PBT-PET (Polybutylece Terephthalate-Polyethylene Terephthalate) composite elastic fibers and preparation method of PBT-PET composite elastic fibers

A technology of elastic fibers and composite materials, applied in fiber processing, stretch spinning, conjugated synthetic polymer artificial filaments, etc., can solve the limitations of the use range and development prospects of T-400 fibers, T-400 spinning production The situation is not stable, PTT component instability and other problems, to achieve the effect of smooth hand feeling, stable size and good stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0023] The technical characteristics of the present invention will be further elaborated below in conjunction with specific embodiments.

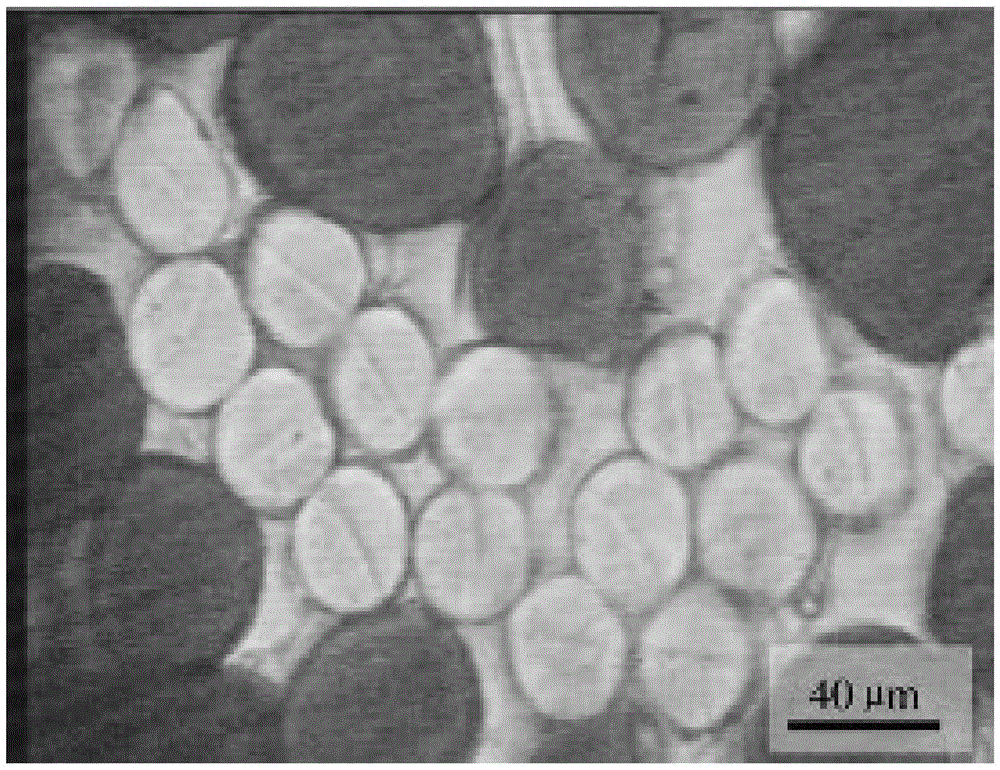

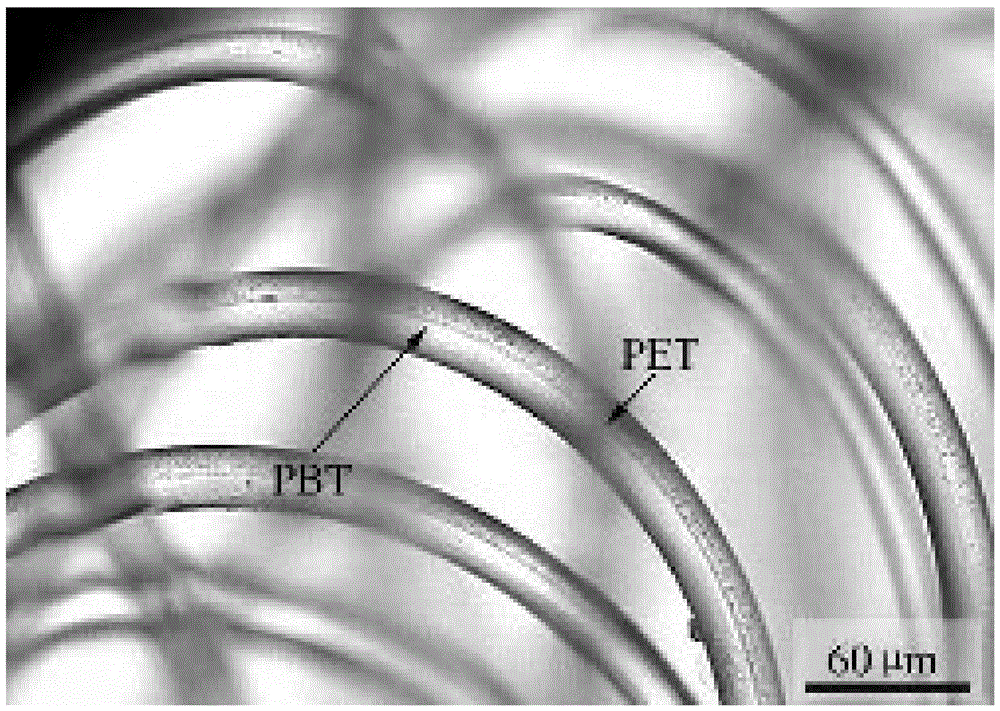

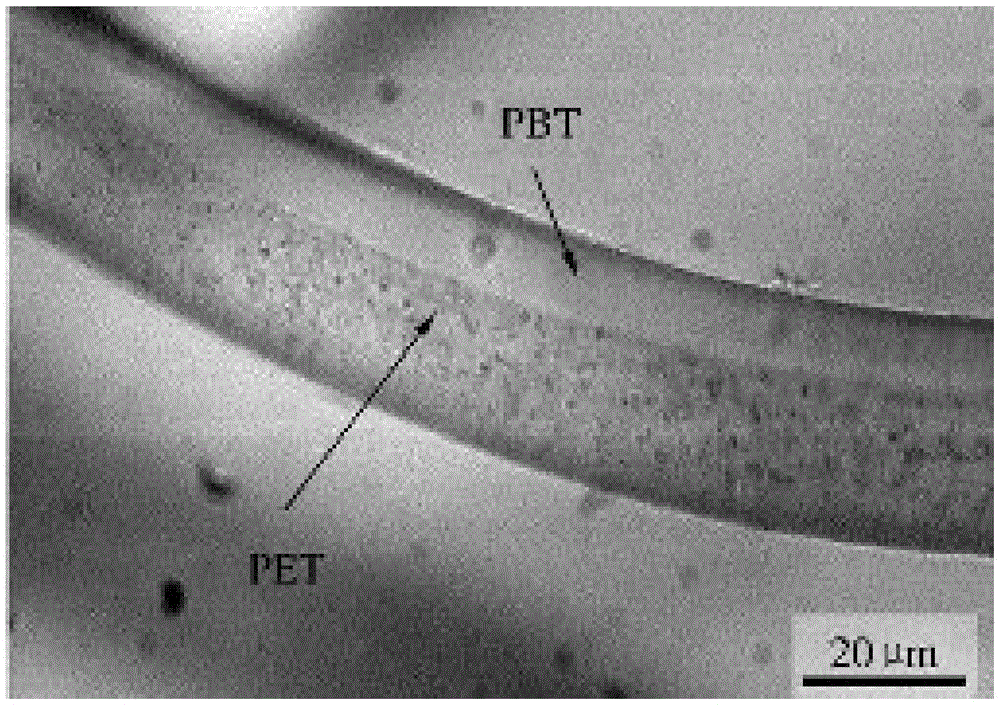

[0024] Such as figure 1 , figure 2 and image 3 As shown, a PBT-PET composite elastic fiber is formed by composite spinning of polybutylene terephthalate and polyethylene terephthalate composite materials after melting to form a spring shape, and its cross section is circular Shaped structure, in which the PET component is on the outside of the helix and the PBT component is on the inside of the helix.

[0025] Such as figure 1 As shown, SEM was used to observe and analyze the cross-sectional structure of the composite fiber. The cross-section of the composite fiber is approximately circular, and the two components fit well without separation marks. There are differences in mechanical properties between the two groups of components, because most of the two components have different heights , that is, the shrinkage elasticity is not goo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com