Tooling fabric with cooling function and uvio-resistant function

An anti-ultraviolet and fabric technology, used in clothing, special outerwear, textiles, etc., can solve the problem of difficulty in maintaining cooling characteristics, and achieve the effect of ensuring clarity, reducing details, and good stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

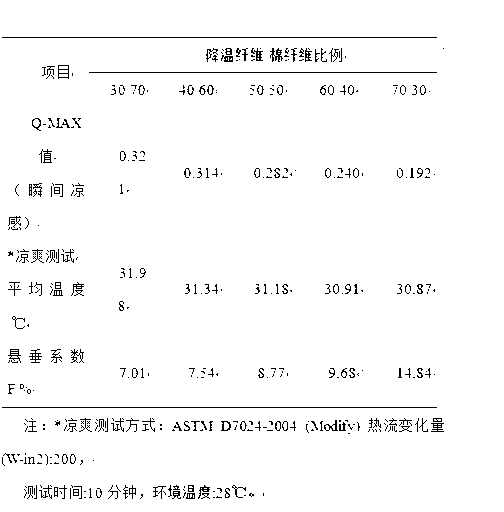

Embodiment 1

[0059] The cooling masterbatch formula is: 65 parts by weight of PA6, 10 parts by weight of jade powder, 3 parts by weight of zirconia powder, 8 parts by weight of silicon dioxide powder, 1 part by weight of stearic acid dispersant, modified polyphenylene 2 parts by weight of ethylene dispersant, 2 parts by weight of low-molecular wax dispersant, and 1 part by weight of titanate coupling agent.

[0060] Workwear fabrics with cooling and anti-ultraviolet functions are made by the following methods:

[0061] (1) Use cooling masterbatch as raw material to make slices;

[0062] (2) Dry the slices: the drying temperature is 150°C, the drying time is 10 hours, and the dew point of the compressed air during drying is -58°C, so that the water content of the slices is reduced to below 30PPM;

[0063] (3) Spin the slices through the spinning box to make nylon-based cooling fibers: the slices are heated in the spinning box to form a thin stream of spinning melt, which is sprayed out fro...

Embodiment 2

[0067] The cooling masterbatch formula is: 66 parts by weight of PA6, 12 parts by weight of jade powder, 4 parts by weight of zirconia powder, 4 parts by weight of silicon dioxide powder, 2 parts by weight of stearic acid dispersant, modified polyphenylene 3 parts by weight of ethylene dispersant, 3 parts by weight of low molecular weight wax dispersant, and 2 parts by weight of titanate coupling agent.

[0068] Workwear fabrics with cooling and anti-ultraviolet functions are made by the following methods:

[0069] (1) Use cooling masterbatch as raw material to make slices;

[0070] (2) Dry the slices: the drying temperature is 160°C, the drying time is 12 hours, and the dew point of the compressed air is -60°C during drying, so that the water content of the slices is reduced to below 30PPM;

[0071] (3) Spin the slices through the spinning box to make nylon-based cooling fibers: the slices are heated in the spinning box to form a thin stream of spinning melt, which is spraye...

Embodiment 3

[0075] The cooling masterbatch formula is: 70 parts by weight of PA6, 15 parts by weight of jade powder, 5 parts by weight of zirconia powder, 10 parts by weight of silicon dioxide powder, 3 parts by weight of stearic acid dispersant, modified polyphenylene 4 parts by weight of ethylene dispersant, 4 parts by weight of low molecular wax dispersant, and 3 parts by weight of titanate coupling agent.

[0076] Workwear fabrics with cooling and anti-ultraviolet functions are made by the following methods:

[0077] (1) Use cooling masterbatch as raw material to make slices;

[0078] (2) Dry the slices: the drying temperature is 170°C, the drying time is 14 hours, and the dew point of the compressed air during drying is -62°C, so that the water content of the slices is reduced to below 30PPM;

[0079] (3) Spin the slices through the spinning box to make nylon-based cooling fibers: the slices are heated in the spinning box to form a thin stream of spinning melt, which is sprayed out ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com