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com