Water-proof, oil-proof, contamination-proof anti-slip fabric and processing method thereof

A processing method and fabric technology, applied in textiles and papermaking, anti-staining/anti-fouling fibers, fiber types, etc., can solve the problems of affecting the use effect, easy movement of textile tablecloths, poor shape, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

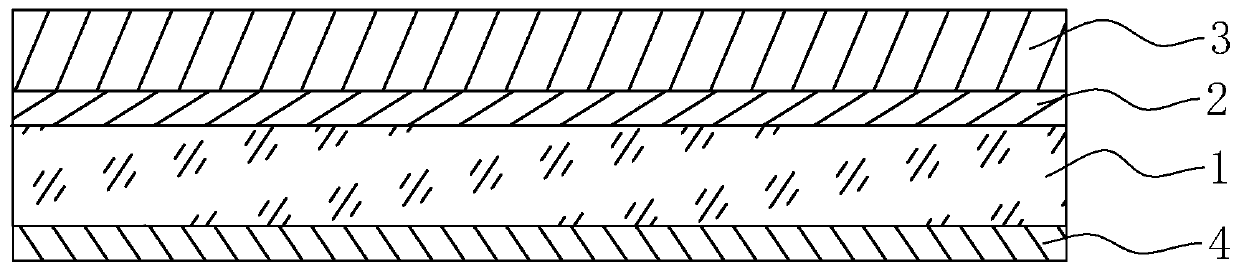

Image

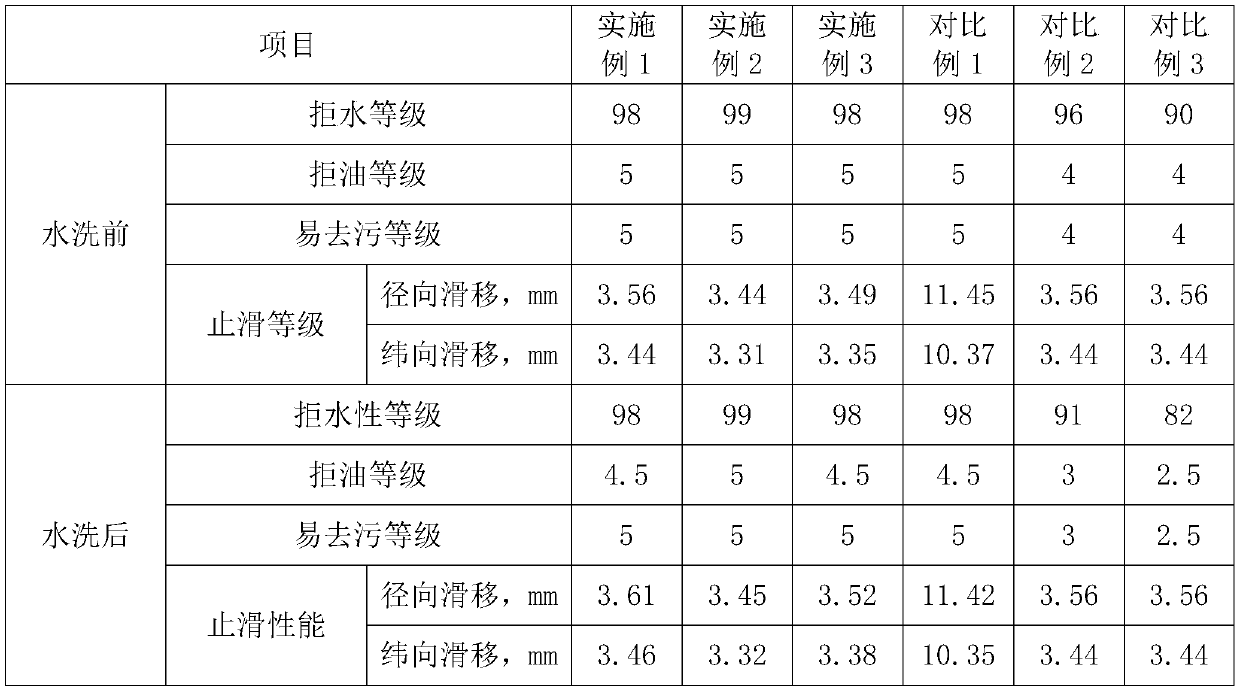

Examples

preparation example

[0038] The C6 waterproofing agent in the following preparation examples is perfluoroalkyl ethyl acrylate, and its CAS is 65605-70-1.

[0039] Preparation example 1 of waterproof finishing agent: Take 45kg of water and 1kg of carbon six waterproofing agent, stir evenly to obtain primer.

[0040] Preparation example 2 of waterproof finishing agent: Take 50kg of water and 2kg of carbon six waterproofing agent, stir evenly to obtain primer.

[0041] Preparation example 3 of waterproof finishing agent: Take 55kg of water and 3kg of carbon six waterproofing agent, stir evenly to obtain primer.

[0042] Second, the preparation example of primer

[0043] The CAS of acrylic acid (esters) is 25035-69-2, selected from the product of Liaoning Xingxing Fine Chemical Co., Ltd. model HU-212; the CAS of acrylamide / ammonium acrylate copolymer is 26100-47-0, selected from Liaoning Xingxing The model of Fine Chemical Co., Ltd. is FS-80F.

[0044] Preparation example 1 of the primer: 40kg of w...

preparation example 1

[0049] Preparation example 1 of topcoat glue: take 90kg of acrylic acid (ester) copolymer, 1kg of formaldehyde and 1kg of dodecylbenzenesulfonic acid, stir evenly to obtain topcoat glue.

preparation example 2

[0050] Preparation example 2 of topcoat glue: Take 100kg of acrylic acid (ester) copolymer, 1.5kg of formaldehyde and 2kg of dodecylbenzenesulfonic acid, stir evenly to obtain topcoat glue.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com