Wrinkle proof film laminated woven bag

A woven bag and film coating technology, applied in the field of plastic woven bags, can solve problems such as wrinkles and unsightly appearance, and achieve the effects of good fastness, strong anti-wrinkle performance and strong tensile strength.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] An anti-wrinkle film-coated woven bag is prepared by the following steps:

[0028] (1) The components of the raw materials are measured in parts by weight, and after mixing, they are dried at 90-100°C. The raw materials include polypropylene, modified filler masterbatch, and reinforcing agent; the polypropylene in the raw materials is molten Polypropylene with an index of 3g / 10min and an isotacticity of 94-96%, the modified filler masterbatch is calcium carbonate with a fineness of 400 mesh, and the reinforcing agent is a heat-resistant-dimensionally stable reinforced polypropylene masterbatch; step (1 ) The components of the raw materials are 100 parts of polypropylene, 40 parts of modified filler masterbatch and 15 parts of reinforcing agent in parts by weight.

[0029] (2) Put the dried raw materials into an extruder to extrude to form a film. The temperature of the feeding section of the extruder is controlled at 190~200°C, the temperature of the compression section...

Embodiment 2

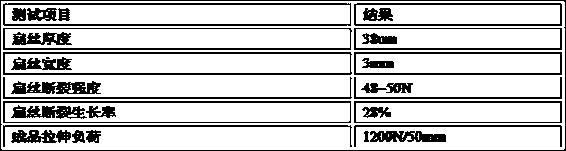

[0038] The physical property test result of the flat wire and finished product that above-mentioned embodiment 1 method makes is as follows:

[0039]

[0040] This test proves that the finished product formed by the present invention has thin thickness and strong tensile properties.

Embodiment 3

[0042] Functional Results Test:

[0043] A kind of anti-wrinkle film-coated woven bag made by the method of the above embodiment 1 and the common woven bag fabric are carried out by a crease recovery performance tester to detect its crease recovery performance, and the comparison results are as follows,

[0044] Test items

warp wrinkle recovery angle

Weft wrinkle recovery angle

Example 1

86

90

Ordinary woven bag

19

15

[0045] The wrinkle recovery angle of Example 1 is obviously larger than that of ordinary woven bags.

[0046] This test proves that the finished product formed by the present invention has obvious anti-wrinkle performance.

PUM

| Property | Measurement | Unit |

|---|---|---|

| surface smoothness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| melt flow index | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com