Load increasing container flat wagon body applicable to running on Thailand meter-gage railway

A container and railway technology, used in railway car body parts, transport passenger cars, transportation and packaging, etc., can solve problems such as large local deformation, deterioration of stress concentration level, and reduced life expectancy, achieve high vertical and torsional stiffness, and relieve stress. Concentration level, effect of vehicle dynamics improvement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The present invention will be described in detail below in conjunction with the accompanying drawings and embodiments.

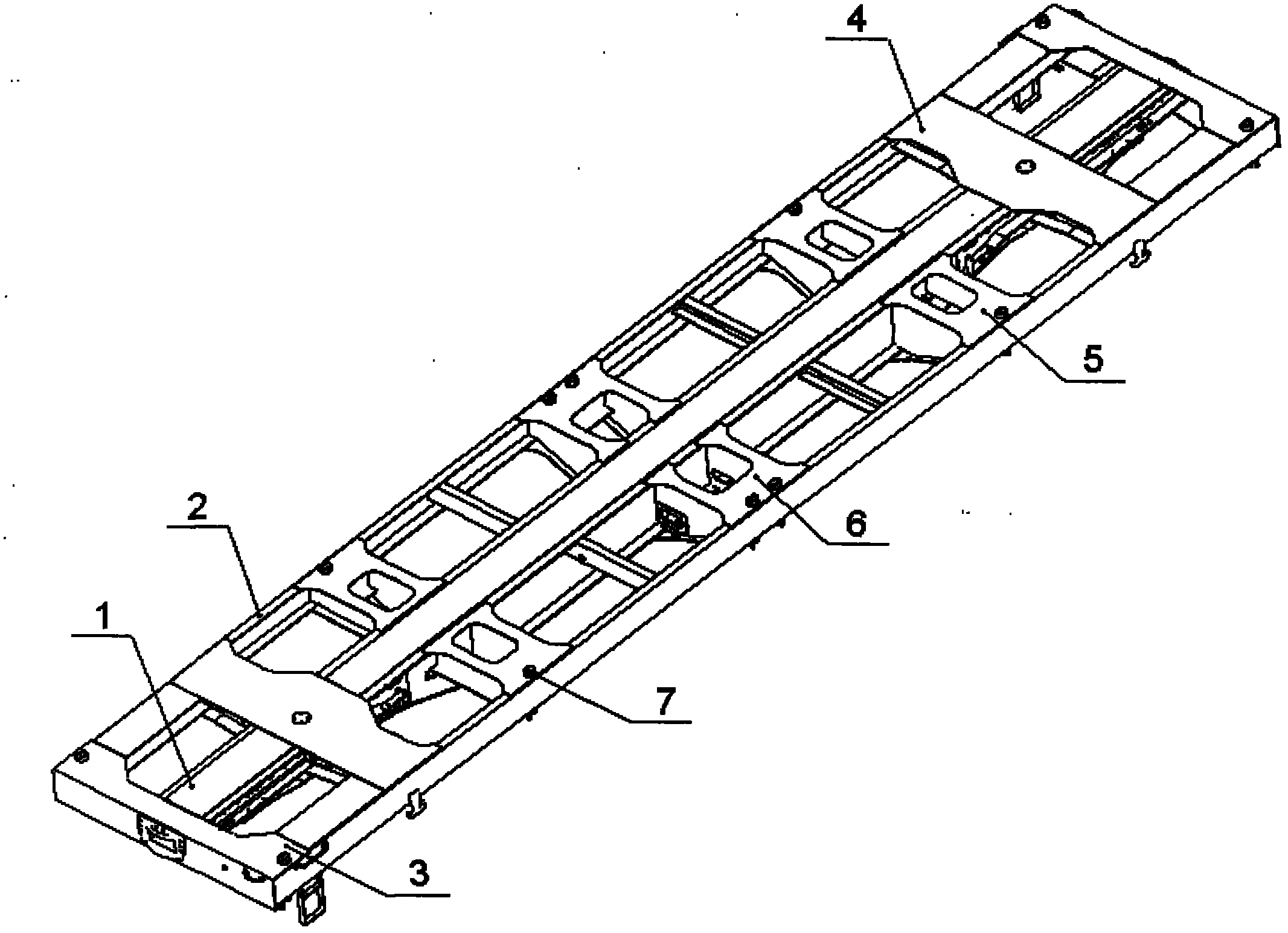

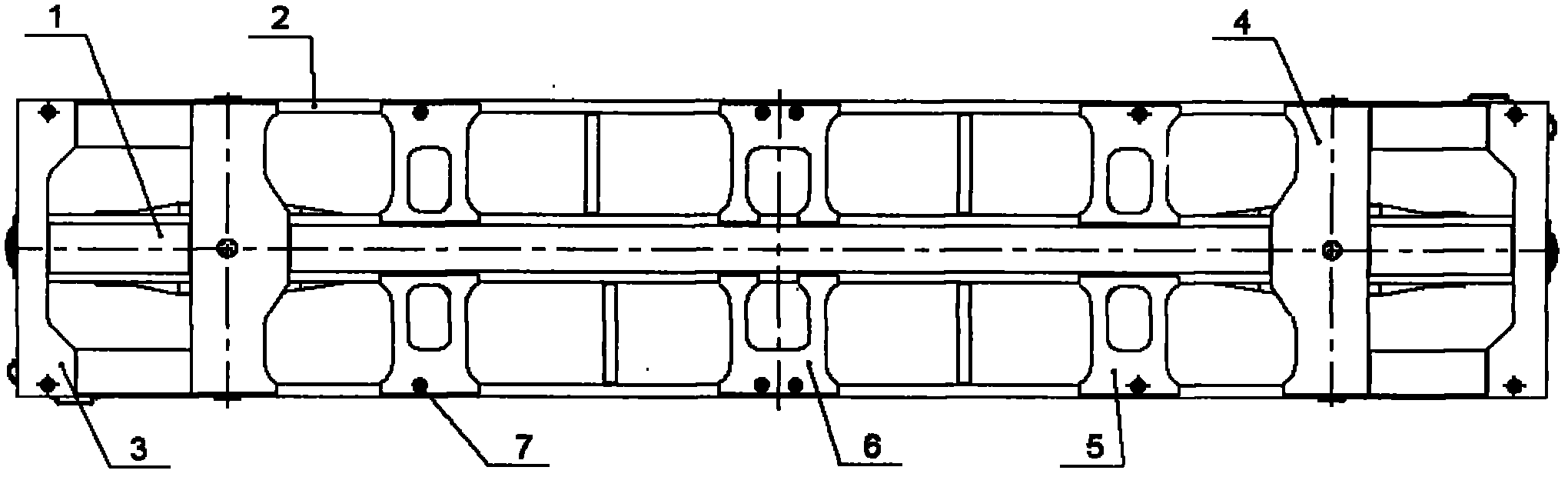

[0024] like figure 1 , figure 2 As shown, the present invention comprises a middle sill composition 1, two side sills 2, two end sills 3, two corbels 4, four single-lock crossbeams 5, two double-lock crossbeams 6 and several containers Locking device 7.

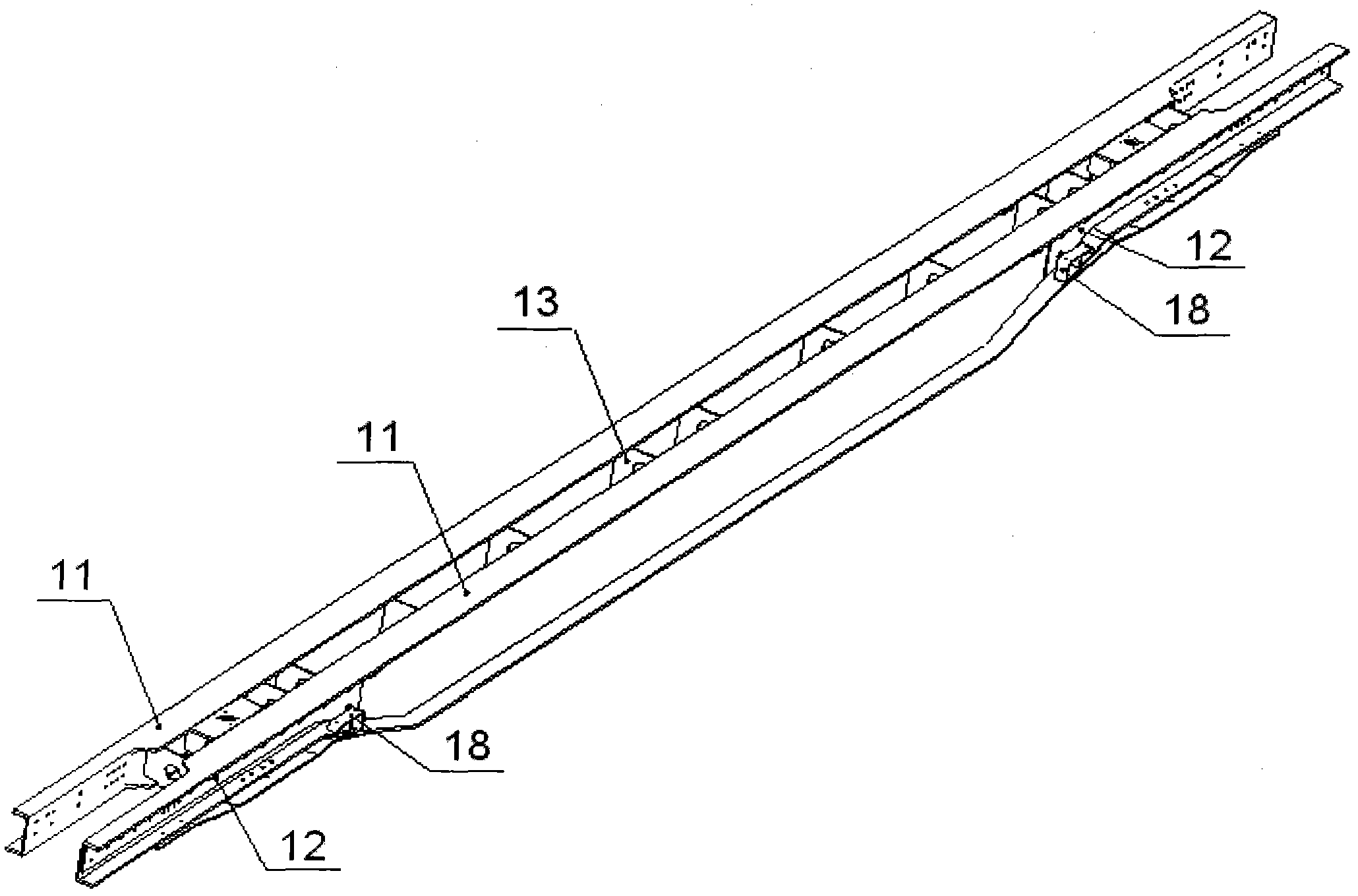

[0025] like Figure 3 ~ Figure 6As shown, the center sill composition 1 consists of a center sill 11, a traction beam web reinforcement plate 12, a center sill partition 13, a center sill upper cover 14, a center sill lower cover 15, an upper center plate 16, and a center plate reinforcement 17 And axle lifting seat 18 forms. There are two middle beams 11 arranged in parallel. The middle beam 11 is cut into a fish-belly shape by using H-shaped steel, so as to realize the transition from the large cross-section height in the middle of the middle beam 11 to the 250mm section height of the traction...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com