Reaction type annular jetting air sucking stirring type floatation machine with rectifying device

A rectifier and counterattack technology, applied in flotation, solid separation and other directions, can solve the problems of insufficient pulp flotation reagents, inability to form a good flow field, low rotation speed, etc., to achieve rich bubbles, high flotation efficiency, The effect of reducing energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

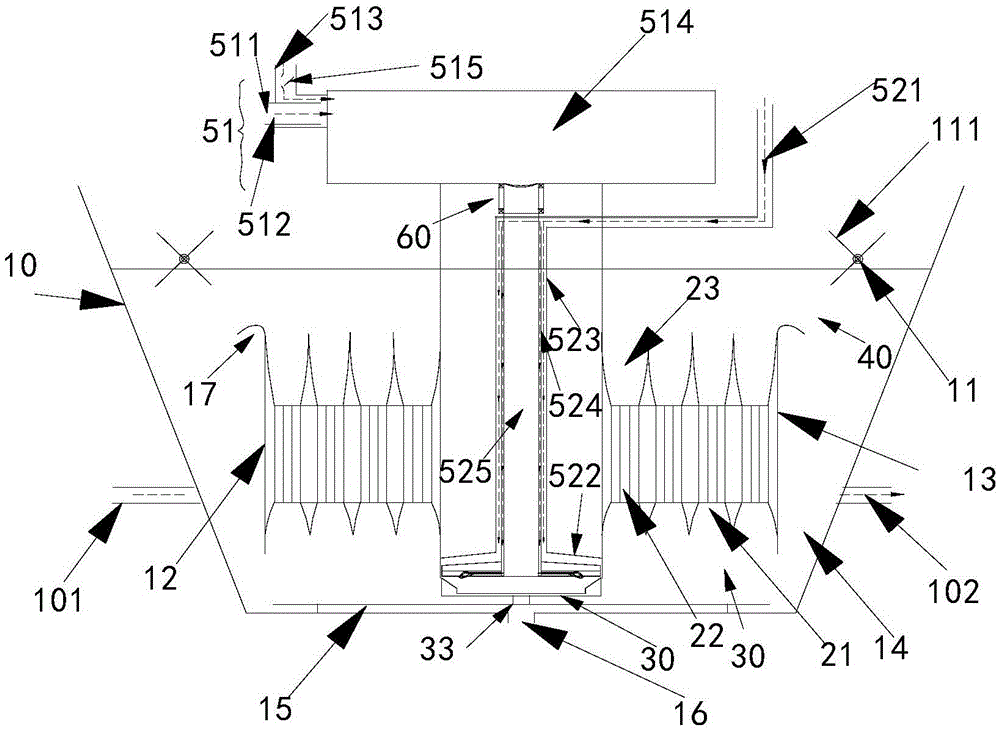

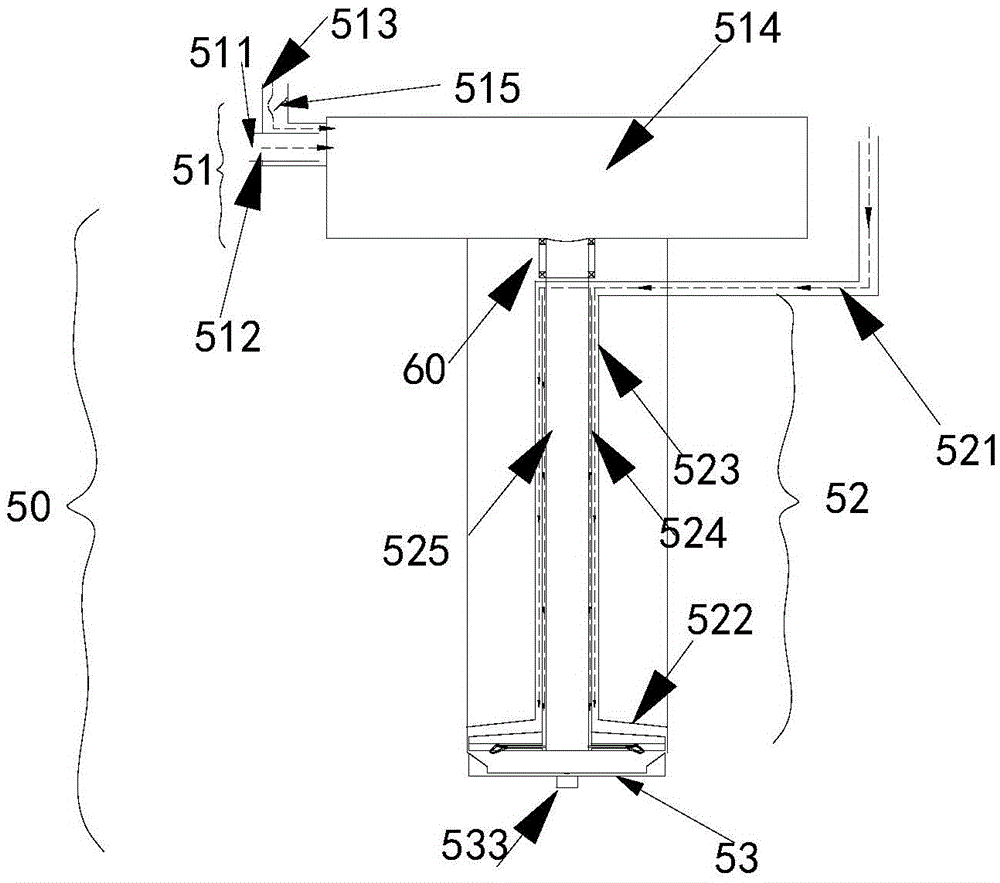

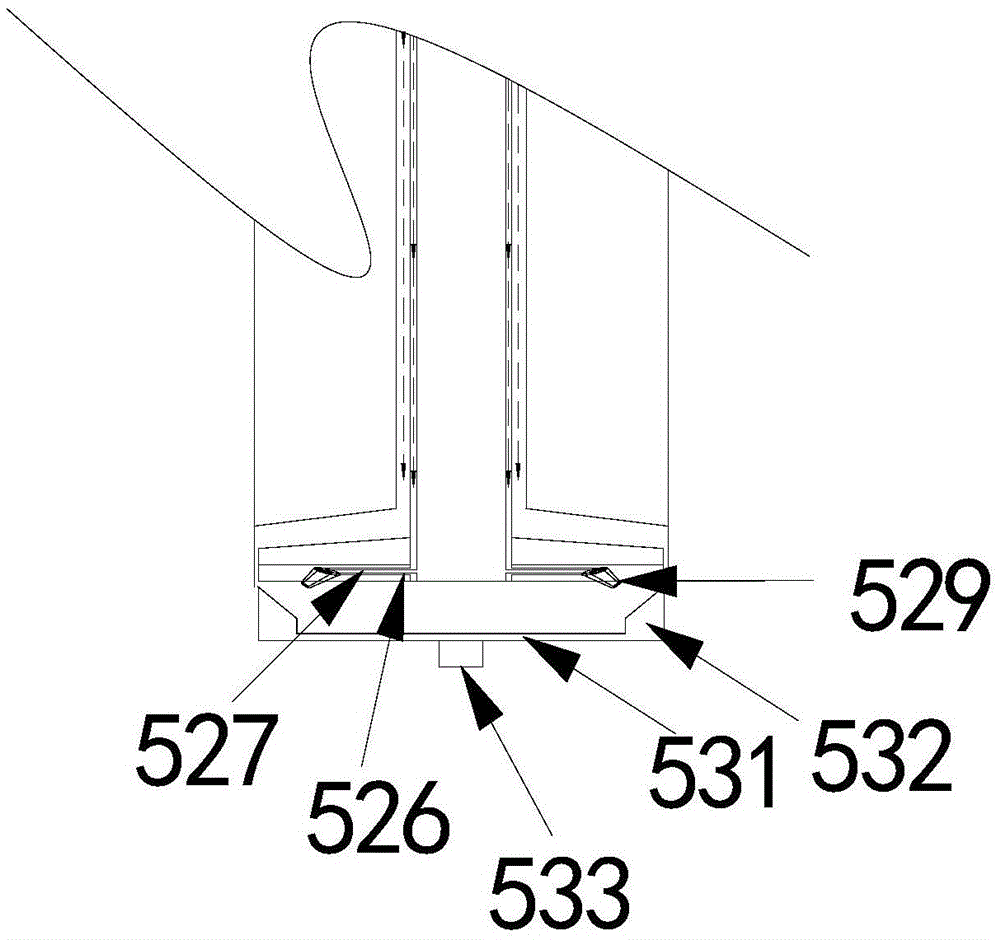

[0032] figure 1 A kind of counterattack type annular space jet-suction agitation type flotation machine with rectifying device shown in it, comprises flotation cell (10), is respectively provided with ore pulp inlet (101) and The pulp outlet (102), the upper side of the flotation cell (10) is provided with a rotary support (11), the rotary support (11) is provided with a scraper (111), the middle of the flotation cell (10) Separator one (12) and separator two (13) are provided with, and the two ends of described separator one (12) and separator two (13) are respectively connected with the two ends inner walls of flotation cell (10) and the tops are Below the height of the rotating support (11), the area between the inner wall of the flotation cell (10) and the partition one (12) and the partition two (12) is the concentrate enrichment zone (14), and the partition A gradual expansion rectification device (20) is arranged between the plate one (12) and the second dividing plate...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com