Porous microstructure multi layer spectroscopy and biosensing

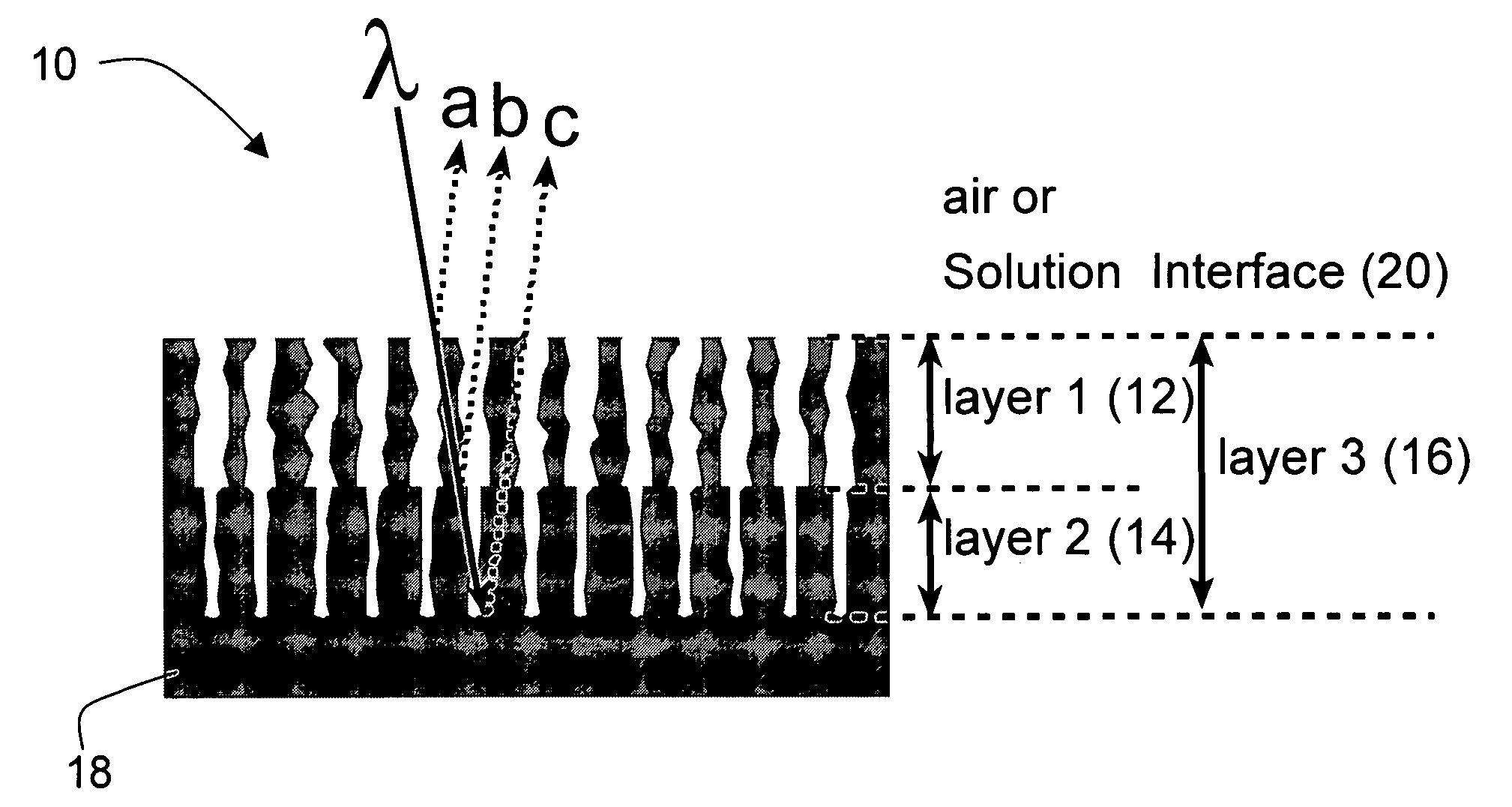

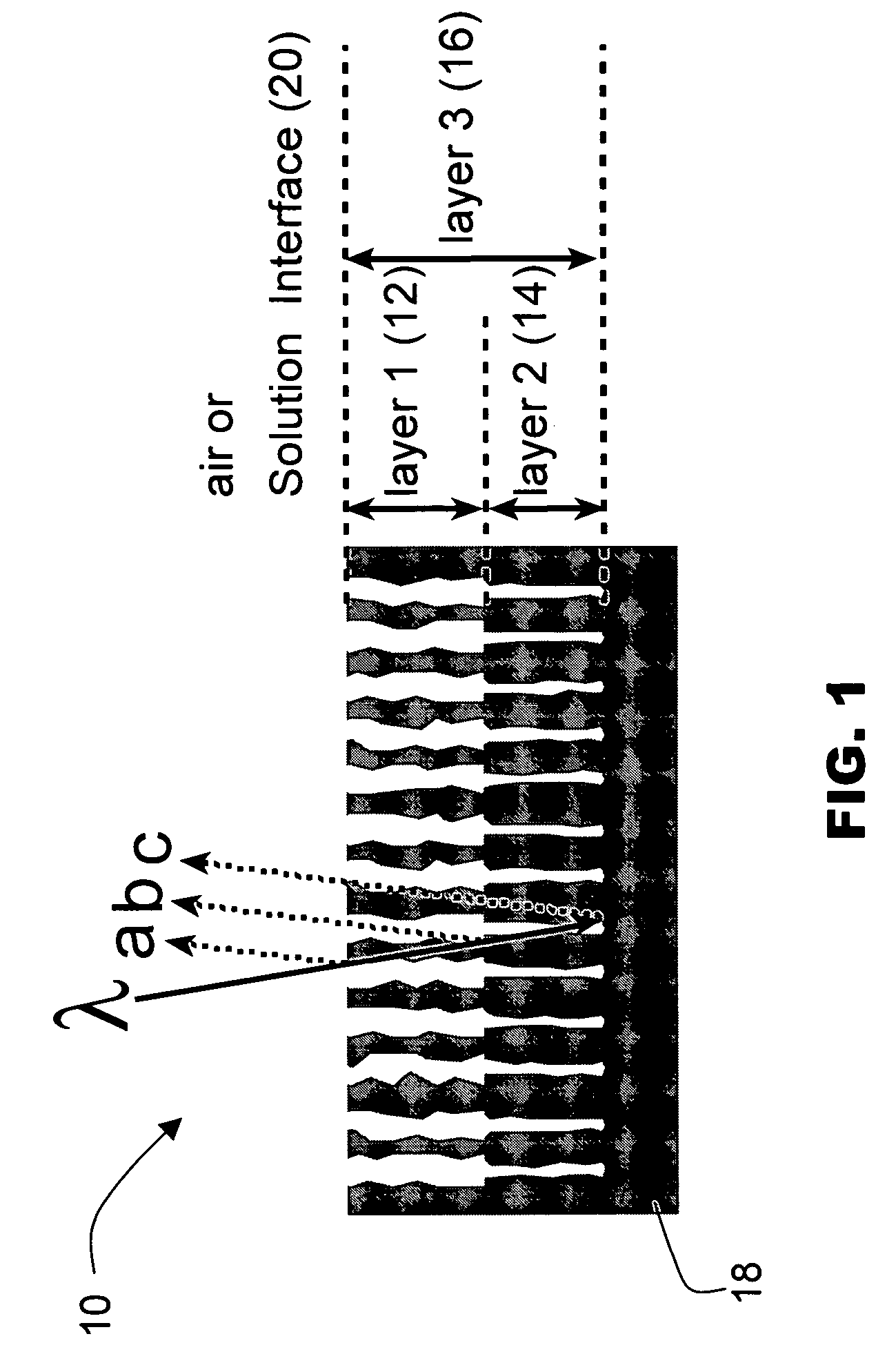

a multi-layer spectroscopy and porous microstructure technology, applied in the field of biosensing, can solve the problems of not being able to account for common measurement conditions, requiring more sensitive equipment, and unable to achieve non-interference based sensing methods that are difficult to use in noisy environments

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

example extensions

OF EXPERIMENTS AND PREFERRED EMBODIMENTS

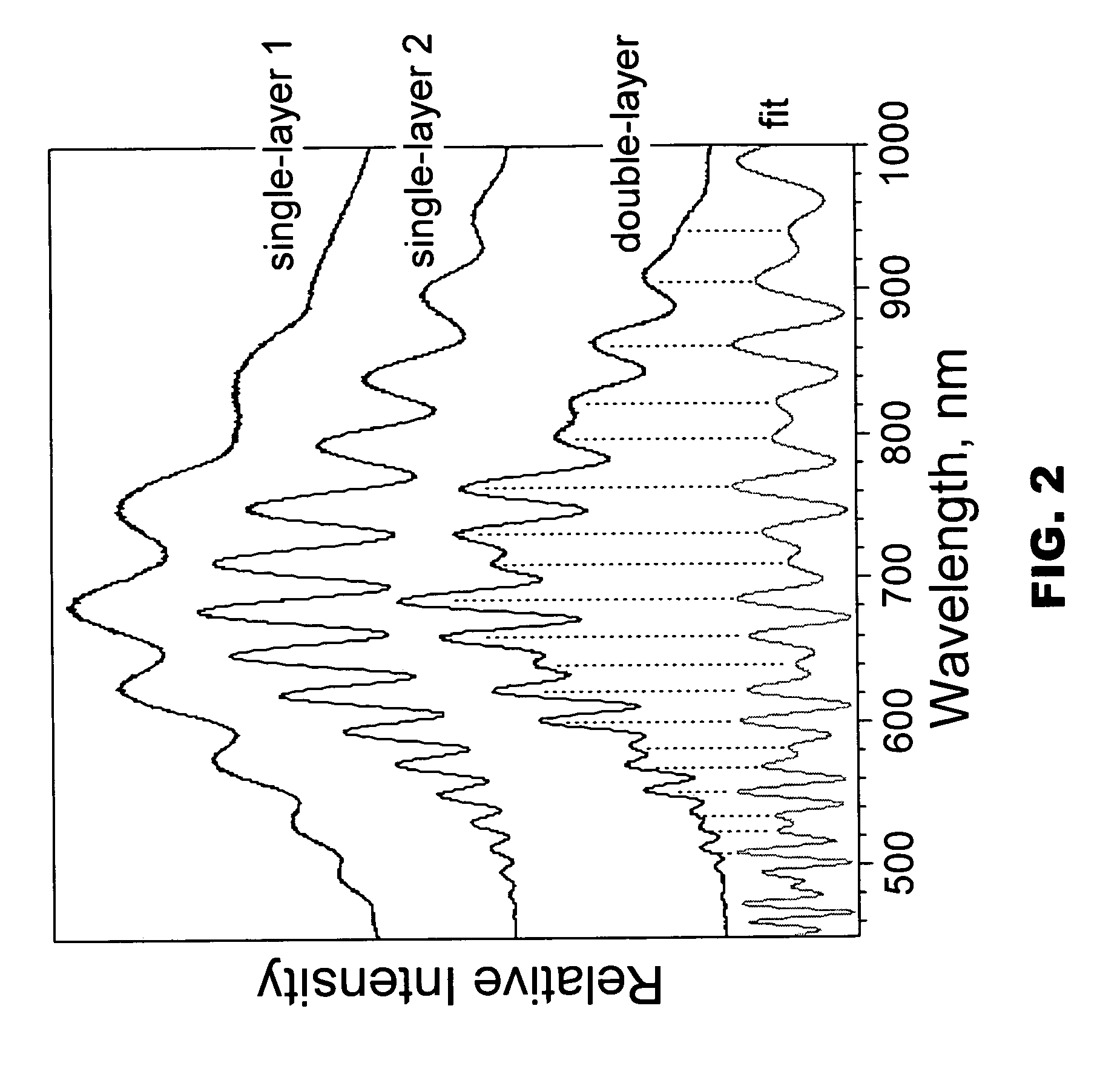

[0088] The approach should also be amenable to other label-free transduction modalities that utilize refractive index changes, such as surface plasmon resonance or microcavity resonance. The built-in reference channel and Fourier method of analysis provides a general means to compensate for changes in sample matrix, non-specific binding, temperature, and other experimental variables.

[0089] An advantage of the interferometric biosensor optical structures of the invention compared to other optical transduction methods is that the sensitivity of the measurement can be improved. Additionally, compared to other optical transduction methods, the equipment needed to monitor binding events can be simplified. The interferometric biosensor of preferred embodiments provides the basis to incorporating sophisticated detection functions, such as correction for drifts due to thermal fluctuation, changes in sample composition, or degradation of the sample ma...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com