Process for manufacturing three-protection automobile seat cushion

A manufacturing process and technology of seat cushions, applied in the direction of thigh cushions, etc., can solve the problems of difficult cleaning, easy sticking of grease and dust, waste of water resources and time, etc., and achieve the effect of rich hand feeling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

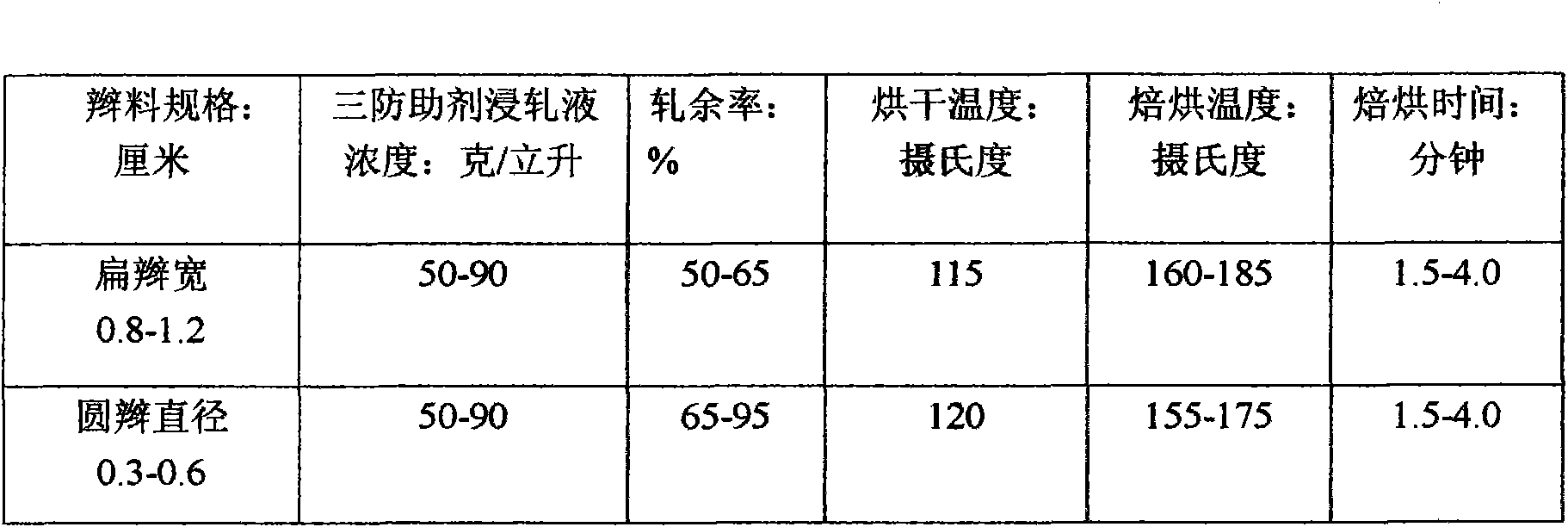

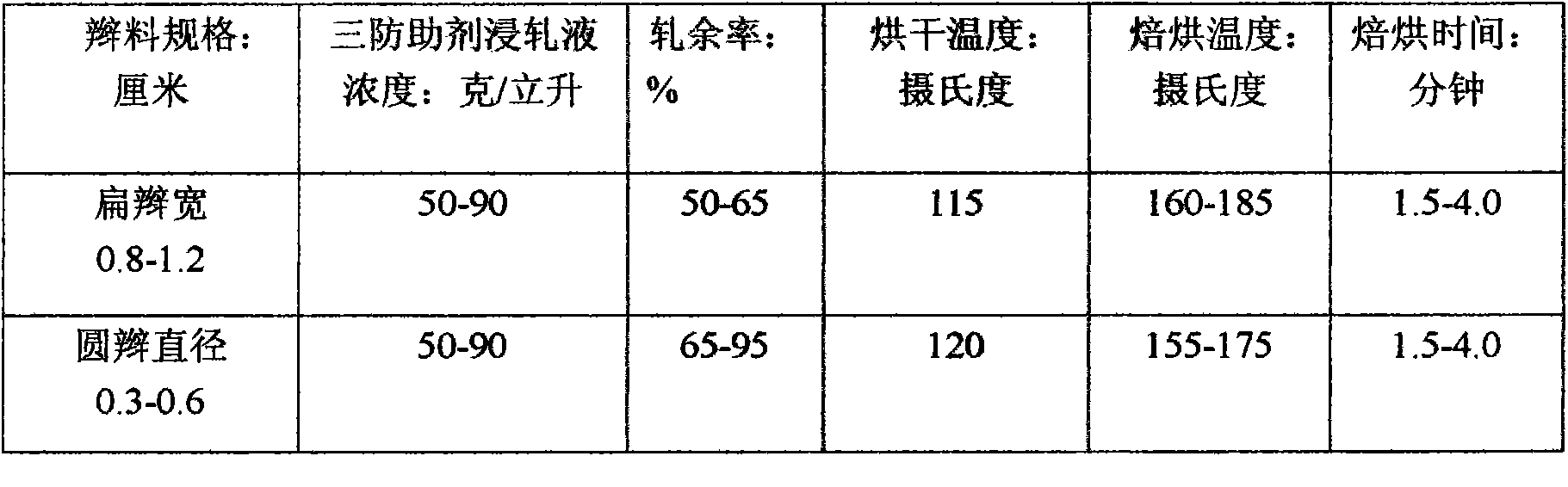

[0007] This specific implementation mode adopts the following technical scheme: its technological process is: braiding the raw material silk first, forming a shaft after braiding, and then padding the three-proof additive after the shafting, drying after the padding, and drying after drying. Baking is then carried out, and after the baking is completed, it will be packaged in cut-off rolls. After the cut-out rolls are packed, it will be knitted by hand, and then sewing will be made after hand-knitting. After sewing, it will be inspected, and then it will be packaged as a finished product. .

[0008] In this specific embodiment, round braided ropes and flat braided ropes with different materials and different process specifications used in automobile seat cushions are produced through the technological process of shafting, padding, drying, baking, and cutting and packaging. Braids with excellent waterproof, oil-proof and anti-fouling functions.

[0009] The processed braid has...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com