Method for forming steel liquid storage cylinder

The technology of a liquid storage tank and a liquid storage tank is applied in other household appliances, household appliances, applications, etc., which can solve the problems of long mold and tooling manufacturing cycle, low equipment utilization rate, and high degree of process coordination, so as to improve the product qualification rate. The effect of resistance to pressure, improving turnover between processes, and improving equipment utilization

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

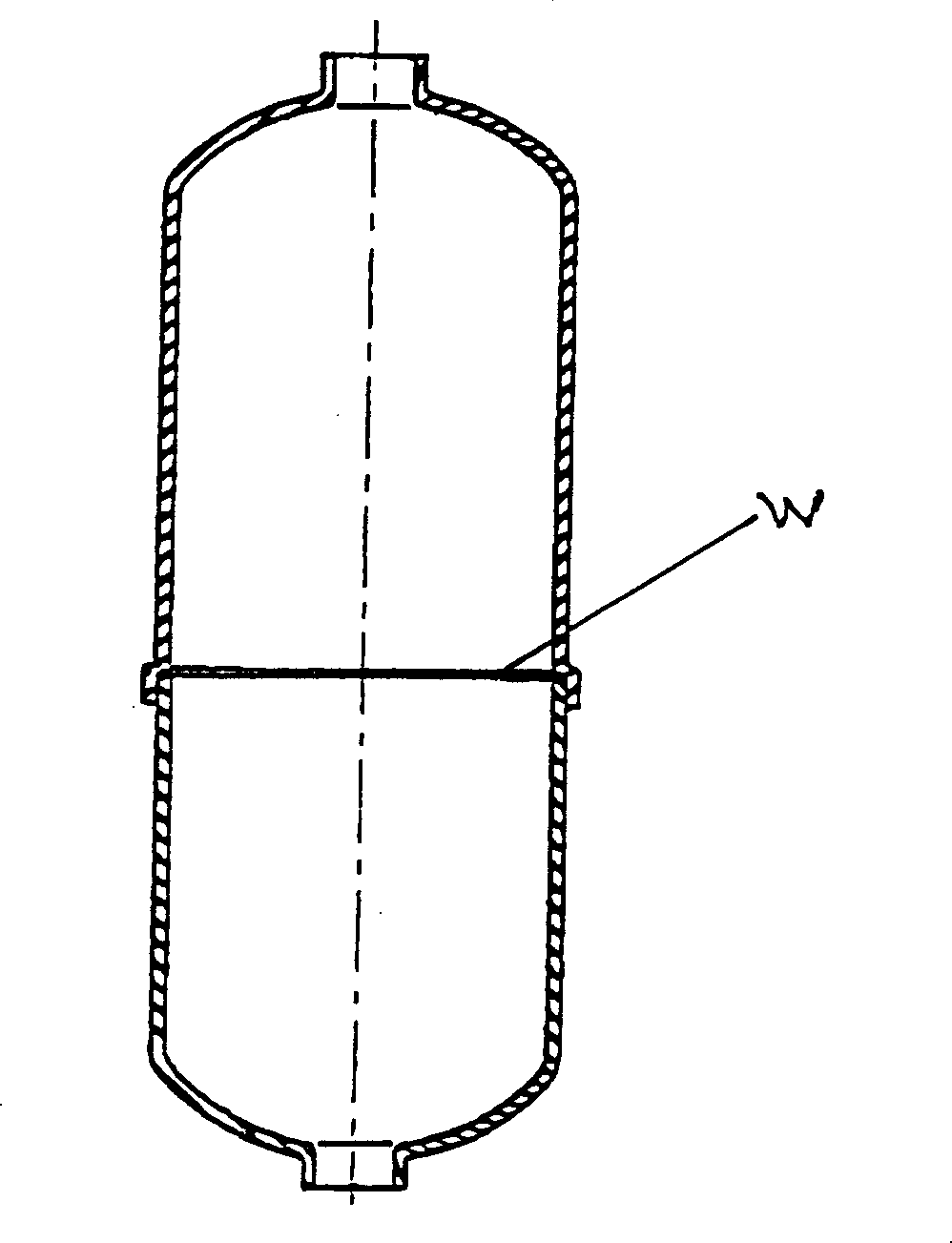

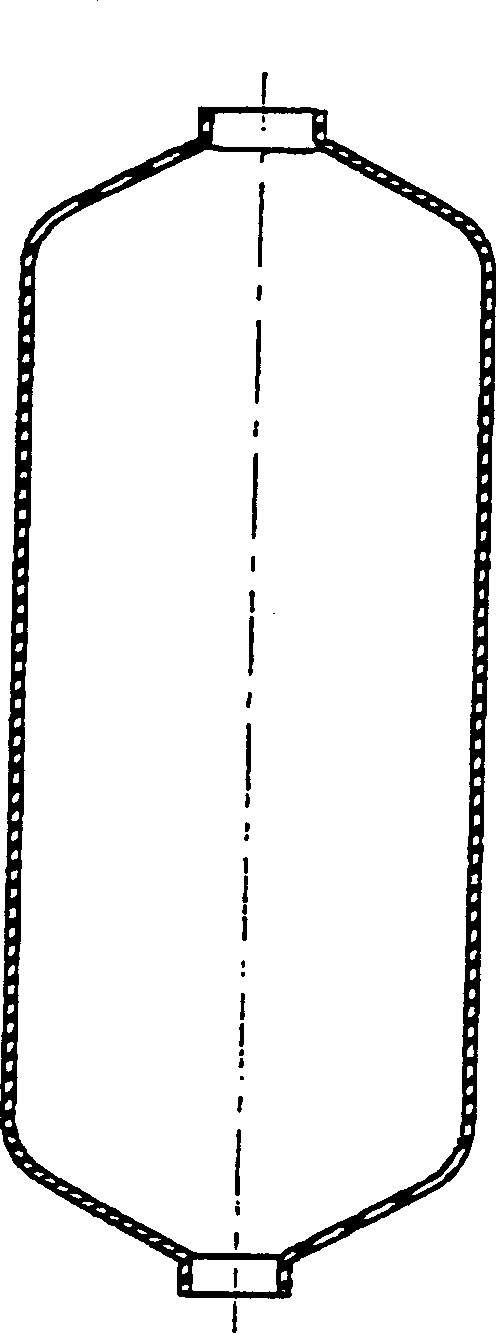

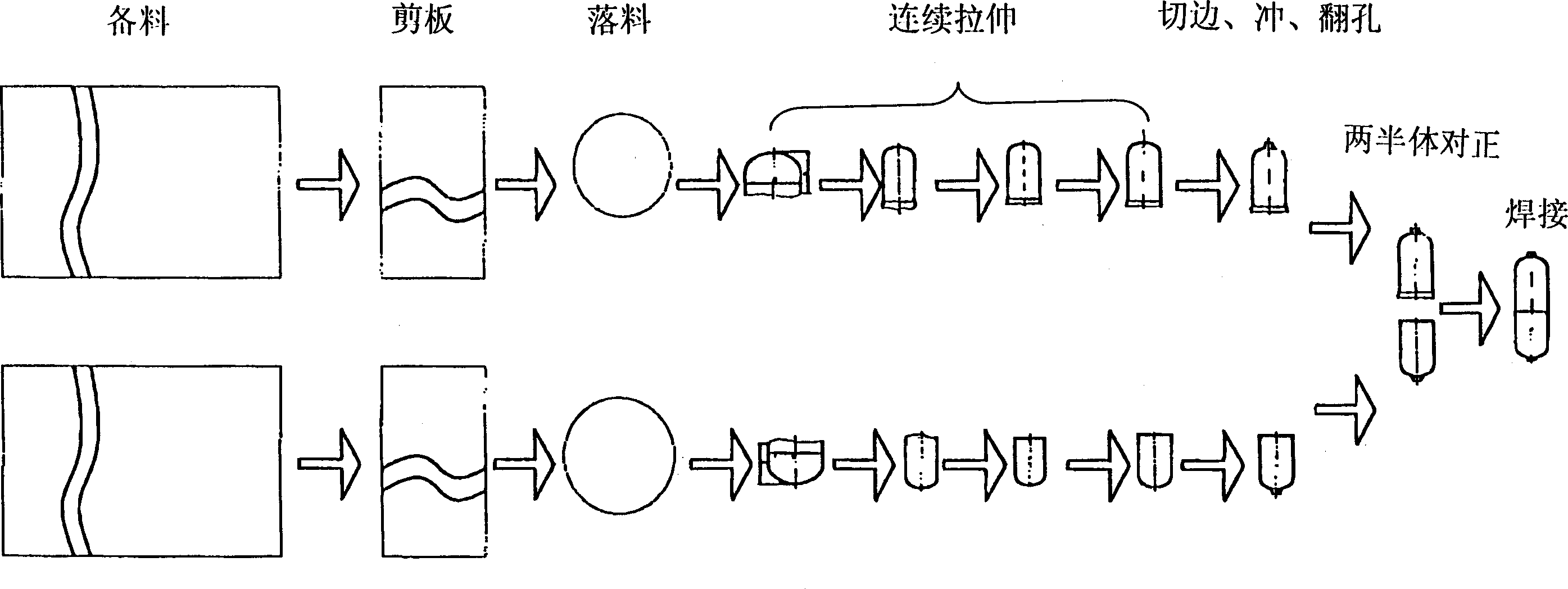

[0011] Such as figure 2 As shown, it is the cylinder structure of the steel liquid reservoir made by the spinning forming method of the present invention, which replaces the figure 1 The shown steel reservoir cylinder structure with circular welds W made by stamping and stretching has a smooth surface without welds. Such as Figure 4 Shown is the spinning forming process flow of the steel liquid storage cylinder of the present invention. The spinning forming method uses ST14 cold-drawn steel pipes as raw materials. After preparing materials, the prepared ST14 cold-drawn steel pipes are cut off and reused. Spinning machine is used for spinning forming, that is to say, it is made into an integral steel reservoir cylinder without welds.

[0012] The spinning forming method of the cylinder body of the steel liquid storage device in the present invention is technically difficult and involves technologies such as material mechanics, material composition, performance, heat treatme...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com