Full-automatic machining equipment for inner cores of car seat cushions

A technology for automobile seat cushions and processing equipment, which is applied in applications, household components, household appliances, etc., can solve the problems of increasing labor intensity of workers, complicated and complicated production and manufacturing processes, etc., and achieves convenient and fast access, transportation, and maintenance. The effect of labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0039] The present invention will be described in further detail below in conjunction with the accompanying drawings.

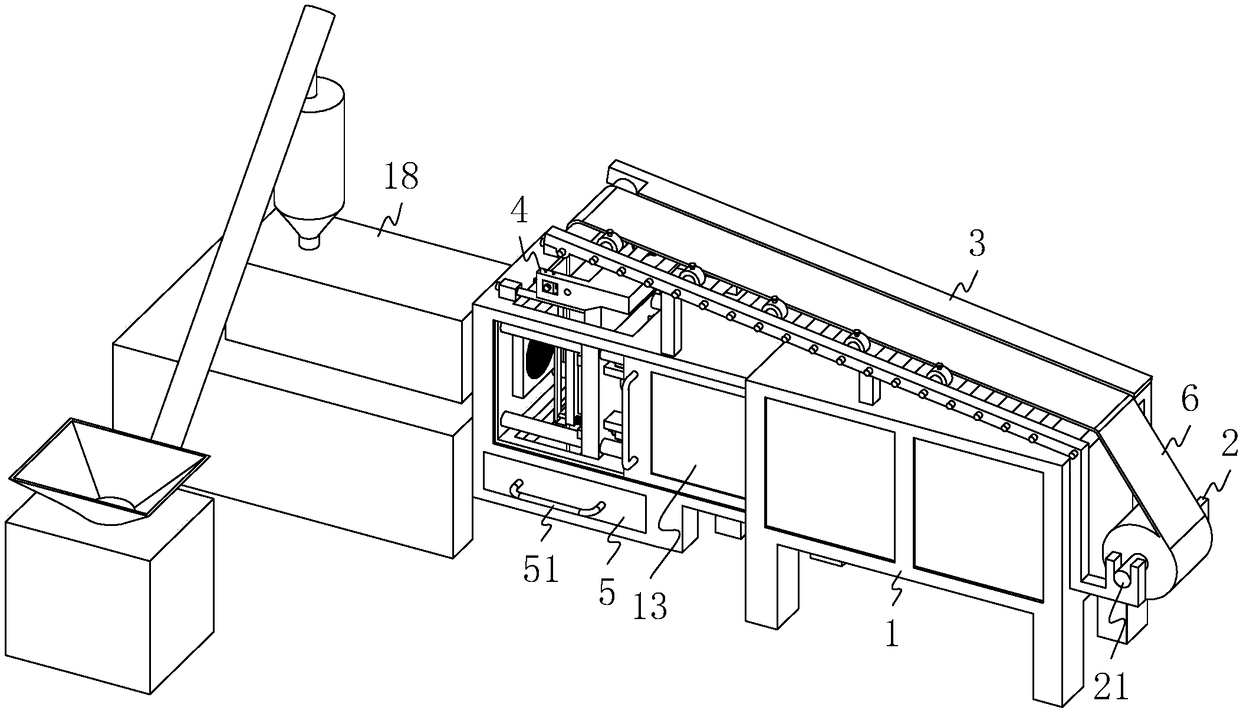

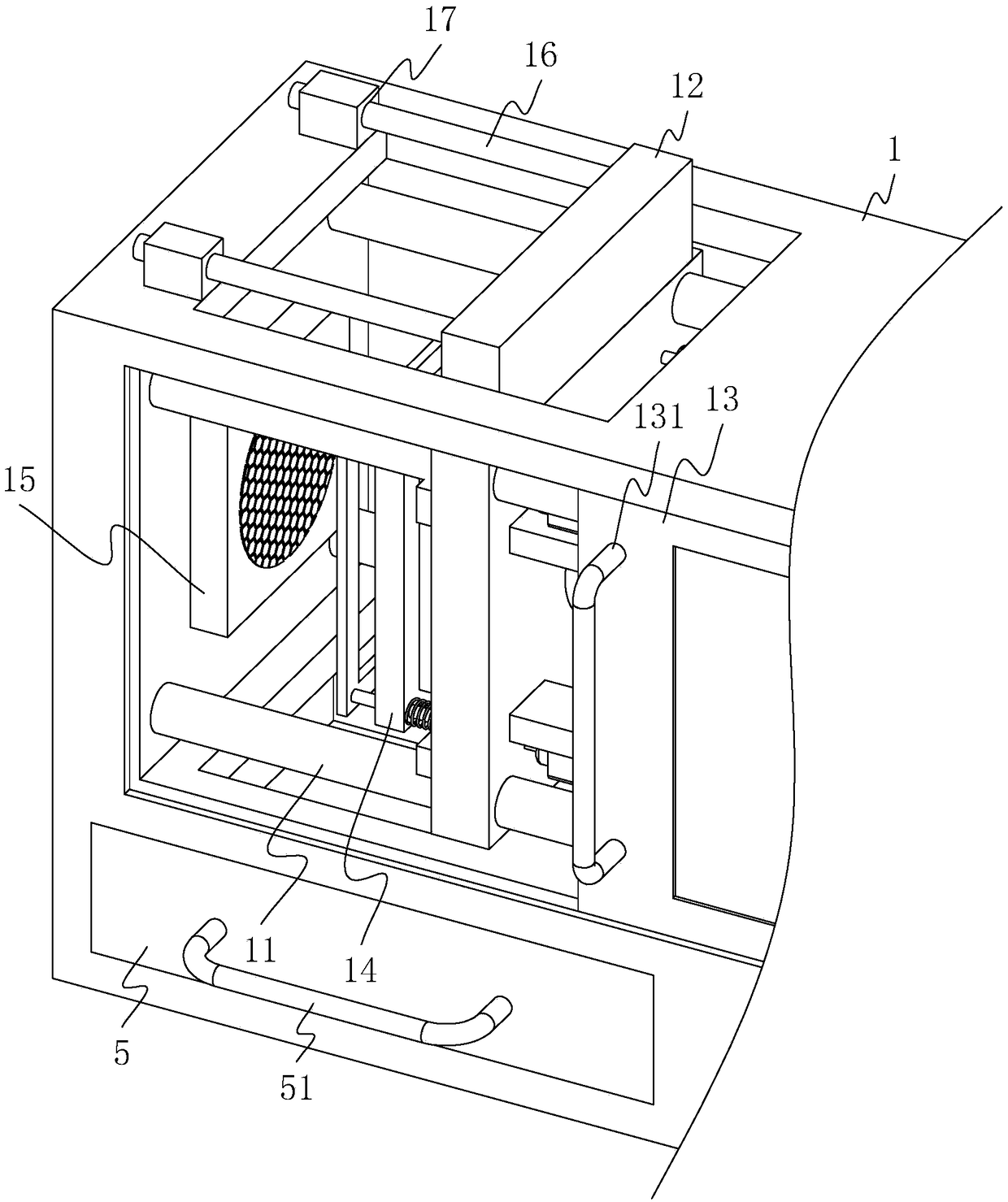

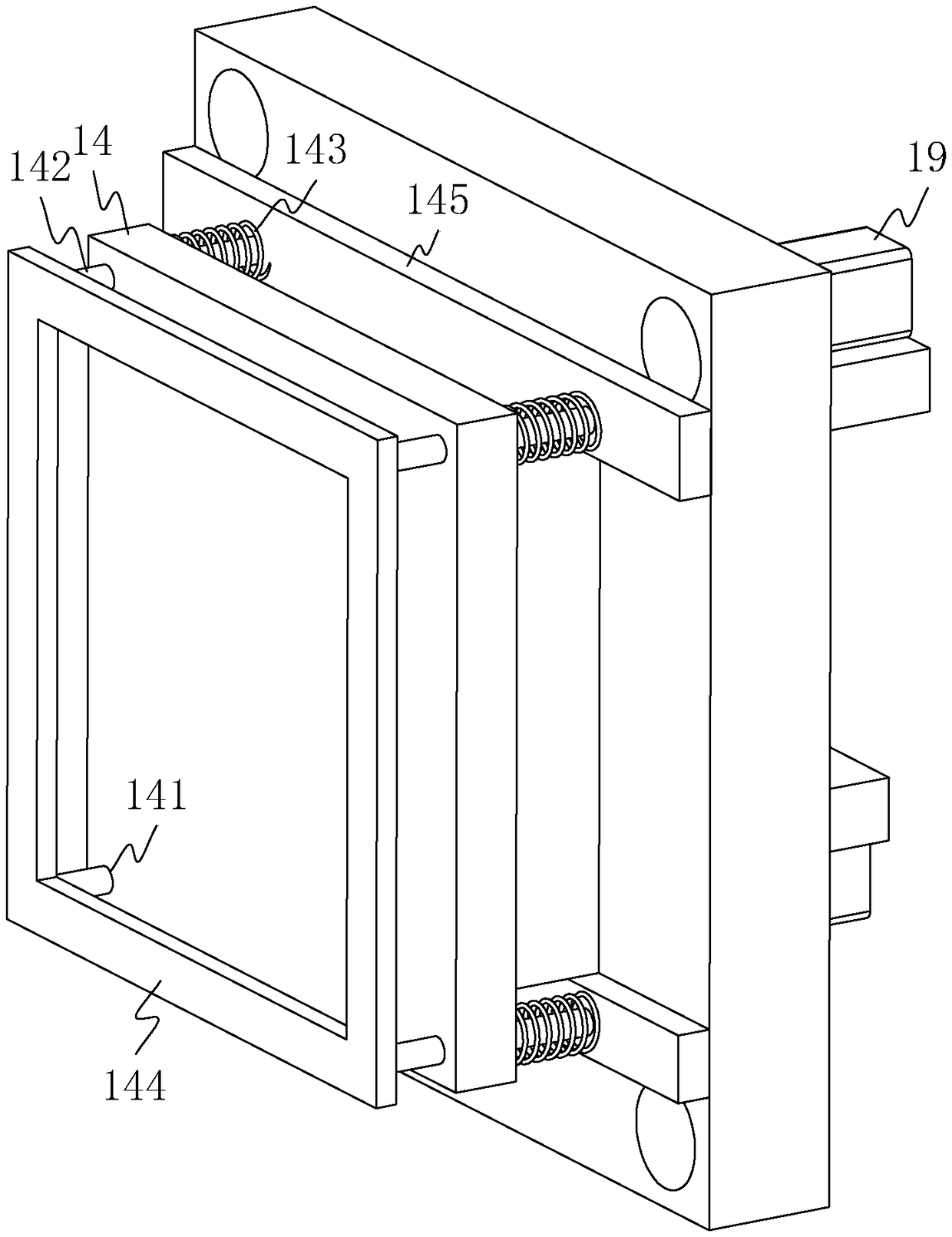

[0040] A kind of automatic processing equipment for the inner core of automobile seat cushion, such as figure 1 , figure 2 As shown, it includes a frame 1, a plurality of mounting rods 11 horizontally arranged inside the frame 1, and mounting seats 12 that are slidably connected to the mounting rods 11. Transparent protective doors 13 are slidably connected to both sides of the frame 1, and the protective doors 13 is provided with a handle 131, the side wall of the mounting base 12 is provided with a movable mold 14, the side wall of the frame 1 close to the mounting base 12 is provided with a fixed mold 15, and the upper end surface of the mounting base 12 is horizontally provided with a pair of guide rods 16, The side wall of the frame 1 is provided with a guide hole 17 for the insertion and sliding of the guide rod 16 , and the side of the frame 1 near ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com