Femtosecond laser etching method to enhance the performance of amorphous silicon thin film solar cells

A technology of solar cells and amorphous silicon thin films, applied in photovoltaic power generation, circuits, electrical components, etc., can solve the problems of inadaptability to amorphous silicon thin film solar cells, etc., achieve shortened interaction time, simple operation process, smooth surface and smooth effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

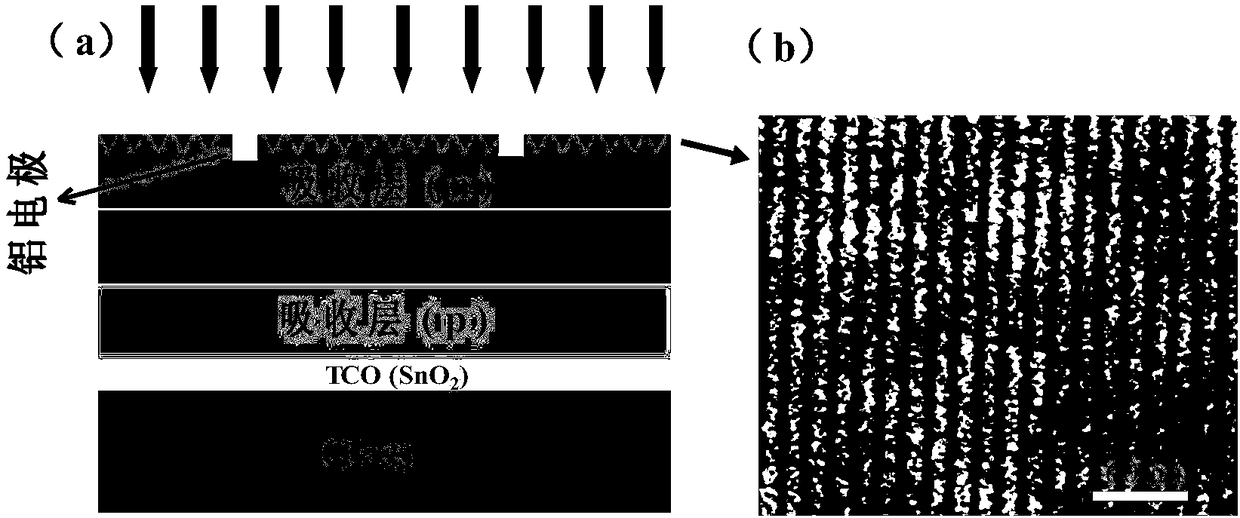

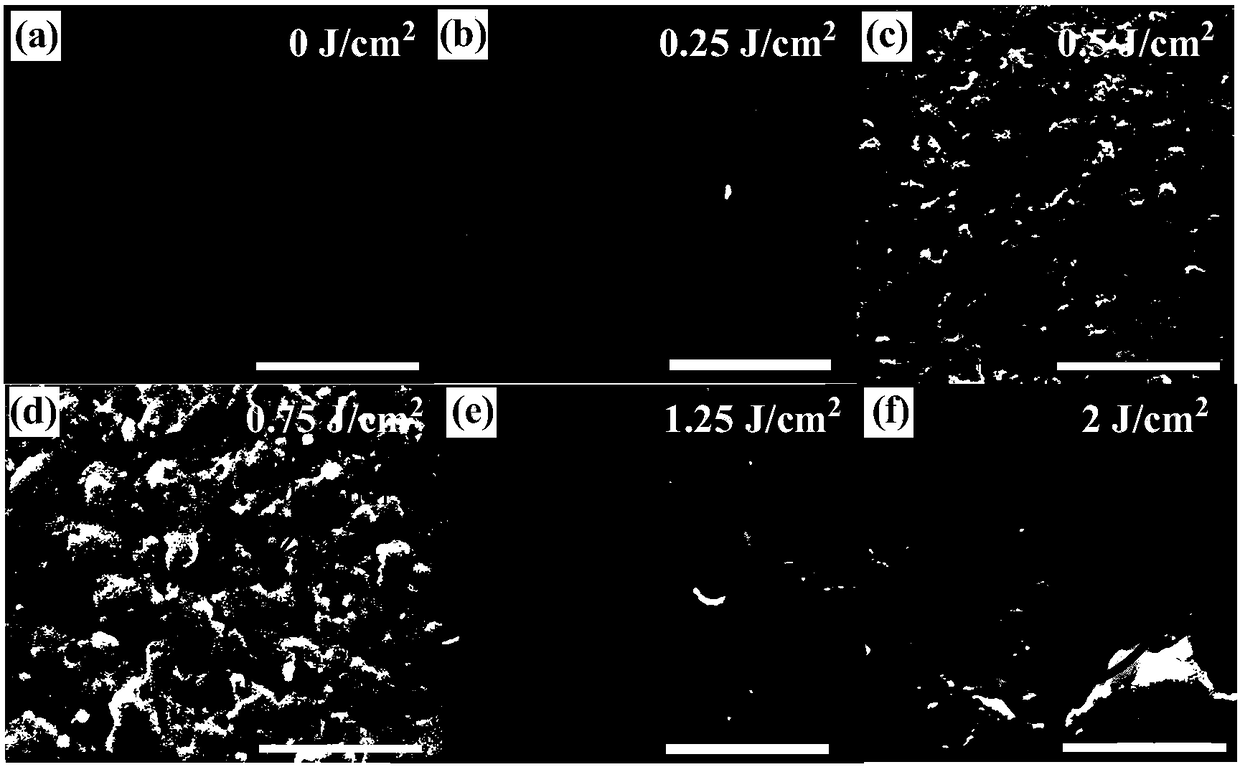

[0042] Such as figure 2 As shown, the femtosecond laser pulse texture etching period T is a certain value, and the femtosecond laser pulse energy W is changed to prepare the porous microstructure anti-reflection layer on the surface of the amorphous silicon thin film solar cell as follows:

[0043] 1.1. Adhere the amorphous silicon thin-film solar cell to the glass slide, and then fix it on the femtosecond laser micro-nano processing platform. 2 ;

[0044] 1.2. The femtosecond laser pulse is focused on the surface of the n-type amorphous silicon film of the thin-film solar cell through a microscope system with a 10× objective lens (numerical aperture of 0.25), forming a spot with a beam waist radius of about 0.5 μm;

[0045] 1.3. Controlled by the computer terminal, the focused femtosecond laser pulse will move at a constant speed along the vertical direction of the platform at a rate of 1mm / s, set the repetition frequency of the femtosecond laser pulse to 1kHz, and set the ...

Embodiment 1

[0074] 1.1. Adhere the amorphous silicon thin-film solar cell prepared in Comparative Example 1 to a glass slide, and then fix it on the femtosecond laser micro-nano processing platform. The stepping accuracy of the platform motor is 0.1 μm, and the solar cell size is 1.5×1.5cm 2 ;

[0075] 1.2. The femtosecond laser pulse is focused on the surface of the n-type amorphous silicon film of the thin-film solar cell through a microscope system with a 10× objective lens (numerical aperture of 0.25), forming a spot with a beam waist radius of about 0.5 μm;

[0076] 1.3. Controlled by the computer terminal, the focused femtosecond laser pulse will move at a constant speed along the vertical direction of the platform at a rate of 1mm / s. Pulse etching period T is 15μm, laser pulse energy (W) 0.5J / cm 2 According to the micromachining parameters, the linearly polarized femtosecond laser pulse will texture the surface of the n-type amorphous silicon film of the amorphous silicon thin fil...

Embodiment 2

[0078] 1.1. Adhere the amorphous silicon thin-film solar cell prepared in Comparative Example 1 to a glass slide, and then fix it on the femtosecond laser micro-nano processing platform. The stepping accuracy of the platform motor is 0.1 μm, and the solar cell size is 1.5×1.5cm 2 ;

[0079] 1.2. The femtosecond laser pulse is focused on the surface of the n-type amorphous silicon film of the thin-film solar cell through a microscope system with a 10× objective lens (numerical aperture of 0.25), forming a spot with a beam waist radius of about 0.5 μm;

[0080] 1.3. Controlled by the computer terminal, the focused femtosecond laser pulse will move at a constant speed along the vertical direction of the platform at a rate of 1mm / s. Pulse etching period T is 15μm, laser pulse energy (W) 0.75J / cm 2 According to the micromachining parameters, the linearly polarized femtosecond laser pulse will texture the surface of the n-type amorphous silicon film of the amorphous silicon thin fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com