Preparation method and application of MnO/C positive electrode electrocatalyst

An electrocatalyst and anode technology, which is applied in the field of MnO/C anode electrocatalyst preparation, can solve the problems of high oxygen evolution overpotential, surface coating dissolution, poor cycle stability, etc., achieve high catalytic activity, improve mineralization ability, The effect of enhancing stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

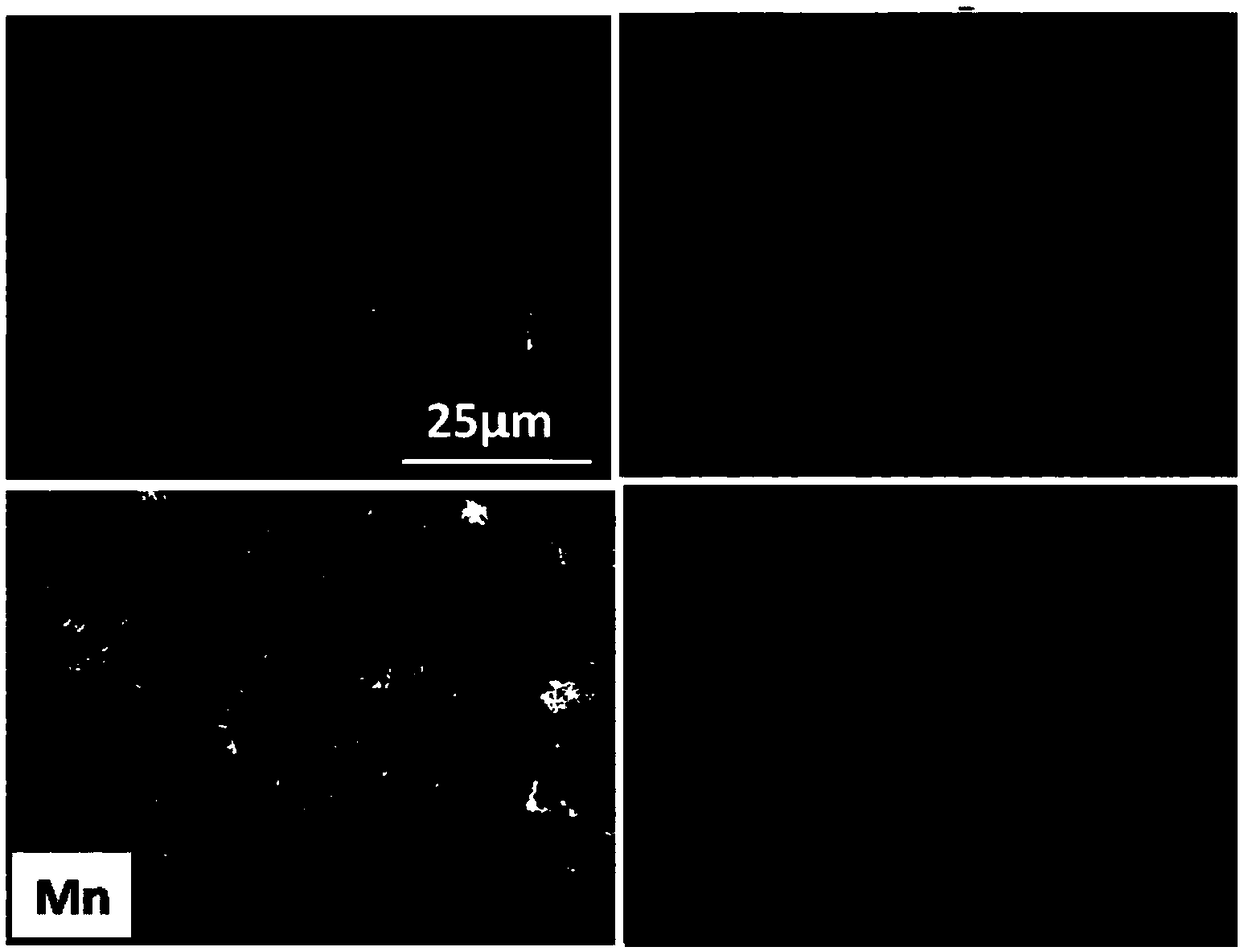

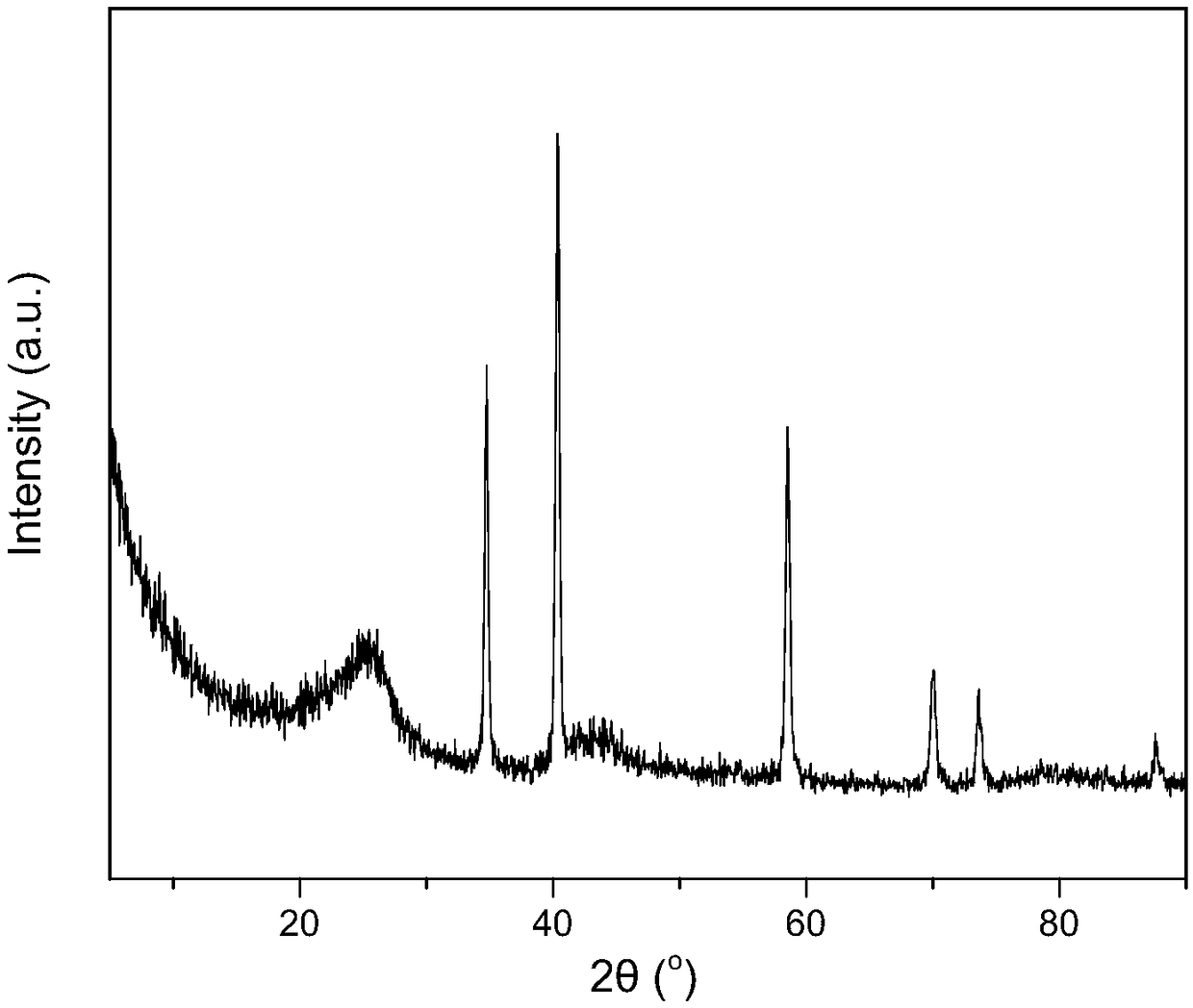

[0029] Dissolve 0.3g of manganese acetate and 0.3g of polyacrylonitrile powder into 10mL of N,N-dimethylformamide and stir to form a transparent solution; soak 0.5g of the cut carbon felt in the transparent solution for 5h, take it out and dry it in the air. Then put it in an oven at 220°C for 1 hour; soak the pre-oxidized carbon felt in the remaining transparent solution for 0.5 hour, take it out and dry it, and put it in an oven at 220°C for 1 hour; repeat the above operation until it is transparent The solution was completely adsorbed on the carbon felt; the final pre-oxidized carbon felt was put into a tube furnace, and was heat-treated at 900 °C for 1 h under the protection of nitrogen to obtain the MnO / C composite material.

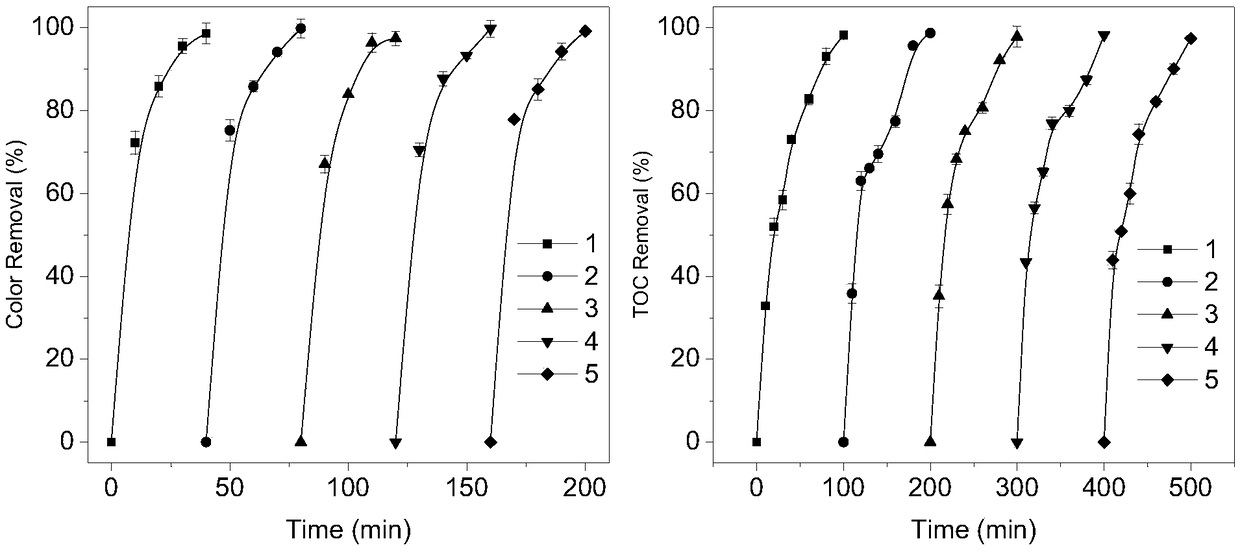

[0030] In the single-chamber three-electrode system, the prepared MnO / C composite was used as the anode, the platinum wire was used as the counter electrode, and the calomel electrode was used as the reference electrode. -1 Na 2 SO 4 As electrolyt...

Embodiment 2

[0032] Dissolve 0.3g of manganese acetate and 0.06g of polyacrylonitrile powder into 6mL of N,N-dimethylformamide and stir to form a transparent solution; soak 0.29g of cut carbon paper in the transparent solution for 10h and take it out to dry. Then put it in an oven at 220°C for 1 hour; soak the pre-oxidized carbon paper in the remaining transparent solution for 0.5 hours, take it out and dry it, and place it in the oven for pre-oxidation treatment for 1 hour; repeat the above operation until the transparent solution is completely Adsorbed onto carbon paper; put the final pre-oxidized carbon paper into a tube furnace, and heat-treat at 700°C for 5h under the protection of nitrogen to obtain MnO / C composite material.

[0033] In the single-chamber three-electrode system, the prepared MnO / C composite was used as the anode, the platinum wire was used as the counter electrode, and the calomel electrode was used as the reference electrode. -1 Na 2 SO 4 As electrolyte, 30mL·s -...

Embodiment 3

[0035] Dissolve 0.3g of manganese acetate and 3g of polyacrylonitrile powder into 27mL of N,N-dimethylformamide and stir to form a transparent solution; soak 1.1g of the cut carbon fiber in the transparent solution for 24 hours, take it out and dry it, and place it Pre-oxidize in an oven at 220°C for 1 hour; soak the pre-oxidized carbon fiber in the remaining transparent solution for 1 hour, take it out and dry it, and place it in the oven for pre-oxidation treatment for 1 hour; repeat the above operation until the transparent solution is completely adsorbed on the carbon fiber ; put the above-mentioned final pre-oxidized carbon fibers into a tube furnace, and heat-treat at 1000° C. for 1 h under the protection of nitrogen to obtain a MnO / C composite material.

[0036] In the single-chamber three-electrode system, the prepared MnO / C composite was used as the anode, the platinum wire was used as the counter electrode, and the calomel electrode was used as the reference electrode...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com