Patents

Literature

226 results about "Automobile seat cushion" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Clean production method of chromium-free automobile cushion leather

The clear production method for Cr-free vehicle seat cushion comprises: hair-saving, combing acid and base for expansion; ammonia-free deliming, dipping weak acid and low slat, Cr-free bating, composite batting, and adding strong-absorption fat for dyeing to treat skin from pig, cattle or sheep. The product has shrinkage temperature up to 110Deg, shows well hand feeling and resistance to thermal and age. This invention reduces material quantity and 30-50% sewage discharge, improves absorption rate, and brings a new way for Cr-free leather.

Owner:SICHUAN UNIV

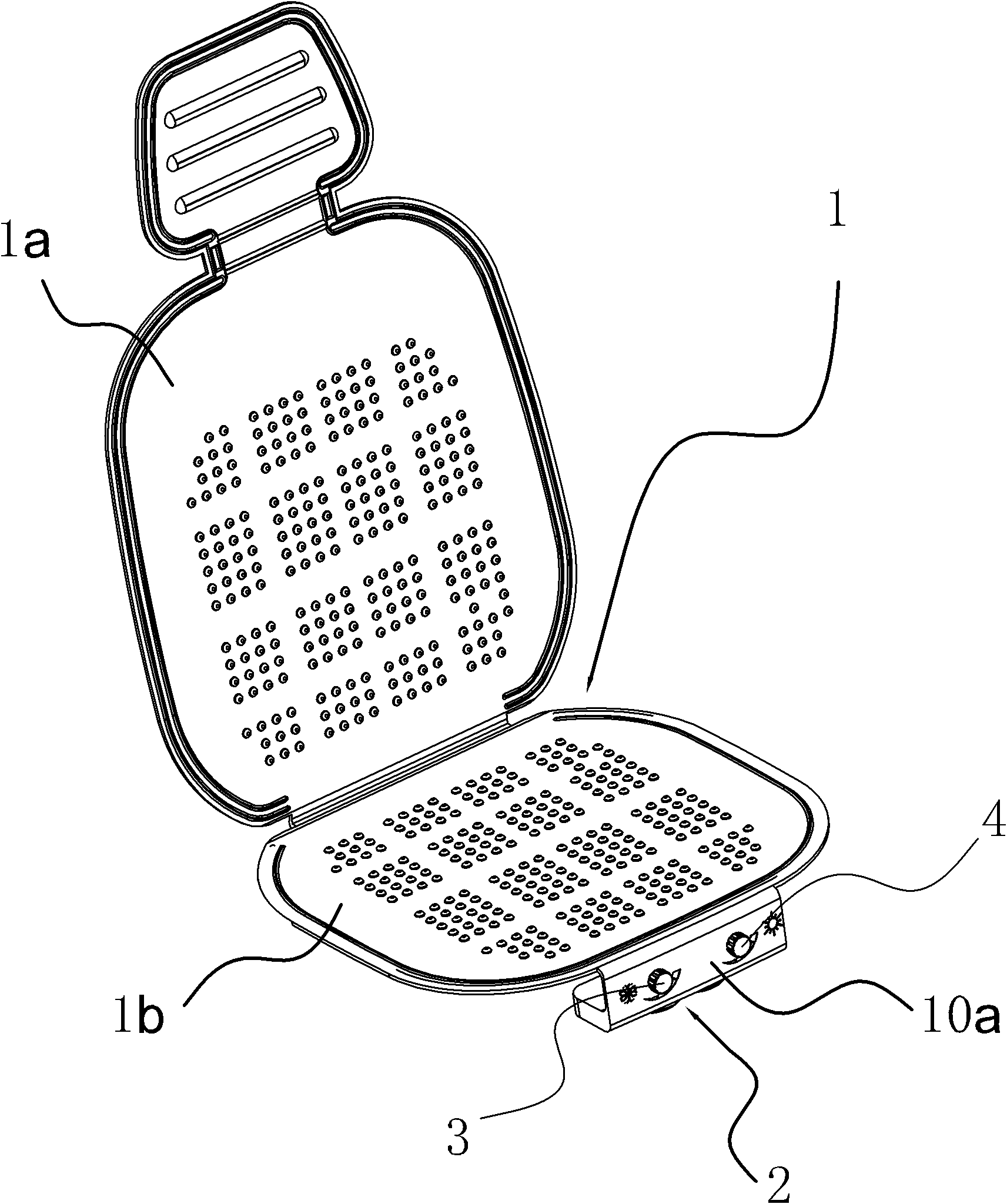

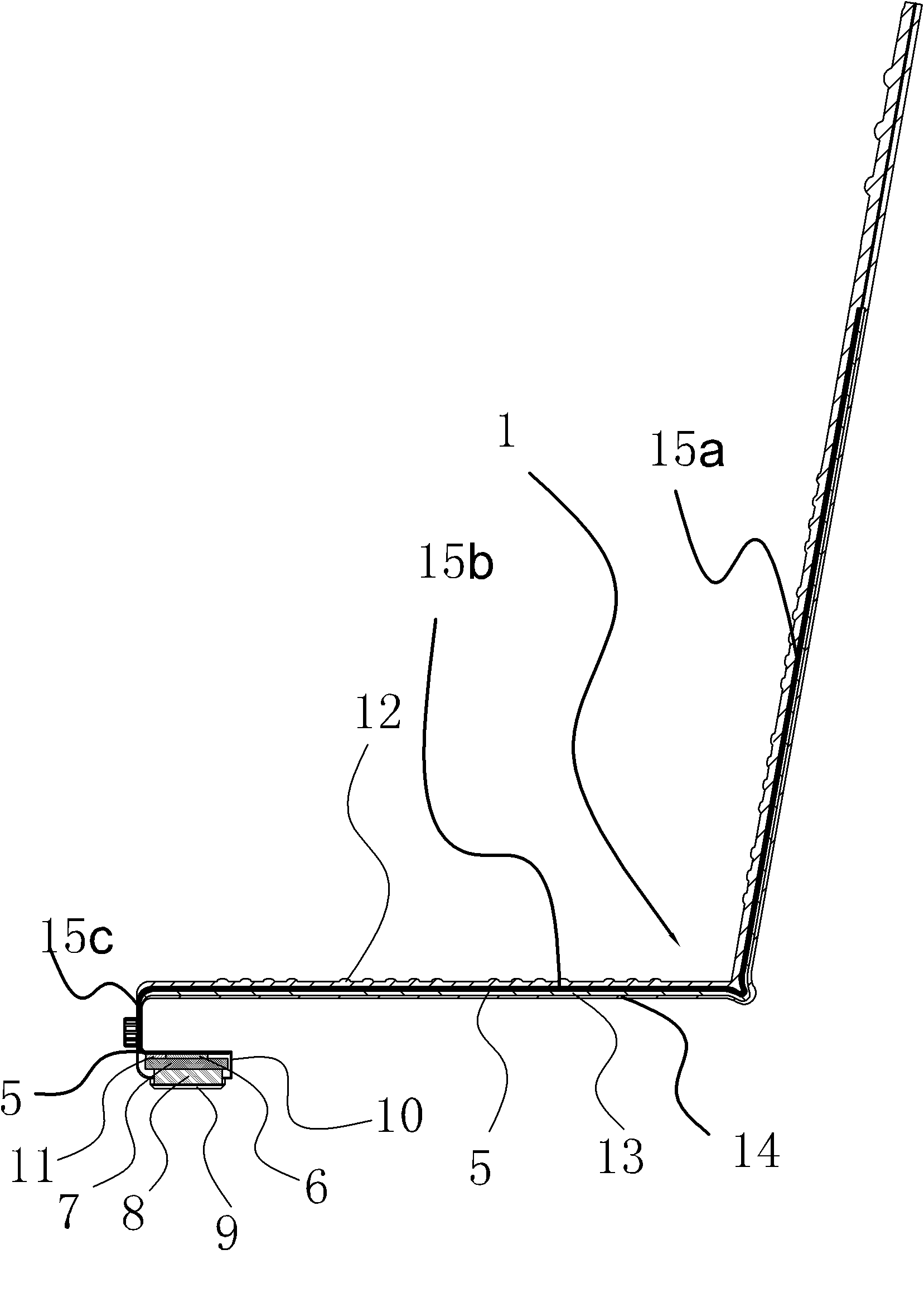

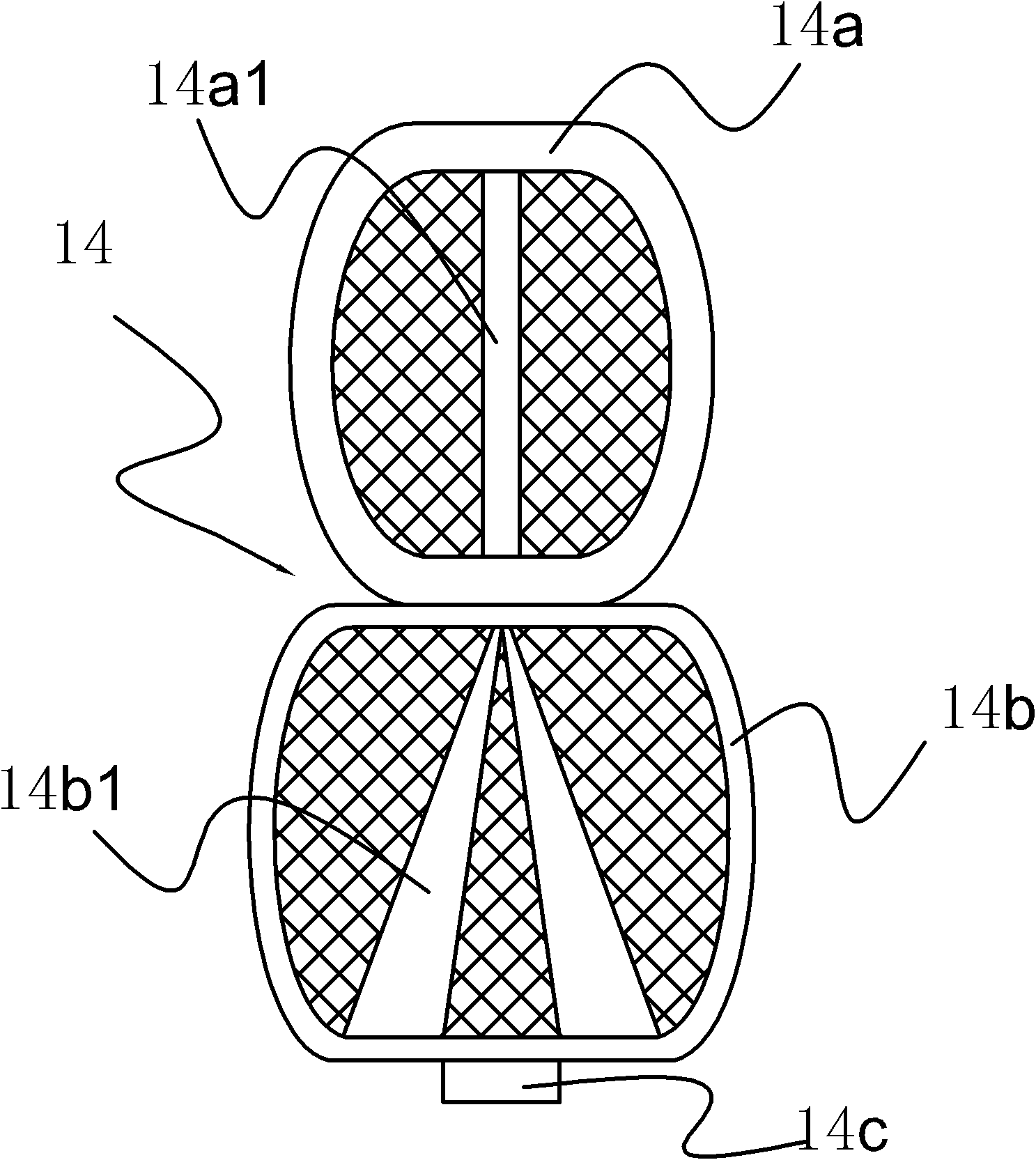

Cold-heat type automobile seat cushion

InactiveCN102310793AIncrease temperatureEffective temperature regulationSeat heating/ventillating devicesTemperature controlEngineering

The invention provides a cold-heat type automobile seat cushion, belonging to the technical field of automobiles and solving the problems that the traditional automobile seat cushion cannot provide refrigerating and heating functions simultaneously. The cold-heat type automobile seat cushion comprises a cushion body which is internally provided with a temperature control member and a temperature-controlled adjusting device for adjusting the cold and heat temperatures of the cushion body. The cold-heat type automobile seat cushion is characterized in that the temperature-controlled member is ametal plate clamped inside the cushion body; the temperature-controlled adjusting device is arranged at the side part of the cushion body and comprises a casing and a conducting strip, a refrigerating strip, a heat radiator and a fan which are sequentially arranged inside the casing; the conducting strip and the metal plate are connected to form a whole; one end face of the refrigerating strip istightly attached and fixed with one side end face of the conducting strip; the other end face of the refrigerating strip is tightly attached and fixed with the heat radiator; and ventilating ports are arranged on the corresponding wall bodies of the casing. The temperature control over the conducting strip is realized by using a semiconductor refrigerating strip, thereby the adjustment on the cold and heat temperature of the cushion body is realized. The cold-heat type automobile seat cushion has a simple structure and convenience for use.

Owner:TAIZHOU TAI CHENG ELECTRONICS TECH

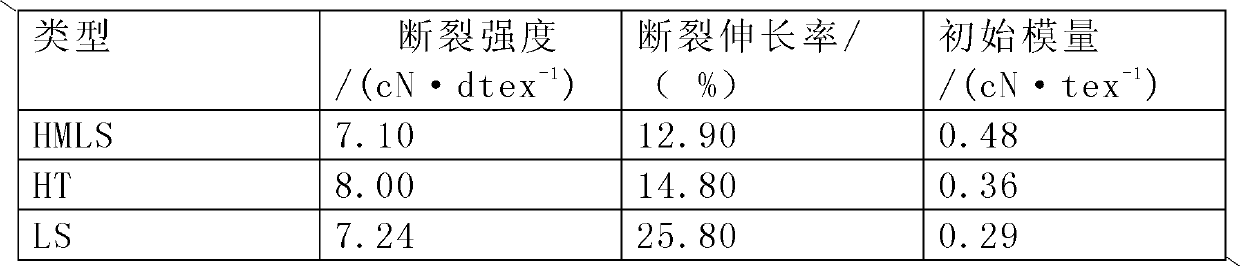

Production method of high strength and environmental-friendly textilene

ActiveCN101994164AEnvironmental performanceHigh mechanical strengthFilament/thread formingYarnUltimate tensile strengthMaterials science

The invention relates to a production method of high strength and environmental-friendly textilene. The method comprises the following steps of: A, extruding; B, coating; C, twisting to form textilene reeled silk by using a twister; and D, weaving the reeled silk into a weaving beam by using a warping machine, weaving a surface net on a rapier loom, and finishing the surface net into the textilene. The textilene produced by the method has environmental performance and higher mechanical strength, is widely used for series products such as beach chairs, bags, handbags, shoes and hats, sunshades, household products, handicrafts, curtains, automobile seat cushions, skid resistant carpets, decoration and the like.

Owner:TAIZHOU DONGHAI PLASTIC PRODS MFG +1

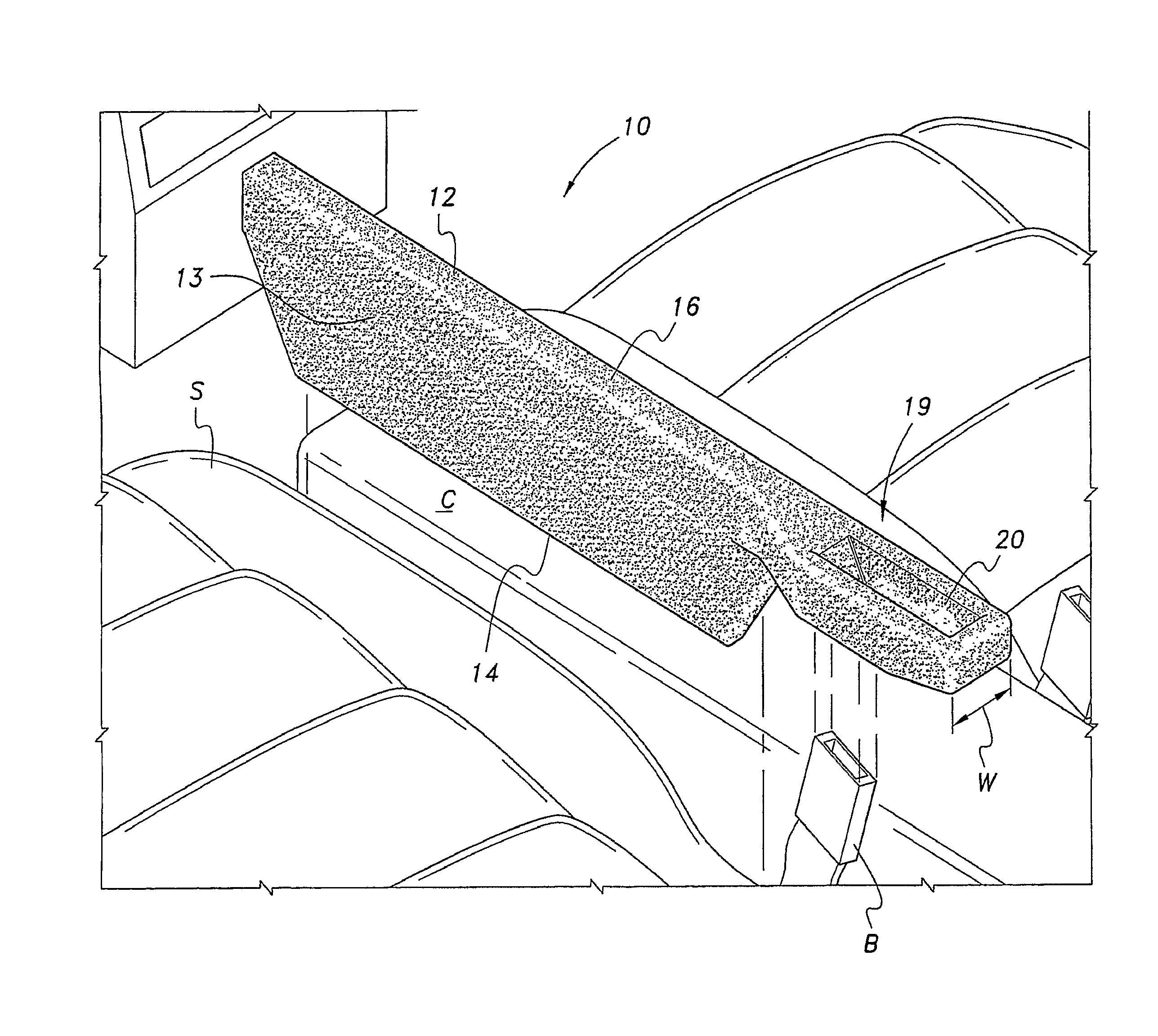

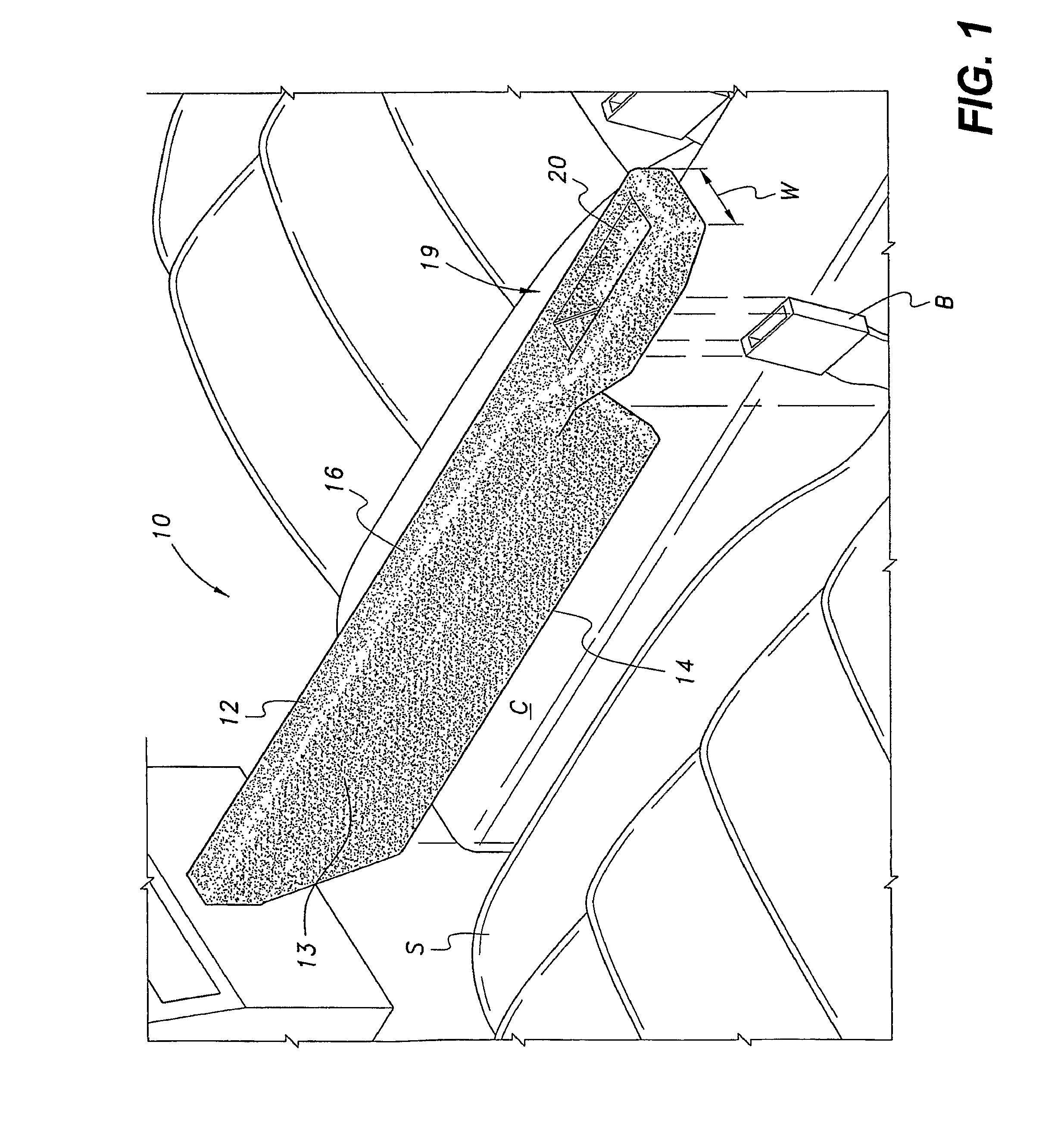

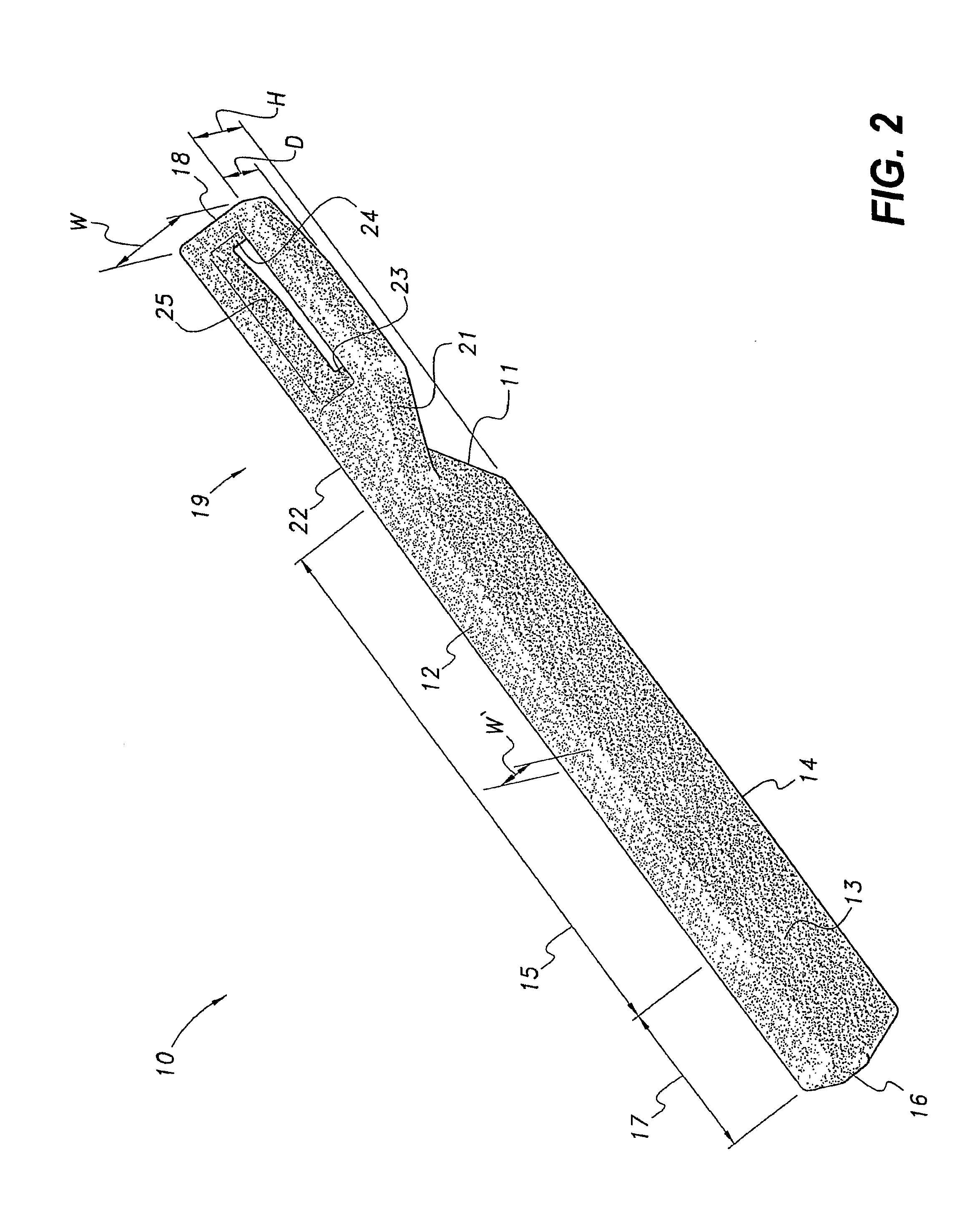

Foam Filler For Placement Between Automobile Seats

The filler device for placement between seats / consoles is a one-piece, rugged polymer body (10) having an elongate blade and a seat belt boss extending either rearward or laterally from the blade. The blade has an upper portion (12) of substantially uniform width throughout its length, and a wedge-shaped lower portion (13) adapted for insertion between the automobile seat cushion and a console (C). The seat belt boss has a greater width than the blade and defines an opening (20) through which the buckle receiver (B) of a seat belt may be inserted to retain the filler wedged in place. In alternative embodiments, the filler (10) may have a cell phone holder or a cup holder extending laterally from the front end of the blade.

Owner:MANLEY JACK M

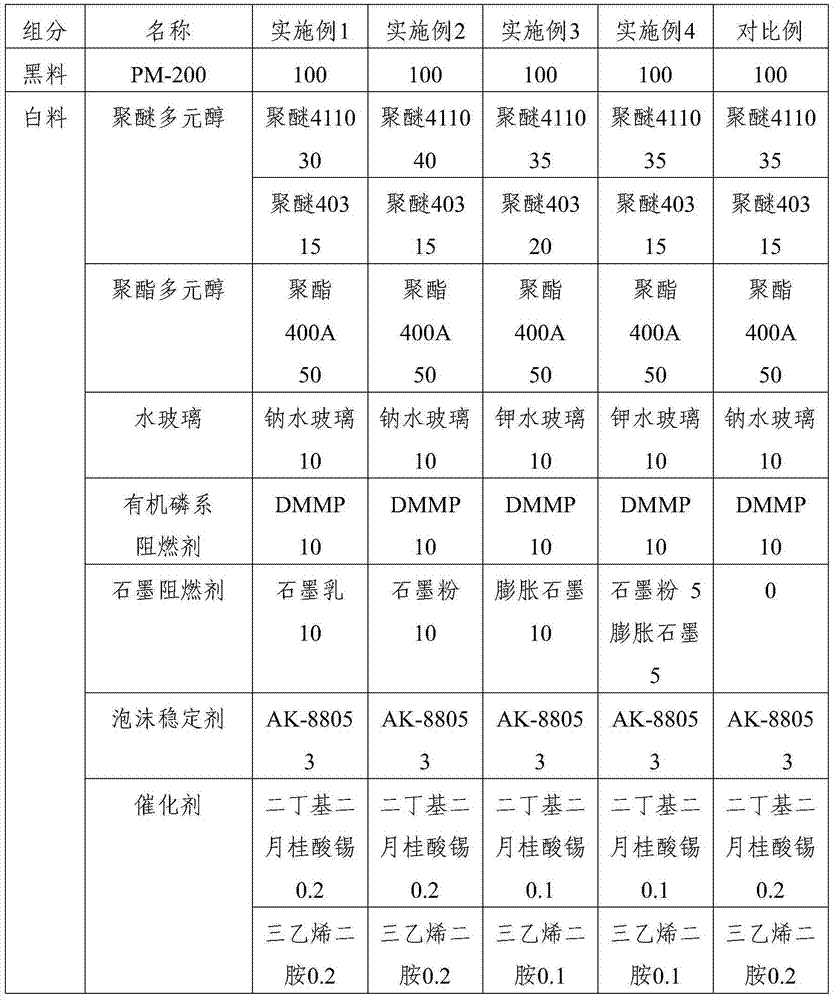

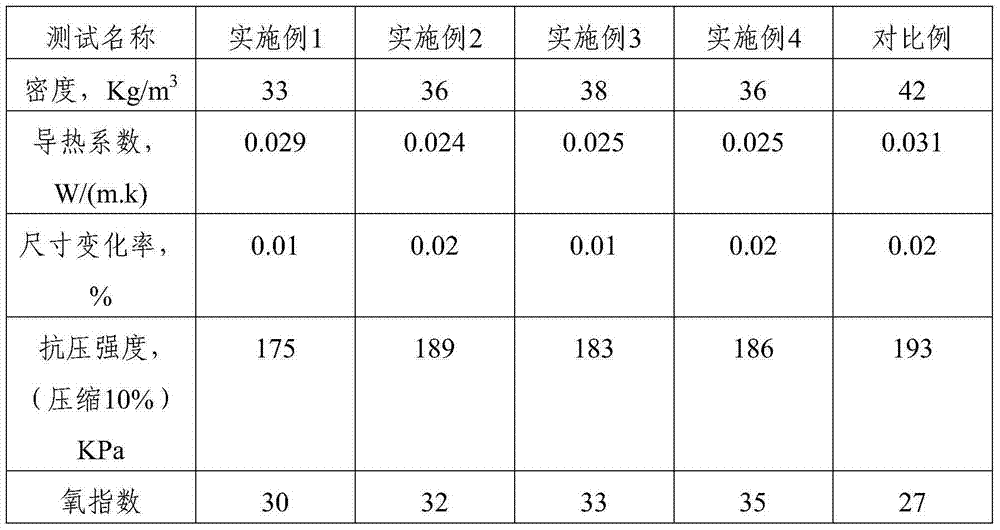

Fire-retardant polyurethane foam and preparation method thereof

The invention relates to fire-retardant polyurethane foam which is characterized by being prepared by foaming of a black material and a white material with a mass ratio of 1:1.2-1.4. The black material is isocyanate; the white material comprises the following components by weight: 5-15 parts of water glass; 40-55 parts of polyether polyol; 40-60 parts of polyester polyol; 0.1-0.5 parts of catalysts; 2-5 parts of foam stabilizers; 5-15 parts of halogen-free fire retardants; and 5-15 parts of graphite fire retardants. The invention also provides a preparation method of the fire-retardant polyurethane foam. According to the invention, water glass instead of chlorofluorocarbon foaming agents is added into existing polyurethane foam formulae, which effectively reduces environment pollution; the combined effect of water glass, halogen-free fire retardants, and graphite fire retardants improves the fire retardance of polyurethane, and the fire-retardant polyurethane foam is applicable to fields of building materials, furniture, insulation materials, automobile seat cushions and interior trims, and the like.

Owner:BEIJING RECHSAND SCI & TECH GRP

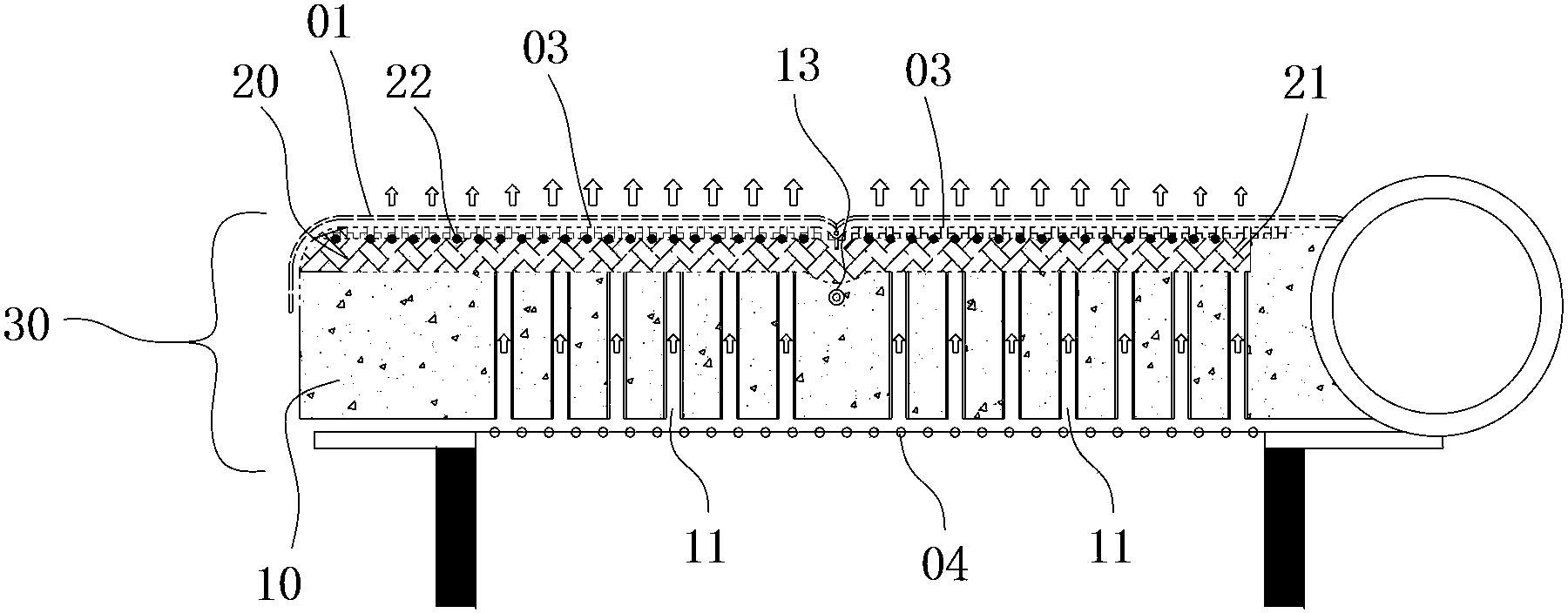

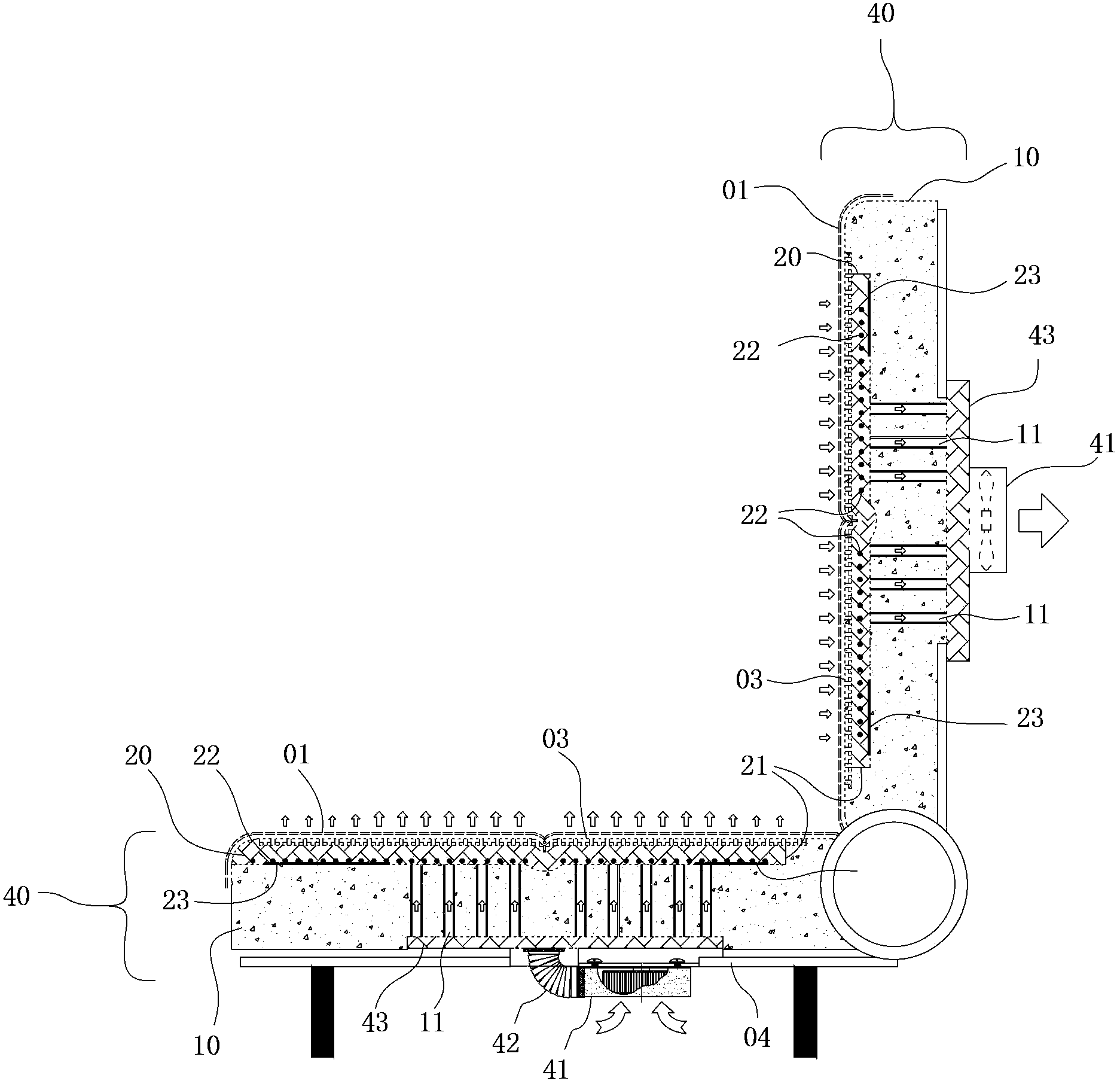

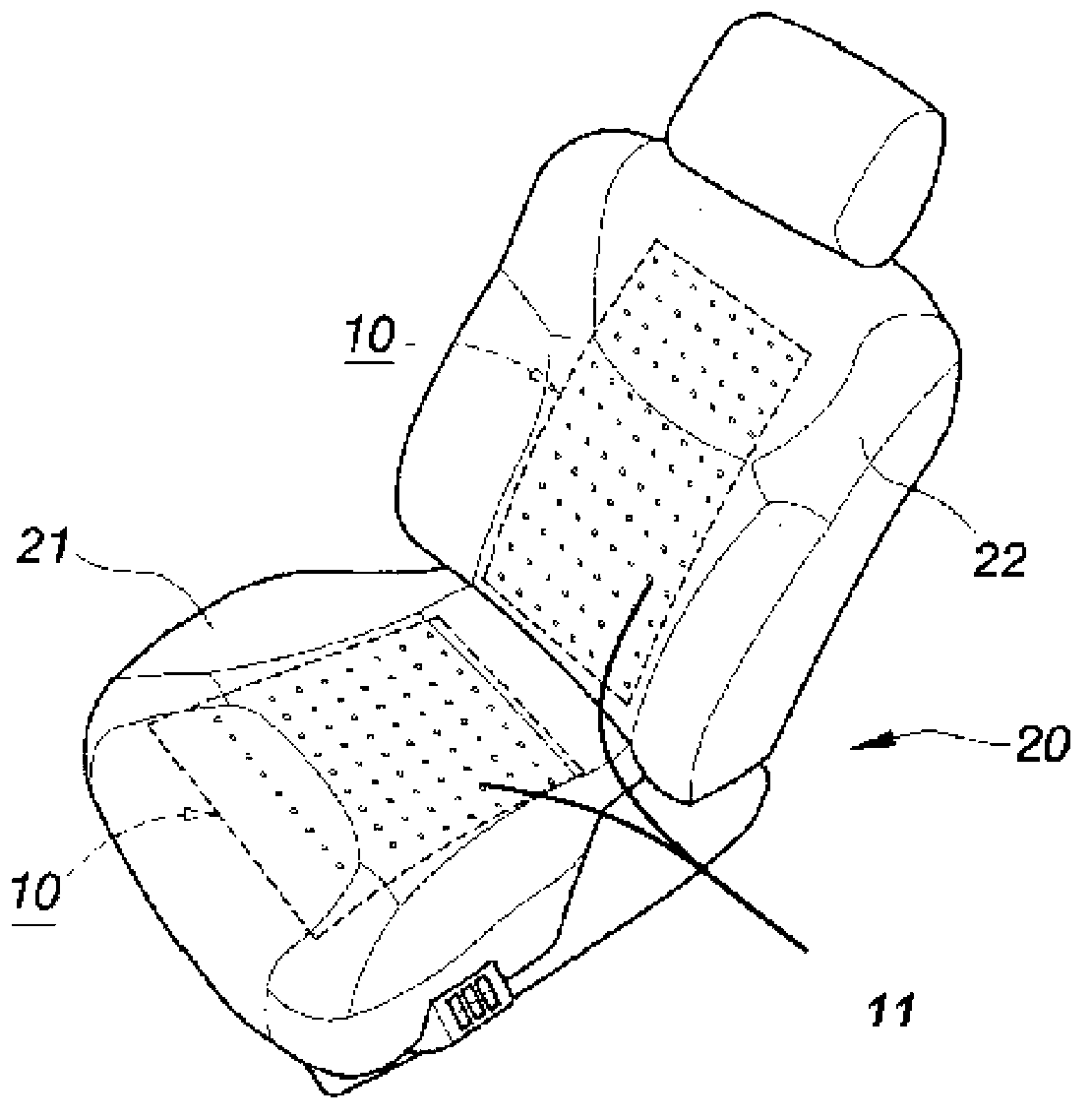

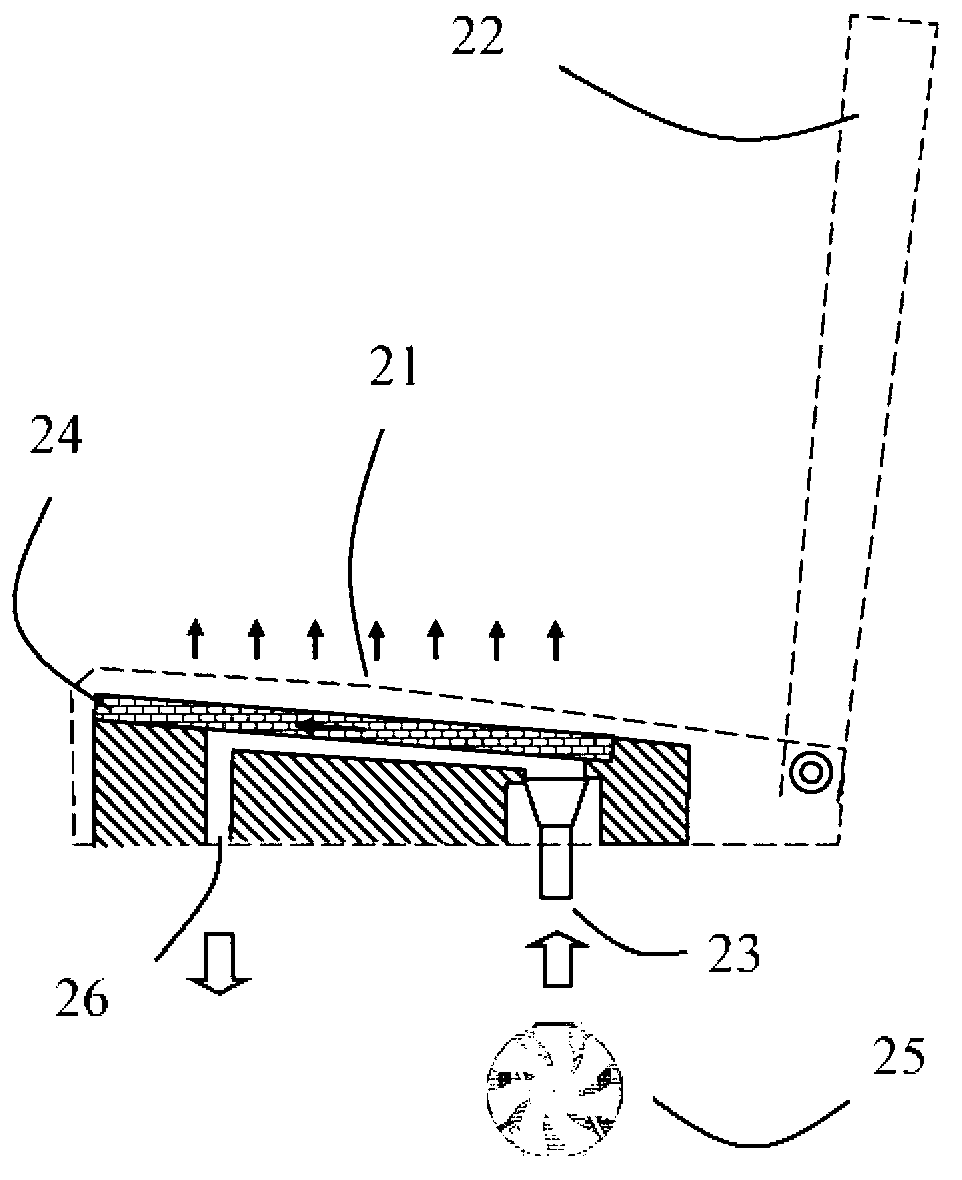

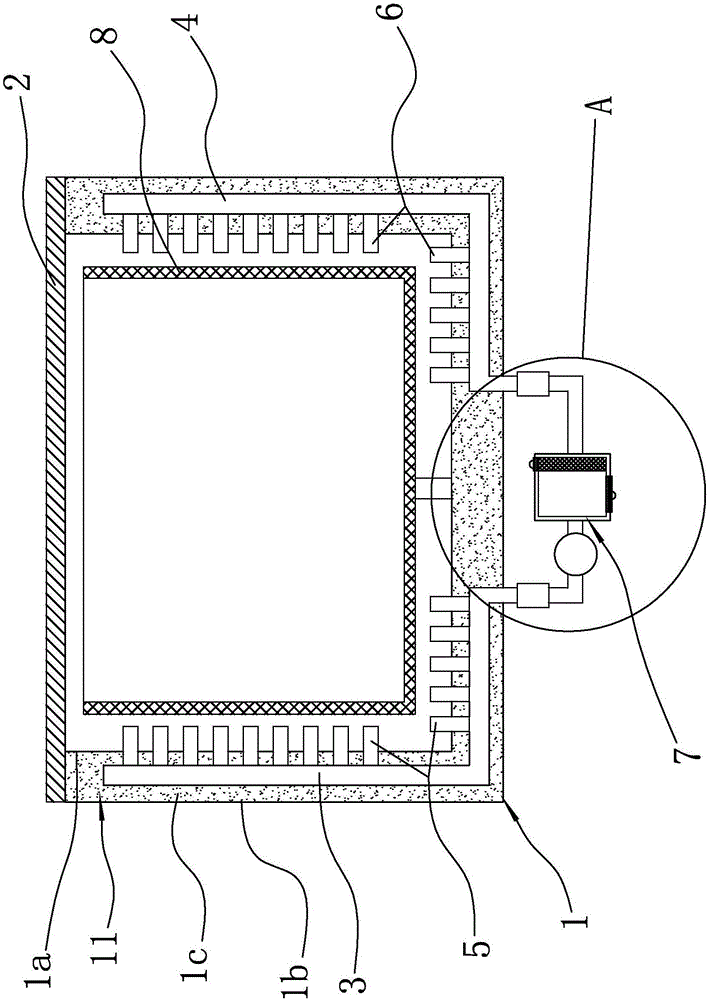

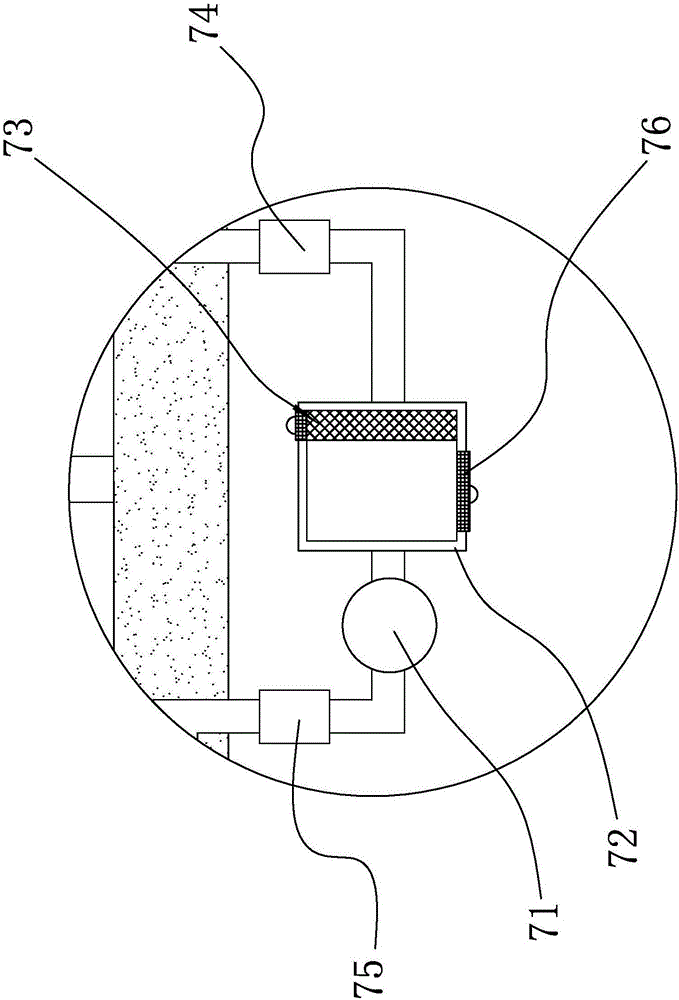

Breathable seat cushion and automobile seat

InactiveCN104340097AAvoid stagnationWith air circulation exchange functionSeat heating/ventillating devicesEngineeringActive ventilation

The invention discloses a breathable automobile seat cushion. The breathable automobile seat cushion comprises a foam cushion body and an electrical heating cushion body, wherein the foam cushion body is provided with a plurality of ventilation holes which penetrate through the thickness of the foam cushion body; the electrical heating cushion body is laid on the upper surface of the foam cushion body and has a ventilation effect. According to the seat cushion, the problem of implementation of low-cost seat surface heating type vehicle seat with an air circulation exchange function is solved, meanwhile, an active ventilation type seat cushion system and a non-active ventilation type seat cushion system are combined, a seat manufacturer does not need to use two different foam cushion forming molds, and a low-cost solution of a high-class comfortable seat is implemented. The invention also discloses an automobile seat.

Owner:LANGFANG JINSESHIGUANG TECH

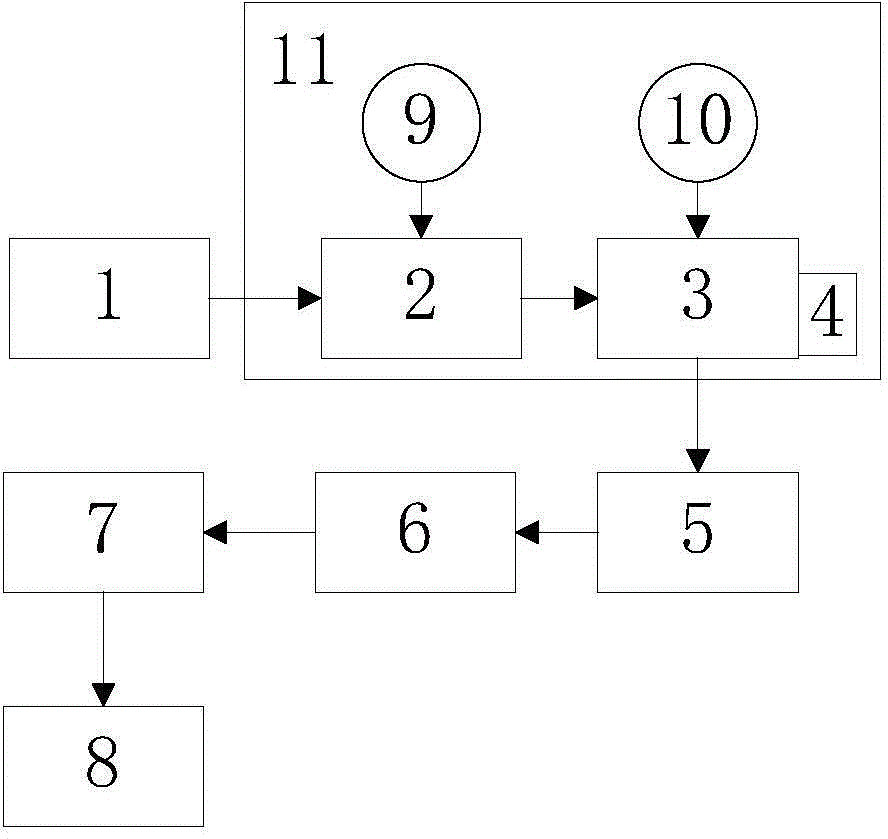

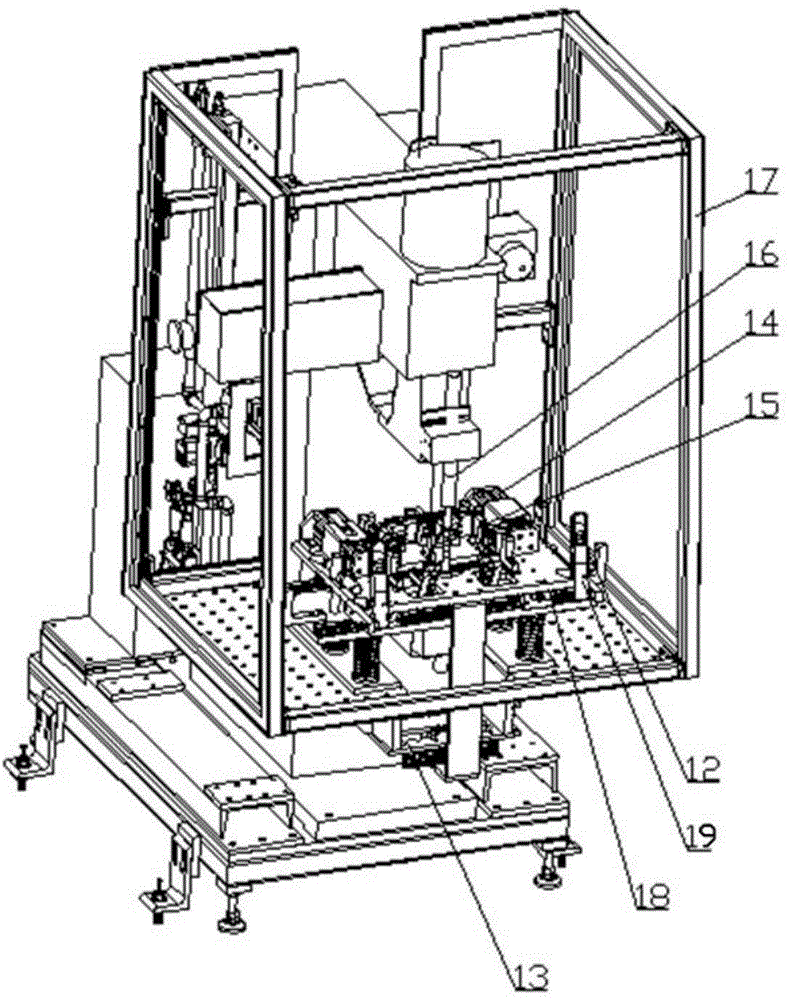

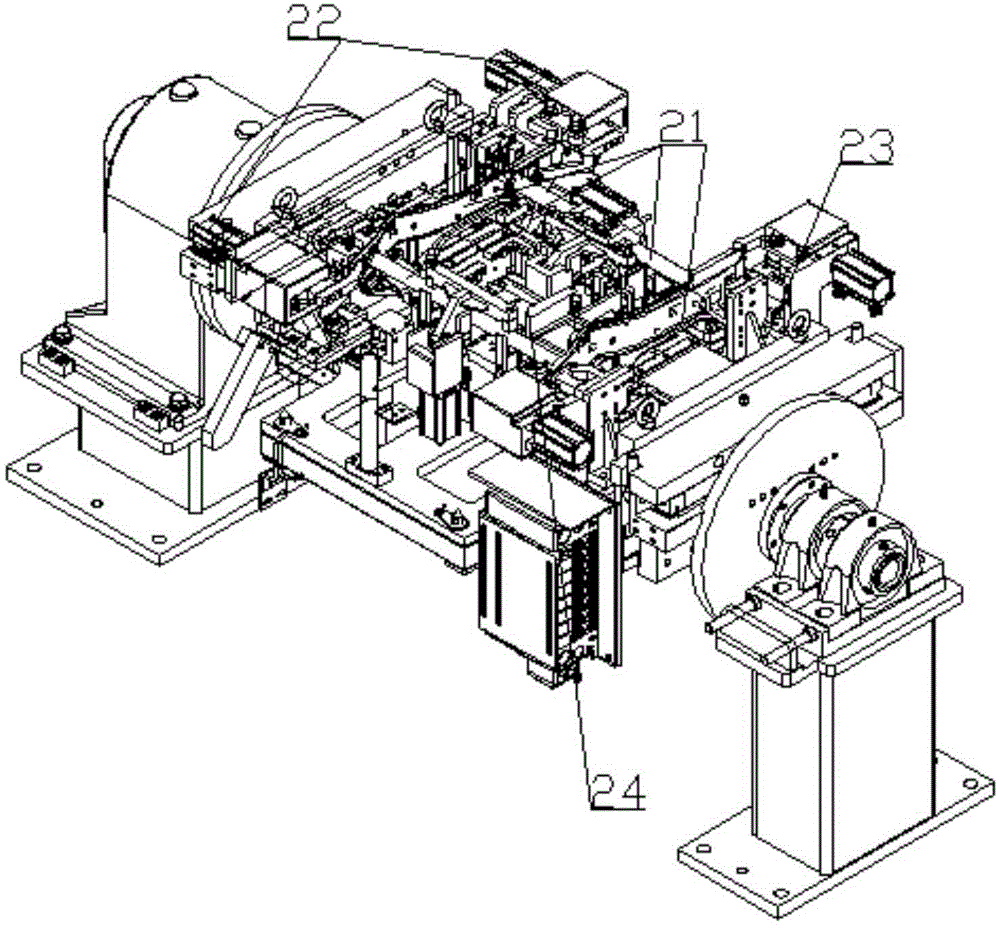

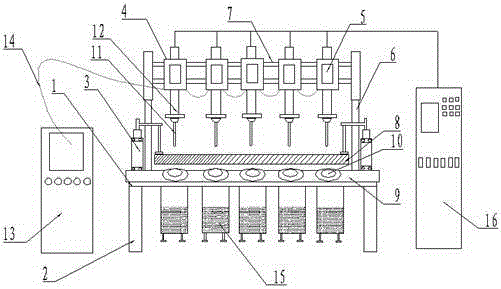

Automobile seat cushion automatic welding production line and production method thereof

InactiveCN104785934AAutomated welding production promotionIncrease the level of automationWelding/cutting auxillary devicesAuxillary welding devicesProduction lineMaterial resources

The invention relates to the technical field of mechanical automation, in particular to an automobile seat cushion automatic welding production line and a production method thereof. A second work position, a third work position, a fifth work position, a sixth work position, a seventh work position and an eighth work position are arranged on one side of a first work position in sequence, arc welding robots are arranged on the second work position and the third work position respectively, a fourth work position is arranged on one side of the third work position, the first work position is a spot welding work position, the second work position, the third work position and the fifth work position are welding work positions, the fourth work position is a hoisting work position, the sixth work position and the eighth work position are detecting work positions, and the seventh work position is a mounting work position. The welding robots are controlled through a PLC, a designed specific clamp is matched to fix and clamp a welding part, automobile seat cushion automatic welding production is completed by the eight work positions, the two arc welding robots and three persons, the automation level of a traditional manual production line is improved, and therefore production efficiency and welding precision are improved, meanwhile, the need for manpower and material resources is reduced, and then automatic welding production of a whole automobile seat is accelerated.

Owner:LAM AUTOMOTIVE WELDING EQUIP SHANGHAI

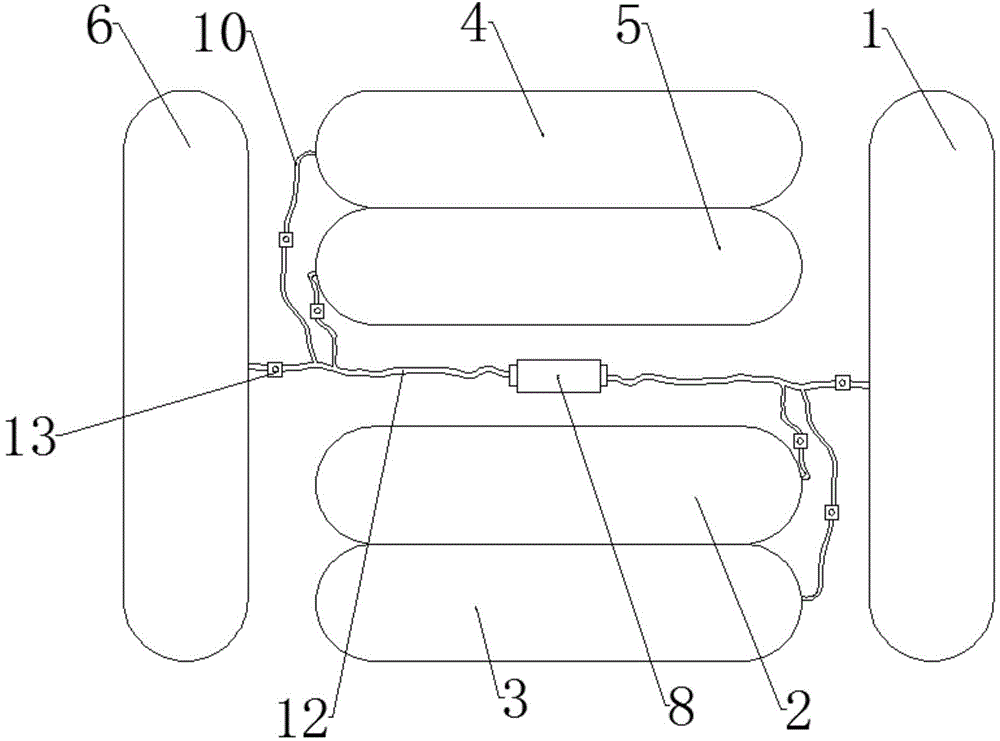

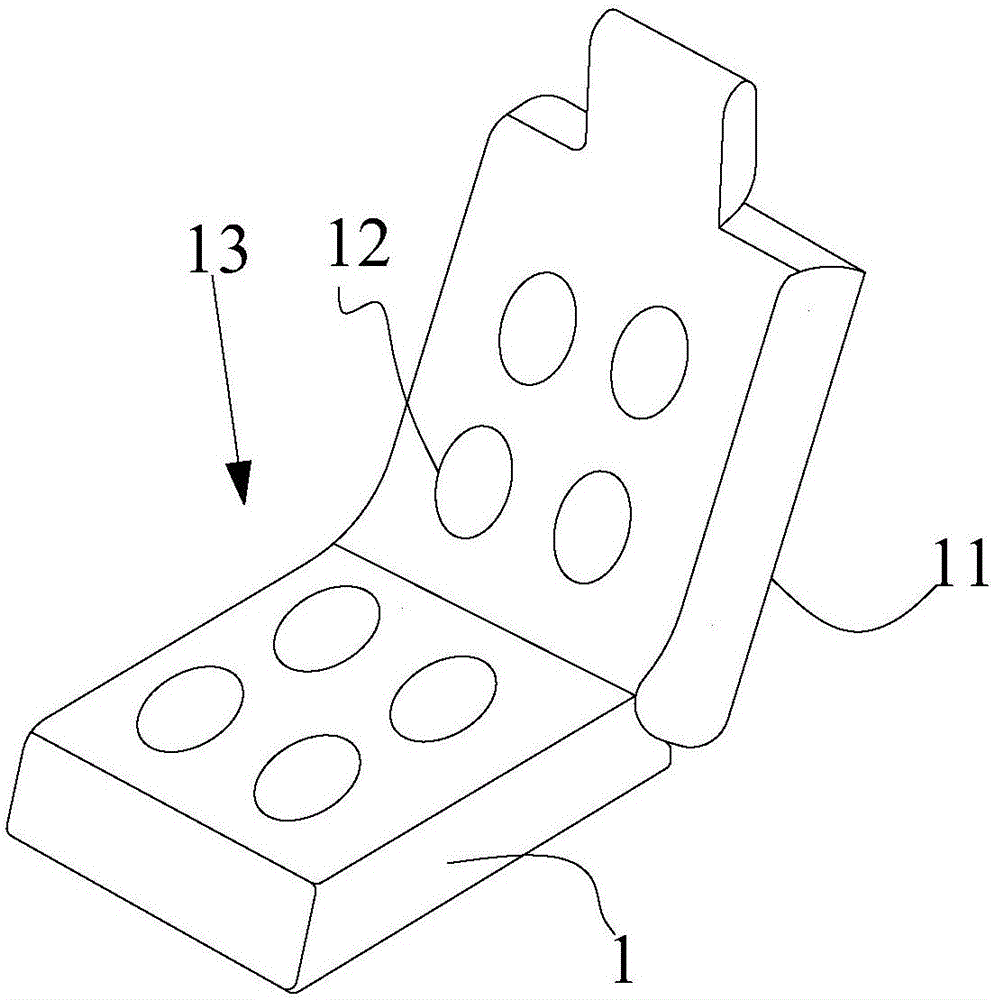

Automobile seat air bag cushion device capable of relieving driving fatigue

InactiveCN104553916AReduce muscle fatigueEase of tensionThigh restsEngineeringMechanical engineering

The invention discloses an automobile seat air bag cushion device capable of relieving driving fatigue. The automobile seat air bag cushion device capable of relieving driving fatigue is arranged on an automobile seat cushion plate and comprises a cushion and air bag combination, a connecting tube and an inflating device, wherein the cushion and air bag combination is arranged on the automobile seat cushion plate; the inflating device is fixed on the lower side of the automobile seat cushion plate; the cushion and air bag combination is connected with the inflating device through the connecting tube; the cushion and air bag combination comprises six independent air bags; the connecting tube comprises a main connecting tube and six connecting branch tubes; each connecting branch tube is correspondingly connected with the corresponding air bag; the inflating device is connected with the connecting branch tubes of the air bags; each connecting branch tube is provided with an opening and closing valve; and a venting door is arranged on the inflating device. Supporting forces in various directions of the seat cushion can be adjusted, the automobile seat air bag cushion device well fits the curve of the hip of a driver or a passenger and is suitable for drivers or passengers with different physical features, the supporting positions and the supporting forces can be changed in real time according to adjustment on sitting postures of the drivers or the passengers, and the driving and sitting fatigue can be reduced effectively.

Owner:JILIN UNIV

Polylactic acid fiber fabric for automobile seat cushion

InactiveCN106012085AGood heat resistance and flame retardant performanceImprove spinnabilityFlame-proof filament manufactureNew-spun product collectionSisal fiberMaterials science

The invention discloses a preparation method of a heat-resistant and flame-retardant polylactic acid fiber fabric for an automobile seat cushion. The method comprises the following steps of (1) preparing raw materials in parts by weight: 80 to 86 parts of PLA polylactic acid, 2 to 3 parts of sisal fiber powder, 0.8 part of bamboo powder, 0.5 to 0.8 part of lupeose, 0.8 part of mica powder and 1 part of CMA flame-retardant agnets; then, adding the materials into a high-speed mixing machine to be uniformly dispersed to obtain modified polylactic acid mixed raw materials; (2) performing melt blending and extrusion on the uniformly mixed polylactic acid mixed raw materials through a double-screw extruding machine to prepare modified polylactic acid master batches; performing vacuum drying; performing spinning on the mixture on a melt spinning machine through round spinning holes to obtain modified polylactic acid fiber, wherein the spinning temperature is 220 DEG C, the winding speed is 1600 m / min, the traction temperature is 85 DEG C, and the traction times is 2.5 times; (3) spinning the modified polylactic acid fiber into an automobile seat cushion fabric.

Owner:张蒙

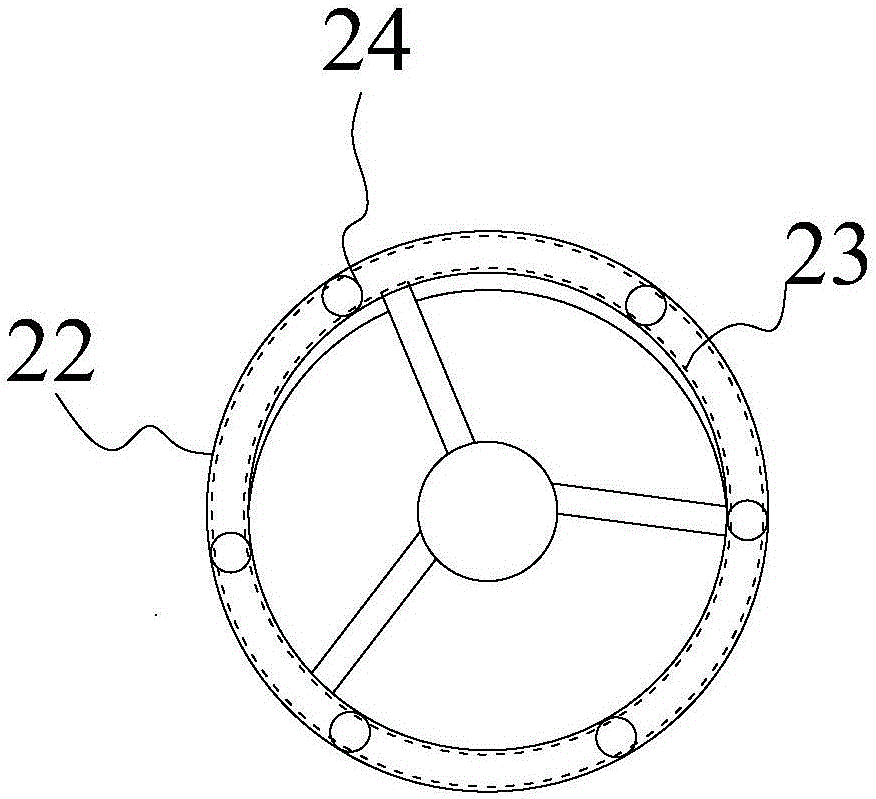

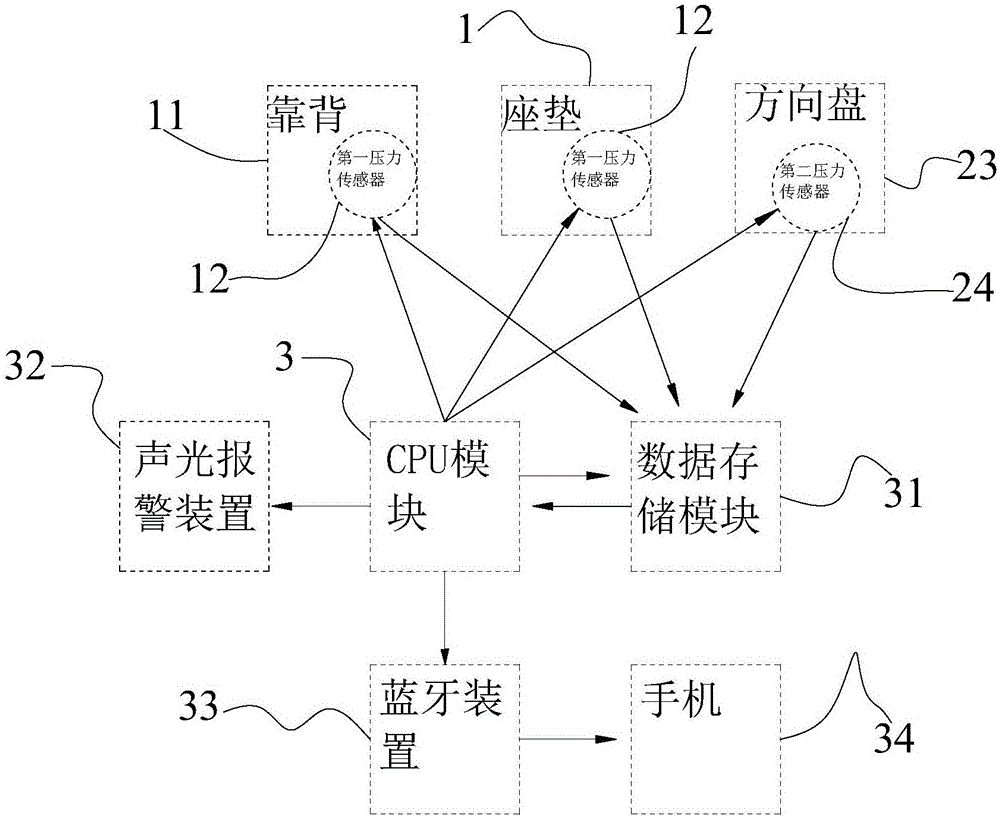

Anti-fatigue-driving device

InactiveCN106515644AMulti-facetedDetectablePedestrian/occupant safety arrangementSignalling/lighting devicesSteering wheelGrip force

The invention discloses an anti-fatigue-driving device which comprises a seat and a steering wheel. The seat comprises a seat cushion and a backrest connected with the seat cushion. The anti-fatigue-driving device is characterized in that pressure sensors are arranged on the seat cushion, the backrest and the steering wheel separately; the pressure sensors are connected with a data storage module and a CPU module separately; the data storage module is connected with the CPU module; the CPU module is connected with an alarming device; the alarming device is either or both of a Bluetooth alarming device and a sound-light alarming device. By arranging the pressure sensors for fatigue detection on the automobile seat cushion, the automobile backrest and the steering wheel, a driver can set a parameter of abnormal driving detection of the anti-fatigue-driving device according to driving conditions, so that the purpose of multi-azimuth and personal customization type fatigue detection is achieved; and particularly the change of gripping force of the steering wheel is sensitive to whether the driver is fatigue or not, so that the accuracy rate of the fatigue detection is improved.

Owner:SHENZHEN HUACAN SCI & TECH

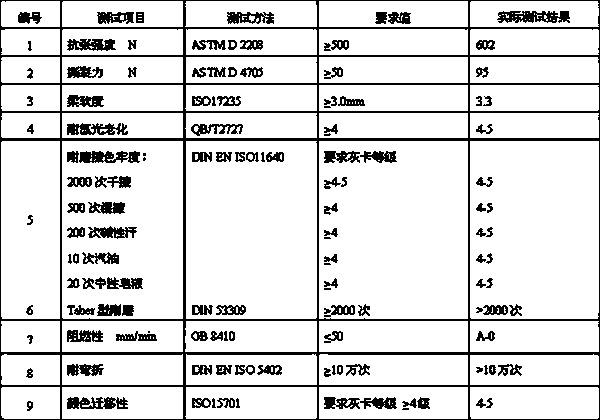

Production technology of contrast-effect automobile seat cushion leather

ActiveCN103667542AFlexibleImprove viewabilityTanning treatmentPre-tanning chemical treatmentFolding enduranceRoom temperature

The invention relates to a production technology of contrast-effect automobile seat cushion leather. The protection technology comprises the steps of liming: dissolving Na2S, NaHS and lime into water in a mass ratio of 1:1:2 to form a liming alkali liquor, reacting fur with the liming alkali liquor in a liquor ratio of 100:100 for 6 h, adding the liming alkali liquor step by step to enable the liquor ratio to increase to 100:200, and continuously reacting for 12 h; retanning: for every 100 parts of fur, adding 100 parts of water, 1 part of a pre-fatting agent and 3 parts of a chrome tanning agent or a chrome-free tanning agent, reacting at the normal temperature for 1 h, adding 2 parts of sodium formate, reacting at the temperature of 40 DEG C for 1 h, and controlling the pH in a range of 3.6-4.0; and finishing: the finishing comprises the steps of roller coating of a bottom layer, embossing, spraying of a color layer, roller coating of an effect layer and spraying of a top layer. The leather produced through the technology is soft, fine in grain side, full in hand feeling, elastic, safe and environment-friendly and has characteristics of wear resistance, folding endurance, light resistance, color migration resistance and the like; and ornamental and pleasant characteristics of the leather are added due to roller coating of the effect layer, and the rigid and non-flexible appearance of ordinary automobile seat cushion leather is changed.

Owner:HAINING SENDE LEATHER

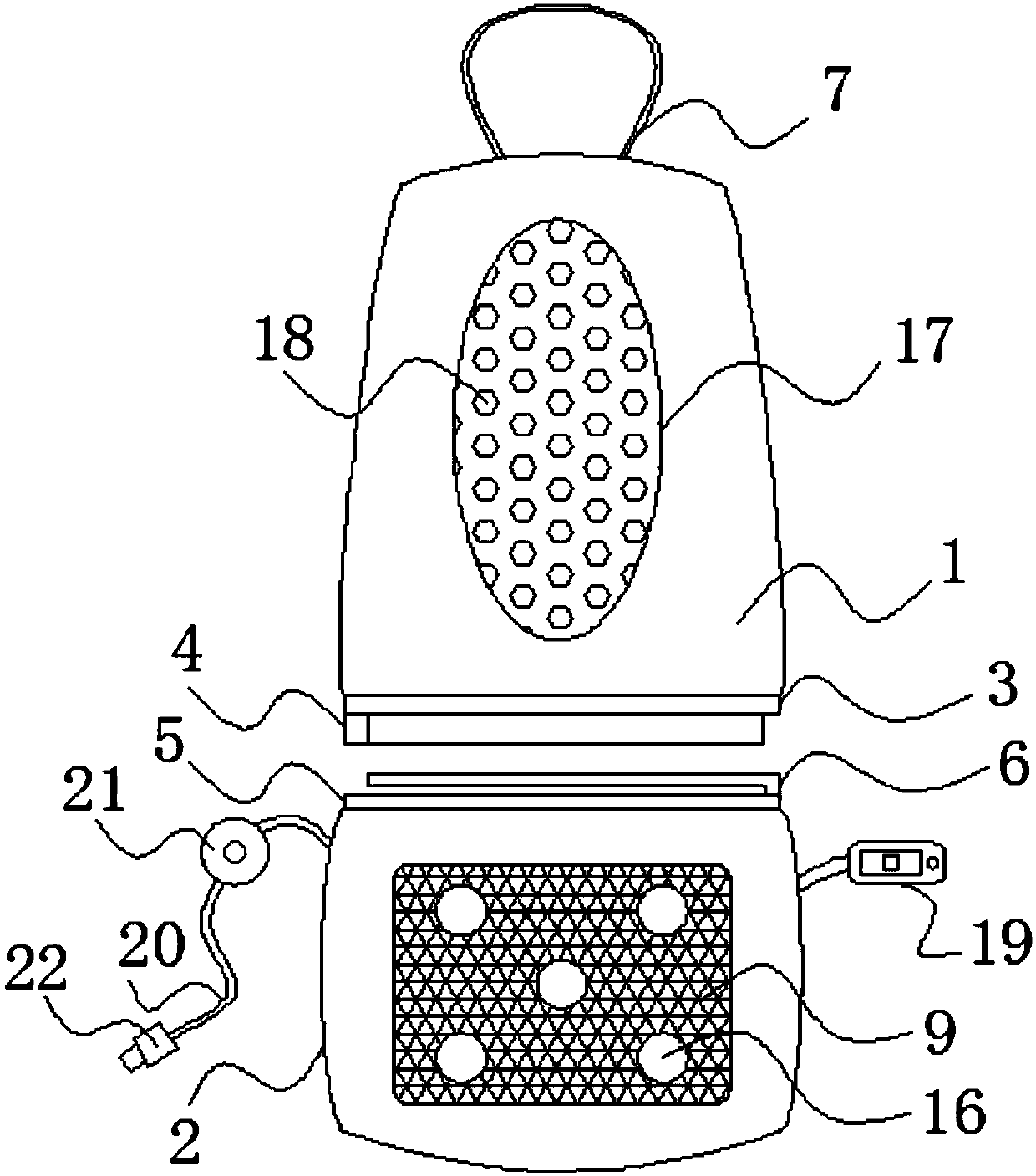

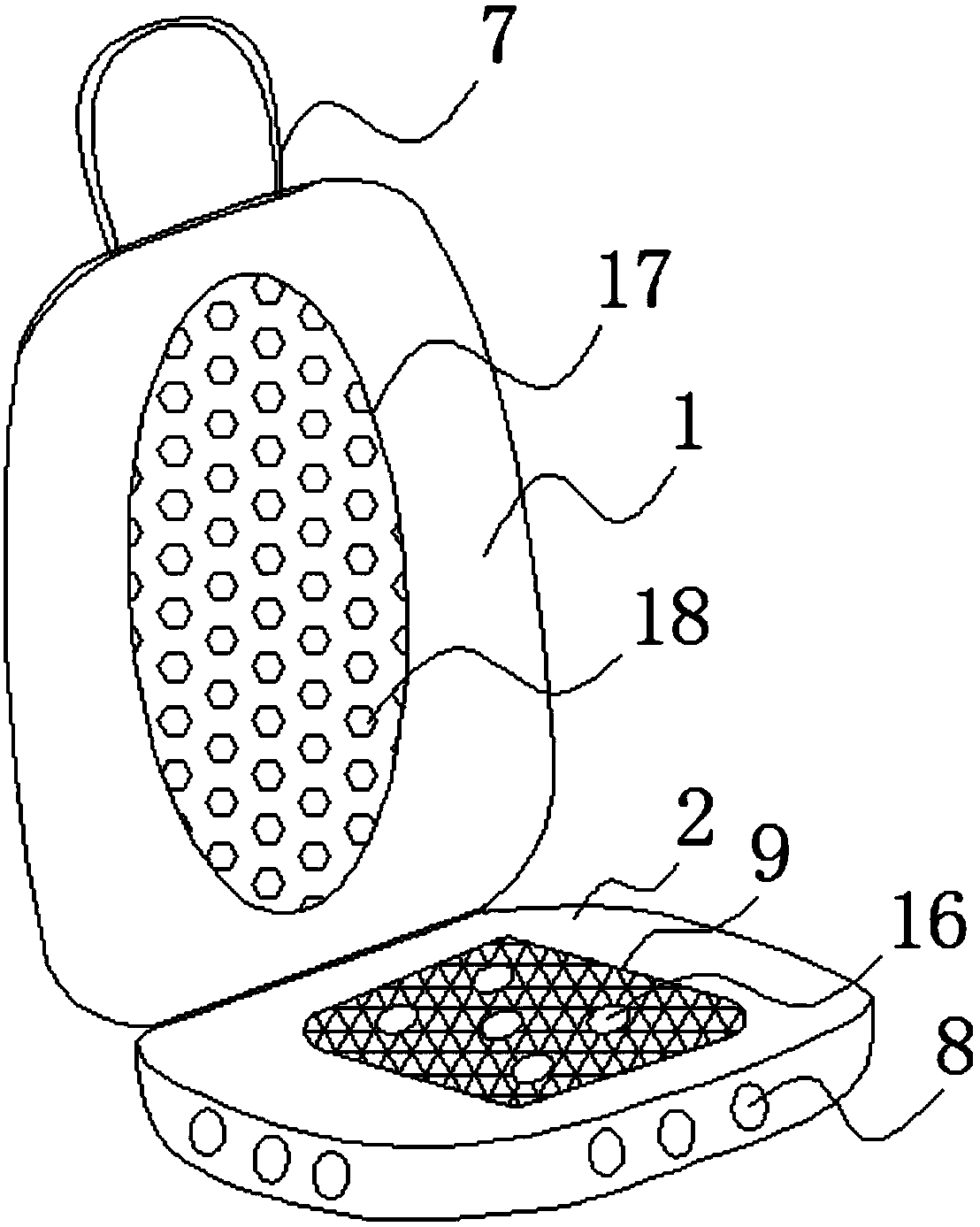

Car seat cushion

InactiveCN105083087ASuit one's needsImprove ride comfort performanceBack restsEngineeringAutomobile seat cushion

The invention discloses a car seat cushion with a waist pillow with the adjustable thickness, and belongs to the technical field of car decoration. The car seat cushion comprises a head cushion, a back cushion and a sitting cushion; the back cushion and the sitting cushion are connected integrally, the head cushion and the back cushion are sewn; and the waist pillow with the adjustable thickness is arranged on the back cushion. The waist pillow with the adjustable thickness is arranged on the back cushion, so that the requirements of different drivers are met, and the riding comfort is improved. As the waist pillow is of an air inflation type structure, and an air inlet is formed in the waist pillow, the thickness can be conveniently adjusted, the structure is simple, using is convenient, and the practicability is higher. The waist pillow and the back cushion are bonded through a hook and loop fastener, and the drivers can select the waist pillow conveniently according to actual requirements.

Owner:NANTONG RONGRUN AUTO PARTS

Production method for non-chrome-tanned ecological automobile seat cushion leather

ActiveCN101812553AFeel goodImprove mechanical propertiesTanning treatmentLeather impregnationSodium bicarbonateEngineering

The invention relates to a production method for non-chrome-tanned ecological automobile seat cushion leather, which comprises that an animal raw skin is produced into automobile seat cushion leather through dehairing, tanning, re-tanning and greasing, coating and trimming. The tanning comprises the following steps that salt is added in bath liquid to regulate baume degree to 8-8.5, 2-4 percent of glutaraldehyde is added in a rotary drum which rotates for 3-5 hours for full penetrating reaction, 5-10 percent of tannin tanning agent is added for combined tanning, sodium bicarbonate is used during tanning to control pH to be 4.0-4.2, the rotary drum rotates again to react for 4-6 hours, temperature is adjusted to be 30-32 DEG C and the rotary drum rotates again for 2-3 hours. The percent refers to the percent of raw materials accounting for the weight of the skin. Since the use of traditional leather chemical materials such as chrome tanning, heavy metal tanning agent, banned dyestuff and the like is avoided in the invention, the hand feeling and the relevant physical and mechanical performance of the leather are improved.

Owner:HAINING SENDE LEATHER

Numerical control punching machine for aluminum plates

InactiveCN105170774AAvoid scatterRealize simulated imitation hole punchingPerforating toolsMetal working apparatusNumerical controlPunching

The invention discloses a numerical control punching machine for aluminum plates. The numerical control punching machine for the aluminum plates comprises a work table, and supporting legs are arranged at the lower end of the work table. A left clamping air cylinder and a right clamping air cylinder which are of symmetrical structures are arranged on a work table top. Vertical supporting columns are arranged on the inner sides of the clamping air cylinders, and two horizontal transverse supports are arranged between the vertical supporting columns. Punching machine heads are fixedly arranged between the transverse supports. The lower ends of the punching machine heads are connected with rotation shafts. The rotation shafts are connected with drills through clamping parts. According to the numerical control punching machine for the aluminum plates, the punching error of every single hole is within 0.1 mm, and the punching efficiency is high. The numerical control punching machine for the aluminum plates can also be applied to punching leather, plastic, solar inner skin and outer skin plates, automobile seat cushions and the like.

Owner:SUZHOU BAOMA NUMERICAL CONTROL EQUIP

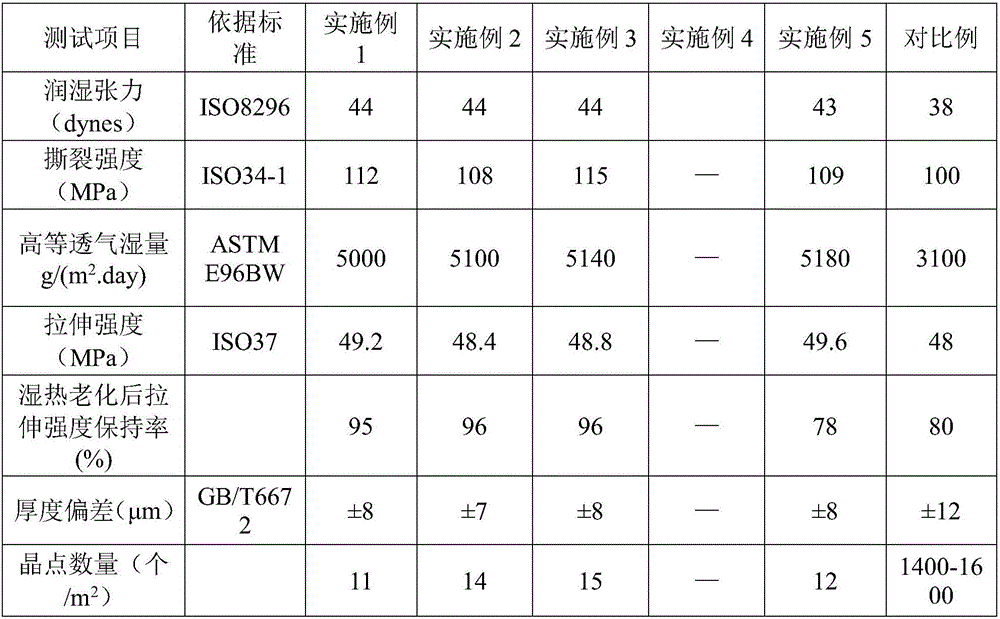

TPU (thermoplastic polyurethanes) film and preparation method thereof

InactiveCN105885394AAir permeability effectImprove breathabilityFlat articlesHigh resistancePolymer science

The invention provides a TPU (thermoplastic polyurethanes) film and a preparation method thereof. The TPU film is prepared from TPU resin, PHA (polyhydroxyalkanoate) resin, a hydrolysis-resistant agent, a light stabilizer and an antioxidant by a calendering technology. The TPU film used for producing automobile seat cushions instead of cattlehide has the advantages of good breathability, high resistance to tear, uniformity in thickness, fewer fisheyes and the like. The preparation method is beneficial to large-scale production and reduction of TPU film cost.

Owner:李英

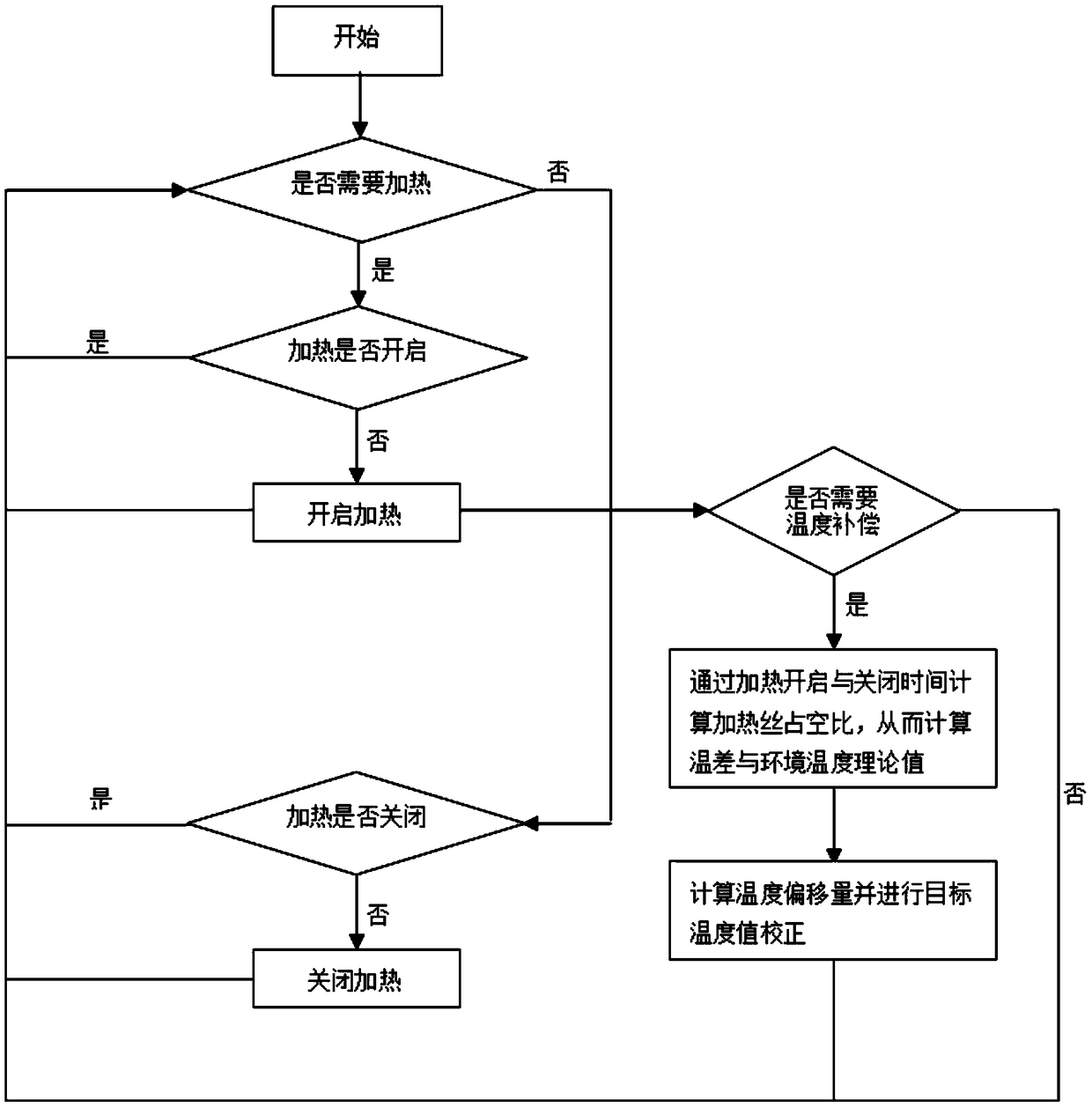

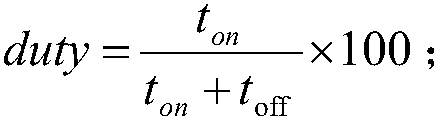

Temperature Compensation Control Method

The invention relates to the technical field of temperature compensation control. In order to solve the problem of low heating temperature control accuracy, the invention provides a temperature compensation control method, which obtains a new target temperature value by calculating a temperature offset and correcting the target temperature value that is actually required to be output, and controlsthe heating wire to heat to the new target temperature value. A temperature compensation control process compensates that heat dissipation amount affect by the ambient temperature and the temperaturesensor detection error, It can reduce the difference between the user's setting temperature and the temperature that the user actually feels, reduce the disturbance of the environment temperature tothe temperature control, and is especially suitable for the heating control of the intelligent toilet seat, automobile seat cushion and other parts which are in direct contact with human body and havehigher requirements for temperature control.

Owner:四川爱创科技有限公司

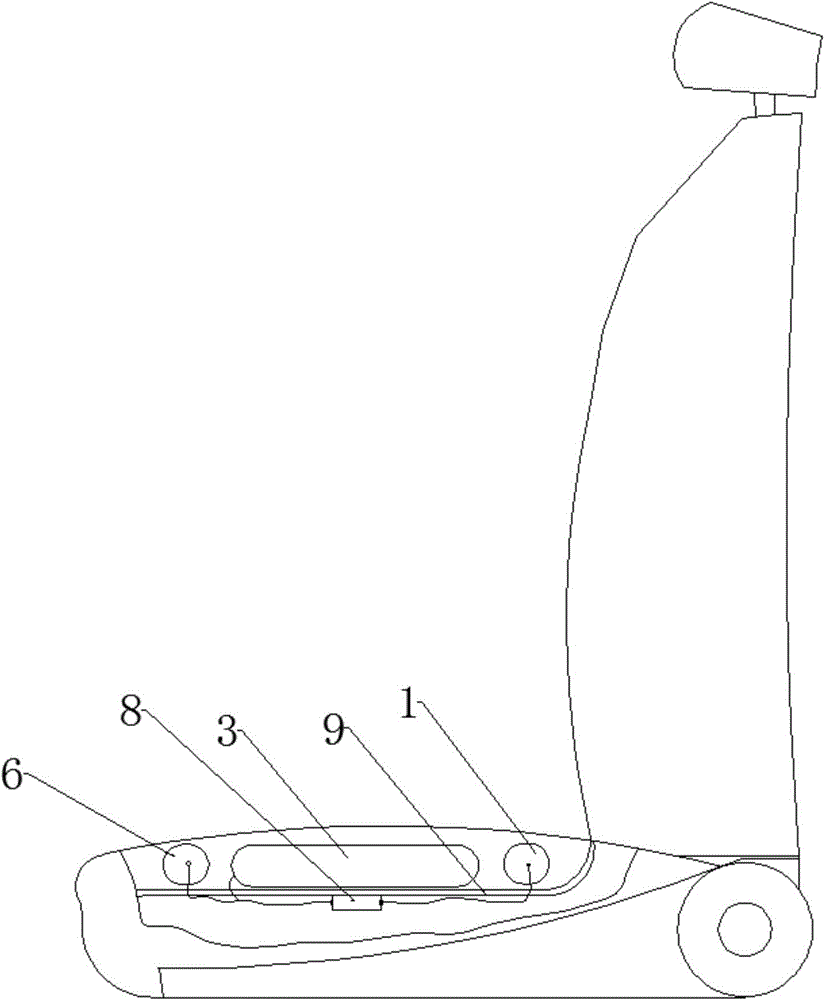

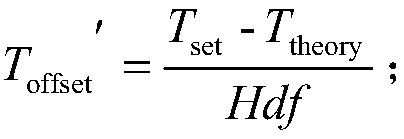

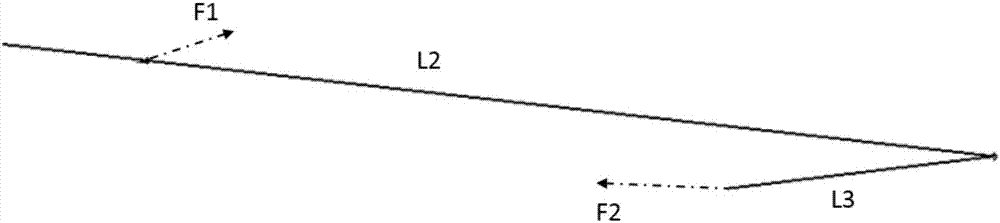

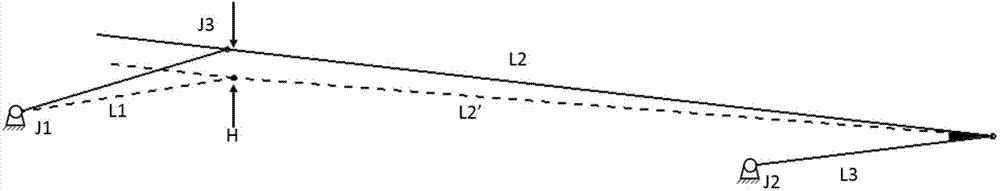

Automobile seat cushion framework with descending prevention function

ActiveCN104773100AEffectively cater to the direction of forceImprove securitySeat framesFixed frameArticulation points

The invention discloses an automobile seat cushion framework with a descending prevention function. The automobile seat cushion framework comprises two side plates, a pair of front connecting rods and a pair of rear connecting rods, wherein the front and rear parts of each side plate are articulated with an upper sliding rail by virtue of one front connecting rod and one rear connecting rod; a descending prevention rod is connected between the two side plates; the outer side edge of each front connecting rod is provided with a flange which is protruded outwards; when the automobile seat cushion framework descends to the bottommost position, the descending prevention rod is withstood by the flanges; when the whole automobile seat cushion framework is collided, the front connecting rods can not rotate around the articulation points of the front connecting rods and the upper sliding rail, and a fixed frame body is formed between the side plates, the front and rear connecting rods and a lower sliding rail. Compared with the prior art, the automobile seat cushion framework has the advantages of being capable of reducing the excessive descending amount caused by clearances between the descending prevention rod and the front connecting rods and the deformation of the side plates, effectively catering to the stress direction of the descending prevention rod, and providing stable support so as to improve the safety performance of a seat.

Owner:YANFENG ADIENT SEATING CO LTD

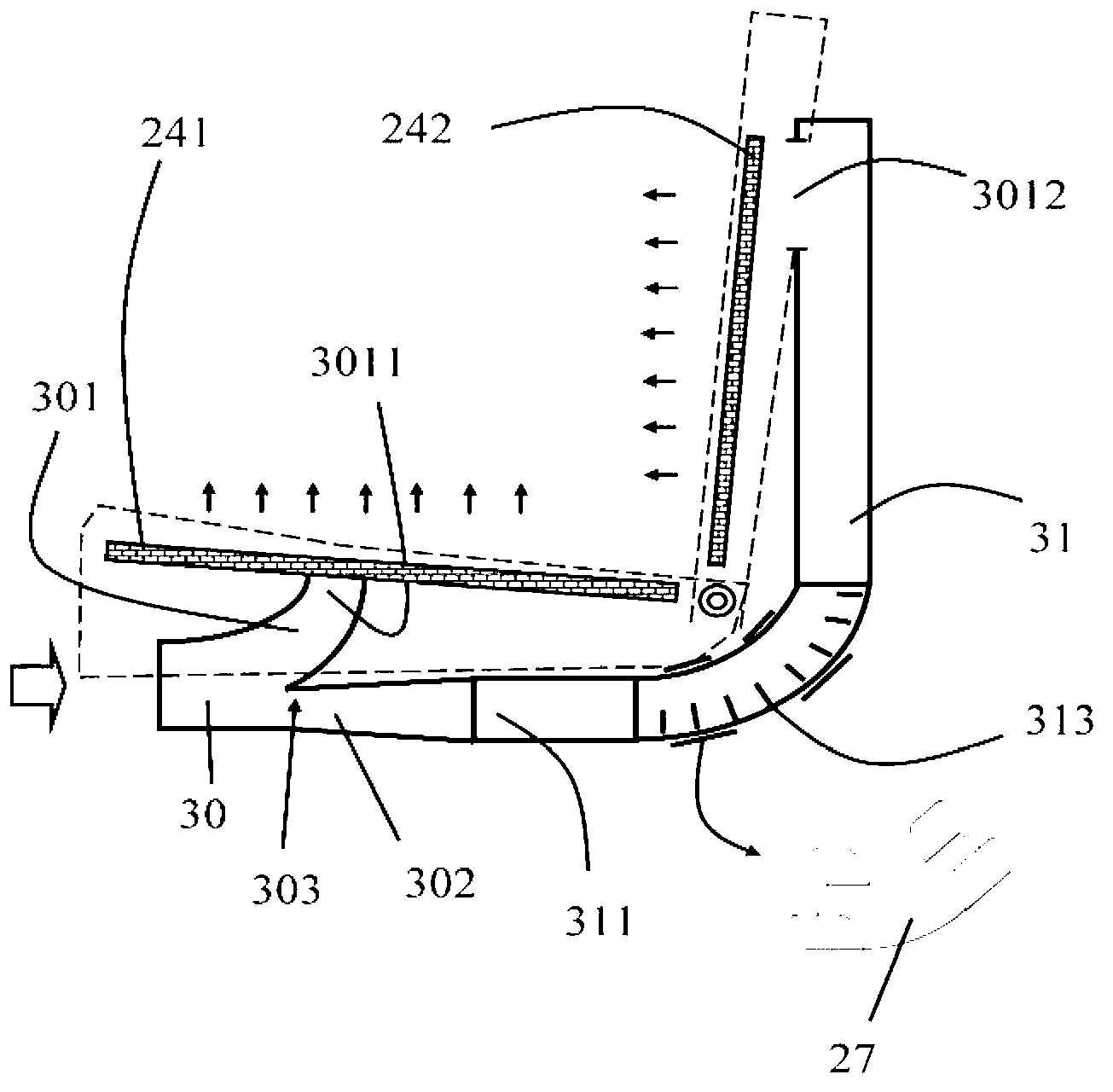

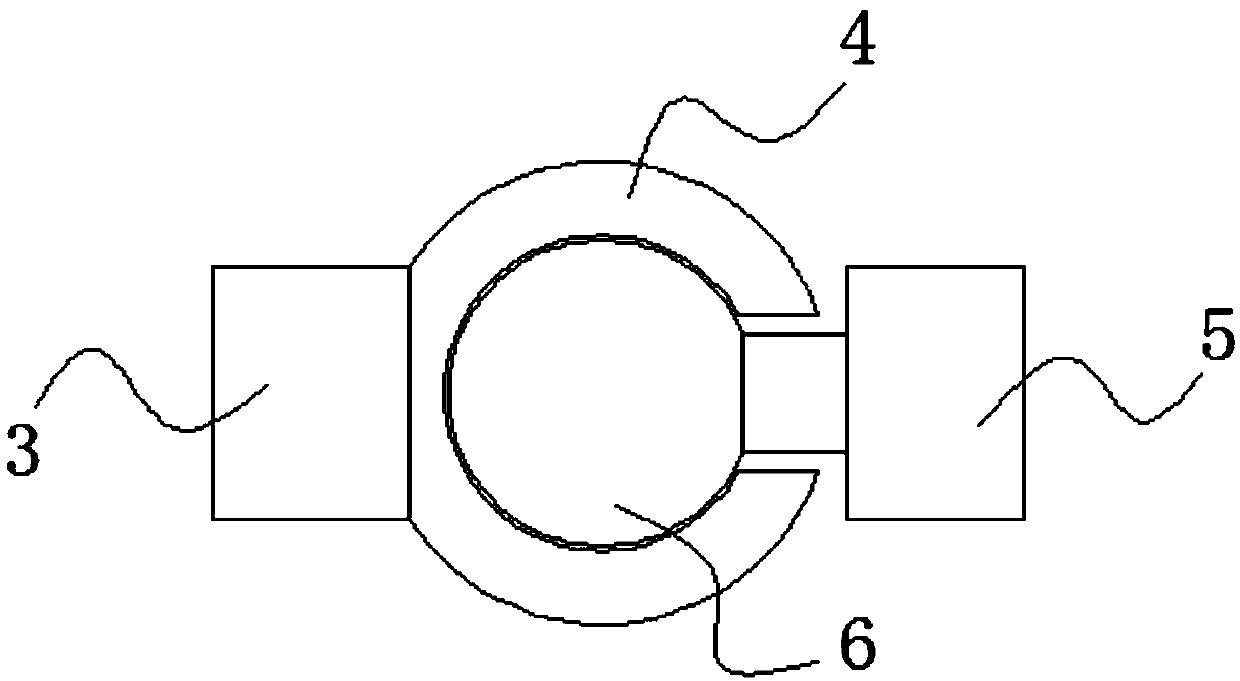

Automobile seat air-conditioning system

InactiveCN103204088AAdjustable temperatureSeat heating/ventillating devicesEngineeringAir conditioning

The invention discloses an automobile seat air-conditioning system which includes an automobile seat cushion and a flow divider pipe, wherein the flow divider pipe is arranged below the automobile seat cushion. Further, the flow divider pipe includes a left air inlet opening, a first flow dividing channel and a second flow dividing channel, wherein the first flow dividing channel extends from the arc of the left air inlet opening to upward right, a channel inner wall is winding upward in an arc shape, and thus an upward first air outlet opening is formed; the second flow dividing channel extends from the left air inlet opening to the right and a right connection opening is formed; a lower part of the pipe wall of the first flow dividing channel is connected in a tangent manner with an upper part of the pipe wall of the second flow dividing channel, and a tip facing the left air inlet opening is formed in the flow divider pipe. The automobile seat air-conditioning system having the arc-shaped flow divider pipe provides a fan for transverse air intake for the flow divider pipe, and guides the air-conditioning air intake to smoothly upward right to the seat cushion by using the arc-shaped flow divider pipe. The automobile seat air-conditioning system can at the same time guide the air-conditioning air flow to the back of the seat to adjustment temperature at the back for a driver.

Owner:张家杰

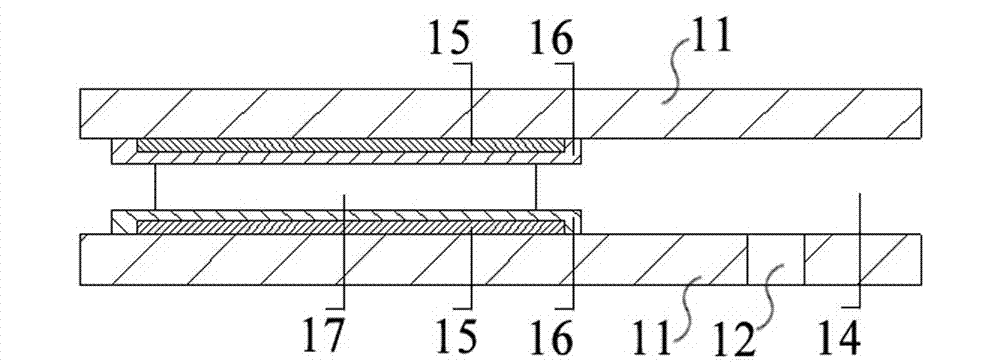

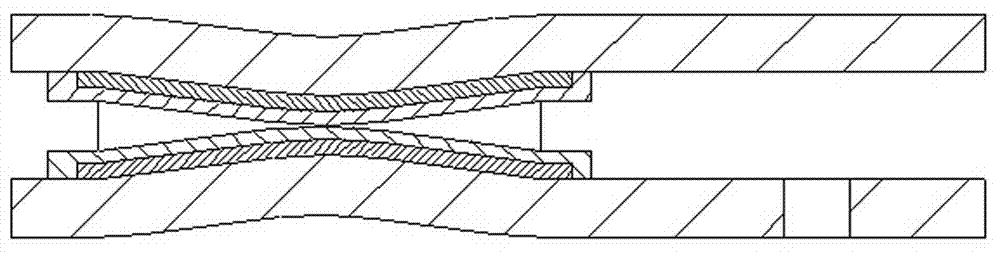

Manufacture method of improved automobile seat cushion cover

InactiveCN106273964AImprove qualityComfortable rideSeat coveringsTextile treatment containersSurface layerAutomobile seat cushion

The invention provides a manufacture method of an improved automobile seat cushion cover, and belongs to the technical field of fabric dyeing. The technical problems that an existing automobile seat cushion cover is uncomfortable in riding, poor in texture, low in quality and the like are solved. The manufacture method of the improved automobile seat cushion cover comprises the following steps of 1 bottom-layer fabric selecting, wherein PVC film is selected as a bottom-layer fabric; 2 surface-layer fabric selecting, wherein flannel cloth is selected as a surface-layer fabric; 3 middle-layer fabric selecting, wherein a warp knitting fabric is selected as a middle-layer fabric; 4 dyeing treating; 5 attaching, wherein the surface-layer fabric is attached to one side face of the middle-layer fabric through an attaching device, the bottom-layer fabric is attached to the other side face of the middle-layer fabric through the attaching device, and the surface-layer fabric, the middle-layer fabric and the bottom-layer fabric form a seat cushion cover fabric; 6 drying, wherein the seat cushion cover fabric is dried through a drying device; 7 sewing, wherein the seat cushion cover fabric is sewn into an automobile seat cushion cover through a sewing machine. The automobile seat cushion cover manufactured through the method has the advantages of being comfortable in riding and the like.

Owner:广西海得曼汽车科技有限公司

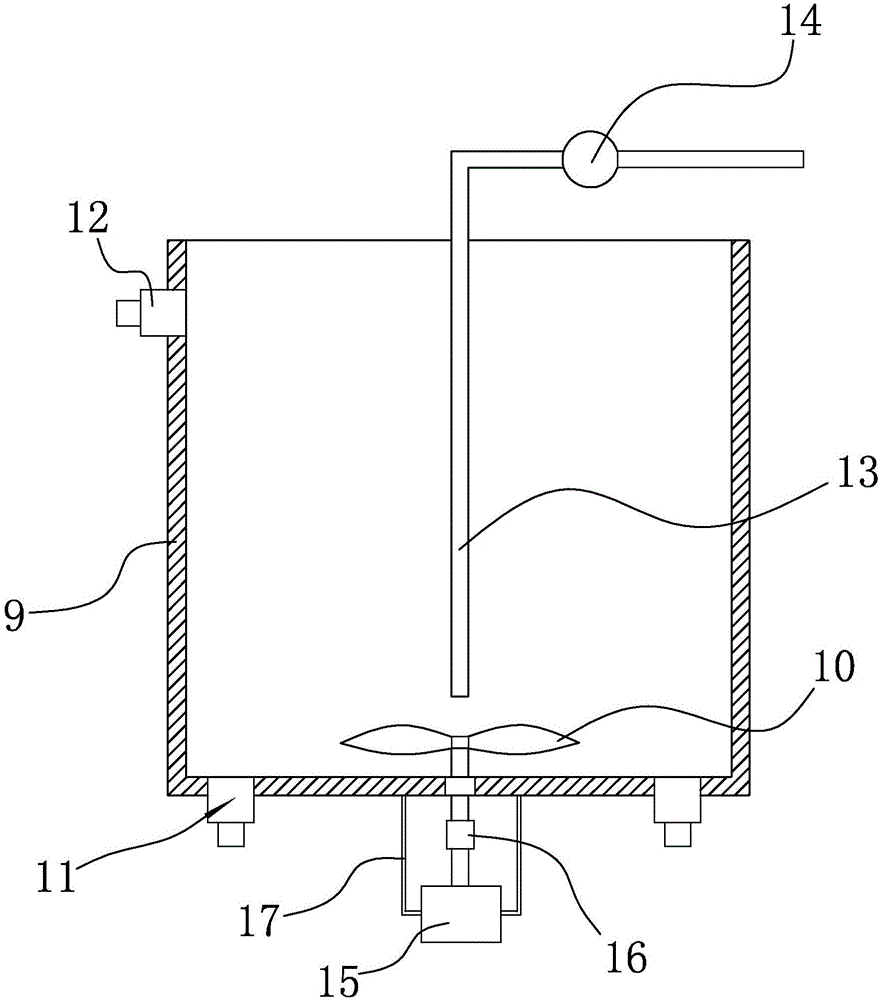

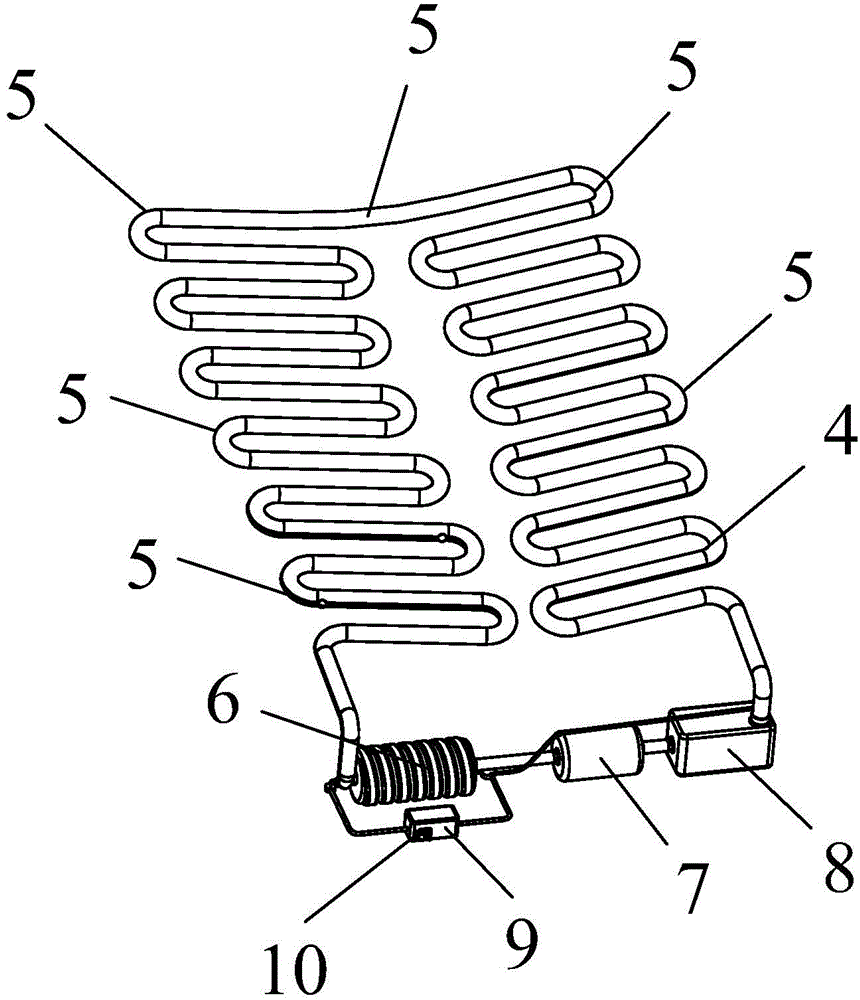

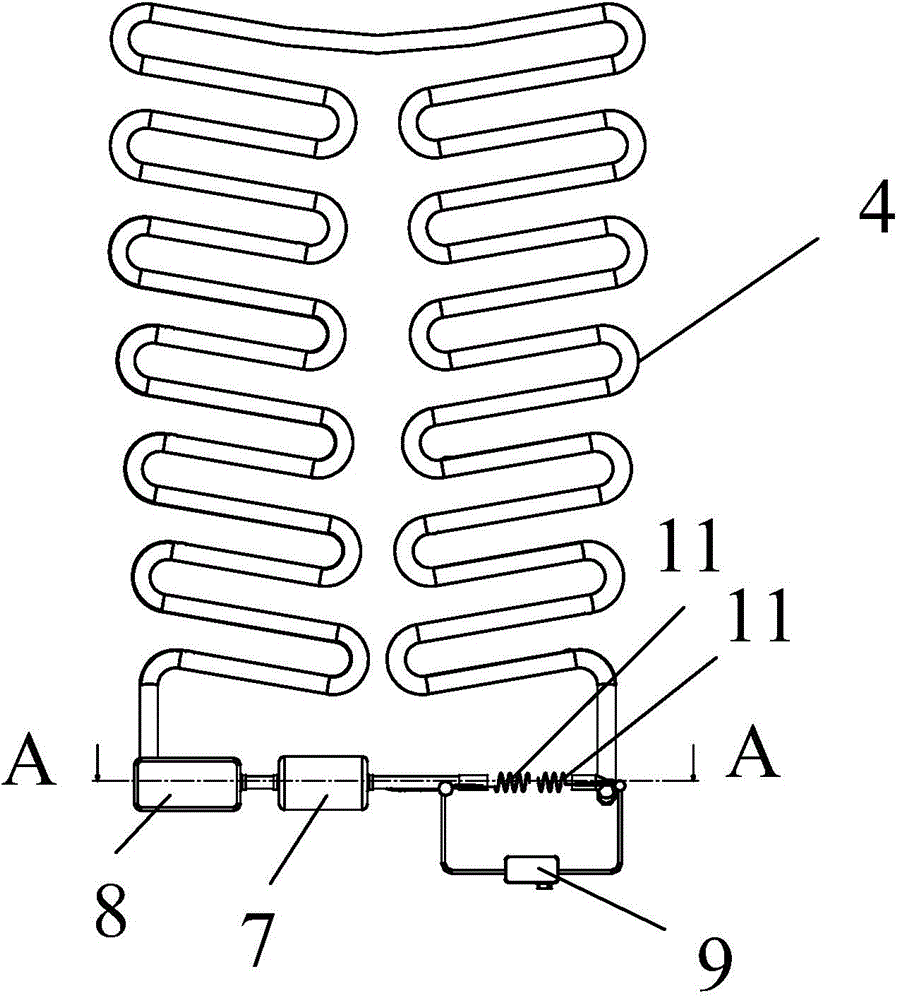

Automobile seat heating cushion

InactiveCN104786885APlay a protective effectWill not cause safety accidentsSeat heating/ventillating devicesCar seatLiquid storage tank

The invention discloses an automobile seat heating cushion. The automobile seat heating cushion comprises a heating seat cushion and a heating device arranged in foams of the heating seat cushion, wherein the heating device comprises a bent circulating heat conduction pipe; a liquid outlet end of the circulating heat conduction pipe is communicated with a liquid storage tank; a liquid inlet end of the circulating heat conduction pipe is communicated with a heating chamber; a heating wire is arranged in the heating chamber and is connected with a control unit through a lead wire to form a loop; and the heating wire comprises at least two heating wire units which are not connected. The heating cushion disclosed by the invention utilizes conductive liquid to heat; once if the conductive liquid leaks, the amount of the conductive liquid in the heating chamber is reduced, so that the heating wire is in short circuit and the power can be automatically off, and furthermore, the protection effect is realized and the safety accidents are not caused; and furthermore, a heat sensor is used for feeding a monitored temperature back to the control unit and the control unit is used for adjusting the heating temperature according to the received temperature and the temperature needed by a driver, and the automobile seat cushion is relatively comfortable.

Owner:SHIYAN BRANCH OF DONGFENG LEAR AUTOMOBILE SEAT CO LTD

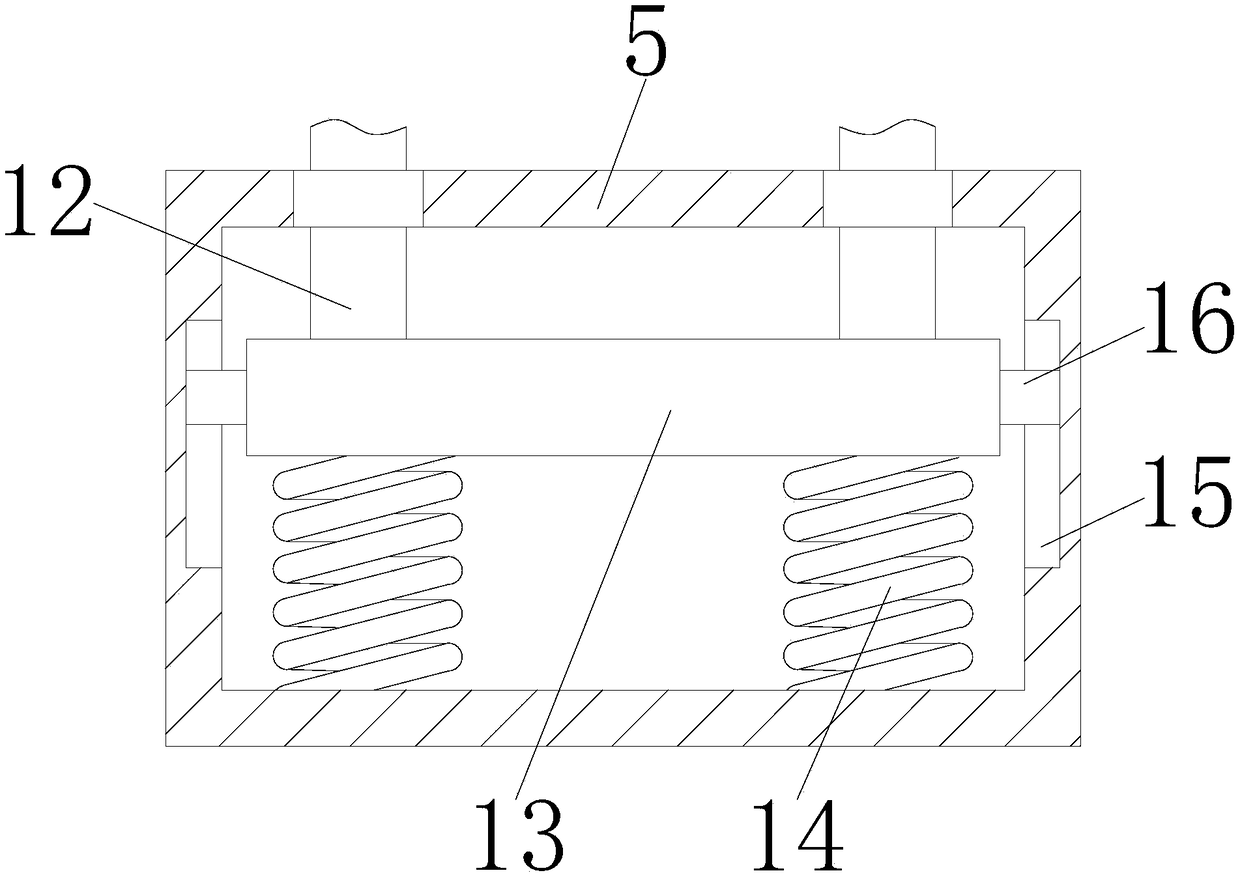

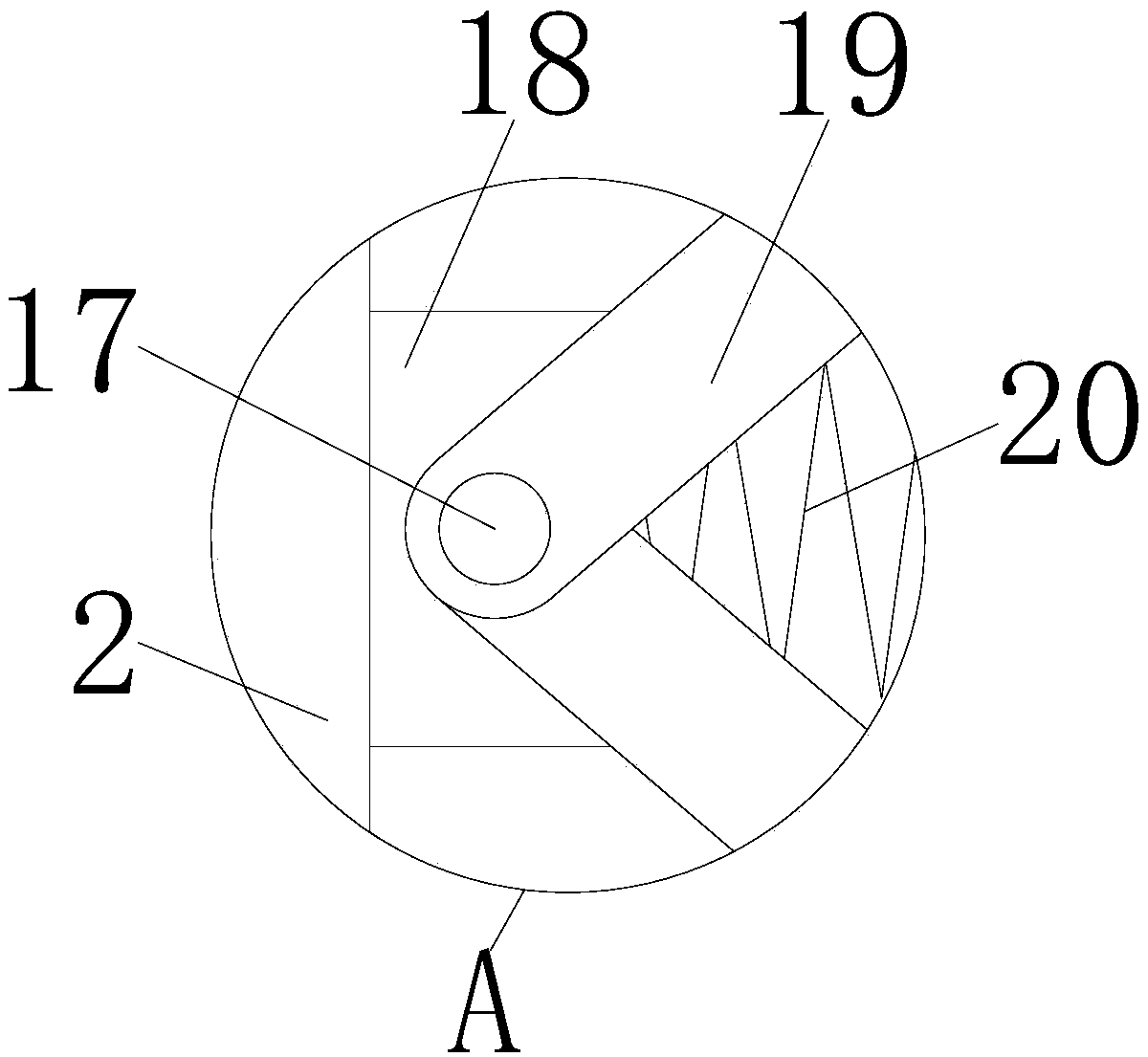

Shock absorbing type automobile seat cushion

InactiveCN109109695AImprove shock absorptionImprove practicalitySeat suspension devicesSlide plateEngineering

Owner:浙江仕善汽车科技股份有限公司

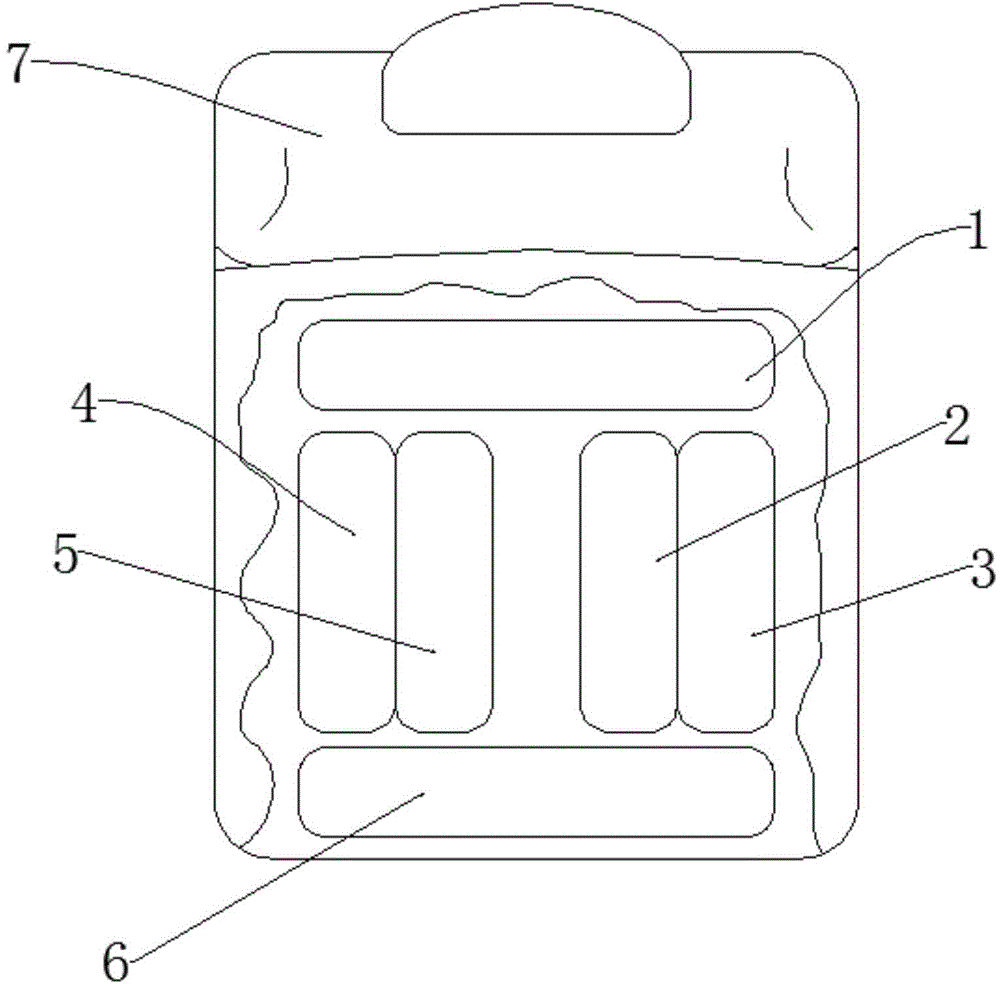

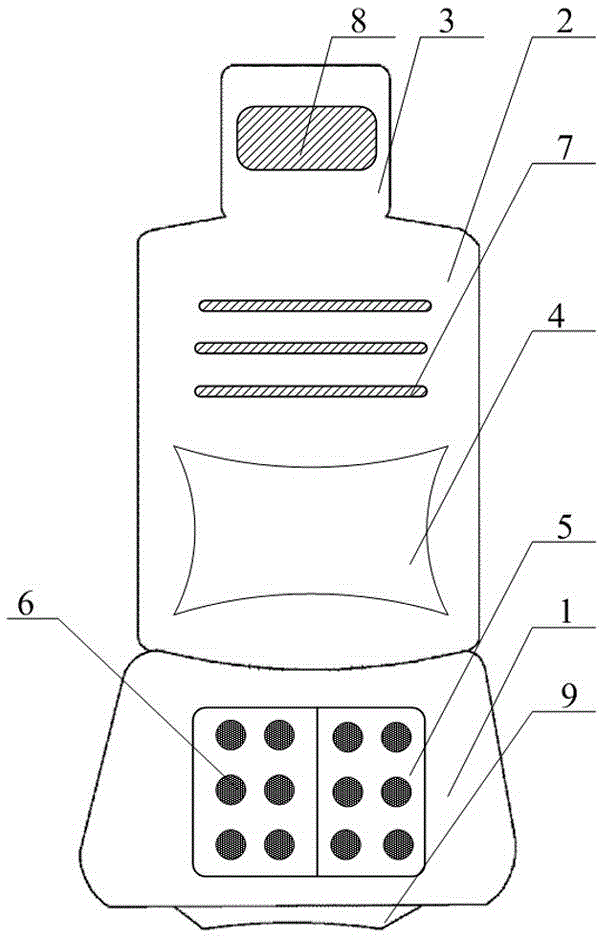

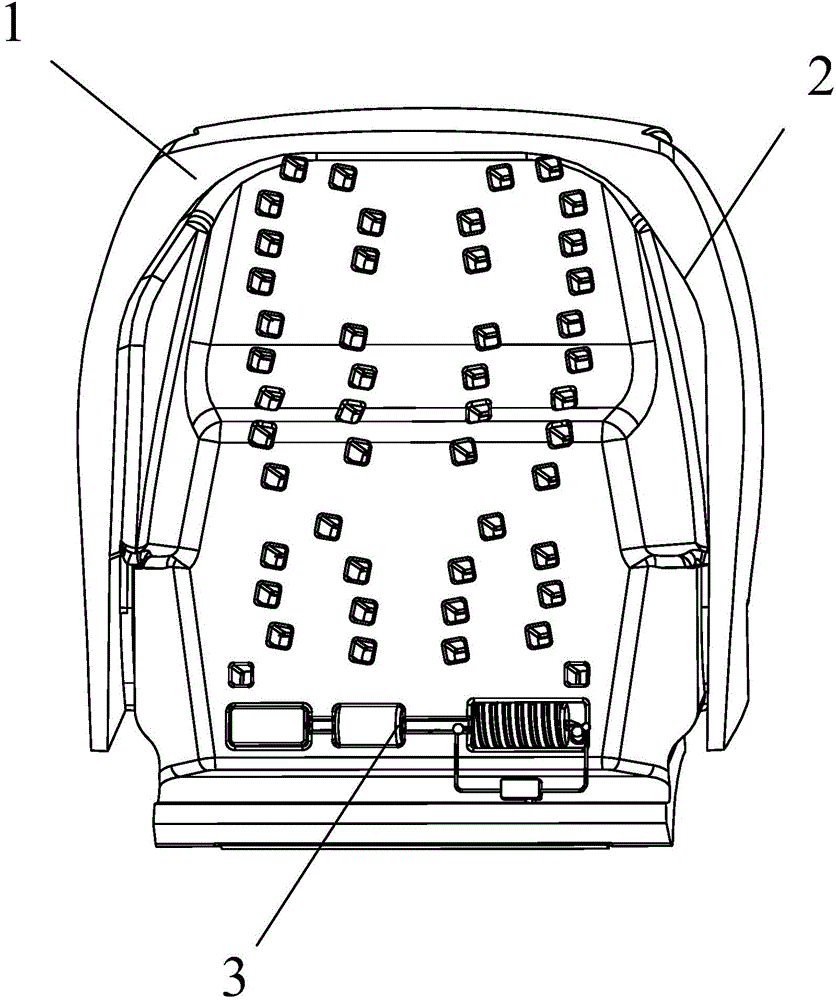

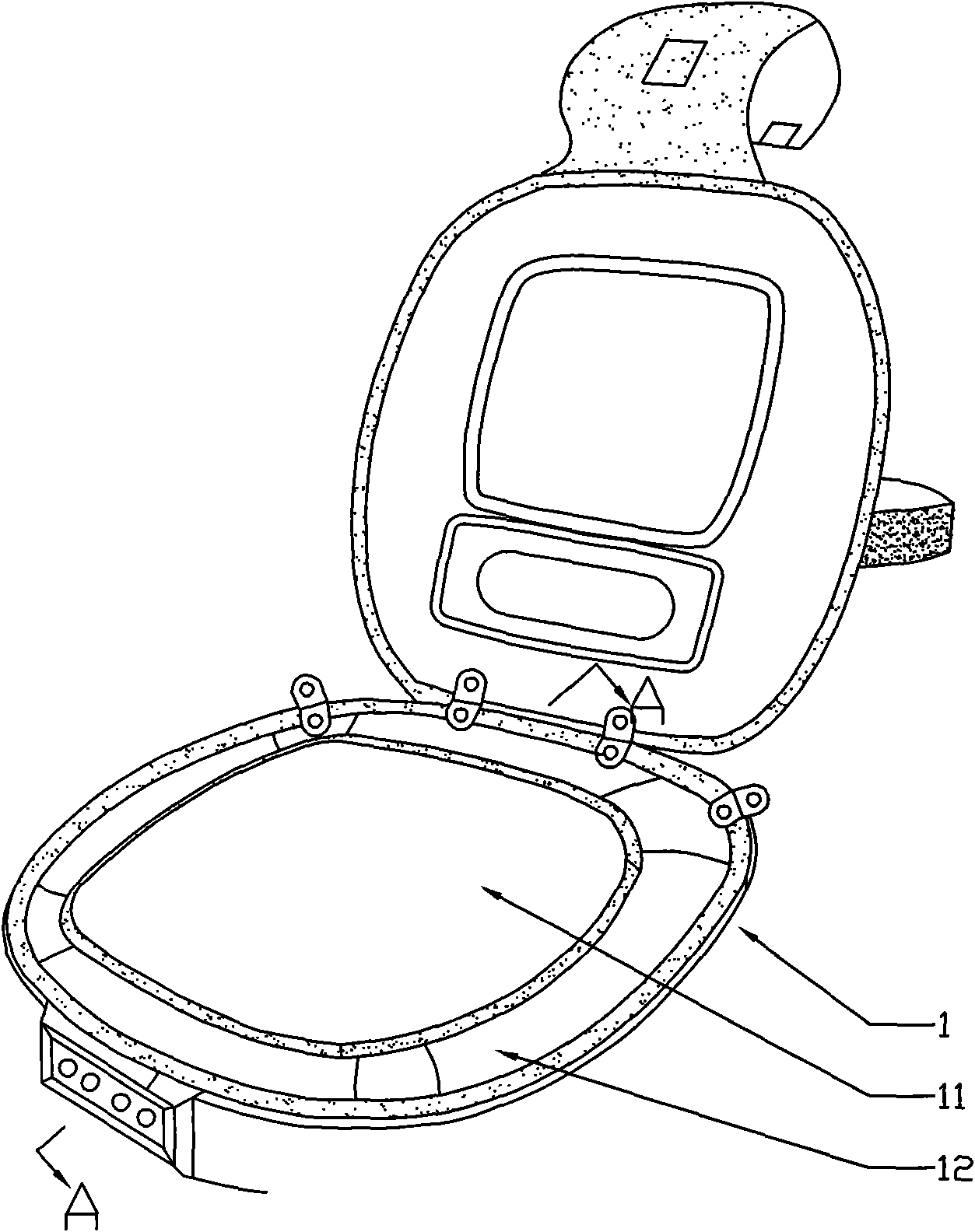

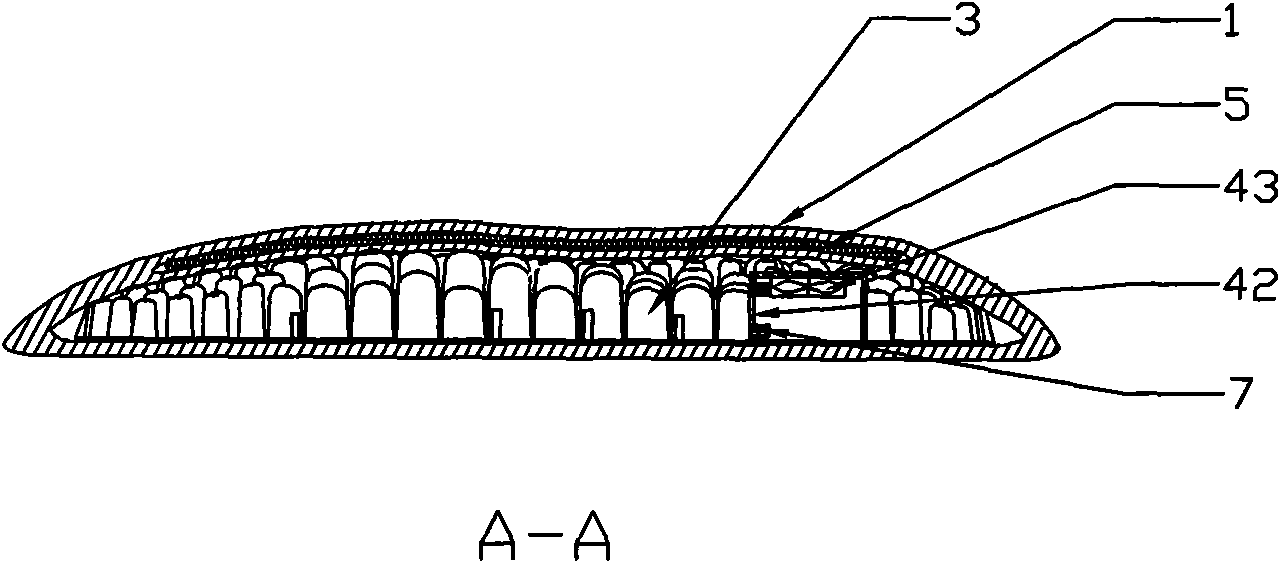

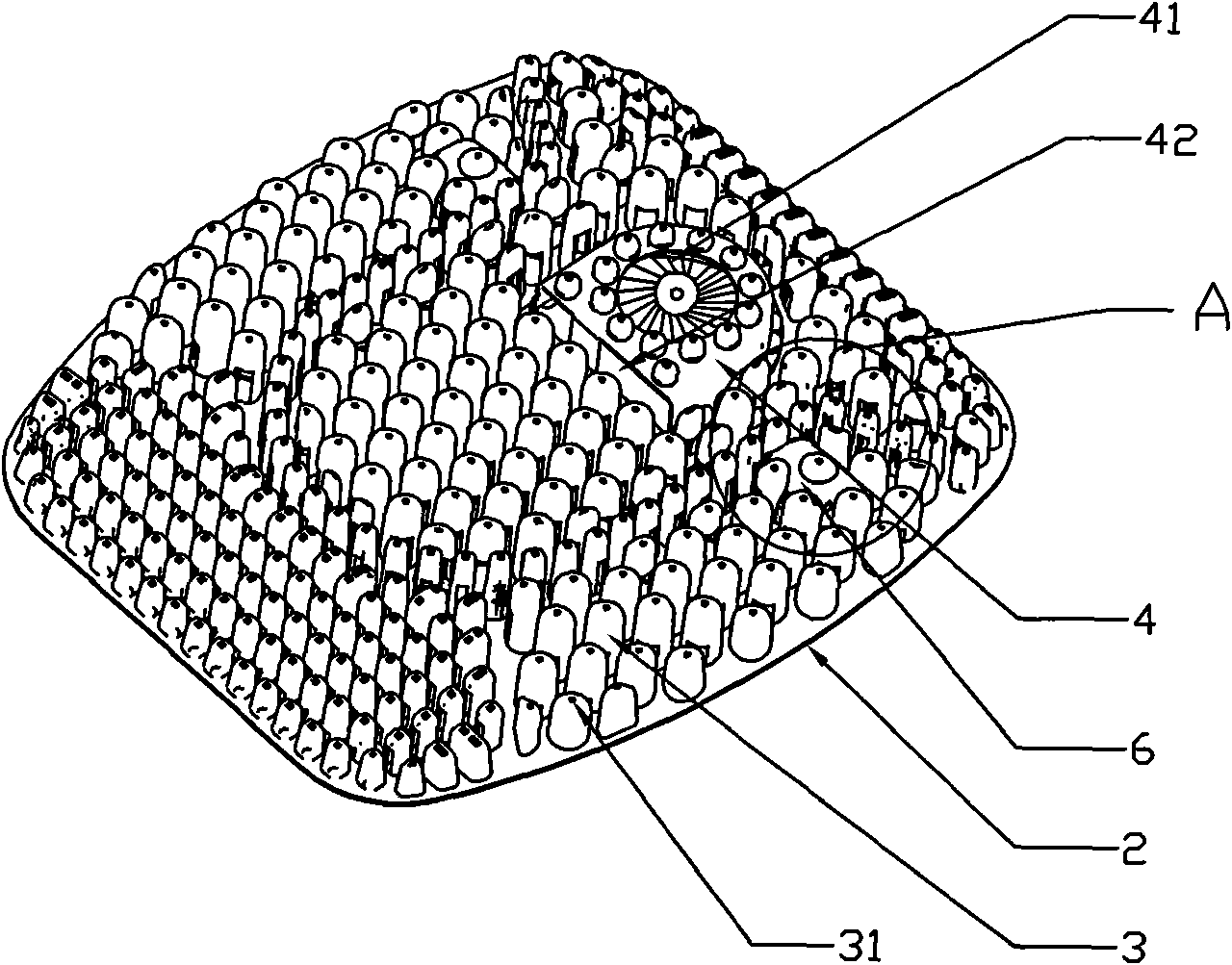

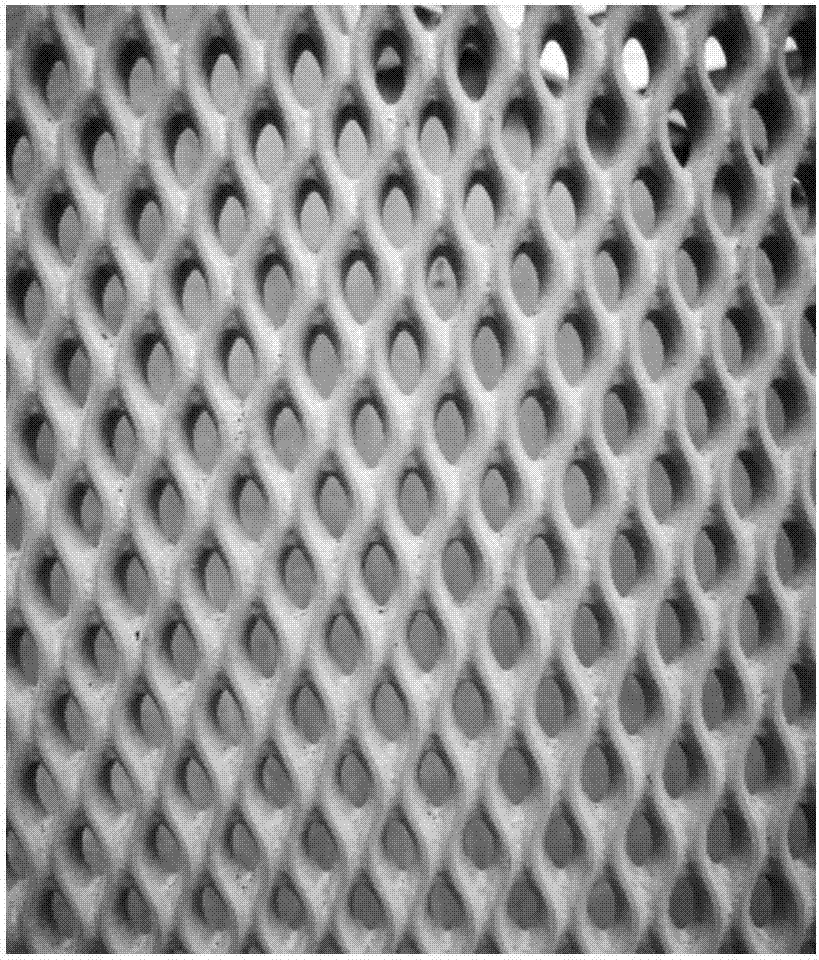

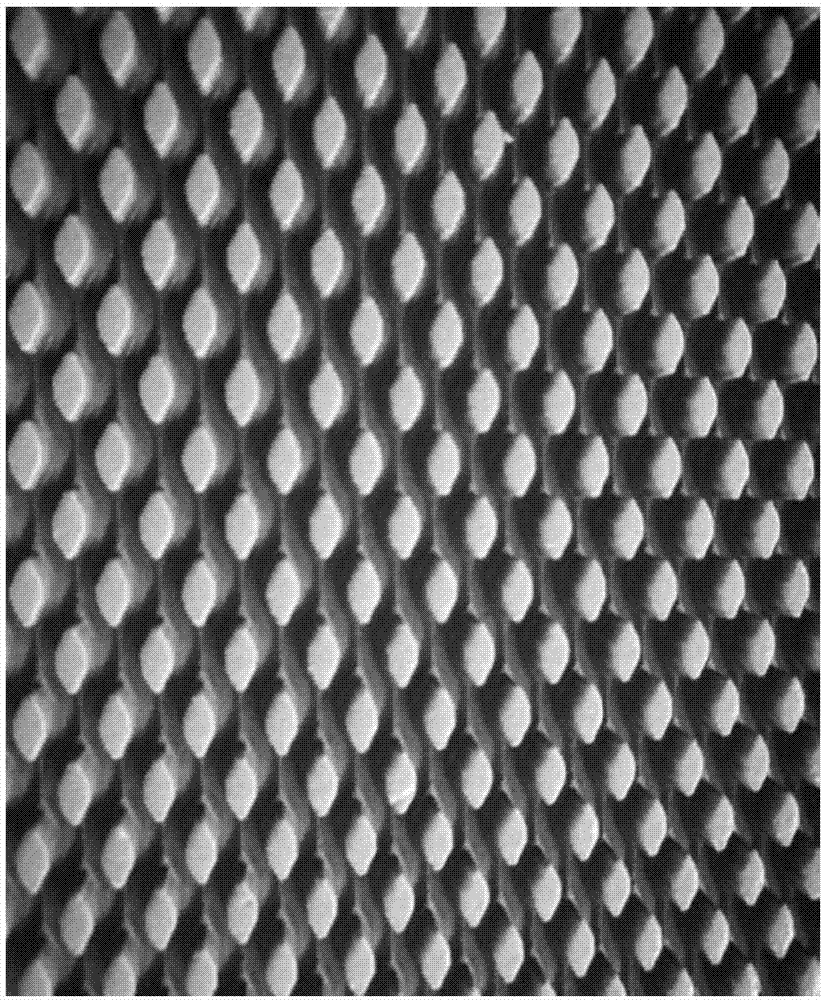

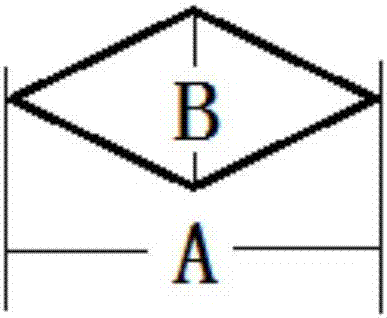

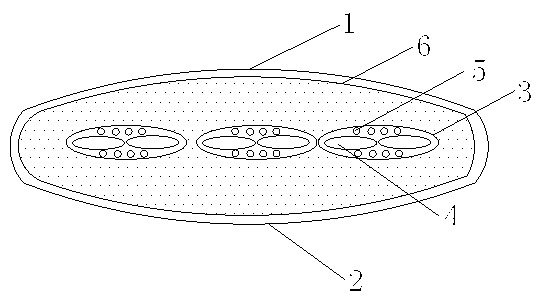

Automobile seat cushion

InactiveCN101537809APromote circulationDoes not affect driving concentrationSeat heating/ventillating devicesHuman bodyMassage

The invention discloses an automobile seat cushion which has the advantages of good effects on heat elimination and dehumidification and the functions for activating blood without sense, massaging and relieving fatigue. The automobile seat cushion comprises a seat cushion cover (1) and a cushion plate (2), wherein the cushion plate (2) is placed in the seat cushion cover (1), the stressed surface of the cushion plate (2) is provided with a plurality of bulged massage heads (3) which are in the shape of hollow columns, the tops of the massage heads (3) are in ball-nose shape, and the massage heads (3) the tops of which are in ball-nose shape can generate the senseless massage function on the stressed surface of a human body without influencing traffic safety in traffic jolt. The invention can be widely applied to the field of automobile seats.

Owner:珠海格林维行车电子设备科技有限公司

Novel breather hole EVA (Ethylene Vinyl Acetate) foamable material for automobile seat cushion and preparation method of novel breather hole EVA foamable material

The invention discloses a novel breathable hole EVA (Ethylene Vinyl Acetate) foamable material for an automobile seat cushion and a preparation method of the novel breathable hole EVA foamable material. The novel breathable hole EVA foamable material with a hollow breathable hole structure is prepared by the process flow of weighing, banburying, mill mixing, tablet discharging, vulcanizing and foaming, cooling and forming, and processing of EVA copolymer EVA, low density high pressure polyethylene (LDPE), POE (PolyOlefin Elastomer), a foaming agent, zinc oxide, stearic acid, a peroxide crosslinking agent, heavy calcium carbonate and a pigment. The reasonable size design of the breathable hole structure guarantees the ventilation performance of the breathable hole structure, and is especially suitable for blistering summer; meanwhile, the condition that compressive durability of the breathable hole structure is affected due to excessive hollowing-out treatment is avoided; the foaming material is prepared by adopting a reasonable ratio of the EVA foaming material, and the optimal design ratio in flexibility, comfortableness, durability and easily-cleaning function is achieved. The novel breathable hole EVA foamable material applied to preparation of the automobile seat cushion has the advantages of excellent softness, comfortableness and breathability, easiness in cleaning, durability and low price.

Owner:SANSD JIANGSU ENVIRONMENTAL PROTECTION TECH

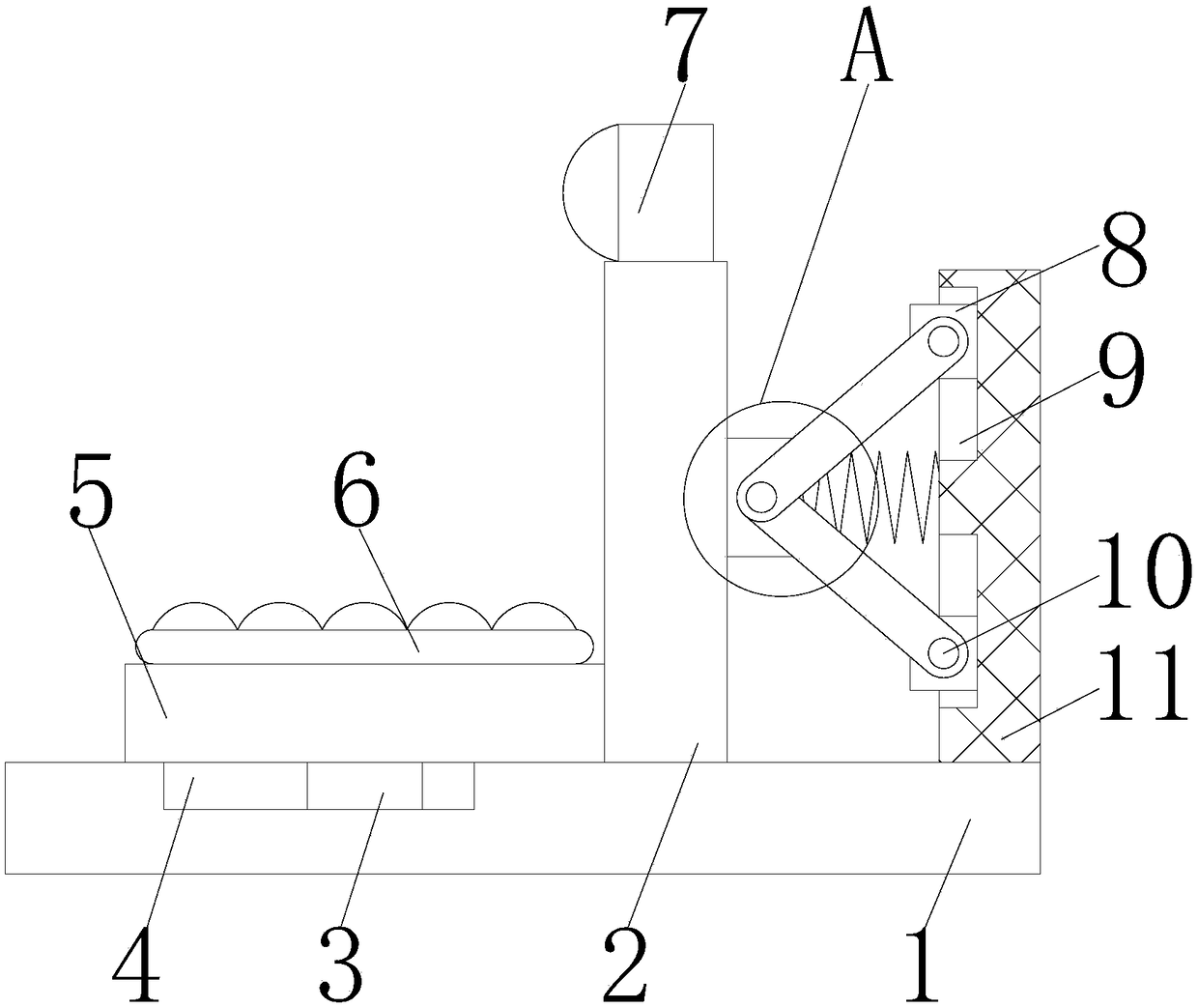

Heat pad special for automobil

InactiveCN108891316AImprove comfortReduce driving fatigueSeat heating/ventillating devicesThigh restsElectricityComputer module

The invention discloses a heating pad special for automobiles, include a bottom housing, Back housing, Cushion, electric heating device, Electric heating wire, back massage module and buttock massagemodule, the automobile seat cushion can be heated by the electric heating device and the electric heating wire, At that motor, output shaft, Rocker arm, driving pulley, Swing lever, longitudinal chute, Slide Block, Wavy Surface, the driving pulley, the driven pulley, the driven rotating shaft, the first connecting rod and the second connecting rod drive the back massage module and the hip massagemodule under the action of the driving pulley, so that the buttock and the back of the vehicle owner are massaged, the vehicle owner gets good physiotherapy and health care when riding or driving, thecomfort degree of the vehicle owner can be improved and the fatigue driving of the vehicle owner can be effectively alleviated; The massage device has a local telescopic function under the action ofa column-shaped sliding sleeve, a sliding column, a massage head and a spring, so that the massage device can automatically match the best position according to the position of the vehicle owner, andthe massage effect is greatly improved.

Owner:广州市欧之星商贸有限公司

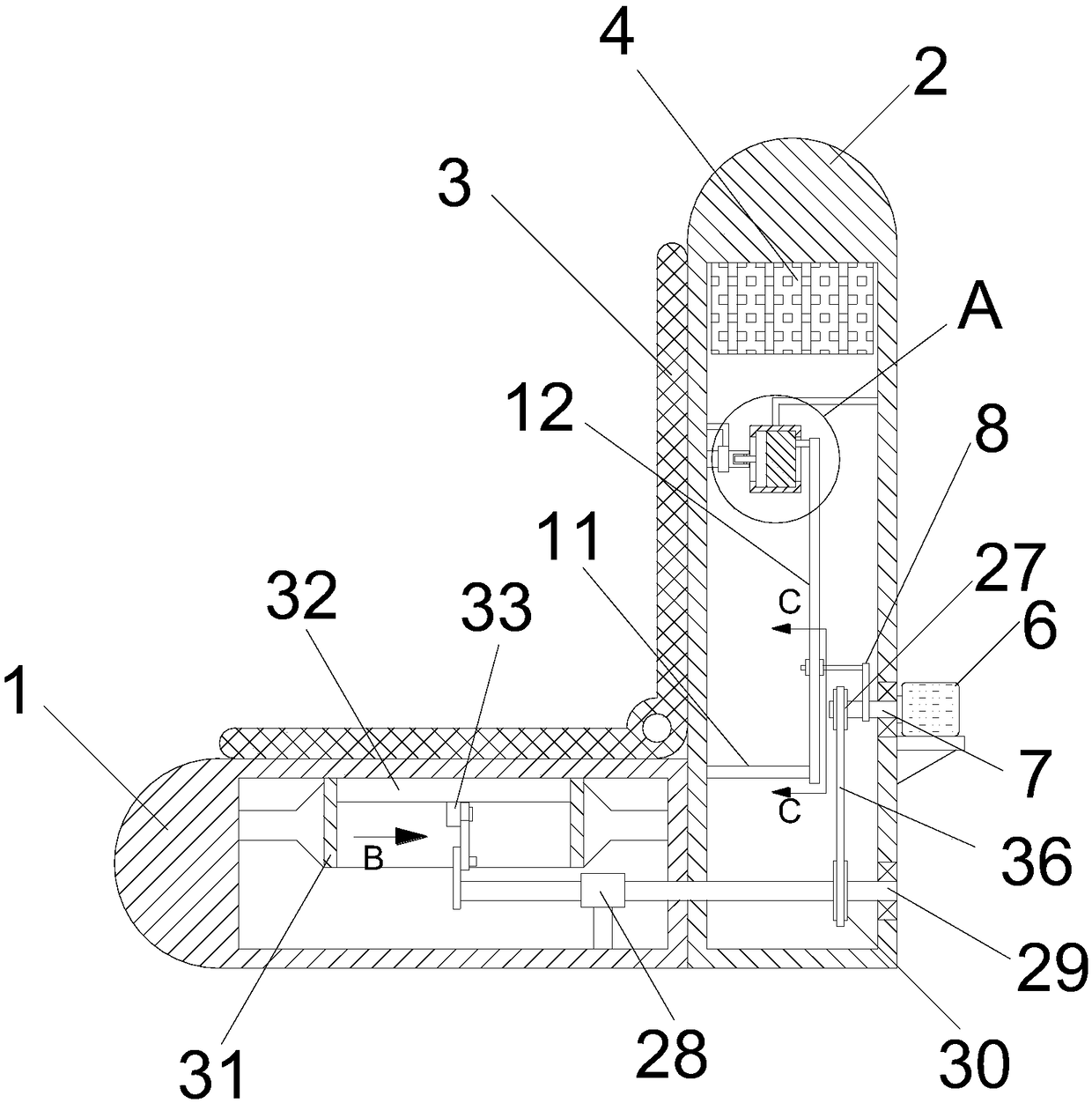

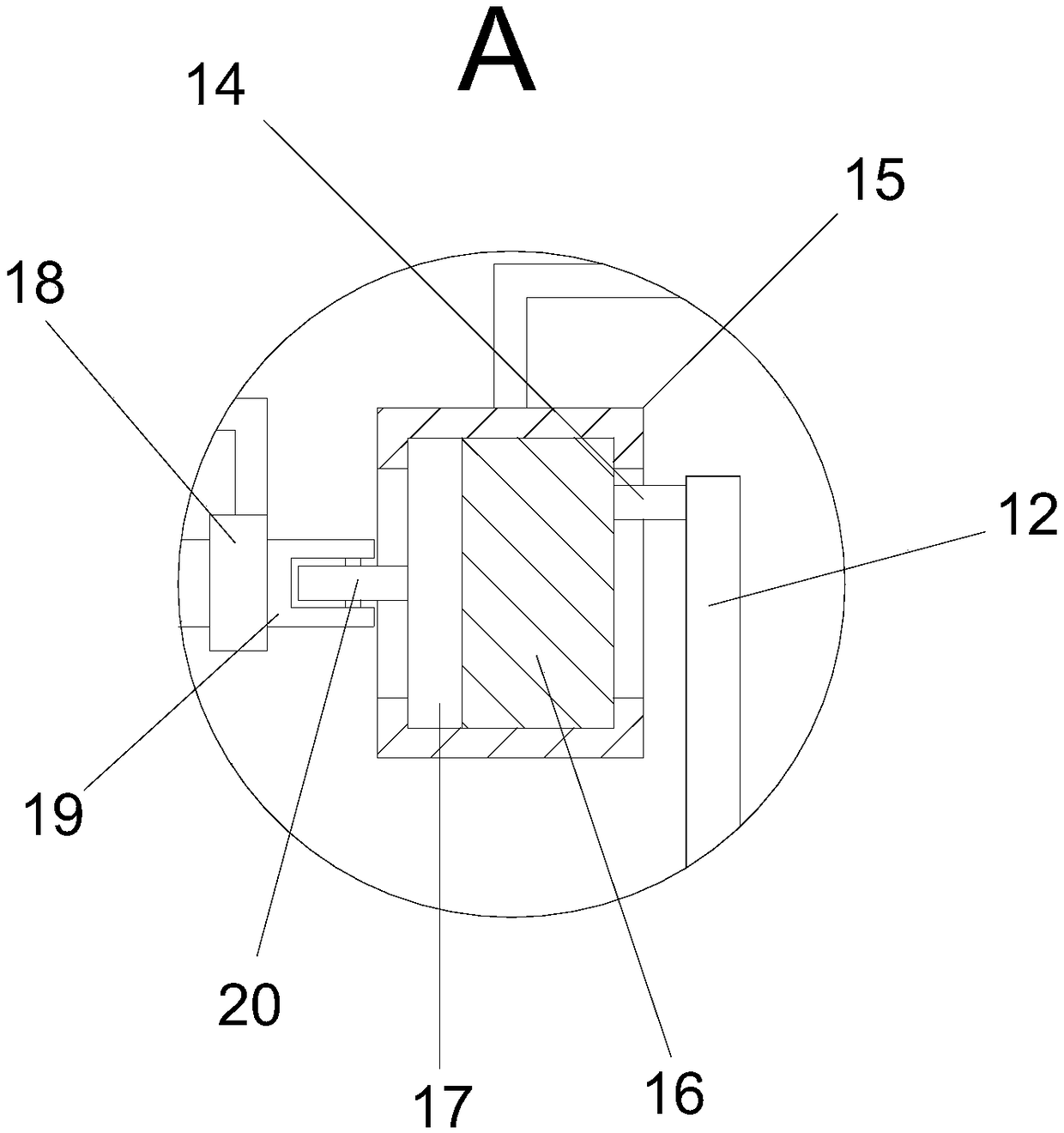

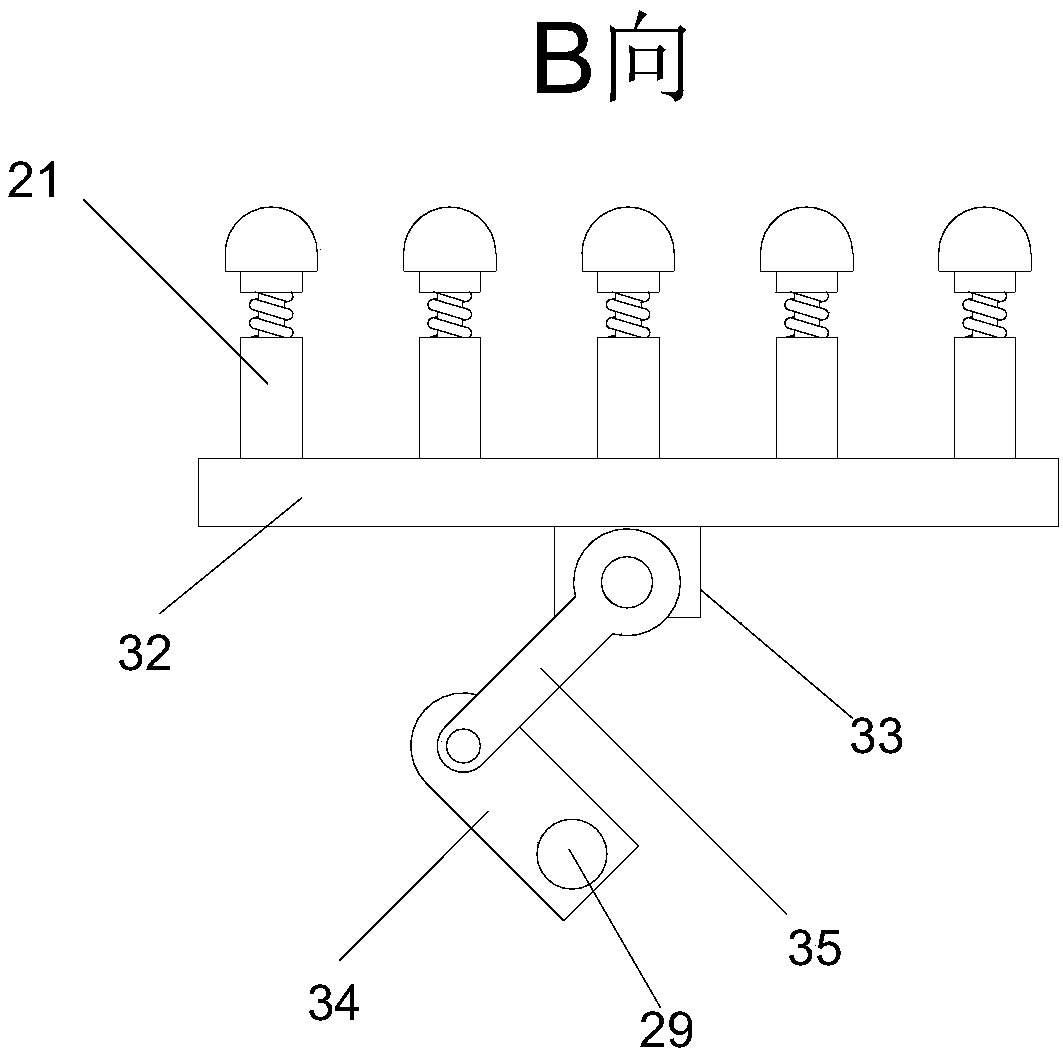

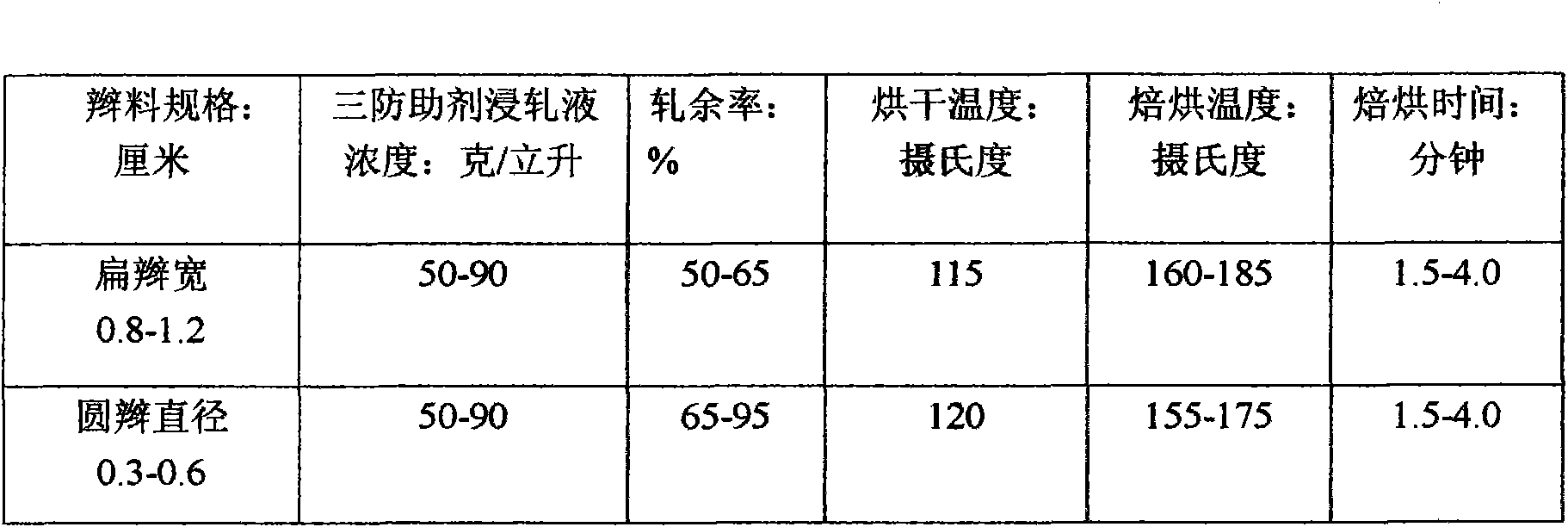

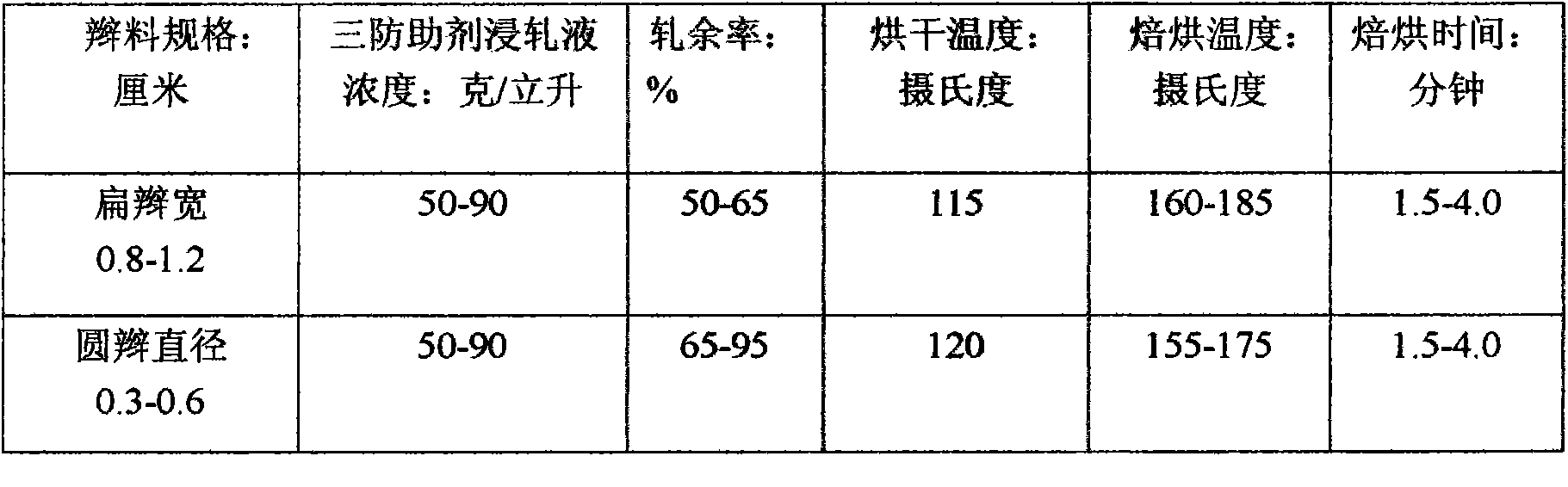

Process for manufacturing three-protection automobile seat cushion

The invention provides a process for manufacturing a three-protection automobile seat cushion, relating to the field of automobile seat cushions. The process comprises the following steps: plaiting raw material threads, forming axis, and padding in a three-protection auxiliary; drying, baking, and cutting and rolling the material; manually weaving, and sewing; and inspecting and packaging into a finished product. By utilizing the unique performance of a three-protection auxiliary nanometer technology, through a special process means, the three-protection arrangement material can be applied to the surface of plaited material fibers, the cushion has rich hand feel, and the cushion is ensured to be far away from various harmful bacteria and pollution, and has the advantages of water resistance, oil resistance, and no damage to the original style of the fibers.

Owner:张振和

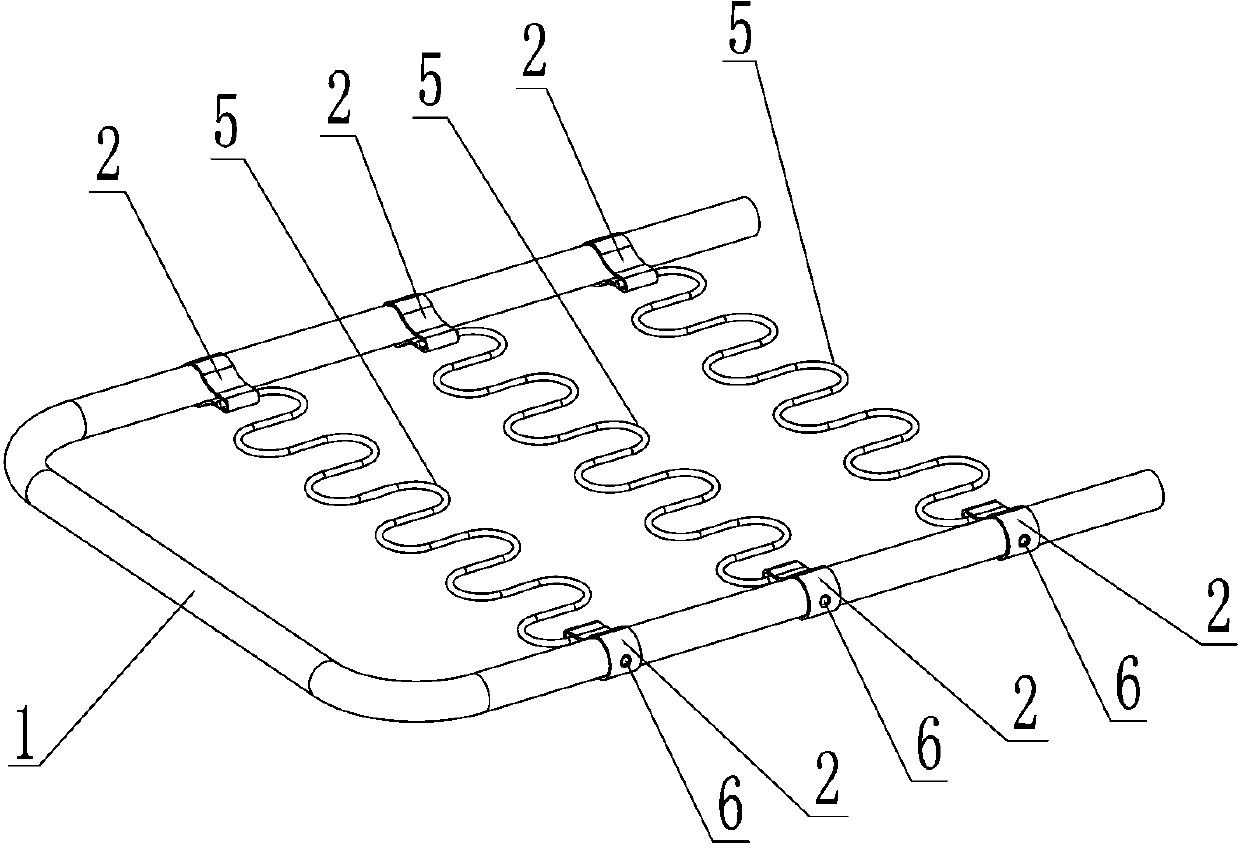

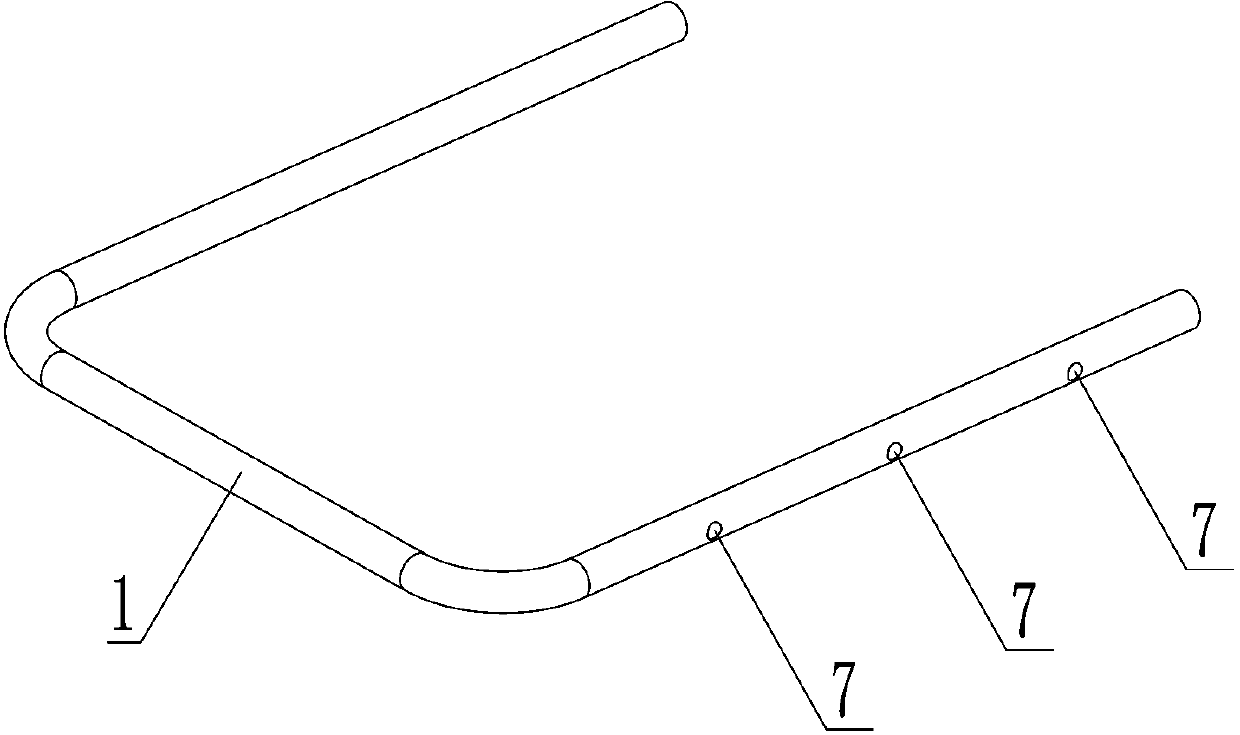

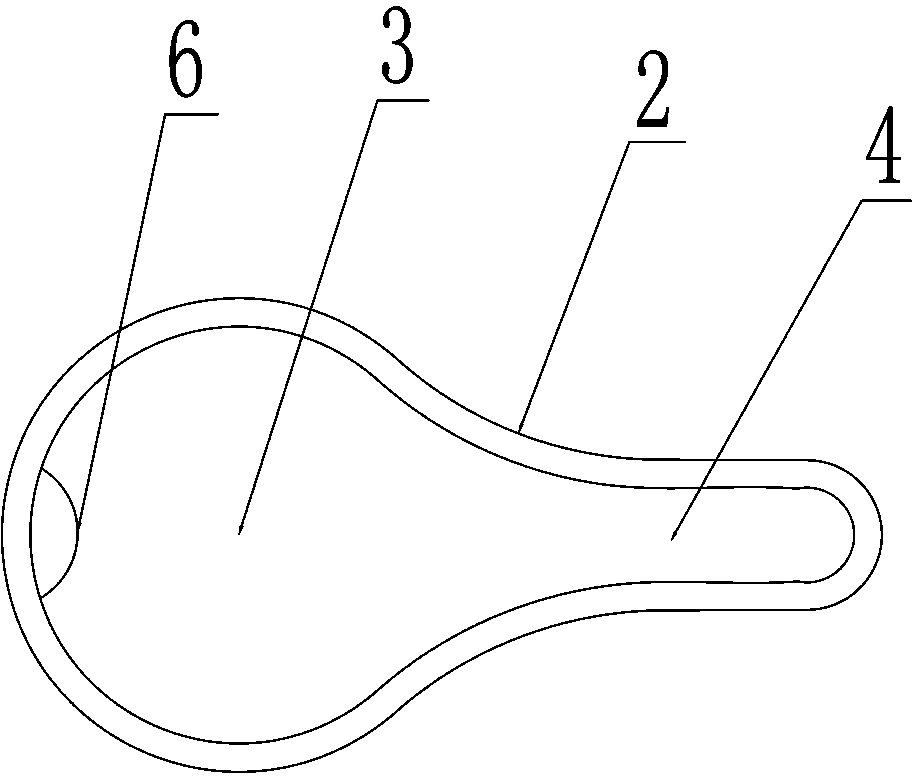

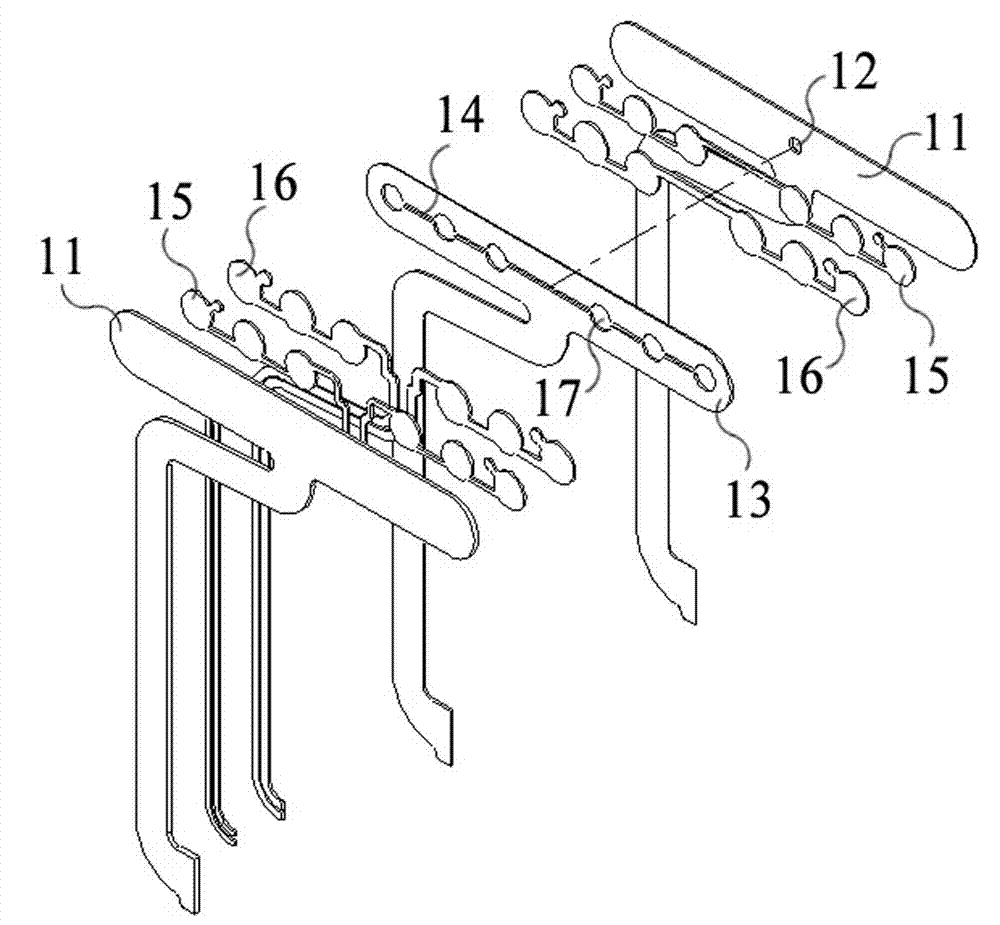

Automobile seat cushion framework structure

InactiveCN104192034AIncrease productivityEasy to disassemble and maintainSeat framesEngineeringMechanical engineering

The invention discloses an automobile seat cushion framework structure. The automobile seat cushion framework structure comprises a U-shaped seat cushion frame, and multiple pairs of spring fixing parts are sequentially and symmetrically arranged on two U-shaped arms of the U-shaped seat cushion frame at intervals. Each spring fixing part comprises a clamping hole and a spring positioning hole, wherein the clamping hole can clamp the corresponding U-shaped arm in a sleeved mode, and the spring positioning hole can be hooked by a spring. One serpentine spring is arranged between each pair of spring fixing parts, the two ends of each serpentine spring are hooked in the spring positioning holes of the corresponding spring fixing parts on the two sides, and each spring fixing part and the U-shaped arm clamped by the spring fixing part in a sleeved mode are fixedly limited through a limiting mechanism. The automobile seat cushion framework structure has the advantages of being convenient to install and maintain and high in enterprise productivity.

Owner:ZHANGJIAGANG LONGJING AUTOMOBILE PARTS

Automobile seat cushion convenient to disassemble and assemble

InactiveCN107933390AReduce fatigueNot hotSeat heating/ventillating devicesBack restsEngineeringAutomobile seat cushion

The invention discloses an automobile seat cushion convenient to disassemble and assemble. The automobile seat cushion comprises a back cushion and a sitting cushion, wherein the bottom of the back cushion is fixedly connected with a first fixing strip; the bottom of the first fixing strip is fixedly connected with a fixing groove; the sitting cushion is fixedly connected with a second fixing strip in a position corresponding to the fixing groove; the second fixing strip is fixedly connected with a fixing rod; the back cushion and the sitting cushion are mutually hinged through the fixing groove and the fixing rod; a grid mesh is arranged at the upper end of the sitting cushion; the upper end of the interior of the sitting cushion is fixedly connected with a first clapboard; a heating board is arranged at the bottom of the first clapboard; the bottom of the heating board is fixedly connected with a second clapboard; a vibrator is arranged at the bottom of the second clapboard; the bottom of the vibrator is fixedly connected with a third clapboard; and resilient sponge is filled between the bottom end of the interior of the sitting cushion and the third clapboard. The automobile seat cushion disclosed by the invention is reasonable in design and is suitable for production, popularization and application.

Owner:胡仟惠尹

Classification sensor for automobile seat cushion

InactiveCN103085748AEnsure safetyImprove stress resistancePedestrian/occupant safety arrangementForce measurementCar seatSilver paste

The invention discloses a classification sensor for an automobile seat cushion. The classification sensor comprises a plastic sealing block connected with the tail end of a sensor. Technical key points are that: the pressure sensor comprises opposite plastic thin film layers; aluminum foil layer conductive circuits and carbon paste layer conductive circuits are sequentially printed on the plastic thin film layers; the plastic thin film layers with the printed circuits are adhered through an interlayer to form a composite structure in which a plurality of sensing units capable of repeatedly measuring a load on the automobile seat cushion are arranged; and a machine core board for classifying and processing a resistance value signal of each sensing unit is arranged in the plastic sealing block, and is connected with an entire safety airbag electric control center. The classification sensor has the advantages that the expansion degree of a safety airbag is controlled when an accident happens, so that the safety of passengers in an automobile is effectively ensured; silver paste circuits are replaced by the aluminum foil layer conductive circuits, so that the compressive resistance of the sensor is improved; silver paste is replaced by an aluminum foil layer, so that production cost is greatly lowered; and an aluminum corrosion process is adopted instead, so that the production cost is lowered.

Owner:BRILLIANCE AUTO

Massaging and health-care automobile seat cushion

The invention discloses a massaging and health-care automobile seat cushion which comprises a seat cushion surface layer, a seat cushion bottom layer and a seat cushion core, wherein the seat cushion core is arranged in a cavity formed by the seat cushion surface layer and the seat cushion bottom layer; and magnets and massaging beads are arranged in the seat cushion core. The automobile seat cushion can comfort a user and relieve the hip pressure, can prevent and treat hemorrhoids since the magnets are placed in a traditional Chinese medicine bag, and meanwhile, has the functions of calming the nerves and treating the dizziness, and cobblestones can massage acupuncture points of the hip, so that the fatigue of a driver can be relieved, and multiple health-care effects are achieved.

Owner:南通华信敷料有限公司

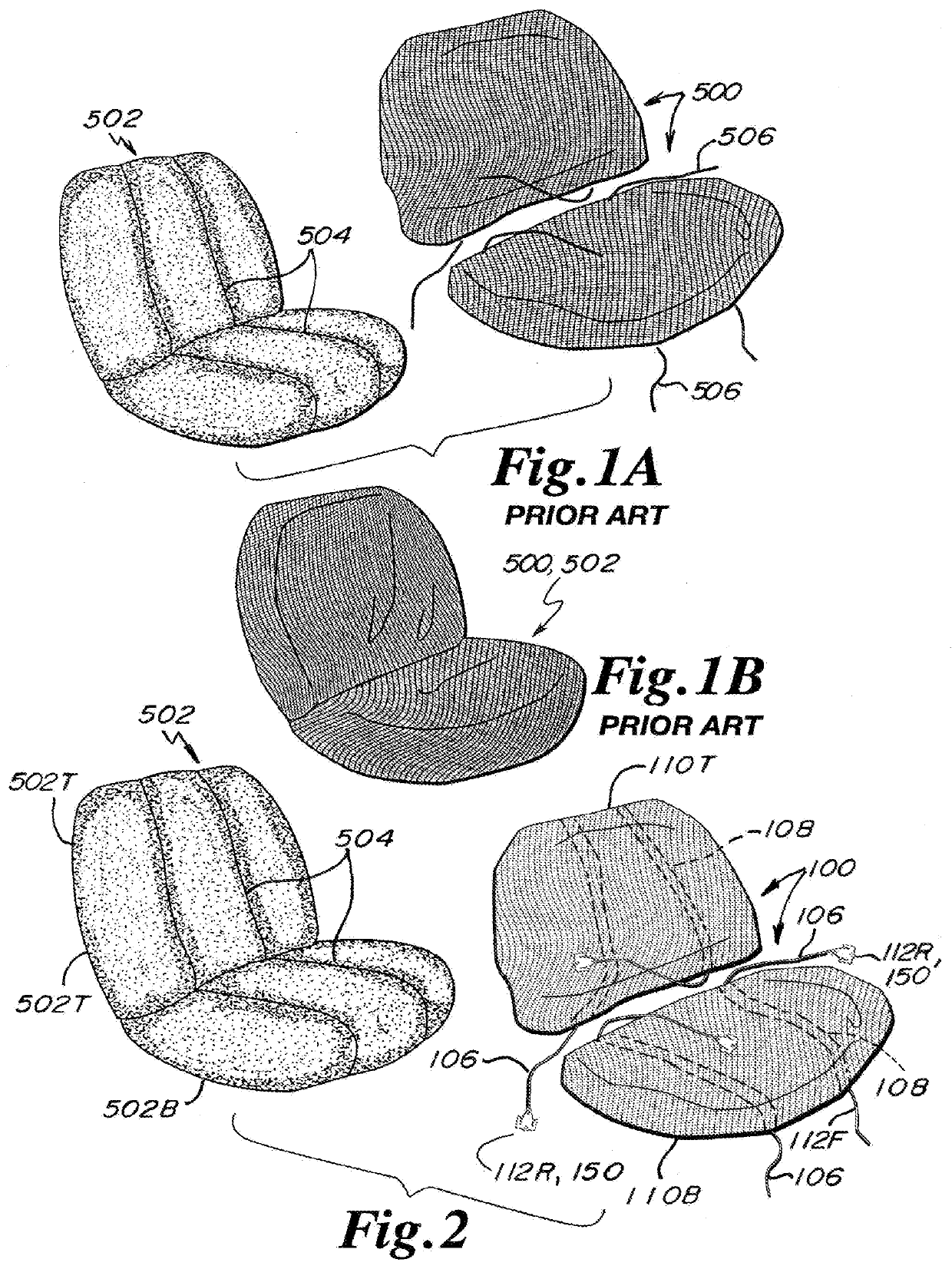

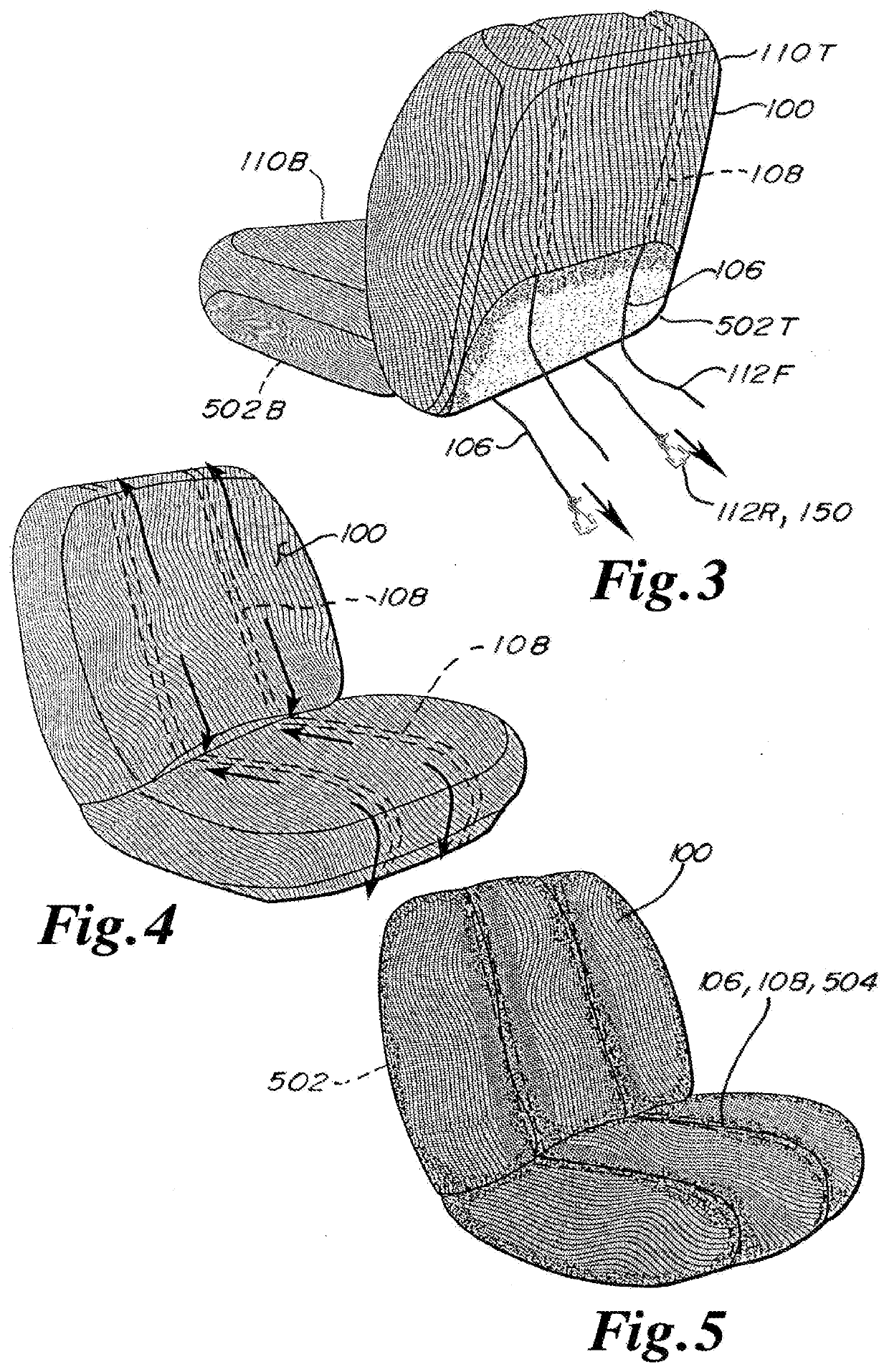

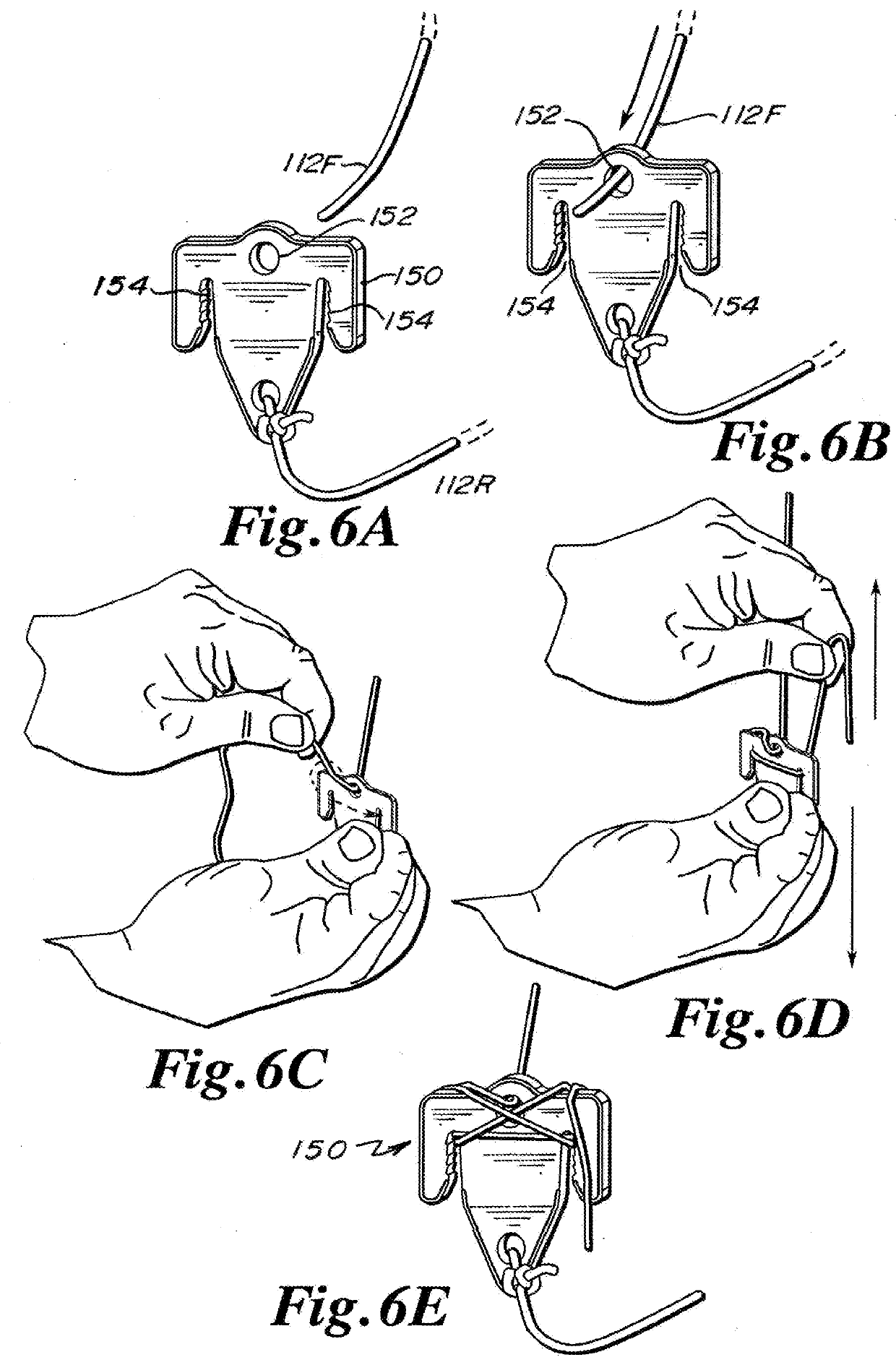

Seat cover for linearly-tufted automobile seats

A seat covering for a tufted automobile seat cushions has cover sheets adapted to fit over and around the cushions with a plurality of open-ended channels integrated therewith. Each channel is aligned and associated with a tuft of the cushion after the cover sheet has been fitted over and around the cushion. The covering has a plurality one or more straps, each passing loosely through an associated one of the channels and having strap ends extending from each open-end thereof. Pulling the extending strap ends of each strap after the cover has been fitted over and around the cushion causes the strap to be pulled into the associated tuft to cause the cover sheet to conform to the tuft. A fastener allows for simple and organized connection of the pulled strap ends.

Owner:ADC SOLUTIONS AUTO LLC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com