Patents

Literature

258results about "Textile solvent-dyeing" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Supercritical carbon dioxide cheese dyeing kettle and waterless supercritical carbon dioxide cheese dyeing method

ActiveCN102787459ATextile treatment containersSolvent treatment with solvent recoveryEngineeringDrill

The invention relates to a supercritical carbon dioxide cheese dyeing kettle and a waterless supercritical carbon dioxide cheese dyeing method. In the dyeing kettle, when carbon dioxide fluid enters a distribution tray from an inlet, blades start rotating clockwise under the effect of pressure; inserted drill rods are driven to rotate by a rotation part; and the rotating speed of the inserted drill rods is increased along with the increase of pressure in a cylinder body. When a cheese is dyed, the cheese on the inserted drill rods is dyed at a speed of 0.2-0.5 r / s. When the rotating cheese is dyed, the cheese is subjected to the pressure of the fluid flowing out from a central shaft; the rotation and bicirculation of the cheese dyeing are realized; the uniform dyeing effect of the dyed cheese can be improved; and the migration ability and the diffusibility can be improved.

Owner:晋江国盛新材料科技有限公司

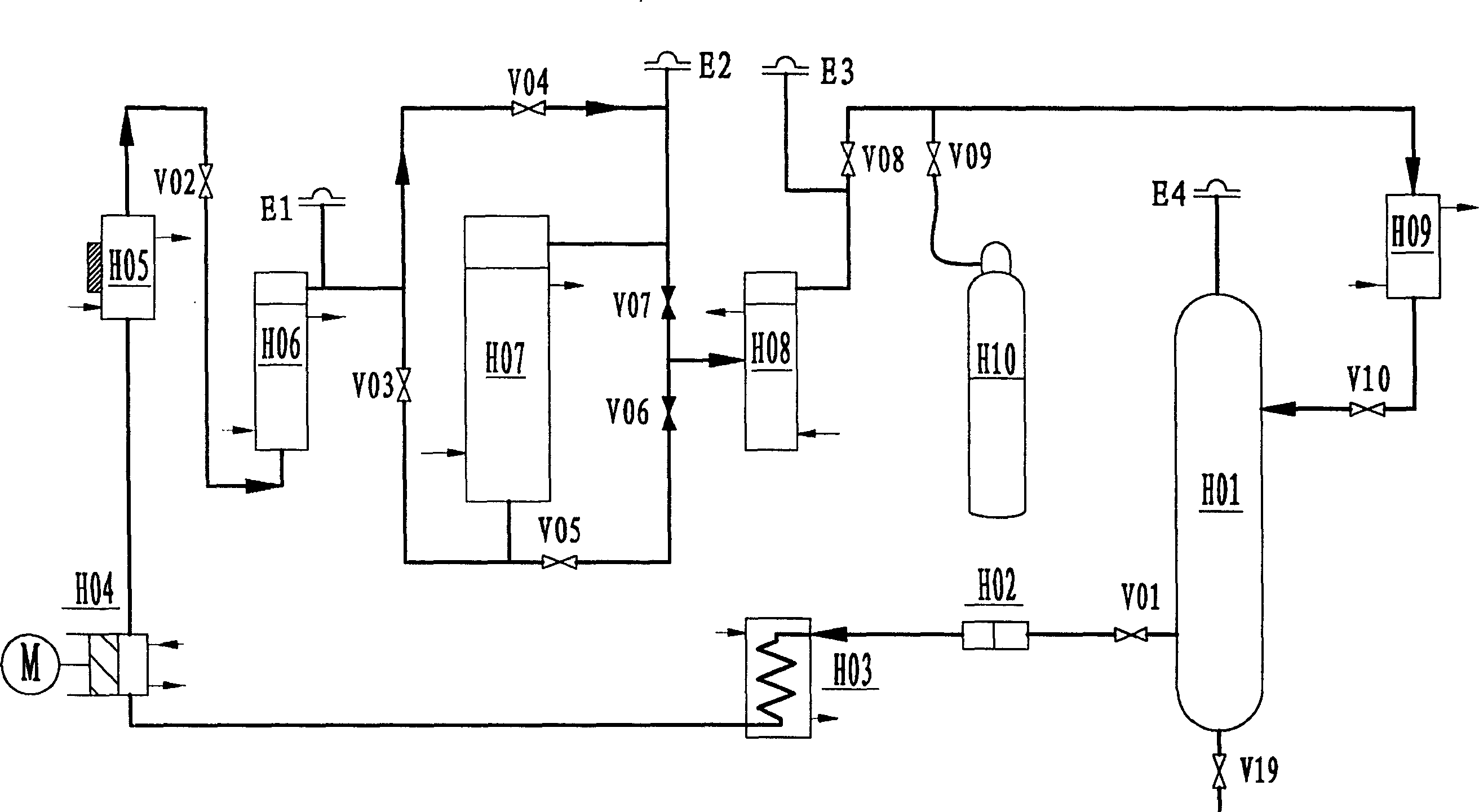

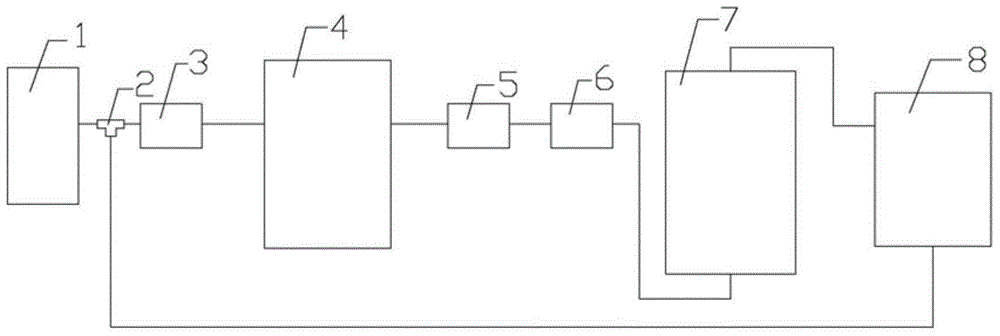

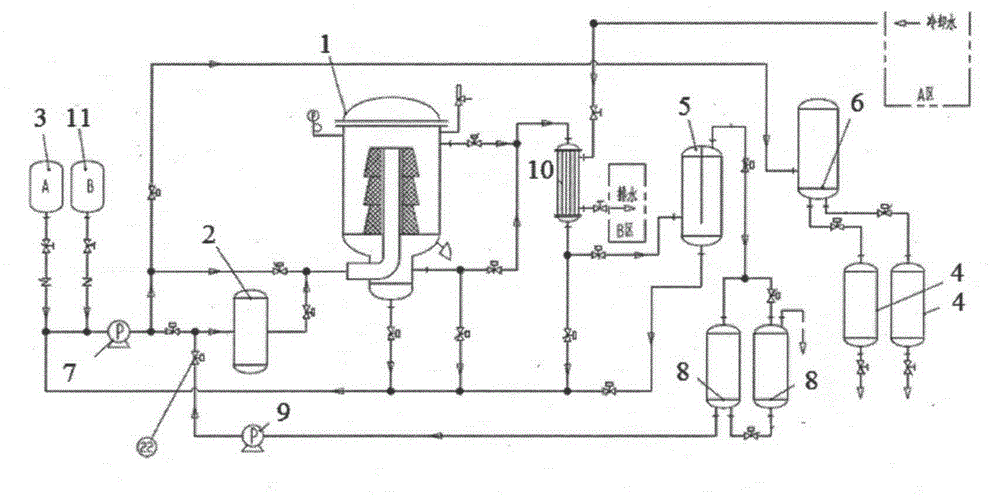

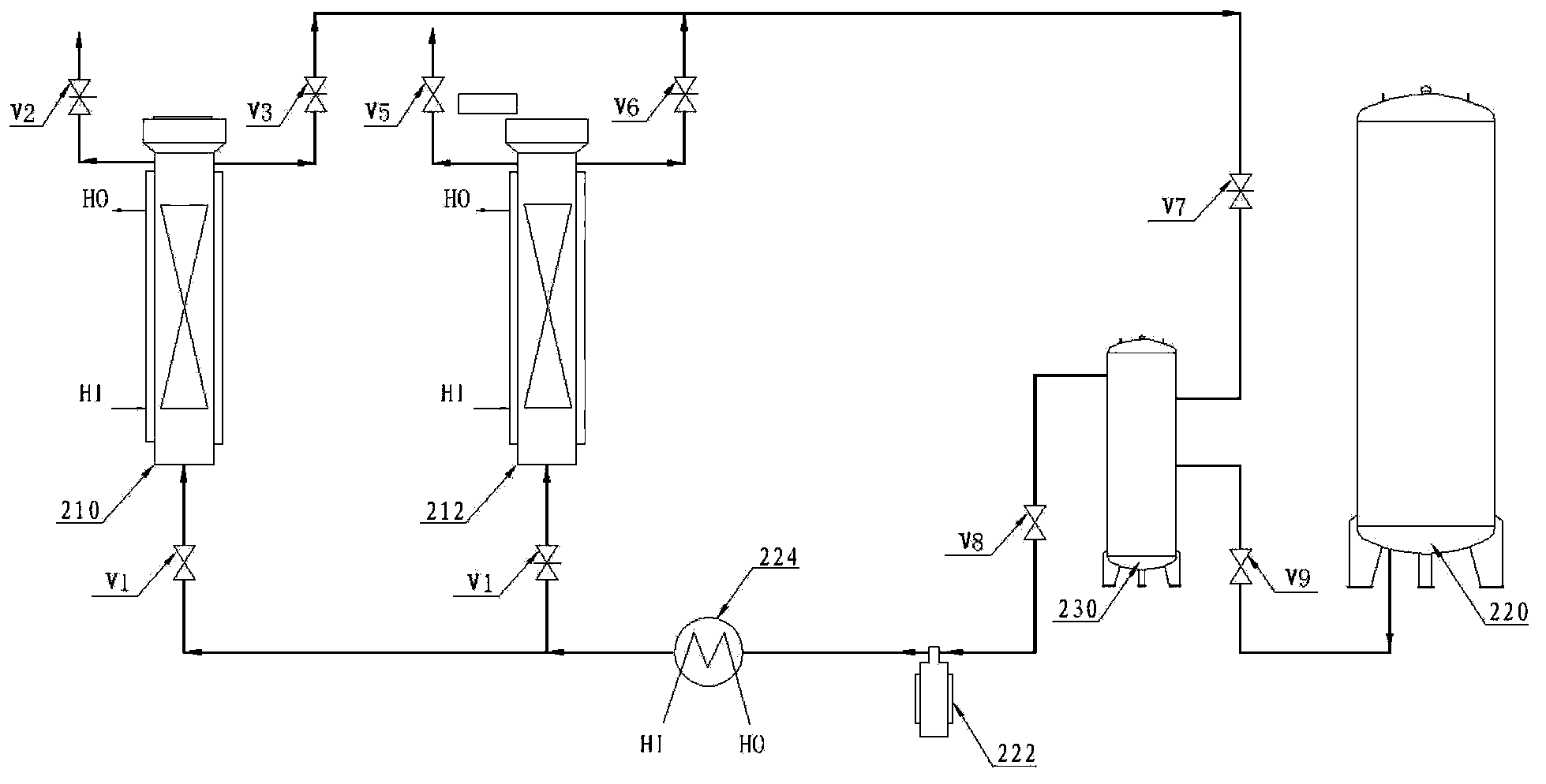

Supercritical carbon dioxide dyeing device and its process

InactiveCN1766194AReduce pollutionImprove dye uptakeSolvent treatment with solvent recoveryTextile/flexible product manufactureCo2 storageHigh pressure

The invention discloses a supercritical carbon dioxide dyeing device, which comprises mainly a CO2 storage tank (H01), a dye kettle (H06), and a dyeing kettle (H07). Wherein, the dyeing technique comprises: cooling the CO2 from HO1 into liquid to send into preheater (HO5) connected to HO6 with carbon-dioxide high-pressure pump (HO4); sending supercritical carbon dioxide to HO7 by HO6; driving the dyed carbon dioxide to pass separator (HO8) and second condenser (HO9) and return to said storage tank (HO1). This invention can recycle 100% residual dye and carbon dioxide as dyeing medium, saves water and dye resource, and reduces pollution.

Owner:DALIAN POLYTECHNIC UNIVERSITY

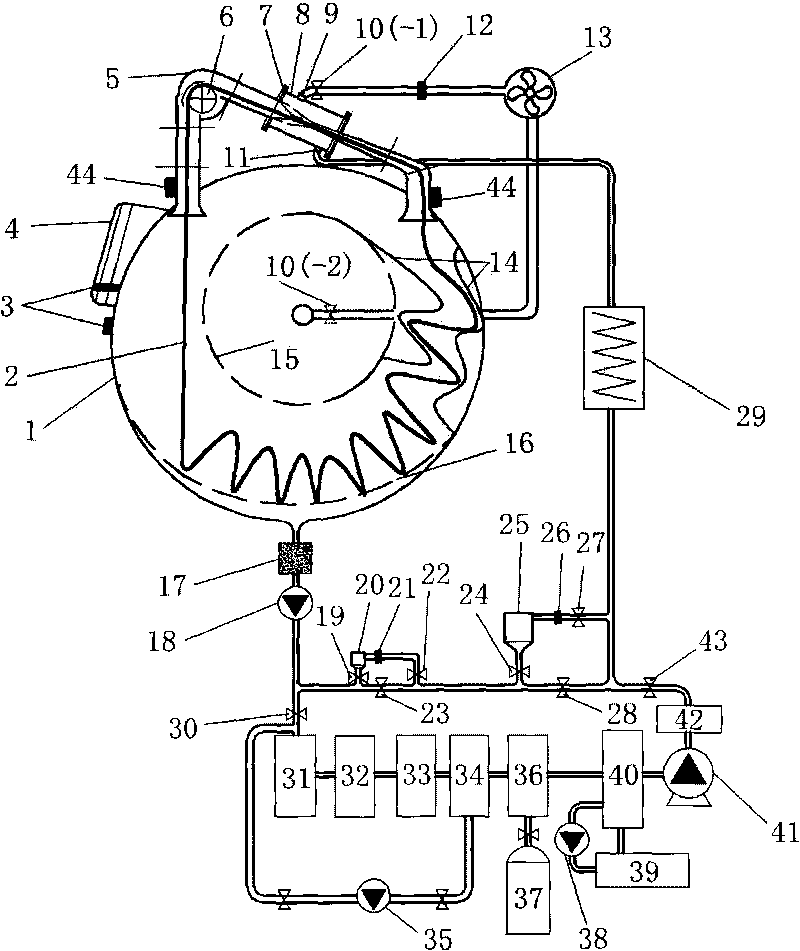

Supercritical fluid dyeing machine

ActiveCN101760914ASave powerLower average tensionTextile treatment containersLiquid/gas/vapor treatment of propelled fabricsWave shapeFree state

The invention discloses a supercritical fluid dyeing machine. A horizontal type cylindrical dyeing kettle, a magnetomotive cloth lifting wheel, a spray cavity, a wave-shaped cloth guide passage in the dyeing kettle, a heat exchanger, a dye kettle or / and an entrainer kettle and a circulating pump are used as main components to form a dyeing circulation system; and both ends of a fan are respectively connected with fluid outlets under the spray cavity and the dyeing kettle and form a cloth feeding system together with the magnetomotive cloth lifting wheel, the spray cavity and an operating opening. A rope-shaped fabric realizes circulated dyeing under the common action of the fluid in the magnetomotive cloth lifting wheel and the spray cavity, and the fluid in the dyeing kettle carries out forced circulation by the circulating pump. The dye and the fluid can realize recycling by a separating and recycling system after dyeing, and the whole dyeing circulation system and the separating and recycling system are clean to achieve the requirement during color changing and dyeing. The supercritical fluid dyeing machine can realize anhydrous dyeing processing on the fabric in a loosening type tension-free state without the production and discharge of pollutants, and has the characteristics of ecology, environmental pollution, wide adaptability of fabric variety, and the like.

Owner:SUZHOU UNIV +2

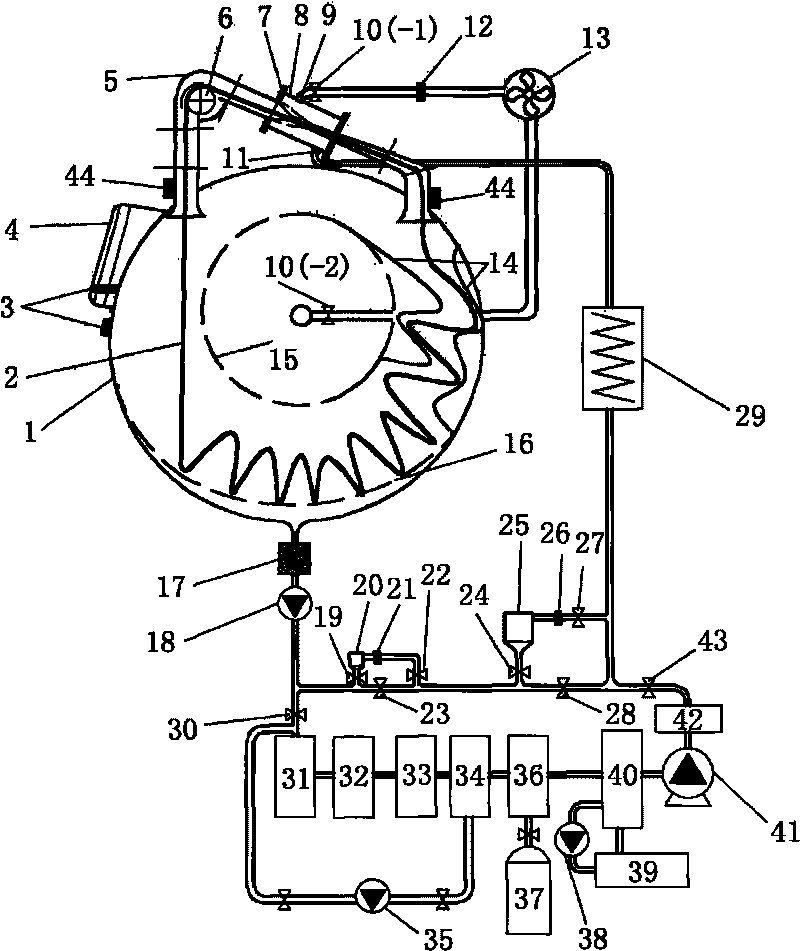

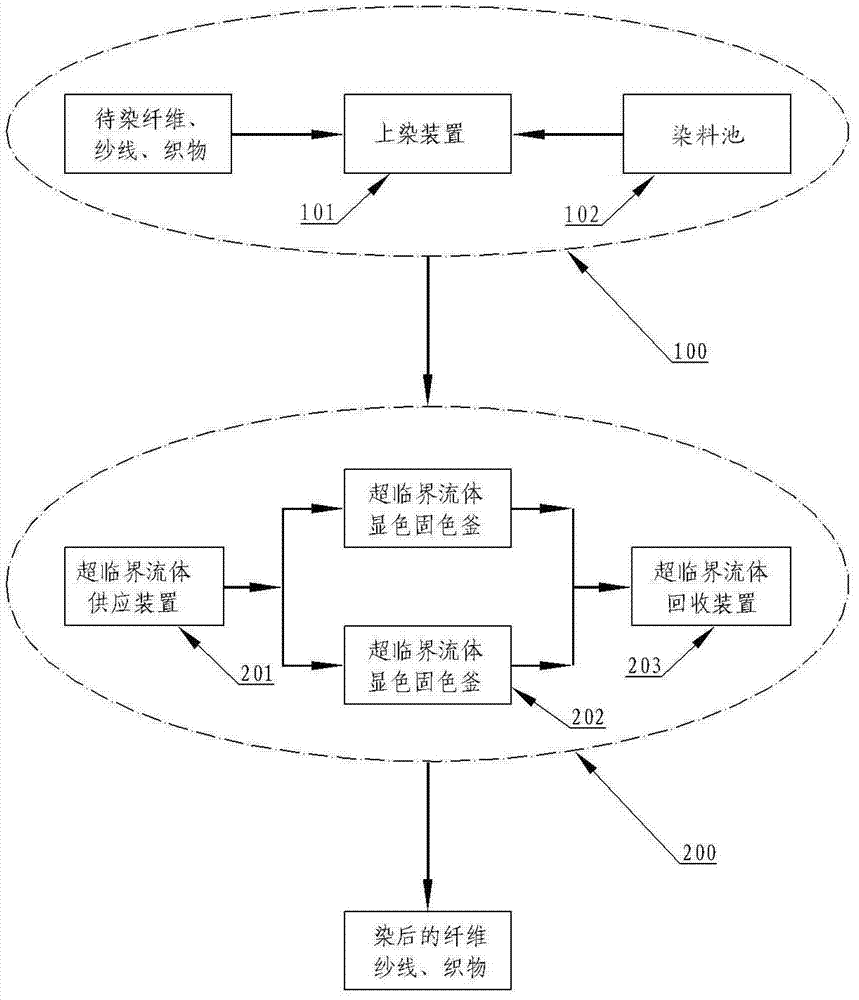

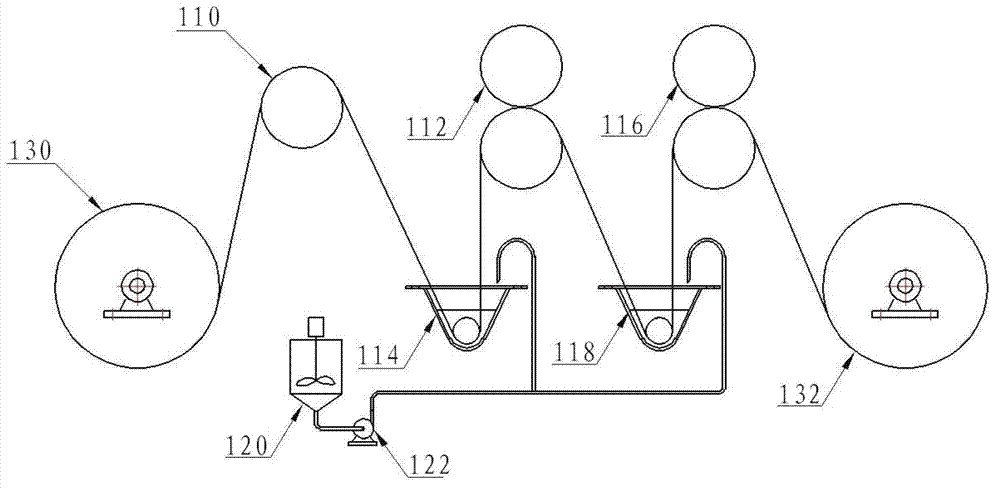

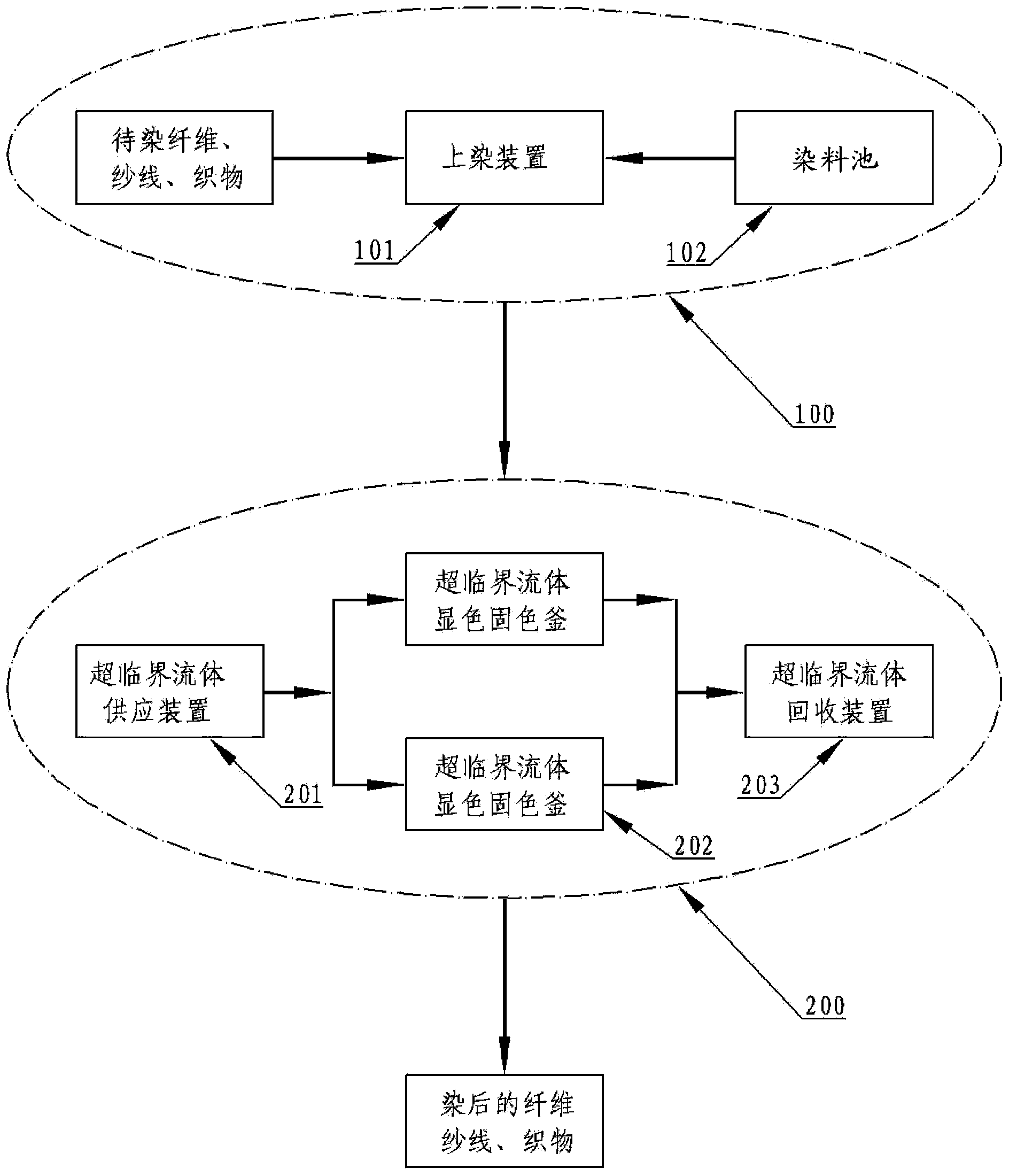

Method and device for static dyeing by adopting supercritical fluid

ActiveCN102817194AMigration does not occurSolve uncontrollable difficultiesTextile treatment containersChemical fixing of textilesSystem pressureStationary state

The invention discloses a method for static dyeing by adopting supercritical fluid. The method comprises the following steps of: (1) dyeing: placing an object to be dyed in an uptake dyeing system for uptake dyeing; (2) static developing and color fixing with the supercritical fluid: placing the dyed object to be dyed in the step (1) in a supercritical fluid developing and color fixing kettle, and adding the supercritical fluid in the supercritical fluid developing and color fixing kettle for the developing and color fixing of the object to be dyed in the static supercritical fluid; and (3) after the developing and color fixing are completed, eliminating system pressure to recover the supercritical fluid, and opening the supercritical fluid developing and color fixing kettle for taking out the object to be dyed. In the method for static dyeing by adopting supercritical fluid, the supercritical fluid is in a stationary state in the developing and color fixing process, so that the phenomenon of dye migration cannot occur, the dyeing quality is easy to control, and the dyeing system does not need to be cleaned in the replacement of the dyeing color. Meanwhile, the invention also discloses a device for realizing the method for static dyeing by adopting the supercritical fluid.

Owner:陈志刚

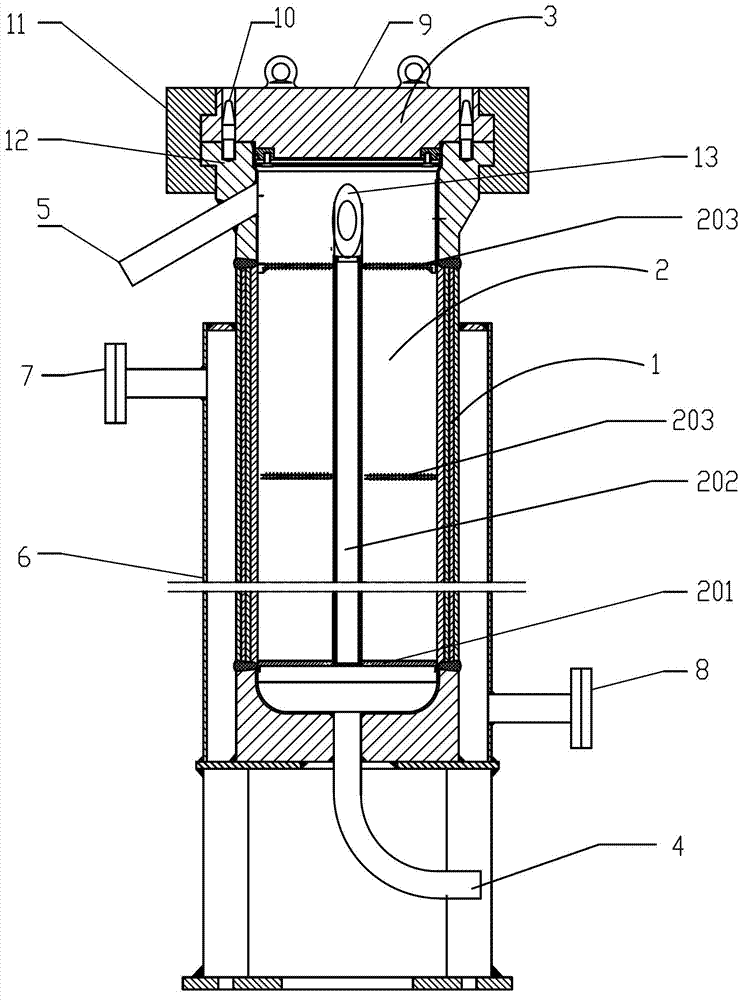

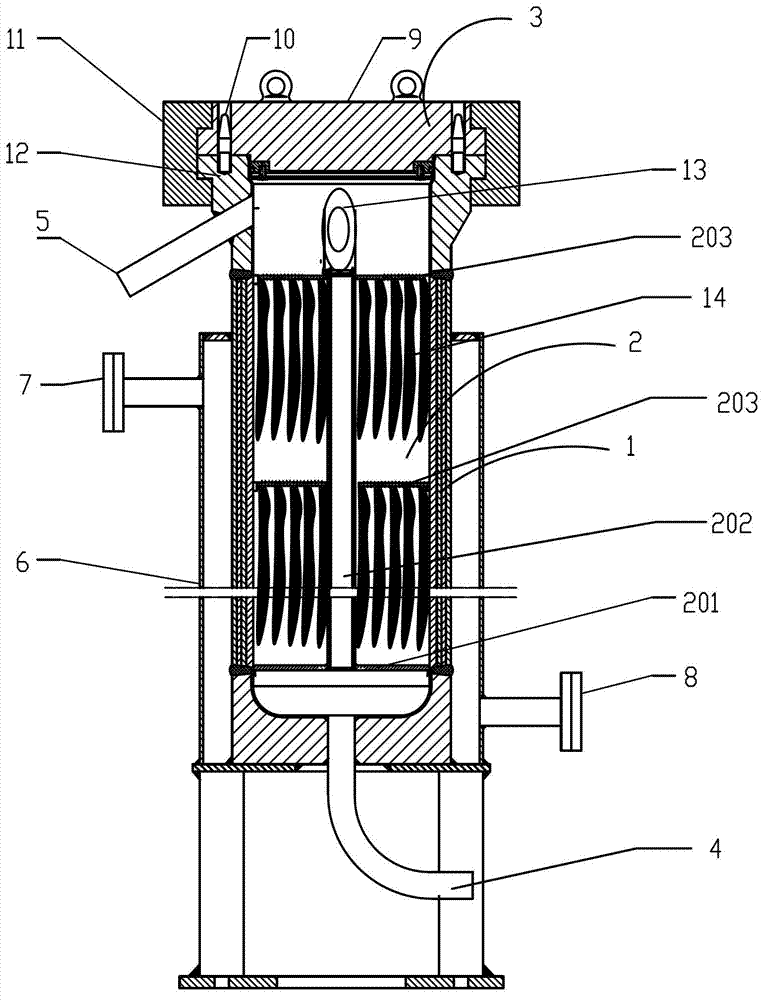

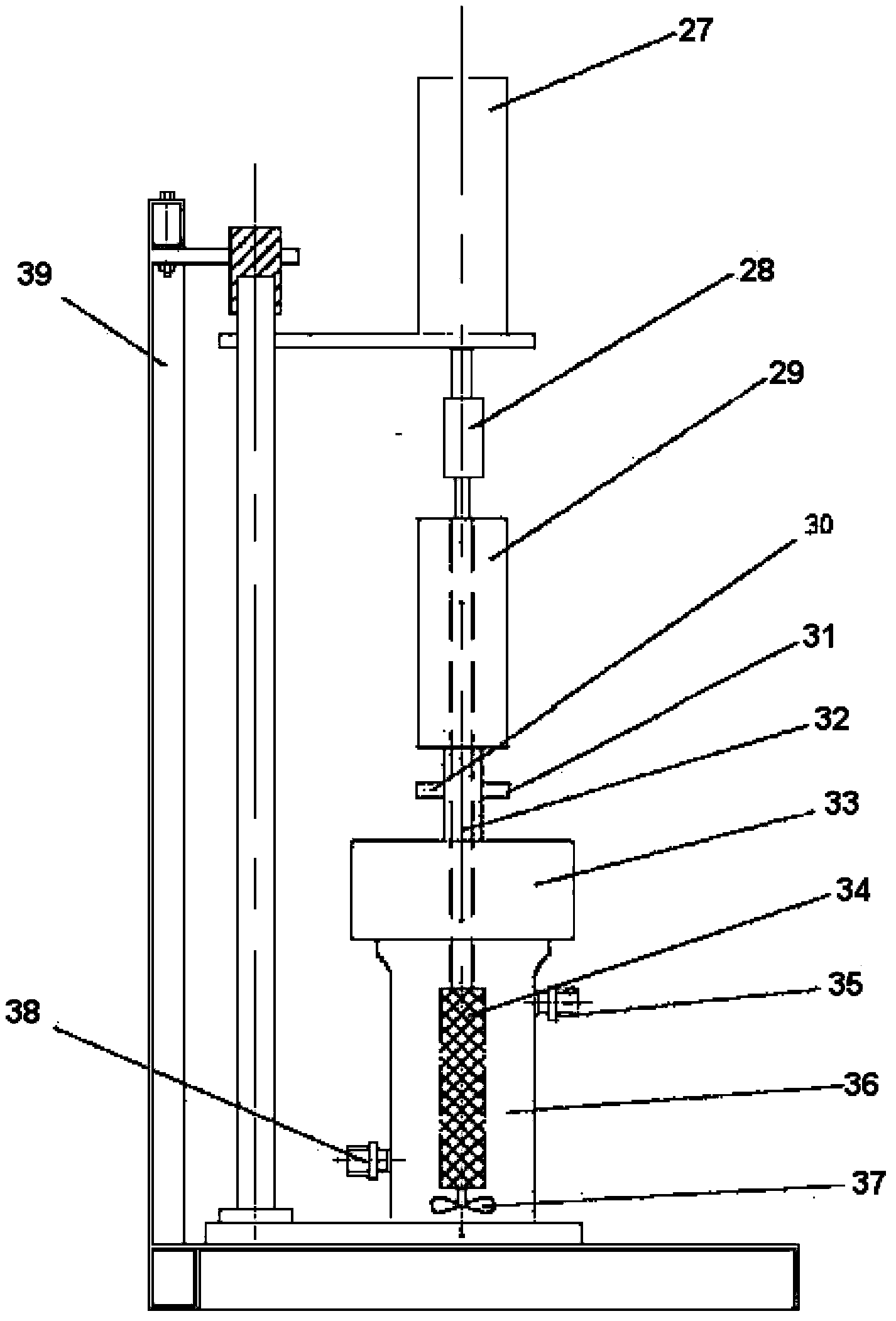

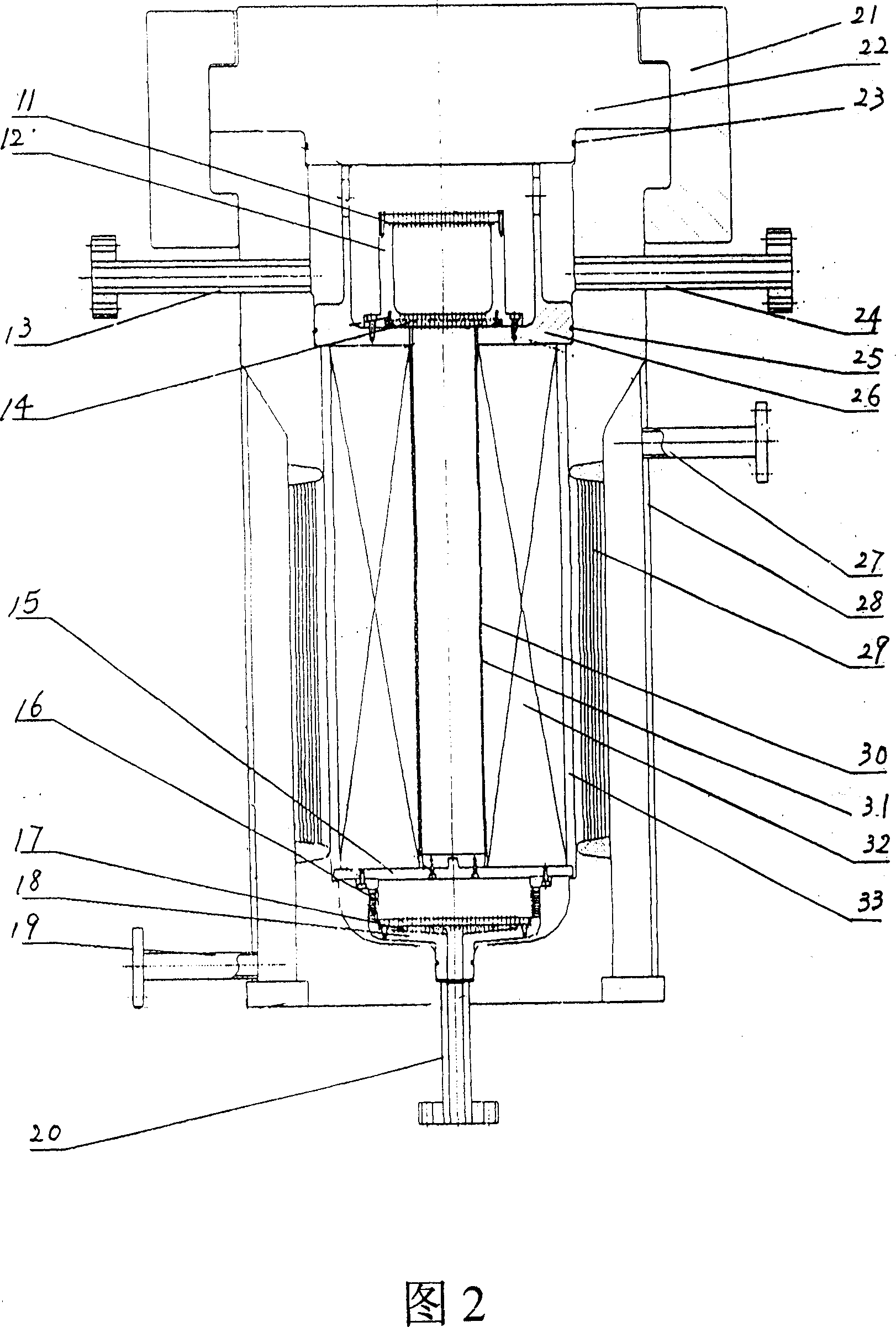

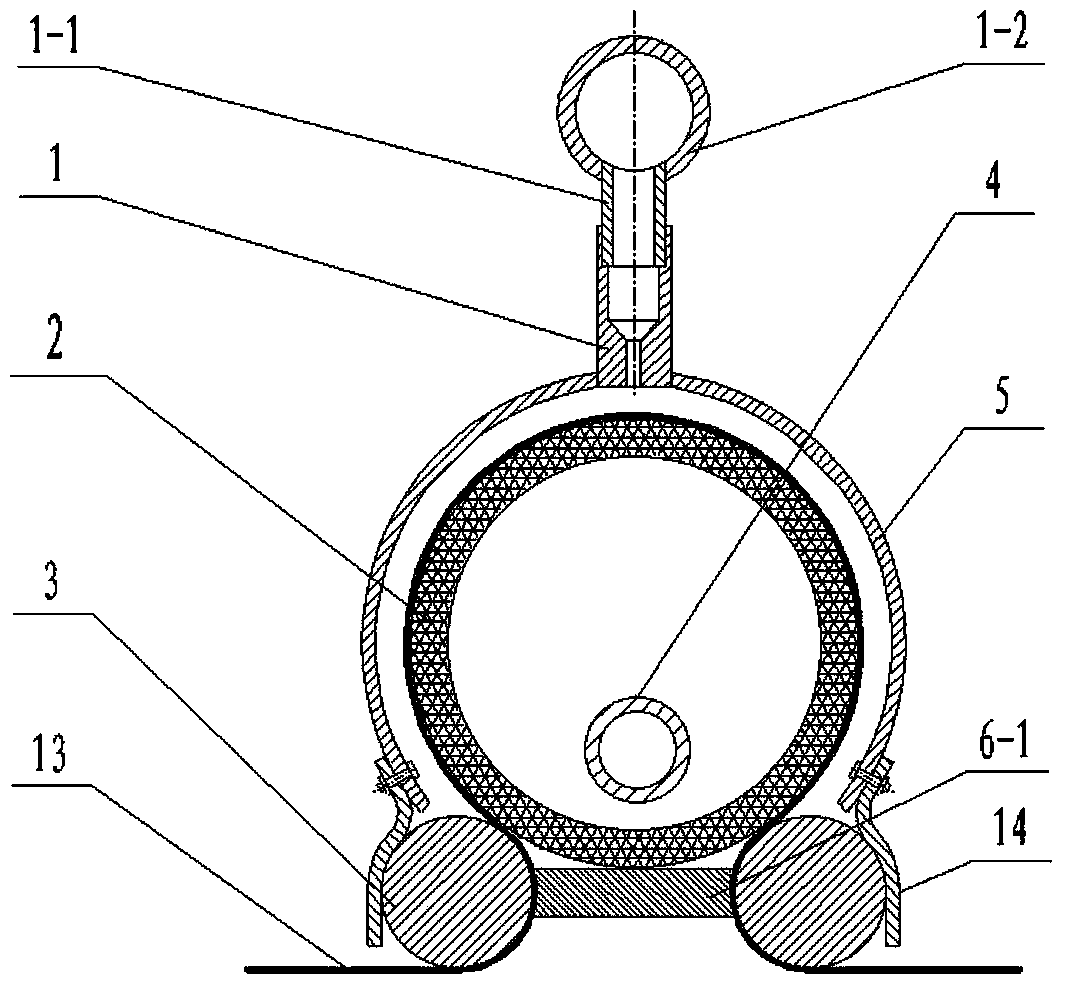

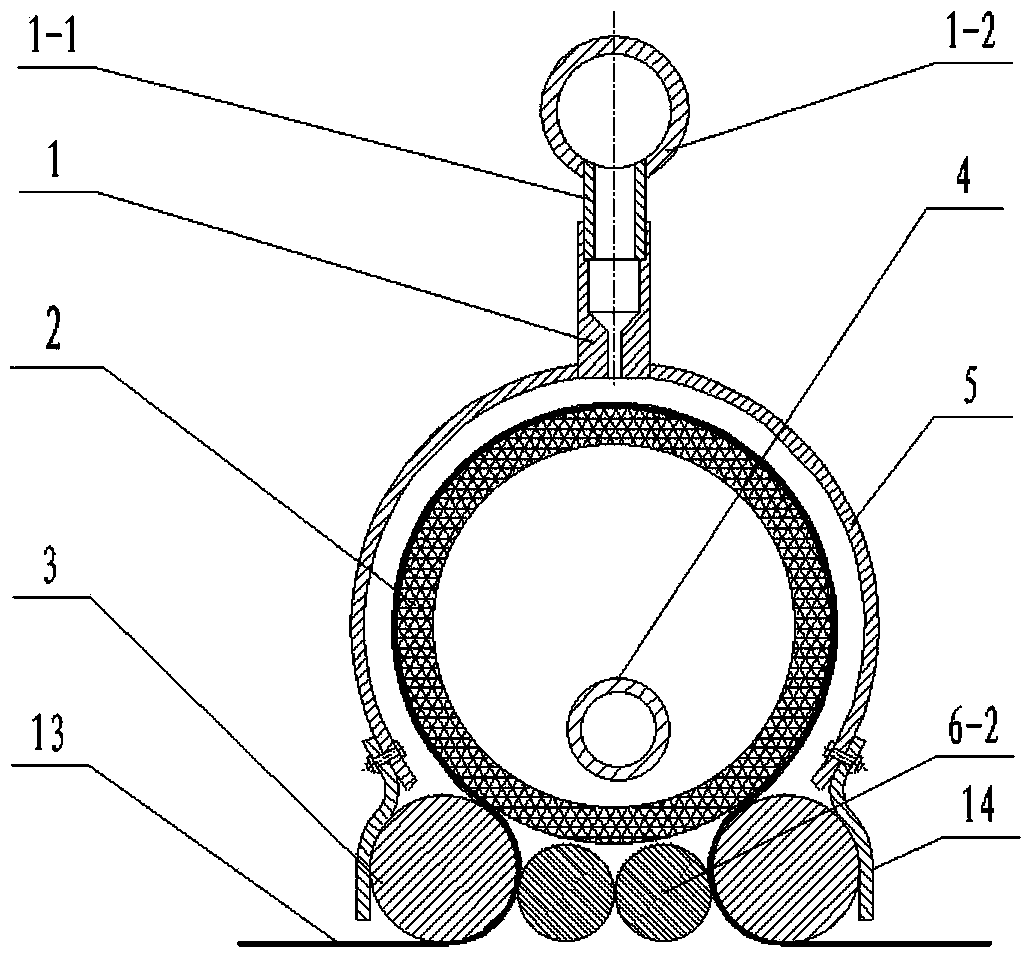

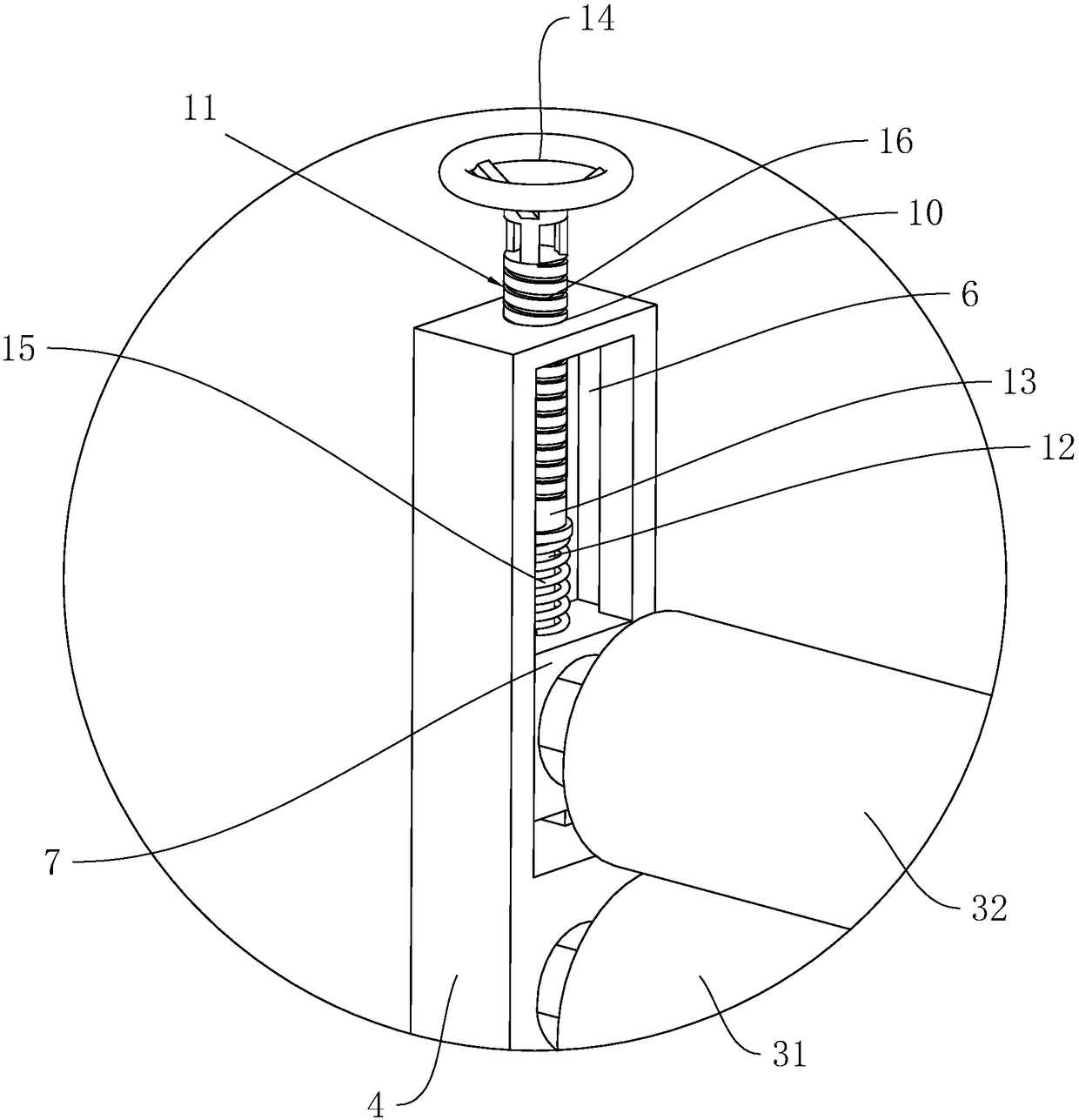

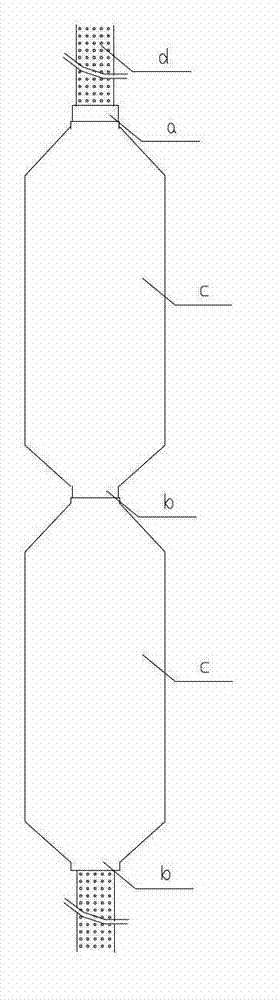

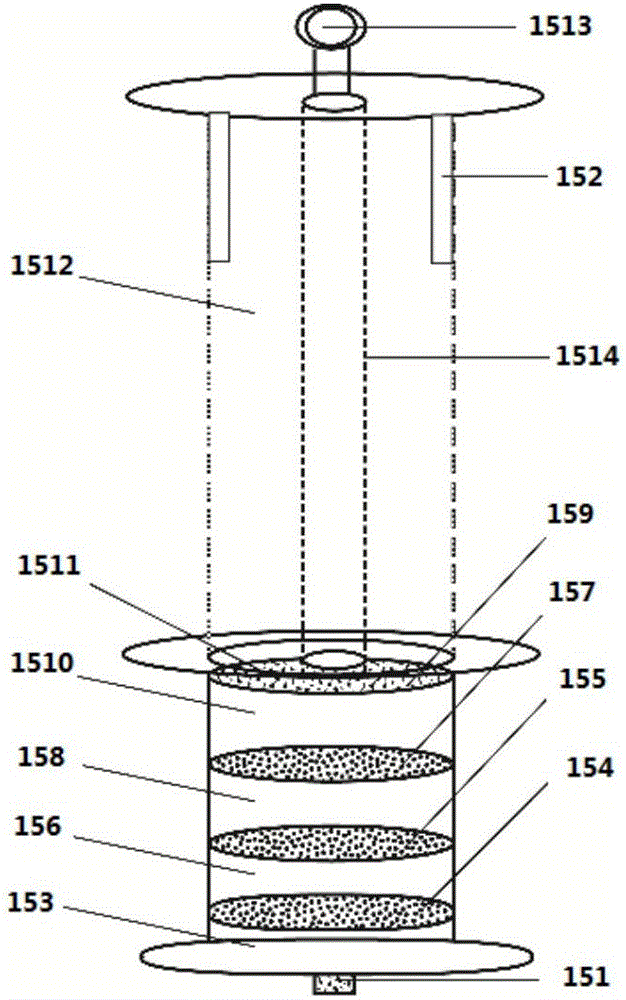

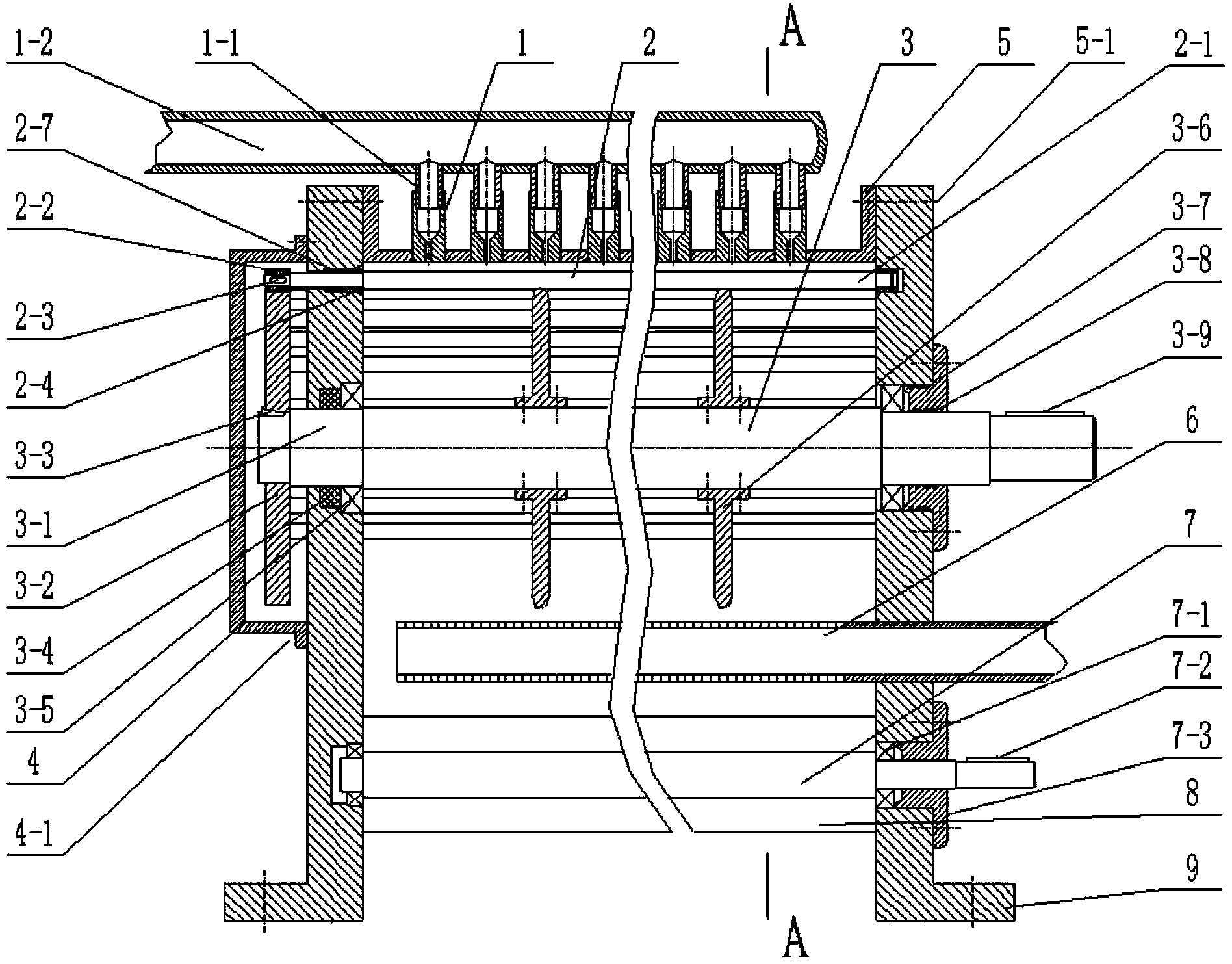

Supercritical carbon dioxide hairball dyeing kettle and waterless dyeing method thereof

ActiveCN102776738AMeet the development requirementsSimple and convenient production and processingTextile treatment containersSolvent treatment with solvent recoveryHairballSupercritical carbon dioxide

The invention relates to a supercritical carbon dioxide hairball dyeing kettle which comprises a cylinder body and a hairball dyeing barrel body fixed in the cylinder body, wherein a movable sealing cover is fixed at the upper end of the cylinder body, and the lower end of the cylinder body is provided with a carbon dioxide liquid outlet; a carbon dioxide liquid inlet is arranged at the upper part of the cylinder body; a heating clamping sleeve is fixed outside the cylinder body; a heating medium outlet is arranged at the upper end of one side of the heating clamping sleeve, and a heating medium inlet is arranged at the lower end of the other side of the heating clamping sleeve; the supercritical carbon dioxide hairball dyeing kettle is characterized in that a hole III is formed in the wall of the hairball dyeing barrel body; a central pipe is fixed to the centre of the hairball dyeing barrel body, and at least one upper limiting cover is fixed to the central pipe; the central pipe has a multi-pore shaft structure; a hole I is formed in a supporting plate at the bottom of the barrel body; a central hole Ia is corresponding to an internal chamber of the central pipe; and a hole II is formed in the upper limiting cover. According to the supercritical carbon dioxide hairball dyeing kettle increased, the direct contacting surface area of the a hairball and the dyeing liquid can be increased, and improves the influence due to the gravity in hairball dyeing can be improved, and the dyeing speed and the dye pickup can be improved, as well as the dyeing uniformity is improved.

Owner:晋江国盛新材料科技有限公司

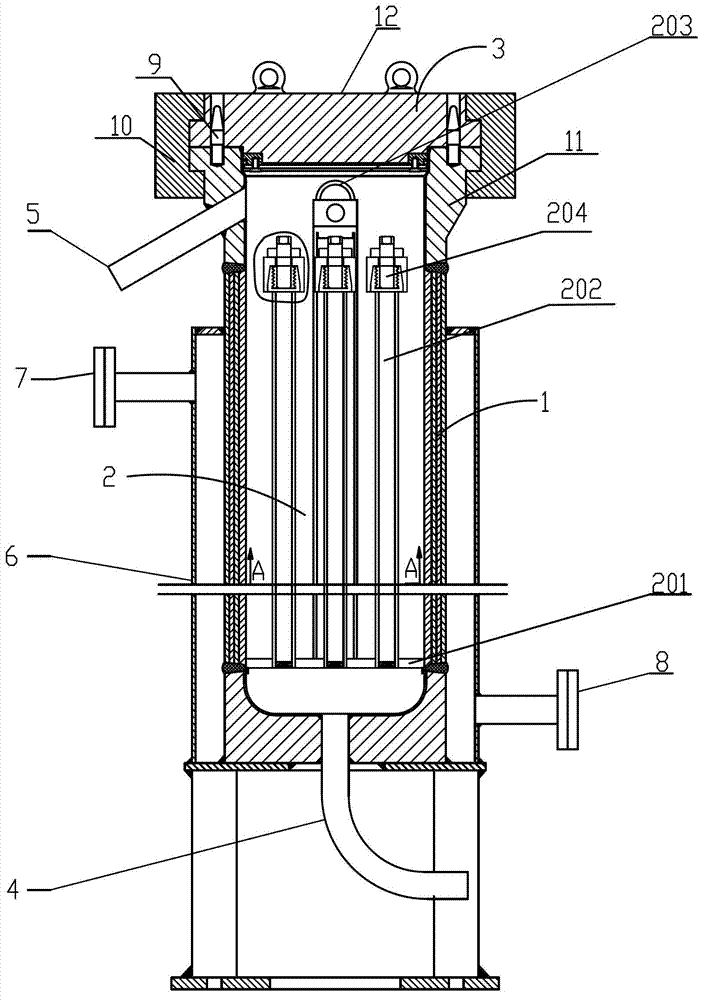

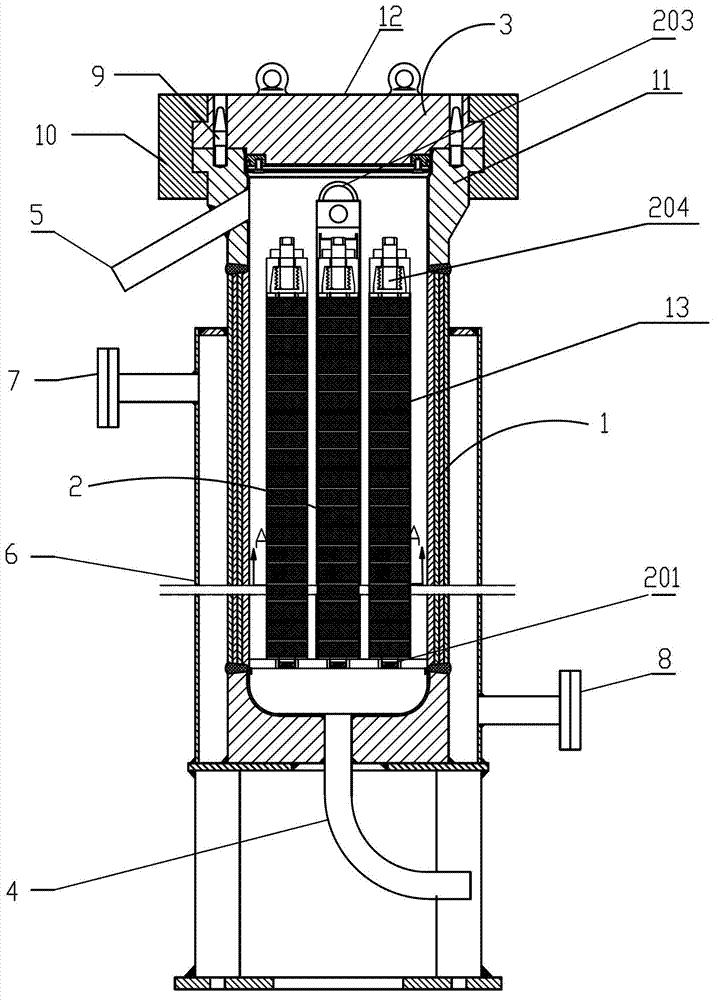

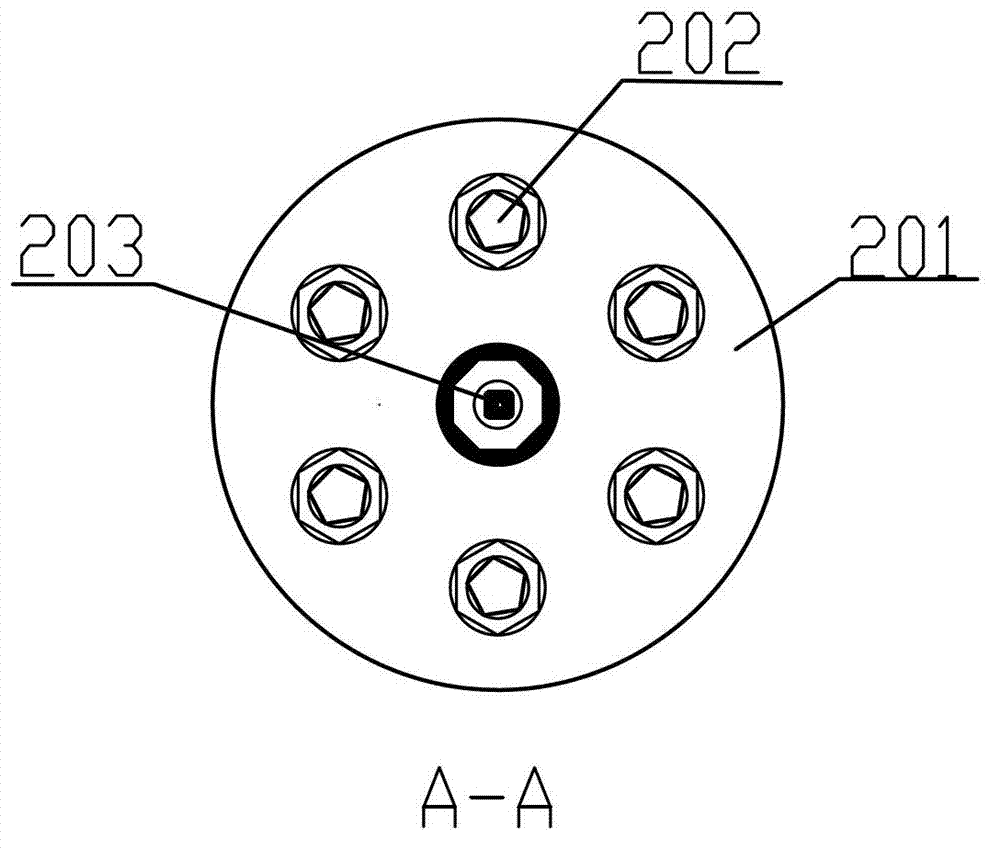

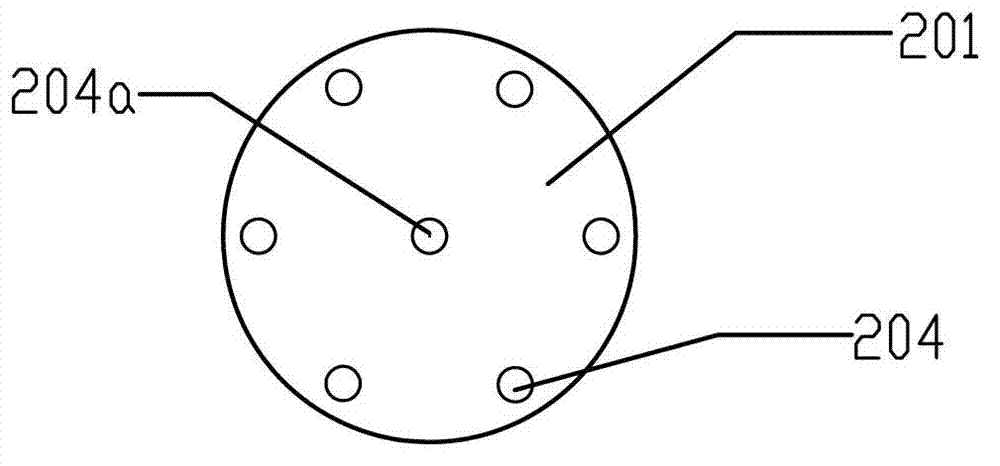

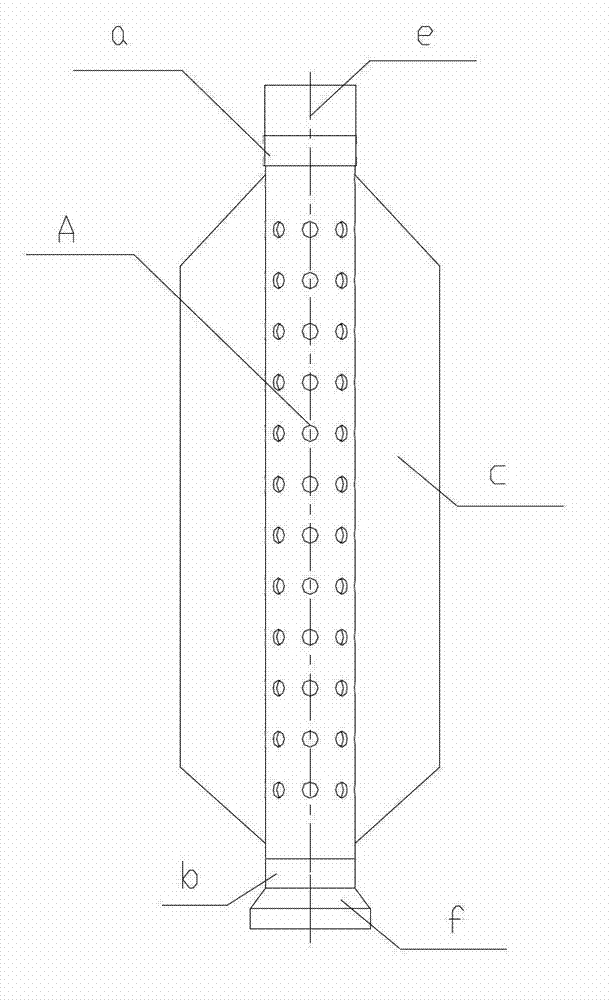

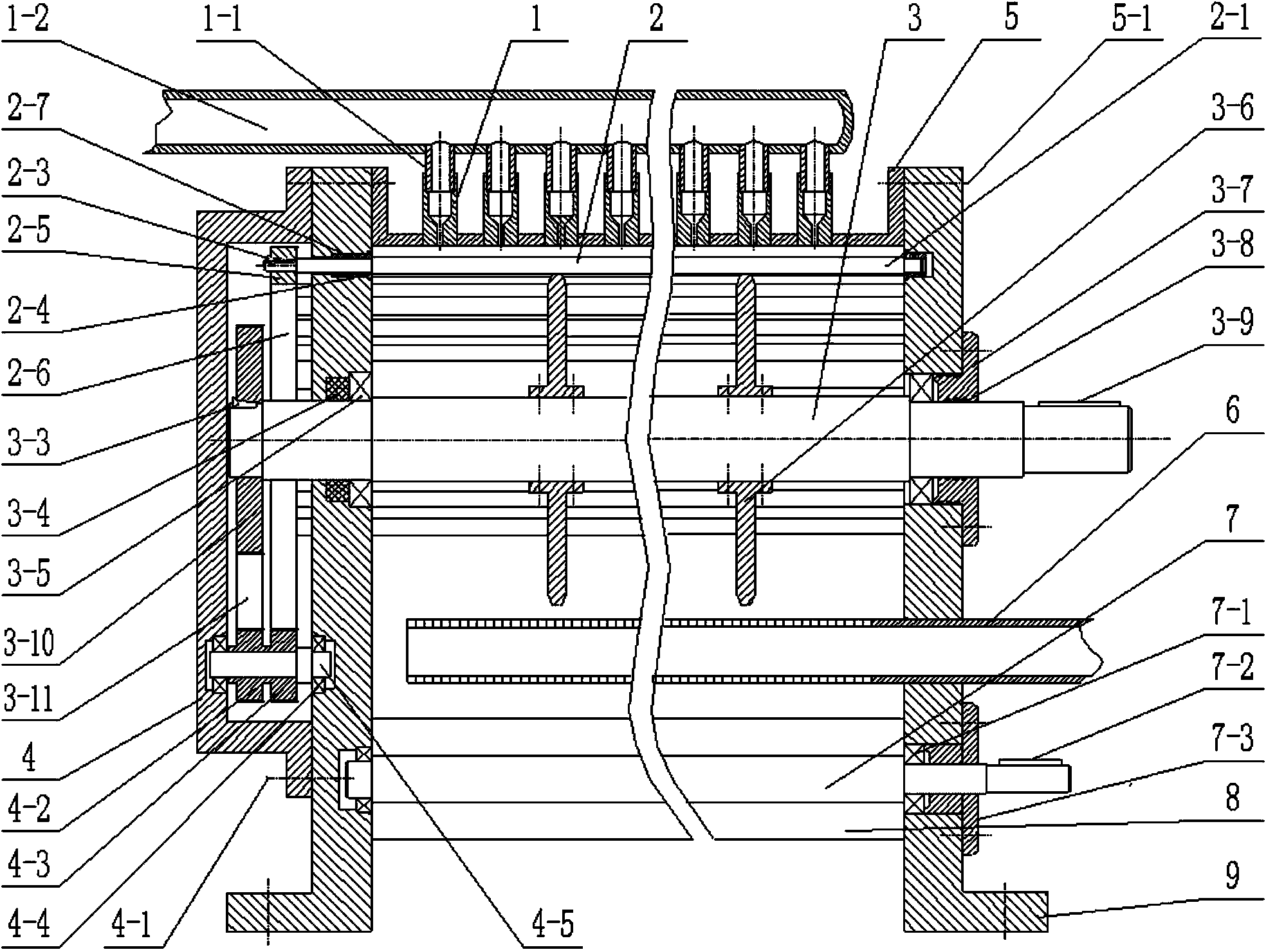

Supercritical carbon dioxide skein dyeing kettle and waterless dyeing method thereof

ActiveCN102776739AGood level dyeingHigh fastnessTextile treatment containersSolvent treatment with solvent recoveryDistributorSupercritical carbon dioxide

The invention relates to a supercritical carbon dioxide skein dyeing kettle which comprises a cylinder and a skein support. The skein support is fixed in the cylinder; a movable sealing cover is fixed at the upper end of the cylinder, a carbon dioxide fluid inlet is arranged at the lower end of the cylinder, and a carbon dioxide fluid outlet is further arranged on the upper portion of the cylinder; a heating jacket is fixed on the outer side of the cylinder; a heating medium outlet is arranged at the upper end of one side of the heating jacket, and a heating medium inlet is arranged at the lower end of the other side of the heating jacket. The supercritical carbon dioxide skein dyeing kettle is characterized in that the skein support consists of a bottom distributor, a supporting tube and two skein frames; the two skein frames are fixed on the supporting tube; the supporting tube is fixed on the bottom distributor and is of a porous shaft structure; a hole is arranged on the bottom distributor; and an inner cavity of the supporting tube corresponds to the hole I.

Owner:晋江国盛新材料科技有限公司

Preparation method of coolmax fiber/wool blend moisture absorbing/releasing tweed

The invention relates to a preparation method of coolmax fiber / wool blend moisture absorbing / releasing tweed. The preparation method is characterized in that the tweed comprises the raw materials of 50% of wool and 50% of coolmax fibers in terms of mass percentage; the preparation method comprises the steps of dyeing and re-combing, spinning, weaving and post-treating; the coolmax fibers and the wool are respectively dyed in the process of dyeing and re-combing, wherein the coolmax fibers are dyed at 120 degrees centigrade by using mesothermal dyestuffs; the pH value is controlled at 3-5, the time for 60 minutes in the dyeing process; and the highly active cleaning agent ECO is employed for washing after the dyeing process. The tweed produced by the preparation method provided by the invention has the advantages of moisture absorbing and releasing, good strength, high fastness and uniform color.

Owner:JIANGSU NIJIAXIANG GROUP WORSTED TEXTILE

Bamboo fiber and mulberry silk interwoven fabric and production process thereof

InactiveCN104294448AThe flashing effect is obviousFeel comfortableTextile solvent-dyeingAnimal materialFiberEngineering

The invention discloses a bamboo fiber and mulberry silk interwoven fabric. The bamboo fiber and mulberry silk interwoven fabric comprises warp and weft which are interwoven, the blending ratio of warp yarn made of mulberry silk to weft yarn made of bamboo fiber is 50:50, the warp density of the bamboo fiber and mulberry silk interwoven fabric is 80-120 pieces per centimeter, and the weft density of the bamboo fiber and mulberry silk interwoven fabric is 30-40 pieces per centimeter. The bamboo fiber and mulberry silk interwoven fabric is natural and environmentally friendly, the mulberry silk serves as the warp yarn, the bamboo fiber serves as the weft yarn, and the fabric has the advantages that the color flashing effect is obvious, the hand feeling is comfortable, and the fabric is deodorized and resistant to bacteria, fresh, cool, durable, wearproof, good in drooping effect and the like.

Owner:JIANGSU SUNSHINE

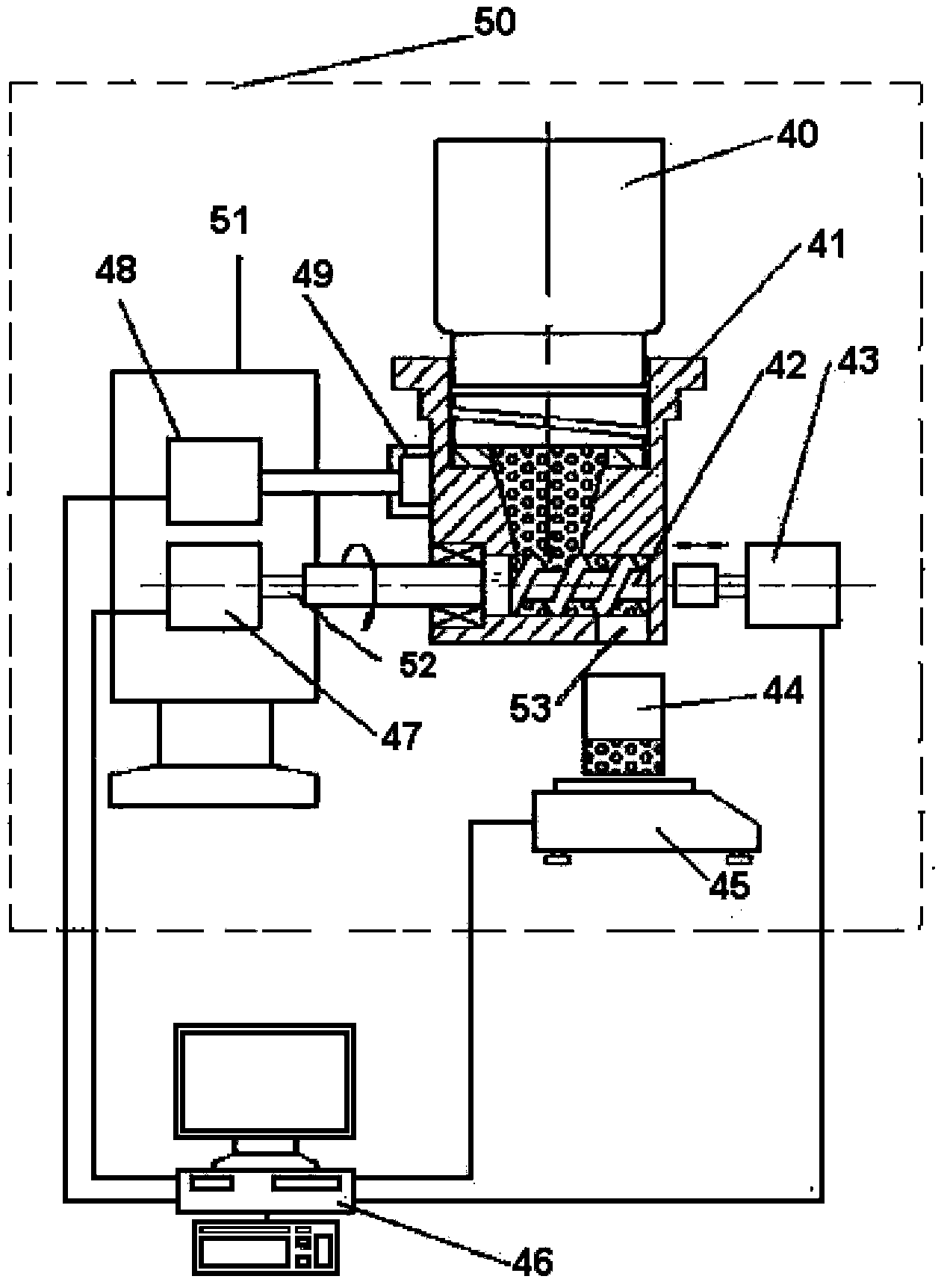

Sample dyeing machine for supercritical CO2 dyeing and dye weighing system

InactiveCN103422288AAccurate weighingSave waterTextile treatment dyeing devicesTextile treatment machine arrangementsWater sourceCo2 storage

Owner:THE HONG KONG RES INST OF TEXTILES & APPAREL

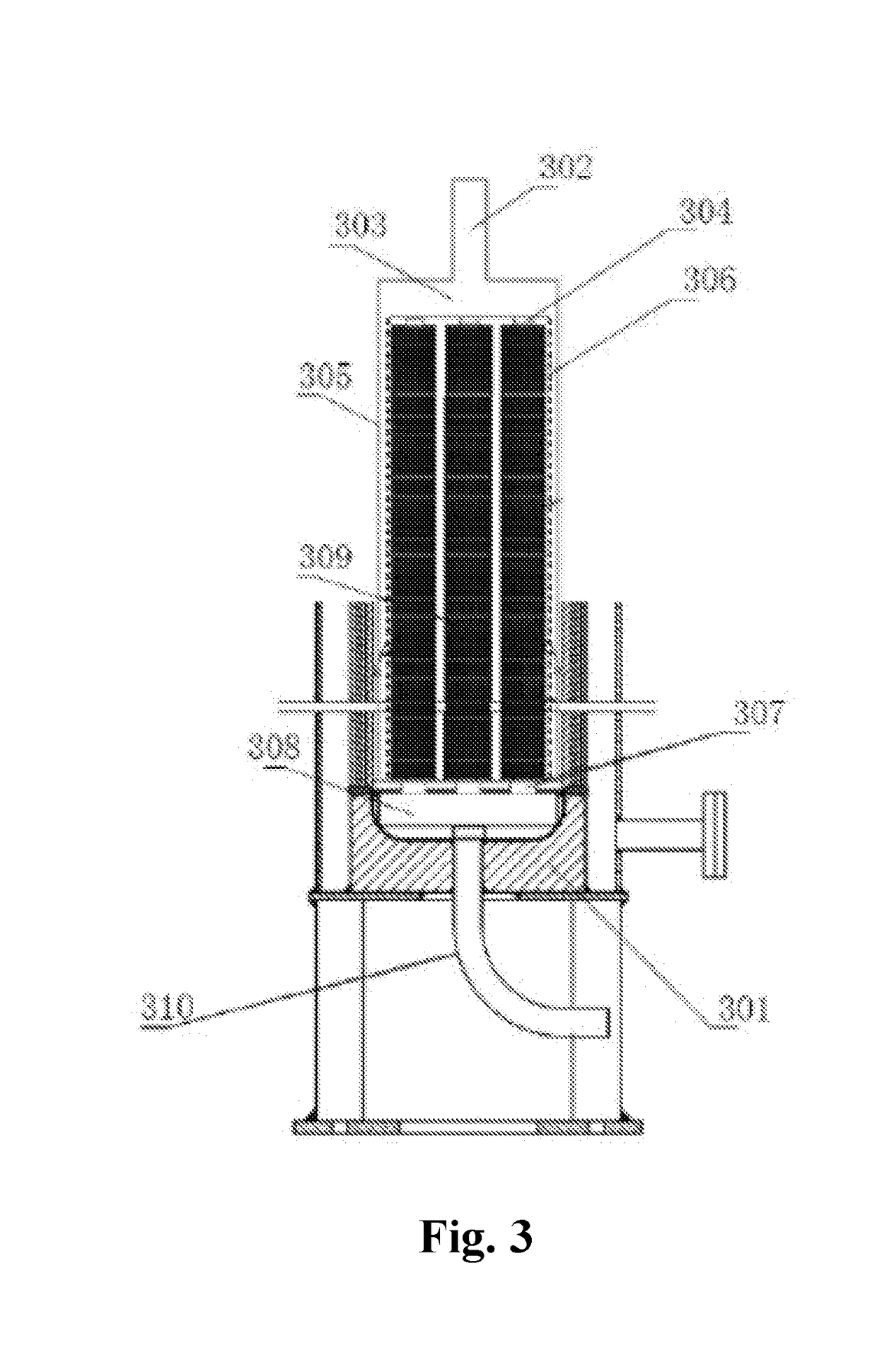

Supercritical carbon dioxide fluid proofing device and dyeing method

ActiveCN105040325AEfficient retentionImprove solubilityTextile treatment dyeing devicesTextile treatment machine arrangementsGas solidEngineering

The invention relates to a supercritical carbon dioxide fluid proofing device and a dyeing method and belongs to the technical field of spinning. The device comprises a dyeing kettle, the dyeing kettle comprises a sample unit supporting rack, multiple sample units and a motor, the sample unit supporting rack is arranged inside a cylinder body of the dyeing kettle, the motor passes through the dyeing kettle in a sealed mode and is connected with the sample unit supporting rack, the multiple sample units are arranged on the sample unit supporting rack, a channel used for allowing the carbon dioxide fluid to flow into the sample units is formed inside the sample unit supporting rack, and the sample units comprise a gas-solid separating membrane, a porous partition plate I, a dye chamber, a porous partition plate II, a sample chamber and a detachable sealing cover II in sequence from near to far at a carbon dioxide fluid inlet and outlet of a detachable sealing cover I. The supercritical carbon dioxide fluid proofing device and the dyeing method have the advantage of putting forward the supercritical carbon dioxide fluid proofing device for the first time.

Owner:DALIAN POLYTECHNIC UNIVERSITY

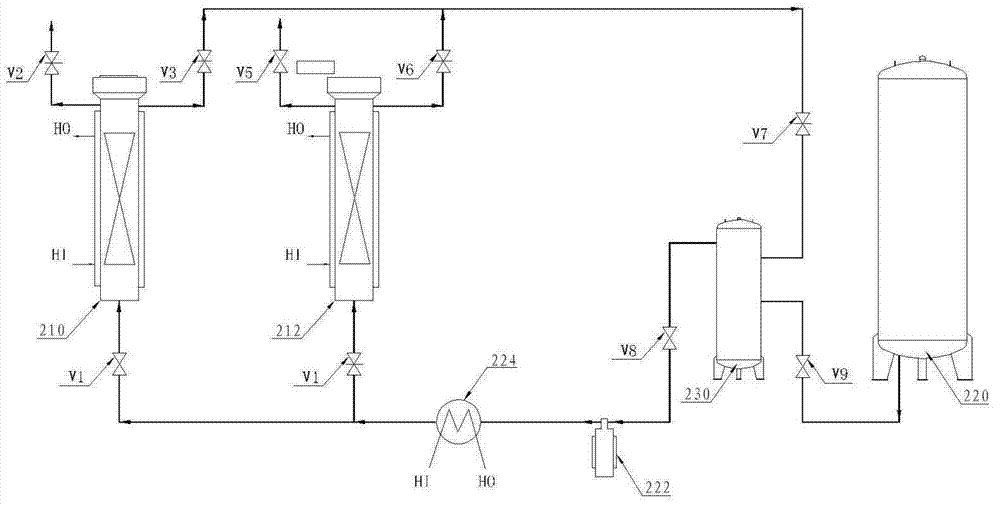

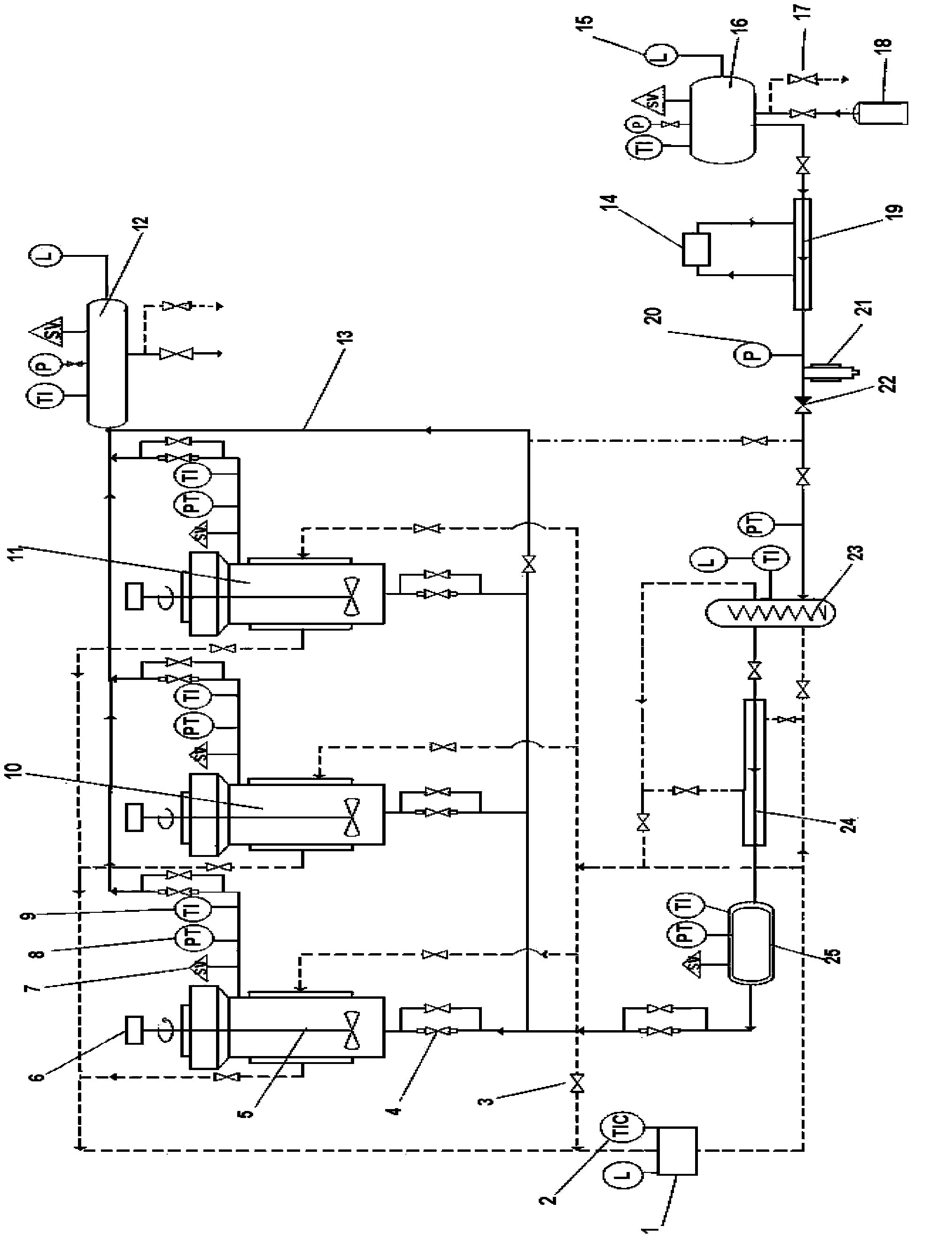

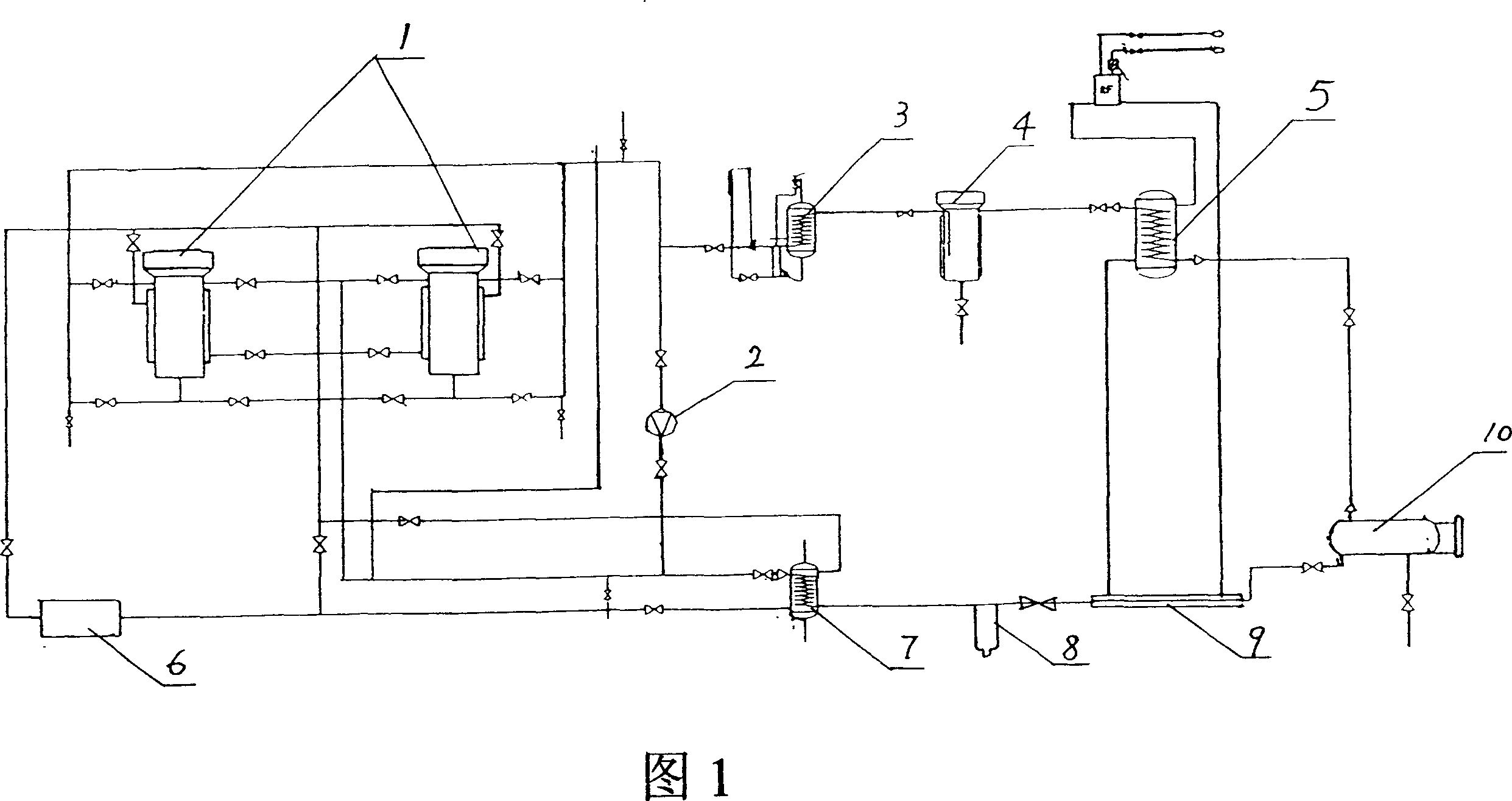

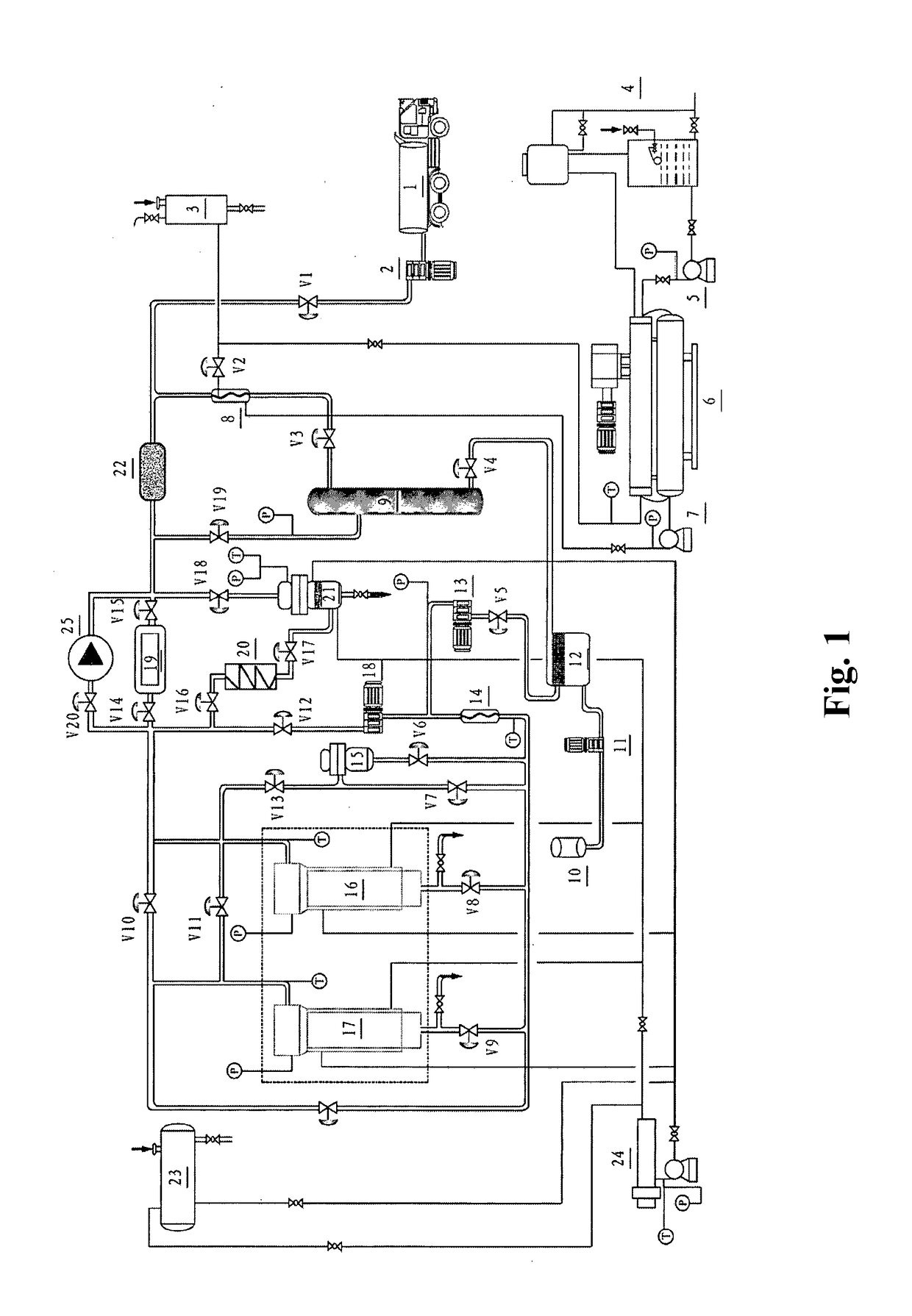

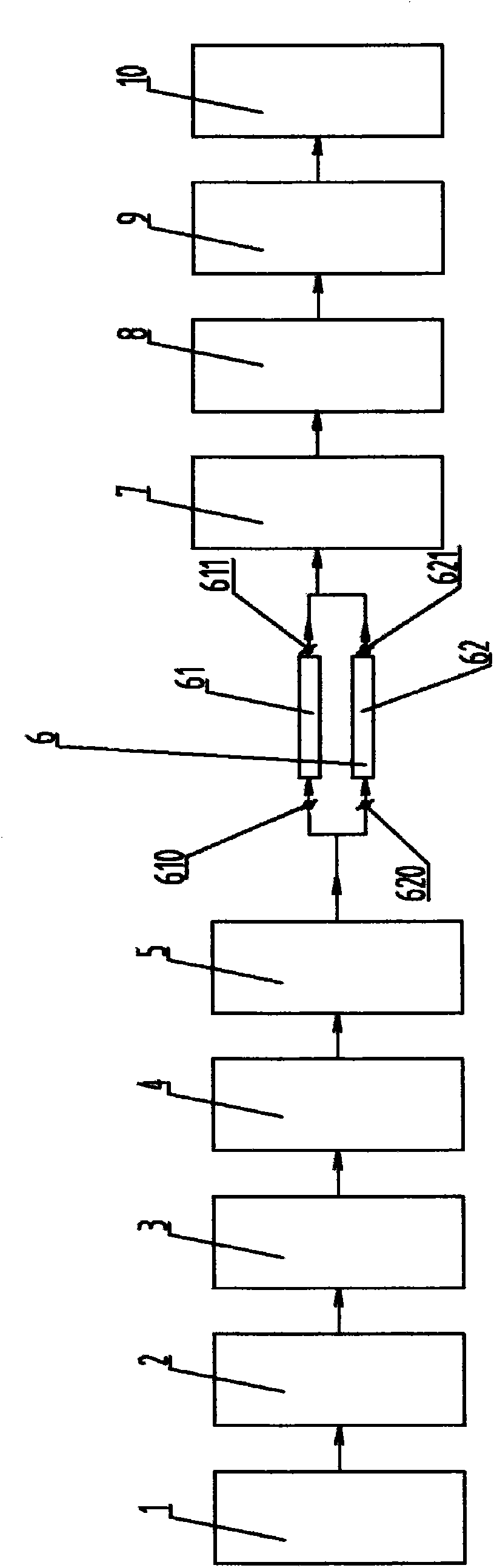

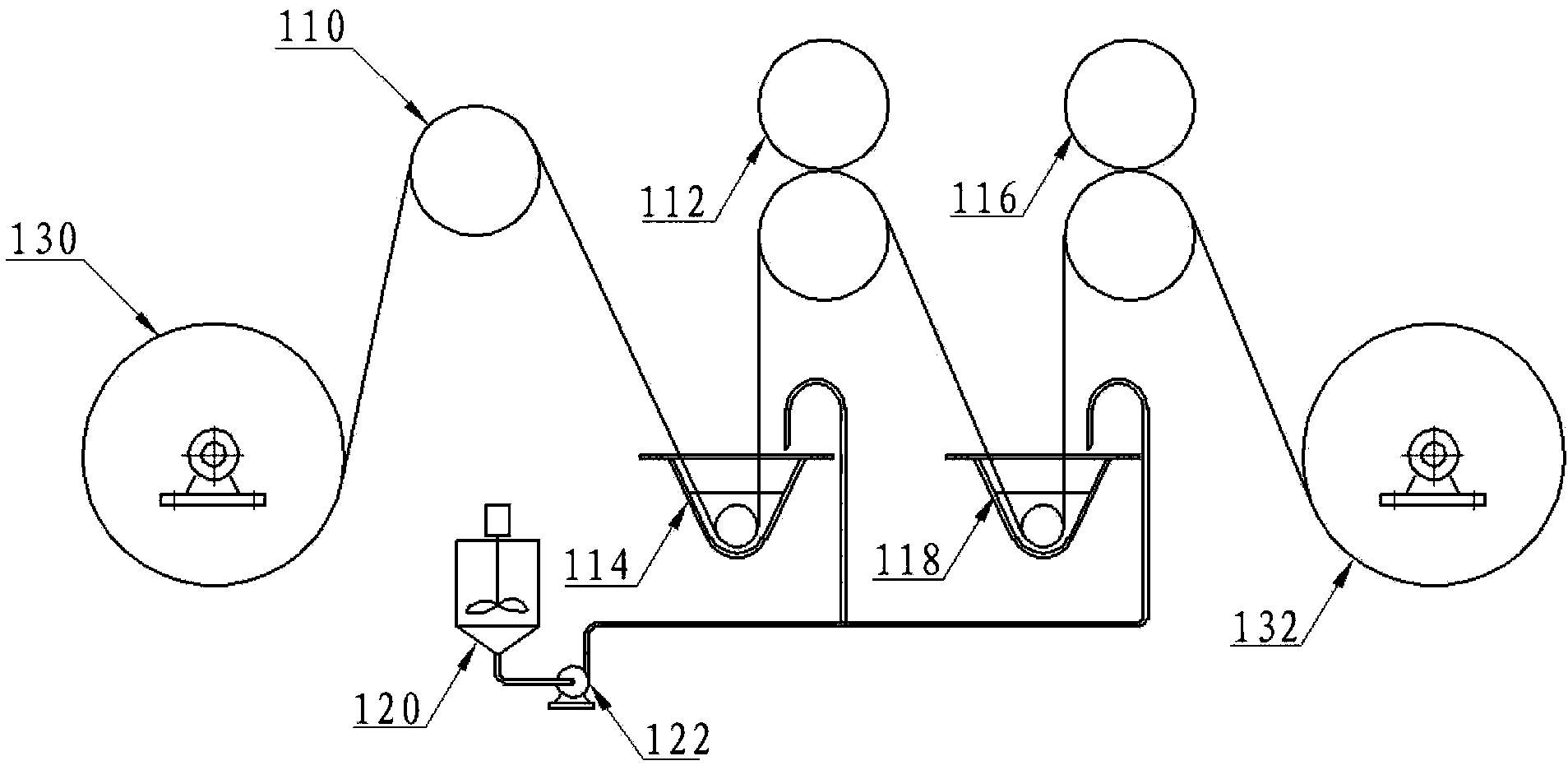

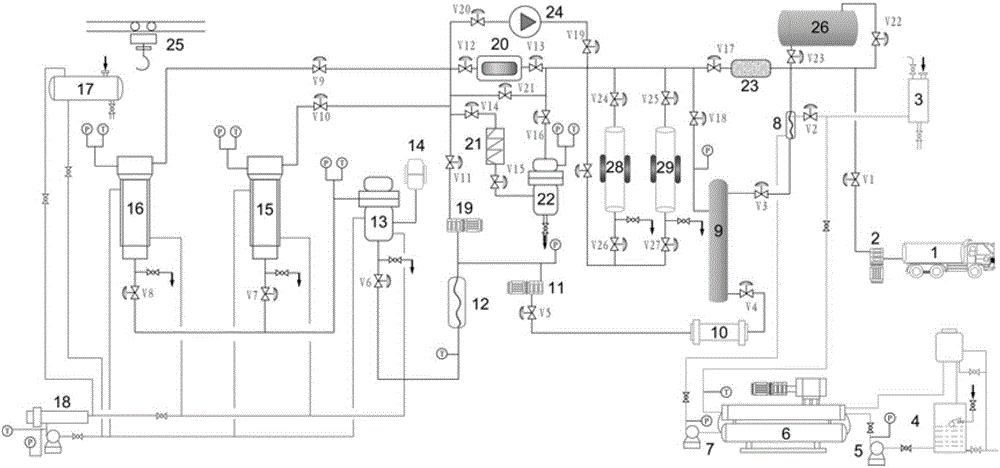

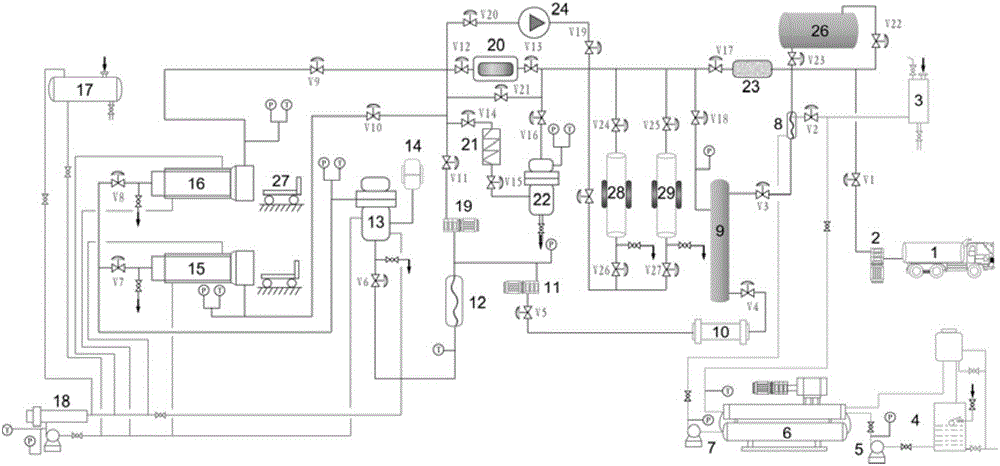

Consecutive production plant for supercritical carbon dioxide dyeing, and consecutive dyeing method

InactiveCN1958923AReduce energy consumptionGuarantee the industrialization of dyeing continuous productionTextile treatment containersSolvent treatment with solvent recoveryProcess engineeringHigh pressure

The present invention relates to a supercritical carbon dioxide dyeing continuous production equipment and its continuous dyeing method for dyeing fabrics. Said equipment includes a dyeing circulation system device which is connected after preheater by means of pipeline, can be cut off by valve and can be independently operated and a dye and carbon dioxide recovery system deice which is placed after the above-mentioned dyeing circulation system device, can be cut off by valve and can be independently operated. Said dye and carbon dioxide recovery system also is communicated with carbon dioxide storage tank by means of pipeline. Besides, said invention also provides the concrete steps of said continuous dyeing method by utilizing the above-mentioned equipment.

Owner:MASSON GROUP

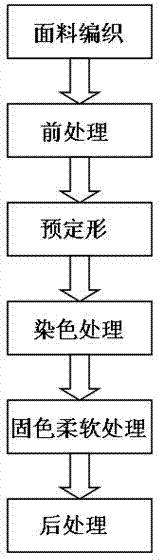

Dyeing and finishing process for lace fabric

InactiveCN102851875AShiny brightProcess arrangement is reasonableFabric breaking/softeningHeating/cooling textile fabricsWear resistantEngineering

The invention provides a dyeing and finishing process for a lace fabric. The dyeing and finishing process comprises the following steps: a) weaving of a fabric; b) pre-processing; c) pre-shaping; d) dyeing treatment; e) dye fixation and mellowing; and f) post-processing. The dyeing and finishing process revealed in the invention has the following advantages: process procedures are reasonably arranged; implementation of the process is scientific and simple; the prepared lace fabric can permanently keep bright sheen, is washable and durable, wear-resistant and non-fading, and has a high market value compared to products of a same kind.

Owner:KUSN CHENGYU ELECTROMECHANICAL TECH

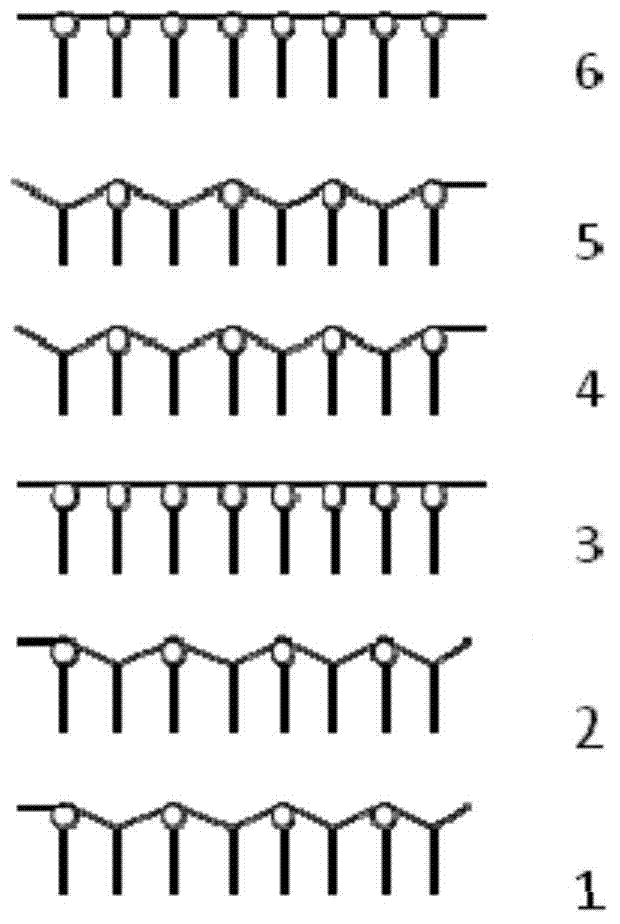

Production technology of warp knitting velvet fabric

InactiveCN106435999AAdd dimensionIncrease brightnessSucessive textile treatmentsWarp knittingFiberAdjuvant

The invention discloses a production technology of warp knitting velvet fabric. The technology comprises the step of weaving, premolding, raising, lustring, shearing, dyeing, adding adjuvants, drying, secondary lustring, secondary shearing and molding. The invention discloses the production technology of the warp knitting velvet fabric. The production technology of the warp knitting velvet fabric is based on the improvement of the production technology of a traditional velvet fabric, greatly improves stereoscopic effect and luster of the dacron superfine fiber velvet fabric, and effectively keeps softness and hand feeling comfort of the velvet itself. The warp knitting velvet fabric is simple in technology and mature in equipment.

Owner:NANTONG TONGZHOU DING DING HAT FACTORY

Production process of Tencel milk fiber home textile fabric

The invention provides a production process of tencel milk fiber home textile fabric. The tencel milk fiber home textile fabric is produced from tencel fiber and milk fiber in the weight ratio of 30-35: 70-65 by blending, weaving, dyeing and finishing; the specifications of the tencel fiber are as follows: the fineness is 1.4-1.5 dtex and the length is 38-40 mm; the specifications of the milk fiber are as follows: the fineness is 1.4-1.5 dtex and the length is 38-40 mm. The production process of the tencel milk fiber home textile fabric is simple in operation, is sustainable, complies with the trend of low-carbon economy and is broad in application prospect; the process flow is shortened; the energy consumption is reduced.

Owner:ZHEJIANG TRUELOVE MEIJIA HLDG CO LTD

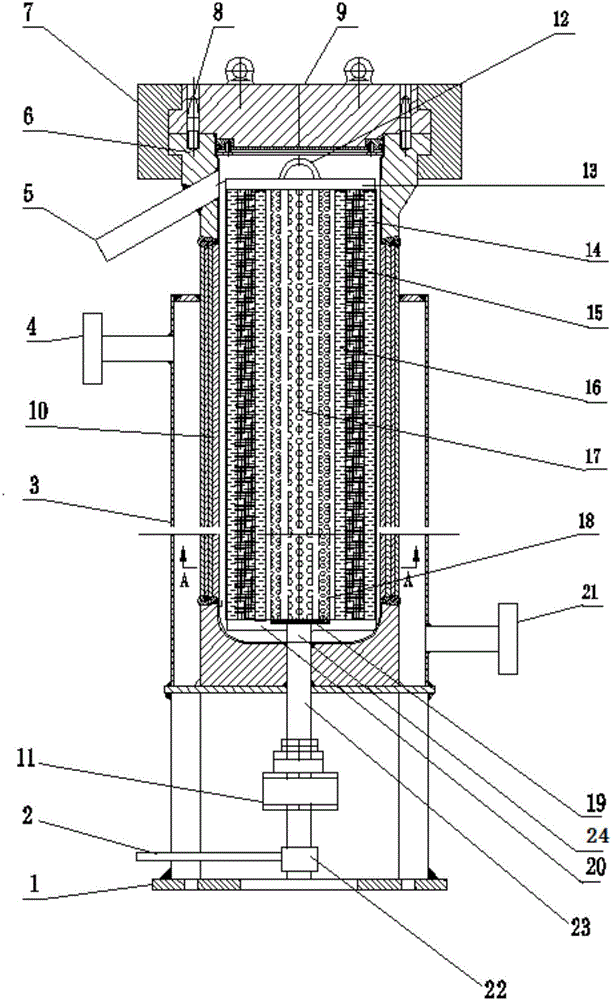

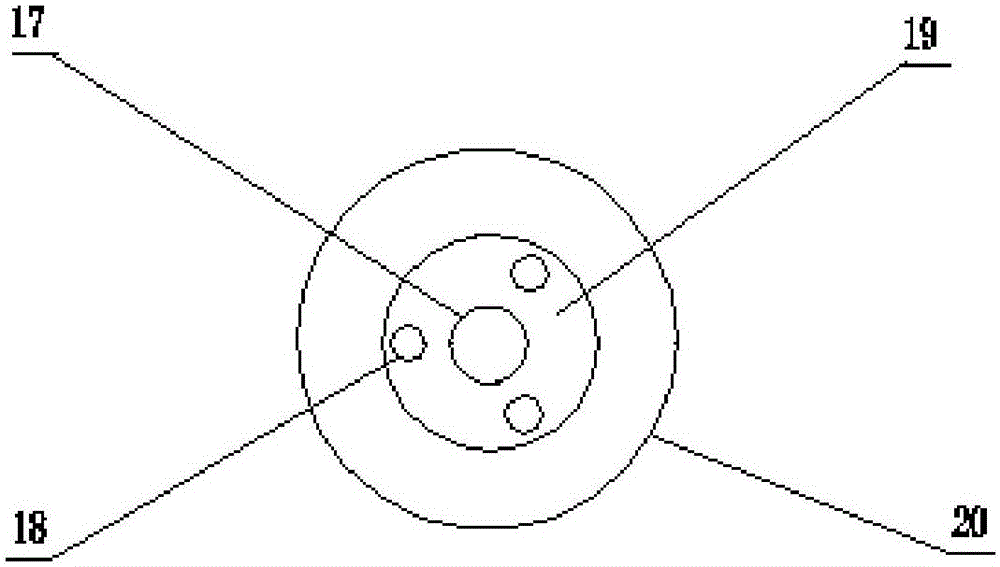

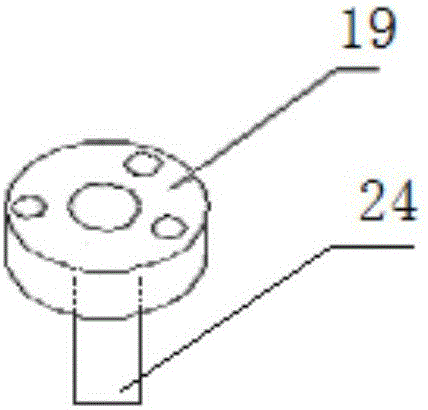

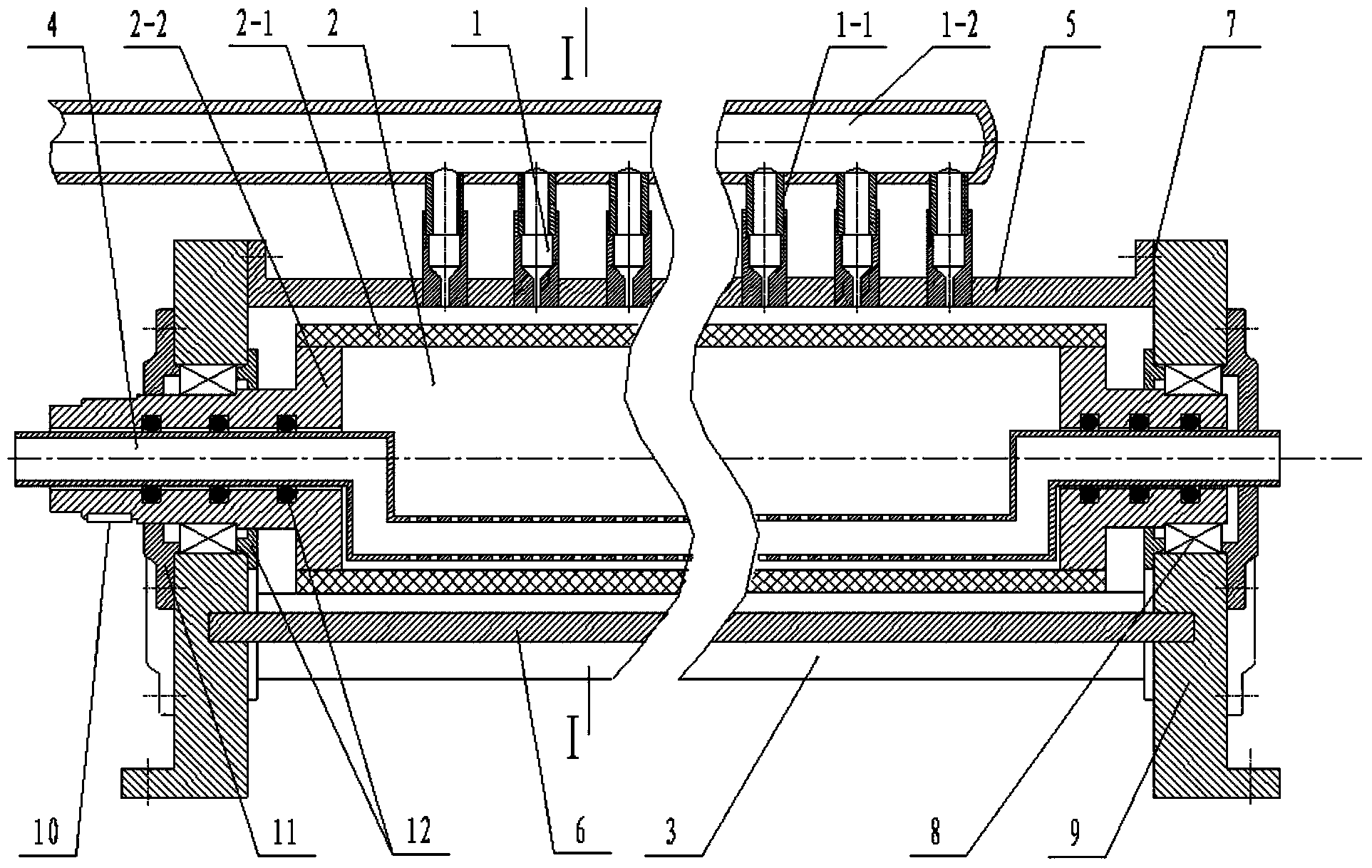

Supercritical carbon dioxide beam dyeing frame, dyeing kettle and dyeing method

ActiveCN105040317AIncrease profitReduce lossTextile treatment containersTextile solvent-dyeingCircular discYarn

The invention discloses a supercritical carbon dioxide beam dyeing frame, dyeing kettle and dyeing method. The dyeing frame comprises a central supporting pipe (17) and a rotating disc (19), the rotating disc (19) is of a hollow cylinder structure, four holes are formed in the upper portion of the rotating disc, a short shaft (24) is arranged on the lower portion of the rotating disc in a communicated mode, and the beam dyeing frame comprises the central supporting pipe (17), a three-arm shaft (18), a beam supporting shaft (16), a beam (15) and a porous cover in sequence from inside to outside with the central supporting pipe (17) as the center; the bottom of the hollow rotating shaft is connected with a carbon dioxide fluid pipe through a rotary sealing device. According to the beam dyeing frame, dyeing kettle and dyeing method, the central supporting pipe and the three-arm shaft rotate in the circumferential direction, large impact force is generated by the carbon dioxide fluid by means of the centrifugal force, dye passes through yarn rapidly, and the dye permeability is improved. According to the steam heating type supercritical carbon dioxide beam dyeing kettle, high-temperature steam inside a textile mill is utilized, a steam heating mode is adopted, and the heat utilization rate is high.

Owner:晋江国盛新材料科技有限公司

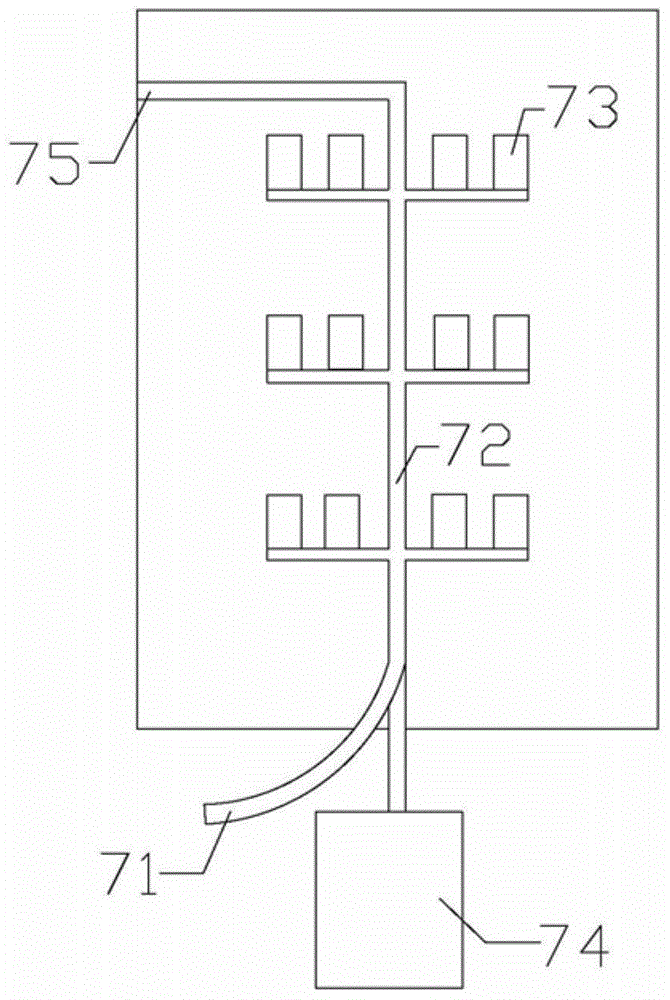

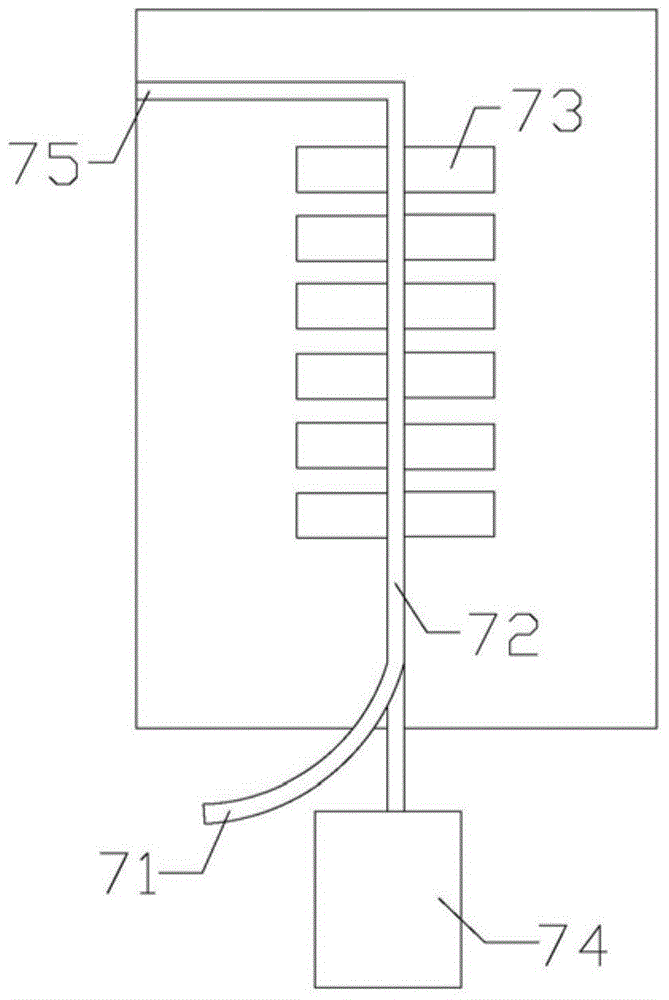

Waterless dyeing device and dyeing method thereof by utilizing activated dye for cotton cone yarns

InactiveCN105239294AAvoid pollutionLow toxicity and environmental protection High flash pointSolvent treatment with solvent recoveryTextile/flexible product manufactureElectricityYarn

The invention provides a waterless dyeing device and dyeing method thereof by utilizing activated dye for cotton cone yarns.The waterless dyeing device by utilizing activated dye for cotton cone yarns is characterized in that the waterless dyeing device comprises a main dye vat; the main dye vat is connected with an electric heating device by a pipeline; the electric heating device is connected with a main pump by a pipeline; the main pump is connected with a solvent storage device and a dye liquor distributor; the main dye vat is connected with a condenser by a pipeline; the condenser is connected with the solvent storage device and the dye liquor distributor by a pipeline; and the main dye vat is connected with a solvent separation device connected with solvent recovery devices by a pipeline. The waterless dyeing device and dyeing method thereof by utilizing activated dye for cotton cone yarns have following beneficial effects: waterless dyeing of purified cotton by utilizing organic solvents is achieved in order to avoid environmental pollution; utilized dyeing solvents featuring low toxicity, environment protection and high flash point, is above 80 DEG C in flash point; and there is no need to carry out anti-explosion operation on the dyeing device and place.

Owner:DONGHUA UNIV

System for Anhydrous Boiling, Bleaching and Dyeing Using Supercritical Carbon Dioxide Fluid

ActiveUS20180371664A1Improve pollutionHigh energy consumptionTextile treatment machine partsDispersed particle separationFiberYarn

An system for anhydrous boiling, bleaching and dyeing using a supercritical carbon dioxide fluid and belongs to the field of textile. The system for anhydrous boiling, bleaching and dyeing of a supercritical carbon dioxide fluid provided by the present invention is provided with a co-solvent system, a boiling, bleaching and dyeing system, and a separation and recovery system which are specially designed. By means of uniform dispersion and dissolution of a co-solvent, dyestuff and carbon dioxide, boiling, bleaching and dyeing production of jute fiber rough yarn can be achieved; meanwhile, the system for anhydrous boiling, bleaching and dyeing using a supercritical carbon dioxide fluid integrates the three functions of boiling, bleaching and dyeing, which can complete the boiling, bleaching and dyeing procedures in one step, and has the characteristic of high-efficiency, thus solving the problems of high contamination and high energy consumption of the jute fiber boiling, bleaching and dyeing procedures.

Owner:YIXING SUNSHINE LINEN TEXTILE CO LTD

Ejector for supercritical fluid jet dyeing

InactiveCN103866515AEliminate deformationEliminate tension damageTextile treatment machine arrangementsTextile solvent-dyeingDissolutionHigh pressure

The invention relates to the field of textile dyeing equipment, in particular to an ejector for supercritical fluid jet dyeing. The ejector is composed of a jet nozzle, jet nozzle branch pipes, a jet nozzle header pipe, a dyeing roller, a backflow pipe, a cloth guide roller, a flow rectification cover, a flow baffle, an overflow fence and a side wall plate. If the jet nozzle header pipe is connected with a supercritical fluid generation subsystem pipeline and the two ends of the backflow pipe are connected with a used-fluid recovery and separation subsystem pipeline, a cleaning ejector or rinsing ejector can be formed. If the jet nozzle header pipe is connected with a dye dissolution subsystem pipeline and the two ends of the backflow pipe are connected with the used-fluid recovery and separation subsystem pipeline, a dyeing ejector can be formed and operates under single-machine drive or group drive. The ejector solves the problems that under the action of a high-pressure jet and traction force, textiles to be dyed are deformed and damaged under tensile force and the pressure drop of the supercritical fluid jet is too large. Various supercritical fluid jet dyeing devices can be formed by combining a plurality of ejectors in different modes according to dyeing process requirements. The ejector is simple and compact in structure and good in manufacturability.

Owner:SHANDONG UNIV

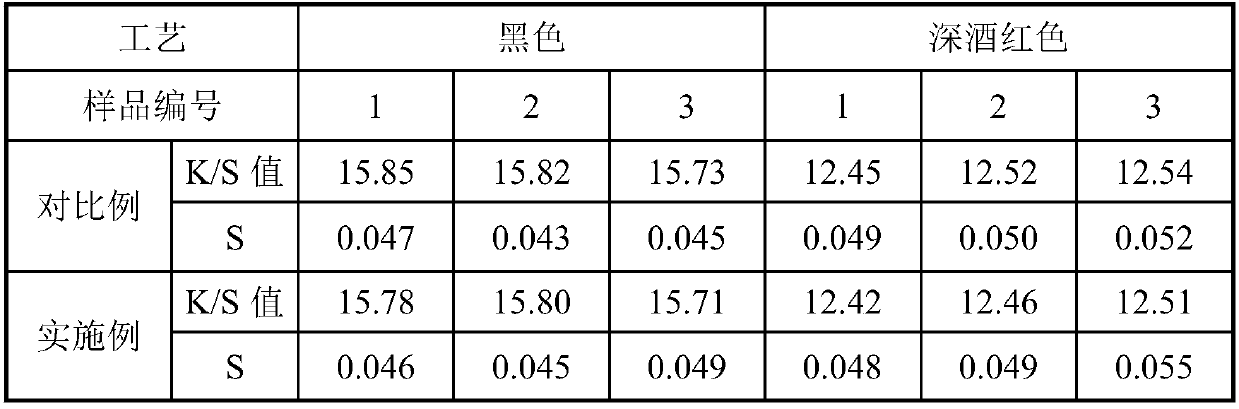

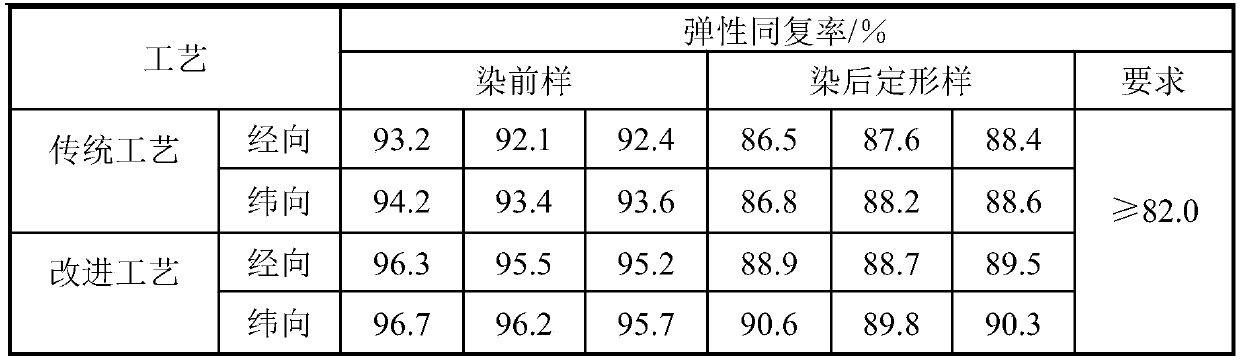

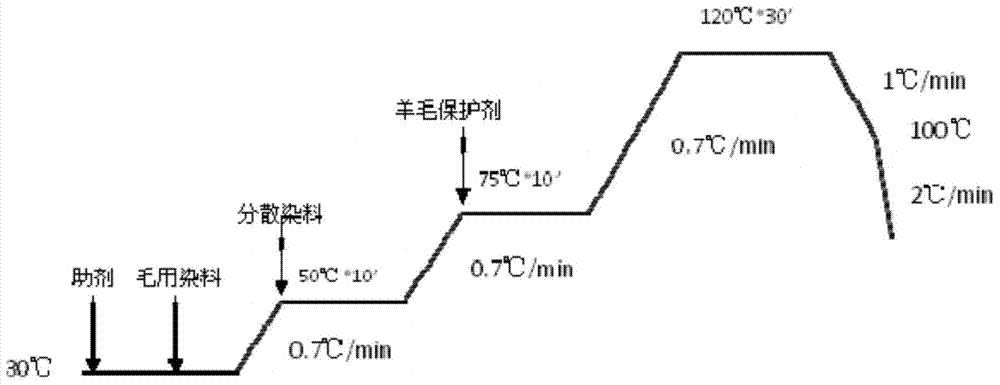

Dyeing process for dacron-spandex all-around elastic fabric

InactiveCN109680514ASame staining depthImprove dyeing effectTextile solvent-dyeingDyeing processSulfonateChange color

The invention discloses a dyeing process for a dacron-spandex all-around elastic fabric. The dyeing process comprises the following steps: S1, pre-treatment of dyeing: selecting a dacron-spandex all-around elastic woven fabric, wherein the content of spandex is 15-25%, and carrying out pre-treatment of dyeing on the fabric; S2, dyeing: adding soft water into a dye vat according to a bath ratio of1: 20 at room temperature and adding a penetrant, a color fixer, a leveling agent, a pH value regulator, a spandex accelerant, an acidic dye, a dispersive dye, a fiber protecting agent and a diffuserinto clean water; S3, reductive cleaning: a cleaning liquid contains caustic soda, sodium hydrosulfite, a cleaning agent and hydroxymethyl sulfonate and S4, foam setting. The invention relates to thedacron-spandex all-around elastic fabric. Compared with a conventional process, the high spandex content dacron-spandex all-around elastic fabric has same dyeing depth in uniformity of dacron-spandexdyeing. The dyeing effect to spandex is better than that of the conventional process, and the washed fabric does not change color and fade away and is relatively good in color fastness.

Owner:桐乡市金达染整科技股份有限公司

Supercritical carbon dioxide fluid dyeing device with two dye vats

InactiveCN104342869ARealize diverse productionSatisfy small batches and multiple varietiesTextile treatment containersTextile treatment machine arrangementsDye injectionInlet valve

A supercritical carbon dioxide fluid dyeing device with two dye vats comprises a liquid carbon dioxide storage tank, a carbon dioxide injection high-pressure pump, a heater, a dye mixing tank, a mixed dye injection high-pressure pump, a dye vat set, a pressure reduction cooler, a separation kettle, a condenser and a precise filter. The supercritical carbon dioxide fluid dyeing device is characterized in that the liquid carbon dioxide storage tank is sequentially connected with the carbon dioxide injection high-pressure pump, the heater, the dye mixing tank, the mixed dye injection high-pressure pump, the dye vat set, the pressure reduction cooler, the separation kettle, the condenser and the precise filter. The dye vat set includes the two dye vats. Each dye vat is connected with a dye vat inlet valve and a dye vat outlet valve. The inlet valve of each dye vat is connected with the mixed dye injection high-pressure pump. The outlet valve of each dye vat is connected with the pressure reduction cooler. The supercritical carbon dioxide fluid dyeing device has the advantages that generation of dyeing waste water and other wastes is avoided, environment-friendly and clean production can be achieved, and the device is low in cost and evident in economical and environmental benefits.

Owner:WUXI CITY HUAYANG DYEING & FINISHING MACHINERY

Imitation fur setting process

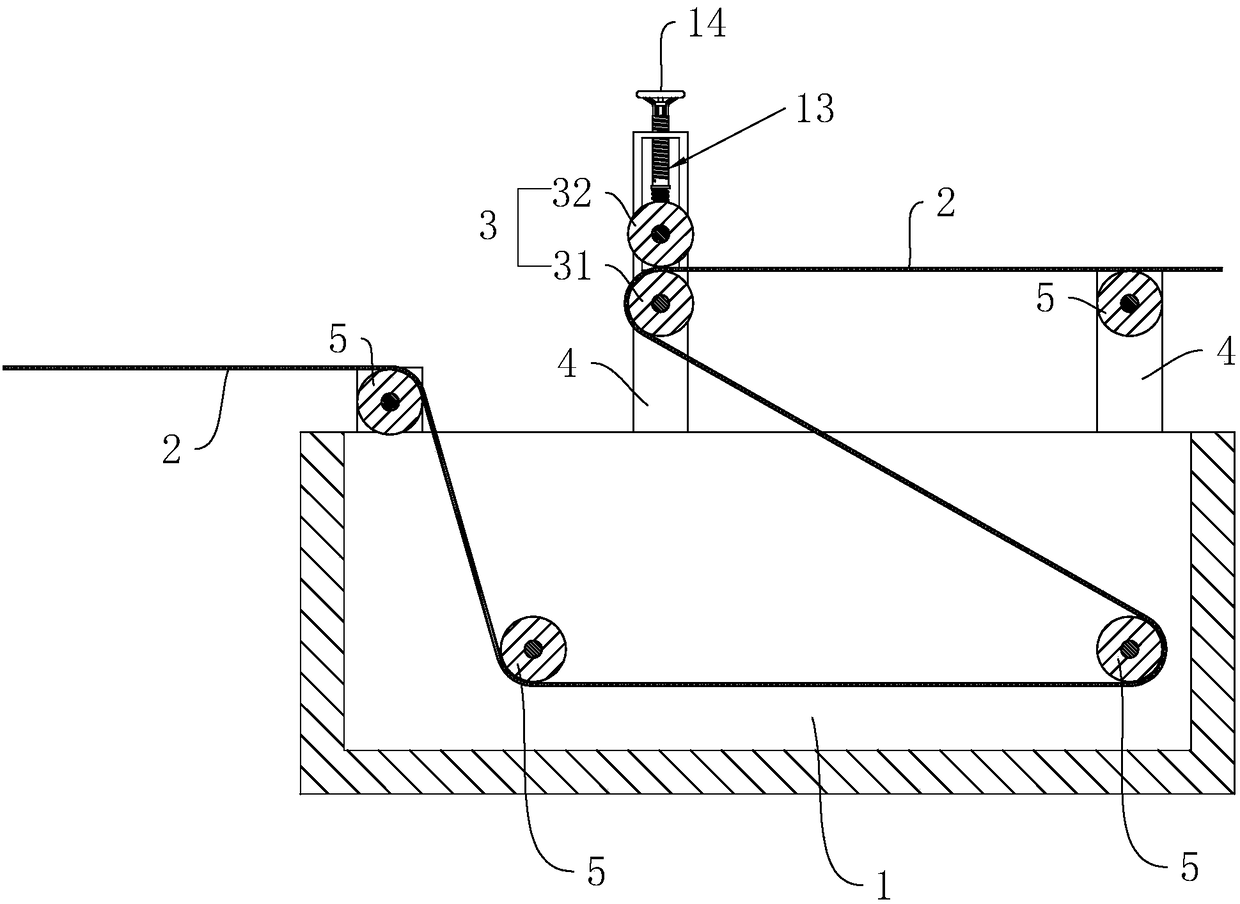

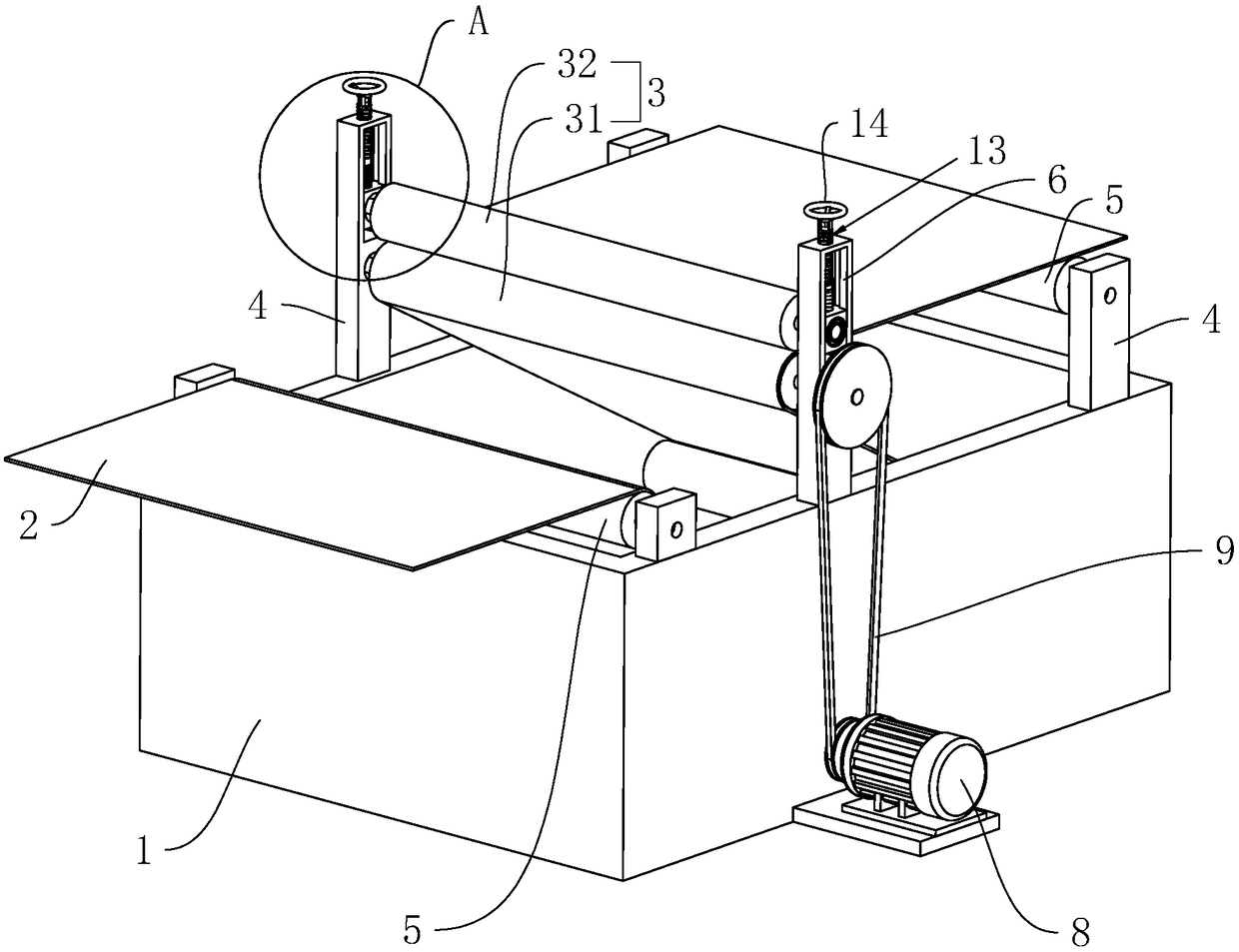

InactiveCN108385313AImprove uniformityQuality improvementSucessive textile treatmentsTwo or more solvent application treatmentFiberWater resources

The invention discloses an imitation fur setting process, and belongs to the technical field of imitation fur processing. The imitation fur setting process is technically characterized in that an imitation fur finished product can be obtained by gray cloth unwinding, cleaning, decontaminating-flushing, dehydrating-scutching, first setting, napping, second setting-drying, third setting-drying, cooling-setting and coiling-warehousing. Through a three-setting process, the fiber uniformity among imitation fur surfaces is improved, and the imitation fur finished product is more attractive and better in quality; a water squeezing roller is provided, so that the moisture in imitation fur between a first roller and a second roller can be squeezed out and reflow into a water groove, the water resource is saved, and the comprehensive utilization rate of the water resource in the water groove is increased. Moreover, a driving assembly is provided, and the second roller is further compressed on the first roller, so that the water squeezing efficiency is increased; meanwhile, the imitation fur setting process can be suitable for water squeezing operation of imitation furs of different thicknesses, and has higher efficiency.

Owner:嘉兴市远大纺织印染有限公司

Method and device for static dyeing by adopting supercritical fluid

ActiveCN102817194BRealize cycle workMeet the needs of large-scale productionTextile treatment containersChemical fixing of textilesProcess engineeringChemistry

The invention discloses a method for static dyeing by adopting supercritical fluid. The method comprises the following steps of: (1) dyeing: placing an object to be dyed in an uptake dyeing system for uptake dyeing; (2) static developing and color fixing with the supercritical fluid: placing the dyed object to be dyed in the step (1) in a supercritical fluid developing and color fixing kettle, and adding the supercritical fluid in the supercritical fluid developing and color fixing kettle for the developing and color fixing of the object to be dyed in the static supercritical fluid; and (3) after the developing and color fixing are completed, eliminating system pressure to recover the supercritical fluid, and opening the supercritical fluid developing and color fixing kettle for taking out the object to be dyed. In the method for static dyeing by adopting supercritical fluid, the supercritical fluid is in a stationary state in the developing and color fixing process, so that the phenomenon of dye migration cannot occur, the dyeing quality is easy to control, and the dyeing system does not need to be cleaned in the replacement of the dyeing color. Meanwhile, the invention also discloses a device for realizing the method for static dyeing by adopting the supercritical fluid.

Owner:陈志刚

Linen-like cool wool knitted underwear fabric and preparation method for same

ActiveCN104323439AImprove comfortAvoid thick and shortWeft knittingTwo or more solvent application treatmentFiberEngineering

The invention relates to a linen-like cool wool knitted underwear fabric and a preparation method for the same. A woven structure of the wool knitted underwear fabric is a combined structure of close-mesh stitches and plain stitches. The preparation method comprises the following steps of performing weaving on a one-sided circular knitting machine according to the woven structure of the underwear fabric, wherein the coil length of the fabric is 13 to 14cm per 50 stitches, and the gram weight of the fabric is 110 to 150g / m<2>; performing dyeing and finishing to obtain the linen-like cool wool knitted underwear fabric by virtue of a one-bath method, wherein the dyeing bath ratio is 1:18. According to the knitted underwear fabric, regular single-stitch multi-column tucking is adopted, so that smaller concave and convex holes are formed, and twill effects are achieved, so that the knitted underwear fabric has certain linen-like effects on appearance, and has the advantages of moisture absorption, sweat releasing, coolness, permeability, bacterium inhibition, mold prevention, smooth hand-feel and the like of a linen fabric, and the shortcomings of thickness, shortness, hardness, difficulty in weaving and the like of bastose are overcome.

Owner:上海嘉麟杰纺织科技有限公司

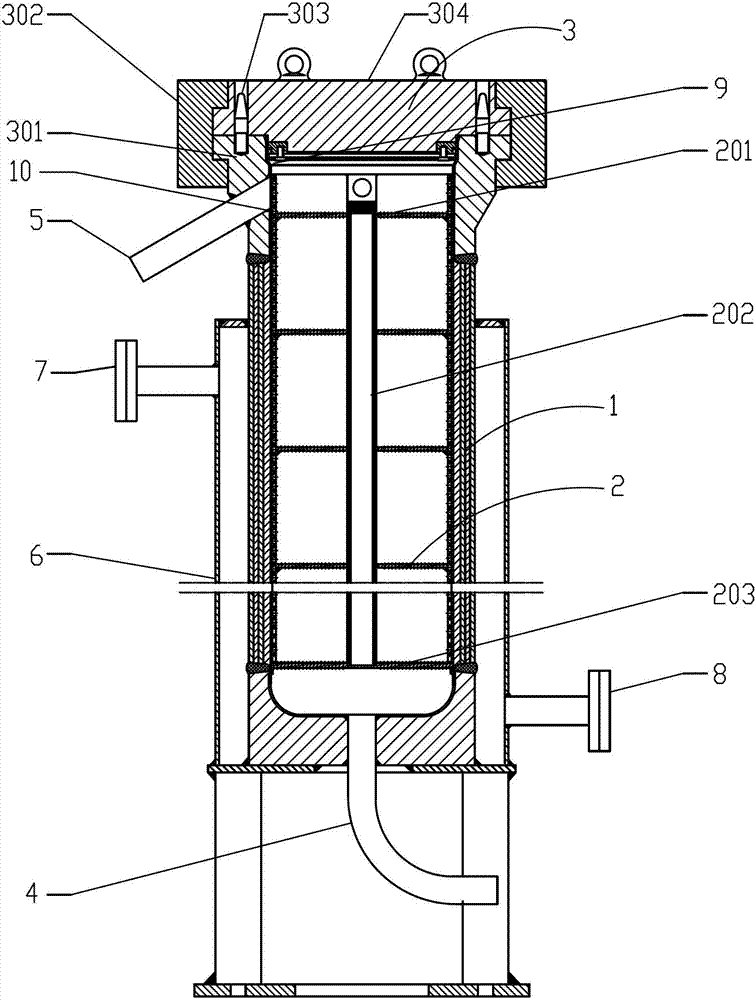

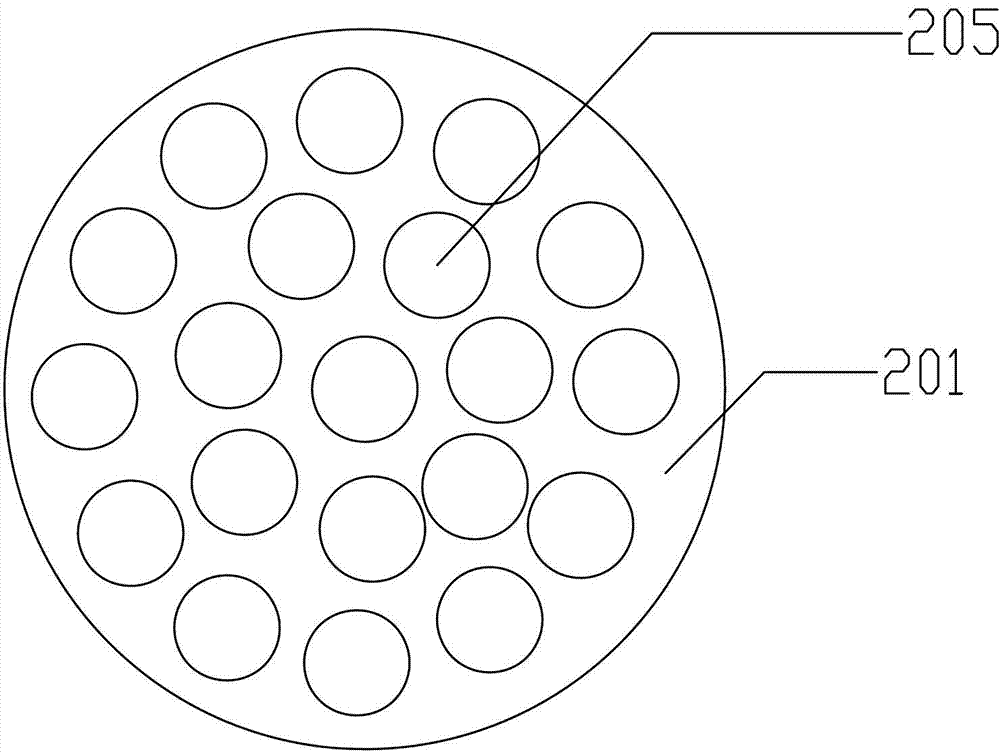

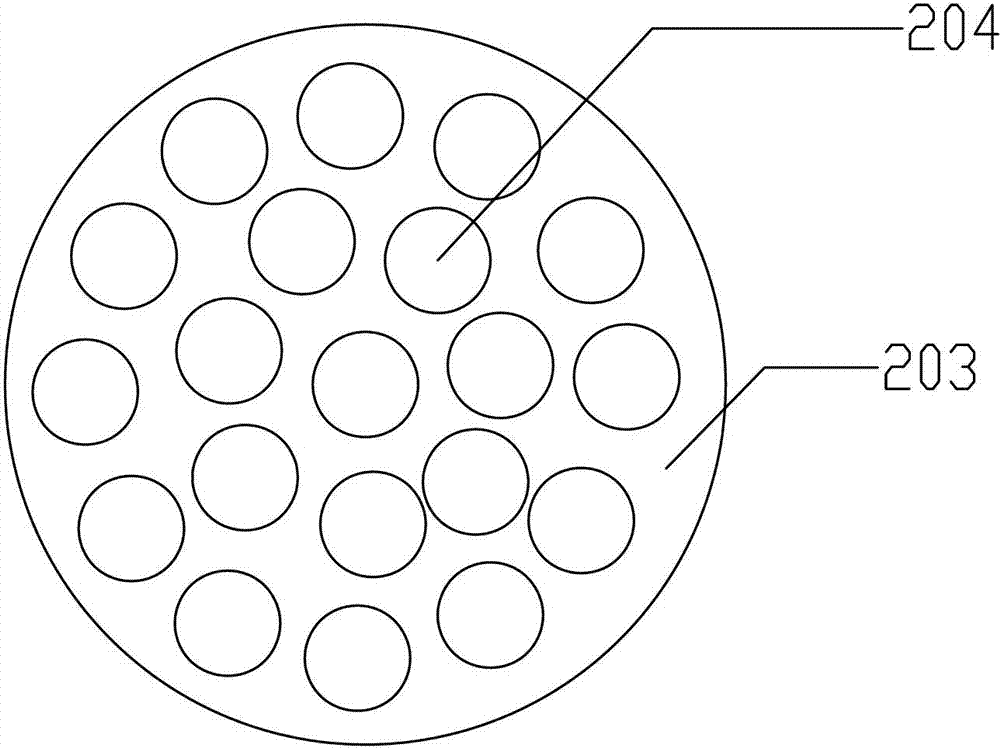

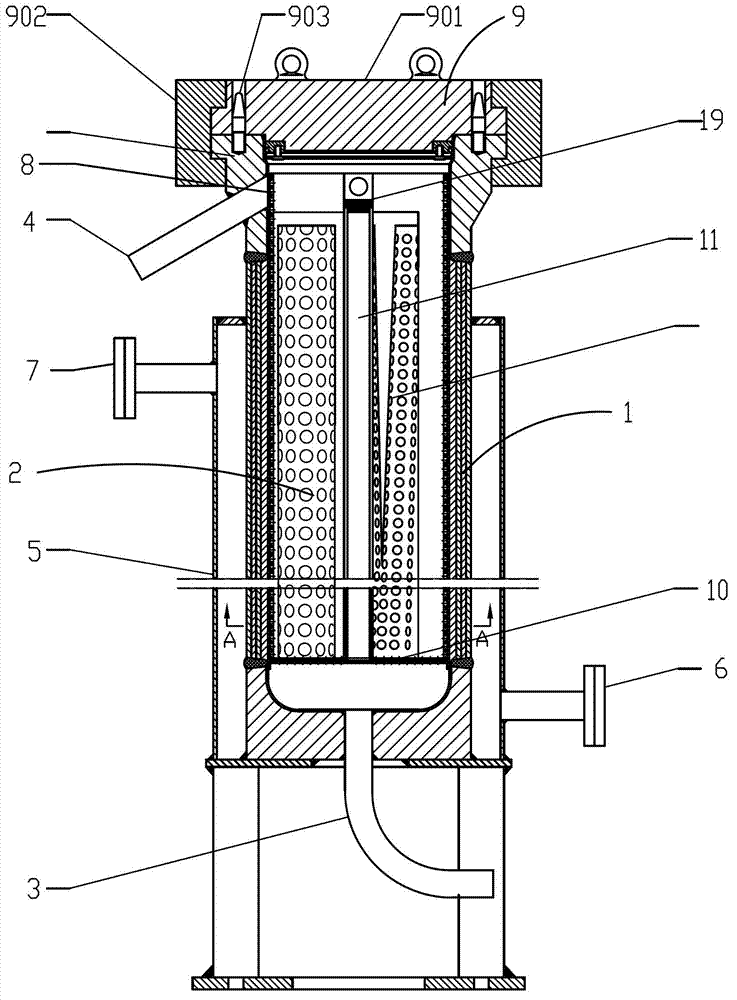

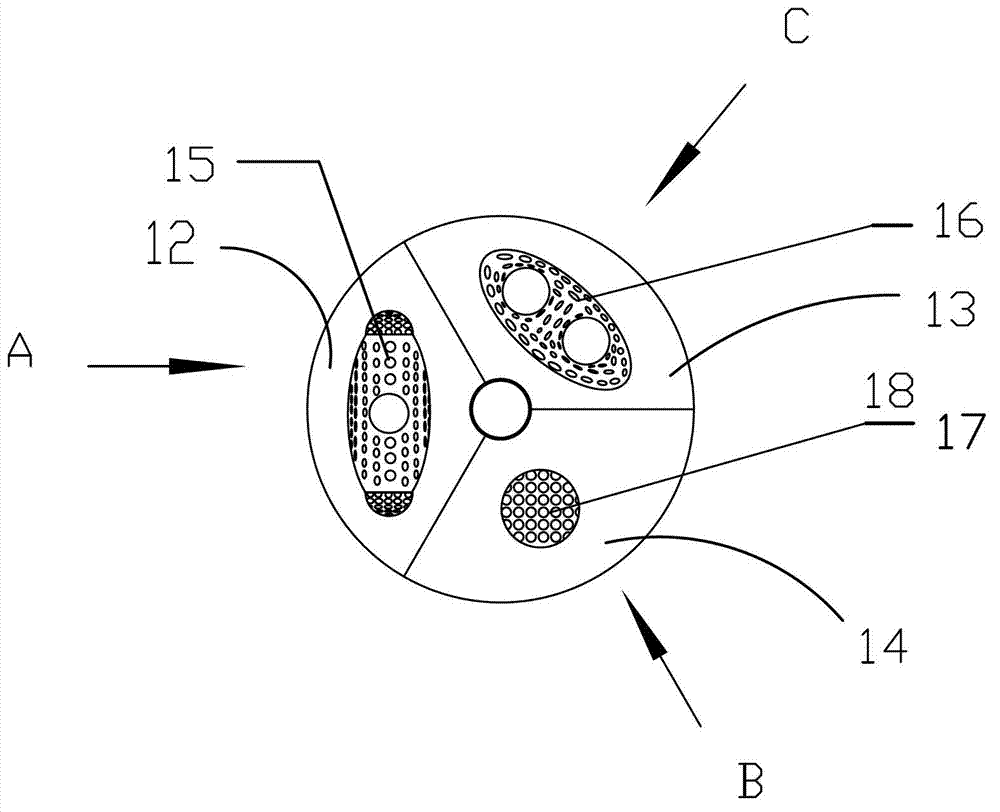

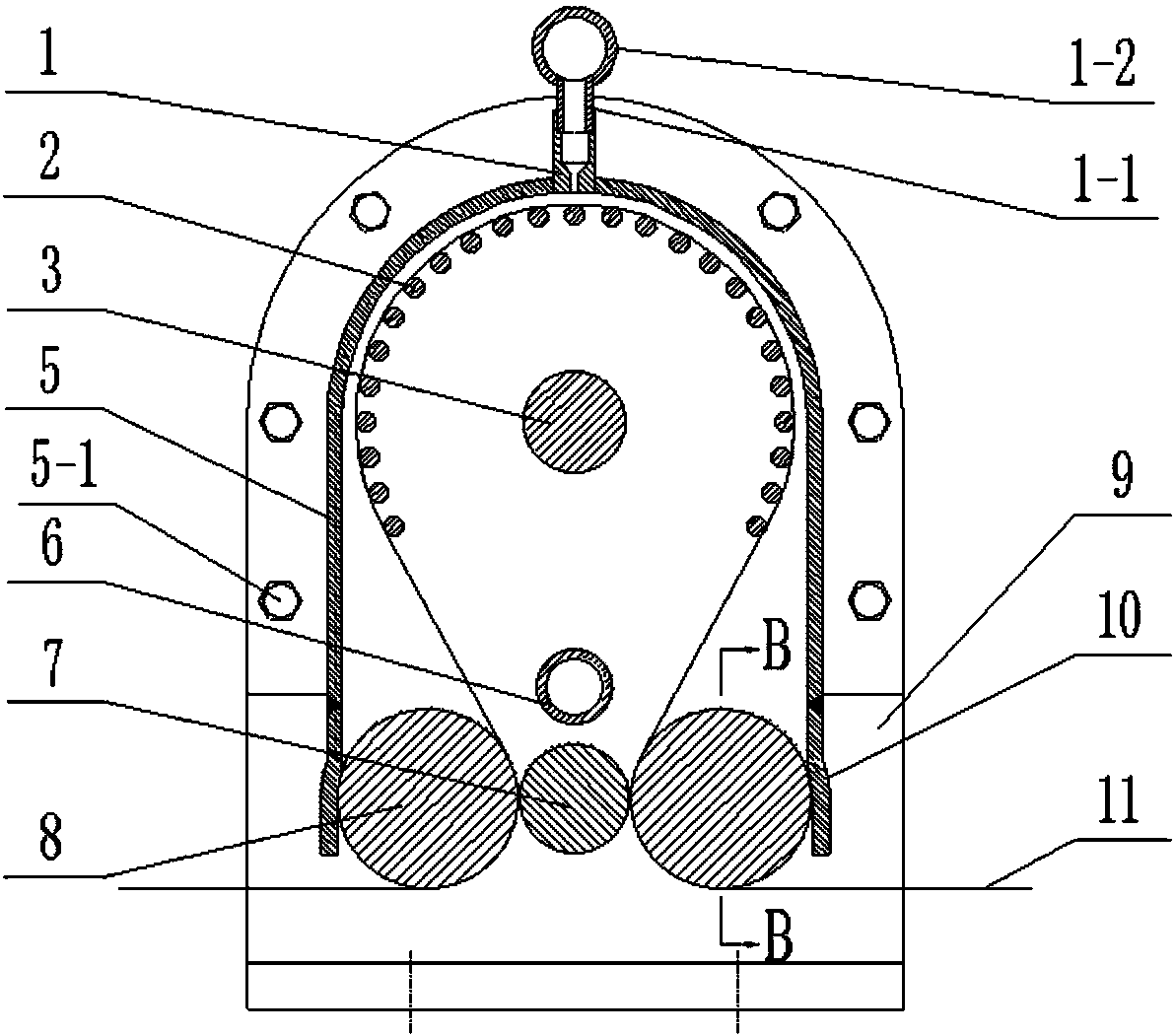

Supercritical carbon dioxide garment dyeing kettle and waterless dyeing method thereof

ActiveCN102776740AAchieve dyeingMeet the development requirementsTextile treatment containersTextile solvent-dyeingDistributorSupercritical carbon dioxide

The invention relates to a supercritical carbon dioxide garment dyeing kettle. The supercritical carbon dioxide garment dyeing kettle comprises a cylinder body and a garment dyeing barrel body, wherein the garment dyeing barrel body is fixed in the cylinder body; a movable sealing cover is installed at the upper end of the cylinder body, a carbon dioxide fluid outlet is arranged at the lower end of the cylinder body, and a carbon dioxide fluid inlet is arranged at the upper part of the cylinder body; a heating jacket is fixedly arranged on the outer side of the cylinder body; and a heating medium outlet is arranged at the upper end of one side of the heating jacket, and a heating medium inlet is arranged at the lower end of the other side of the heating jacket. The supercritical carbon dioxide garment dyeing kettle is characterized in that an area distributor is fixedly arranged at the center of a support plate at the bottom of the garment dyeing barrel body, and divides the garment dyeing barrel body into three areas, namely, a clothes rack area I, a trousers rack area II and an ornament rack area III; a hole is formed in the support plate at the bottom of the garment dyeing barrel and the diameter of the hole is corresponding to the hole diameter of the cylinder body. According to the supercritical carbon dioxide garment dyeing kettle, the influence on degradation factors of fluid flow in the garment dyeing can be improved, and the dyeing uniformity and the dye-uptake can be improved.

Owner:晋江国盛新材料科技有限公司

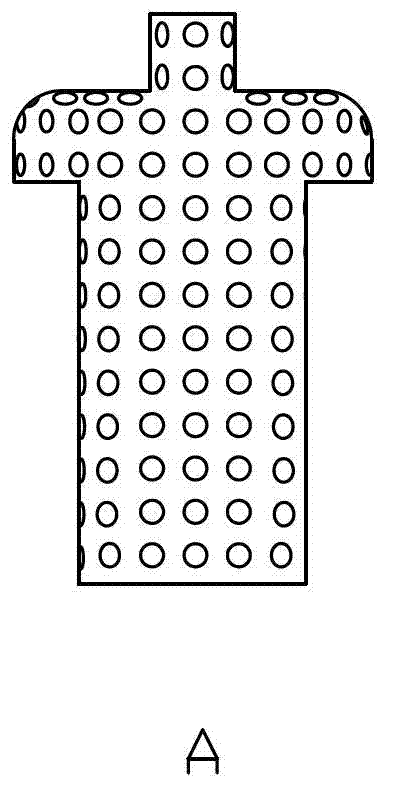

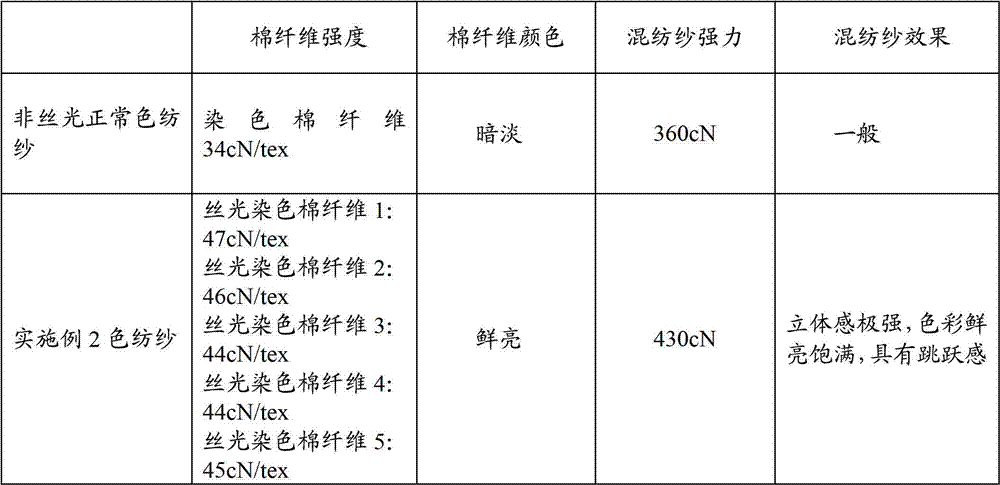

Manufacturing method for colored spun yarn blended with mercerized fiber

ActiveCN102758285AConveniently preparedImprove spinnabilityMercerising of sliversMercerising of tubular fabricsYarnEngineering

The invention discloses a manufacturing method for colored spun yarn blended with mercerized fiber. The manufacturing method comprises the following steps of: preparing rough yarn, mercerizing the rough yarn, dying the rough yarn, drying and loosing the rough yarn, mixing the fiber of the dried rough yarn, carrying out pre-spinning preparation, and spinning. According to the manufacturing method disclosed by the invention, the real mercerized-dyed fiber can be conveniently manufactured by the existing equipment, the fiber intensity of the manufactured mercerized-dyed fiber is greatly enhanced, the manufactured mercerized-dyed fiber is favorable for obviously enhancing the spinnability of the colored spun yarn, the manufactured colored spun yarn is bright and abundant in color, and the stereoscopic impression of the yarn is strong. Meanwhile, the manufacturing method breaks through the limitation that protein fiber which is not alkaline-resisting and the mercerized fiber cannot coexist in the yarn, so that the additional value of cotton fiber is obviously enhanced, and the selection range of customers is enlarged. In addition, the manufacturing method disclosed by the invention is easy to implement, can be implemented with the existing equipment, and provides the possibility and the guarantee for large scale production.

Owner:GUANGDONG ESQUEL TEXTILES CO LTD +2

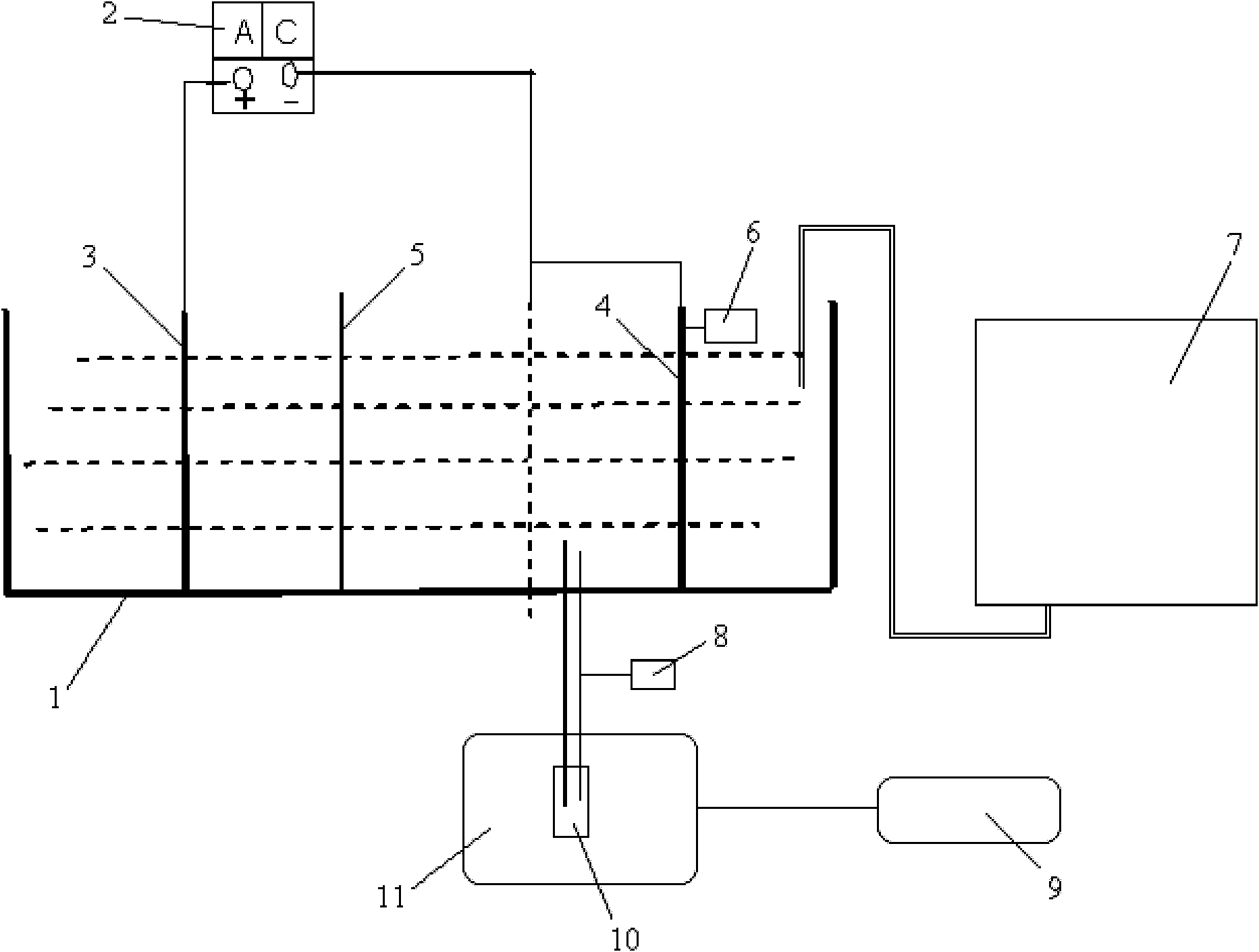

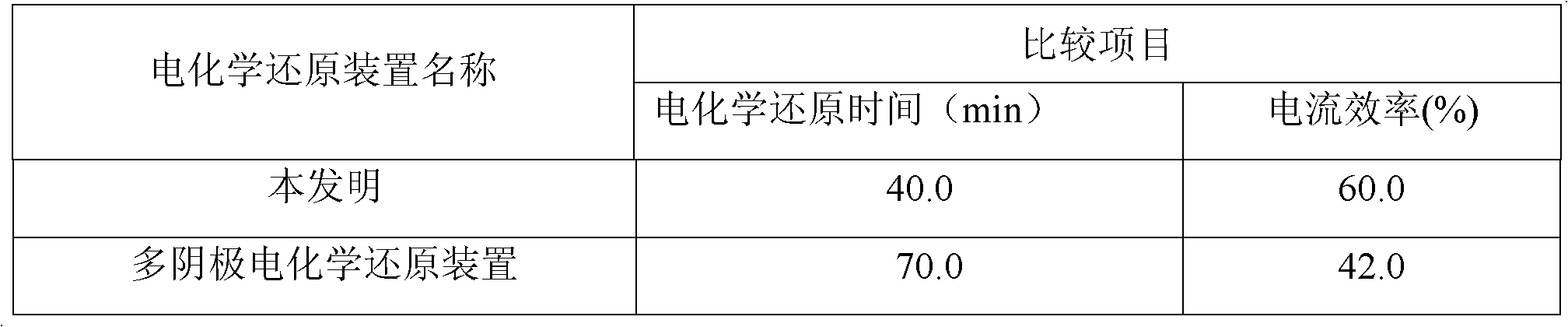

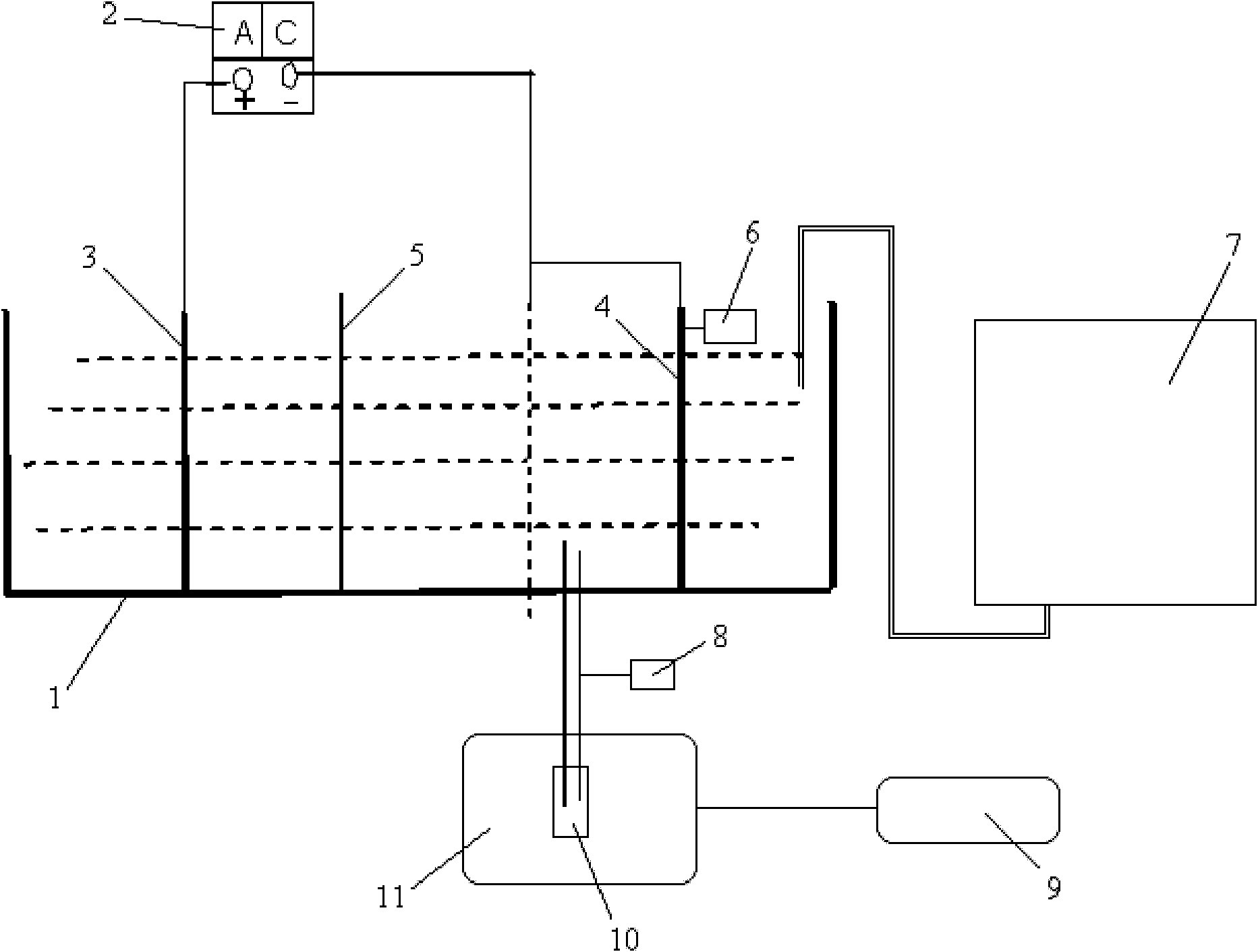

Dyeing apparatus for electrochemical reduction of cotton yarns

InactiveCN102154793AIncrease the chance of mutual contactLess side effectsMaterial analysis by optical meansLiquid/gas/vapor treatment of indefinite length materialsYarnPower flow

The invention relates to a dyeing apparatus for electrochemical reduction of cotton yarns. The dyeing apparatus comprises an electrolytic bath reduction device, a dye concentration on-line monitoring device and a dyeing tank, wherein the electrolytic bath reduction device comprises an electrolytic bath, an anode connected with a positive electrode of a power supply and a cathode connected with a negative electrode of the power supply; an ion exchange isolation membrane is arranged in the electrolytic bath to form an anode region and a cathode region of the electrolytic cell; the anode is arranged in the anode region of the electrolytic bath; the cathode is arranged in the cathode region of the electrolytic bath and is connected with a translation device; the dyeing tank is connected with the cathode region of the electrolytic bath through a first pipeline; and the cathode region of the electrolytic bath is provided with the dye concentration on-line monitoring device in a connecting manner. Through the dyeing apparatus, electrolytic reduction speed of a dye can be increased, and current efficiency can be increased.

Owner:DONGHUA UNIV

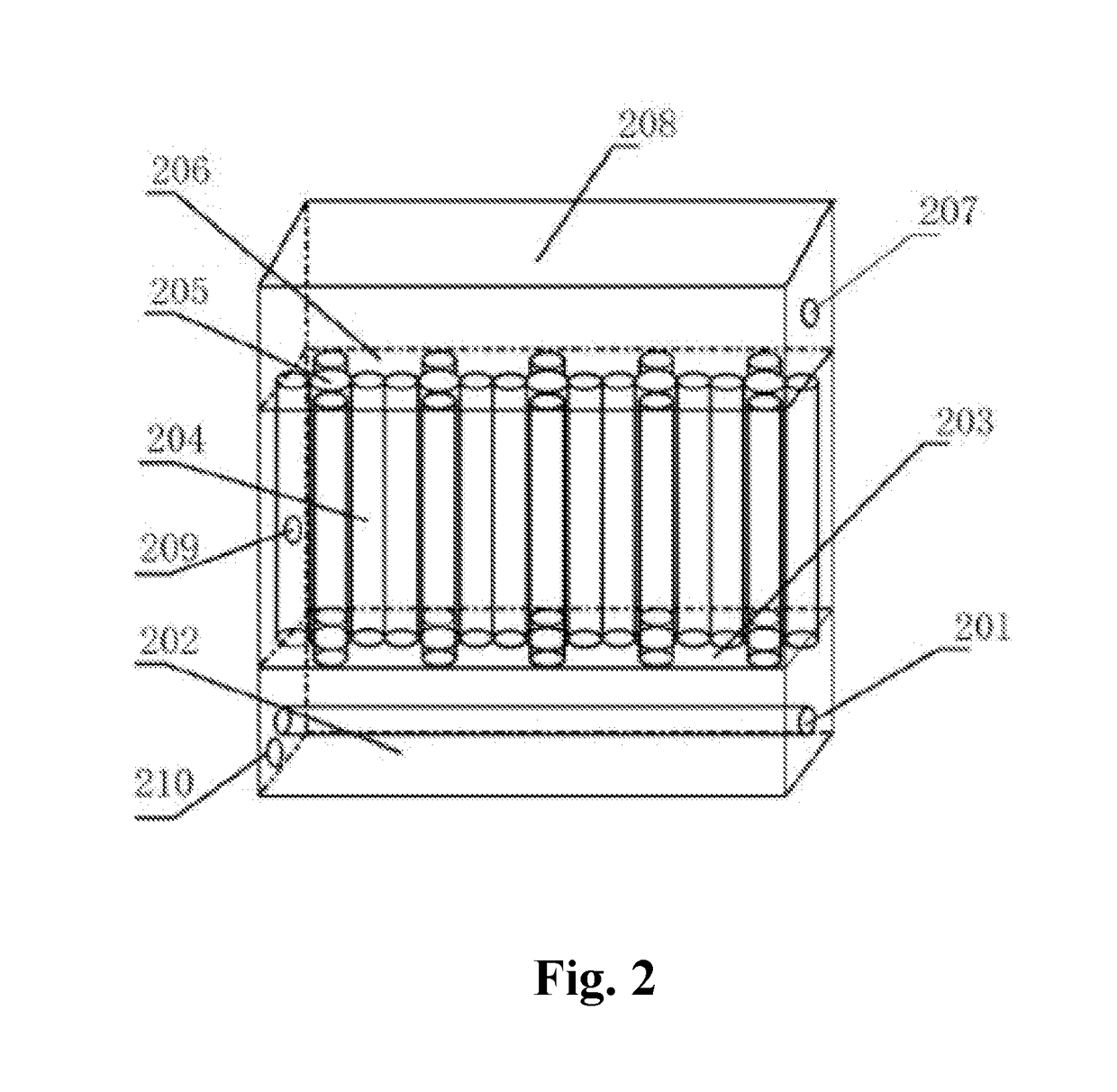

Multi-element dyeing and finishing kettle and industrial supercritical CO2 fluid anhydrous dyeing and finishing equipment with scale of 1000L or more

ActiveCN106835560ASolve the color changing problemRealize finishing productionTextile treatment containersSolvent treatment with solvent recoveryAutomatic controlSupply Storage

The invention discloses a multi-element dyeing and finishing kettle and industrial supercritical CO2 fluid anhydrous dyeing and finishing equipment with the scale of 1000L or more. The industrial supercritical CO2 fluid anhydrous dyeing and finishing equipment mainly comprises a CO2 low-temperature storage tank, a CO2 supply storage tank, a low-temperature delivery pump, an ethanediol head tank, an ethanediol pump, a water cooling tower, a water pump, a refrigerating unit, a condenser, a heat exchanger, a conduction oil system, a conduction oil supplementing system, a precooler, a CO2 booster pump, a dye kettle, a feeder, the multi-element dyeing and finishing kettle, a CO2 circulating pump, a cooler, a separating kettle, an adsorber, a recovery compressor, an online monitoring system and an automatic control system. The equipment is provided with the multi-element dyeing and finishing kettle and therefore is capable of achieving dyeing and finishing production of multiple kinds of monochromatic or polychromatic textiles. The dye kettle has the function of feeding at the right moment and can meet the requirement for fully dissolving dye and adding polychromatic dye; the dyeing and finishing equipment is connected with ultraperformance convergence chromatography and has the online monitoring function. The whole equipment achieves intelligence, automatic processing, energy conservation and environmental protection of the whole anhydrous dyeing and finishing process.

Owner:晋江国盛新材料科技有限公司

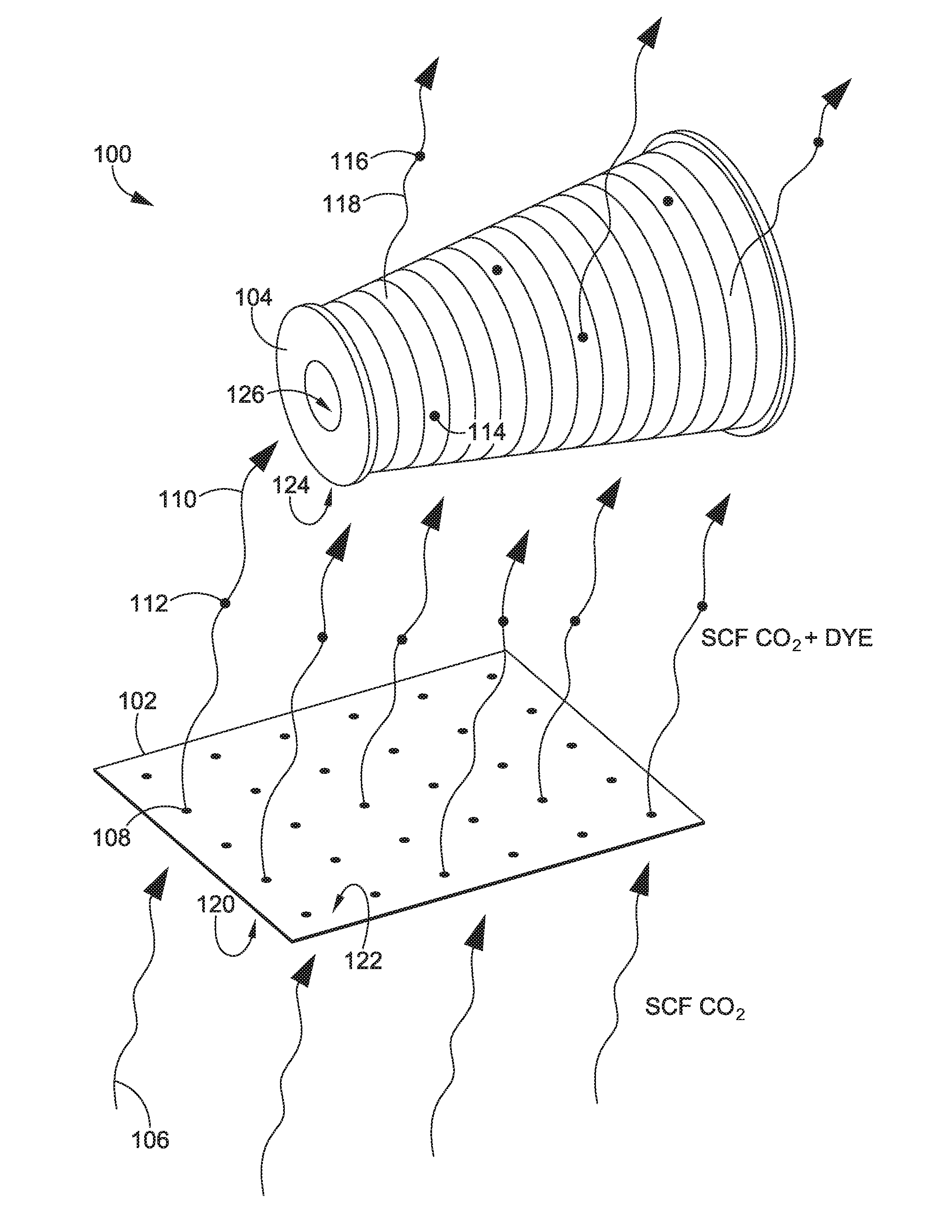

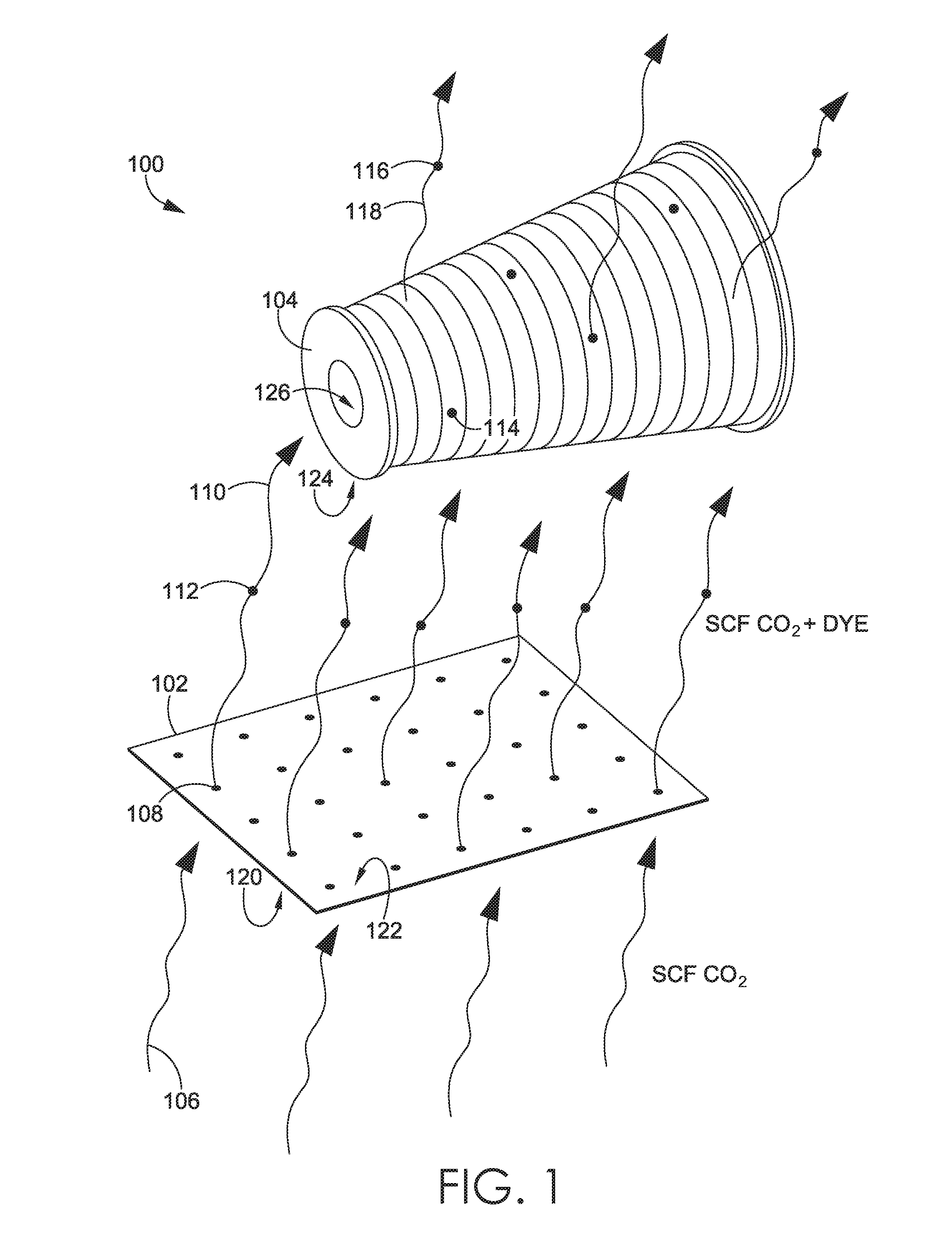

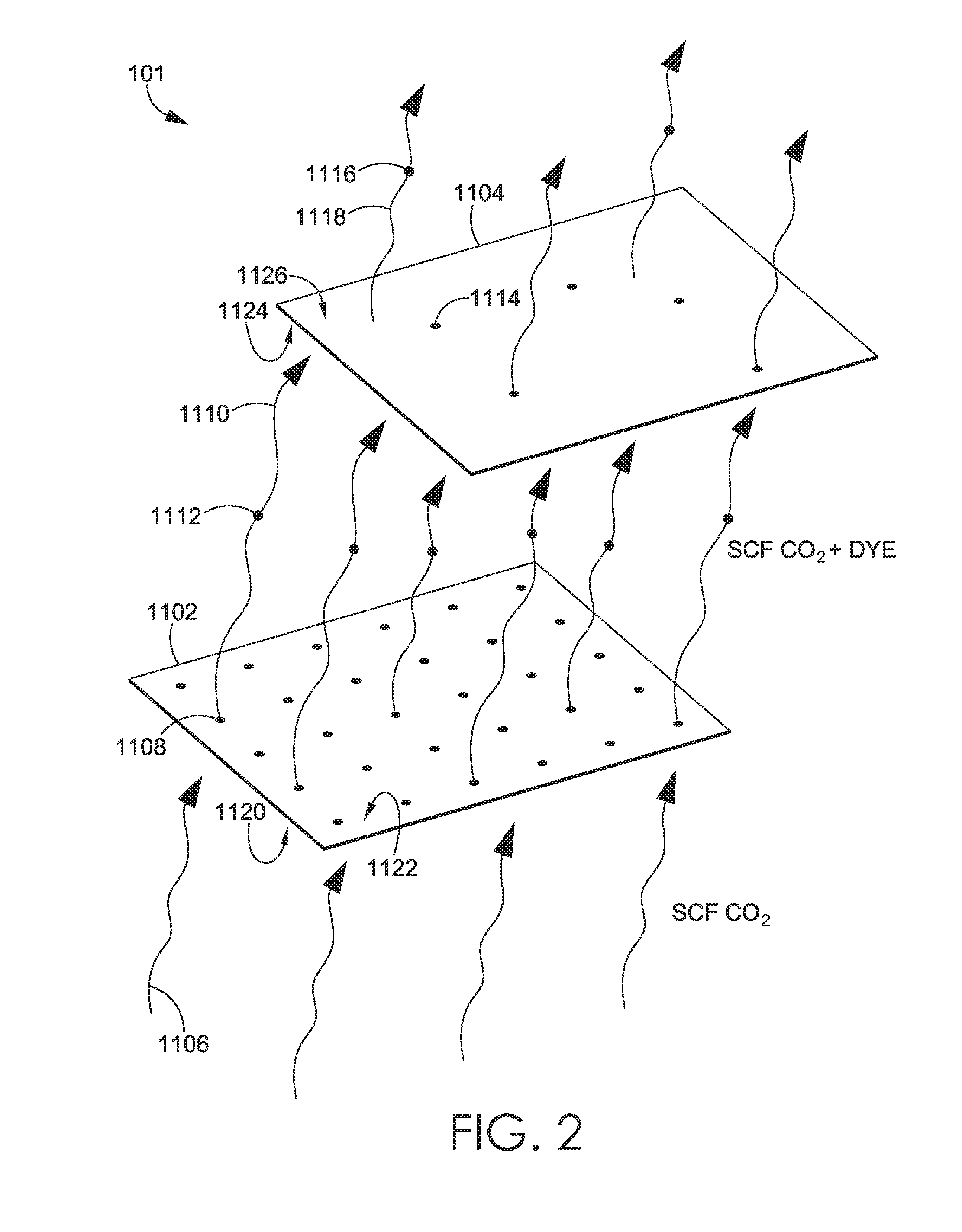

Supercritical fluid rolled or spooled material finishing

Methods are directed to the use of a supercritical fluid for performing a dyeing of a material such that dye from a first material is used to dye a second material. A supercritical fluid is passed through a first material in a pressurized vessel. The supercritical fluid transports the dye from the first material to at least a second material causing a dye profile of the second material to change as a result of dye from the first material perfusing the second material.

Owner:NIKE INC

Finishing method for deepening and stabilizing colors of natural green cottons

The invention discloses a finishing method for deepening and stabilizing colors of natural green cottons. The method comprises the following steps: 1) putting natural green cotton fibers in a solvent to carry out soaking pretreatment and naturally airing the natural green cotton fibers after treatment to obtain the pretreated cotton fibers; and 2) selecting a supercritical fluid dyeing machine with a dye kettle and a dyeing kettle; and filling the dyeing kettle with a bulky material liable to color staining, putting the pretreated cotton fibers in the dye kettle of the supercritical fluid dyeing machine and taking the ethanol with the volume fraction of 94-96% as an entrainer and CO2 as a supercritical fluid to treat the pretreated cotton fibers for 2-4 hours under the pressure of 20-40MPa and temperature of 40-70 DEG C. The natural green cotton fibers treated by the method have the characteristics of deepened, uniform and stabilized colors and the like.

Owner:ZHEJIANG SCI-TECH UNIV

Novel ejector used for supercritical fluid jet dying

InactiveCN103981661AGood workmanshipNot easy to cause dyeing dead zoneTextile treatment machine arrangementsTextile solvent-dyeingSpray nozzleDissolution

The invention relates to the field of textile dying equipment, in particular to a novel ejector used for supercritical fluid jet dying. According to the jet dying technological process, the novel ejector is installed in a supercritical fluid jet dying device and is connected with a supercritical fluid generation subsystem, a dye dissolution subsystem and a used fluid recovery and separation subsystem. The novel ejector is composed of a squirrel-cage-type washing and dying cylinder, a transmission supporting rotor, two lateral wall plates, a gear disk or a synchronous wheel, a driving gear or a synchronous belt, a backflow pipe, a flow adjusting cover, a sealing cover, cloth guide rollers, an anti-overflow roller, spray nozzles, spray nozzle branch pipes and spray nozzle header pipes. According to the novel ejector, dying is implemented in the mode that dyed materials are always in dynamic contact with rolling washing and dying rollers which form the squirrel-cage-type washing and dying cylinder, and therefore dying dead zones are not prone to being caused; meanwhile, deformation and tension damage of the dyed materials are effectively eliminated though the supporting effect of the rolling washing and dying rollers, wherein deformation and tension damage are generated under the effects of high-pressure jet flows and traction force; the novel ejector is simple and compact in structure and excellent in manufacturability.

Owner:SHANDONG UNIV

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com