Patents

Literature

121results about How to "Improve mineralization" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

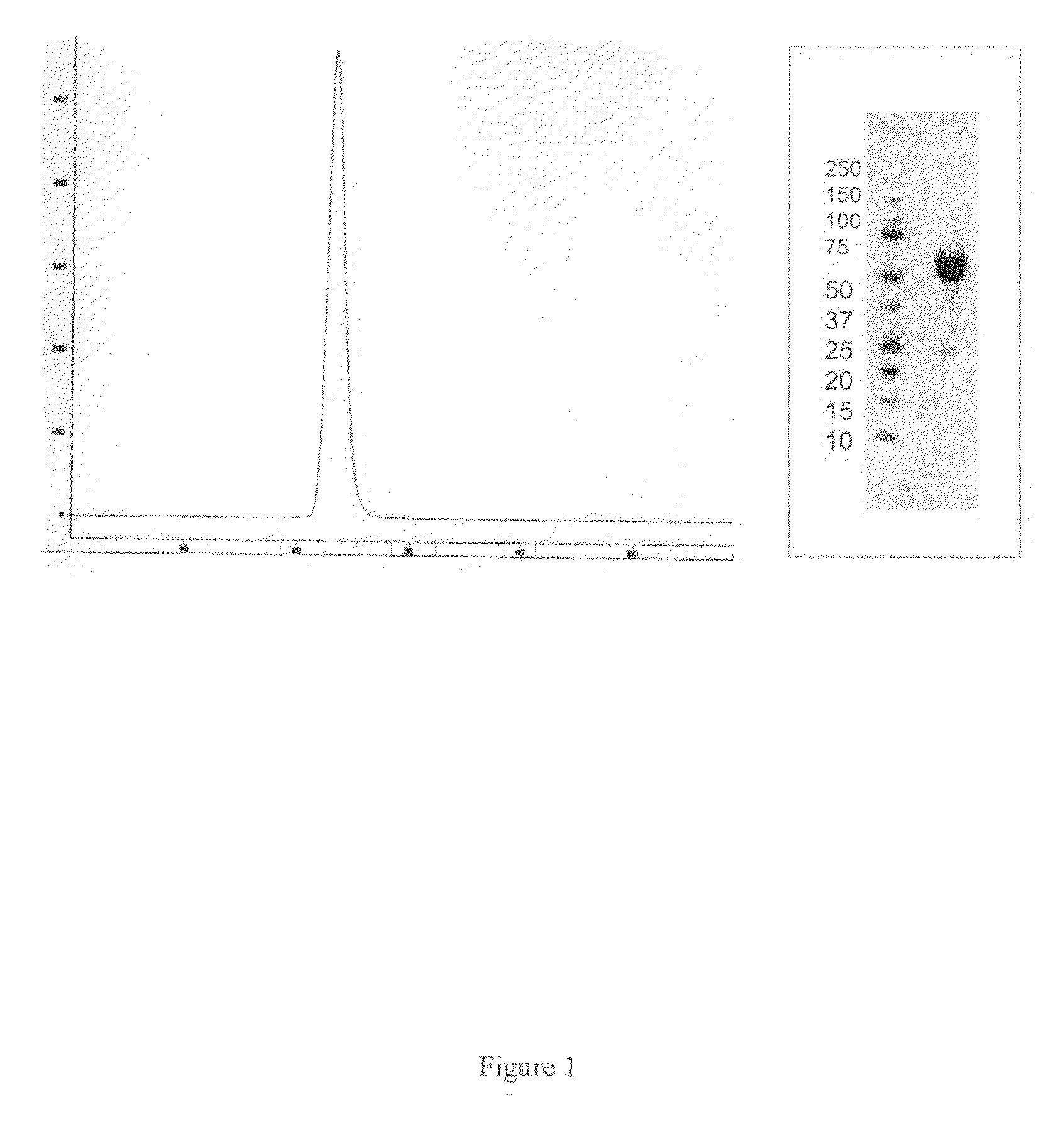

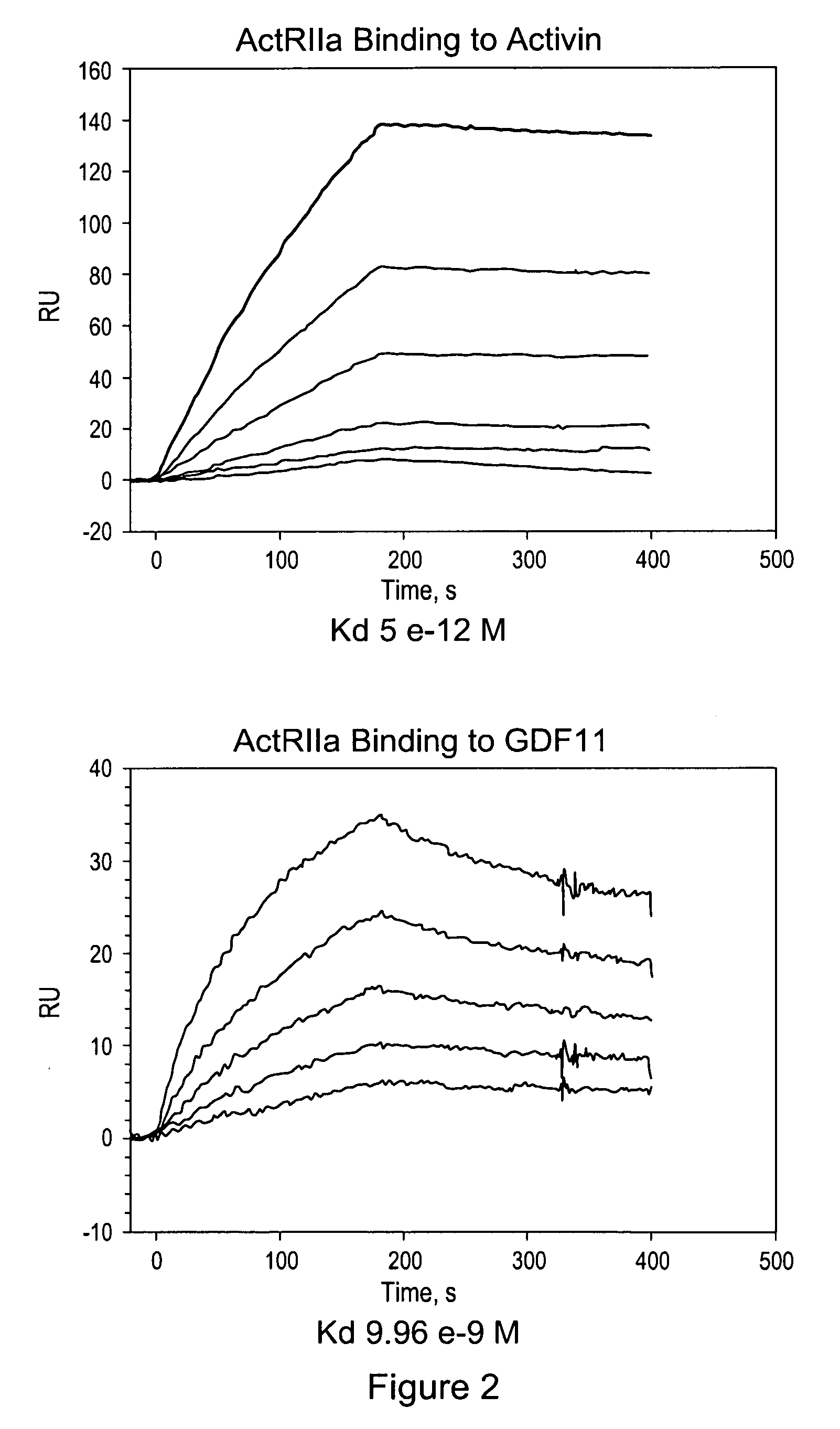

Activin-actriia antagonists and uses for promoting bone growth in cancer patients

ActiveUS20090142333A1Promote growthStimulates of mineralizationPeptide/protein ingredientsAntibody mimetics/scaffoldsIncreased Bone DensityBone growth

In certain aspects, the present invention provides compositions and methods for promoting bone growth and increasing bone density, as well as for the treatment of multiple myeloma.

Owner:ACCELERON PHARMA INC

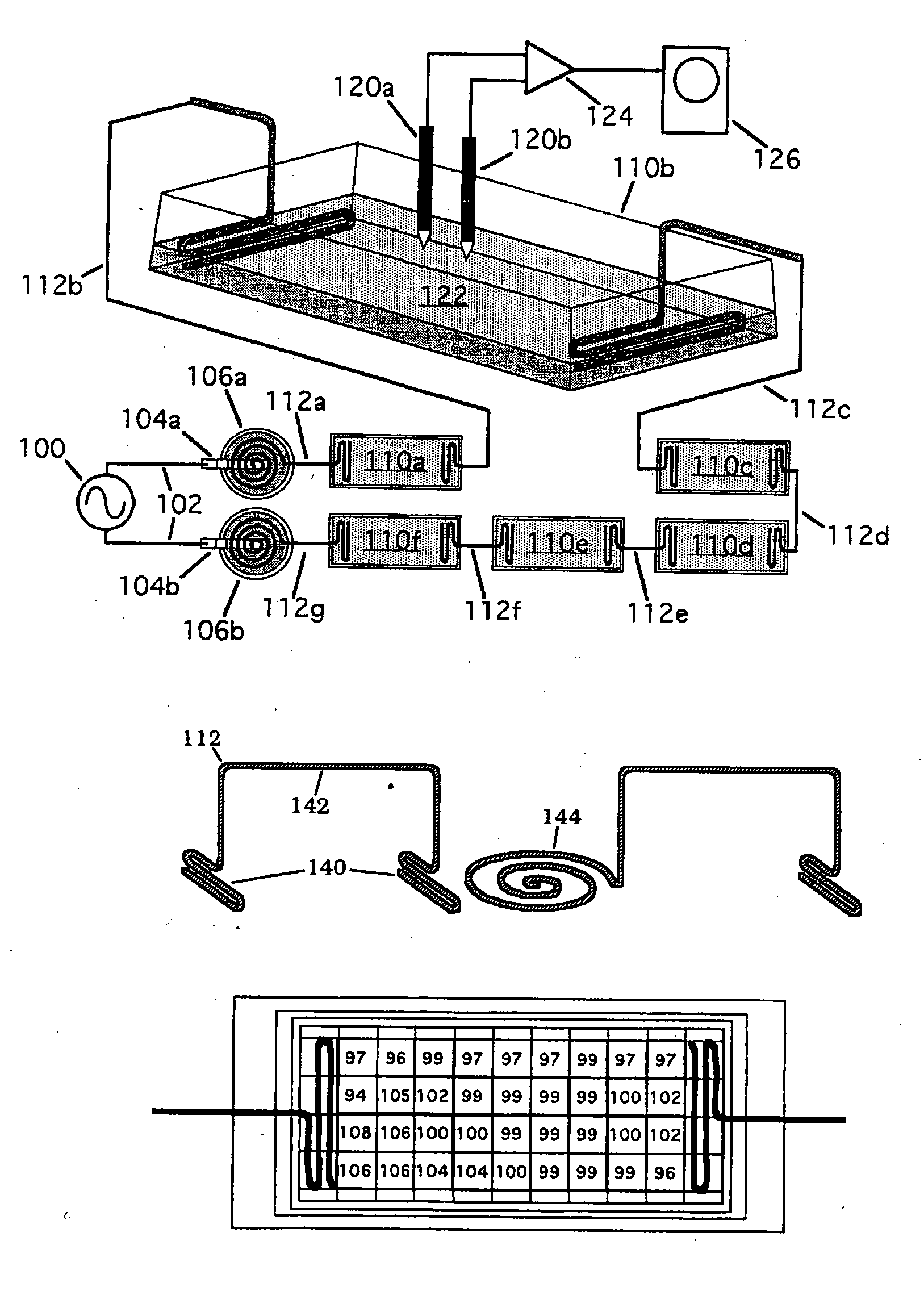

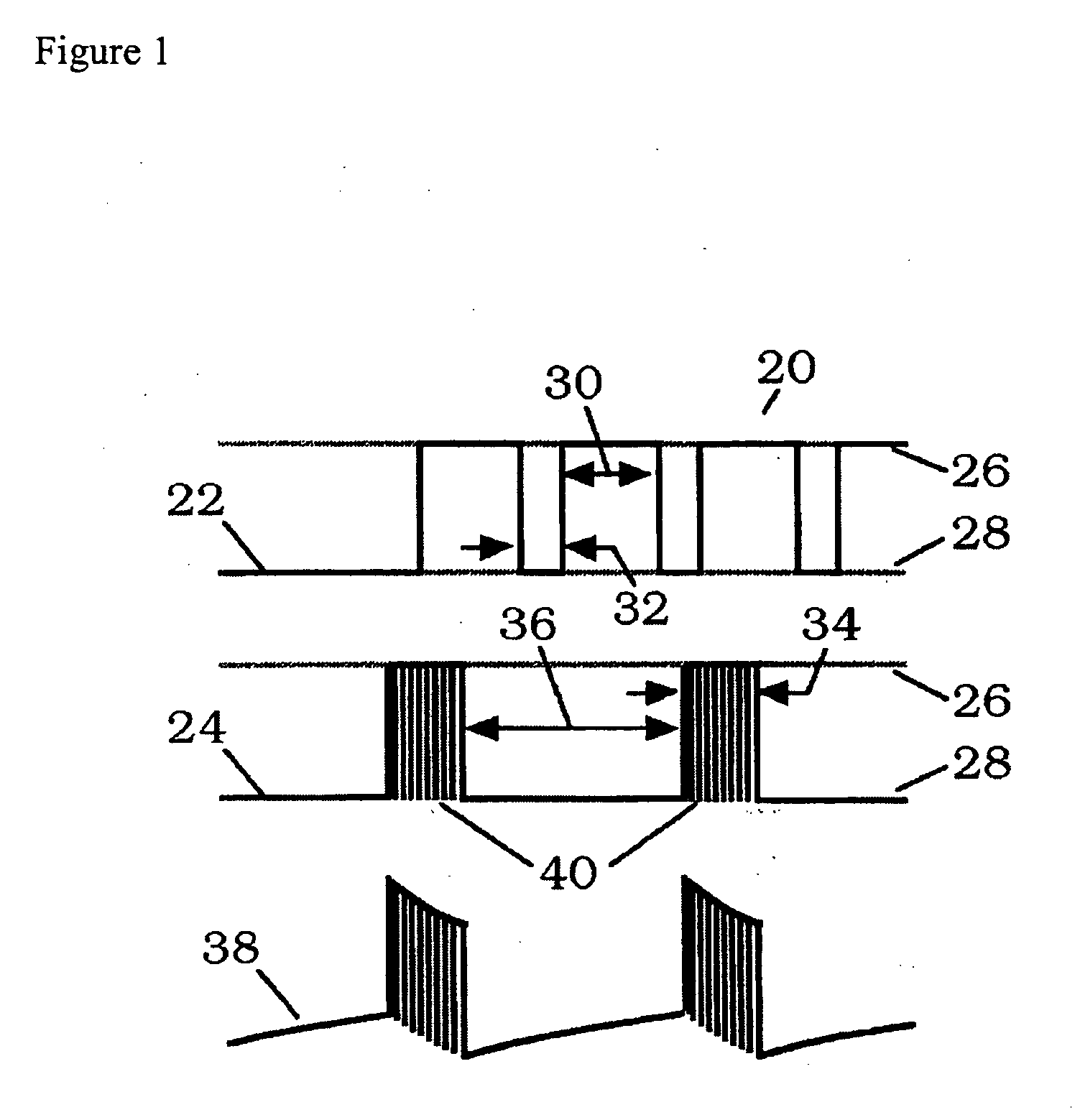

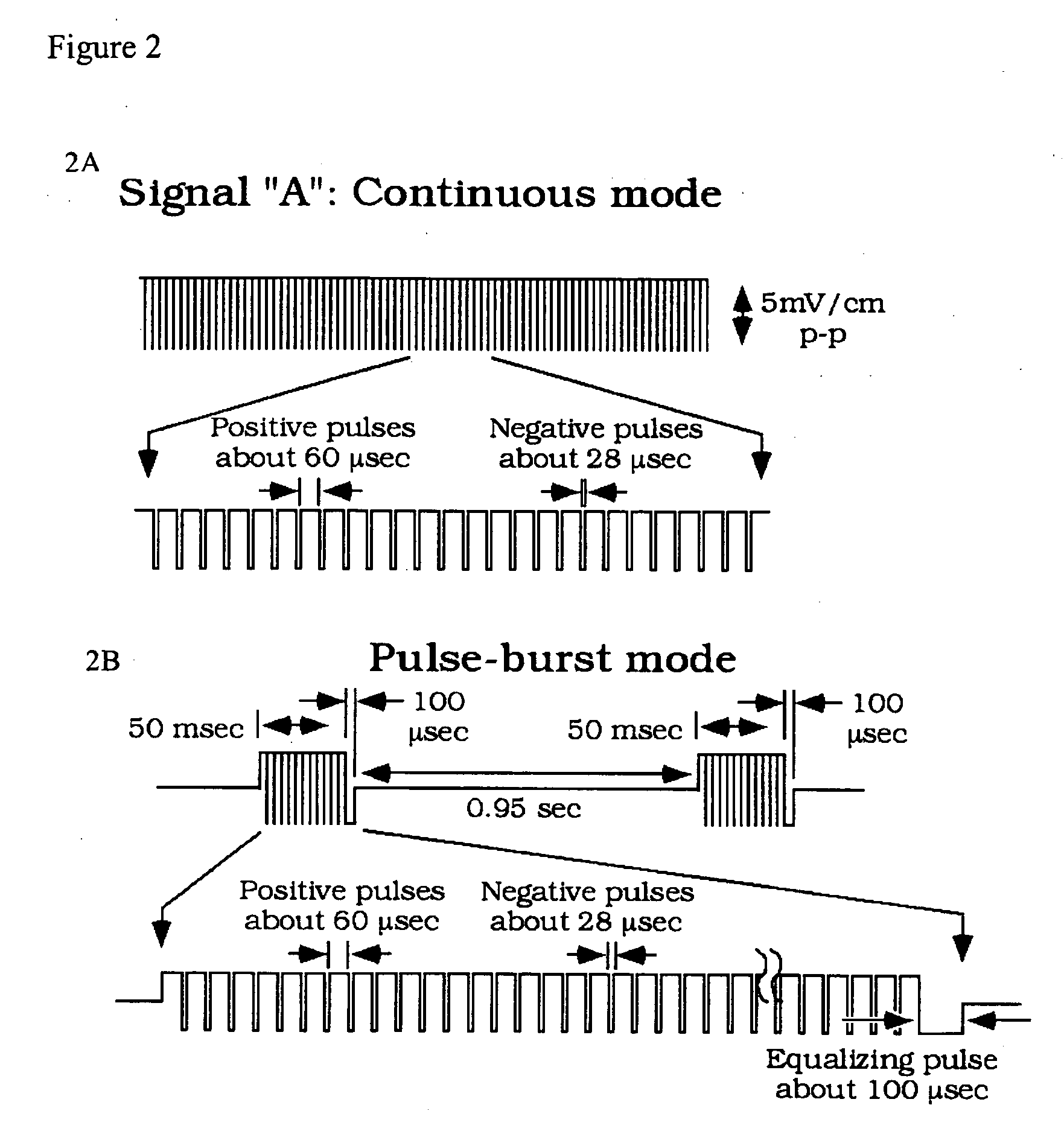

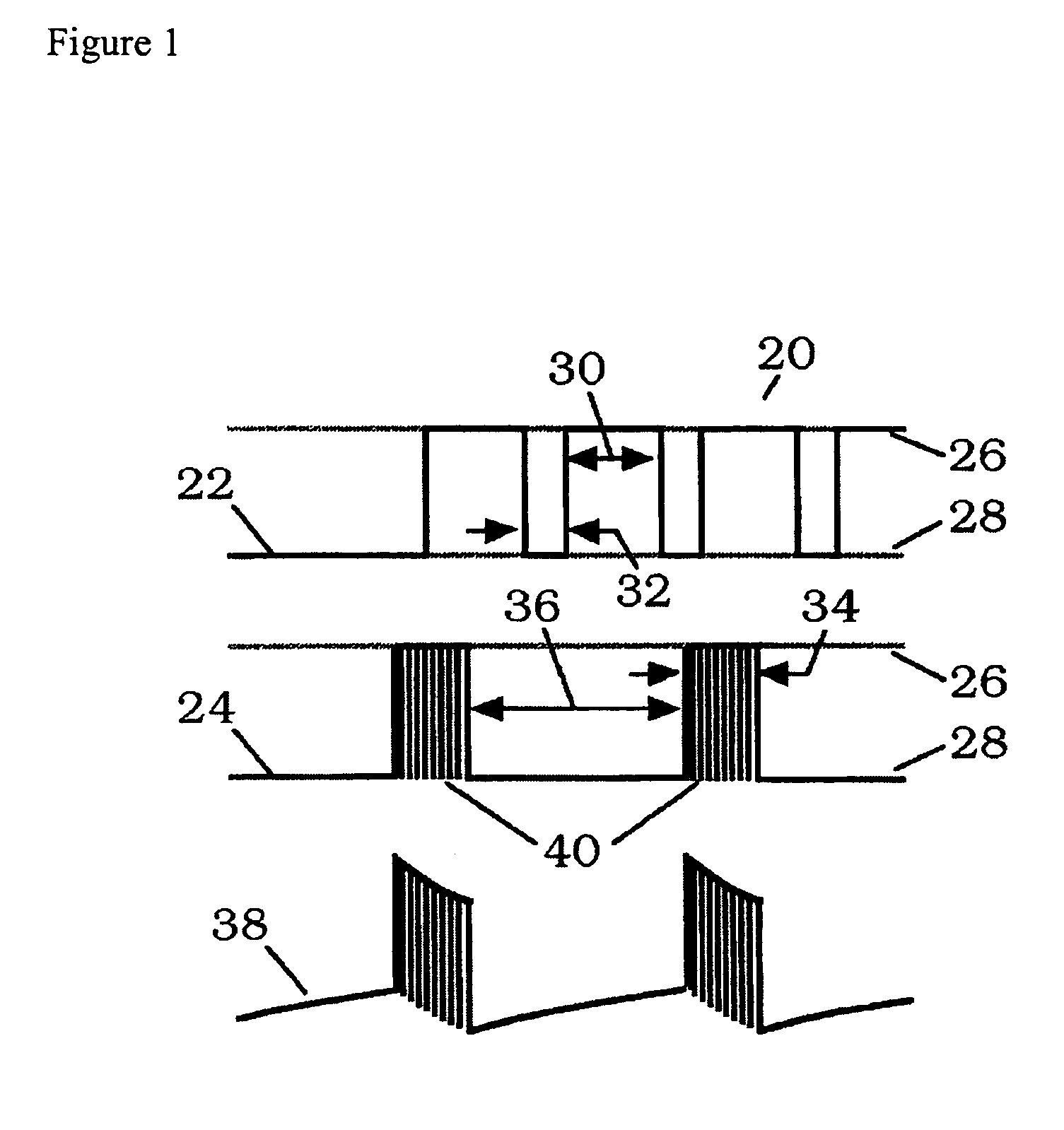

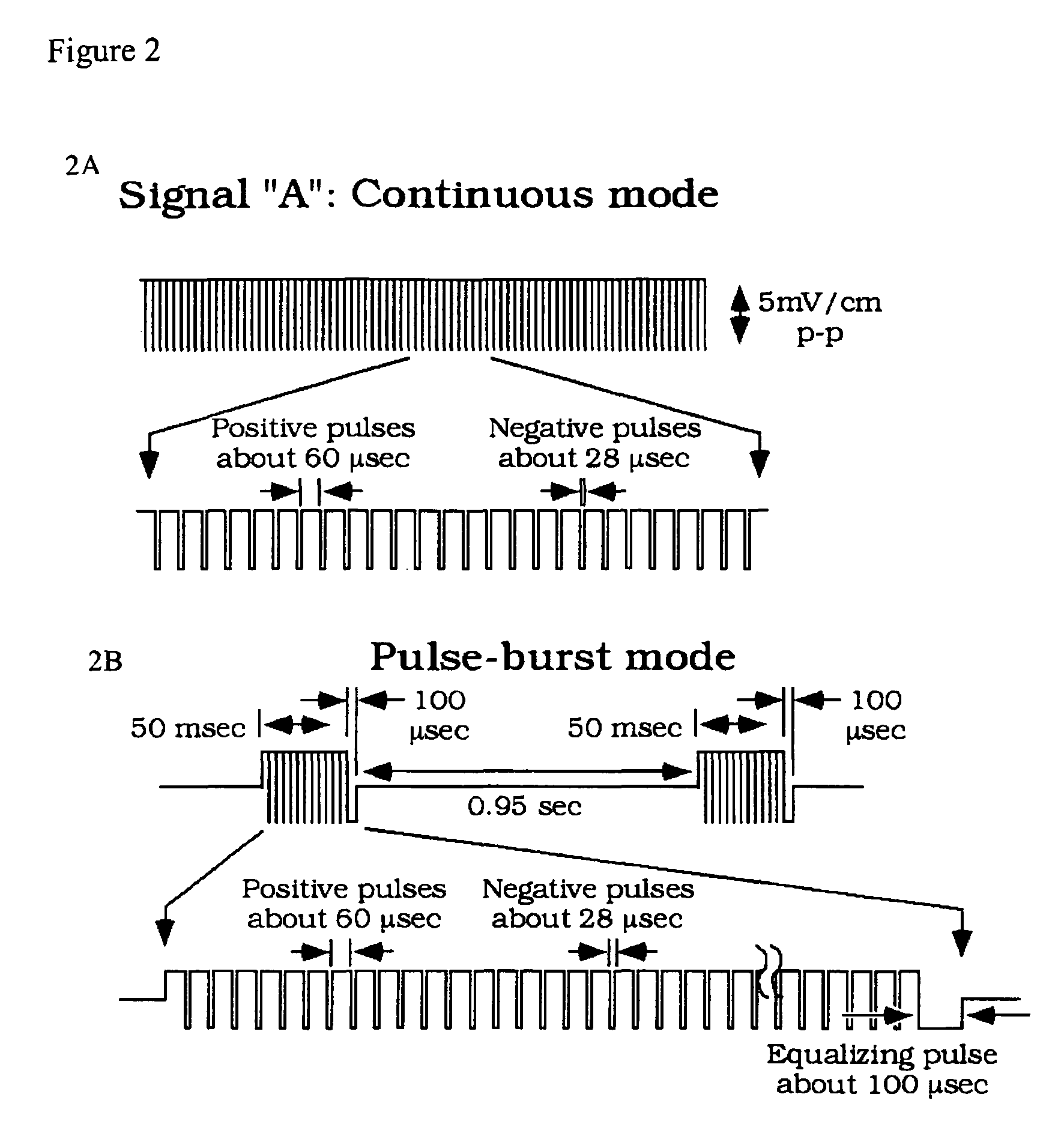

Methods for modulating osteochondral development using bioelectrical stimulation

ActiveUS20060293724A1Maximize utilizationMaximize applicationElectrotherapyStress based microorganism growth stimulationCo administrationOsteoblast

Compositions and methods are provided for modulating the growth, development and repair of bone, cartilage or other connective tissue. Devices and stimulus waveforms are provided to differentially modulate the behavior of osteoblasts, chondrocytes and other connective tissue cells to promote proliferation, differentiation, matrix formation or mineralization for in vitro or in vivo applications. Continuous-mode and pulse-burst-mode stimulation of cells with charge-balanced signals may be used. Bone, cartilage and other connective tissue growth is stimulated in part by nitric oxide release through electrical stimulation and may be modulated through co-administration of NO donors and NO synthase inhibitors. Bone, cartilage and other connective tissue growth is stimulated in part by release of BMP-2 and BMP-7 in response to electrical stimulation to promote differentiation of cells. The methods and devices described are useful in promoting repair of bone fractures, cartilage and connective tissue repair as well as for engineering tissue for transplantation.

Owner:MEDRELIEF

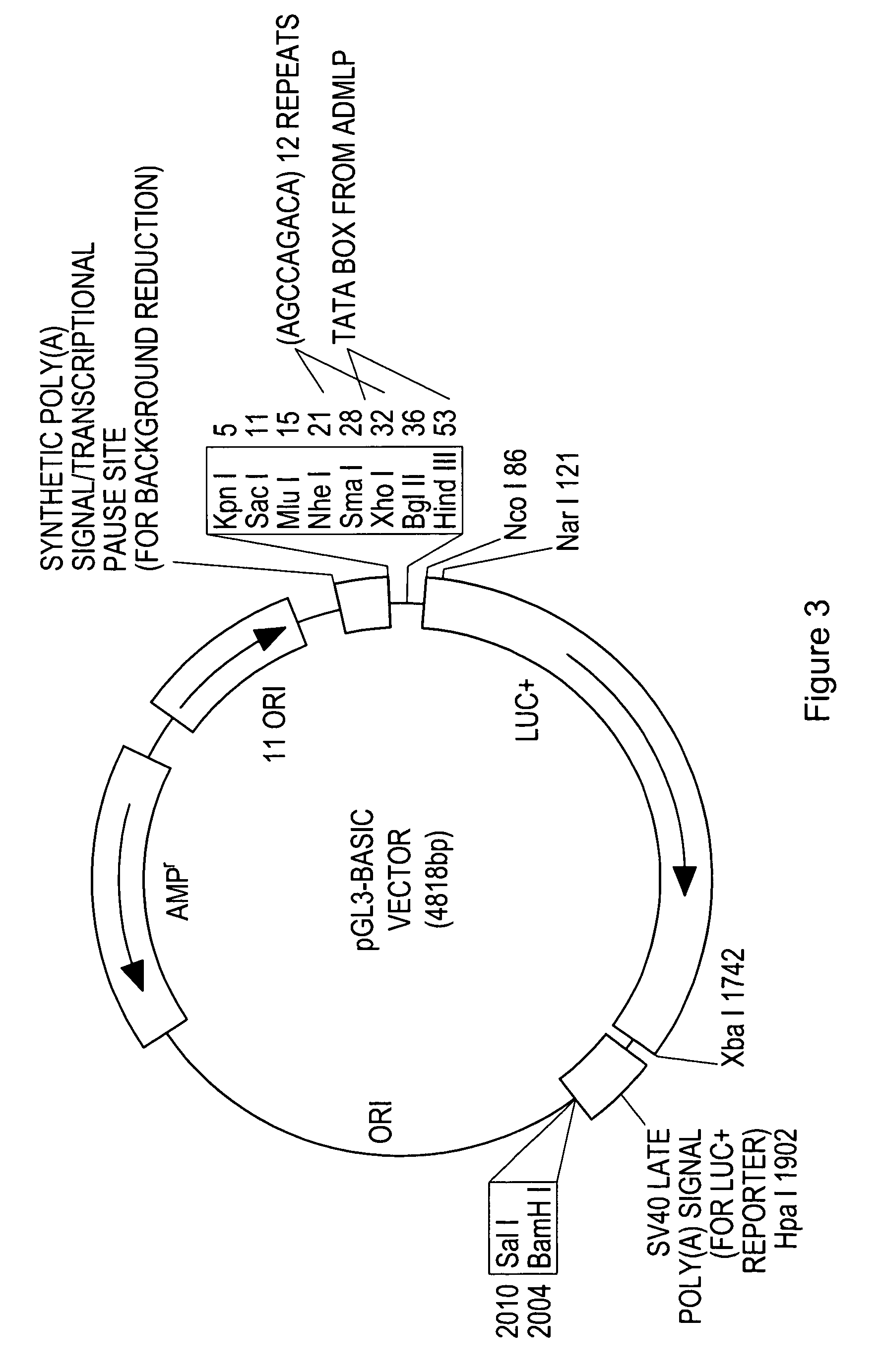

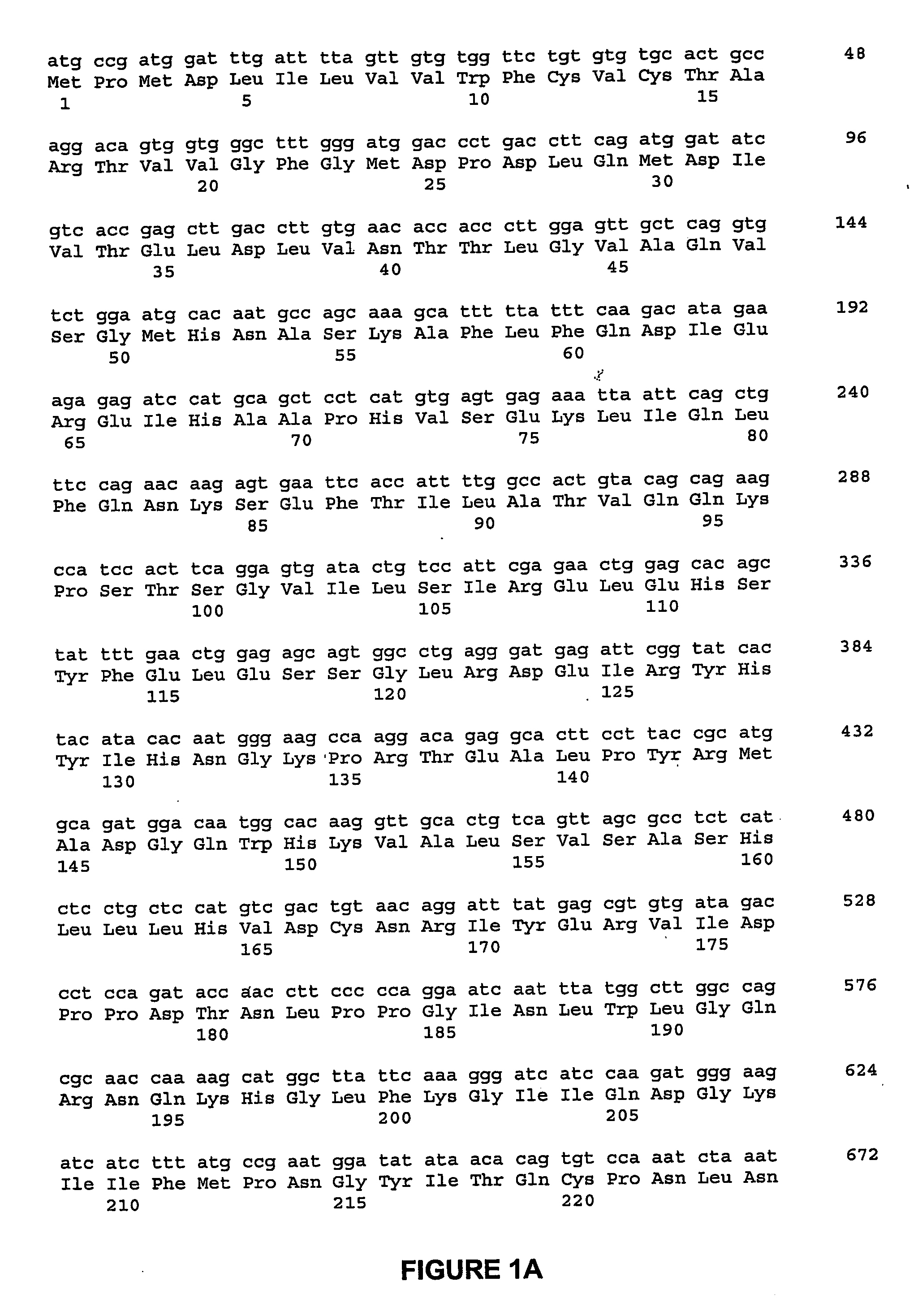

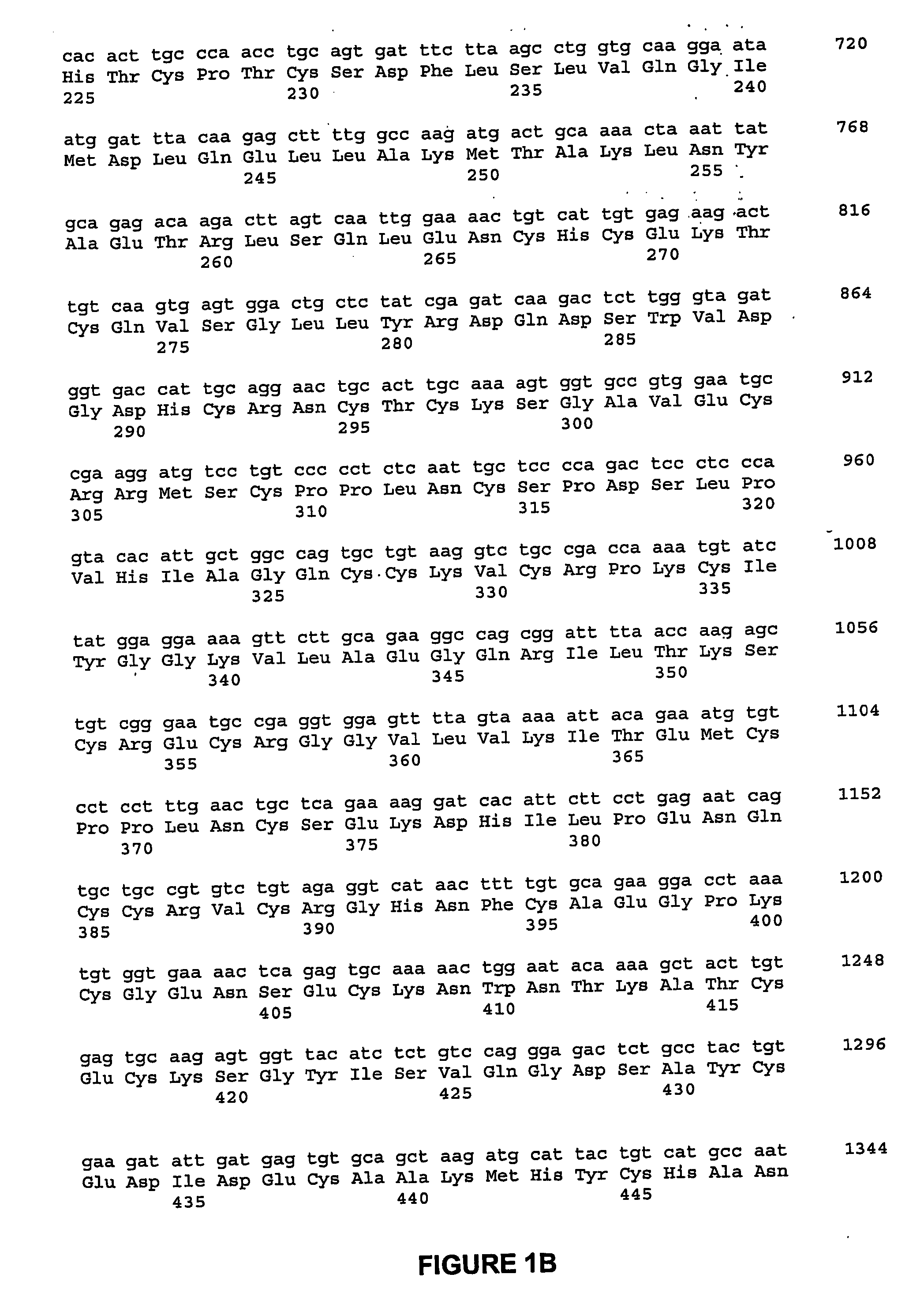

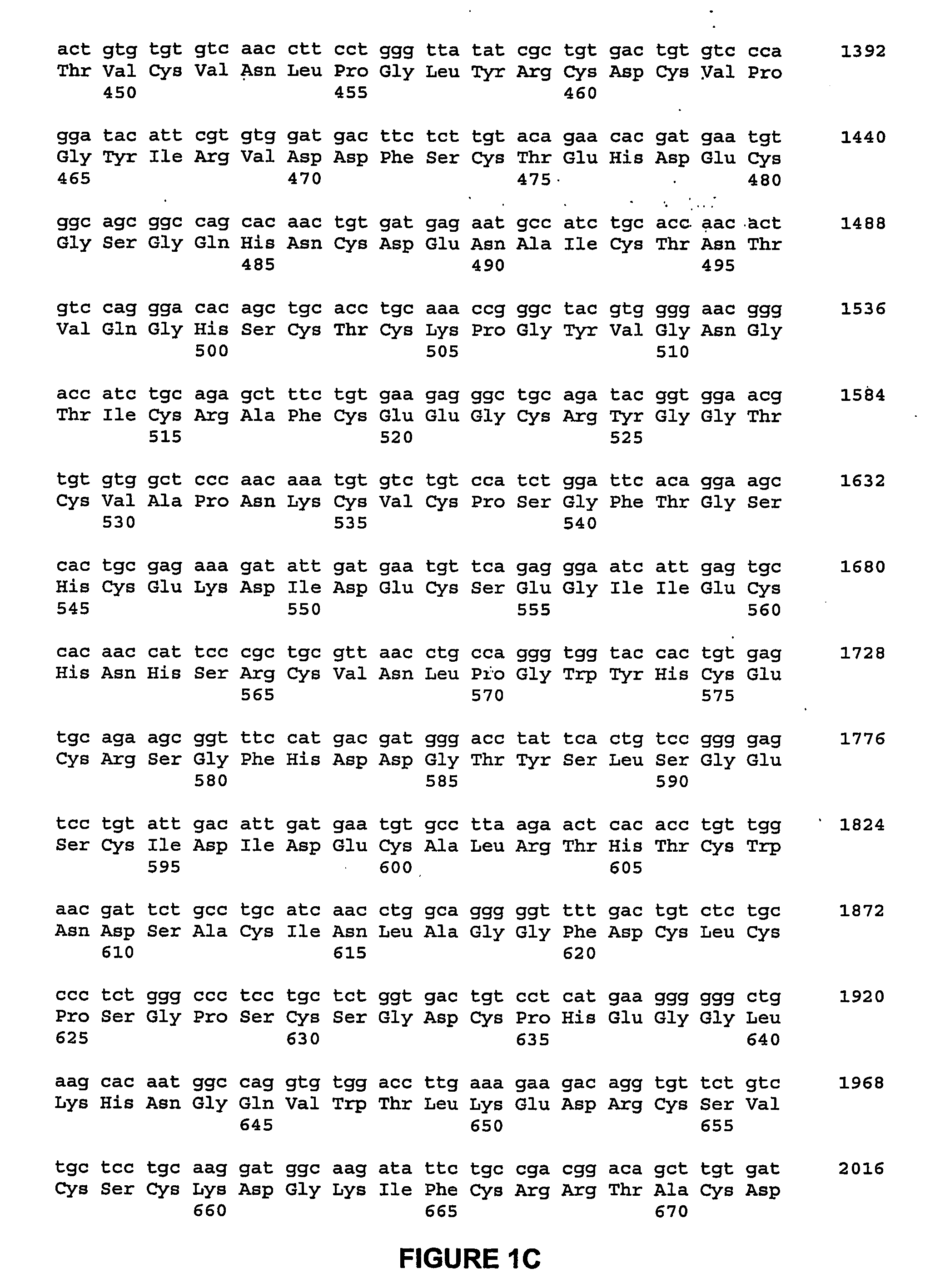

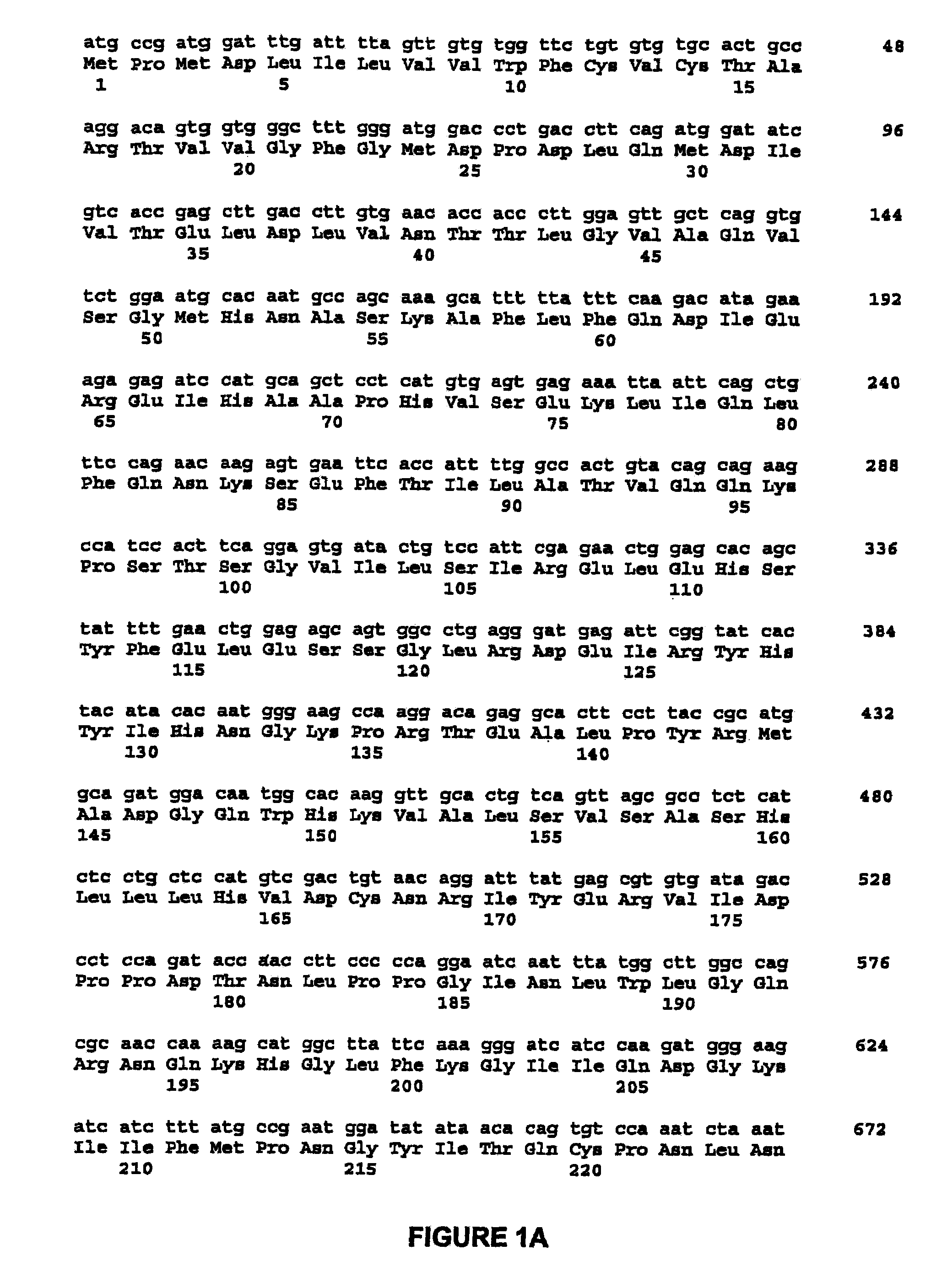

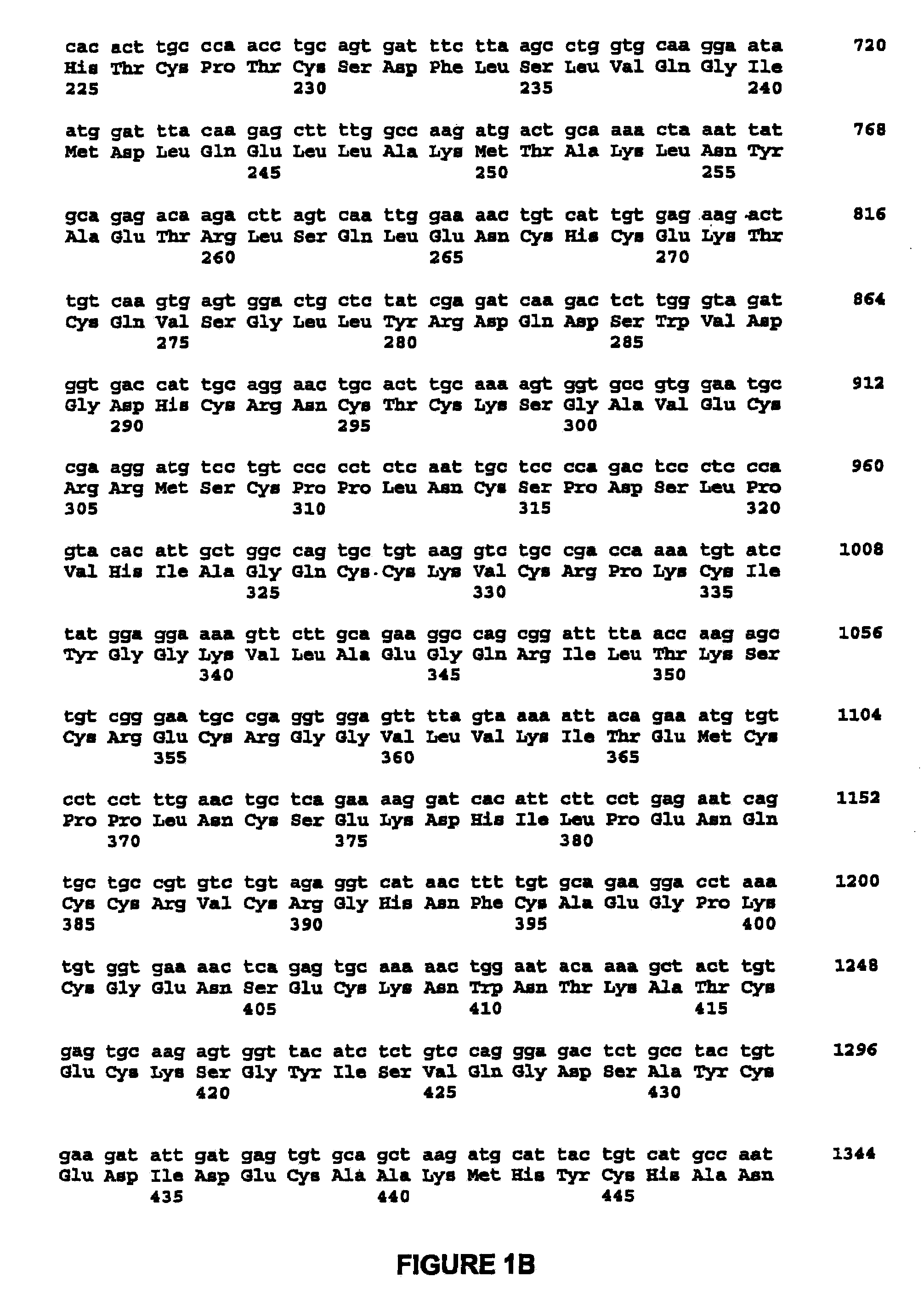

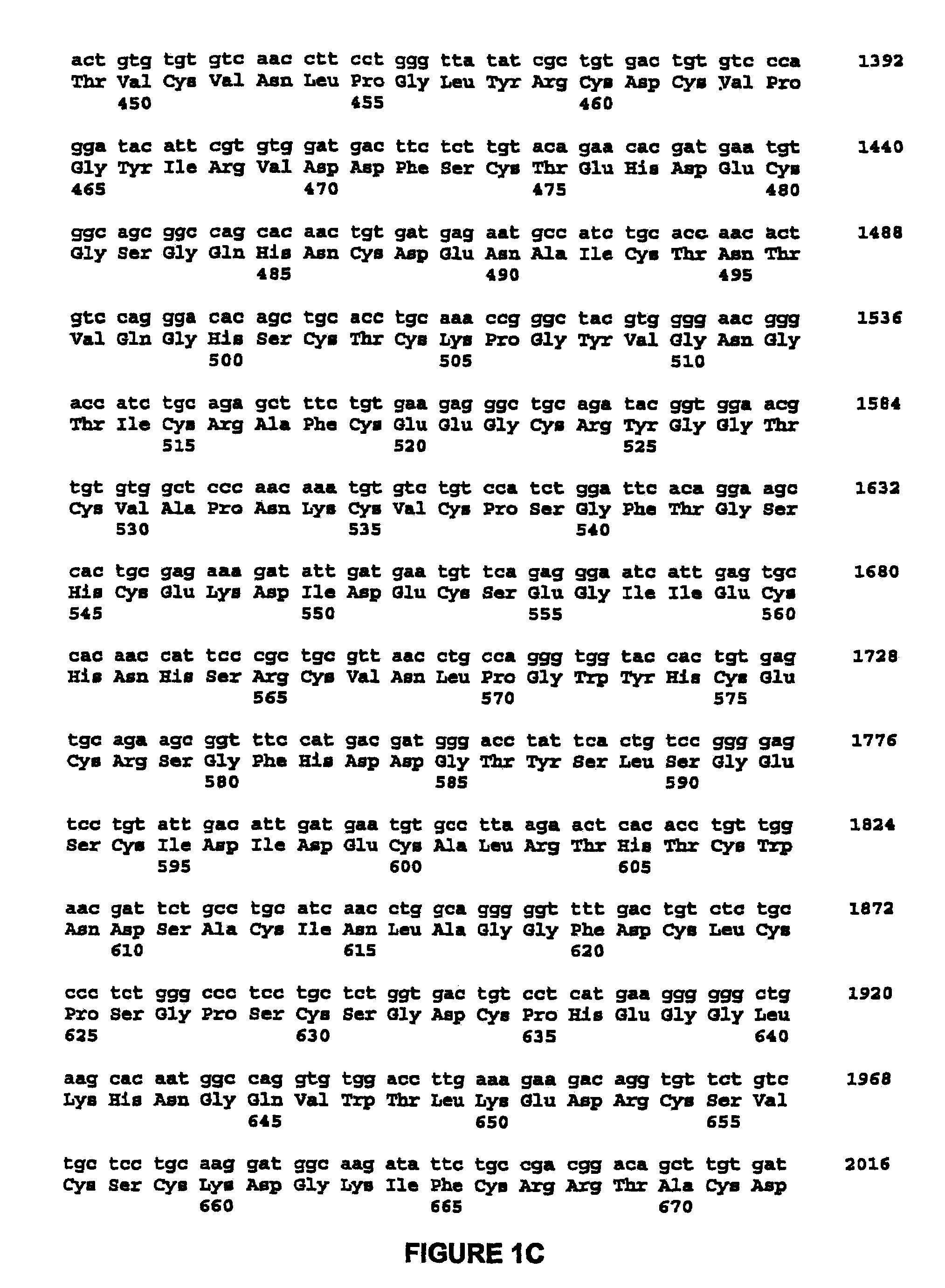

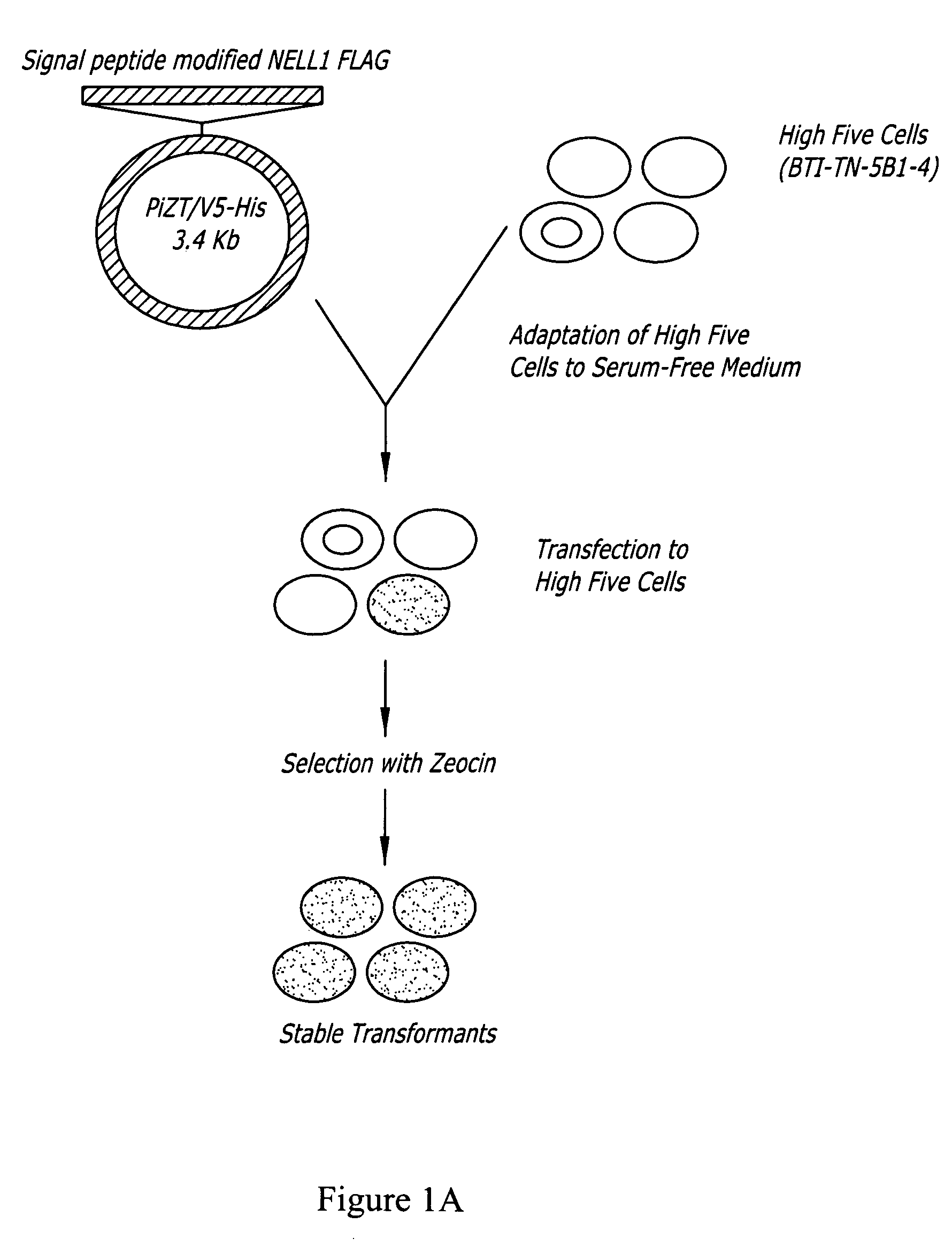

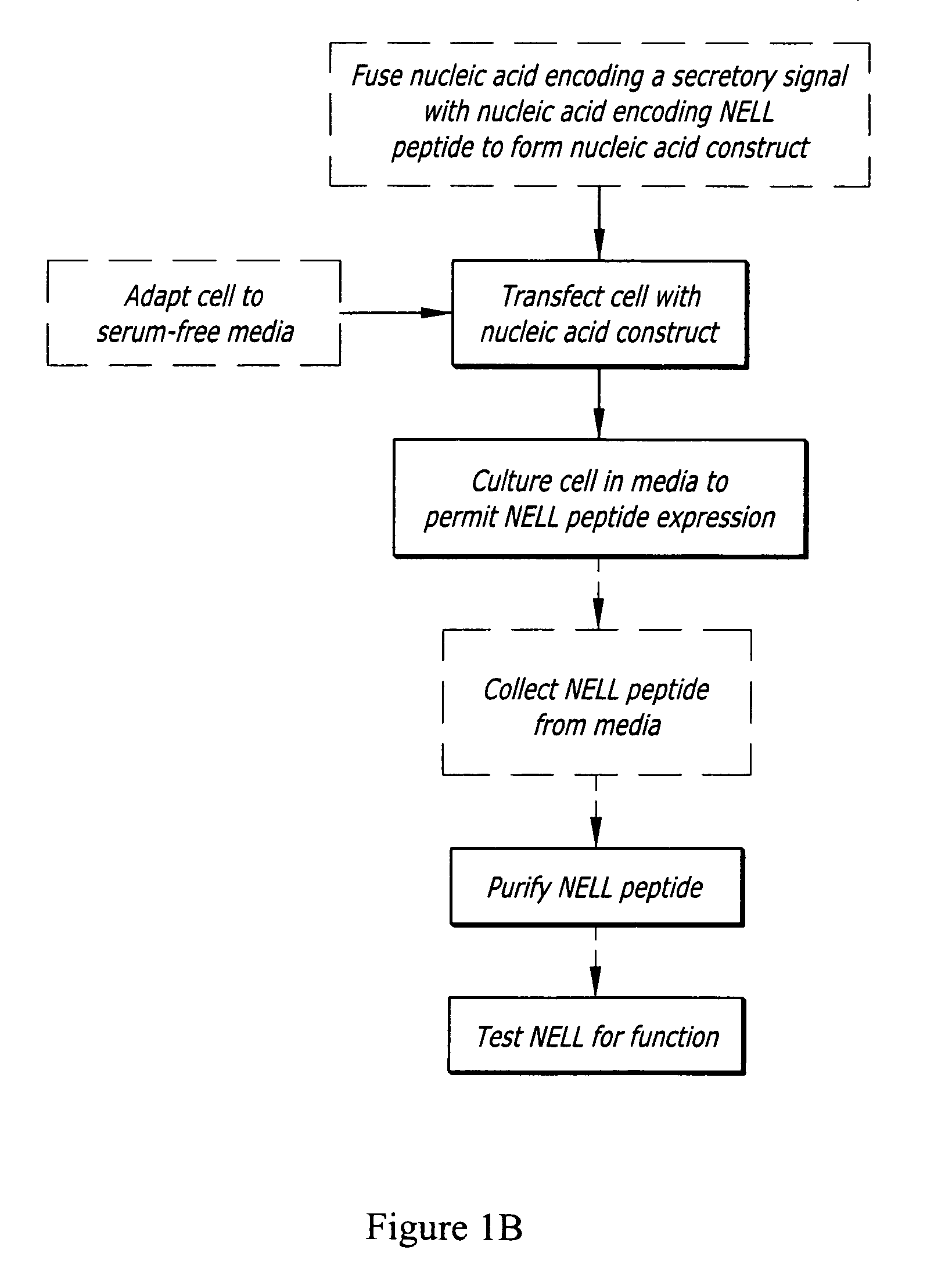

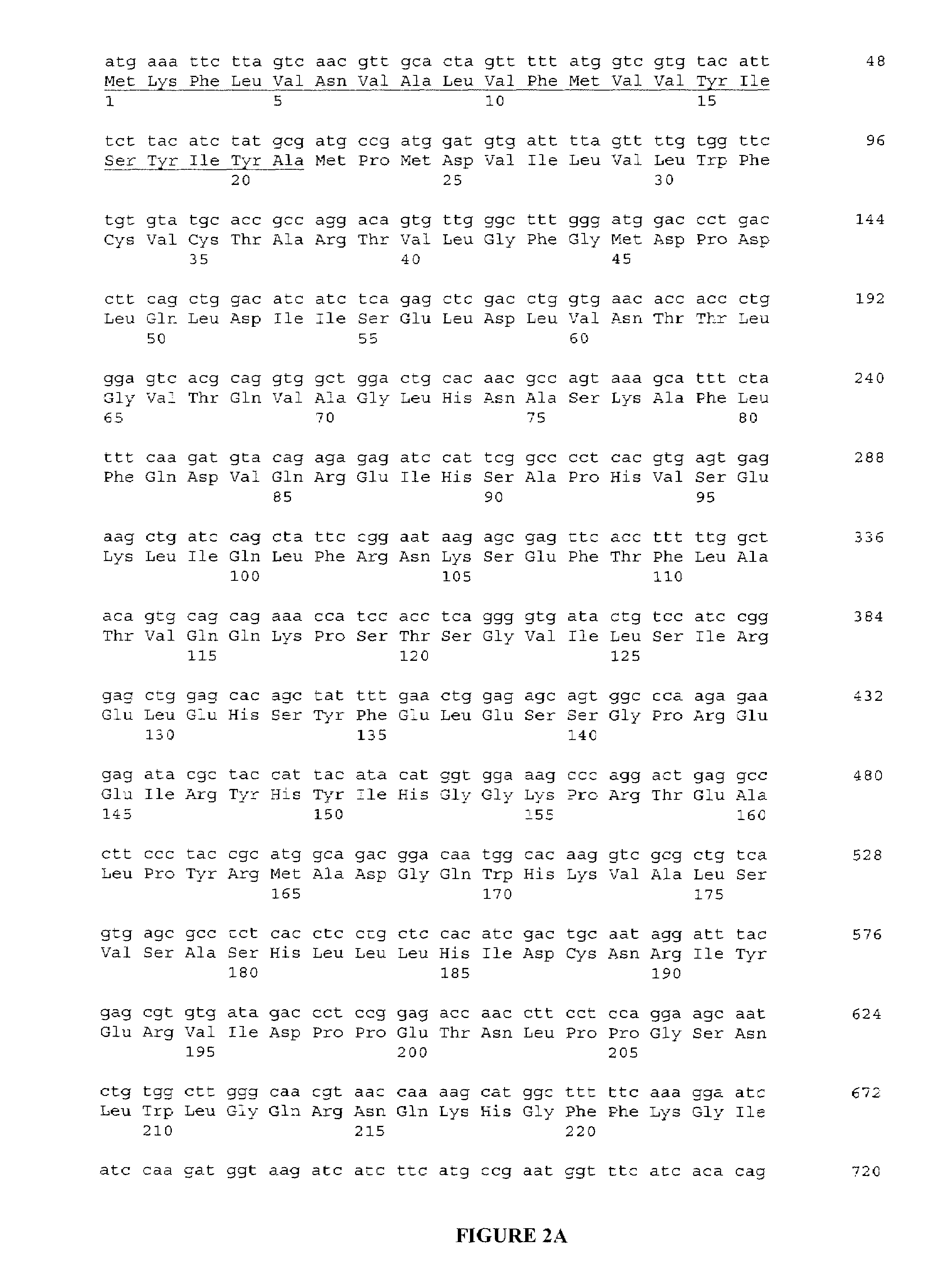

Nell peptide expression systems and bone formation activity of nell peptide

ActiveUS20060292670A1Facilitate protein traffickingFacilitate post production modificationOrganic active ingredientsBacteriaBone formationBone growth factor

The invention generally relates to a bone growth factor, and more particularly to compositions including NELL1, articles of manufacture including NELL1 and methods of using NELL1 to induce bone formation. This invention also provides methods for the expression and purification of NELL1 and NELL2 peptides.

Owner:RGT UNIV OF CALIFORNIA

Process for preparing anti-second-stubble efficient biologic-organic fertilizer

InactiveCN101007746AHigh in nutrientsSimple structureBio-organic fraction processingOrganic fertiliser preparationOrganic fertilizerDomestic animal

The invention discloses a preparing method of anti-heavy stubble highly effective biological organic fertilizer including effective of fertilizer, effective of medicine and unwanted bacterium of inhibiting soil, which comprises the following steps: mixing domestic animal manure zymosis agent, chemical mixing fertilizer and alta-mud in proportions; grinding; getting composite fertilizer; spraying bacterium agent on the surface of composite fertilizer; adding microbiological bacterium agent; mixing; dewatering; pelleting.

Owner:扬州市森大肥业有限公司

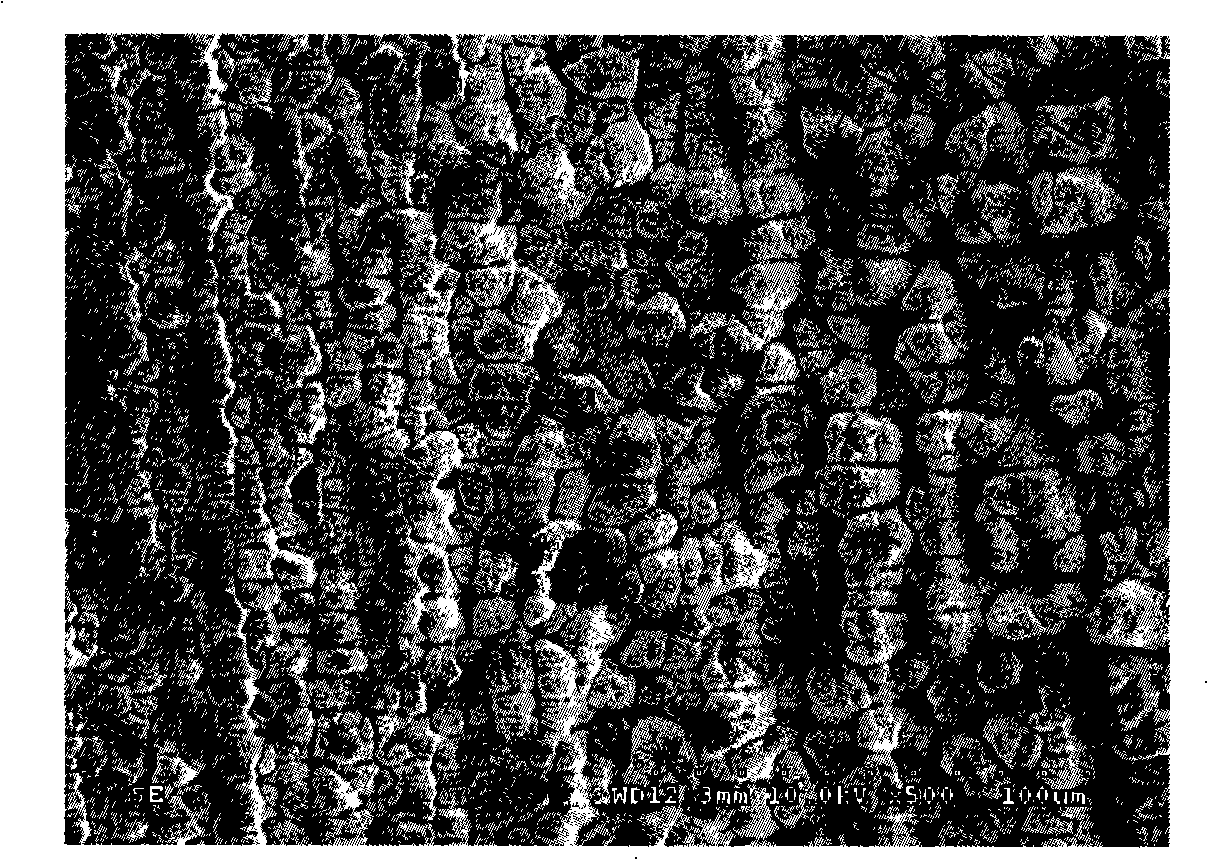

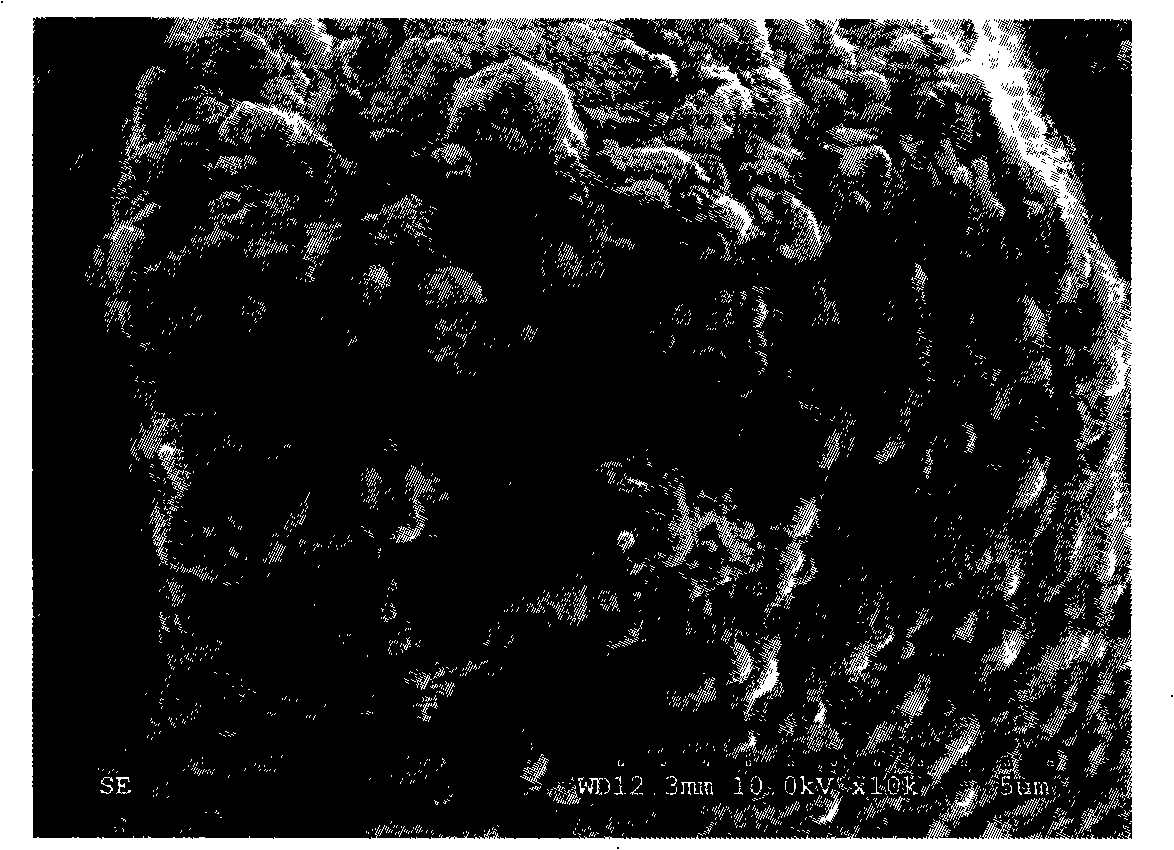

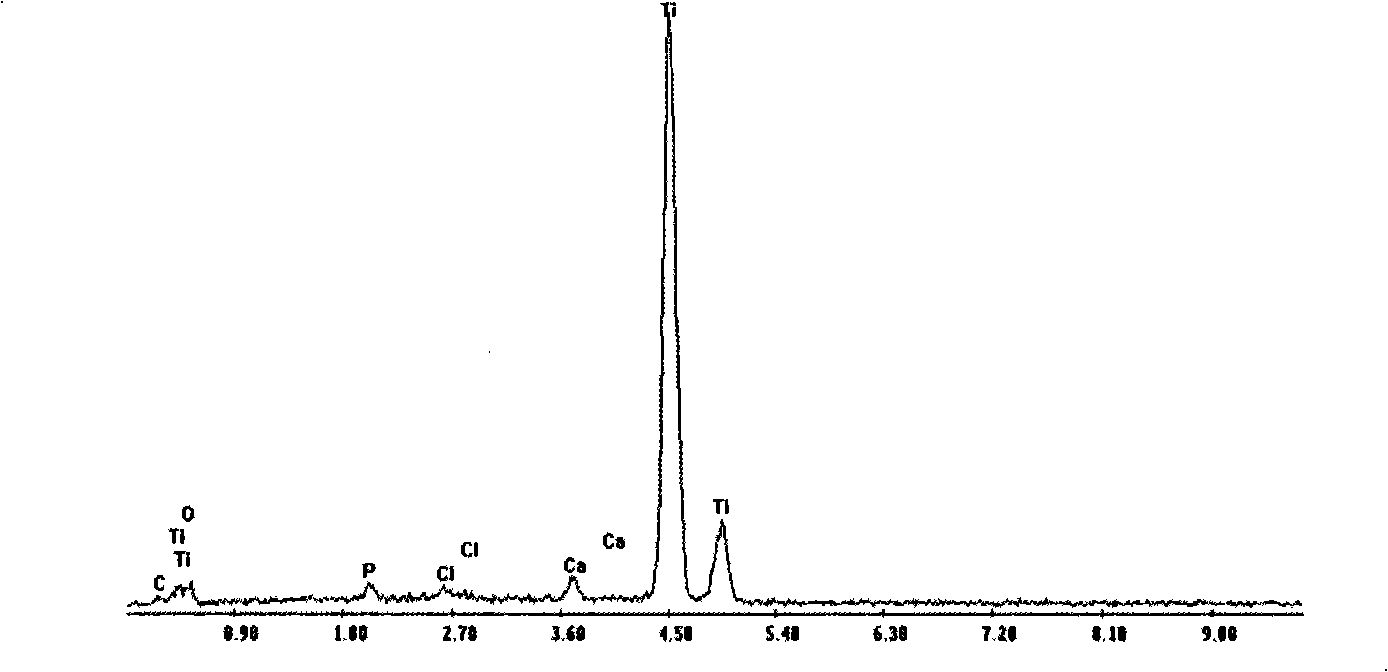

Application of femtosecond laser in titanium or titanium alloy implantation material surface treatment

InactiveCN101264550ALower ablation thresholdLittle thermal impactTeeth fillingBone implantApatitePhosphate

The invention relates to an application of a femto-second laser in the treatment of titanium or titanium alloy implanting material surface, belonging to the technical field of application of laser in the material surface treatment, which comprises the following steps: in the air, the femto-second laser pulses are arranged over the massive titanium or titanium alloy materials, are vertically focused on the surface to form a focal point, the laser spot radius of which is 5 Mum, the processing parameters of the femto-second laser are: the PRF is 1 kHz, the single pulse energy is 50 to 300 micro-joules, the pulse width is 50 femto-seconds, the pulse center wavelength is 800 nm, the laser processing line spacing is 10 to 100 Mum, and the laser scanning speed is 0.2 to 1.0mm / s; the polarization direction of the femto-second laser is adjusted to be parallel with the scanning direction of the femto-second laser, the femto-second laser is used to scan the entire surface of the massive titanium or titanium alloy materials which have been immersed in hydroxyl apatite suspension liquid for 5 minutes, so the surface of the titanium or titanium alloy materials present uniform rough peak-like protrusions and a pattern of porous cyclist regular structure, and is loaded with the titanium-based biomedical material of calcium and phosphate salt.

Owner:HEBEI UNIV OF TECH +2

Nell peptide expression systems and bone formation activity of nell peptide

ActiveUS7544486B2Facilitate protein trafficking and post production modificationPromote secretionOrganic active ingredientsBacteriaBone formationBone growth factor

The invention generally relates to a bone growth factor, and more particularly to compositions including NELL1, articles of manufacture including NELL1 and methods of using NELL1 to induce bone formation. This invention also provides methods for the expression and purification of NELL1 and NELL2 peptides.

Owner:RGT UNIV OF CALIFORNIA

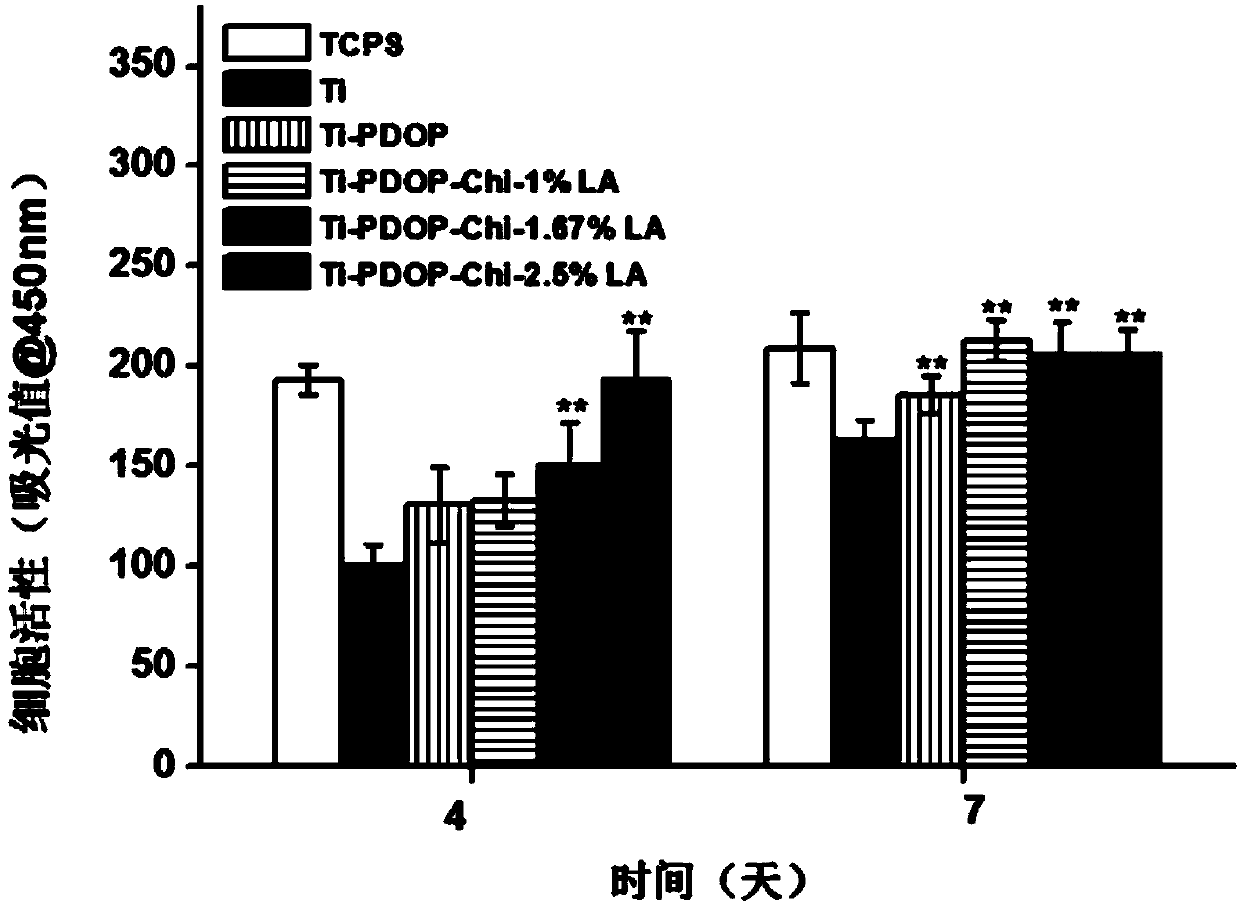

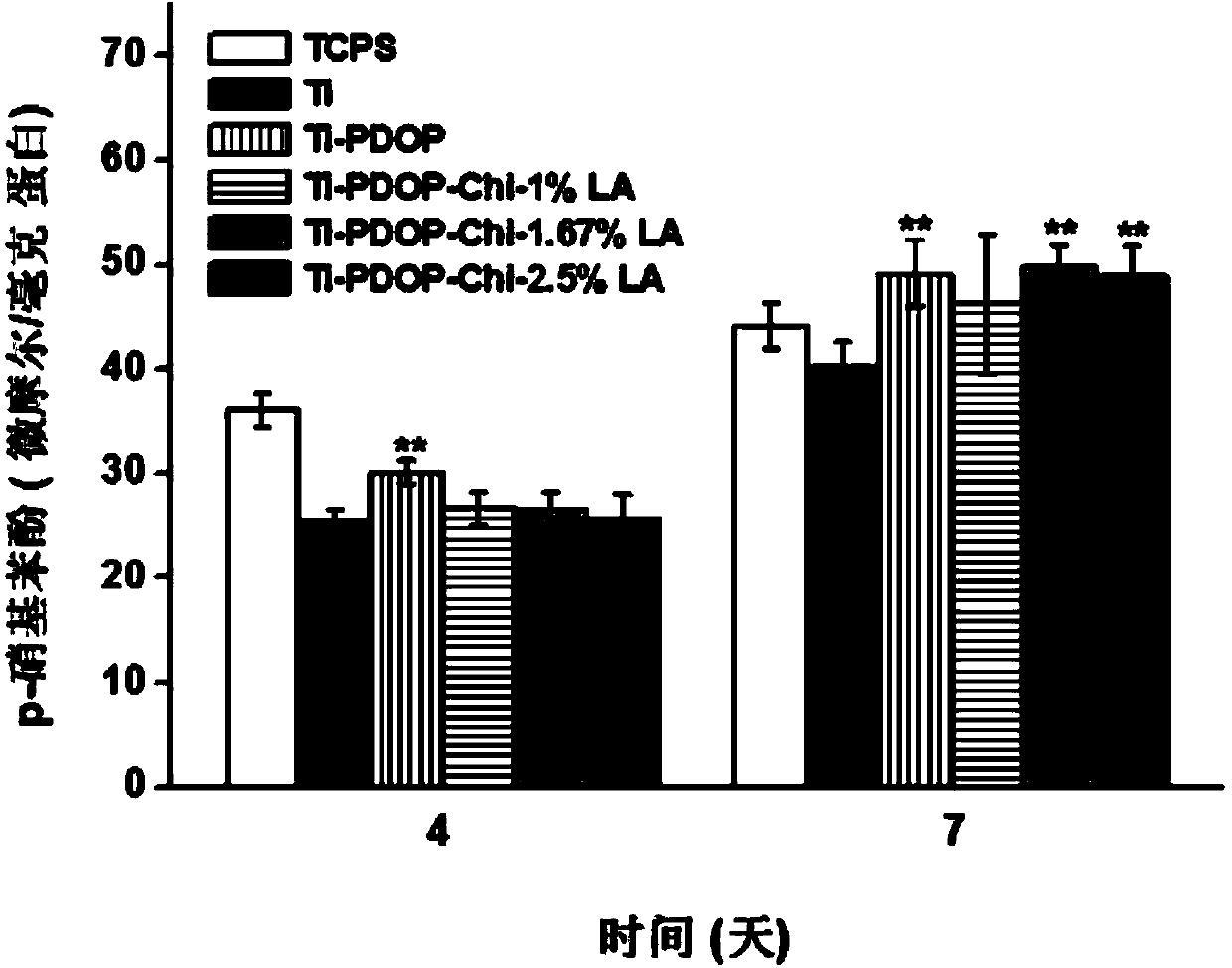

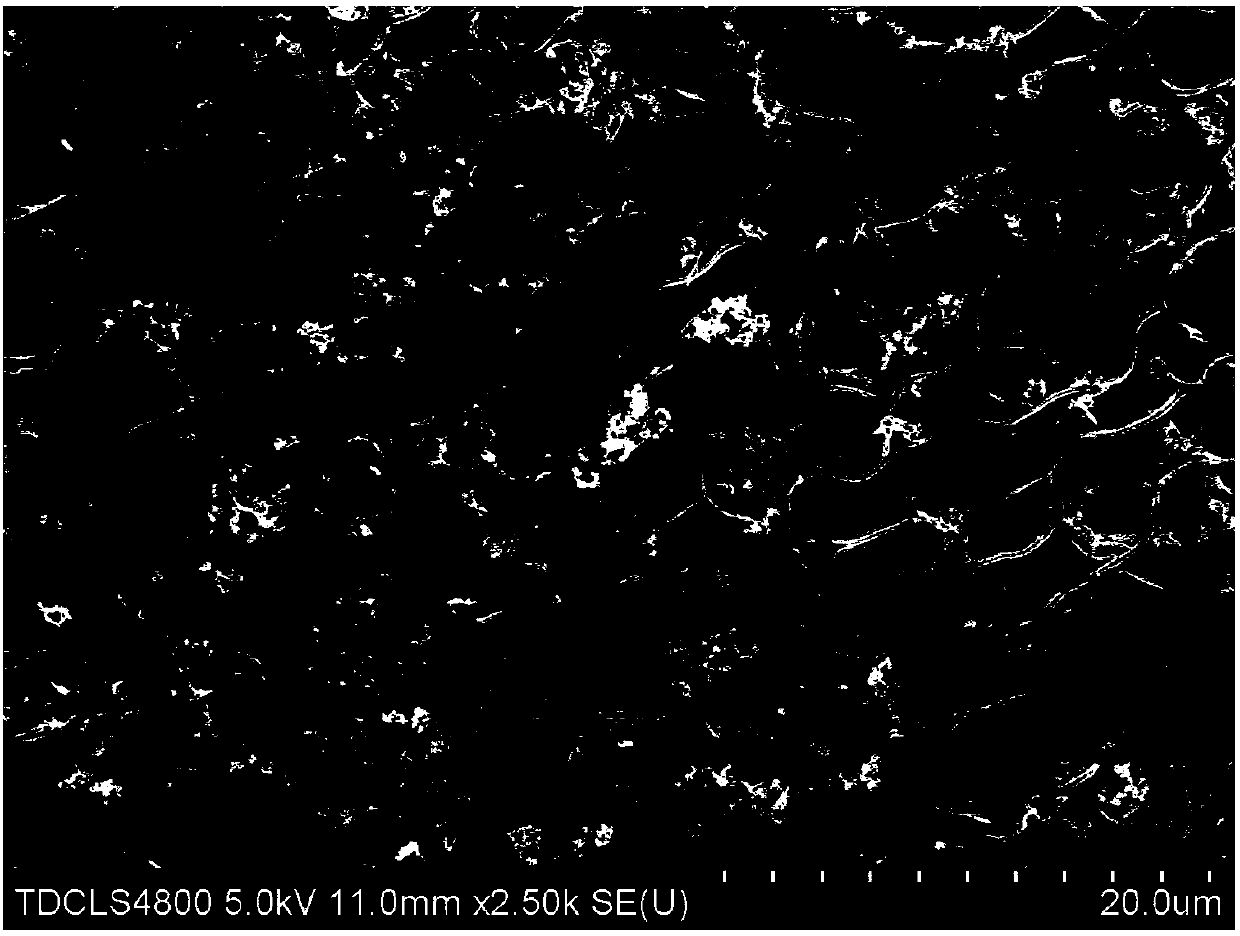

Medical titanium alloy with antibacterial and osteocyte-facilitating functions and preparation method thereof

InactiveCN104005016AImprove antibacterial propertiesImprove osseointegrationMetallic material coating processesProsthesisBone cellAdsorption method

The invention provides a preparation method of nanolayer medical titanium alloy with antibacterial and osteocyte-facilitating functions. The method comprises the following steps: firstly, preparing different concentrations of chitosan-lauric acid (1%, 1.67% and 2.5%) conjugates by esterification reaction; secondly, utilizing a physical adsorption method and a chemical fixation method, adopting poly-dopamine as an intermediate layer, fixing the chitosan-lauric acid conjugates on the surface of a titanium implant, so as to build a nano structure layer with dual antibacterial and osteocyte proliferation facilitating properties on the titanium material surface, so as to regulate and control the biological function of the osteocyte, and improve the short-term antimicrobial capability of the titanium implant.

Owner:CHONGQING UNIV

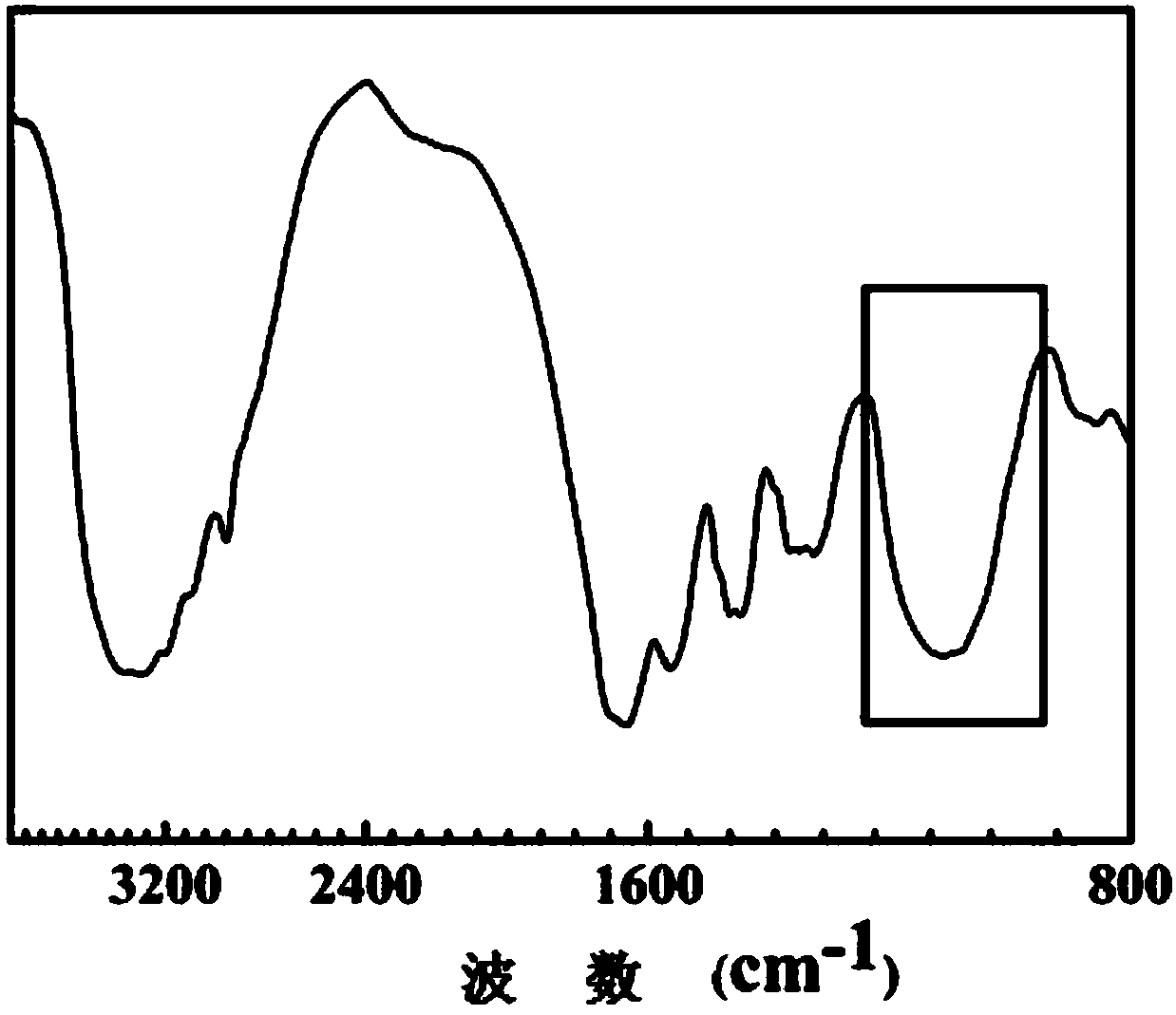

Multifunctional bio-charcoal and preparation method thereof

The invention relates to a multifunctional bio-charcoal and a preparation method thereof. According to the technical scheme, the preparation method comprises the steps of dipping biomass into 1-15wt% caustic alkali solution for 1-50h, washing with water to be neutral, and drying to obtain treated biomass; then charring the treated biomass in a tube furnace in mixed gas at 300-900 DEG for 1-130h to obtain the multifunctional bio-charcoal. The biomass is one of rice straw, wheat straw, sawdust, wood, green grass, fruit peel and animal tissue waste; the biomass contains 30-60wt% of volatile organic carbon of charcoal, 10-40wt% of fixed carbon, 1-30wt% of ash and 10-60wt% of water. The preparation method disclosed by the invention has the characteristics of low production cost, high yield, simple process, controllable production process and environment friendliness, and the prepared multifunctional bio-charcoal has a good adsorption effect on heavy metals and high stability and can be used for repairing water bodies, solid matrixes and soil which are polluted by heavy metals.

Owner:WUHAN UNIV OF SCI & TECH

Device for treating organic wastewater by ozone and active carbon and method therefor

InactiveCN1884125ASimple methodSimple and efficient operationWater/sewage treatment by sorptionWater/sewage treatment by oxidationPollutantGrain shape

The invention discloses an organic waste water disposing device through ozone or activated carbon, which comprises the following parts: outer cylinder, circulating cylinder with the same shaft of outer cylinder, inlet on the bottom of outer cylinder, aerating device on the bottom of inner cylinder. The disposing method comprises the following steps: pumping organic waste water in the device from inlet; putting grain-shaped activated carbon in the device; inputting ozone gas; circulating to flow the activated carbon in the space of inner cylinder and outer cylinder pushed by ozone gas.

Owner:ZHEJIANG UNIV

Dental Mineralization

A method is provided for mineralizing a dental surface or subsurface including contacting the dental surface with a protein disrupting agent and stabilized amorphous calcium phosphate (ACP) or amorphous calcium fluoride phosphate (ACFP).

Owner:MELBOURNE UNIV OF THE

Composite microbial fertilizer for preventing and controlling diseases of continuous crop and its preparing method

InactiveCN1986417ASignificant disease effectGood preventive effectSuperphosphatesMagnesium fertilisersMicroorganismAgricultural science

The composite microbial fertilizer for preventing and controlling diseases of continuous crop consists of high efficiency composite microbial preparation 10-35 wt%, inorganic fertilizer 5-30 wt% and activated turf as fertilizer matrix 60-85 wt%. The composite microbial preparation consists of microbial preparation and adsorbent. The composite microbial fertilizer can plant high efficiency microbe colony to inhibit the growth and propagation of germ for successful continuous crop planting. In addition, the present invention is favorable to optimizing soil microbe colony structure, allocating soil nutrients reasonably and raising soil production capacity.

Owner:北京中龙创科技有限公司

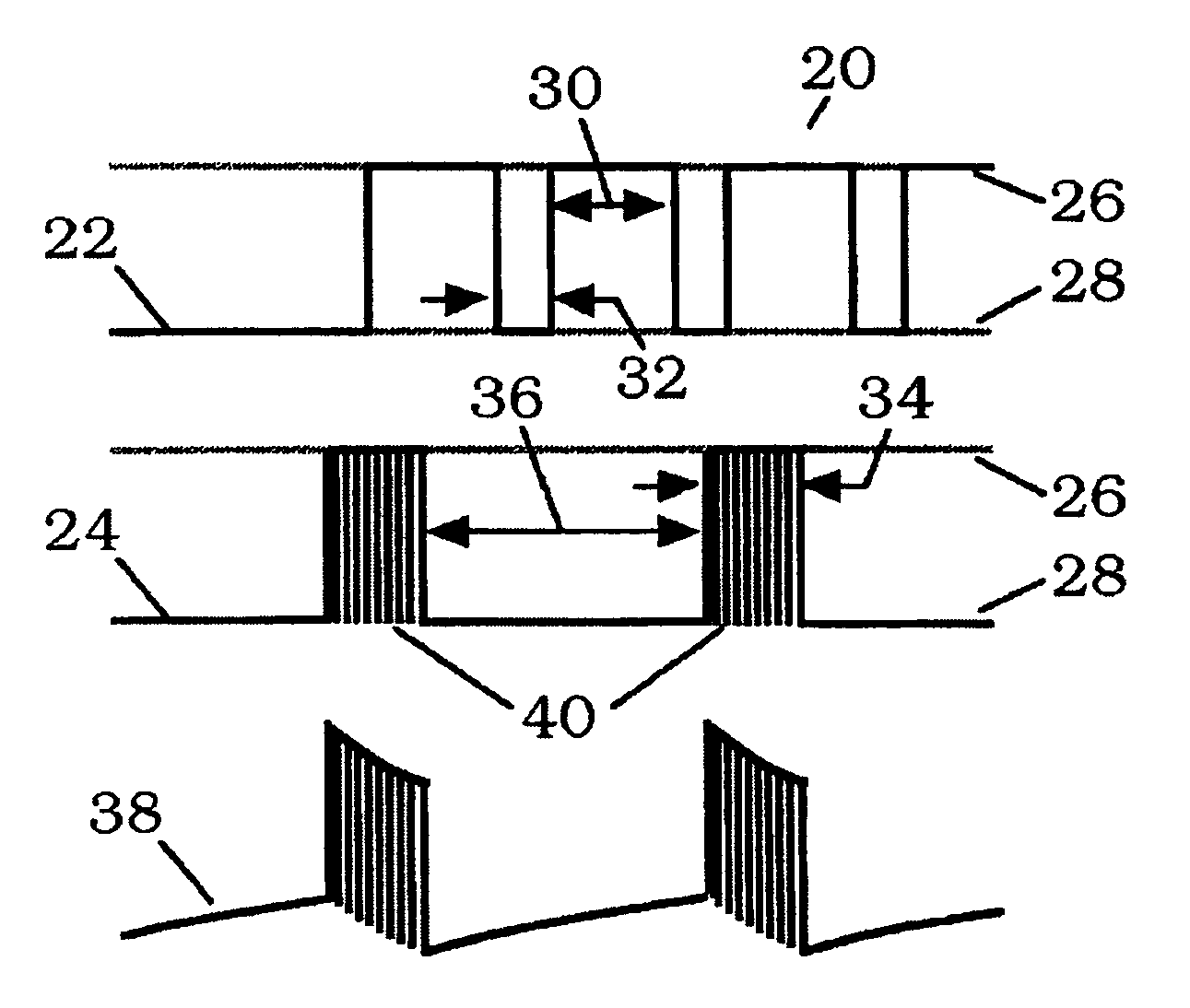

Methods for modulating osteochondral development using bioelectrical stimulation

ActiveUS7840272B2Minimal stressAccelerated and more permanent healingElectrotherapyStress based microorganism growth stimulationCo administrationOsteoblast

Compositions and methods are provided for modulating the growth, development and repair of bone, cartilage or other connective tissue. Devices and stimulus waveforms are provided to differentially modulate the behavior of osteoblasts, chondrocytes and other connective tissue cells to promote proliferation, differentiation, matrix formation or mineralization for in vitro or in vivo applications. Continuous-mode and pulse-burst-mode stimulation of cells with charge-balanced signals may be used. Bone, cartilage and other connective tissue growth is stimulated in part by nitric oxide release through electrical stimulation and may be modulated through co-administration of NO donors and NO synthase inhibitors. Bone, cartilage and other connective tissue growth is stimulated in part by release of BMP-2 and BMP-7 in response to electrical stimulation to promote differentiation of cells. The methods and devices described are useful in promoting repair of bone fractures, cartilage and connective tissue repair as well as for engineering tissue for transplantation.

Owner:MEDRELIEF

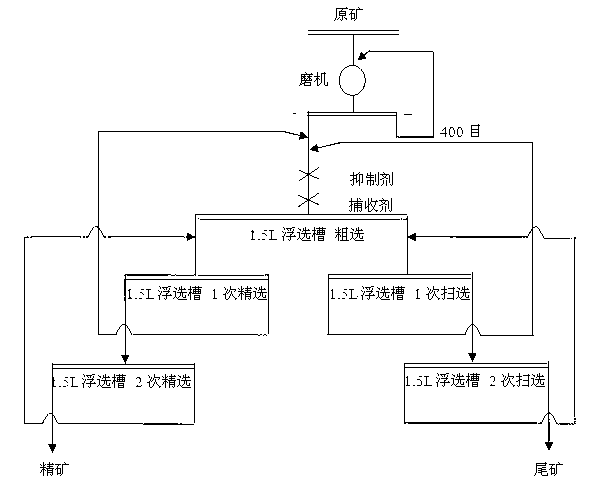

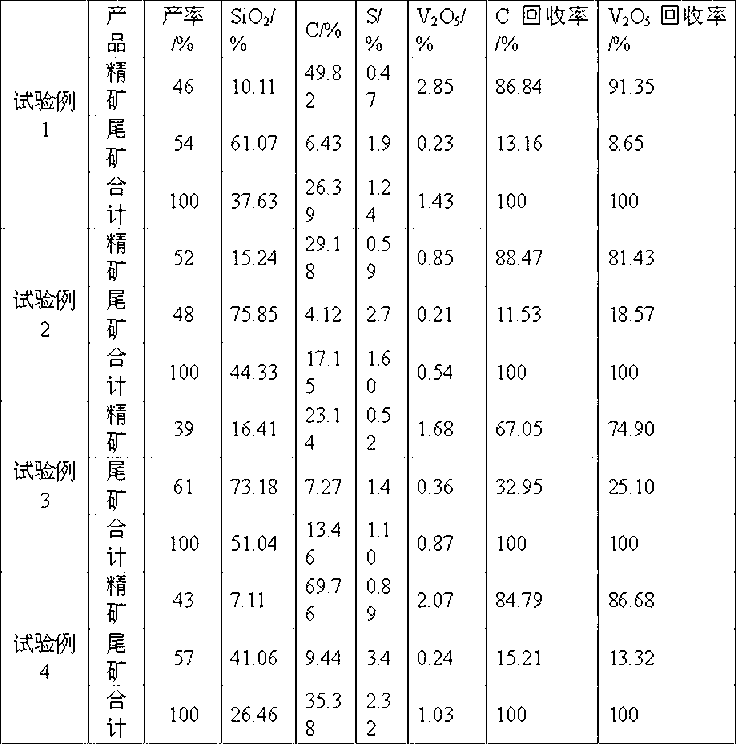

Composite beneficiation reagent for extracting vanadium from stone coal

The invention relates to a composite beneficiation reagent for extracting vanadium from stone coal. The composite beneficiation reagent for extracting the vanadium from the stone coal is characterized in that the composite beneficiation reagent is composed of a component A, a component B, a component C, a component D and water, the component A is kerosene and / or diesel oil, the component B is quaternary ammonium salt class matter and / or aliphatic amine hydrochloride class matter, the component C is any one or more of alcohol ranging from C4 to C8, 4-methyl-cyclohexyl-methanol, MIBC, terpenic oil, methyl triisopropoxy silane, and the component D is any one or more of alkyl-sulfonate ranging from C8 to C12, OP-10 and Tween-60. The composite beneficiation reagent for extracting the vanadium from the stone coal is prepared by a plurality of components according to a certain proportion and a rule, combination of the components of the reagent can be adjusted according to different mineral properties so that a series of flotation reagents can be prepared, and thebest use effect is achieved.

Owner:GUIZHOU BRANCH CHINA ALUMINUM IND

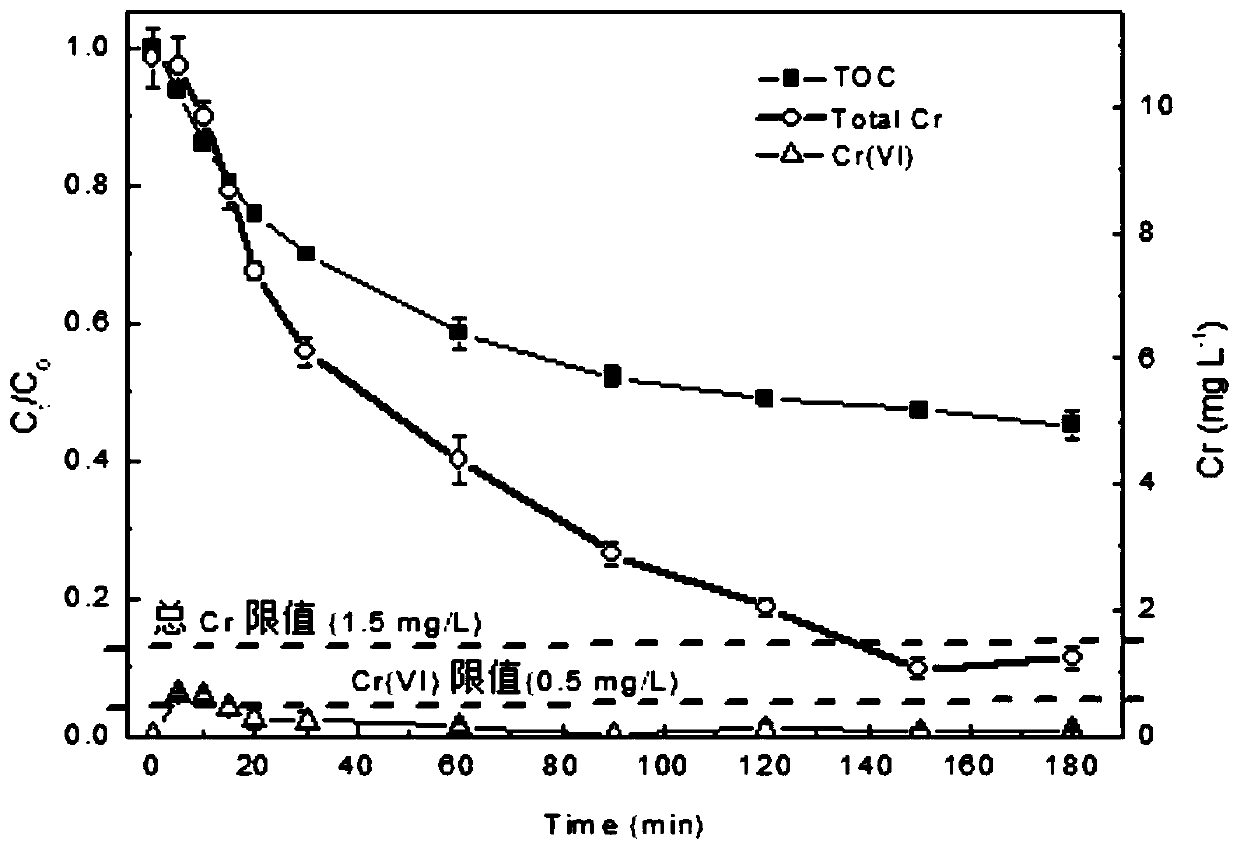

A method for treating trivalent chromium complex wastewater and synchronously recovering chromium with reducing compound agent combined with ultraviolet light

ActiveCN108439533BHas a reducing effectLow residual concentrationWater/sewage treatment by irradiationWater contaminantsPhoto irradiationUltraviolet lights

The invention discloses a method for treating trivalent chromium complexing wastewater and synchronously recycling chromium by combination of a reducing composite chemical agent and ultraviolet light,and belongs to the field of waste water treatment. A method for treating a copper complex and synchronously removing copper by combination of a reducing composite chemical agent / UV comprises the following steps: A, chemical feeding: feeding the reducing composite chemical agent in trivalent chromium complexing wastewater and stirring, and regulating pH of the wastewater to be 4-10; B, ultravioletillumination: carrying out ultraviolet light illumination treatment on the waste water which is stirred uniformly, and separating out chromium in a precipitate mode; and C, chromium recycling: recycling chromium by a solid-liquid separating method. By the method, trivalent-chromium-containing complexing wastewater such as leather making, electroplating and dyestuff can be safely and effectively treated, and the chromium can be recycled.

Owner:温州大学苍南研究院

Expression system of NELL peptide

ActiveUS7691607B2Improve clinical rate and effectivenessGood effectBacteriaSkeletal disorderPeptideChemistry

Owner:RGT UNIV OF CALIFORNIA

Pottery fragments capable of adsorbing, purifying, mineralizing and generating alkalescence food

InactiveCN101264435AGood water permeabilityImprove purification effectOther chemical processesWater/sewage treatment by substance additionLithiumAlkalinity

The invention relates to a pottery piece capable of adsorbing, purifying, mineralizing and generating weak alkalinity food and a manufacturing method thereof, belonging to the technical field of daily articles; wherein, the pottery piece is characterized in that the health care pottery piece is round pad shape; the diameter is 5cm to 10cm; the thickness is 5mm to 10 mm; a medical stone grain, a tourmaline grain, a clay and a microelement addition agent are mixedly sintered to form the pottery piece, which is also characterized in that the weight ratios of the medical stone grain, the tourmaline grain, the clay and the microelement addition agent are 30-40: 5-10:50-65:0.02-0.05; wherein the microelement additives are lithium, strontium and zinc; the weight ratio of the lithium, strontium and zinc is 1-2:2-3:3-5. The manufacture process comprises the following steps: a billet is made of the mixture of the medical stone grain, the tourmaline grain, the clay and the microelement addition agent; the billet is air-dried, sintered in high temperature and cooled, and the product is obtained. The pottery piece has the advantages of purifying and mineralizing water, discharging negative ion ionized water, radiating far infrared ray and releasing microelements favorable to human body.

Owner:讷文波 +1

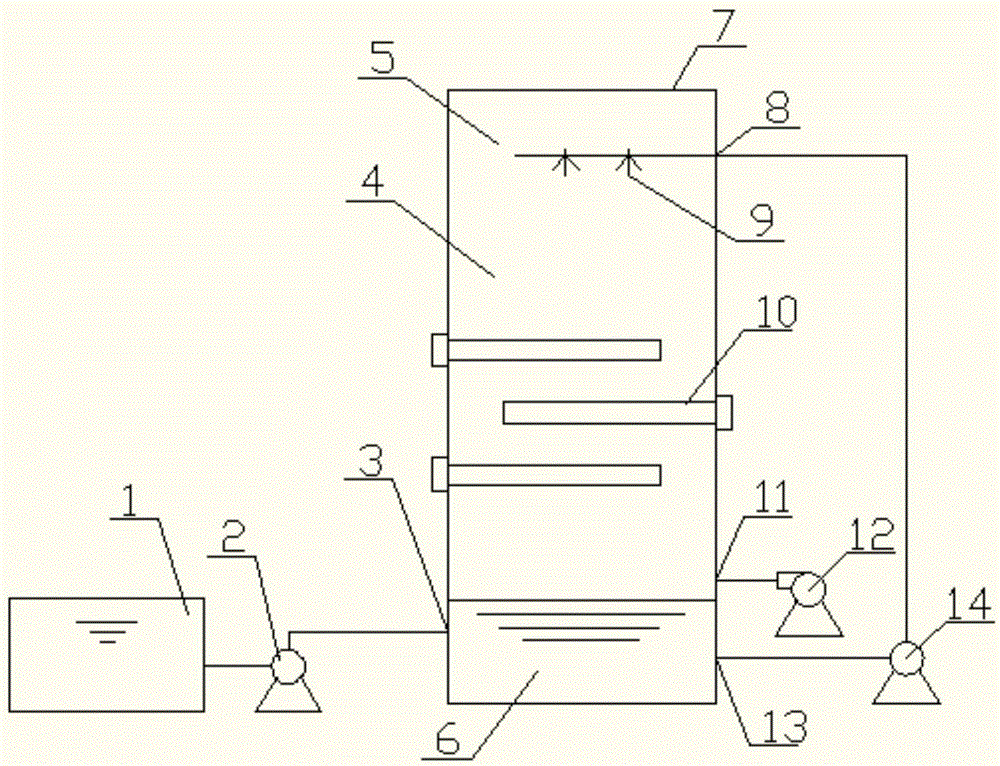

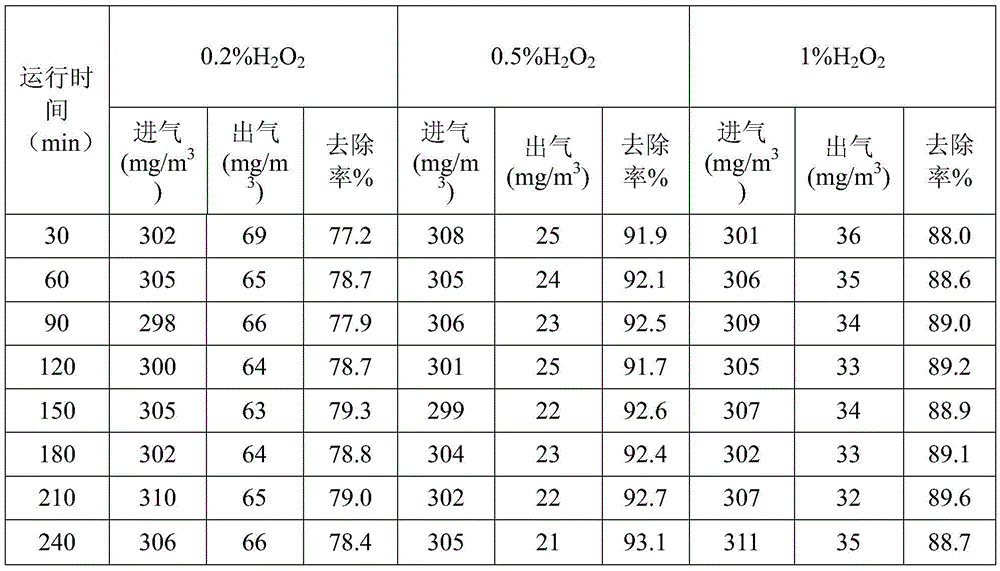

Circulating spraying type ultraviolet Fenton oxidation organic waste gas treatment system and method

ActiveCN105536481APromote circulationIncrease mass transfer rateGas treatmentDispersed particle separationFenton reagentUltraviolet

The invention discloses a circulating spraying type ultraviolet Fenton oxidation organic waste gas treatment system and method. The treatment system comprises a spraying oxidation reaction chamber, an induced draught fan and a hydrogen peroxide adding device. An exhaust port is formed in the top of the spraying oxidation reaction chamber. A hydrogen peroxide inlet, a gas inlet and a Fenton reagent outlet are formed in the lower portion of the spraying oxidation reaction chamber. A Fenton reagent inlet is formed in the upper portion of the spraying oxidation reaction chamber. The induced draught fan is connected with the gas inlet. The hydrogen peroxide adding device is connected with the hydrogen peroxide inlet through a pressure pump. The Fenton reagent outlet is connected with the Fenton reagent inlet through a circulation pump. A Fenton reagent is contained in an inner cavity of the spraying oxidation reaction chamber. A spraying device is arranged on the upper portion in the inner cavity of the spraying oxidation reaction chamber and connected with the Fenton reagent inlet. A plurality of ultraviolet modulator tubes are arranged on the portion, above the liquid level of the Fenton reagent and below the spraying device, of the inner wall of the spraying oxidation reaction chamber. The ultraviolet modulator tubes are installed on the inner wall of the spraying oxidation reaction chamber in a parallel and crossed mode. The circulating spraying type ultraviolet Fenton oxidation organic waste gas treatment system and method are easy to operate, Fe2+ in the Fenton reagent is recycled, and the utilization rate of H2O2 is increased.

Owner:ZHEJIANG UNIV OF TECH

Molecules involved in regulation of osteoblast activity and osteoclast activity, and methods of use thereof

ActiveUS20090053189A1Increasing formationImprove mineralizationCompound screeningApoptosis detectionOsteoblastBone formation

The present invention is based, at least in part, on the identification of molecules involved in the differentiation and / or activity of osteoblasts and osteoclasts. Accordingly, the present invention provides methods of identifying modulators of bone formation, mineralization, and / or osteoclastogenesis and methods for treating disorders that would benefit from modulation of bone formation, mineralization, and / or osteoclastogenesis using agents identified as described herein.

Owner:CORNELL UNIVERSITY

Dental mineralization

ActiveUS8673363B2Improve mineralizationBiocideCosmetic preparationsNuclear chemistryAmorphous calcium phosphate

A method is provided for mineralizing a dental surface or subsurface including contacting the dental surface with a protein disrupting agent and stabilized amorphous calcium phosphate (ACP) or amorphous calcium fluoride phosphate (ACFP).

Owner:MELBOURNE UNIV OF THE

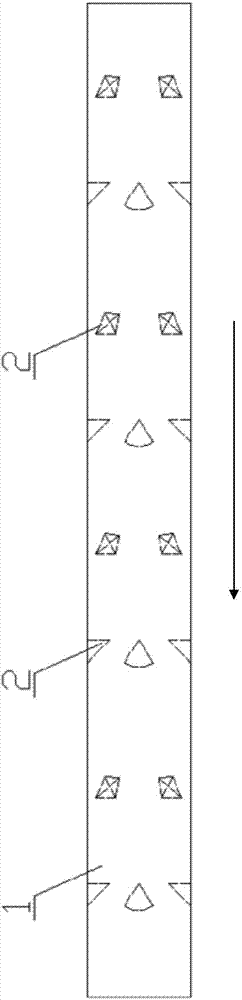

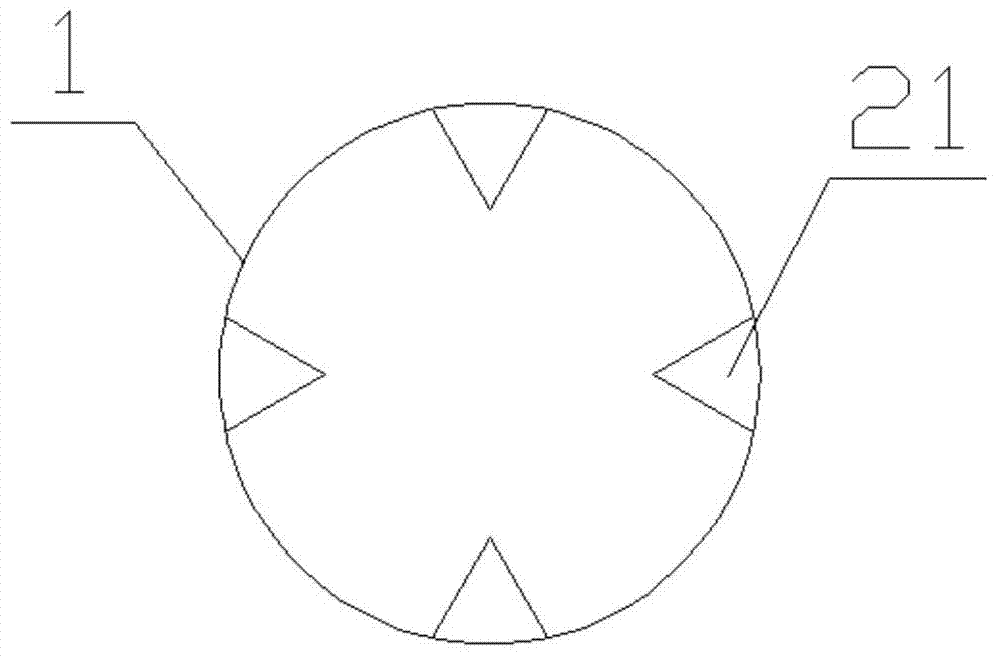

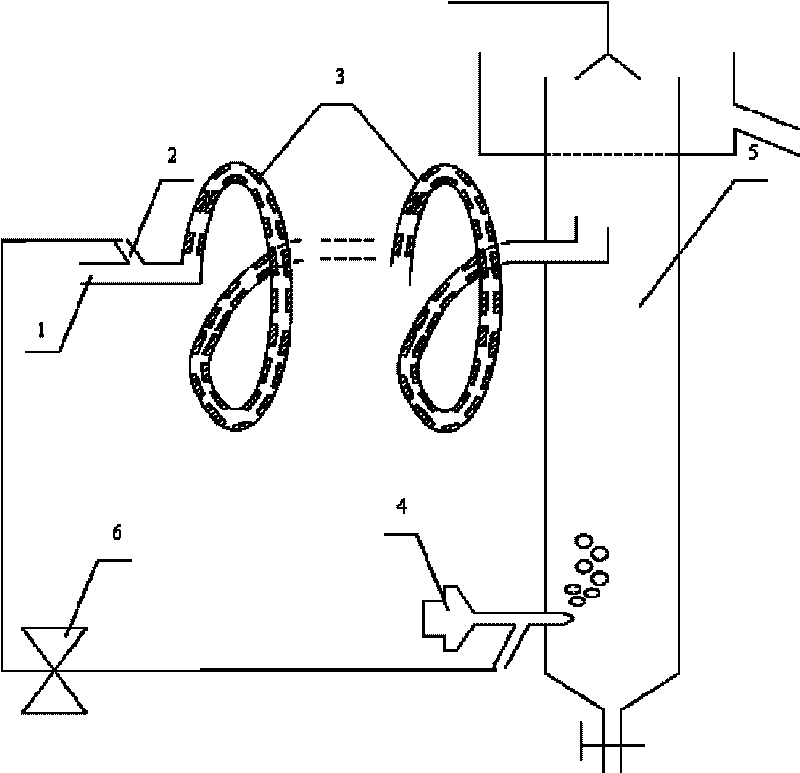

Pipe flow section device applicable to mineralized fine grain minerals

ActiveCN104511374AIncreased turbulence intensityIncrease the probability of collisionVortex flow apparatusFlotationEngineeringMaceral

The invention discloses a pipe flow section device applicable to mineralized fine grain minerals. The device comprises a pipeline (1) between the downstream of a bubble generator of a flotation column and an inlet end of a rotating flow inlet end, wherein the inner pipe wall of the pipeline (1) along the inner pipe wall of a pipeline axis is provided with at least a row of vortex generators (2), and the vortex generators are a plurality of protuberances (21) surrounding the inner pipe wall. The vortex generator in the pipe can be changed by the vortex generator set in the pipeline, therefore the collision probability between mineral grains and bubbles can be improved, the turbulence intensity in the pipe can be gradually enhanced, the mineral effect can be enhanced, and the recovery ratio of the fine minerals can be improved.

Owner:CHINA UNIV OF MINING & TECH

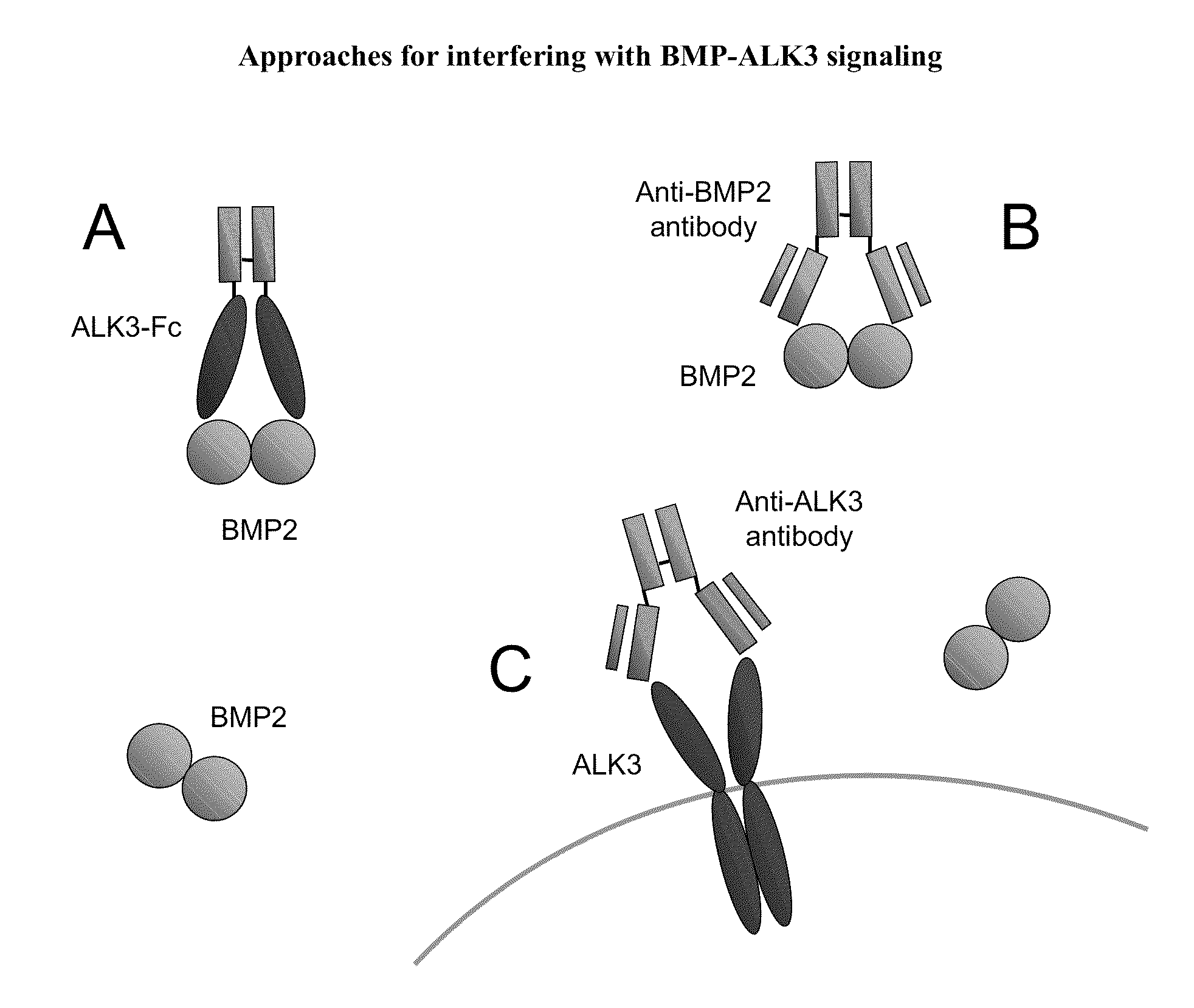

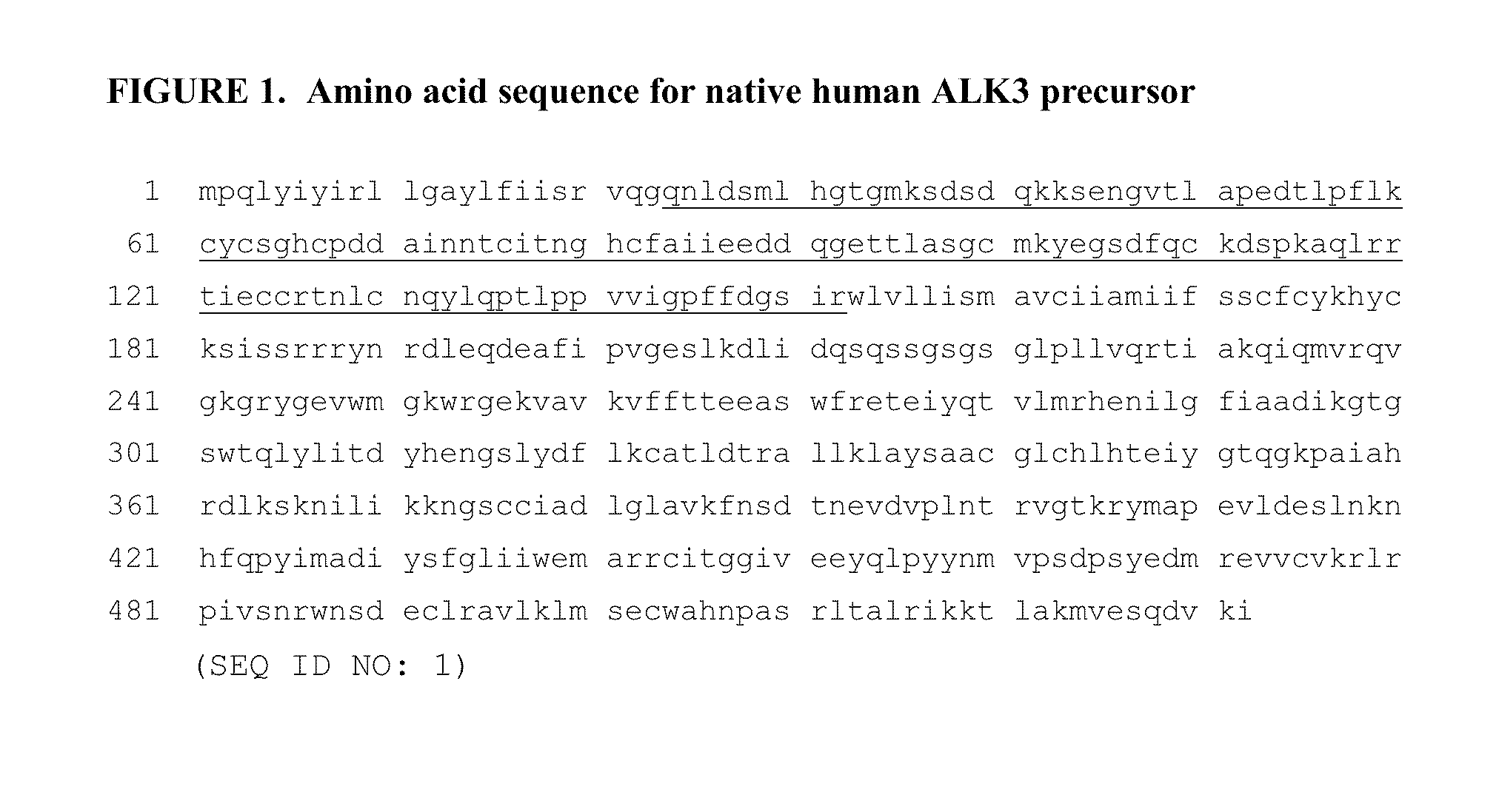

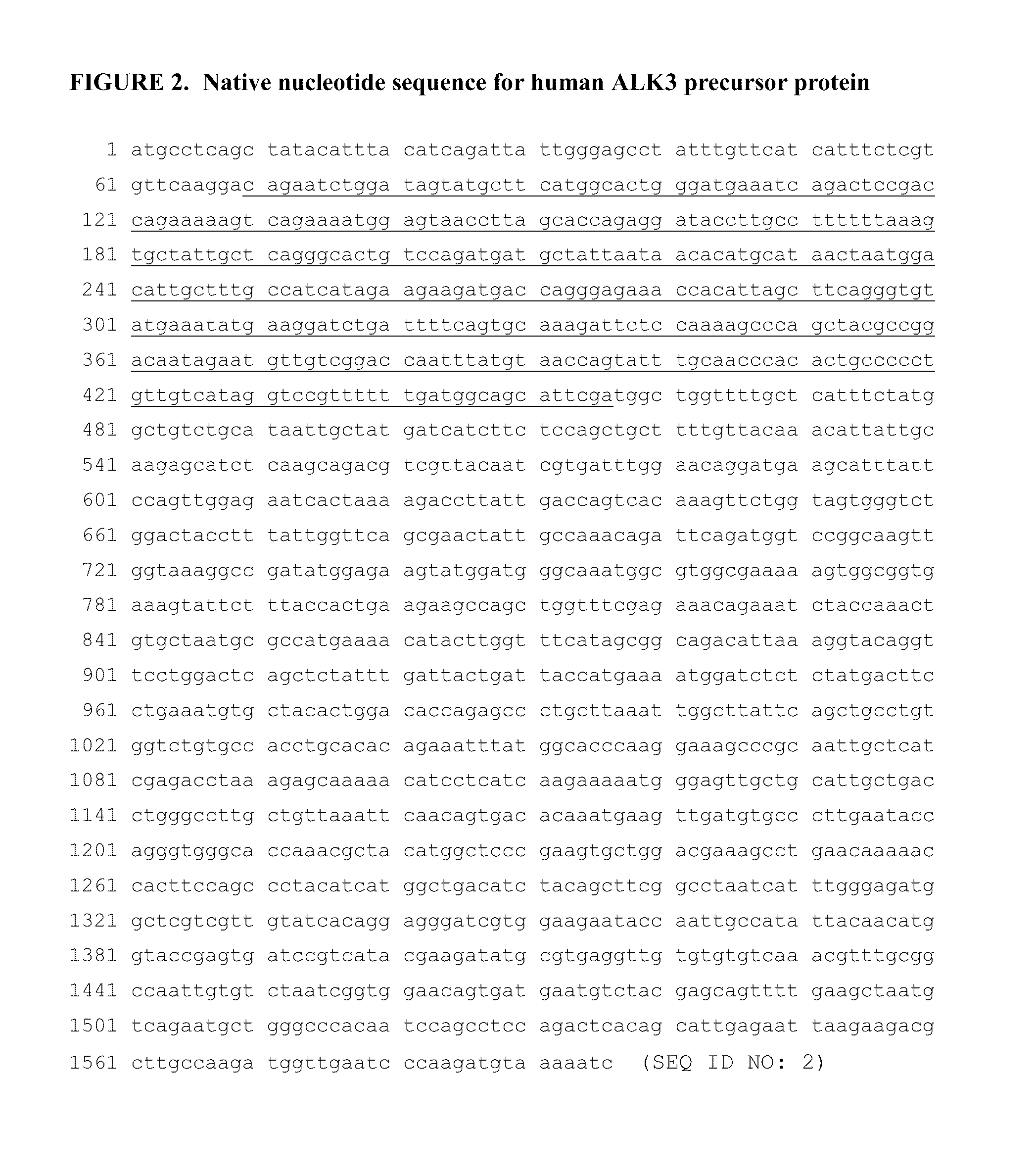

Bmp-alk3 antagonists and uses for promoting bone growth

ActiveUS20100266612A1Promote growthStimulates of mineralizationPeptide/protein ingredientsAntibody mimetics/scaffoldsIncreased Bone DensityBone growth

In certain aspects, the present invention provides compositions and methods for promoting bone growth and increasing bone density and strength. In certain embodiments, the present invention provides ALK3 polypeptides, including ALK3-Fc fusion proteins.

Owner:ACCELERON PHARMA INC

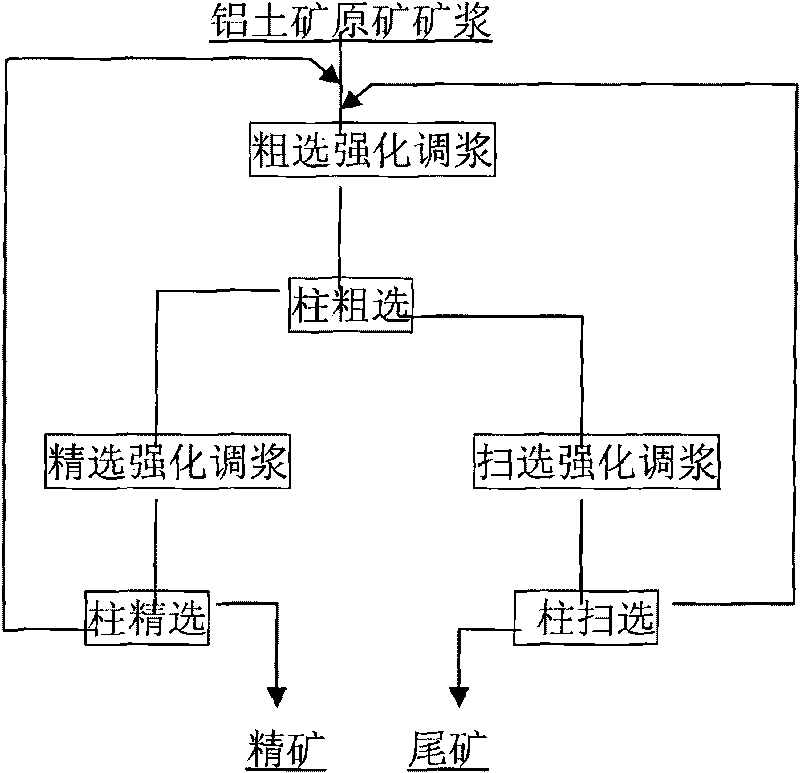

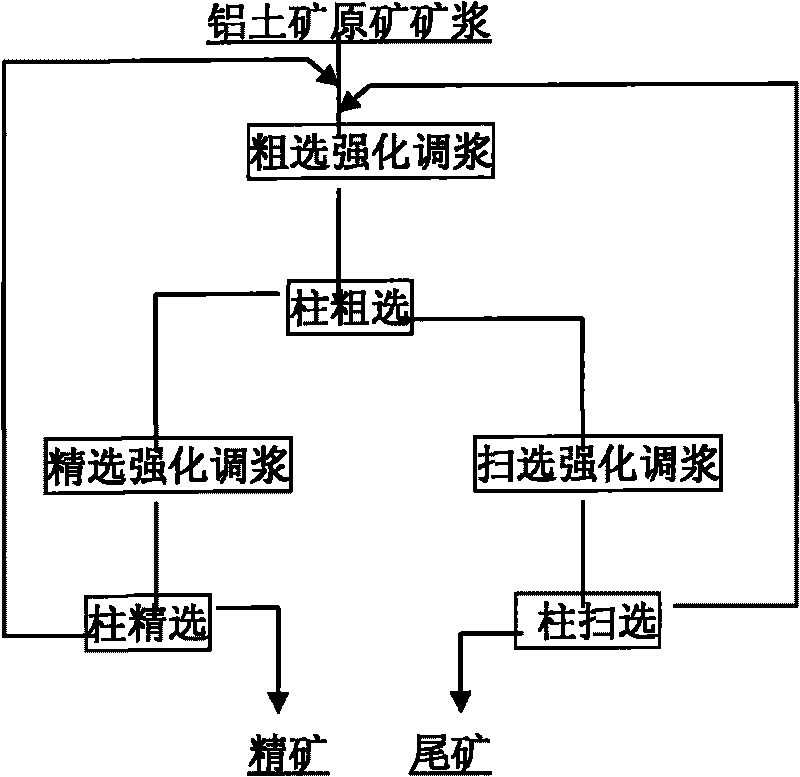

Bauxite column-type floatation method

The invention provides a bauxite column-type floatation method, and relates to bauxite ore-dressing and desilication, in particular to a low-grade diasporite bauxite ore-dressing and desilication method. The method is characterized in that a floatation process comprises the following steps: (1) adding flotation reagent for pulp regulation to bauxite raw ore pulp and adopting a flotation column for rough flotation; (2) adding the flotation reagent for pulp regulation again to flotation concentrate pulp overflowing from the flotation column for rough flotation, adopting the flotation column forconcentration and obtaining concentrate; (3) adding the flotation reagent for pulp regulation to tailings flowing at the bottom of the flotation column for rough flotation to perform column scavenging; and (4) returning the tailings obtained by adopting the flotation column for concentration in the step (2) and scavenging concentrate obtained in the step (3) to the process of adding the flotationreagent for pulp regulation to the bauxite raw ore pulp in the step (1). The method has the advantages of reasonable process, good industrial implementation effects, good flotation indexes and low reagent consumption.

Owner:中铝中州铝业有限公司

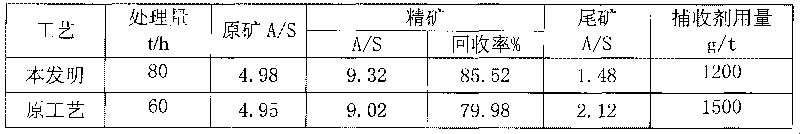

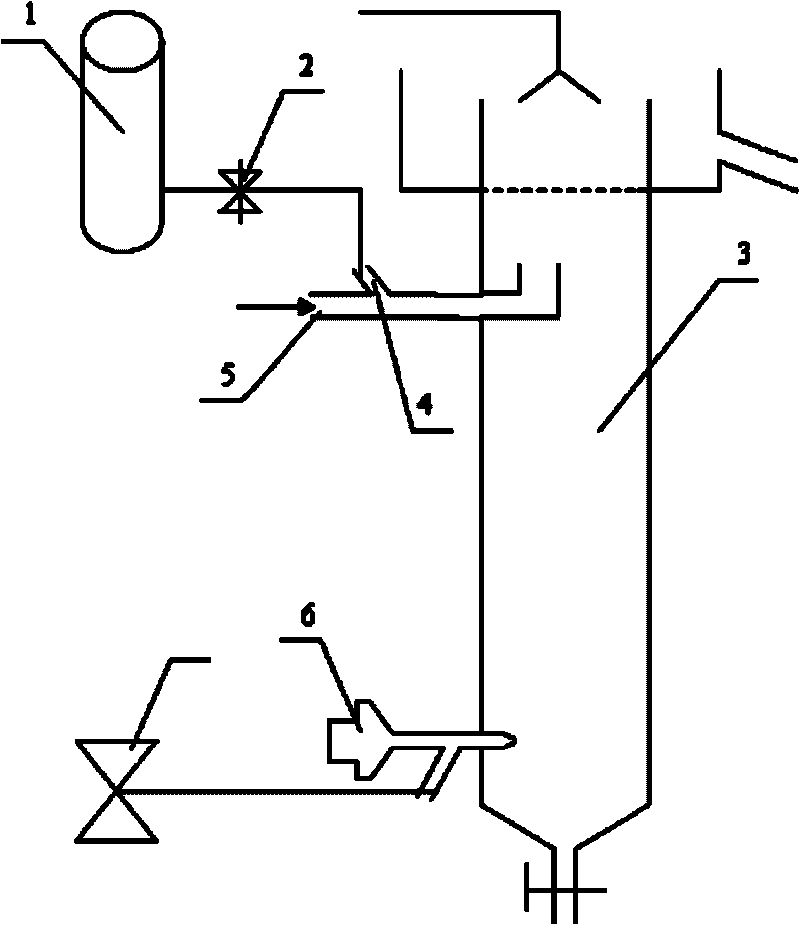

Process for performing sulfide ore flotation by using liquid carbon dioxide

The invention discloses a process for performing sulfide ore flotation by using liquid carbon dioxide. The process aims at the problems that in the sulfide ore flotation, because sulfide ores are easy to be crushed and overground and air bubbles can collide with mineral grains of the sulfide ores difficultly, the flotation and collection effects are not good. The flotation process adopting the liquid carbon dioxide comprises the following steps of: introducing the liquid carbon dioxide (1) together with a flotation pulp entering from an air inlet (4) and a feed opening (5) into a flotation column (3) through a pressure reducing valve (2); performing carbon dioxide gasification; growing air bubbles on the surfaces of hydrophobic ore grains; and performing adverse impact with the air bubbles generated by a magnetic bubble generator (6) in the flotation column (3) so as to achieve the flotation of sulphide. The method achieves that ore pulp is mineralized sufficiently and evenly in the flotation column, has enough flotation time, large air bubble quantity, superfine sizes, uniform dispersion, good flotation and collecting effect, no pollution and the like, and the method can be used in the fields of metal mines, chemical engineering, environmental protection and the like.

Owner:CENT SOUTH UNIV

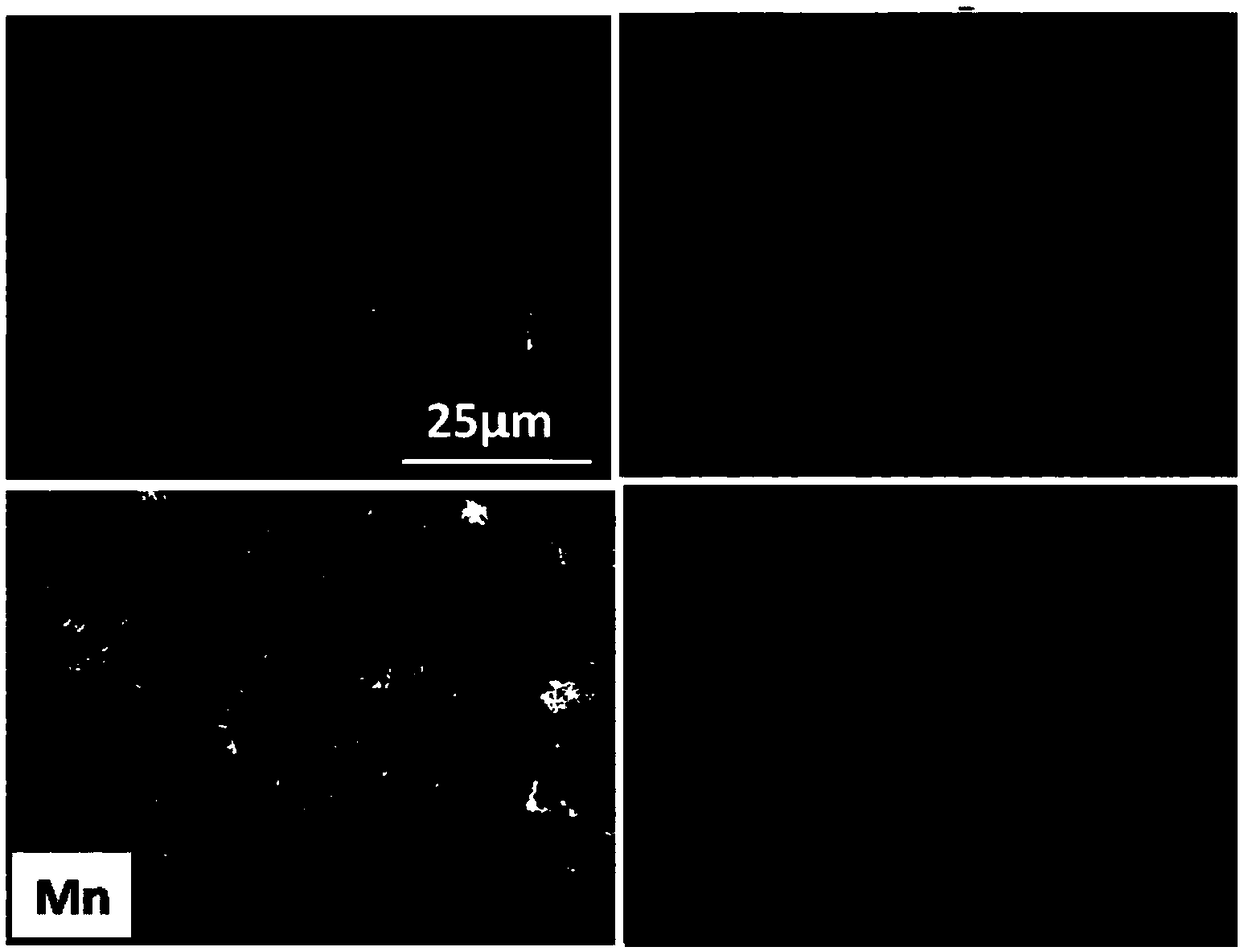

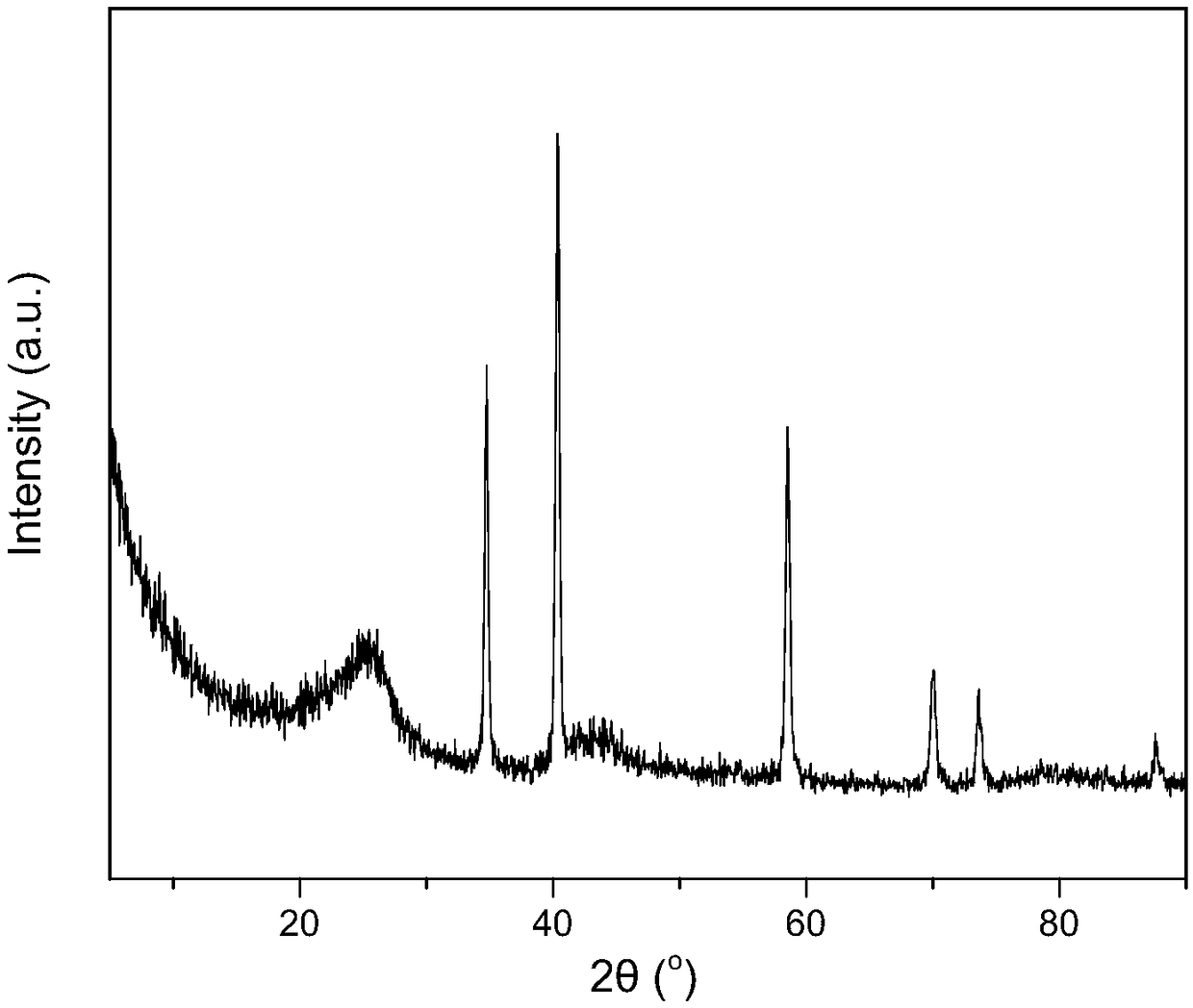

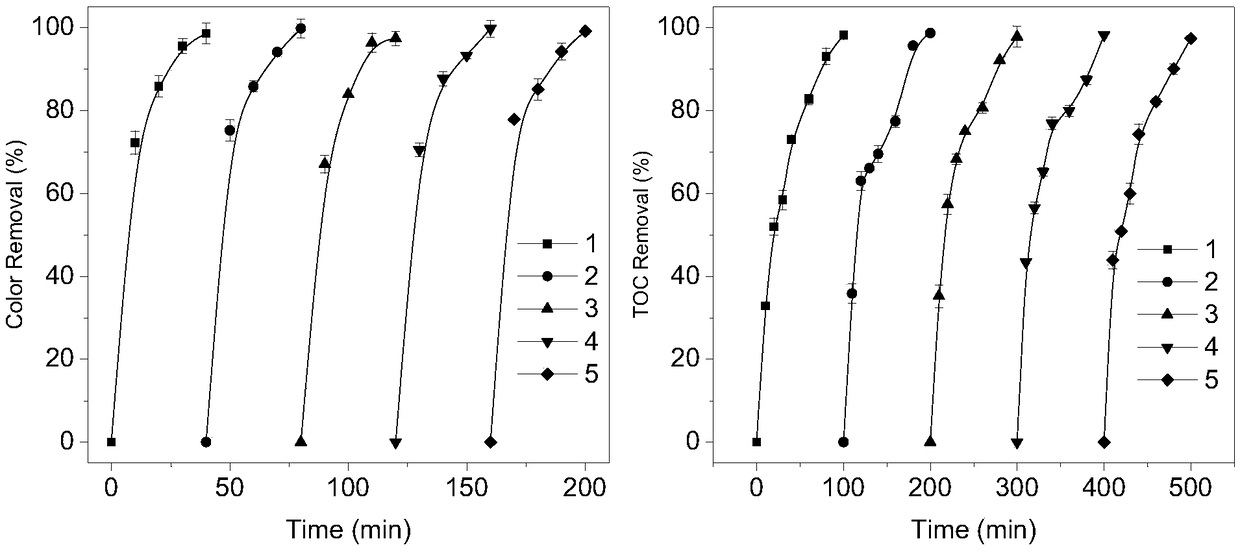

Preparation method and application of MnO/C positive electrode electrocatalyst

ActiveCN108808024AHigh catalytic activityImprove cycle stabilityCell electrodesWater/sewage treatment by oxidationDyeing wastewaterHeat treated

The invention discloses a preparation method and application of a MnO / C positive electrode electrocatalyst. A cheap and easily available carbon material is selected as a base material, the surface ofthe carbon material is loaded with pure-phase MnO by a simple impregnation and high temperature heat treatment process, the prepared MnO / C composite material is used as a positive electrode of a battery, and oxygen gas is catalyzed to oxidize dye wastewater at low voltage. The MnO / C positive electrode electrocatalyst not only greatly improves the mineralization ability of the dye wastewater and shortens the degradation time, but also has good cycle stability.

Owner:合肥庐阳科技创新集团有限公司

High-strength mineralized hydrogel and applications of high-strength mineralized hydrogel in bone repair

InactiveCN108690309AImprove mineralizationImprove bindingTissue regenerationProsthesisCross-linkOsseointegration

The invention discloses a high-strength mineralized hydrogel and applications of the high-strength mineralized hydrogel in bone repair. According to the present invention, N-acryloyl glycinamide and vinylphosphonic acid are used as raw materials and are co-polymerized in the presence of an initiator to prepare a hydrogel, calcium ions and phosphorus ions are deposited in situ in the gel to form hydroxyapatite, the mineralized hydrogel pipe has good tensile performance and good compressive performance due to the physical cross-linking effect of the hydrogen bond and the ion cross-linking effectof the hydroxyapatite and the gel matrix in the gel structure, and due to the presence of hydroxyapatite, the osseointegration and bone repair ability of the gel pipe is improved.

Owner:TIANJIN UNIV

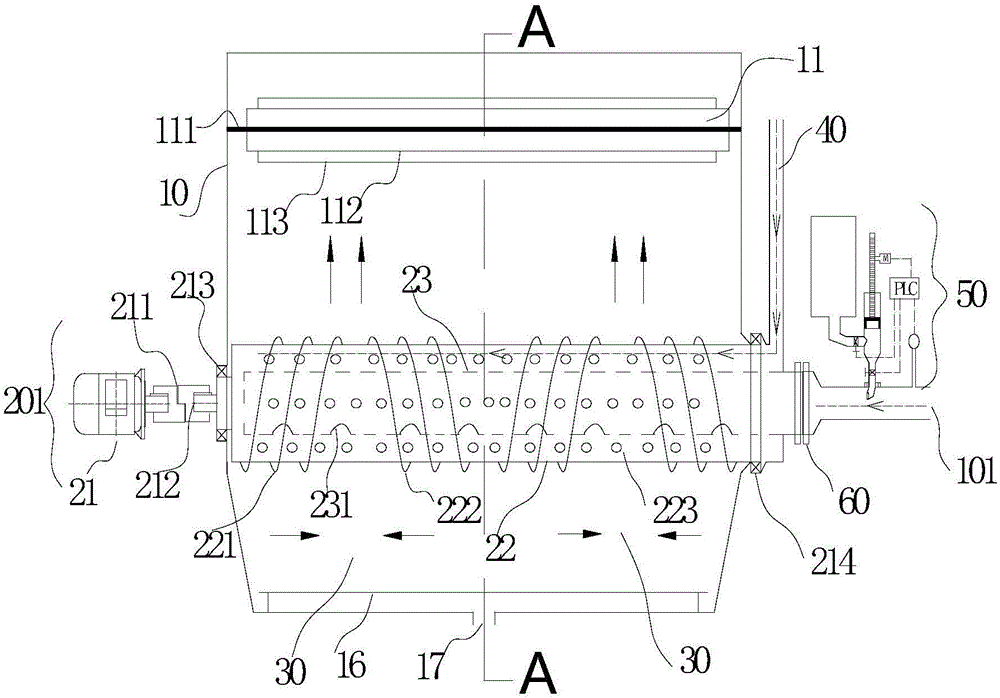

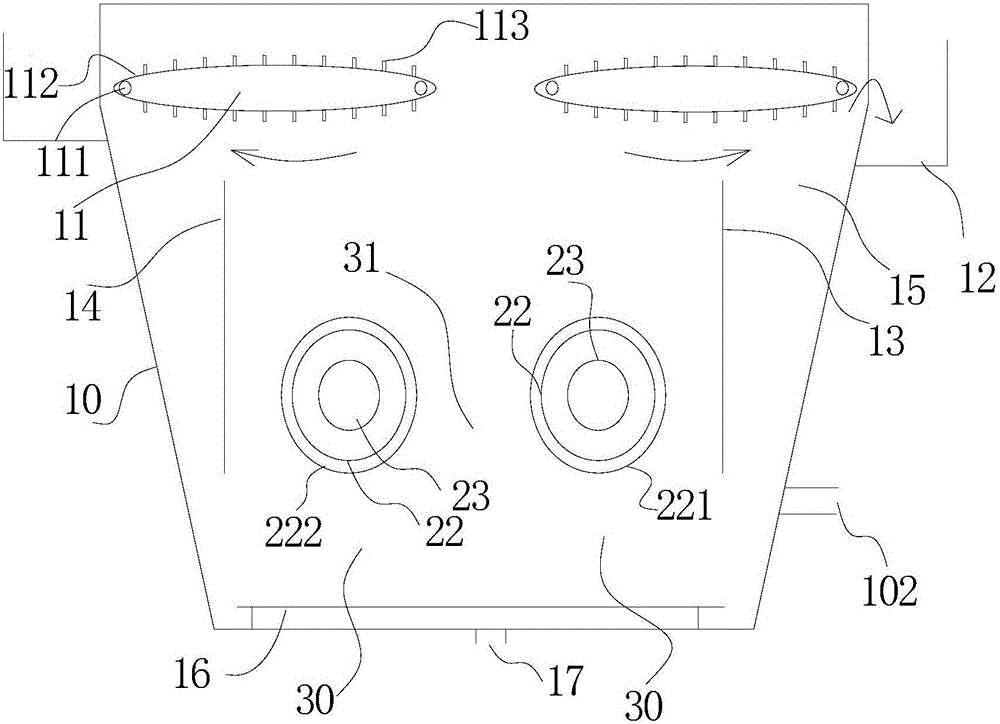

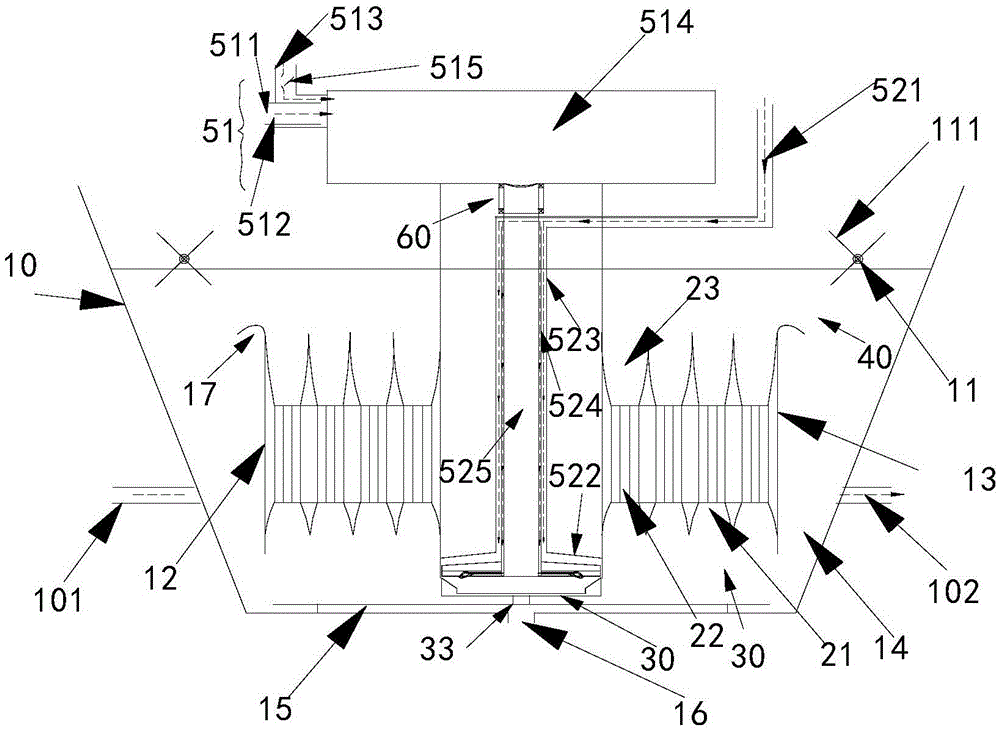

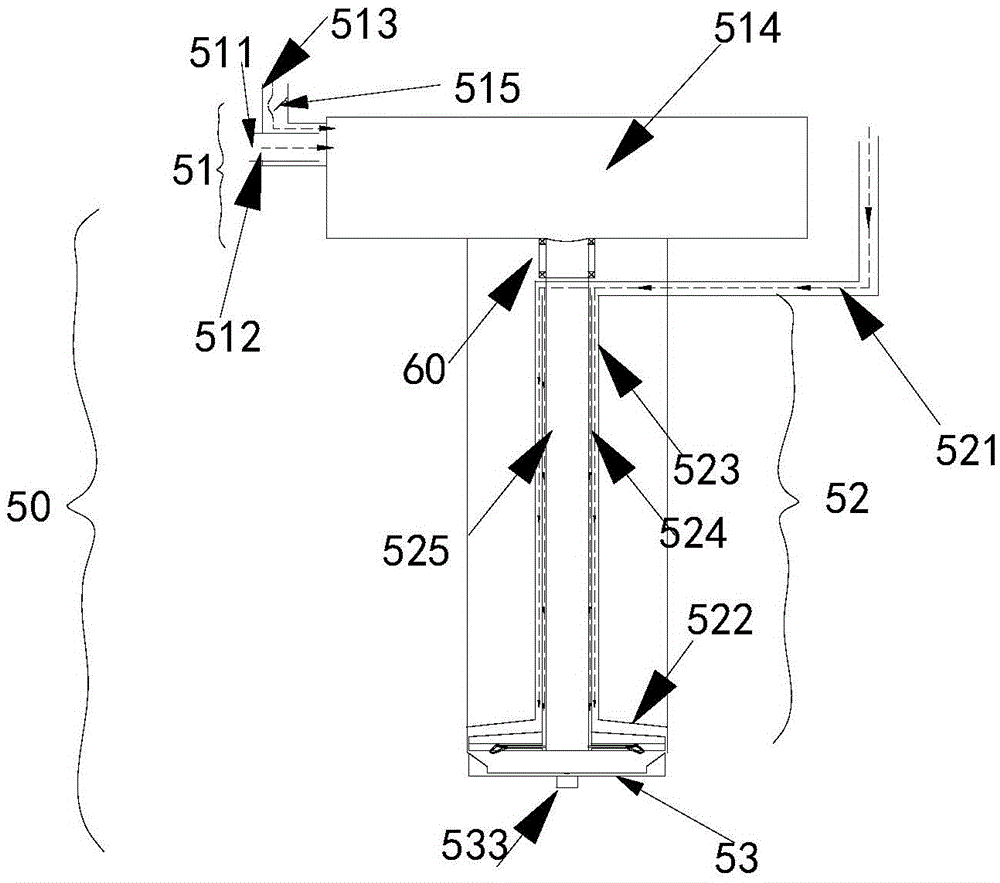

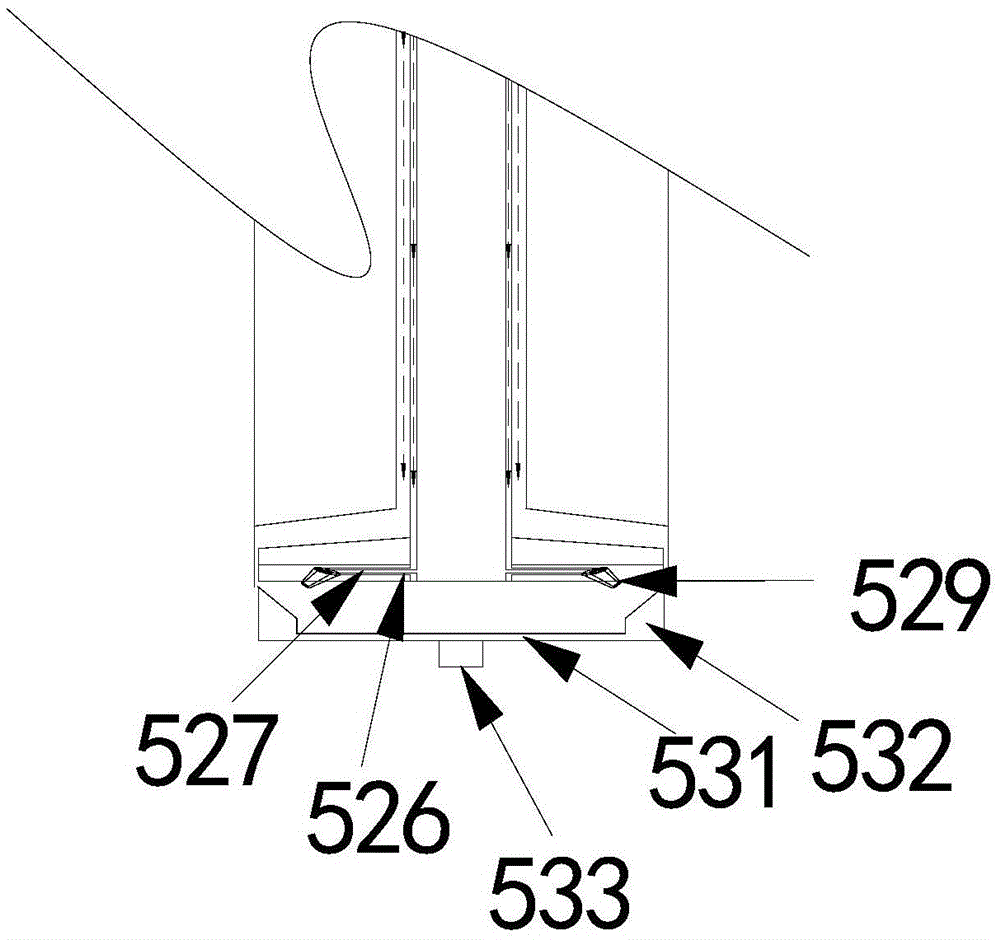

Flotation equipment integrating quantitative chemical adding, reverse stirring and central pulp conditioning

ActiveCN105964415ASimple structureReduce dosageRotary stirring mixersTransportation and packagingImpellerEngineering

The invention belongs to the technical field of pulp conditioning and floating of coal slime, and particularly relates to flotation equipment integrating quantitative chemical adding, reverse stirring and central pulp conditioning. The flotation equipment at least comprises a flotation tank, stirring mechanisms and a quantitative chemical adding system; the stirring mechanisms are horizontally arranged inside the flotation tank in a paired mode, forward spinning impellers and reverse spinning impellers are arranged on the surfaces of drums, and second discharge ports are formed in the surfaces of the drums; material feed pipes are installed inside the drums, first discharge ports are formed in the lower sides of the material feed pipes, and flow separating blocks are uniformly arranged on the inner walls of the material feed pipes; the stirring mechanisms have the cutting, spraying, spinning-spraying and stirring effects and have the effect of mixing three phases four times; gaps are reserved between the drums and the material feed pipes, when the drums rotate at high speed, negative pressure is formed in the gaps, air is sucked, and air flow is cut and dispersed by the second discharge ports; the quantitative chemical adding system is arranged on a pipeline of an ore pulp inlet, and chemicals can be quantitatively added according to the flow of the ore pulp. The flotation equipment further comprises a circulatory foam scraping mechanism for scraping all foam on the tank surface. The flotation equipment has the advantage that ore pulp pretreatment equipment is not needed.

Owner:ANHUI UNIV OF SCI & TECH

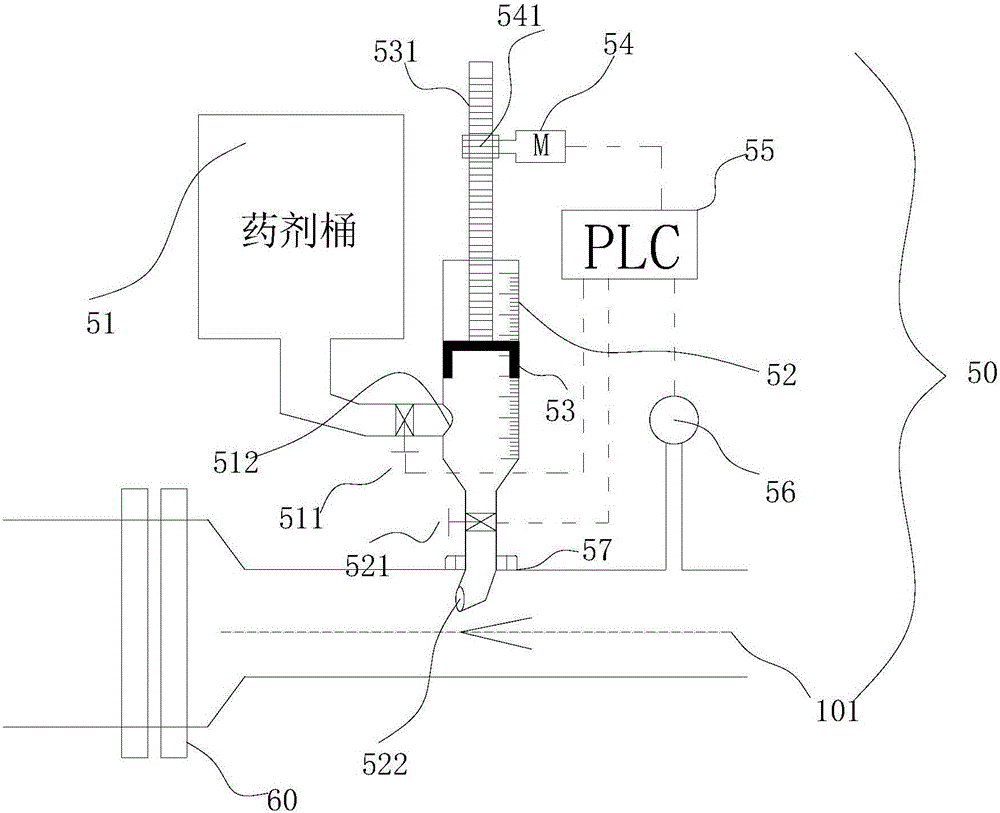

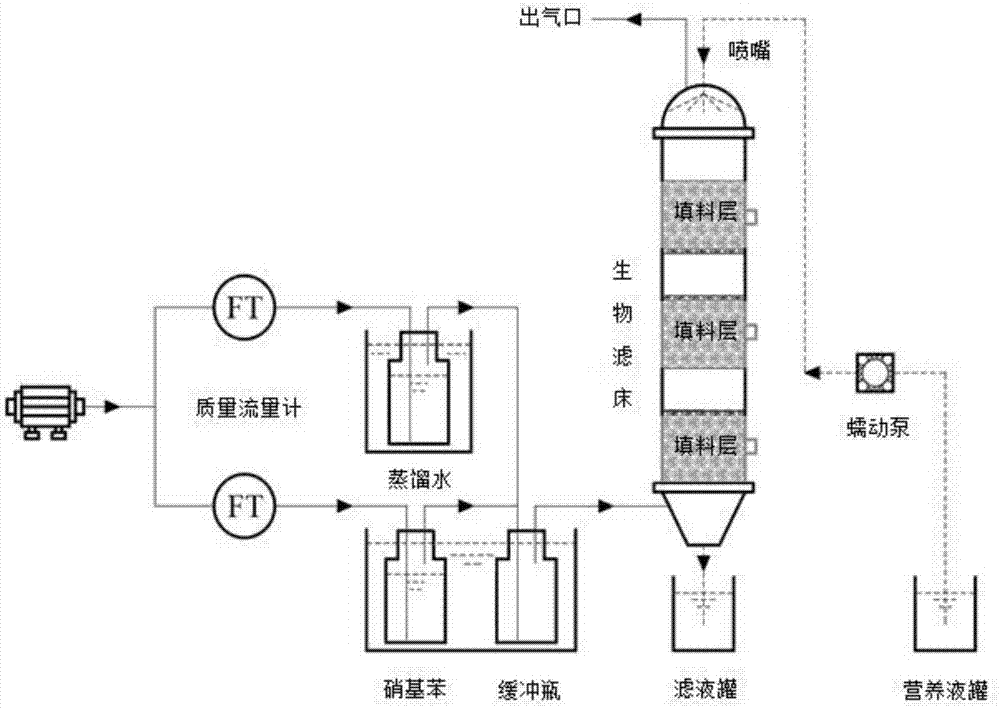

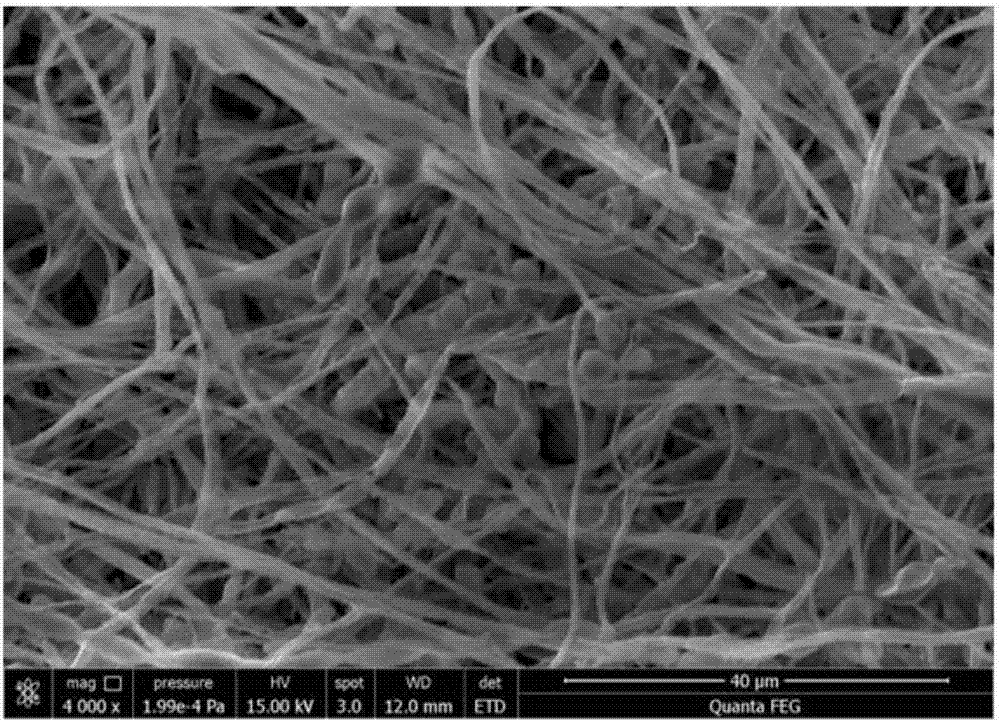

Method for treating nitrobenzene exhaust gas by coupling bacterium biological filter bed

ActiveCN106914127AIncrease biodiversityImprove mineralizationGas treatmentDispersed particle separationBacterial FilterChemistry

The invention relates to a method for treating nitrobenzene exhaust gas by a coupling bacterium biological filter bed. Polyurethane foam is used as a filler, the aerobic activated sludge of a nitrobenzene wastewater treatment plant is used as an inoculated strain, and the pH of the nutrient solution is adjusted to 5.0 so that a fungal-bacterial coupled biological filter bed is constructed. Fungi can directly contact with nitrobenzene exhaust gas through hyphae so that the problem that hydrophobic VOCs in the traditional bacterial filter bed have low mass transfer efficiency is solved. Based on the high biological diversity and mineralization capacity of bacteria, fungal metabolites can be further mineralized into carbon dioxide and water. When the nitrobenzene concentration is 300 to 500 mg*m<-3>, the removal rate can reach 95% to 97%, and the removal load can reach 52.4 to 85.5 g*m<-3>*h<-1>.

Owner:NANJING POLYTECHNIC INSITUTE

Reaction type annular jetting air sucking stirring type floatation machine with rectifying device

The invention belongs to the technical field of mineral separation and particularly relates to a reaction type annular jetting air sucking stirring type floatation machine with a rectifying device. A reaction type annular jetting air sucking mechanism is arranged between a pair of baffles, ore pulp kinetic energy can be sufficiently utilized, nozzle counter force is used for driving an impeller to rotate, jetting flow drives air around an annular jetting pipe, in addition, negative-pressure air sucking is formed under a cover, secondary air sucking is achieved, and air is sufficiently mixed with ore pulp. Meanwhile, a gradually-enlarging rectifying device is erected between the baffles, surface tension of mineralized particles can be effectively overcome, and secondary mineralization and bubble concentration are accelerated. The mineralization process can be better conducted, and therefore the floatation efficiency is improved. An automatic adjusting valve is arranged in a floatation reagent adding pipe, the feeding amount of a floatation reagent can be adjusted according to the fed material jetting speed, energy consumption is reduced, and the reagent use amount is reduced.

Owner:ANHUI UNIV OF SCI & TECH

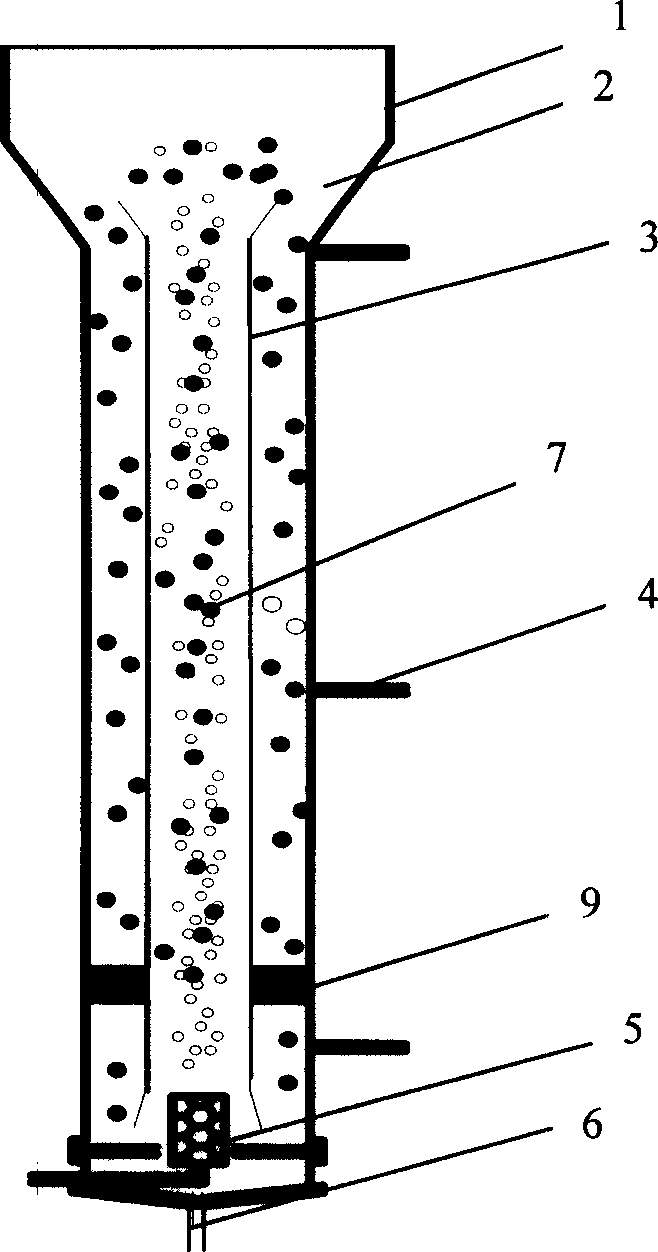

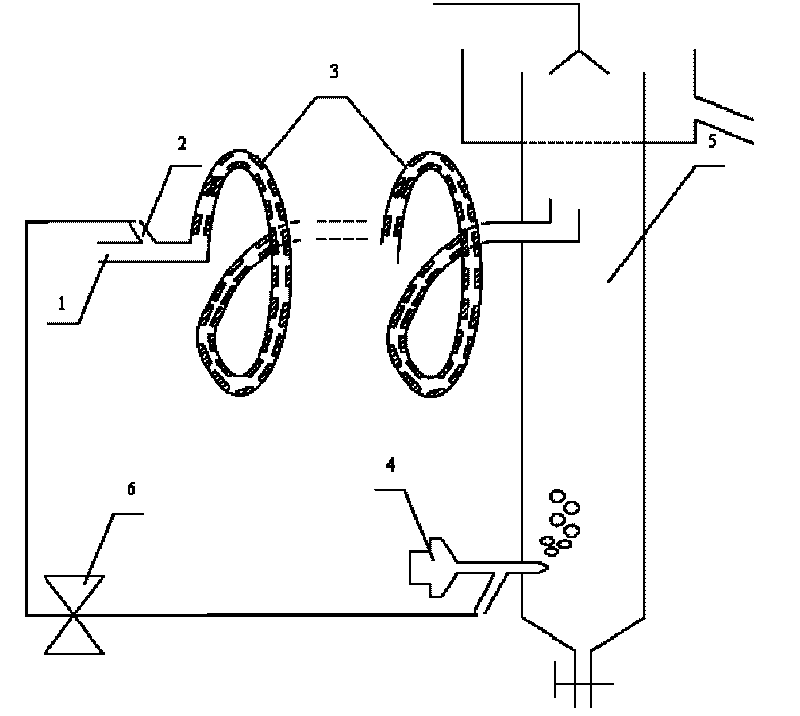

Flotation column

The invention discloses a flotation column which comprises a flotation column body (5) and a bubble generator (4), wherein one end of a spiral pipeline (3) is connected with a feed opening (1), an air inlet (2) is arranged beside the feed opening (1), the other end of the spiral pipeline (3) is connected with the upper part of the flotation column body (5), the bubble generator (4) is connected with the lower end of the flotation column body (5) by adopting an external inserting mode, and both the air inlet (2) and the bubble generator (4) are connected with an air pump (6). An ore slurry can be fully sheared and mineralized by the flotation column by utilizing the spiral pipeline, the generated bubbles are superfine and have better dispersion effect, and the flotation column has the characteristics of simple structure, stable operation, difficult blockage, good mineralization effect and the like, can be suitable for floating a plurality of metals or nonmetals, is a new generation of high-efficiency flotation column and can be applied to multiple fields of metal mines, coal, environmental protection and the like.

Owner:CENT SOUTH UNIV

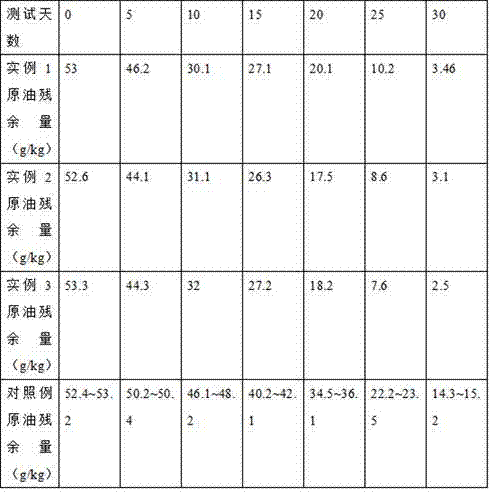

Petroleum-polluted soil restoration method

InactiveCN107457256AImprove biological activityImprove bioavailabilityContaminated soil reclamationRestoration methodPlant soil

The invention discloses a petroleum-polluted soil restoration method, belonging to the field of polluted soil treatment. According to the method, cultivated animals are focused and are assisted with feeds, nutrient substances are supplied to petroleum-polluted soil, a surfactant is fed into the petroleum-polluted soil for chemical cleaning so as to transfer pollutants from the surfaces of soil particles into a water phase, so that the contact area between the pollutants and microorganisms is enlarged, and the bio-availability of the pollutants is improved. A plant-planting soil system is capable of accelerating the removal the pollutants, each excreta or enzyme released by the plants is capable of promoting the biodegradation of organic pollutants and strengthening the mineralization effect of rhizosphere microorganisms. Besides, by effectively improving soil conditions of vegetation and improving the gas permeability of soil, the degradation efficiency of the organic pollutants can be improved. The method can be used solving the problems of low degradation efficiency and unthorough degradation effect as a single control condition is adopted in existing microorganism treatment methods and the functions of the microorganisms cannot be adequately exerted.

Owner:常州蓝旗亚纺织品有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com