Patents

Literature

134results about How to "Protect parts" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

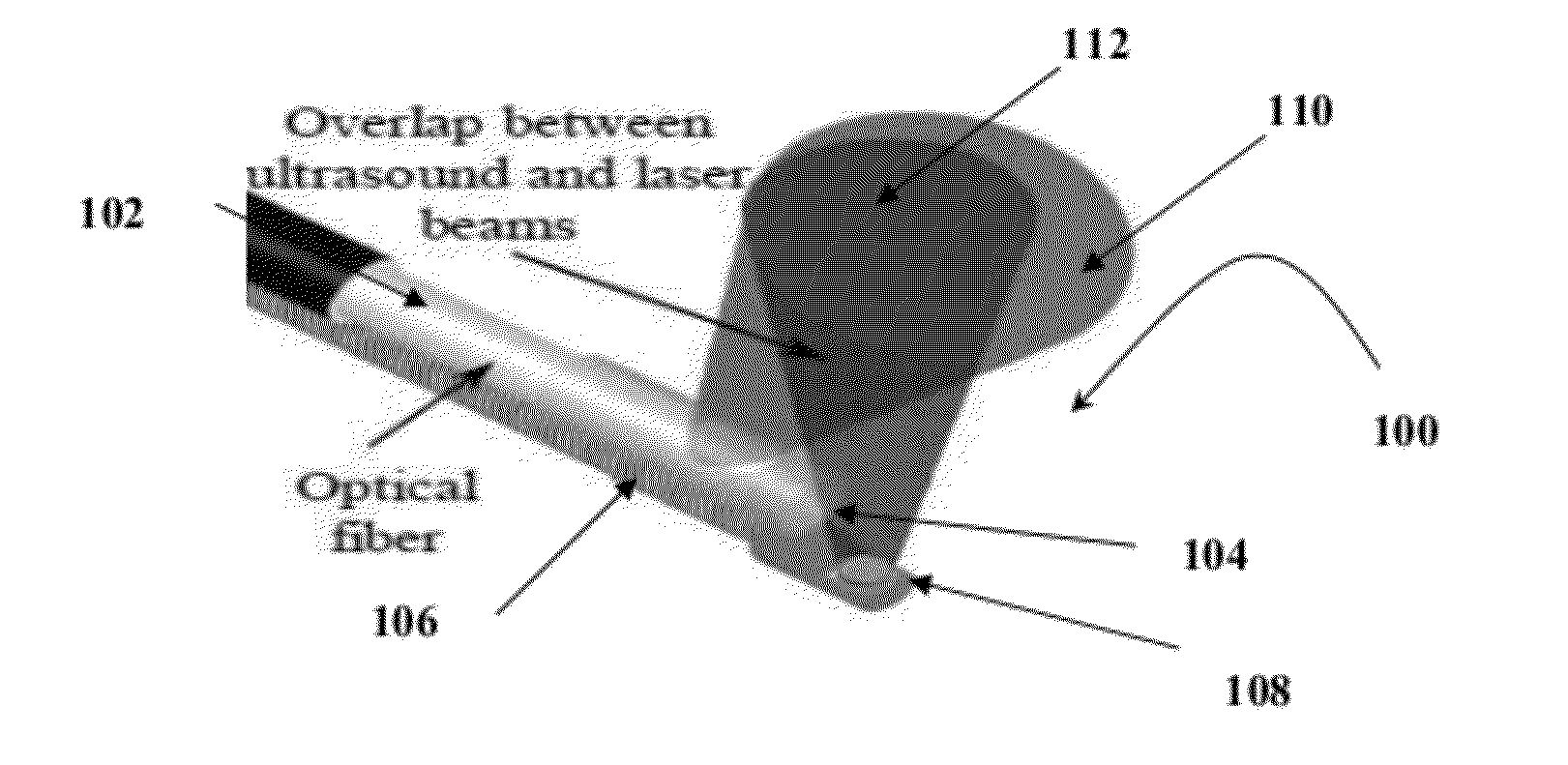

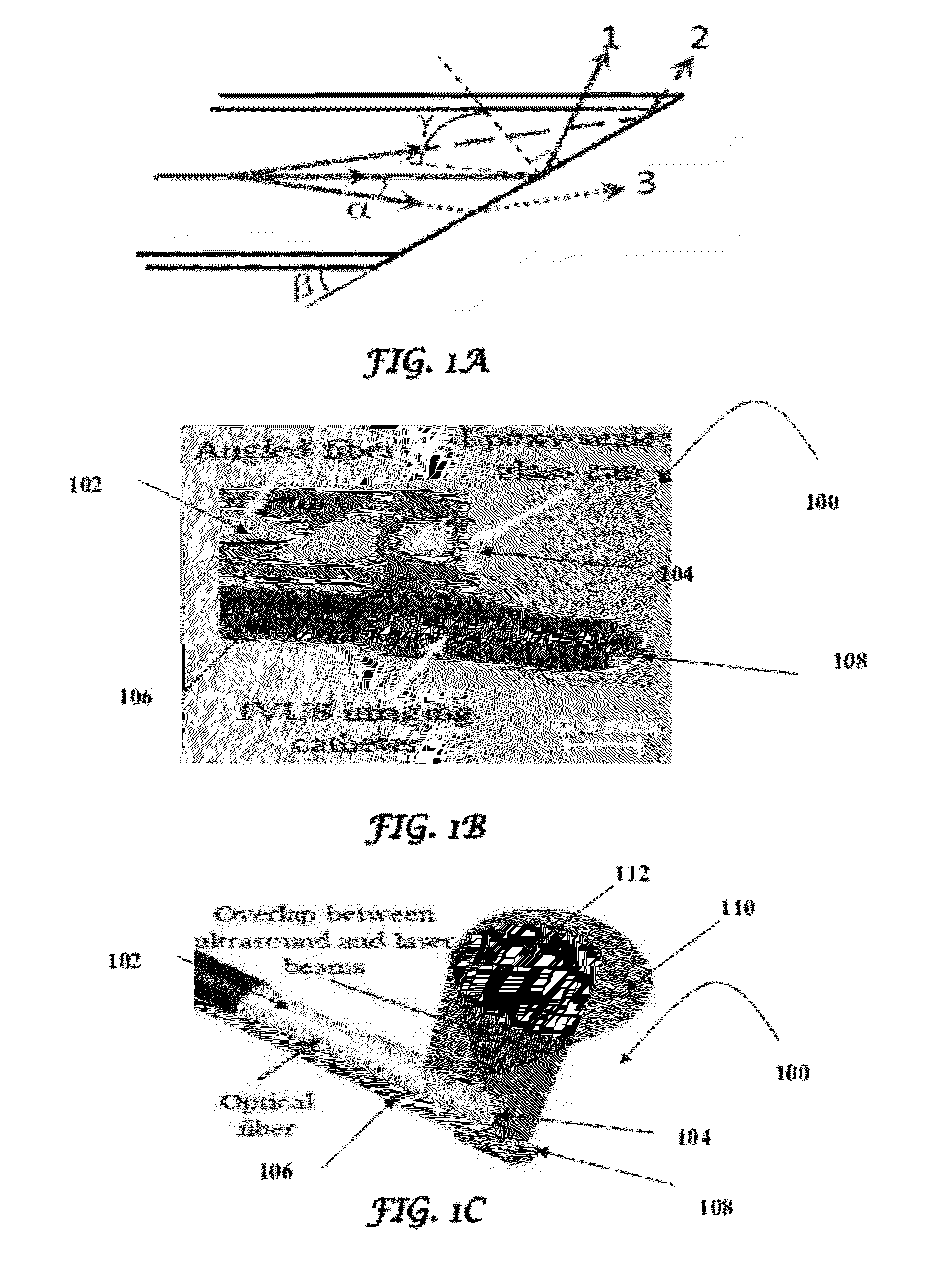

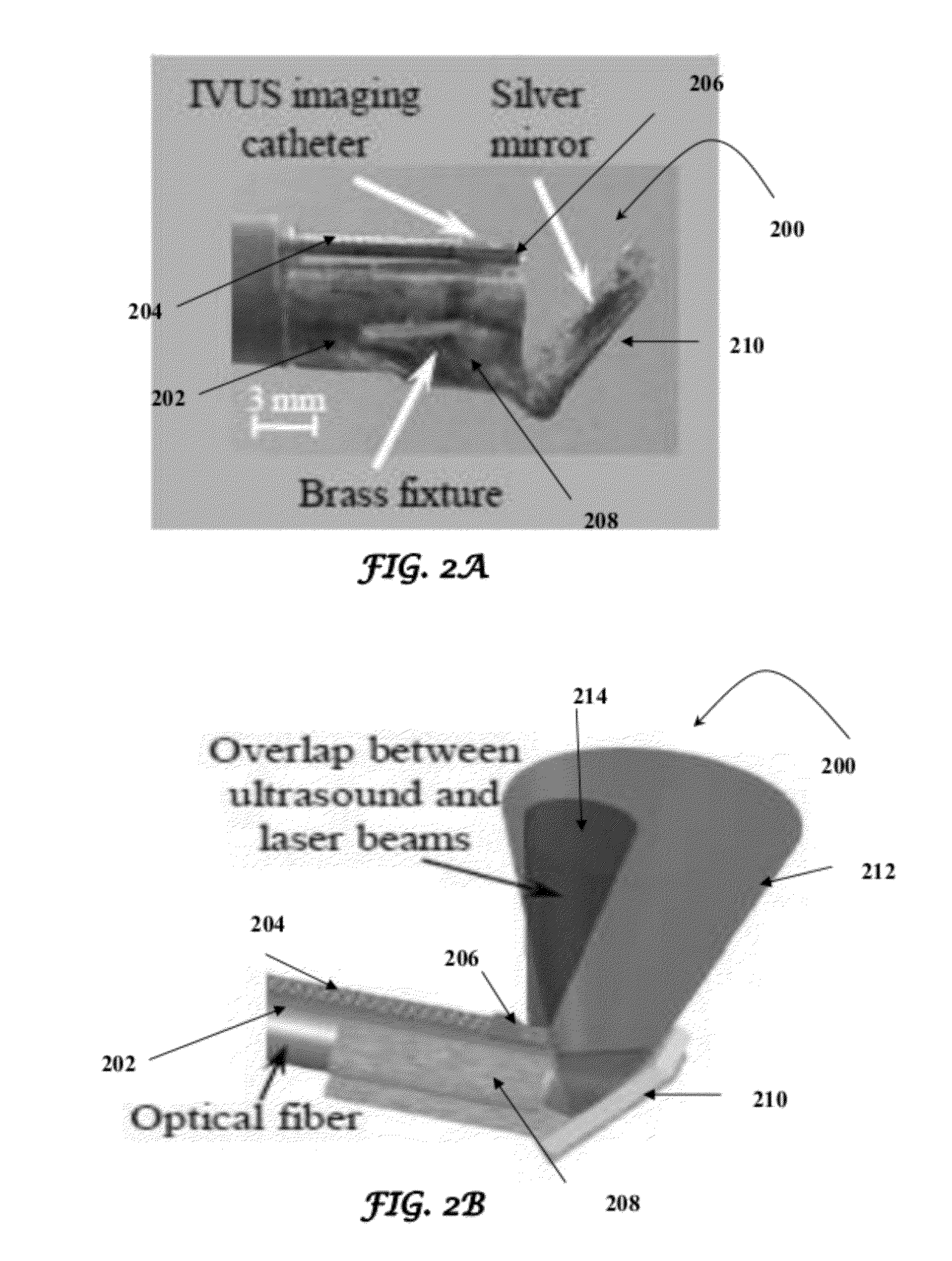

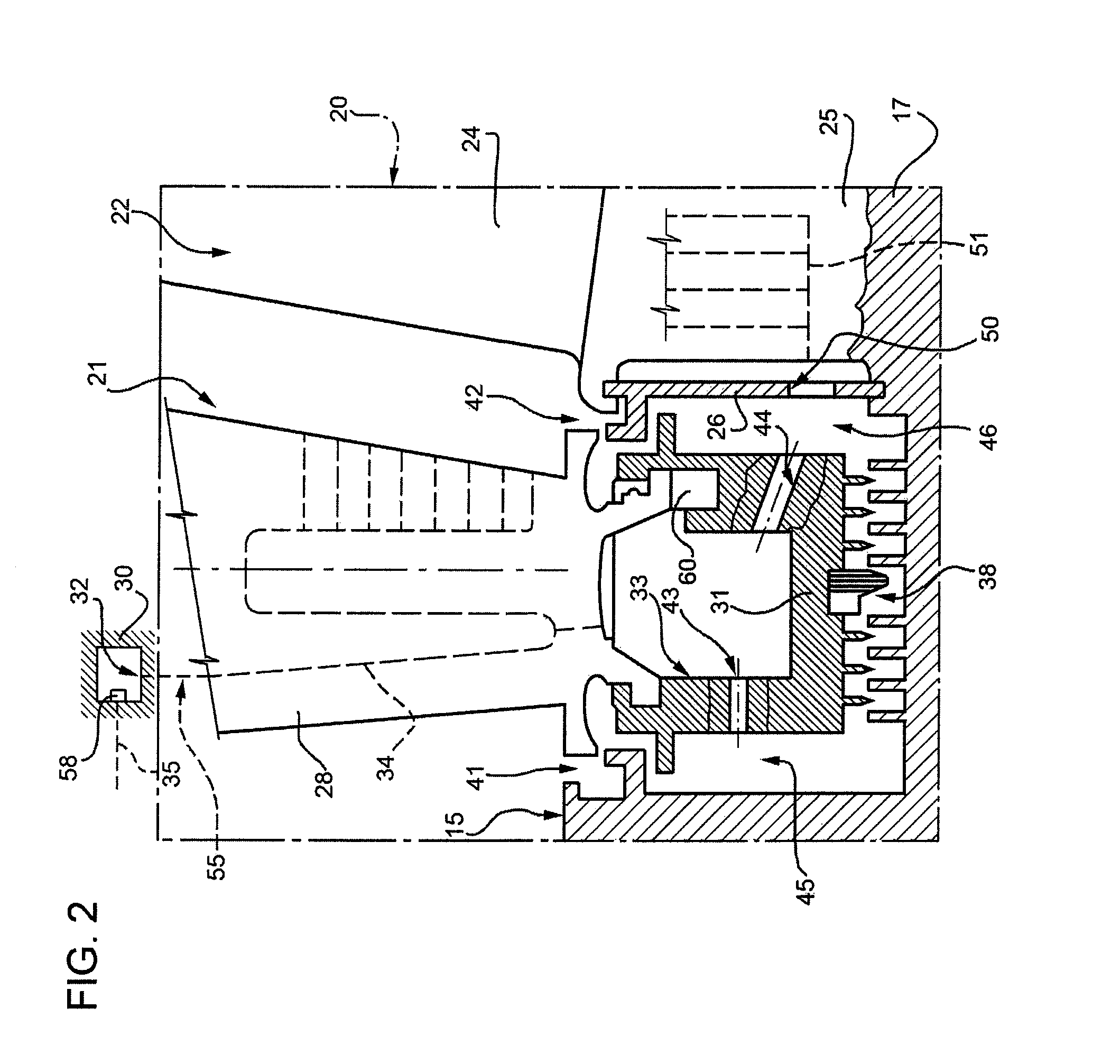

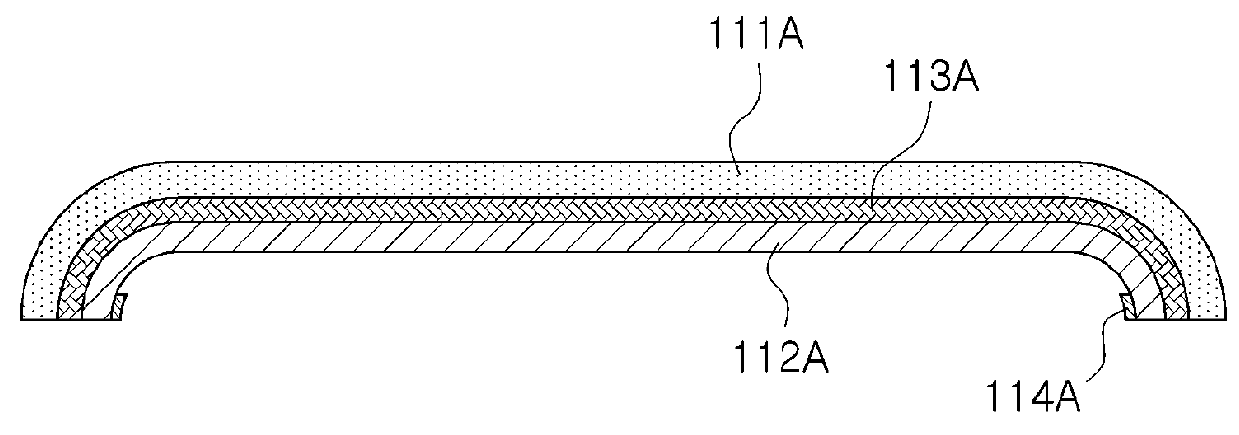

Catheter for intravascular ultrasound and photoacoustic imaging

InactiveUS20120271170A1Protect partsAvoid mechanical damageUltrasonic/sonic/infrasonic diagnosticsUltrasound therapyUltrasonic sensorElastography

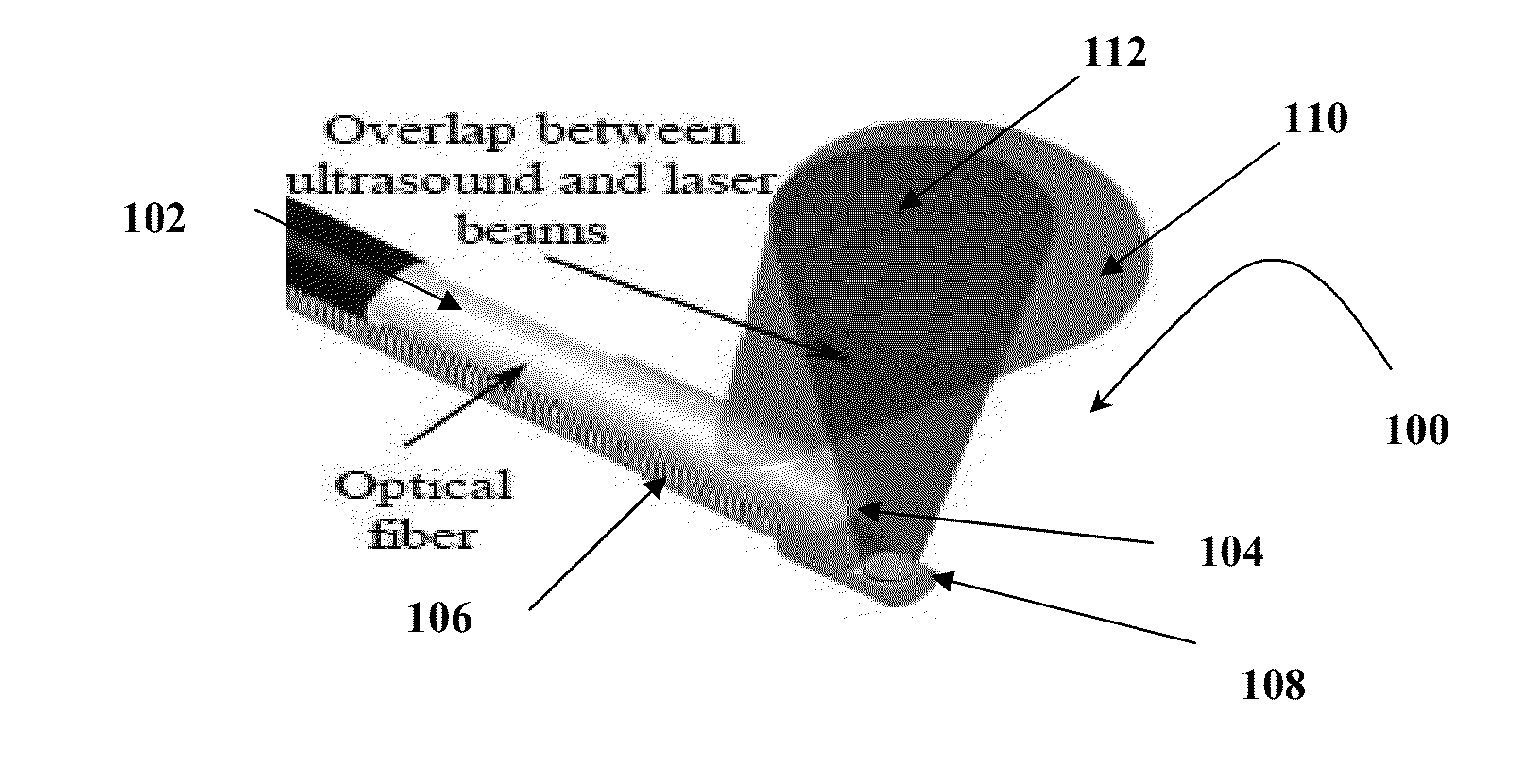

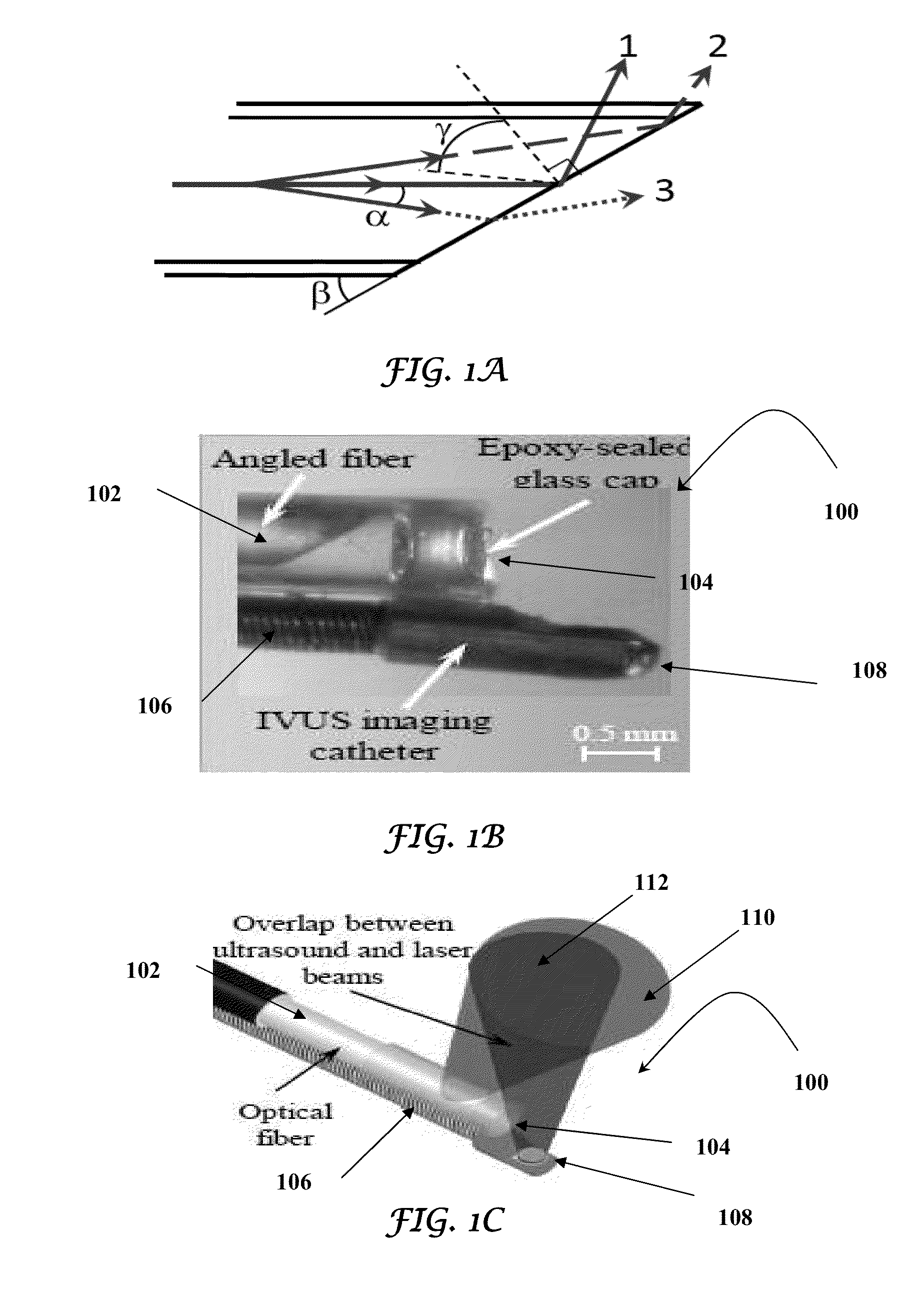

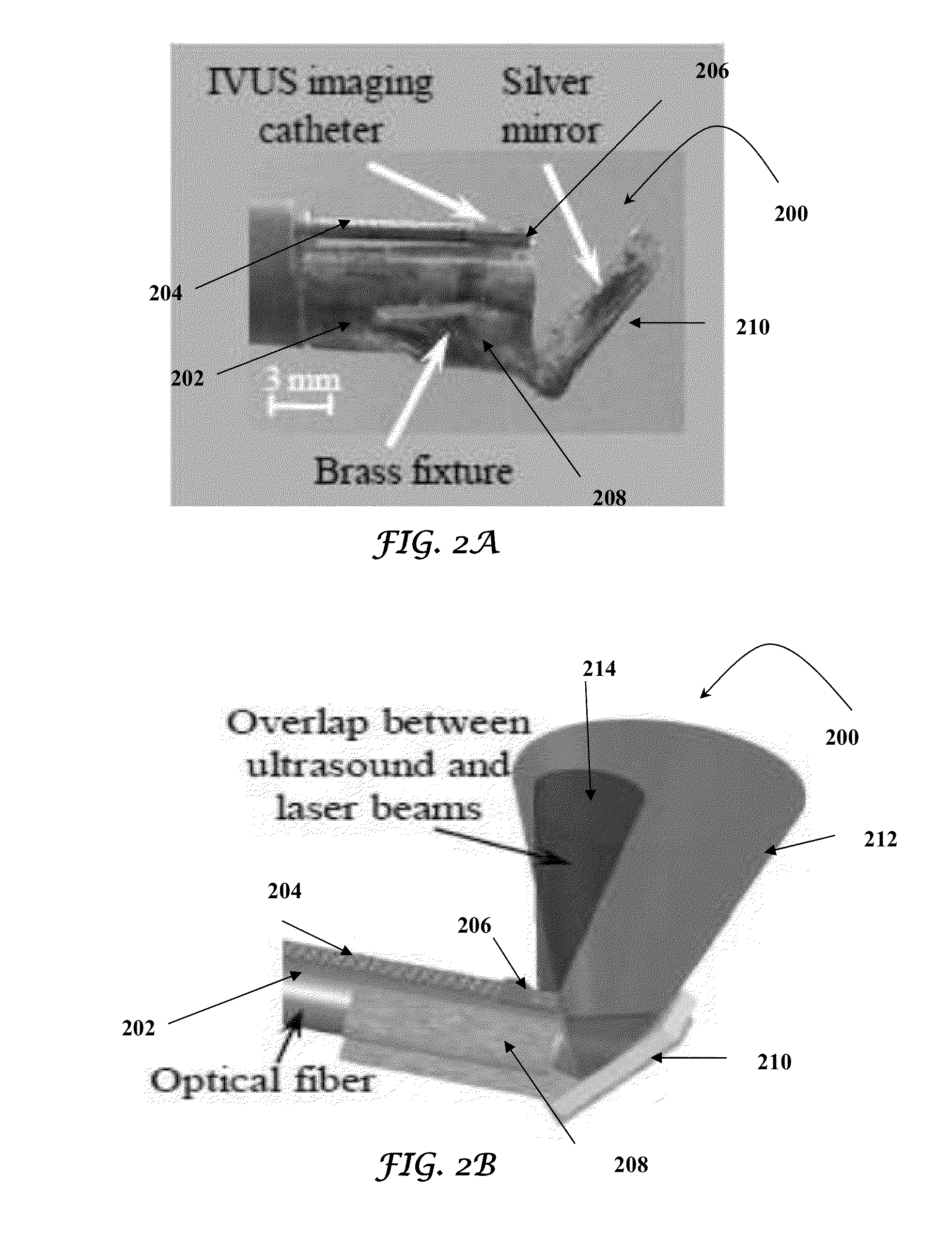

A design and a fabrication method for an intravascular imaging and therapeutic catheters for combined ultrasound, photoacoustic, and elasticity imaging and for optical and / or acoustic therapy of hollow organs and diseased blood vessels and tissues are disclosed in the present invention. The invention comprises both a device—optical fiber-based intravascular catheter designs for combined IVUS / IVPA, and elasticity imaging and for acoustic and / or optical therapy—and a method of combined ultrasound, photoacoustic, and elasticity imaging and optical and / or acoustic therapy. The designs of the catheters are based on single-element catheter-based ultrasound transducers or on ultrasound array-based units coupled with optical fiber, fiber bundles or a combination thereof with specially designed light delivery systems. One approach uses the side fire fiber, similar to the one utilized for biomedical optical spectroscopy. The second catheter design uses the micro-optics in the manner of a probe for optical coherent tomography.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

Mold resistant acoustical panel

ActiveUS7056582B2Retaining its effectivenessIncrease concentrationFibreboardSolid waste managementSodium PyrithioneSlurry

A composition for a slurry for manufacture of acoustical panels includes one or more fillers, one or more binders, water and zinc pyrithione. At least of the fillers and / or binders includes microbial nutrients in an amount of at least 1% based on the dry weight of the acoustical panel. In another embodiment of the invention, acoustical panels include a core having a plurality of opposing surfaces and being at least ⅛ inches thick. The core comprises the dried product of a slurry of fillers, binders and water. Zinc pyrithione is present in at least one of the core and a coating applied to at least one of the surfaces of the core.

Owner:USG INTERIORS INC

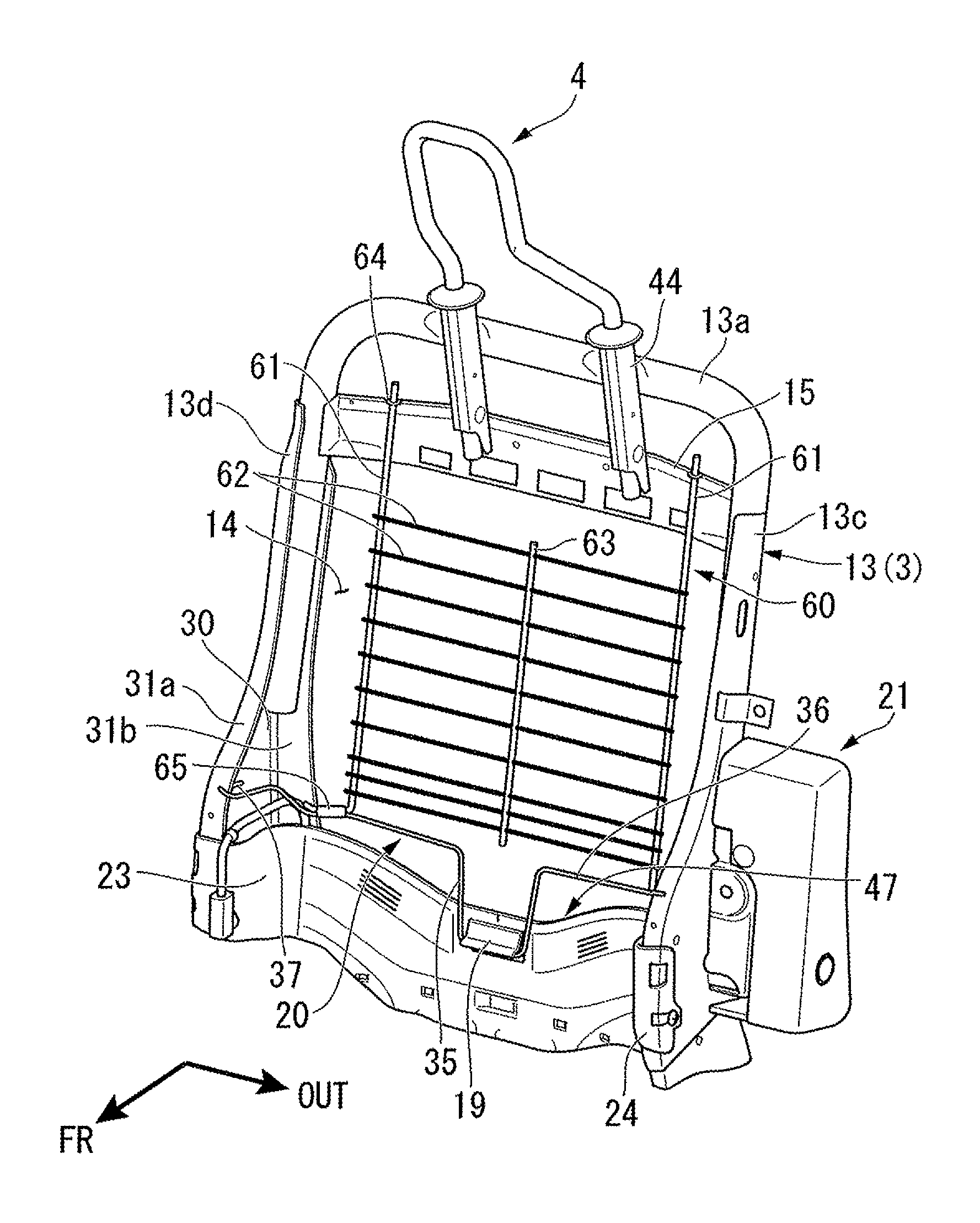

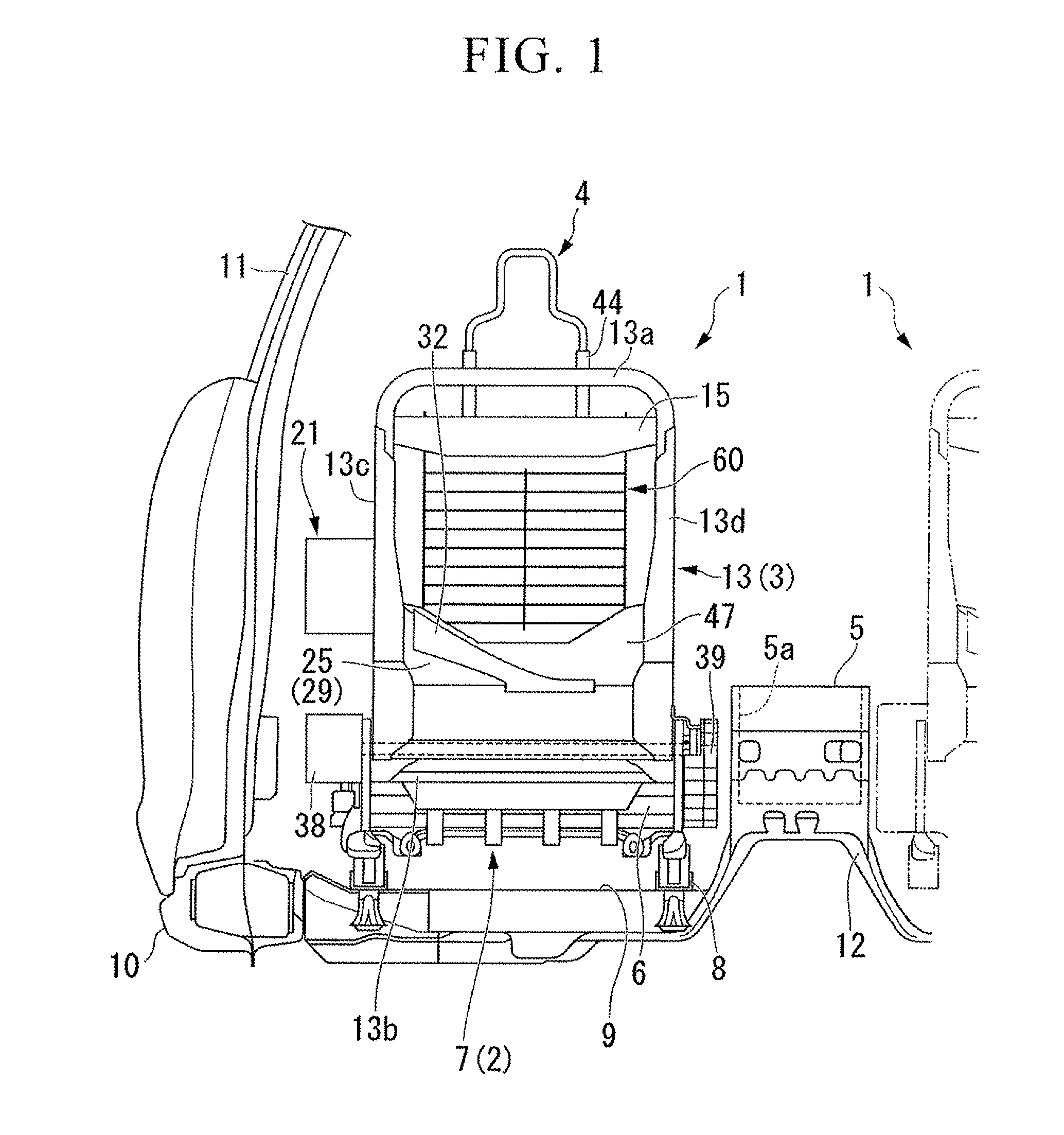

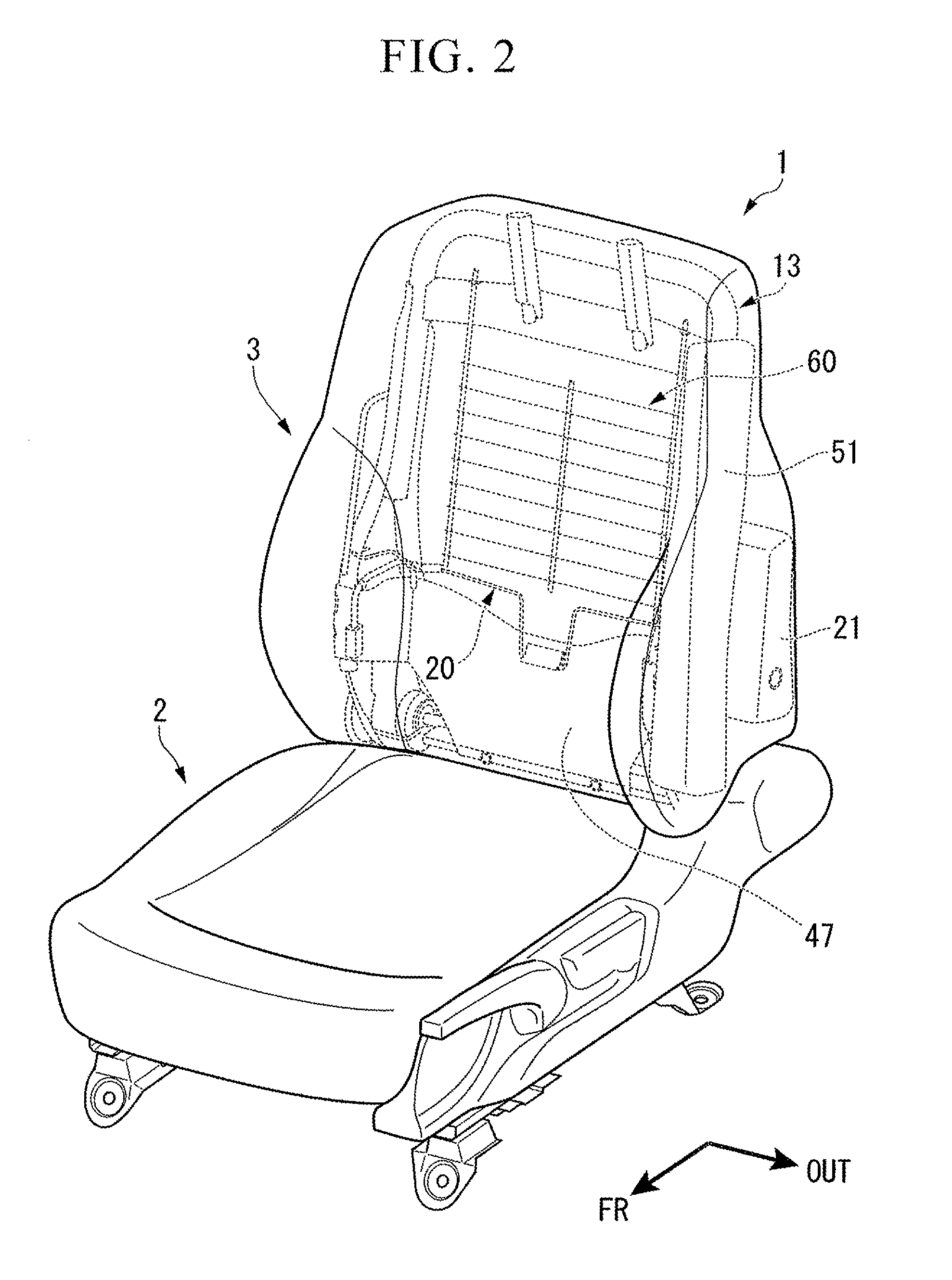

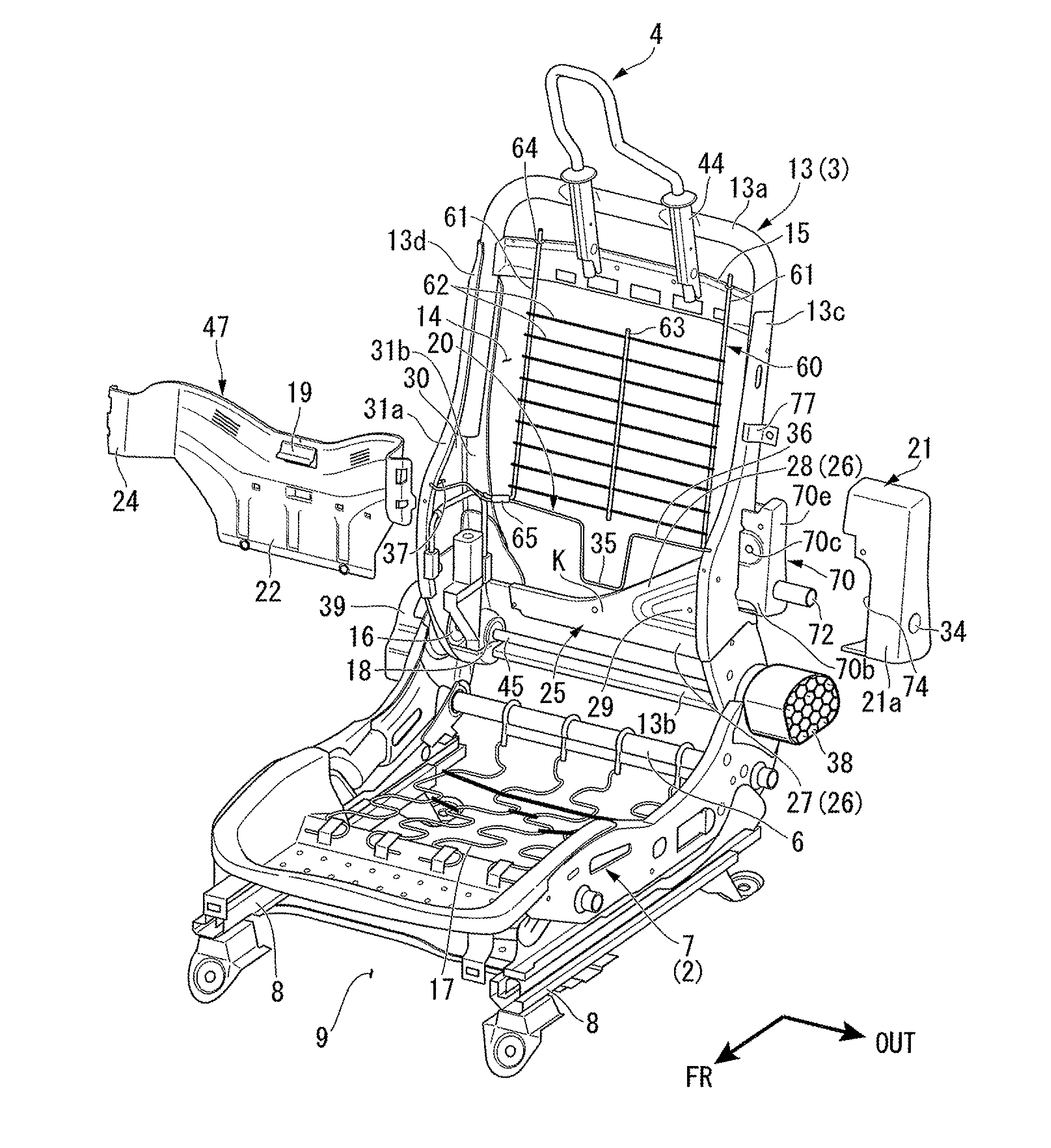

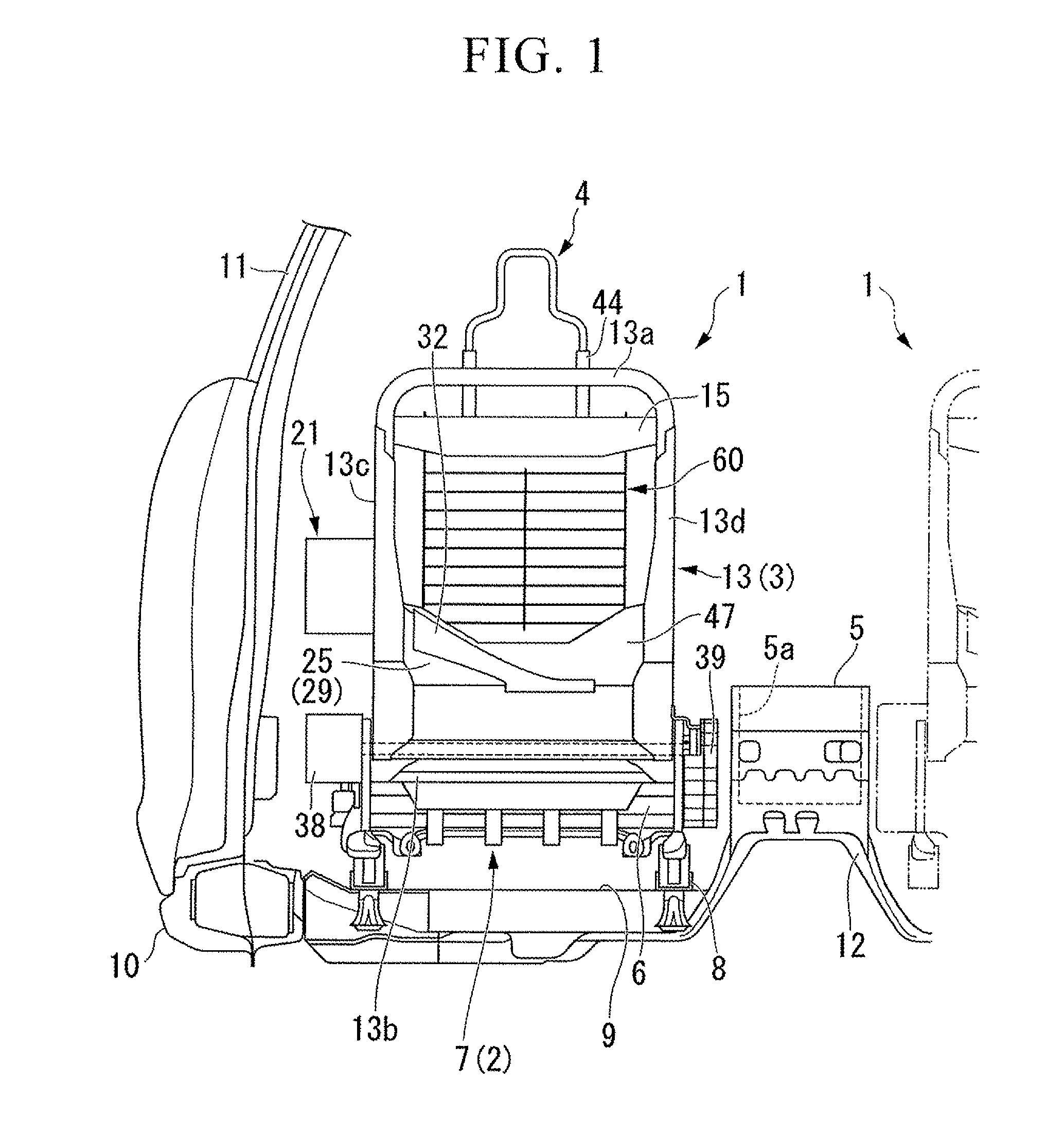

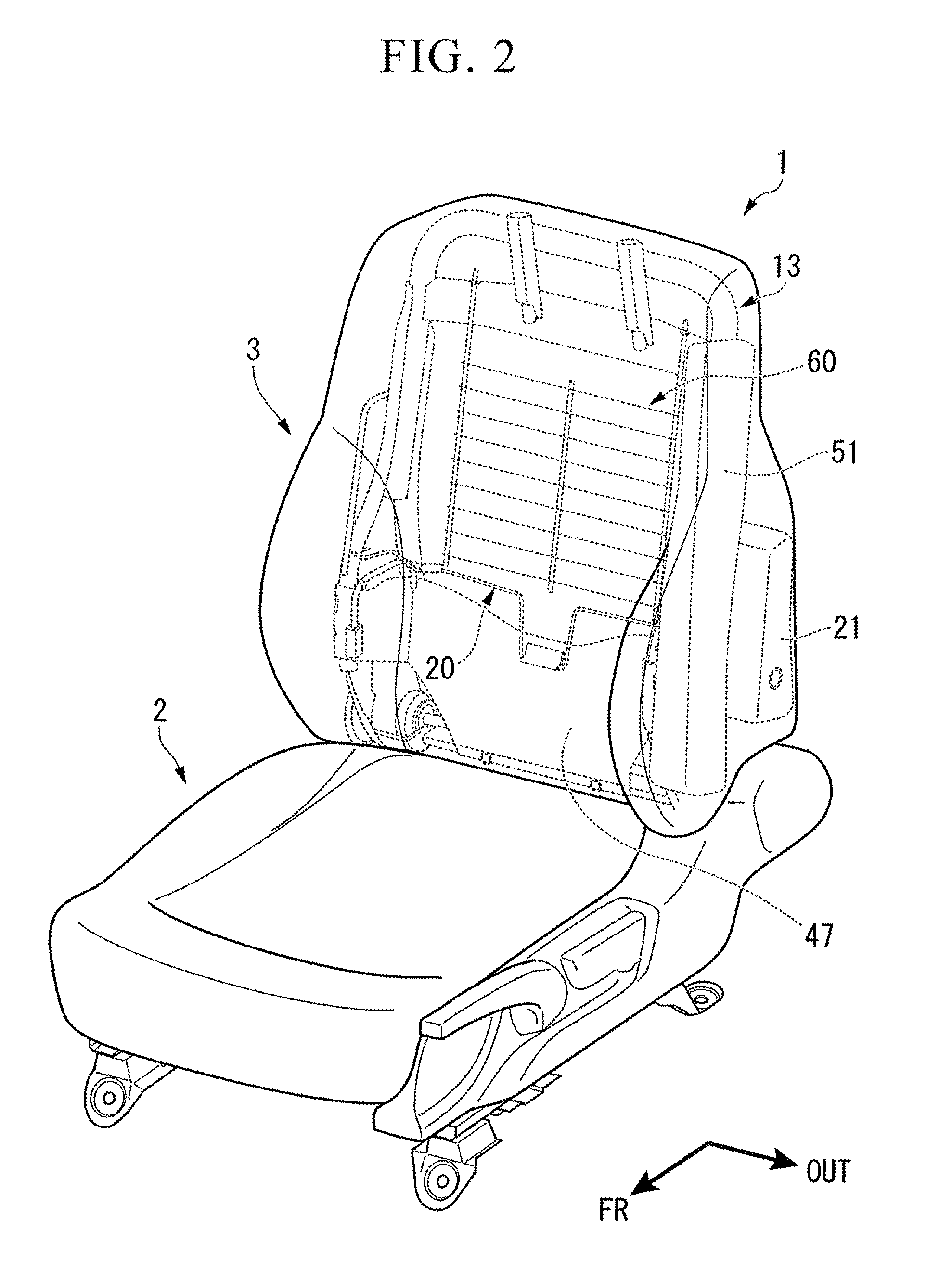

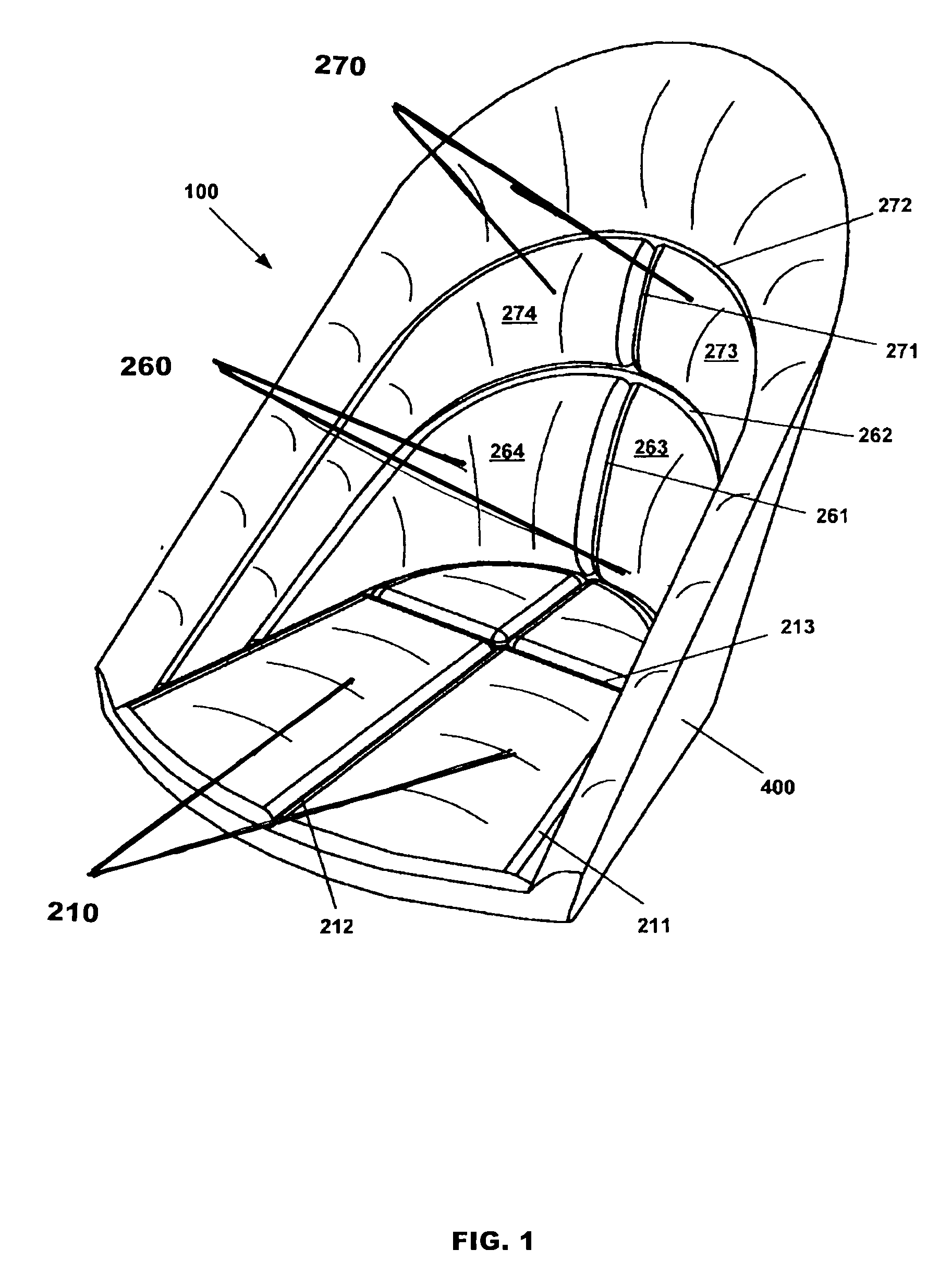

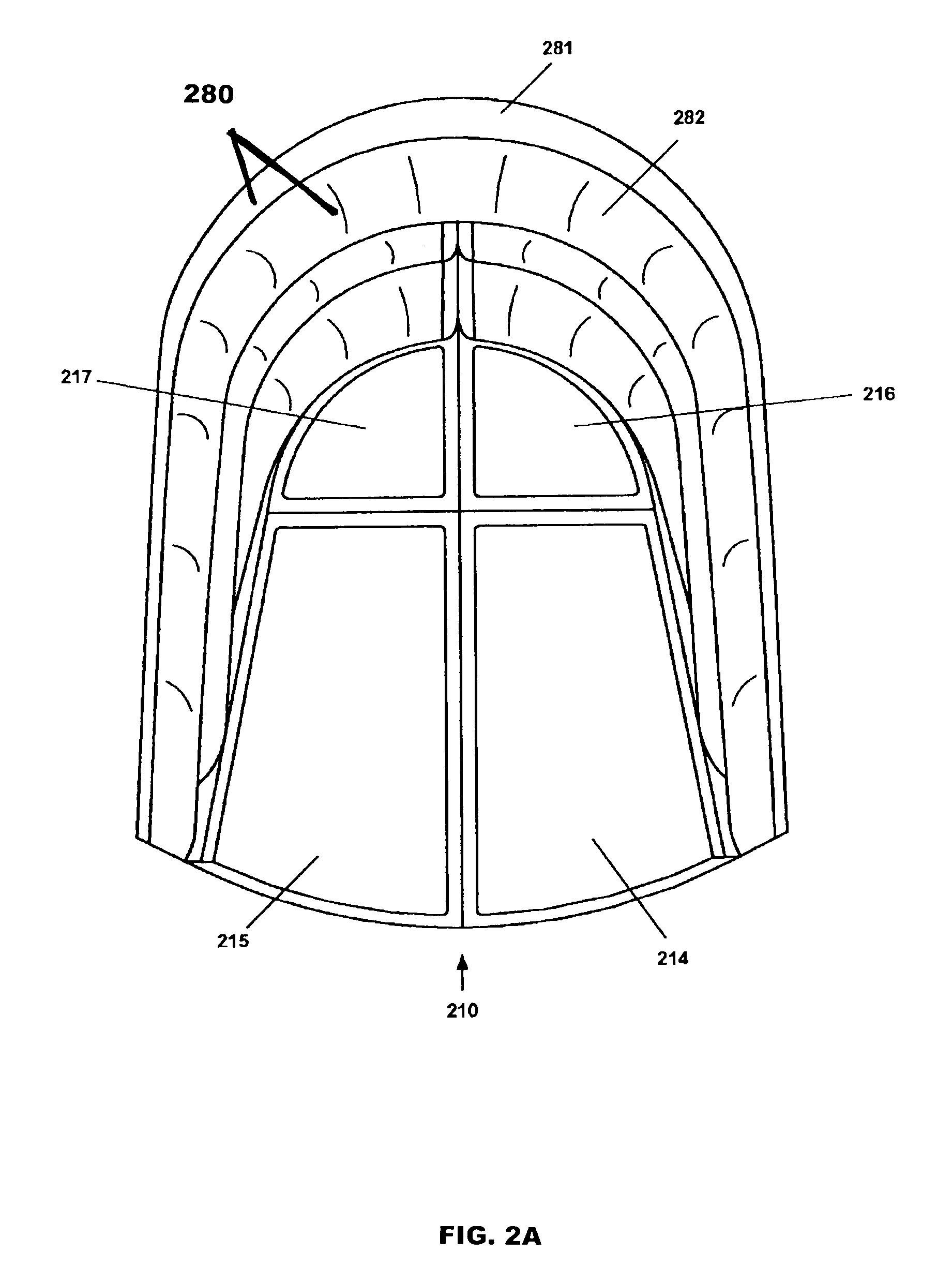

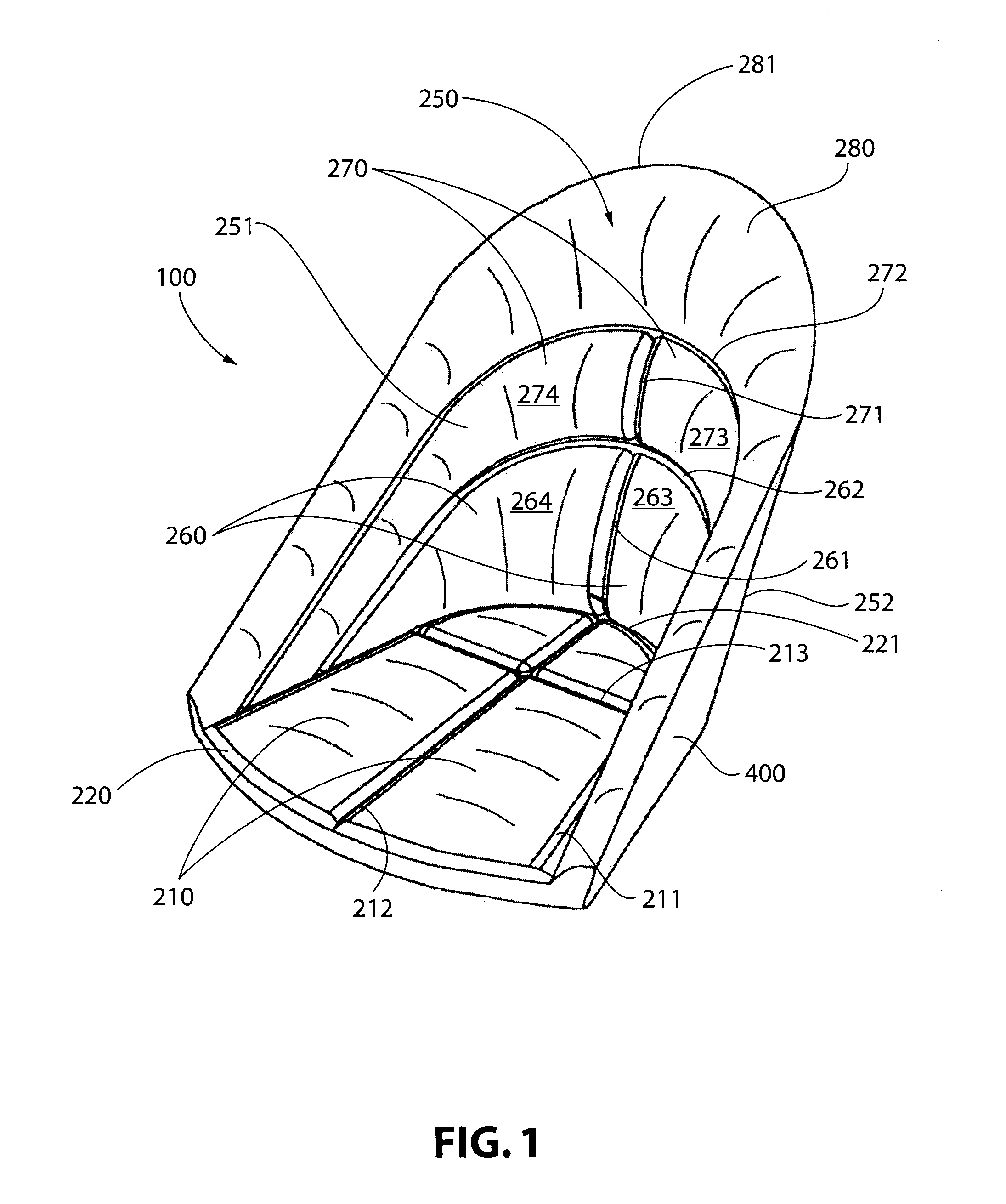

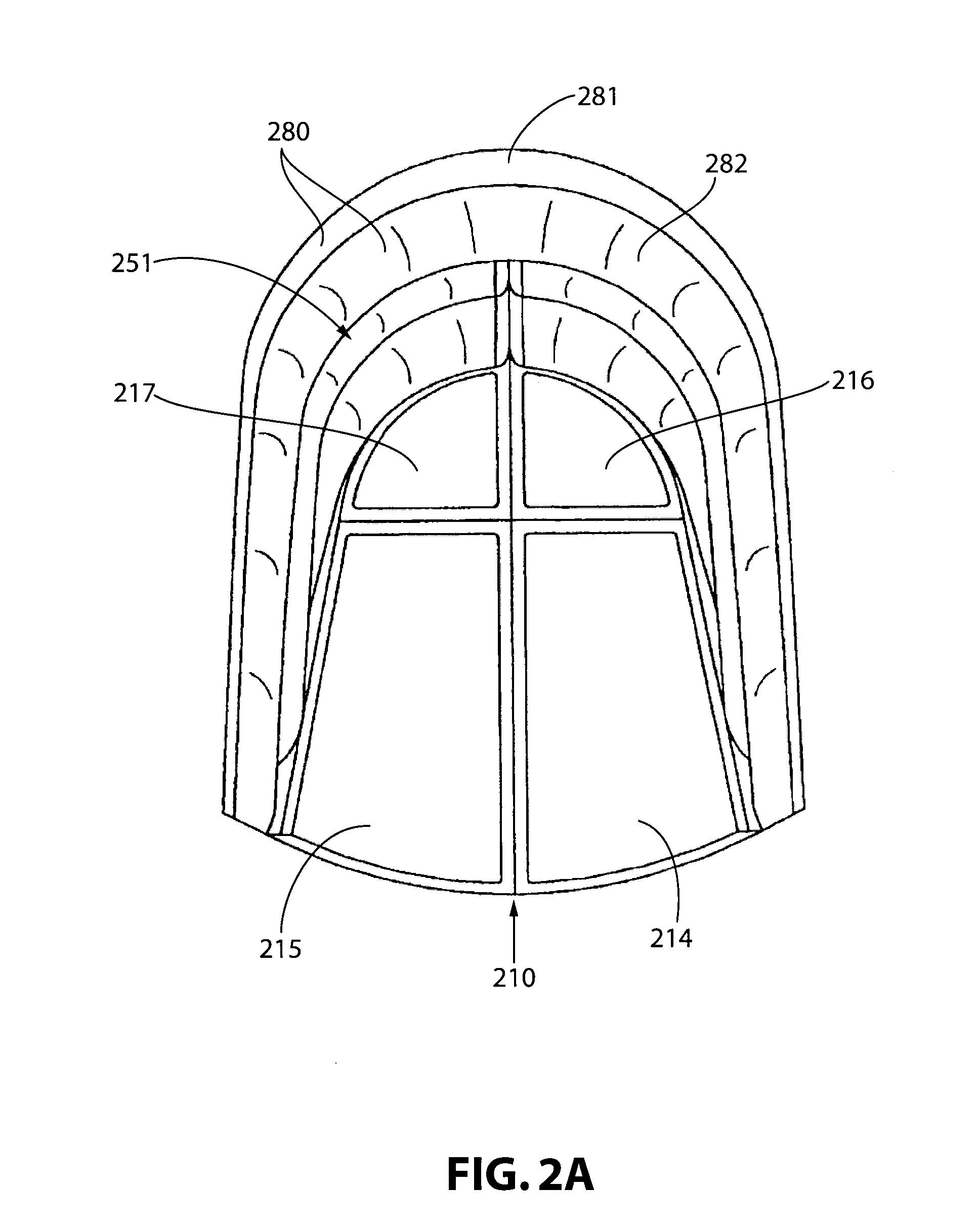

Seat back frame

Owner:HONDA MOTOR CO LTD +1

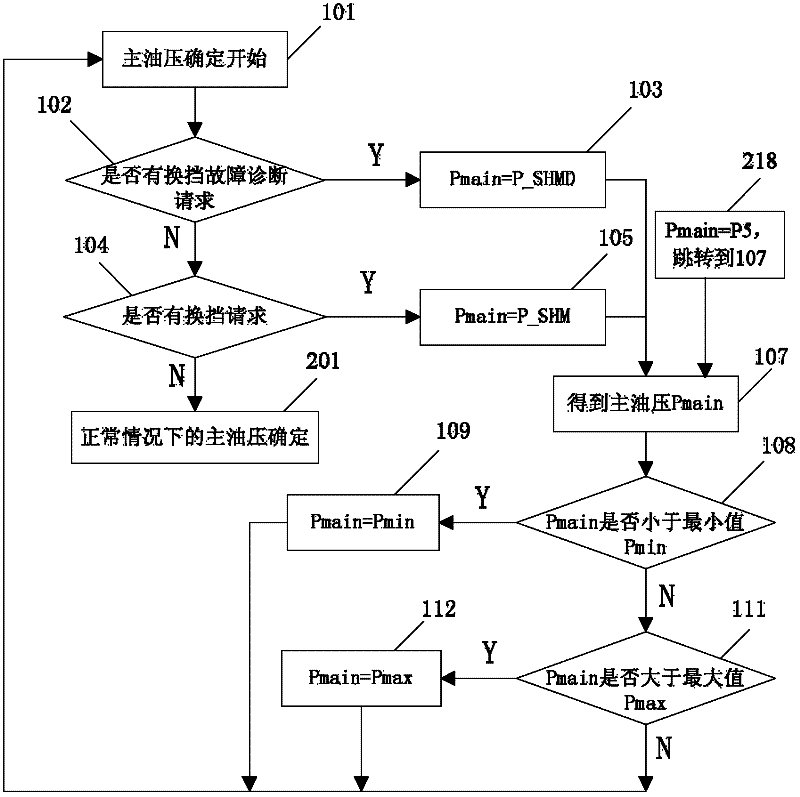

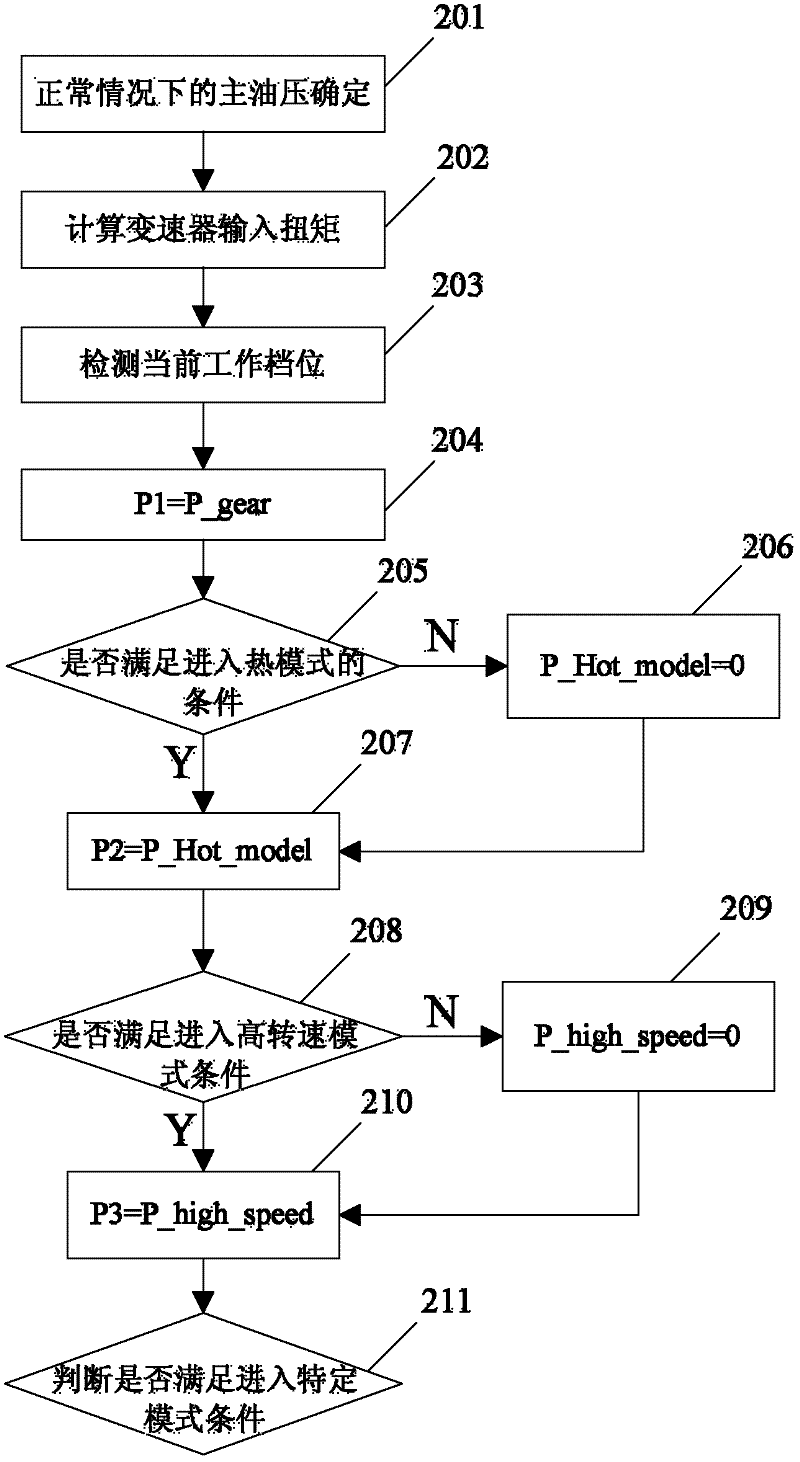

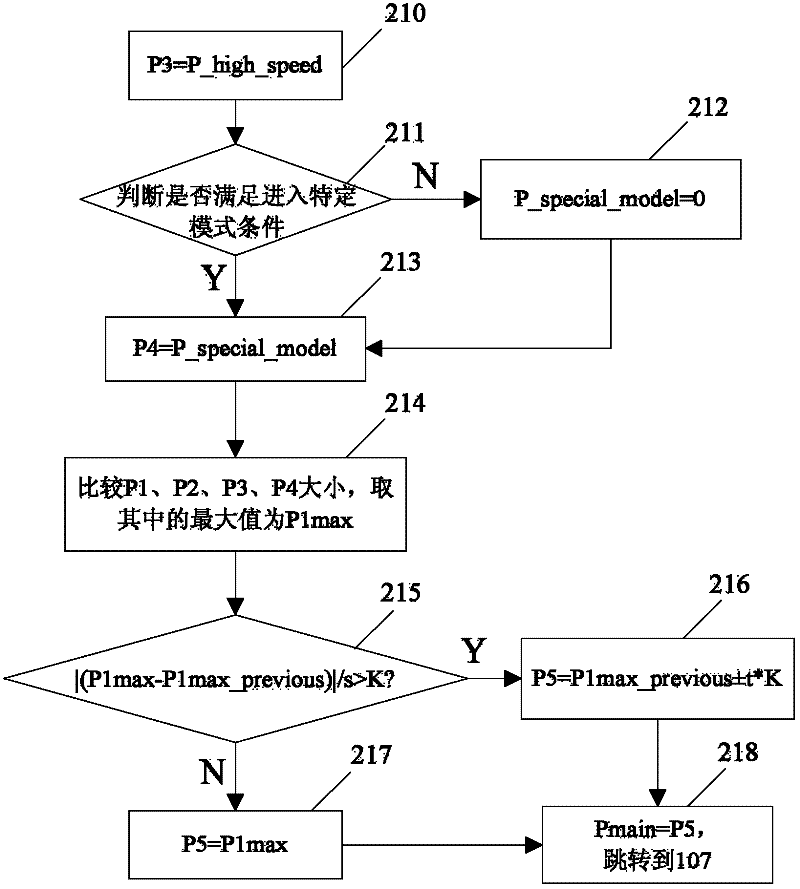

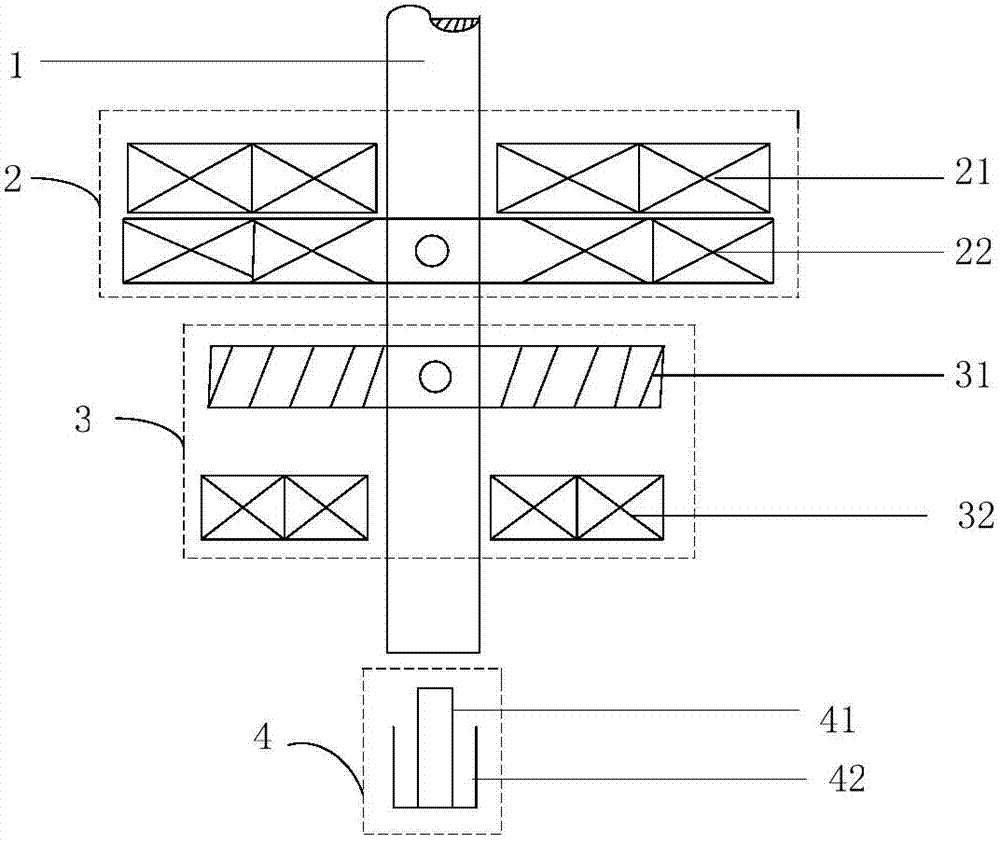

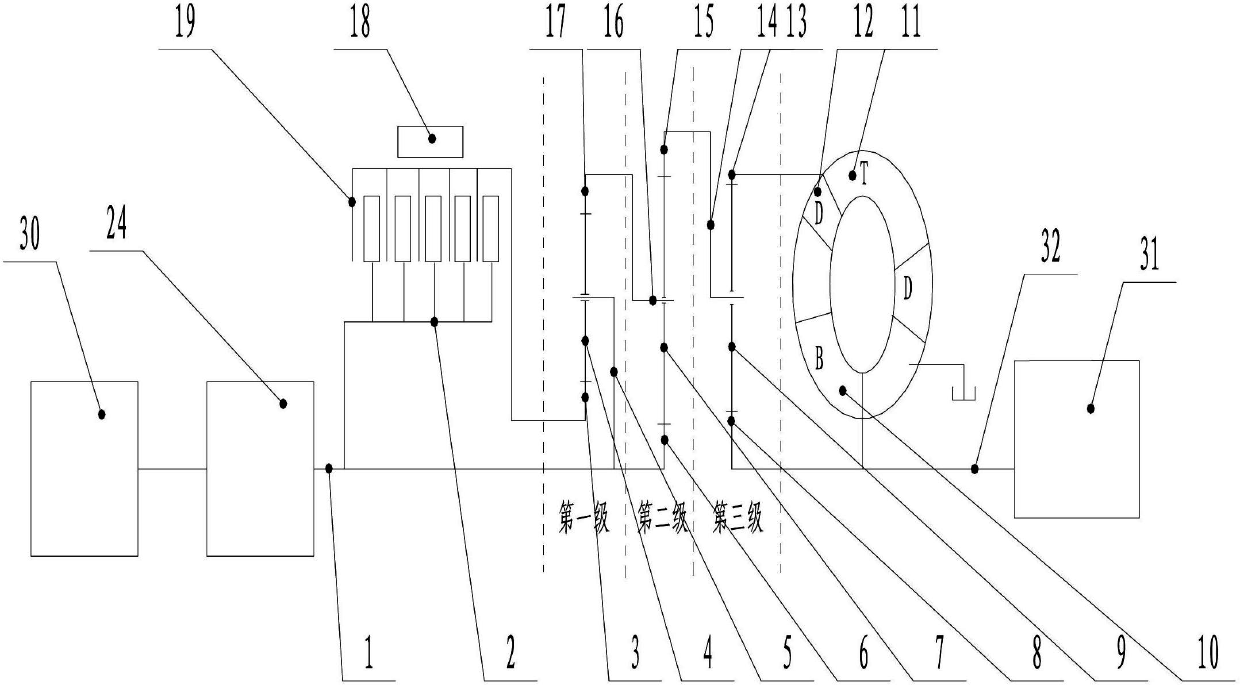

Main oil pressure control method for automatic transmission

ActiveCN102537314APerfect function of oil pressure controlImprove transmission efficiencyGearing controlAutomatic transmissionEngineering

The invention relates to a main oil pressure control method for an automatic transmission, which can be used for selecting proper oil pressure according to different conditions. The proper main oil pressure value is determined by judging parameters such as the state of the transmission, main oil pressure needed by a current gear, main oil pressure needed by a hot mode, main oil pressure needed by a high-speed mode, main oil pressure needed by a specific mode and the like, so that sufficient lubrication is realized, and the efficiency of the automatic transmission can be ensured. The main oil pressure control method is applied to all automotive automatic transmissions.

Owner:ZHEJIANG GEELY AUTOMOBILE RES INST CO LTD +1

Seat back frame

ActiveUS20110298267A1Partial protectionEnhance impact absorptionOperating chairsBack restsEngineeringBack rests

Owner:HONDA MOTOR CO LTD +1

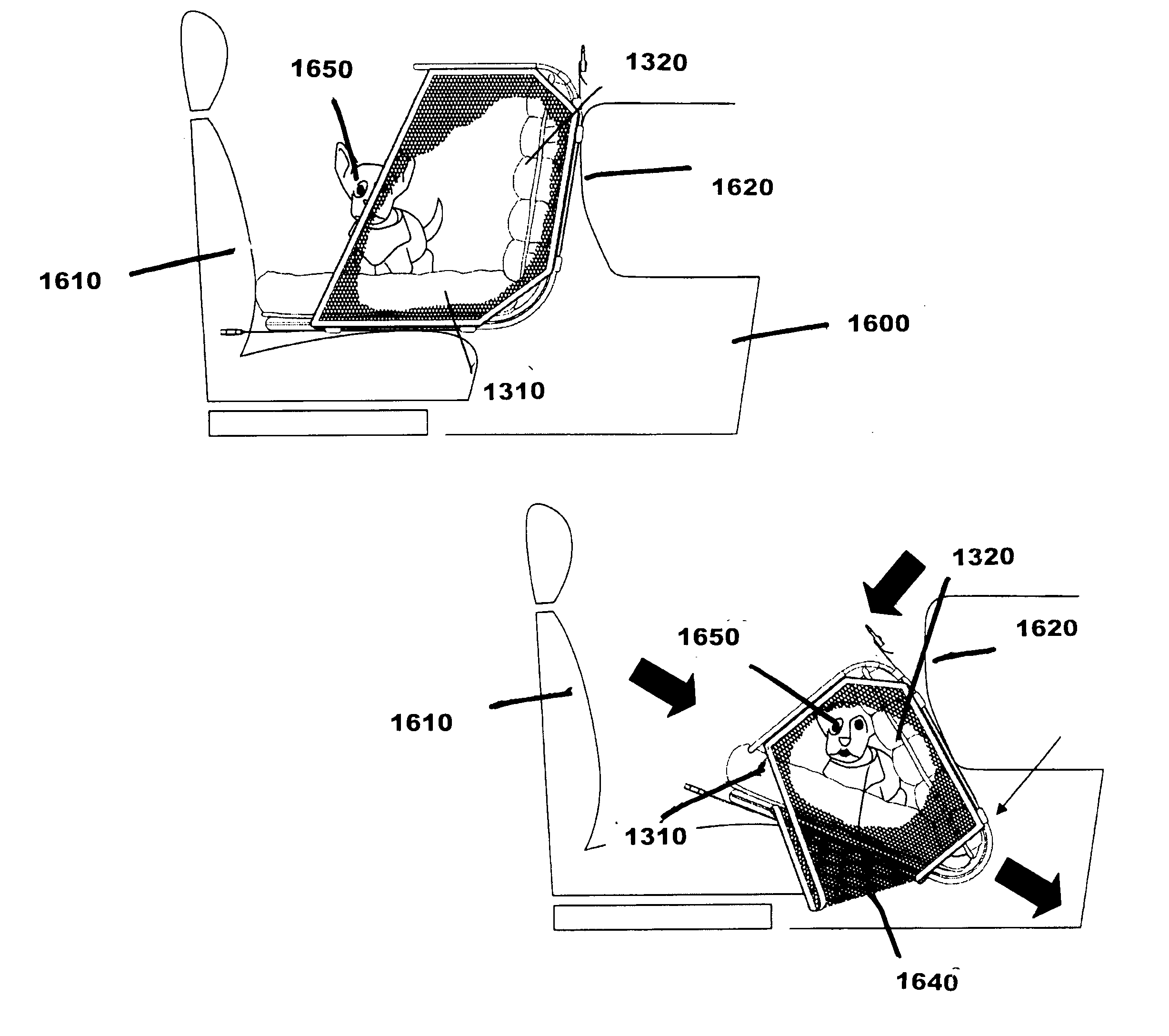

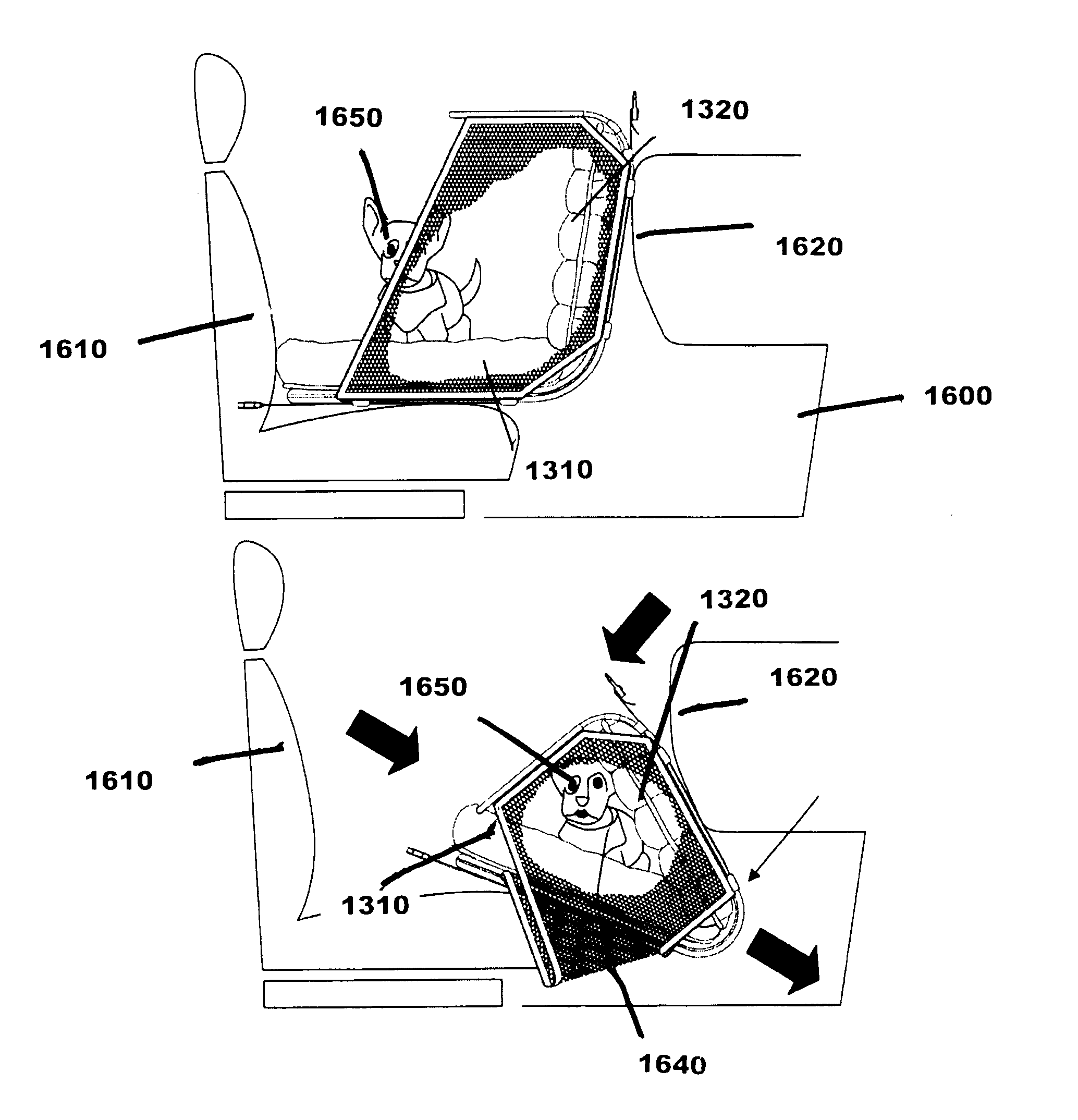

Pet Impact Protector

ActiveUS20090126638A1Easy to installEasy to removeVehicle seatsPedestrian/occupant safety arrangementCar seatImpact area

A pet impact protector is disclosed. This device is directed to a cleanable, removable device for a vehicle car seat comprising a contiguous pliable material having a pet seating area and a pet capture area. The pet impact protector is designed such that the force of the pet impact protector plus the pet, upon impact with the vehicle during a stop or slowing of the vehicle, causes the pet impact protector to partially collapse and form a protective impact area around the pet. This device is directed to the reduction of injury to a pet riding in a vehicle during an accident, stop or slowdown of the vehicle.

Owner:BENNETT GARY RAY

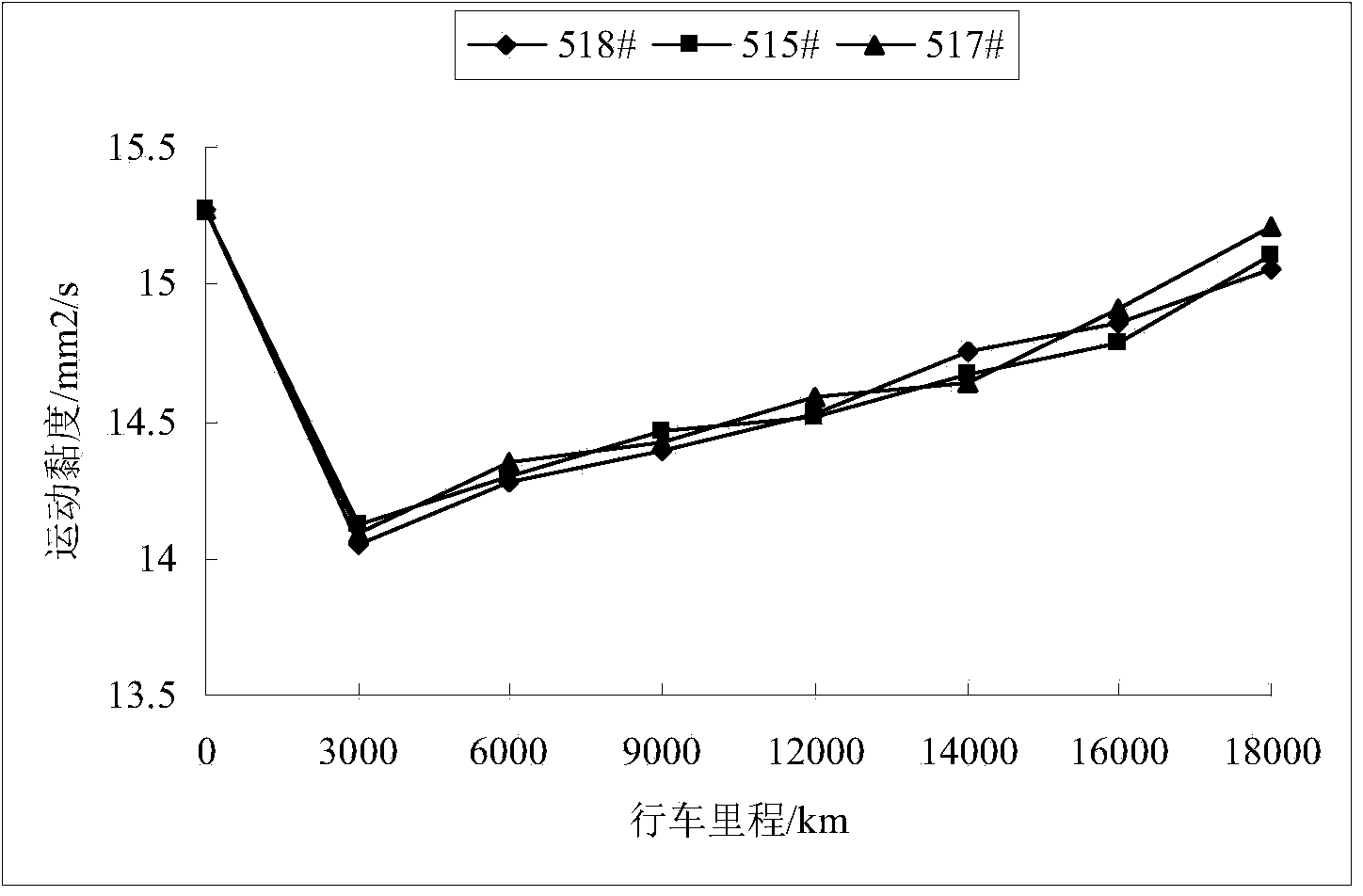

Special lubricating oil for fuel gas engine of public transport automobile

ActiveCN104342266AAntioxidant time is longImprove protectionLubricant compositionThiadiazolesPolyisobutylene succinimide

The invention discloses special lubricating oil for a fuel gas engine of a public transport automobile. The special lubricating oil is prepared from blended base oil, binary ethylene-propylene rubber, polymethacrylate, alkylphenol calcium sulfide, high-base-number calcium alkylbenzenesulfonate, polyisobutylene succinimide, boronated polyisobutylene succinimide, alkylated phenyl-alpha-naphthylamine, p,p'-dioctyl diphenylamine, a hindered phenol type antioxidant, dialkyl molybdenum dithiocarbamate, copper nanoparticle anti-wear additives, methyl silicone oil and thiadiazole polysulfide. According to the lubricating oil composition oil product, the sulfate ash content is lower than 0.5%, the content of phosphorus is lower than 0.03%, and the base number is 3-8mgKOH / g. According to the special lubricating oil for the fuel gas engine of the public transport automobile, aiming at the special requirements of the public transport automobile on engine oil, different additive varieties and charging sequences are adopted, so that physical and chemical indicators and use performance of the special lubricating oil are better than natural gas engine lubricating oil of the same grade, and the special lubricating oil has excellent cleaning and dispersion properties, lubricating property, abrasion resistance and oxidation resistance.

Owner:陕西通用润滑科技有限公司

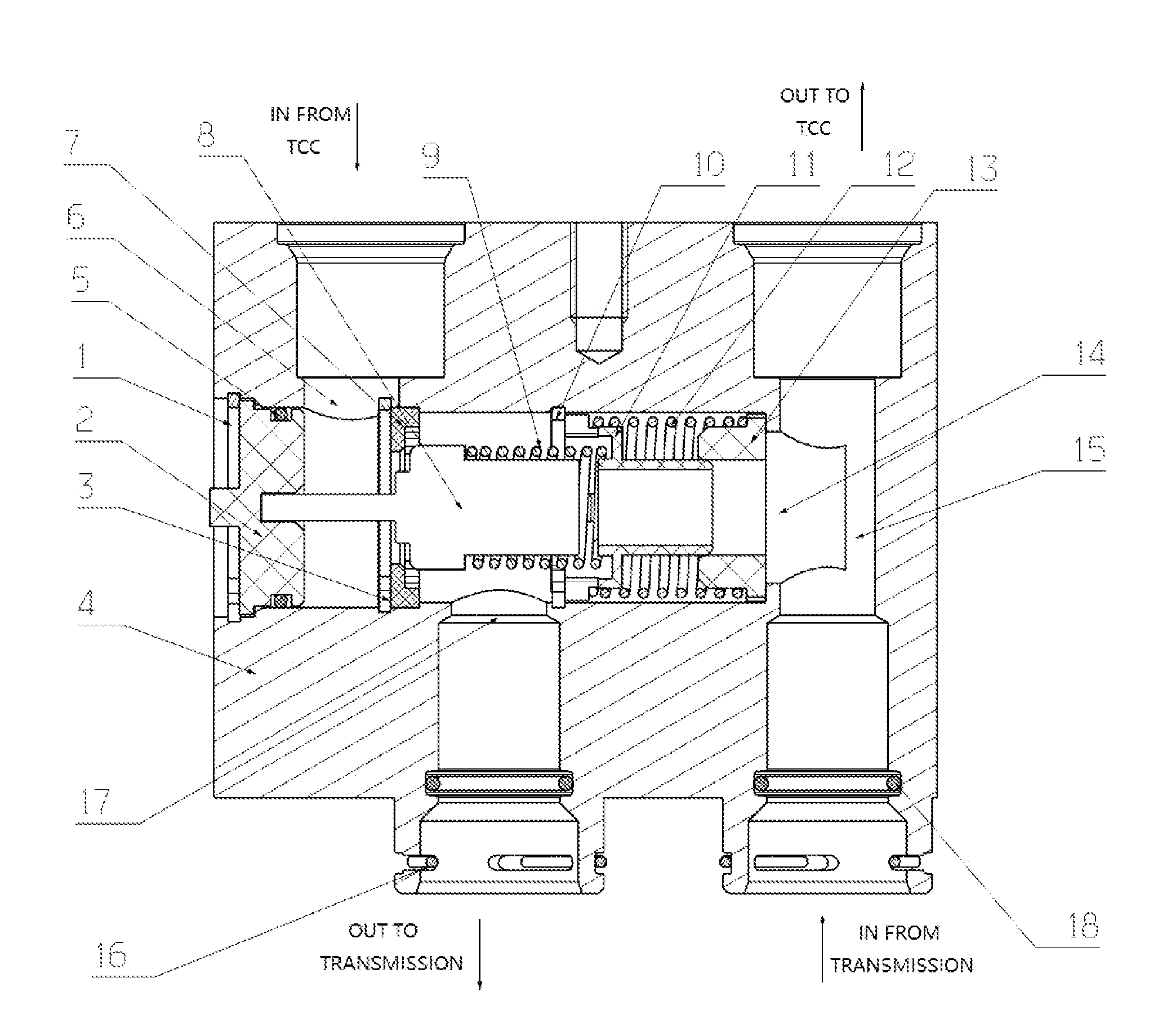

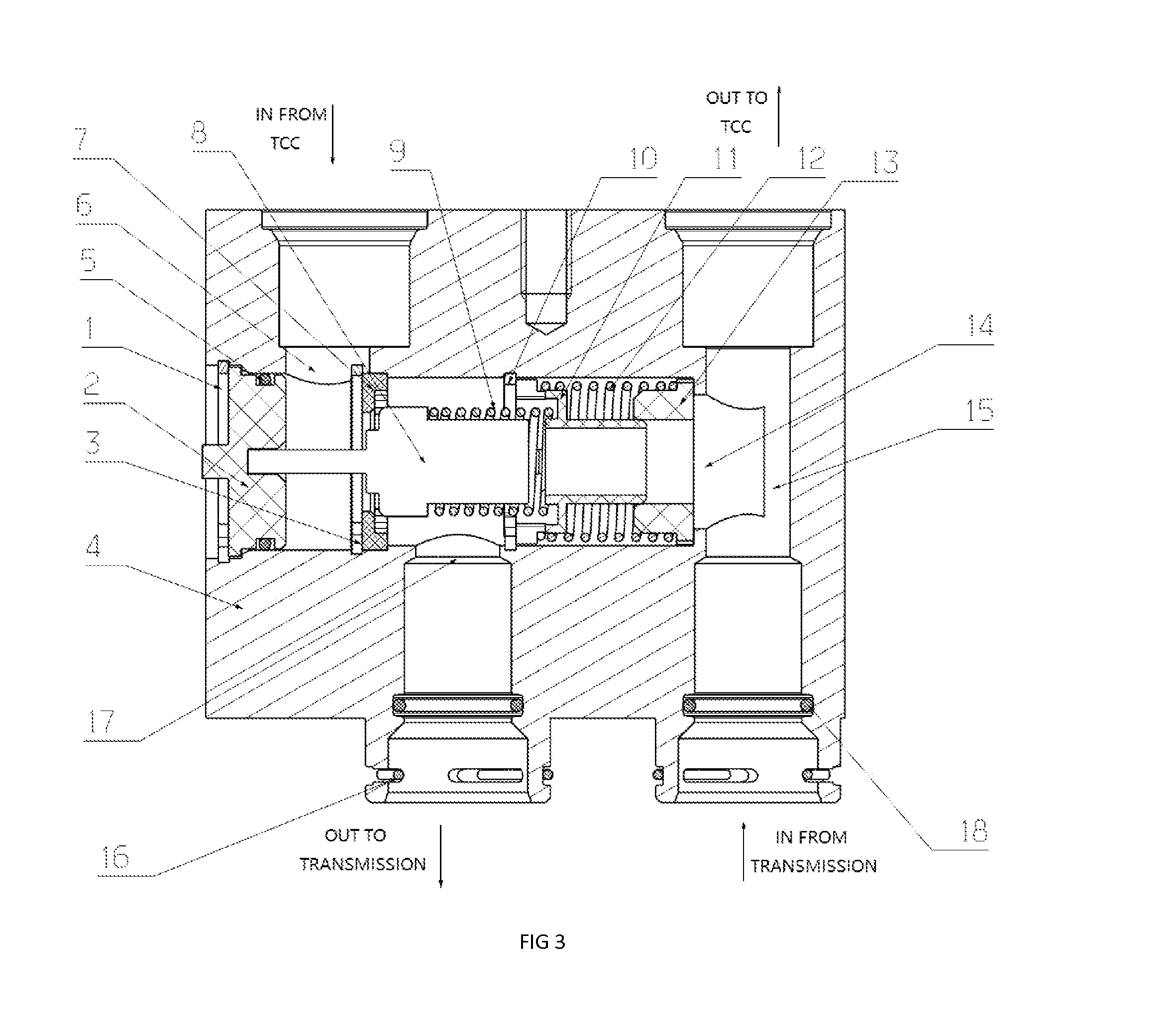

Temperature-regulating Valve of Transmission Oil Cooling System in A Passenger Car

InactiveUS20160047459A1Easy to produceProtect partsOperating means/releasing devices for valvesGear lubrication/coolingEngineeringOil cooling

A temperature-regulating valve comprises a valve body, two circlips, two small O-rings and a valve core, wherein the valve core is located in the chamber of the valve body and comprises a big retainer ring, an end cap, medium retainer ring, a big O-ring, a restraint block, a thermal component, a compression spring, small retainer ring, a slide block, a return spring and a release pressure plate.

Owner:AIR INT THERMAL SYST R & D SHANGHAI

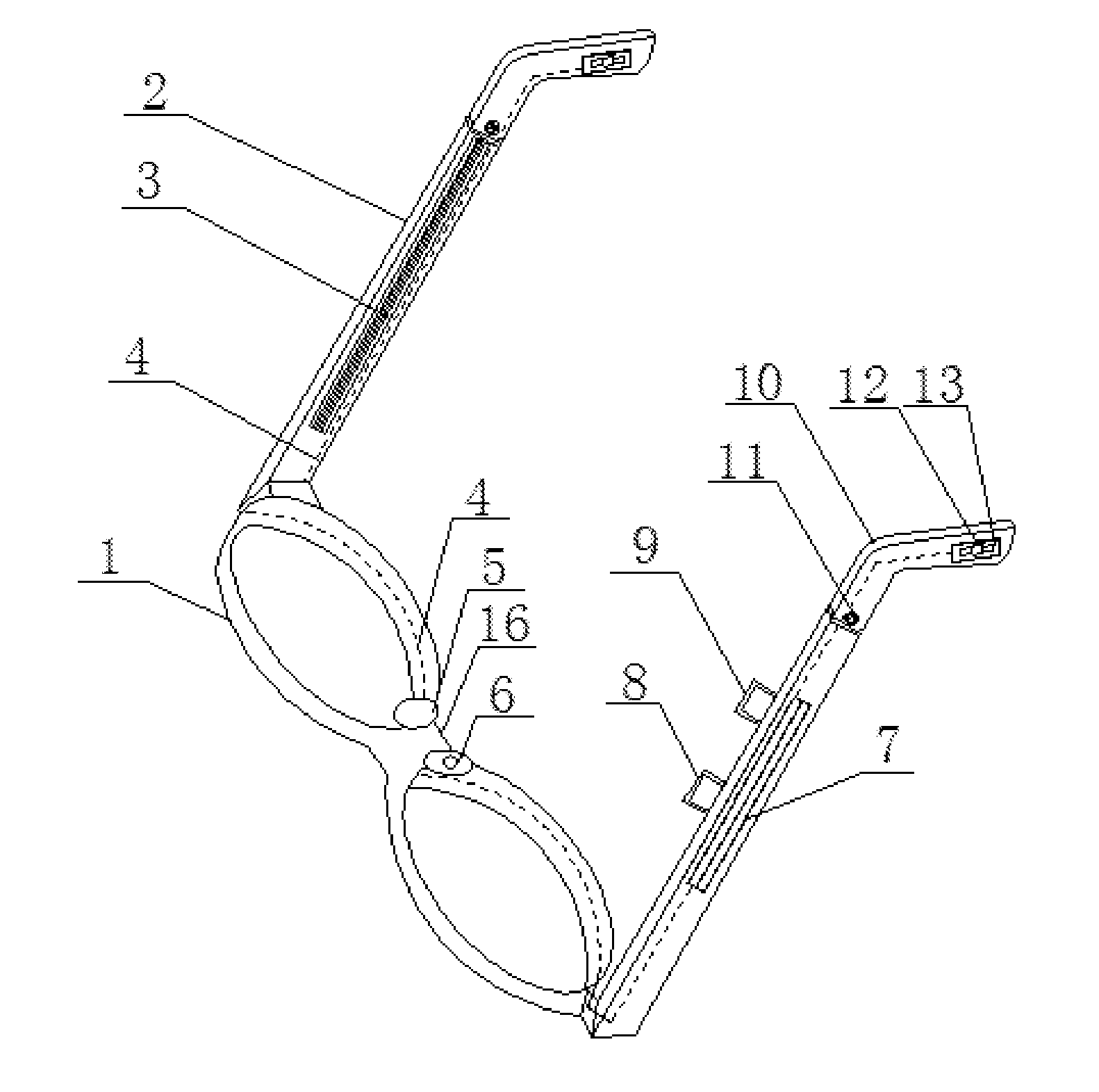

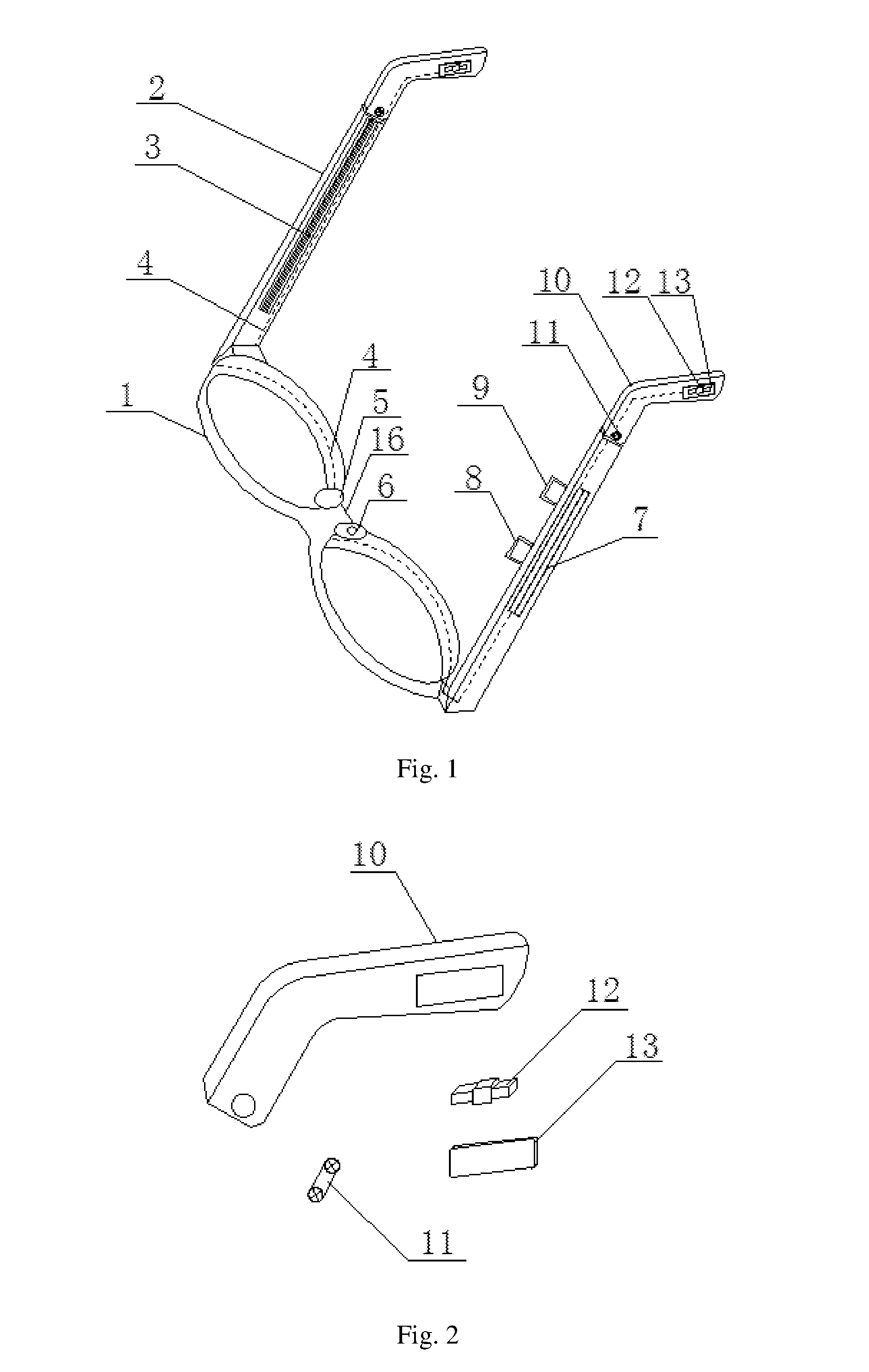

Lightweight Bone Conduction Bluetooth Glasses

InactiveUS20160246076A1Improve waterproof performanceEasy to cleanMicrophonesSignal processingEyewearEngineering

The invention relates to the field of electronic information technology and discloses lightweight bone conduction Bluetooth glasses, including glasses frames, glasses legs, glasses feet, a nose bridge and nose pads, wherein a lithium battery and a Bluetooth circuit board are set within the glasses legs, bone conduction speakers are set within both glasses feet, a microphone is set within the glasses legs or on the nose bridge or the nose pads, conducting wires are set within the glasses frames, the glasses legs and the glasses feet, and the microphone, the lithium battery, the Bluetooth circuit board and the bone conduction speaker are connected through the conducting wires. The bone conduction Bluetooth glasses of the invention are similar to ordinary glasses, and the user can answer the call without taking a mobile phone out, thus freeing both hands and ears, hearing and speaking clearly, protecting privacy, and reducing radiation.

Owner:HANGZHOU SHUANGWANYUE ELECTRONICS TECH CO LTD

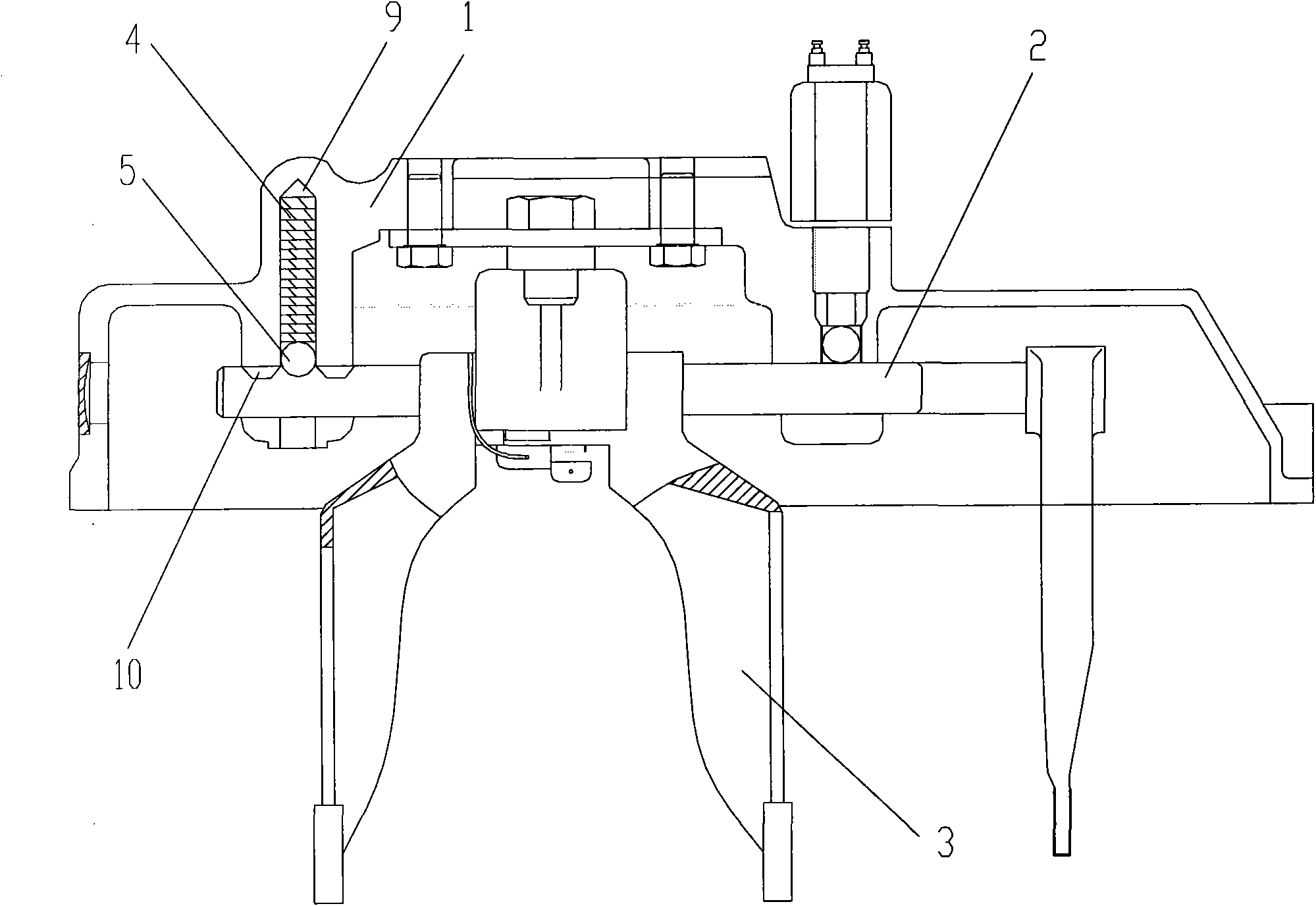

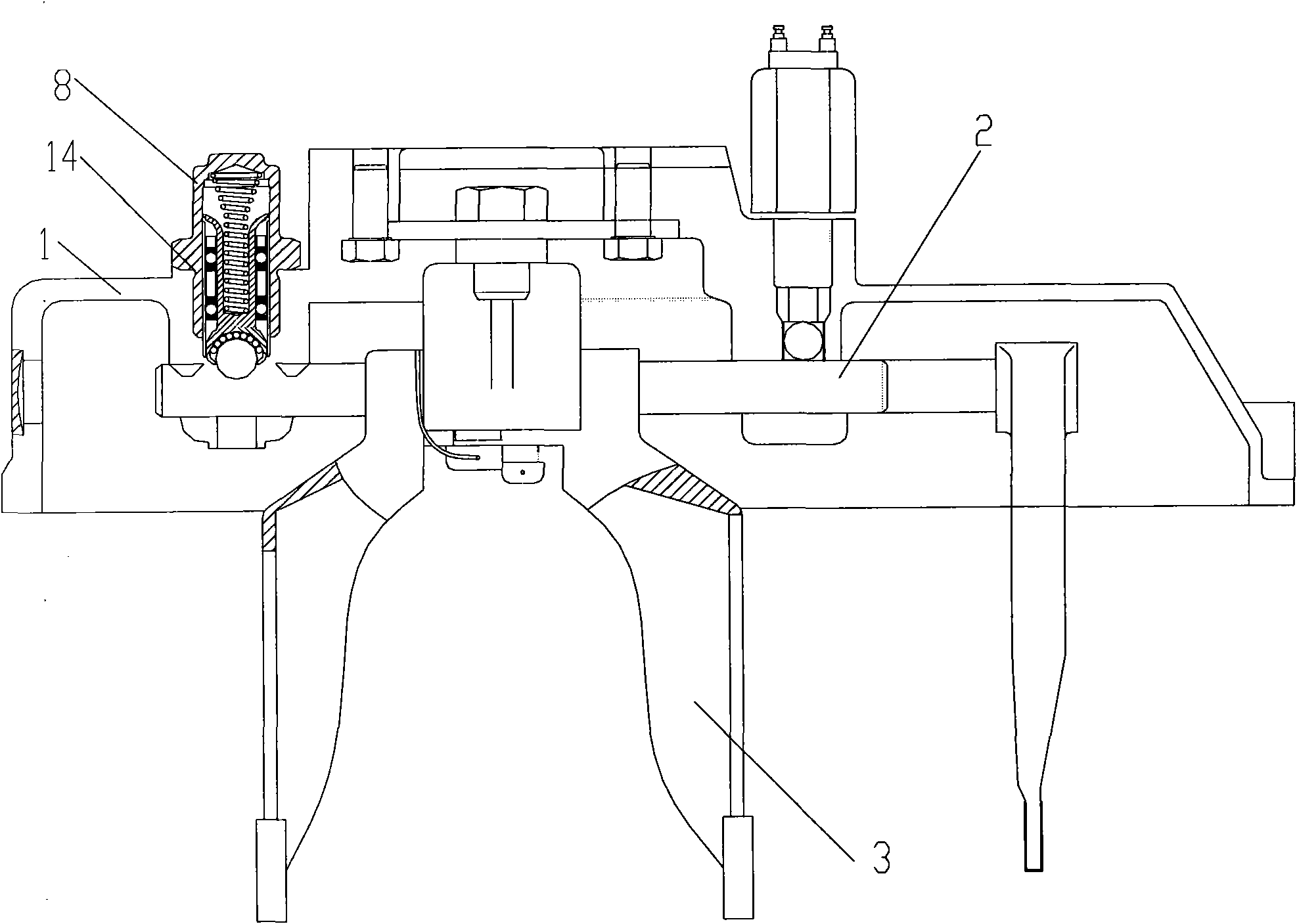

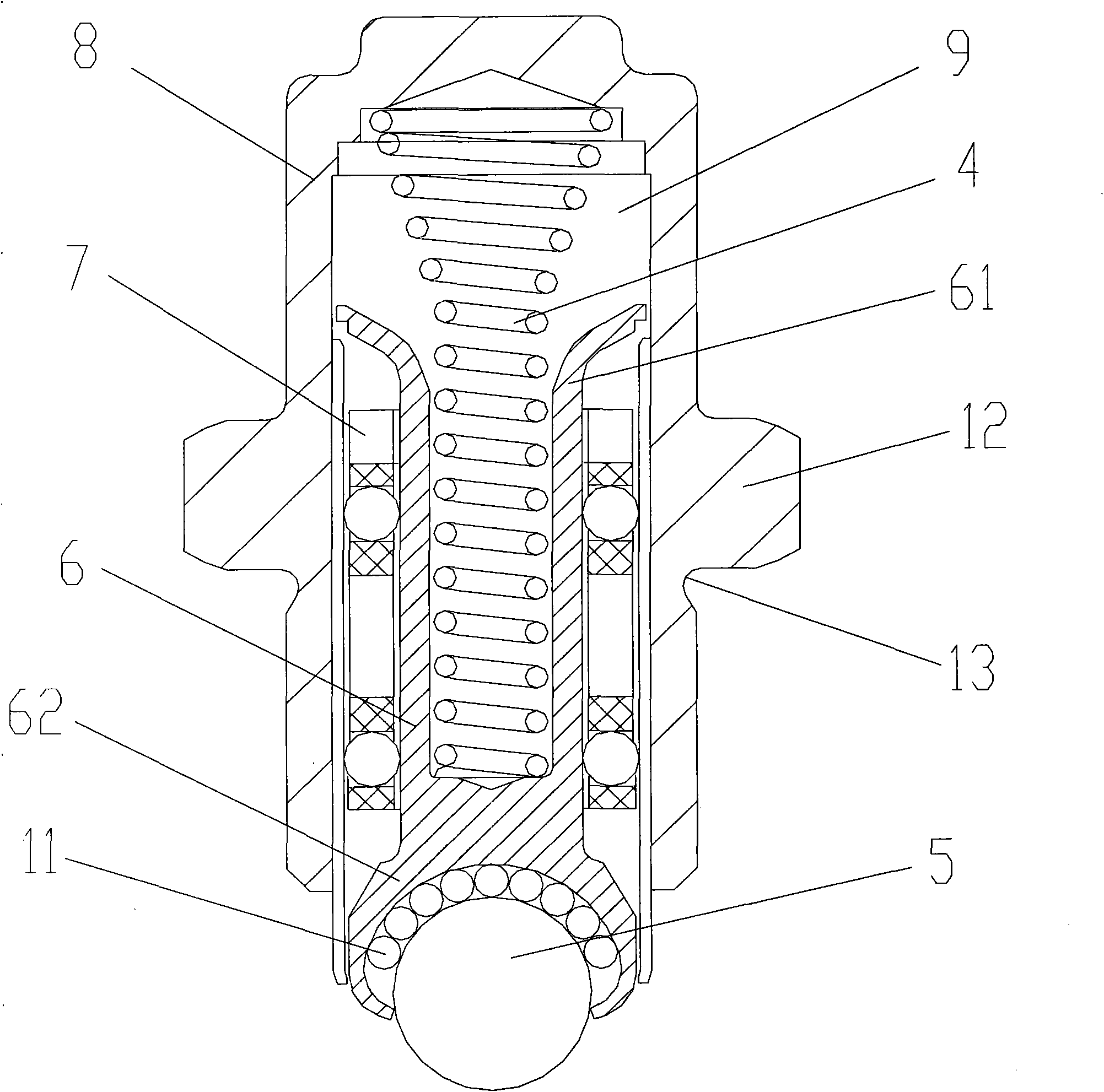

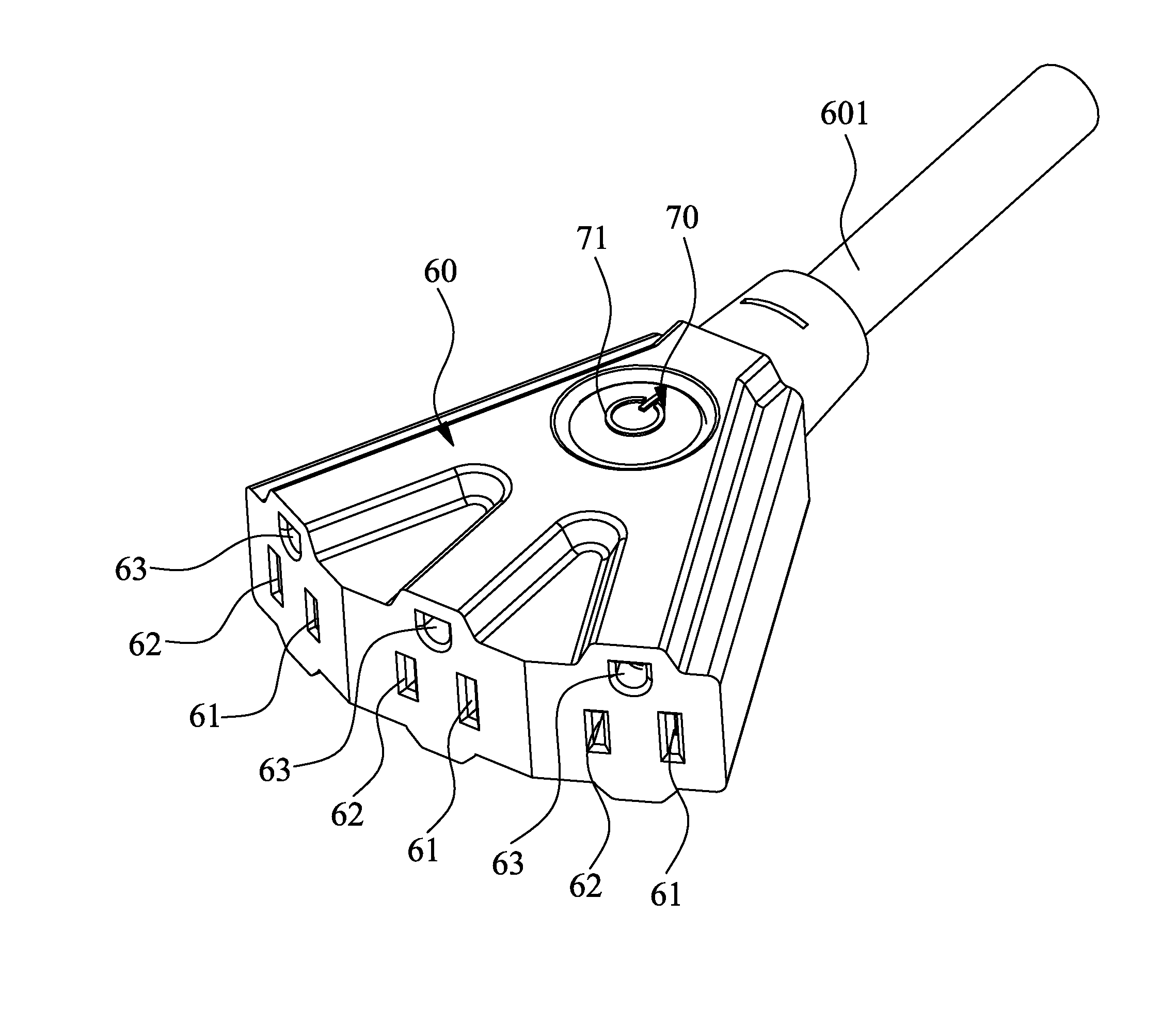

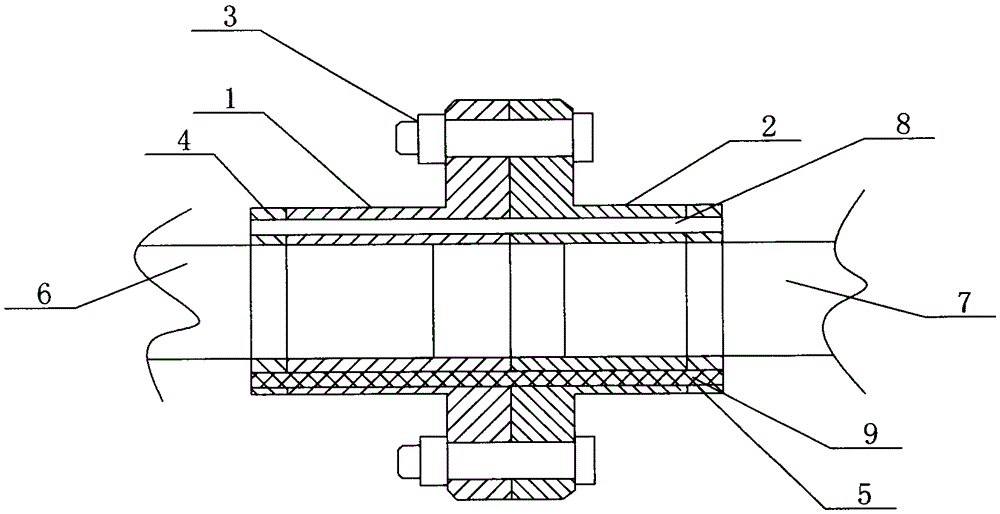

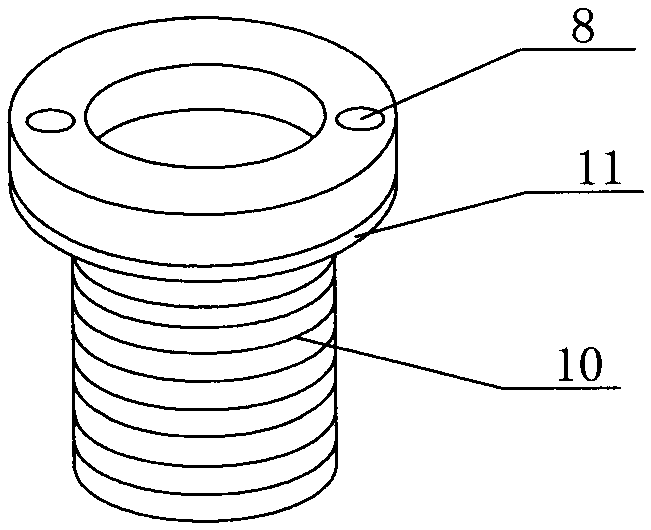

Self-locking device of transmission control mechanism

InactiveCN102384254AProtect partsReduce frictionControlled membersGearing controlRolling resistanceSelf locking

The invention relates to a self-locking device of a transmission control mechanism. The self-locking device comprises a shell (8), a gear-shifting fork shaft (2), a self-locking spring (4) and self-locking steel balls (5), wherein the shell (8) is provided with a cavity (9), the self-locking spring (4) is accommodated in the cavity (9), a plurality of grooves (10) are formed on the gear-shifting fork shaft (2), and the self-locking steel balls (5) are arranged in the grooves (10) in a press-fit manner through the self-locking spring (4), the self-locking device further comprises a spring bracket (6) and a bearing (7) in the cavity (9), the self-locking spring (4) is arranged on the upper part (61) of the spring bracket, the self-locking steel balls (5) are arranged at the lower part (62) of the spring bracket, and the bearing (7) is arranged between the spring bracket (6) and the shell (8). The self-locking device can be used for converting sliding friction among the self-locking steel balls (5), the self-locking spring (4) and the shell (8) into rolling friction, so that the friction force is reduced, the parts of the self-locking device are protected, and the hand feel and the comfortableness for gear shifting are improved.

Owner:BEIQI FOTON MOTOR CO LTD

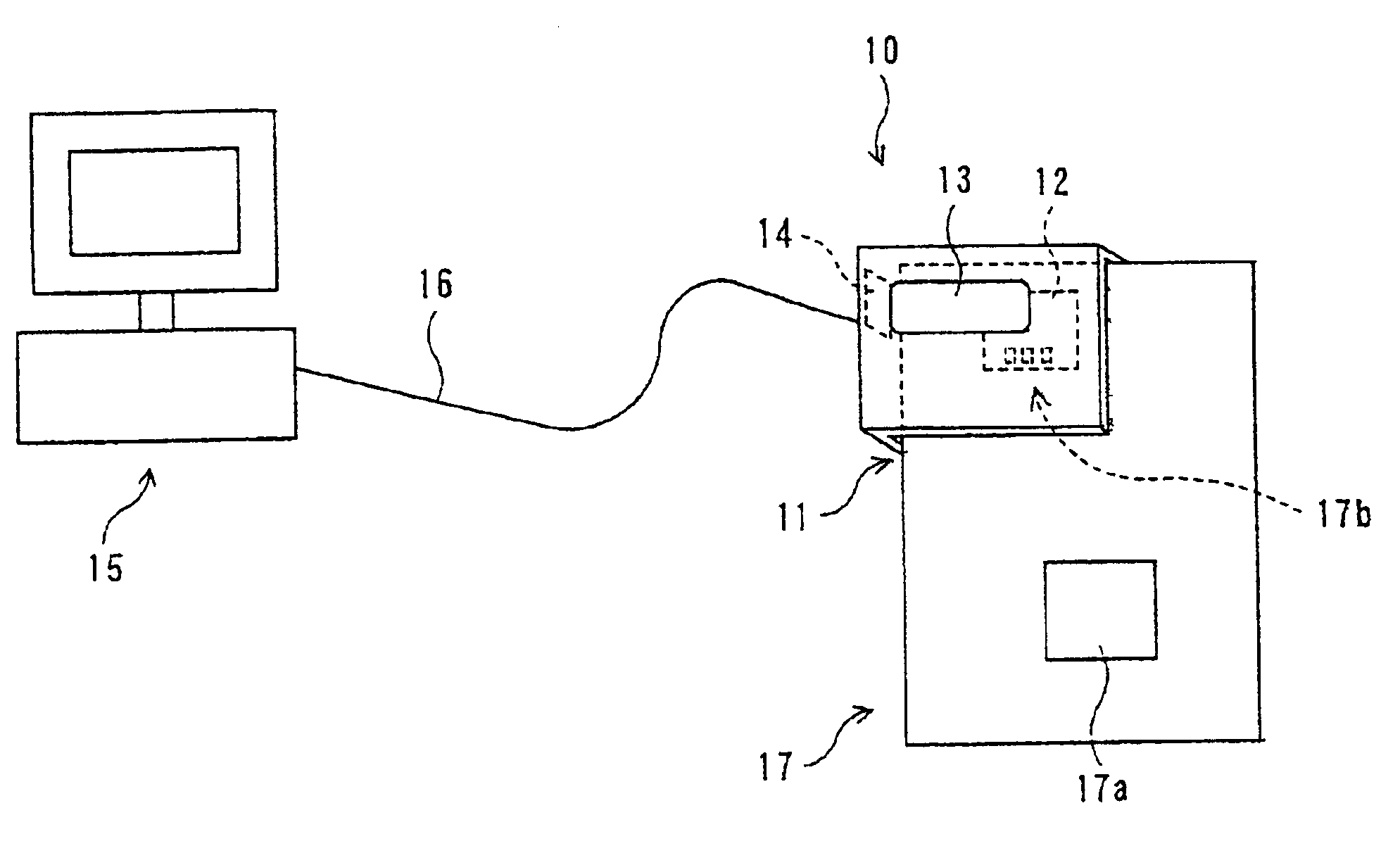

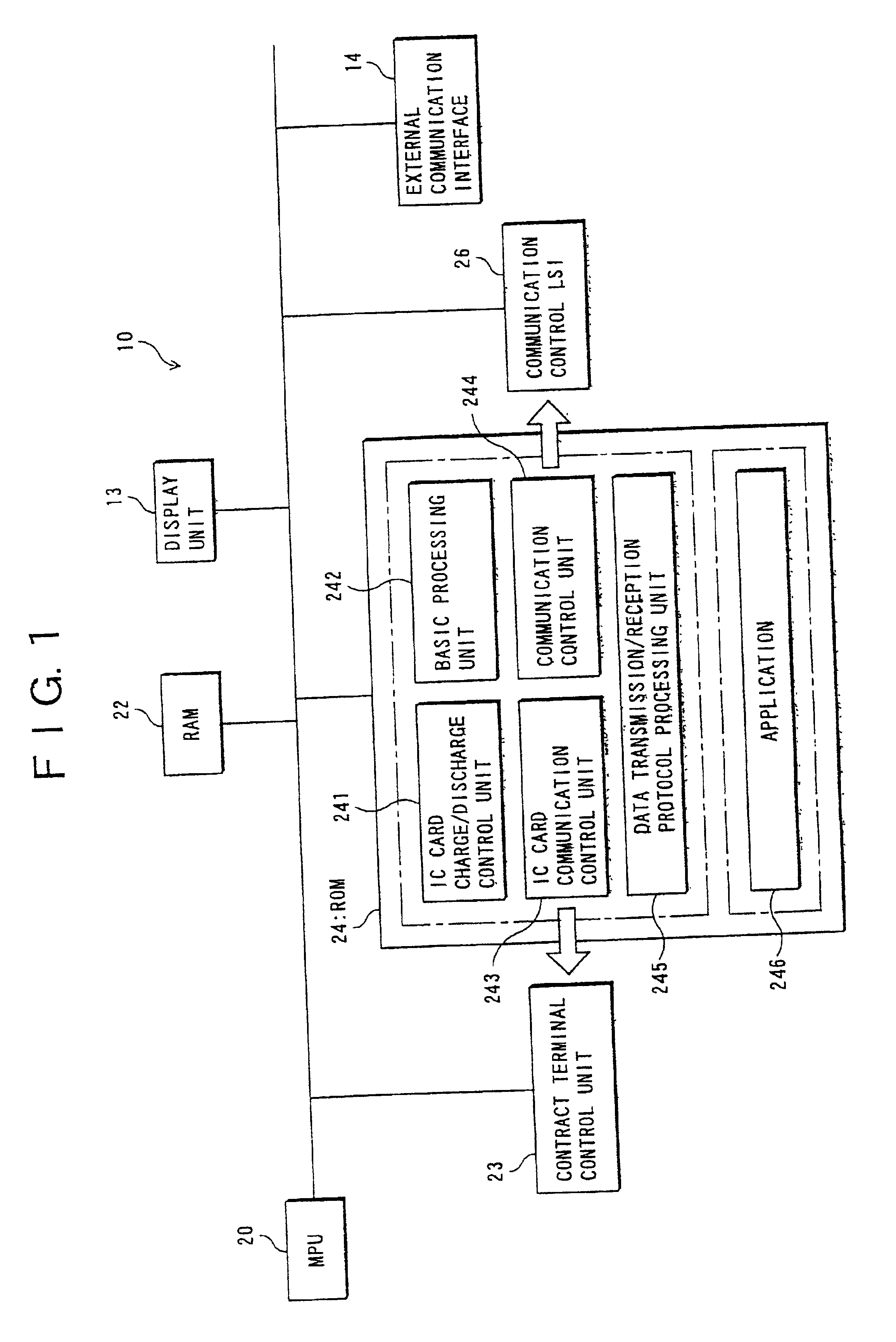

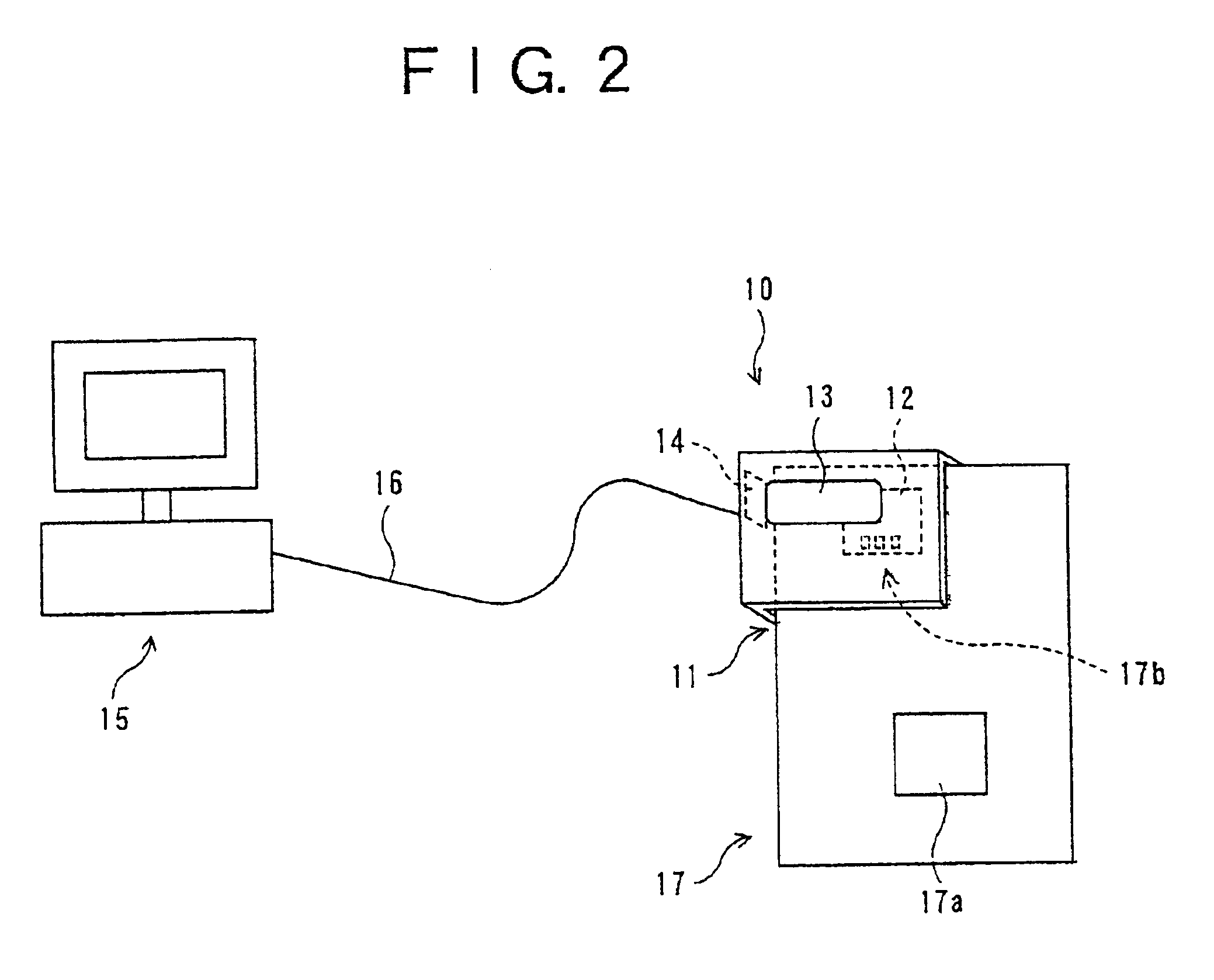

Portable card unit processing apparatus

InactiveUS6769609B2Reduce spacingEasy to operateComplete banking machinesFinanceComputer hardwareComputer science

The processing apparatus including a first communicating section (23, 243), a connecting unit (14) for being detachably connected to an external apparatus, a second communicating section (26, 244), a display section (13), and a control section (26, 244) so as to transfer data between the card unit and the external apparatus while the external apparatus is connected to the connecting section, (14), and controlling the first communicating section (23, 243) and the display section (13) so as to read data from the storage section of the card unit and to display the read-out data on the display section (13) while the external apparatus is disconnected from the concentrating section (14).

Owner:FUJITSU LTD

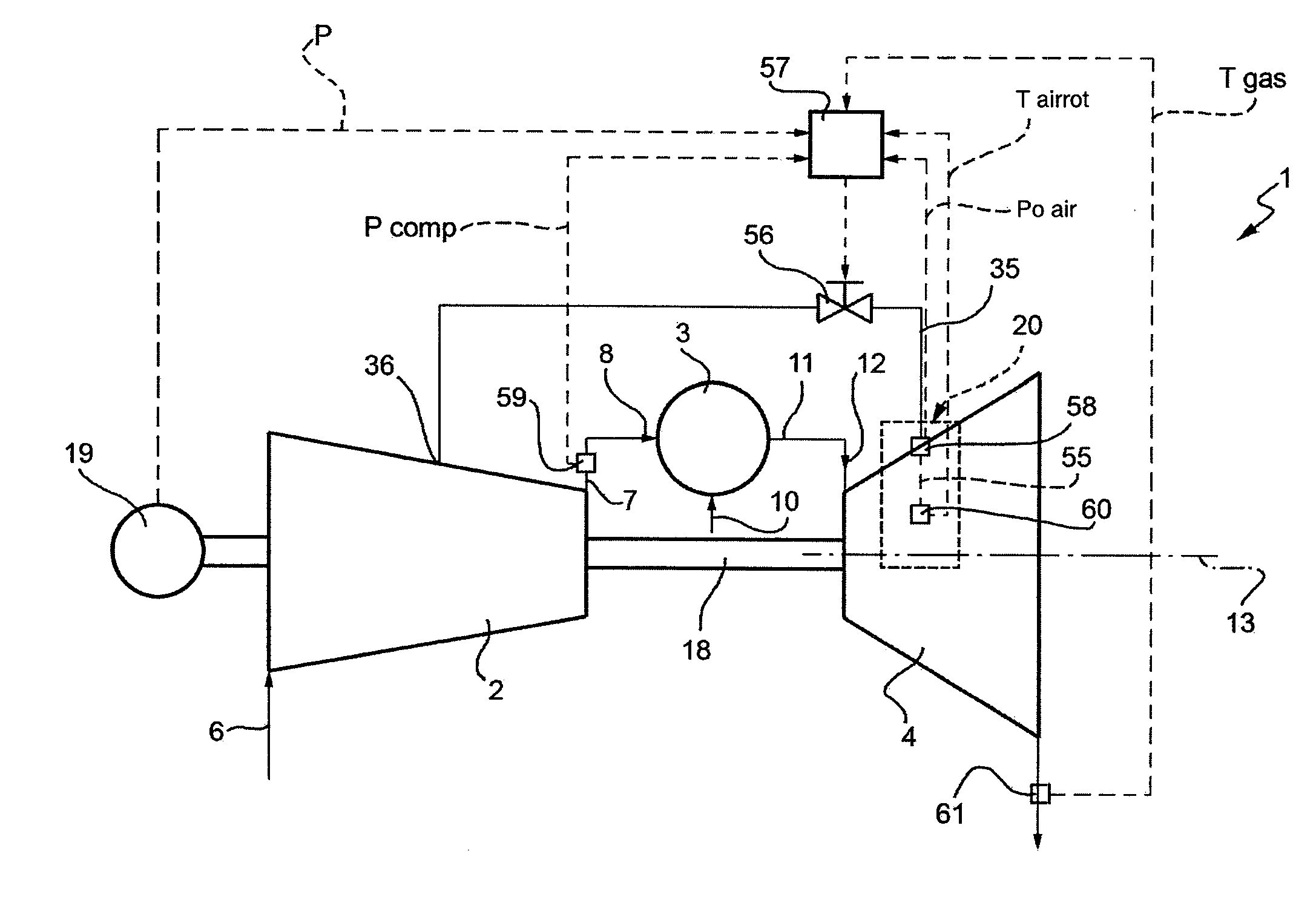

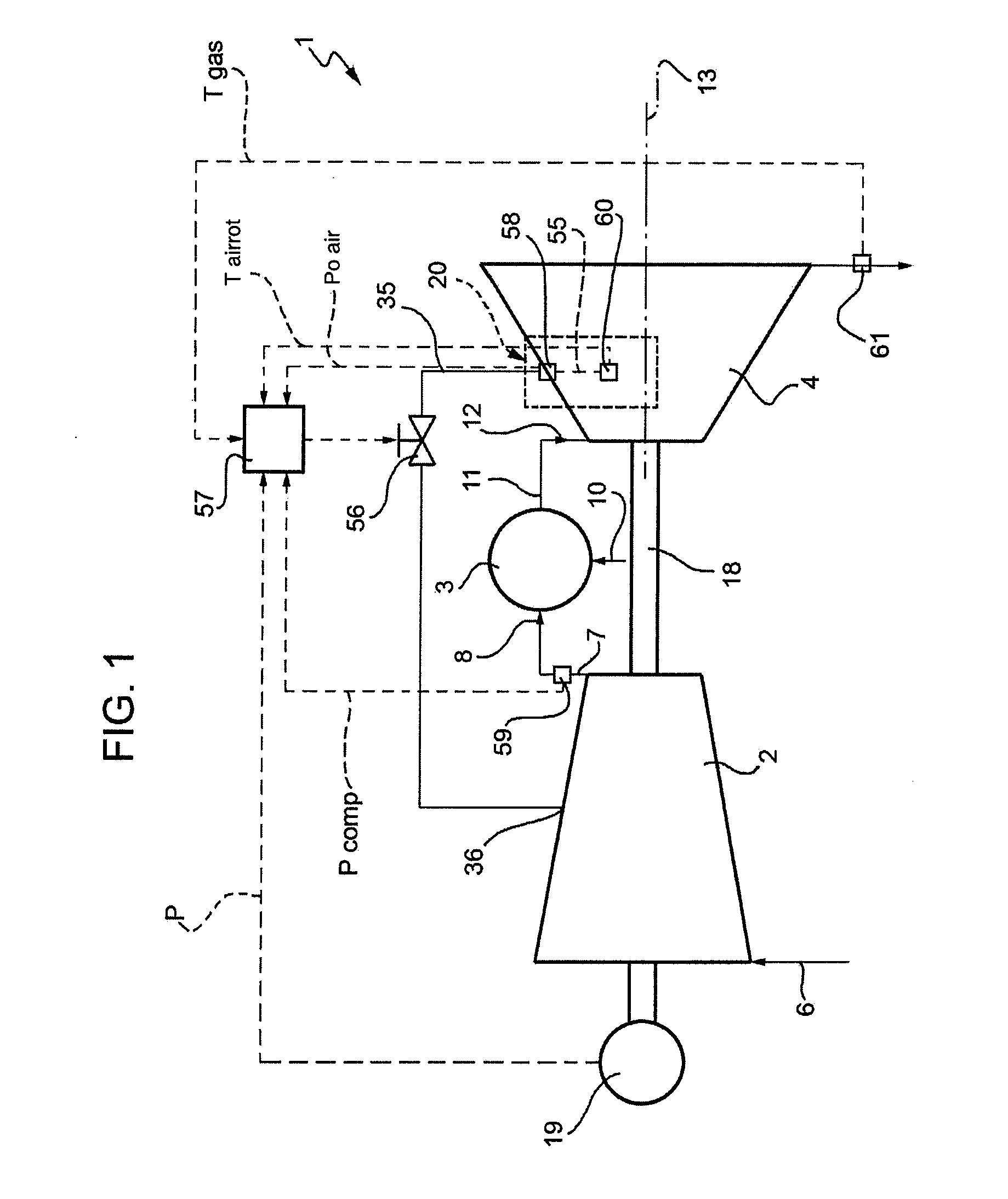

Control method for cooling a turbine stage in a gas turbine

InactiveUS20120111020A1Improve reliabilityExtend working lifeEngine fuctionsTurbine/propulsion engine coolingCombustionTurbine

A control method for cooling a turbine stage of a gas turbine, whereby cooling air is bled from combustion air flowing in a compressor of the gas turbine, and is fed to a cooling circuit staring from a stator of the turbine stage; and cooling airflow is adjusted as a function of the pressure at the inlet of the cooling circuit, and as a function of the combustion air pressure at the exhaust of the compressor; more specifically, there is a feedback control setting a setpoint, which is predetermined as a function of the power output of the turbine to reduce contaminating emissions.

Owner:ANSALDO ENERGIA SPA

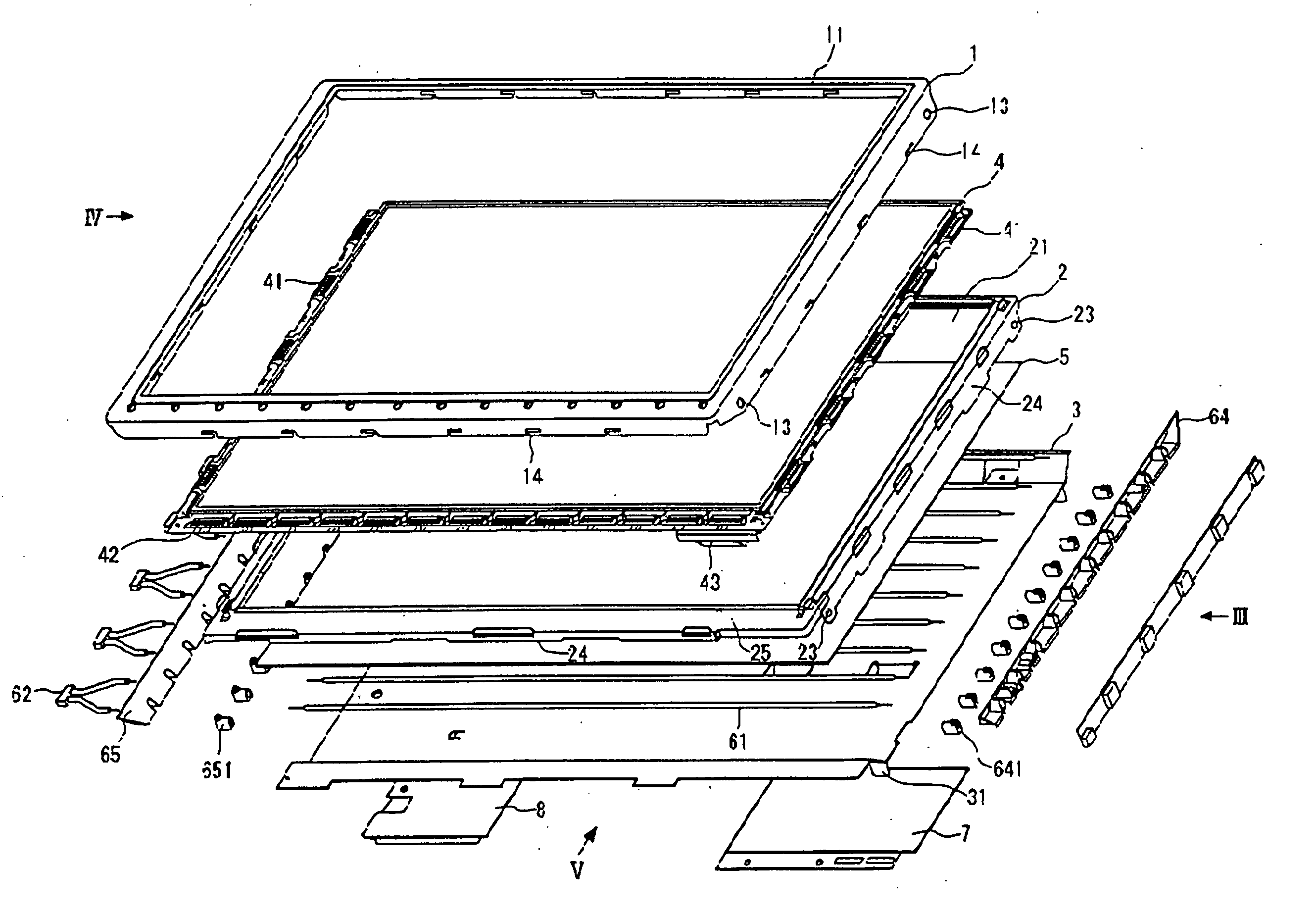

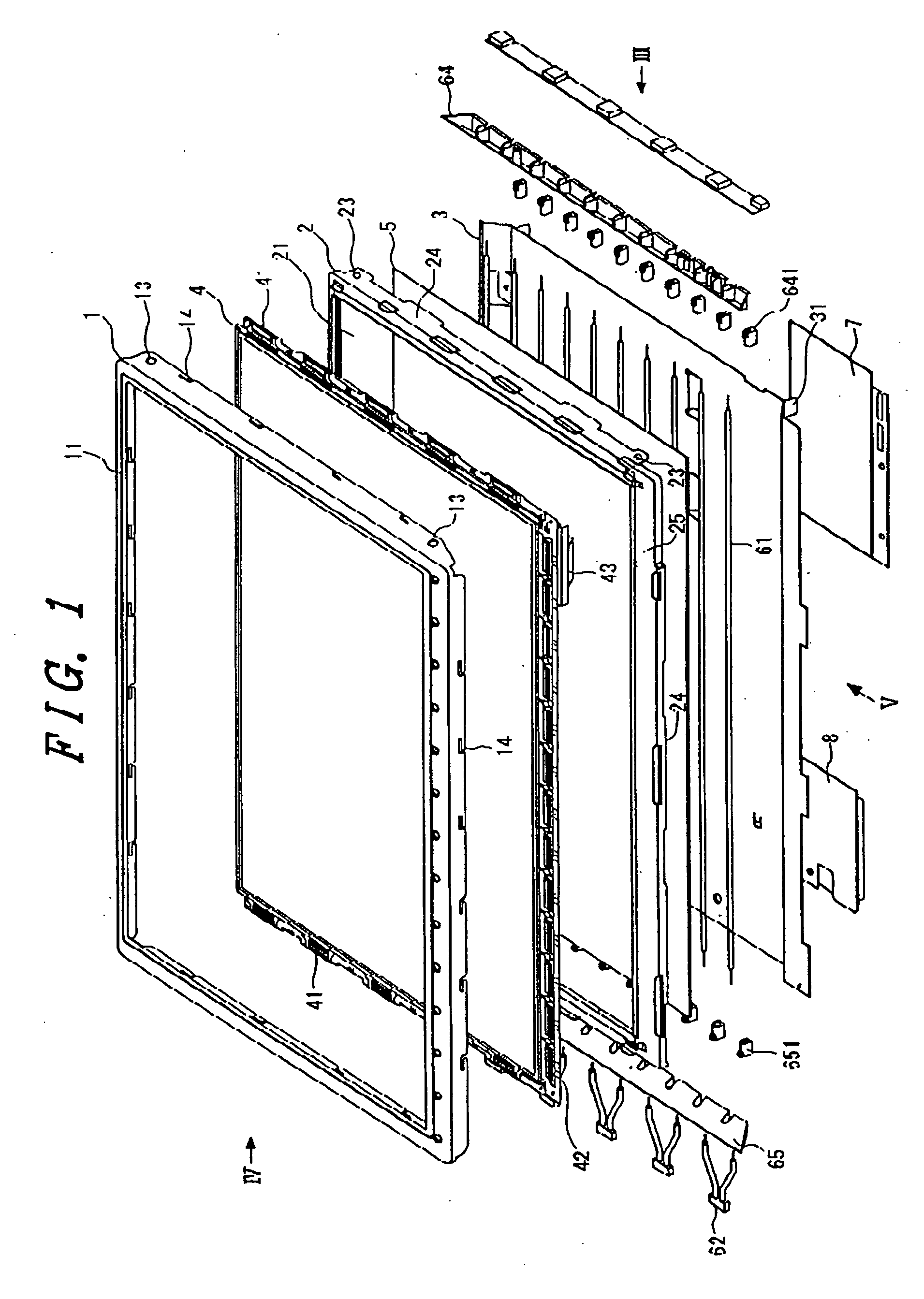

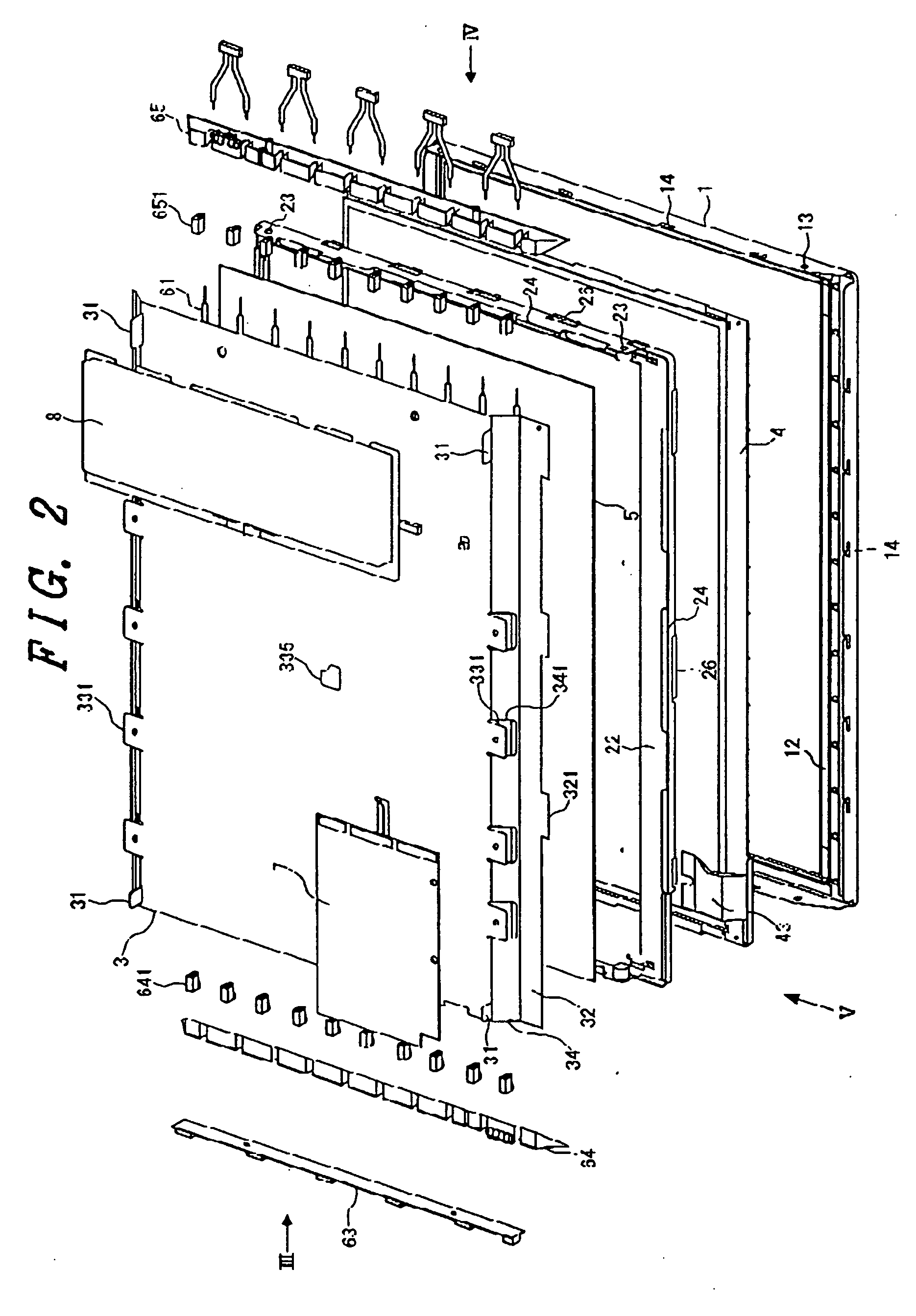

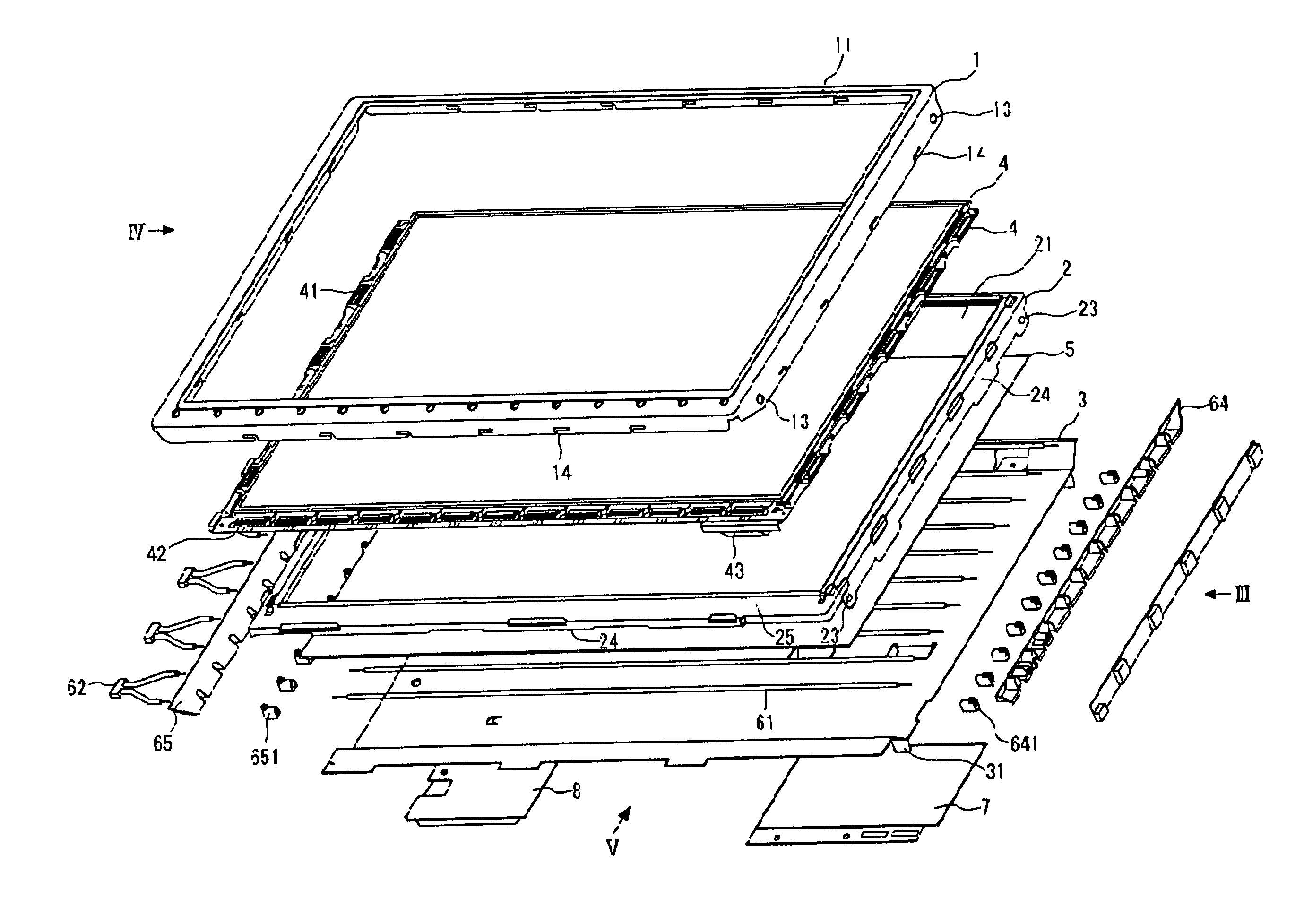

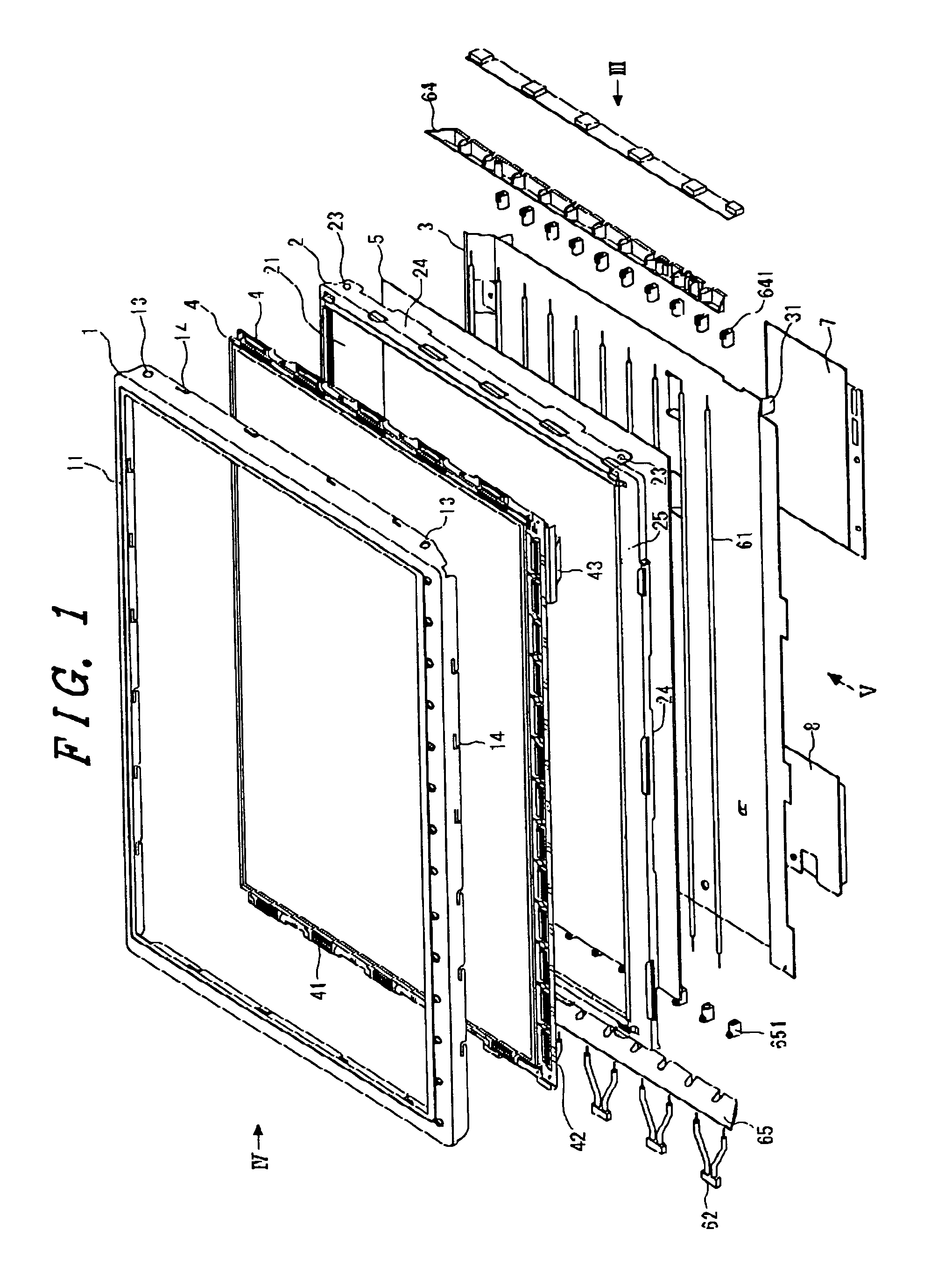

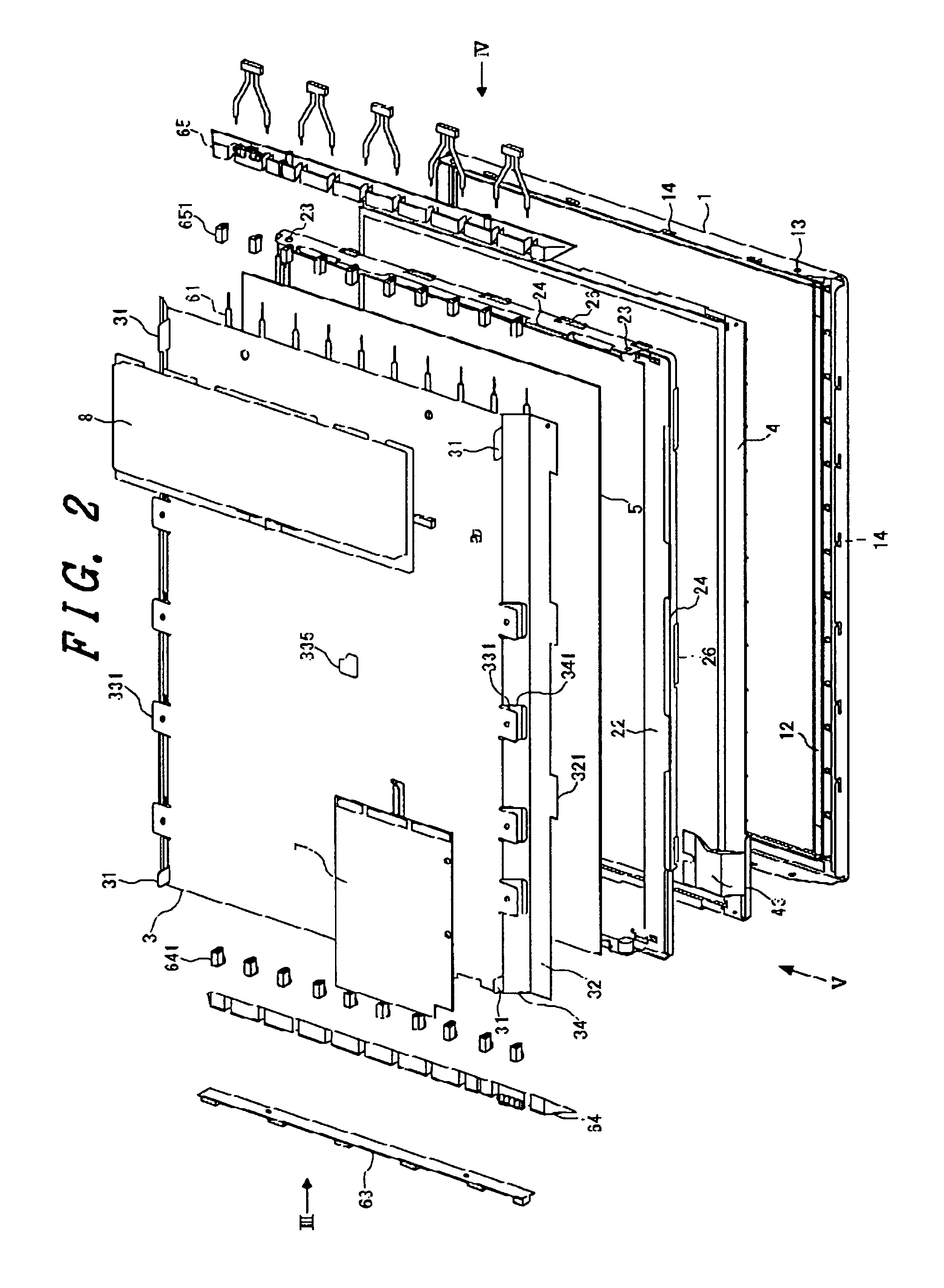

Liquid crystal display device

InactiveUS20060038934A1Reduce the burden onIncrease the burdenNon-linear opticsLiquid-crystal displayCold cathode

The object of the present invention is to make parts and kinds of liquid crystal display devices in common for cope stably and flexibly with commercial products of computer makers and television makers which have been promoted in various kinds, for simplifying maintenance of a liquid crystal display unit mounted on computers, display monitors therefor or televisions, and preferably for enabling to omit positional adjustment of a light source unit and a liquid crystal display panel during the maintenance of the liquid crystal display device. For this object, the invention provides a liquid crystal display device comprising first, second, and third housings, a liquid crystal display panel fixed between the first and second housings, a light source (cold-cathode fluorescent tubes) fixed to the third housing, the second and third housings being detachable to one another, being constructed by overlapping the first, second and third housings with each other, wherein a timing-converter board fixed to an opposite side surface of the third housing to a side surface to which the light source is fixed, and protrusions formed on the opposite side surface so as to determine a maximum thickness of the liquid crystal display device.

Owner:PANASONIC LIQUID CRYSTAL DISPLAY CO LTD +1

Catheter for intravascular ultrasound and photoacoustic imaging

InactiveUS8932223B2Protect partsAvoid mechanical damageOrgan movement/changes detectionSurgeryElastographyUltrasonic sensor

A design and a fabrication method for an intravascular imaging and therapeutic catheters for combined ultrasound, photoacoustic, and elasticity imaging and for optical and / or acoustic therapy of hollow organs and diseased blood vessels and tissues are disclosed in the present invention. The invention comprises both a device—optical fiber-based intravascular catheter designs for combined IVUS / IVPA, and elasticity imaging and for acoustic and / or optical therapy—and a method of combined ultrasound, photoacoustic, and elasticity imaging and optical and / or acoustic therapy. The designs of the catheters are based on single-element catheter-based ultrasound transducers or on ultrasound array-based units coupled with optical fiber, fiber bundles or a combination thereof with specially designed light delivery systems. One approach uses the side fire fiber, similar to the one utilized for biomedical optical spectroscopy. The second catheter design uses the micro-optics in the manner of a probe for optical coherent tomography.

Owner:BOARD OF RGT THE UNIV OF TEXAS SYST

Live wireoutdoor socket with lamp

InactiveUS20130078861A1Save spaceConvenient to install and useCoupling device detailsEngineeringTransformer

An outdoor socket with lamp includes a main body, a live wire terminal, a neutral wire terminal, an LED illumination unit, a transformer, an outer casing, and a switch. Through two insertion portions at the front side of the main body, the LED illumination unit is vertically inserted in a fixing trough. The present invention provides a better waterproof effect, which can be used outdoors. The light of the LED illumination unit illuminates forward, providing an illumination effect. The fixing trough is disposed between the two adjacent insertion portions, which saves space and is compact.

Owner:CHENG CHI WEN

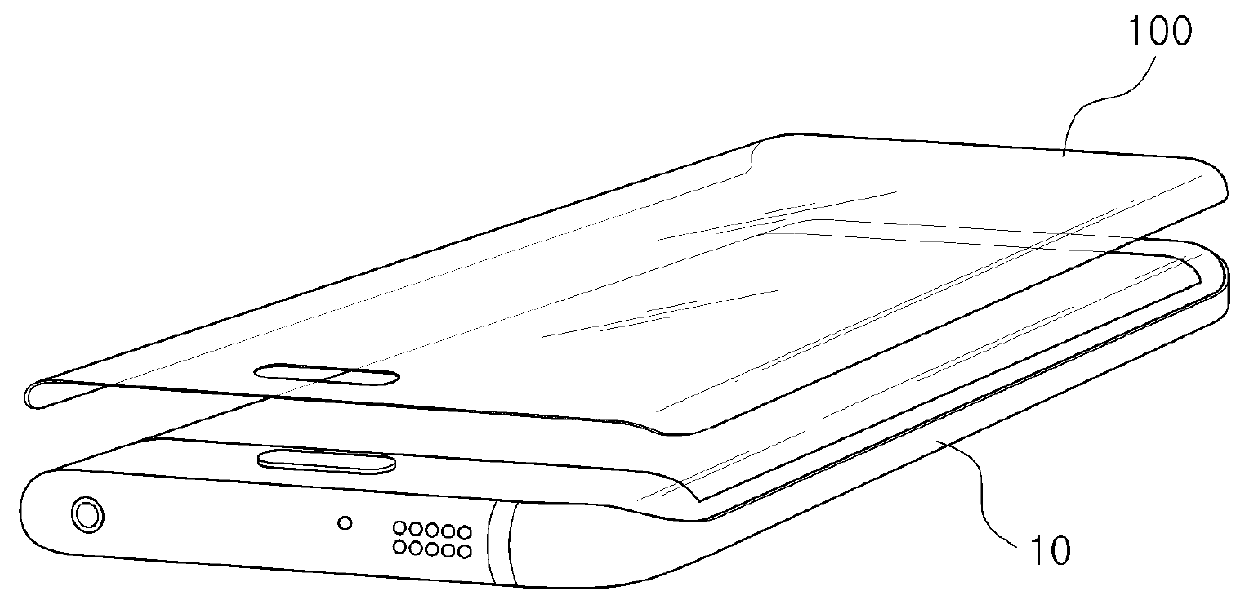

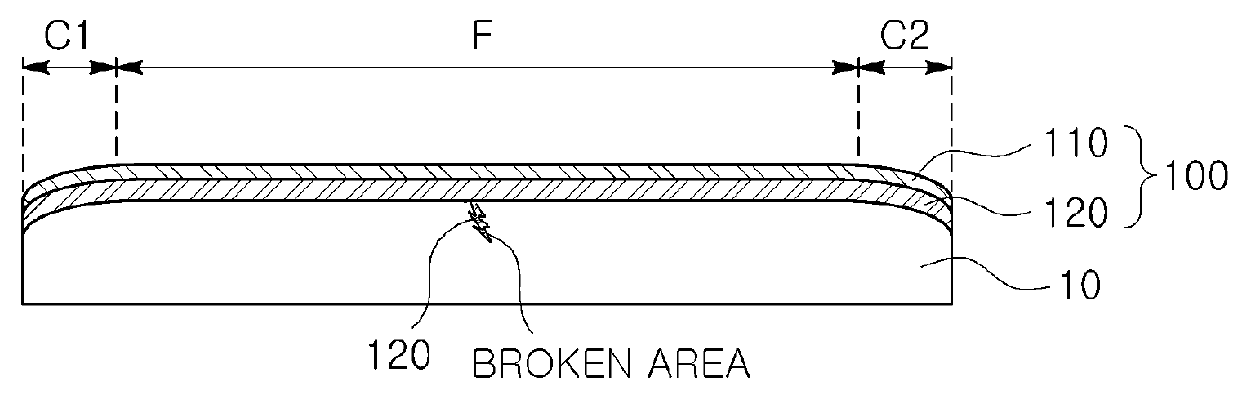

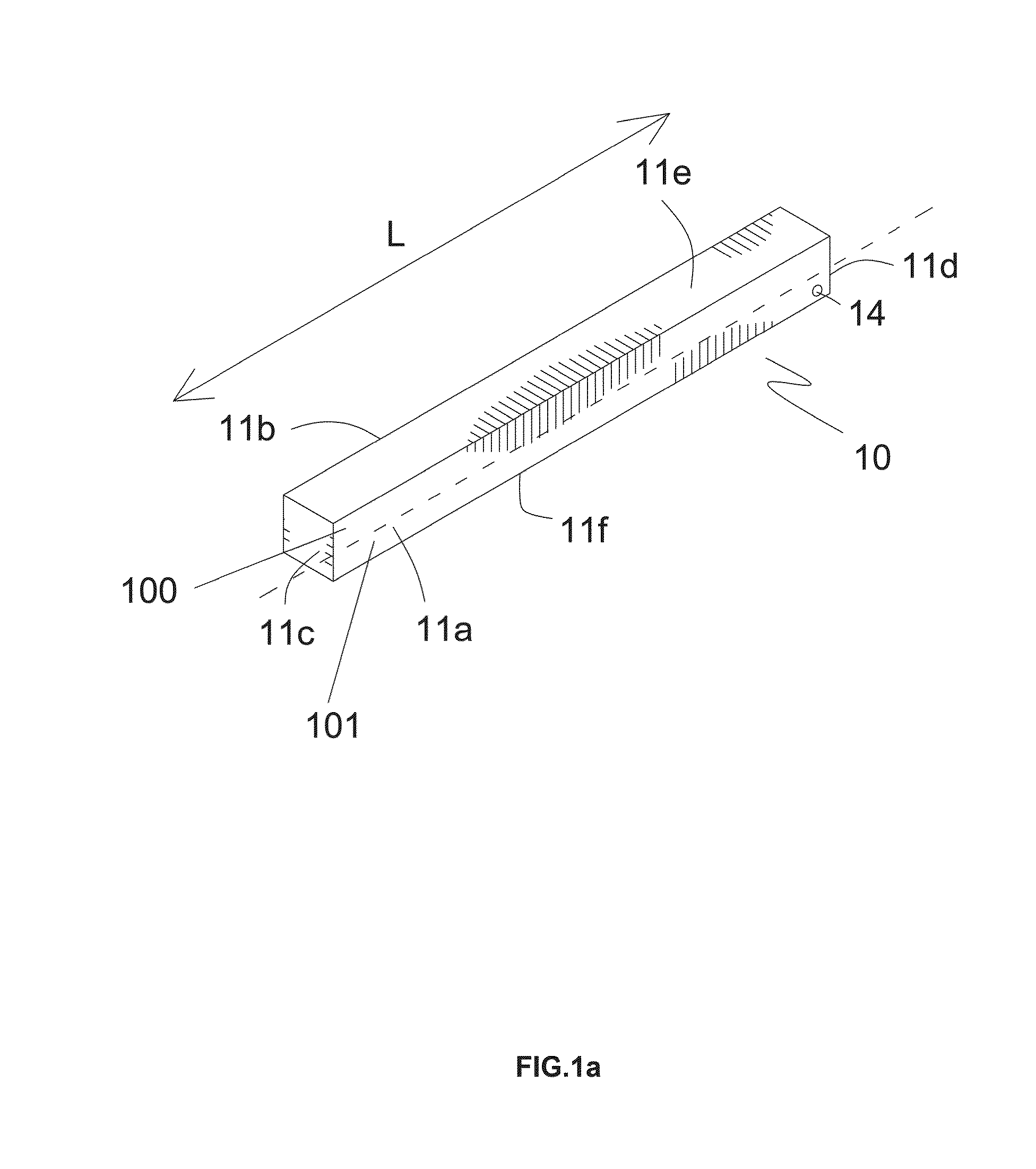

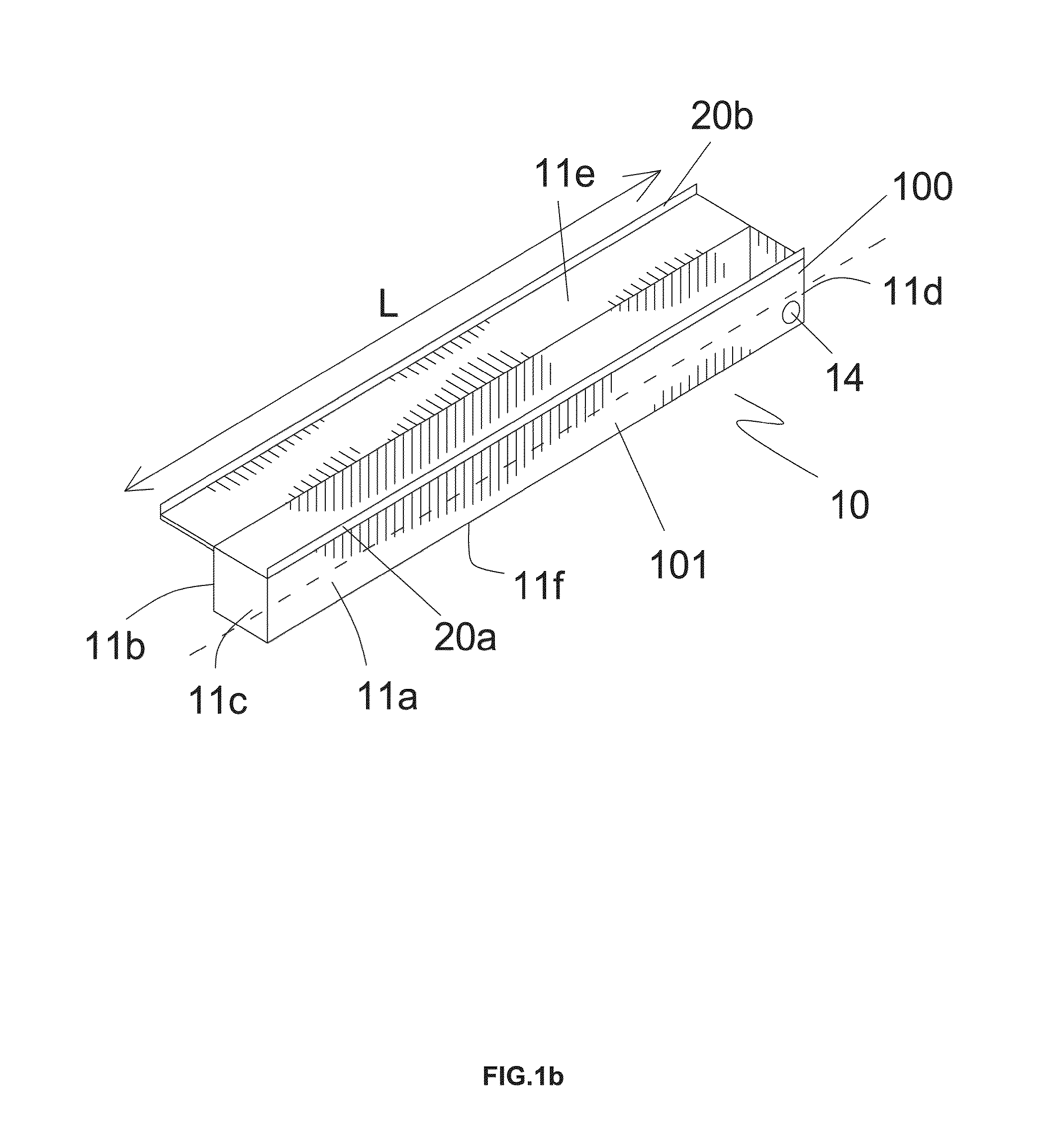

Display part protector for a smart device and method of adhering the display part protector to the surface using the device

InactiveUS20180272657A1Reduce the risk of injuryGood lookingDigital data processing detailsEster polymer adhesivesDisplay deviceBiomedical engineering

Disclosed are a protector having a protecting and restoring function of a display part of a smart device and a method of adhering the display part protector. The display part protector for the smart device according to the present disclosure includes a protector part adhered to at least one of a flat display area, and a curved display area of a smart device having at least one of the flat display area and curved display area and an adhesive layer which is formed by spreading a flow-able adhesive composition between an entire area of a lower surface of the protector part and a display area of the smart device and then curing the flowable adhesive composition and adheres the entire area of the lower surface of the protector part to the flat display area and the curved display area.

Owner:WHITESTONE

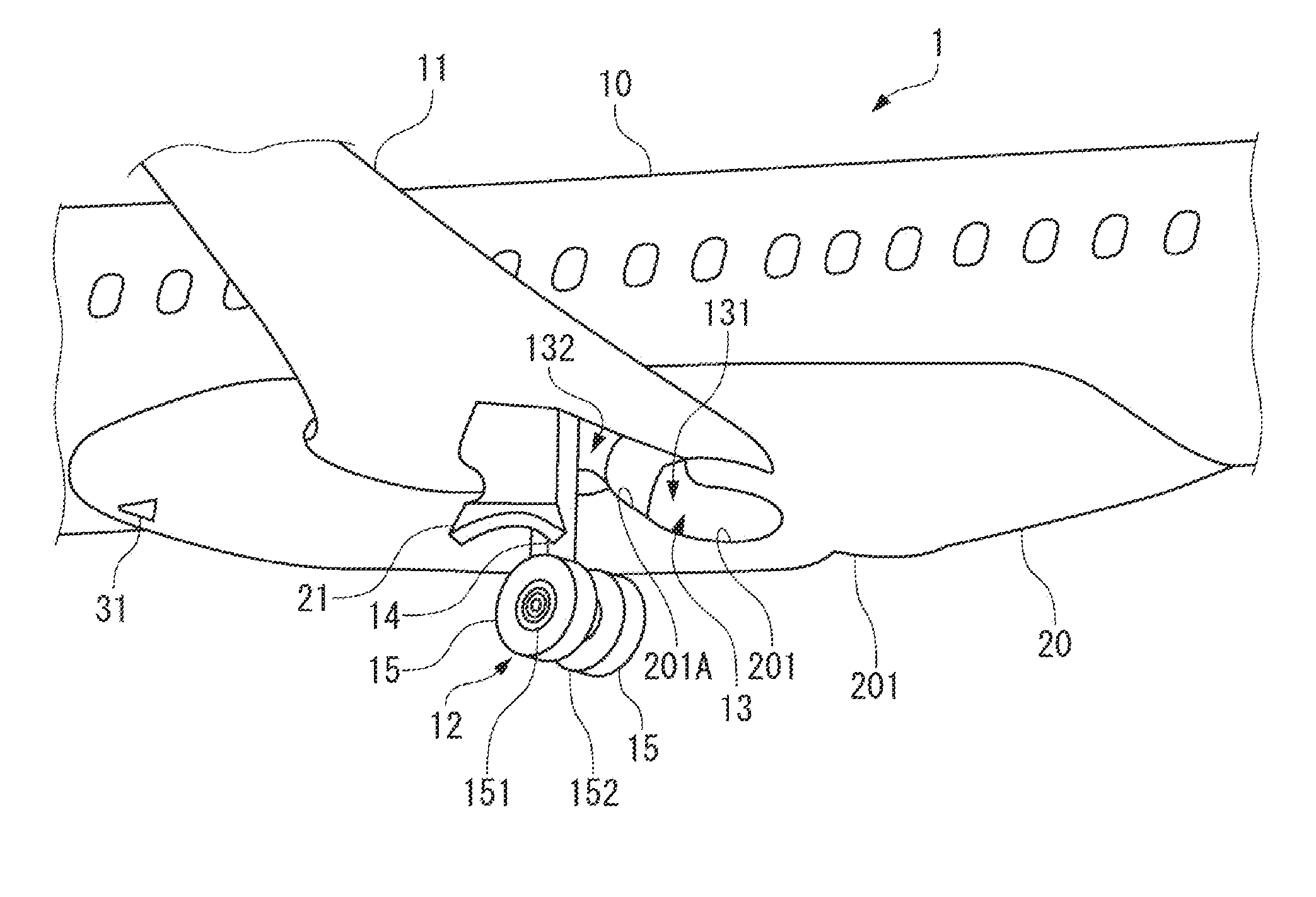

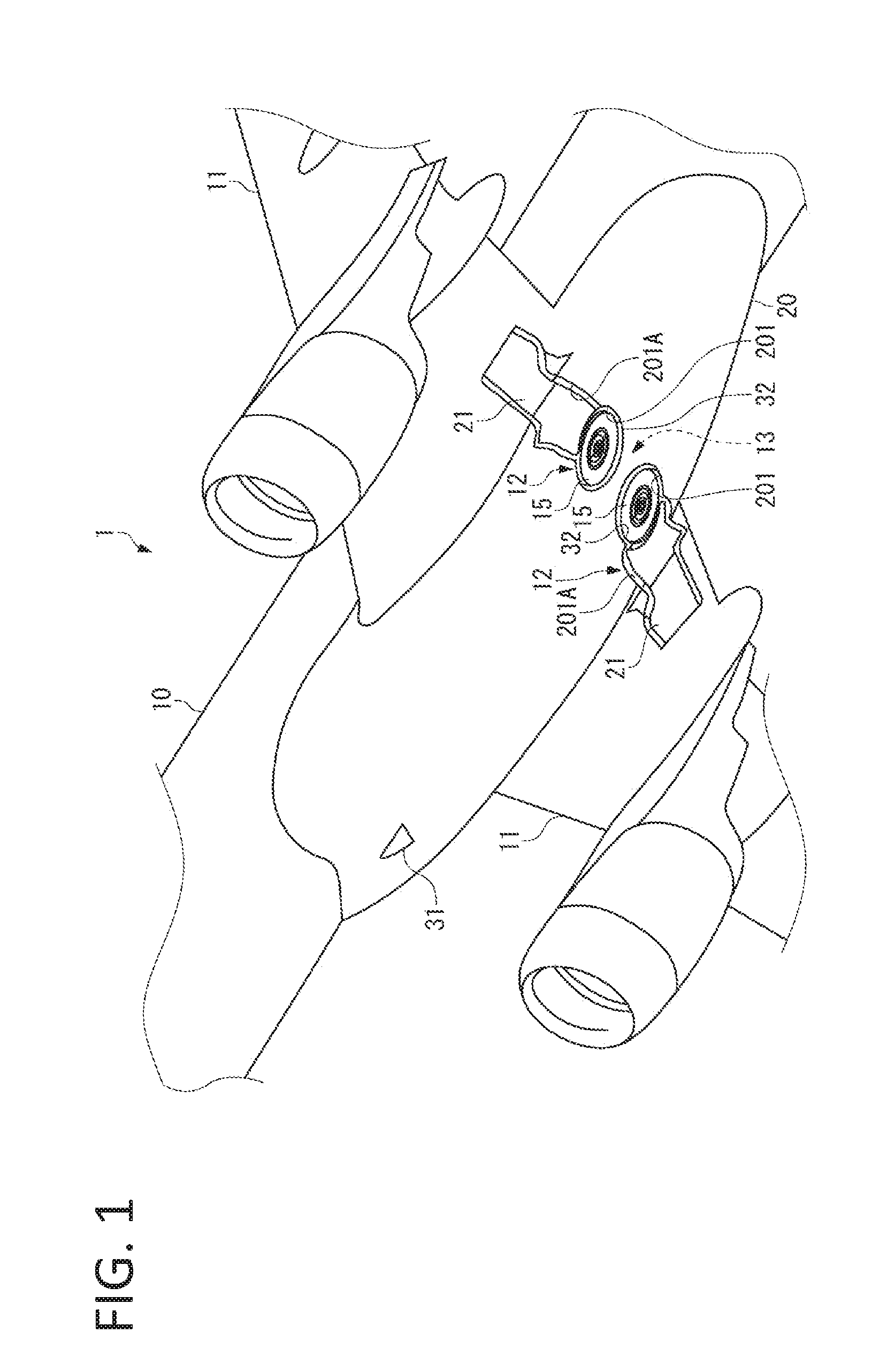

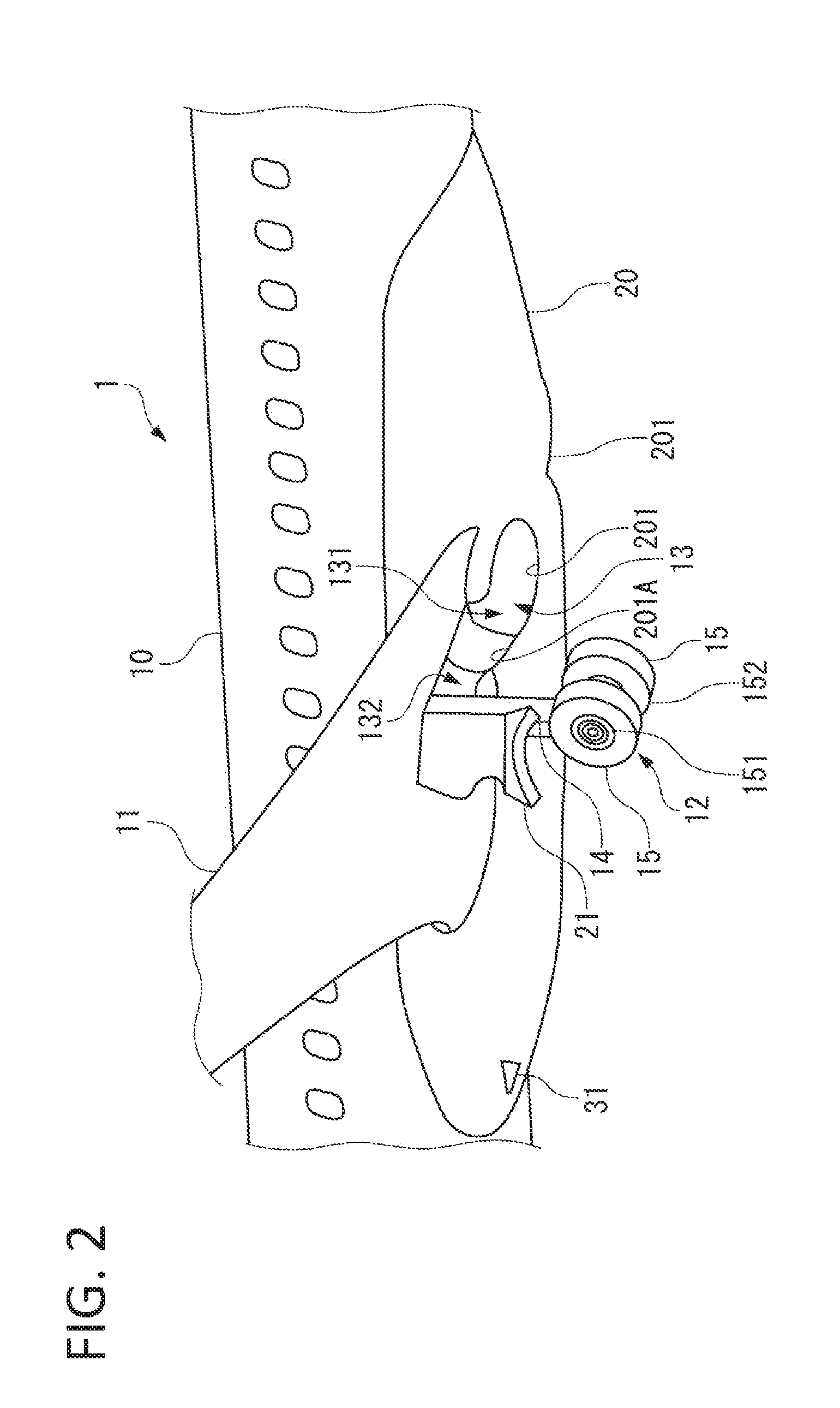

Heat removal structure of aircraft main landing gear bay

ActiveUS20160214720A1Protect partsAircraft accessoriesAir-treatment apparatus arrangementsFuselageAirplane

An aircraft includes: a fairing which covers a lower part of a fuselage having a main landing gear bay (MLG bay), and defines a ventilation cavity communicating with the MLG bay between the fairing and the fuselage; and a heat removal system which removes heat generated from the MLG inside the MLG bay to the outside of the MLG bay by suctioning / discharging air through an inlet port and an outlet port leading from the ventilation cavity or the MLG bay to external air. The fairing defines a wheel opening through which a wheel of the MLG enters and exits, and defines a ventilation port, which functions as one of the inlet and outlet ports, between the fairing and an outer peripheral part of the wheel exposed from the wheel opening to the lower side of the MLG bay when the MLG is retracted.

Owner:MITSUBISHI AIRCRAFT

Liquid crystal display device

The object of the present invention is to make parts and kinds of liquid crystal display devices in common for cope stably and flexibly with commercial products of computer makers and television makers which have been promoted in various kinds, for simplifying maintenance of a liquid crystal display unit mounted on computers, display monitors therefor or televisions, and preferably for enabling to omit positional adjustment of a light source unit and a liquid crystal display panel during the maintenance of the liquid crystal display device. For this object, the invention provides a liquid crystal display device comprising first, second and third housings, a liquid crystal display panel fixed between the first and second housings, a light source (cold-cathode fluorescent tubes) fixed to the third housing, the second and third housings being detachable to one another, being constructed by overlapping the first, second and third housings with each other, wherein a timing-converter board fixed to an opposite side surface of the third housing to a side surface to which the light source is fixed, and protrusions formed on the opposite side surface so as to determine a maximum thickness of the liquid crystal display device.

Owner:PANASONIC LIQUID CRYSTAL DISPLAY CO LTD +1

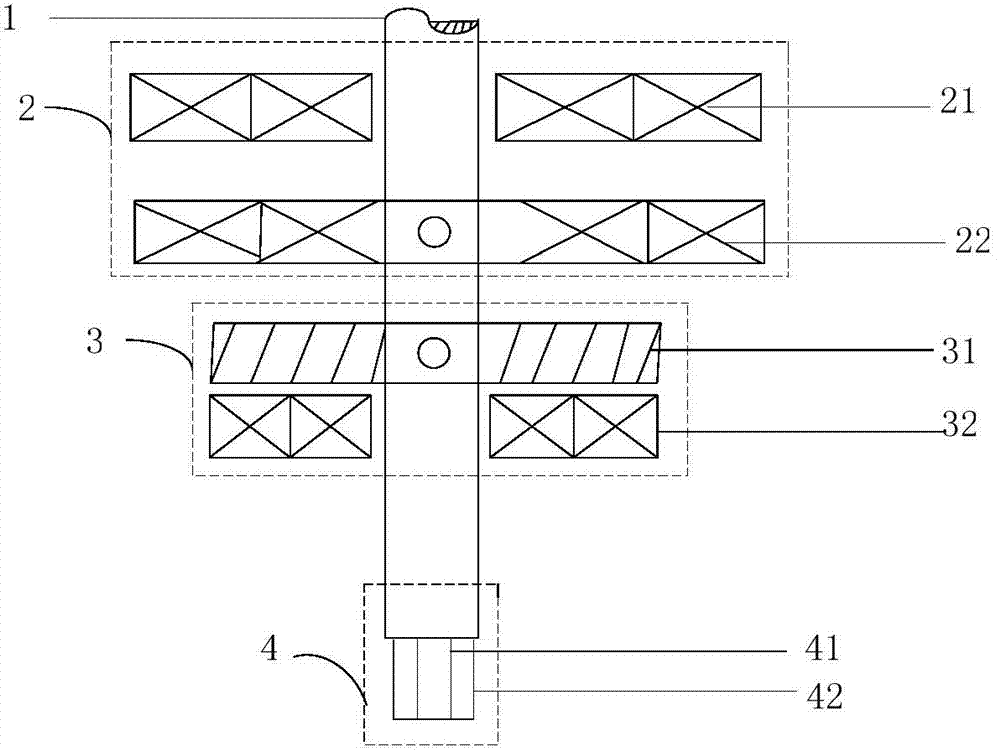

Non-symmetric repulsion mechanism

InactiveCN104124110AImprove driving efficiencyProtect partsProtective switch operating/release mechanismsNon symmetricHeavy load

The invention discloses a non-symmetric repulsion mechanism. The non-symmetric repulsion mechanism comprises a transmission rod, a main quick repulsion unit, an auxiliary quick repulsion unit and a buffer unit. The main quick repulsion unit is composed of a movable repulsion coil and a first fixed repulsion coil. The auxiliary quick repulsion unit is composed of a movable repulsion aluminum plate and a second fixed repulsion coil. The movable repulsion coil and the movable repulsion aluminum plate are fixed to the transmission rod, and the first fixed repulsion coil and the second fixed repulsion coil are fixed to a repulsion mechanism coil mounting plate. The non-symmetric repulsion mechanism makes full use of the characteristic of high efficiency under heavy load of a coil-coil type repulsion structure to improve the driving efficiency of the repulsion mechanism and reduces the collision between the repulsion plate and the repulsion coil as well as between the repulsion coils to prolong the service life of the repulsion mechanism. A user can flexibly choose an opening unit and a closing unit as application occasion required. The non-symmetric repulsion mechanism is simple in structure, quick in movement, high in drive efficiency, long in service life and flexible in operation.

Owner:HUAZHONG UNIV OF SCI & TECH +1

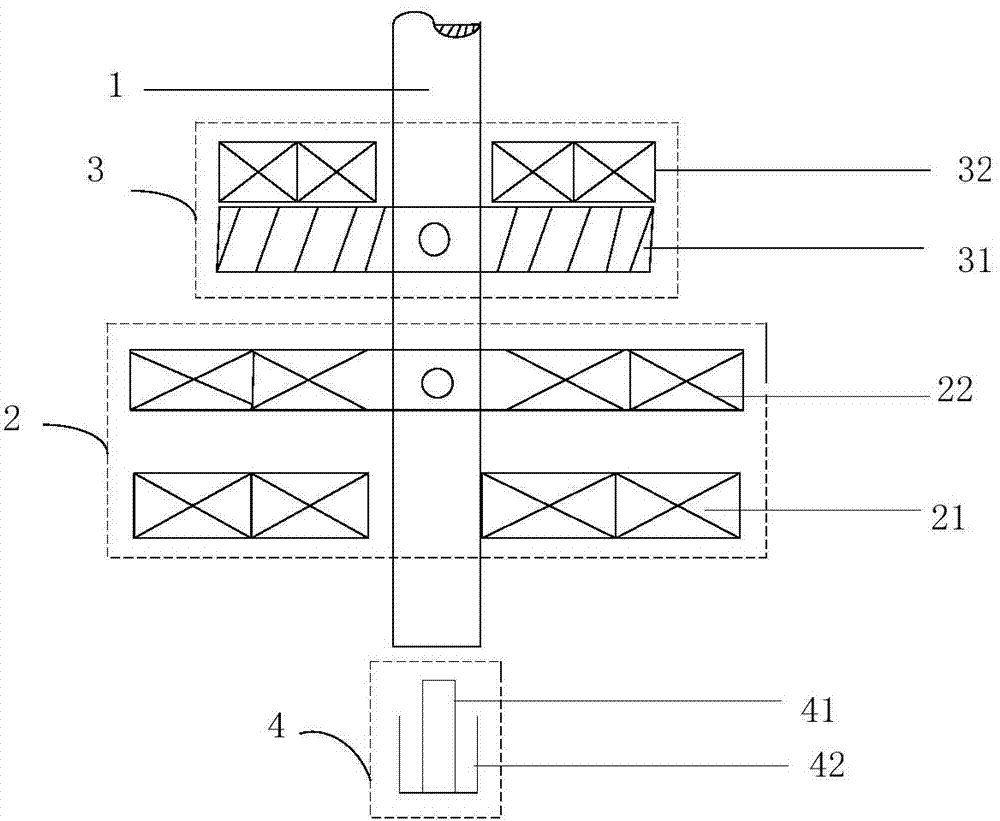

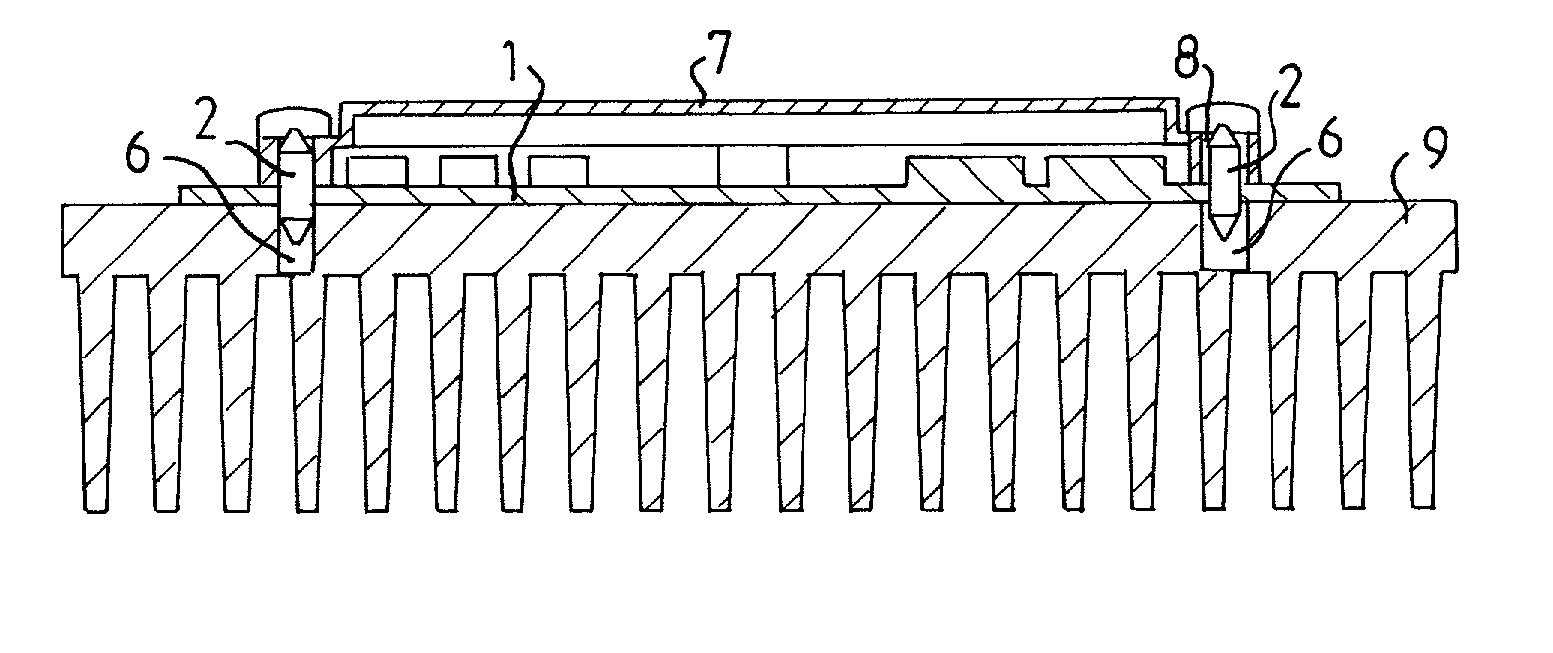

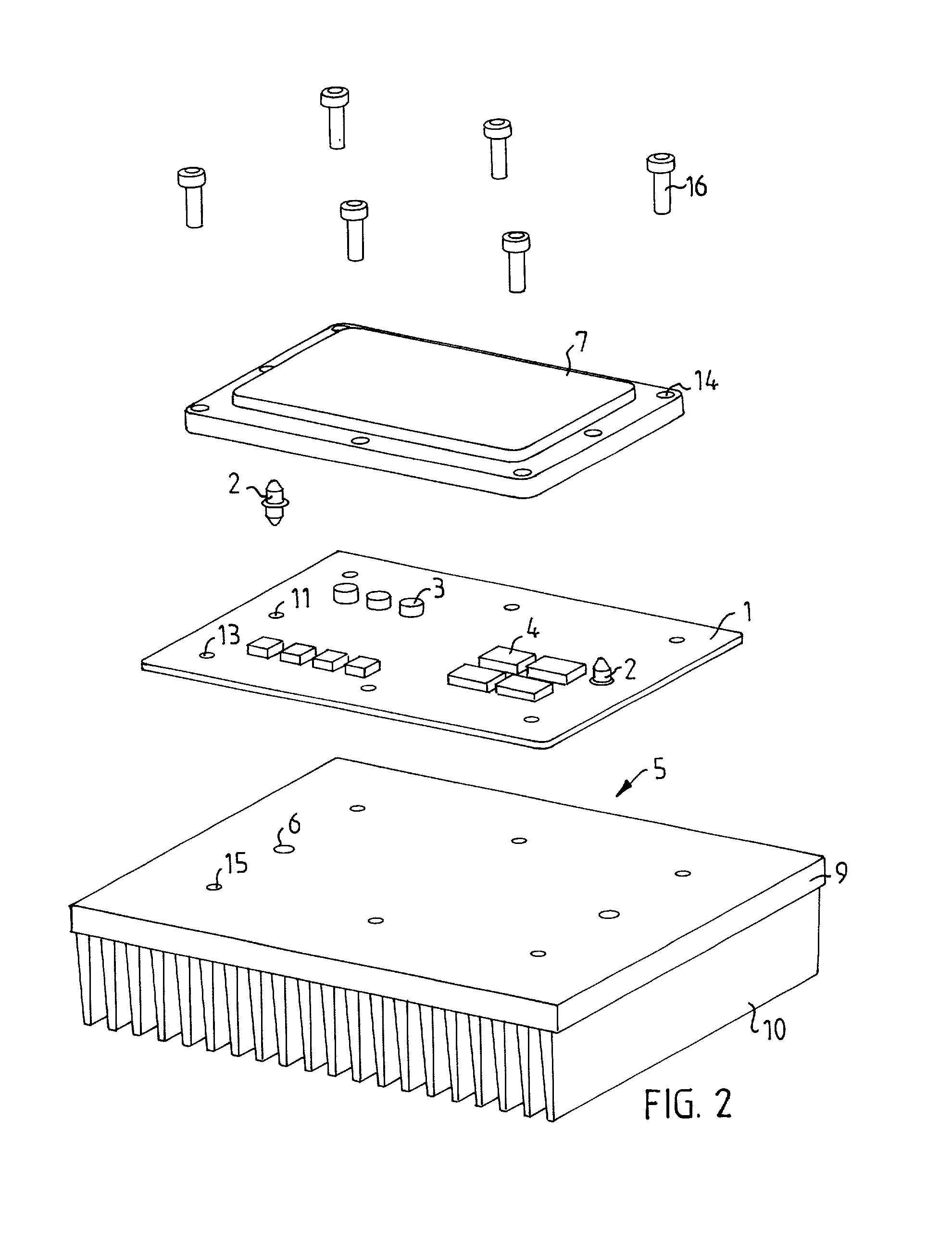

Method and apparatus for improving mounting

InactiveUS20020050058A1Cost efficientEffective timePrinted circuit assemblingLine/current collector detailsEngineeringMechanical engineering

The present invention relates to a method for fastening a printed board to an element. The method comprises the steps of: mounting at least one guide element to said printed board before said printed board is guided towards said element, fastening said at least one guide element to said printed board by soldering before said printed board is guided towards said element, and positioning said printed board on said element with the help of said at least one guide element. The invention also relates to a guide element for the method.

Owner:TELEFON AB LM ERICSSON (PUBL)

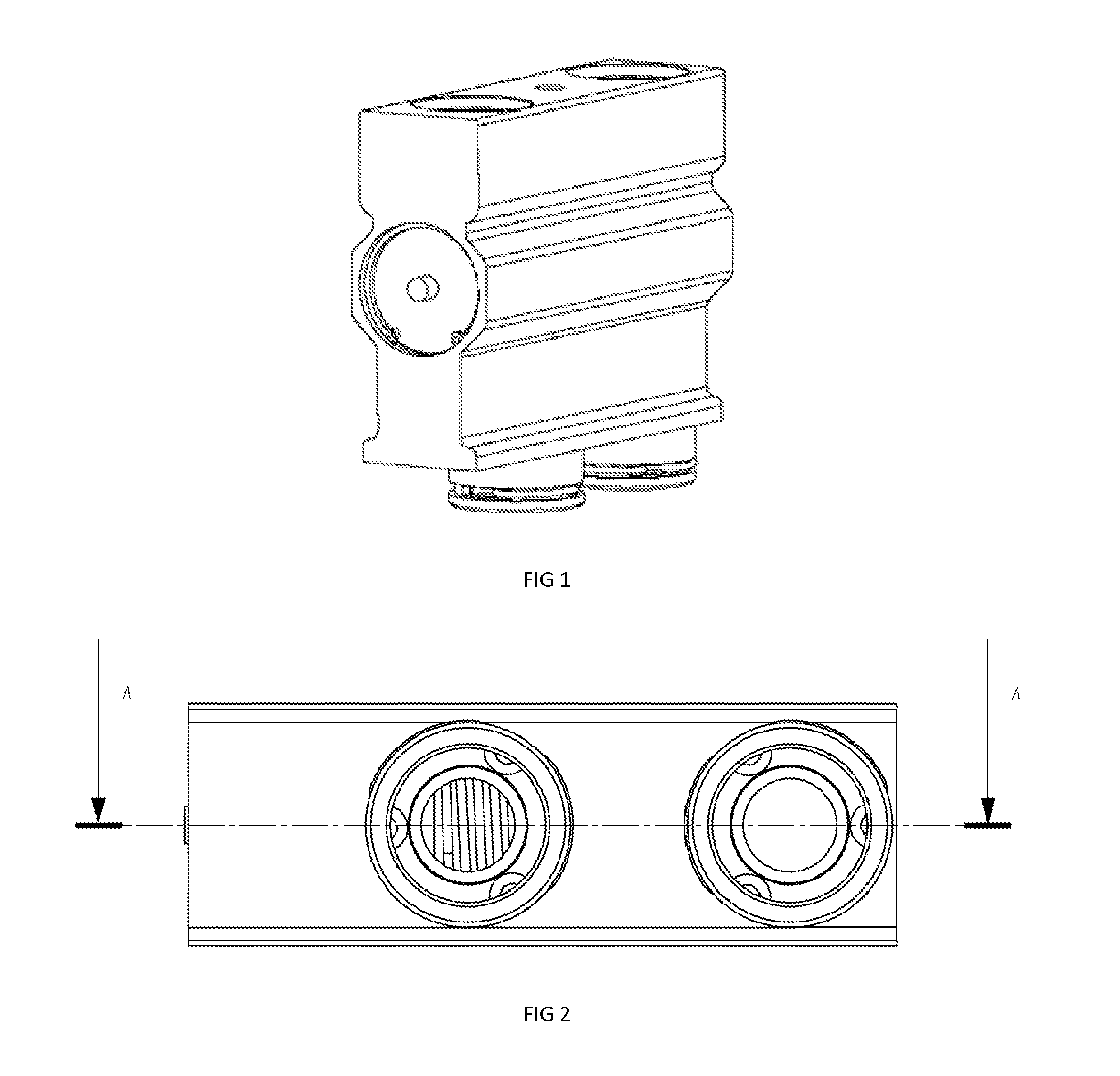

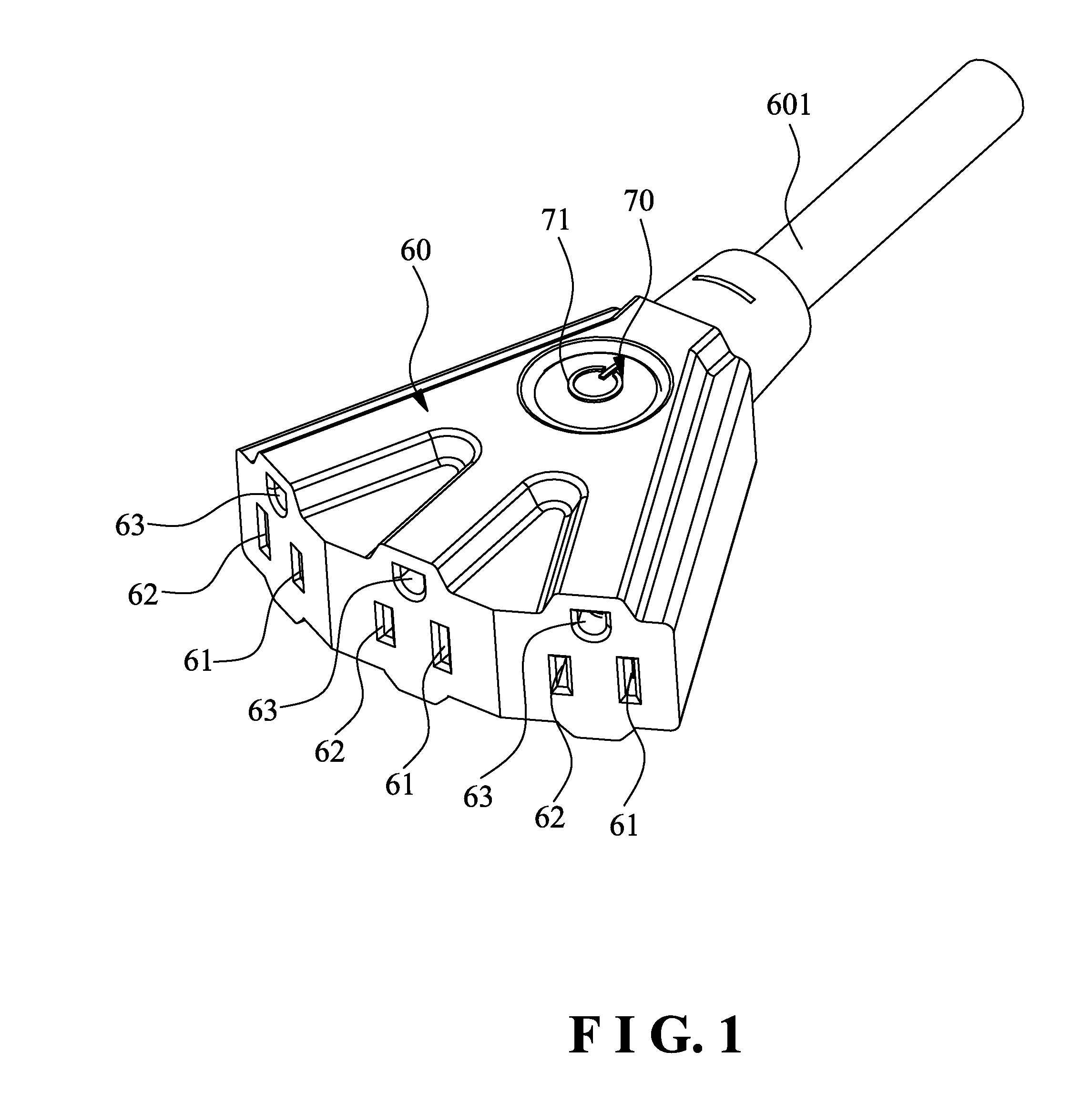

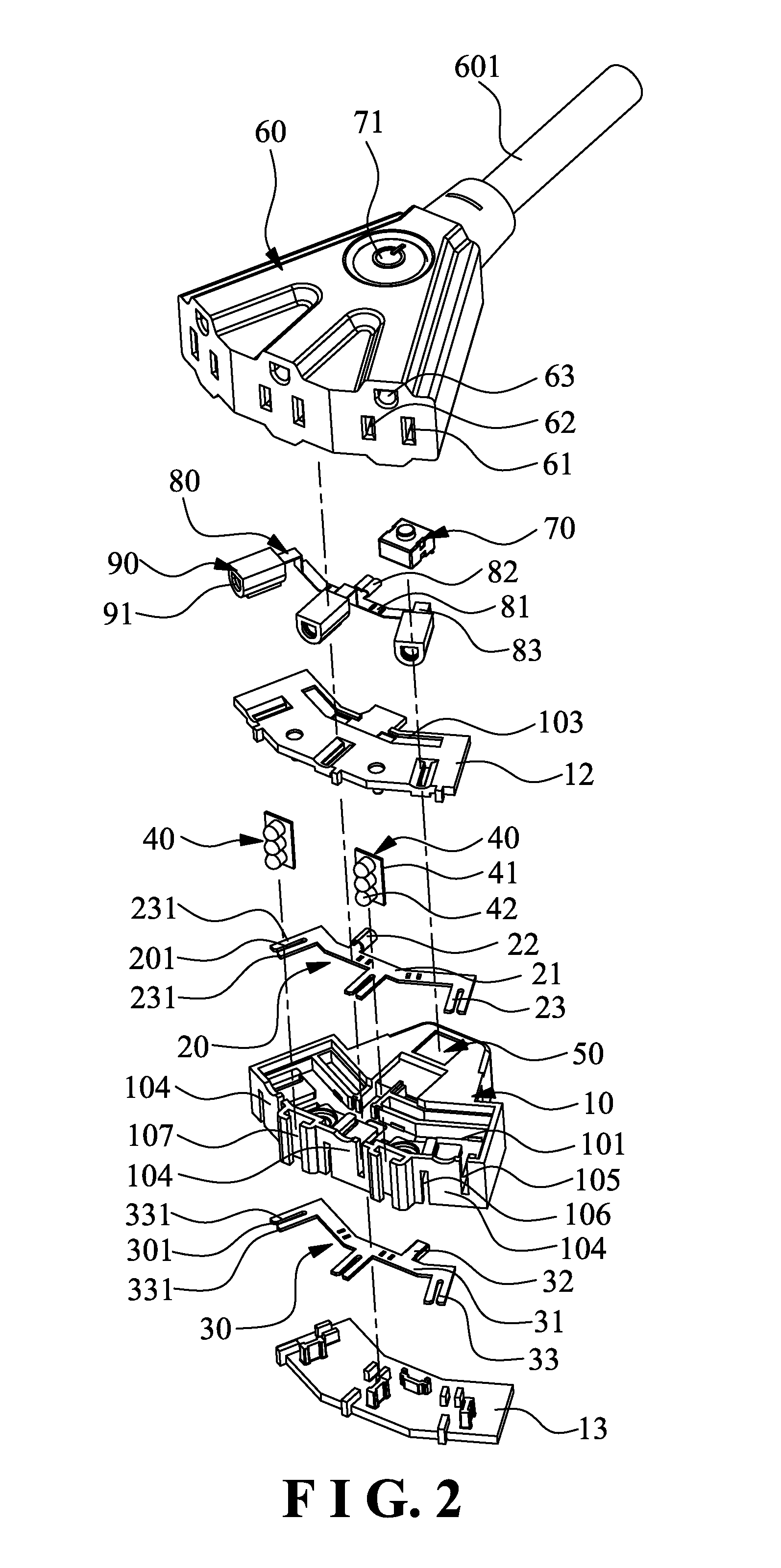

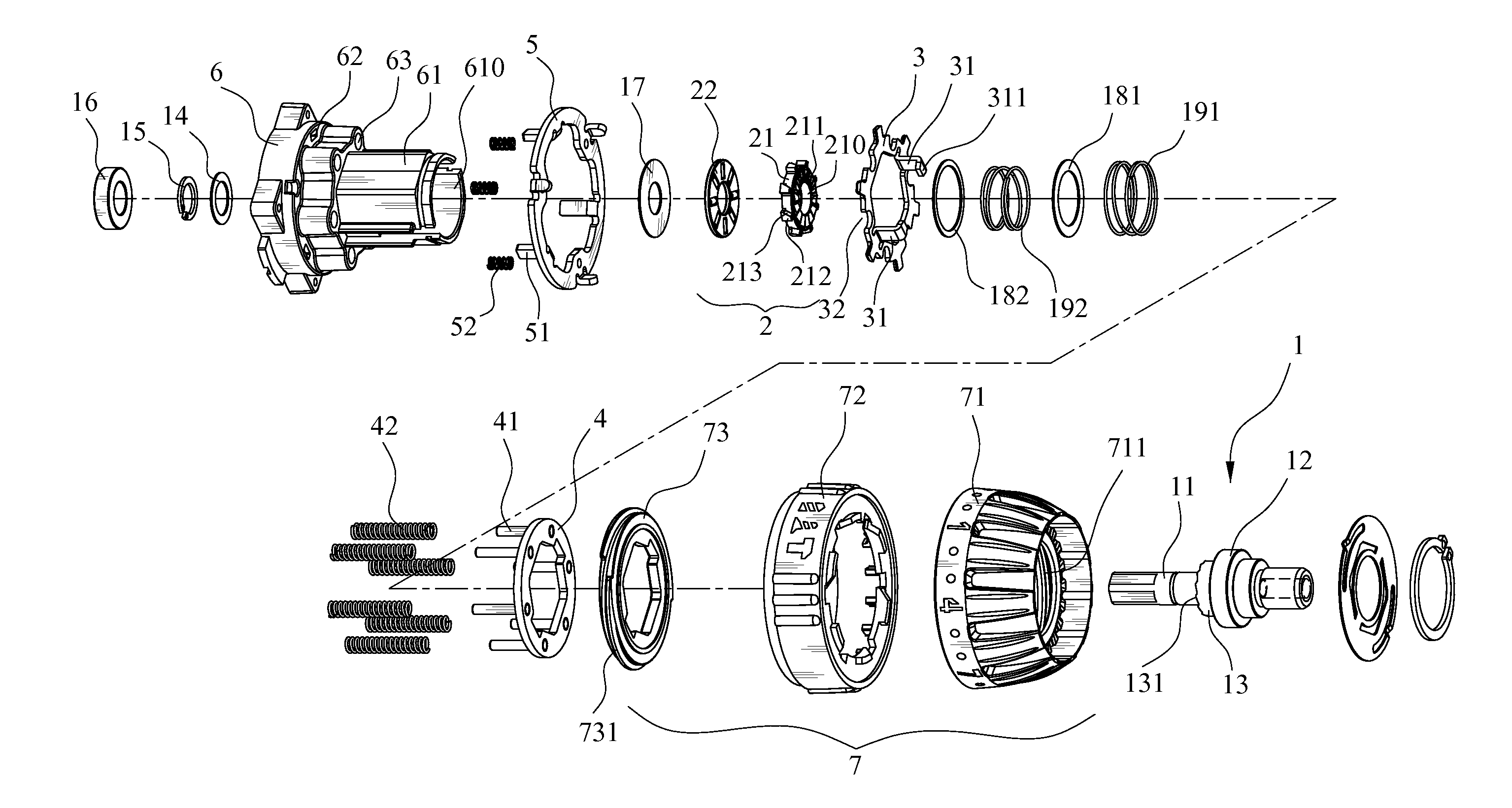

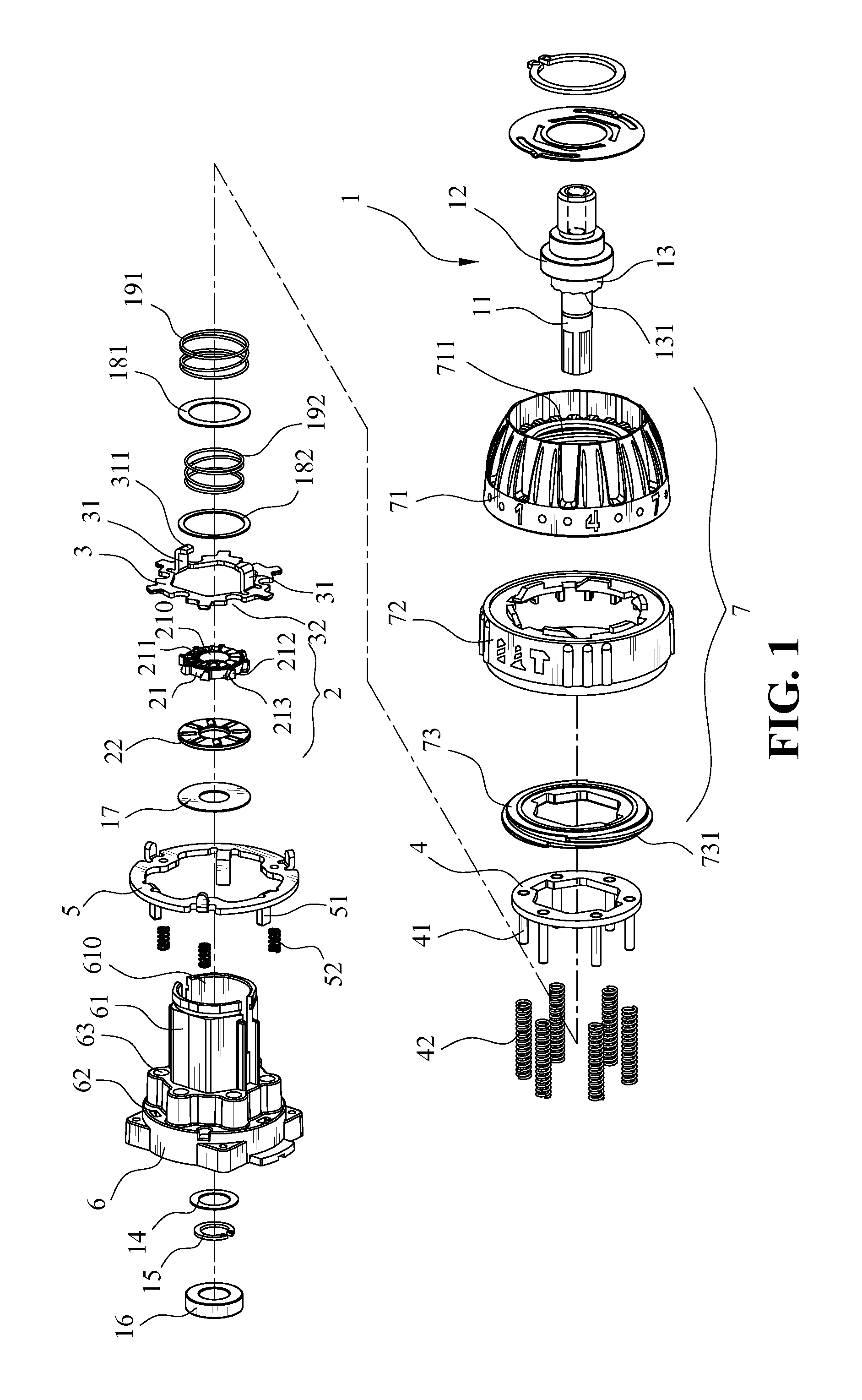

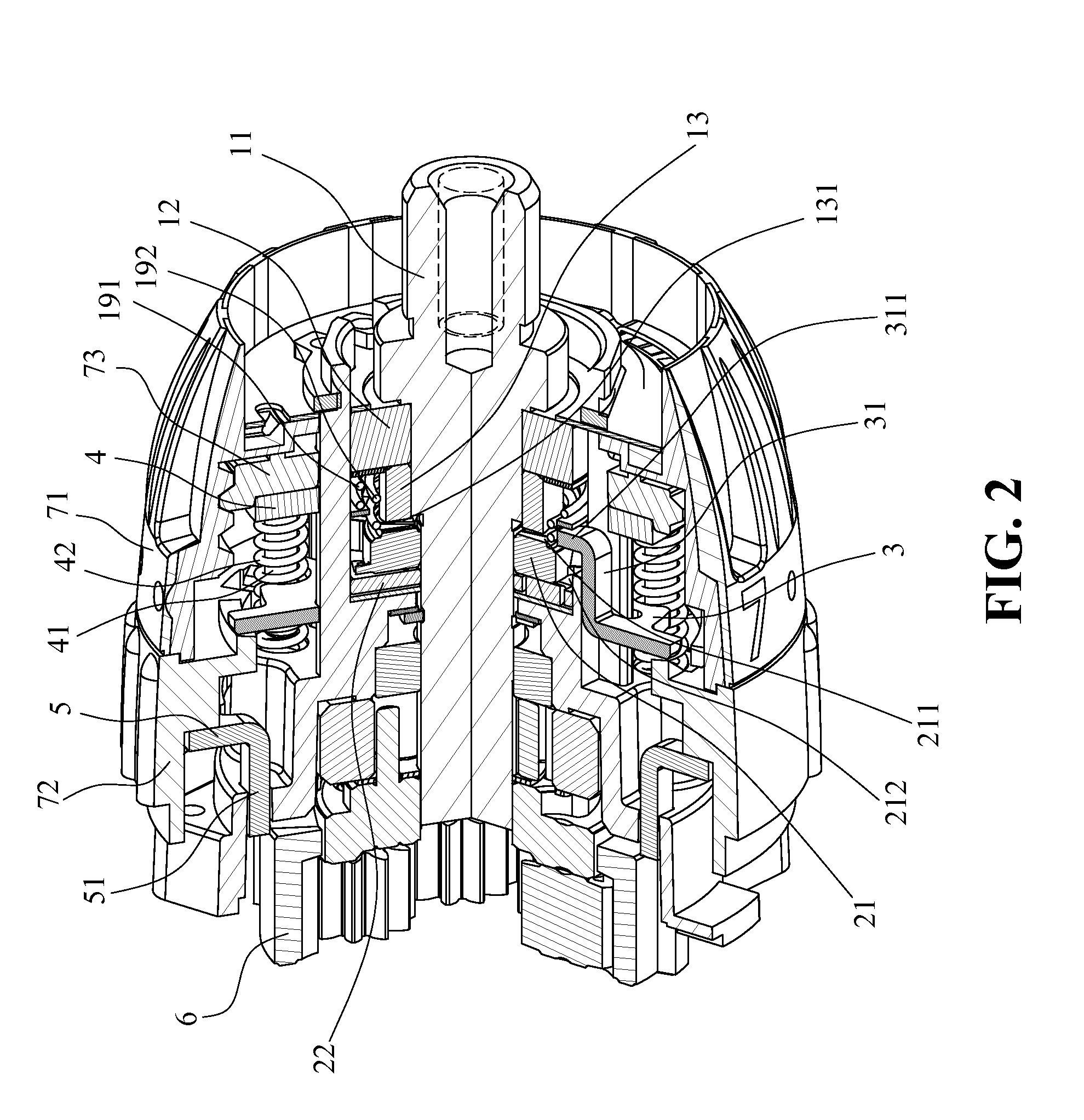

Output device for power tool having protection mechanism

ActiveUS20120037388A1Overcome disadvantagesProtect partsPortable power-driven toolsPower driven toolsProtection mechanismOutput device

An output device for a power tool includes an output unit, a stationary ratchet gear unit, a spring disposed between the output shaft unit and the stationary ratchet gear unit, a locking member having pawls, a case accommodating the aforementioned parts and a control device threadedly connected to the case. The output unit includes an output shaft with a first bearing and a movable ratchet gear which have movable ratchet teeth facing stationary ratchet teeth of a stationary ratchet gear. The stationary ratchet gear includes ribs and each rib has an inclined surface. When the pawls are not engaged with the ribs, the output shaft can outputs power in a form of rotation in both directions. When the pawls are engaged with the ribs, the output shaft outputs power in a form of rotation in a forward direction combined with vibration or rotation in a reverse direction without vibration.

Owner:TRINITY PRECISION TECH

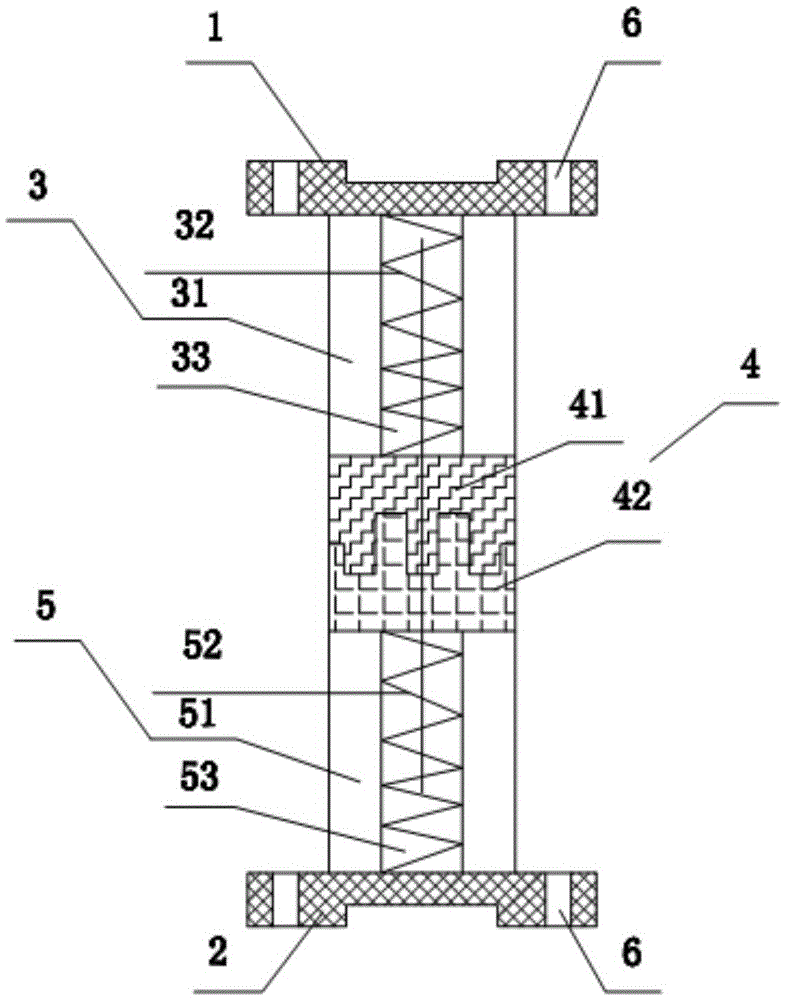

Mechanical equipment damping device

InactiveCN105605150AReduce vibration amplitudeProtect the groundNon-rotating vibration suppressionMechanical equipmentEngineering

The invention provides a mechanical equipment damping device which comprises an upper mounting plate, a lower mounting plate, an upper damping mechanism, a middle damping mechanism and a lower damping mechanism, wherein the upper damping mechanism comprises a first rubber column and a first spring; the middle part of the first rubber column is provided with a first through hole for containing the first spring; the middle damping mechanism comprises a first damping block and a second damping block; a staggered superposition structure is arranged between the first damping block and the second damping block; the lower damping mechanism comprises a second rubber column and a second spring; the middle part of the second rubber column is provided with a second through hole for containing the second spring; the upper mounting plate and the first damping block are respectively provided with a first spring mounting part; the lower mounting plate and the second damping block are respectively provided with a second spring mounting part; and the upper mounting plate and the lower mounting plate are respectively provided with a connecting hole. The mechanical equipment damping device is simple in structure and convenient for mounting, and can enhance the damping efficiency and increase the compression resistance; and the mechanical equipment damping device can implement multistage damping on mechanical equipment.

Owner:TIANJIN SHENGTONG TECH CO LTD

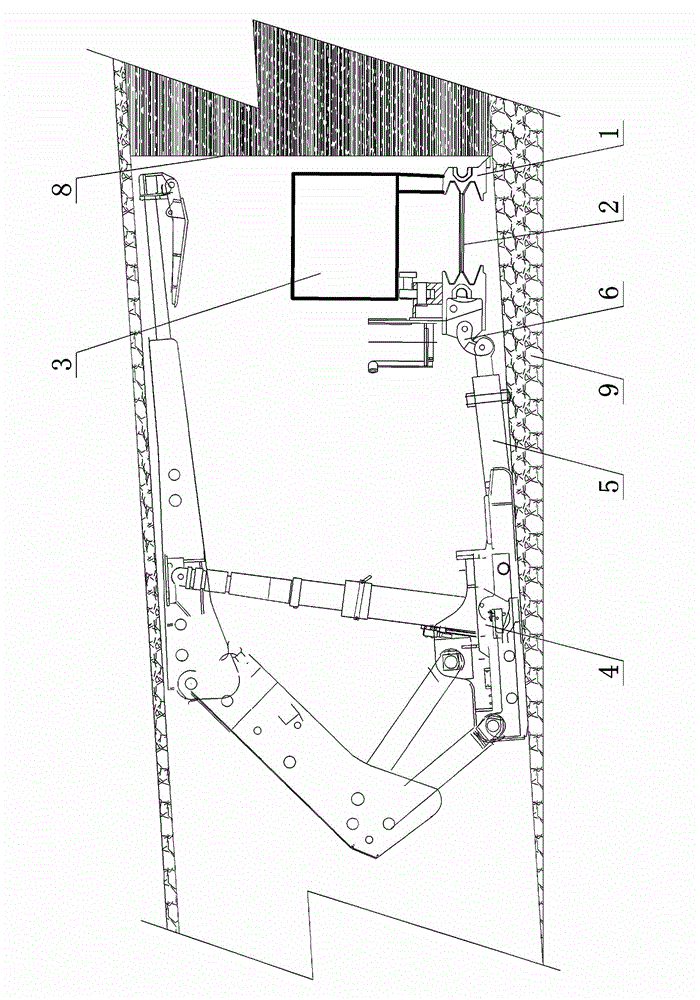

Leveling device for scraper conveyor

InactiveCN102976062AReduce coal wall deviationAvoid coal wall deviationEarth drilling and miningSupporting framesCoal miningHinge angle

The utility modelinvention relates to a leveling device for a scraper conveyor. The leveling device for the scraper conveyor comprises the scraper conveyor and a hydraulic support, wherein the scraper conveyor is provided with a working face chute; the hydraulic support is provided with a slide push rod; a coal mining machine is located on the scraper conveyor; the working face chute and the slide push rod are connected in a hinging way through an adjusting arm; the adjusting arm is in a bending shaftpe; a hinge hole is formed in one end of the adjusting arm; the end of the adjusting arm is connected with the working face chute in the hinging way through a pin shaft; two symmetric arms extending along bending convex arc edges are located on two sides of the other end of the adjusting arm; another hinge hole is formed in each symmetric arm; the slide push rod of the hydraulic support is located between the two symmetric arms; and the slide push rod of the hydraulic support is connected with the hinge holes of the symmetric arms in the hinging way through pin shafts. The leveling device for the scraper conveyor not only can adjust the levelness of the scraper conveyor on a lane bottom plate of a mining working face and enable a coal wall cut by the coal mining machine to be naturally vertical for reduction and prevention on the rib fall of the coal wall, but also is simple in structure, easy to operate, convenient to load and unload and low in fault rate.

Owner:CHONGQING SONGZAO COAL & ELECTRICITY CO LTD

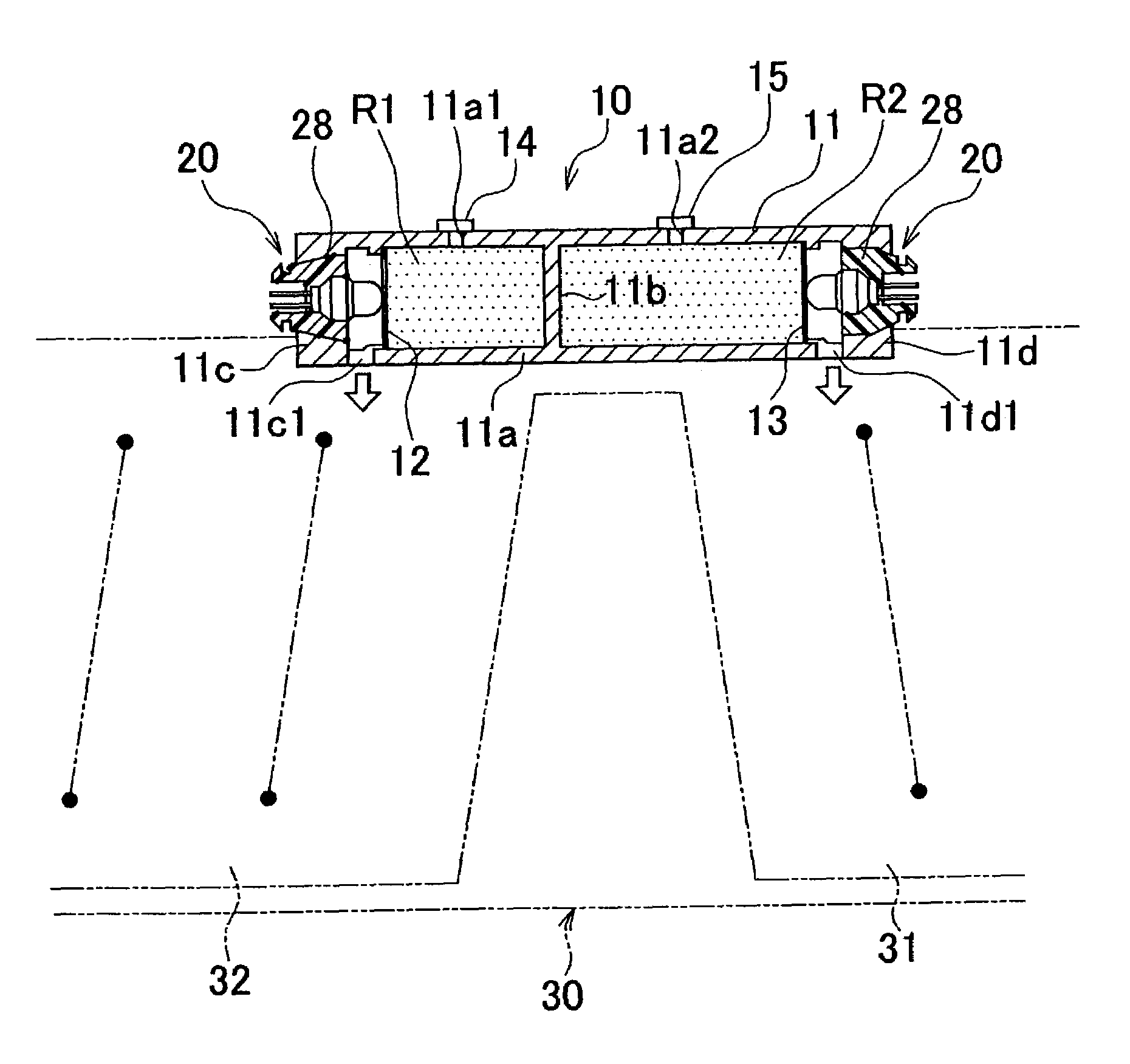

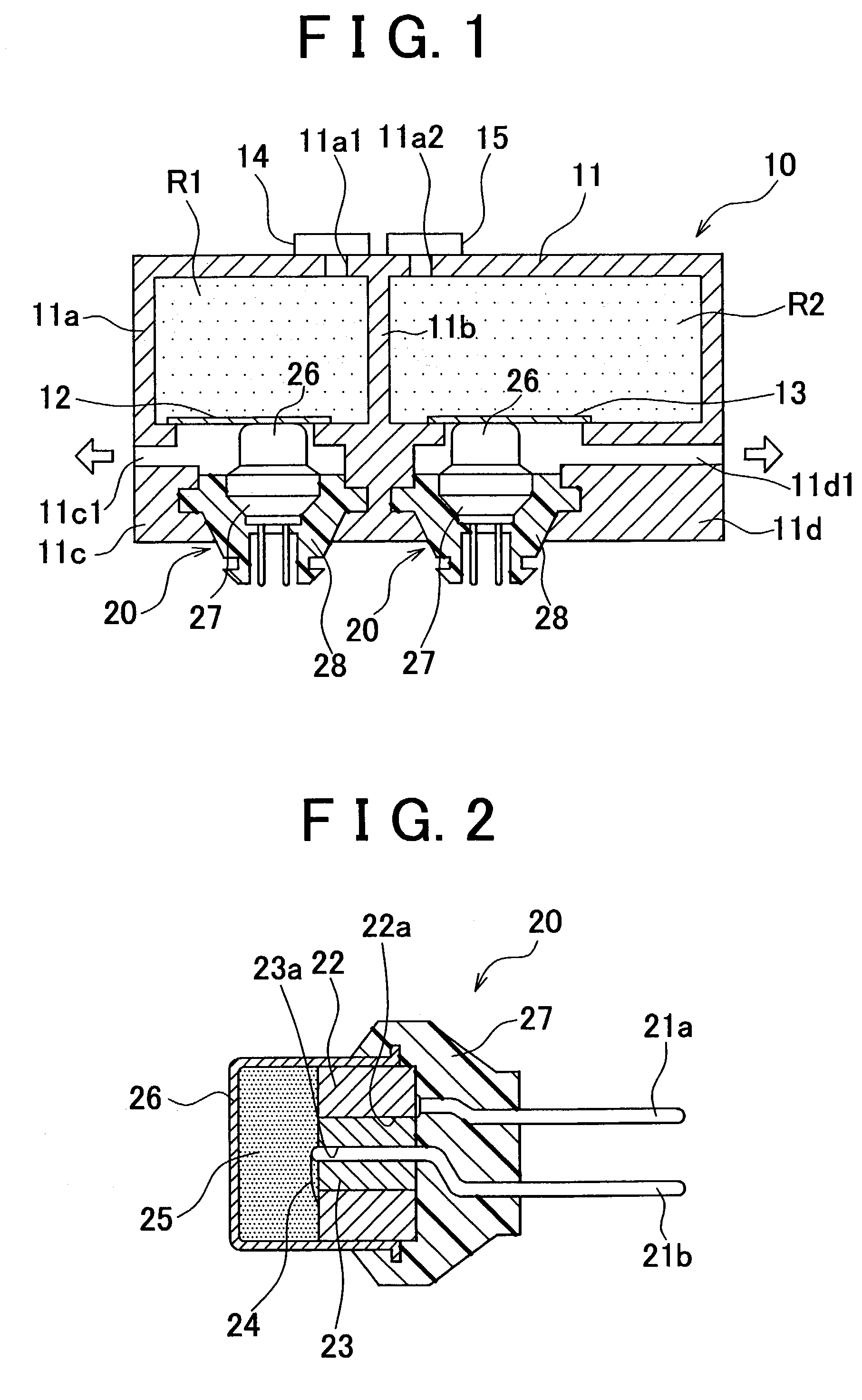

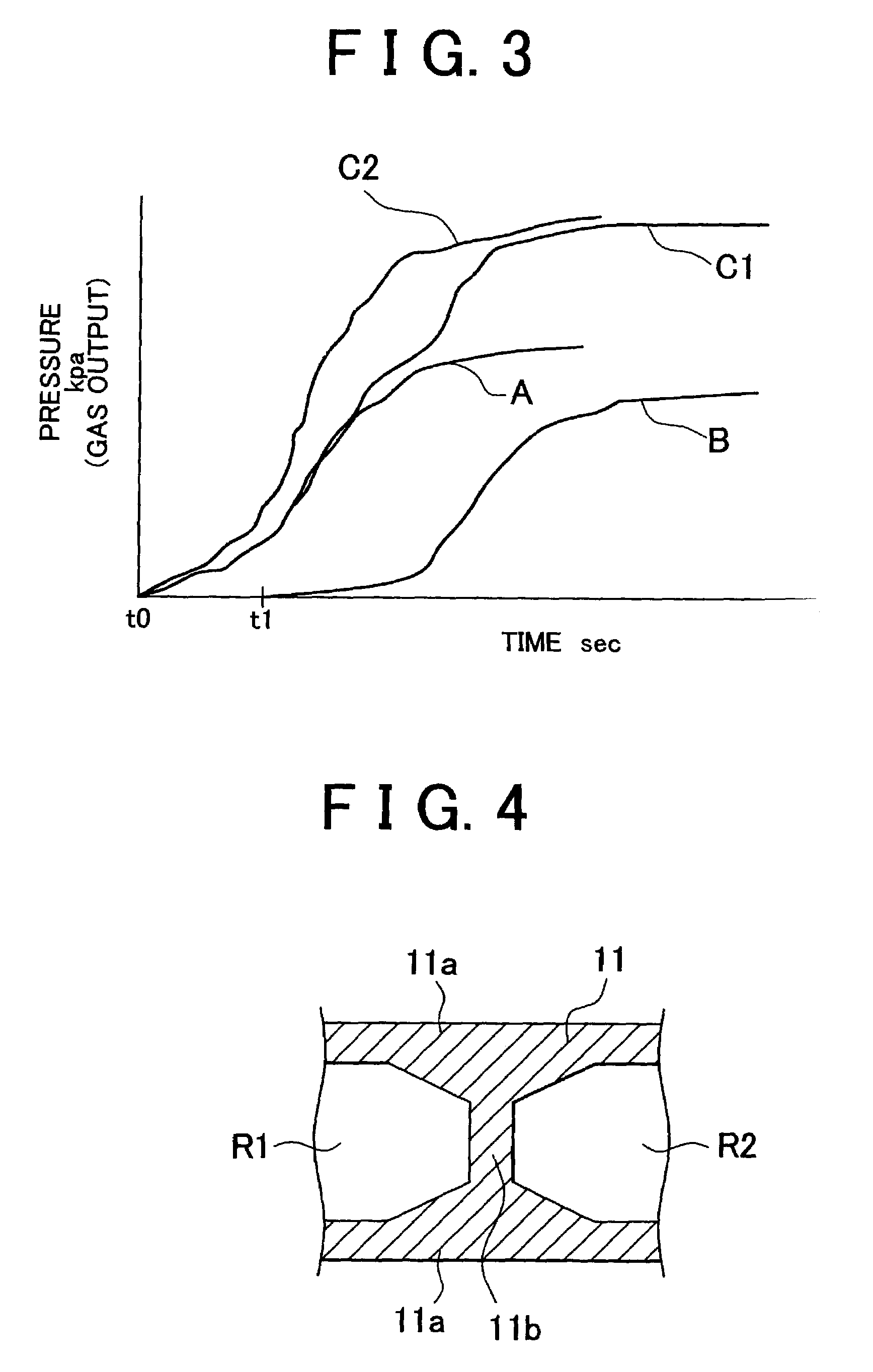

Inflator

InactiveUS7192051B2Simple adjustmentProtect partsPedestrian/occupant safety arrangementGas generation devicesHigh pressureHigh pressure gas

Owner:TOYOTA JIDOSHA KK

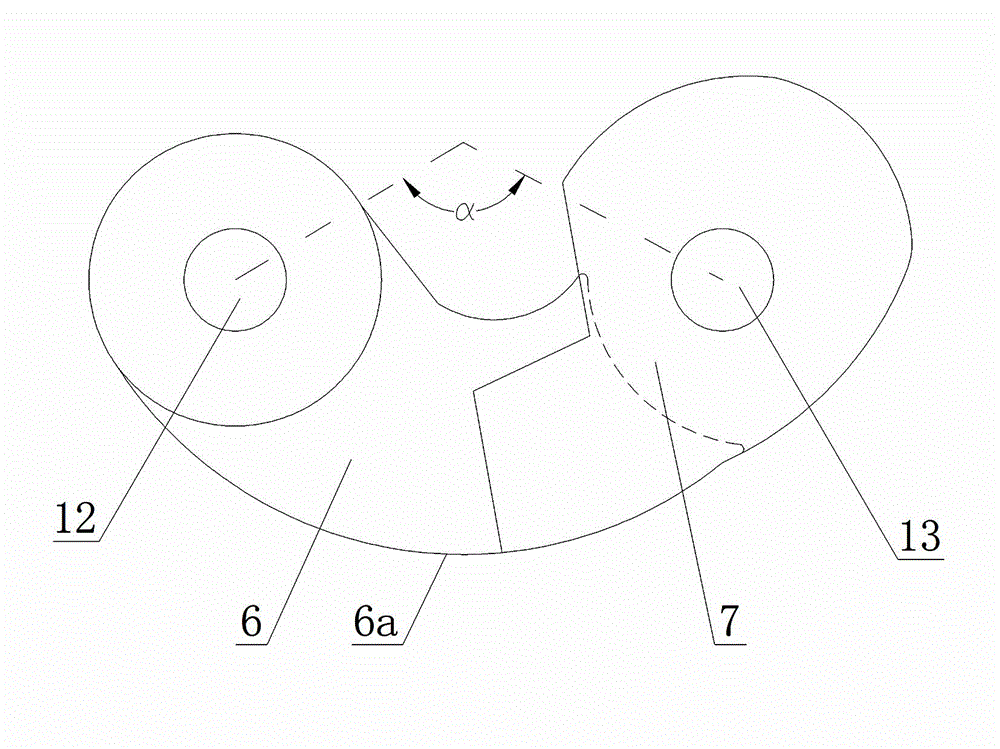

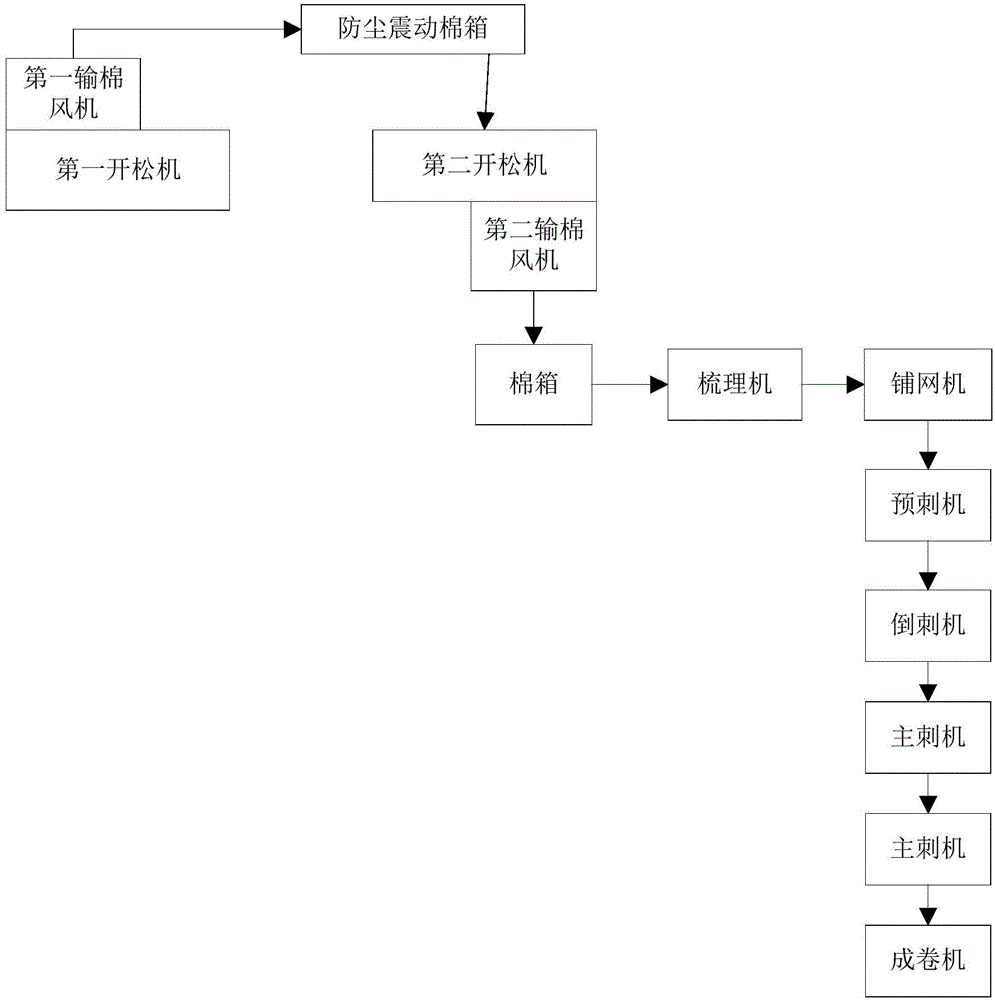

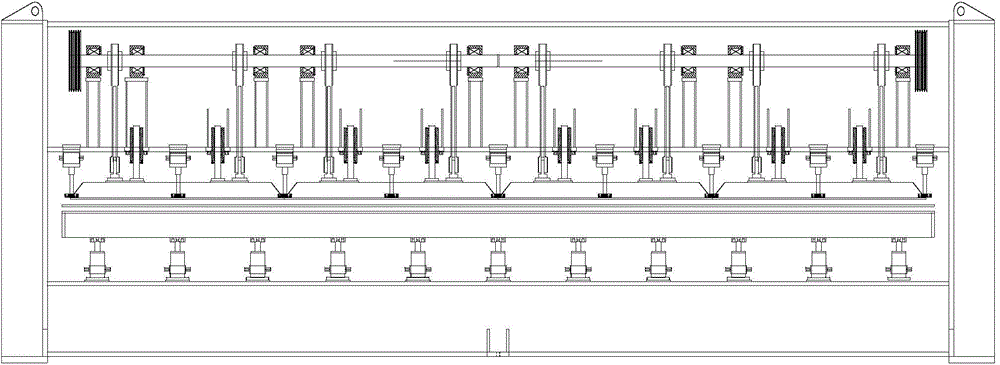

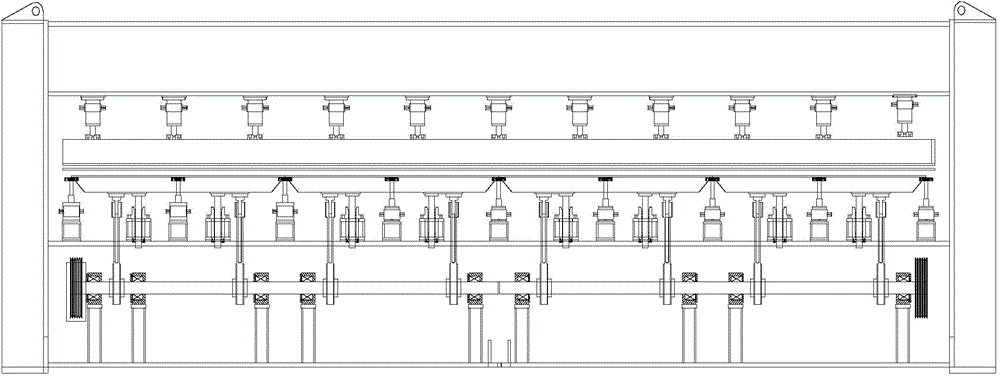

Non-woven cloth production line

ActiveCN104131417AImprove finished product qualityCause secondary pollutionContinuous processingFibre feedersProduction linePunching

The invention discloses a non-woven cloth production line which comprises an opening device, a combing machine, a lapping machine, a needle-punching device and an uncoiler, wherein the opening device, the combing machine, the lapping machine, the needle punching device and the uncoiler are sequentially connected. The opening device comprises a first opening mechanism and a second opening mechanism, the first opening mechanism comprises a first opening machine and a first cotton conveying fan connected with the first opening machine, the second opening mechanism comprises a second opening machine and a second cotton conveying fan connected with the second opening machine, and a dust proof vibrating cotton box is disposed between the first opening machine and the second opening machine; the needle-punching device comprises a pre-needling machine, a reversing needling machine and at least one main needling machine, the pre-needling machine, the reversing needling machine and the at least one main needling machine are sequentially connected, the pre-needling machine and the main needling machine are respectively provided with an upper fulcrum parking portion, each upper fulcrum parking portion comprises an auxiliary transmission mechanism and a pneumatic mechanism, and the auxiliary transmission mechanism and the pneumatic mechanism of each upper fulcrum parking portion are arranged on one side of the machine frame. The production line is smooth in connection, and the surface of produced non-woven cloth is smooth, uniform in weight and thickness and good in air permeability.

Owner:QINGDAO KAISHUO MACHINERY TECH CO LTD

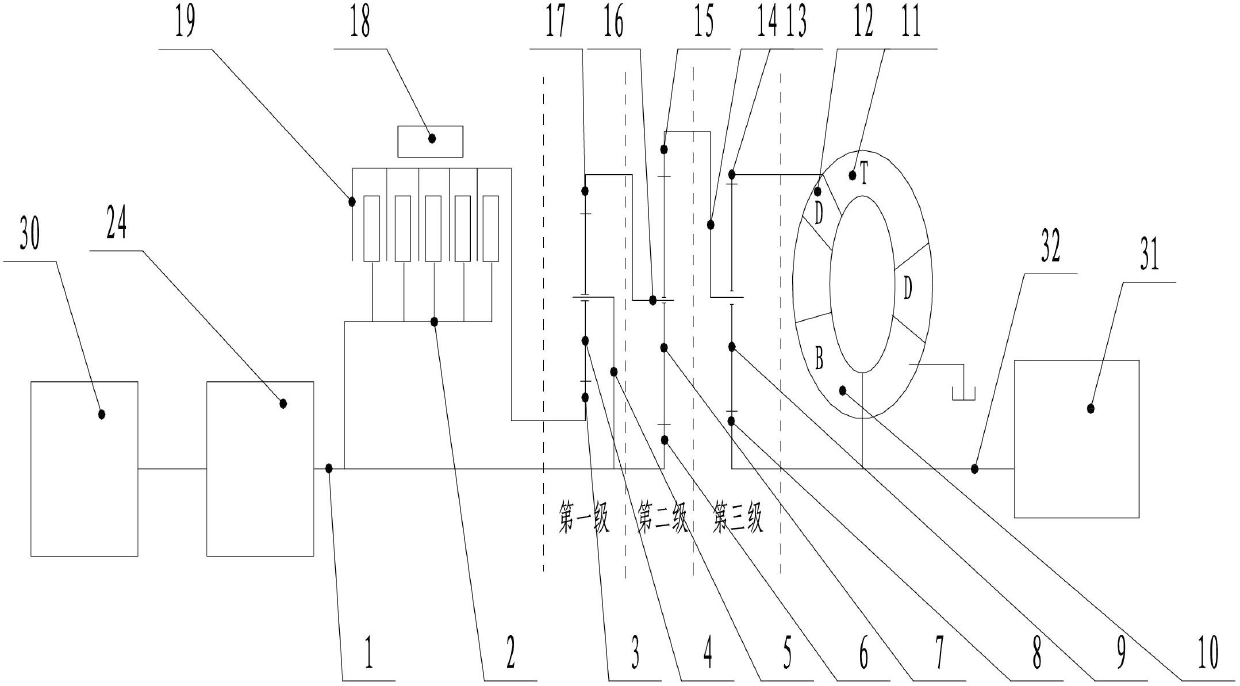

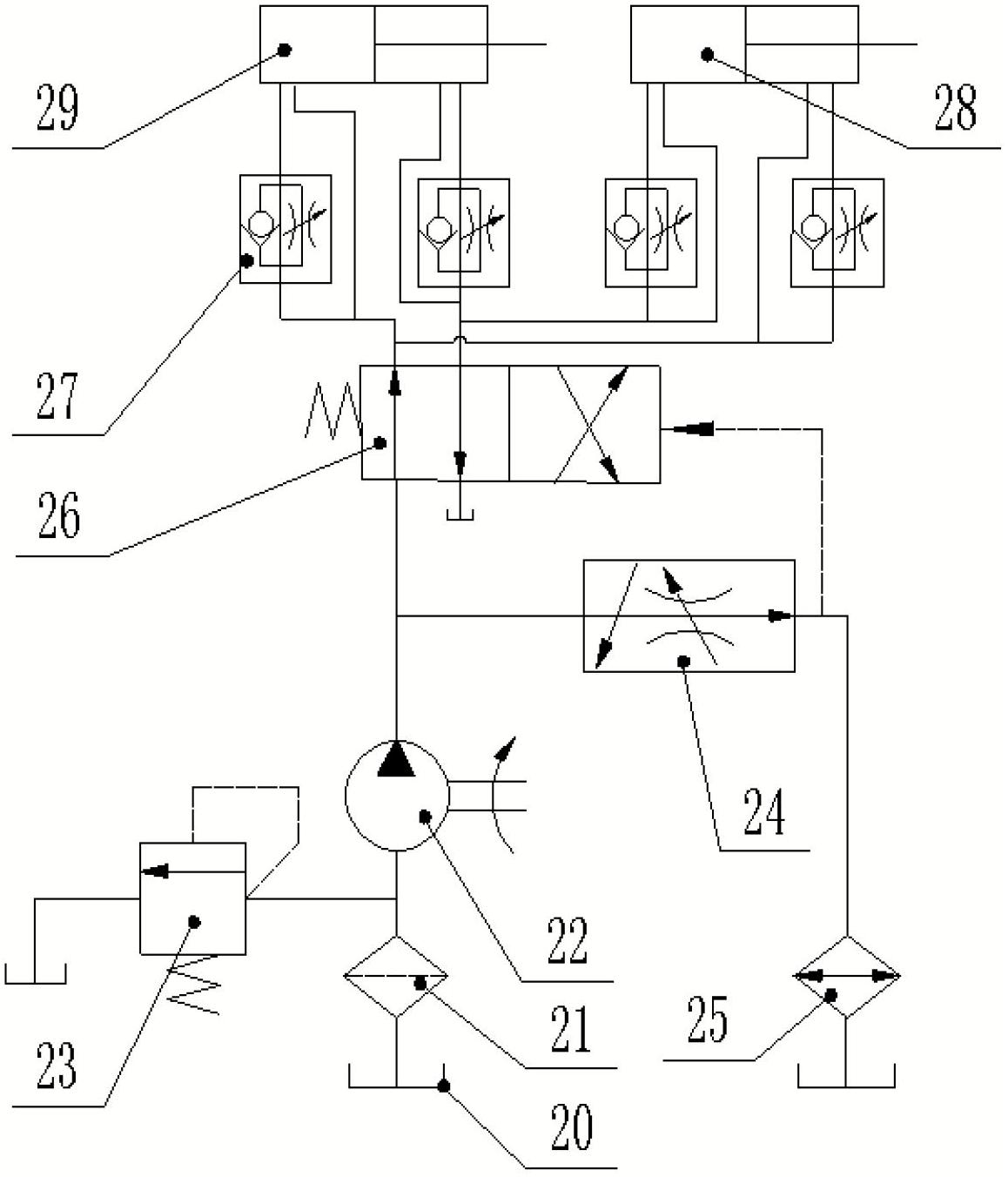

Wind power generation hydraulic control shifting voltage stabilizer

InactiveCN102678876AAdapt to increased wind speed rangeWith shift functionGear lubrication/coolingGearing controlThree levelControl theory

The invention belongs to the technical field of wind power generation and relates to a wind power generation hydraulic control shifting voltage stabilizer. According to the wind power generation hydraulic control shifting voltage stabilizer, automatic gearshift can be achieved, and the range of wind speed adaptation of a wind motor is remarkably improved. The wind power generation hydraulic control shifting voltage stabilizer comprises a three-level planet gear transmission mechanism, a gearshift actuating mechanism, a hydraulic control system, a speed increaser and an adjustable torque converter, a first level sun wheel is connected with a driving disc of a direct gear clutch, a first level gear ring is connected with a second level planetary frame, a second level gear ring is connected with a third level planetary frame, a first level planetary frame, a driven disc of the direct gear clutch and a second level sun wheel are respectively connected with an output shaft of the speed increaser, a centrifugal speed regulating valve is arranged on the output shaft of the speed increaser, a speed increasing gear brake is arranged on the side of the driving disc of the direct gear clutch, a third level gear ring is connected with a turbine of the torque converter, a third level sun wheel and a pump wheel of the torque converter are respectively connected with a generator input shaft, and each level of planet wheels is meshed with one corresponding sun wheel and one corresponding gear ring which are at the same level and is connected with one corresponding planetary frame at the same level through a bearing.

Owner:NORTHEASTERN UNIV

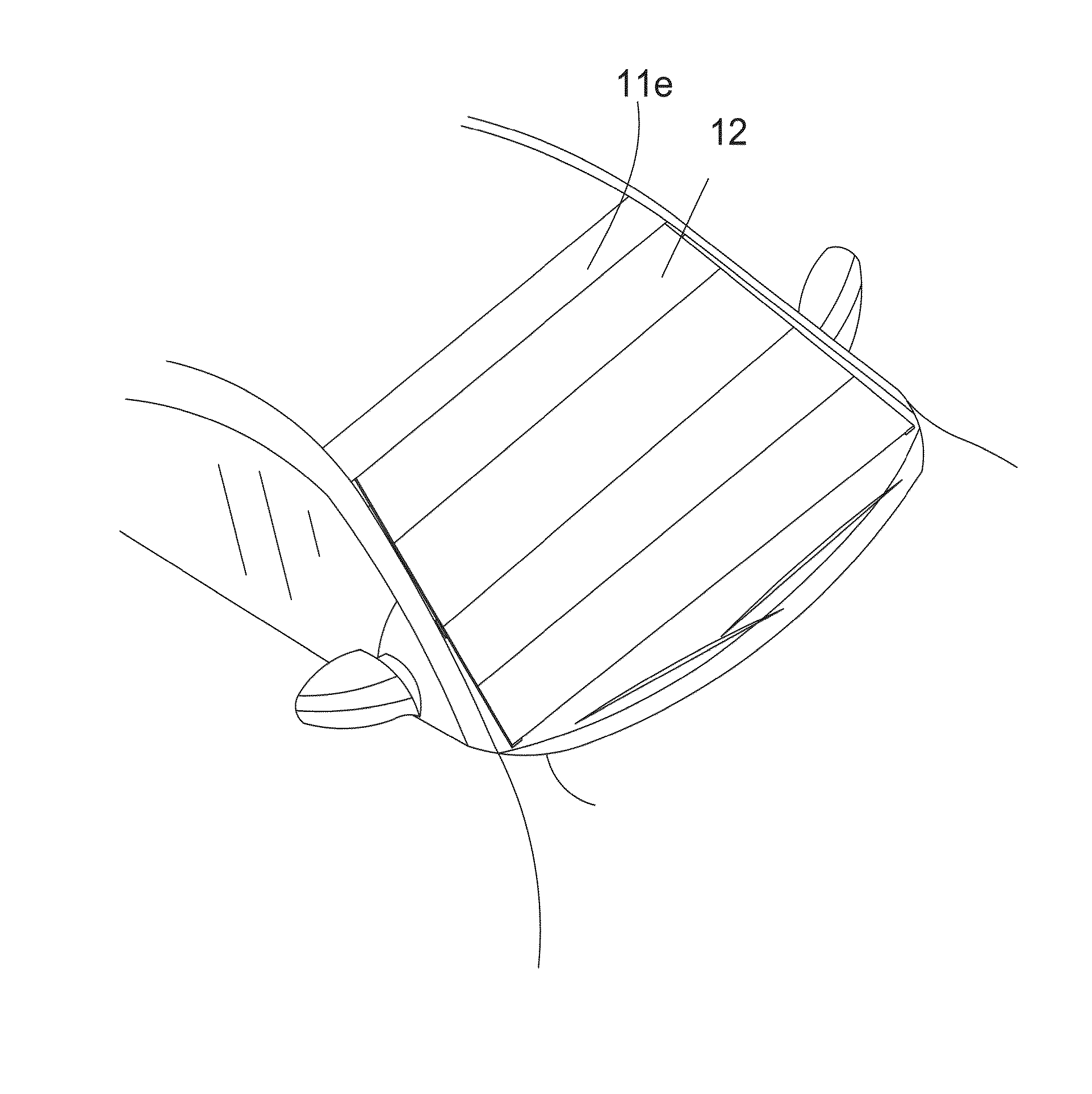

Customized vehicle shielding system

ActiveUS9283834B1Easy to operateProtect partsArmoured vehiclesRemovable external protective coveringsTeleoperationAutomotive engineering

The present invention relates to a customized vehicle shielding system used for shielding at least a part of a vehicle, wherein such system essentially comprises a housing with a plurality of walls, a shielding material adapted to alternate between an extended position and a retracted position, a mechanism for extending and retracting the shielding material, and draining means. A user can operate the system of the present invention remotely. The vehicle shielding system of the present invention has self-cleaning capability.

Owner:KHOURY JOHNNY MICHEL

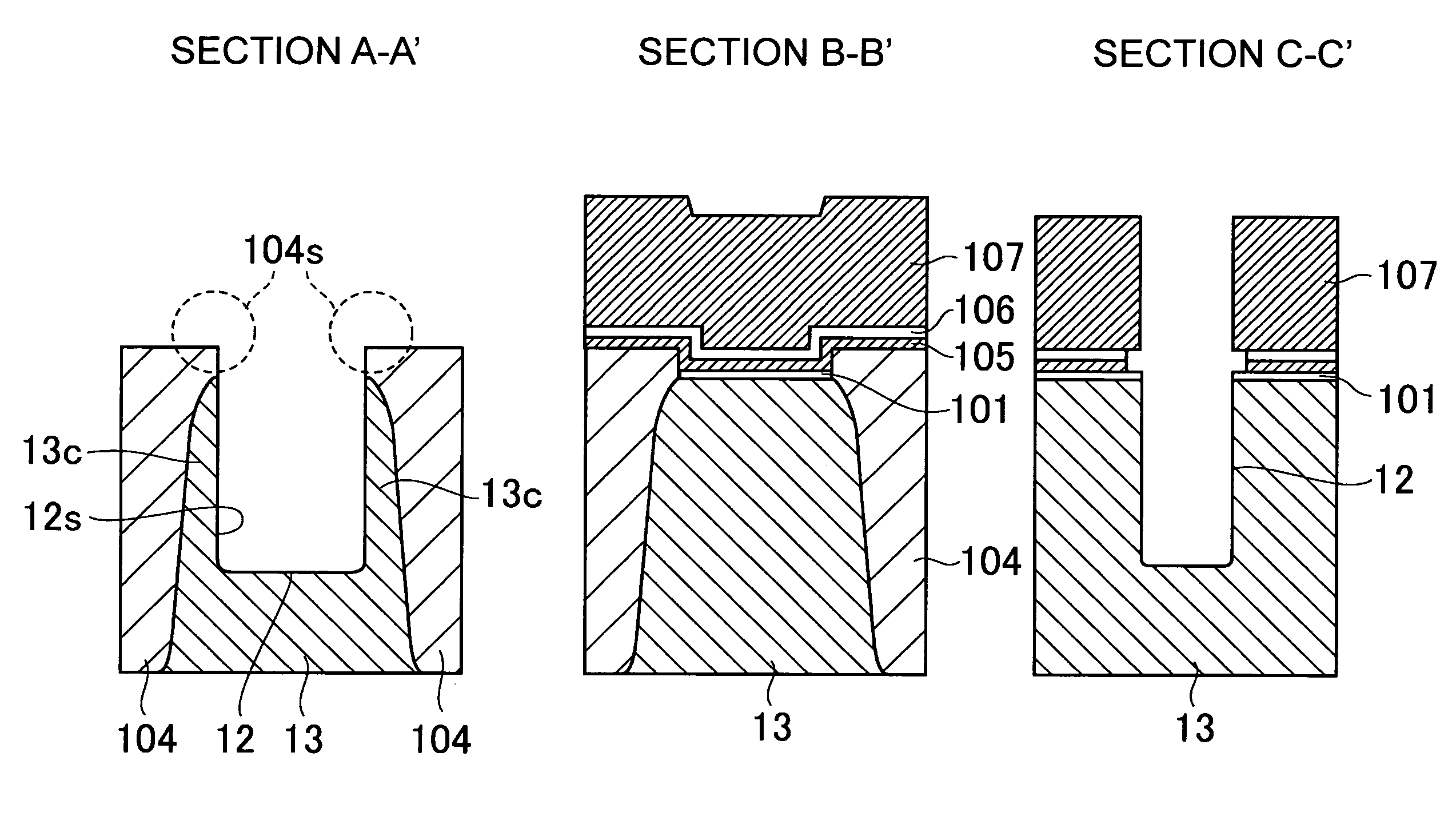

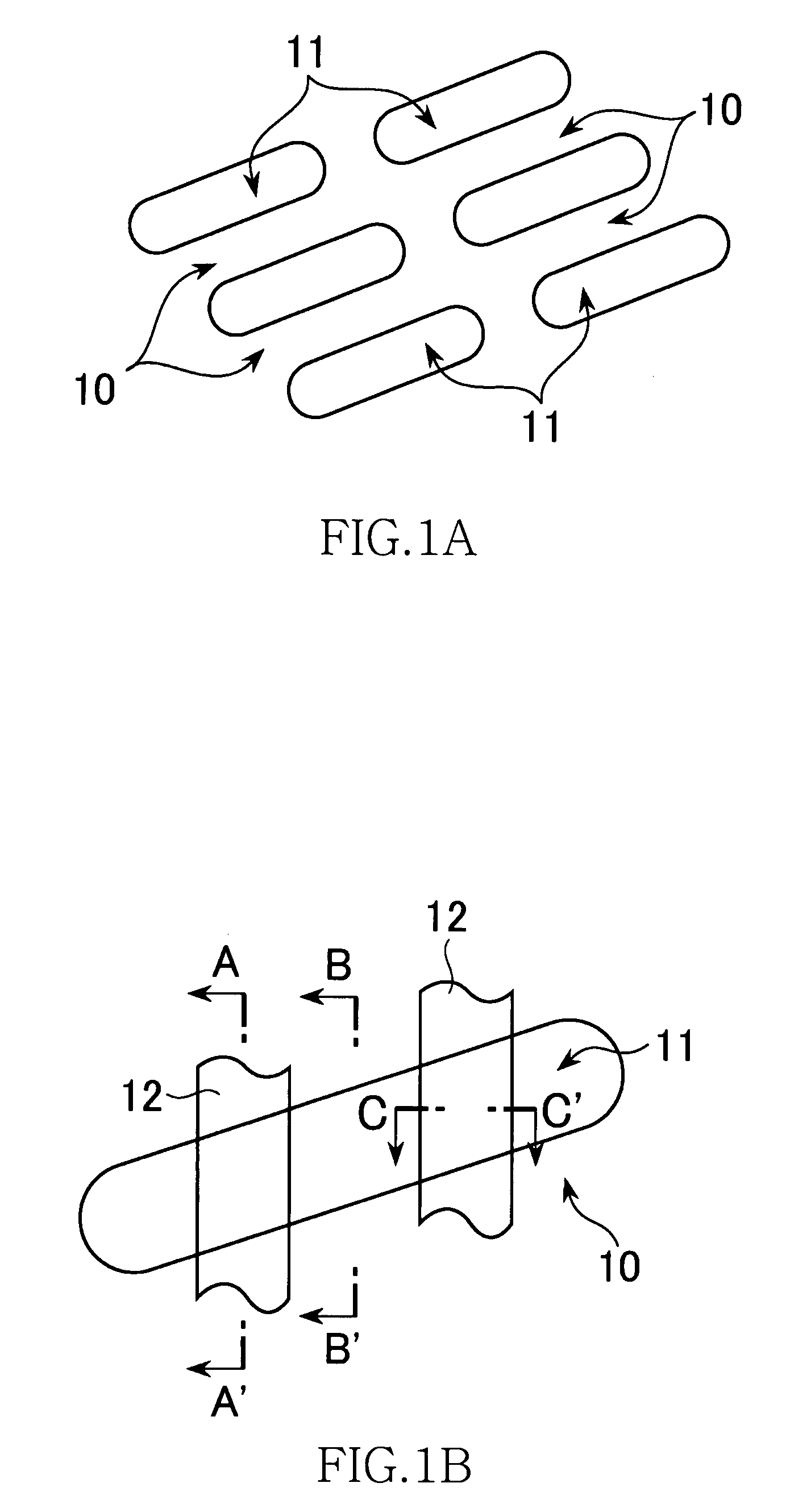

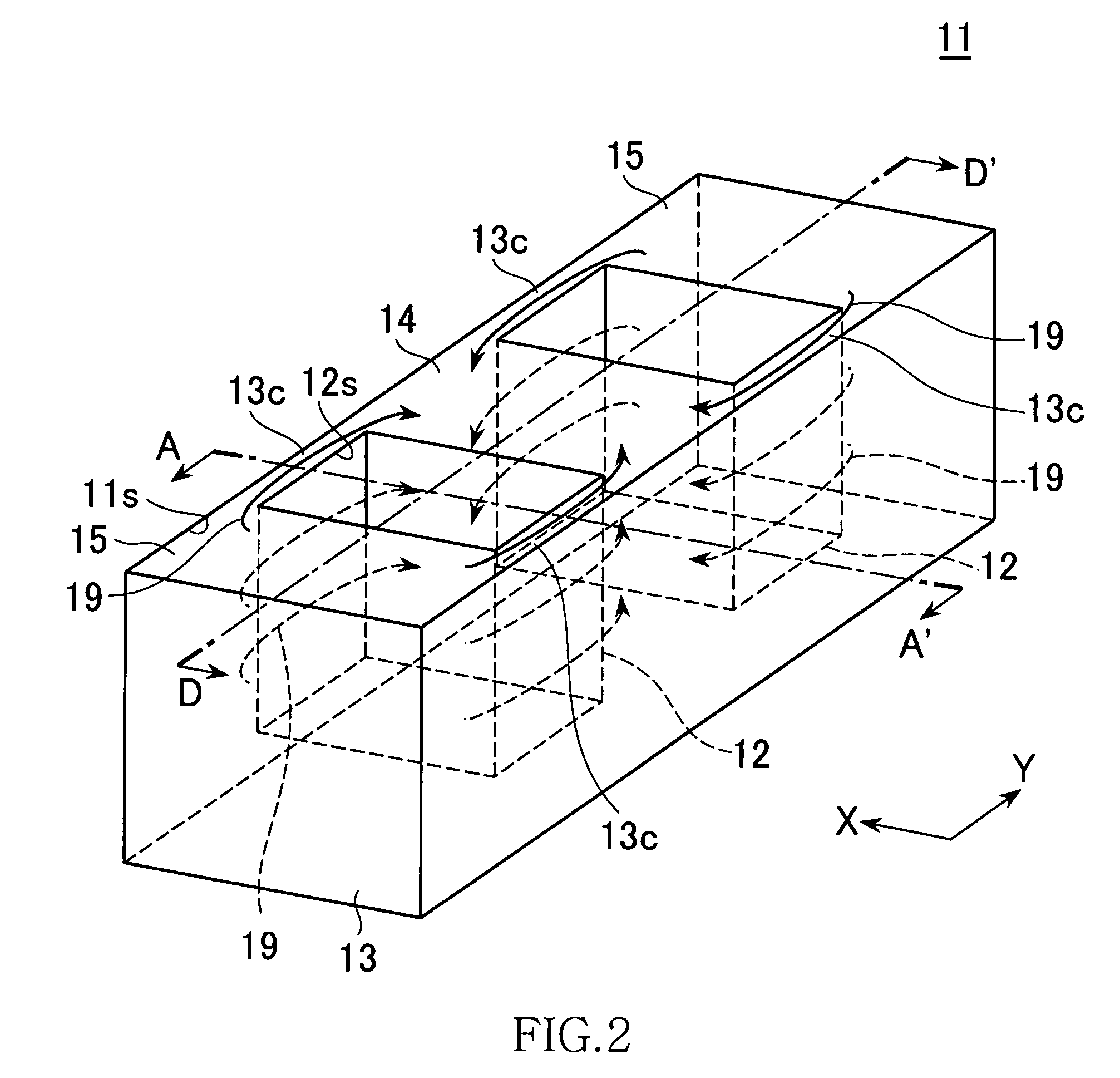

Method of manufacturing semiconductor device having trench-gate transistor

ActiveUS7816208B2Reduce power supply voltageSuppress leakage currentSolid-state devicesSemiconductor/solid-state device manufacturingTrench gateSemiconductor

A method of manufacturing a semiconductor device includes: a first step of forming an STI region and an active region surrounded by the STI region on a semiconductor substrate; a second step of forming a protection film protecting a shoulder part of the STI region in a boundary between the active region and the STI region; a third step of forming a gate trench in the active region so as to leave a part of the semiconductor substrate located between a side surface of the STI region and a side surface of the gate trench;a fourth step of forming a gate insulating film on the side surface of the gate trench; a fifth step of forming a gate electrode, at least a part of the gate electrode being buried in the gate trench; and a sixth step of forming a source region and a drain region in regions located on both sides of the gate trench in an extension direction of the gate trench, respectively, so that the part of the semiconductor substrate functions as a channel region.

Owner:MICRON TECH INC

Pet impact protector

ActiveUS8104429B2Easy to install and removeProtect partsVehicle seatsPedestrian/occupant safety arrangementEngineeringImpact area

A pet impact protector is disclosed. This device is directed to a cleanable, removable device for a vehicle car seat comprising a contiguous pliable material having a pet seating area and a pet capture area. The pet impact protector is designed such that the force of the pet impact protector plus the pet, upon impact with the vehicle during a stop or slowing of the vehicle, causes the pet impact protector to partially collapse and form a protective impact area around the pet. This device is directed to the reduction of injury to a pet riding in a vehicle during an accident, stop or slowdown of the vehicle.

Owner:BENNETT GARY RAY

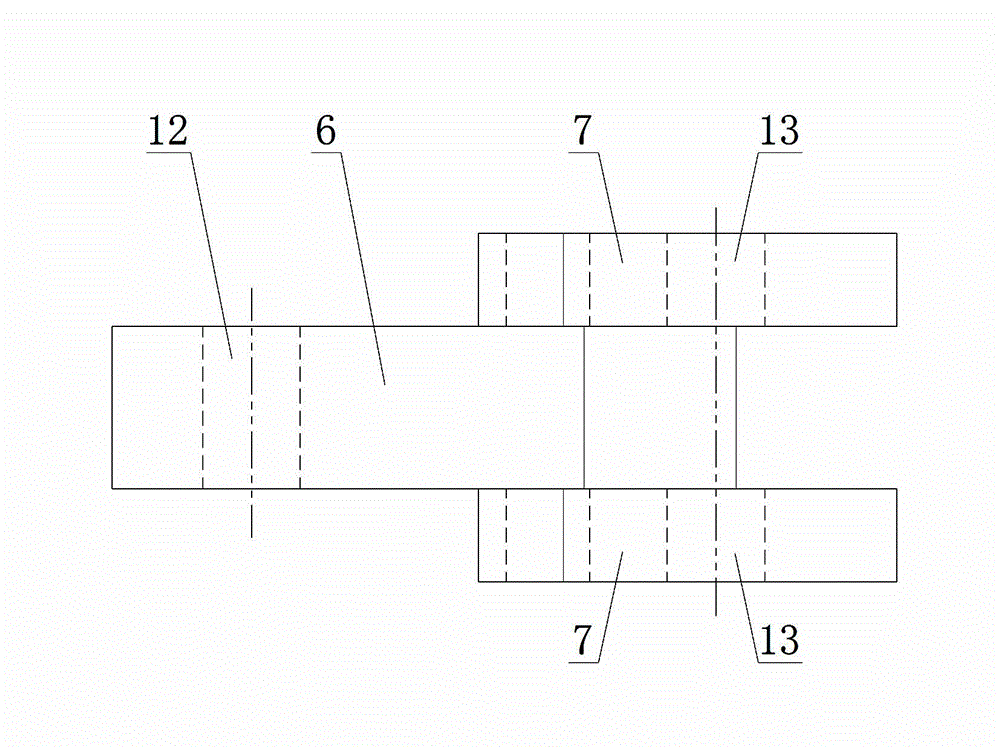

Coupling convenient to dismount

The invention relates to the technical field of couplings, in particular to a coupling convenient to dismount. The coupling comprises a left half coupling body, a right half coupling body, a fixed bolt, a left shaft sleeve and a right shaft sleeve. The left half coupling body and the right half coupling body are fixedly connected through the fixed bolt; an input shaft is connected with the left half coupling body through the left shaft sleeve, and an output shaft is connected with the right half coupling body through the right shaft sleeve; and the left shaft sleeve, the left half coupling body, the right half coupling body and the right shaft sleeve are each provided with a pin through hole. Fixed pins are arranged in the pin through holes. A transmission shaft can be dismounted without hammering, the transmission shaft and all parts of the coupling are effectively protected, and the service life is prolonged.

Owner:镇江市润州联轴器厂

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com