Supercritical carbon dioxide cheese dyeing kettle and waterless supercritical carbon dioxide cheese dyeing method

A technology of carbon dioxide and dyeing method, applied in the field of textile printing and dyeing, can solve the problems of insufficient fluffy and plump dyed yarns, high water and energy consumption, and poor leveling performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

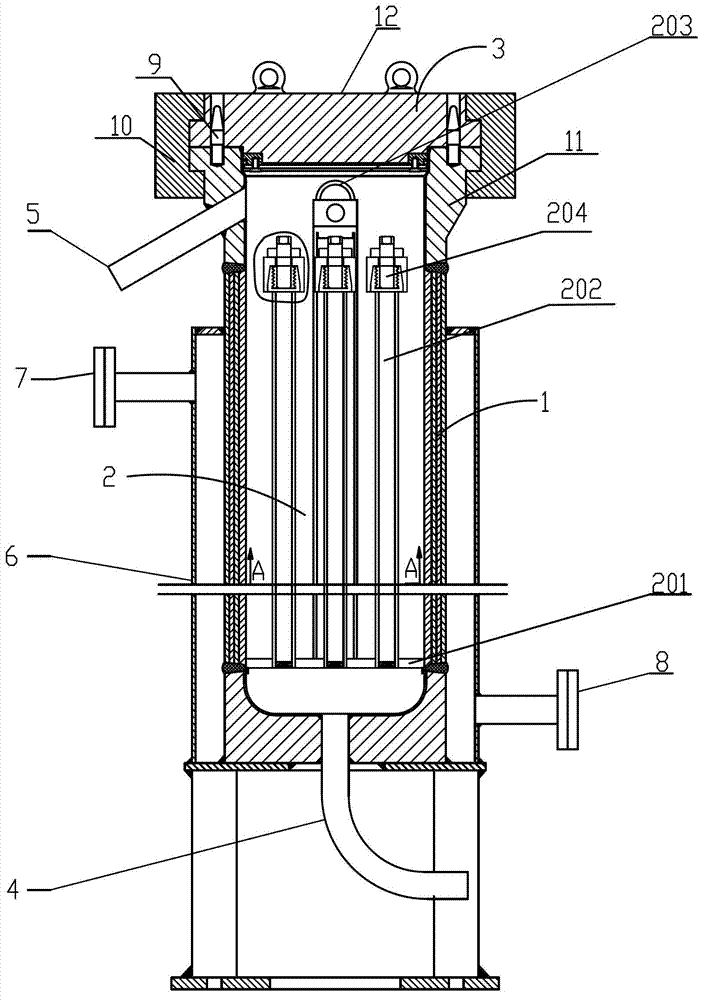

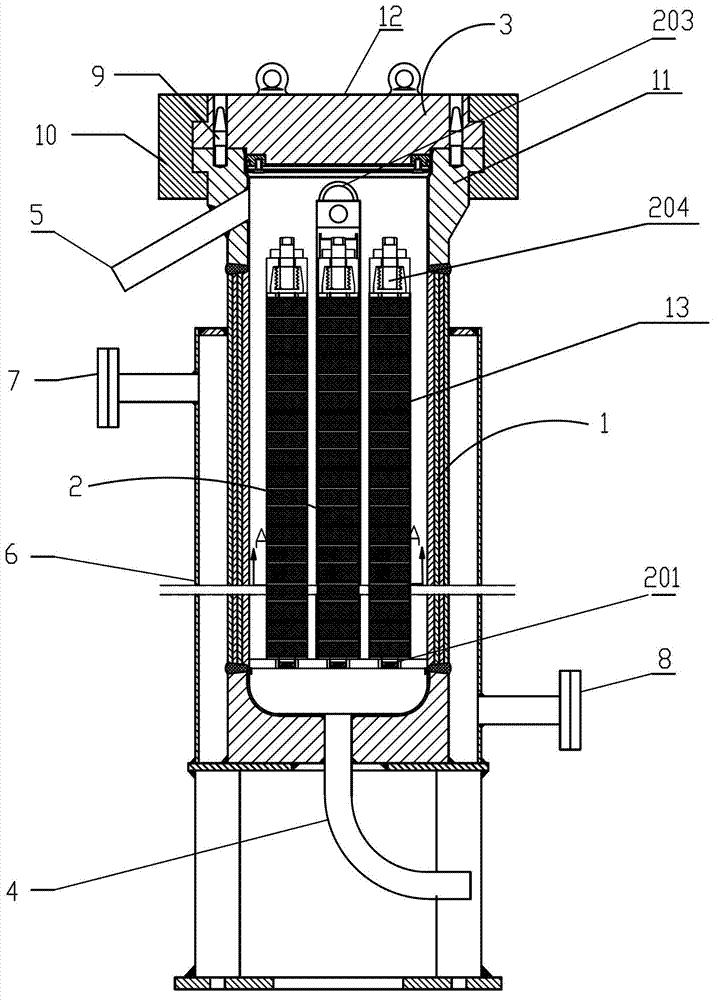

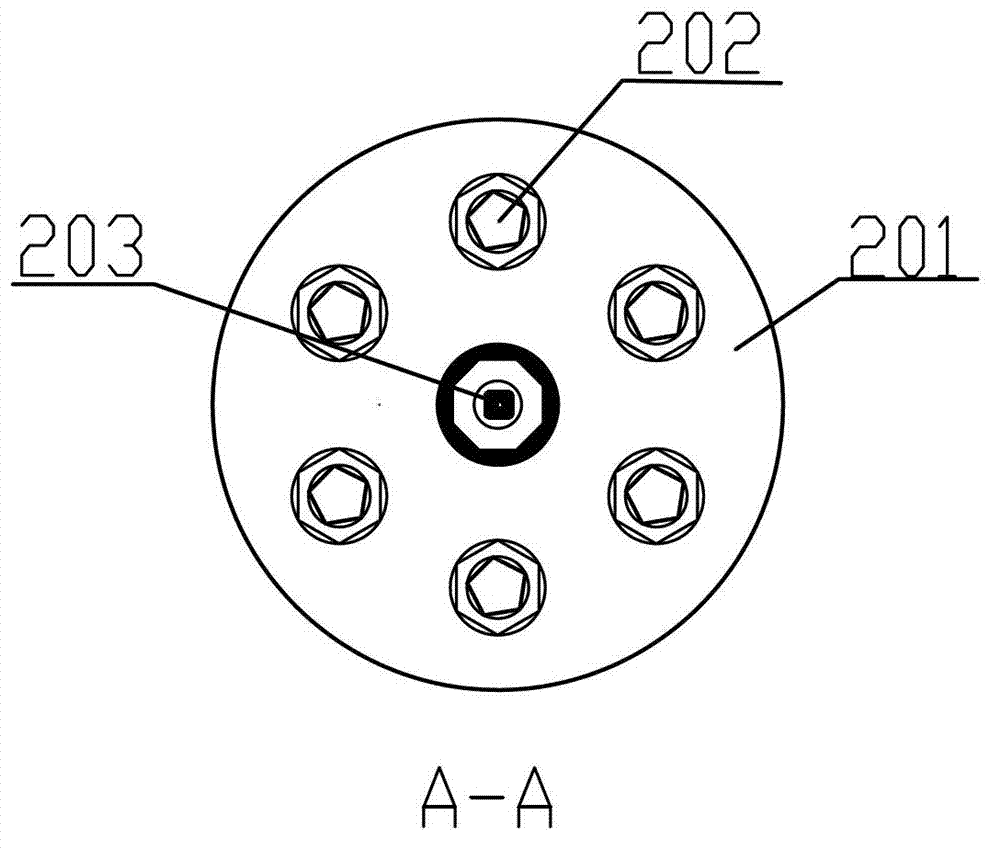

[0025] The carbon dioxide cheese dyeing kettle of the present invention comprises a cylinder body 1 and a cheese support 2; the cheese support 2 is fixed in the cylinder body 1; the upper end of the cylinder body 1 is fixed with a movable sealing cover 3, and the lower end is provided with a carbon dioxide fluid inlet 4, The upper part of the cylinder 1 is also provided with a carbon dioxide fluid outlet 5; a heating jacket 6 is fixed on the outside of the cylinder 1; the upper end of one side of the heating jacket 6 is provided with a heating medium outlet 7, and the lower end of the other side is provided with a heating medium inlet 8. It is characterized in that the cheese support 2 is composed of a distribution site 201, a central axis 203 and six inserts 202; There are 6 inserts 202 distributed; the inserts 202 are movably connected with the distribution site 201, and can rotate freely around the connection; the central axis 203 is a porous shaft structure; the distributio...

Embodiment 2

[0028] Put 3kg of reactive disperse black dye into the dye kettle, and put 90kg of wool cheese into the special support for cheese. Turn on the refrigeration system, when the pressure of the storage tank drops to 4~4.3MPa, the liquid level of the storage tank rises to 425~427mm, and carbon dioxide gas starts to be introduced. Then, turn on the heater and oil pump to heat the temperature to 90-95°C, start the high-pressure pump to pressurize to 22-23 MPa, and dye for 28-31 minutes. After dyeing, turn off the high-pressure pump, heater and oil pump, release the pressure, cool down and keep it at 3~4MPa, 32~34℃ to recover carbon dioxide and dye, and take out the dyed wool cheese. After dyeing, the color fastness to washing of the cheese can reach grade 3, the color fastness to rubbing can reach grade 4, and the color fastness to light and weather can reach grade 4. The color fastness of wool cheese dyed with traditional reactive disperse black dyes is 3-4 grades. After using spe...

Embodiment 3

[0030]Take out 3.5kg of disperse dark blue dye and put it into the dye kettle, put 35kg of cashmere cheese into the special cheese holder, turn on the refrigeration system, reduce the pressure of the storage tank to 4MPa, the liquid level of the storage tank rises to 421-424mm, and start to introduce carbon dioxide gas. Turn on the heating system and raise the temperature to 130-135°C. Turn on the high-pressure pump, increase the pressure to 20-21MPa, and dye for 30-33 minutes. After dyeing, turn off the high-pressure pump and heating system, release the pressure, lower the temperature to 3.5-4MPa, 38-41°C, recover carbon dioxide and dye, and take out the dyed cheese. After dyeing, the color fastness to washing of cheese yarn is grade 4, the color fastness to rubbing is grade 5, and the color fastness to washing can reach grade 4. The color fastness of package yarn dyed with traditional disperse dark blue dyes is 3-4 grades, and the color fastness of cashmere cheese yarn dyed...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Aperture | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com