Patents

Literature

54results about How to "Improve qualification" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

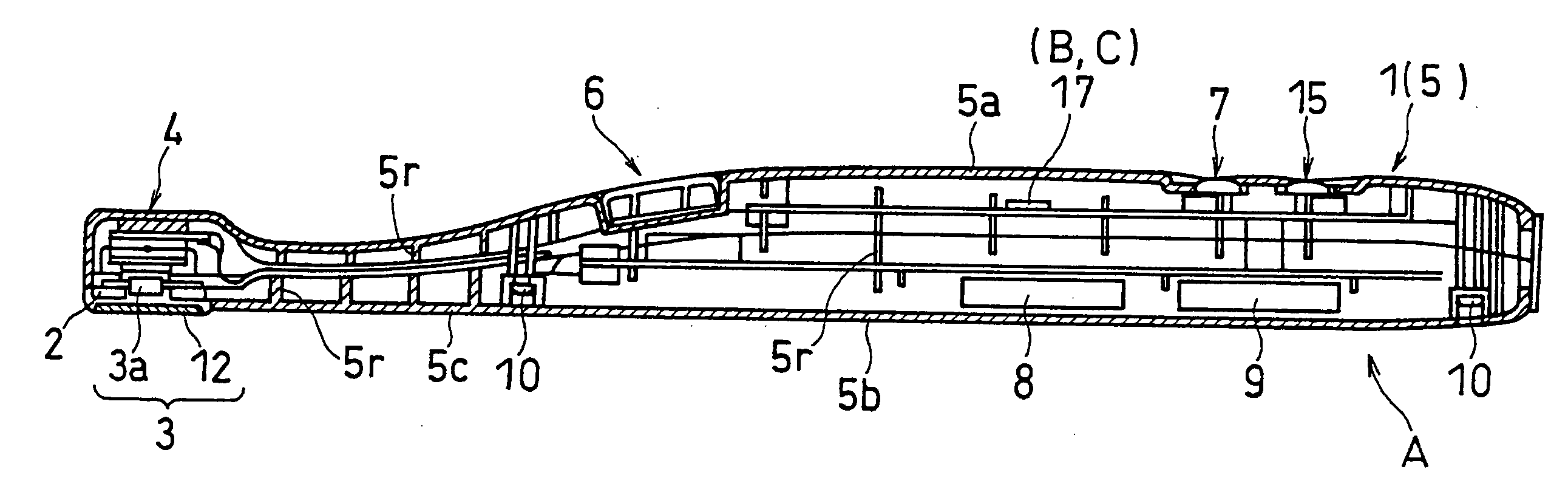

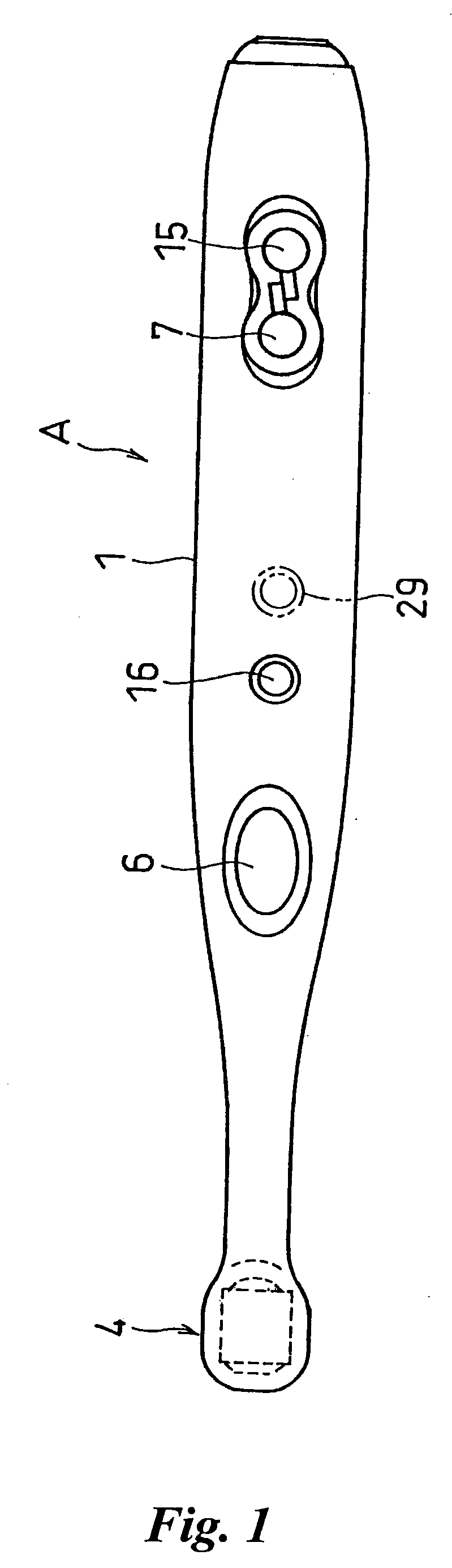

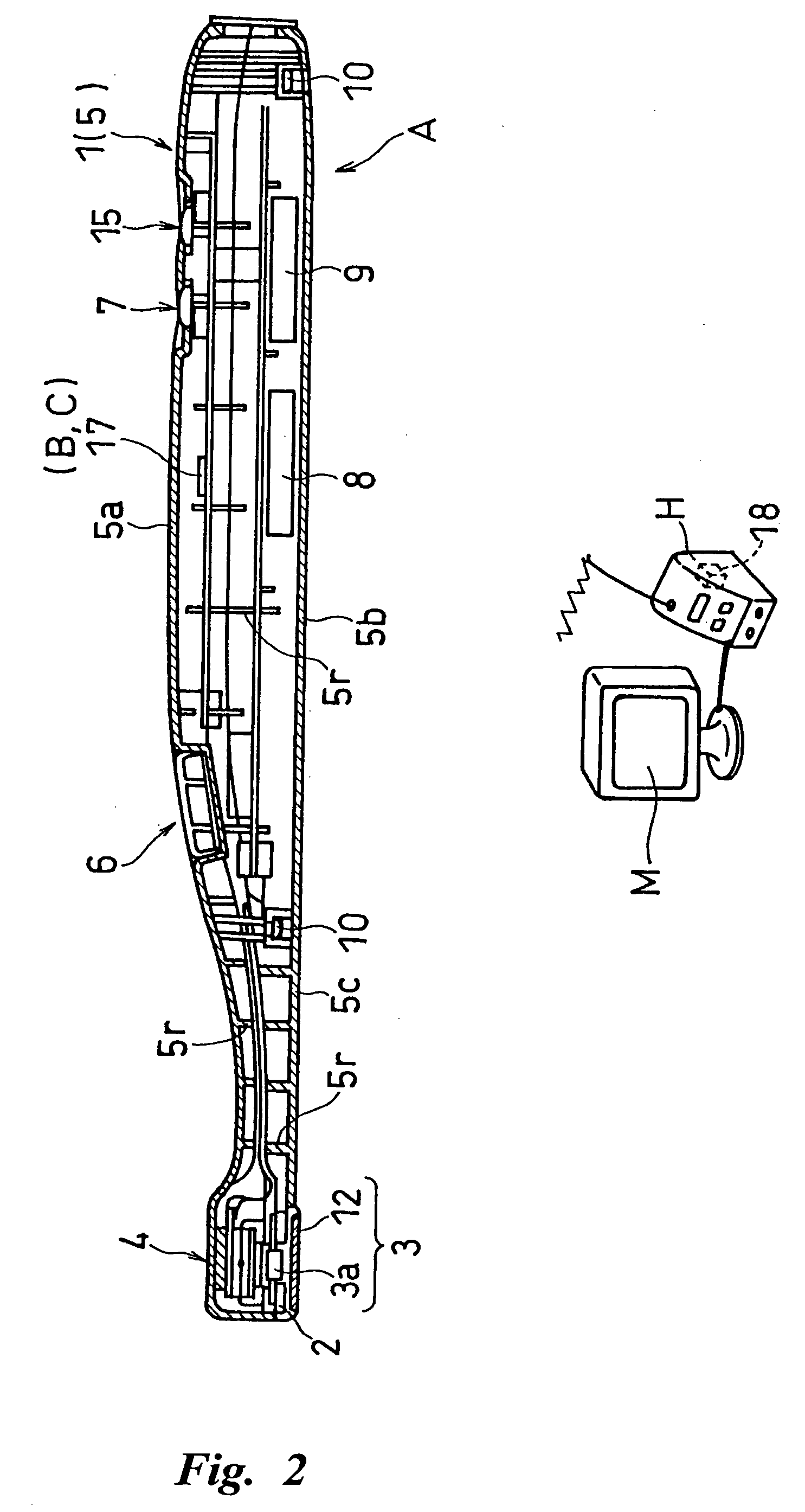

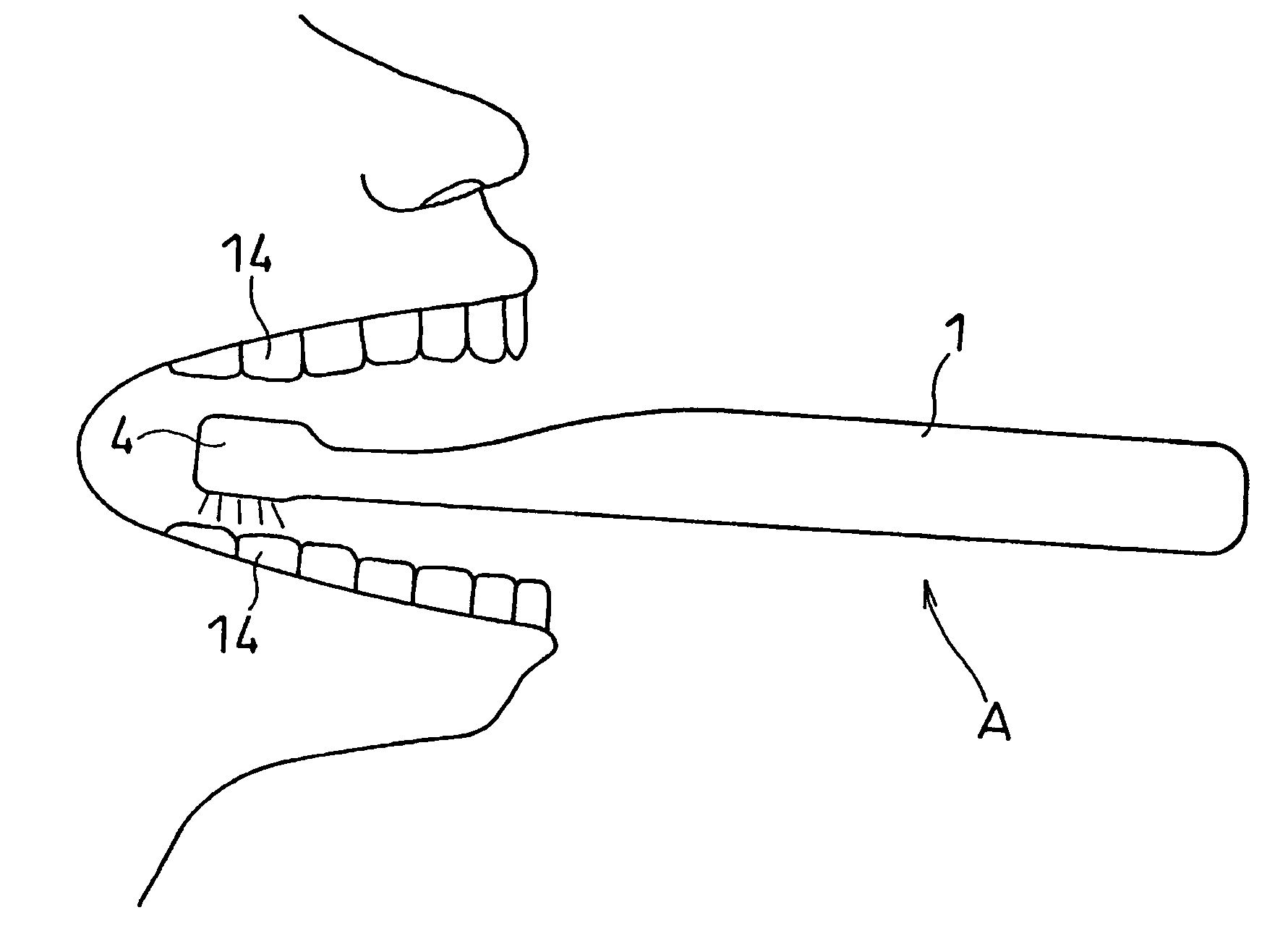

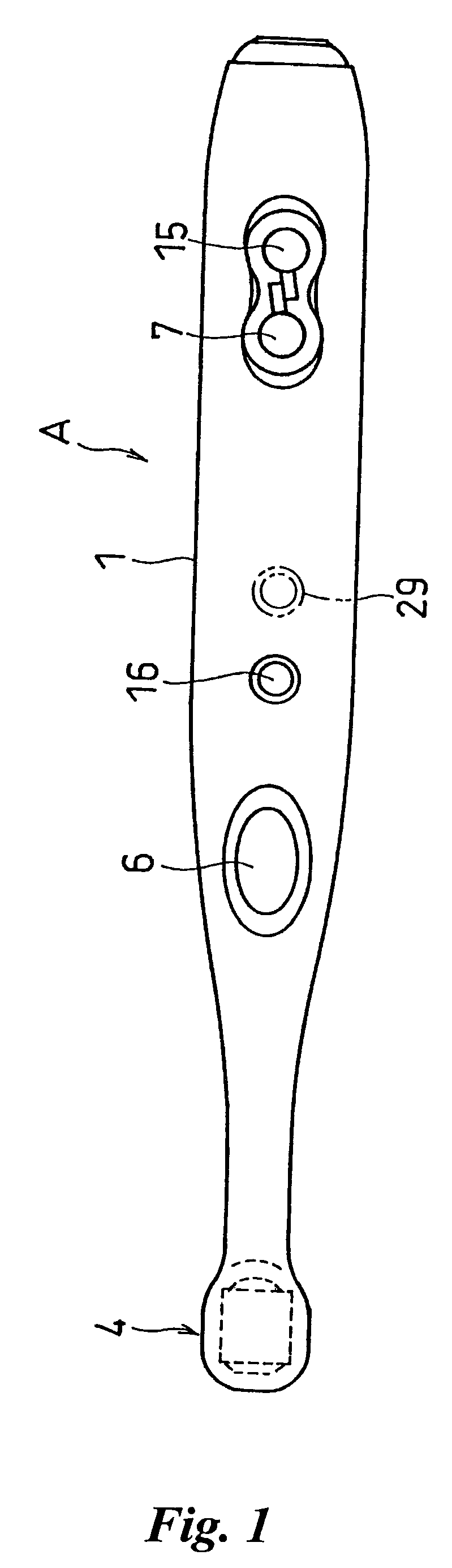

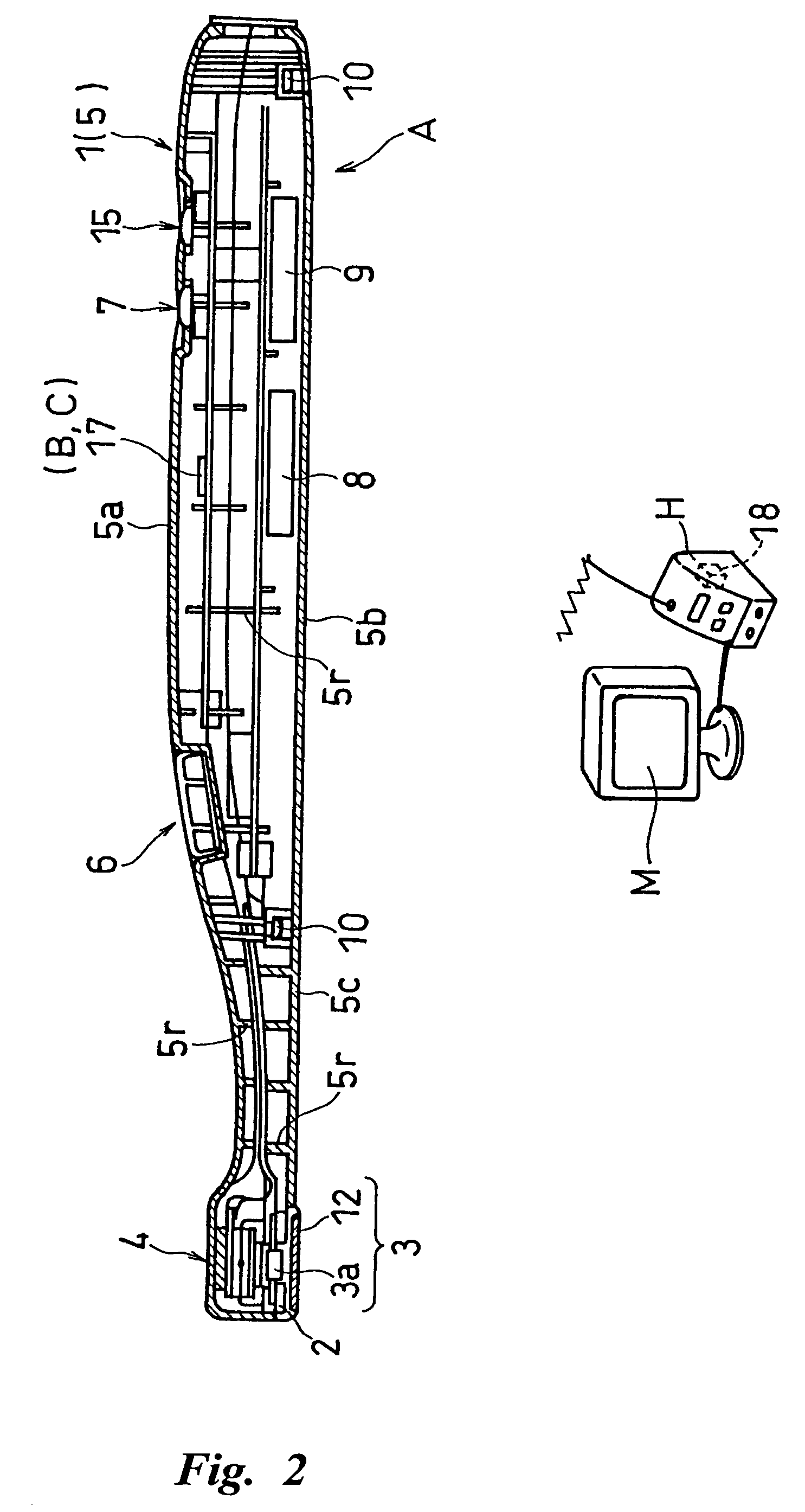

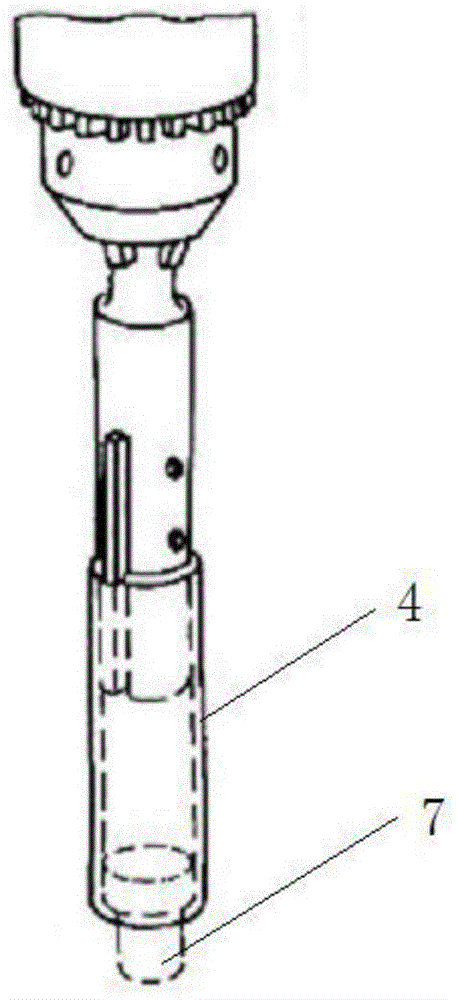

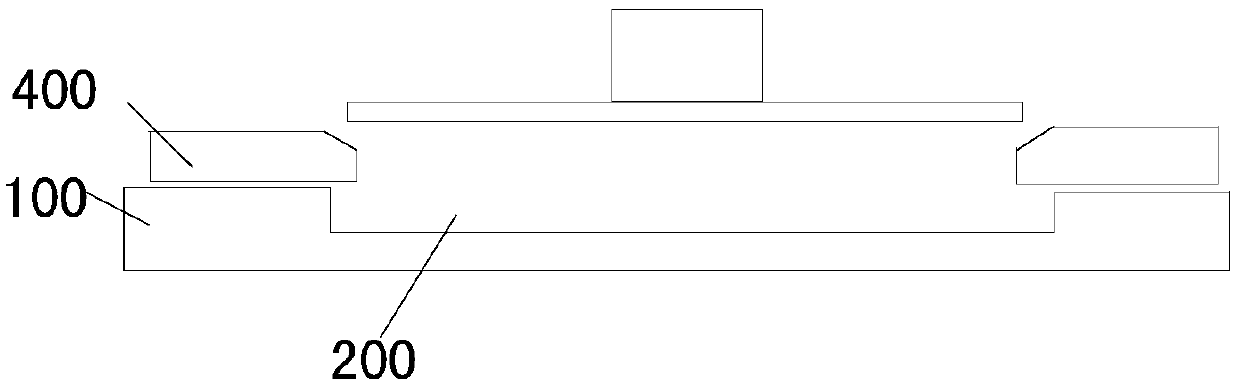

Diagnostic imaging apparatus

InactiveUS20050003323A1Reduce adverse effectsAccurate diagnostic image informationSurgeryEndoscopesFluorescenceHand held

A diagnostic imaging apparatus of hand piece type suitable for medical or dental use, comprising a main body held by operator's fingers, a luminous means for irradiating at least one of lights selected from excitation light, infrared light and ultraviolet light, and an imaging means provided in a forward portion of the main body. The imaging means comprises a solid-state image sensing device and an optical means for forming an optical image of a diagnosis object to be examined on the solid-state image sensing device and is so constructed as to output a predetermined diagnostic image information by receiving the light reflected from the diagnosis object and / or the fluorescence generated from the diagnosis object when irradiation of light from the luminous means to the diagnosis object is performed.

Owner:MORITA MFG CO LTD

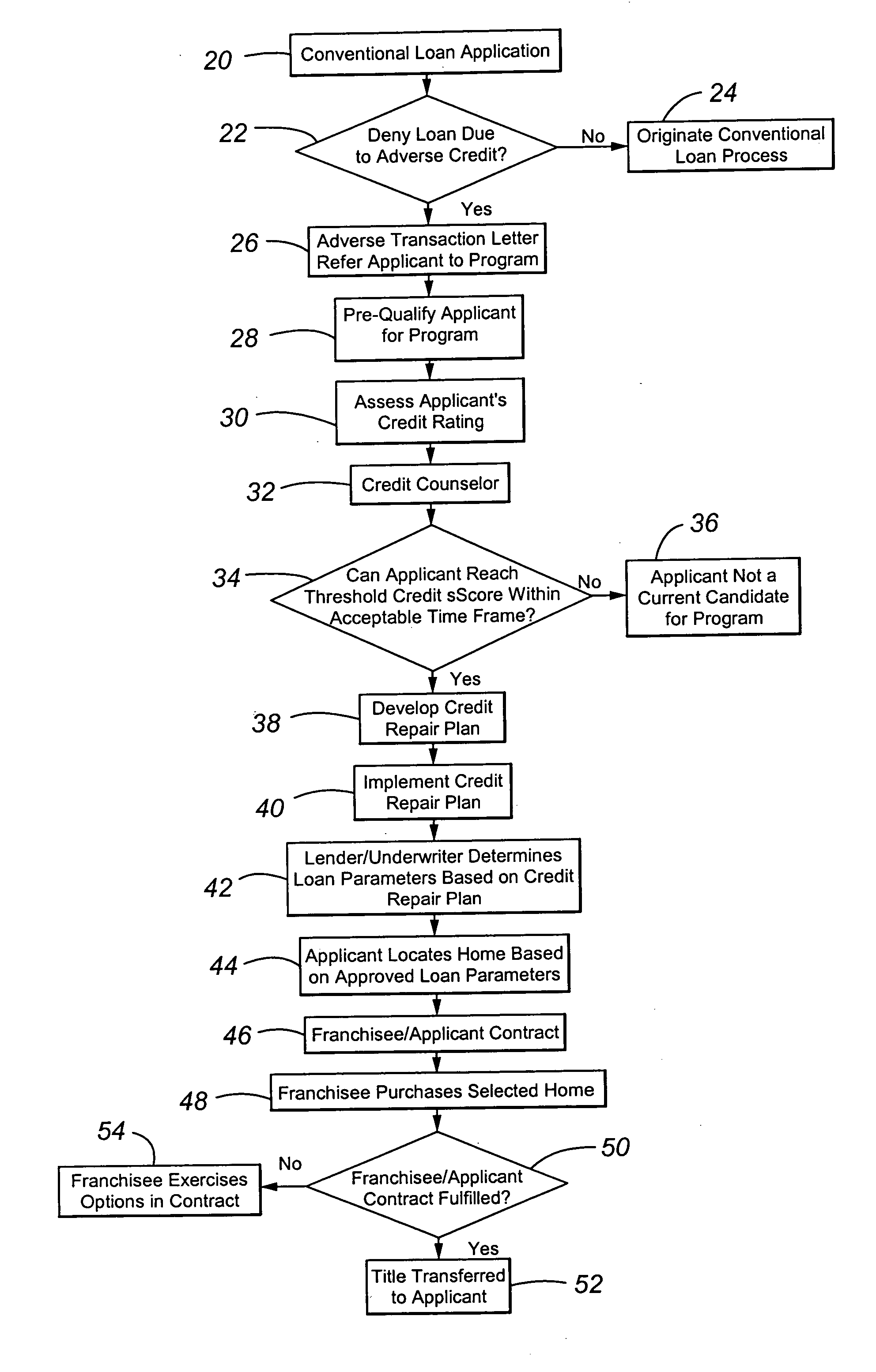

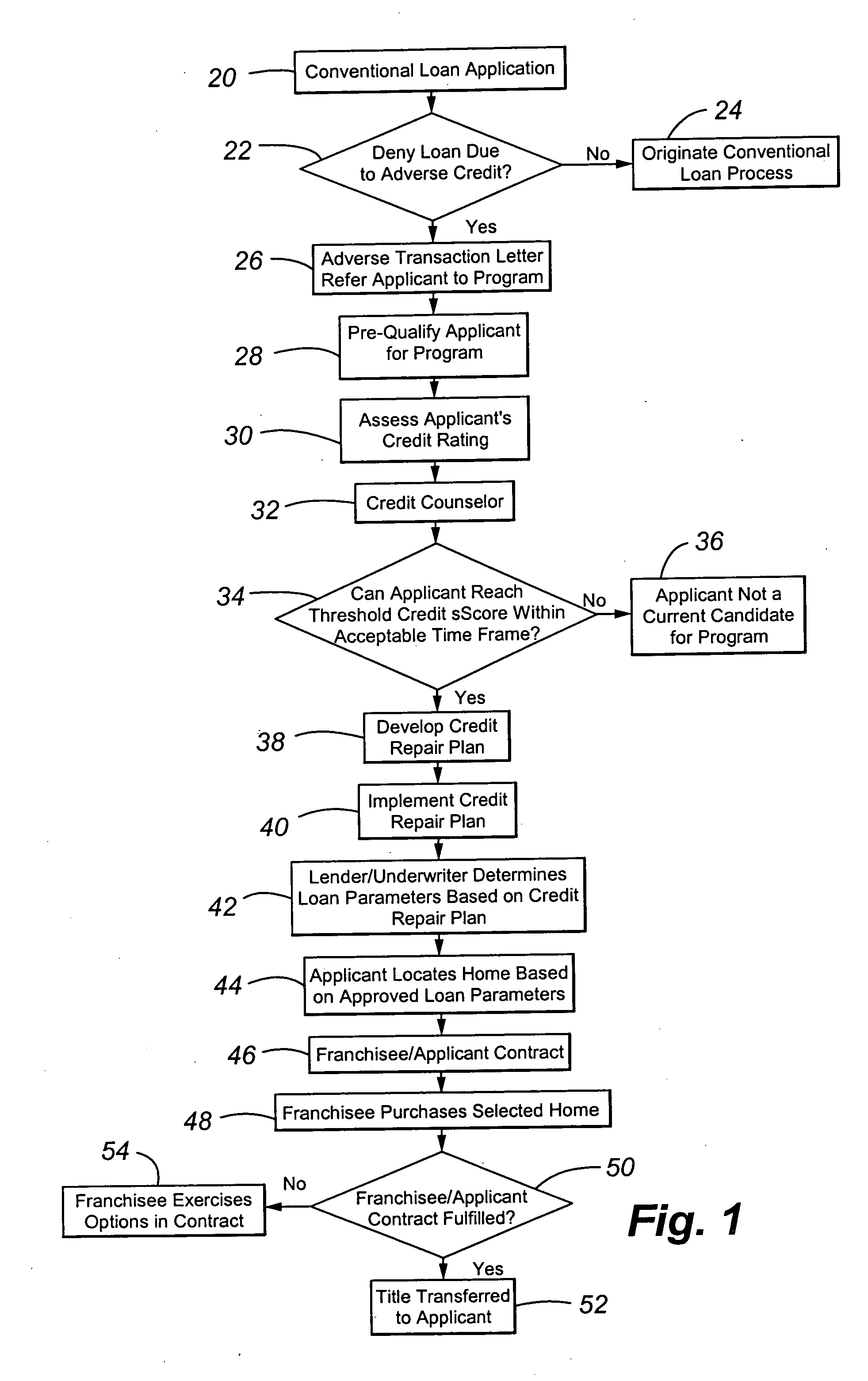

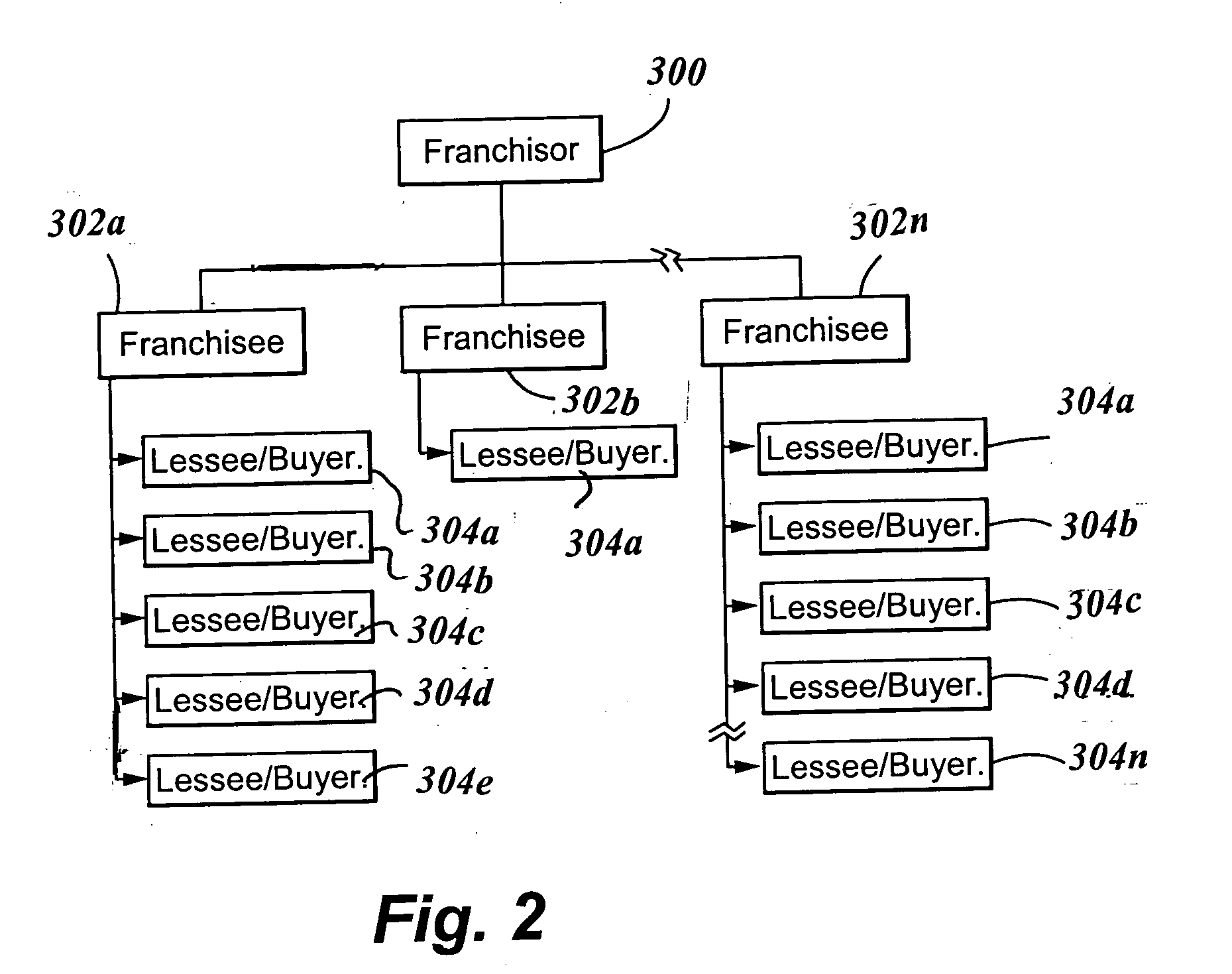

Method of financing home ownership for sub prime prospective home buyers

InactiveUS20050251474A1Increase ratingsImprove qualificationFinancePayment architectureProgram planningFranchise

A program for purchasing homes is disclosed. The program is primarily intended for individuals with a poor or sub prime credit rating that precludes them from qualifying for conventional home loan financing. The individuals improve their credit rating as part of the program. The program is preferably operated as a franchise in which franchisees initially purchase homes on behalf of the individuals, lease the homes to the individuals according to a contract entered prior to purchasing the home and, upon successful fulfillment of the lease, the home is sold to the individual using conventional financing. The fulfillment of the lease-to-own contract assists in improving the individual's credit rating and assists in positioning the individual to qualify for conventional home loan financing.

Owner:SHINN MICHAEL +4

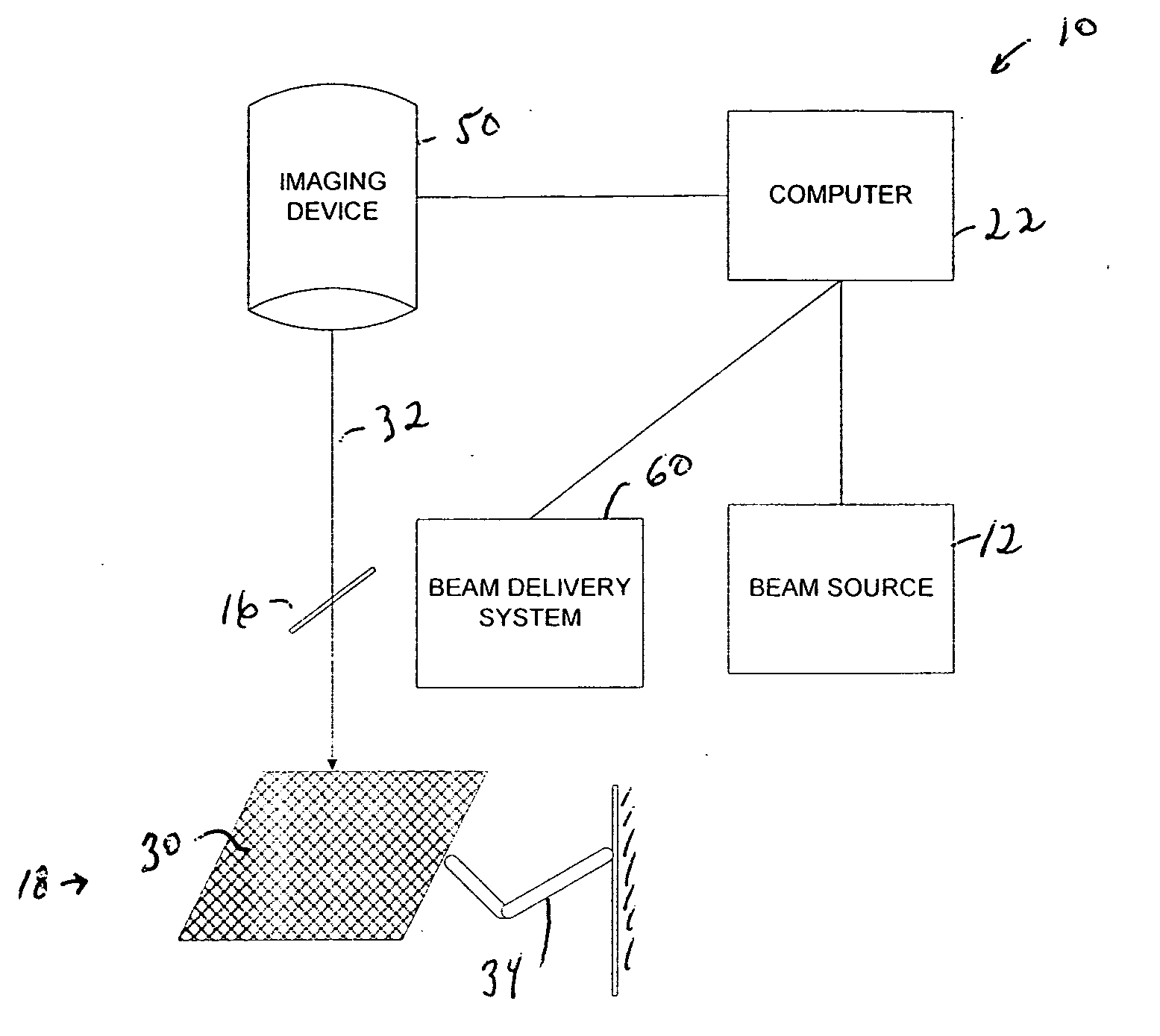

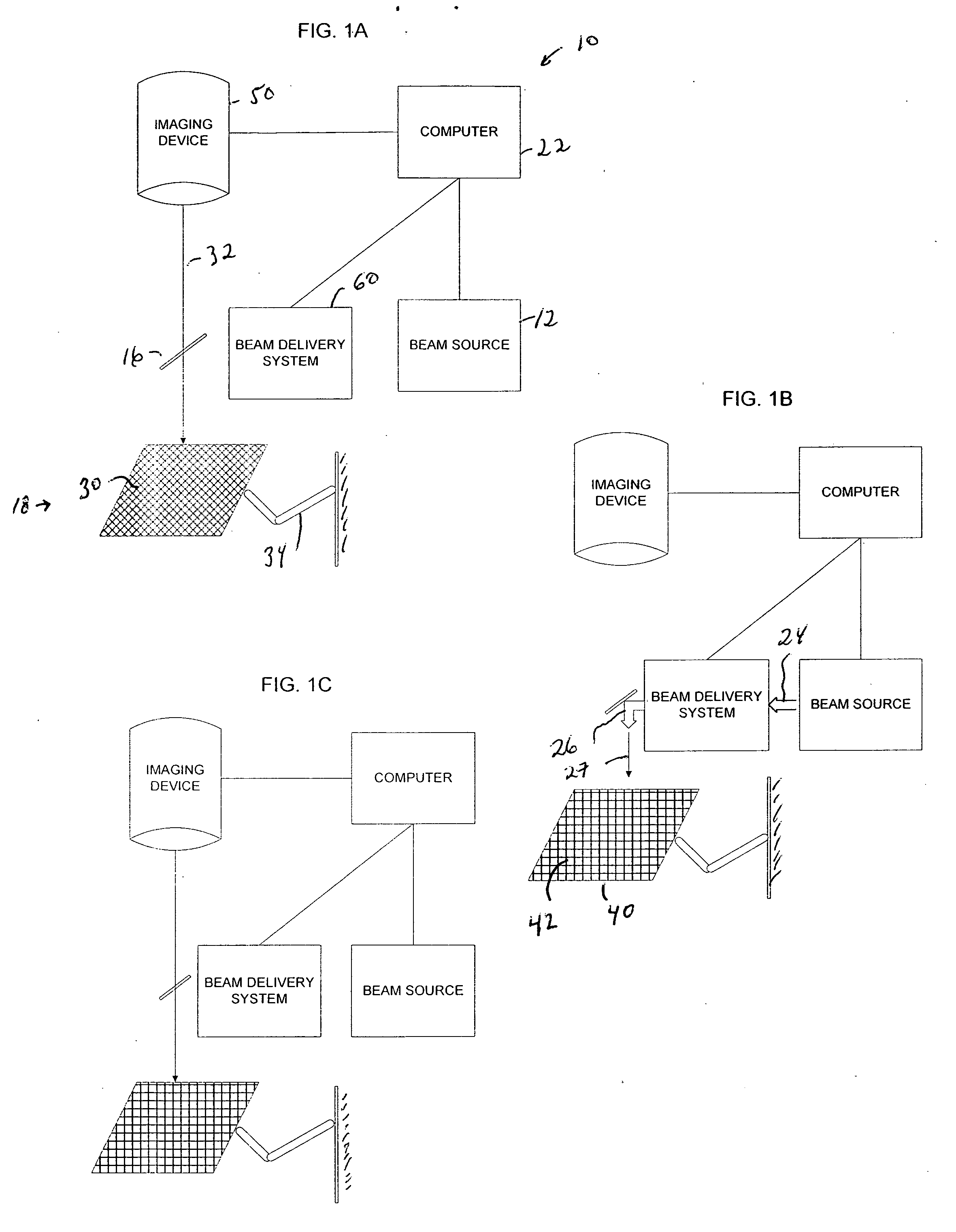

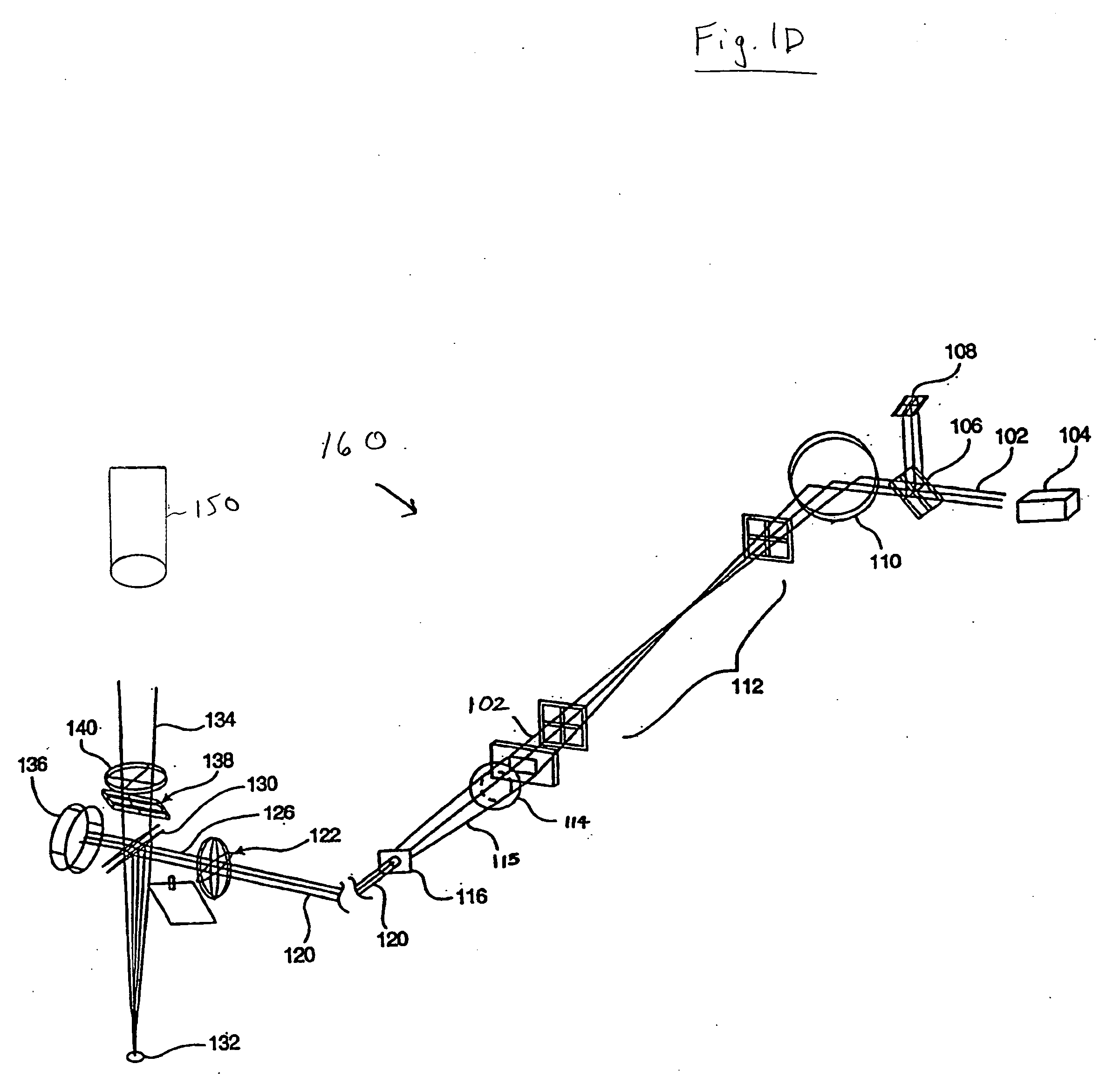

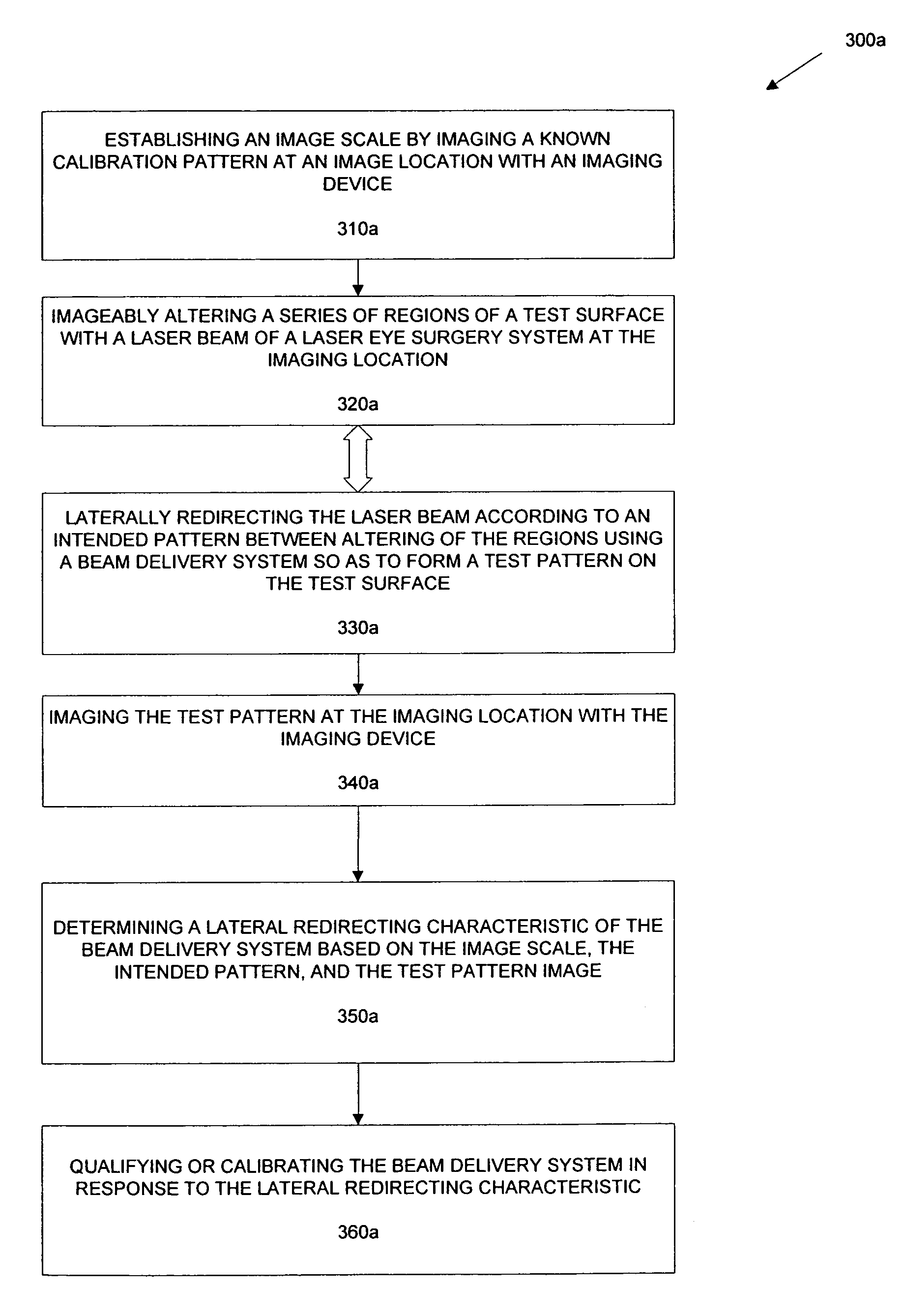

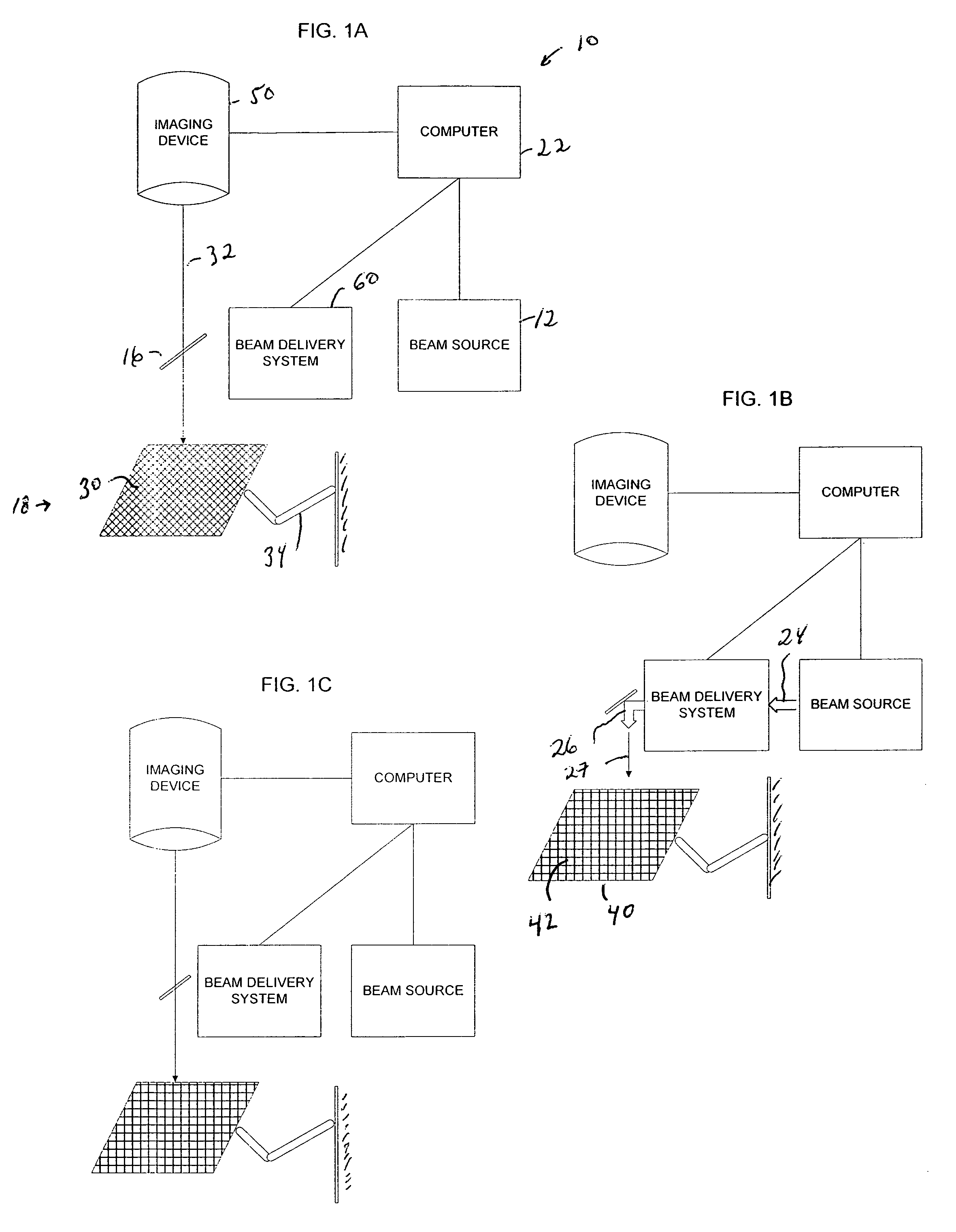

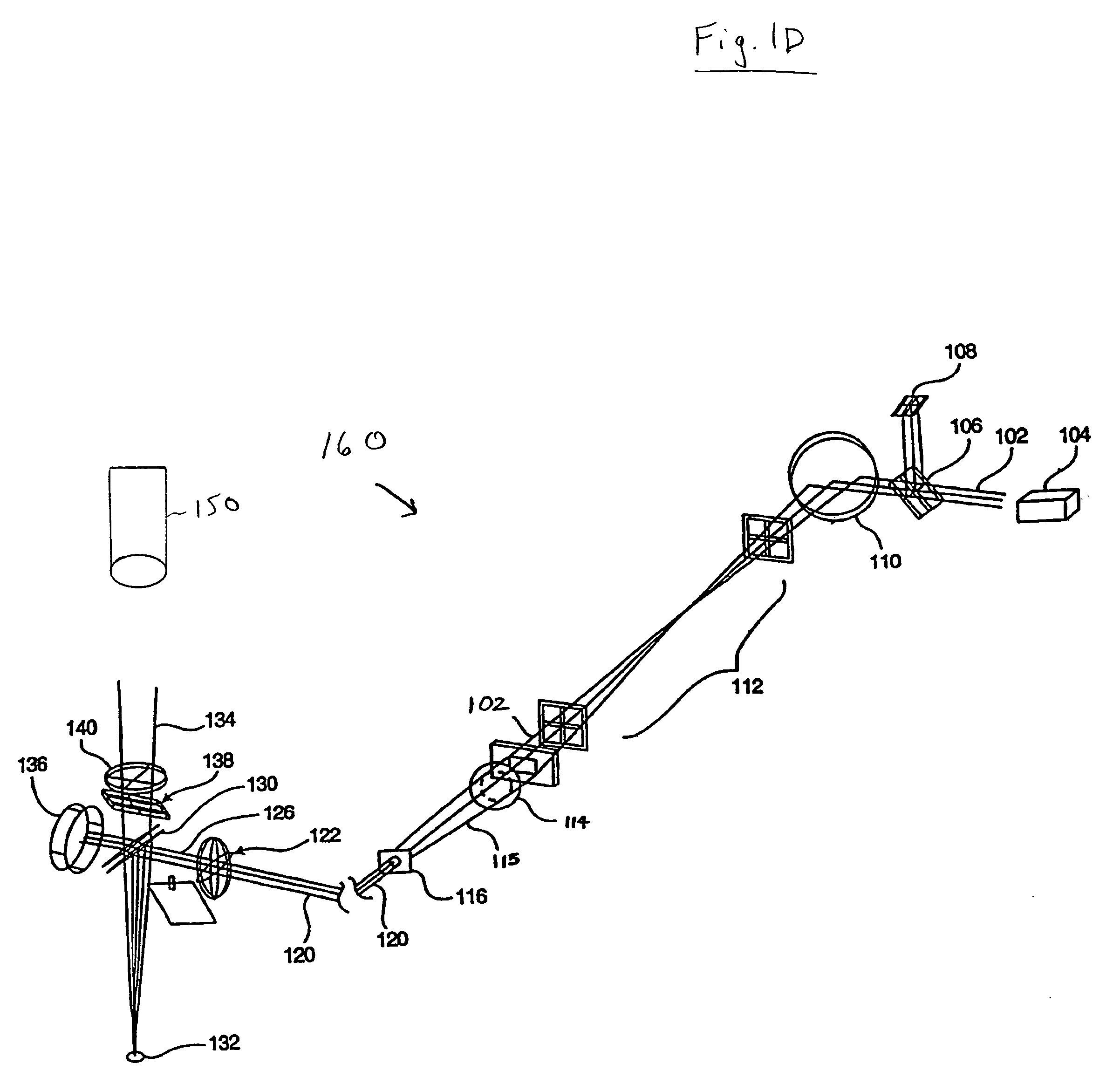

Systems and methods for qualifying and calibrating a beam delivery system

ActiveUS20070173792A1Improve qualificationImprove calibration accuracyLaser surgerySurgical instrument detailsLight beamImage scale

Systems and methods for testing a laser eye surgery system are provided. Methods include establishing an image scale based on a calibration pattern, imageably altering a series of regions of a test surface with the laser system, laterally redirecting a laser beam to form a test pattern, imaging the test pattern, determining a lateral redirecting characteristic of the beam delivery system, and qualifying or calibrating the beam delivery system. Systems can include an input module that accepts an input member such as a calibration pattern parameter, a calibration pattern image, an intended pattern parameter, a test pattern image, an imaging device position, a calibration pattern position, a test pattern position, and a beam delivery system position, a characterization module that determines a beam delivery system characteristic, and an output module that generates a calibration for the beam delivery system of the laser eye surgery system.

Owner:AMO MFG USA INC

Diagnostic imaging apparatus

InactiveUS7570984B2No fear of X-ray exposureEasy to handleSurgeryEndoscopesFluorescenceUltraviolet lights

A diagnostic imaging apparatus of hand piece type suitable for medical or dental use, comprising a main body held by operator's fingers, a luminous means for irradiating at least one of lights selected from excitation light, infrared light and ultraviolet light, and an imaging means provided in a forward portion of the main body. The imaging means comprises a solid-state image sensing device and an optical means for forming an optical image of a diagnosis object to be examined on the solid-state image sensing device and is so constructed as to output a predetermined diagnostic image information by receiving the light reflected from the diagnosis object and / or the fluorescence generated from the diagnosis object when irradiation of light from the luminous means to the diagnosis object is performed.

Owner:MORITA MFG CO LTD

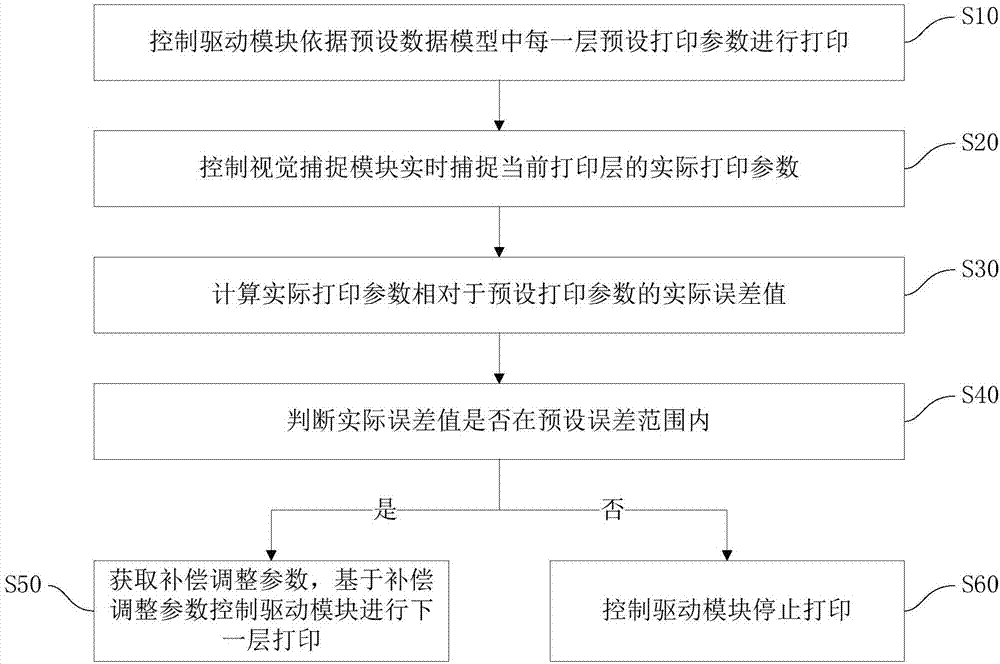

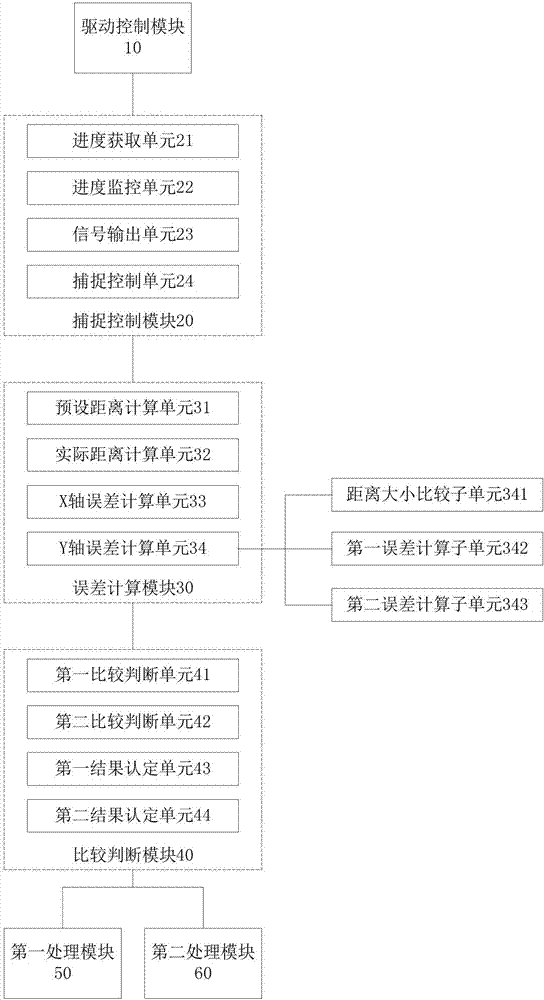

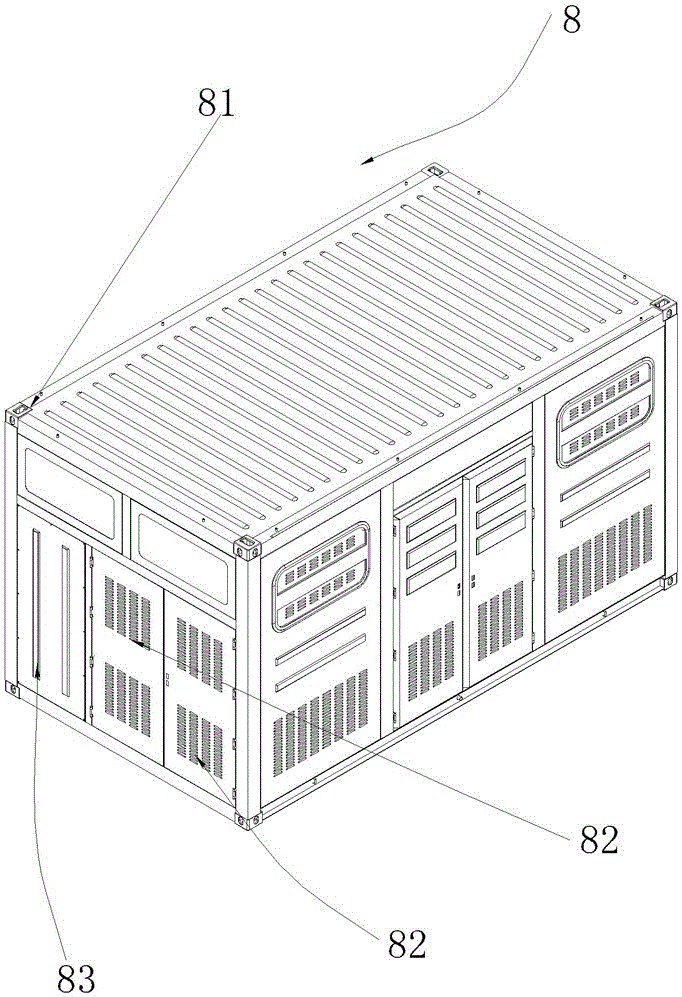

3D printing closed-loop control method and device, 3D printer and storage medium

ActiveCN107187058AImprove qualificationSave printing materials and printing timeAdditive manufacturing apparatusManufacturing data aquisition/processingParameter controlData model

The invention discloses a 3D printing closed-loop control method and device, a 3D printer and a storage medium. The 3D printing closed-loop control method comprises the steps of controlling a driving module to perform printing according to preset printing parameters of each layer in a preset data model, controlling a visual capturing module to capture actual printing parameters of a current printing layer in real time, calculating the actual error value of the actual printing parameters relative to the preset printing parameters, judging whether the actual error value is within a preset error range or not, obtaining compensation adjustment parameters and controlling the driving module to carry out next-layer printing on the basis of the compensation adjustment parameters if the actual error value is within the preset error range; and controlling the driving module to stop printing if the actual error value is not within the preset error range. According to the 3D printing closed-loop control method, by monitoring the abnormal effect in the printing process in real time, compensation control is performed or printing is stopped, and therefore the qualified rate of the printed product can be improved, and printing time and printing materials can be saved.

Owner:东莞远铸智能科技有限公司

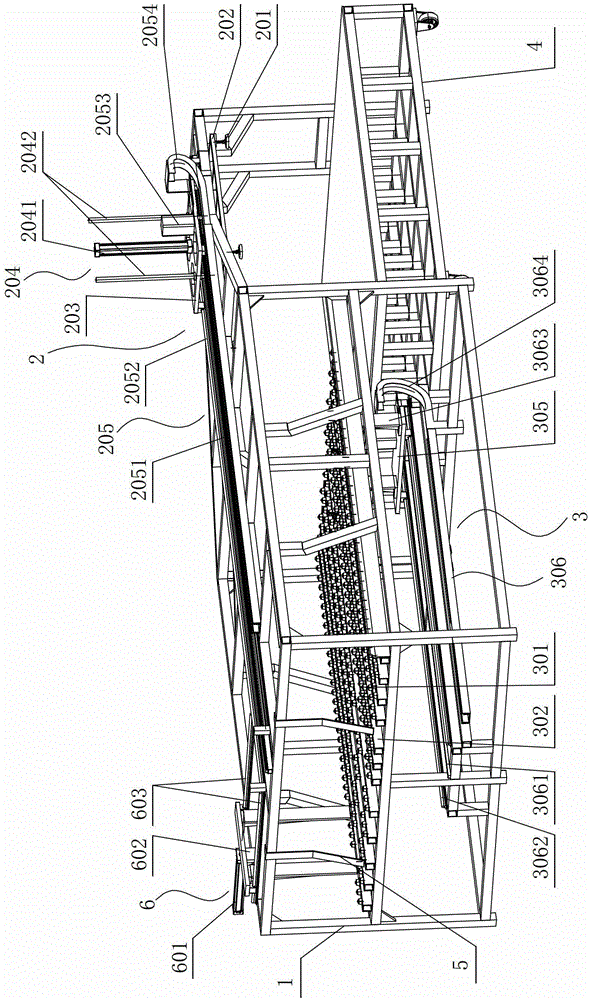

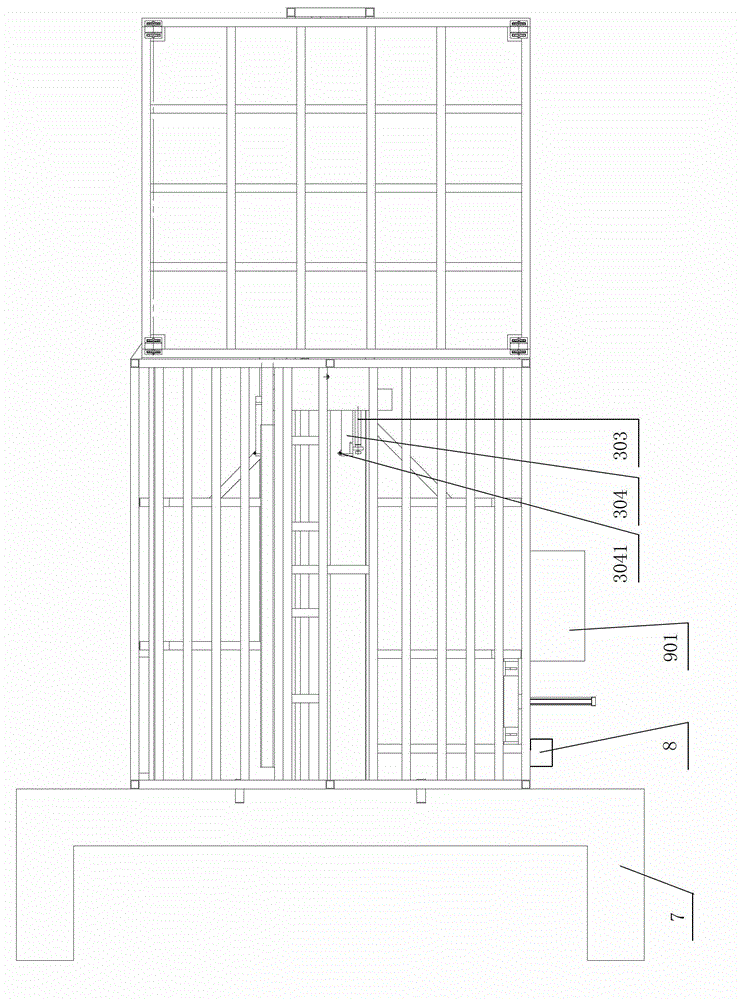

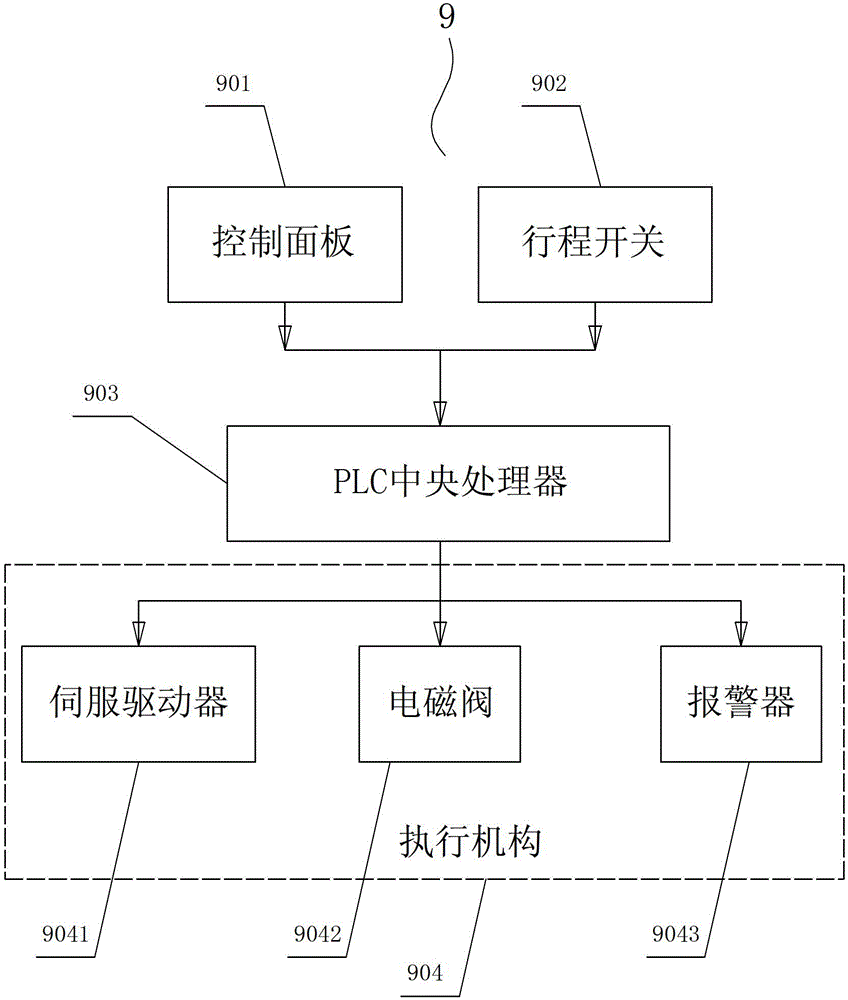

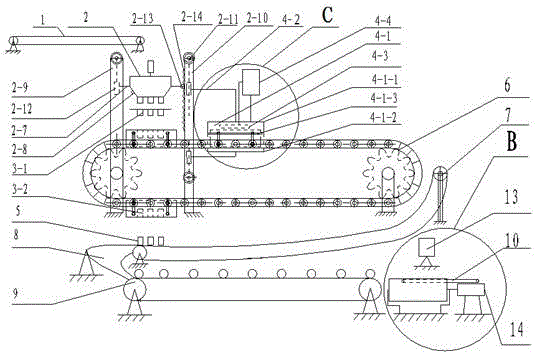

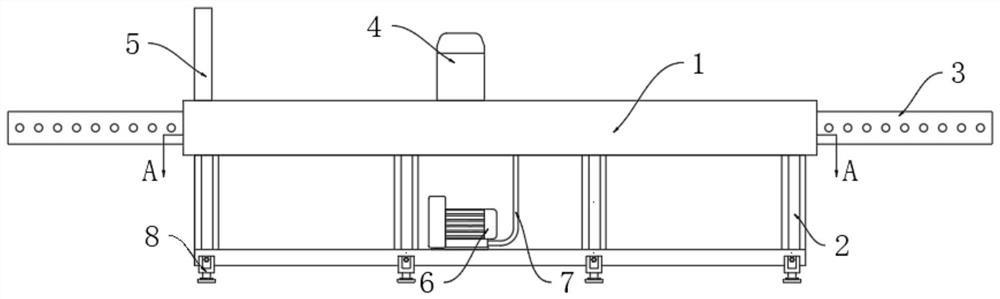

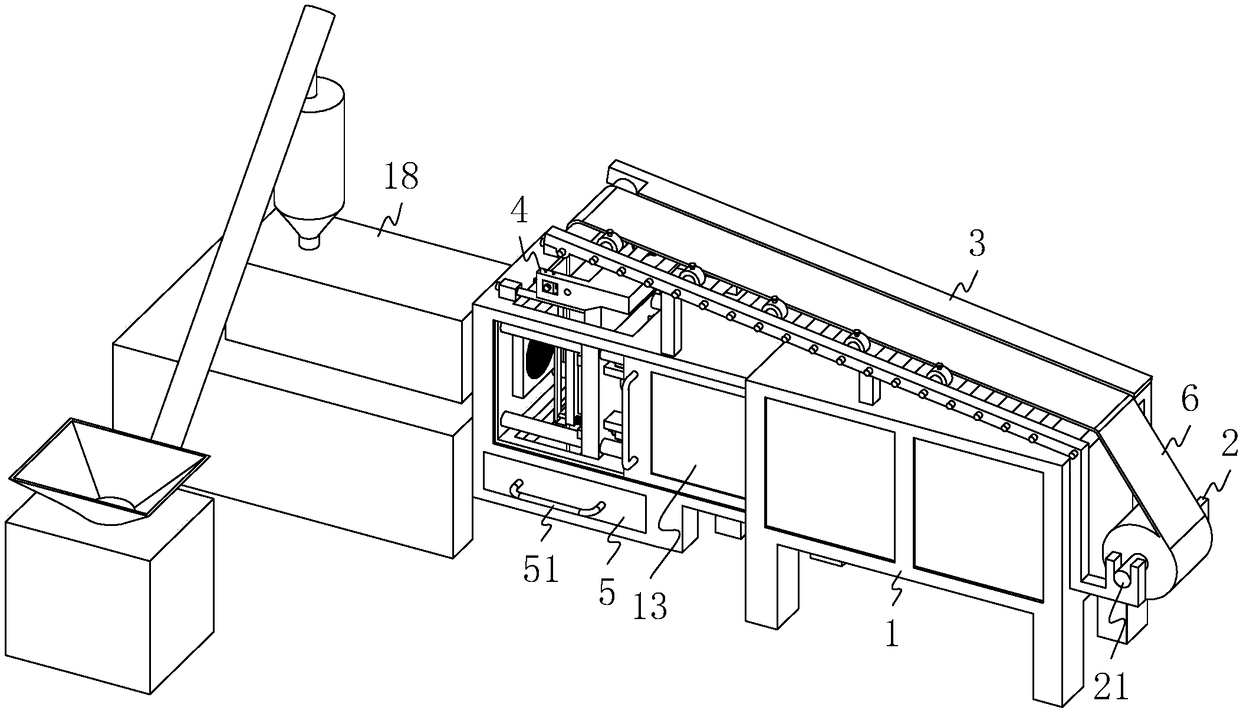

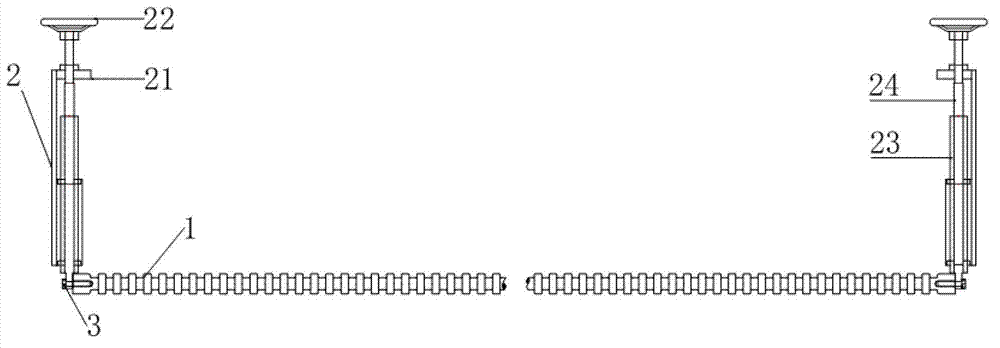

Automatic steel plate cropping material feeding mechanism

ActiveCN102909285ARealize fully automatic feedingAutomatic continuous pushMetal-working feeding devicesPositioning devicesControl setProgrammable logic controller

An automatic steel plate cropping material feeding mechanism is characterized by comprising a frame, a feeding device, a ramming device and a programmable logic controller (PLC) control integrated system used for controlling the feeding device and the ramming device. The feeding device is arranged at the top of the frame, the ramming device is arranged in the middle at one end of the frame, and the ramming device is connected with a material inlet of a shearing machine. A steel plate is arranged below the other end of the frame, and the feeding device and the ramming device are respectively connected with the PLC control integrated system through a control line. The whole process of the automatic steel plate cropping material feeding mechanism needs no manual operation, can achieve full-automatic feeding and improve qualified rate of slabs, greatly improves production efficiency, avoids potential safety hazards caused by manual operation, and is high in safety performance.

Owner:LIUZHOU LIUHE FANGSHENG MACHINERY

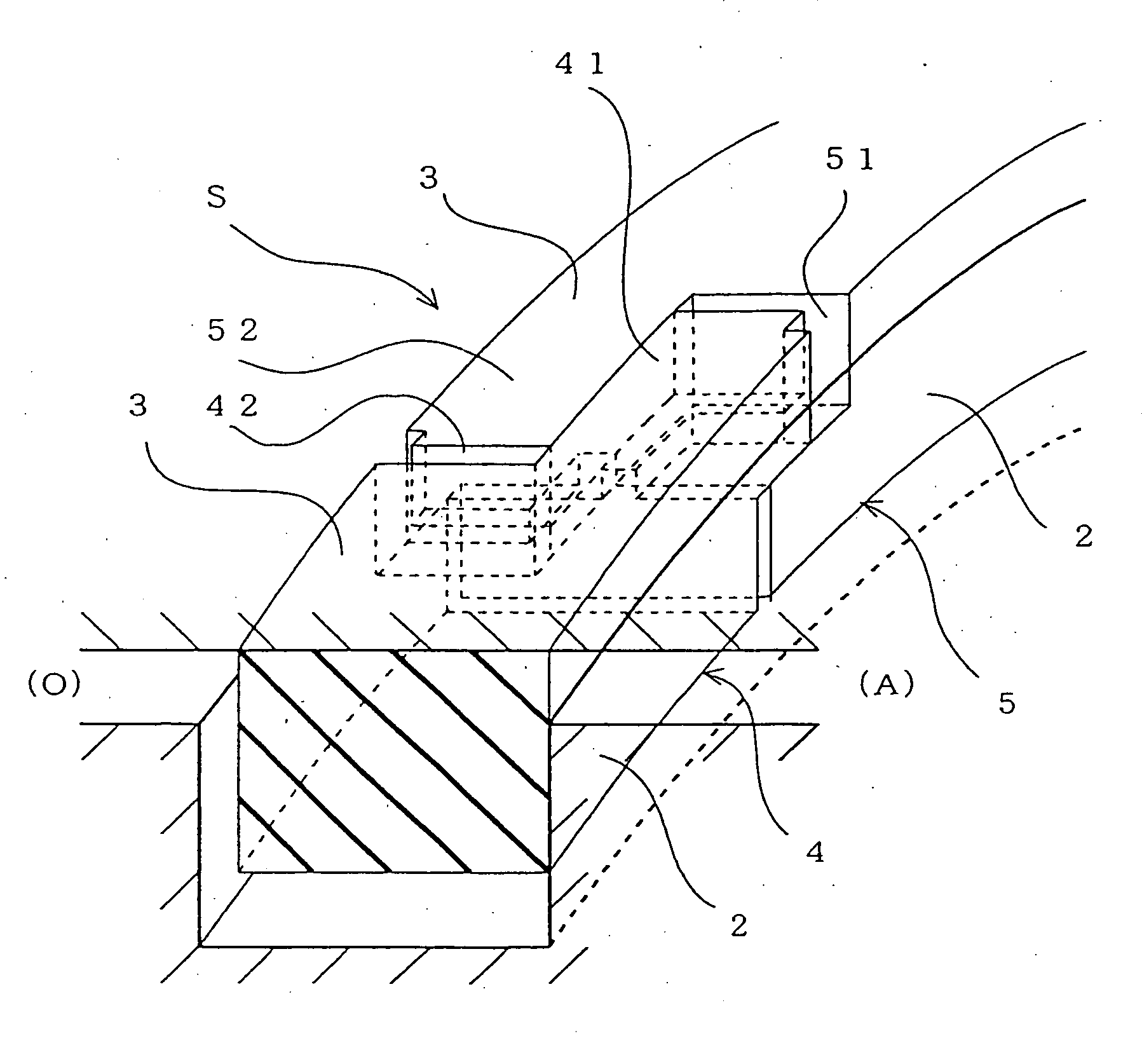

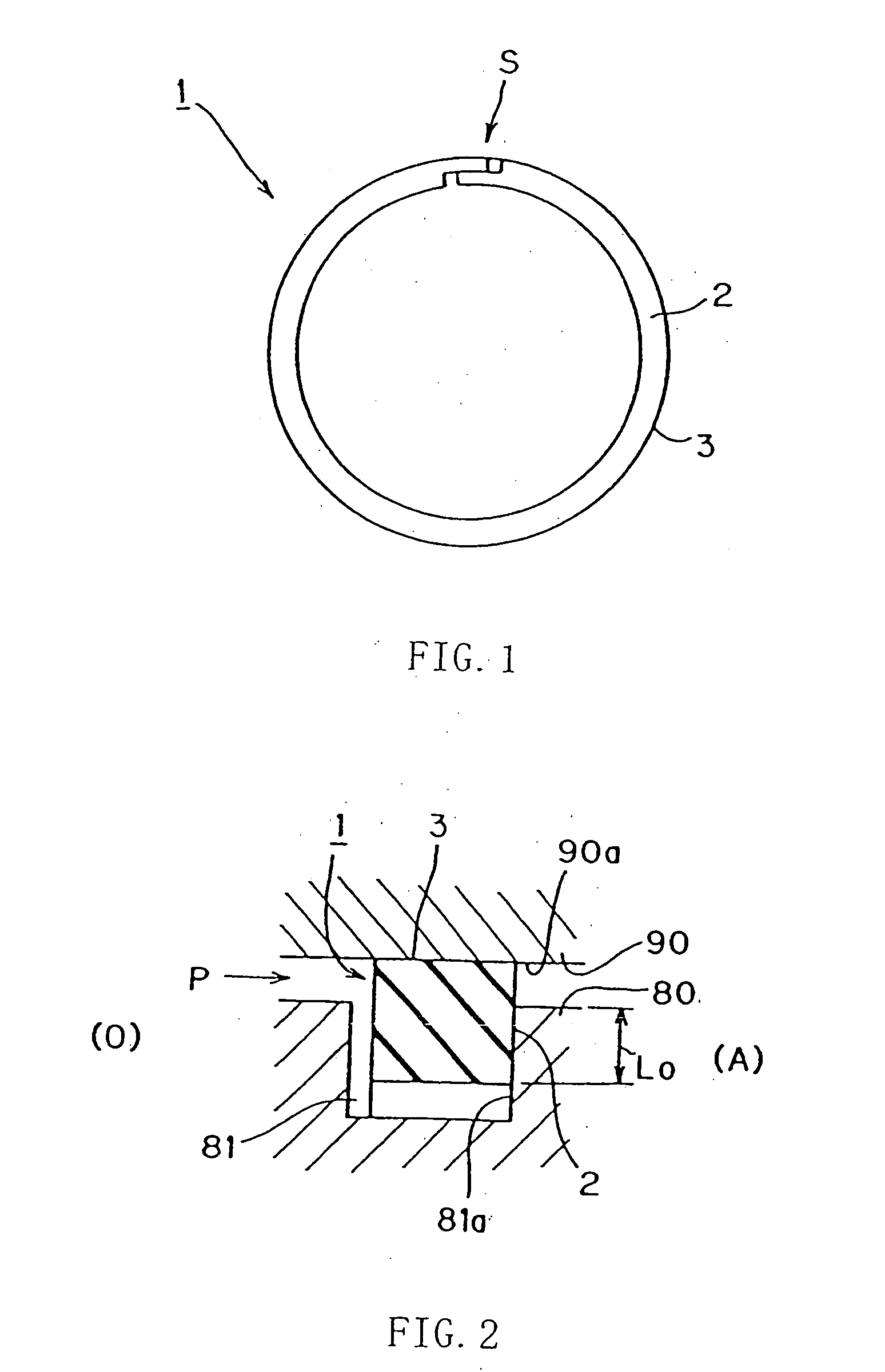

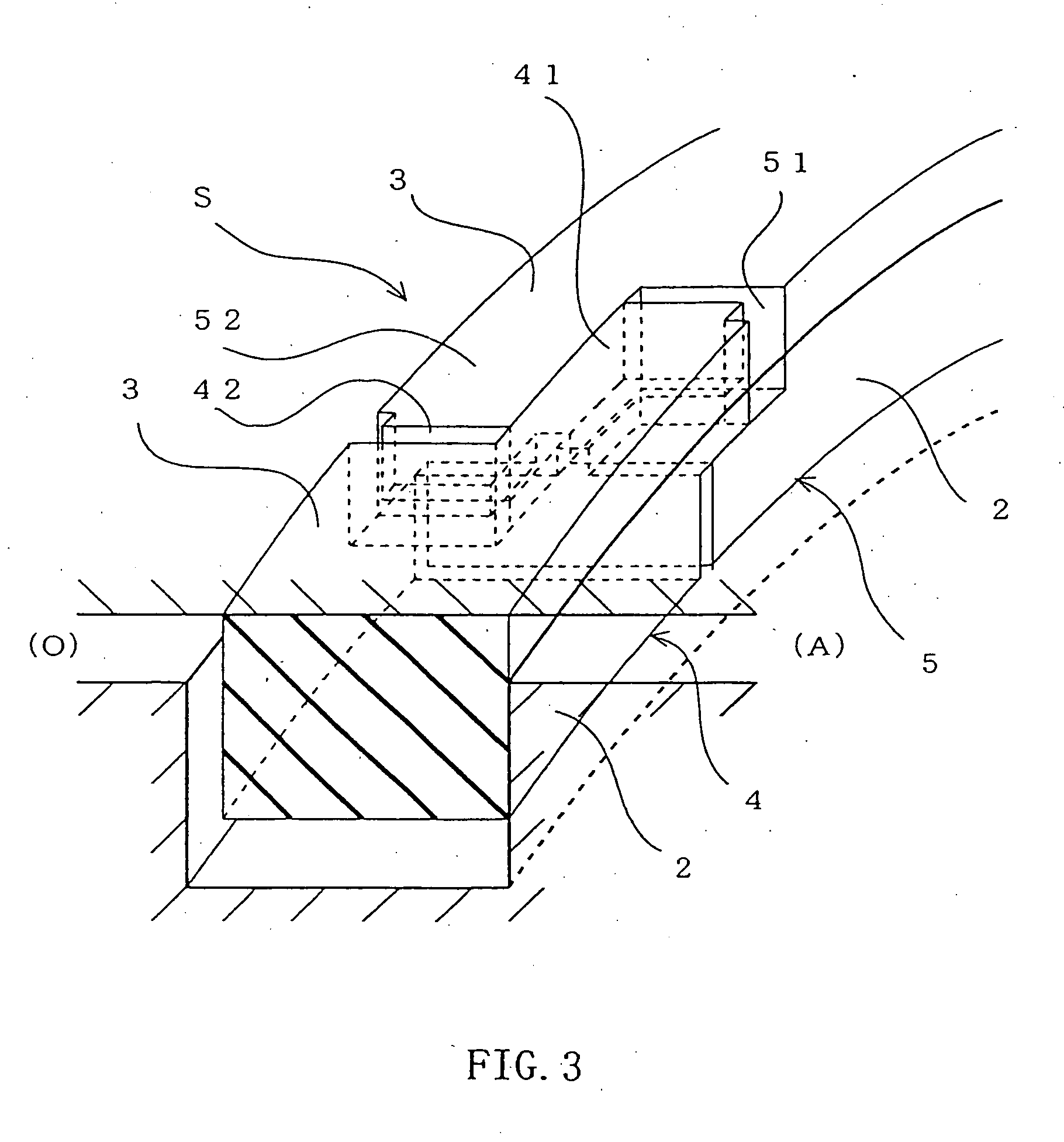

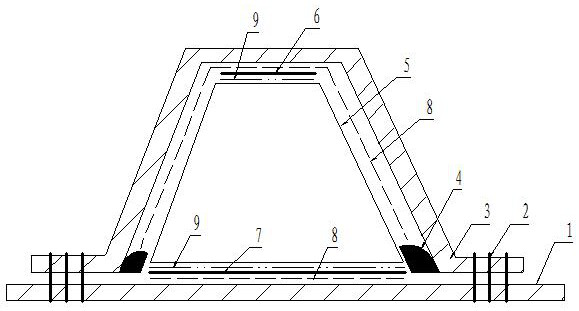

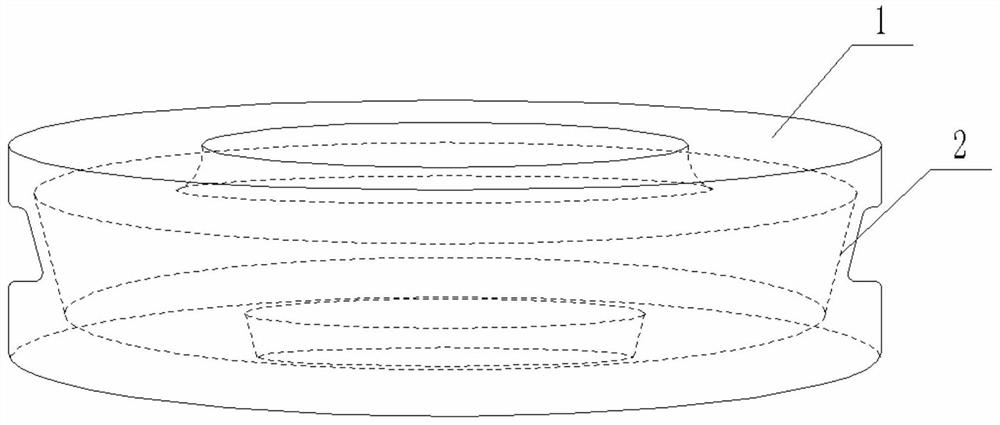

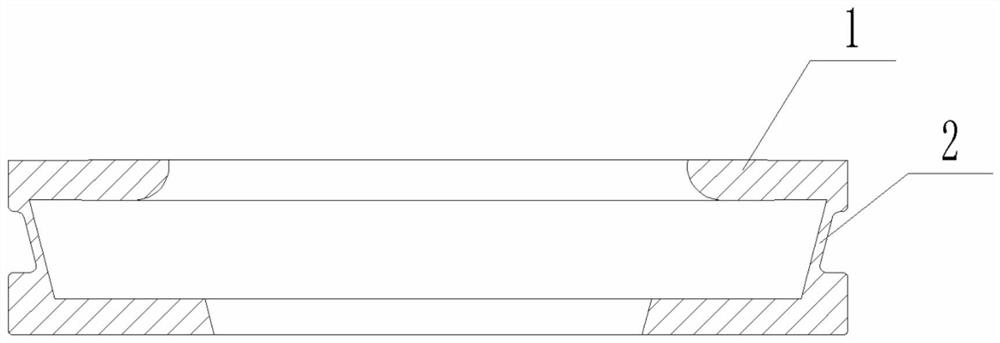

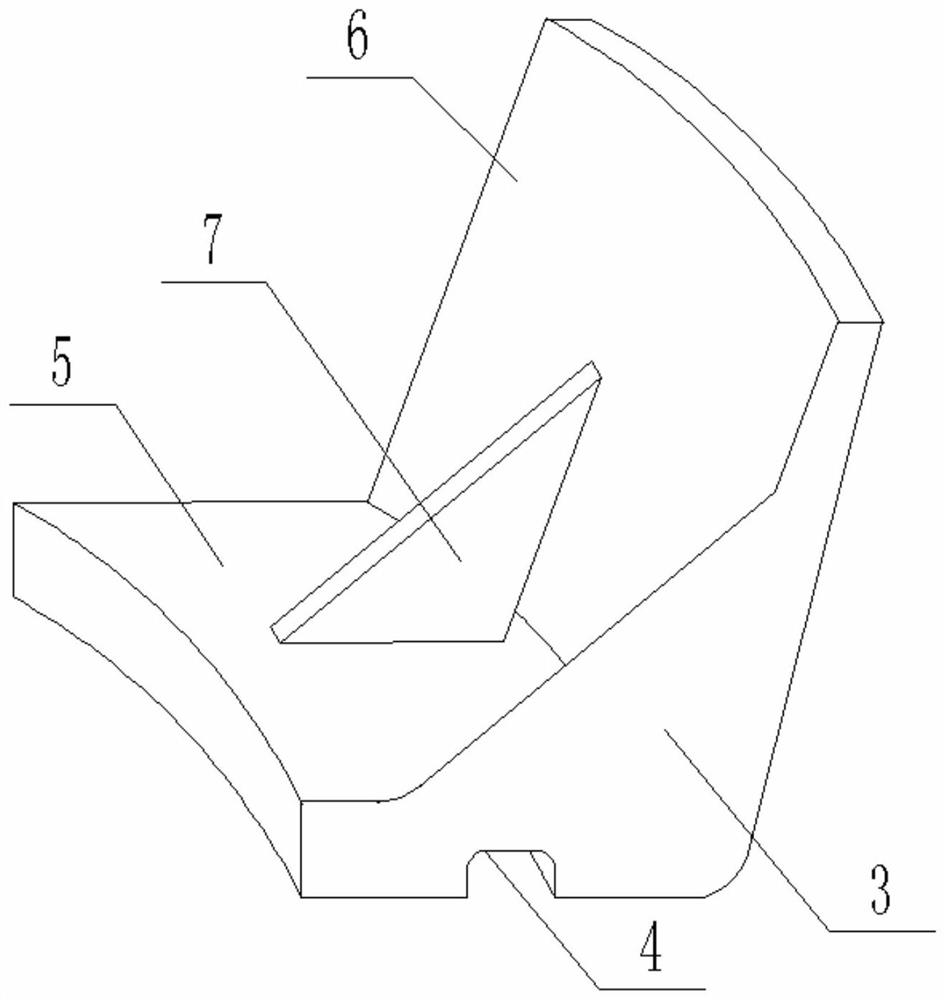

Seal ring

InactiveUS20050116426A1Improve wear resistanceImprove abilitiesEngine sealsPiston ringsFree rotationEngineering

A seal ring for sealing an annular clearance between two members which are disposed for free rotations relative to each other. At a cut portion which is cut at a portion of the seal ring, there is formed a passage for allowing leakage when the cut end portions engage with each other. This passage is given a sectional shape of square or the like. This passage improves an abrasion resistance.

Owner:NOK CORP

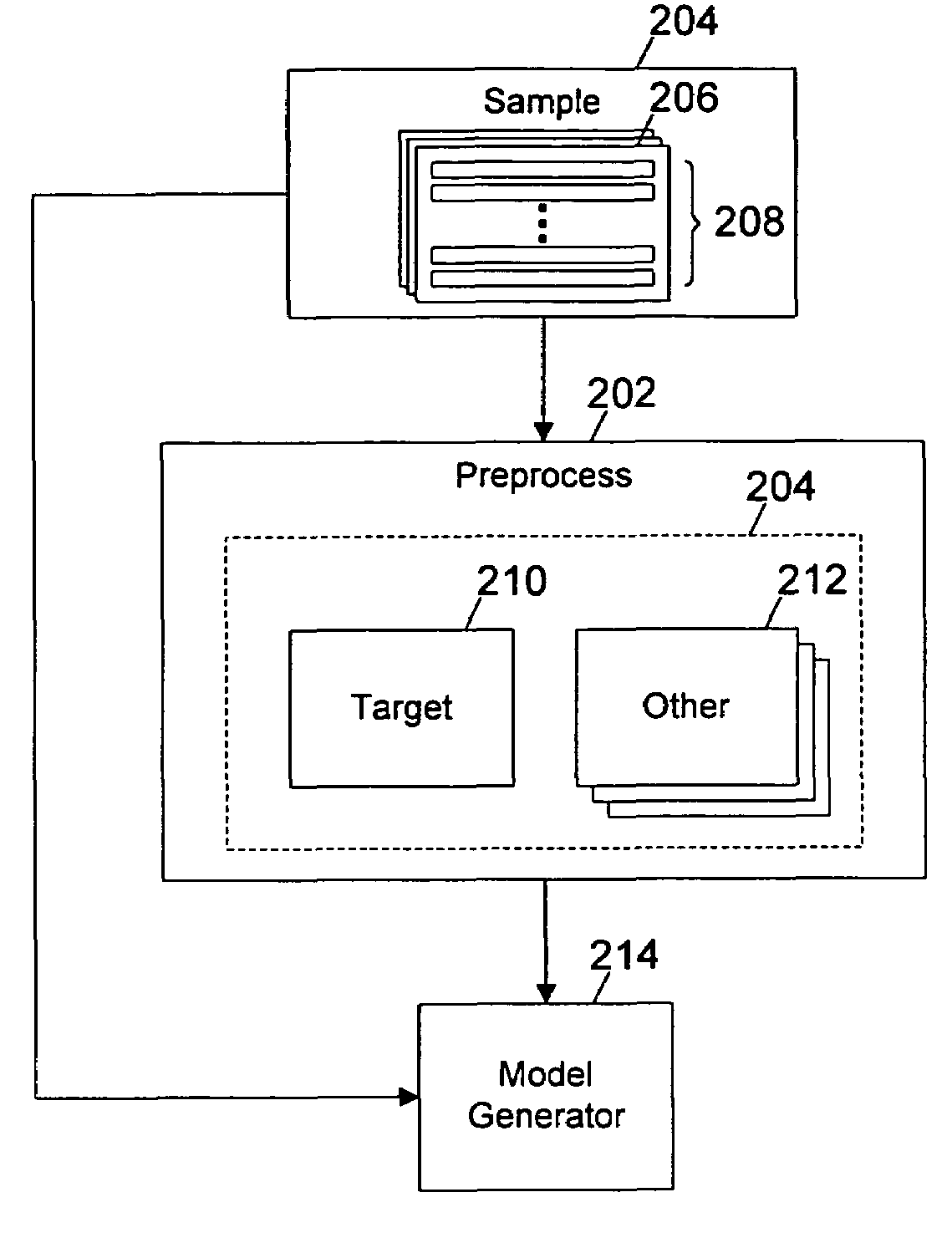

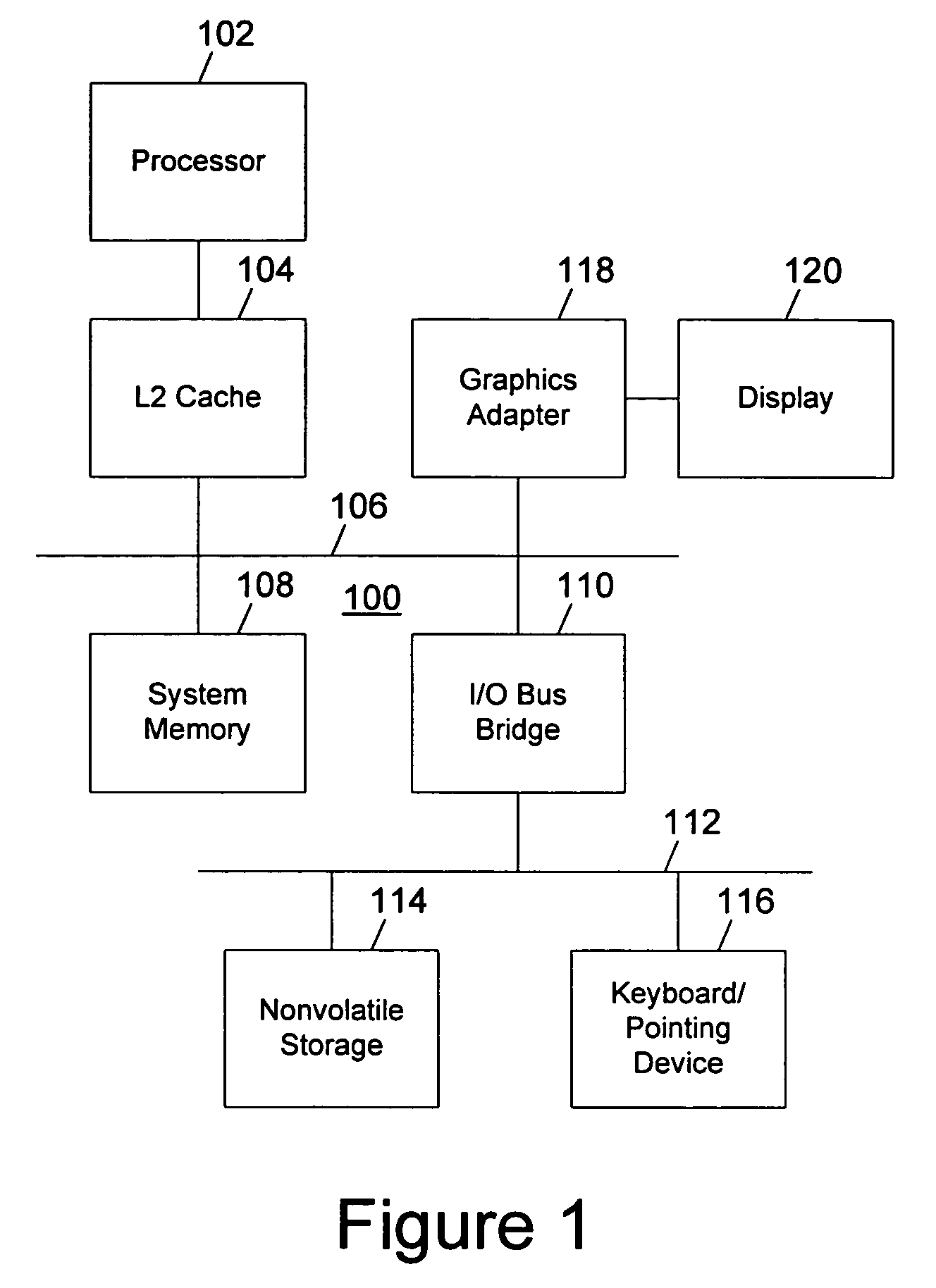

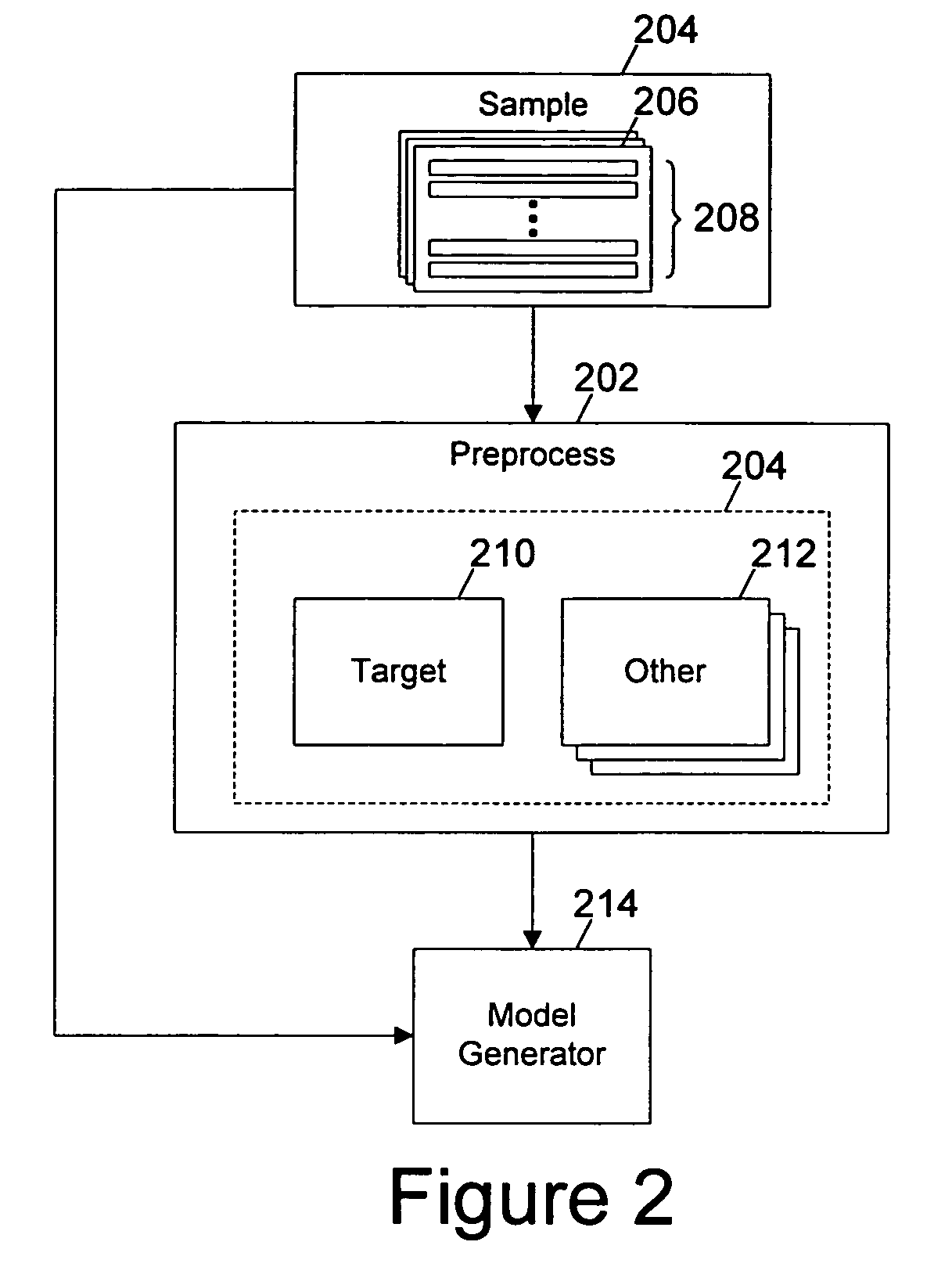

Method for computing models based on attributes selected by entropy

InactiveUS7107192B1Facilitate data analysisImprove qualificationCharacter and pattern recognitionComputation using non-denominational number representationData setComputer science

Attributes of a data set to be employed in generating a predictive model are analyzed based on entropy, chi-square, or similar statistical measure. A target group of samples exhibiting one or more desired attributes is identified, then remaining attribute values for the target group are compared to corresponding attribute values for the whole sample population. A subset of all available attributes is then selected from those attributes which exhibit, when comparing attribute values of target group samples to attribute values for the whole sample population, the greatest relative difference or divergence. This subset is employed to generate the predictive model. Efficiency in generating the predictive model and the accuracy of the resulting predictive model is improved, since fewer attributes are employed and less computational resources are required.

Owner:IBM CORP

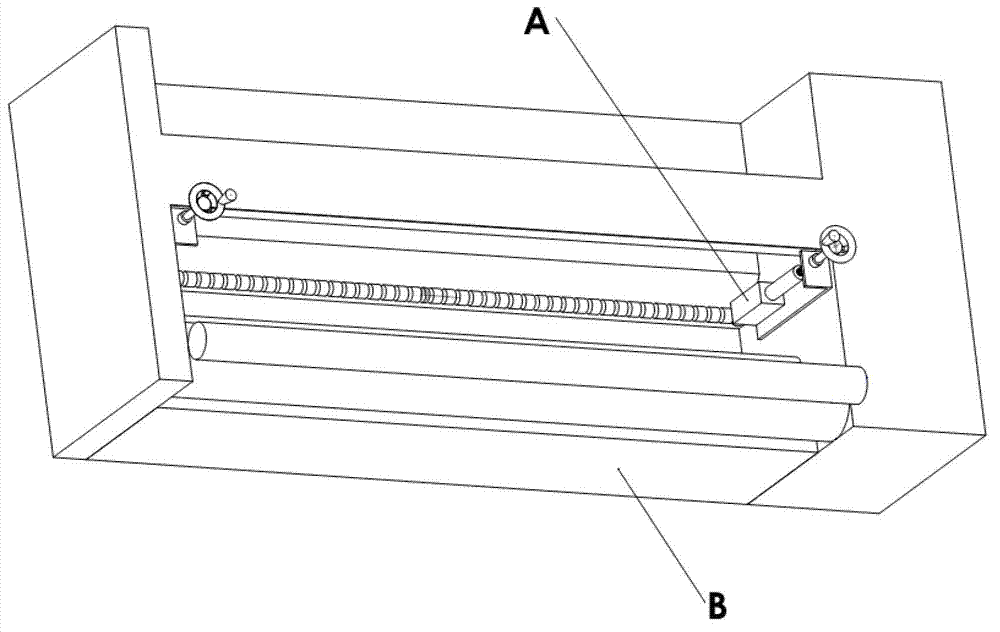

Main roller slotting method of multi-wire cutting machine

InactiveCN101879759AImprove qualificationFine working devicesStone-like material working toolsWire cuttingEngineering

The invention relates to a main roller slotting method of a multi-wire cutting machine. In the method, when each 1 unit of increase of the wearing capacity of a steel wire is measured, corresponding main roller slotting spaces are sequentially reduced by 0.5 to 1 same unit. By adopting the method of the invention, because the main roller slotting spaces are sequentially reduced, reverse compensation can be carried out for results that the steel wire is gradually changed from thick to thin and a cut gap is changed from large to small, so that a cut silicon slice is kept uniform, and the qualified rate of products is improved.

Owner:ZHEJIANG GUIHONG ELECTRONICS TECH

Flywheel gluing system and motor rotor production device

InactiveCN109332107ASolve the phenomenon of flingingExcellent adhesionLiquid surface applicatorsCleaning using toolsEngineeringFlywheel

The invention relates to the technical field of motor rotor production. The flywheel gluing system comprises a first positioning working table and a flywheel gluing device; the first positioning working table includes a fixing frame, a second air cylinder, a spline shaft, a jacking cone disk, a first belt transmission assembly, a positioning base, a positioning pinch plate, a glue collecting bucket collecting assembly, a rotating connecting sleeve and a first motor; and the flywheel gluing device comprises a second rotating air cylinder installation frame, a second rotating air cylinder, a rotating arm, a third linear rail shifting assembly, a second air cylinder and a first glue scraping machine. The flywheel gluing system has the advantages that flywheel gluing is uniform, glue cannot drip into a working area, and the glue bonding effect is better.

Owner:陈荣乾

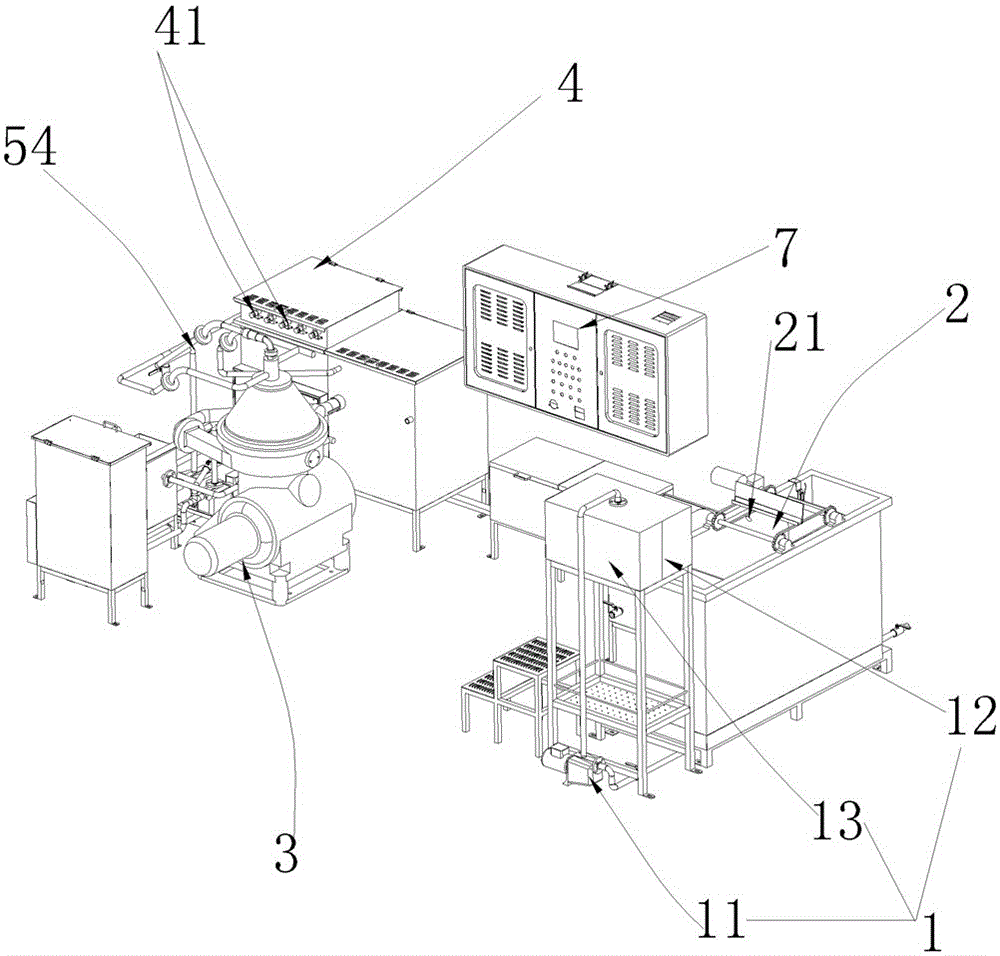

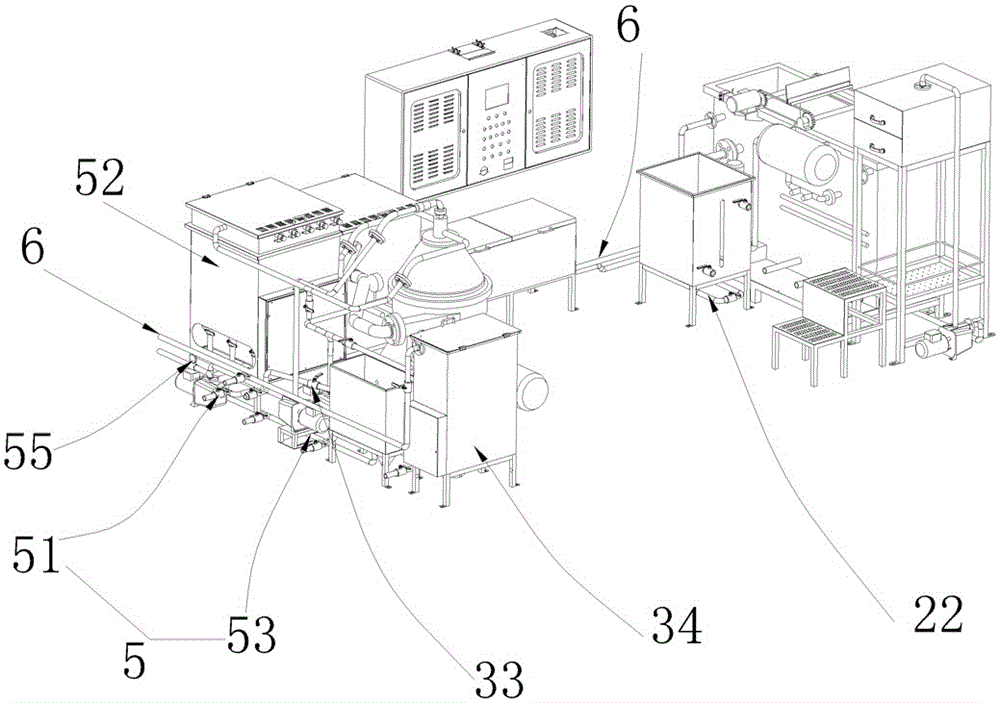

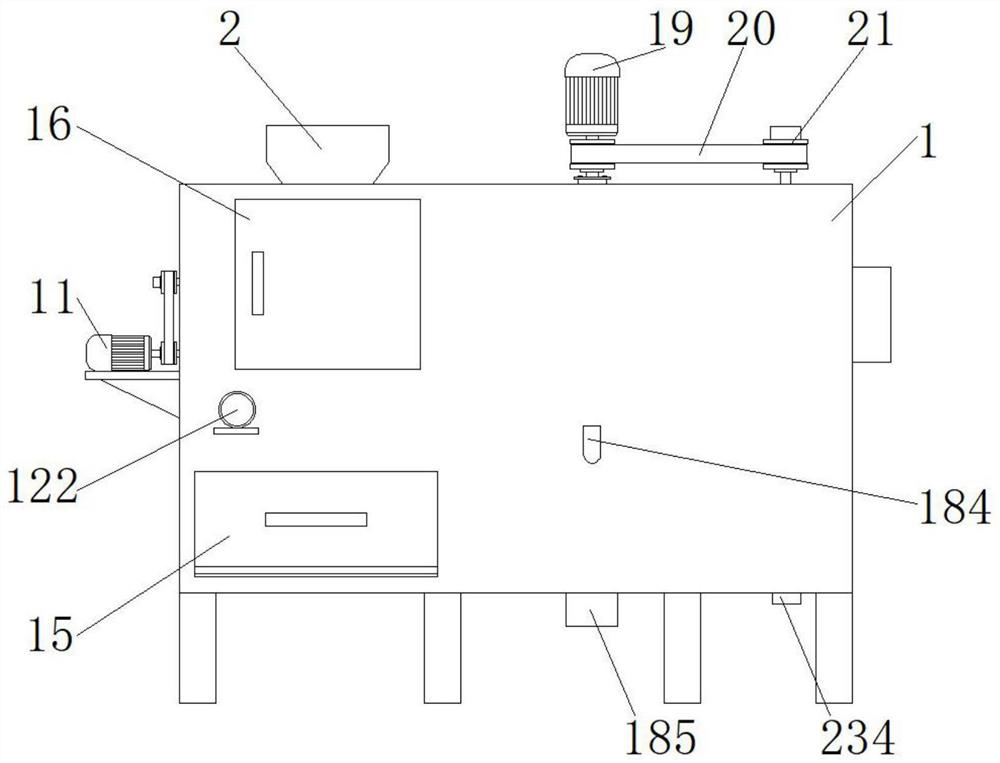

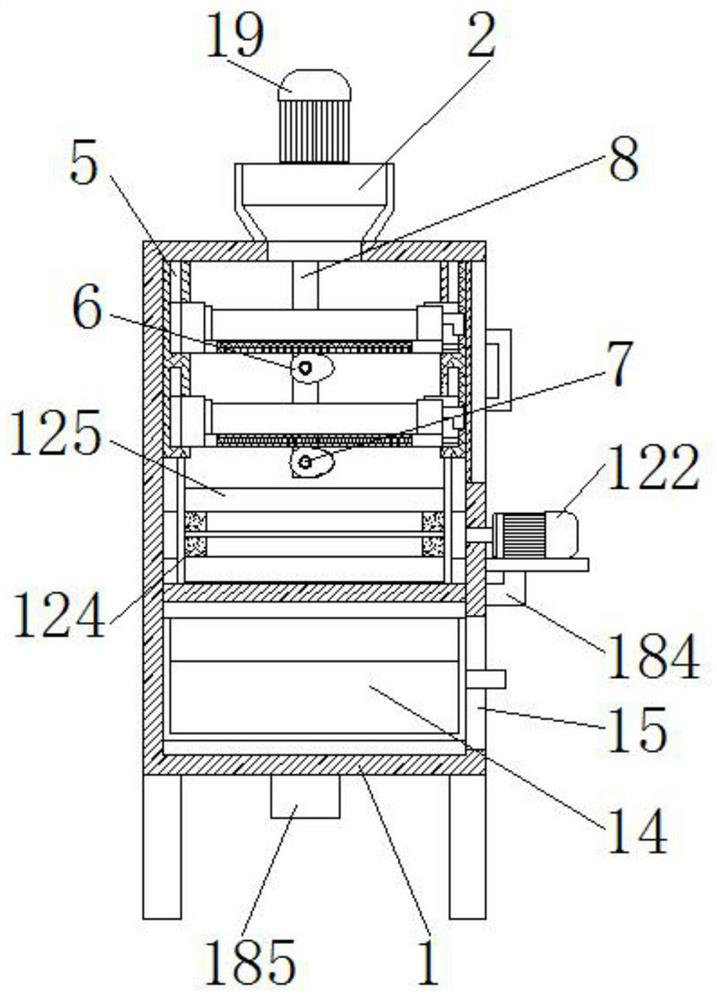

Cutting liquid recycling equipment and recycling method thereof

InactiveCN105081868AAdvantage equipmentAdvantage Recycling MethodFiltration circuitsMaintainance and safety accessoriesRecovery methodSlag

The invention discloses cutting liquid recycling equipment and a recycling method thereof. The equipment comprises an automatic loading device, a dissolved air flotation machine, a high-speed centrifuge, a UV photolytic sterilization device, an automatic discharge device and a PLC, wherein the automatic loading device is provided with a feed pump and a feed transfer box having a filter screen inside; a discharge pump and a discharge box are arranged on the automatic discharge device; and the feed pump and the discharge pump are respectively in electric connection with the output end of the PLC. The equipment can reduce the manpower resource and the labor intensity while improving the treatment efficiency, reduces the industrial sewage emission, and can clearly distinguish cutting liquid, waste oil and waste slag; and recovered materials are free of bacteria and stink, so that the production efficiency and data and the production environment and the treatment clearness are maximal, and users clearly master the operation conditions of the equipment.

Owner:SHENZHEN TIANDEYI ENVIRONMENT TECH

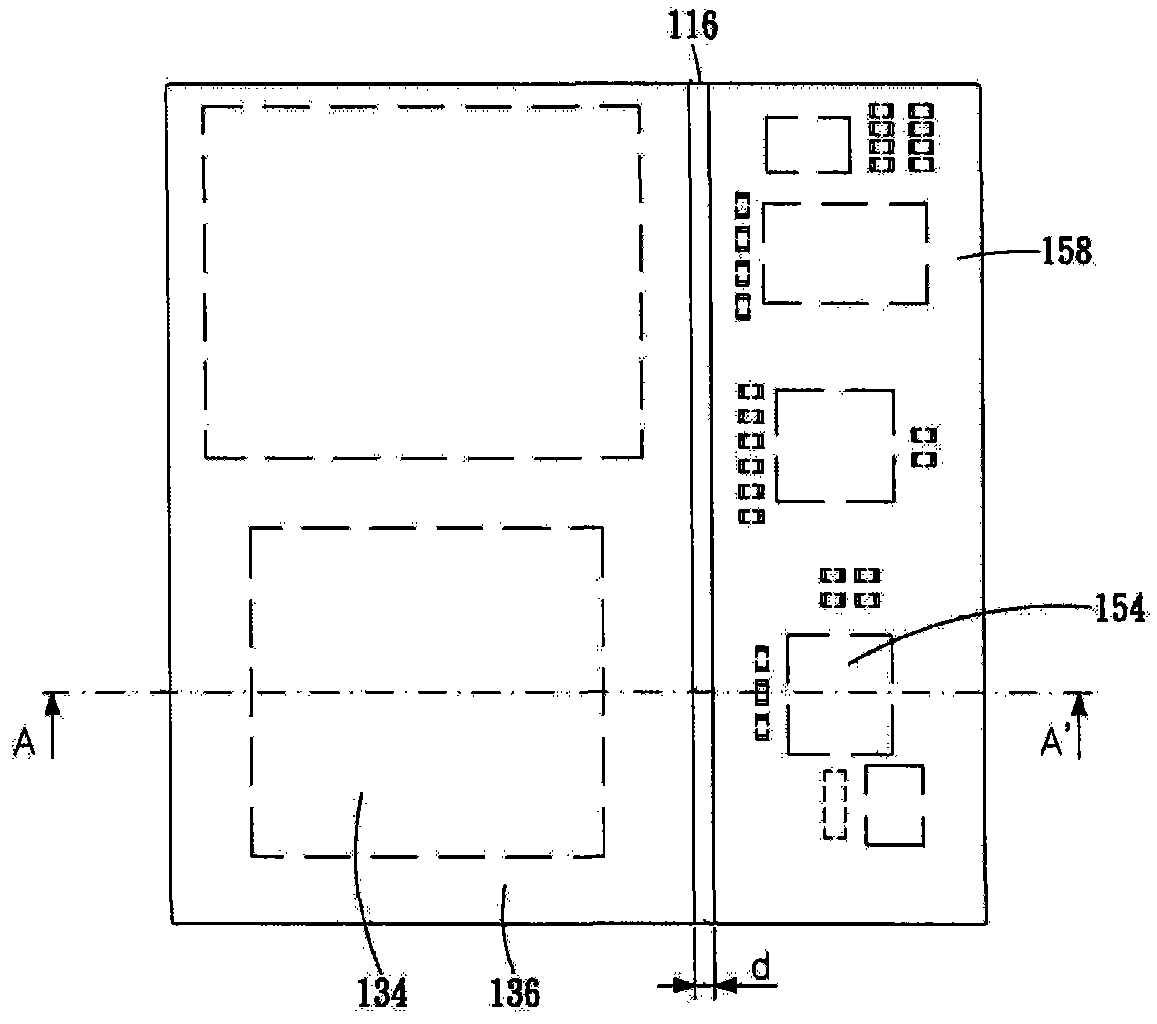

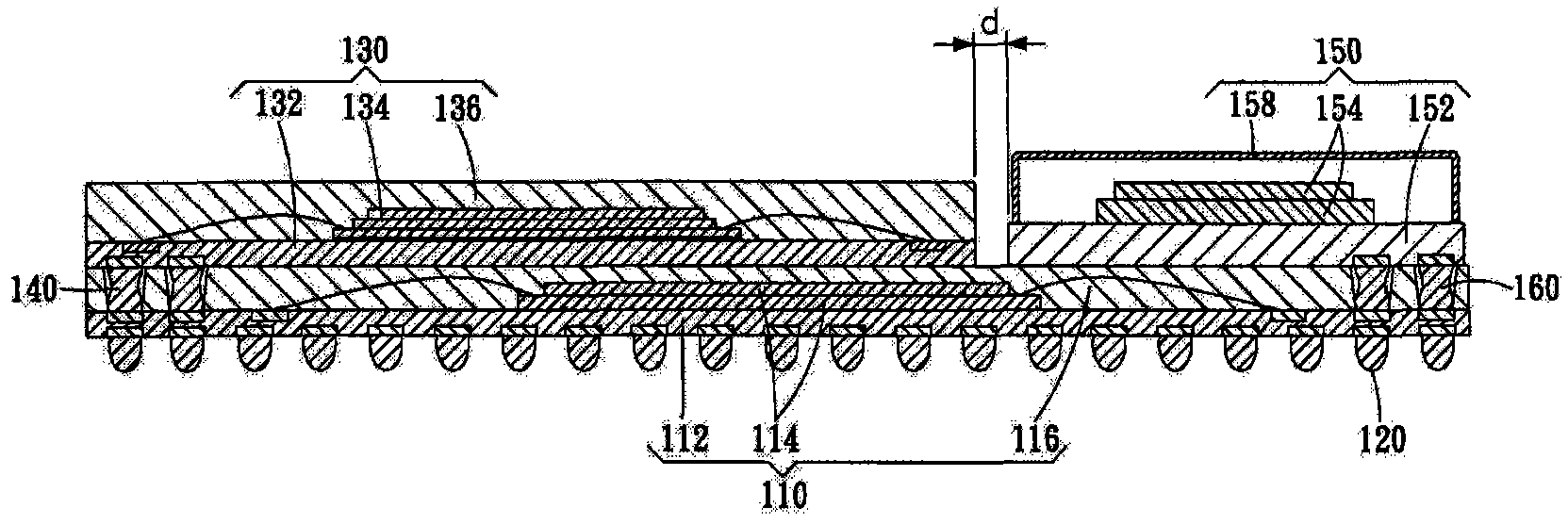

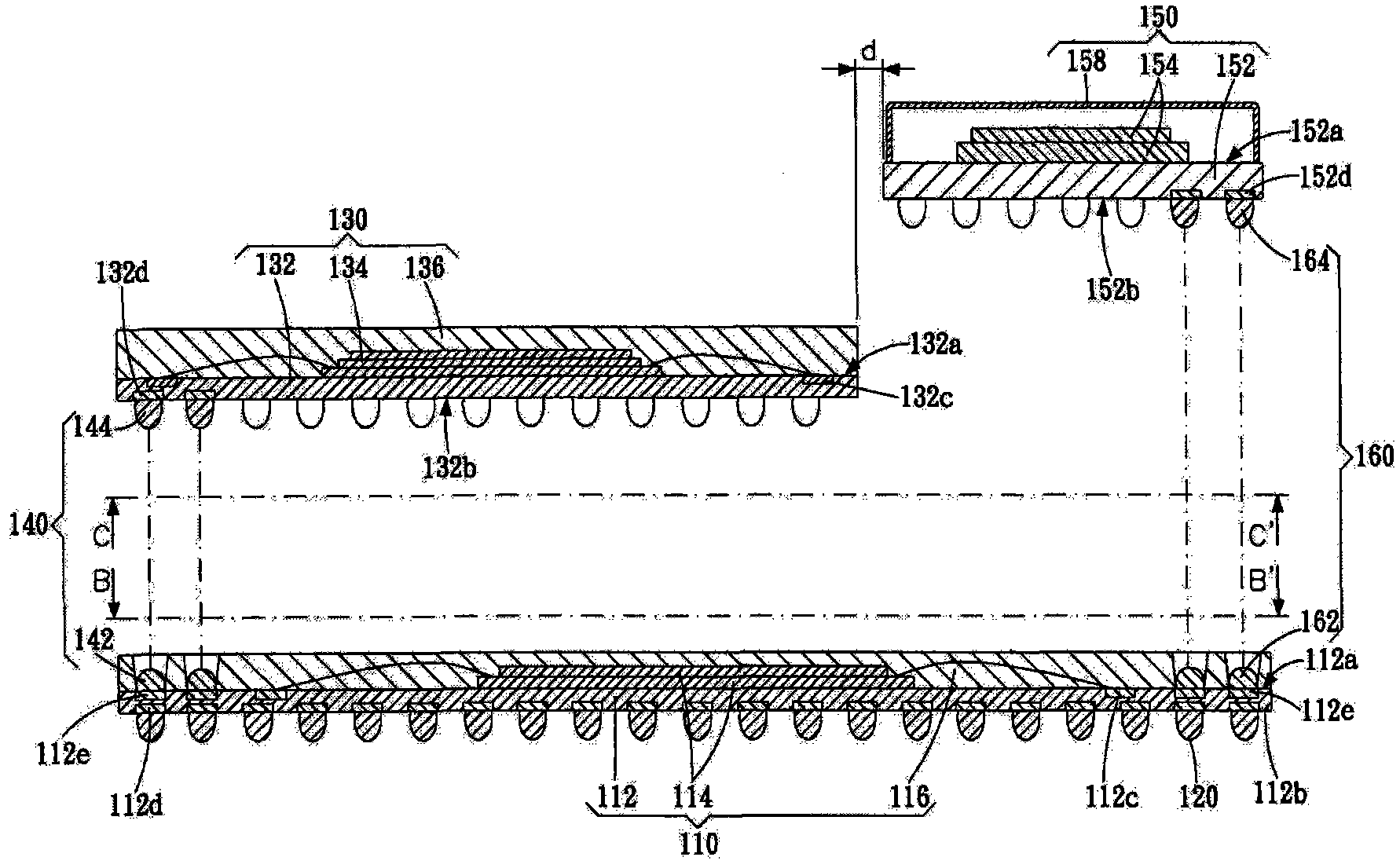

Stacking-type semiconductor package structure

InactiveCN103035627AImprove qualificationImprove cooling effectSemiconductor/solid-state device detailsSolid-state devicesElectrical conductorSemiconductor package

A stacking-type semiconductor package structure includes a first package body, multiple first connecting conductors, a second package body, multiple second connecting conductors, an electronic function module, and multiple third connecting conductors. The first connecting conductors are disposed on a lower surface of the first package body and connected electrically to the first package body. The second package body and the electronic function module are disposed on an upper surface of the first package body. The second connecting conductors are connected electrically between the first package body and the second package body, and the third connecting conductors are connected electrically between the first package body and the electronic function module. The second package body has an electronic function different from that of the electronic function module.

Owner:CHIPSIP TECH CO LTD +1

Systems and methods for qualifying and calibrating a beam delivery system

ActiveUS8968279B2Increasing overall system cost and complexityImprove accuracyLaser surgerySurgical instrument detailsTransport systemComputer module

Systems and methods for testing a laser eye surgery system are provided. Methods include establishing an image scale based on a calibration pattern, imageably altering a series of regions of a test surface with the laser system, laterally redirecting a laser beam to form a test pattern, imaging the test pattern, determining a lateral redirecting characteristic of the beam delivery system, and qualifying or calibrating the beam delivery system. Systems can include an input module that accepts an input member such as a calibration pattern parameter, a calibration pattern image, an intended pattern parameter, a test pattern image, an imaging device position, a calibration pattern position, a test pattern position, and a beam delivery system position, a characterization module that determines a beam delivery system characteristic, and an output module that generates a calibration for the beam delivery system of the laser eye surgery system.

Owner:AMO MFG USA INC

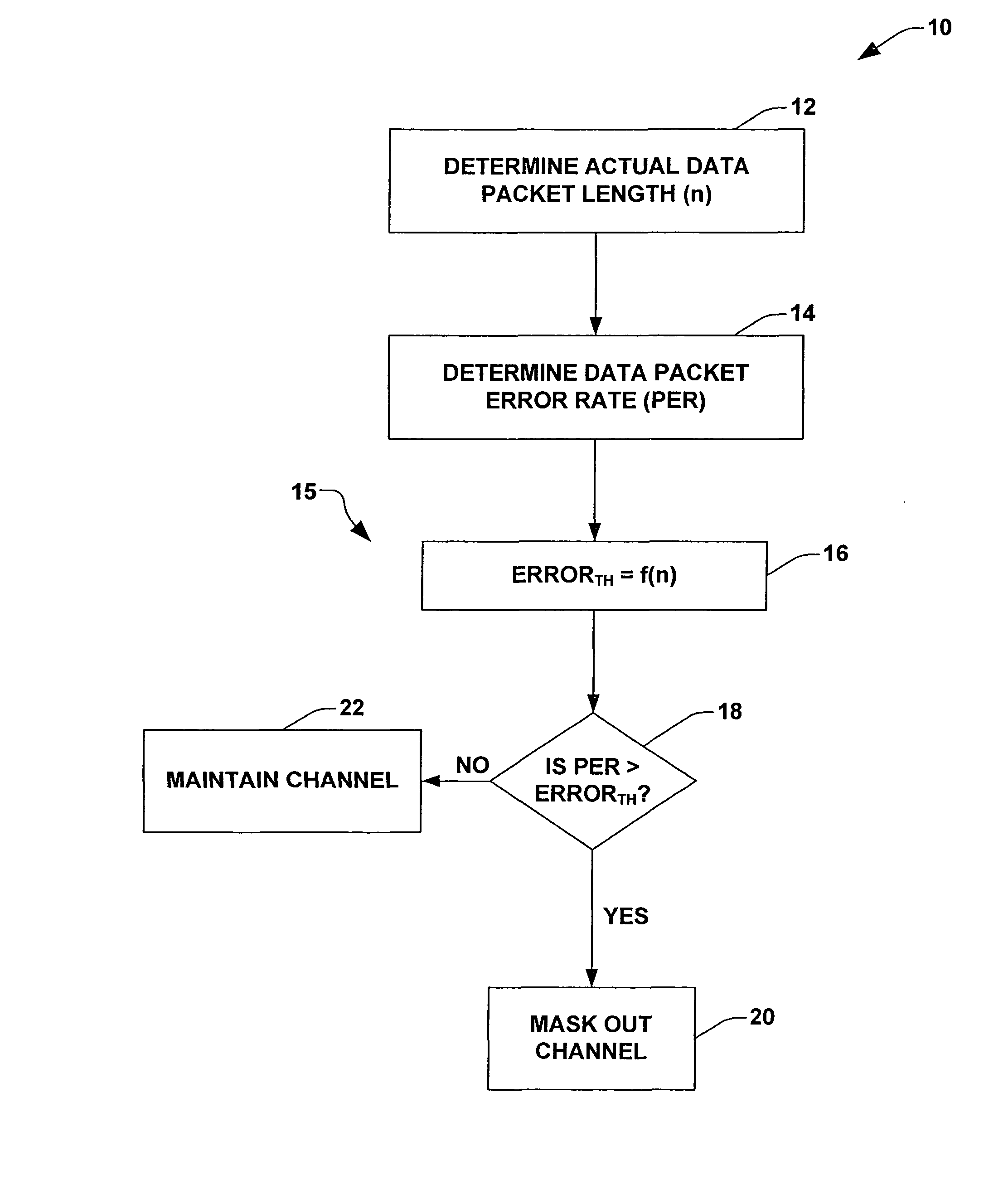

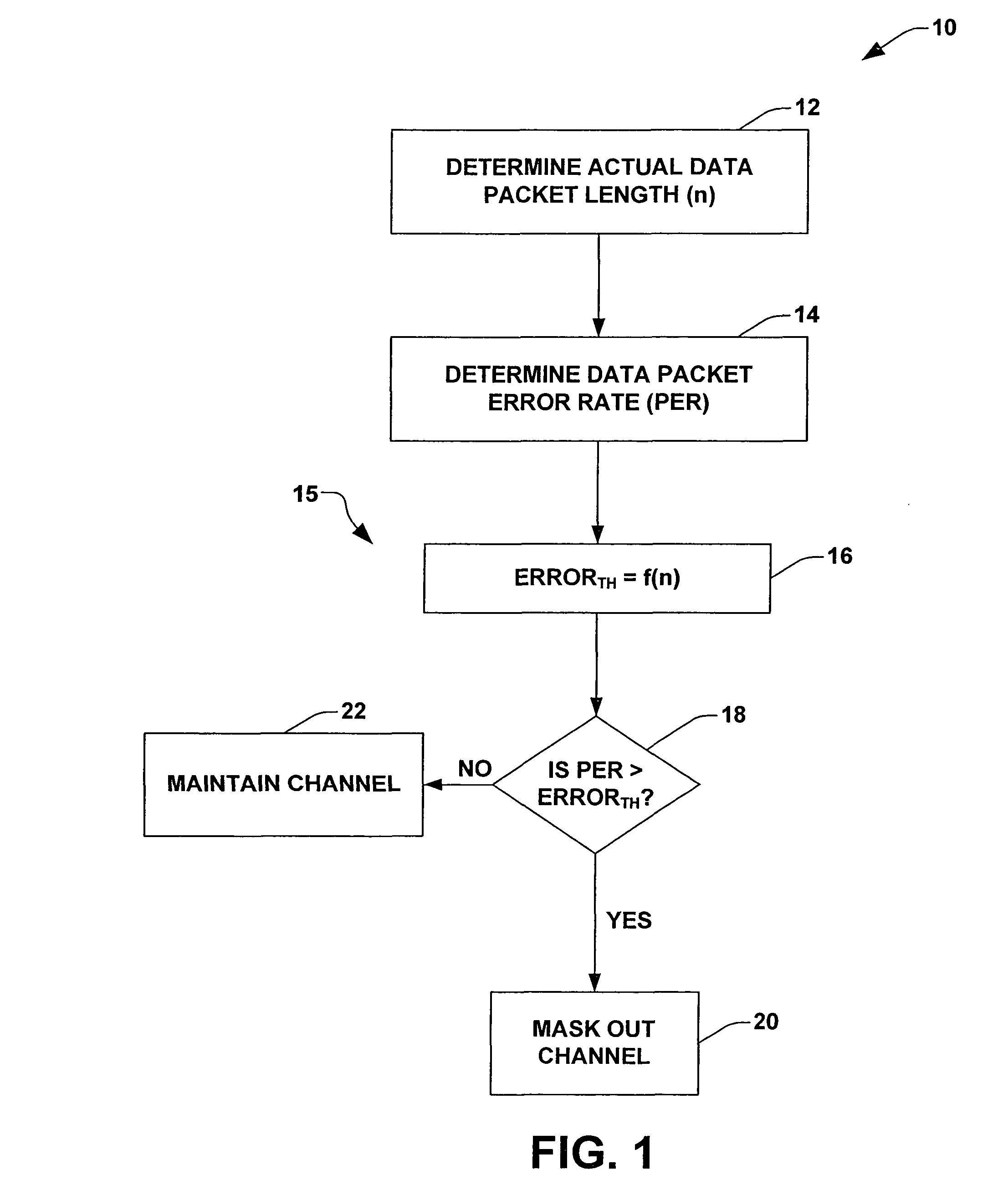

Channel qualification and selection in a multichannel radio system by packet error rate measurement

InactiveUS7903626B2Improve qualificationReliable choiceError detection/prevention using signal quality detectorCode conversionRate ratioRate measurement

In a method for channel qualification and selection, an actual data packet length and a data packet error rate in a received data packet are determined, and are used for a qualification decision. The measured data packet error rate is compared with a previously calculated data packet error threshold value, which depends on an assumed bit error rate and the ratio of a possible actual to a maximum data packet length.

Owner:INTEL CORP

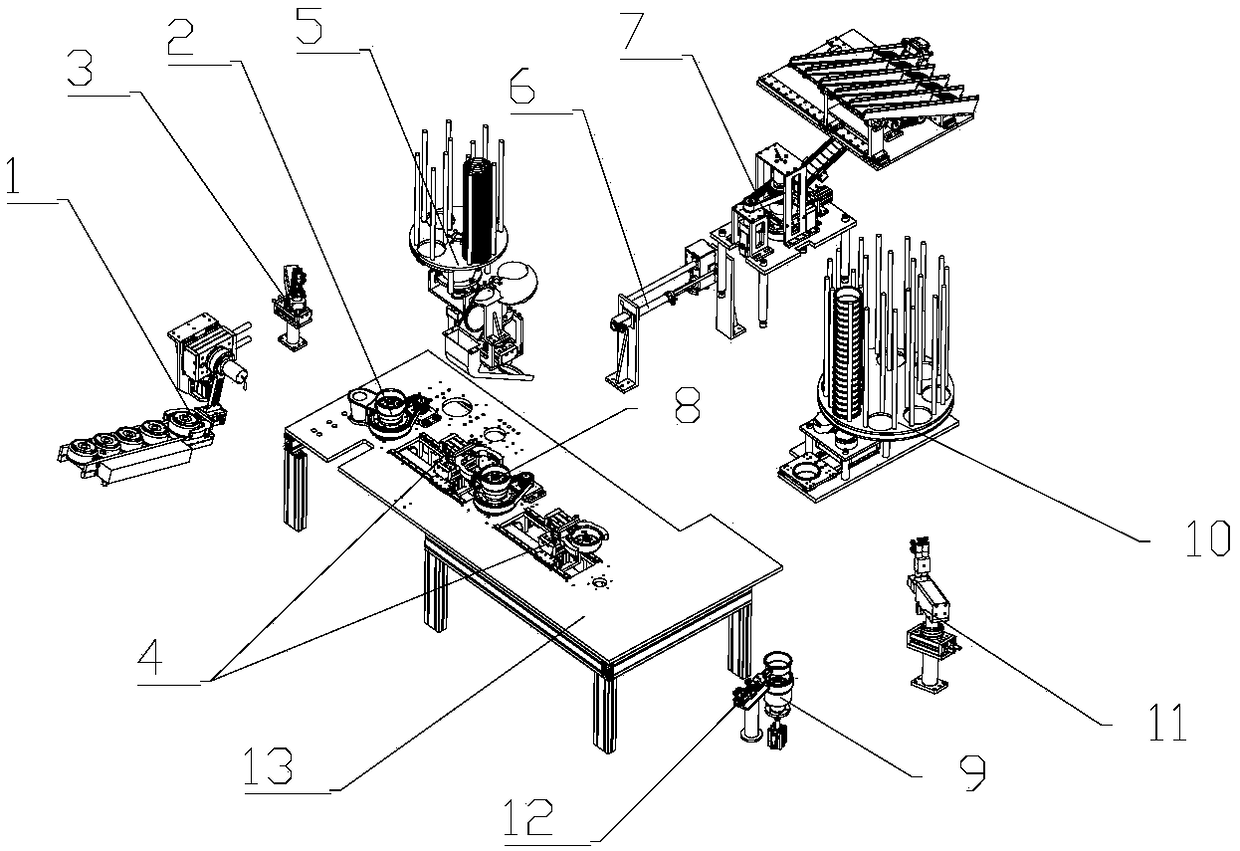

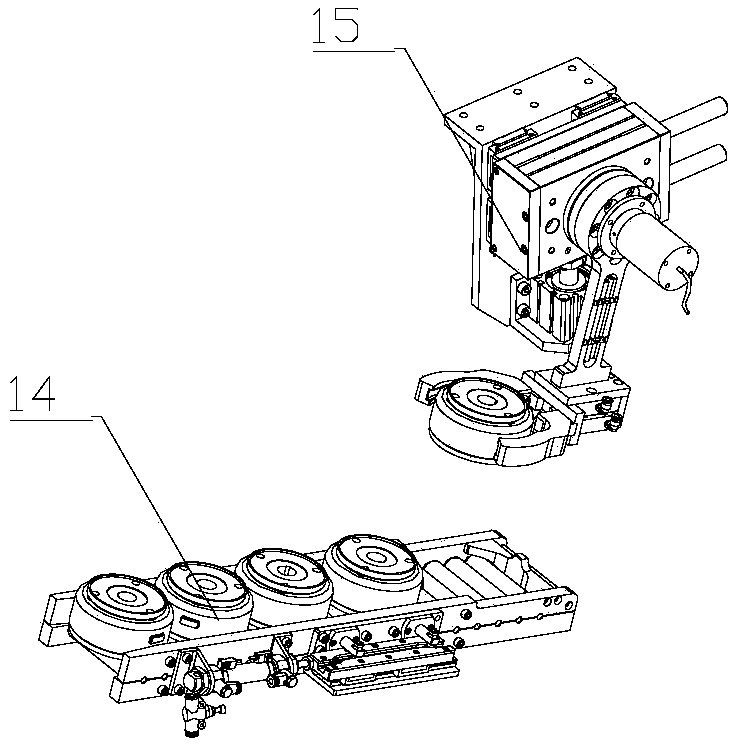

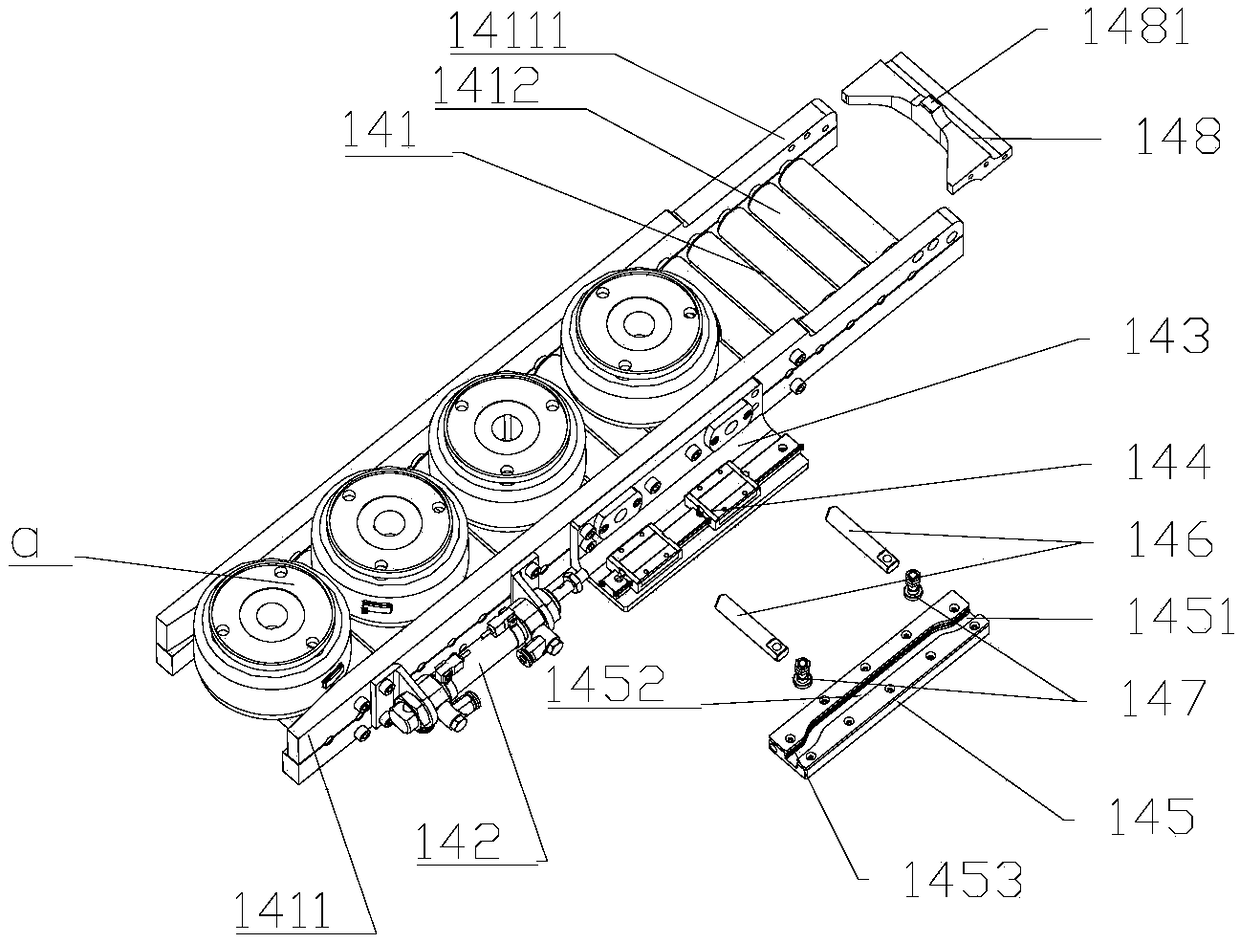

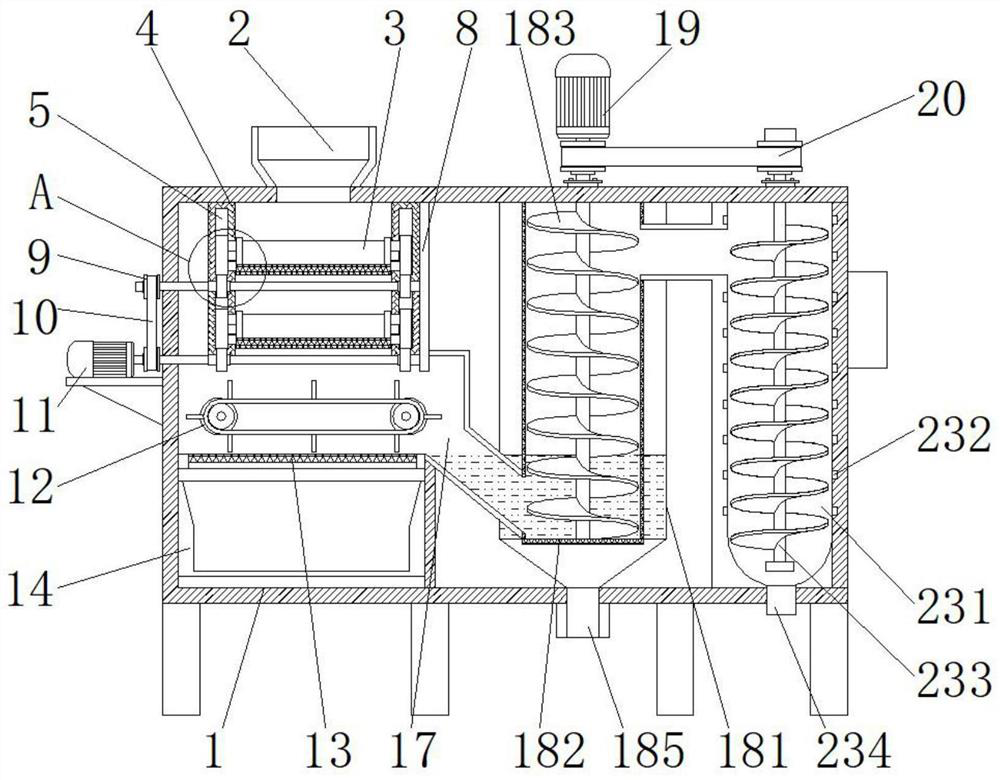

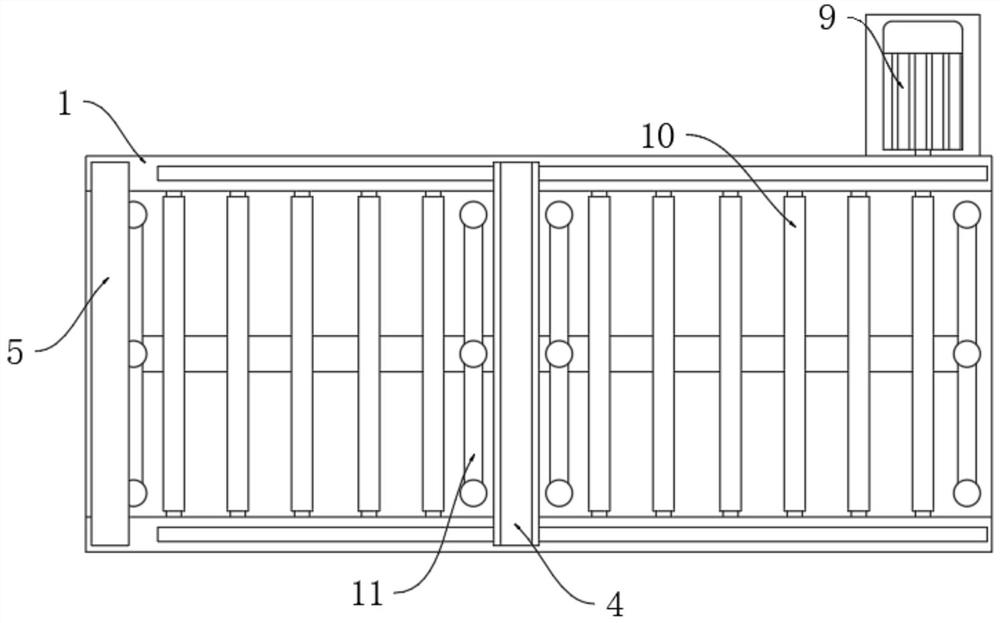

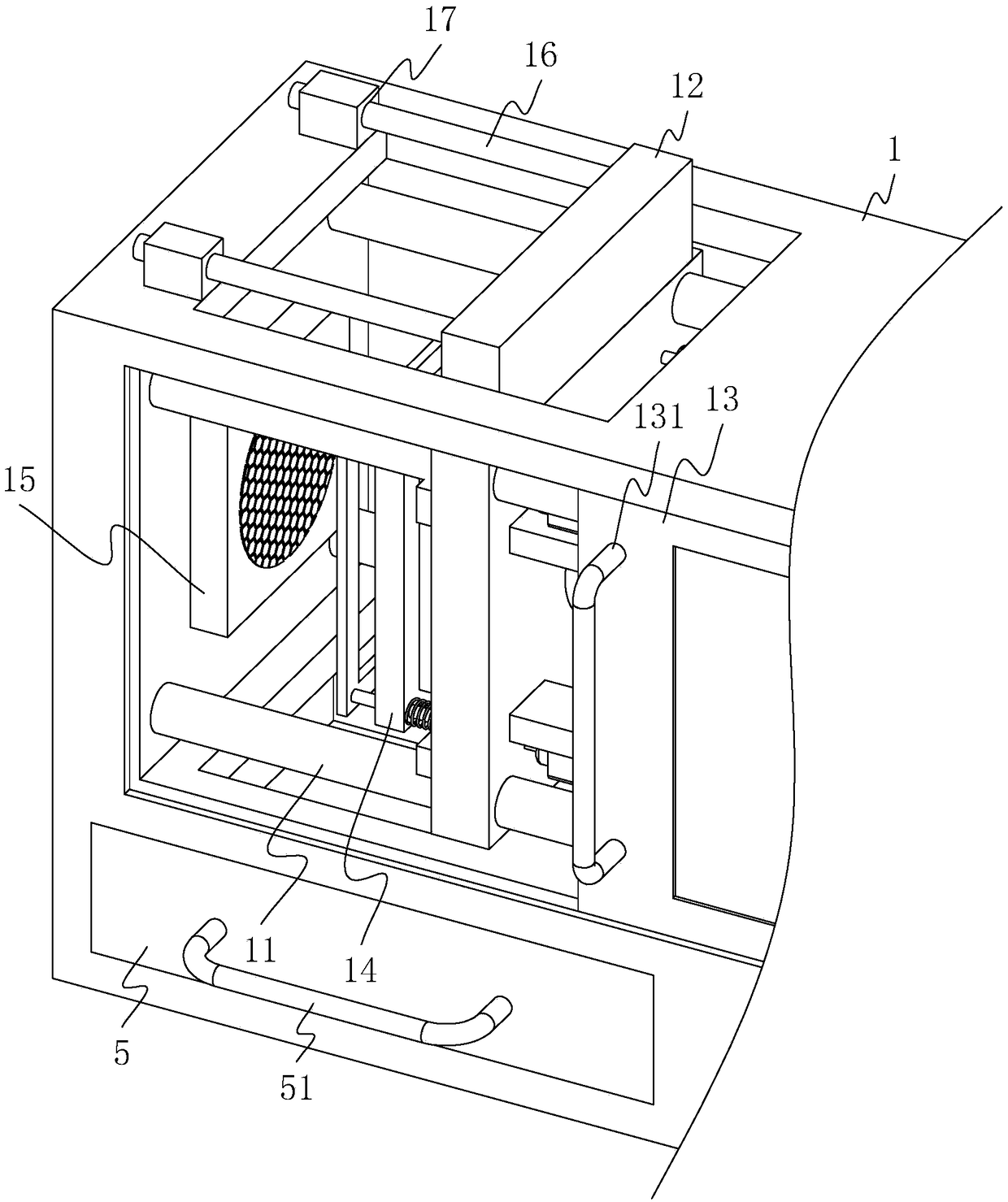

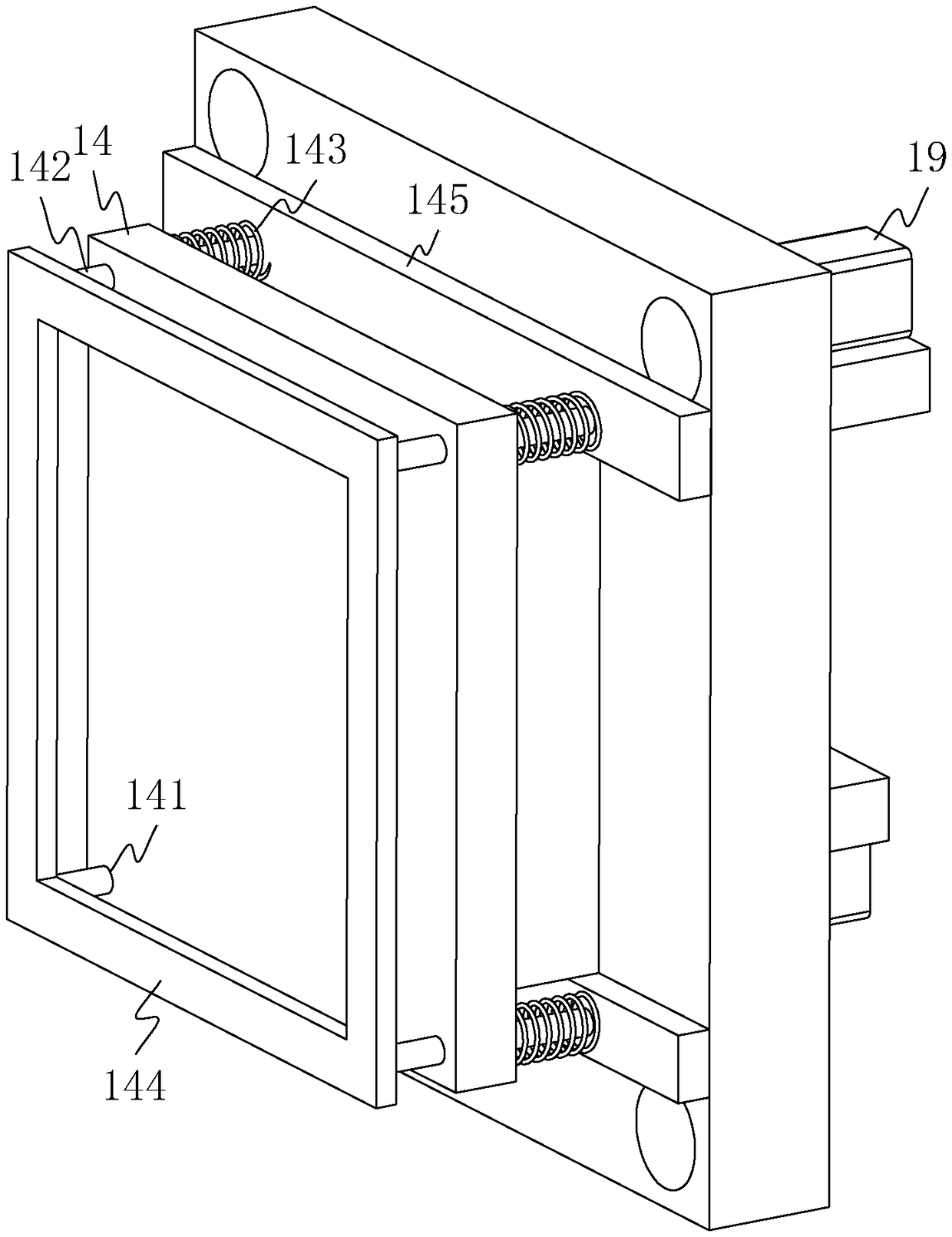

Metallurgical auxiliary material core-wrapped blocks and production device thereof

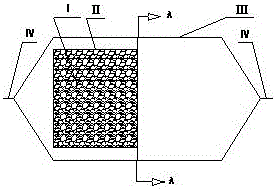

The invention relates to a metallurgical auxiliary material product, in particular to metallurgical auxiliary material core-wrapped blocks and a production device thereof, and belongs to molten iron alloy treatment. The core-wrapped blocks are characterized by being composed of core materials, flexible wrapping films and rigid wrapping covers; press-fit edges are arranged at the two ends, and the core-wrapped blocks are in a lump shape; the diameter ranges from 60 mm to 350 mm; the grain size of the core materials is smaller than 50 mm; the vacuum degree of flexibly-wrapped blocks is smaller than or equal to 200 pa. The production device is formed by connecting a feeding belt, a feeding device, a block mold, a mold conveying chain belt, a vacuum flexible wrapping device, a flexibly-wrapped block conveying device, a rigid wrapping device and a finished product conveying belt. Metallurgical auxiliary materials are conveyed to a feeding bin through the feeding belt, pushed by a feeding screw to be fed, charged into the mold and packaged into the flexibly-wrapped blocks in a flexible wrapping mode in a vacuum chamber; the rigid wrapping device wrap performs roll wrapping, press fit and cutting so that the core-wrapped blocks can be formed. The core-wrapped blocks have the advantages of being novel in concept, small in superficial area, good in sealing performance and metallurgical function, convenient to transport, store and use and high in recovery rate, lowering loss and reducing environmental pollution. The production device is compact in structure, reasonable in arrangement, convenient to operate and high in finished product yield.

Owner:杜先奎

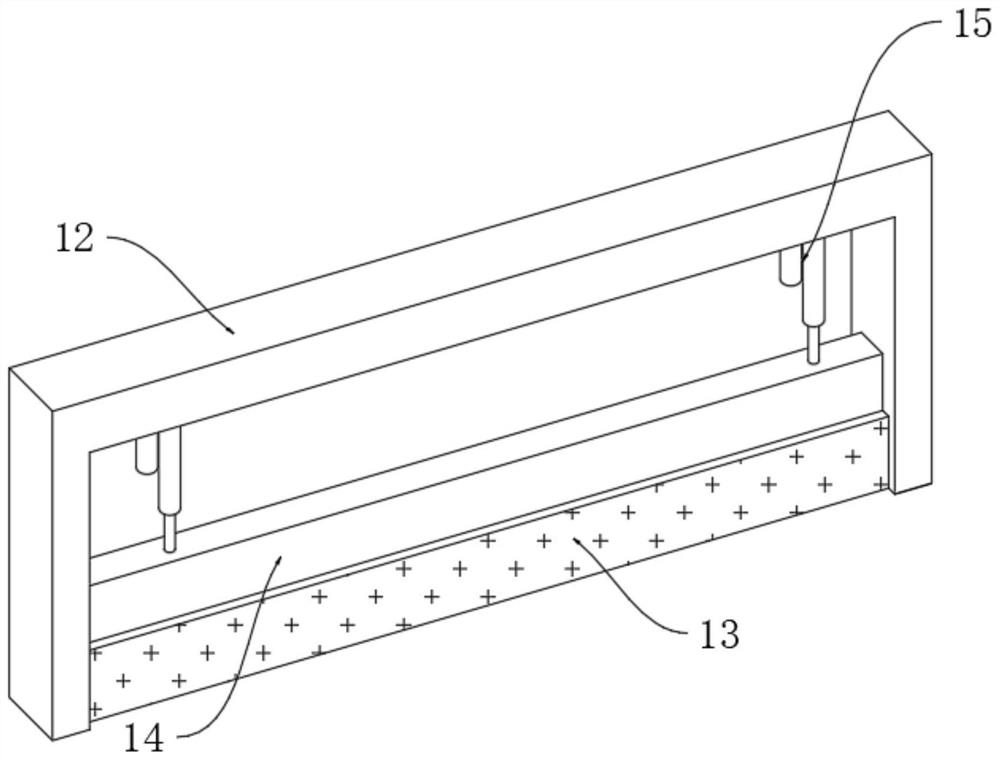

Rib positioning method of reinforced wallboard

ActiveCN112571815AGuaranteed not to shiftPrevent the problem of rib position deviationDomestic articlesMechanical engineeringComposite material

The invention discloses a rib positioning method of a reinforced wallboard, and belongs to the technical field of composite material preparation. The rib positioning method of the reinforced wallboardis characterized by comprising the following steps: a, determining the position of a rubber soft mold through a clamping plate, marking the position of a lower backing plate on the rubber soft mold,and marking the position of the lower backing plate on a skin; b, taking down the rubber soft mold and the lower backing plate, bonding the lower backing plate to the rubber soft mold through a double-sided adhesive tape, and laying a layer of toughening film on the skin, specifically, the toughening film is located under the lower backing plate; c, filling an R area formed by the rubber soft moldand the lower backing plate with a core material; and d, fixing an upper backing plate above the rubber soft mold by adopting a double-sided adhesive tape, laying a layer of toughening film on the inner molded surface of a rib except the brim sewing area, and assembling the rib on the rubber soft mold through a positioning clamping plate. According to the method, the rib can be firmly fixed to the skin, and cannot deviate in the carrying and sewing process, and the percent of pass of finished products is greatly increased.

Owner:CHENGDU AIRCRAFT INDUSTRY GROUP

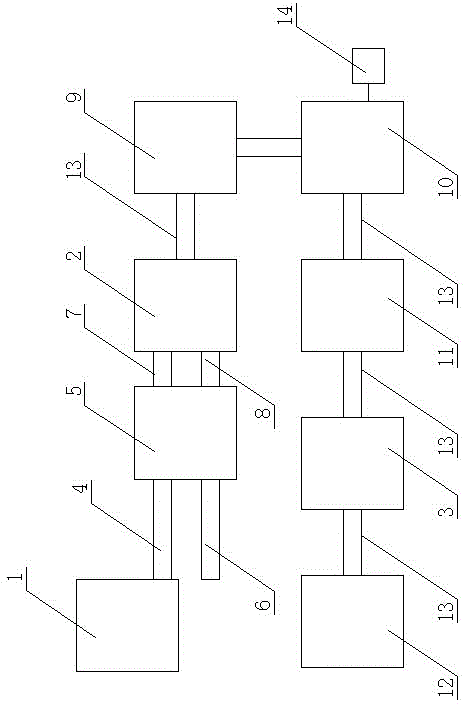

Ultrahigh molecular weight polyethylene lining composite pipe production method and device

ActiveCN104534193ASimple procedureConvenient processing operationRigid pipesFlangingMaterial selection

The invention discloses an ultrahigh molecular weight polyethylene lining composite pipe production method and device, and relates to the field of composite pipe production method and device equipment. The ultrahigh molecular weight polyethylene lining composite pipe production method comprises the steps of pretreatment, material selection, composition, destressing, constant length cut and flanging. The ultrahigh molecular weight polyethylene lining composite pipe production device is characterized in that an outlet of a size reducing machine is provided with a lining pipe conveying device to be connected with one inlet of a cleaning machine, the other inlet of the cleaning machine is provided with a steel pipe conveying device, the cleaning machine is provided with a lining pipe outlet and a steel pipe outlet which are connected with corresponding inlets of a composite mold machine, the composite mold machine, a placement table, a heating box, a constant length cutting machine, a flanging machine and a coupling screw-on machine are connected in sequence, and a composite pipe conveying device is arranged between every two adjacent devices. The ultrahigh molecular weight polyethylene lining composite pipe production method is simple, the lining composition effect is good, the phenomenon that an outer pipe is stripped or disengaged from an inner pipe is avoided, the technological difficulty degree is low, working efficiency is high, the product percent of pass is high, the product quality is improved, the product has the ultrahigh wear resistance, and manufactured composite pipes are long in using period.

Owner:大庆高新区法尔文得新材料有限公司

Processing method of low-expansion-coefficient nylon heat-insulating strip master batch

The invention discloses a low-expansion-coefficient nylon heat-insulating strip master batch. The master batch is prepared from nylon 66 resin, alkali-free glass fibers, an antioxidant, calcium sulfate whiskers, black master batch and inorganic filler according to the mass ratio of 50 to 25 to 0.8 to 11.5 to 0.7 to 12. The invention also discloses a processing method of the master batch. The processing method comprises the following steps of step 1, preparing raw materials; step 2, premixing the raw materials; step 3, melting the raw materials and granulating; step 4, screening; and step 5, cleaning and drying. The master batch can be screened, cleaned, dried in a same device, labor consumption and energy consumption are effectively reduced, movement of multiple devices of the master batchis avoided, abrasion damage to the master batch is reduced, the quality of the master batch is better, nylon 66 resin is adopted as a raw material of the master batch, the master batch has the characteristics of high mechanical strength, high melting point and the like, so that the melt-extruded master batch has the advantages of low expansion coefficient, high heat resistance, high strength, high toughness and the like.

Owner:安徽中鑫宏伟科技有限公司

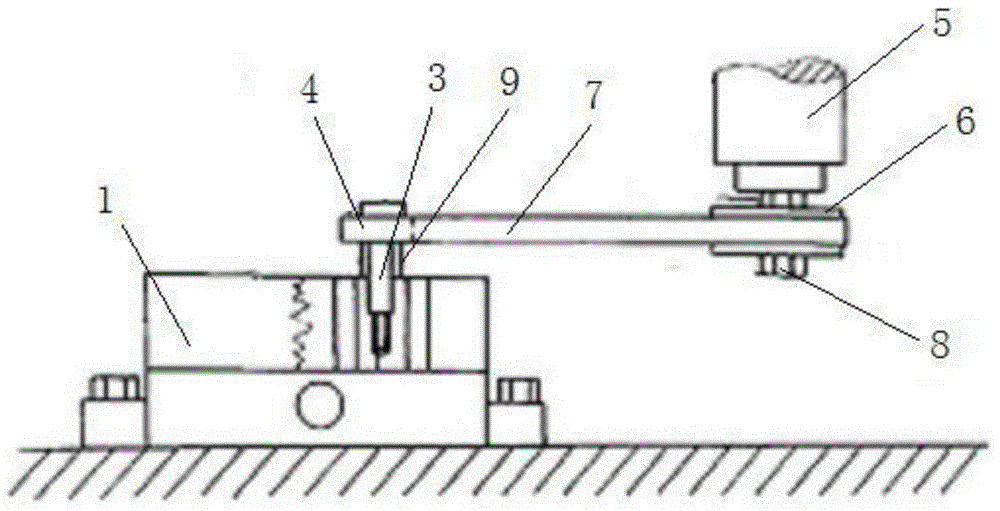

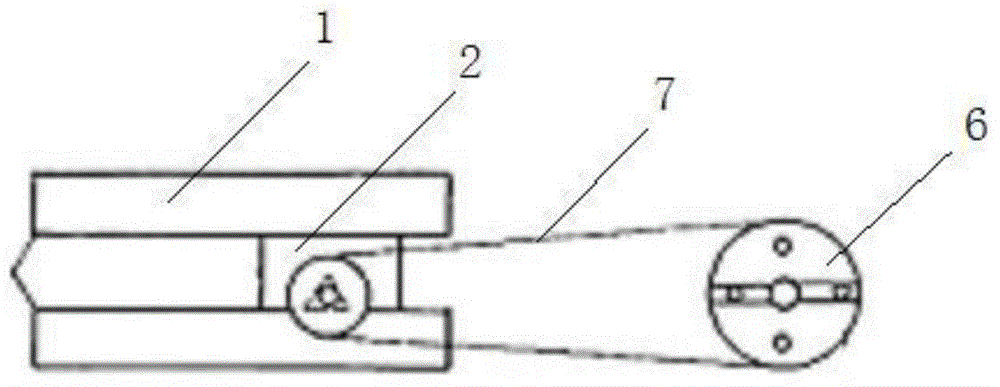

Abrasive belt device for deburring of deep and narrow trench

InactiveCN104827373ASimple structureEasy to manufactureBelt grinding machinesMachine toolRotating disc

The invention discloses an abrasive belt device for deburring of a deep and narrow trench. The abrasive belt device comprises a clamping table, wherein a V-type block is clamped in the clamping table and provided with a shaft; the top end of the shaft extends out of the V-type block; the extending end is sleeved with a bearing; the other side of the clamping table is provided with a machine tool shaft installed on a machine tool; the machine tool shaft and the shaft are parallel; a rotary disc is arranged at the end of the machine tool shaft in a sleeving mode; the rotary disc and the bearing are located on the same horizontal line; an abrasive belt is arranged between the rotary disc and the bearing in a sleeving mode. The abrasive belt device is simple in structure and convenient to manufacture; through the abrasive belt device added at the machine tool shaft of the machine tool and composed of the clamping table, the abrasive belt and the like, deburring of the deep and narrow trench of a metal part is finished through rotation of the machine tool shaft conveniently, and the acceptability of the metal part with the deep and narrow trench is improved.

Owner:铜陵市永生机电制造有限责任公司

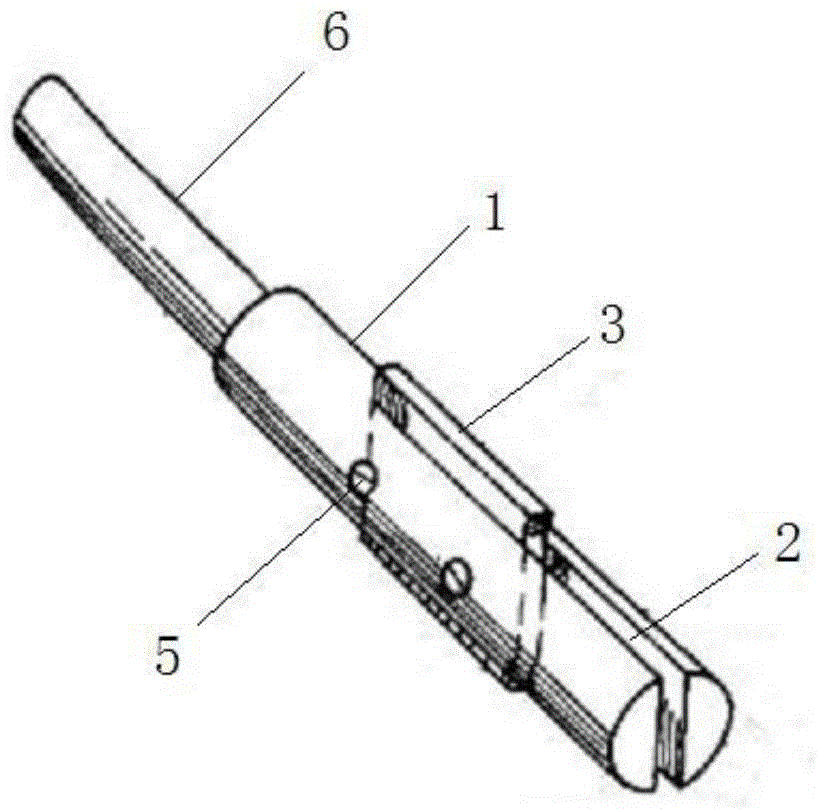

Tool for scraping burrs of short pipe end

The invention discloses a tool for scraping burrs of a short pipe end. The tool comprises a cylindrical rod, a clamping groove is formed in one end of the cylindrical rod in the axial direction, a scraper is clamped in the clamping groove, the side wall of the scraper stretches out of the clamping groove, and the scraper is arranged on the axial surface of the cylindrical rod in a protruding mode. The tool is simple in structure and convenient to manufacture, the scraper protruding out of the surface of the cylindrical rod is clamped in the cylindrical rod, the rotation of the cylindrical rod can be conveniently utilized, the scraper is driven to remove the burrs on the end face of the short pipe end, and the qualification rate of a short pipe product is increased.

Owner:铜陵市永生机电制造有限责任公司

Processing device for hot bending glass

The invention discloses a processing device for hot bending glass, relates to the technical field of glass production and processing devices, and aims to solve the problems that glass is easy to vibrate and damage due to cutting under the condition that the glass is not fixed, and most of glass is manually rectified when being put into a platform, so that errors are generated, and the glass cutting end surface is uneven. A driving shaft is arranged in the operation table shell, a cutting base and a limiting mechanism are arranged above the operation table shell, the cutting base is located onone side of the limiting mechanism, a fixing frame is arranged below the driving shaft, and deviation rectifying plate grooves are formed in the two sides of the interior of the operation table shell.

Owner:江苏佳成特种玻璃制造有限公司

A lathe fixture suitable for processing thin-walled ring block parts

ActiveCN112475951BAvoid vibrationImprove qualificationWork clamping meansPositioning apparatusMachining deformationAero engine

The invention relates to the technical field of aero-engines, in particular to a lathe fixture suitable for processing thin-walled ring-block parts, which is used for clamping thin-walled ring-block parts with thin walls that need to be processed. , the fixture is a circular disk surface, and a plurality of independent fixed blocks are evenly and symmetrically arranged on it. All the fixed blocks form a ring that is concentric with the circular disk surface of the fixture; Arrange the same number of unit fixtures as the fixed block, and evenly open square holes at the bottom of the fixed block, corresponding to the position of the unit fixture; each set of unit fixtures includes a pressing platen and a tensioning platen to fix the process edge and thin-walled ring block parts on the fixture in multiple directions . The invention effectively improves the clamping rigidity of the thin-walled ring block type parts by turning, avoids the chattering in the parts processing, reduces the processing deformation, greatly improves the qualified rate of the parts, and saves the cost.

Owner:SHENYANG LIMING AERO-ENGINE GROUP CORPORATION

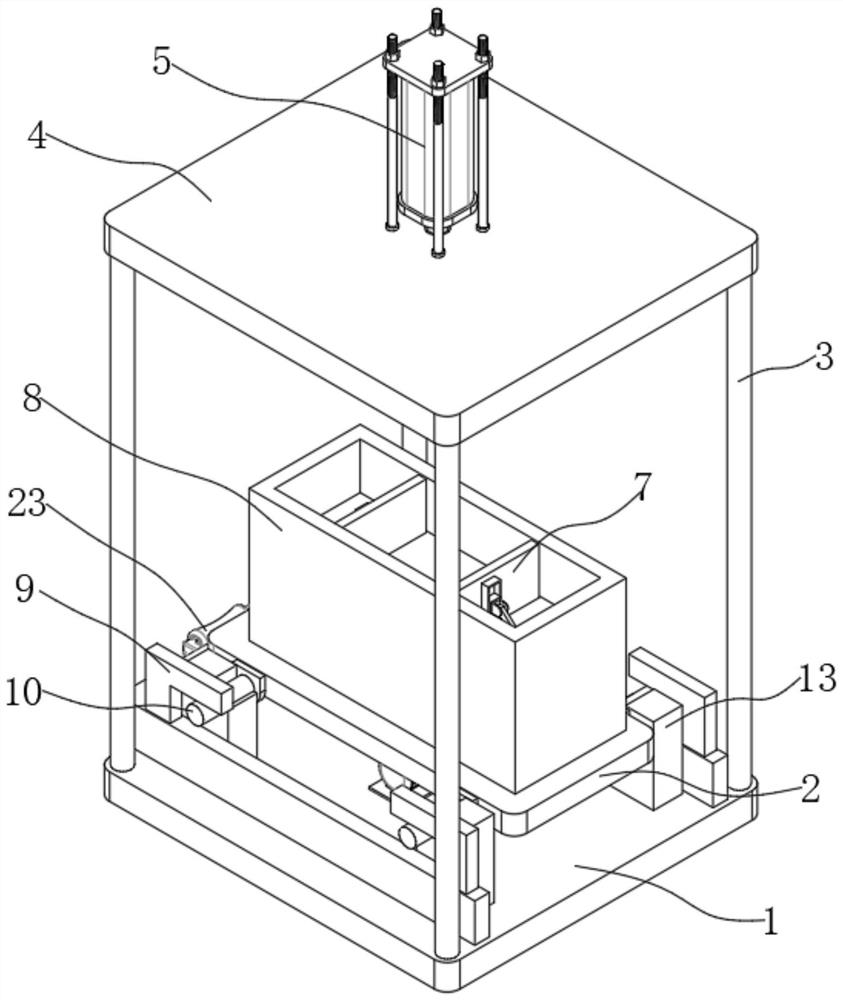

Forging die with casting positioning function

InactiveCN113333659AImprove qualificationReduce misalignmentForging/hammering/pressing machinesForging press drivesPhysicsEngineering

The invention discloses a forging die with a casting positioning function. The forging die comprises a base and a supporting plate, four supporting columns are fixedly installed on the upper surface of the base, a top plate is jointly and fixedly installed on the tops of the four supporting columns, and a pressure applying device for extruding a casting is arranged on the upper surface of the top plate; four supporting blocks are fixedly connected to the upper surface of the base, two clamping rollers are fixedly installed at the symmetrical positions of the front surface and the rear surface of the supporting plate, the clamping rollers are placed in grooves formed in the tops of the supporting blocks, and a driving mechanism capable of enabling the supporting plate to turn over in different directions is arranged on the upper surface of the base; and a mounting frame is fixedly mounted on the upper surface of the supporting plate, and a bearing mechanism for placing the casting to facilitate forging is arranged in the mounting frame. The forging die has the advantages of being good in centering effect, small in offset generated by an upper die body and a lower die body, and high in forging qualification rate.

Owner:赵玉敏

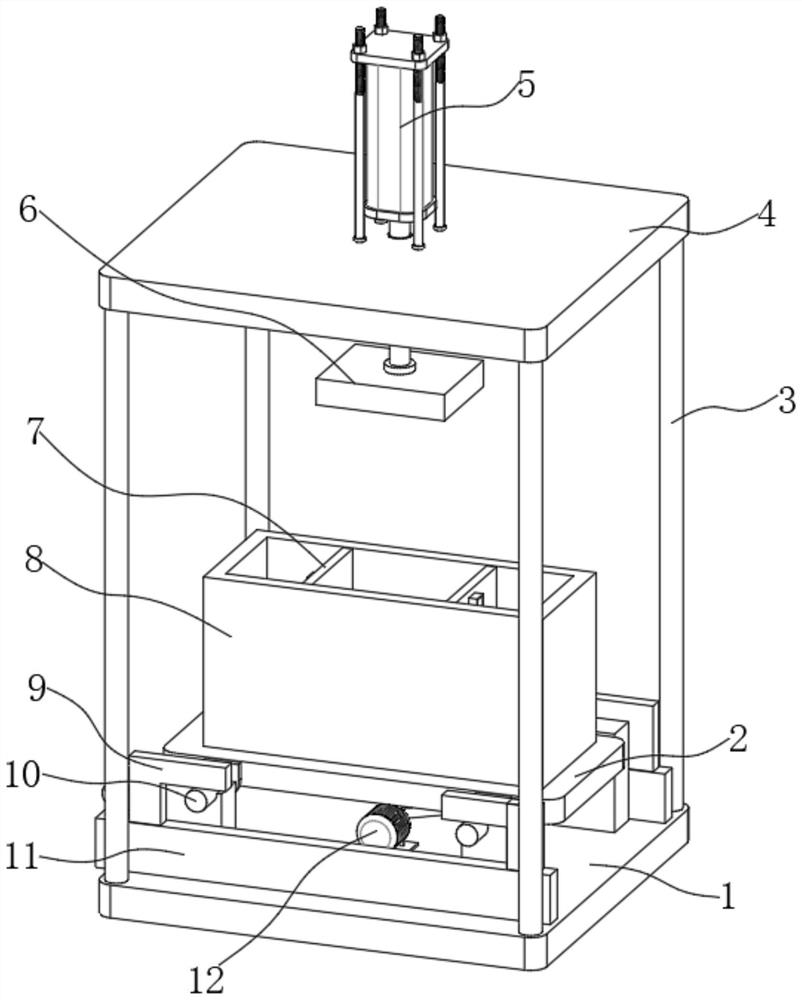

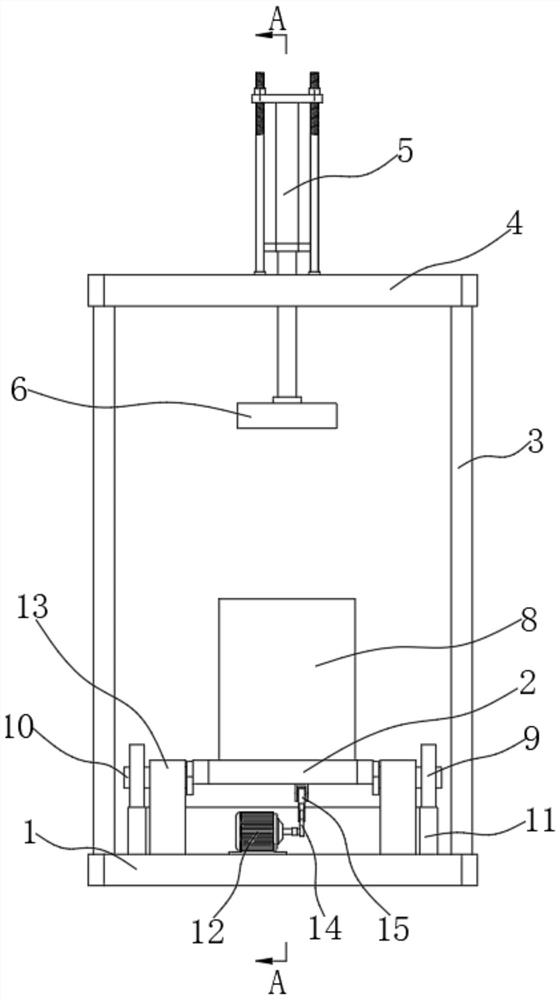

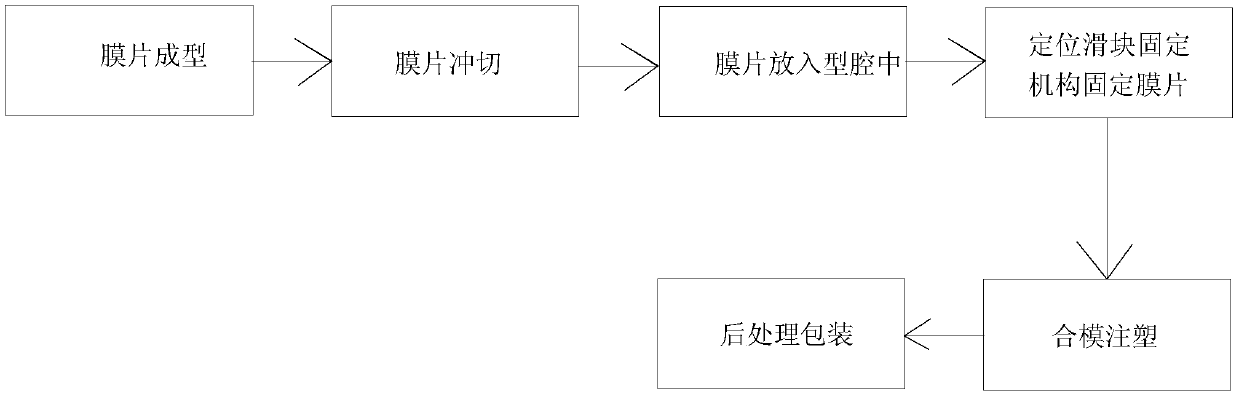

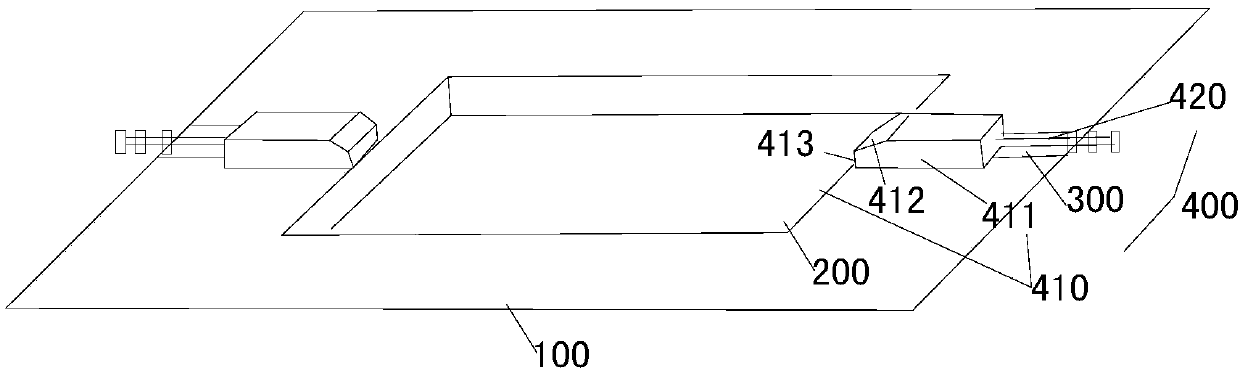

INS film laminated product production process and diaphragm sliding block fixing mechanism during injection molding

PendingCN109624193ASolve mobilePrevent the phenomenon of compression moldingCoatingsAfter treatmentEngineering

The invention discloses an INS film laminated product production process and a diaphragm sliding block fixing mechanism during injection molding. The production process comprises the following technological steps of conducting diaphragm molding, conducting diaphragm cutting, putting a diaphragm into a mold cavity, fixing the diaphragm through a locating sliding block fixing mechanism, conducting mold closing and injection molding and conducting after-treatment and packaging. Through the INS film laminated product production process, the problems that the height of the side face of a product issmall and structural diaphragms to be overturned cannot be fixed are solved; the problem of moving of the diaphragms in the mold cavity is effectively solved; the phenomenon that the diaphragms are pressed during mold closing is prevented; and the product quality and the qualified rate are improved.

Owner:ATRA PLASTICS SHANGHAI

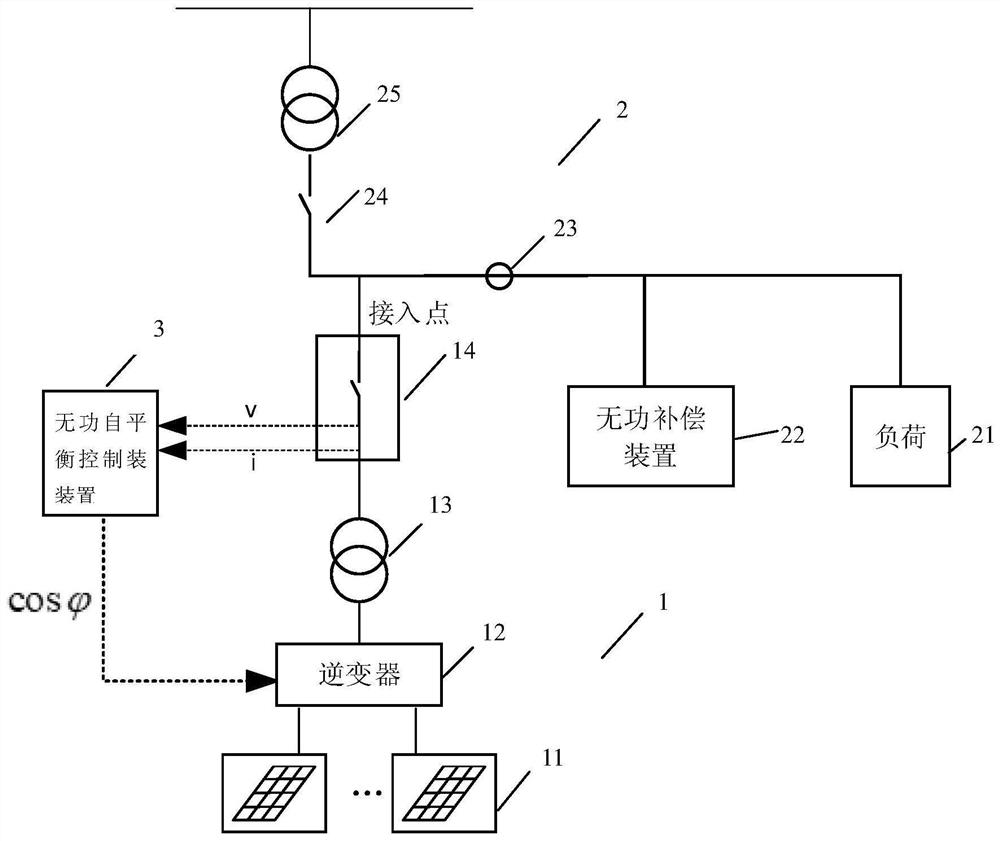

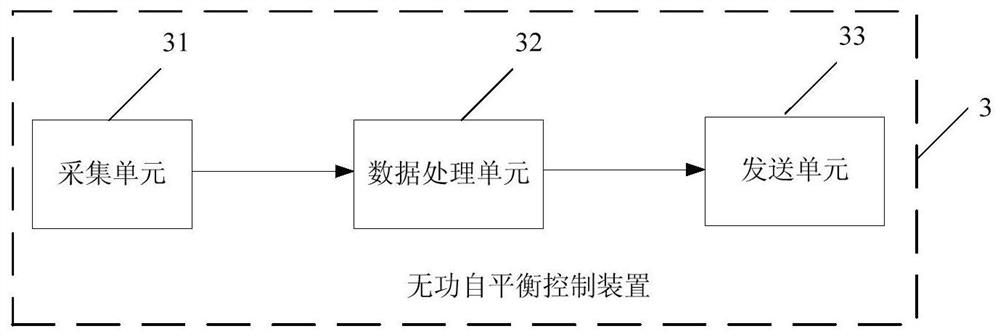

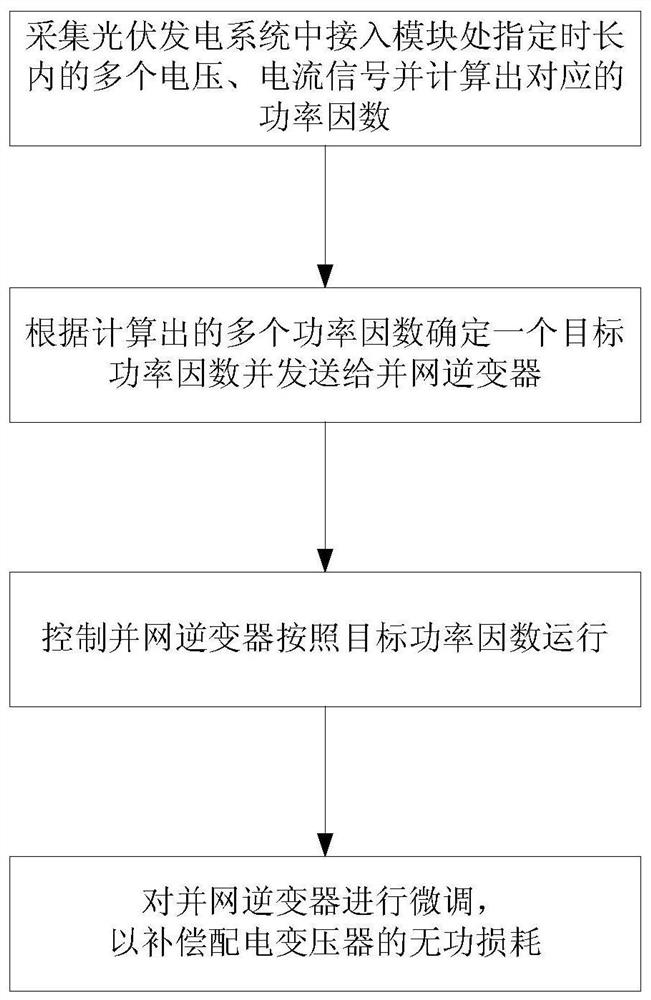

Distributed photovoltaic power station system and reactive self-balancing control method

ActiveCN112653178ACompensation for reactive power lossPrevent misoperationSingle network parallel feeding arrangementsReactive power adjustment/elimination/compensationGrid connected inverterControl engineering

The invention discloses a distributed photovoltaic power station system and a reactive self-balancing control method. The system comprises a photovoltaic power generation system, the photovoltaic power generation system comprises a photovoltaic module, a grid-connected inverter, a photovoltaic transformer and an access module which are connected in sequence, and the output end of the access module is connected to a user low-voltage power distribution system. The system further comprises a reactive self-balancing control device connected with the photovoltaic power generation system, and the reactive self-balancing control device collects a plurality of voltage and current signals at the access module within a specified time length, calculates a corresponding power factor, determines a target power factor according to each calculated power factor and sends the target power factor to the grid-connected inverter to control the grid-connected inverter to operate according to the target power factor. The system has the advantages of being simple in structure, low in cost, capable of achieving reactive self-balance and improving the power factor of a gateway point, good in reactive adjustment control effect and the like.

Owner:ZHUZHOU NAT ENG RES CENT OF CONVERTERS

Full-automatic machining equipment for inner cores of car seat cushions

The invention discloses full-automatic machining equipment for inner cores of car seat cushions and relates to the field of machining equipment for the inner cores of the car seat cushions. The equipment comprises a rack, mounting rods horizontally arranged inside the rack and a mounting seat glidingly connected to the mounting rods; a moving die is arranged on the side wall of the mounting seat;a fixed die is arranged on the side wall of one side, close to the mounting seat, of the rack; sliding holes penetrate through the periphery of the moving die; sliding rods slide inside the sliding holes; a pressing frame abutting against the side wall of the moving die is arranged at one end of each sliding rod; a pair of connecting plates for fixing every two corresponding sliding rods into a whole is arranged at the rest ends of the sliding rods; and air cylinders for driving the connecting plates to move are arranged on the side wall of one side, far away from the pressing frame, of the mounting seat. The equipment has the advantages and effects as follows that an automatic clamping mechanism and a full-automatic feeding mechanism for sweat absorption net cloth are arranged, so that the sweat absorption net cloth is fed automatically while clamped and fixed automatically, the manpower is saved, the production efficiency is improved, and the high automation effect is realized.

Owner:台州三匠汽车用品有限公司

Smelting and pouring process of L245 pipeline steel

ActiveCN112593038AControl curling cracksReduce curling cracksManufacturing convertersProcess efficiency improvementAcid etchingSteelmaking

The invention discloses a smelting and pouring process of L245 pipeline steel, and relates to the technical field of metallurgical steelmaking. The production steps of the L245 pipeline steel are strictly controlled, and the process comprises the steps of molten iron component inspection, steel pressing production rhythm control, L245 narrow component control, converter continuous casting, whole-process N content detection, converter smelting process control, optimization of high pulling speed stability of all section blank types of continuous casting, optimization of continuous casting pouring process control and increase of the casting blank corner acid quality detection link. Through acid etching detection of the N content in molten iron and a casting blank in the production process, the N content of a product in the production process is controlled to be 32 ppm on average, the N content of a finished product is controlled to be 48 ppm on average, the N content is reduced by 10-20 ppm compared with the prior art, and the total product inclusion content is reduced by 0.5-1.5 level compared with the prior art; and the edge curling cracks of the pipeline steel are effectively controlled, the casting blank defect offline rate is reduced to 2% or below from 5%, the product qualification rate is increased to 99% or above, a foundation is laid for stabilizing subsequent high-quality variety steel production, and the effect is remarkable.

Owner:TANGSHAN YANSHAN IRON & STEEL CO LTD

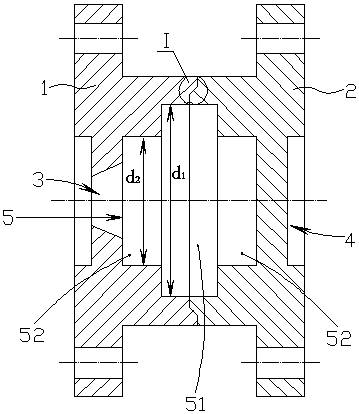

Special casting mold for double-floating ring blank of floating oil seal

PendingCN108356235AImprove qualityImprove qualificationFoundry mouldsFoundry coresCircular discDrive shaft

The invention discloses a special casting mold for a double-floating ring blank of a floating oil seal. The special casting mold comprises a left disc-shaped half mold and a right disc-shaped half mold which are matched with each other, a casting material inlet is formed in the left disc-shaped half mold, and a transmission shaft mounting and positioning groove is formed in the right disc-shaped half mold; when the left disc-shaped half mold and the right disc-shaped half mold cooperate oppositely, a mold cavity communicating with the casting material inlet is formed inside the left disc-shaped half mold and the right disc-shaped half mold, the mold cavity is composed of a middle mold chamber and two side mold chambers which are positioned on the two sides of the middle mold chamber, and the radial dimension d1 of the middle mold chamber is larger than the radial dimension d2 of the two side mold chambers. The double-floating ring blank for centrifugal casting is composed of a middle ring and floating rings with the reduced diameters of the left side and the right side, so that the floating rings with the reduced diameters of the left side and the right side are machined into the floating rings used for two floating oil seals, the quality is good, and the product percent of pass is high.

Owner:铁岭桦林浮动油封有限公司

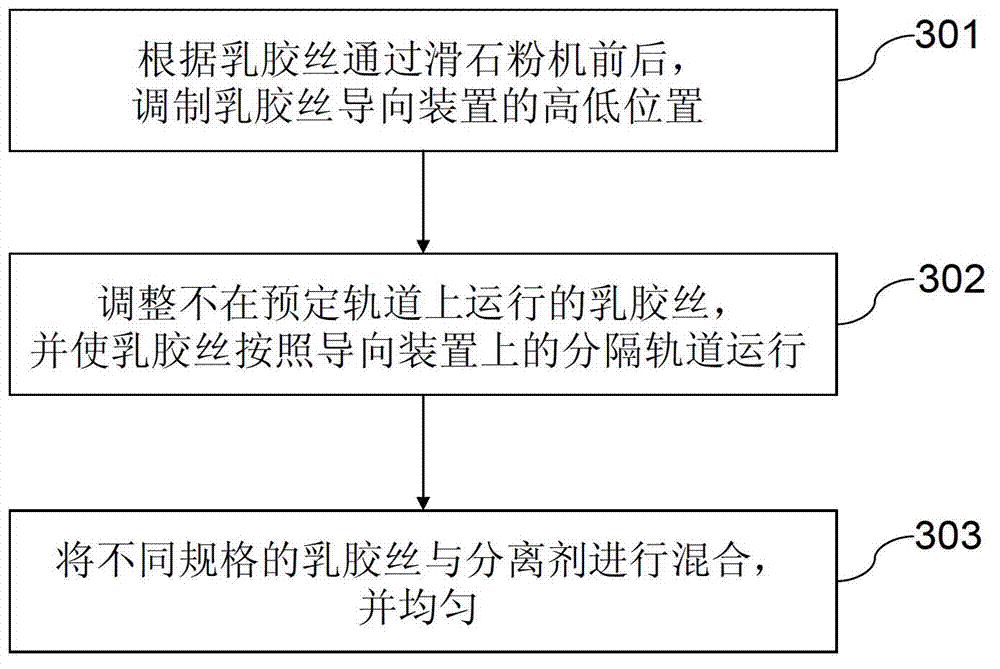

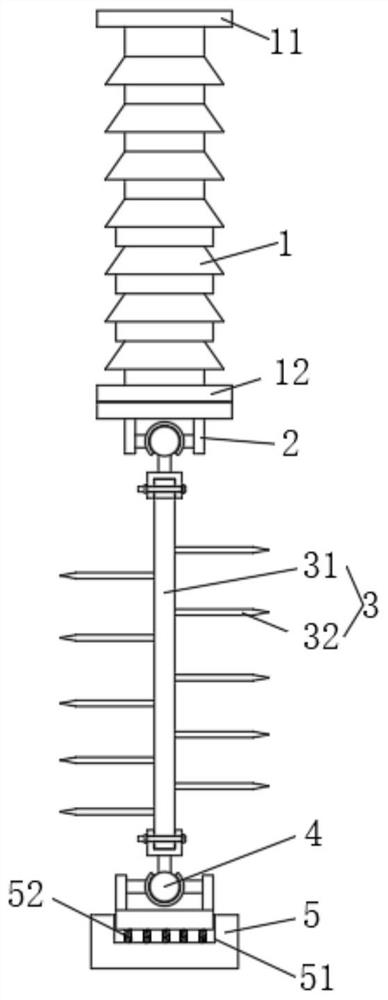

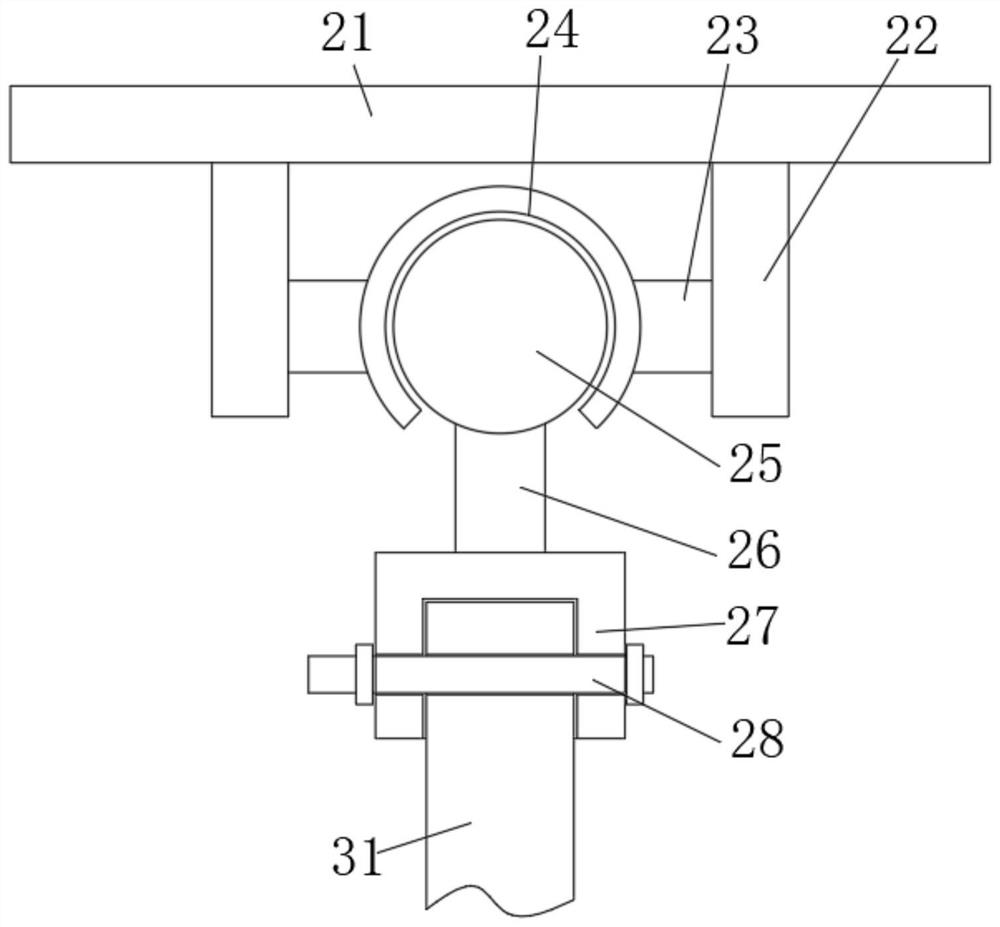

Latex thread separation guide adjusting device and method

The invention discloses a latex thread separation guide adjusting device and method. The device comprises a guide separation mechanism and an adjusting mechanism. The adjusting method comprises the following steps of: adjusting the high-low position of a latex thread guide device by an adjusting structure before and after latex thread passes through a talc powder machine; adjusting the latex thread not running on a predetermined track, and enabling the latex thread to run along a separation track on the guide device; and uniformly mixing the latex threads of different specifications with a separation agent. The device and method disclosed by the invention are suitable for different working interfaces when the latex threads of different specifications are mixed with the separation agent (talc powder), and the separation agent is uniformly consumed on different working interfaces in a mixing process; and the phenomenon of thread sticking is completely avoided, all latex threads can be sufficiently mixed with the separation agent (talc powder) for sure, and the whole product qualification rate is improved by 0.5-1.5%.

Owner:广东国兴乳胶丝有限公司

Efficient environment-friendly white cement production method

ActiveCN113860762AImprove qualificationIncrease productivityCombination devicesCement productionPotassium feldsparProcess engineering

The invention provides an efficient environment-friendly white cement production method which comprises the following steps: S1, raw material preparation; S2, clinker preparation: conveying a part of petroleum coke in a powder state to an outlet end of a rotary kiln, and burning at the outlet end to heat the rotary kiln; conveying the other part of the petroleum coke into a decomposing furnace at the bottom end of the cyclone preheater, and burning the petroleum coke in the decomposing furnace to heat the cyclone preheater; s2, feeding the raw material prepared in the step S1 into the cyclone preheater, and performing multi-stage preheating on the raw material; enabling the raw materials obtained after preheating to enter a rotary kiln to be calcined, preparing the clinker, in the calcining process, discharging flue gas at the kiln head to a kiln head electric dust collector, and discharging flue gas at the kiln tail to a kiln tail bag-type dust collector; s3, preparing a finished product; the petroleum coke is introduced as the calcining raw material so that the production efficiency can be effectively improved, and the restriction of coal on white cement quality improvement and the disadvantage of high price of natural gas are solved; meanwhile, alkali-containing pyrophyllite and potassium feldspar are introduced as raw materials to eliminate sulfur generated in petroleum coke calcination.

Owner:阿尔博波特兰安庆有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com