Patents

Literature

139 results about "Porous microstructure" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

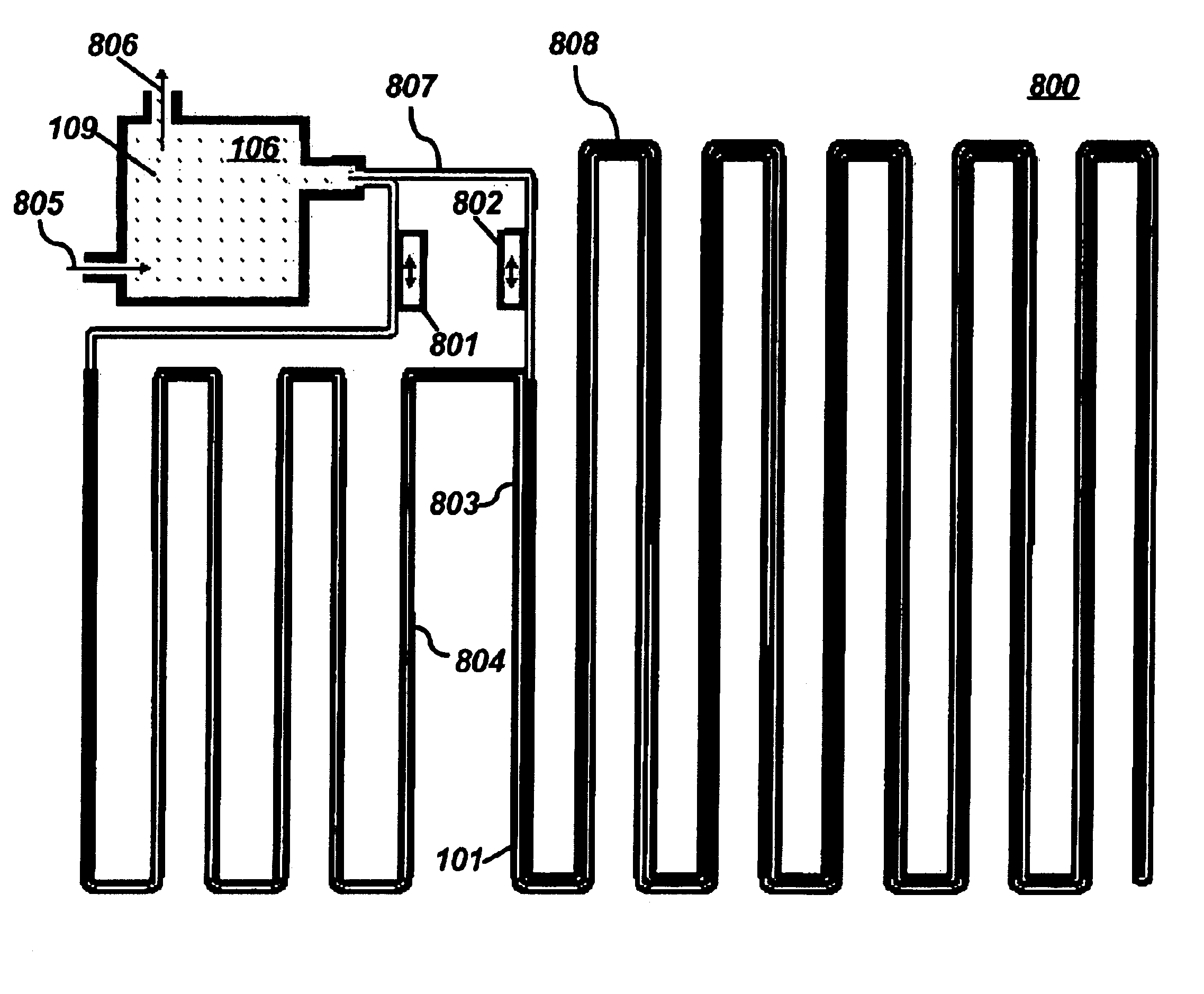

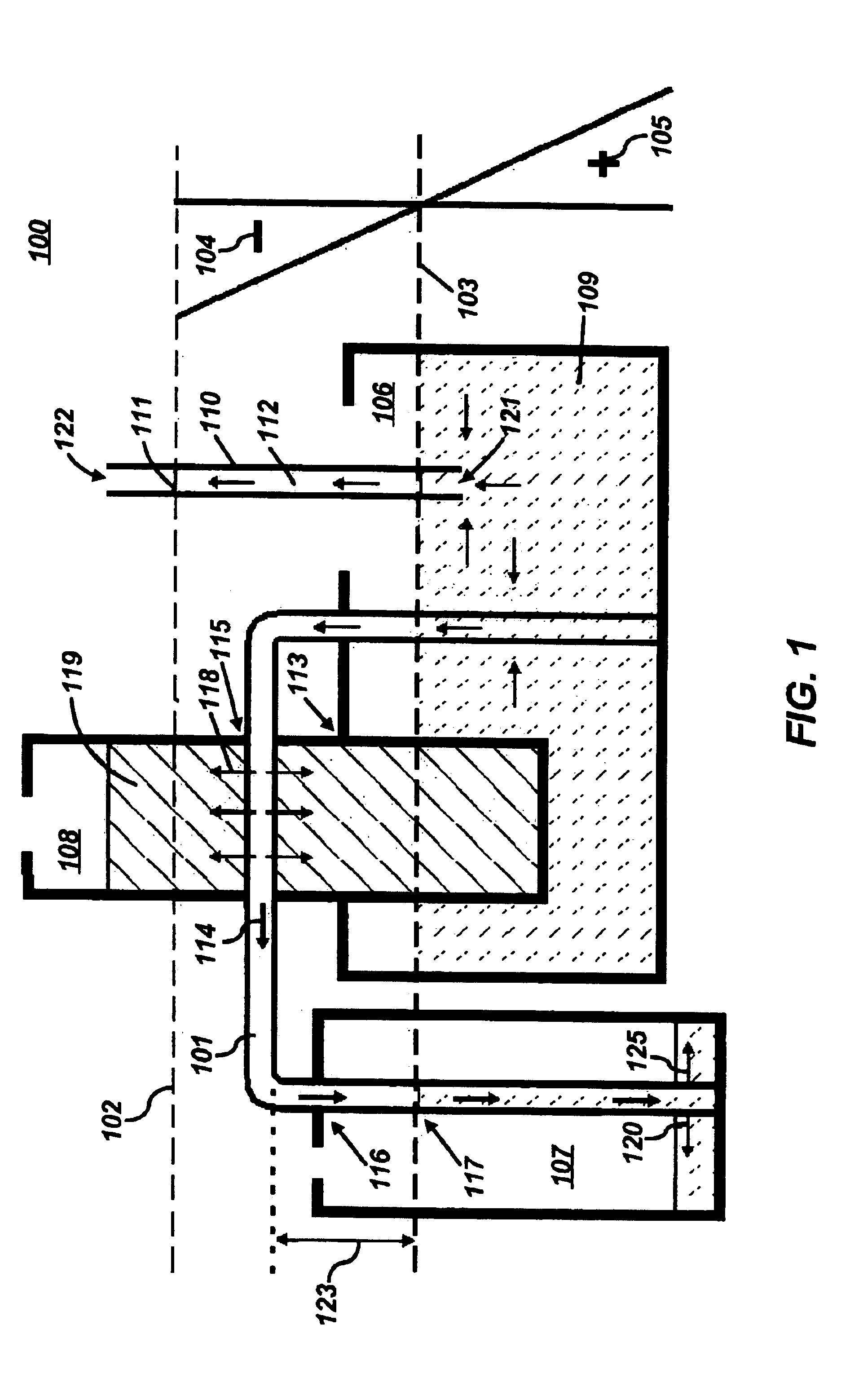

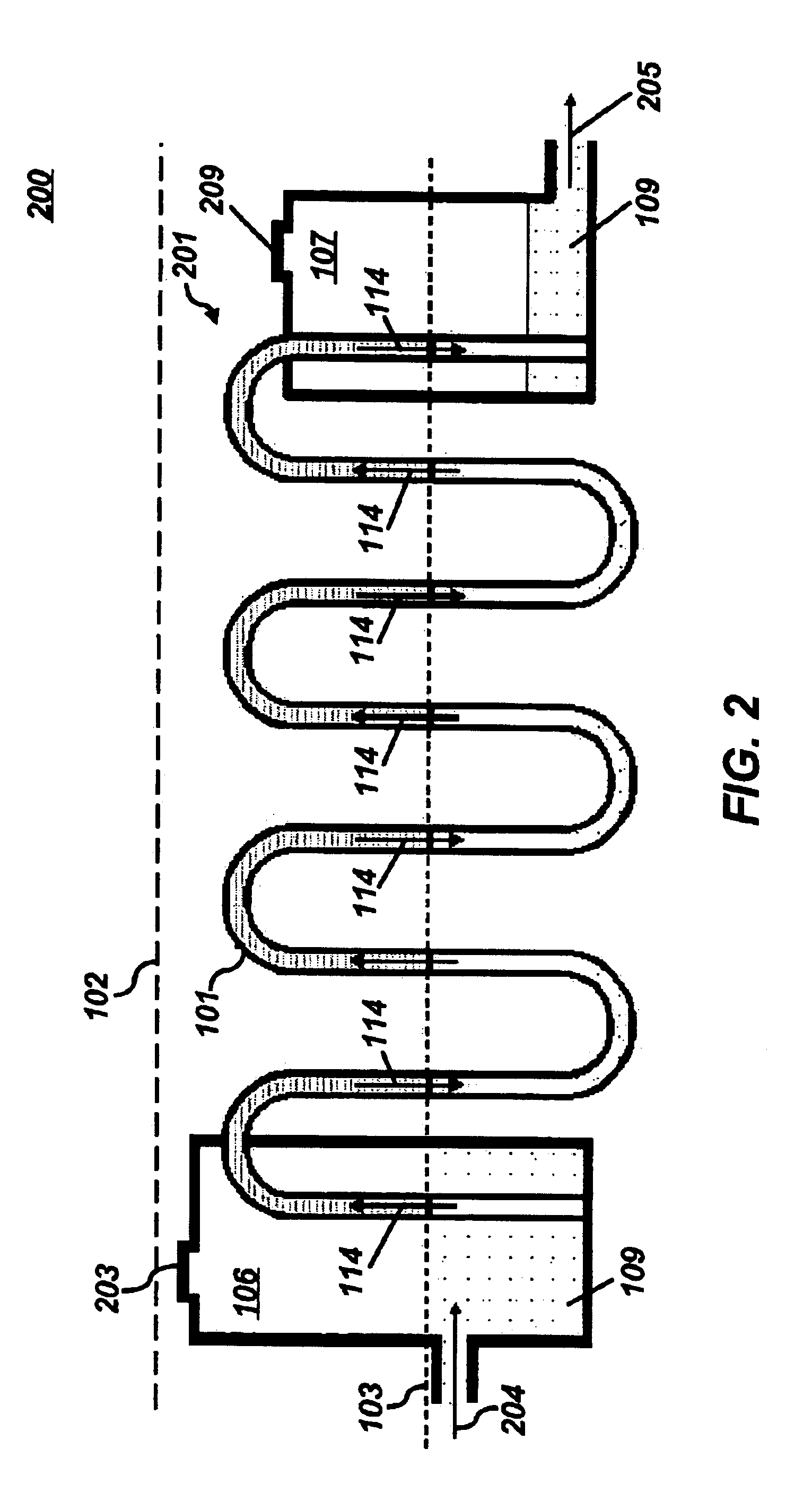

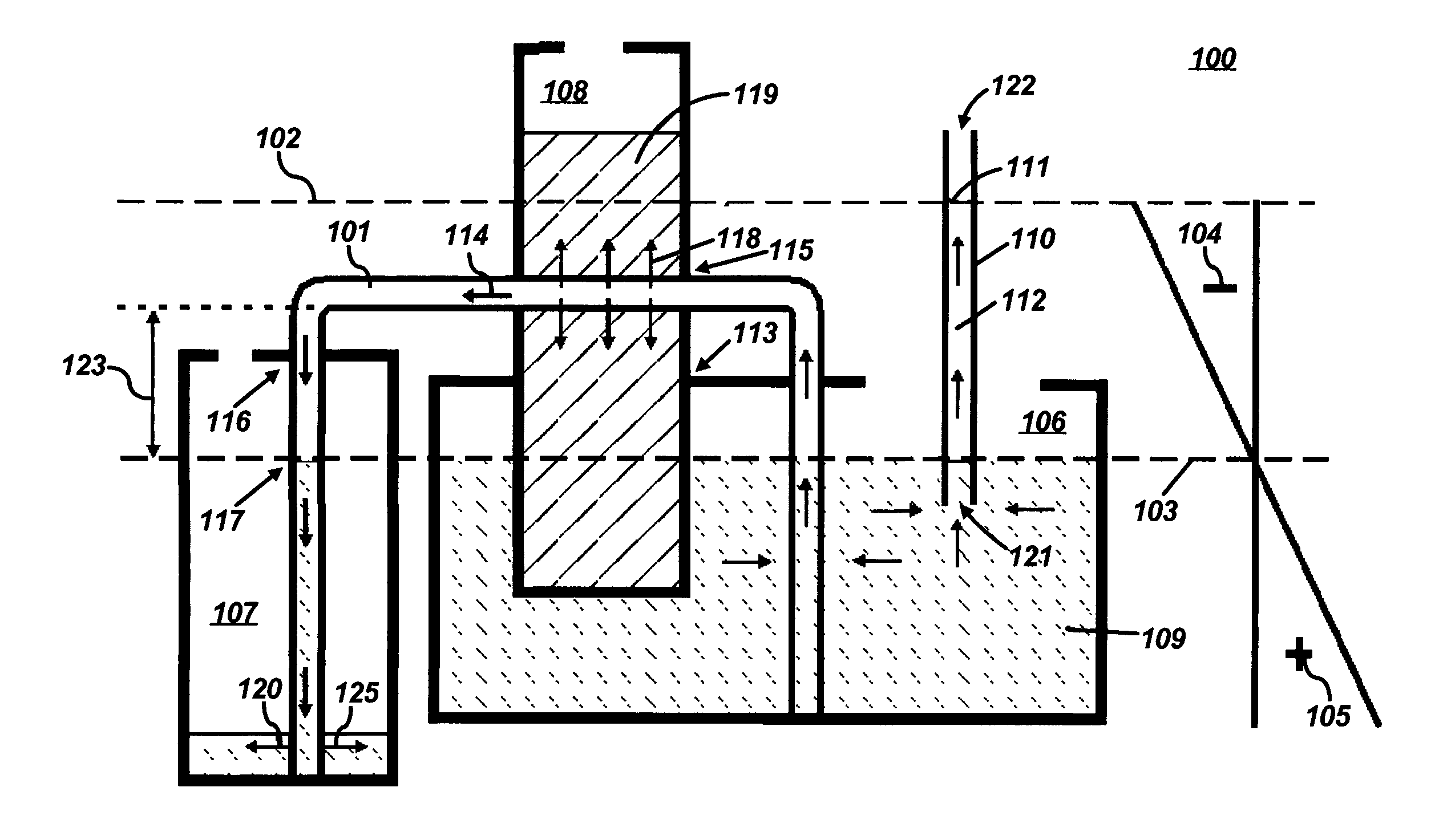

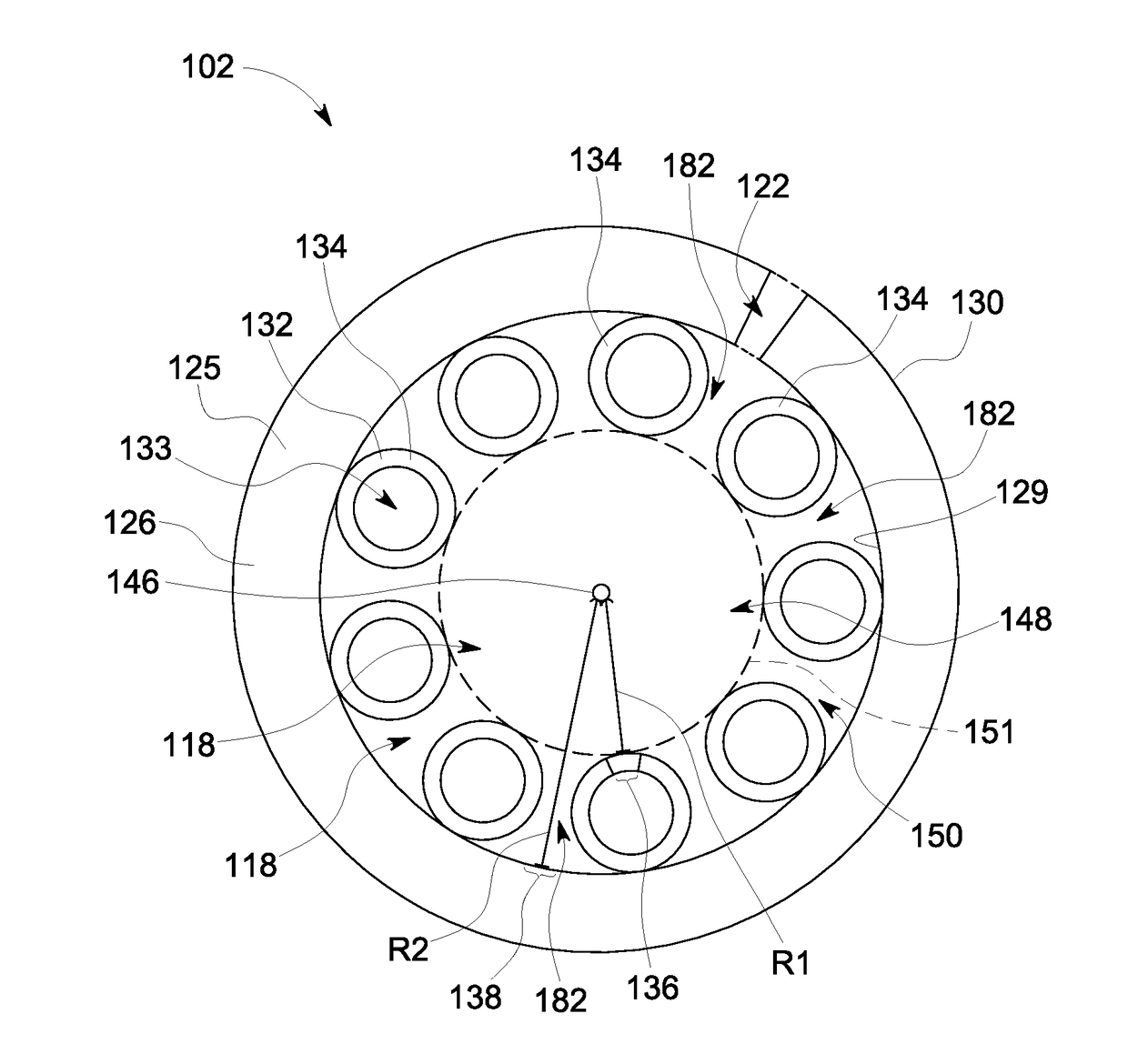

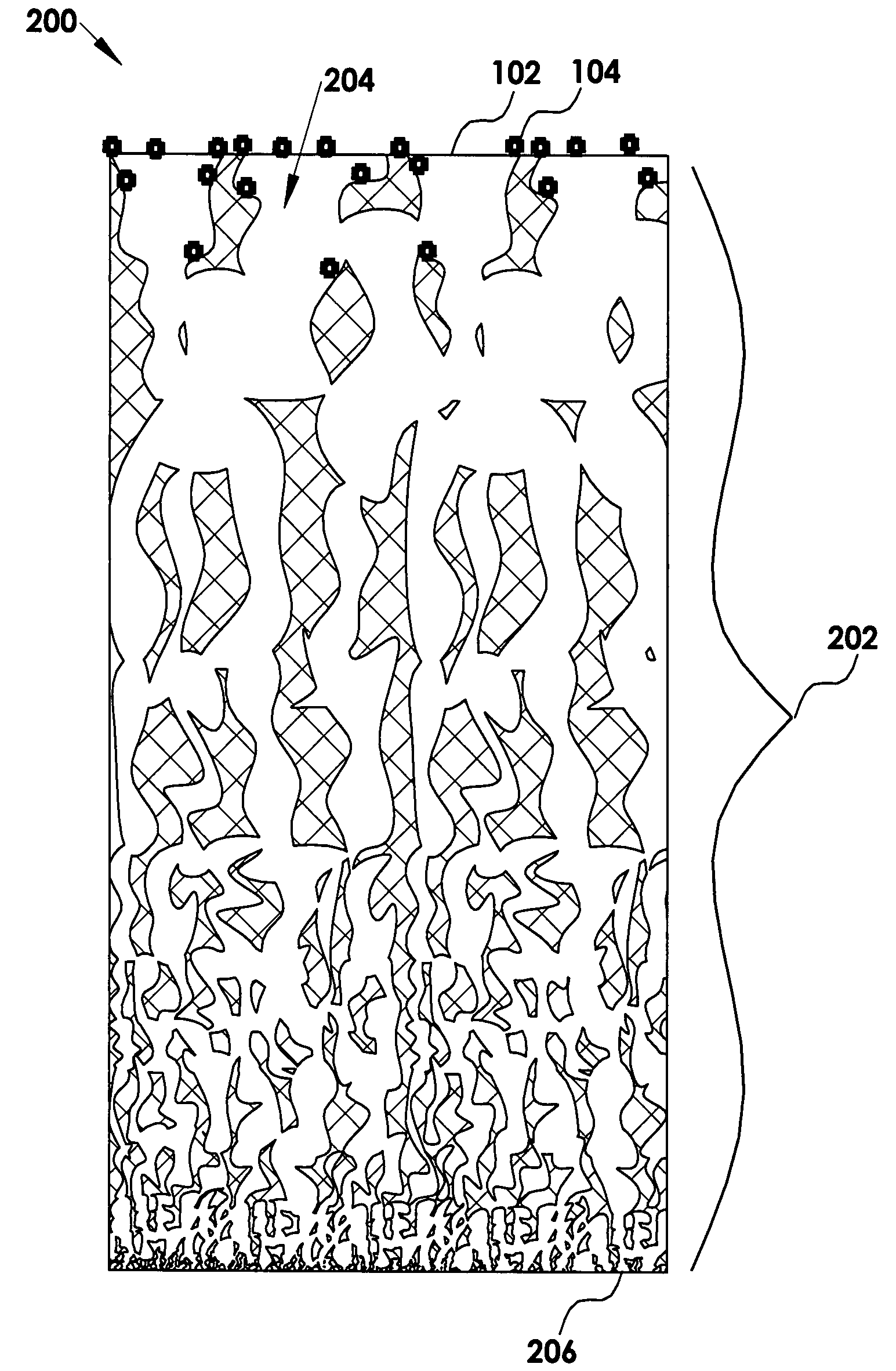

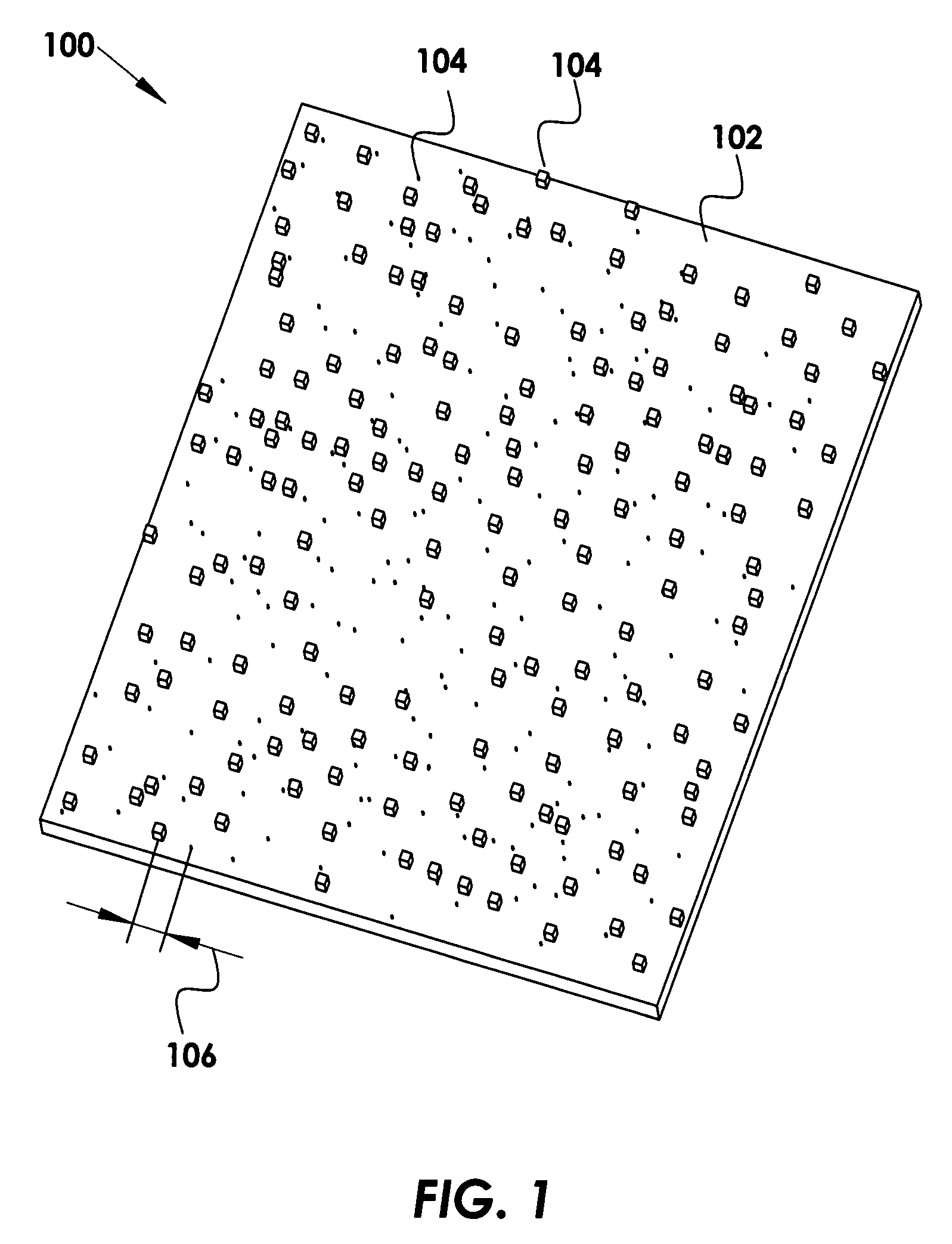

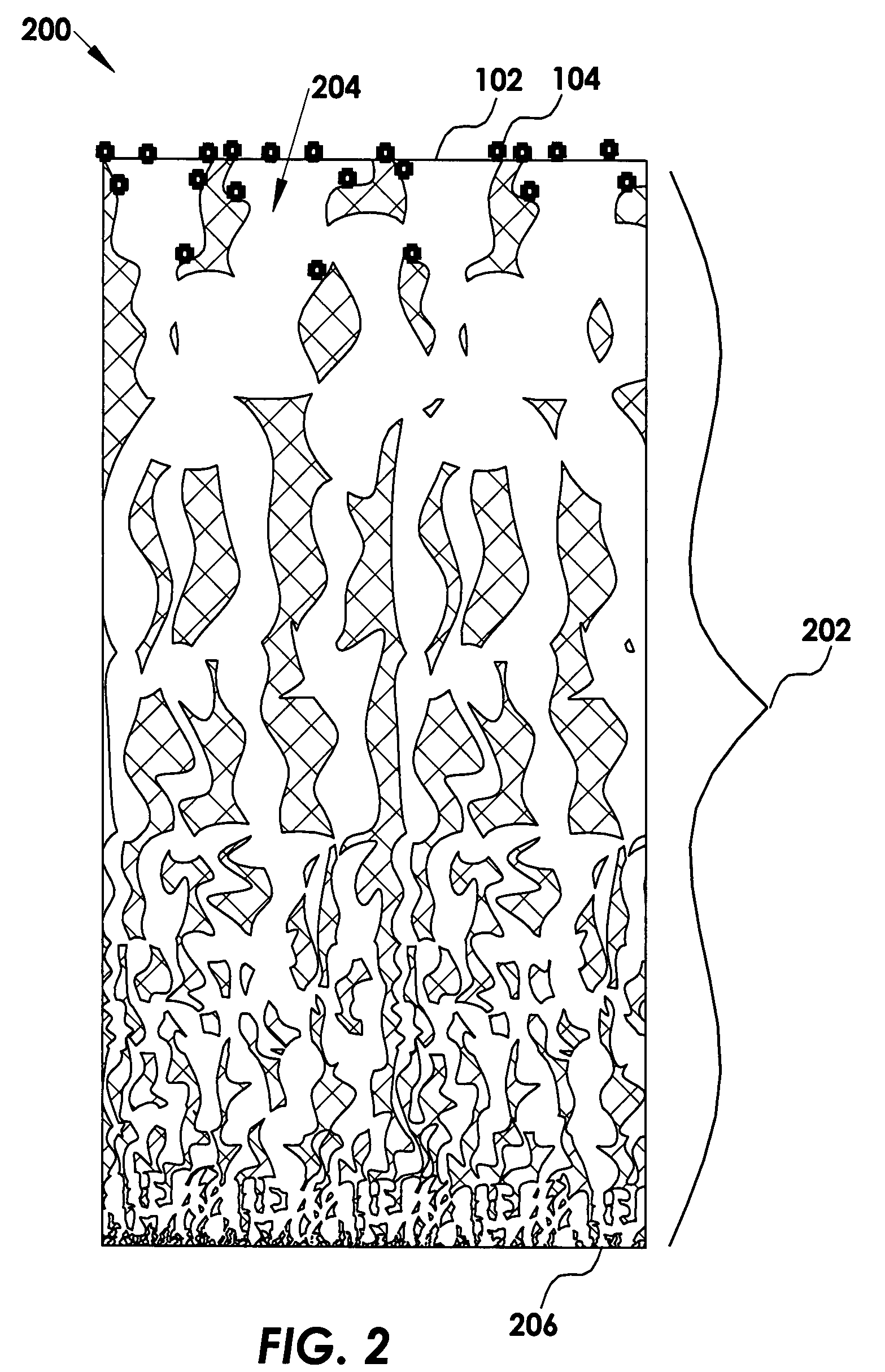

Irrigation and drainage based on hydrodynamic unsaturated fluid flow

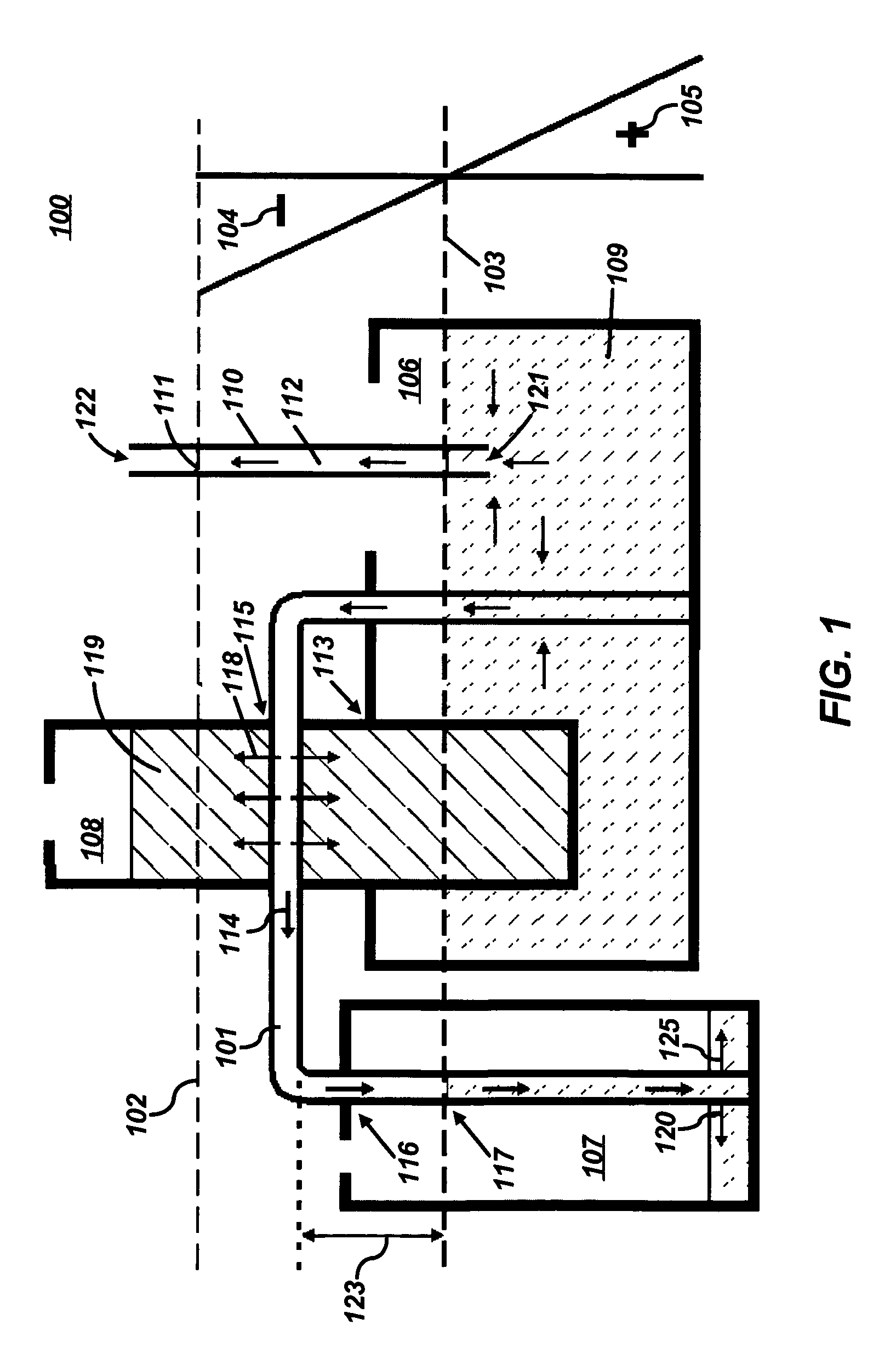

InactiveUS6918404B2Improve the level ofHigh porosityPipeline systemsMachines/enginesEnvironmental engineeringPorous microstructure

Irrigation and drainage systems are disclosed, including a saturated zone and at least one pipe in communication with the saturated zone. The pipe(s) can be configured to comprise a tubarc porous microstructure for conducting water from the saturated zone to an unsaturated zone in order to drain the water from the saturated zone. The water can be delivered from the saturated zone to the unsaturated zone through the tubarc porous microstructure, thereby permitting the water to be harnessed for irrigation or drainage through the hydrodynamic movement of the water from one zone of saturation or unsaturation to another.

Owner:TUBARC TECH

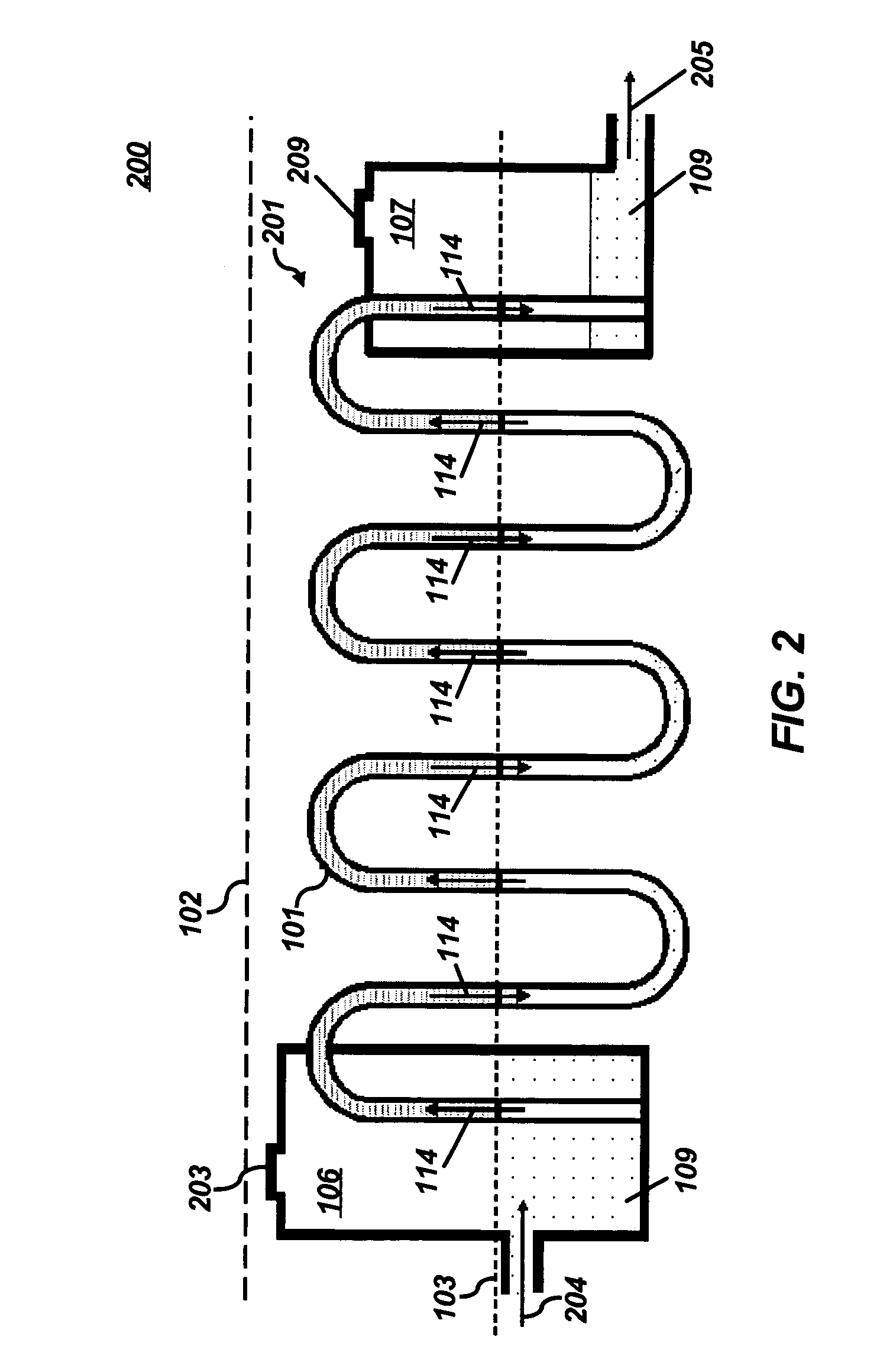

Ink refill and recharging system

InactiveUS7066586B2Improve reliabilityPrecise deliveryPipeline systemsPrintingEngineeringPrint-through

Ink refill systems are disclosed. In general, an ink source comprising a saturated zone and a tubarc porous microstructure for conducting ink from the saturated zone to an unsaturated zone are provided. The ink can be delivered from the saturated zone to the unsaturated zone through the tubarc porous microstructure, thereby permitting the ink to be harnessed for ink writing and / or printing through the unsaturated hydrodynamic flow of the ink from one zone of saturation or unsaturation to another.

Owner:TUBARC TECH

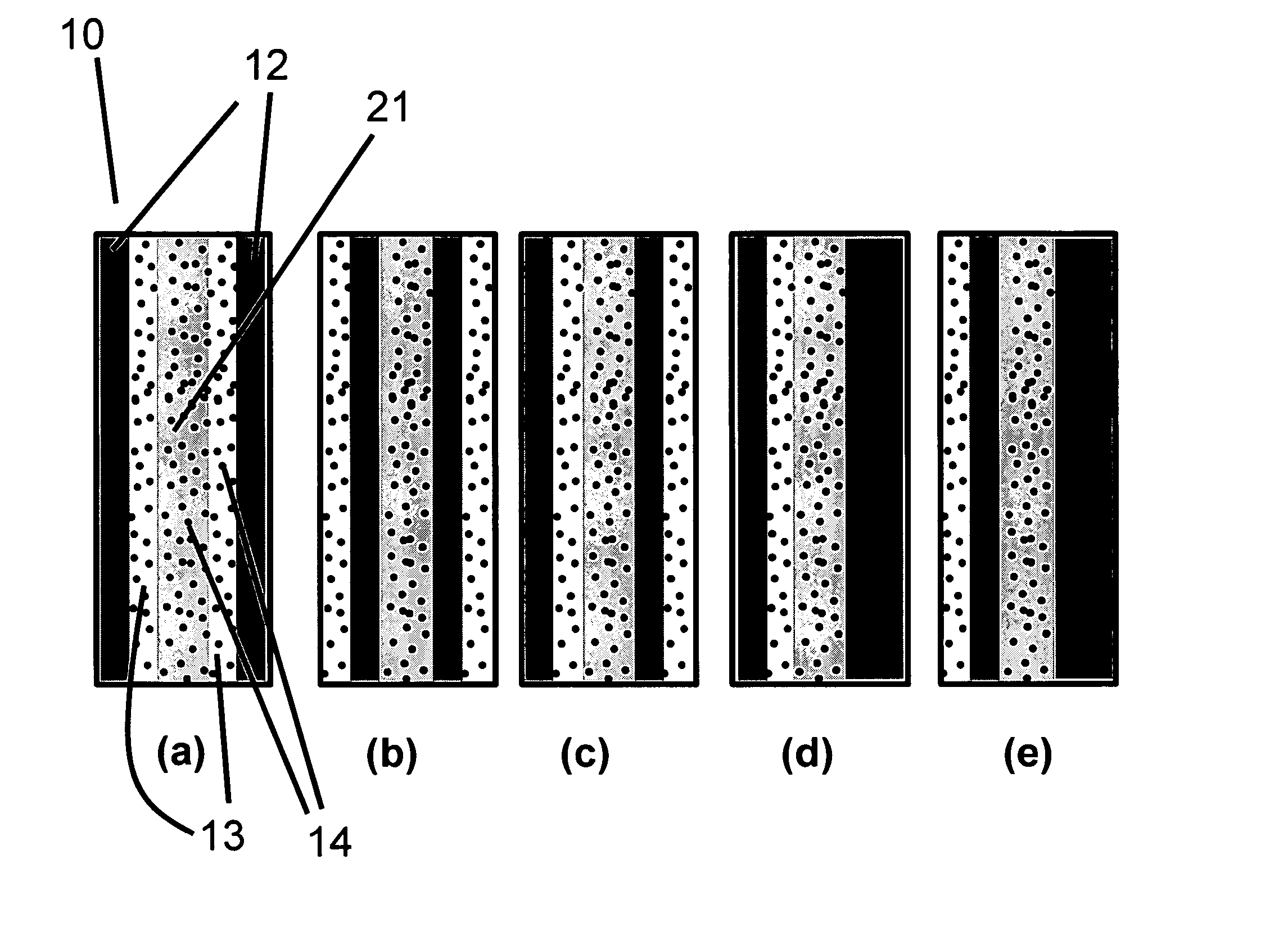

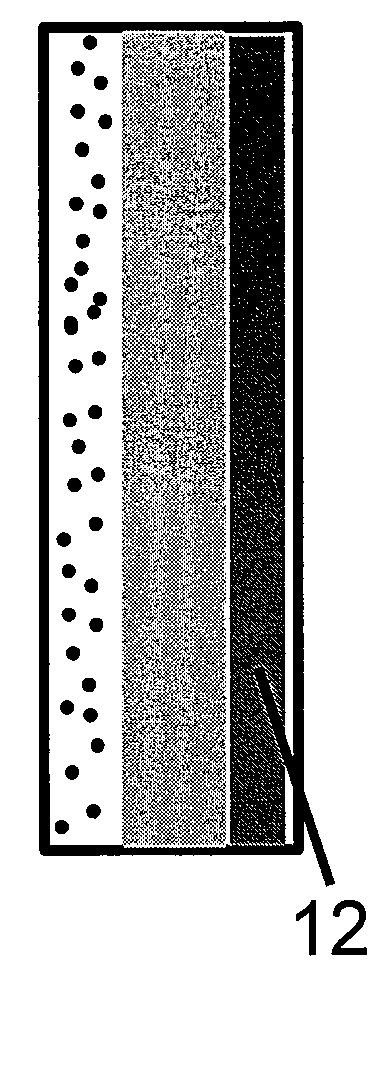

Solid polymer electrolyte and process for making same

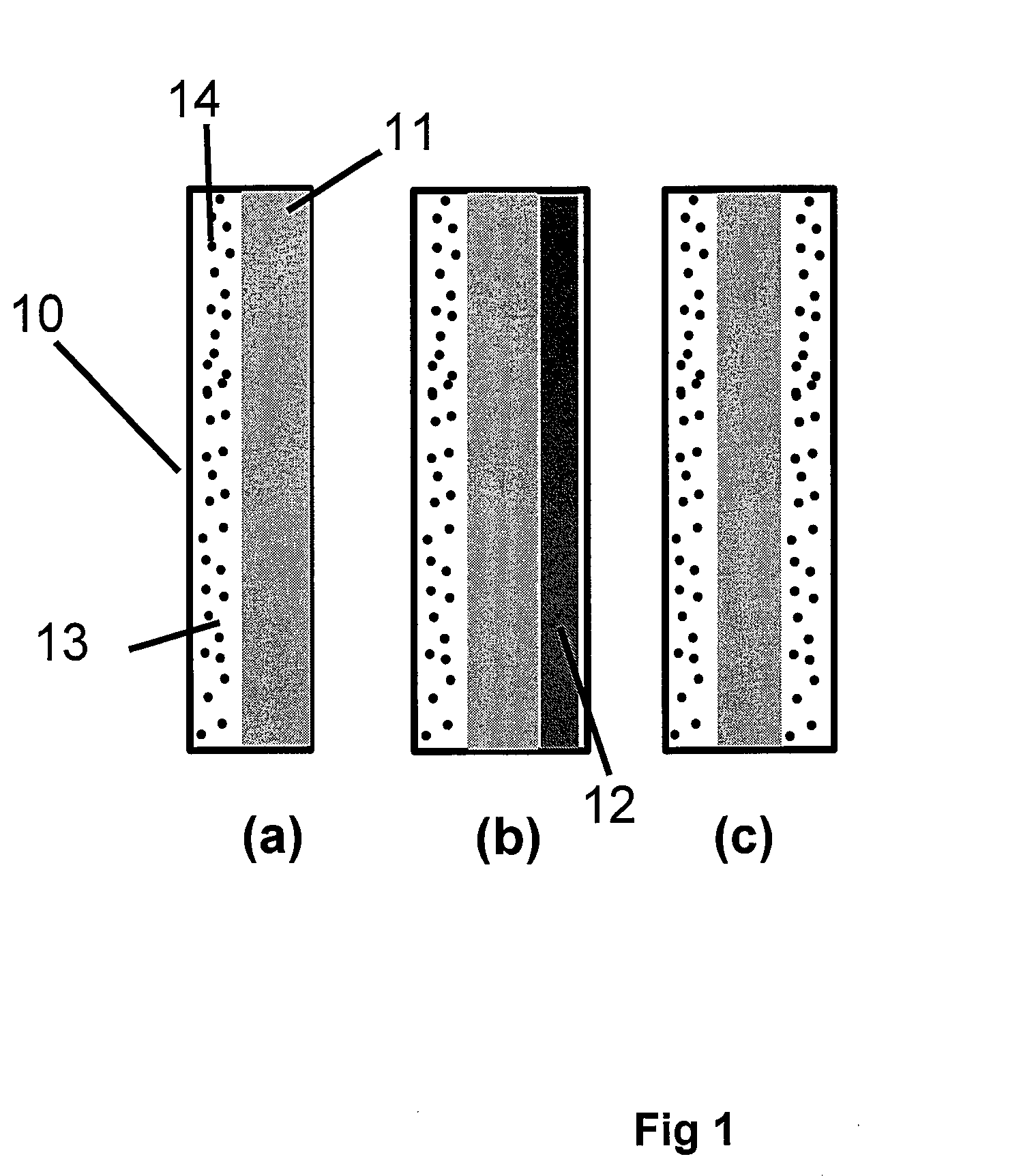

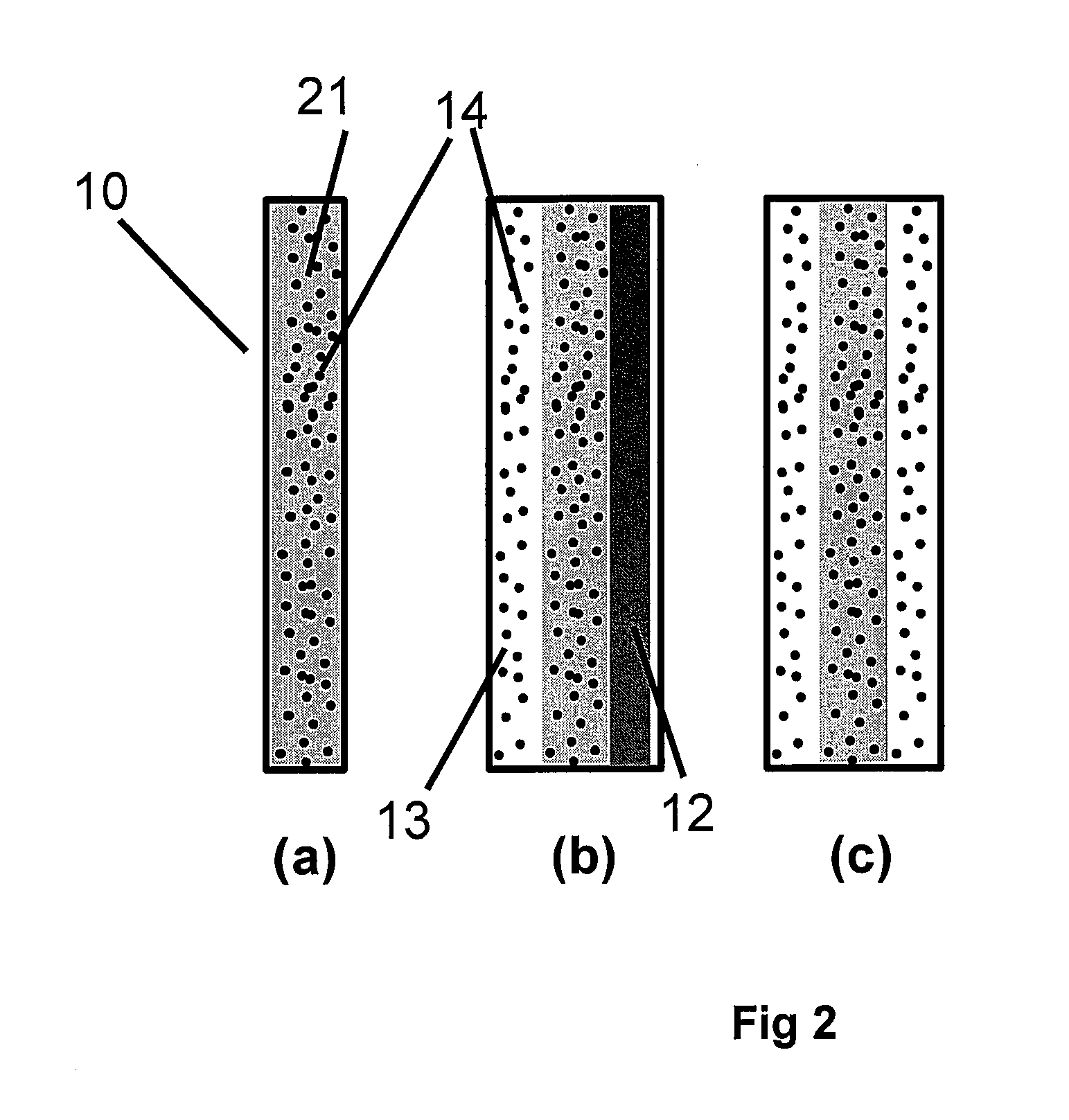

ActiveUS20070072036A1Enhanced release propertiesIon-exchanger regenerationFinal product manufactureFiberIon exchange

A solid polymer electrolyte membrane having a first surface and a second surface opposite the first surface, where the solid polymer electrolyte membrane has a failure force greater than about 115 grams and comprises a composite membrane consisting essentially of (a) at least one expanded PTFE membrane having a porous microstructure of polymeric fibrils, and (b) at least one ion exchange material impregnated throughout the porous microstructure of the expanded PTFE membrane so as to render an interior volume of the expanded PTFE membrane substantially occlusive; (c) at least one substantially occlusive, electronically insulating first composite layer interposed between the expanded PTFE membrane and the first surface, the first composite layer comprising a plurality of first carbon particles supporting a catalyst comprising platinum and an ion exchange material, wherein a plurality of the first carbon particles has a particle size less than about 75 nm, or less than about 50 nm, or less than about 25 nm.

Owner:WL GORE & ASSOC INC

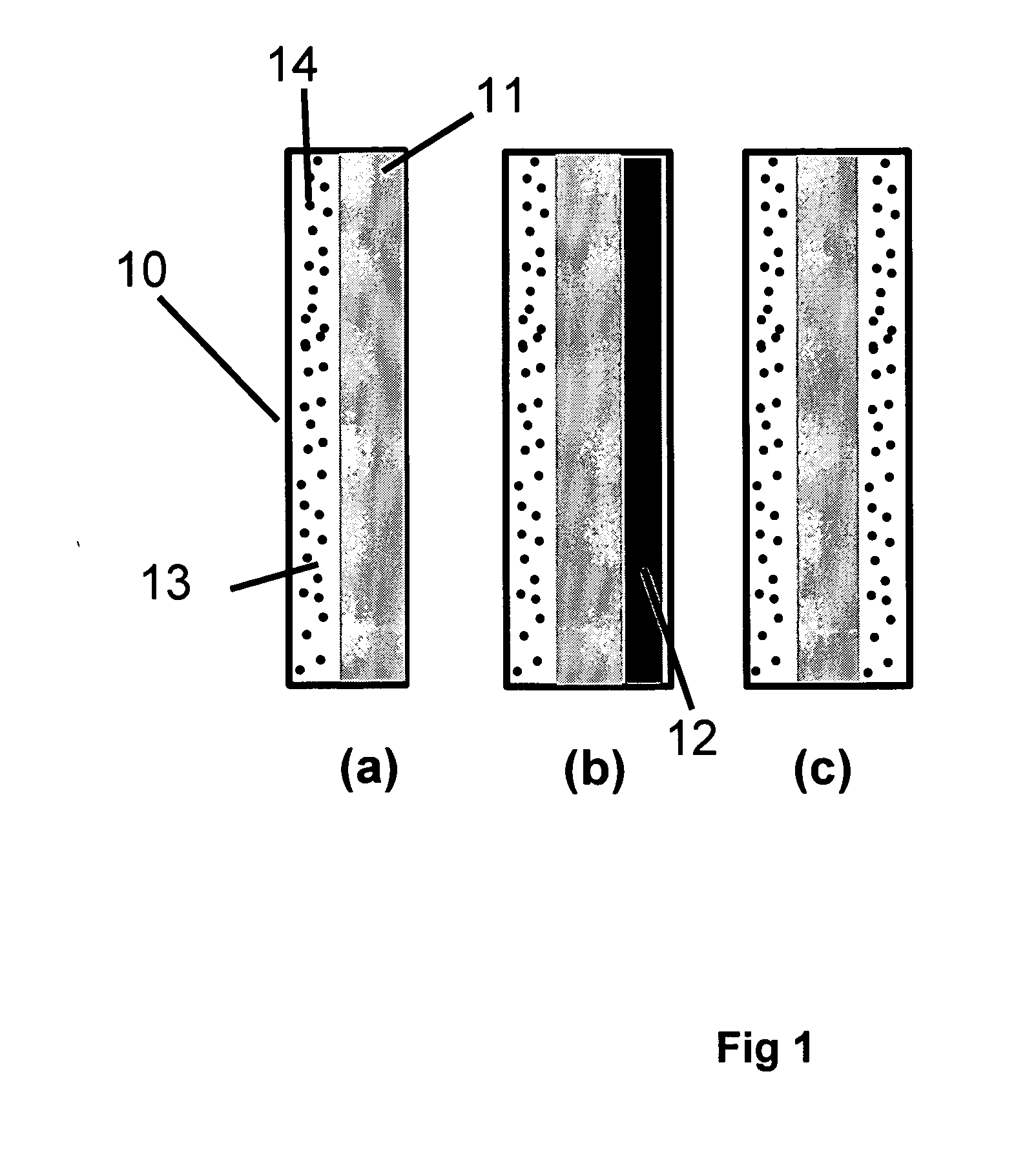

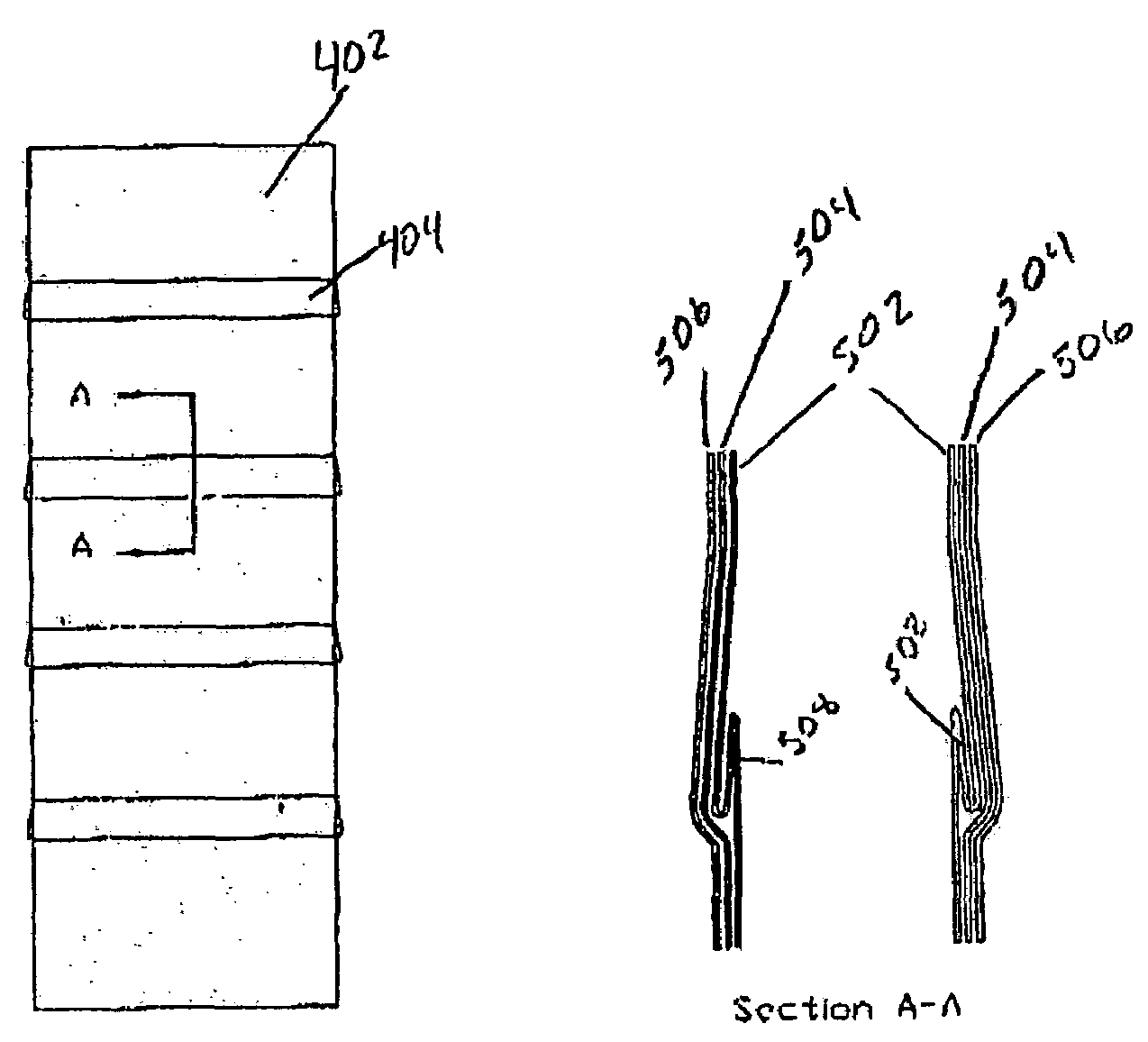

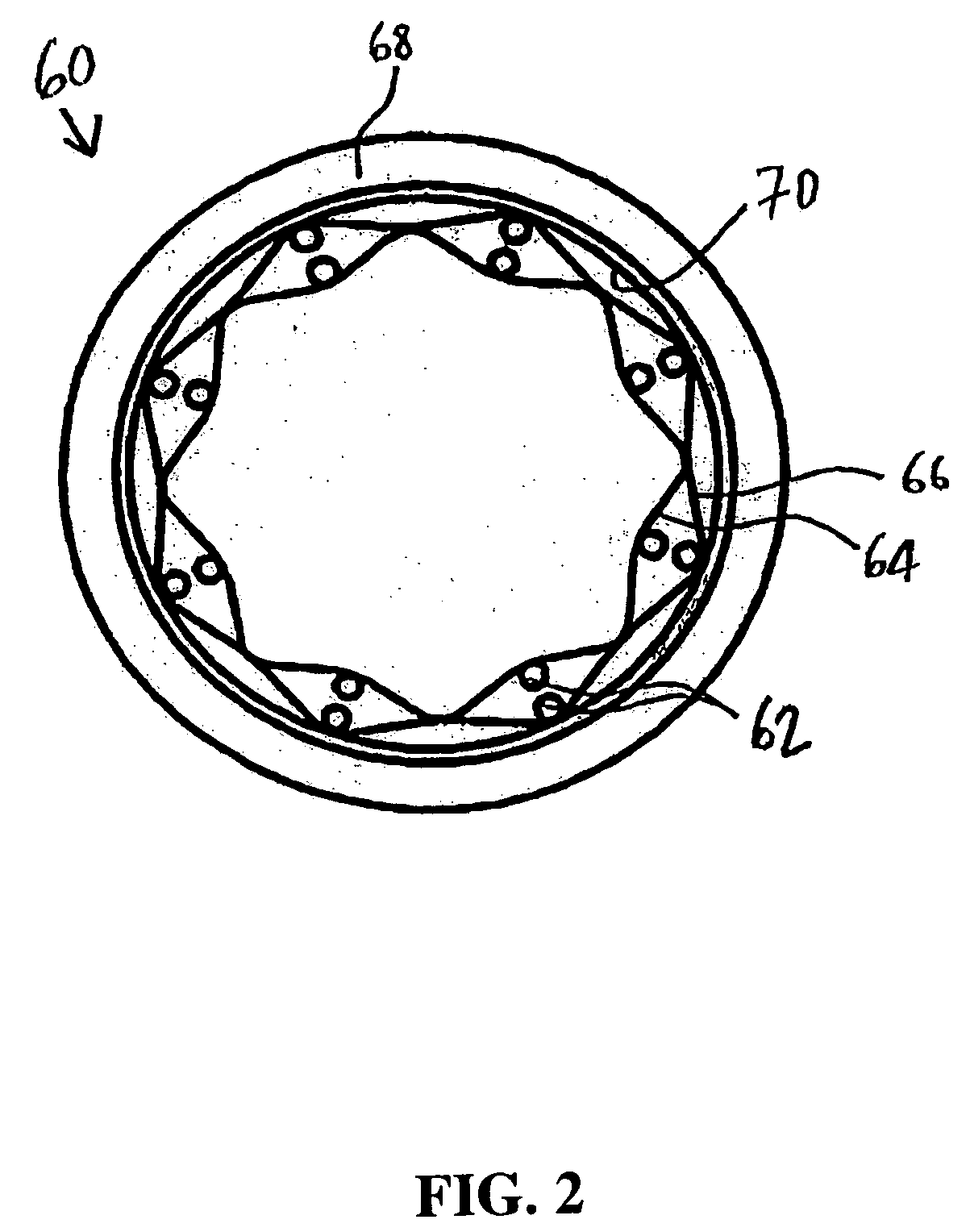

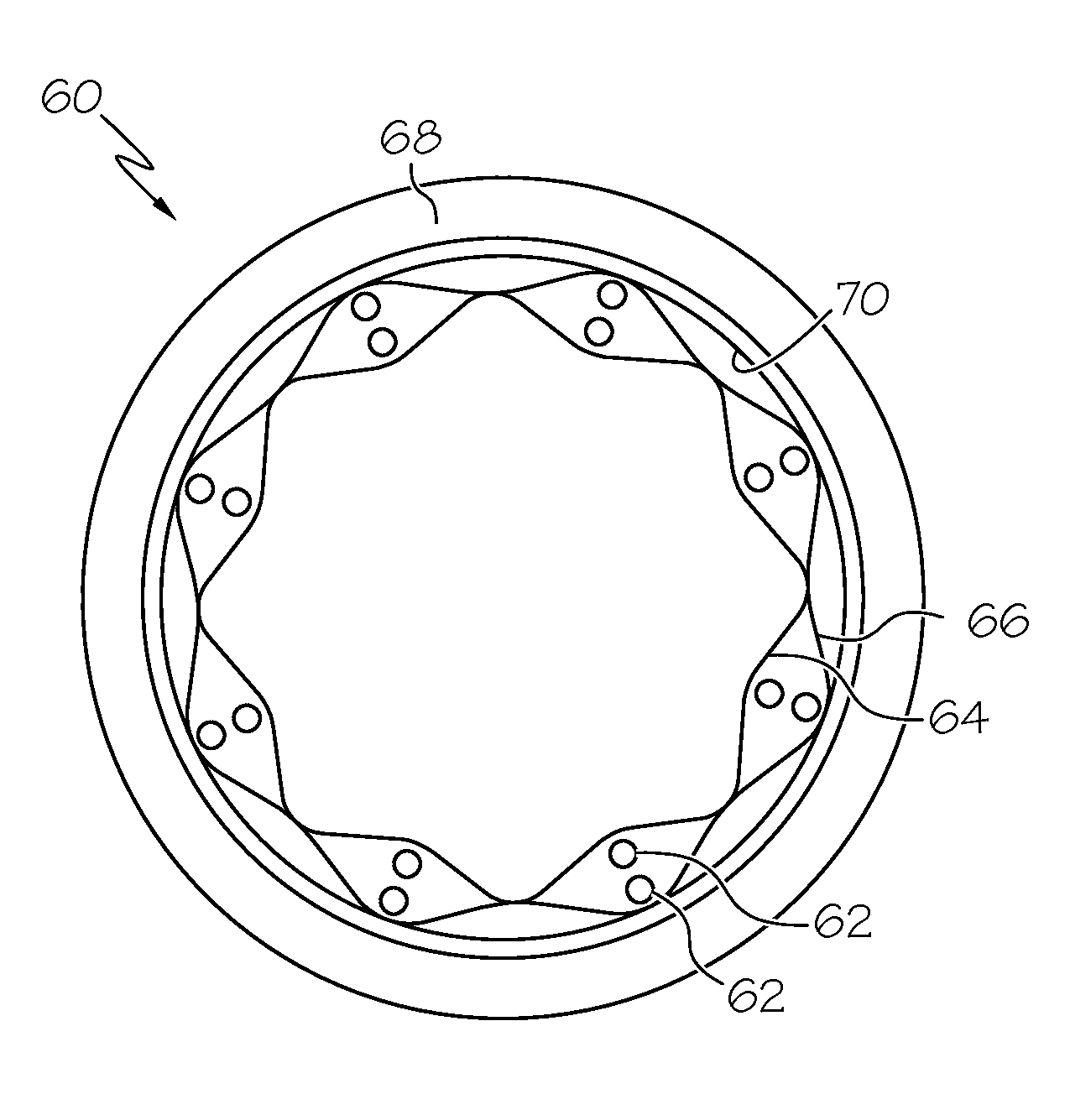

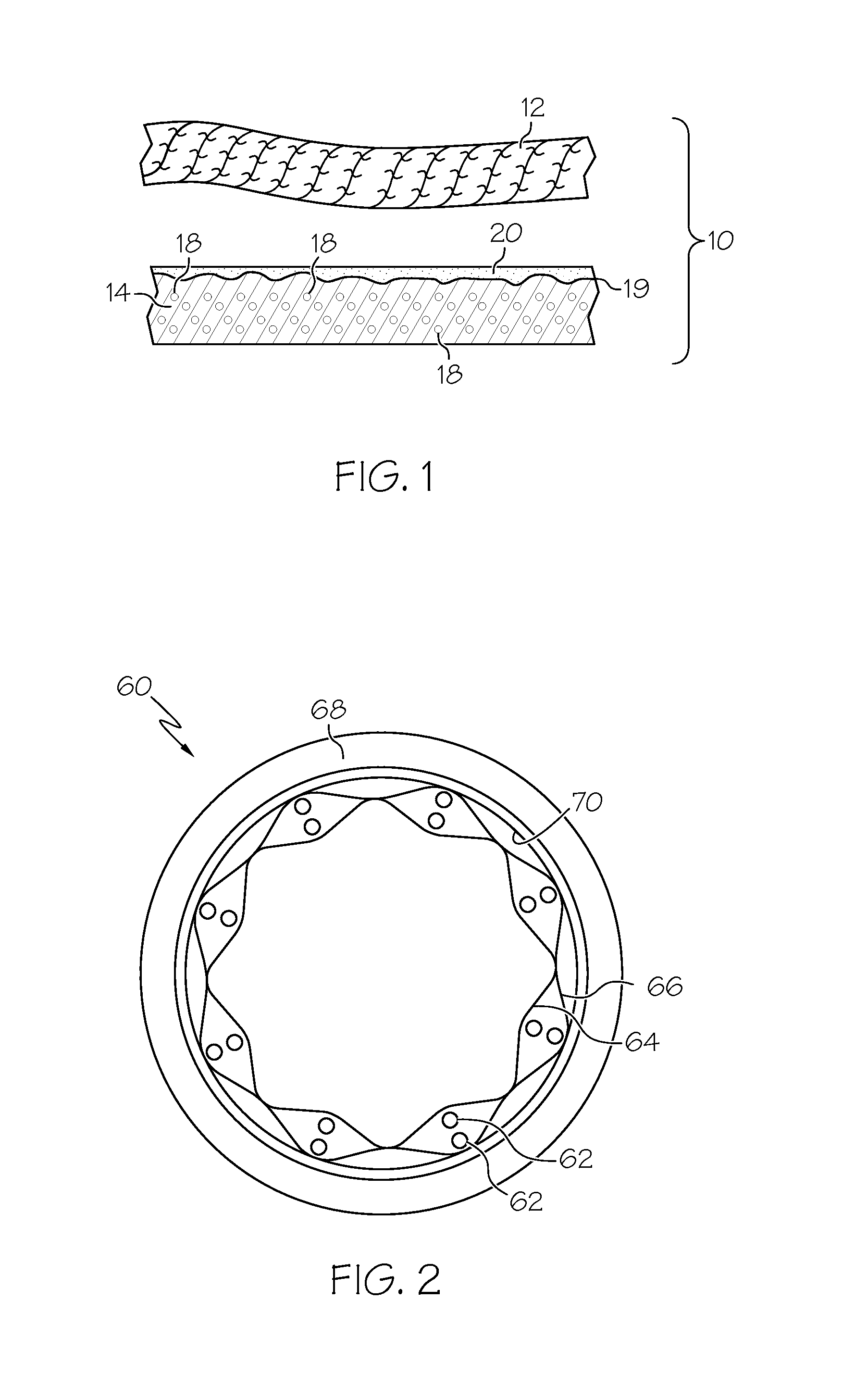

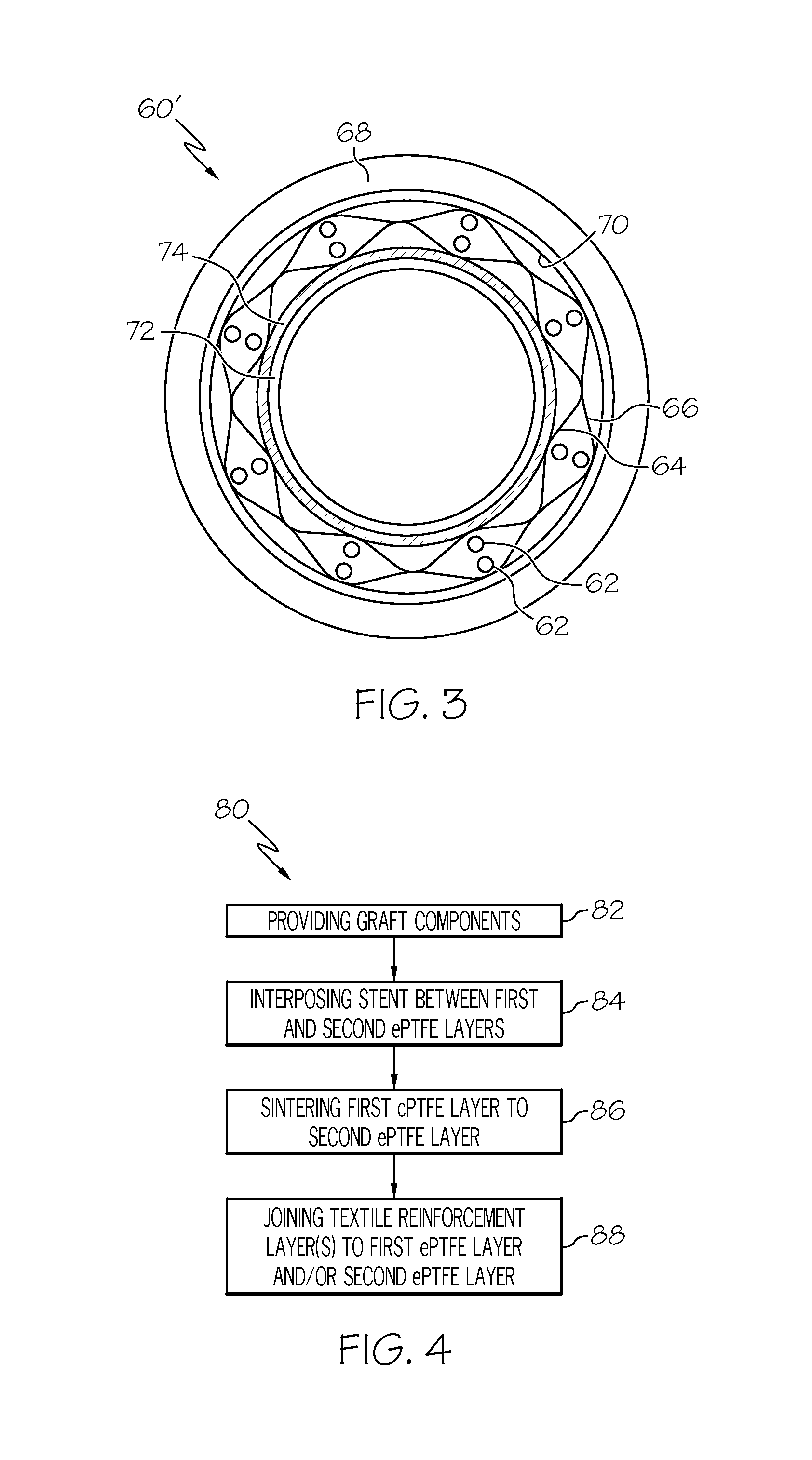

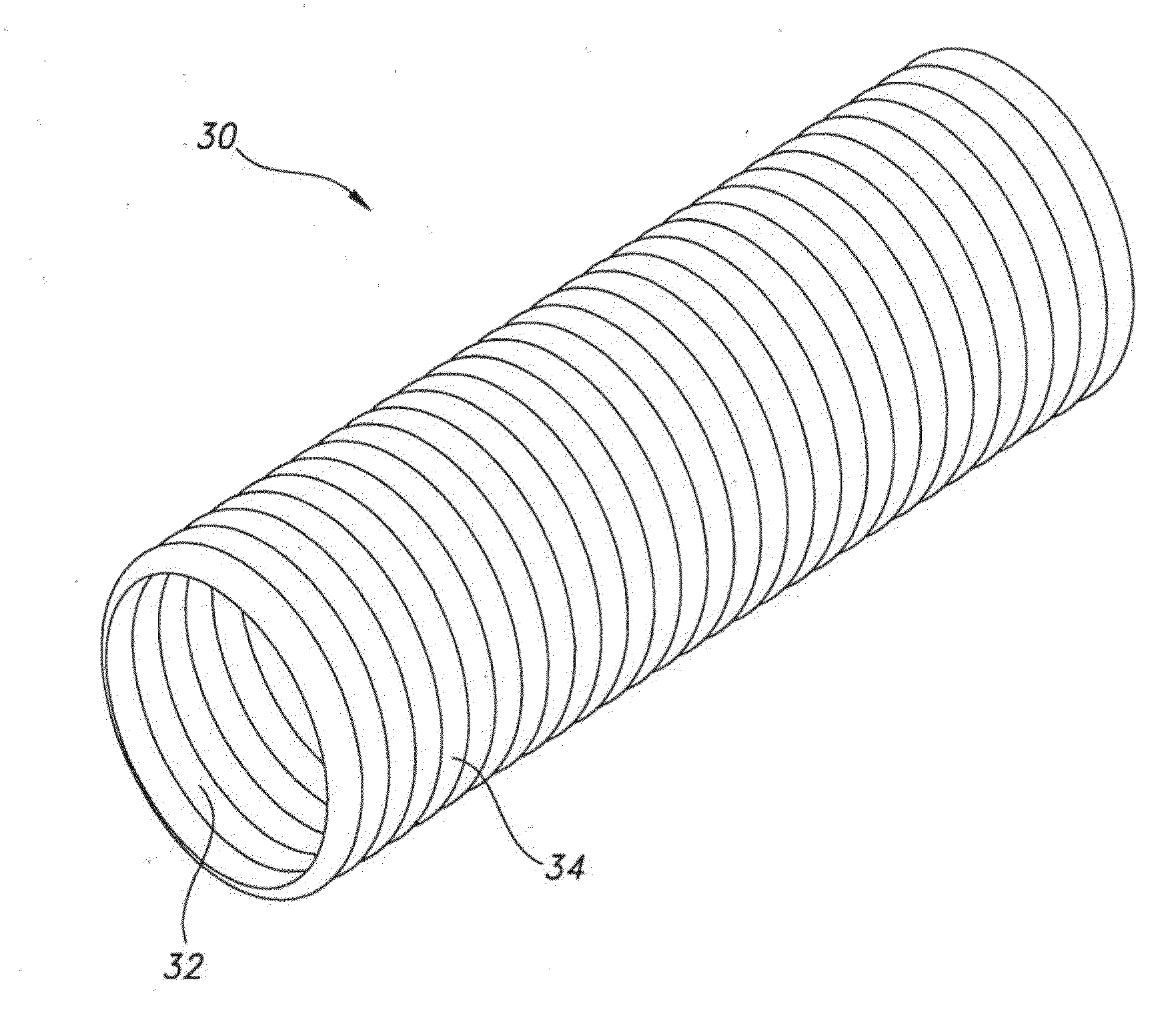

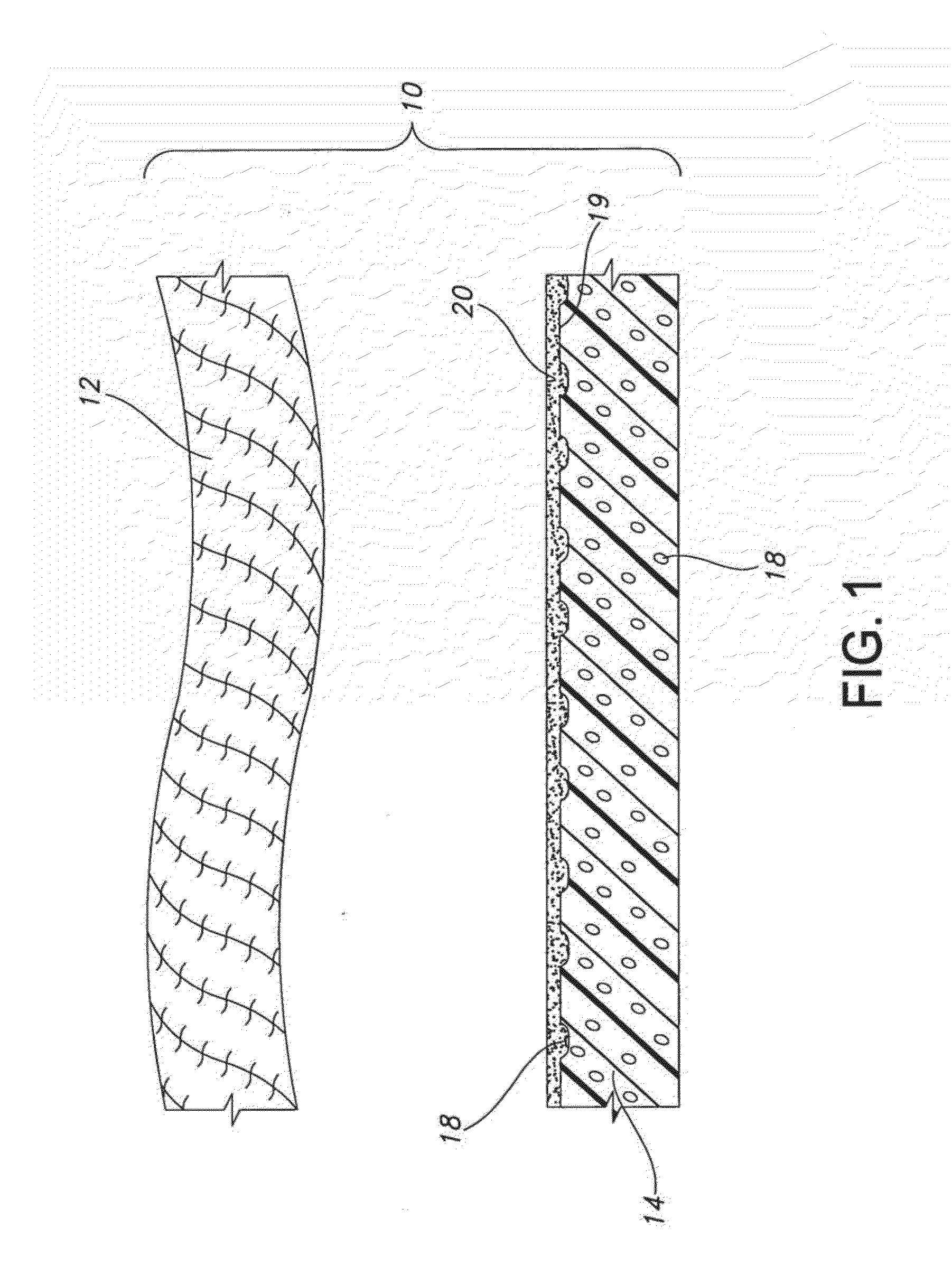

Pleated composite ePTFE/textile hybrid covering

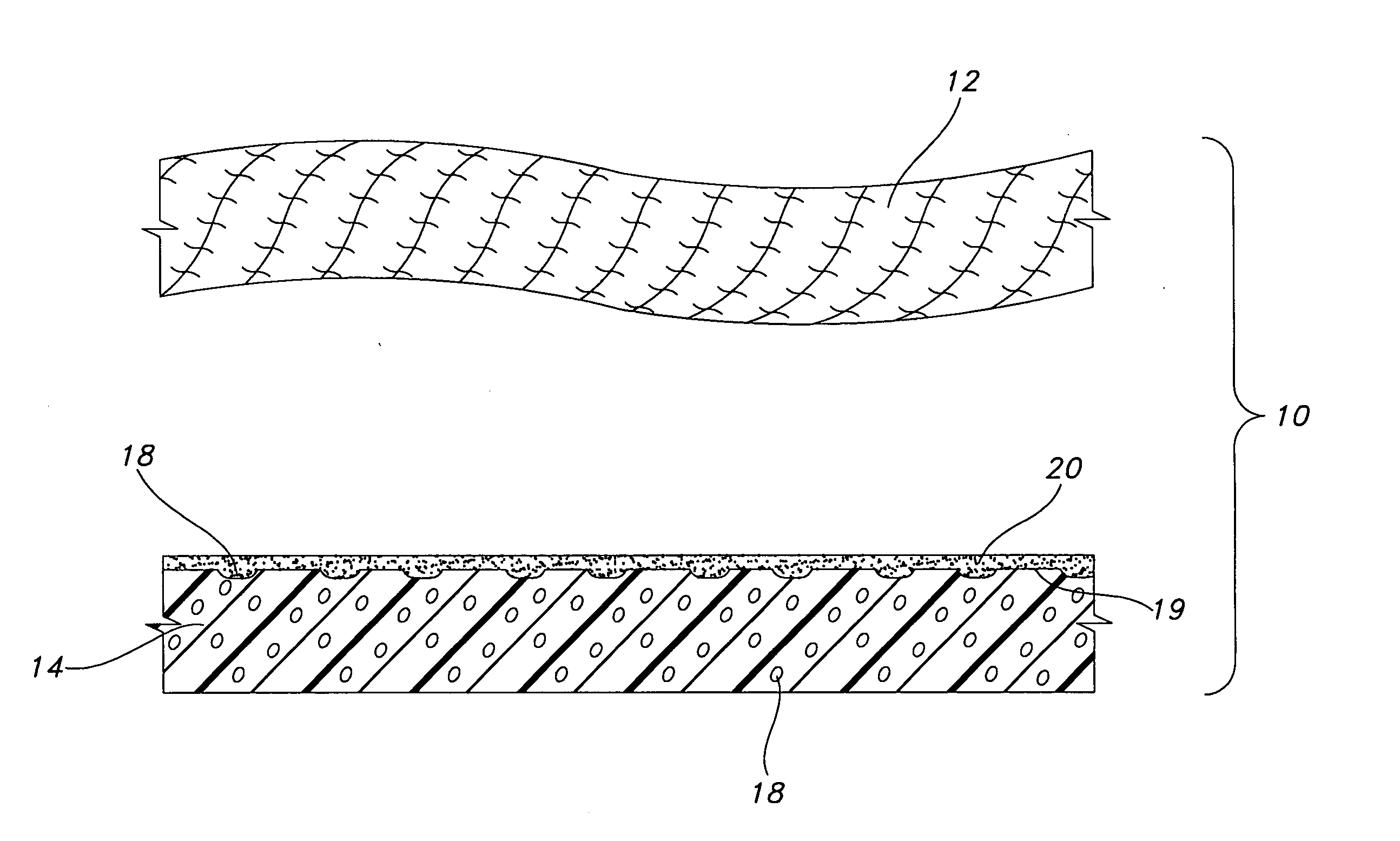

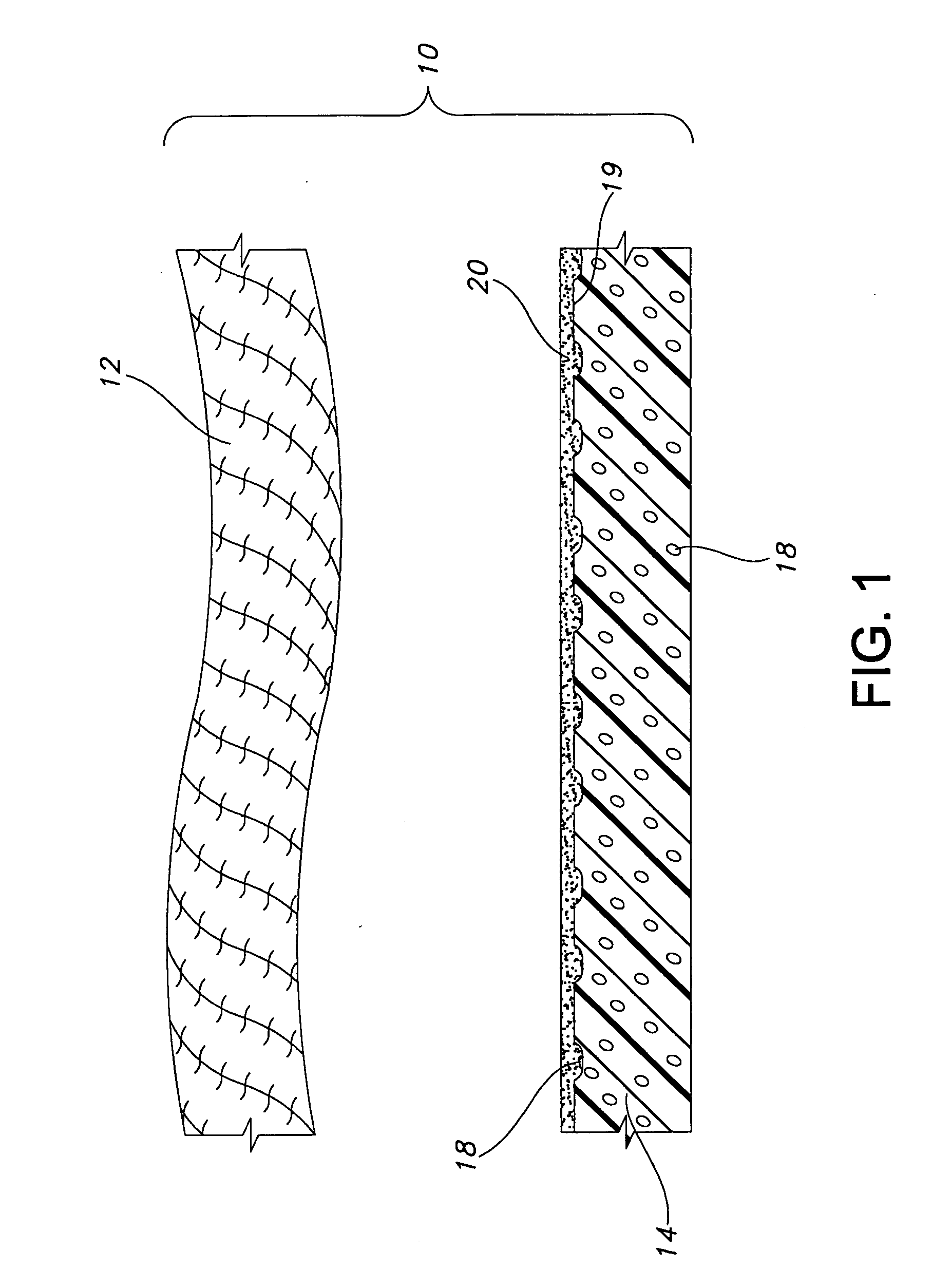

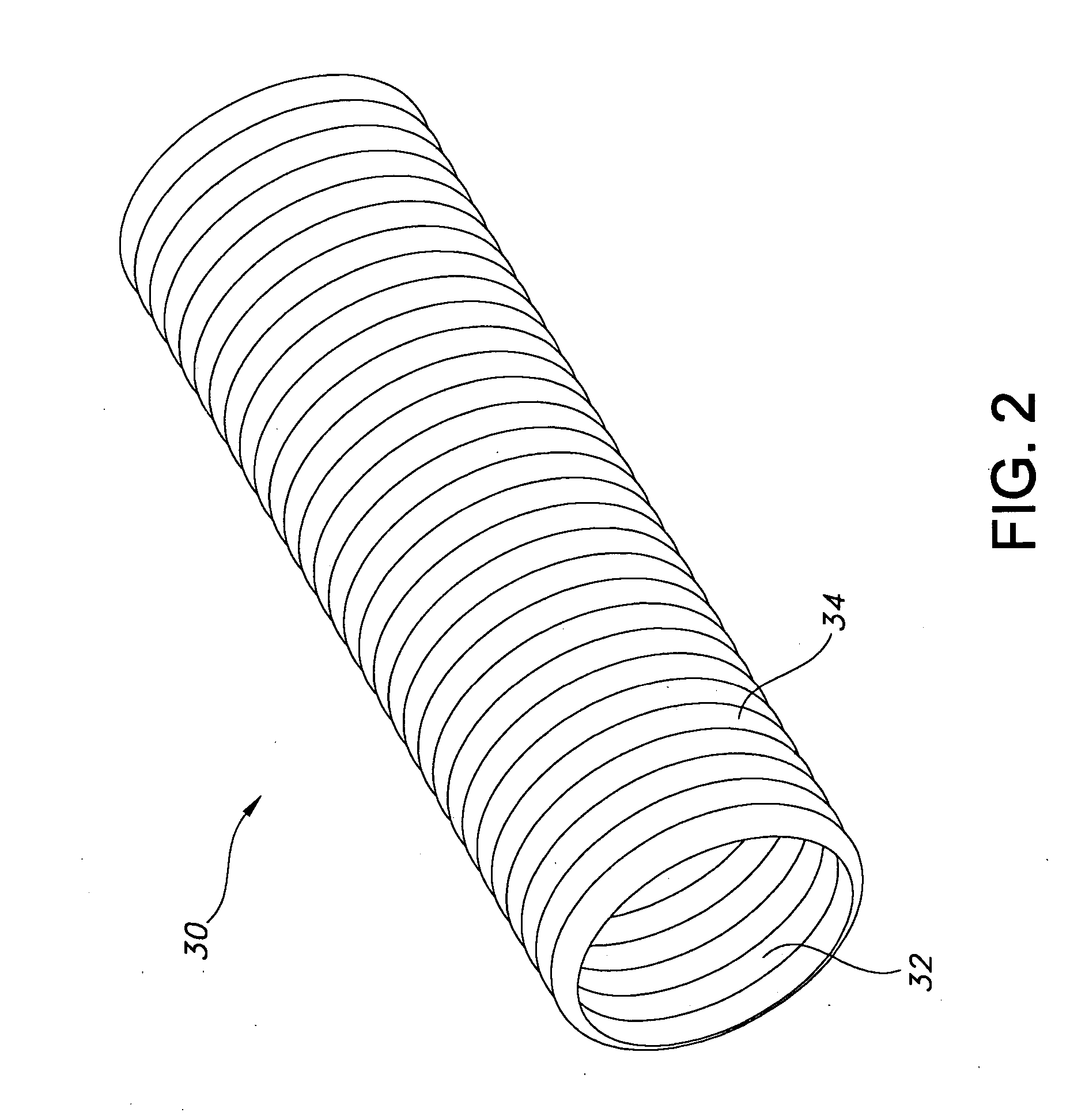

InactiveUS7510571B2Enhanced tissue ingrowthHigh suture retention strengthStentsLayered productsFiberFibril

A composite multilayer implantable material having a first inner tubular layer formed of expanded polytetrafluoroethyene having a porous microstructure defined by nodes interconnected by fibrils, wherein said first layer has a plurality of pleated folds, a second tubular layer formed of textile material circumferentially disposed exteriorly to said first layer; and having an elastomeric bonding agent applied to one of said first layer or second layer and disposed within the pores of said microstructure for securing said first layer to said second layer.

Owner:LIFESHIELD SCI

Composite ePTFE/textile prosthesis

InactiveUS20060264138A1Enhanced tissue ingrowthHigh suture retention strengthStentsPedestrian/occupant safety arrangementFiberFibril

A composite intraluminal prosthesis which is preferably used as a vascular prothesis includes a layer of ePTFE and a layer of textile material which are secured together by an elastomeric bonding agent. The ePTFE layer includes a porous microstructure defined by nodes interconnected by fibrils. The adhesive bonding agent is preferably applied in solution so that the bonding agent enters the pores of the microstructure of the ePTFE. This helps secure the textile layer to the ePTFE layer.

Owner:BOSTON SCI SCIMED INC

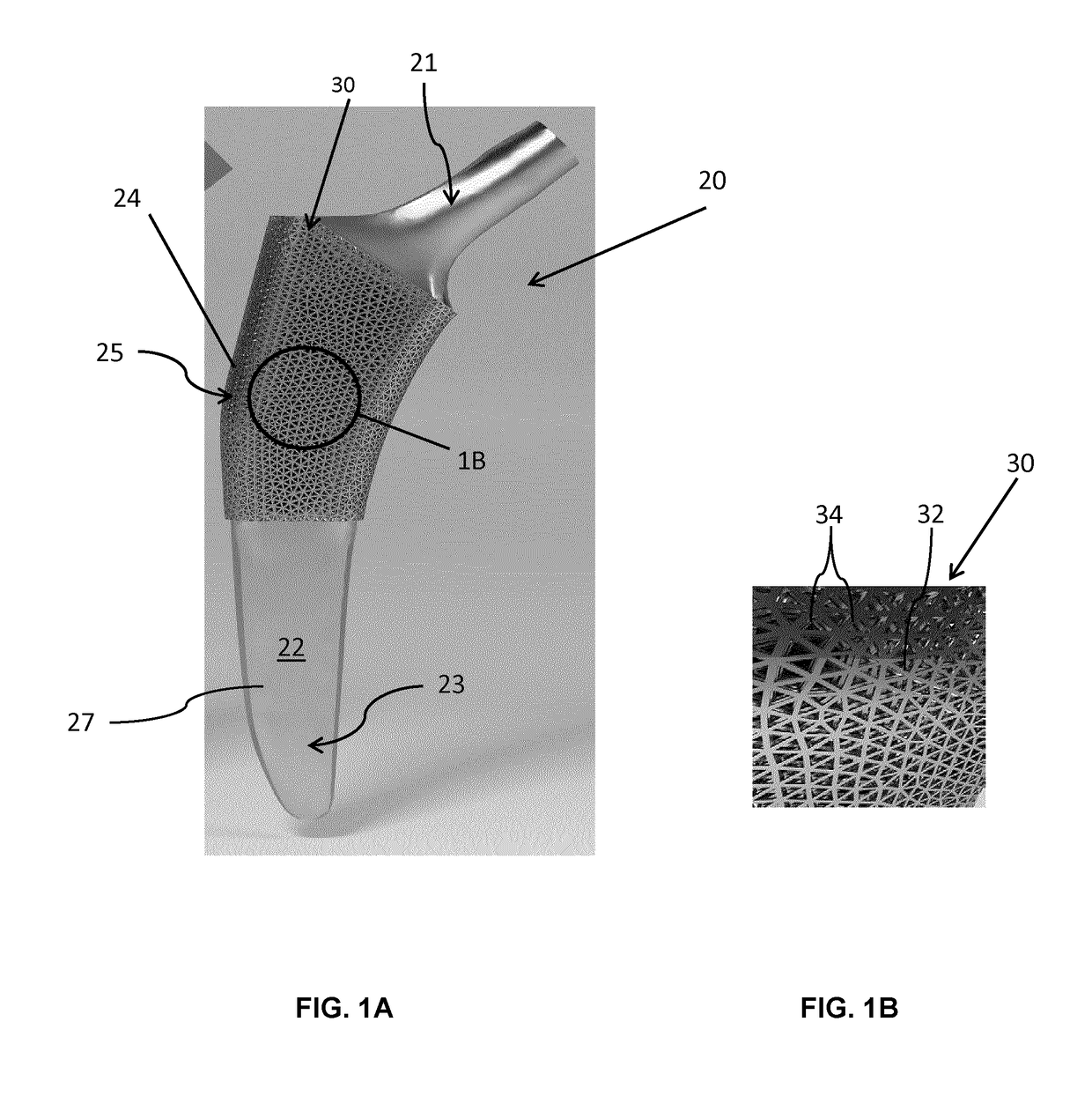

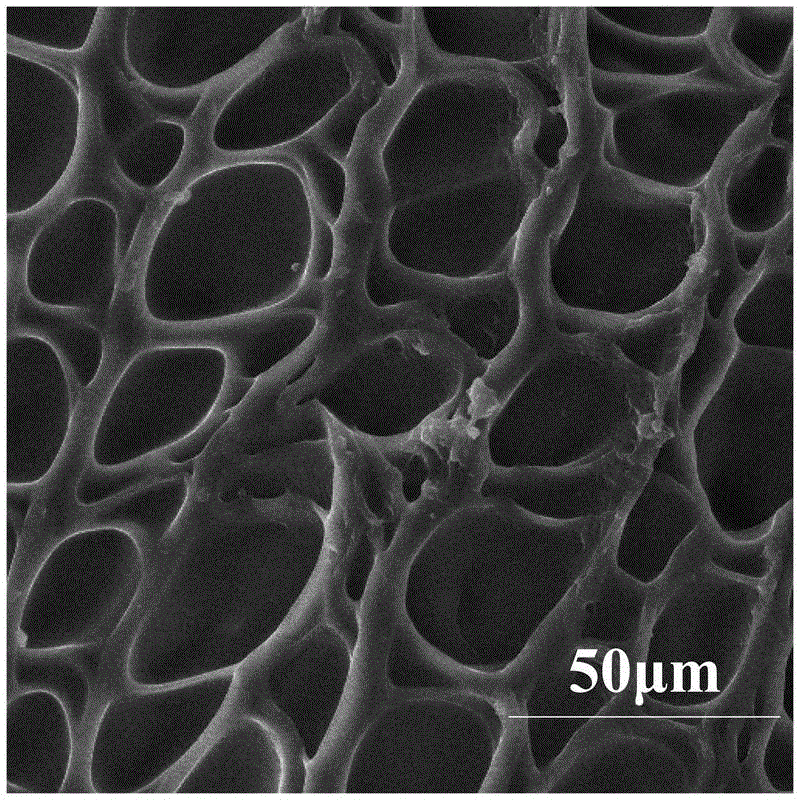

Structural porous biomaterial and implant formed of same

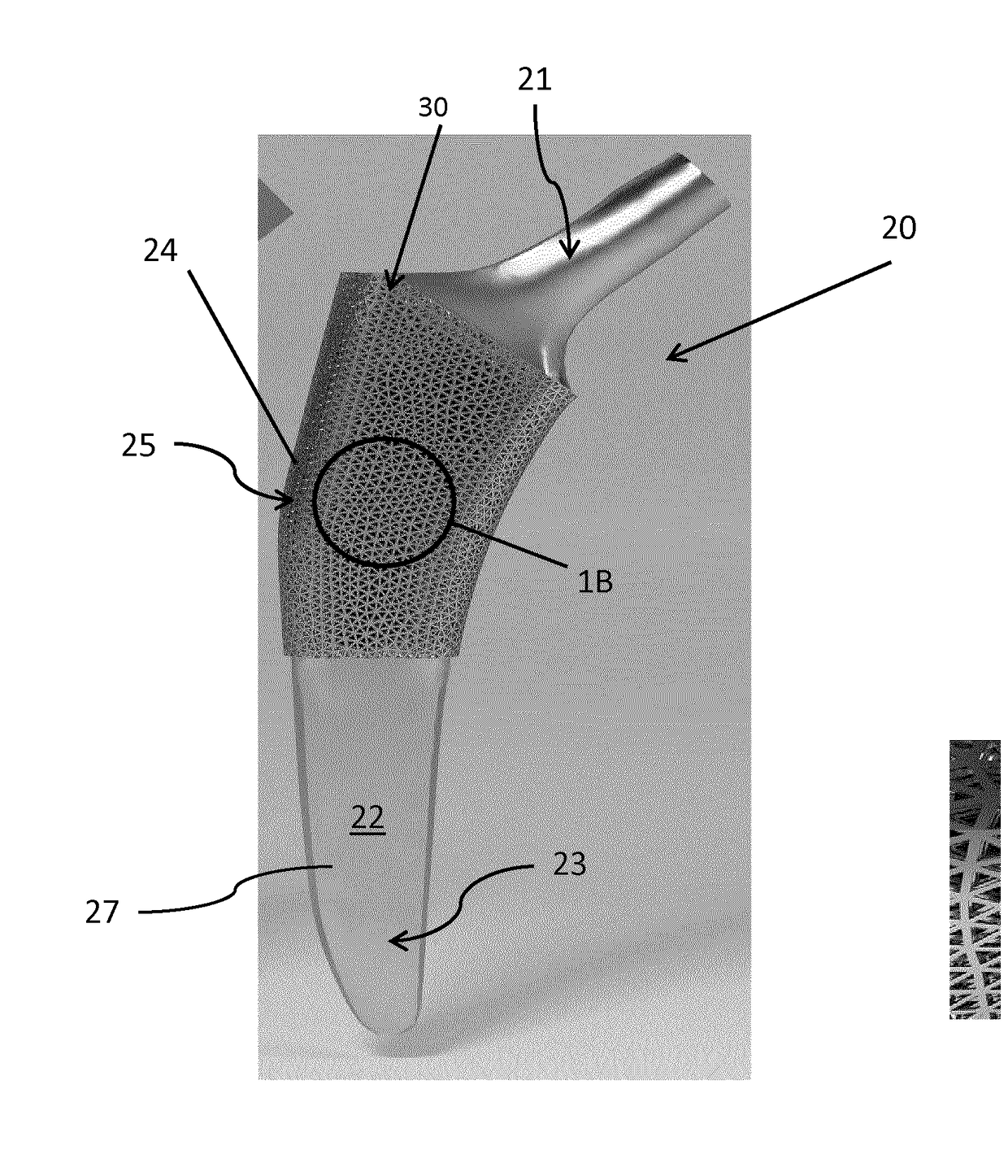

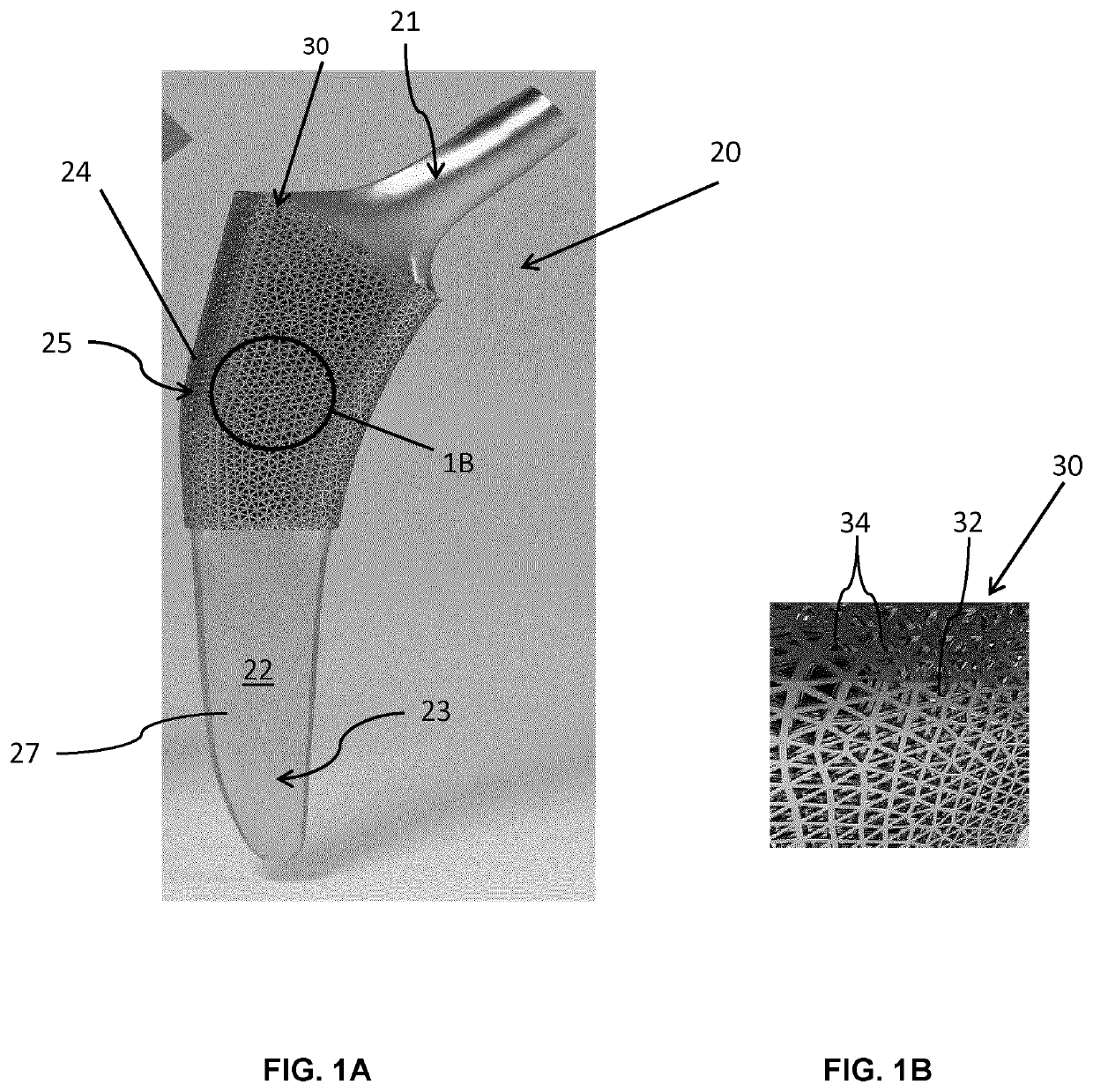

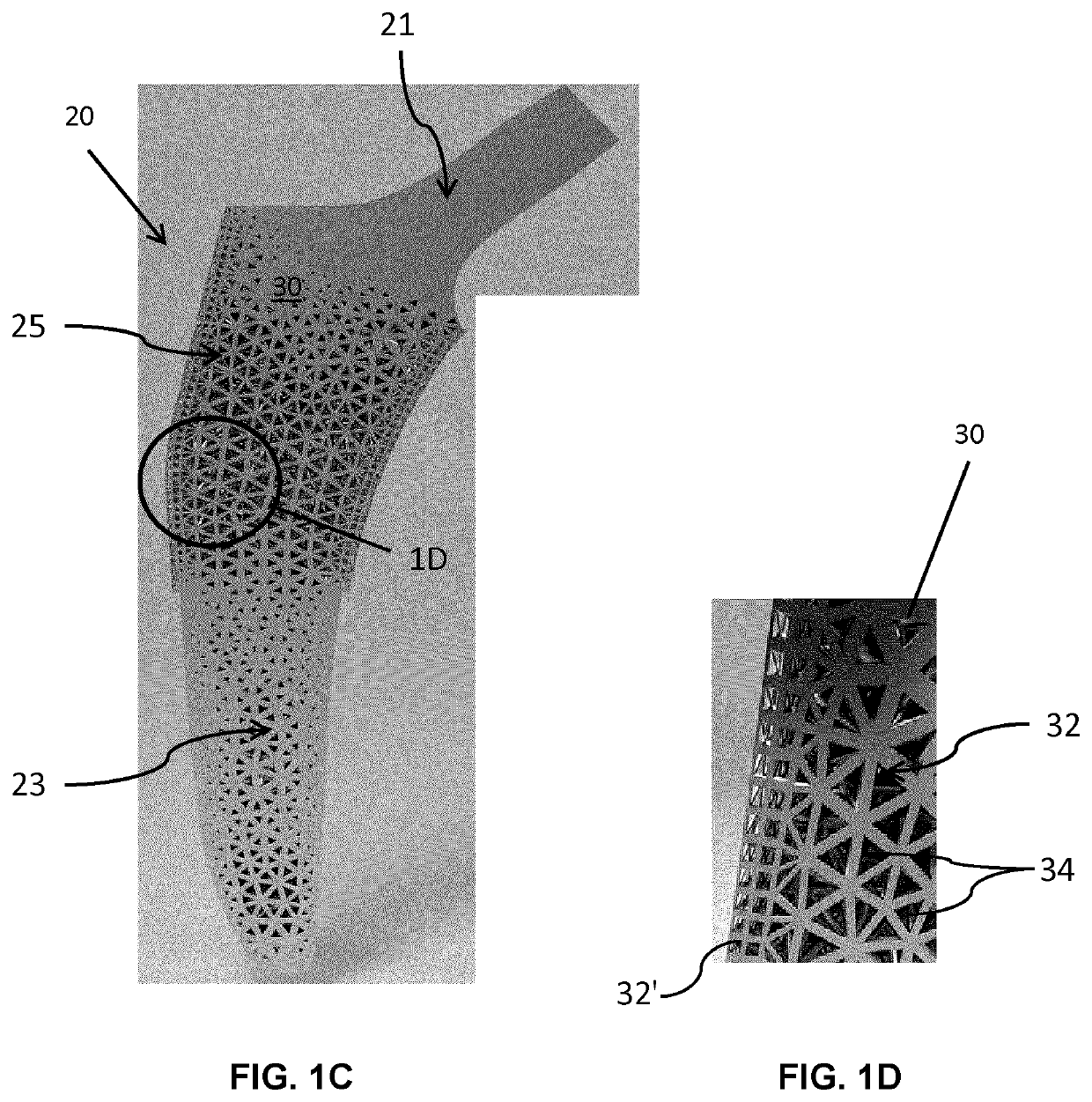

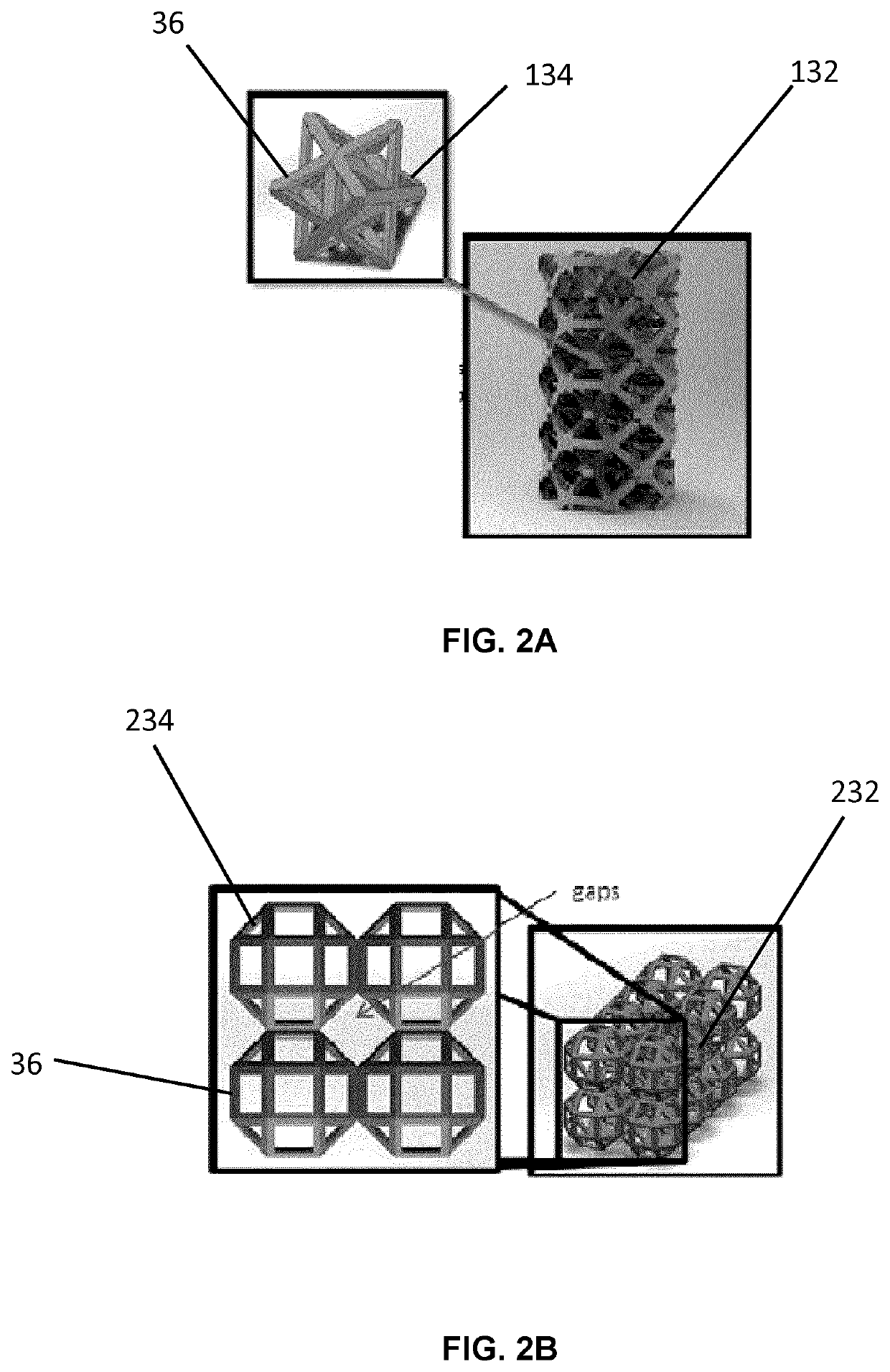

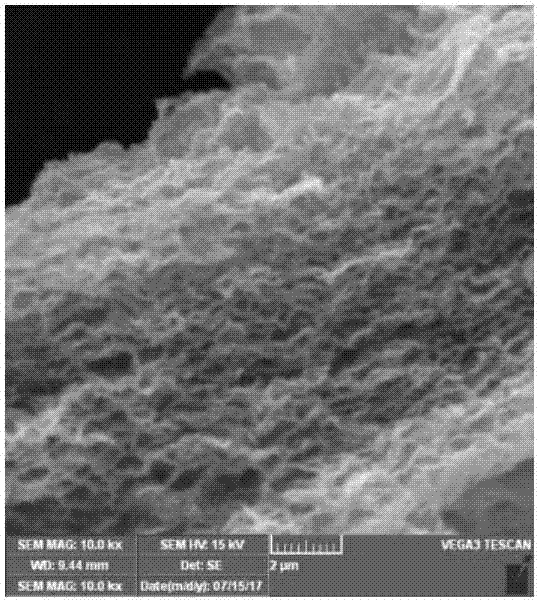

ActiveUS20170095337A1Improve mechanical propertiesJoint implantsIncreasing energy efficiencyImplantPorous microstructure

An implant comprising a porous microstructure is disclosed which has an external surface, where at least a region of the external surface is formed of the porous microstructure. The microstructure is defined by at least one lattice of cells. Each cell has a predetermined cell topology and a plurality of edges. One or more of the edges of each cell connect to an adjacent cell along a corresponding edge thereof. Collectively, the cells have a periodic or aperiodic arrangement within the at least one lattice.

Owner:MCGILL UNIV

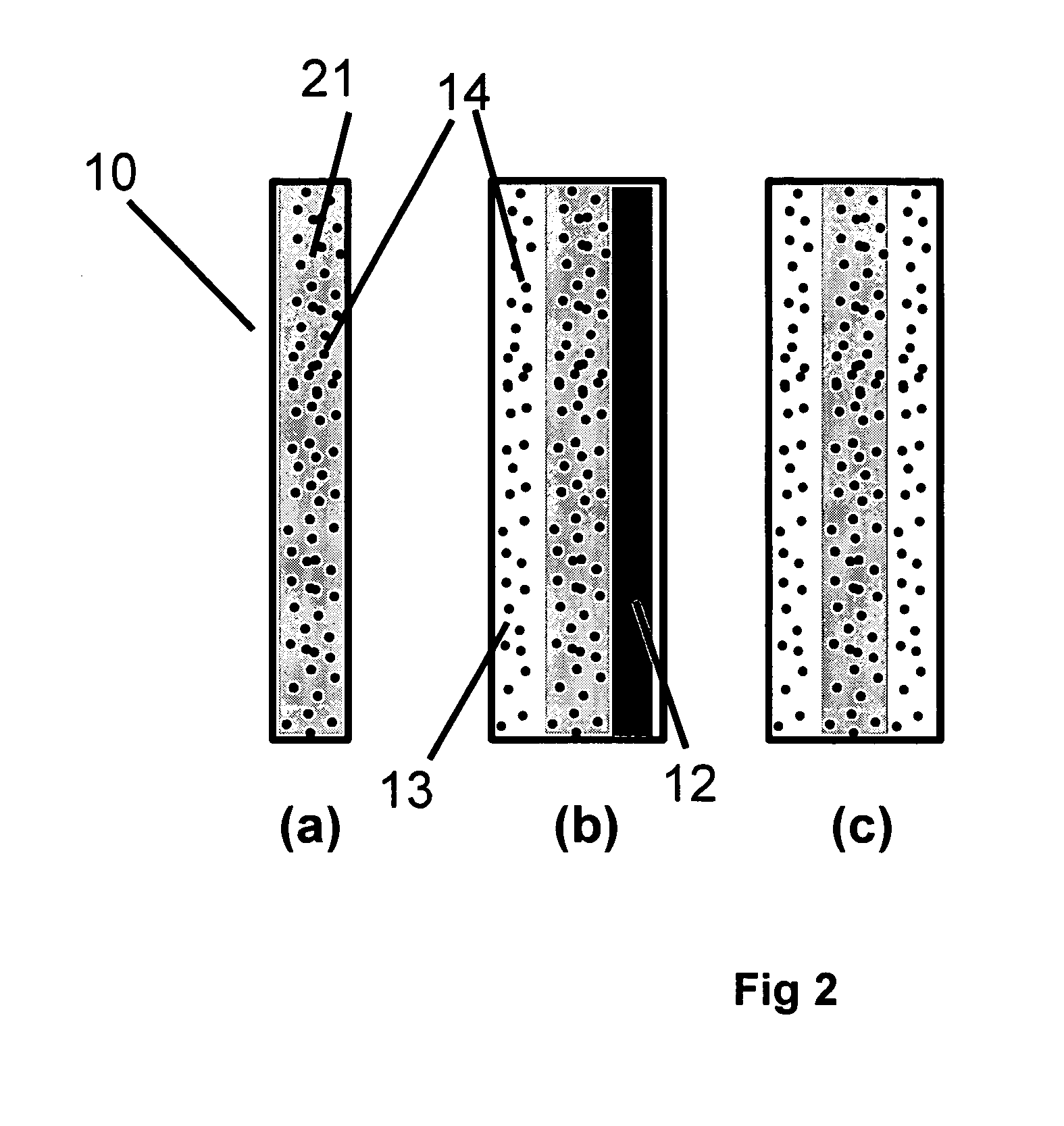

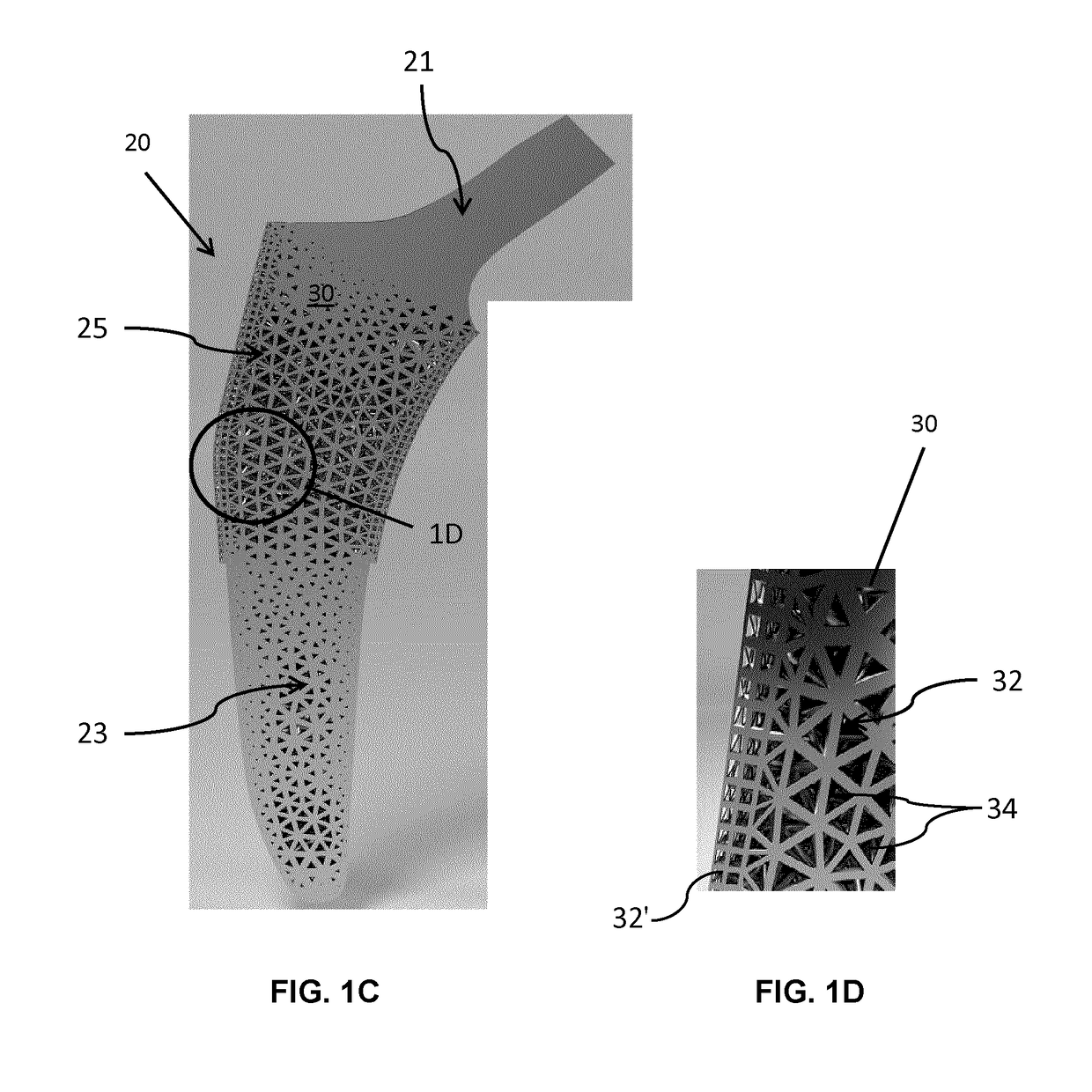

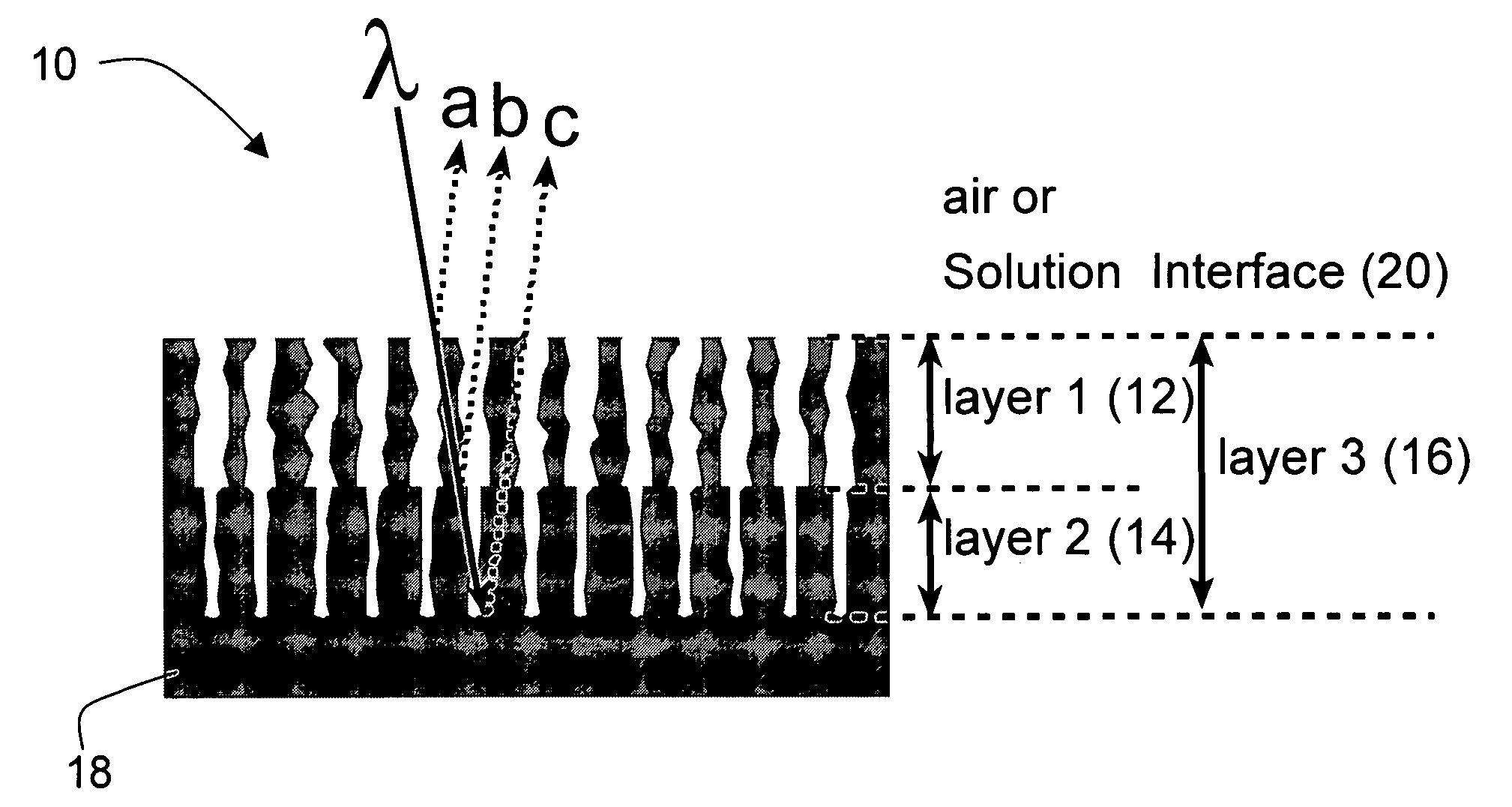

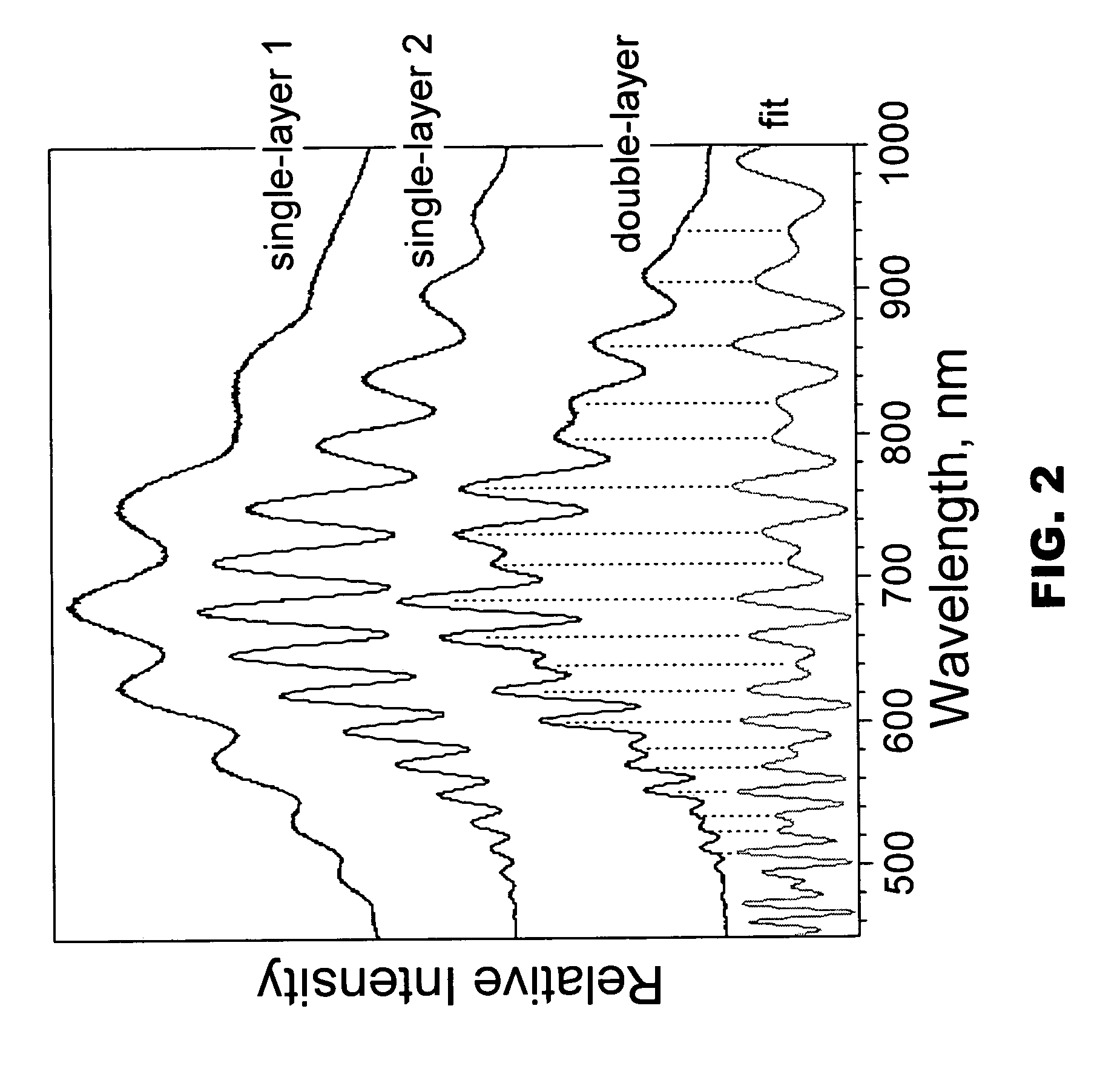

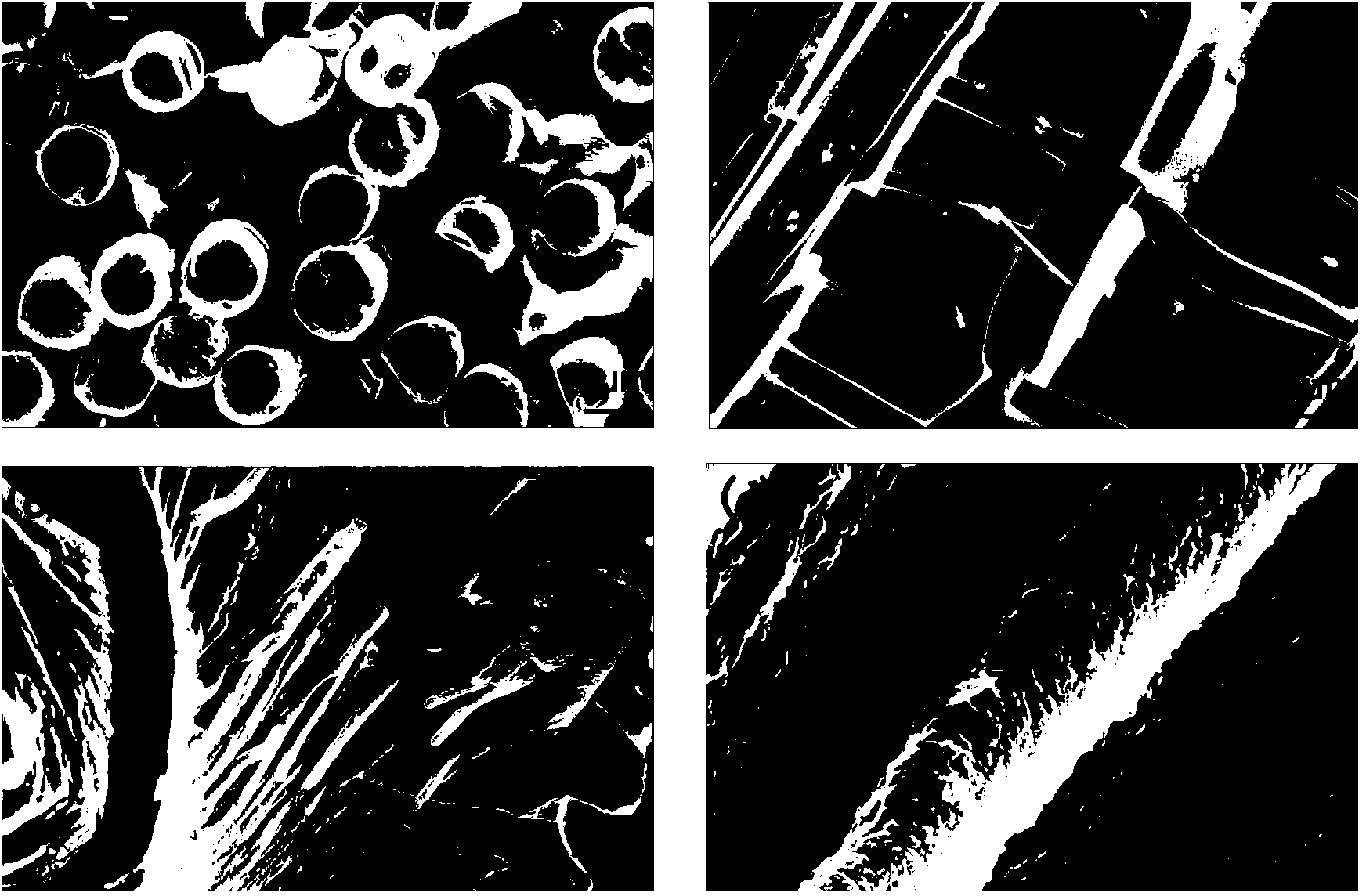

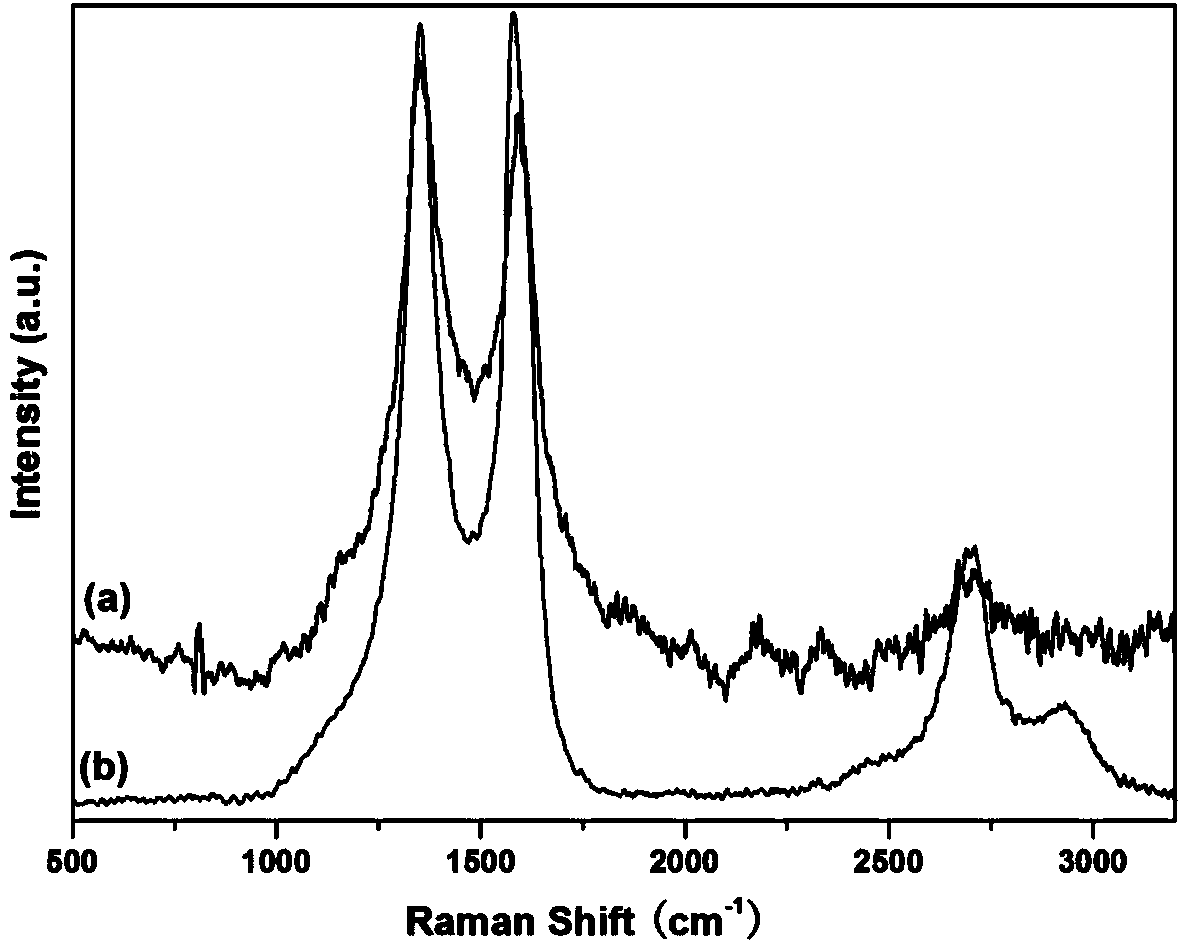

Porous microstructure multi layer spectroscopy and biosensing

InactiveUS20070108465A1Scattering properties measurementsSpectrum generation using multiple reflectionSpectroscopyPorous silicon

A preferred embodiment biosensor is a multi-layer micro-porous thin film structure. Pores in a top layer of the micro-porous thin film structure are sized to accept a first molecule of interest. Pores in a second layer of the micro-porous thin film structure are smaller than the pores in the top layer and are sized to accept a second molecule of interest that is smaller than the first molecule of interest. The pores in the second layer are too small to accept the first molecule of interest. The pores in the top layer and the pores in the second layer are sized and arranged such that light reflected from the multi-layer micro-porous thin film structure produces multiple superimposed interference patterns that can be resolved. In preferred embodiments, the multi-layer micro-porous thin film structure is a porous silicon thin film multi-layer structure formed on a silicon substrate, such as a silicon wafer. Specific and nonspecific binding can be detected with biosensors of the invention. The position of peaks in the Fourier transform of the reflection spectrum and the shift in peak amplitudes can be used to determine the presence and quantity of targeted biological molecules of interest.

Owner:RGT UNIV OF CALIFORNIA

Composite ePTFE/textile prosthesis

A composite intraluminal prosthesis which is preferably used as a vascular prosthesis includes a layer of ePTFE and a layer of textile material which are secured together by an elastomeric bonding agent. The ePTFE layer includes a porous microstructure defined by nodes interconnected by fibrils. The adhesive bonding agent is preferably applied in solution so that the bonding agent enters the pores of the microstructure of the ePTFE. This helps secure the textile layer to the ePTFE layer.

Owner:LIFESHIELD SCI

Amphoteric cellulose material and application thereof

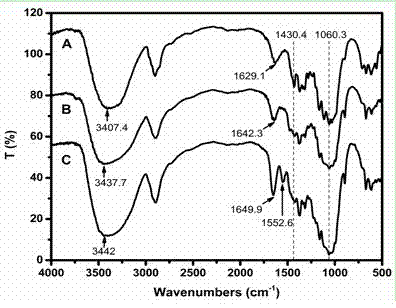

InactiveCN103497278ARenewableDegradableOther chemical processesWater/sewage treatment by sorptionCellulosePolymer science

The invention discloses amphoteric cellulose material and application thereof. Cellulose is subjected to alkali pretreatment to obtain alkali cellulose and achieve hydroxyl activation; 3-chloro-2 hydroxypropyl trimethyl ammonium chloride is used as etherifying agent to perform quaternization modification on the alkali cellulose so as to obtain quaternized cellulose; ceric ammonium nitrate is used as initiator and monomer 2-acrylamide-2-methyl propane sulfonic acid to perform sulphonation on the quaternized cellulose. The prepared quaternized and sulfated cellulose has good hydrophilicity, high reaction activity, bulky macrostructure and porous microstructure, is capable of adsorbing negatively charged anion, negatively charged anionic compound, positively charged cation and positively charged compound in the same time, is high in adsorption capacity, is applicable to the fields such as treatment of heavy metal ion waste water and treatment of organic waste water, and can also serve as functional carriers of other materials.

Owner:SUZHOU UNIV

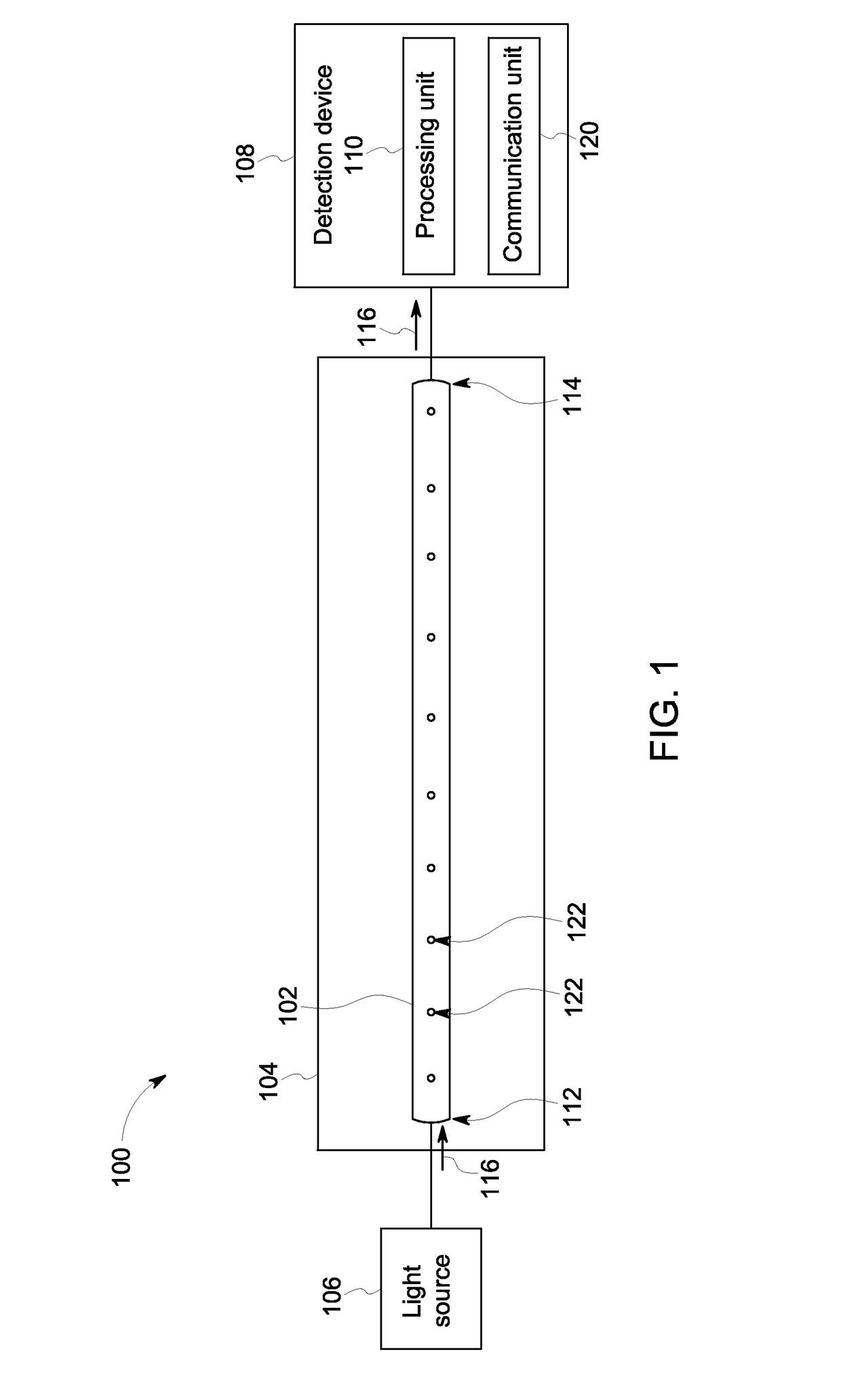

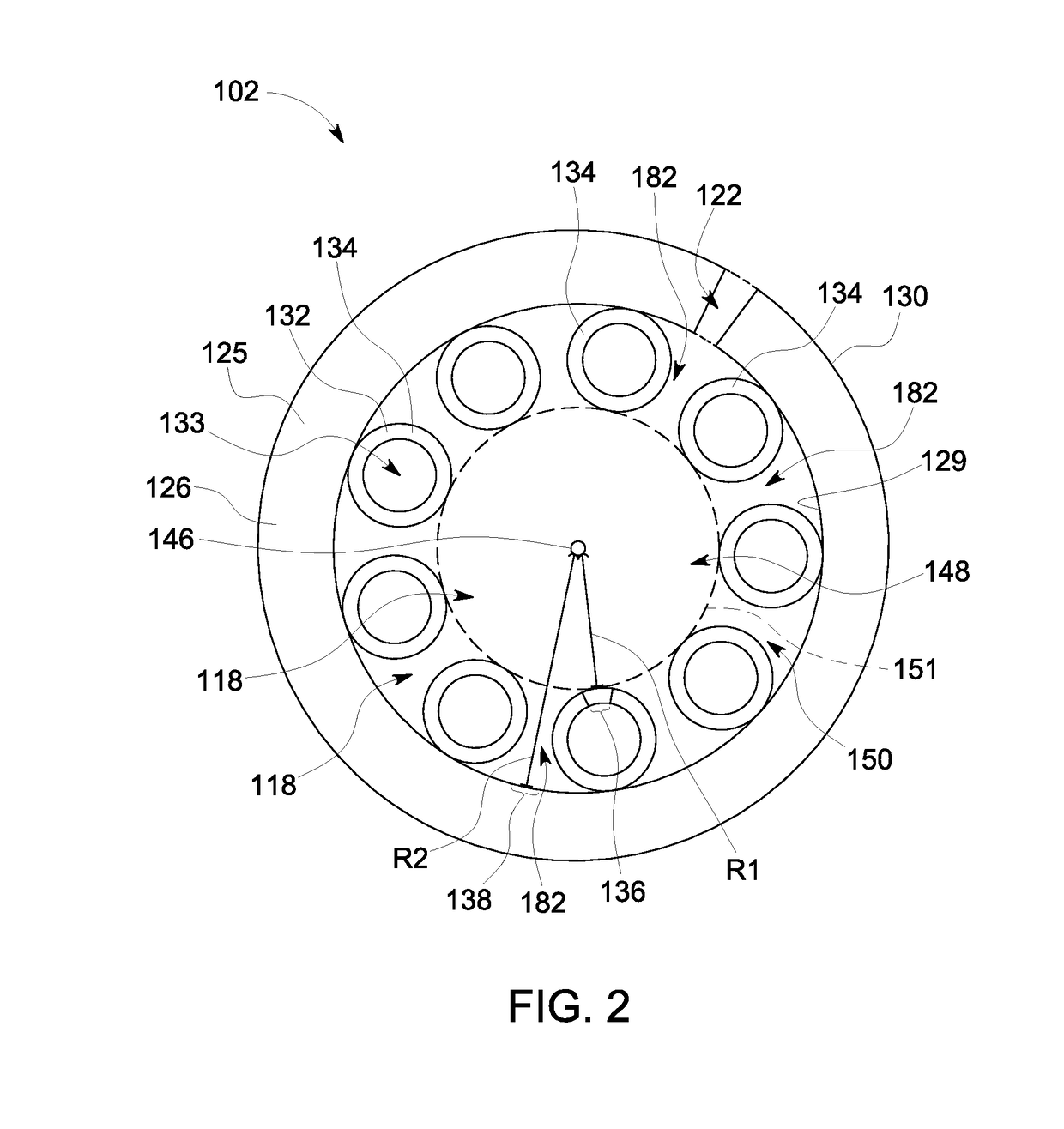

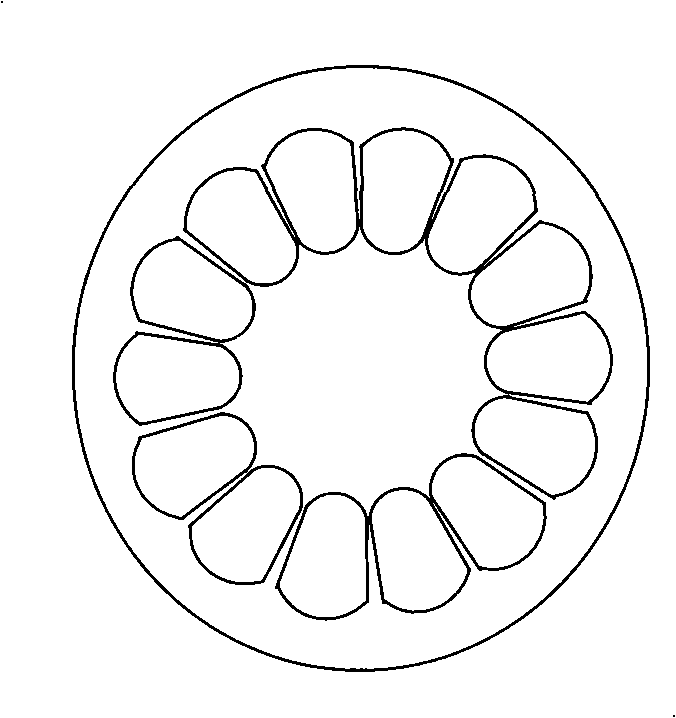

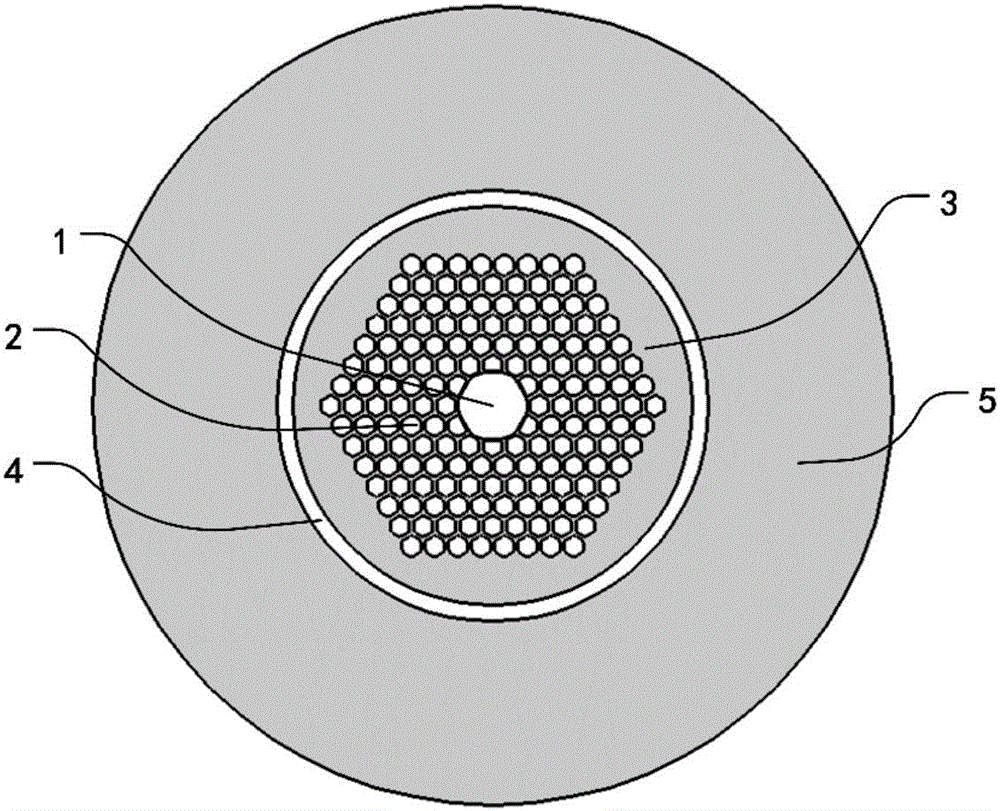

Microstructured optical fibers for gas sensing systems

Microstructured optical fiber (MOF) includes a cladding extending a length between first and second ends. The cladding includes an inner porous microstructure that at least partially surrounds a hollow core. A perimeter contour of the hollow core has a non-uniform radial distance from a center axis of the cladding such that first segments of the cladding along the perimeter contour have a shorter radial distance from the center axis relative to second segments of the cladding along the perimeter contour. The cladding receives and propagates light energy through the hollow core, and the inner porous microstructure substantially confines the light energy within the hollow core. The cladding defines at least one port hole that extends radially from an exterior surface of the cladding to the hollow core. Each port hole penetrates the perimeter contour of the hollow core through one of the second segments of the cladding.

Owner:BAKER HUGHES OILFIELD OPERATIONS LLC

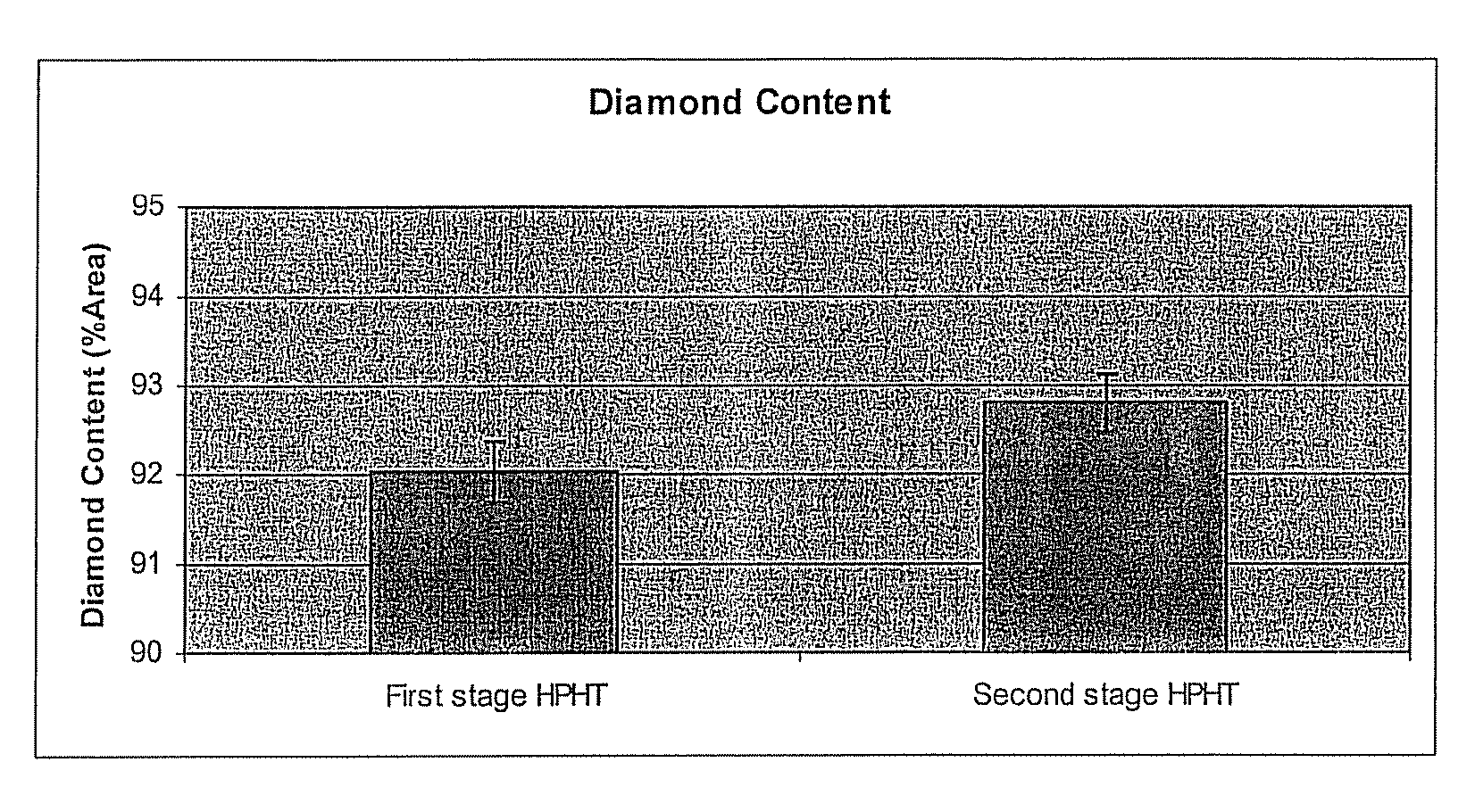

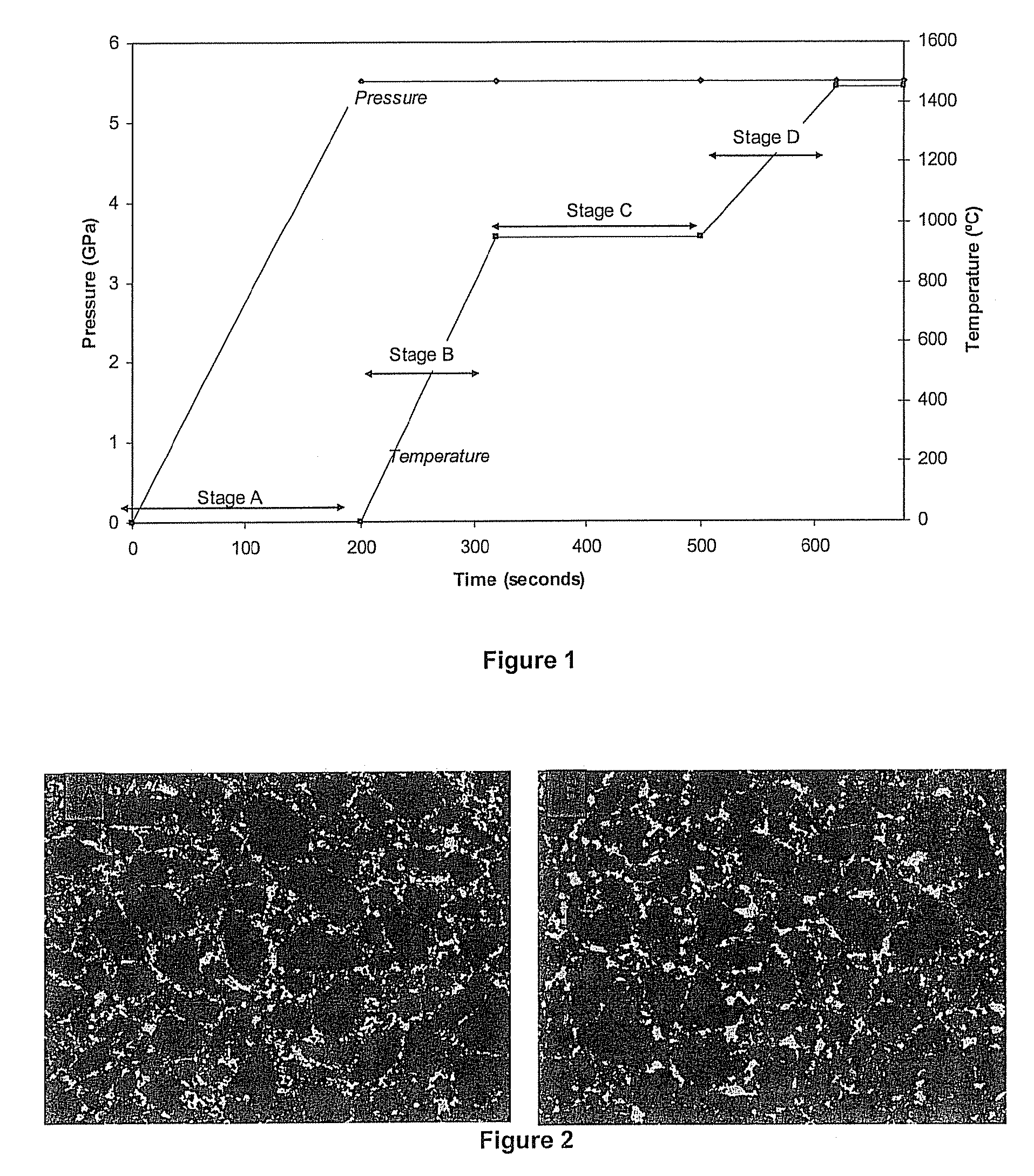

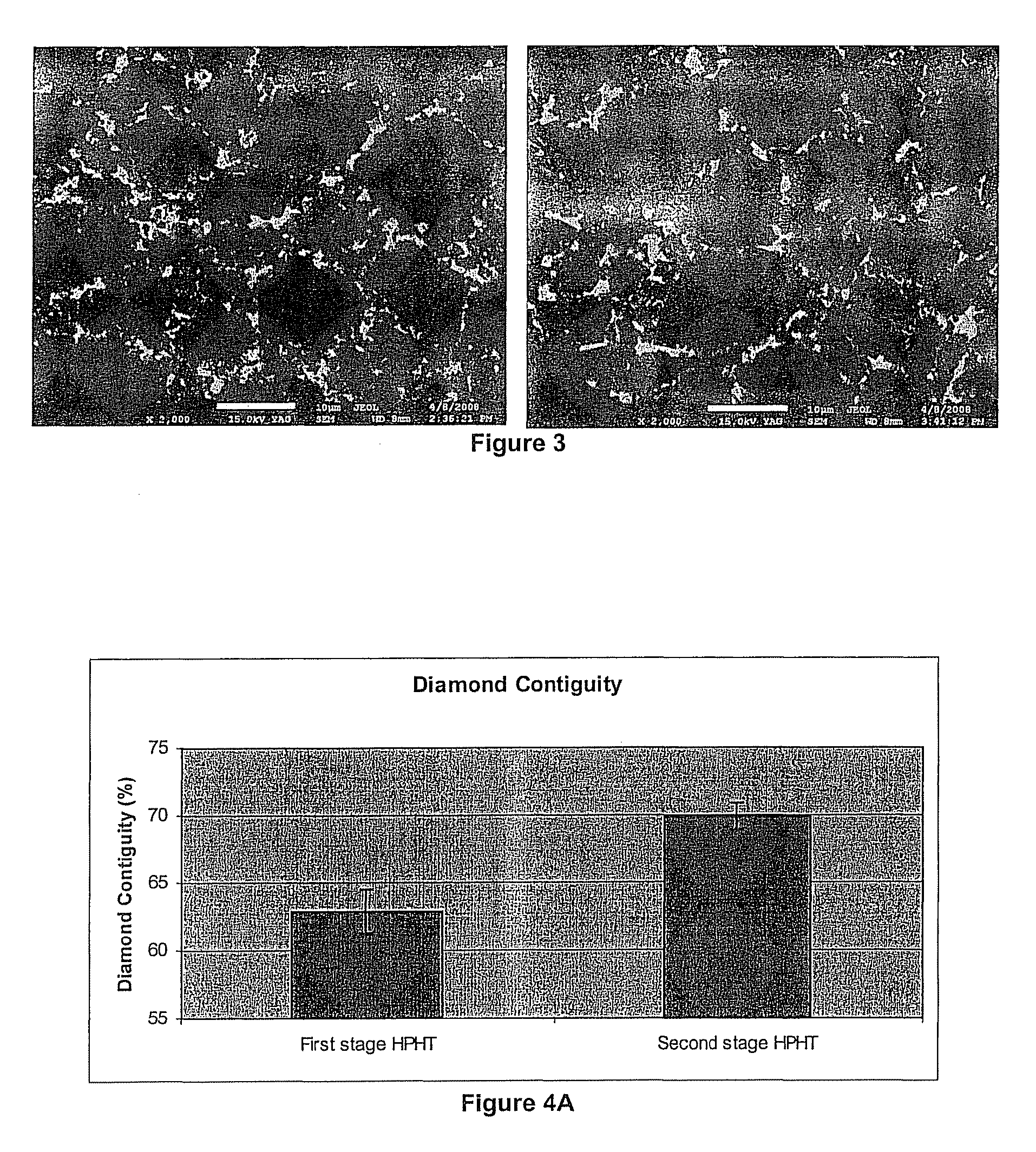

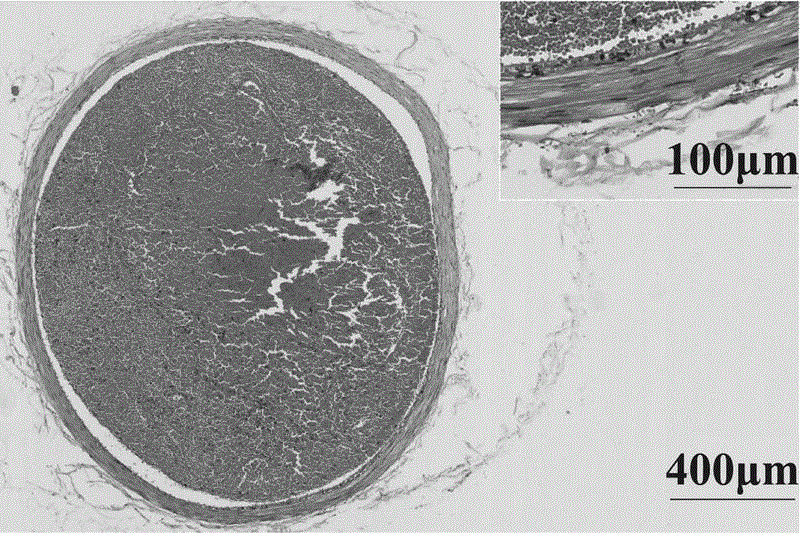

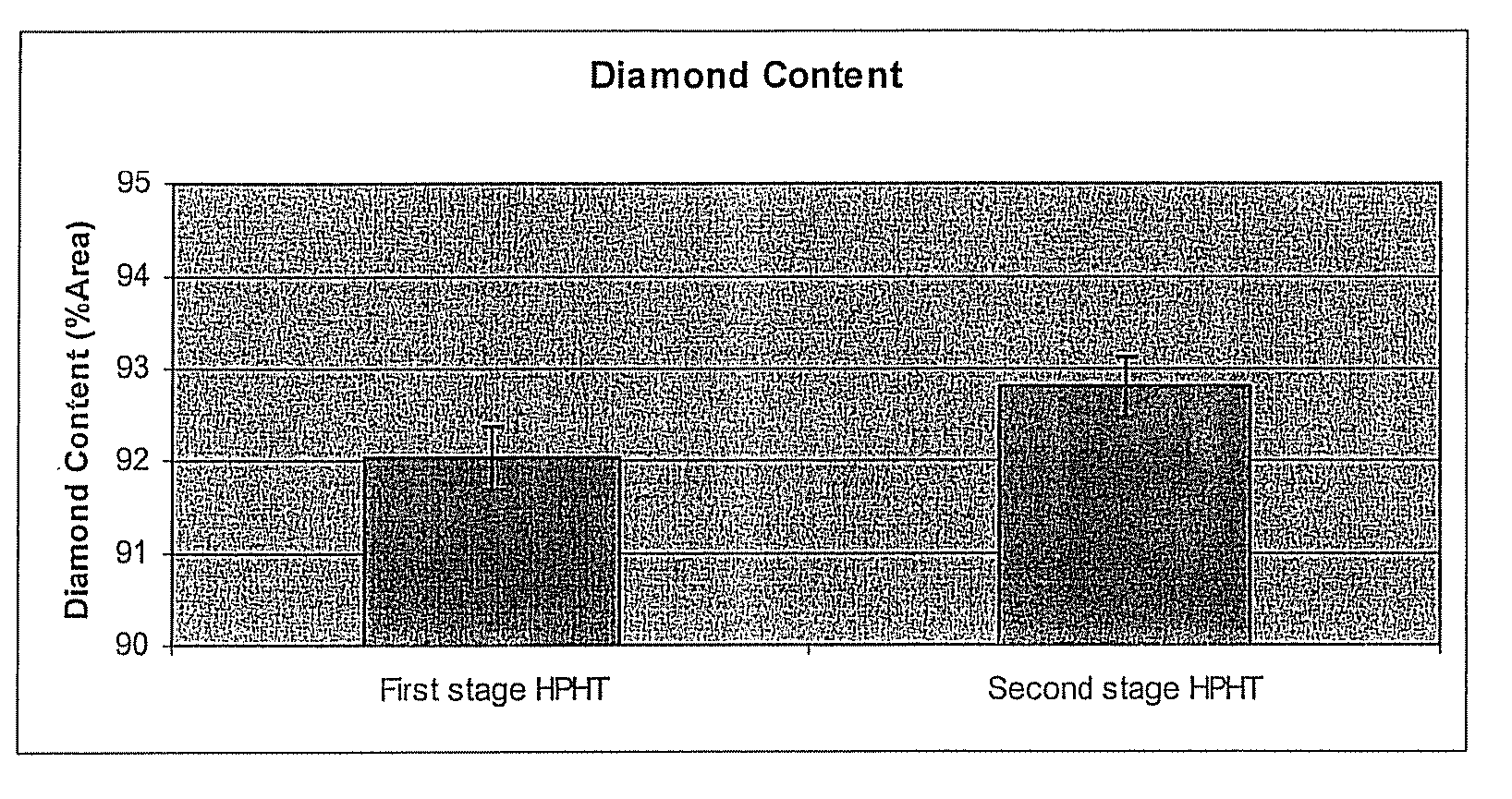

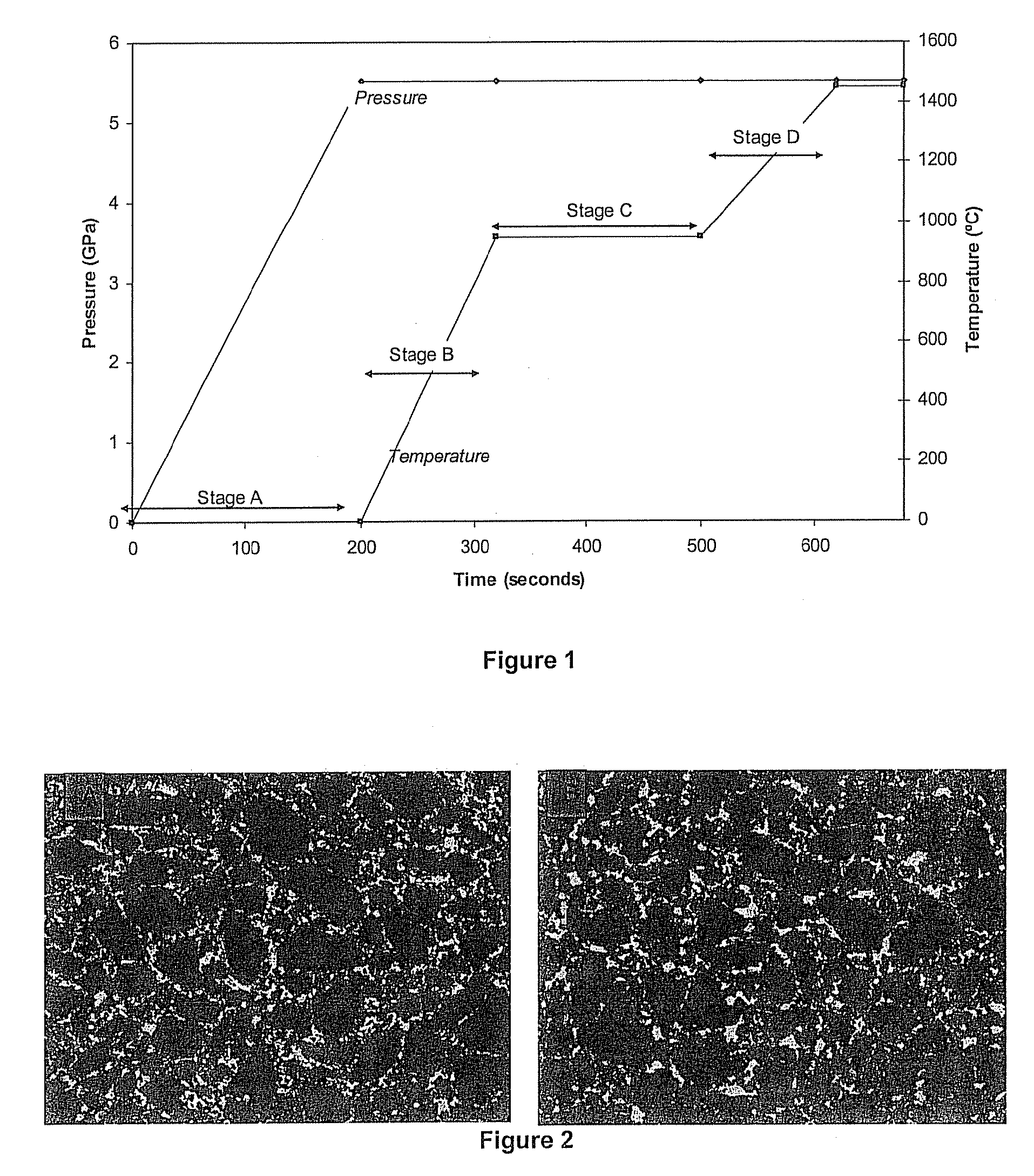

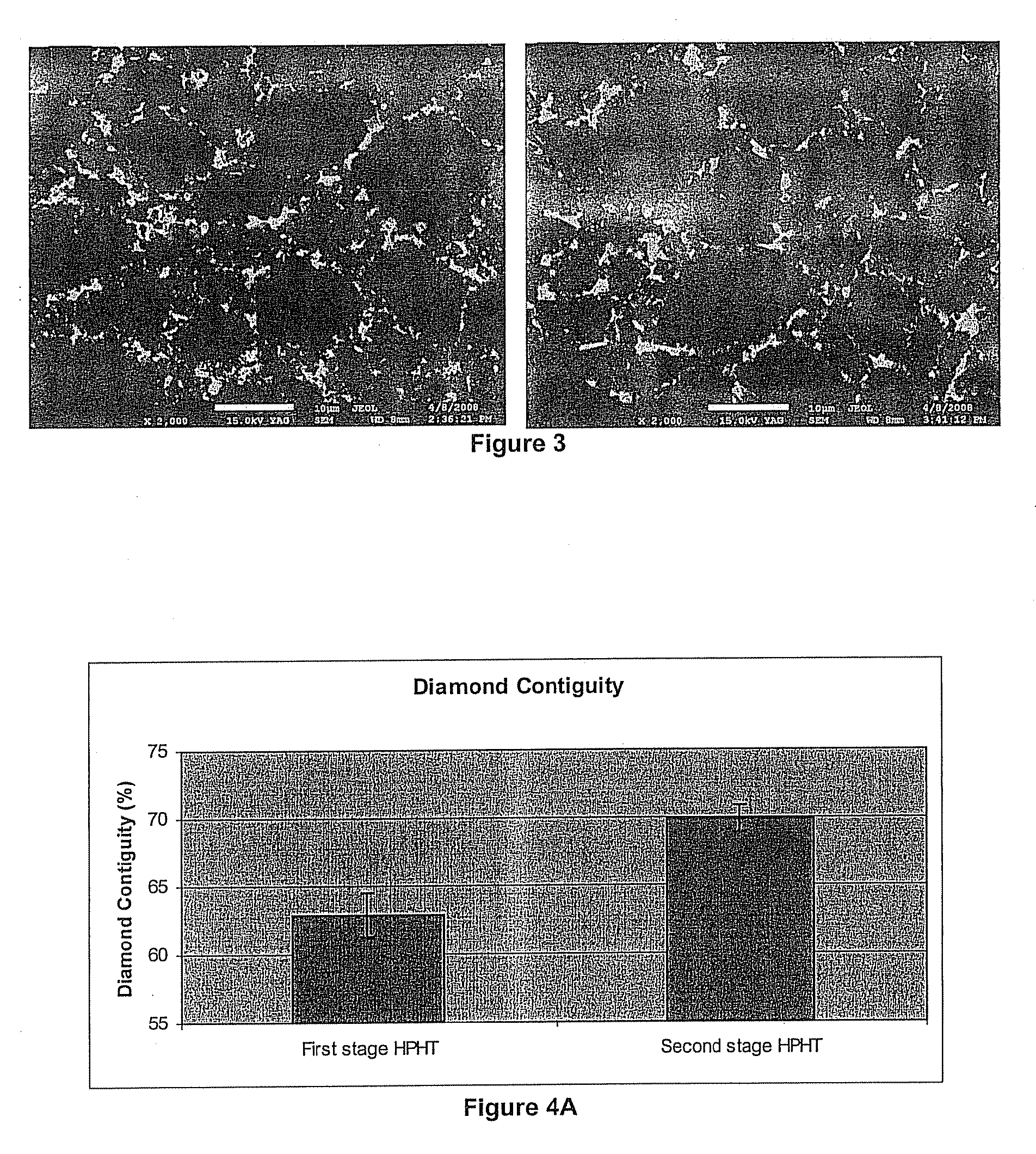

Method for producing a PCD compact

ActiveUS8485284B2High diamond contiguity and densityGood abrasionPigmenting treatmentPressurized chemical processPolycrystalline diamondAlloy

A method of producing a composite diamond compact comprising a polycrystalline diamond (PCD) compact bonded to a cemented carbide substrate is provided. The method includes the steps of: providing a PCD table, preferably a PCD table with diamond-to-diamond bonding and a porous microstructure in which the pores are empty of second phase material bringing together the PCD table and a cemented carbide substrate in the presence of a bonding agent to form an unbonded assembly; subjecting the unbonded assembly to an initial compaction at a pressure of at least 4.5 GPa and a temperature below the melting point of the bonding agent for a period of at least 150 seconds; and thereafter subjecting the unbonded assembly to a temperature above the melting point of the bonding agent and a pressure of at least 4.5 GPa for a time sufficient for the bonding agent to become molten and bond the PCD table to the substrate to form a composite diamond compact.

Owner:ELEMENT SIX ABRASIVES

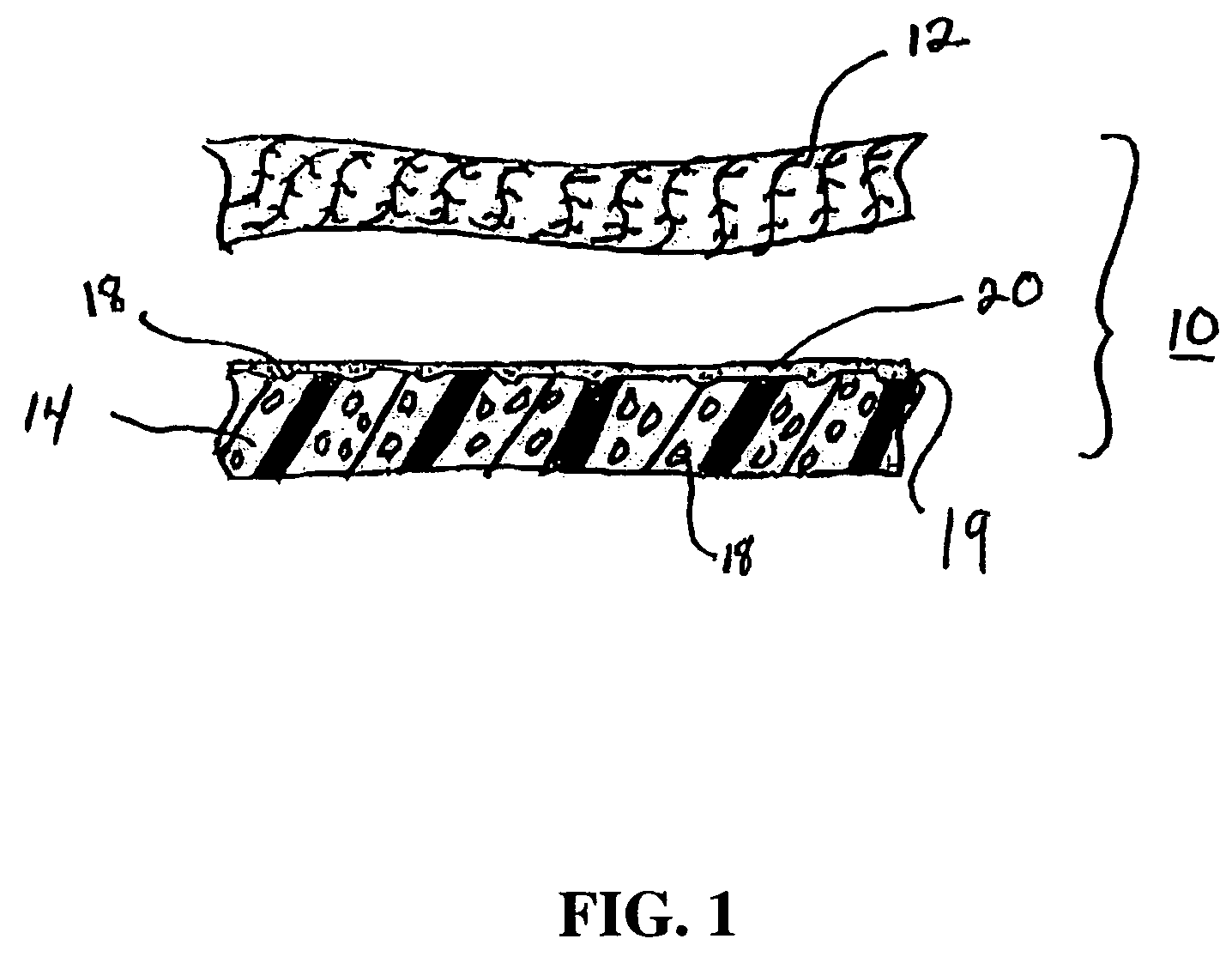

Composite ePTFE/Textile Prosthesis

PendingUS20130095264A1Enhanced tissue ingrowthEnhanced thrombo-resistanceStentsPedestrian/occupant safety arrangementFiberProsthesis

A composite intraluminal prosthesis which is preferably used as a vascular prothesis includes a layer of ePTFE and a layer of textile material which are secured together by an elastomeric bonding agent. The ePTFE layer includes a porous microstructure defined by nodes interconnected by fibrils. The adhesive bonding agent is preferably applied in solution so that the bonding agent enters the pores of the microstructure of the ePTFE. This helps secure the textile layer to the ePTFE layer.

Owner:MAQUET CARDIOVASCULAR LLC

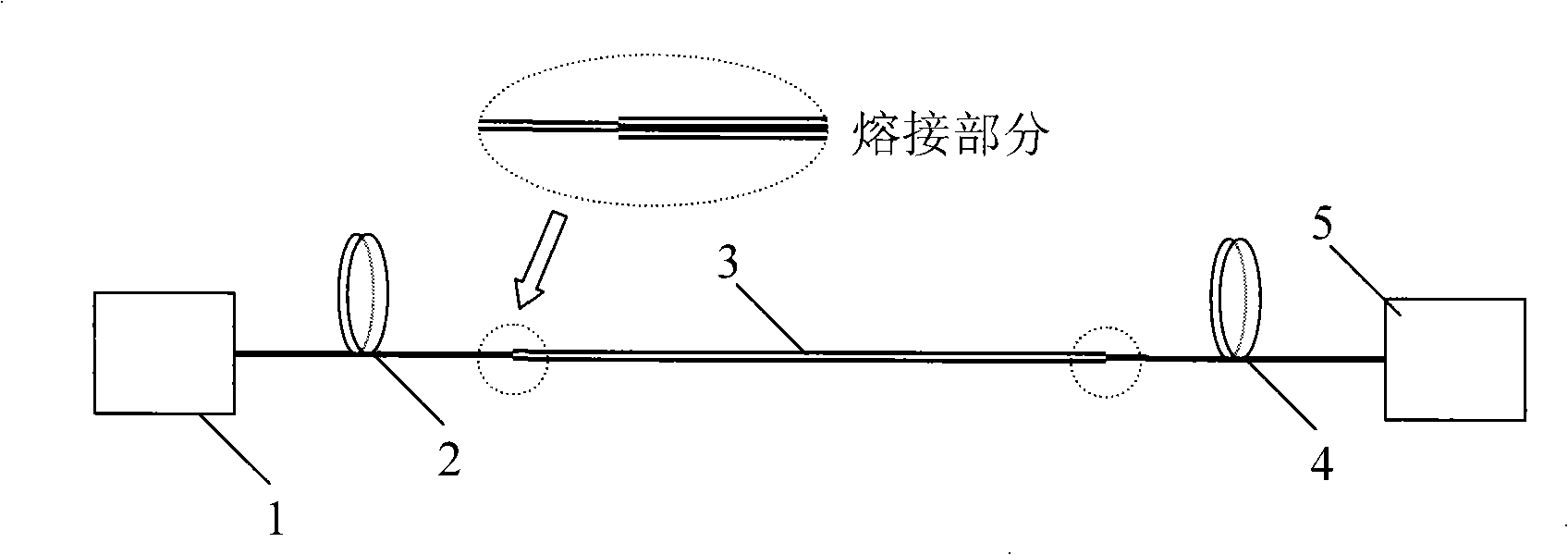

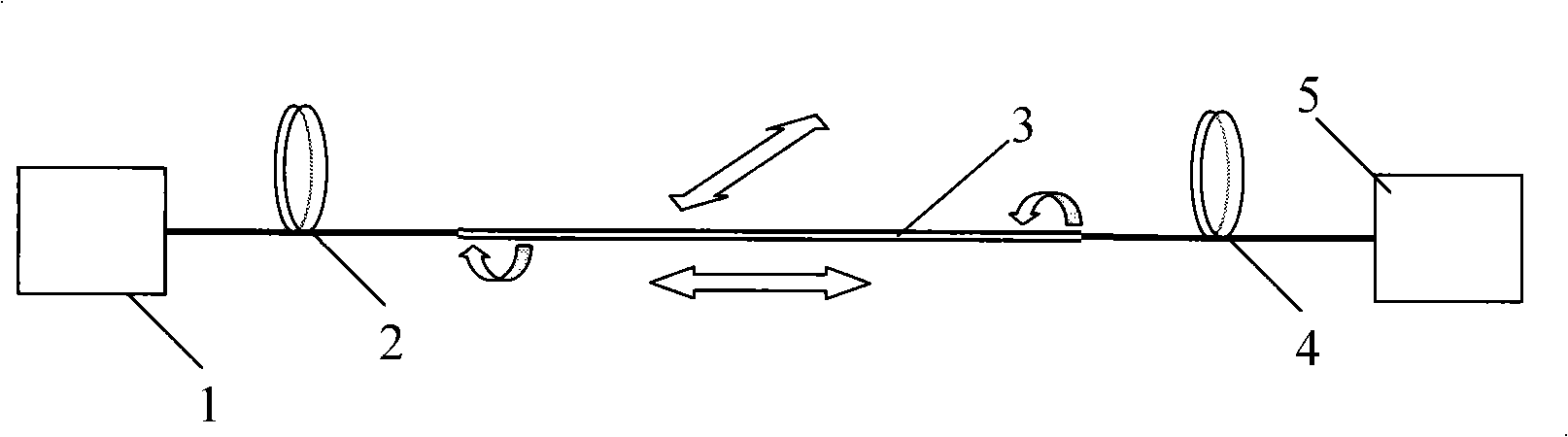

Strain transducer based on porous microstructure optical fibre

InactiveCN101261117AHigh sensitivityRealize insulation isolation detectionCladded optical fibreForce measurement by measuring optical property variationMicro structurePhotovoltaic detectors

The invention provides a strain sensor based on porous micro-structure optical fibre, which is characterized in that the strain sensor is composed of a light source, a lead-in single-mode optical fibre, a porous micro-structure optical fibre, a lead-out single-mode optical fibre and a photoelectric detector, which are connected in series and sequence. The porous micro-structure optical fibre is a pure silica core which is enwound by a ring of sector air holes; the edges of the core present ratchet wheel shaped structure. The strain sensor can measure tension strain, flexibility strain and torsion strain, and has the advantages of high sensitiveness, high temperature resistance and electromagnetic radiation resistance.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

Gold-containing catalyst for preparing vinyl chloride by using acetylene method as well as preparation method and application of catalyst

InactiveCN102327777ANo pollution in the processThere will be no deactivationMolecular sieve catalystsPreparation by halogen halide additionMicro structureEthyl Chloride

The invention discloses a gold-containing catalyst for preparing vinyl chloride by using an acetylene method as well as a preparation method and application of the catalyst. The catalyst contains a gold element, a lanthanum element, a cobalt element, a co-catalytic metal element and a carrier with a porous micro-structure. The gold accounts for 0.3%-2% by mass of the catalyst; the gold element in the catalyst comes from gold chlorides or gold nitrates; the cobalt element comes from chlorides of the cobalt or cobalt nitrates; and the lanthanum element comes from lanthanum chlorides or lanthanum nitrates. The catalyst disclosed by the invention in use is free from inactivation phenomenon caused by sublimation of industrial catalyst mercury chloride, has no pollution to the environment, overcomes defects of high toxicity and high pollution of the conventional industrial catalyst mercury chloride, has the characteristics of simple preparation method, high conversion rate of the acetylene and selectivity of the vinyl chloride, long service life up to 1000 hours or more, high temperature resistance, and high intensity and is renewable, and the conversion rate of the acetylene and selectivity of the vinyl chloride approximate to or exceed the technical indexes of the mercury chloride catalyst.

Owner:TIANJIN UNIV +1

Method for in-situ synthesis of SiC nanowires modified carbon/carbon composite preform by sol-gel method

The invention relates to a method for in-situ synthesis of a SiC nanowires modified carbon / carbon composite preform by a sol-gel method. Since a silica sol-gel system with a porous microstructure is firstly obtained by the sol-gel method, the contact area of the reaction is increased to a greater extent, and the grown nanowires have certain directionality, which is conductive to improving the mechanical properties of materials. The nanowires are immersed in a 2D carbon felt, the obtained silicon source capable of generating SiC nanowires is uniformly dispersed and has low decomposition temperature, the grown nanowires can be stably and uniformly dispersed in the carbon felt, and the efficiency of the densification can be greatly improved. The carbon sources provided by isothermal CVI process deposition natural gas and capable of generating SiC nanowires are reacted with silicon source to generate nanowires and a part of carbon sources are formed into pyrolytic carbon and coated on the surface of nanowires, and the phenomena of the falling, growing and breakage of nanowires occurring in the course of obtaining high-density C / C composite material by the subsequent densification are effectively avoided.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

Multi-functional cermet anodes for high temperature fuel cells

An anode in a Direct Carbon Fuel Cell (DCFC) is provided. The anode includes a cermet anode that can be made of nickel-copper / yttria-stabilized zirconia oxide (Ni—Cu / YSZ) or nickel-copper / gadolina-doped ceria (Ni—Cu / GDC). The surface of the cermet anode is functionalized by decorating it with dispersed catalytic particles. The particles can be made of various materials such as ruthenium (Ru), rhodium (Rh), palladium (Pd), rhenium (Re), osmium, (Os), iridium (Ir), platinum (Pt), gold (Au), or any combination of the particles' alloys and mixtures. Decorating is a process where discrete particles are deposited to the anode surface. In general the particles are not able to contact each other and have a well-defined separation. The cermet anode has a graded porous microstructure spanning from a macropore outer region to a submicron inner region, where the pore span is from tens of microns to hundreds of nanometers.

Owner:DIRECT CARBON TECH

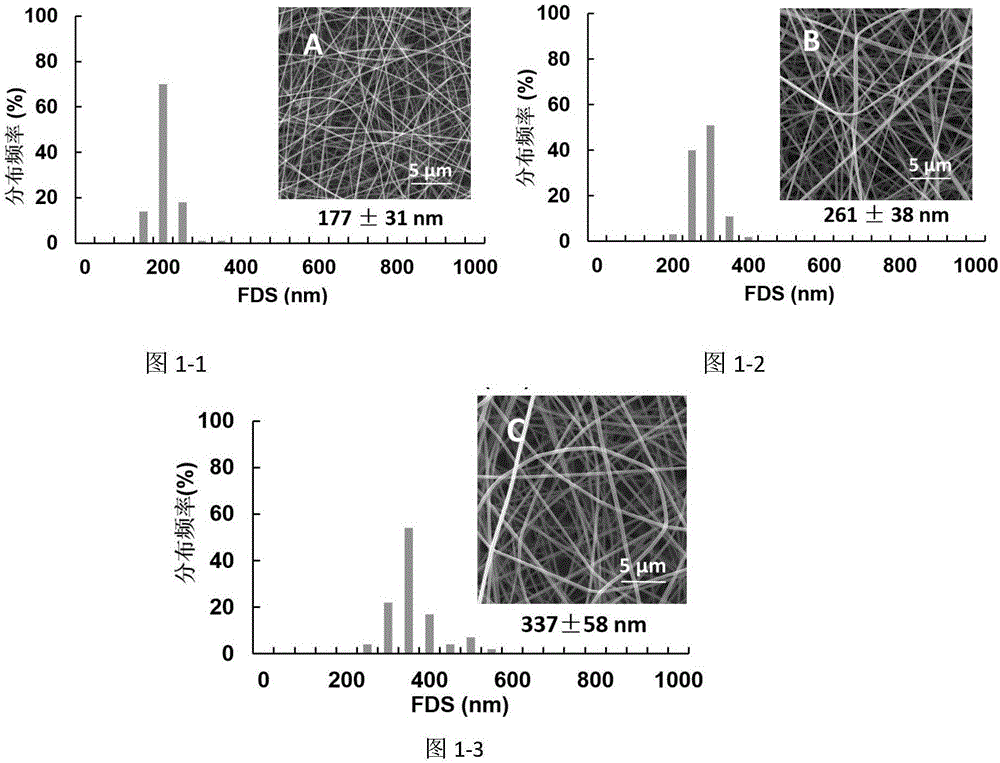

Electrospun polyvinyl alcohol-based tannic acid anti-oxidation nanofiber membrane

ActiveCN106319757AImproves antioxidant activityHigh elongation at breakMonocomponent synthetic polymer artificial filamentNon-woven fabricsFiberMechanical property

The invention relates to an electrospun polyvinyl alcohol-based tannic acid anti-oxidation nanofiber membrane. A prepration method includes the steps of tannic acid-metal ion self-assembly complex solution preparation, polyvinyl alcohol fiber-forming matrix preparation, polyvinyl alcohol-based tannic acid-metal ion complex electrospinning solution preparation and anti-oxidation nanofiber membrane preparation through electrospinning. By the utilization of the dual effects of polyphenol efficient anti-oxidation activity of tannic acid molecular structures and self-assembly chelation crosslinking between the tannic acid molecular structures and metal ions, with polyvinyl alcohol being a membrane-forming matrix, a chelated net structure of tannic acid and the metal ions is constructed by the utilization of the electrospinning technology to enhance fiber mechanical properties, a nanfiber porous microstructure is used for efficiently exerting anti-oxidation activity of tannic acid, a high mechanical property and anti-oxidation function integrated forming technology for preparing the nanofiber membrane in a one-step mode is created, and the polymer nanofiber membrane is endowed with the dual functional characteristics of anti-oxidation and mechanical property enhancement.

Owner:TIANJIN JIESHENG DONGHUI FRESH PRESERVATION TECH

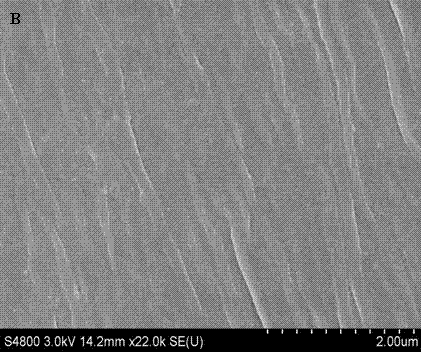

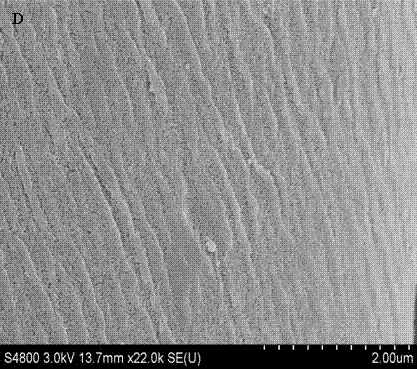

Dimension-adjustable porous micro-structured surface antifouling material

ActiveCN102399487AImprove hydrophobicityImprove antifouling performanceAntifouling/underwater paintsPaints with biocidesPolymer scienceAcrylonitrile

The invention belongs to the technical field of marine life fouling prevention, and relates to a dimension-adjustable porous micro-structured surface antifouling material prepared from mixed materials of organosilicon acrylic acid copolymer resin, an amine nucleation promoter, and a curing agent according to a certain volume ratio. First, organosilicon acrylic acid copolymer resin, the amine nucleation promoter, and the curing agent are well mixed, and the mixture is used for coating, such that a dimension-adjustable porous micro-structured surface is formed under room temperature. The volumeof the amine nucleation promoter takes 0.5% to 2.0% of the volume of organosilicon acrylic acid copolymer resin, and the volume of the curing agent takes 1%-3% of the volume of organosilicon acrylic acid copolymer resin. A mass ratio of a prepolymer containing double-bond organosilicon to propylene monomers is 2:1-1:2. The content of acrylonitrile monomers takes 0-25% of a total mass of the propylene monomers. The adjusting method is advantaged in simple technology, reliable principle, convenient adjustment, and flexible operation. The material is advantaged in good antifouling effect, and issuitable to be used in equipment fouling preventing occasions in various marine environments.

Owner:725TH RES INST OF CHINA SHIPBUILDING INDAL CORP

Solid Polymer Electrolyte and Process for Making Same

A solid polymer electrolyte membrane having a first surface and a second surface opposite the first surface, where the solid polymer electrolyte membrane has a failure force greater than about 115 grams and comprises a composite membrane consisting essentially of (a) at least one expanded PTFE membrane having a porous microstructure of polymeric fibrils, and (b) at least one ion exchange material impregnated throughout the porous microstructure of the expanded PTFE membrane so as to render an interior volume of the expanded PTFE membrane substantially occlusive; (c) at least one substantially occlusive, electronically insulating first composite layer interposed between the expanded PTFE membrane and the first surface, the first composite layer comprising a plurality of first carbon particles supporting a catalyst comprising platinum and an ion exchange material, wherein a plurality of the first carbon particles has a particle size less than about 75 nm, or less than about 50 nm, or less than about 25 nm.

Owner:WL GORE & ASSOC INC

Structural porous biomaterial and implant formed of same

ActiveUS10842634B2Improve mechanical propertiesJoint implantsIncreasing energy efficiencyImplantPorous microstructure

An implant comprising a porous microstructure is disclosed which has an external surface, where at least a region of the external surface is formed of the porous microstructure. The microstructure is defined by at least one lattice of cells. Each cell has a predetermined cell topology and a plurality of edges. One or more of the edges of each cell connect to an adjacent cell along a corresponding edge thereof. Collectively, the cells have a periodic or aperiodic arrangement within the at least one lattice.

Owner:MCGILL UNIV

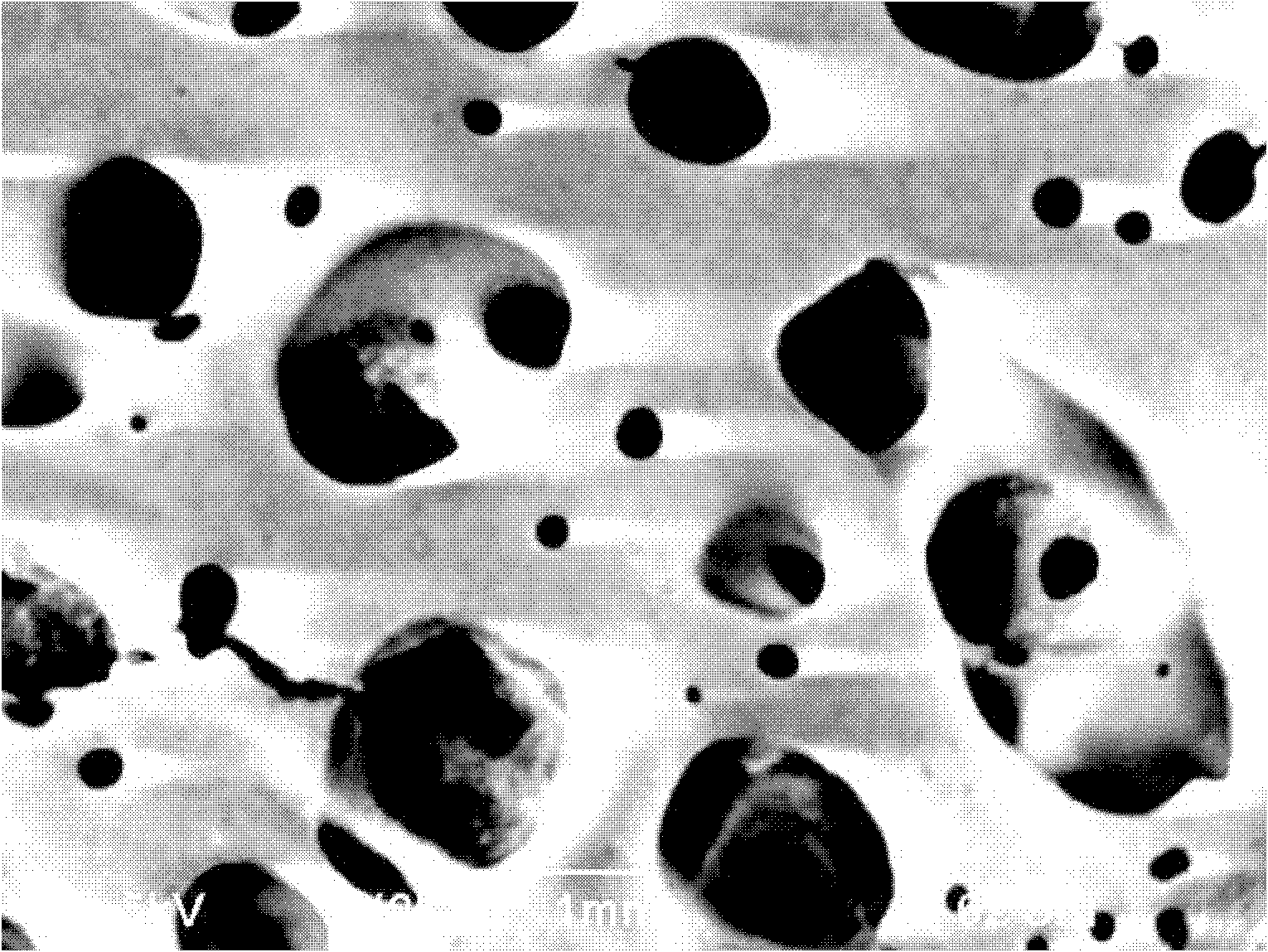

Preparation method of nano ferroferric oxide porous heavy metal adsorbing material

InactiveCN107486132AEasy to operateImprove adsorption capacityOther chemical processesWater contaminantsMicrosphereSolvent

The invention relates to a preparation method of a nano ferroferric oxide porous heavy metal adsorbing material. A three-dimensional microsphere template is prepared through a SiO2 microsphere, and then is fully impregnated in a Fe3O4 precursor solution, and drying, sintering and soaking are performed to obtain the nano ferroferric oxide porous heavy metal adsorbing material with controllable pore size and specific surface area. The microsphere template is fully impregnated through the precursor solution, the template is removed through heating and solvent soaking while the ferroferric oxide is produced, then a pure ferroferric oxide phase and a porous microstructure are obtained, and the high-specific surface area porous adsorbing material is further obtained; the adsorbing material is strong in adsorbing capacity; the method can control the mespore size to be 2-50 nm, a large pore to be more than 50 nm, and the scope of the specific surface area to be 100-1600 m<2> / g; the porous adsorbing material has a strong adsorbing capacity for the heavy metal ions like Pb, Cr, Cd, As, Ni and Cu, and the preparation method has the advantages of simple operation, controllable structure, low preparation cost and broad market prospect.

Owner:湖南明裕环保科技有限公司

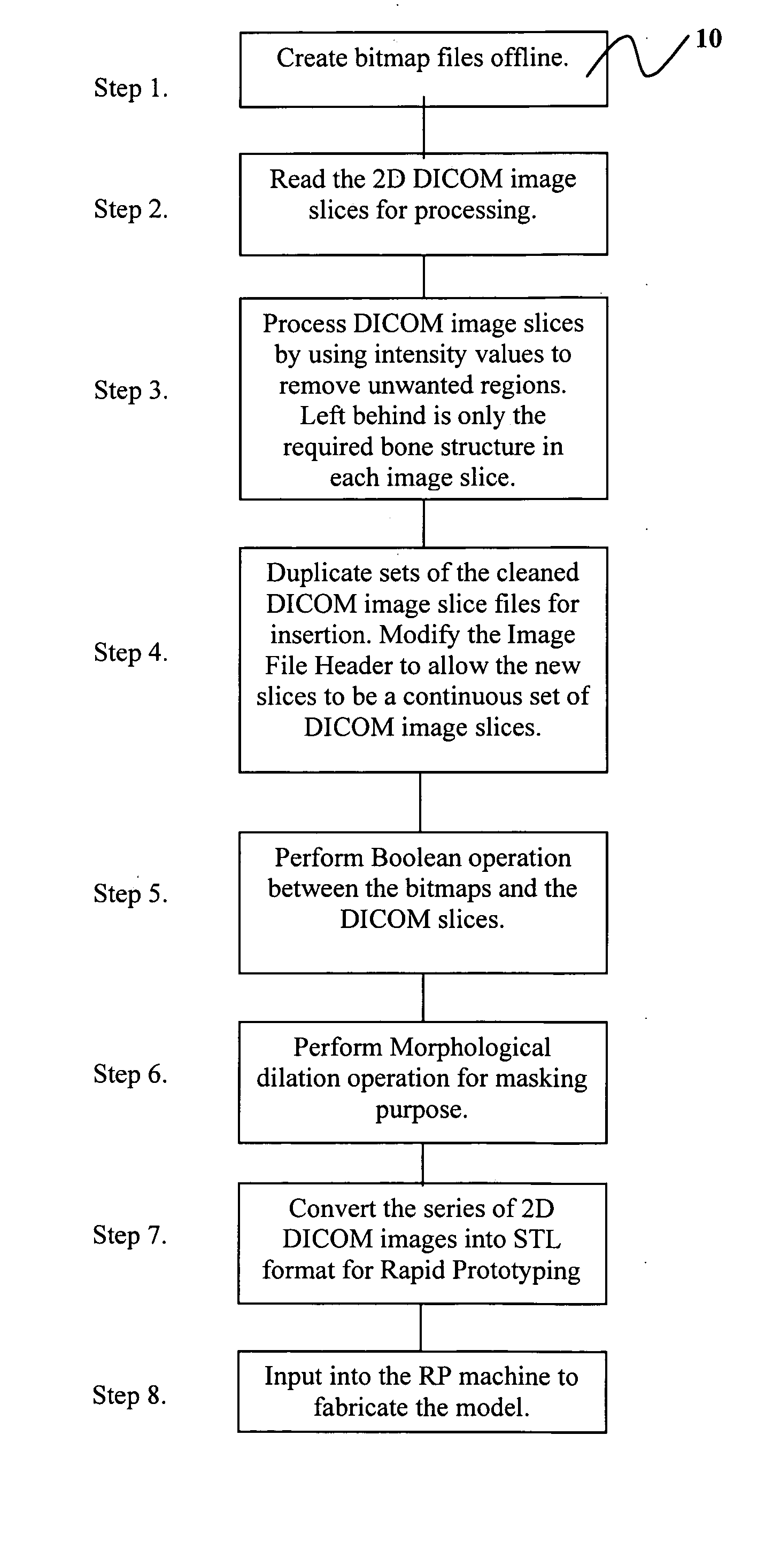

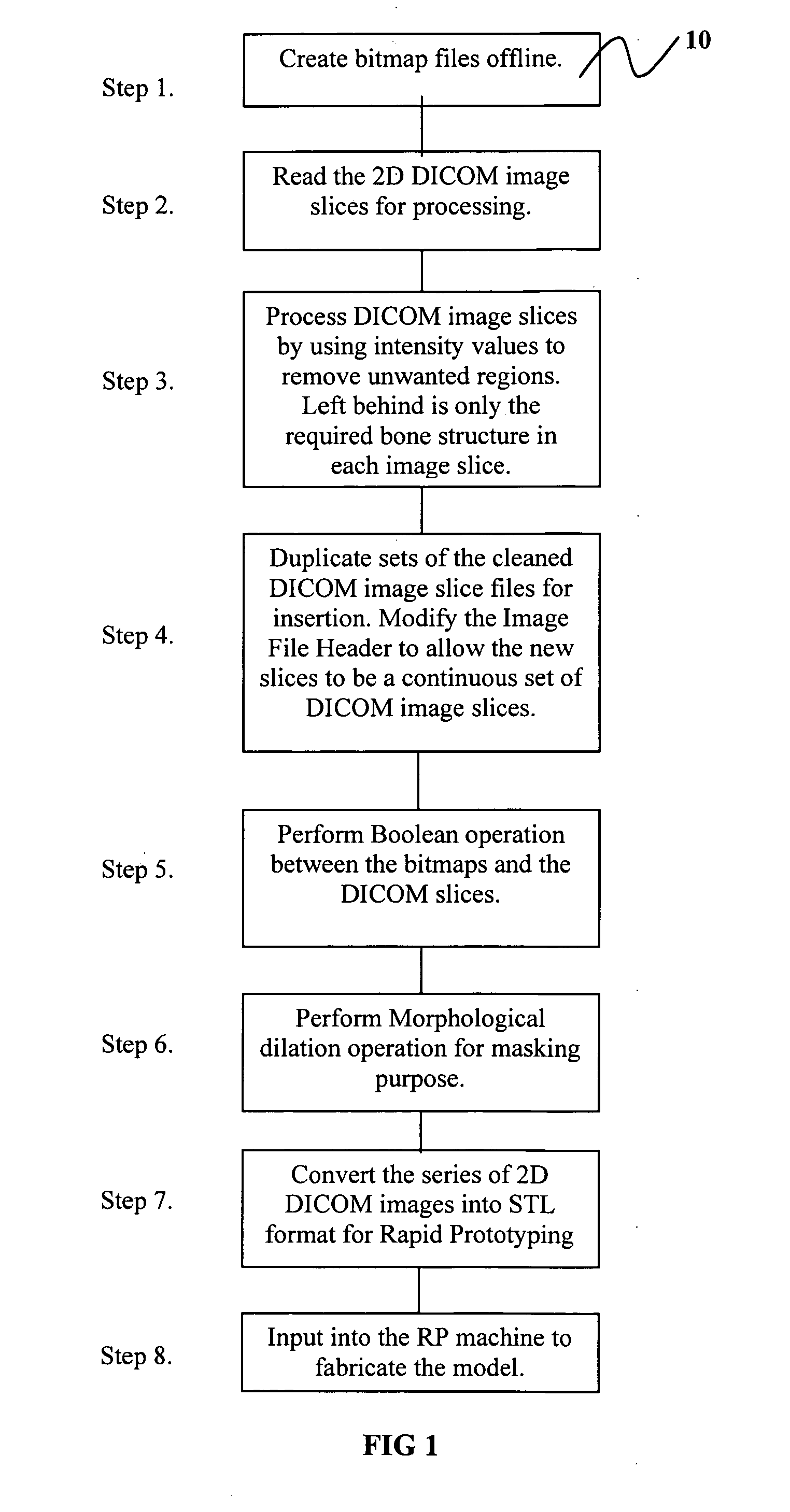

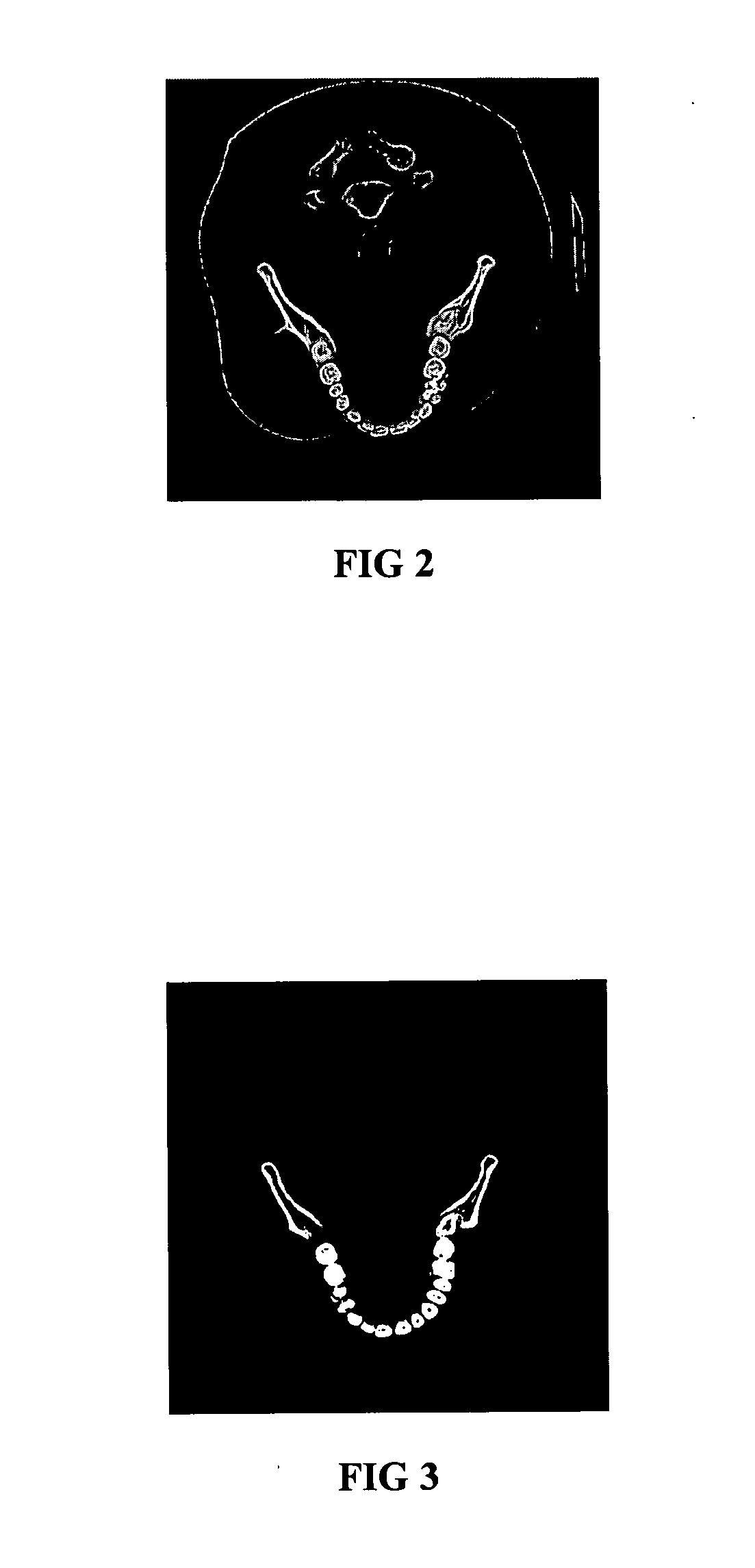

Method for designing 3-dimensional porous tissue engineering scaffold

InactiveUS20060129328A1Easy to manufactureRapid fabrication techniqueAnalogue computers for chemical processesTomographyDiagnostic Radiology ModalityPatient data

The present invention provides a method for designing three-dimensional scaffold structures that are anatomically accurate and possess the necessary internal porous micro-architecture design, wherein the porous micro-architecture is necessary for the proliferation and colonization of cultured cells that lead to tissue formation. The design method of the present invention utilizes the patient data derived from medical imaging modalities (e.g., CT or MRI) in combination with computer data manipulation techniques. The present invention further provides that the resultant scaffold design can be easily manufactured by Rapid Prototyping fabrication techniques.

Owner:NANYANG POLYTECHNIC

Inorganic-organic hybrid three-dimensional interpenetrating network hydrogel materials and preparation method and application thereof

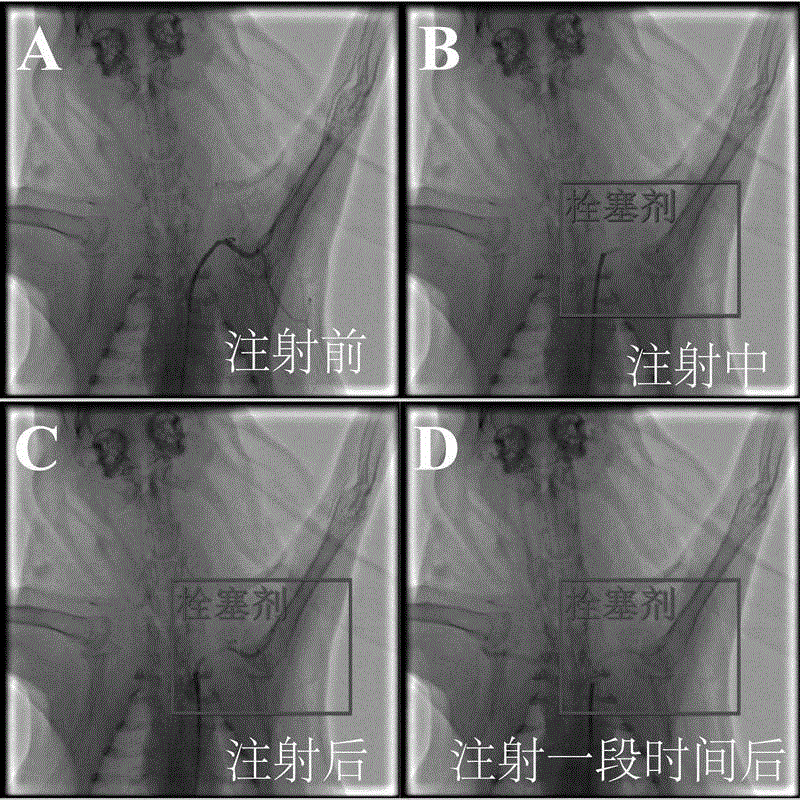

The invention belongs to the field of the hydrogel material application and the technical field of novel medical materials and particularly relates to inorganic-organic hybrid three-dimensional interpenetrating network hydrogel materials and a preparation method and an application thereof. The inorganic-organic hybrid three-dimensional interpenetrating network hydrogel materials comprise inorganic material enhanced first supermolecular hydrogel and room temperature in-situ polymerized second polymer hydrogel. Polymer monomers form a second polymer hydrogel network in a first network formed by inorganic materials and dendritic polymers through in-situ polymerization to form the inorganic-organic hybrid three-dimensional interpenetrating network hydrogel and accordingly the mechanical performance of the inorganic-organic hybrid three-dimensional interpenetrating network hydrogel is high. The sol state is transformed into the gel state in the polymerization process due to the in-situ polymerization of the second polymer hydrogel network and accordingly the injection performance of the inorganic-organic hybrid three-dimensional interpenetrating network hydrogel is good. The inorganic-organic hybrid three-dimensional interpenetrating network hydrogel is of a porous microstructure and accordingly the adsorption capability or the load capacity of the inorganic-organic hybrid three-dimensional interpenetrating network hydrogel are high and X-ray developer or small molecule drugs can be loaded.

Owner:FUDAN UNIV +1

Method for Producing a PCD Compact

ActiveUS20110072730A1High diamond contiguity and densityGood abrasionPigmenting treatmentPressurized chemical processPolycrystalline diamondAlloy

A method of producing a composite diamond compact comprising a polycrystalline diamond (PCD) compact bonded to a cemented carbide substrate is provided. The method includes the steps of: providing a PCD table, preferably a PCD table with diamond-to-diamond bonding and a porous microstructure in which the pores are empty of second phase material bringing together the PCD table and a cemented carbide substrate in the presence of a bonding agent to form an unbonded assembly; subjecting the unbonded assembly to an initial compaction at a pressure of at least 4.5 GPa and a temperature below the melting point of the bonding agent for a period of at least 150 seconds; and thereafter subjecting the unbonded assembly to a temperature above the melting point of the bonding agent and a pressure of at least 4.5 GPa for a time sufficient for the bonding agent to become molten and bond the PCD table to the substrate to form a composite diamond compact.

Owner:ELEMENT SIX ABRASIVES

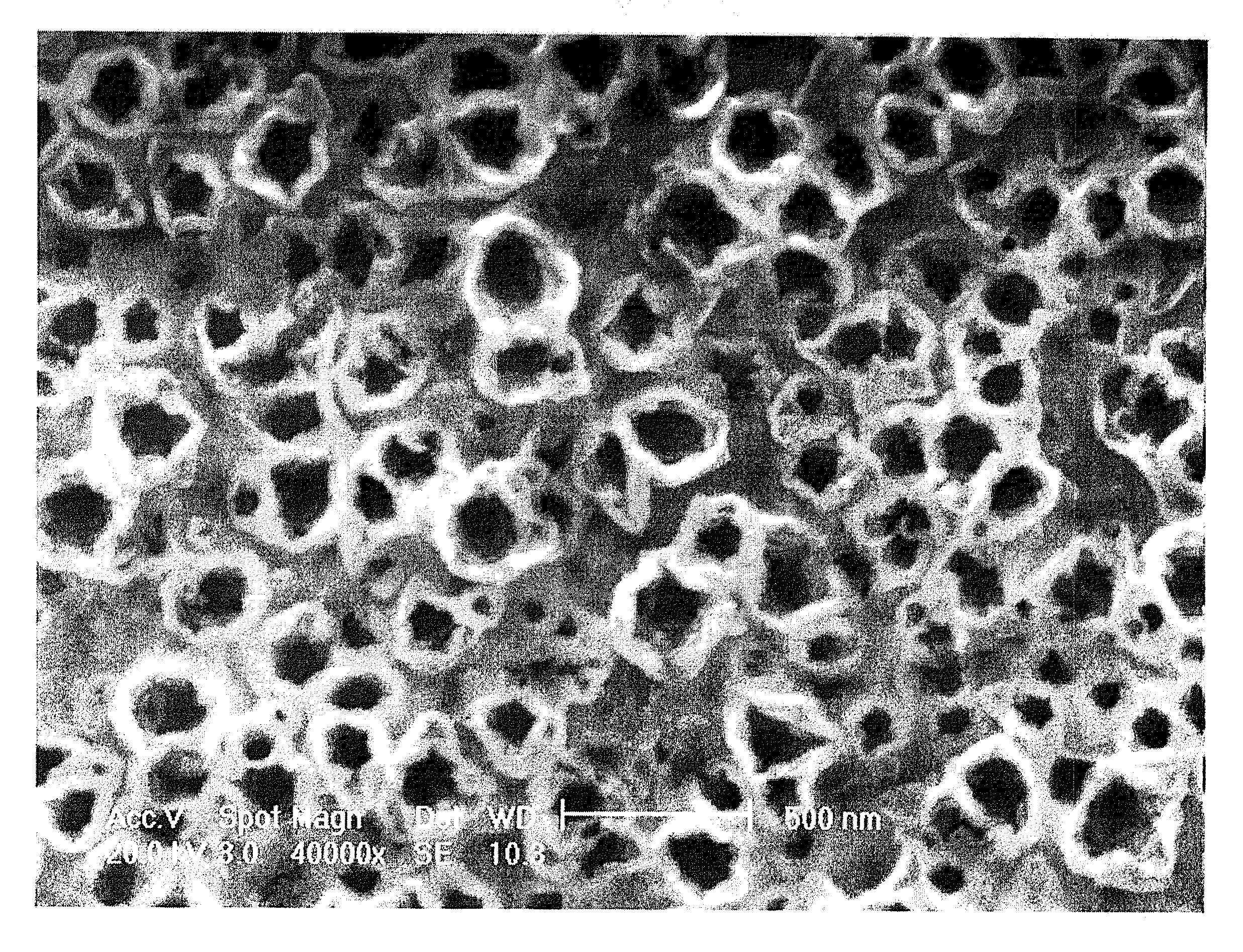

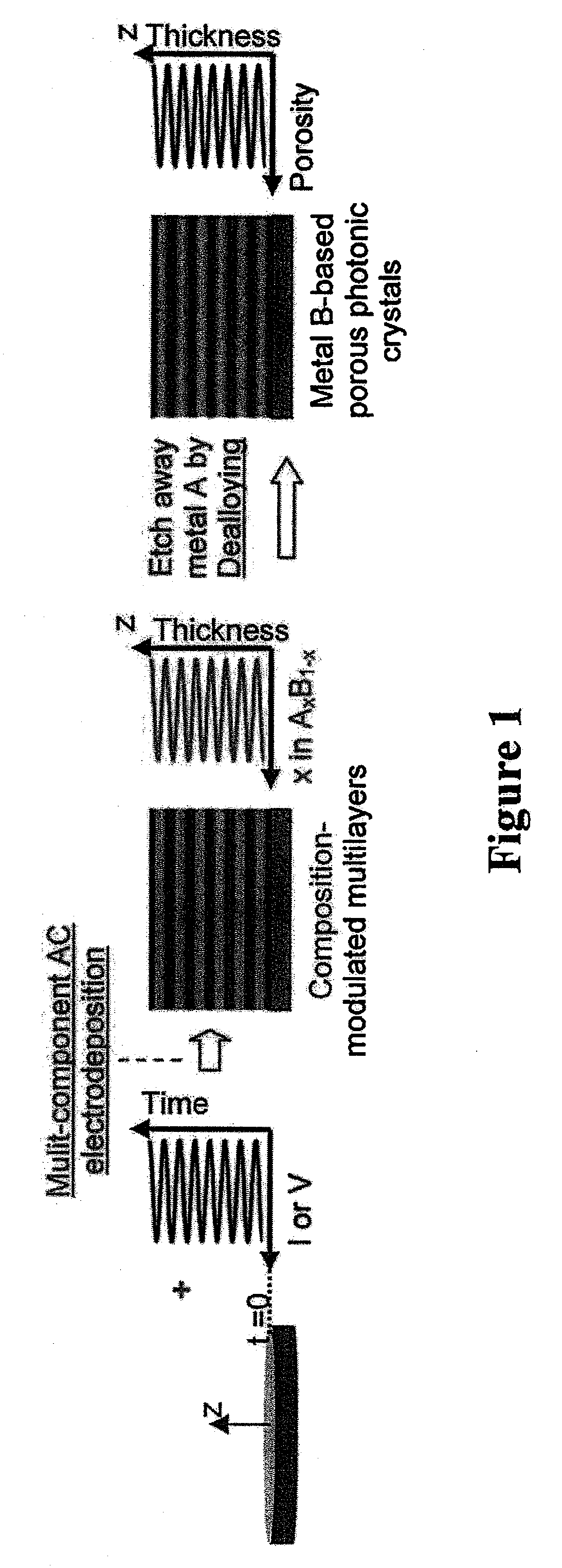

Method of making foraminous microstructures

InactiveUS20100147800A1Simple structureImprove efficiencyPaper/cardboard articlesDecorative surface effectsPhotonicsDepth direction

A foraminous microstructure or film that has photonic or plasmonic properties is made by forming a structure or film composed of at least two constituent materials so that the compositional ratio of the constituent materials varies in a depth direction of the structure, and then removing one of the materials from the structure.

Owner:CITY UNIVERSITY OF HONG KONG

Processing method for cleaning perlite, and cleaning perlite

ActiveCN105250147ALow expansionImprove cleaning and degreasing abilityCosmetic preparationsToilet preparationsCombustionManganese oxide

The invention discloses a processing method for cleaning perlite. The processing method comprises the following steps: weighing raw materials consisting of, by mass, 68 to 70% of silica, 12.5 to 15% of alumina, 1 to 1.5% of iron oxide, 3.5 to 4% of sodium oxide, 0.5 to 2% of calcium oxide, 3 to 3.5% of potassium oxide, 0.1 to 0.4% of manganese oxide and 4 to 6% of water, with the balance being perlite ore sand; preheating and retaining the raw materials in a preheating furnace with a temperature of 300 to 350 DEG C for 20 to 25 min; then adding the preheated raw materials into an expansion generation furnace and carrying out contact combustion at a temperature of 950 to 1000 DEG C; and carrying out retention for 1 to 5 s after occurrence of expansion so as to prepare the cleaning perlite. The cleaning perlite prepared in the invention has a whiteness as high as more than 98, uniform particle sizes, an average particle size of 1 mm and a porous microstructure, is light, loose and soft, can be crushed by slight pressing of fingers, shows water and oil absorbing ability and good cleaning effect and can be widely used as a raw material for daily washing chemicals like a liquid soap or a hand cleaner.

Owner:广东盛达穗南环保科技有限公司

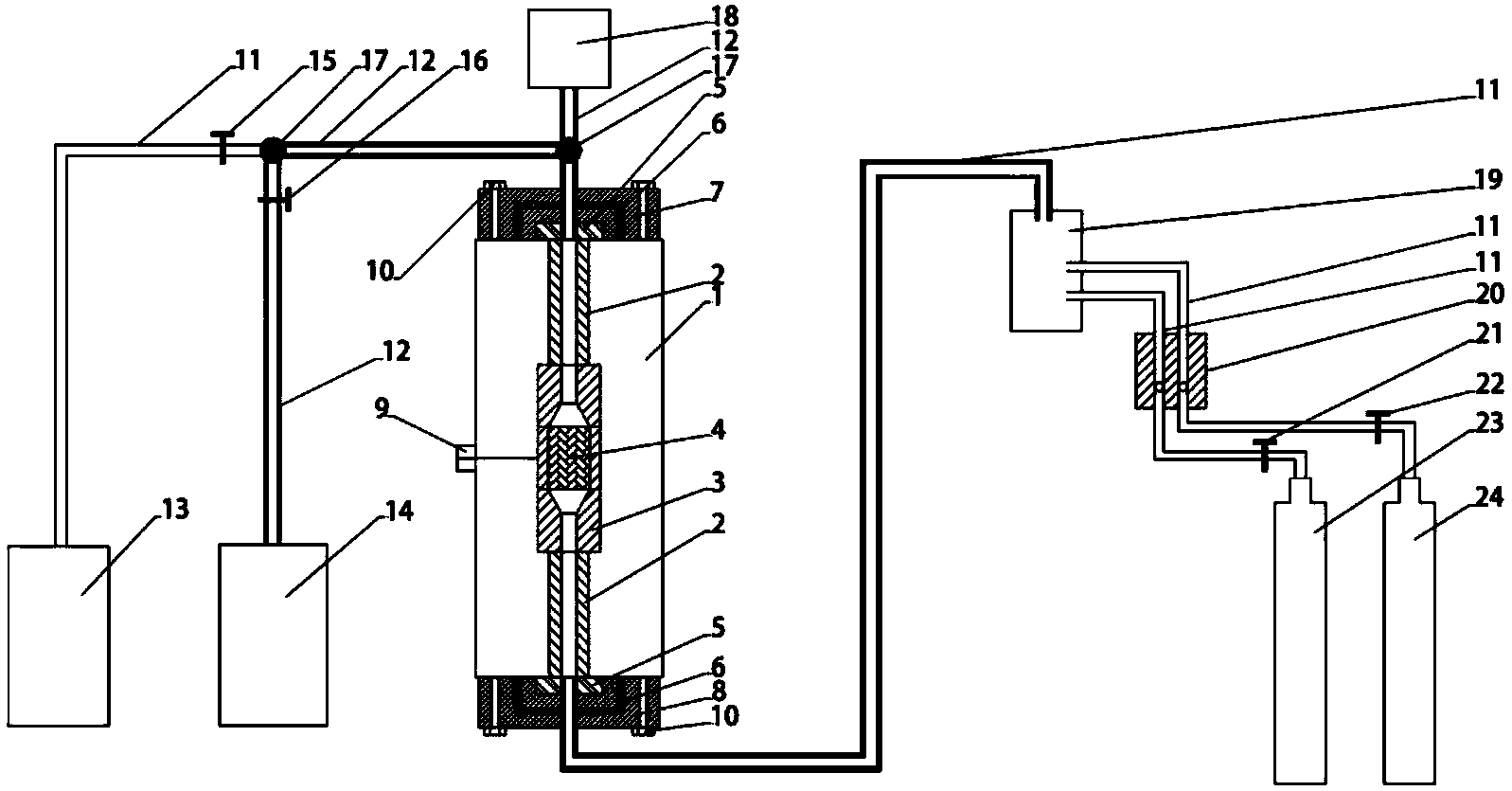

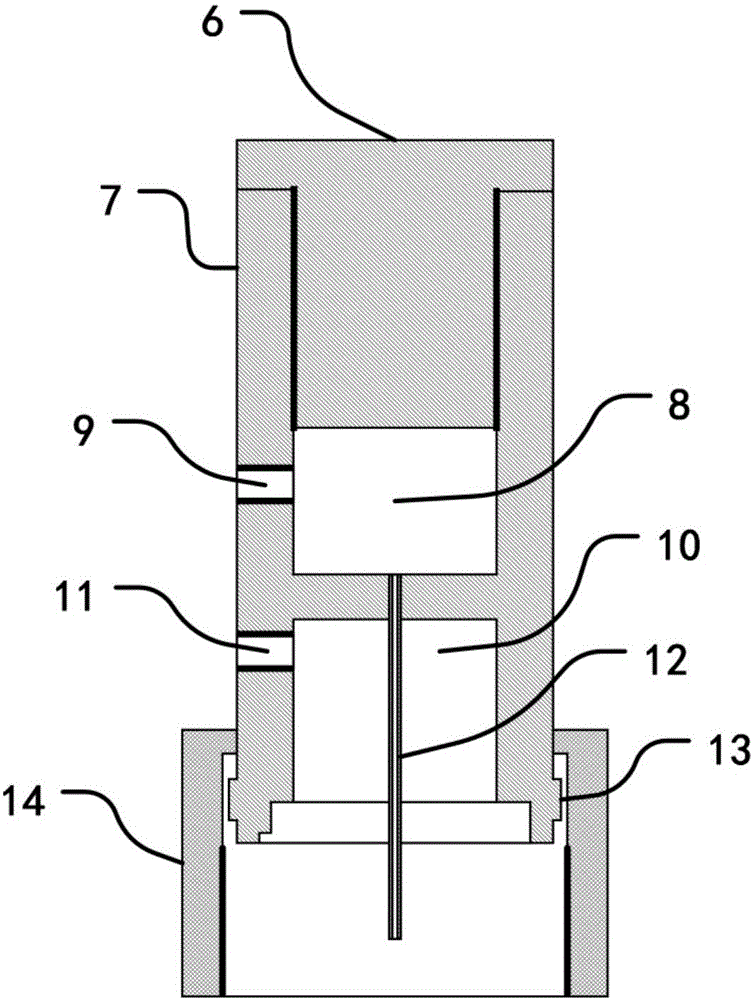

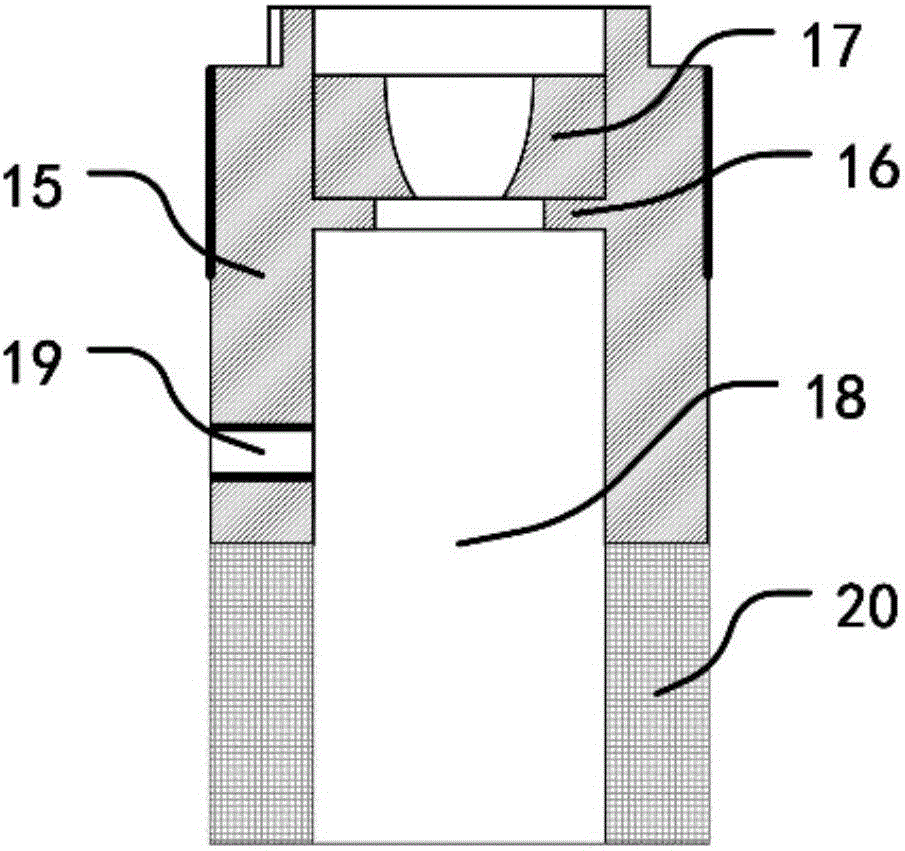

An air pressure control method and device used for photonic band gap optical fiber drawing

ActiveCN106495464AStable air pressureSolve the problem of independent and precise control of regional air pressureGlass making apparatusEngineeringIntermediate Fiber

The invention discloses an air pressure control method and device used for photonic band gap optical fiber drawing, and belongs to the technical field of optical fiber manufacturing. The method includes firstly inserting an intermediate into an intermediate fixing table, sealing the intermediate and the intermediate fixing table with sealing glue, connecting a single-cavity body and a double-cavity body in a threaded manner, with a fiber core duct being inserted into an intermediate fiber core during connection, and after assembling is finished, communicating a fiber-core-cavity gas pipe port, a cladding-cavity gas pipe port and an outer-cavity gas pipe port to a gas chamber of an air pressure control electric part through gas guiding pipes separately to achieve independent air pressure control of three regions which are a fiber core cavity, a cladding cavity and an outer cavity. The method and the device overcome a problem of independent precise air pressure control of the three regions during a photonic band gap optical fiber drawing process. The method and the device have universality and are suitable for porous micro-structured optical fiber drawing requiring independent air pressure control for separated regions. A pressure difference is adopted to determine on-off control time of an electromagnetic valve, thus controlling a gas flux through the pressure difference and increasing air pressure control precision.

Owner:BEIHANG UNIV

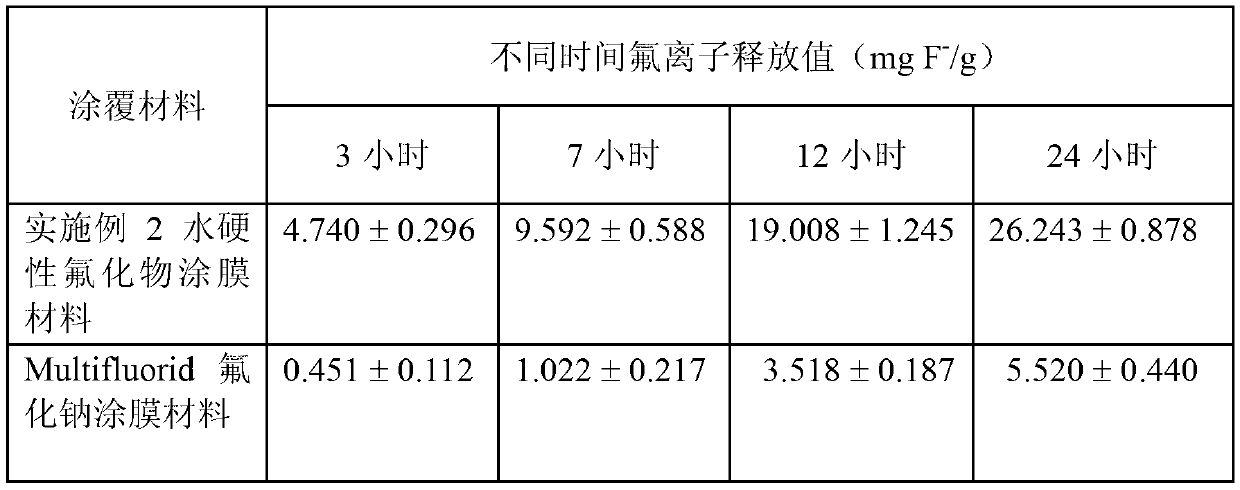

Hydraulic fluoride varnish material

InactiveCN103211710ARelease fullyImprove hydrophilicityImpression capsDentistry preparationsSolubilityMagma

The invention relates to a hydraulic fluoride varnish material, which includes a film-forming material, a fluoride and a volatile solvent, and also includes an adhesion promoter and a suspending aid. The fluoride is superfine inorganic fluoride powder with good water solubility and its adding amount in a coating material is 1-7mg / ml; the particle size of the inorganic fluoride powder is 0.1-10.0 micrometers; and the content of the film-forming material in the coating material is 20%-90%. The hydraulic fluoride varnish material provided in the invention is a premixed single-component fluoride particle suspending magma and contains 5% of fluoride. During application, the hydraulic fluoride varnish material is directly daubed on a tooth surface, needs no blow drying, and gradually hardens into a film after encountering saliva in the oral cavity. The hardened varnish has a porous microstructure, and has good hydrophilicity, can fully release fluorine ions, and bring tooth fluorination and caries prevention functions into play.

Owner:STOMATOLOGICAL HOSPITAL NO 4 ARMY SURGEON UNIV PLA

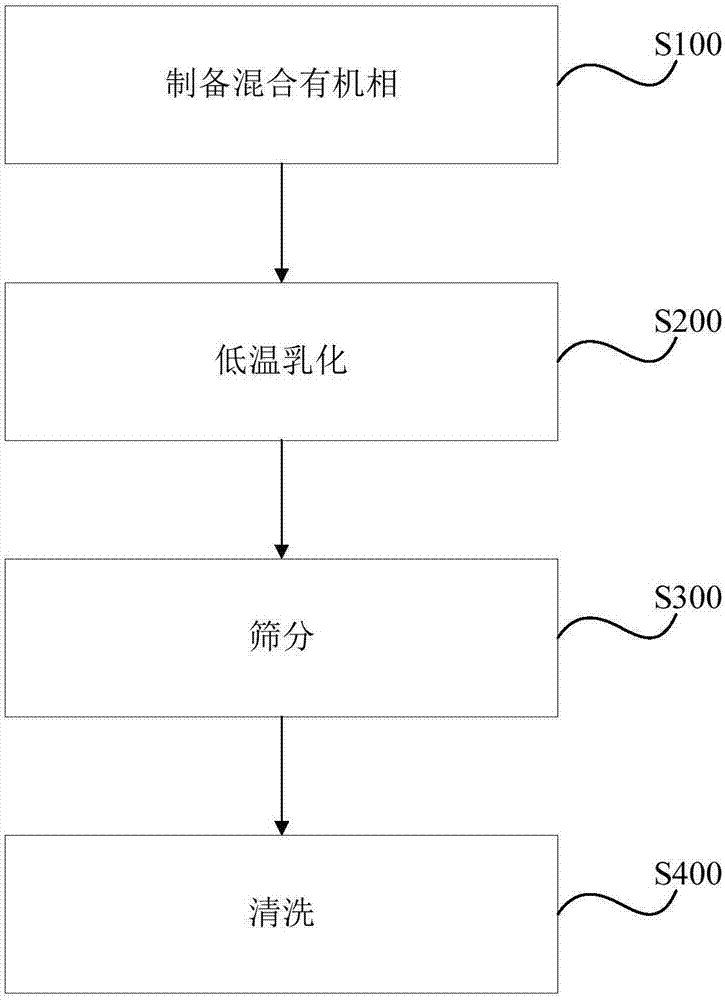

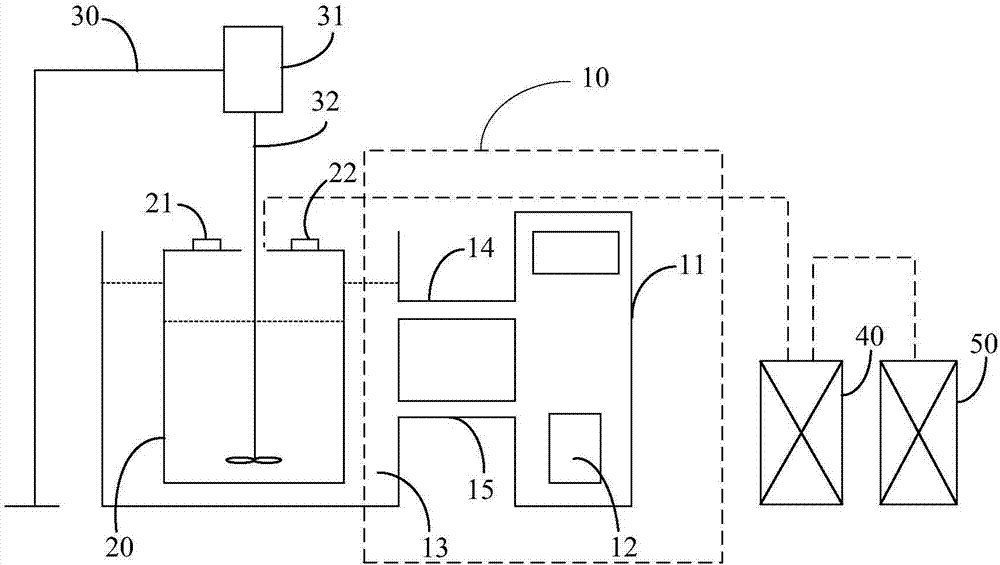

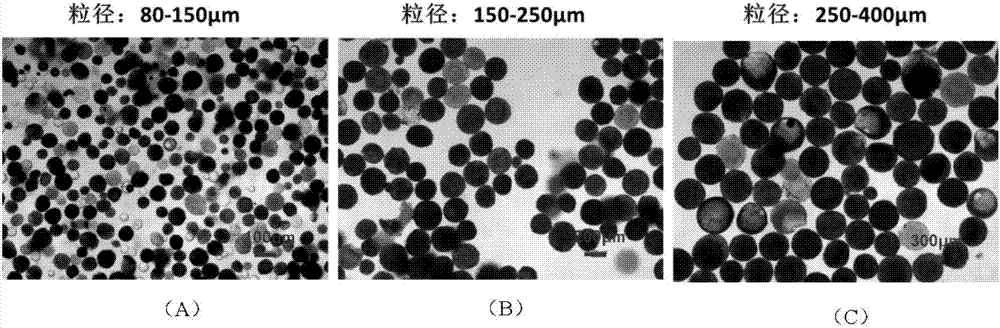

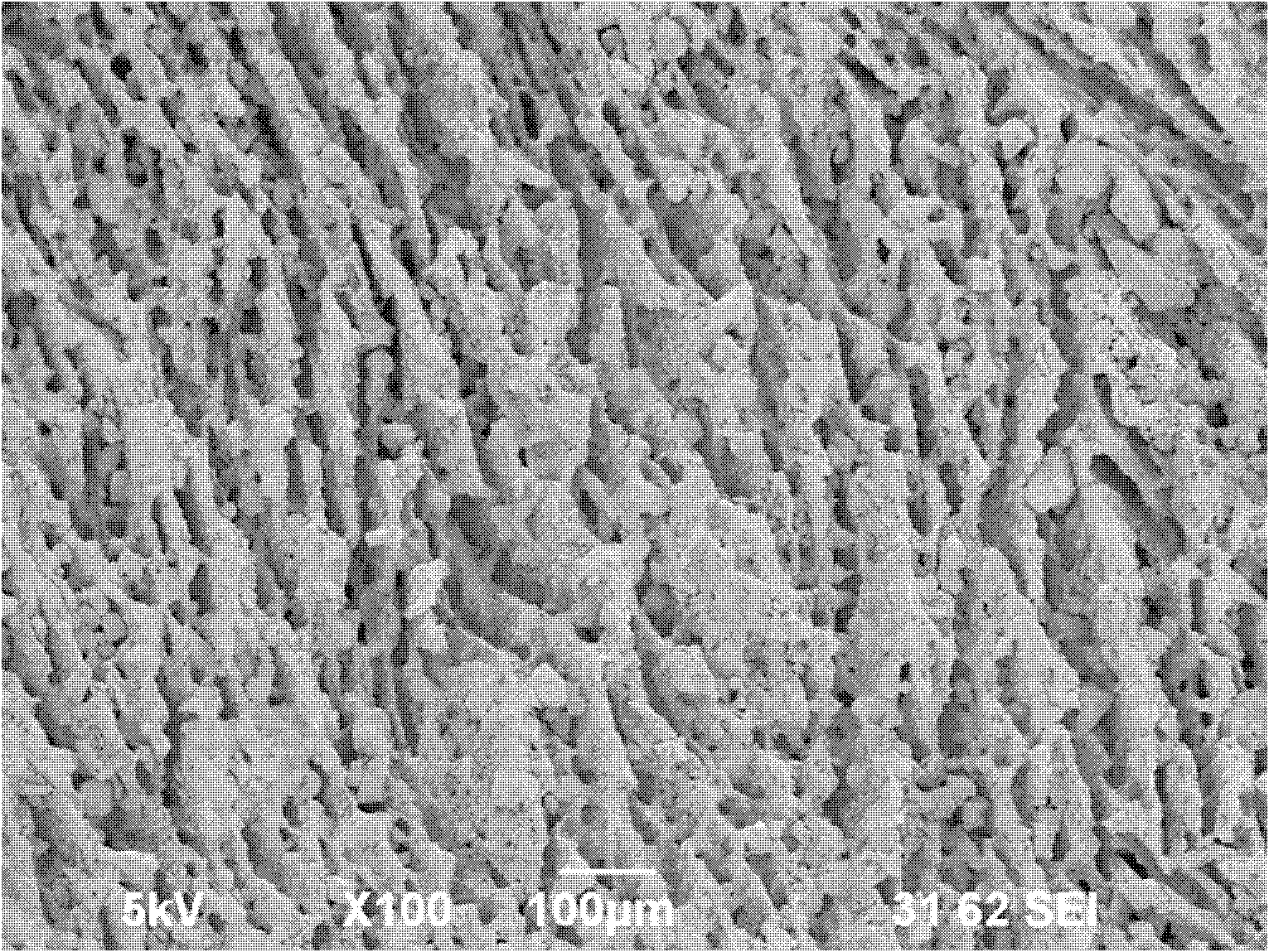

Porous microcryogel cell three-dimensional culture carrier, and preparation method and preparation system thereof

PendingCN106978384AImprove cooling effectBioreactor/fermenter combinationsBiological substance pretreatmentsCultured cellBioreactor

The invention discloses a porous microcryogel cell three-dimensional culture carrier, and a preparation method and a preparation system thereof. The preparation method comprises the following steps: preparing a mixed organic phase; adding an aqueous phase solution to the mixed organic phase, and carrying out stirring process, ultrasonic process or microfluid process emulsifying to prepare a uniform water-in-oil emulsion system; filtering the water-in-oil emulsion system to leave a carrier material to be cleaned; and cleaning the carrier material in order to obtain the porous microcryogel cell three-dimensional culture carrier, wherein the emulsification step is carried out at a temperature not higher than 0 DEG C. The preparation method can realize the homogeneous mass production of the porous microcryogel cell three-dimensional culture carrier, and the porous microcryogel cell three-dimensional culture carrier has a large porosity, keeps the cell activity at a high level, promotes cell functions, has high mechanical elasticity, and can well protect the cultured cells from being damaged by high mechanical shearing force in a bioreactor in order to improve the survival rate of the cells.

Owner:TSINGHUA UNIV +1

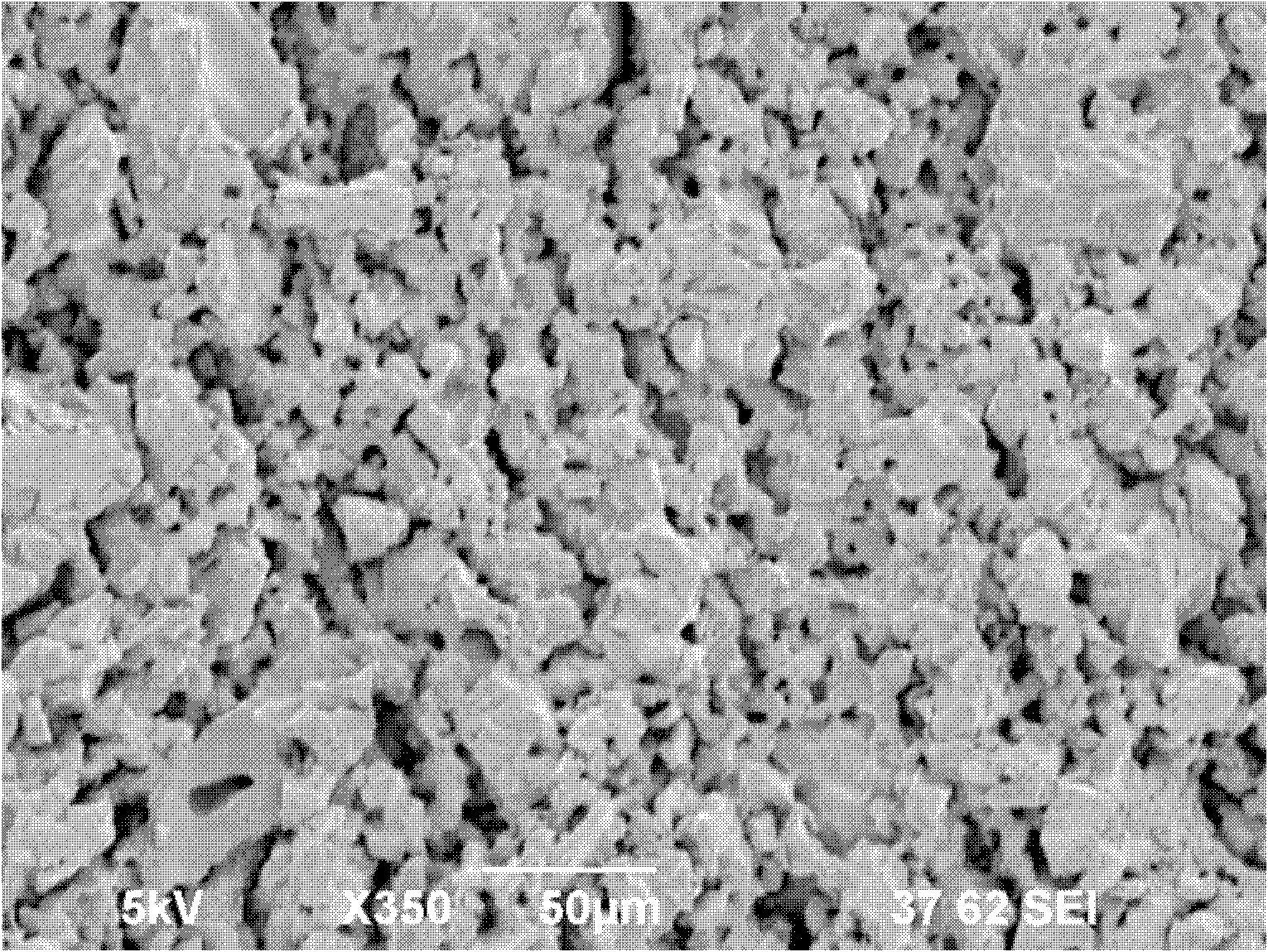

Preparation method of porous Al2O3 ceramic

The invention relates to a preparation method of porous Al2O3 ceramic. The preparation method comprises the steps: adopting sintered-plate shaped alundum powder as raw material, adopting water glass solution as a binding agent, mixing the sintered-plate shaped alundum powder and the water glass solution into suspending liquid, fully stirring, injecting the obtained suspending liquid into a mold, freezing the suspending liquid in a vacuum freeze dryer, carrying out continuous drying thoroughly under vacuum state on the frozen suspending liquid, then demolding the sample, placing the demolded sample into a high-temperature box-type electric furnace, rising the temperature to 1500-1600 DEG C, keeping the temperature for 2 hours, and cooling naturally along the furnace to obtain the porous Al2O3 ceramic. As a vacuum freeze drying technique is adopted, the invention does not add any organic or inorganic chemical harmful substances, does not need special templates, and adopts ice as a hole-making template; and after the ice crystal is sublimated and removed, the ceramic particles obtain a porous microstructure of negative duplicates for growth of the ice crystal. The preparation method better inherits the ice crystal appearance, also does not need the processes of removing the templates, such as calcining, chemical etching and the like, not only has simple technique, but also has unique hole structure, and is easy to obtain a special hole structure.

Owner:SHAANXI UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com