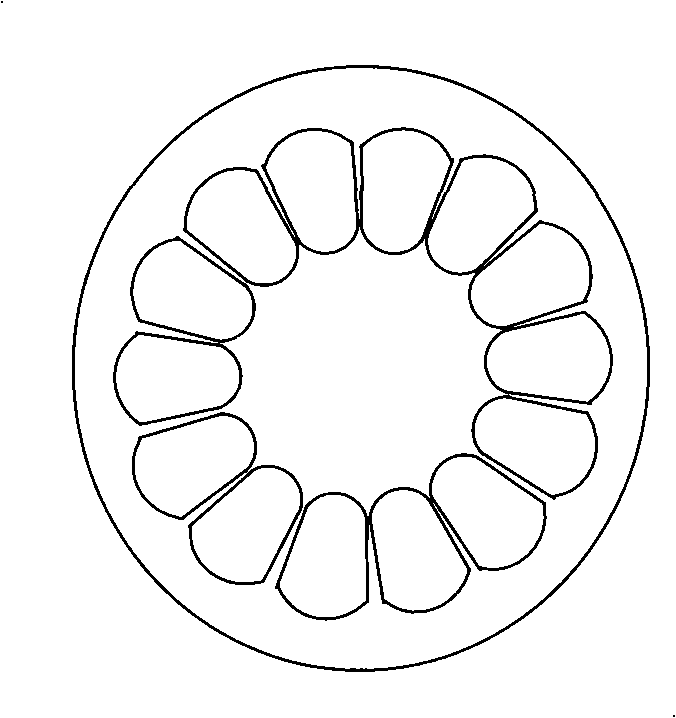

Strain transducer based on porous microstructure optical fibre

A microstructure optical fiber and strain sensor technology, applied in the field of sensing, can solve the problems of difficult control of the melting taper process, high price of photonic crystal fibers, etc., and achieve the effects of being conducive to popularization and application, low price and high sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

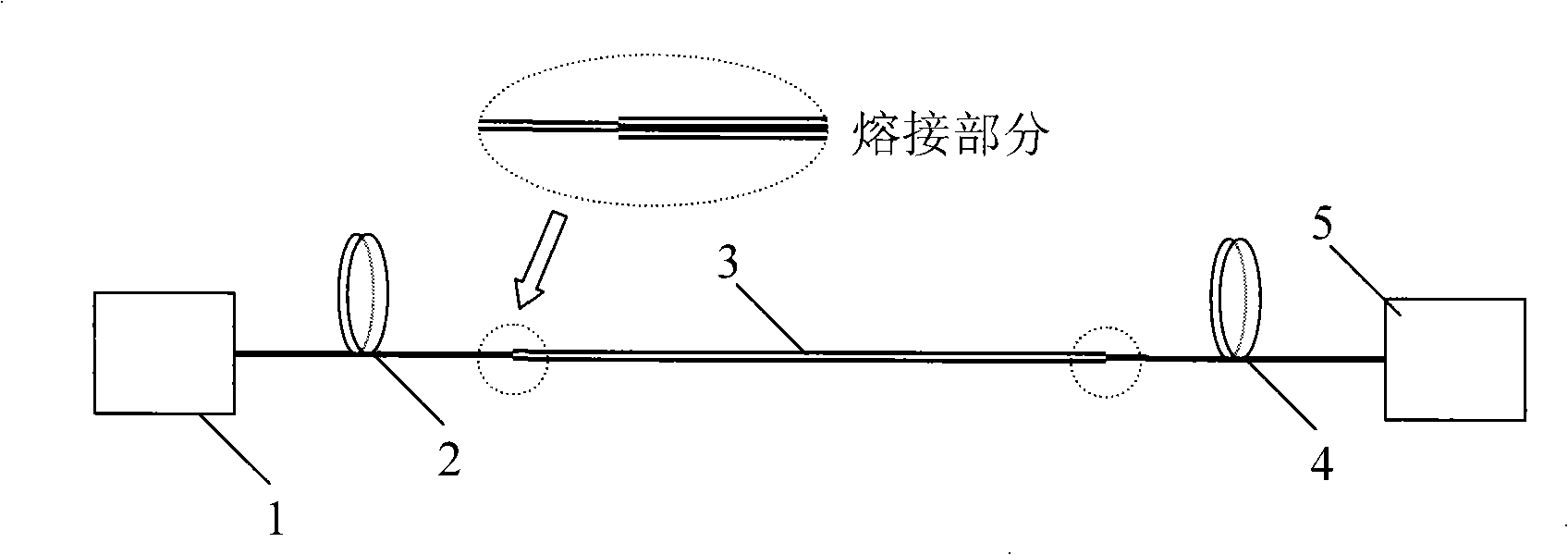

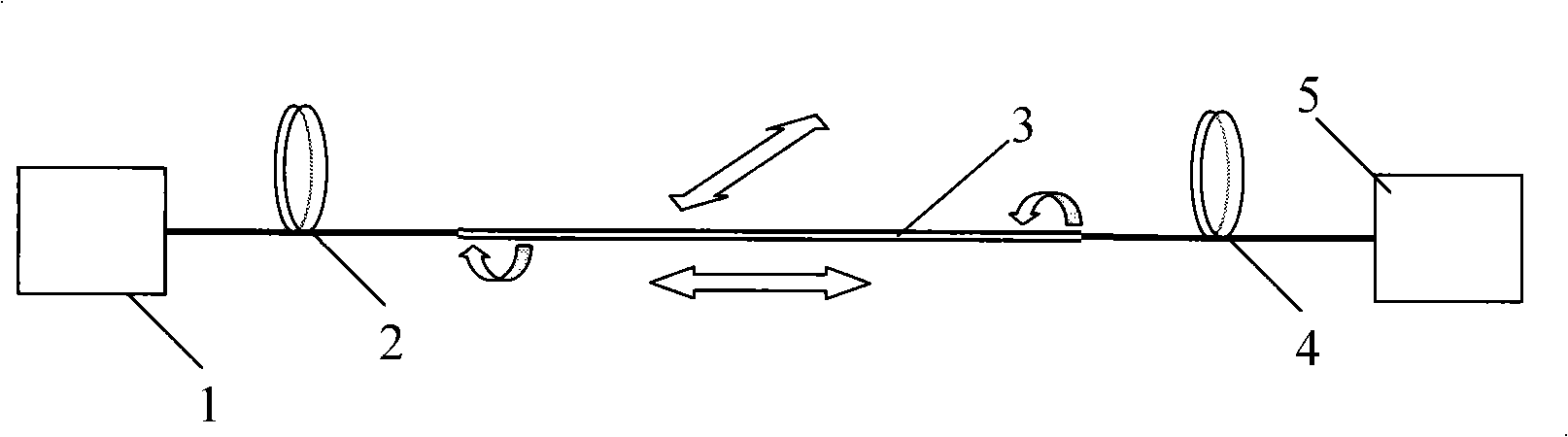

Method used

Image

Examples

Embodiment 2

[0032] Example 2 as Figure 5 As shown, the porous microstructure optical fiber 3 is fixed on the surface of the component 6 with an adhesive. When a force perpendicular to the direction of the fiber is applied, the member 6 will generate bending strain, while the porous microstructured optical fiber 3 maintains the same deflection as the member 6 . The strain of the porous microstructure optical fiber 3 includes both tensile strain and bending and shearing strain. The tensile strain will cause the translation of the transmission spectrum, and the bending and shearing strain will cause the shape of the transmission spectrum to change. As in Example 1, using the single longitudinal mode or multi-longitudinal mode light source 1, the deflection of the optical fiber 3 can be derived by measuring and deriving the change of the received optical power of the single-mode optical fiber 4, and thus the bending strain of the component 6 can be obtained.

Embodiment 3

[0033] Example 3 as Figure 6 As shown, the center of the cylindrical member 9 has a through hole running through the entire length, through which the porous microstructure optical fiber 3 passes and is fixed therein. When the cylindrical member 9 is subjected to torque, a torsional strain will be generated, and the porous microstructure optical fiber 3 maintains the same torsional strain as the cylindrical member 9, and the torsional strain will cause changes in the shape of the transmission spectrum of the device. As in Examples 1 and 2, using a single longitudinal mode or multi-longitudinal mode light source 1, the torsional strain of the porous microstructured optical fiber 3 can be inverted by measuring and deriving the change of the received optical power of the single-mode optical fiber 4, and the cylindrical Torsional strain of member 9.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com