Application of femtosecond laser in titanium or titanium alloy implantation material surface treatment

A femtosecond laser and surface treatment technology, used in bone implants, laser welding equipment, metal processing equipment, etc., can solve the problems of particle deposition in liquid, affecting surface patterning processing, reducing laser intensity, etc., to promote wound healing. Healing, small ablation threshold, small effect of thermal influence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0038] In the first step, the 10×10×3mm 3 The massive pure titanium material is polished step by step with 400-800 water sandpaper, ultrasonically cleaned with deionized water, and then placed in a clean open container for use;

[0039] In the second step, in the air, place the femtosecond laser pulse directly above the bulk pure titanium material processed in the first step, and use a 10x objective lens to focus vertically on its surface to form a focus with a laser spot radius of 5 μm;

[0040] In the third step, add hydroxyapatite suspension in the container of the first step, so that the liquid level is 2mm higher than the surface of the block titanium or titanium alloy material, and the composition of the hydroxyapatite suspension used is:

[0041] Ingredient Concentration

[0042] Nano-hydroxyapatite 20g / L

[0043] Polyvinylpyrrolidone 30g / L

[0044] Tris hydroxymethyl aminomethane 10g / L

[0045] Calcium Chloride Dihydrate 5g / L

[0046] solvent is water

[0047] Ad...

Embodiment 2

[0052] In the first step, the 10×10×3mm 3 The bulk titanium alloy material is polished step by step with 400-800 water sandpaper, ultrasonically cleaned with deionized water, and then placed in a clean open container for use;

[0053] In the second step, in the air, place the femtosecond laser pulse directly above the bulk titanium alloy material processed in the first step, and use a 10x objective lens to focus vertically on its surface to form a focus with a laser spot radius of 5 μm;

[0054] The third step is to add hydroxyapatite suspension in the container of the first step so that the liquid level is 3mm higher than the surface of the block titanium alloy material. The composition of the hydroxyapatite suspension used is:

[0055] Ingredient Concentration

[0056] Nano-hydroxyapatite 8g / L

[0057] Polyvinylpyrrolidone 10g / L

[0058] Trishydroxymethylaminomethane 5g / L

[0059] Calcium Chloride Dihydrate 2g / L

[0060] solvent is water

[0061]Using 10% dilute nitric...

Embodiment 3

[0066] The other steps and conditions are the same as in Example 1, except that the laser single pulse energy is set to 150 microjoules, the laser scanning speed is 1.0 mm / s, the laser processing line spacing is 50 microns, and the hydroxyapatite suspension used is The liquid formula is:

[0067] Ingredient Concentration

[0068] Nano Hydroxyapatite 15g / L

[0069] Polyvinylpyrrolidone 20g / L

[0070] Tris 8g / L

[0071] Calcium Chloride Dihydrate 3g / L

[0072] The solvent is water

[0073] Adjust the pH value of the hydroxyapatite suspension to 5 with 10% dilute nitric acid or dilute hydrochloric acid.

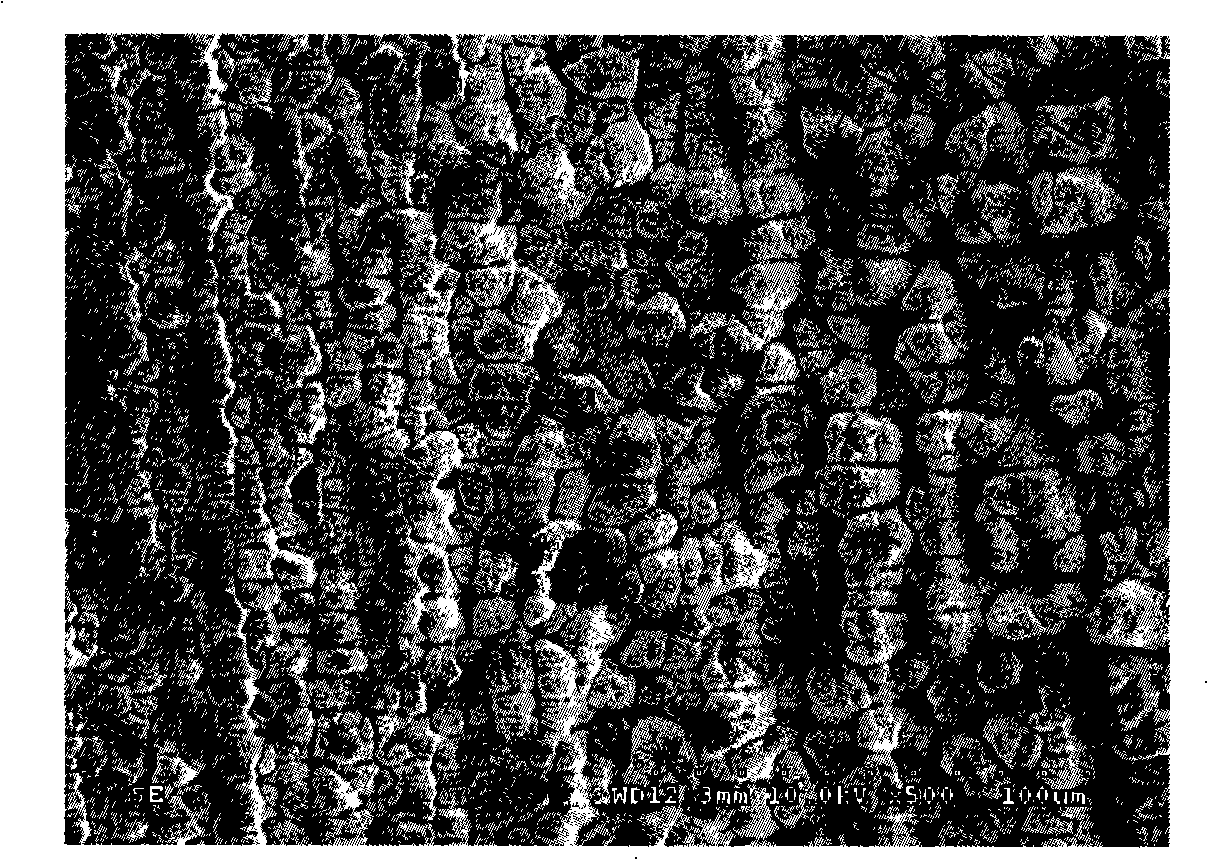

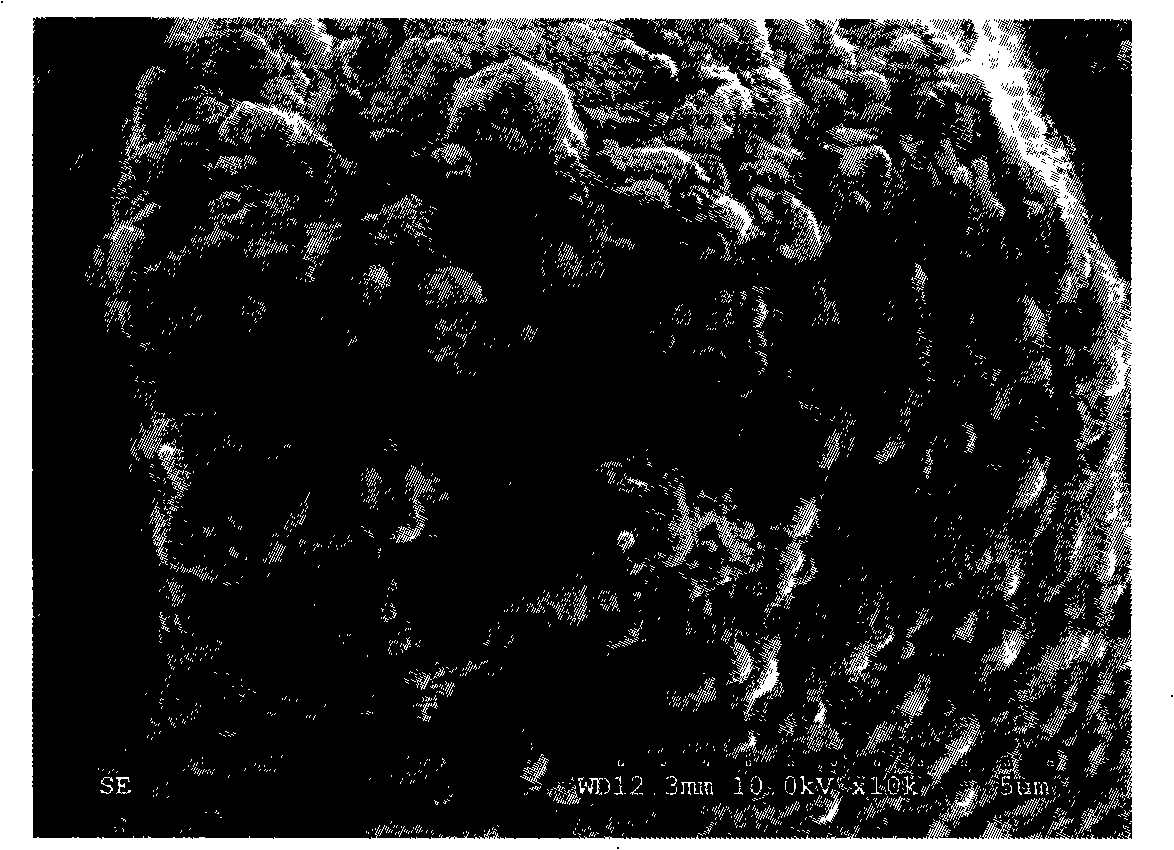

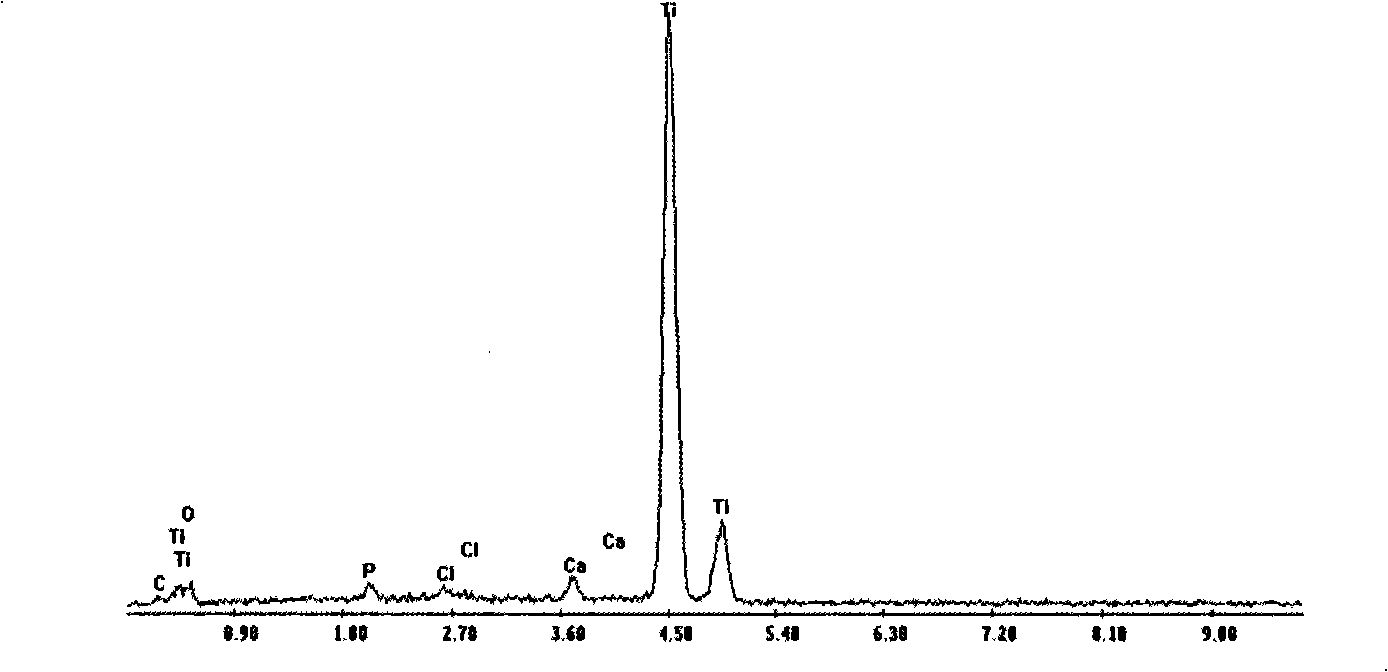

[0074] After irradiation treatment, the bulk pure titanium material forms a surface composed of regularly arranged peak-like protrusions of 5-10 μm in size and submicron micropores, and these peak-like protrusions are covered with a large number of submicron-sized small particles. At the same time, calcium and phosphate salts are loaded on the surface of the bulk pure tita...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com