Online detection system and detection method for hydraulic equipment

A technology of hydraulic equipment and detection system

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

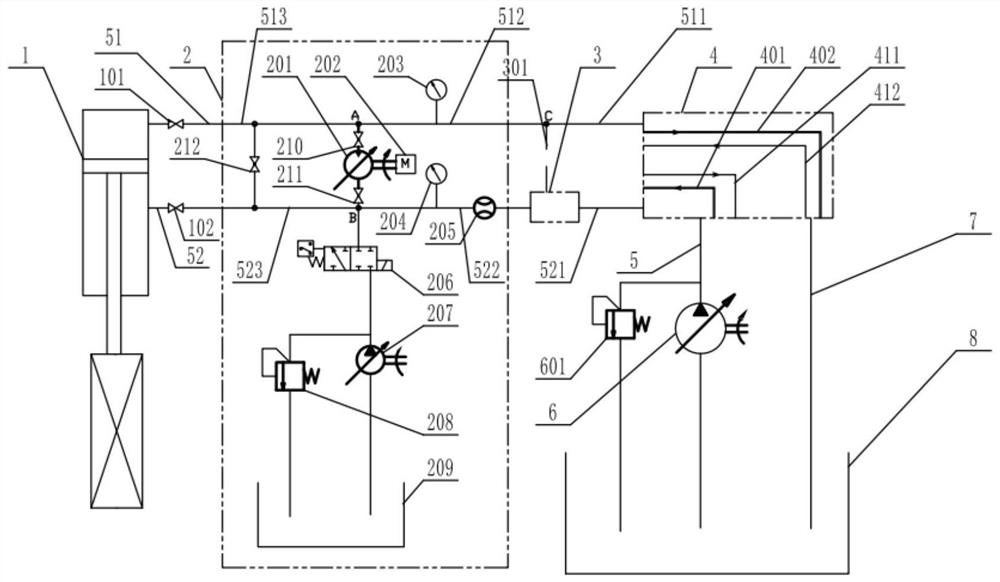

[0070] Such as figure 1 As shown, the embodiment of the present invention provides an online detection system for hydraulic equipment. The online detection system for hydraulic equipment includes: a hydraulic cylinder 1 , a hydraulic control system, and a detection circuit 2 .

[0071] Specifically, the hydraulic cylinder 1 is used to open and close the gate, and the hydraulic cylinder 1 has a rodless cavity and a rod cavity; the hydraulic control system communicates with the rodless cavity through a rodless cavity pipeline 51, The hydraulic control system communicates with the rod chamber through the rod chamber pipeline 52, and the rodless chamber pipeline 51 and the rod chamber pipeline 52 are respectively provided with a rodless chamber valve 101 and a rod chamber pipeline. chamber valve 102; the detection circuit 2 includes a hydraulic motor 201 and a communication valve 212 respectively arranged in parallel with the hydraulic cylinder 1, and the communication valve 212 i...

Embodiment 2

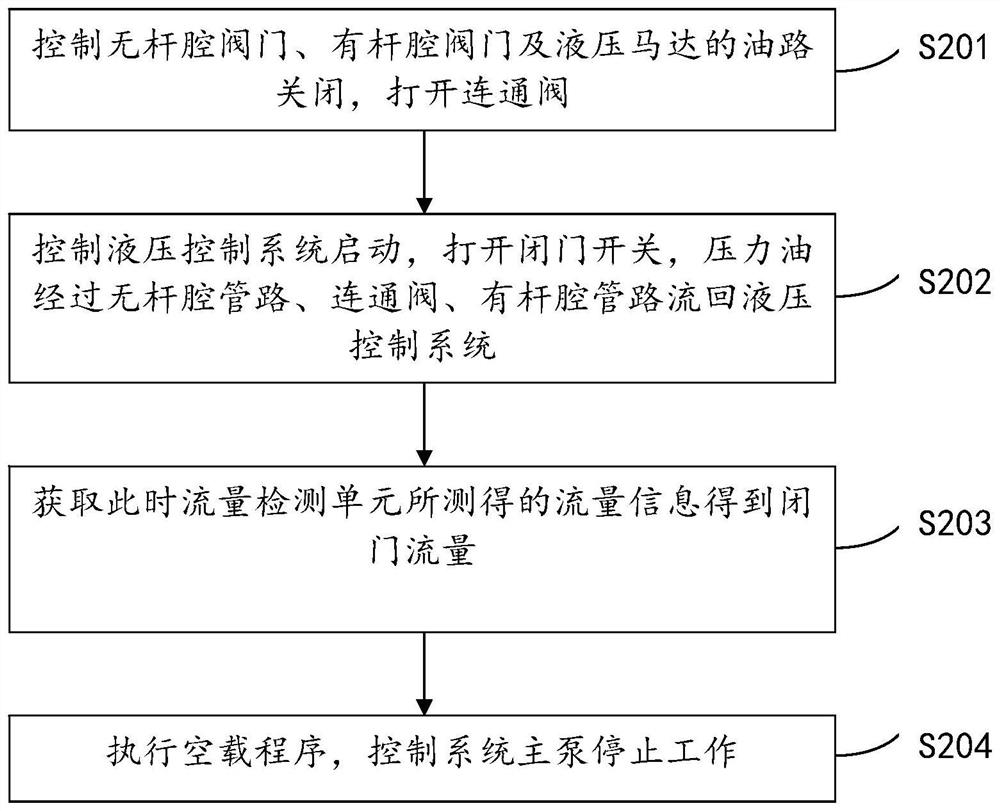

[0100] Such as Figure 1 to Figure 4 As shown, the embodiment of the present invention provides an online detection method for hydraulic equipment, and the online detection method includes the online detection system for hydraulic equipment described in Embodiment 1 above.

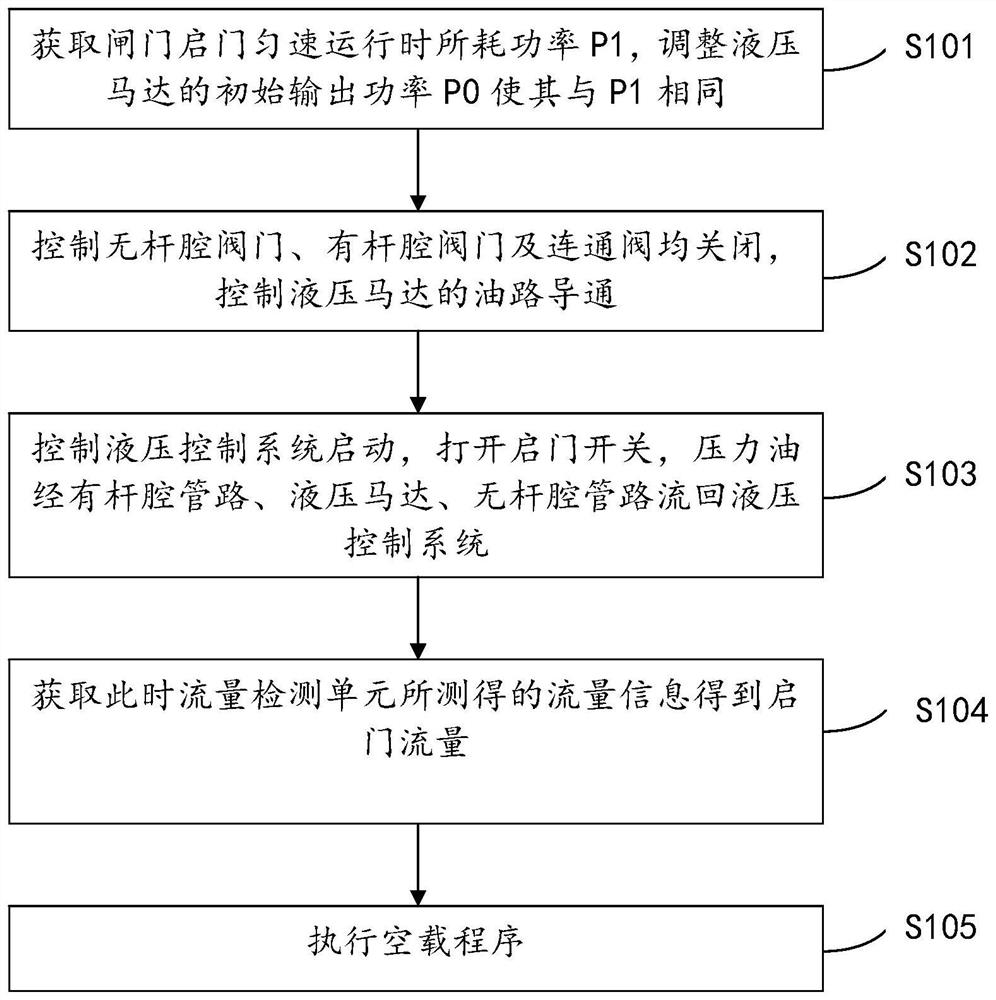

[0101] In the first implementation of this embodiment, the hydraulic equipment online detection method includes door opening pressure, flow (speed) detection method, combined with figure 1 , figure 2 As shown, the door opening flow detection method includes:

[0102] Execute the door opening detection program, which specifically includes the following steps:

[0103] S101: Obtain the power P1 consumed when the gate is opened at a constant speed, and adjust the initial output power P0 of the hydraulic motor 201 to be the same as P1;

[0104] S102: control the non-rod chamber valve 101, the rod chamber valve 102 and the communication valve 212 to be closed, and control the conduction of the oil circuit o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com