Formula and preparation process of easily degradable natural material for shoes

A natural material and easy-to-degrade technology, applied in footwear, applications, clothing, etc., can solve the problem of long-term degradation of pure EVA materials and achieve good slip resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

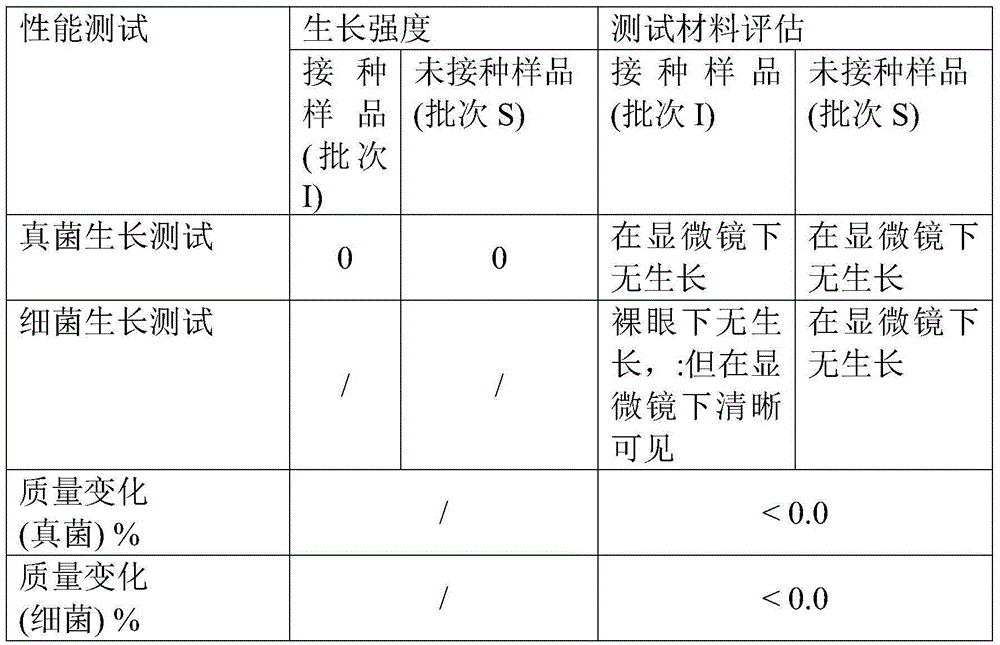

Examples

Embodiment 1

0.8

[0068] Among the above schemes, the proportion of natural particles is

[0069]

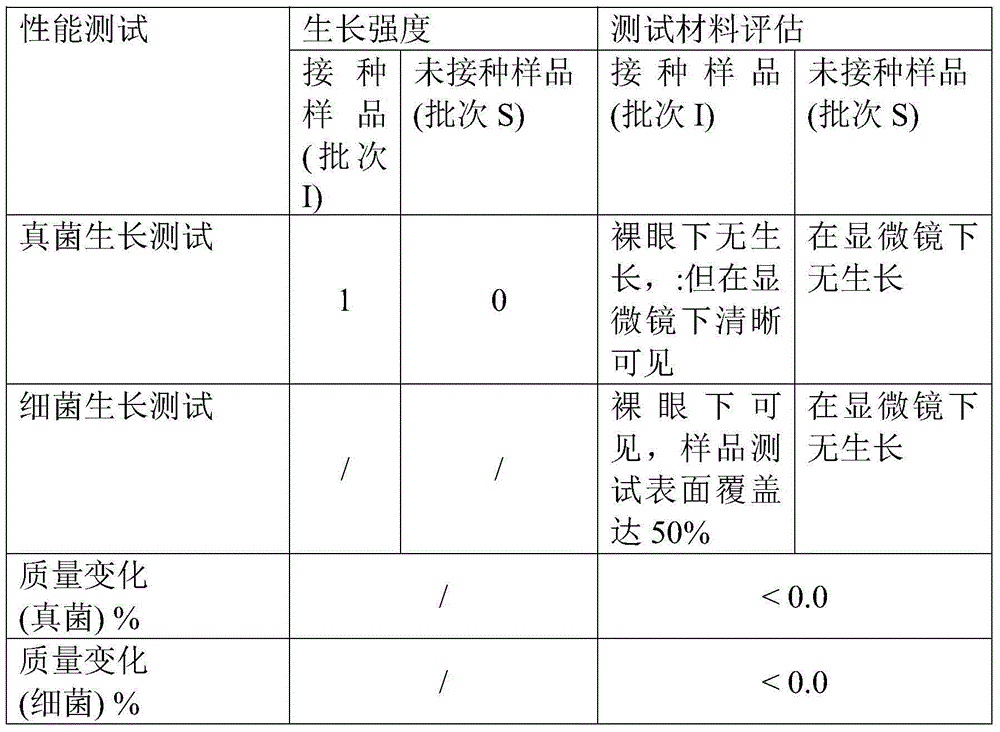

Embodiment 2

[0072] Among the above schemes, the proportion of natural particles is

[0073]

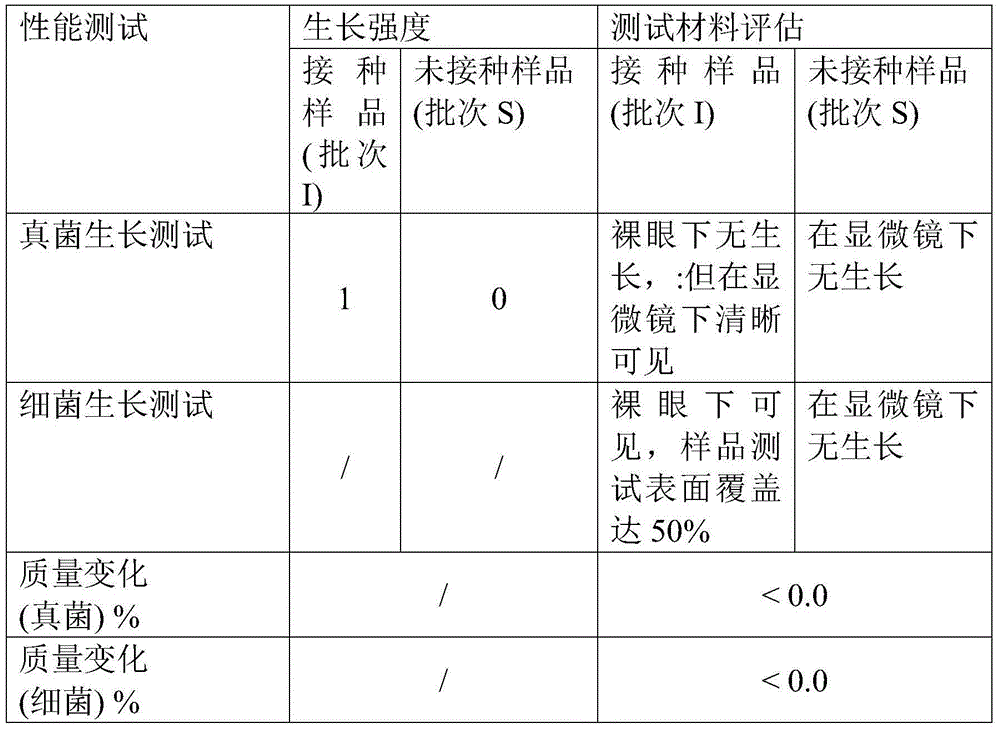

Embodiment 3

0.3

[0077] Among the above schemes, the proportion of natural particles is

[0078]

plan 1

Scenario 2

Option 3

sweet potato starch

51

14

35

Glycerin

43

13

44

46

14

40

[0079] In the above-mentioned embodiment, the formula of scheme 1 is produced according to the following process:

[0080] Step 1: Pour EVA, polyethylene oxide, filler, natural particles, zinc oxide, stearic acid, degradation agent into the blender, stir and heat, first heat to 90-91°C to melt the material, and then increase the temperature to 119°C-120°C, then add bridging agent and foaming agent, then raise the temperature to 133°C-134°C, and pour the materials into the internal mixer;

[0081] Step 2: Banbury the materials in a banbury mixer, the banbury time is 12 minutes, and the temperature is 120-121°C;

[0082] Step 3: Pour the mixed material into the open mixer, lower the temperature to 75...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com