Non-woven cloth production line

A production line and non-woven fabric technology, applied in the direction of non-woven fabrics, textiles, papermaking, fiber processing, etc., can solve the problems of time-consuming and labor-intensive disassembly, potential safety hazards, uneven force on the needle plate, etc., to avoid secondary pollution , good workshop environment, and the effect of improving the quality of the whole machine

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described in detail below in conjunction with the accompanying drawings and specific embodiments, but the present invention is not limited to these embodiments.

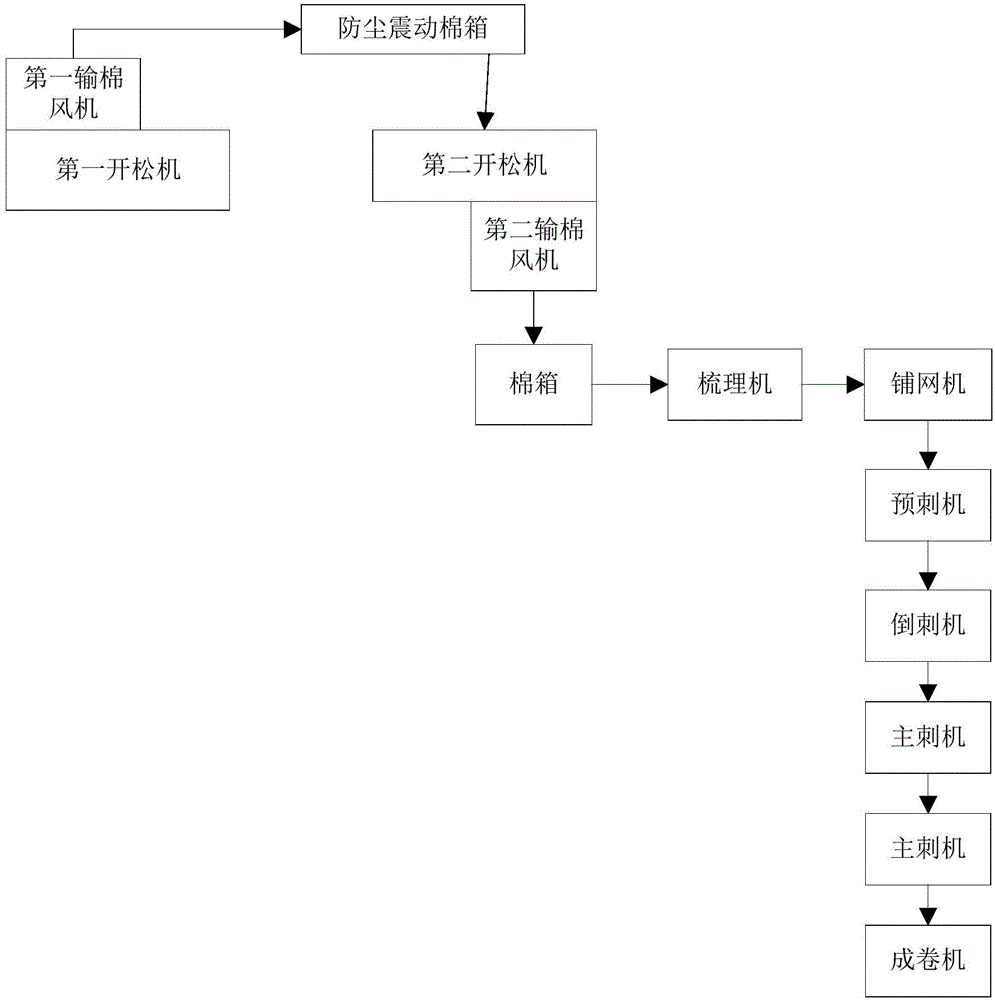

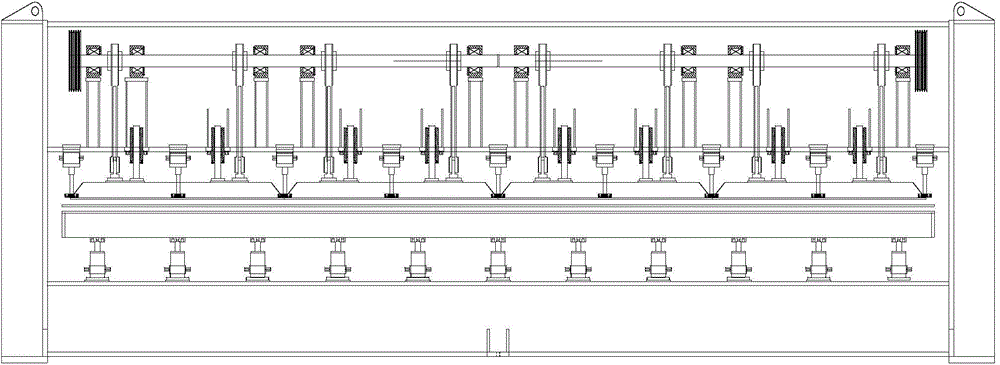

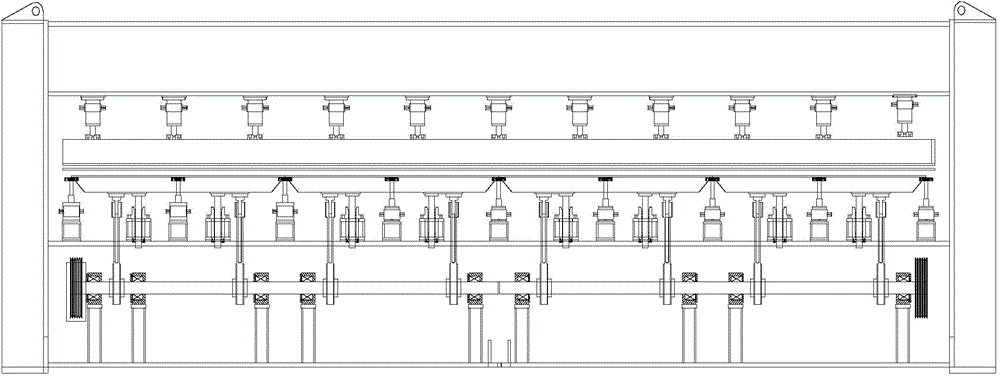

[0033] Such as figure 1 As shown, a non-woven fabric production line includes an opening device, a carding machine, a web-laying machine, a needle-punching device and a lapping machine connected in sequence.

[0034] Such as figure 1 and Figure 6 As shown, the opening device includes a first opening mechanism and a second opening mechanism, the first opening mechanism includes a first opening machine and a first cotton delivery fan connected with the first opening machine, and the second opening machine Loose mechanism comprises the second loosening machine 32 and the second cotton conveying blower 33 that links to each other with the second opener 32, is provided with the magnet that is used to absorb metal impurity in the second cotton conveying blower 33, and on the ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com