Patents

Literature

83results about How to "Strong wrinkle resistance" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

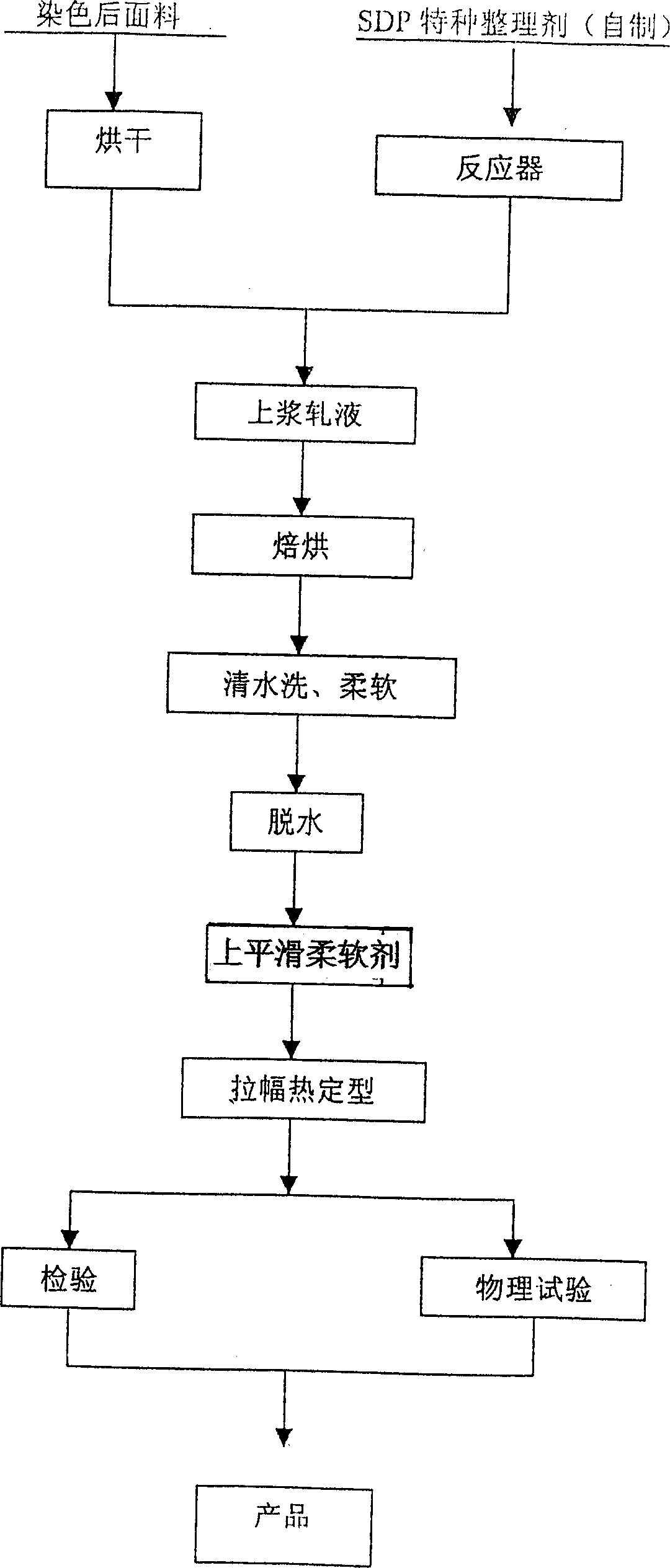

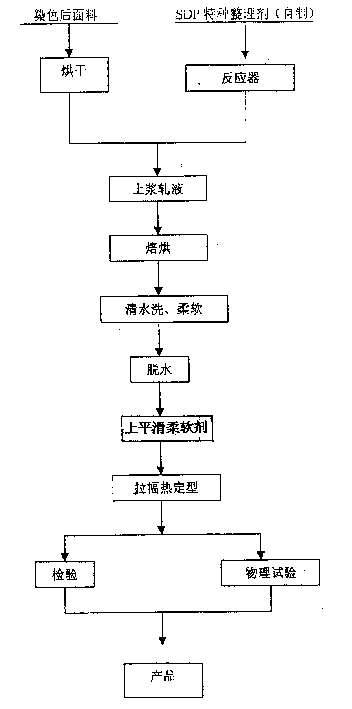

Shrinkproof, wrinkle-proof, non-deforming cotton knitted shell-fabric dyeing and finishing process

InactiveCN1405395ASoft touchFeel smoothFibre treatmentHeating/cooling textile fabricsWrinkle skinEngineering

The invention is a dyeing technique of shrink-proof, wrinkle-proof and un-deformable cotton knitted plus material. It includes: after dyeing, dry grey cloth, add prescribed rinsing and homemade special arranging agent (SDP) to the reactor and then constantly stir them and adjust pH value and after complete reaction, being sizing and pressing liquid, and then carry through cross-linking, baking, washing, softening, dehydration, smearing smoothing agent, stentering shaping, verifying and packing. Its character: the baking technique: the temperature 150-180 degree C, the time 2-3 minutes and baking tech8nique is continually carried through in the hot-shaping stenter; the length of shaping machine is 24m and it has 8 box regions, 1-3 baking region and 4-7 shaping region whose technical time is 40s.

Owner:YONGFENG TEXTILE SHAGHAI

Processing method for warp knitted mink velvet fabric

The invention discloses a processing method for warp knitted mink velvet fabric, and belongs to the technical field of velour processing. The processing method comprises the steps of velvet structure silk and bottom structure silk selection and warping conducted by a warping machine, weaving, dissection, carding, preshaping, dyeing, napping, shearing, lustre finishing, fleecing and post-shaping. The processing method has the advantages that the fabric velvet face is strong in velvet feeling and soft in texture, the velvet is mellow, soft and good in elasticity, the velvet has abundant and stable forms, the breathability and heat retention are good, the velvet effect will not be weakened after the fabric is repeatedly washed, size stability is ideal, deformation will not occur in the using process, and the velvet face is soft and smooth in velvet feeling after dyeing and softening due to the fact that preshaping and post-shaping are adopted and compare favourably with natural mink fur; due to the facts that polyester silks are used as the velvet structure silks and the bottom structure silks of the fabric, and the velvet structure silks and the bottom structure silks are reasonable in specification, the mink velvet fabric has excellent strength, and is high in crease resistant property, washable and excellent in durability.

Owner:CHANGSHU SHENHUA KNITTING

Antistatic cotton-polyester blend clothing material

InactiveCN1811034AHigh cotton contentImprove breathabilityOther chemical processesWoven fabricsPolyesterFiber

The antistatic cotton-polyester blend clothing material contains cotton of 21*21 count in 50-70 wt%, chemical fiber of 127*66 or 45 / 2*21 count in 29-49 wt% and conducting fiber of 130*66 count in 1 wt%. It has high cotton content and embedded conducting fiber resulting in excellent antistatic effect, high permeability from proper cotton / polyester ratio, certain brightness, high stiffness, high color fastness and fire retarding function, and can meet the requirement of antistatic clothing for workers in petrochemical and other industry.

Owner:YI HE STOCK

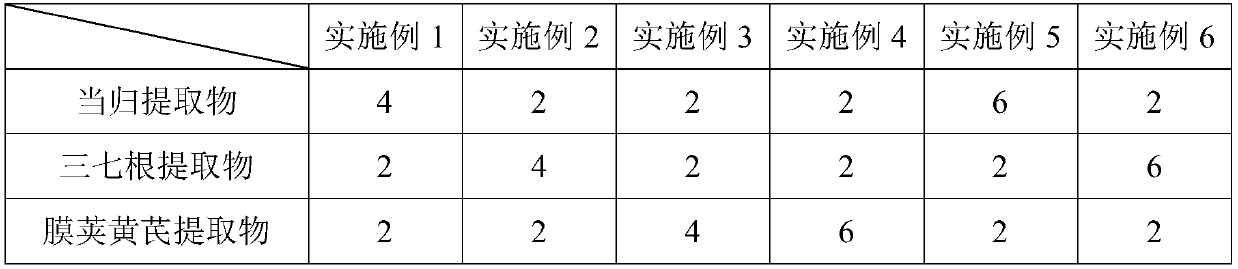

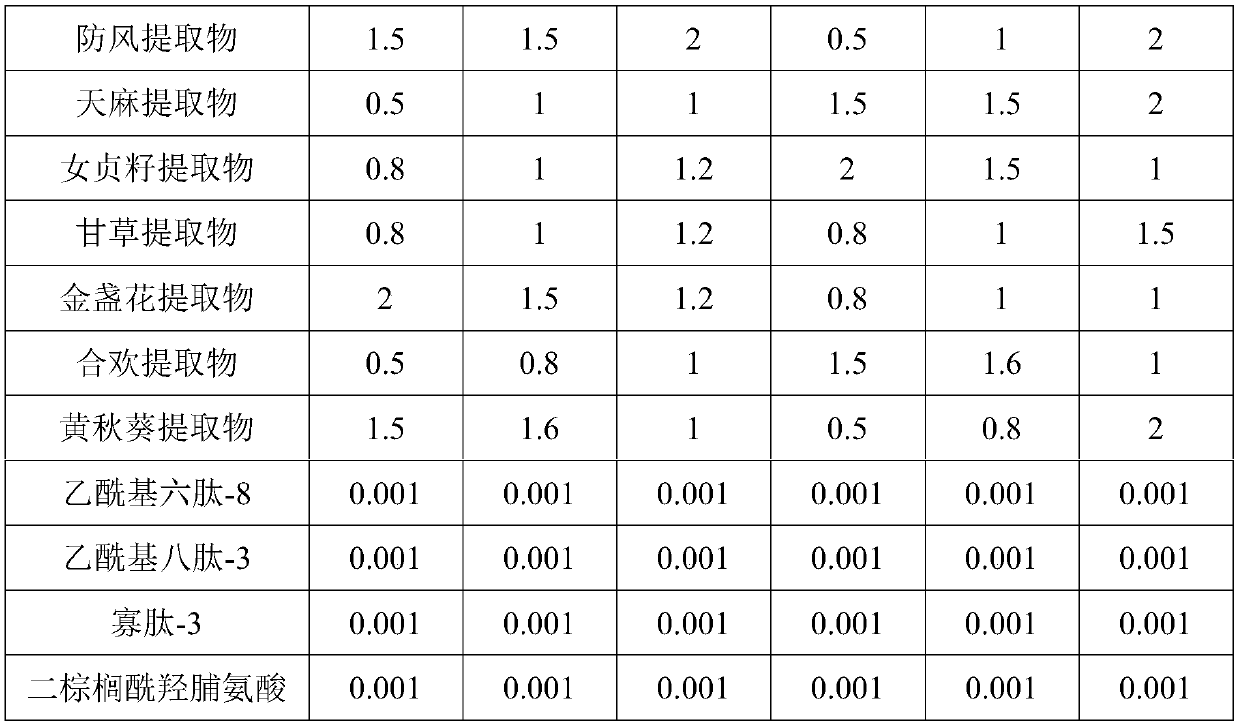

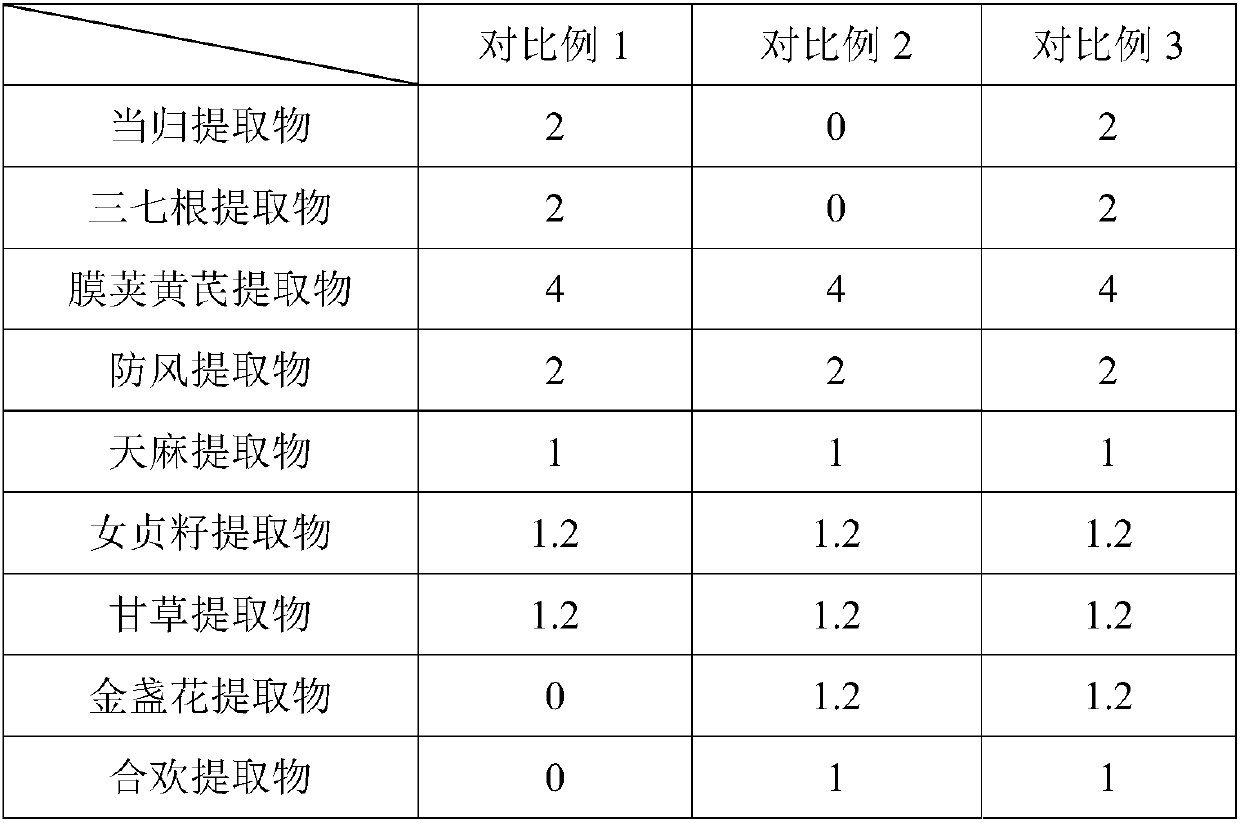

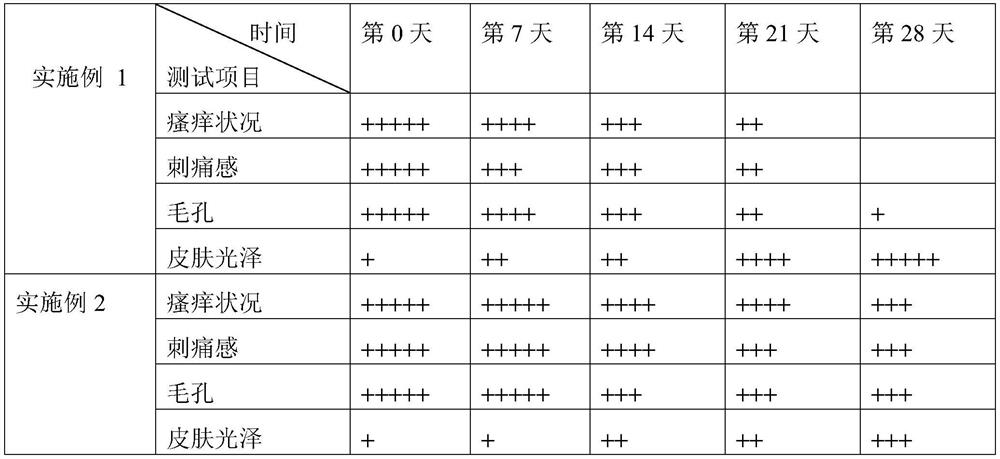

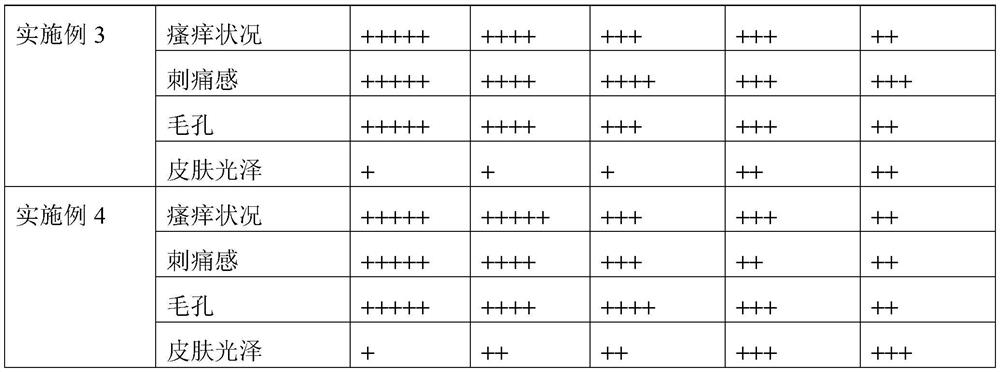

Anti-wrinkle compact composition, emulsion and preparation method and application thereof

InactiveCN109528612ATo promote metabolismIncrease moistureCosmetic preparationsToilet preparationsSide effectBULK ACTIVE INGREDIENT

The invention relates to an anti-wrinkle compact composition, an emulsion and a preparation method and application thereof. The anti-wrinkle compact composition comprises the following active ingredients: angelica sinensis, panax notoginseng, astragalus membranaceus, saposhnicovia divaricata, gastrodia elata, glossy privet fruits, glycyrrhiza, calendula, albizzia julibrissin, okra, acetyl hexapeptide-8, acetyl octapeptide-3, oligopeptides-3 and dipalmitoyl hydroxyproline. The anti-wrinkle compact composition taking Chinese herbal medicines as main materials and biological small molecular substances as auxiliary materials is safe and free of toxic and side effects. The anti-wrinkle compact composition not only has a strong anti-ageing effect, but also can alleviate various uncomfortable symptoms of skin, improve sensitive skin, smoothen the nutritional channel and the energy channel of the skin and recover elasticity of the skin and improve the brightness of the skin, so that the skin is young, healthy and active. Therefore, the anti-wrinkle compact composition is suitable for preparing skincare products.

Owner:广州市普高管理咨询有限公司

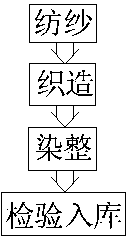

Preparation method of cotton and polyester slub ply fancy inlay fabric

The invention discloses a preparation method of a cotton and polyester slub ply fancy inlay fabric. The preparation method comprises the following steps: (a) spinning; (b) weaving; (c) dyeing and finishing; (d) checking and warehousing, wherein yarns comprise warp yarns and weft yarns; the weft yarns are ply slub yarns of cotton slub yarns and polyester slub yarns; the ply proportion of the cotton slub yarns to the polyester slub yarns is 16:1; the weft yarns are combed cotton and polyester blended slub yarns; the ratio of the using amounts of the combed cotton to the polyester is 65 percent:35 percent. The preparation method has a simple and convenient flow; through innovative design and weaving process, the fabric which is prepared from normal raw material yarns has the unique effects such as a lattice pattern and multicolor dyeing, meanwhile has the advantages of strong wrinkling resistance, high strength, easiness in drying after washing and the like, and has good wearability.

Owner:KUSN ZHOUSHI TOWN JISHENG CLOTHING FACTORY

Woolen sweater

InactiveCN101871151AReduce tensionHigh tensile strengthWeft knittingWarp knittingWear resistanceLow shrinkage

The invention discloses a woolen sweater, which is formed by knitting 30 to 50 weight percent of wool, 5 to 15 weight percent of cashmere, 10 to 30 weight percent of nylon, and 20 to 40 weight percent of artificial cotton. The woolen sweater has the advantages of low shrinkage, difficult pilling, static resistance, wear resistance, difficult deformation, low cost and the like.

Owner:太仓市隆丝达针织时装有限责任公司

Durable lavender aroma type long stapled cotton/fine denier nylon knitted fabric product

ActiveCN103556479AGood hygroscopicityImprove breathabilityWeft knittingEssential-oils/perfumesFiberEmulsion

The invention relates to a knitted fabric product and particularly relates to a durable lavender aroma type long stapled cotton / fine denier nylon knitted fabric product which has good air permeability and can be washed by a machine. The knitted fabric product is braided by long stapled cotton and fine denier nylon and is treated by an after-finishing solution containing nano lavender essential oil microcapsules; the grain diameter of the nano lavender essential oil microcapsules is 3-15 nanometers and the nano lavender essential oil microcapsules are prepared from natural lavender essential oil and chamomile essential oil in the volume ratio ranging from 6:1 to 10:1 by a fine emulsion polymerization method; a preparation method of the nano lavender essential oil microcapsules comprises the following steps: preparing a polyurethane prepolymer; preparing a polyurethane emulsion; carrying out primary curing to form primary microcapsules; and carrying out secondary curing to obtain the stable microcapsules. According to the durable lavender aroma type long stapled cotton / fine denier nylon knitted fabric product, the advantages of two fibers can be expressed sufficiently by combining the long stapled cotton and the fine denier nylon; the essential oil microcapsules can penetrate into the knitted fabric product and can be broken when being extruded or moved by an external force to slowly release aroma, and the aroma keeping time is prolonged.

Owner:POLARGOOSE CLOTHING

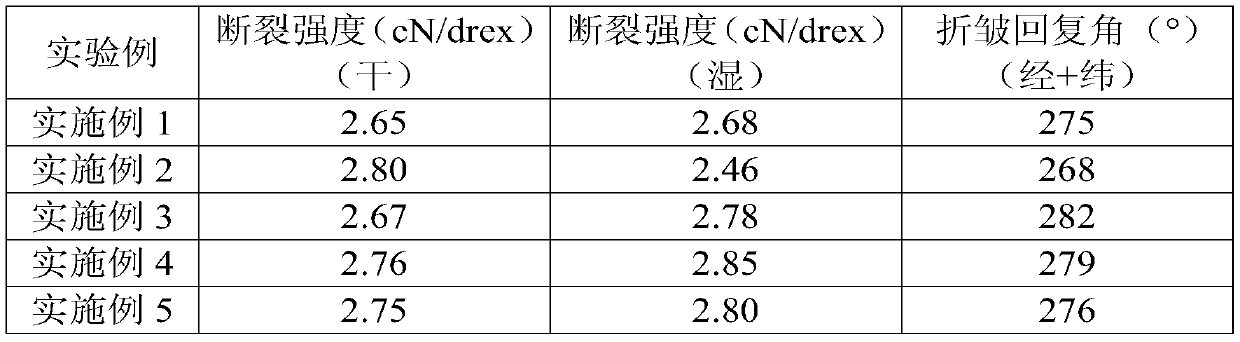

High elasticity anti-wrinkle textile fabric and preparation method thereof

The invention discloses a high elasticity anti-wrinkle textile fabric and a preparation method thereof. The high elasticity anti-wrinkle textile fabric is formed by weaving warps and wefts. Urtica fibers and long stapled cotton in a mass ratio of (3-5): 3 are taken as the warps and Urtica fibers and long stapled cotton in a mass ratio of (1-2): 3 are taken as the wefts. The yarns also comprise polyester type spandex, and the mass ratio of the polyester type spandex and the combination of urtica fibers and long stapled cotton is (0.2-0.5): 6. According to the high elasticity anti-wrinkle textile fabric, the urtica fibers, the polyester type spandex and the long stapled cotton are taken as the warps and the urtica fibers and long stapled cotton are taken as the wefts. The urtica fibers and long stapled cotton assist each other. Assisted by the polyester type spandex, the prepared textile fabric has good elasticity, excellent drape effect, and is good in wrinkle resistance, uniform to color, soft and warm, comfortable in hand feeling and ventilative and durable.

Owner:FUJIAN FYNEX TEXTILE SCI & TECH

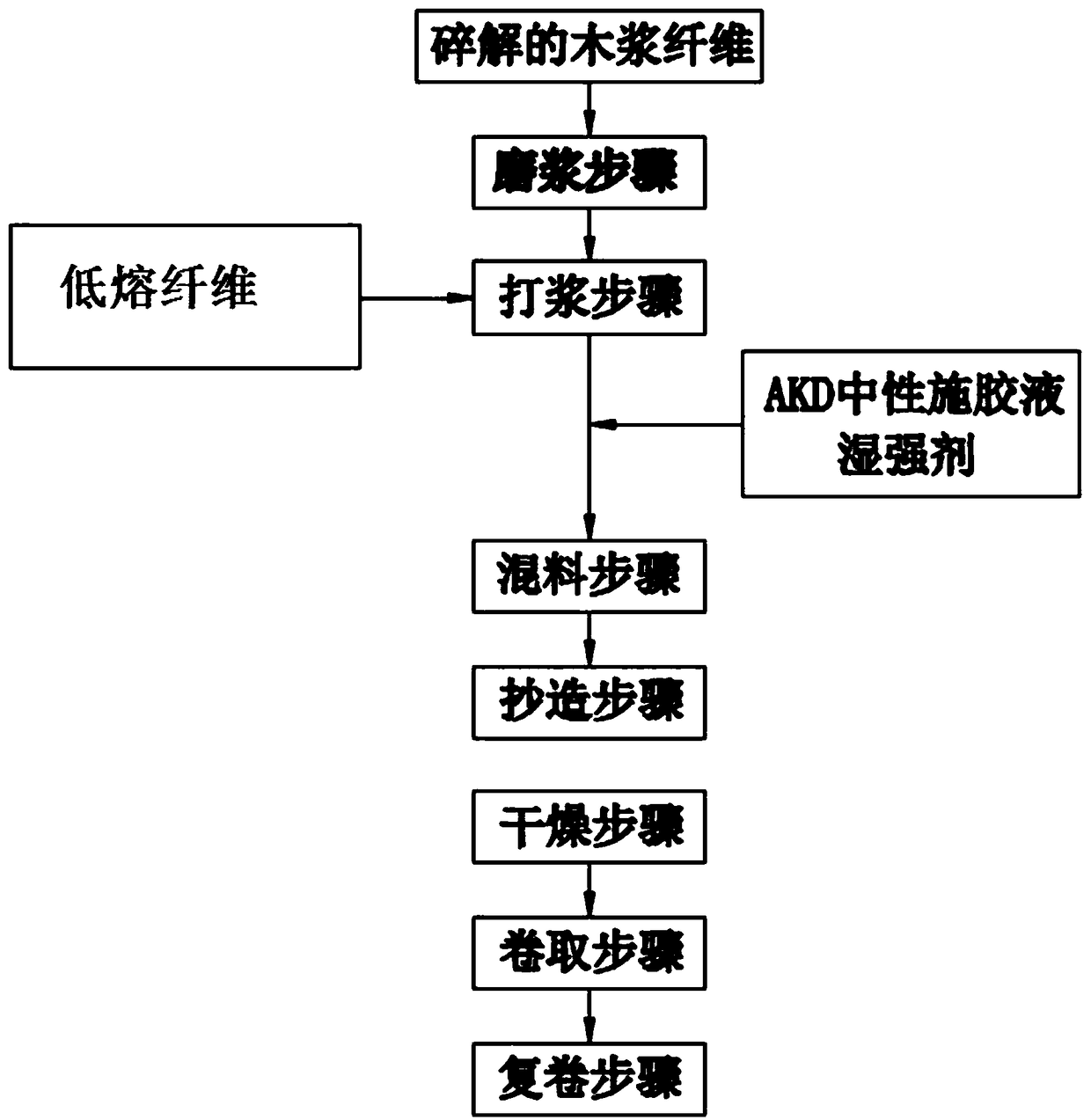

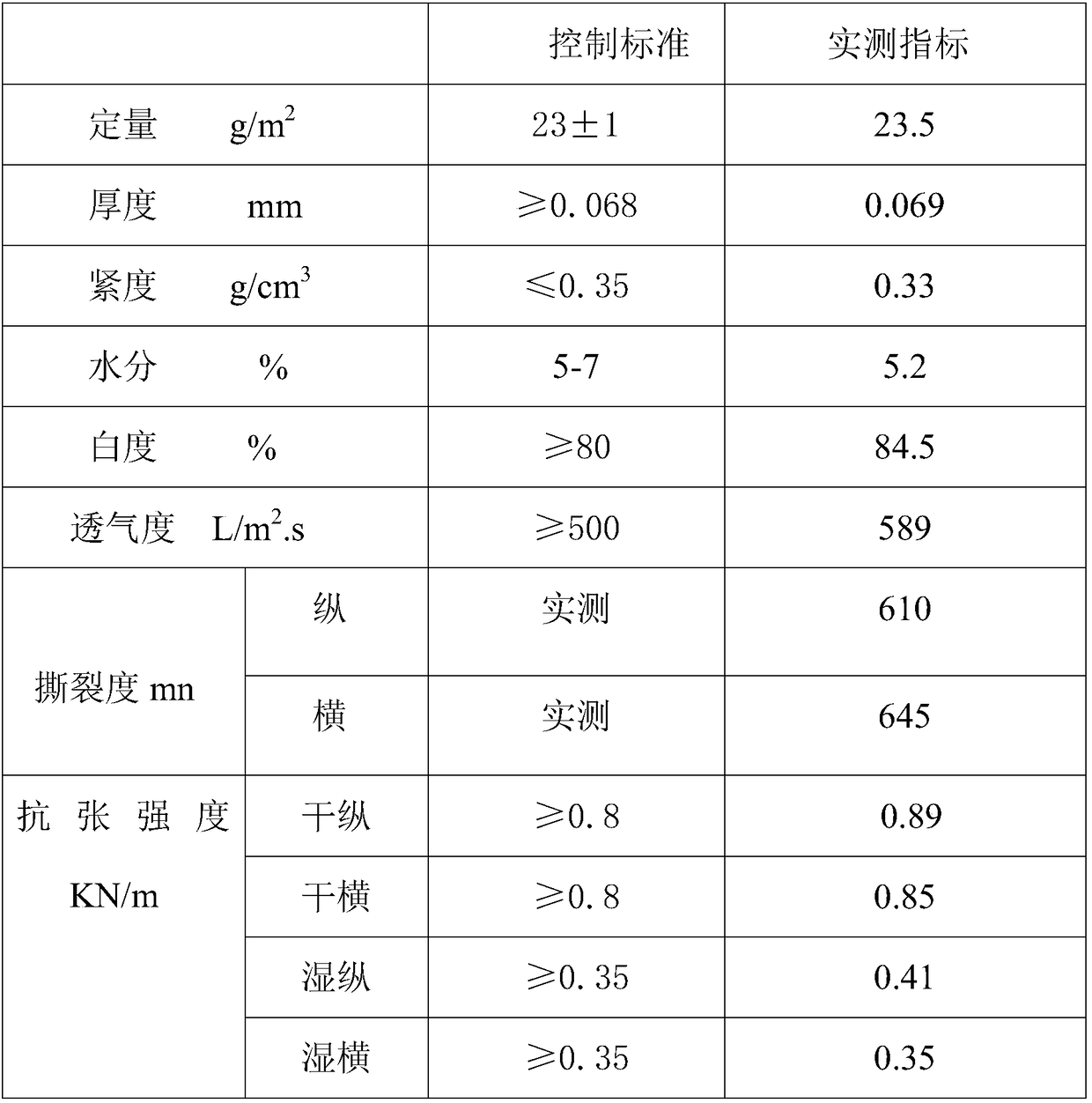

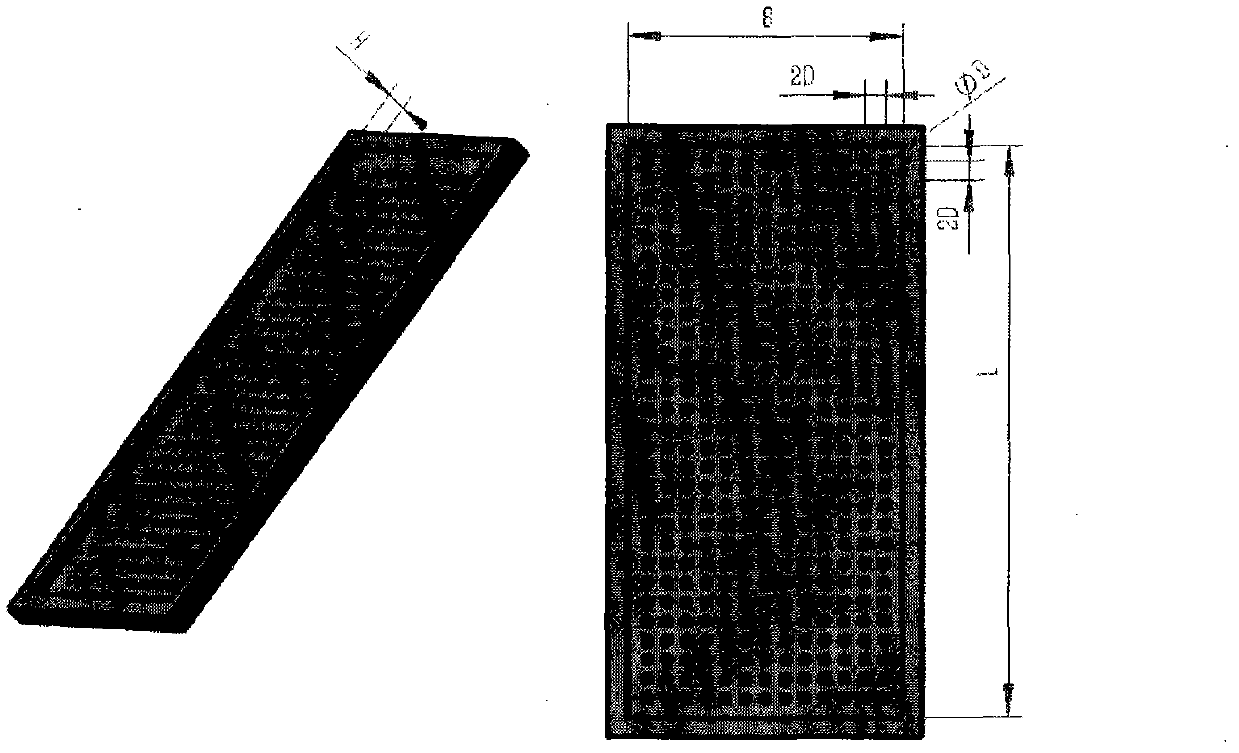

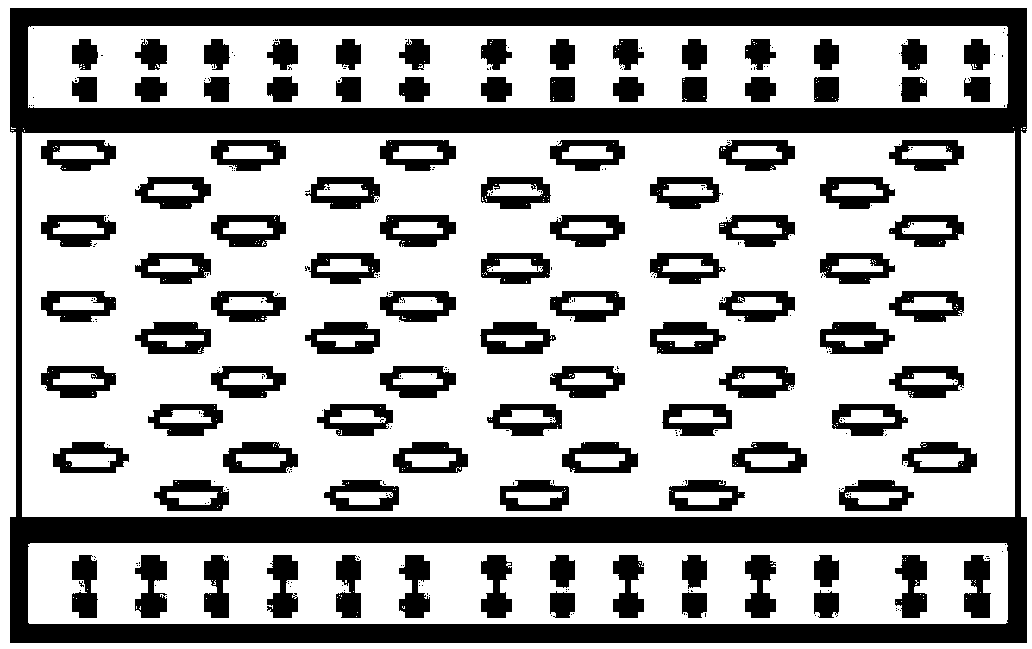

High-permeable medical adhesive tape base material and preparation method thereof

ActiveCN108914670AStrong air permeabilityStrong wrinkle resistanceWater-repelling agents additionPulp beating methodsPolyesterPunching

The invention discloses a high-permeable medical adhesive tape base material and a preparation method thereof. The adhesive tape base material comprises wood pulp fibers, polyester fibers, low meltingfibers, AKD neutral sizing liquid and wet strength agent liquid. The preparation method comprises a pulping step, a papermaking step, a drying step and a reeling step. In the pulping step, the AKD neutral sizing liquid and the wet strength agent liquid are added to a pulping pool and uniformly mixed. The high-permeable medical adhesive tape base material is prepared by mixing and pulping treatment of pure plant fibers and synthetic fibers through papermaking of a papermaking machine, and has the advantages of softness and loosening, homogeneous fibers, high air permeability, strong wrinkle resistance, easy-tearing while a product meets strength, uniform gluing and the like. The high-permeable medical adhesive tape base material is directly formed through adhesion between the fibers and melted adhesion without surface gluing reinforcement treatment, simple in processing technology, and low in manufacturing cost, and is a substitute good of a current medical cloth-based base material and a punching PE base material. Along with continuous improvement of human health requirements, a demand gap is large, and market prospect is extremely extensive.

Owner:山东杰高新材料科技(集团)有限公司

Antibacterial rabbit hair textile material

The invention discloses an antibacterial rabbit hair textile material. The textile material mainly comprises yarns; the yarns are formed by mutually twisting rabbit hair fibers, chitosan fibers, acrylic fibers and polyamide fibers, wherein the rabbit hair fibers account for 10 to 35 percent of the yarns, the chitosan fibers account for 10 to 85 percent of the yarns, the acrylic fibers account for 5 to 15 percent of the yarns, and the polyamide fibers account for 5 to 10 percent of the yarns; and the rabbit hair fibers are prepared by blending rabbit fleece and chemical fibers. By the way, the textile material can improve the comfort of textiles, has good crease resistance and strong damp heat regulating capacity, reduces the water absorption, is convenient to clean, prevents mites from being propagated, has bioactivity and biocompatibility, and can effectively inhibit the bacteria such as staphylococcus aureus, escherichia coli, candida albicans and the like; and the textile material in contact with the human skin can promote the function of sterilizing enzyme activating tissues in the human body, the waste can be decomposed by microbes, and the natural environment is not polluted.

Owner:江苏红运果服饰有限公司

Preserved fresh flower and making method thereof

The invention discloses a preserved fresh flower and a making method thereof, and relates to the technical field of preserved fresh flower making. The making method of the preserved fresh flowers comprises the following steps: S1, pretreatment; S2, dehydration and decolorization treatment; S3, dyeing treatment; and S4, drying for obtaining the preserved fresh flower. The obtained preserved fresh flower is good in overall texture, high in color saturation and high in fresh flower reproduction rate. The petals of the obtained soft preserved fresh flower are soft in texture, graceful in posture, bright in color, high in saturation degree, dry in surface and free of dye residues; the obtained preserved fresh flower has thick petals, firm texture, soft texture, strong wrinkle resistance, bright color, high saturation, dry petal surface and no dye residue.

Owner:TIANJIN NORMAL UNIVERSITY

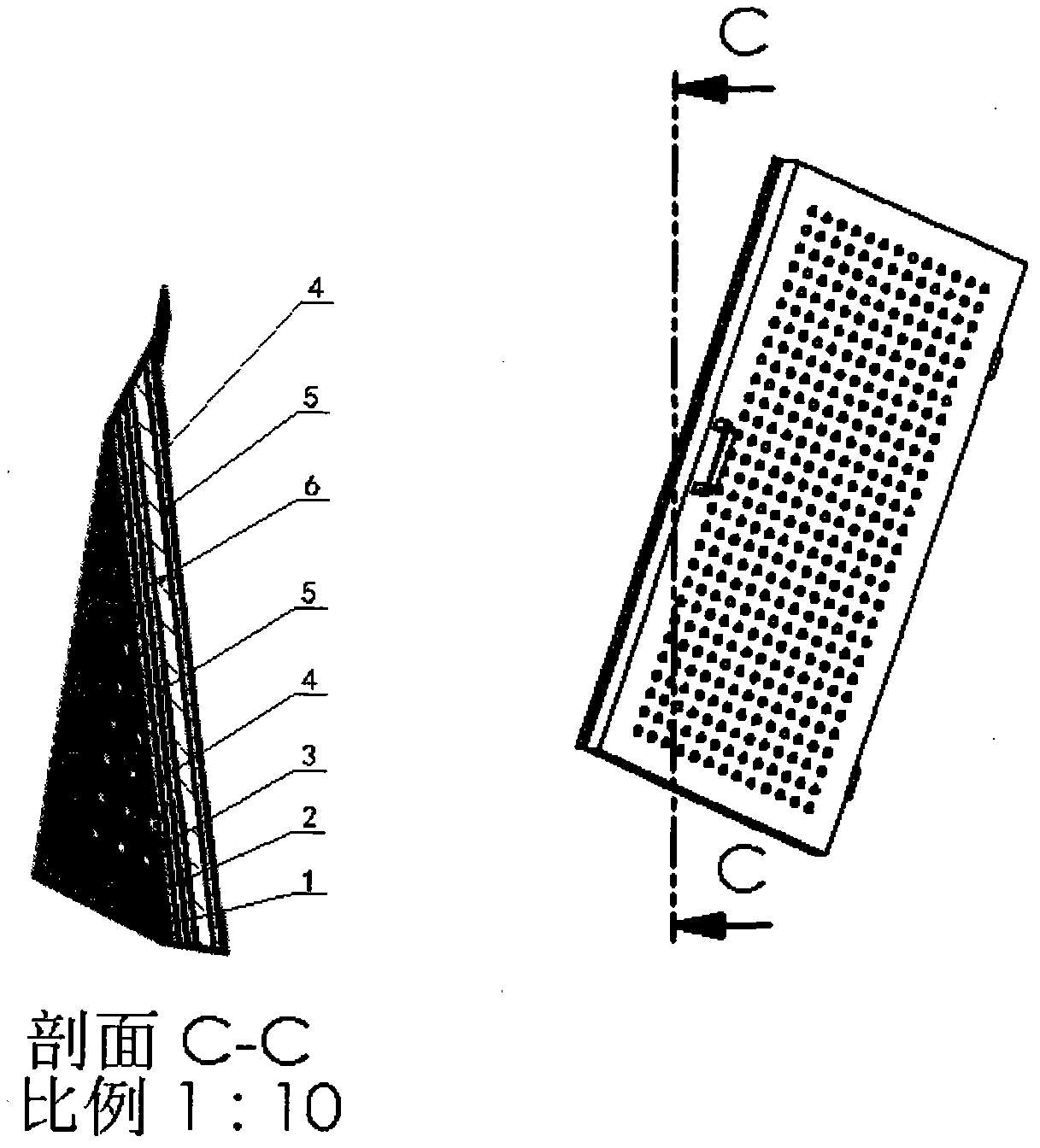

Sound-insulation noise-reduction system of roll-packing machine

InactiveCN104217711AReduce incentive energyReduce Occupational InjuriesNoise insulation doors/windowsSound producing devicesFiberEngineering

The invention discloses a method and device for sound insulation and noise reduction and relates to the field of tobacco processing, in particular to a sound-insulation noise-reduction system which is mounted on a roll-packing device of a roll-packing workshop of a cigarette factor to serve as a protection door for sound insulation and noise reduction. The sound-insulation noise-reduction system is characterized in that the device is composed of a casing, a rubber coating, a sound-absorbing cloth cover, a sound-absorbing foam metal plate, a fiber sound-absorbing plate, toughened vacuum glass and the like, the rubber coating used for noise reduction coats the inner side of the casing, the sound-absorbing cloth cover, the sound-absorbing foam metal plate, the fiber sound-absorbing plate and the toughened vacuum glass are sequentially mounted on the rubber coating, and then the fiber sound-absorbing plate and the sound-absorbing foam metal plate are mounted. The device is applied to the noise source portion of the roll-packing device of the roll-packing workshop or is used for being produced into the protection door and the like for sound absorption and noise reduction, pollution of the noise source can be controlled, and the effect is obvious.

Owner:李新亮

Preparation method of anti-wrinkle real silk fabrics in hollow structure

InactiveCN103014972AImproves wrinkle recoveryElasticWeft knittingWarp knittingFiberRecovery performance

The invention relates to a preparation method of anti-wrinkle real silk fabrics in a hollow structure. According to the preparation method, centre yarns and cocoon silks in a moist state in a reeling silk bath are coated together, water soluble fibers of the centre yarns in core covering silks are dissolved through refining, and the manufacture of hollow real silk is completed at the reeling silk stage. The preparation method has the advantages that the production cost is low, the process is simple, the hollow real silk has the elasticity, the anti-wrinkle recovery performance of the real silk is enhanced, the anti-wrinkle performance of finished products is high, the wrinkling cannot be generated after washing, and the wide application can be realized.

Owner:JIANGSU HUAJIA SILK +1

Fabrication process of anti-wrinkling and damp-proof decoupage handicraft article

InactiveCN103568679AFor long-term storageHigh feasibilitySpecial ornamental structuresPlastic filmMaterials science

The invention relates to the technical field of decoupage handicraft articles and discloses a fabrication process of an anti-wrinkling and damp-proof decoupage handicraft article. The fabrication process comprises the following process steps of (1) fabricating a metal-coated plastic film; (2) fabricating a composite base material layer; (3) pressing reinforcing ribs; (4) additionally arranging accessory decoration layers. The fabrication process has the advantages that the process is simple, and the operation is convenient; the limitations caused by traditional materials are overcome, the feasibility for creating scissor-cut contents is greatly improved, an overall product is relatively attractive, the anti-pressure ability of a three-dimensional design is improved, and the anti-wrinkling and damp-proof decoupage handicraft article can keep a preferable three-dimensional effect after being pressed; furthermore, carriers of the article have strong wrinkling resistance, cannot be influenced by dampness and insolation, can be cleaned and repeatedly used and are convenient to be daily cleaned by people, and the economization and environmental protection purposes are achieved.

Owner:冯劲才

Collagen juice drink

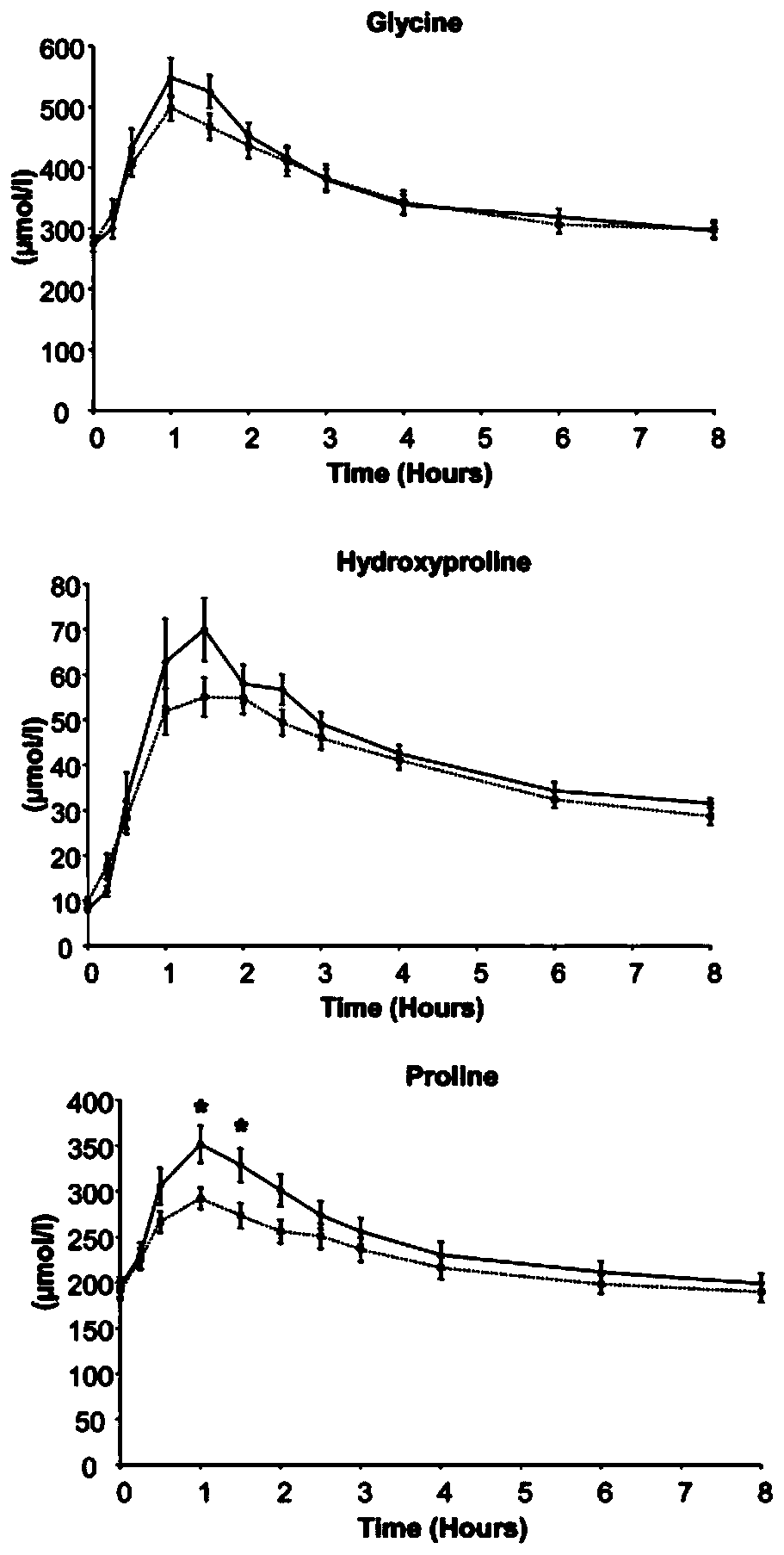

InactiveCN110810681AIncrease elasticityReduce harmNatural extract food ingredientsFood ingredient functionsBiotechnologySucrose

The invention discloses a collagen juice drink. The collagen juice drink is produced from the following raw materials in parts by weight: 2-5% of 53-Hz small-molecule water, 30-45% of a high-purity small-molecule fish collagen peptide, 8-15% of rosa roxburghii extract liquid, 5-10% of chenopodium album extraction liquid, 10-18% of a grape skin extract, 3-8% of brown rice extraction liquid, 6-10% of acai berry extraction liquid, 7-12% of blood orange extraction liquid, 4-8% of a grape seed extract, 3-6% of acerola cherry extract liquid, 0.1-0.3% of vitamin c, 0.5-1% of stevioside, 0.2-0.8% of sucralose and 0.1-0.3% of red clover isoflavone. The collagen juice drink has the efficacy of skin care, and effectively improves the density and the diameter of collagen fibers, and change of the content of skin moisture is significantly improved, so that the skin moisture and the skin elasticity are improved; the depth of wrinkles is decreased; and the capability of a human body of generating collagen is stimulated, so that the anti-wrinkle capability is improved.

Owner:云南曼蔻生物科技有限公司

Mounting painting and preparation method thereof

InactiveCN104476975AThe picture is clear and vividReduce manufacturing costSpecial ornamental structuresWoven fabricsRegular distributionGeneral Appearance

The invention discloses a mounting painting. The mounting painting comprises a paining core and a back base, wherein the mounting painting is made of ghatpot silk by a computer spraying and painting or transfer printing technique; the back base is used for mounting the painting core; the painting core is formed by weaving polyester filament yarns by virtue of a warp yarn and weft yarn structure; a plurality of polyester filament yarns as the warp yarns and weft yarns are not involved in weaving so as to form relatively long floating threads; weaving points formed by different floating threads are positioned on the surface of the painting core to form discontinuous distribution, and the plurality of weaving points form regular distribution on the surface of the painting core; the back base is formed by the mutual interweaving of cotton filament yarns and polyester filament yarns which are perpendicular with each other; the cotton filament yarns and the polyester filament yarns are interwoven regularly in a mutually staggered mode. The painting can be basically consistent with original paintings or pictures in color; the general appearance of the painting is clear and vivid; the production cost is relatively low.

Owner:湖州天强绫绢工艺品有限公司

Manufacturing process of composite leather clothing

ActiveCN104188159AImprove work efficiencyImprove aestheticsProtective garmentSpecial outerwear garmentsEngineeringMechanical engineering

The invention relates to a manufacturing process of composite leather clothing. The composite leather clothing made through the manufacturing process is high in tearing strength, a lining does not need to be sewn through a backend workshop, and the ready-to-wear clothing manufacturing and using efficiency is greatly improved. The manufacturing process comprises the steps of color matching, tailoring and sewing. In the sewing process, the clothing piece splicing joint positions of composite feather are cut up through a cutting machine, one face of each cutting position of the composite feather is sewn with one face of another clothing piece in a machine sewing mode, and the other face of each cutting position is sewn with the other face of another clothing piece in a hand sewing mode. In the sewing process, a thread sewing tool is used for assistance, the composite leather with leather on one face and worsted on the other face is adopted, the front and back worsted is outward, the feather on the rear piece is outward, the appearance of the clothing presents two different textures, the attention of consumers is attracted better, the lining does not need to be sewn through the backend workshop in the flow production process, and finished product sewing is automatically completed. The work efficiency of the ready-to-wear clothing can be greatly improved, meanwhile, the percent of pass of products can be greatly improved, production cost can be lowered, and the attractiveness, comfort degree, practicality and fashion degree of the ready-to-wear clothing can be improved.

Owner:ZHEJIANG NUOZHI FINERY

Method for dyeing and finishing cotton knitted fabric in one step

InactiveCN102747565AReduce consumptionReduce manufacturing costHeating/cooling textile fabricsVegetal fibresCooking & bakingCarboxylic acid

The invention discloses a method for dyeing and finishing cotton knitted fabric in one step, belonging to the technical field of the process for dyeing and finishing textile fabric. The method comprises the following steps: adding a predetermined amount of clear water in a container, adding a finishing agent, stirring without stop, adjusting the pH value to 4.5-6, adding a dye after the materials react completely, putting the grey fabric to be dyed in the container, dyeing, crosslinking, baking, cleaning, softening, dewatering, applying a smoothening softener, stentering and thermosetting, inspecting and packaging. The finishing agent is prepared from 40-50% by weight of citric acid and 50-60% by weight of butane tetracarboxylic acid, and the finishing agent accounts for 30-50% by weight in the clear water. The cotton knitted fabric processed by adopting the process has the advantages of soft and smooth feel, very strong shrink and wrinkle resisting capacity and excellent breathability. The method has the advantages of low energy consumption and low production cost.

Owner:SHAOXING UNIVERSITY

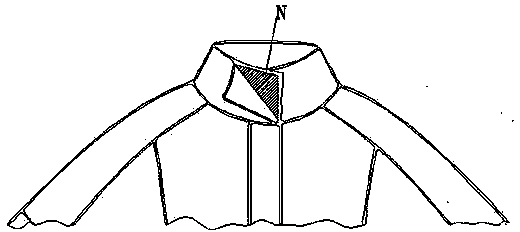

The manufacturing process of composite leather jacket

ActiveCN104188159BImprove work efficiencyImprove aestheticsProtective garmentSpecial outerwear garmentsEngineeringMechanical engineering

The invention relates to a manufacturing process of composite leather clothing. The composite leather clothing made through the manufacturing process is high in tearing strength, a lining does not need to be sewn through a backend workshop, and the ready-to-wear clothing manufacturing and using efficiency is greatly improved. The manufacturing process comprises the steps of color matching, tailoring and sewing. In the sewing process, the clothing piece splicing joint positions of composite feather are cut up through a cutting machine, one face of each cutting position of the composite feather is sewn with one face of another clothing piece in a machine sewing mode, and the other face of each cutting position is sewn with the other face of another clothing piece in a hand sewing mode. In the sewing process, a thread sewing tool is used for assistance, the composite leather with leather on one face and worsted on the other face is adopted, the front and back worsted is outward, the feather on the rear piece is outward, the appearance of the clothing presents two different textures, the attention of consumers is attracted better, the lining does not need to be sewn through the backend workshop in the flow production process, and finished product sewing is automatically completed. The work efficiency of the ready-to-wear clothing can be greatly improved, meanwhile, the percent of pass of products can be greatly improved, production cost can be lowered, and the attractiveness, comfort degree, practicality and fashion degree of the ready-to-wear clothing can be improved.

Owner:ZHEJIANG NUOZHI FINERY

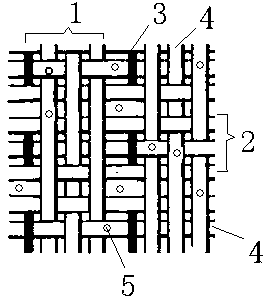

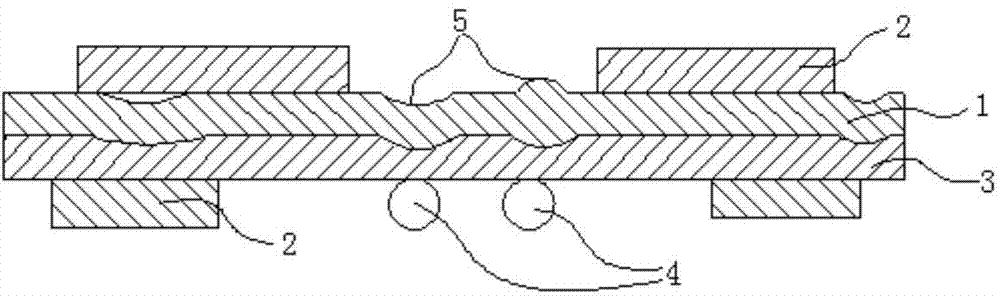

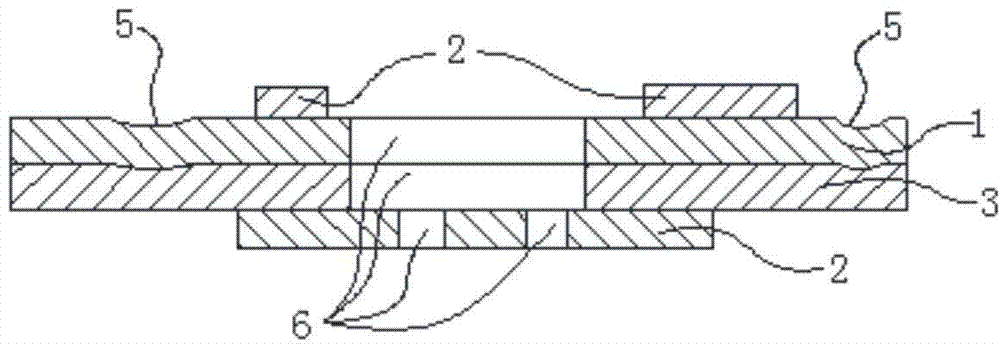

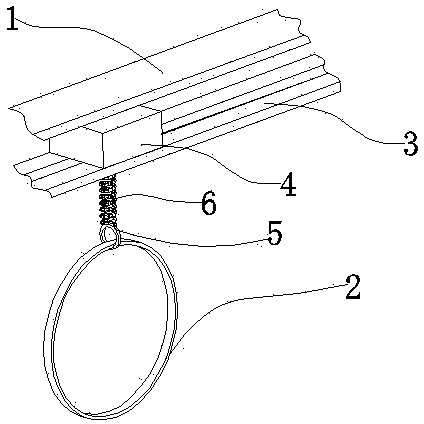

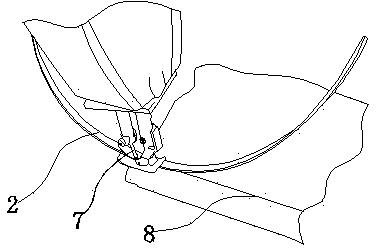

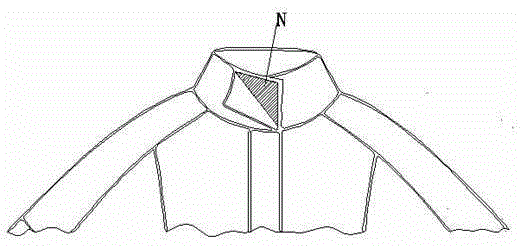

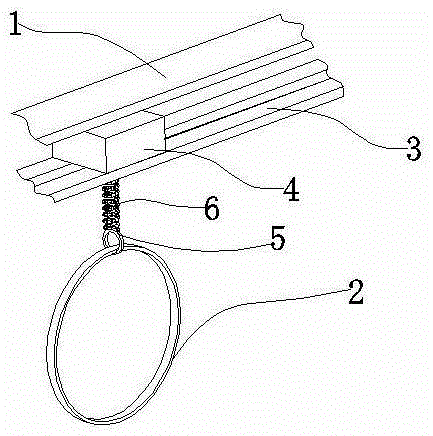

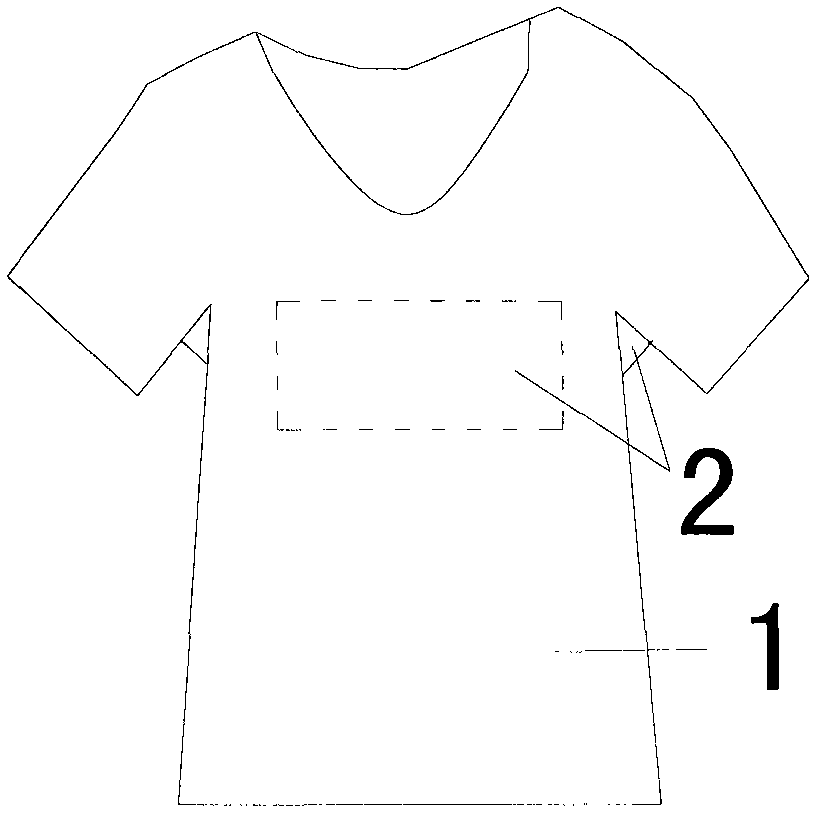

Sweat-absorbing T-shirt with crease-resist function

The invention relates to a sweat-absorbing T-shirt with a crease-resist function. The sweat-absorbing T-shirt comprises a T-shirt body (1), wherein armpit portions, the front chest portion, and the back portion of the T-shirt body (1) are all provided with sweat-absorbing cloth (2), the sweat-absorbing cloth (2) is arranged on the inner layer of the T-shirt body (1) and is made of a bamboo and jute fiber blended yarn knitted fabric, the fabric is sewn to form the T-shirt body (1), and a polyurethane (PU) resin layer is coated on the outer surface of the fabric. Due to the fact that the armpit portions, the front chest portion, and the back portion of the T-shirt body (1) are all provided with the sweat-absorbing cloth (2), sweat can be effectively absorbed, people feel comfortable to wear the T-shirt, and the T-shirt has the crease-resist function.

Owner:陈国银

Polyester reflection film as well as preparation method and application thereof

ActiveCN108773141ALow densityImprove reflectivitySynthetic resin layered productsPhotovoltaic energy generationPolyesterPolyethylene terephthalate glycol

The invention discloses a polyester reflection film. The polyester reflection film is of an AB double-layered film structure or an ABA three-layered film structure, wherein an A-layer film is preparedfrom the following components in parts by mass through mixing: 40 to 68 parts of polyethylene terephthalate, 7 to 35 parts of titanium dioxide master batch, 10 to 25 parts of barium sulfate master batch and 1 to 3 parts of organic silicon particle master batch; a B-layer film is prepared from the following components in parts by mass through mixing: 65 to 90 parts of the polyethylene terephthalate, 2 to 20 parts of the titanium dioxide master batch and 3 to 15 parts of the organic silicon particle master batch. The polyester reflection film is a white polyester reflection film and has the advantages of low density, high reflectivity, good stiffness and strong wrinkle resistance; the thickness of a thin film is greater than 50mum and less than 500mum and the density is 0.9 to 1.2g / cm<3>; the thin film can be suitable for requirements of a reflection film for a large-size liquid crystal display device on the flatness and he stiffness. High-temperature-resisting organic silicon particlescan be added into the polyester reflection film (a middle layer) to realize micro-foaming of a polyester thin film; the film can be stably formed and the preparation cost is low.

Owner:安徽思瑞盟新材料有限公司

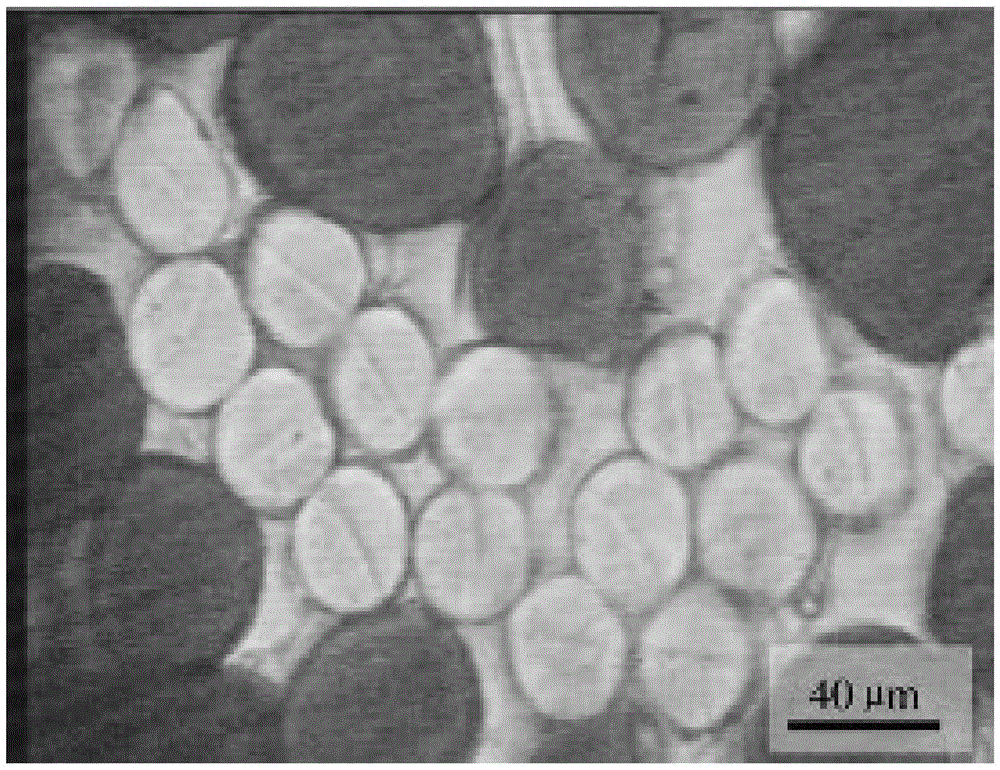

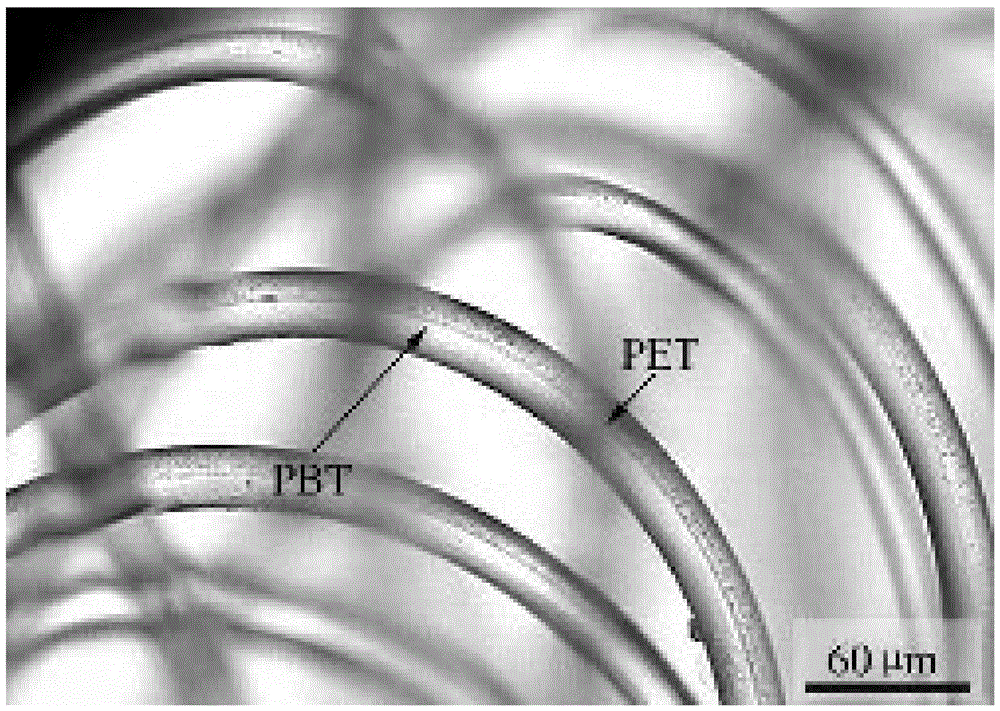

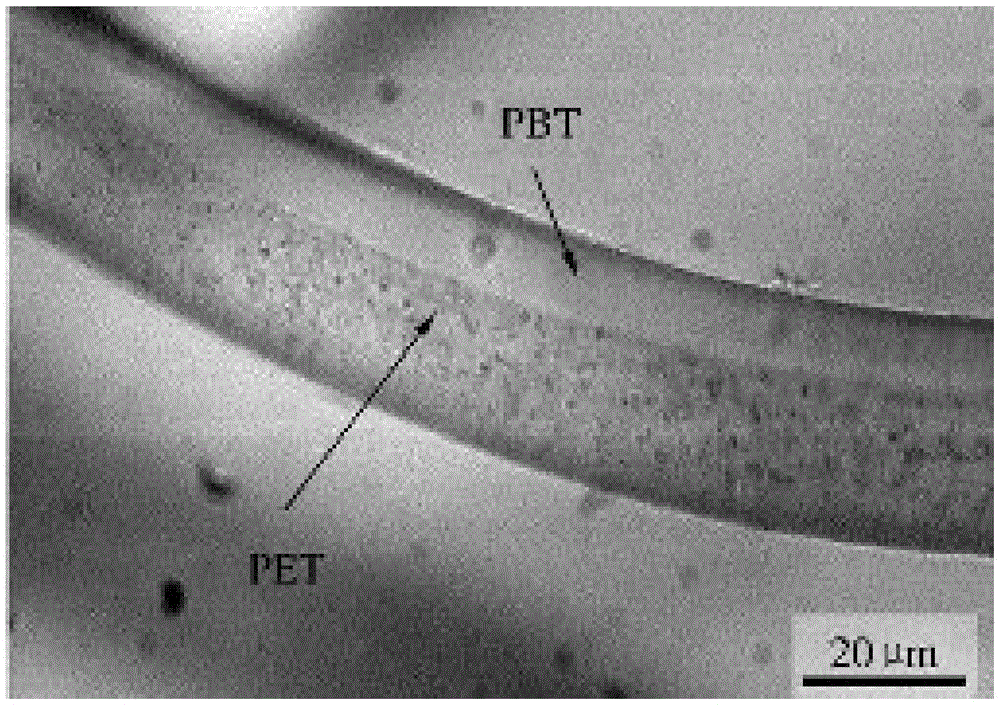

PBT-PET (Polybutylece Terephthalate-Polyethylene Terephthalate) composite elastic fibers and preparation method of PBT-PET composite elastic fibers

InactiveCN105603574APermanent three-dimensional curlIncrease elasticityArtificial filament heat treatmentConjugated synthetic polymer artificial filamentsPolytetramethylene terephthalatePolyethylene terephthalate glycol

The invention discloses PBT-PET (Polybutylece Terephthalate-Polyethylene Terephthalate) composite elastic fibers and a preparation method of the PBT-PET composite elastic fibers. A polybutylene terephthalate and polyethylene terephthalate composite material is fused and then is compounded and spun into a spring shape, and a cross section thereof is in a round structure, wherein a PET component is distributed at the outer side of a spiral and a PBT component is distributed at the inner side of the spiral; the content ratio of the PET to the PBT is (3 to 7):(7 to 3). The PBT-PET composite elastic fibers have the following beneficial effects that (1) the PBT is used for replacing original PTT (Polytrimethylene Terephthalate) and PET composite spinning and a monofilament breaking problem of T-400 fibers in a warp-wise spinning process is solved; (2) the fibers have the advantages of high rebound resilience, good stability, soft fabric, good drapability, flat cloth surface, strong crease resistance, moisture adsorption and quick drying, smooth hand feeling, stable size, no need of ironing and easiness of being cared; (3) the PBT-PET composite elastic fibers can be used for independently and purely weaving and also can be interwoven with cotton, sticky fibers, dacron, chinlon and the like. Textiles of the PBT-PET composite elastic fibers can be widely applied to fabrics of trousers and skirts, sports wear, stockings, jean fabrics, underwear, top-grade woman dresses and the like.

Owner:WUJIANG JIALI ADVANCED FIBER CO LTD

One-way moisture absorbent shirt fabric used in winter and processing technology thereof

InactiveCN110241498AImprove dehumidification effectStrong wrinkle resistanceMulti-ply fabricsPolyesterYarn

The invention discloses a one-way moisture absorbent shirt fabric used in winter and a processing technique thereof and relates to the technical field of textiles. The shirt fabric is a double-layer fabric, a surface layer is formed by core-spun yarns of 60S pure cotton-coated polypropylene fiber 20D filaments and 60S pure cotton / polyester fiber (65 / 35) strands, an inner layer is formed by 150DDTY polyester fiber filaments, and the gram weight of a finished product is about 145g / m<2>. The specific processing technique comprises the following steps: (1) raw material selection, (2) blowing, (3) cotton carding, (4) drawing, (5) roving, (6) yarn spinning, (7) core-spun yarn making, (8) making of polyester fiber-cotton blended yarns, (9) spooling, (10) doubling, (11) yarn twisting, (12) warping, (13) slashing, (14) weaving, (15) dyeing and finishing and (16) roll formation. The shirt fabric made by the processing technique has the advantages of good moisture absorption, good moisture wicking property, strong crease resistance, good elasticity, difficult deformation, stiffness and smoothness, good style retention and good comfort and is suitable for large-scale popularization.

Owner:JIHUA 3542 TEXTILE CO LTD

Water lily flower extract as well as preparation method and application thereof

ActiveCN114469814AQuality improvementImprove qualityCosmetic preparationsToilet preparationsBiotechnologyOrganosolv

The invention discloses a water lily flower extract as well as a preparation method and application thereof, and belongs to the technical field of plant extraction. The preparation method comprises the following steps: (1) adding a dried nymphaea tetragona flower product into an organic solvent aqueous solution with the volume ratio of 50%-90% according to the solid-liquid ratio of 1g: 20mL-60mL, extracting at the temperature of 20-65 DEG C, and separating to obtain an extracting solution; and (2) adjusting the pH value of the extract to 7-9, then removing the organic solvent, and drying to obtain the nymphaea candida presl extract. By means of the technology, efficient enrichment and extraction of skincare functional components in the nymphaea candida presl are achieved, and the content of main components ellagic acid and isoquercitrin in the extract is relatively high. The extract has strong oxidation resistance and wrinkle resistance, and has great application prospects in the fields of cosmetics, food, medical products and the like.

Owner:ZHEJIANG UNIV +1

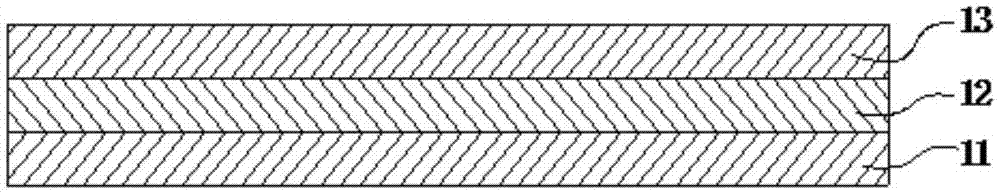

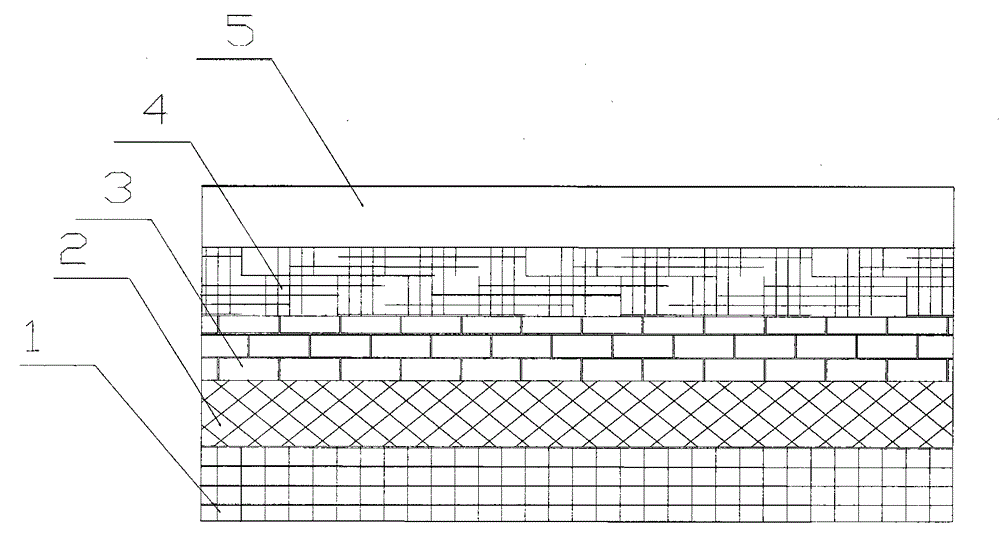

Waterproof, antibacterial, warming, elastic and durable fabric

InactiveCN105882057AGood thermal effectGood waterproof effectSynthetic resin layered productsWoven fabricsAnti wrinkleAntibacterial effect

The invention relates to a waterproof, antibacterial, warming, elastic and durable fabric, which comprises a basic layer (1), an inner layer (2), a fabric layer (3), and an outer layer (4) from inner to outer. The basic layer (1) is prepared by weaving warps and wefts together. The warps and wefts are prepared by weaving nano silver fibers. The inner layer (2) is used for keeping warm. The outer layer (4) and the fabric layer (3) are laminated together, the outer layer (4) is made of a windproof, waterproof, and breathable membrane, and the fabric layer (3) is made of fabrics. The fabric is prepared by weaving wefts and warps up and down, the warps are made of non-elastic filaments, the wefts are made of elastic filaments, the wefts comprises first wefts and second wefts, the first wefts and second wefts are laminated on each other, and the wefts, first wefts, second wefts are weaved up and down to form a five dual-layer tissue structure. The provided fabric can improve the antibacterial effect, and has a durable elasticity, and a very strong anti-wrinkle effect.

Owner:王世杰

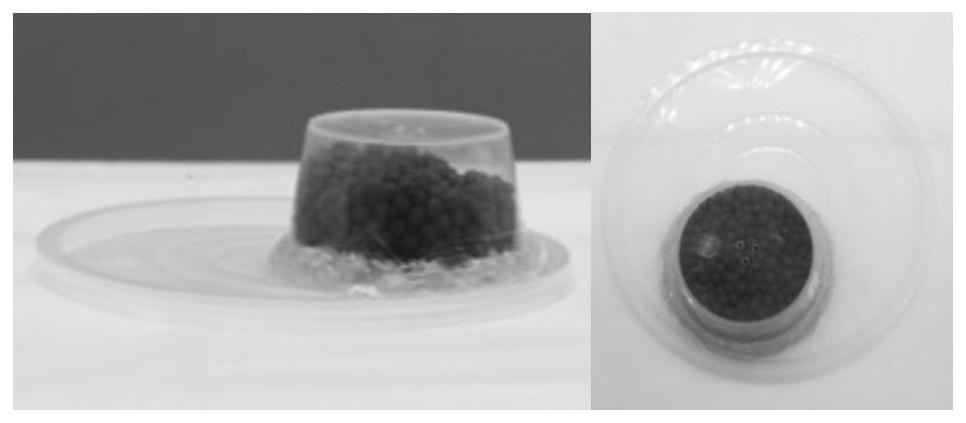

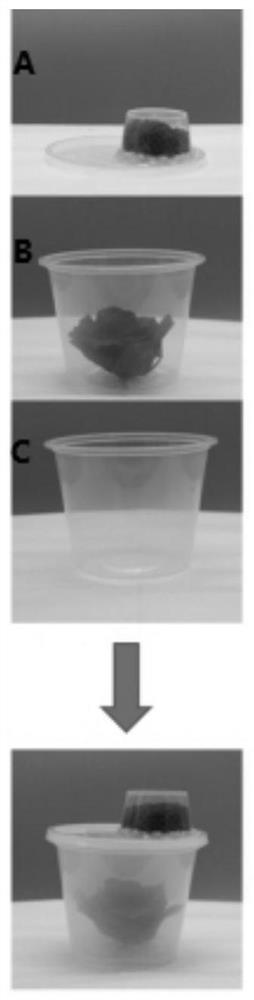

Epidermal stem cell in-vitro culture kit and application thereof

PendingCN114164164AImprove sticking rateImprove conversion efficiencyEpidermal cells/skin cellsArtificial cell constructsStem cell cultureBiochemistry

The invention provides an epidermal stem cell in-vitro culture kit and application thereof. The epidermal stem cell in-vitro culture kit comprises an adherence-promoting culture medium and a transformation-promoting culture medium, the adherence promoting culture medium comprises a stem cell culture medium, a cell culture supplement, fetal calf serum, adherence promoting cell factors and IL-3, and the concentration of IL-3 is 80-120 ng / mL; the transformation-promoting culture medium comprises a stem cell culture medium, a cell culture supplement, a transformation-promoting cell factor, fibronectin and IL-3, and the concentration of IL-3 is 40-80 ng / mL. The invention also provides an epidermal stem cell in-vitro culture method, an epidermal stem cell and an anti-wrinkle injection. The optimized culture medium is matched with the culture method, a large number of epidermal stem cells with high purity can be rapidly obtained, and the epidermal stem cells serving as components of the anti-wrinkle injection are obvious in effect and high in value.

Owner:深圳市申友健康管理有限公司

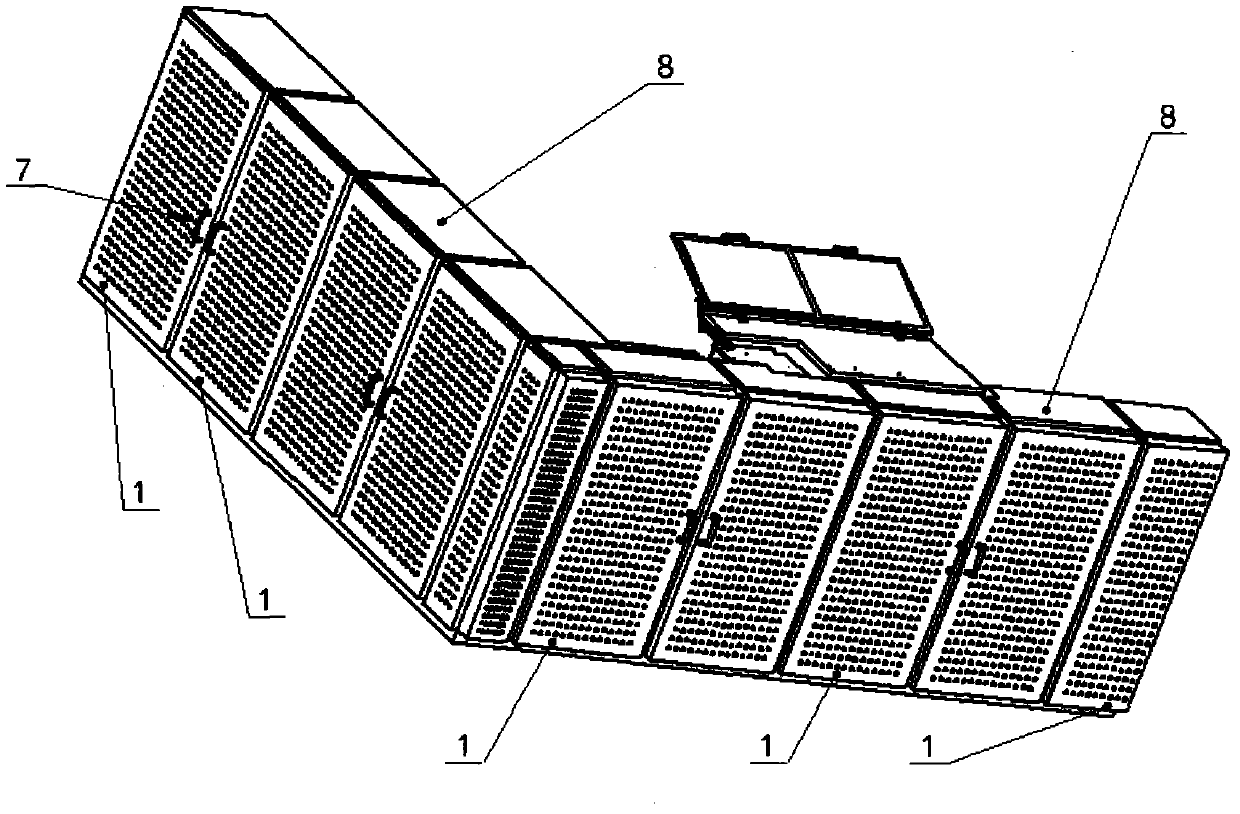

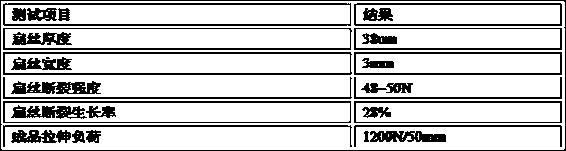

Wrinkle proof film laminated woven bag

The invention discloses a wrinkle proof film laminated woven bag and relates to the technical field of plastic woven bags. All raw material components are mixed according to weight part ratio, and then are subject to drying treatment at the temperature of 90 to 100 DEG C; the raw materials comprise polypropylene, modified filling masterbatches and a reinforcing agent; in the raw materials, the polypropylene adopts the polypropylene with the melt index of 3g / 10min and the isotacticity of 94 to 96 percent, the modified filling masterbatches are made of calcium carbonate with the fineness of 400meshes, and the reinforcing agent adopts the special masterbatches used for increasing intensify and enhancing rigidity, which is heat-resistant and stable in dimension; the wrinkle proof film laminated woven bag has the advantages that the flat filament thickness is enven, the shrinkage ratio is low, warps and wefts in circular woven cloth are prevented from folding, marriages and chromatic aberration are avoided, the fastness in film lamination is excellent, a composite layer is even, bubbles and wrinkles are avoided, the entire thickness is small, and the tensile strength is strong.

Owner:GUANGDONG WEIFU PACKAGING MATERIAL

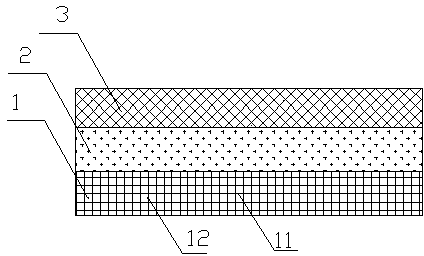

Anti-radiation and antibacterial fabric with lasting elasticity

InactiveCN104339777AImprove radiation protection performanceImprove the protective effectClothingsMetal layered productsFiberYarn

The invention relates to an anti-radiation and antibacterial fabric with lasting elasticity. The fabric comprises a base layer (1), wherein the base layer (1) is formed by connecting warps (11) with wefts (12); the warps (11) and the wefts (12) are formed by spinning nano-silver fibers; an aluminium alloy film (2) is bonded on the upper surface of the base layer (1); an antistatic layer (3) is arranged on the aluminium alloy film; the base layer is made from a fabric; the fabric is formed by interweaving warps and wefts up and down; the warps are unelastic yarns; the wefts are elastic yarns; the wefts comprise first wefts and second wefts; the first and second wefts are overlapping wefts of each other; the warps and the first and second wefts are interwoven with each other up and down to form a single backed weave structure. The fabric can shield radiation and can effectively inhibit occurrence of the phenomenon of electrostatic discharge; the adopted fabric has lasting elasticity and has especially strong anti-wrinkle effects.

Owner:JIANGYIN ZEWAN TRADE

Placenta freeze-dried powder smearing facial mask and preparation method thereof

InactiveCN112190532AGood moisturizing effectPowerful whiteningCosmetic preparationsAntipyreticCosmos bipinnatusUmbilical cord

The invention discloses a placenta freeze-dried powder smearing facial mask and a preparation method thereof, and belongs to the technical field of cosmetics. The placenta freeze-dried powder smearingfacial mask comprises powder and solvent, wherein the powder and the solvent are calculated at a mass ratio of 2-3:10-20; the powder comprises the following ingredients in parts by weight: 50 parts of placenta freeze-dried powder, 20 parts of Cosmos bipinnata Cav. powder and 5 parts of green tea powder; and the solvent comprises 250-500 parts by weight of umbilical cord blood NK cell culture supernate. The smearing facial mask disclosed by the invention takes natural ingredients as raw materials, all ingredients are synergistically cooperated, and therefore, the smearing facial mask has efficacy of inhibiting bacteria, diminishing inflammation, preserving moisture, whitening and resisting senility, can be used for improving the state of the skin, is safe and convenient and is suitable forall skin types.

Owner:广州瑞铂茵健康科技有限公司

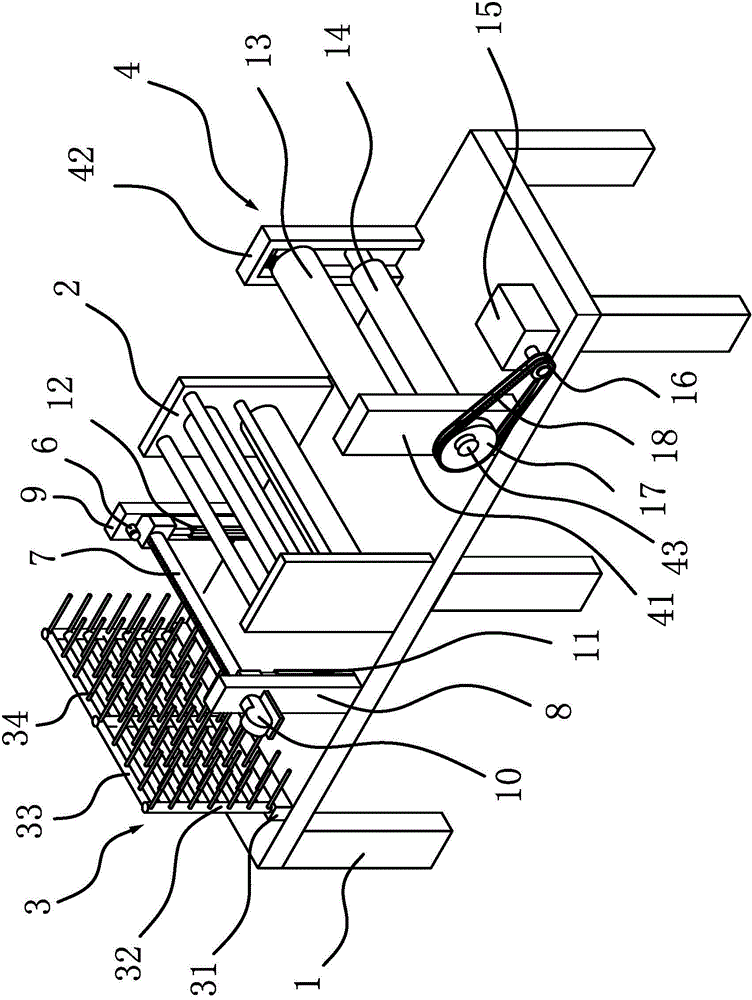

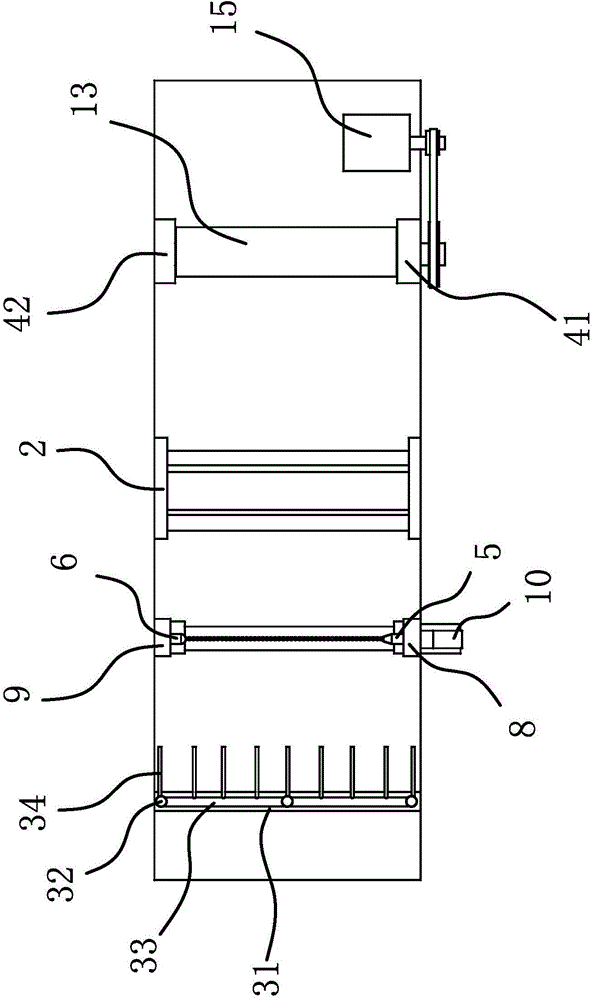

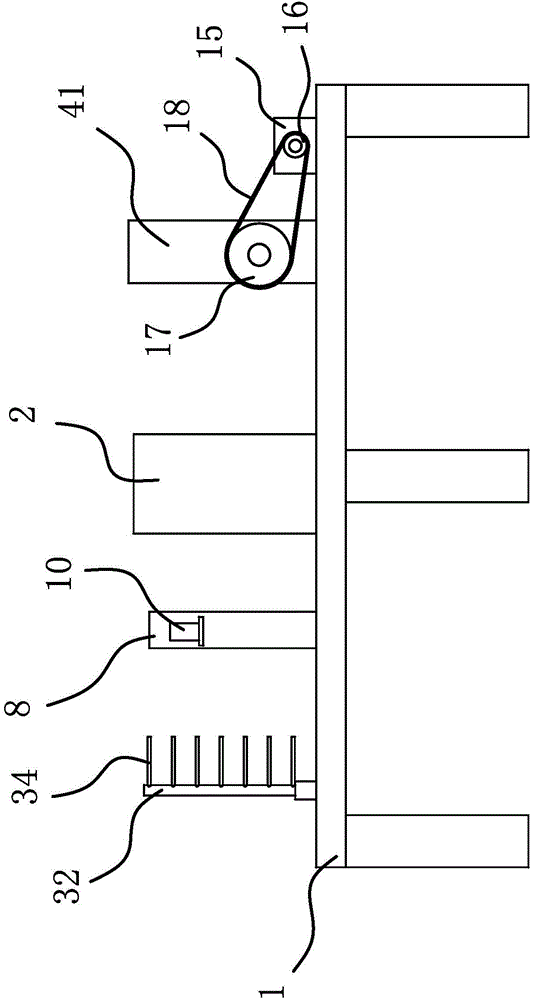

Jacquard sofa fabric and processing equipment thereof

ActiveCN104957904AGood elasticityStrong wrinkle resistanceWarp knittingSynthetic resin layered productsPolyesterCotton cloth

The invention provides jacquard sofa fabric and processing equipment thereof and belongs to the technical field of sofa fabric. By adoption of the jacquard sofa fabric, the problems of poor elasticity, weak wrinkle resistance and poor permeability and the like of the sofa fabric in the prior are solved. The jacquard sofa fabric comprises a protective layer, a jacquard layer and a cotton-cloth base layer which are connected by an adhesive. The jacquard sofa fabric is characterized in that the protective layer is made of artificial leather; the cotton-cloth base layer is made of natural silks; the jacquard layer is formed by mutual interweaving of radial yarns and weft yarns, and the radial yarns are vertical to the weft yarns; the radial yarns are plant fibers or silks, and the weft yarns are ramie, bamboo fiber or polyester fiber. The jacquard sofa fabric provided by the invention has the advantages of good elasticity, strong wrinkling resistance and good permeability and the like.

Owner:桐乡市凤凰纺织股份有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com