Patents

Literature

107results about "Solvent treatment with solvent recovery" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Use of absorbent materials to separate water from lipophilic fluid

InactiveUS6855173B2Safe separationEfficient and cost-effectiveOrganic detergent compounding agentsIon-exchanger regenerationEmulsionAbsorbent material

The present invention relates to the use of absorbent materials for separating water from an emulsion comprising water and lipophilic fluid. The methods, systems, and compositions of the present invention expose the emulsion to absorbent materials such that water is absorbed out of the emulsion in order to facilitate the recovery of the lipophilic fluid.

Owner:THE PROCTER & GAMBLE COMPANY

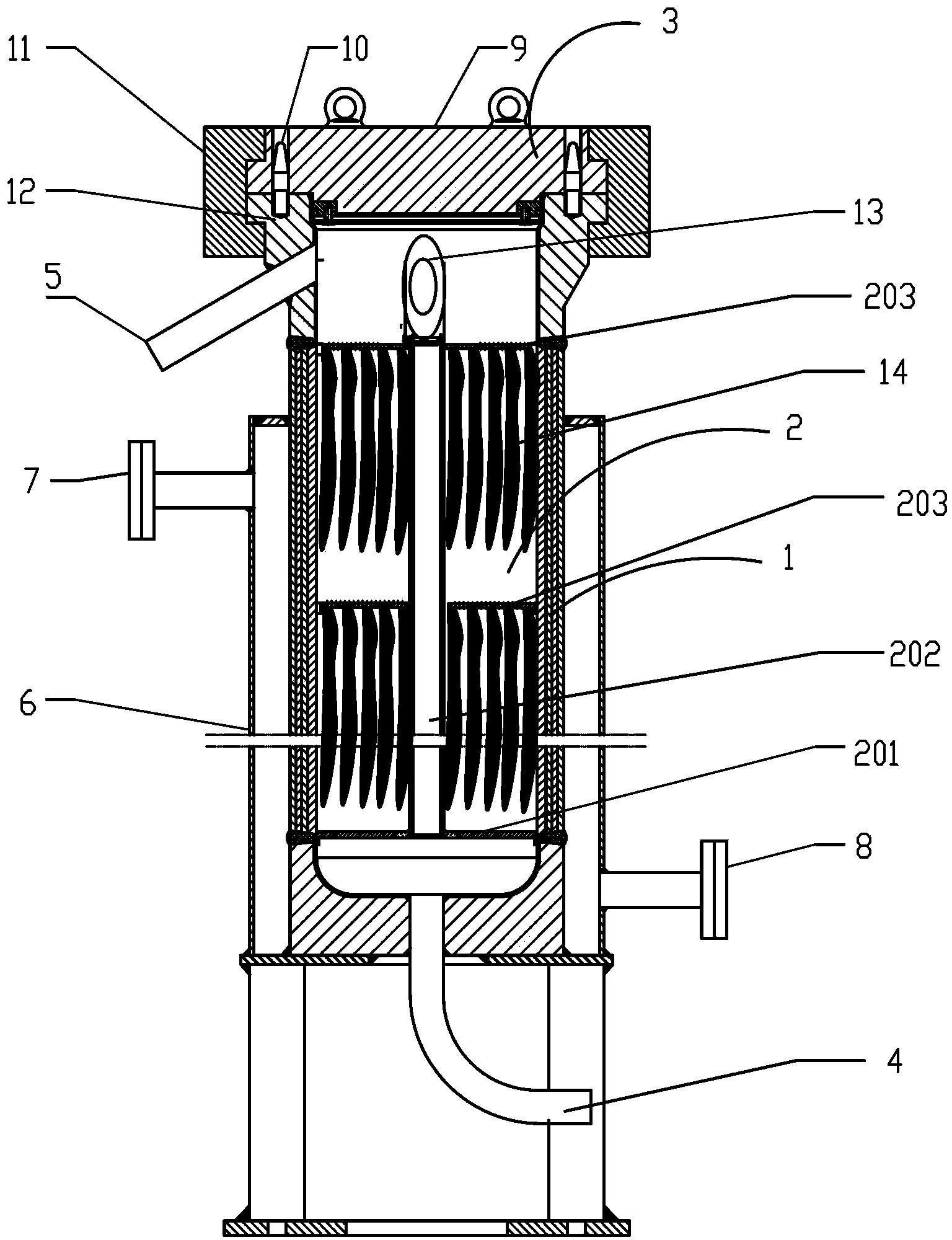

Supercritical carbon dioxide cheese dyeing kettle and waterless supercritical carbon dioxide cheese dyeing method

ActiveCN102787459ATextile treatment containersSolvent treatment with solvent recoveryEngineeringDrill

The invention relates to a supercritical carbon dioxide cheese dyeing kettle and a waterless supercritical carbon dioxide cheese dyeing method. In the dyeing kettle, when carbon dioxide fluid enters a distribution tray from an inlet, blades start rotating clockwise under the effect of pressure; inserted drill rods are driven to rotate by a rotation part; and the rotating speed of the inserted drill rods is increased along with the increase of pressure in a cylinder body. When a cheese is dyed, the cheese on the inserted drill rods is dyed at a speed of 0.2-0.5 r / s. When the rotating cheese is dyed, the cheese is subjected to the pressure of the fluid flowing out from a central shaft; the rotation and bicirculation of the cheese dyeing are realized; the uniform dyeing effect of the dyed cheese can be improved; and the migration ability and the diffusibility can be improved.

Owner:晋江国盛新材料科技有限公司

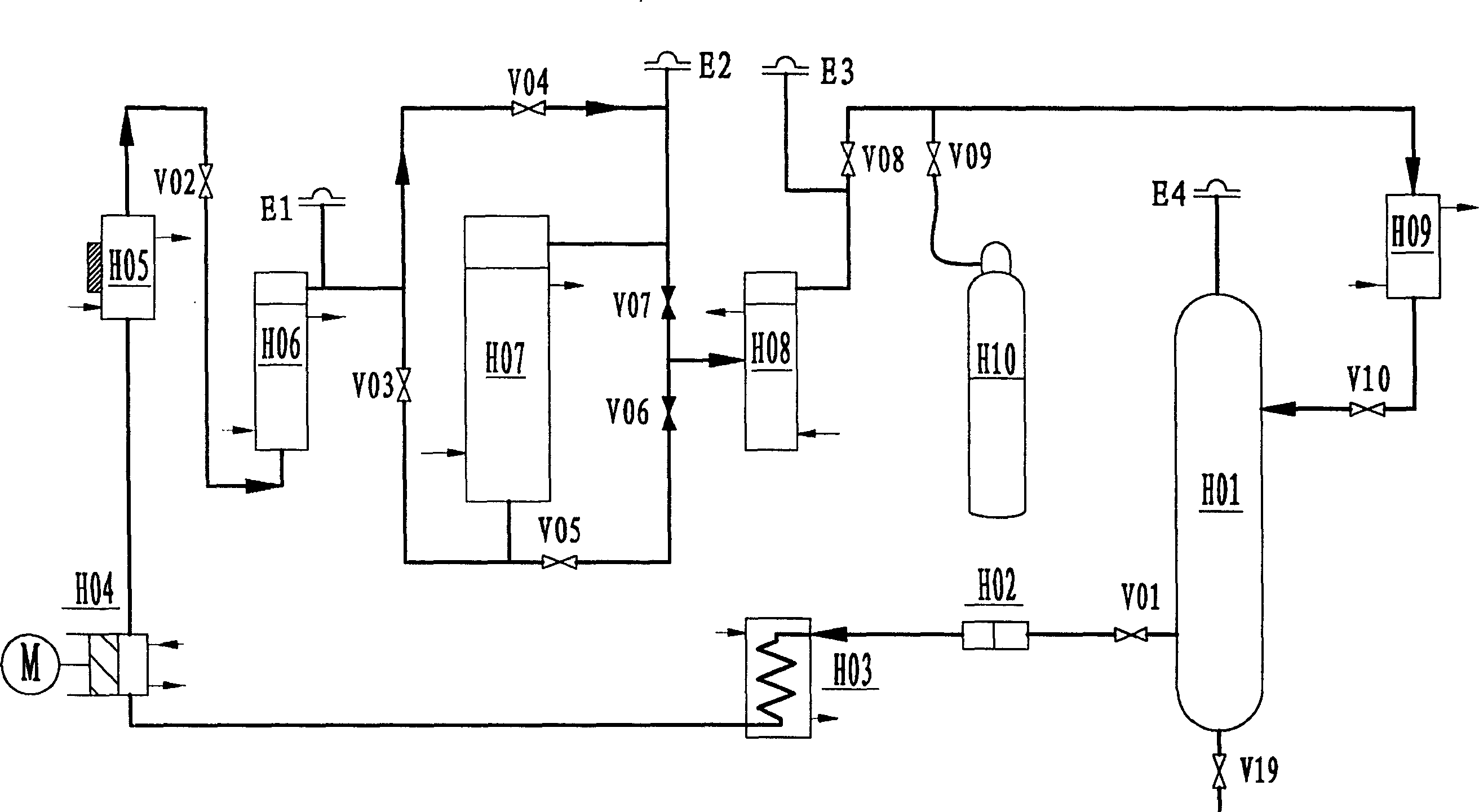

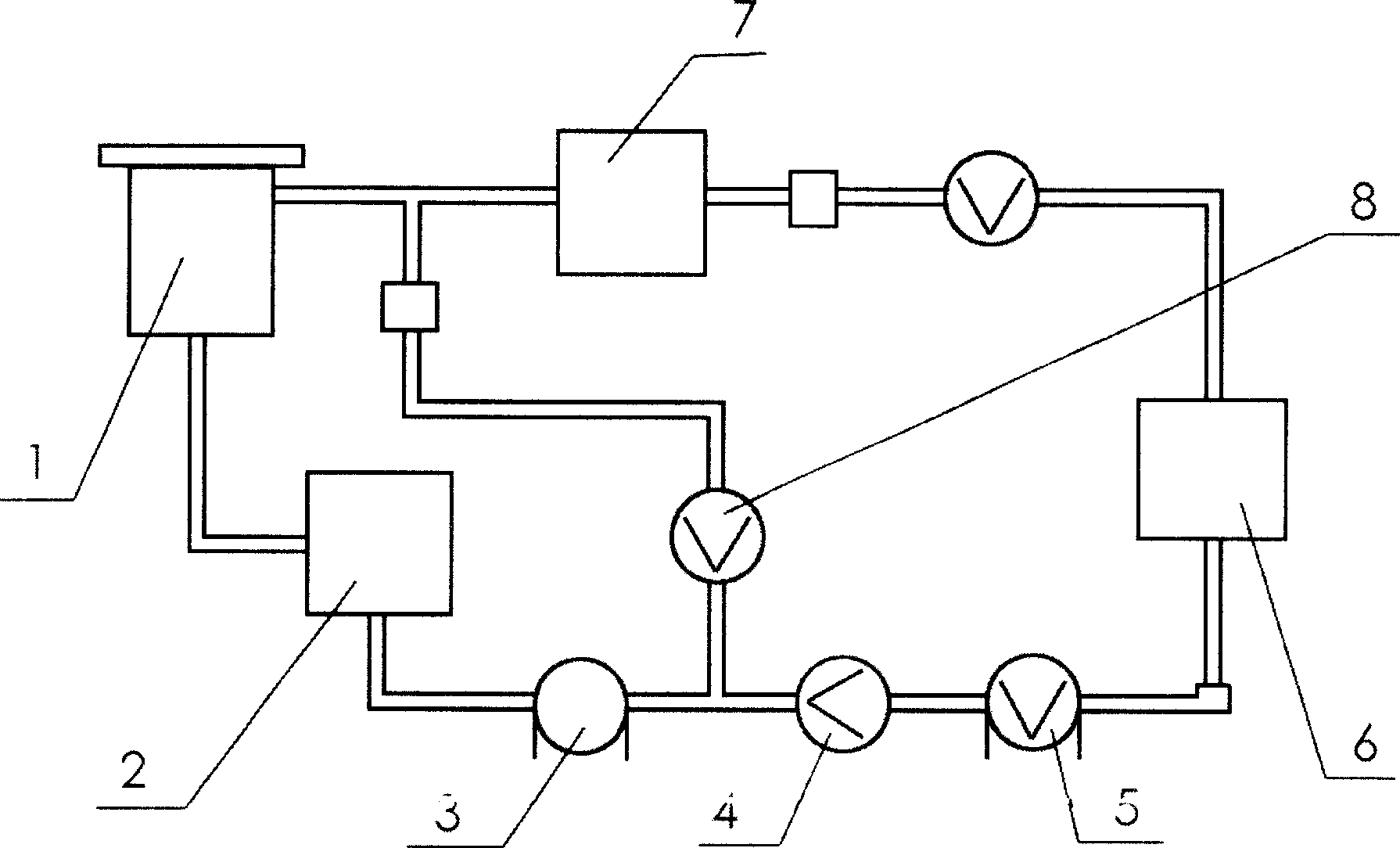

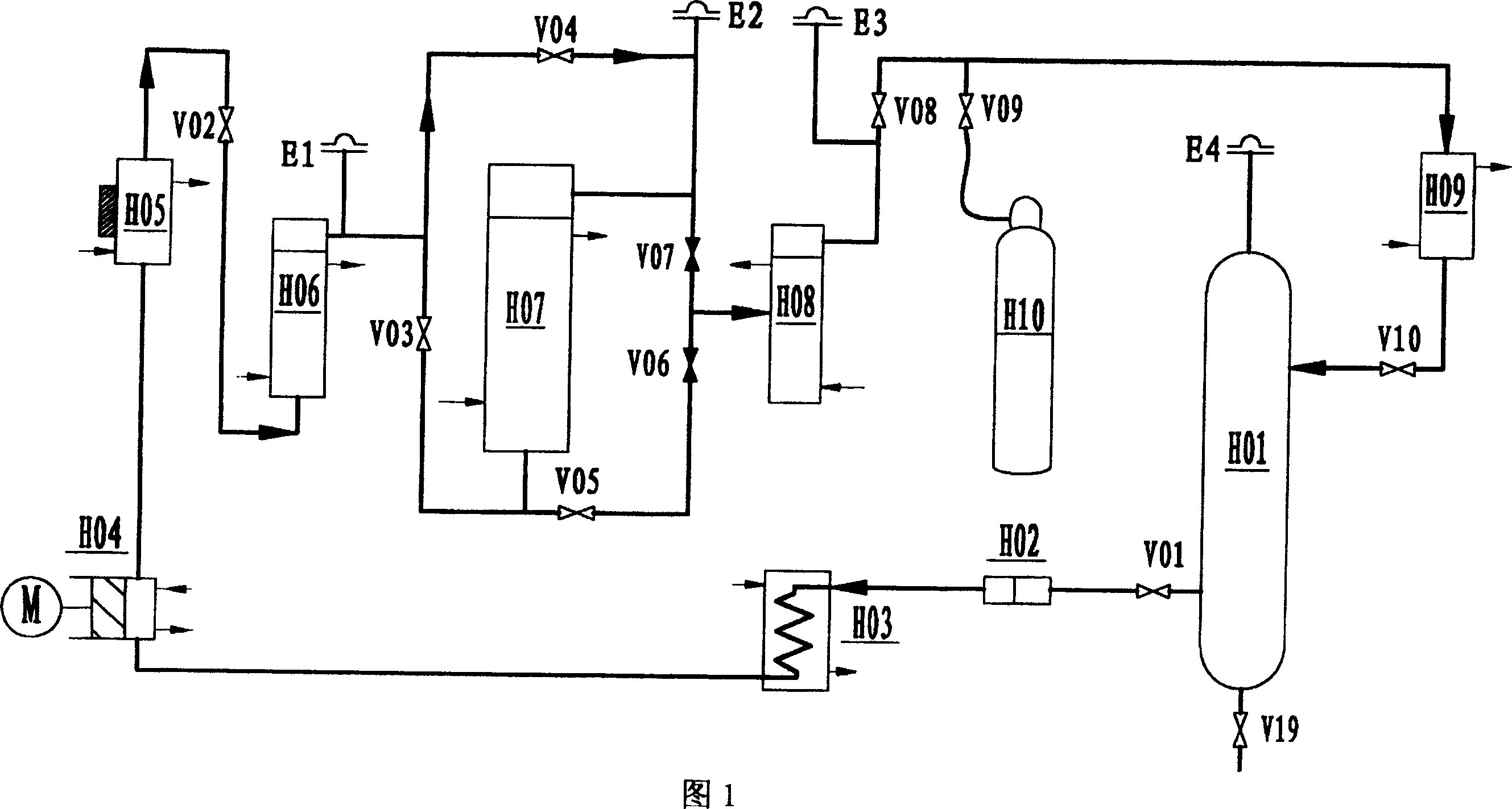

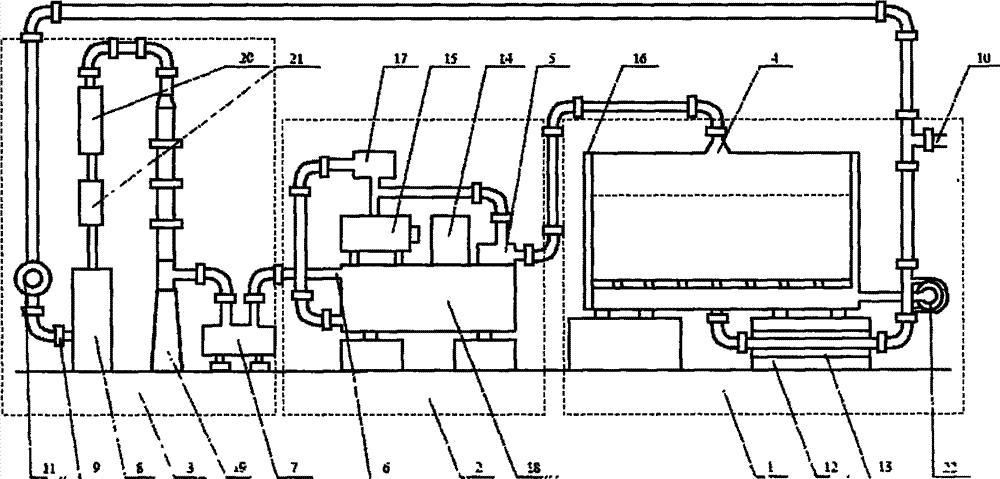

Supercritical carbon dioxide dyeing device and its process

InactiveCN1766194AReduce pollutionImprove dye uptakeSolvent treatment with solvent recoveryTextile/flexible product manufactureCo2 storageHigh pressure

The invention discloses a supercritical carbon dioxide dyeing device, which comprises mainly a CO2 storage tank (H01), a dye kettle (H06), and a dyeing kettle (H07). Wherein, the dyeing technique comprises: cooling the CO2 from HO1 into liquid to send into preheater (HO5) connected to HO6 with carbon-dioxide high-pressure pump (HO4); sending supercritical carbon dioxide to HO7 by HO6; driving the dyed carbon dioxide to pass separator (HO8) and second condenser (HO9) and return to said storage tank (HO1). This invention can recycle 100% residual dye and carbon dioxide as dyeing medium, saves water and dye resource, and reduces pollution.

Owner:DALIAN POLYTECHNIC UNIVERSITY

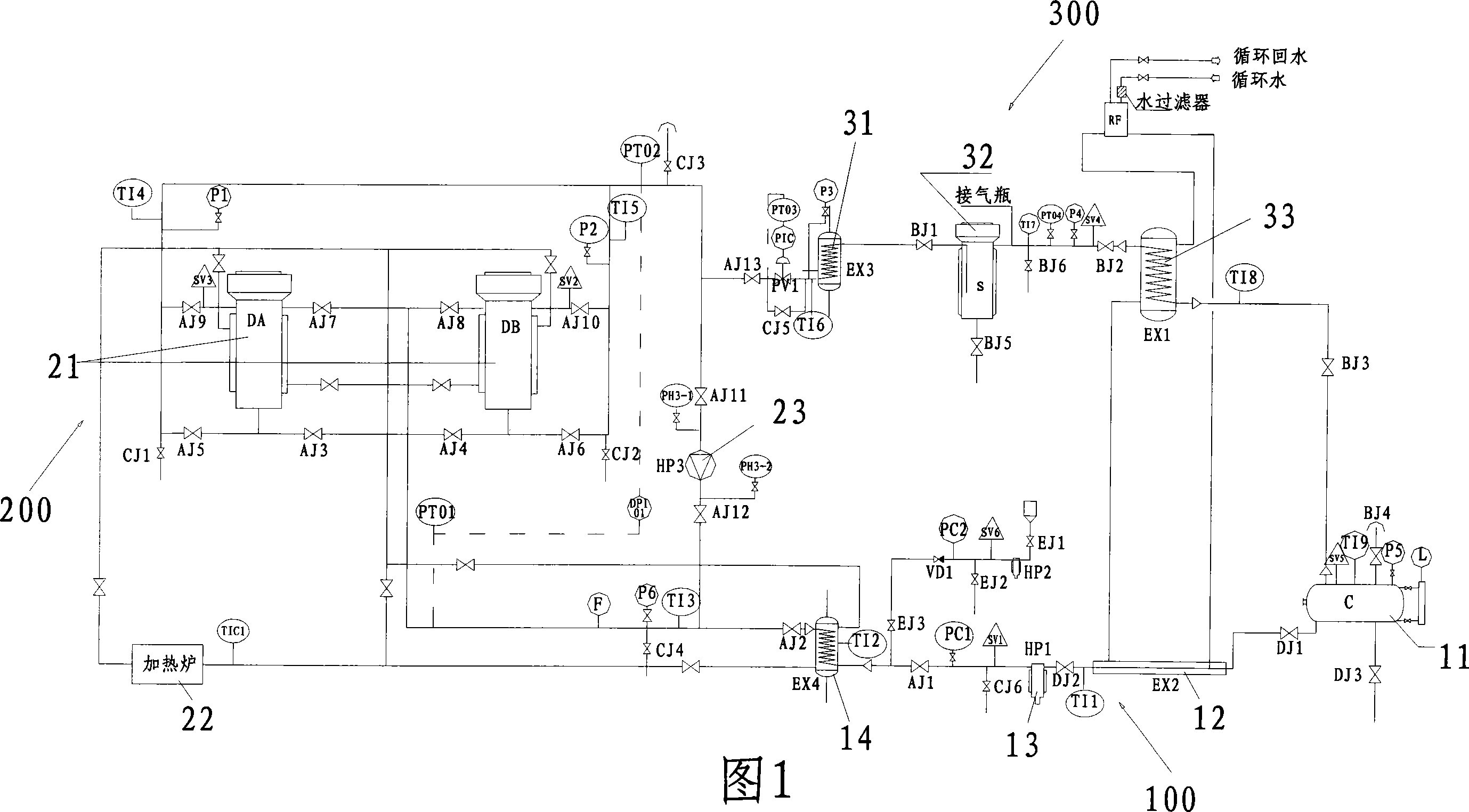

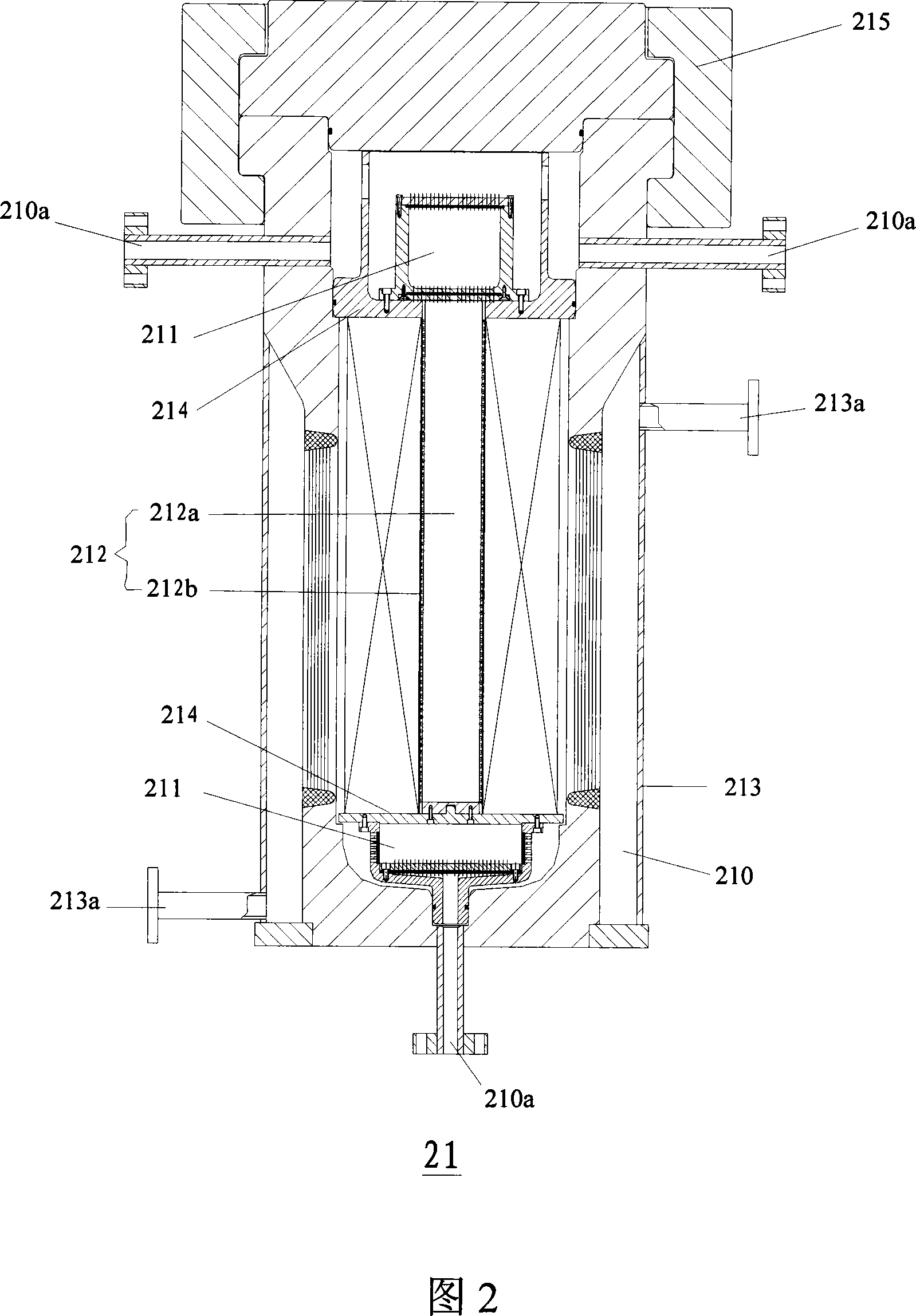

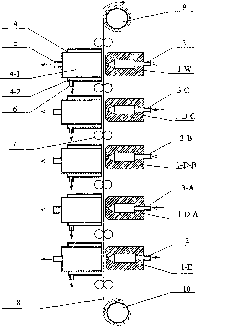

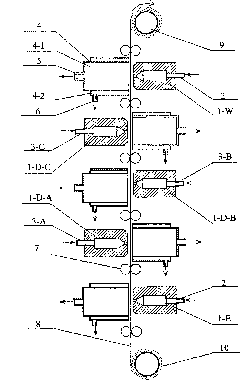

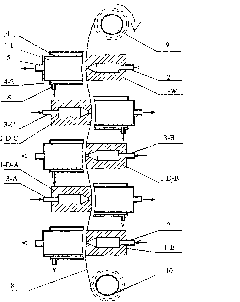

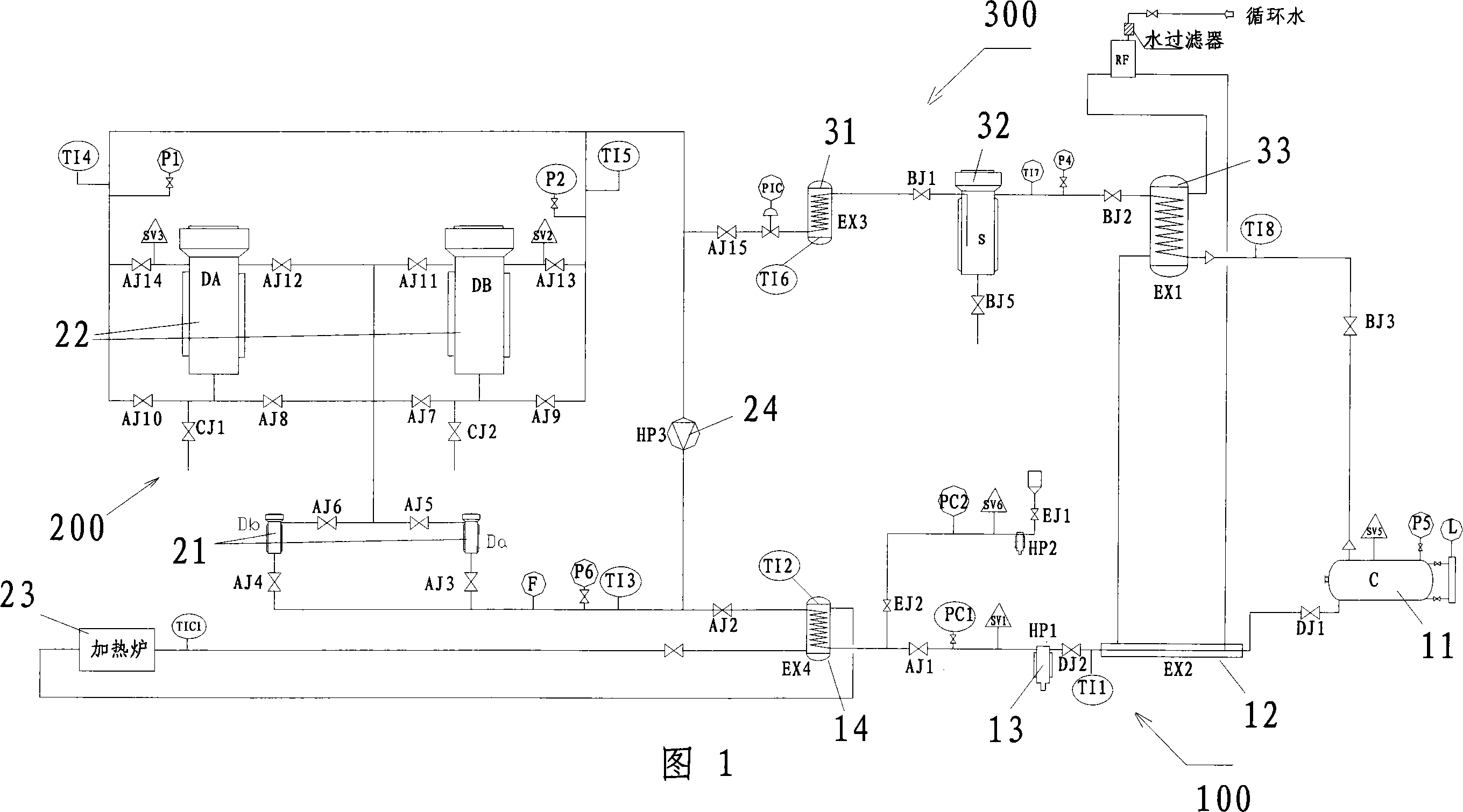

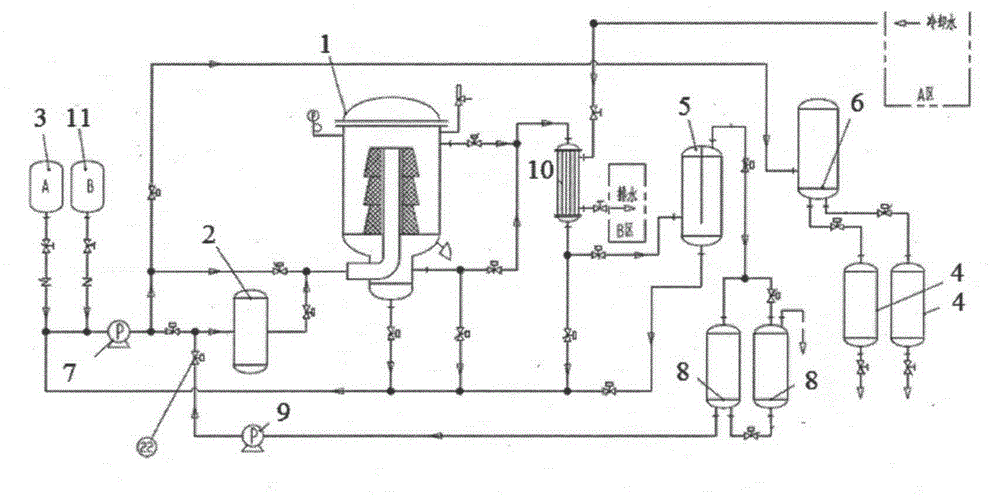

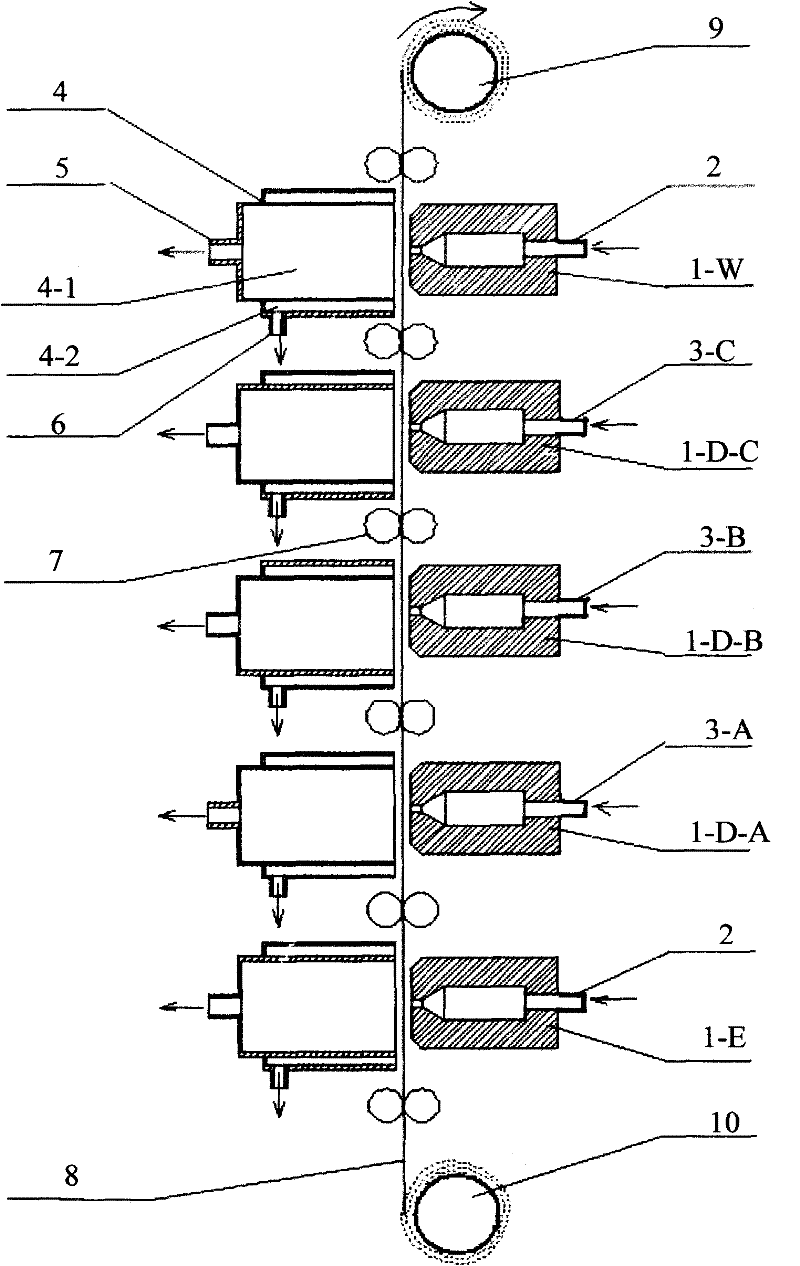

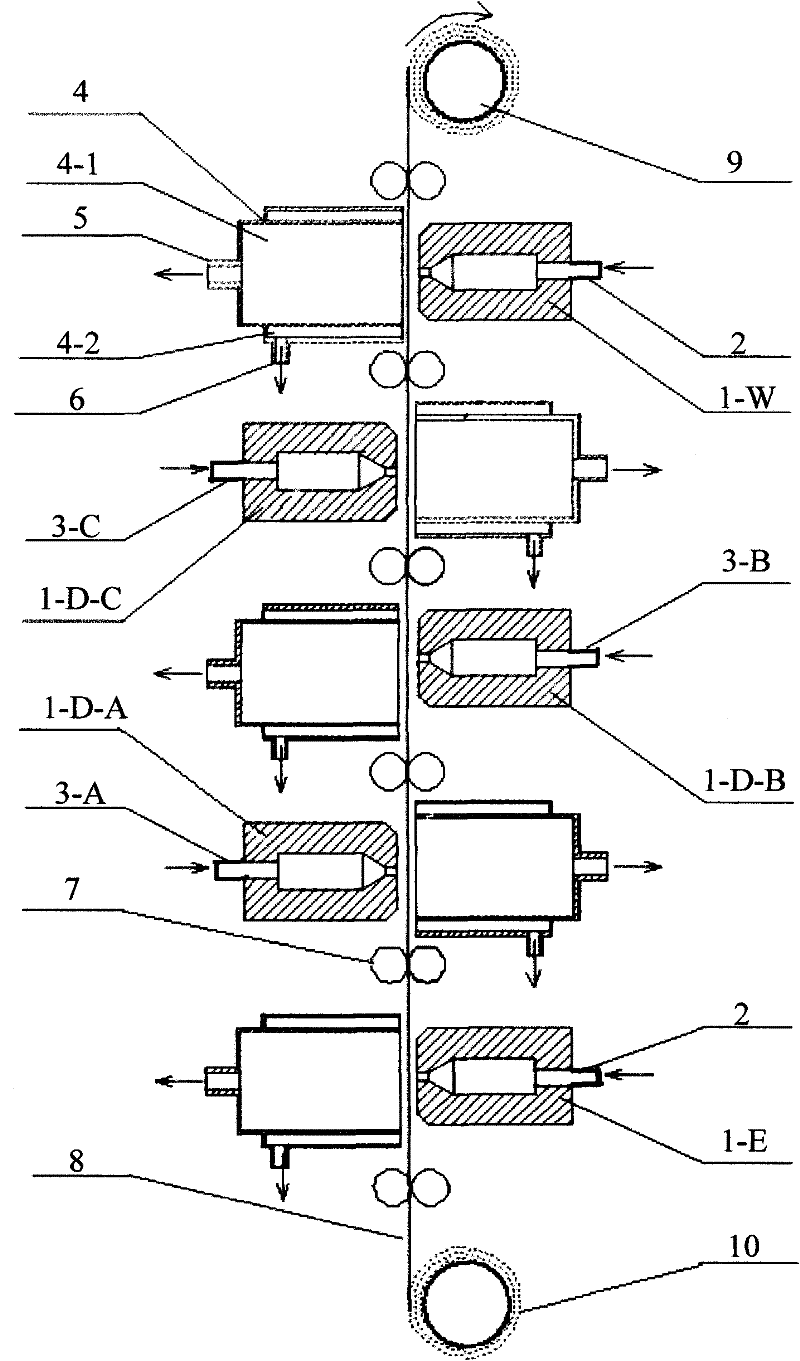

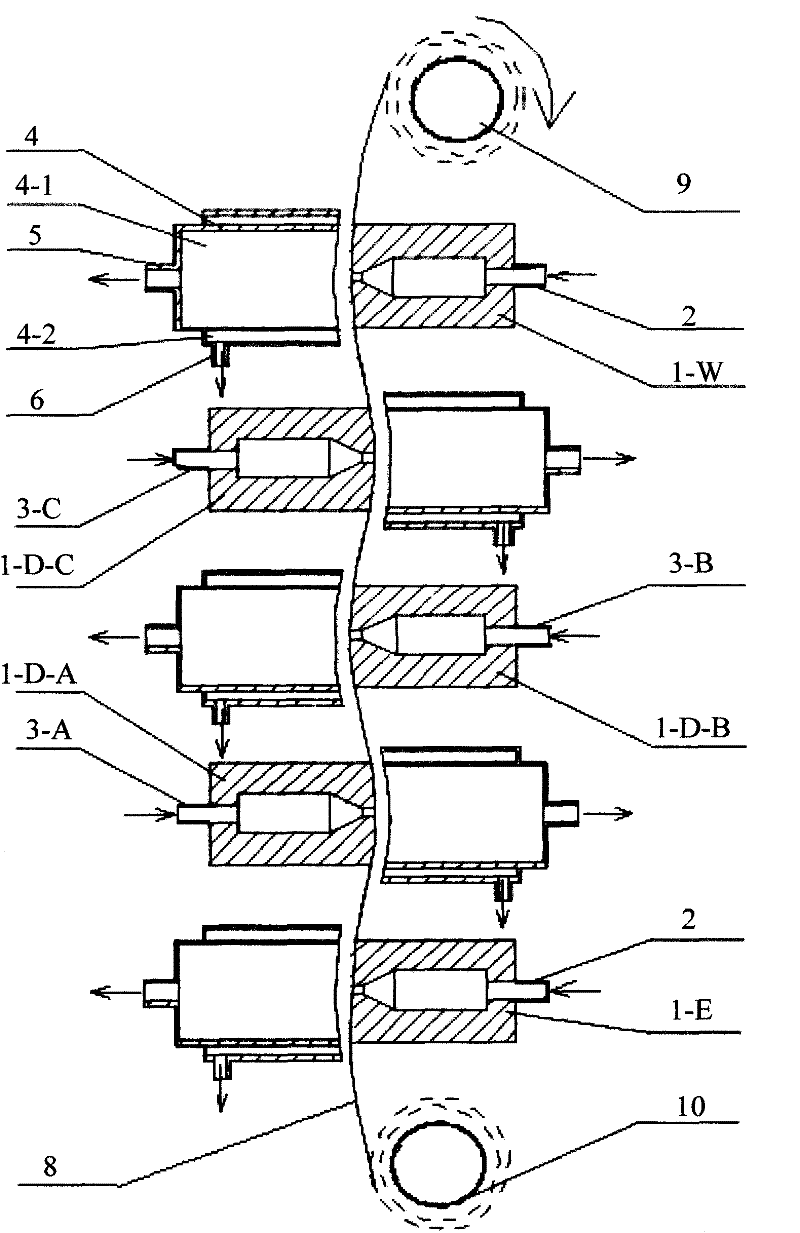

Production system adopting super-critical fluid to conduct continnous dyeing and production technology

InactiveCN101024922AReduce lossReduce energy consumptionSolvent treatment with solvent recoveryTextile/flexible product manufactureEngineeringEnergy consumption

The invention is a producing system for making continuous dyeing by supercritical fluid, used in continuous industrialized production, comprising interconnected supercritical fluid suppliers, dyeing circulator and supercritical fluid recovery device, where the dyeing circulator comprises at least two integrated dyeing kettles. On the one hand, the invention combines the existing dyeing kettle and dye kettles into a device, namely integrated dyeing kettle, thus making it able to complete two process steps of dye dissolving and fabrics dyeing in the same kettle, reducing circulating losses of dye and supercritical fluid in pipeline and largely reducing energy consumption and raising production efficiency; on the other hand, it adopts at least two integrated dyeing kettles for alternatively and uninterruptedly dyeing for meeting the industrial continuous production requirement. And the invention further provides a production process for continuous dyeing by the producing system.

Owner:MASSON GROUP

Liquid waterless staining technique

InactiveCN1958941ASolve the pollution of the environmentSimple processSolvent treatment with solvent recoveryTextile/flexible product manufactureStaining techniqueFiber

The present invention relates to a fluid waterless dyeing technique, in the concrete, it relates to a dyeing technique using carbon dioxide as dye carrier under the supercritical condition. The invented dyeing technique includes dyeing process and dyeing equipment. Its dyeing process includes the following steps: heating and pressurizing liquid CO2 in dyeing system and making said liquid CO2 into supercritical fluid; utilizing circulation pump to make CO2 be continuously and circularly reciprocated between dyeing tank and dye tank, dissolving dye while dyeing textile, then using new CO2 to wash dyed textile, after the dyed textile is washed, said equipment releases pressure, recovering CO2 and dye. Said dyeing equipment includes dyeing system and recovery separation system, said two systems one connected by means of pipeline.

Owner:辽宁腾达集团股份有限公司

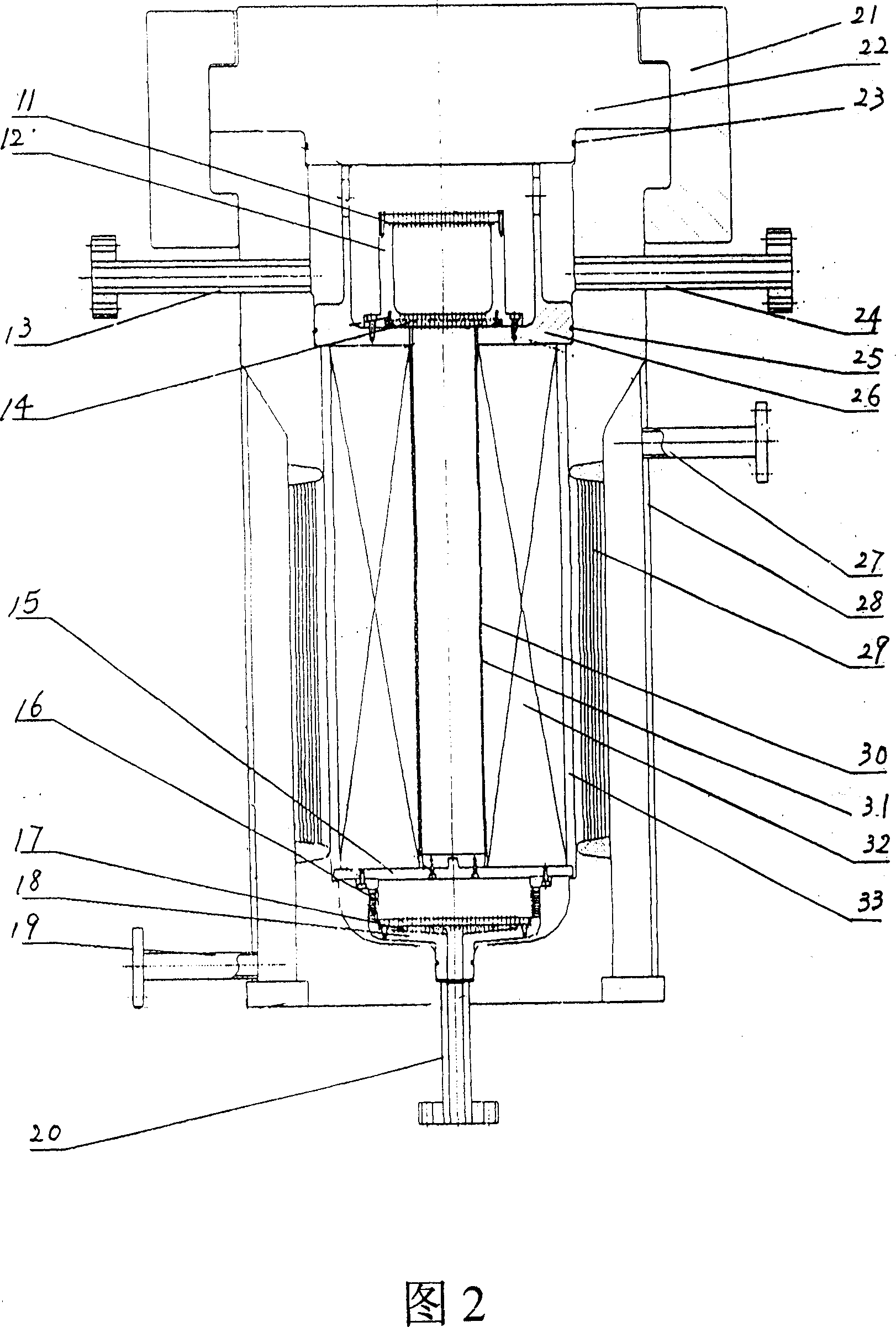

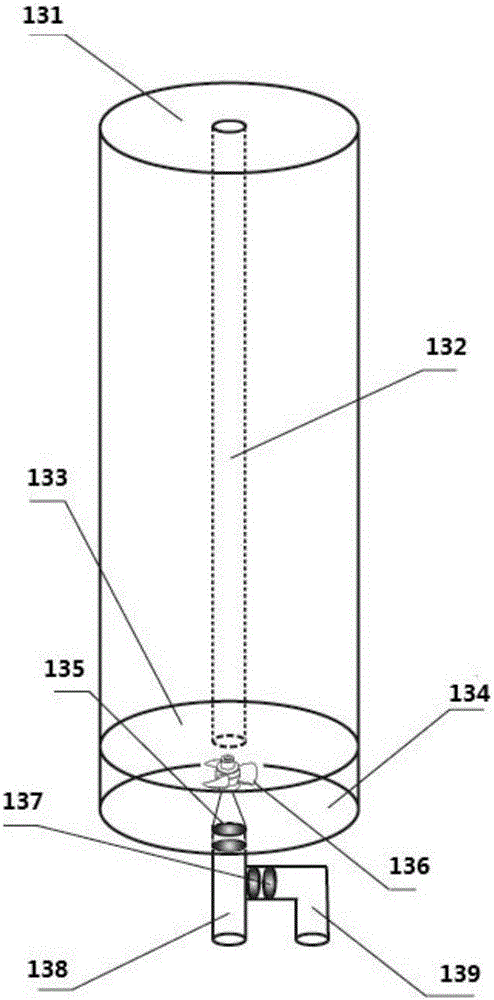

Supercritical carbon dioxide hairball dyeing kettle and waterless dyeing method thereof

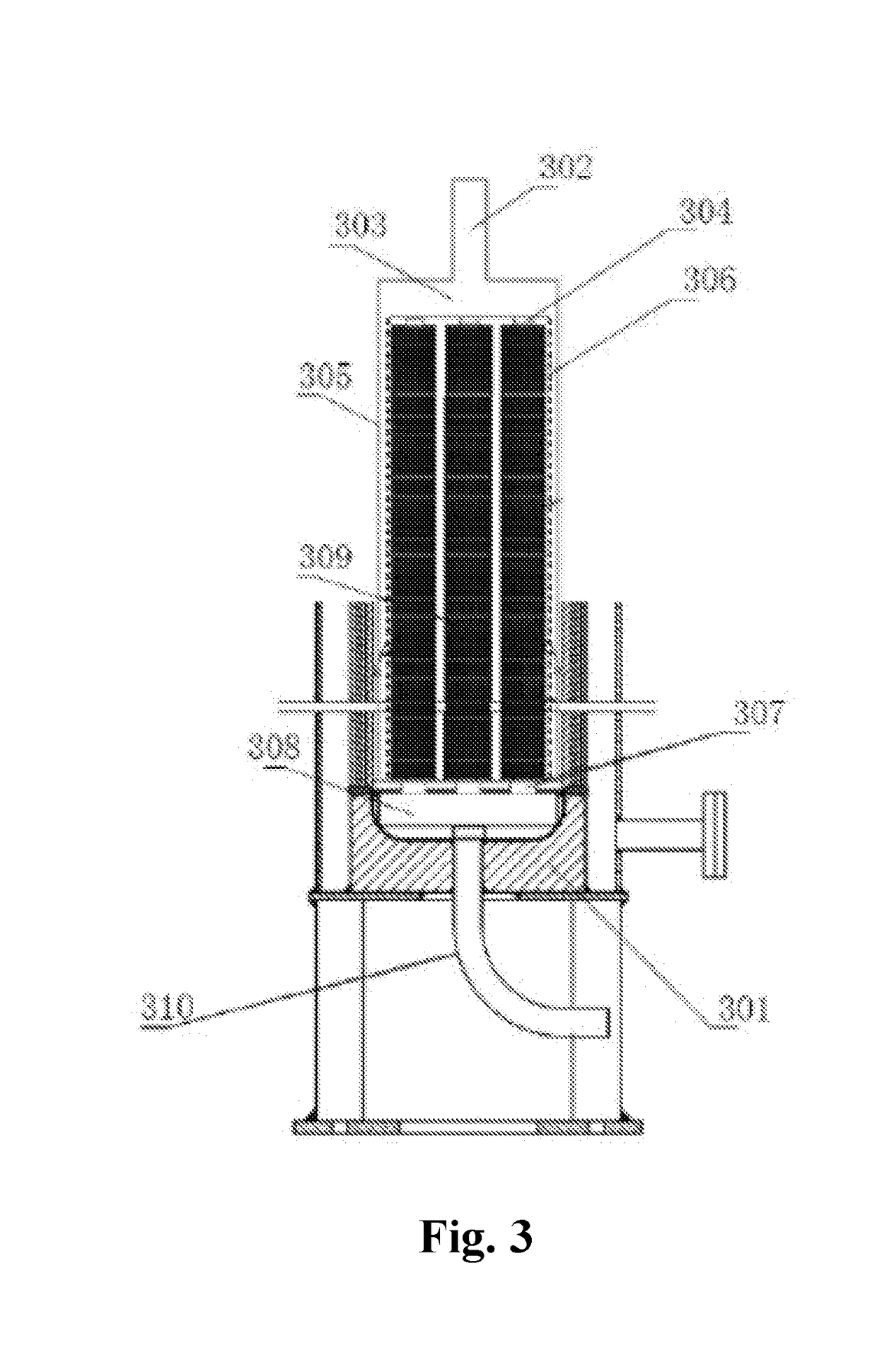

ActiveCN102776738AMeet the development requirementsSimple and convenient production and processingTextile treatment containersSolvent treatment with solvent recoveryHairballSupercritical carbon dioxide

The invention relates to a supercritical carbon dioxide hairball dyeing kettle which comprises a cylinder body and a hairball dyeing barrel body fixed in the cylinder body, wherein a movable sealing cover is fixed at the upper end of the cylinder body, and the lower end of the cylinder body is provided with a carbon dioxide liquid outlet; a carbon dioxide liquid inlet is arranged at the upper part of the cylinder body; a heating clamping sleeve is fixed outside the cylinder body; a heating medium outlet is arranged at the upper end of one side of the heating clamping sleeve, and a heating medium inlet is arranged at the lower end of the other side of the heating clamping sleeve; the supercritical carbon dioxide hairball dyeing kettle is characterized in that a hole III is formed in the wall of the hairball dyeing barrel body; a central pipe is fixed to the centre of the hairball dyeing barrel body, and at least one upper limiting cover is fixed to the central pipe; the central pipe has a multi-pore shaft structure; a hole I is formed in a supporting plate at the bottom of the barrel body; a central hole Ia is corresponding to an internal chamber of the central pipe; and a hole II is formed in the upper limiting cover. According to the supercritical carbon dioxide hairball dyeing kettle increased, the direct contacting surface area of the a hairball and the dyeing liquid can be increased, and improves the influence due to the gravity in hairball dyeing can be improved, and the dyeing speed and the dye pickup can be improved, as well as the dyeing uniformity is improved.

Owner:晋江国盛新材料科技有限公司

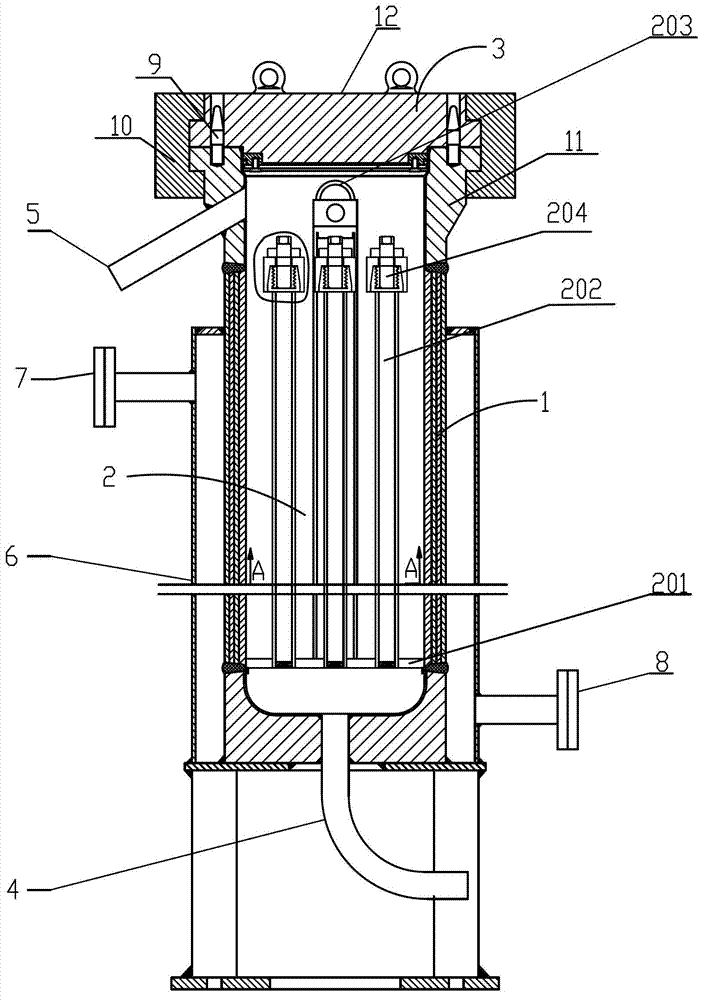

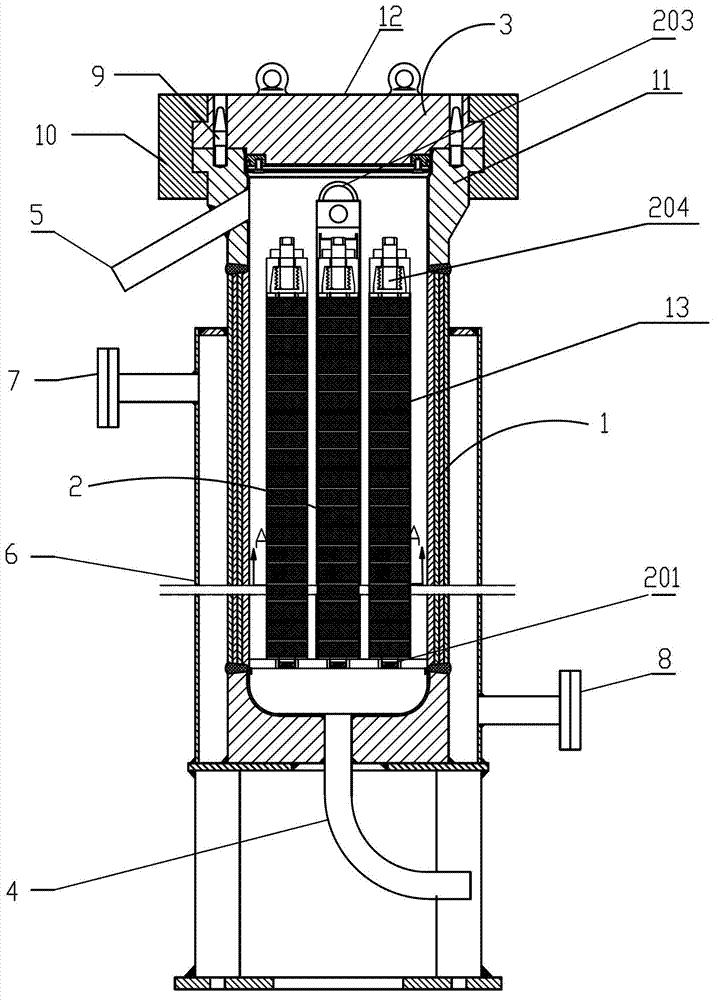

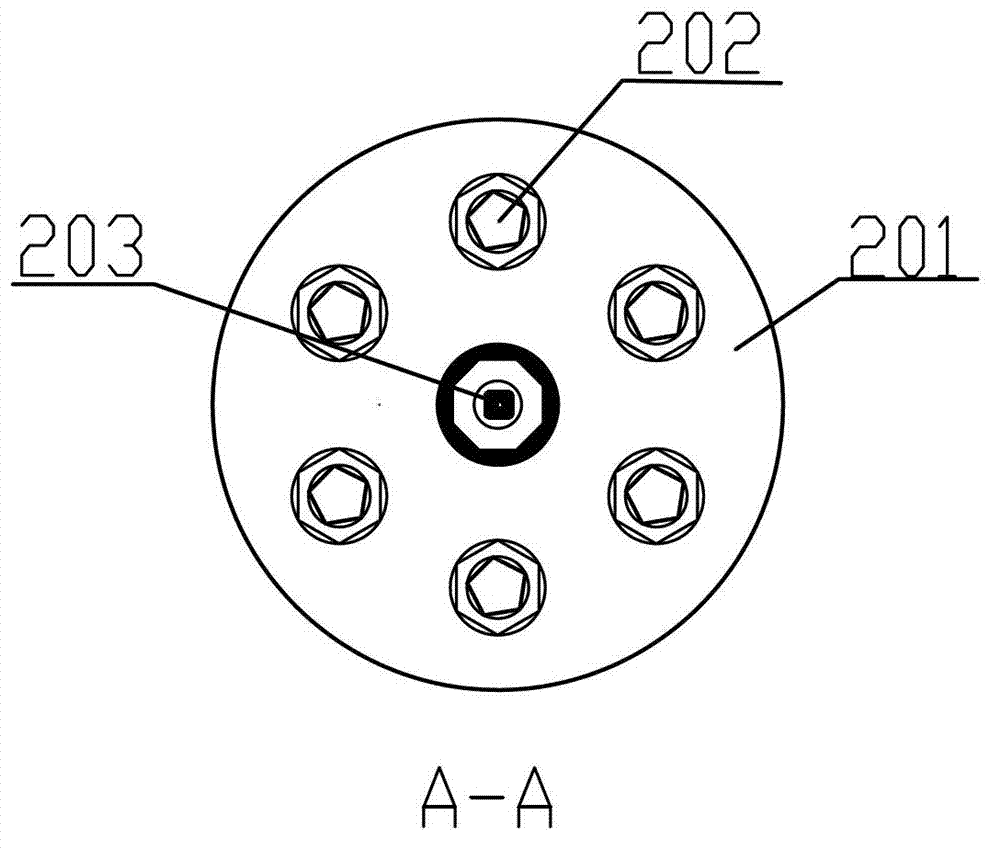

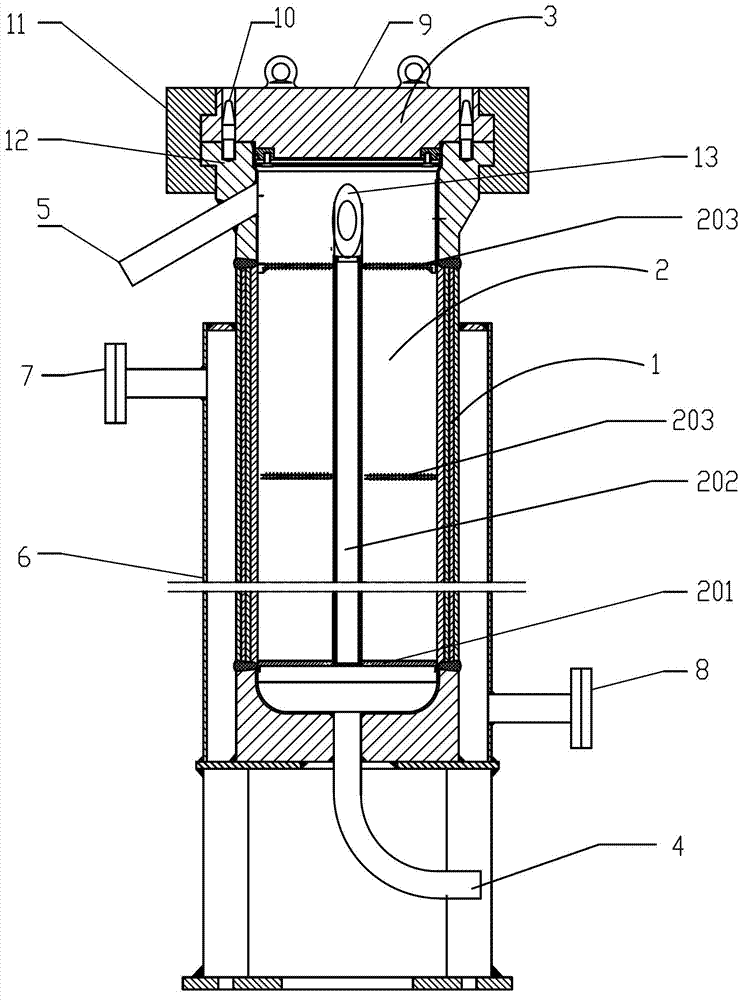

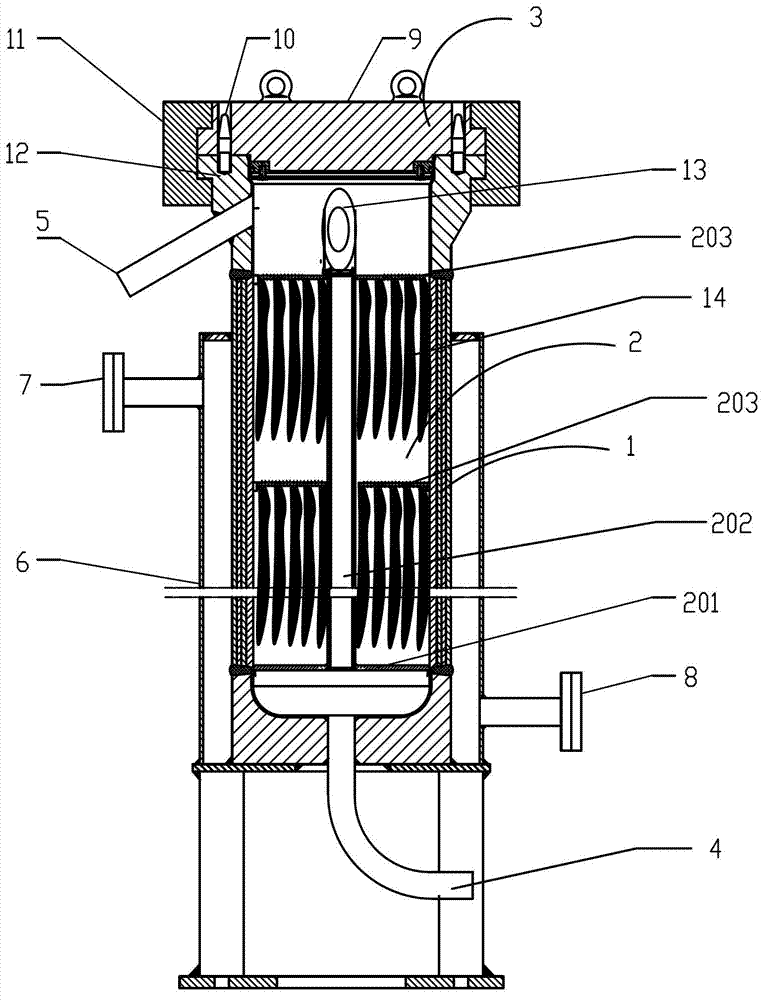

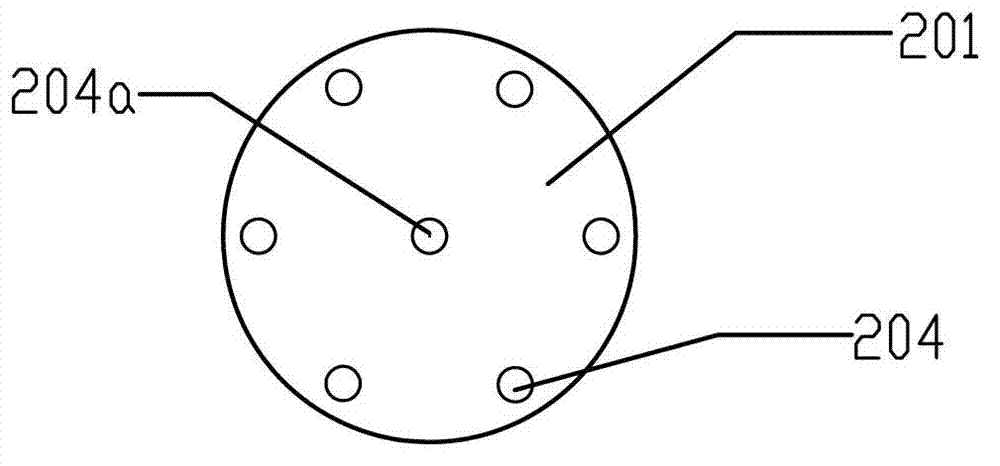

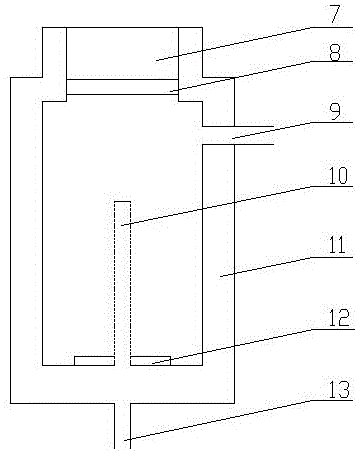

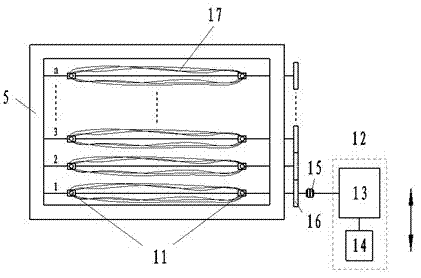

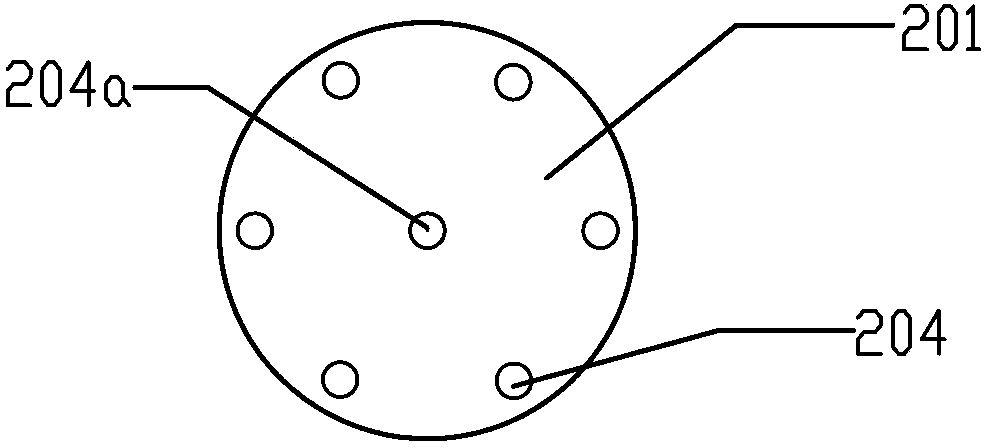

Supercritical carbon dioxide skein dyeing kettle and waterless dyeing method thereof

ActiveCN102776739AGood level dyeingHigh fastnessTextile treatment containersSolvent treatment with solvent recoveryDistributorSupercritical carbon dioxide

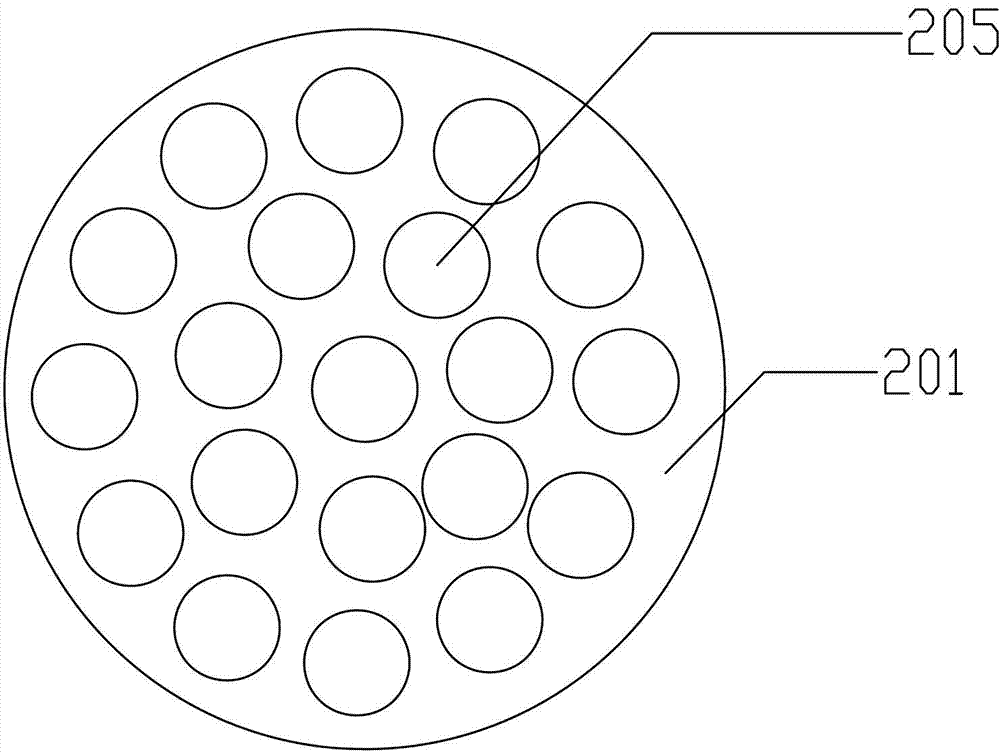

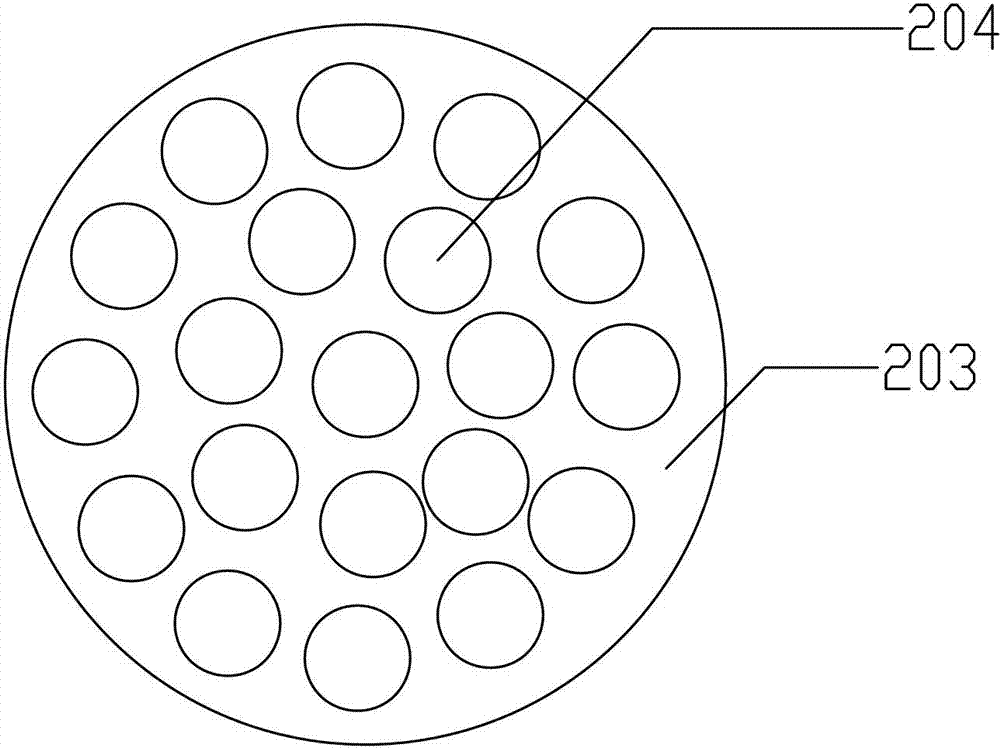

The invention relates to a supercritical carbon dioxide skein dyeing kettle which comprises a cylinder and a skein support. The skein support is fixed in the cylinder; a movable sealing cover is fixed at the upper end of the cylinder, a carbon dioxide fluid inlet is arranged at the lower end of the cylinder, and a carbon dioxide fluid outlet is further arranged on the upper portion of the cylinder; a heating jacket is fixed on the outer side of the cylinder; a heating medium outlet is arranged at the upper end of one side of the heating jacket, and a heating medium inlet is arranged at the lower end of the other side of the heating jacket. The supercritical carbon dioxide skein dyeing kettle is characterized in that the skein support consists of a bottom distributor, a supporting tube and two skein frames; the two skein frames are fixed on the supporting tube; the supporting tube is fixed on the bottom distributor and is of a porous shaft structure; a hole is arranged on the bottom distributor; and an inner cavity of the supporting tube corresponds to the hole I.

Owner:晋江国盛新材料科技有限公司

Supercritical fluid spray-dyeing device

InactiveCN101798735ASimple structureOperational securityTextile treatment machine partsSolvent treatment with solvent recoveryDying processesSpray nozzle

Owner:SHANDONG UNIV

Continuous dyeing supercritical fluid system and process

InactiveCN101021047AAdapt to the trend of large-scale productionIncrease productivityTextile treatment machine partsSolvent treatment with solvent recoveryDyeingEngineering

Owner:MASSON GROUP

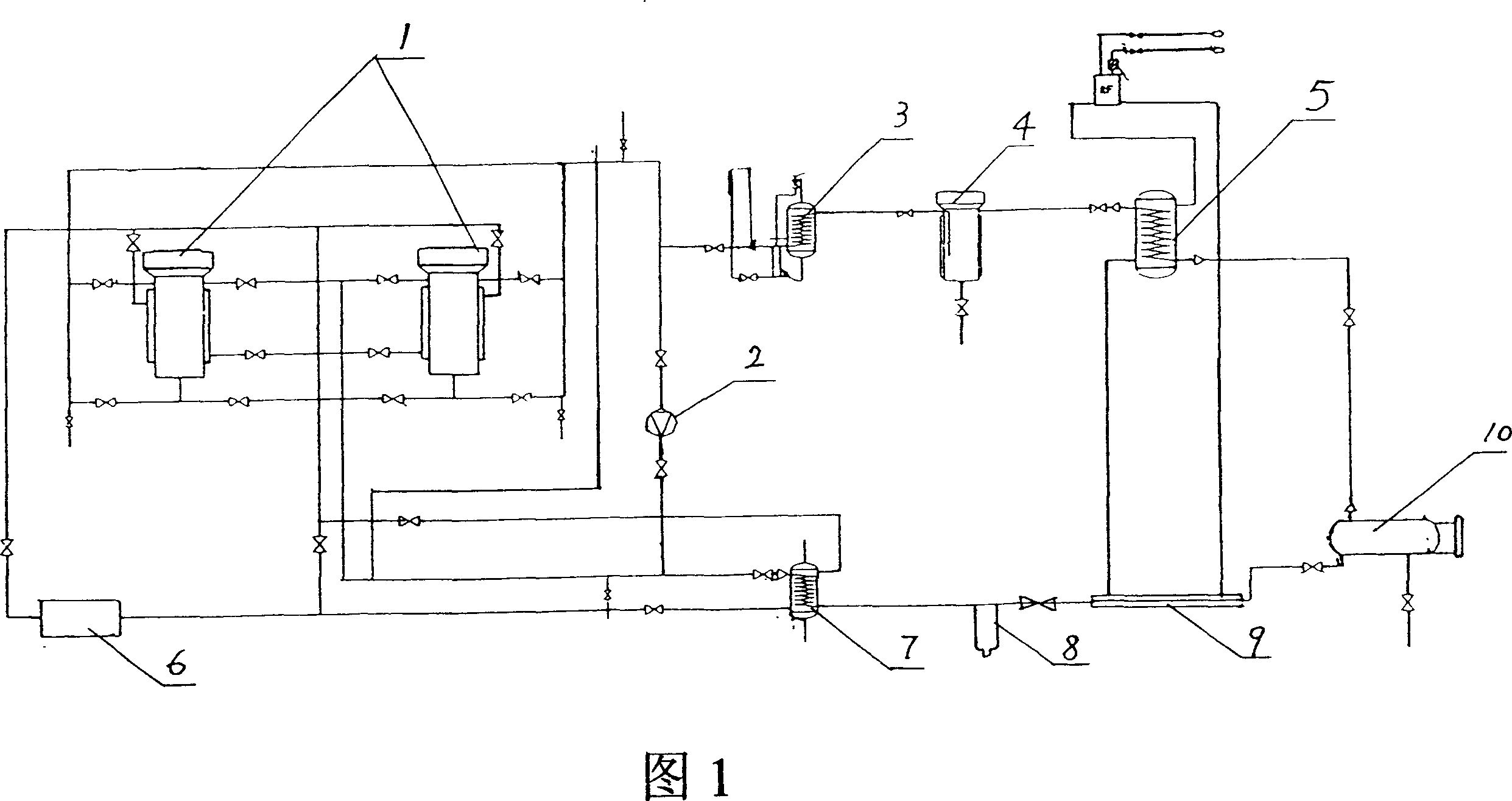

Consecutive production plant for supercritical carbon dioxide dyeing, and consecutive dyeing method

InactiveCN1958923AReduce energy consumptionGuarantee the industrialization of dyeing continuous productionTextile treatment containersSolvent treatment with solvent recoveryProcess engineeringHigh pressure

The present invention relates to a supercritical carbon dioxide dyeing continuous production equipment and its continuous dyeing method for dyeing fabrics. Said equipment includes a dyeing circulation system device which is connected after preheater by means of pipeline, can be cut off by valve and can be independently operated and a dye and carbon dioxide recovery system deice which is placed after the above-mentioned dyeing circulation system device, can be cut off by valve and can be independently operated. Said dye and carbon dioxide recovery system also is communicated with carbon dioxide storage tank by means of pipeline. Besides, said invention also provides the concrete steps of said continuous dyeing method by utilizing the above-mentioned equipment.

Owner:MASSON GROUP

Supercritical CO2 waterless dyeing system and cloth dyeing method thereof

InactiveCN105297320AImprove permeabilityImprove solubilityTextile treatment containersSolvent treatment with solvent recoveryCirculating pumpCotton material

The invention discloses a supercritical CO2 waterless dyeing system and a cloth dyeing method thereof. The method comprises the following steps of A, preparing and storing of CO2; B, cooling; C, pressurizing; D, heating, wherein a heating device is utilized for enabling CO2 to form supercritical fluid, and the supercritical fluid is heated to 120-150 DEG C; E, dyeing, wherein a circulating pump pushes a mixture of the supercritical fluid and dye to circularly flow inside a circulation channel, cloths inside a pressure kettle are dyed, the pressure inside the pressure kettle is 28-30 MPA, the temperature is 120-150 DEG C, the circulation flowing time is 20-40 min, and the circulation flow is not smaller than 10 M<3> per hour; F, pressure relieving, wherein a nanoscale color masterbatch is dissolved through the supercritical CO2 fluid, the cloths are dyed, and dyeing technological conditions such as pressure, temperature and time are optimized at the same time so as to improve the dyeing efficiency and dyeing quality.

Owner:梁鼎天 +1

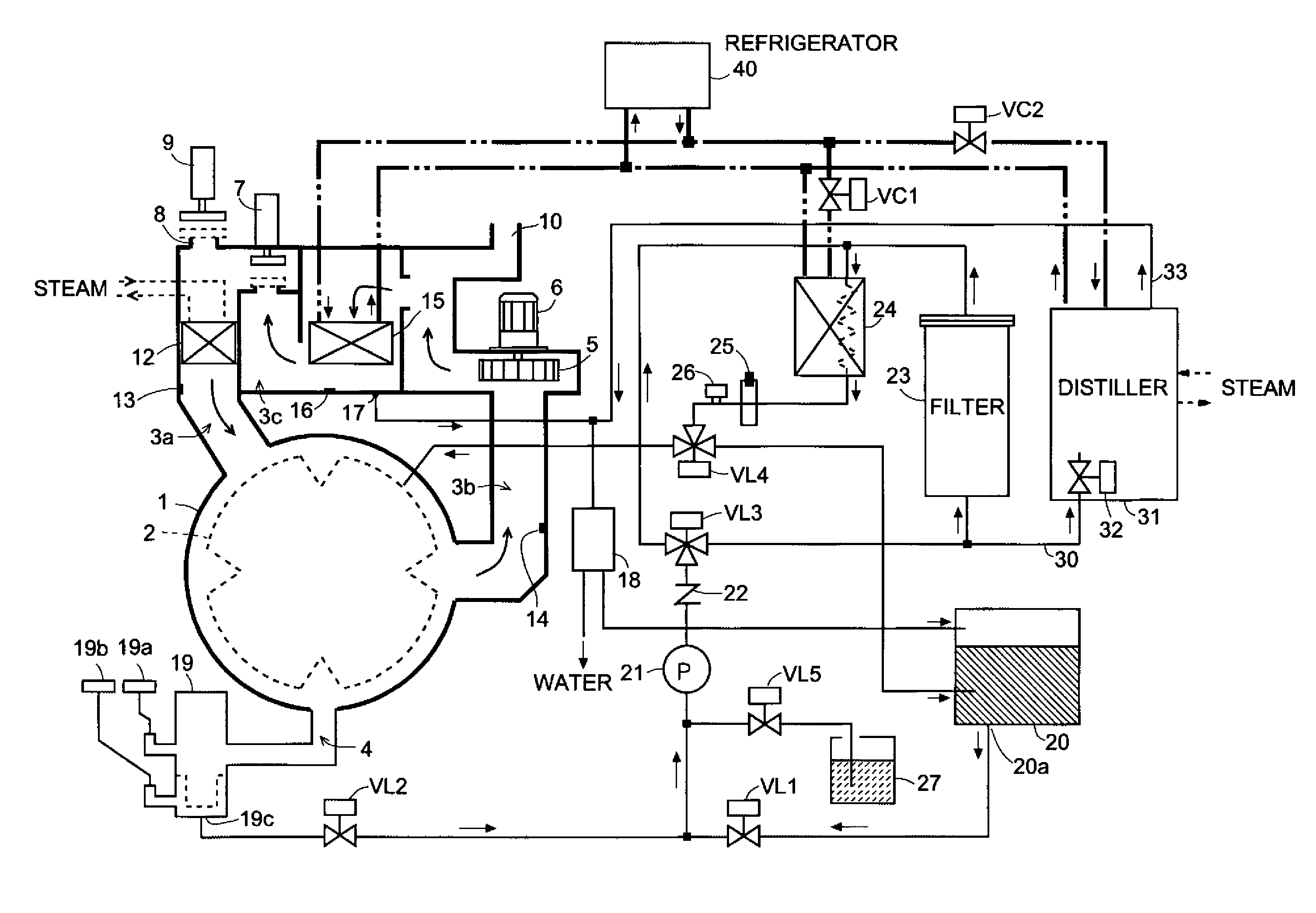

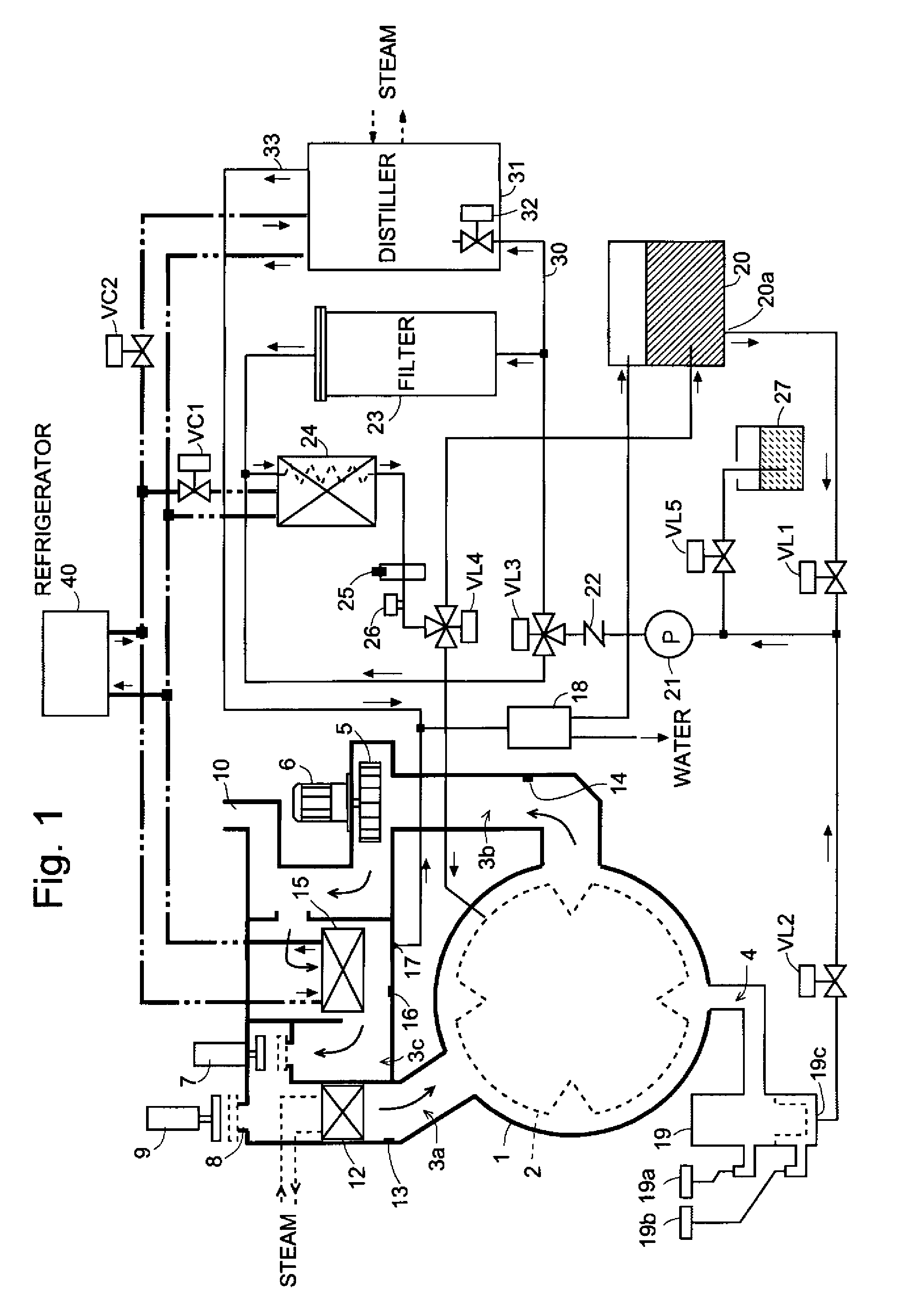

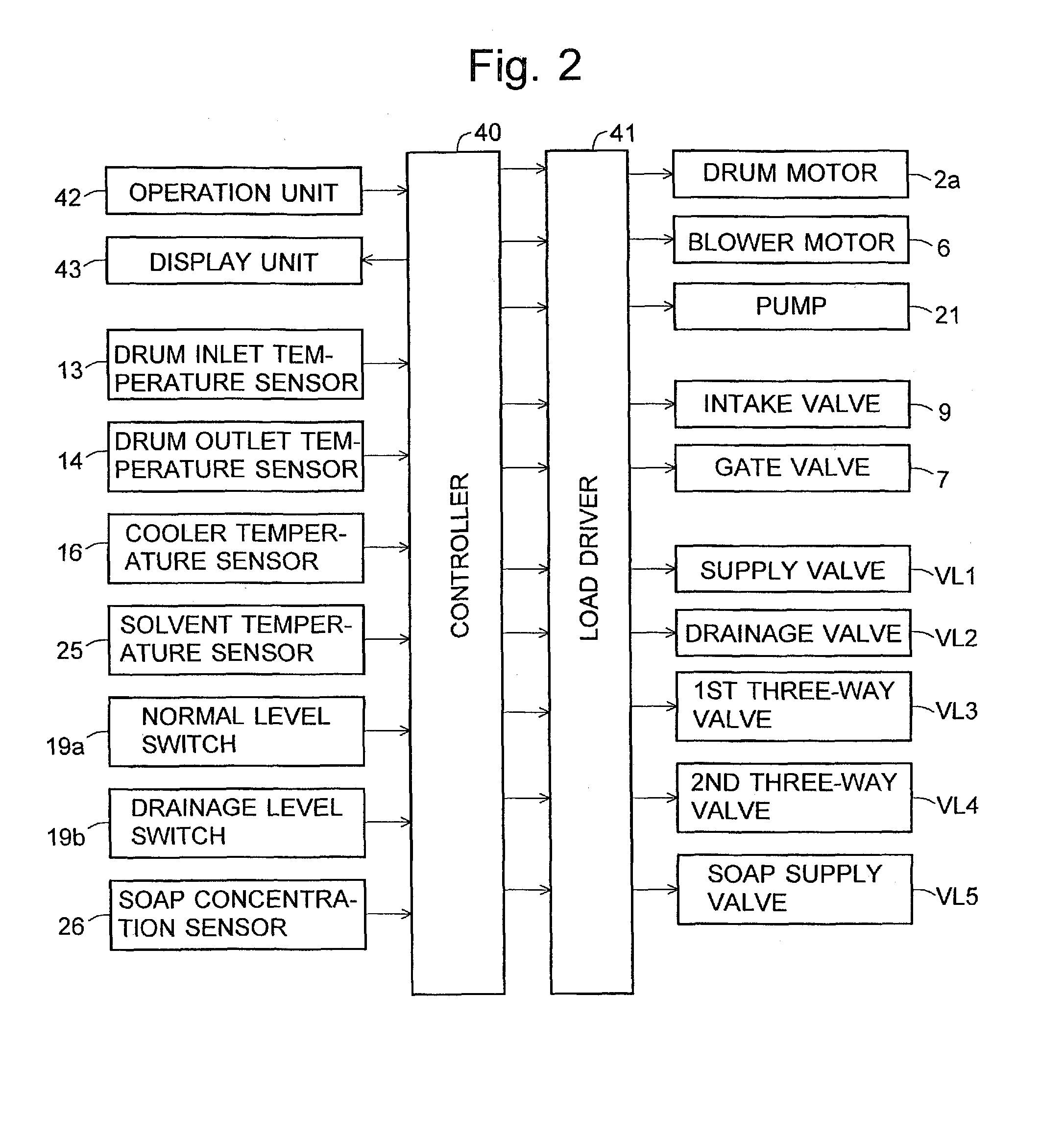

Dry-cleaning machine

ActiveUS7882716B2Effective recoveryAvoid recoveryDry-cleaning apparatusOther washing machinesActivated carbon filtrationLiquid storage tank

A vaporized solvent emitted from the laundry in the drum during the drying process is condensed within an air passage. From this passage a liquid mixture (solvent and water) is guided to a first liquid storage tank 50 through a liquid mixture line 51. An air relief pipe 52 is connected to an intermediate point of this line so that air coming from the air passage is released through an activated carbon filter 53 to the outside. The outlet end 51a of the liquid mixture line 51 is immersed in the solvent in the upper layer within the first liquid storage tank 50. Due to the hydraulic pressure acting on the outlet end 51a, the air tends to flow toward the air relief pipe 5. This reduces the current pressure of the air coming from the air passage and alleviates its influence within the first liquid storage tank 50, so that a vertical motion of the interface between the solvent and water due to the current pressure is suppressed. Thus, unwanted matter gathering around the interface is prevented from sticking to a filter, and the solvent is prevented from being discharged.

Owner:QINGDAO HAIER WASHING MASCH CO LTD +1

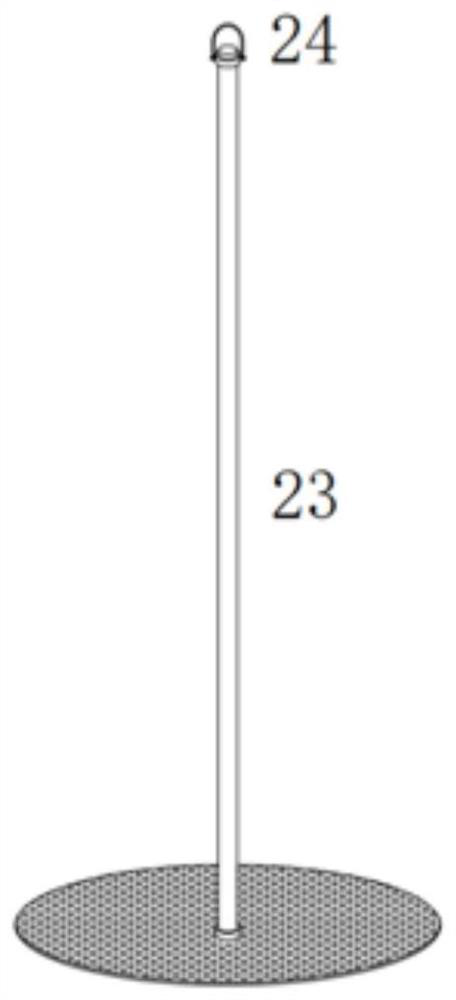

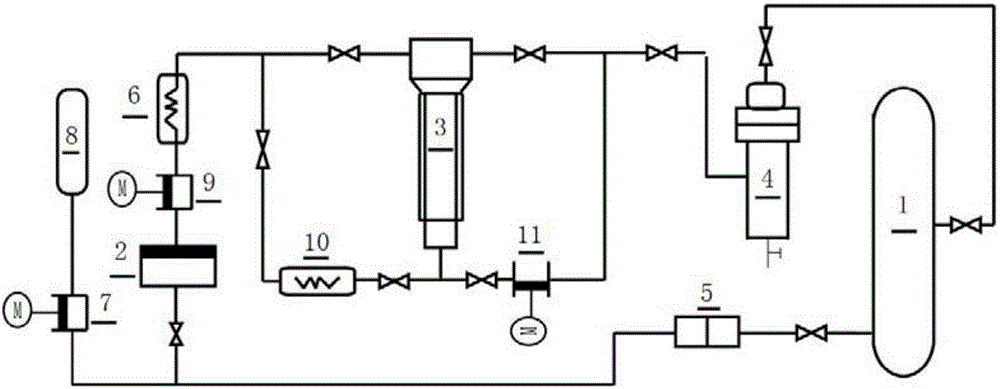

Cone yarn anhydrous dyeing equipment and method and product

ActiveCN106757915AGood colorImprove permeabilityTextile treatment containersSolvent treatment with solvent recoveryYarnEngineering

The invention provides cone yarn anhydrous dyeing equipment and method and a product. The cone yarn anhydrous dyeing equipment comprises a dye kettle, a dyeing kettle, a recycling kettle and a dyeing circulating system communicated with the dye kettle, the dyeing kettle and the recycling kettle. The cone yarn anhydrous dyeing equipment is characterized in that a cone yarn inlet is formed in the top of the dyeing kettle, a sealing cover is arranged on the cone yarn inlet, a yarn center shaft is vertically arranged in the middle in the dyeing kettle, and the yarn center shaft is an air outlet pipe with fluid release holes formed in the pipe wall; an air inlet pipe is arranged at the bottom of the dyeing kettle and communicated with the air outlet pipe, and a dyeing kettle outlet is formed in the dyeing kettle; the dyeing circulating system comprises a CO2 gas storage cylinder, a booster pump, a circulating pump and a pipeline. Various dyes are placed in the dye kettle, cone yarn is placed in the dyeing kettle, CO2 is introduced into the dye kettle, the dyes are gradually dissolved and reach the dyeing kettle along with CO2 fluid, and the coloring and dispersing processes are started. The advantages of being high in production efficiency, good in level dyeing effect, high in safety and suitable for anhydrous dyeing of the dacron cone yarn are achieved.

Owner:QINGDAO JIFA GROUP

Waterless dyeing device and dyeing method thereof by utilizing activated dye for cotton cone yarns

InactiveCN105239294AAvoid pollutionLow toxicity and environmental protection High flash pointSolvent treatment with solvent recoveryTextile/flexible product manufactureElectricityYarn

The invention provides a waterless dyeing device and dyeing method thereof by utilizing activated dye for cotton cone yarns.The waterless dyeing device by utilizing activated dye for cotton cone yarns is characterized in that the waterless dyeing device comprises a main dye vat; the main dye vat is connected with an electric heating device by a pipeline; the electric heating device is connected with a main pump by a pipeline; the main pump is connected with a solvent storage device and a dye liquor distributor; the main dye vat is connected with a condenser by a pipeline; the condenser is connected with the solvent storage device and the dye liquor distributor by a pipeline; and the main dye vat is connected with a solvent separation device connected with solvent recovery devices by a pipeline. The waterless dyeing device and dyeing method thereof by utilizing activated dye for cotton cone yarns have following beneficial effects: waterless dyeing of purified cotton by utilizing organic solvents is achieved in order to avoid environmental pollution; utilized dyeing solvents featuring low toxicity, environment protection and high flash point, is above 80 DEG C in flash point; and there is no need to carry out anti-explosion operation on the dyeing device and place.

Owner:DONGHUA UNIV

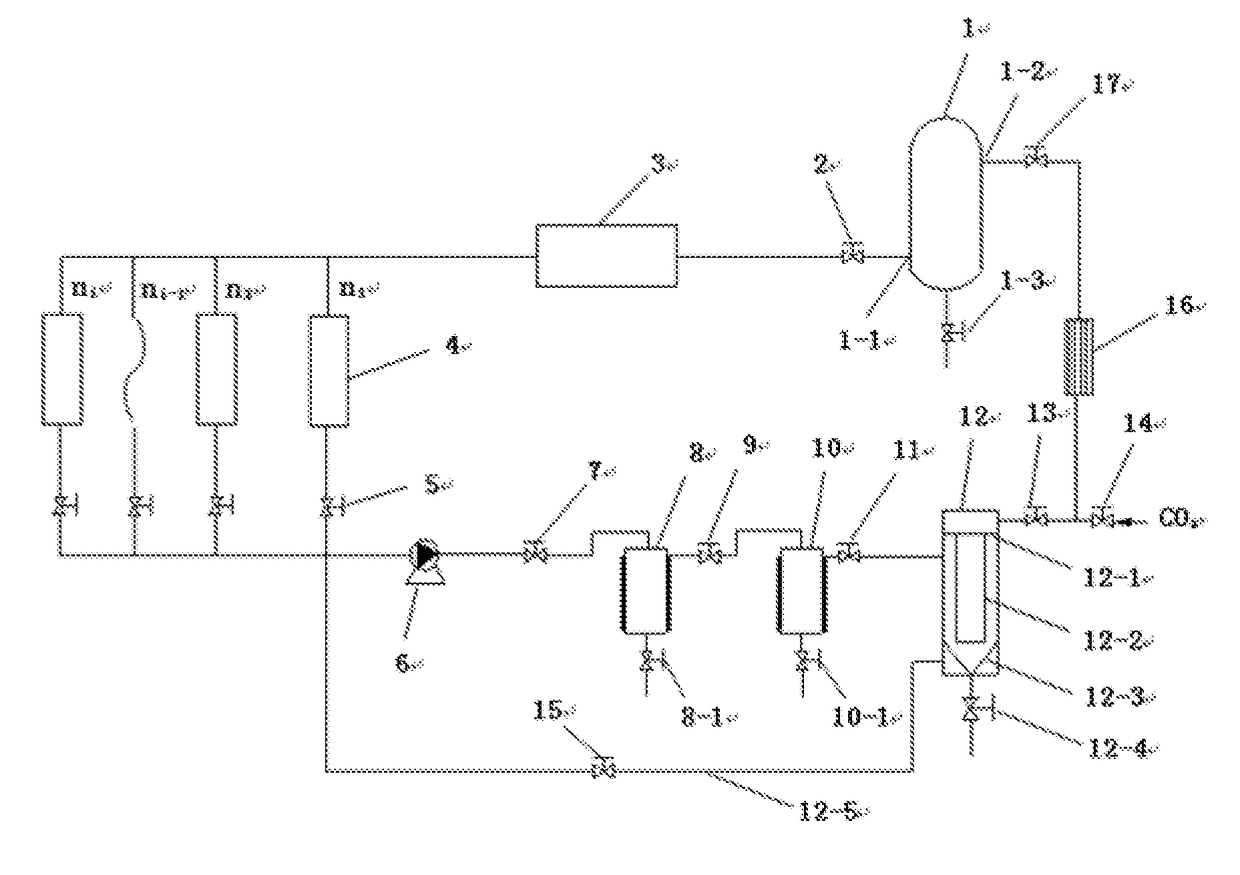

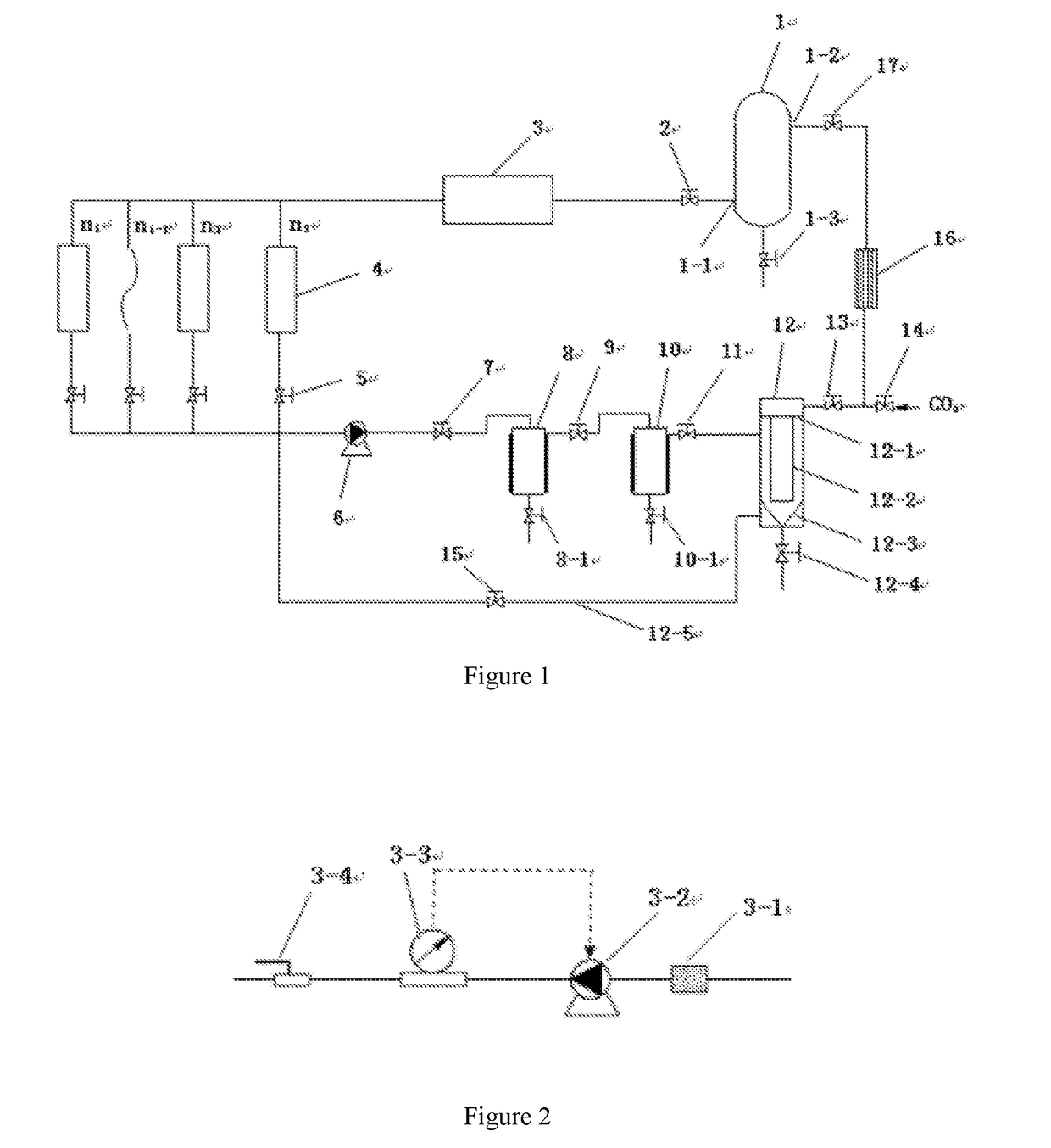

System for Anhydrous Boiling, Bleaching and Dyeing Using Supercritical Carbon Dioxide Fluid

ActiveUS20180371664A1Improve pollutionHigh energy consumptionTextile treatment machine partsDispersed particle separationFiberYarn

An system for anhydrous boiling, bleaching and dyeing using a supercritical carbon dioxide fluid and belongs to the field of textile. The system for anhydrous boiling, bleaching and dyeing of a supercritical carbon dioxide fluid provided by the present invention is provided with a co-solvent system, a boiling, bleaching and dyeing system, and a separation and recovery system which are specially designed. By means of uniform dispersion and dissolution of a co-solvent, dyestuff and carbon dioxide, boiling, bleaching and dyeing production of jute fiber rough yarn can be achieved; meanwhile, the system for anhydrous boiling, bleaching and dyeing using a supercritical carbon dioxide fluid integrates the three functions of boiling, bleaching and dyeing, which can complete the boiling, bleaching and dyeing procedures in one step, and has the characteristic of high-efficiency, thus solving the problems of high contamination and high energy consumption of the jute fiber boiling, bleaching and dyeing procedures.

Owner:YIXING SUNSHINE LINEN TEXTILE CO LTD

Method for modifying continuous multistage cotton and linen yarns

InactiveCN102787460AGood flexibilityImprove wrinkle resistanceTextile treatment machine partsSolvent treatment with solvent recoveryLiquid ammoniaYarn

The invention relates to a method for modifying continuous multistage cotton and linen yarns, which is characterized in that cotton and linen yarns are hanked and subjected to liquid ammonia modifying and drafting at the same time, and are then subjected to microwave drying and drafting simultaneously. The drafting is carried out during the liquid ammonia modifying and the microwave drying, so the cotton and linen yarns are modified through various modes of liquid ammonia, drafting, microwave and the like, and the softness, wrinkle resistance, crack resistance, smooth type, bulkiness, dyeing property and the like of the cotton and linen yarns can be improved.

Owner:DONGHUA UNIV +1

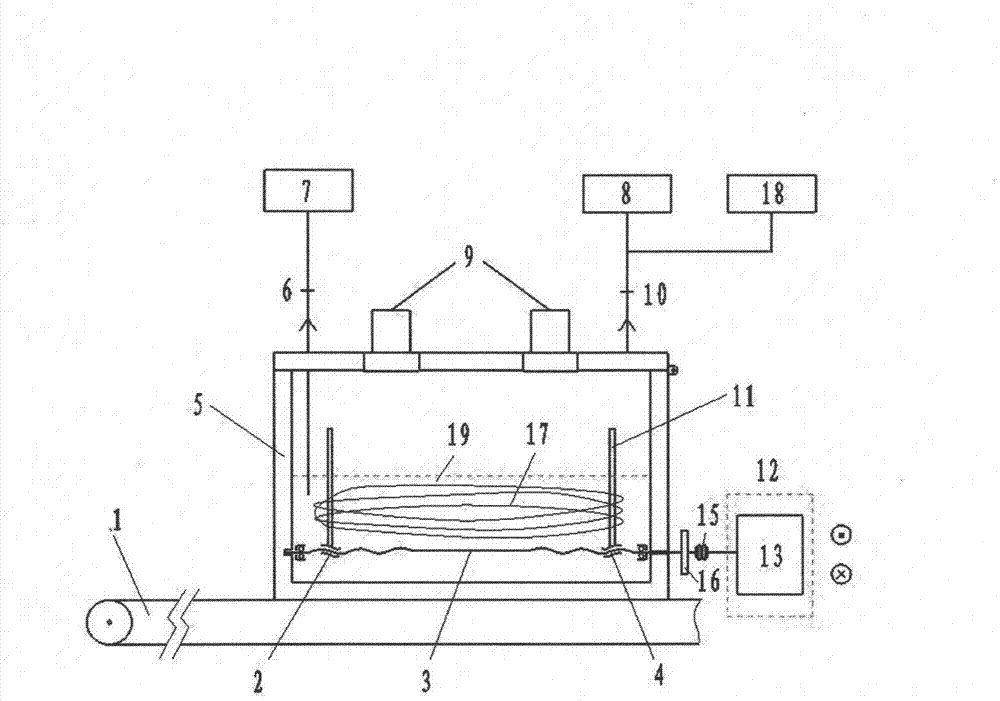

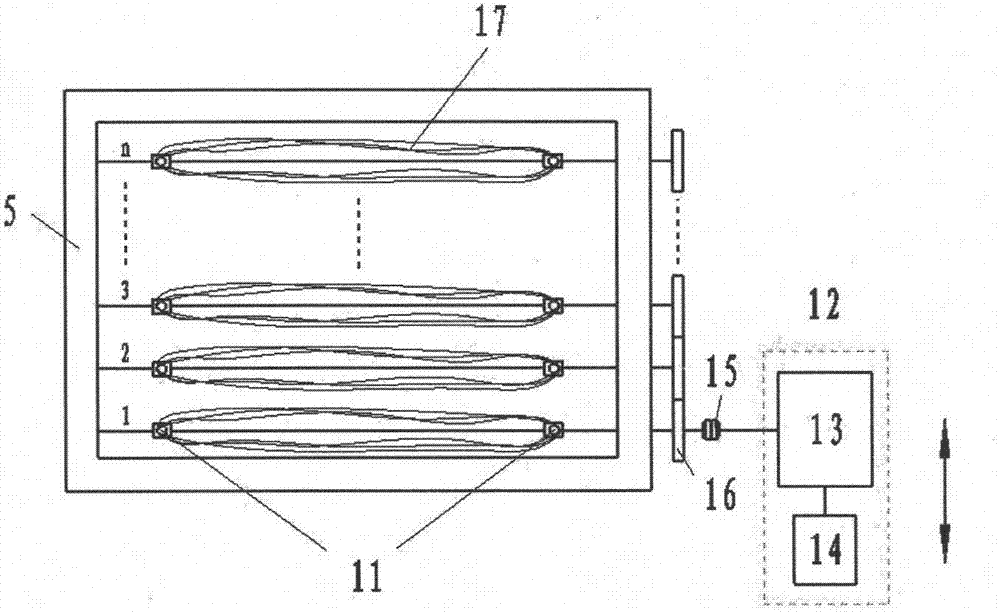

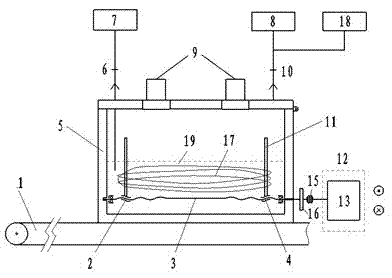

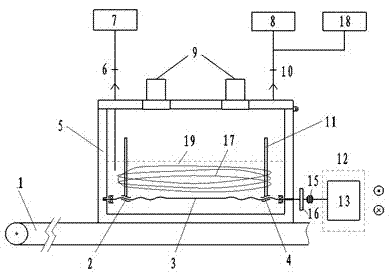

Continuous multi-station cotton yarn modifying device and method

InactiveCN102212941AGood flexibilityImprove wrinkle resistanceSucessive textile treatmentsDrying solid materials with heatYarnMicrowave

The invention relates to a continuous multi-station cotton yarn modifying device and method. The modifying device comprises a conveyer belt; the conveyer belt is provided with a treatment box; at least one microwave generator, a first quick connector and a second quick connector are arranged on an end cover above the treatment box, wherein the first quick connector can be connected with a liquid ammonia transfer system positioned above a specified station of the treatment box, and the second quick connector can be connected with an ammonia transfer system and an air conveying system positioned above a specified station of the treatment box; and at least two groups of drafting mechanisms are arranged in the treatment box, wherein the left lead screw and the right lead screw of the first group of drafting mechanism are connected with a drafting driving system. The continuous multi-station cotton yarn modifying device disclosed by the invention can be used for modifying cotton yarns withliquid ammonia and drafting cotton yarns simultaneously, carrying out the operations of microwave drying and drafting simultaneously, and modifying cotton yarns by multiple methods of liquid ammonia,drafting, microwaves and the like; and according to the device and the method disclosed by the invention, the flexibility, wrinkle resistance, crack resistance, smoothness, bulkiness, chromaticity and the like can be improved.

Owner:DONGHUA UNIV +1

Method for quickly preparing nano thermal insulation material by supercritical drying

PendingCN111778649AEliminate curing and molding stepsAvoid contactFibre treatmentSolvent treatment with solvent recoverySupercritical dryingFiber

The invention discloses a method for quickly preparing a nano thermal insulation material by supercritical drying. The method combines liquid preparation, dipping, gelation and drying. After fiber felt rolls are directly immersed in a drying kettle for molding and solidification, the fiber felt rolls are directly heated to dry with supercritical methanol or ethanol, so as to achieve complete sealing to prepare the nano thermal insulation material. The method omits the curing and molding step of fiber felt, injects gel solution into the drying kettle, uses the adsorption performance of the fiber felt to remove the excess gel, and directly performs supercritical drying after gelation. The method has simple process, is easy to realize complete automation, saves much equipment investment, at the same time avoids a large amount of organic solvent volatilization and personnel contact with volatiles, and the waste heat recovery in the production process can save energy to the greatest extent.

Owner:中化学华陆新材料有限公司

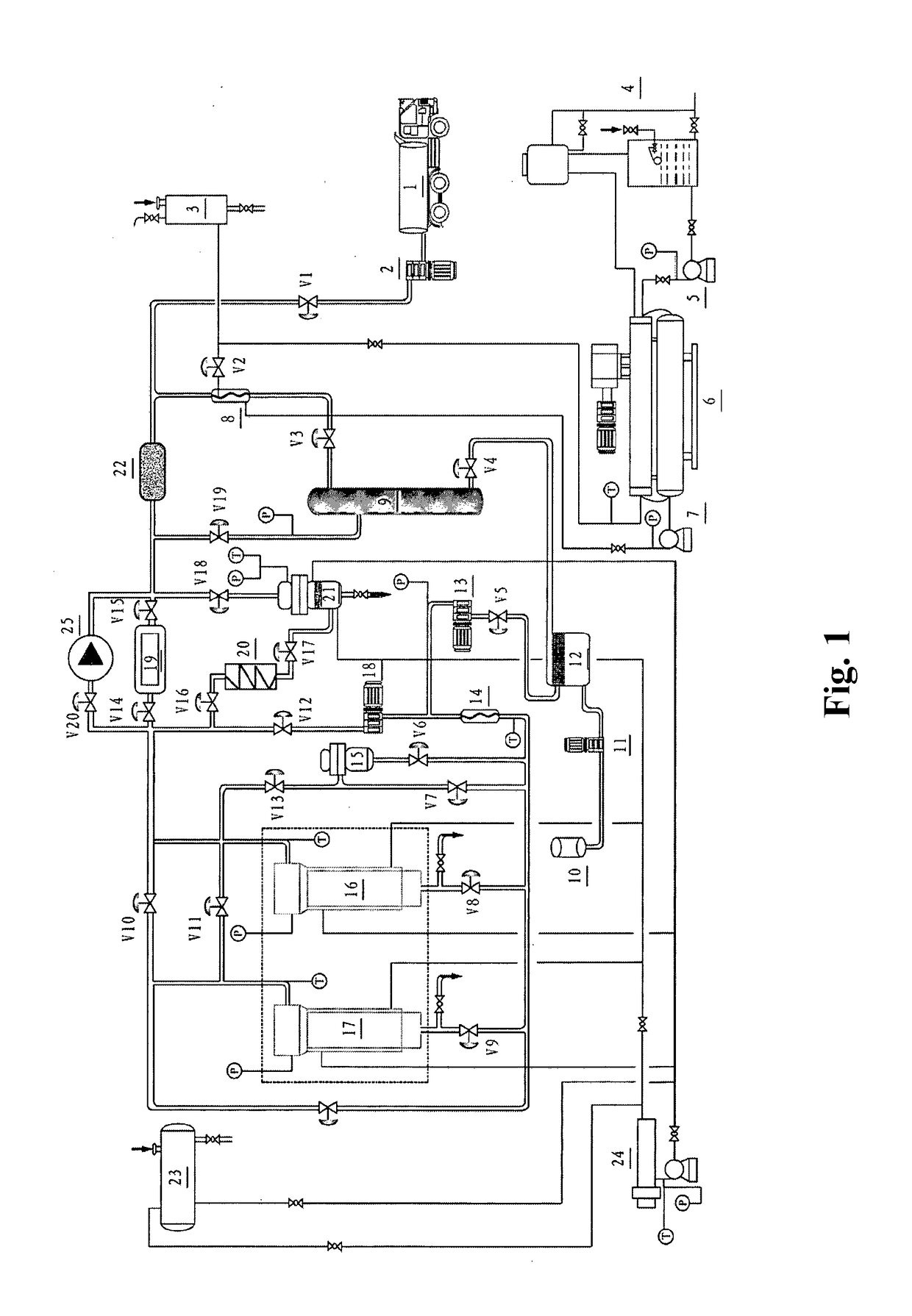

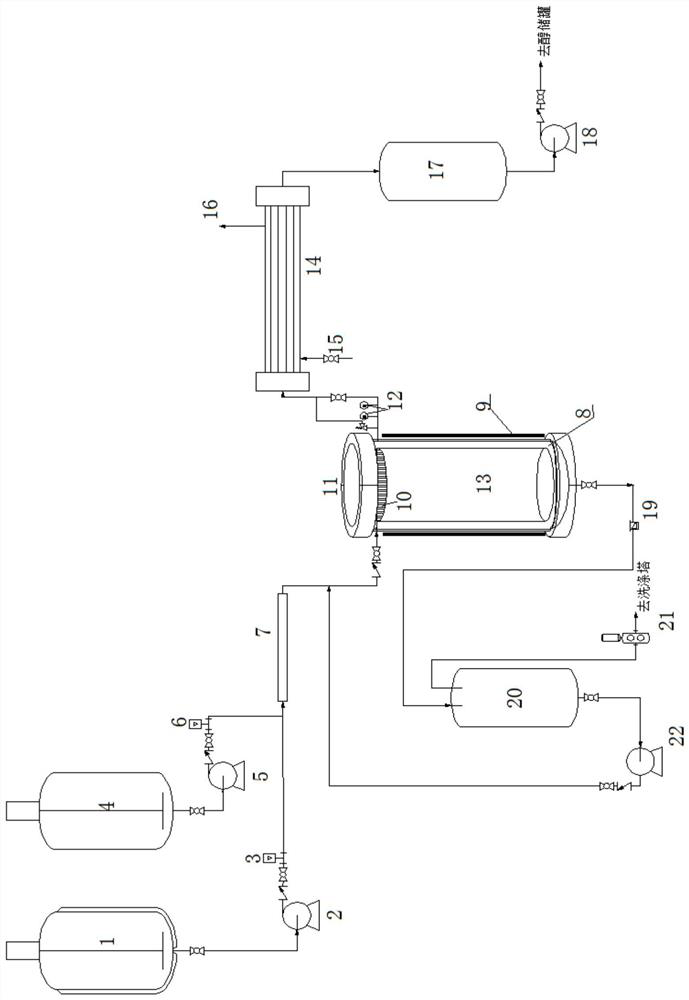

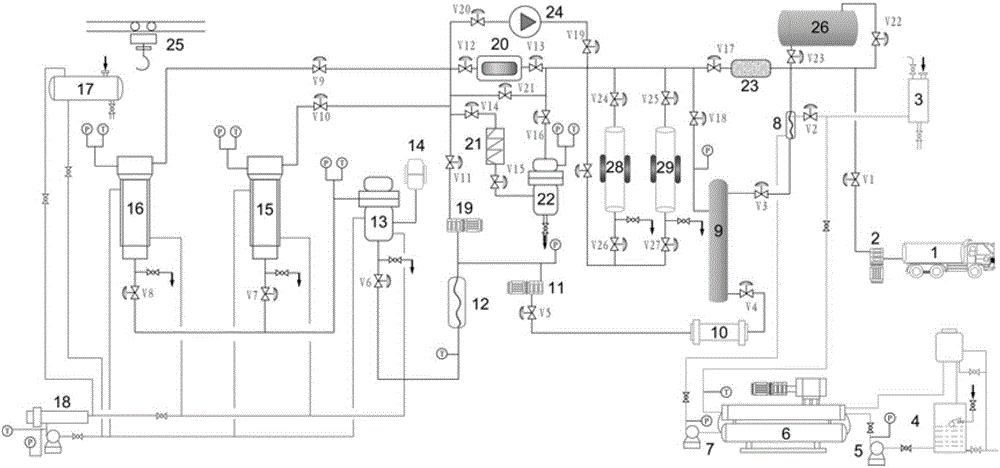

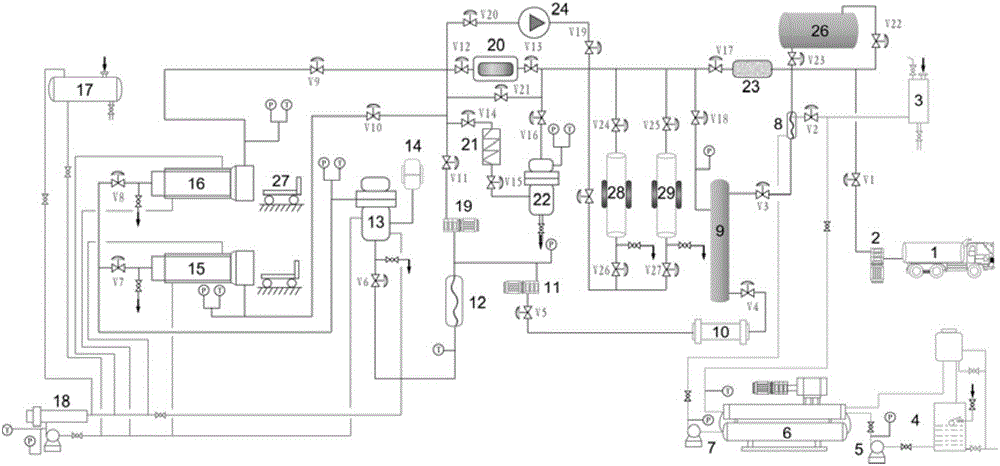

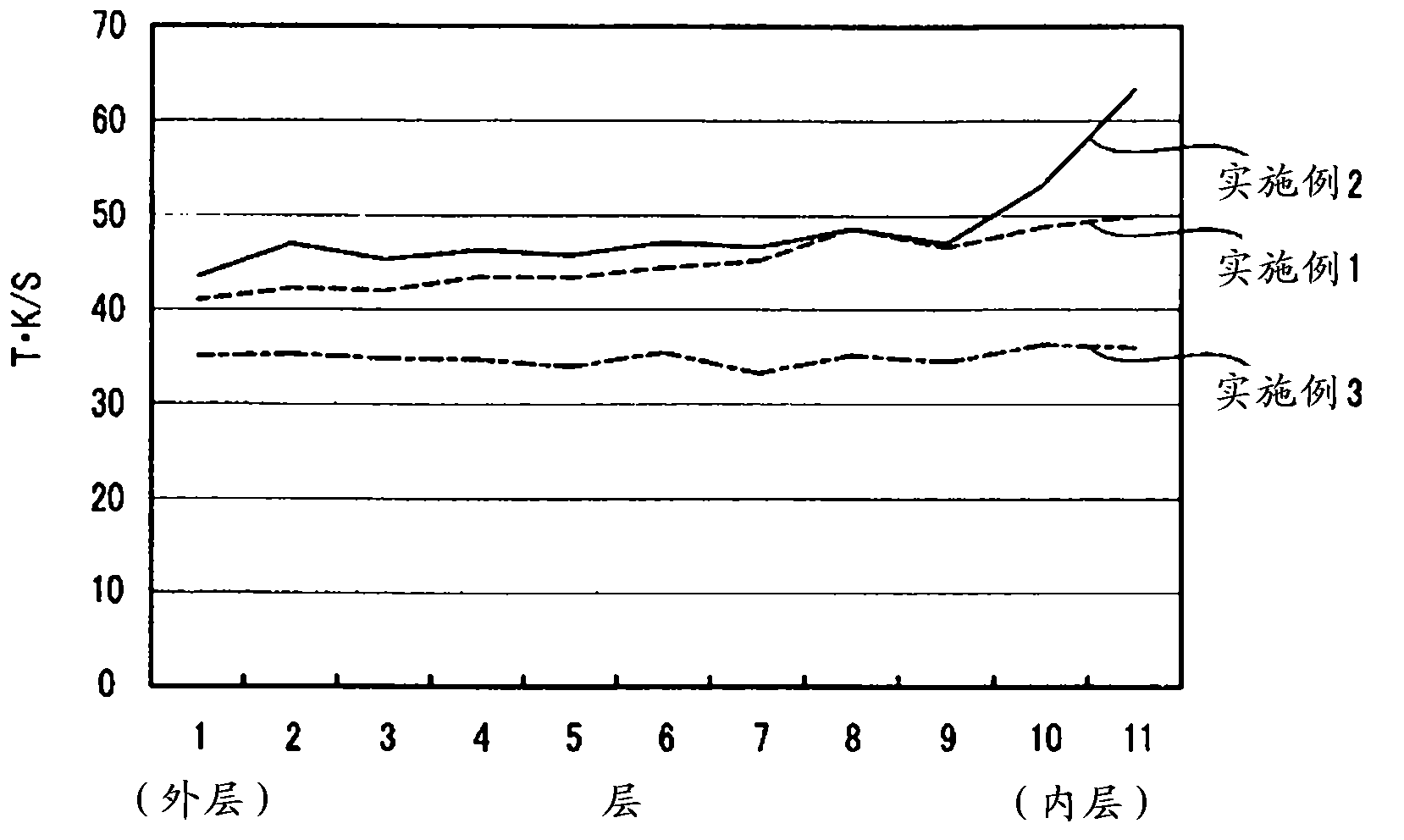

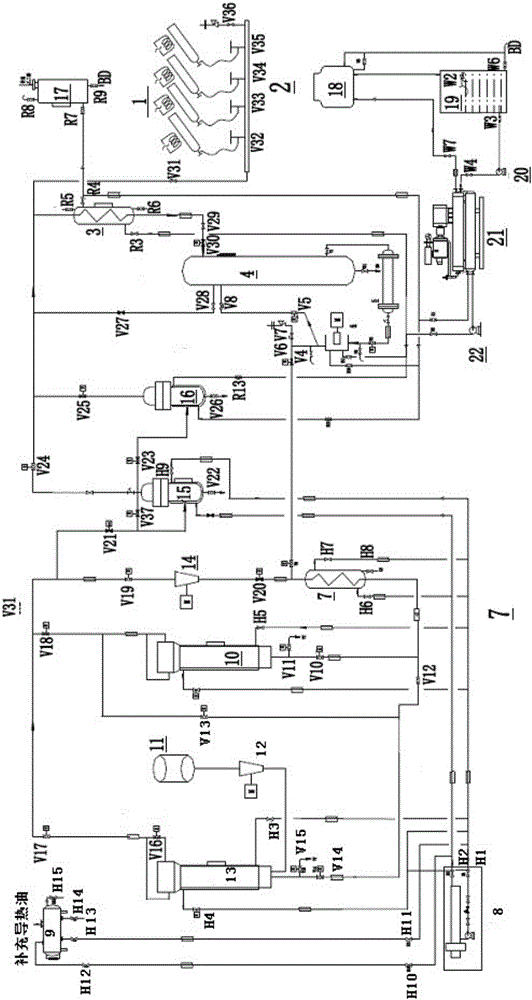

Multi-element dyeing and finishing kettle and industrial supercritical CO2 fluid anhydrous dyeing and finishing equipment with scale of 1000L or more

ActiveCN106835560ASolve the color changing problemRealize finishing productionTextile treatment containersSolvent treatment with solvent recoveryAutomatic controlSupply Storage

The invention discloses a multi-element dyeing and finishing kettle and industrial supercritical CO2 fluid anhydrous dyeing and finishing equipment with the scale of 1000L or more. The industrial supercritical CO2 fluid anhydrous dyeing and finishing equipment mainly comprises a CO2 low-temperature storage tank, a CO2 supply storage tank, a low-temperature delivery pump, an ethanediol head tank, an ethanediol pump, a water cooling tower, a water pump, a refrigerating unit, a condenser, a heat exchanger, a conduction oil system, a conduction oil supplementing system, a precooler, a CO2 booster pump, a dye kettle, a feeder, the multi-element dyeing and finishing kettle, a CO2 circulating pump, a cooler, a separating kettle, an adsorber, a recovery compressor, an online monitoring system and an automatic control system. The equipment is provided with the multi-element dyeing and finishing kettle and therefore is capable of achieving dyeing and finishing production of multiple kinds of monochromatic or polychromatic textiles. The dye kettle has the function of feeding at the right moment and can meet the requirement for fully dissolving dye and adding polychromatic dye; the dyeing and finishing equipment is connected with ultraperformance convergence chromatography and has the online monitoring function. The whole equipment achieves intelligence, automatic processing, energy conservation and environmental protection of the whole anhydrous dyeing and finishing process.

Owner:晋江国盛新材料科技有限公司

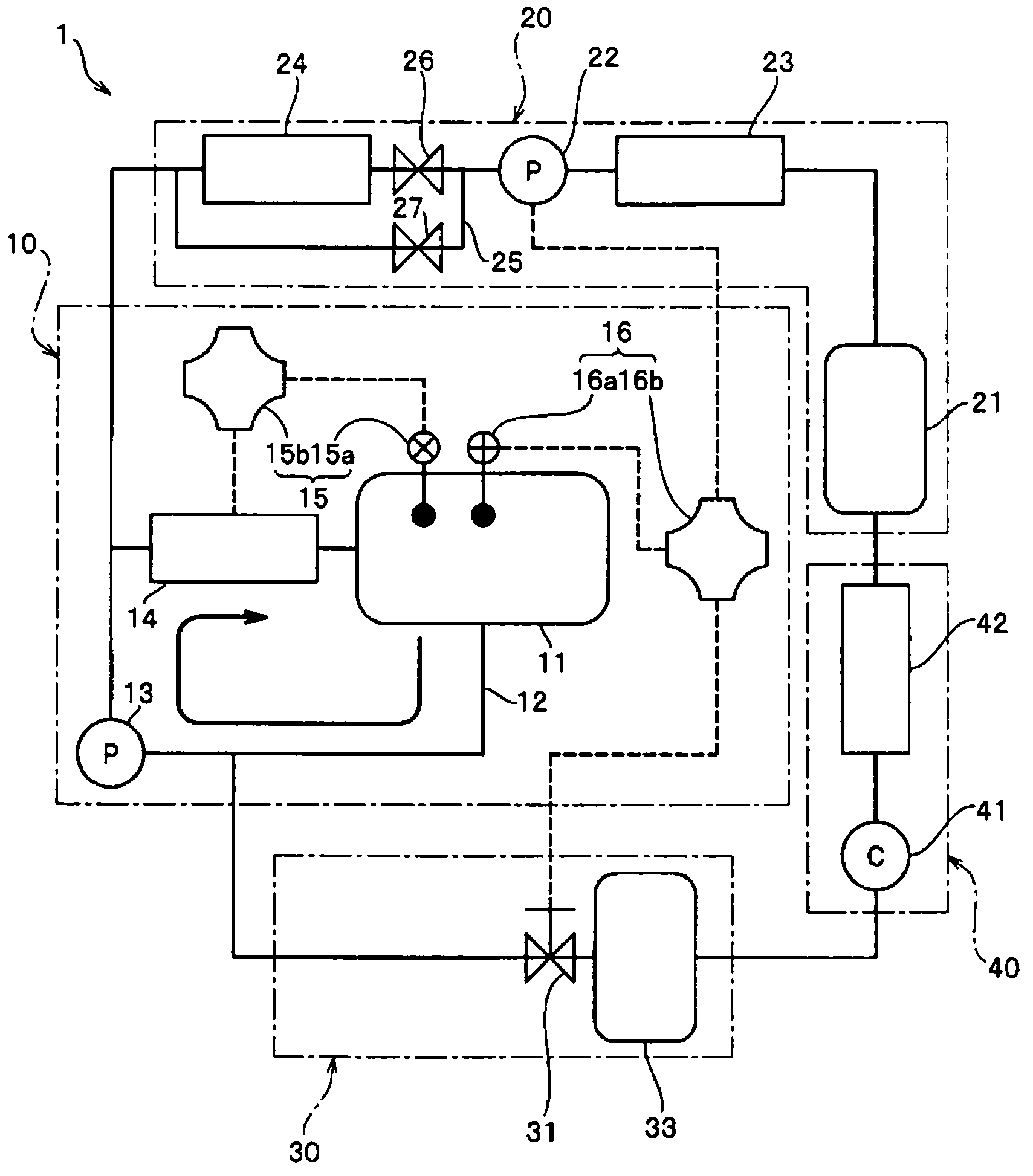

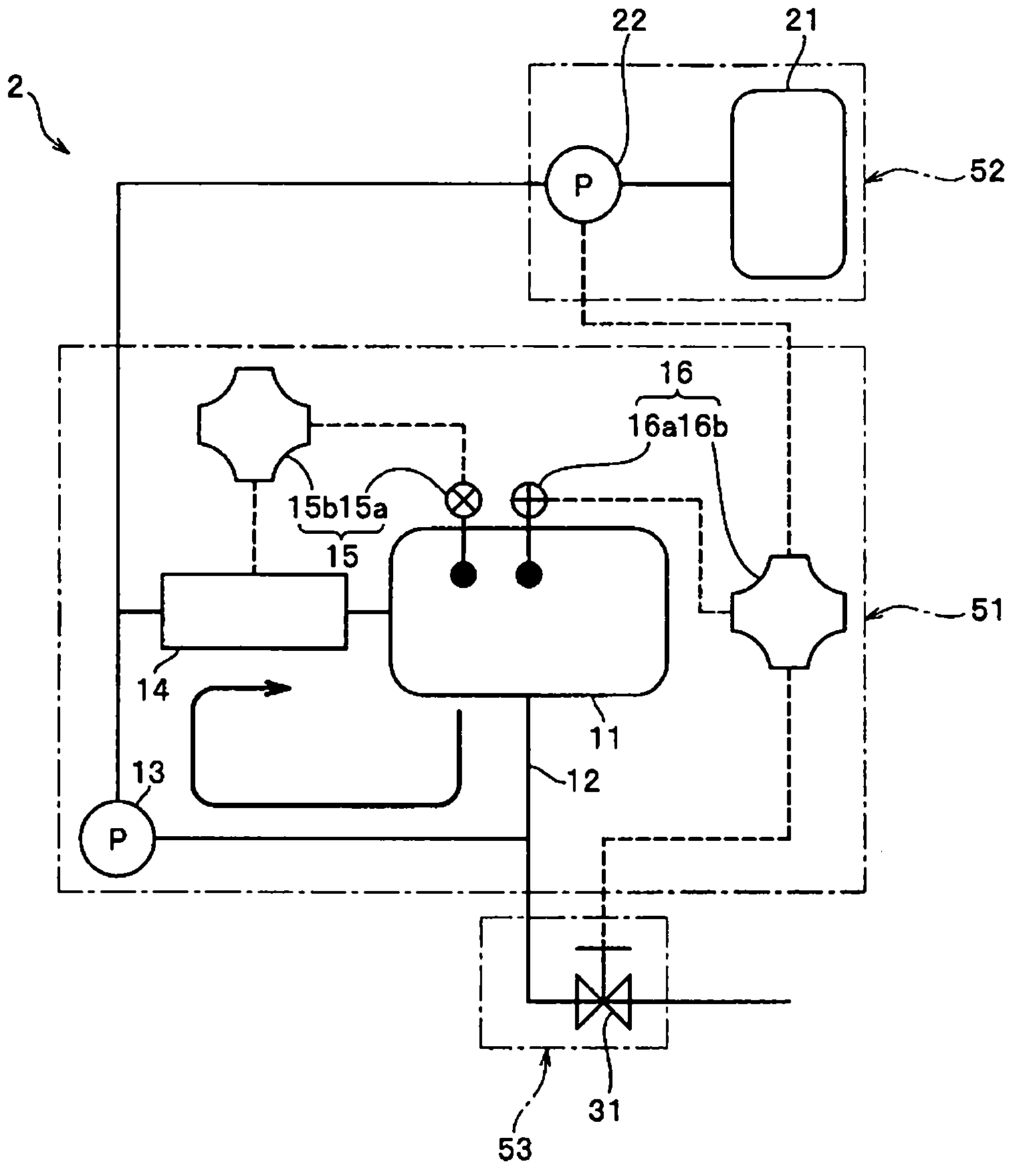

Cleaning method and cleaning device

ActiveCN103339316APrevent precipitationReduce the amount of adhesionDetergent mixture composition preparationSolvent treatment with solvent recoveryCleaning methodsPrecipitation

Provided is a cleaning method for cleaning a product which is contained in an autoclave (11) and is dyed by circulating a fluid in a supercritical state in which dye is dissolved and the autoclave (11) after the dyeing is terminated, the cleaning method being characterized in that after the dyeing is terminated, a pure fluid in the supercritical state which does not contain the dye is continuously introduced into the autoclave (11), thereby gradually reducing the concentration of the dye in the fluid in the supercritical state which exists in the autoclave (11) to perform the cleaning continuously. As a result, it is possible to effectively clean the product and the autoclave (11) with the supercritical fluid while suppressing precipitation of the dye dissolved in the supercritical fluid, and significantly improve the cleaning efficiency because the cleaning process is performed continuously from the dyeing process.

Owner:YKK CORP +1

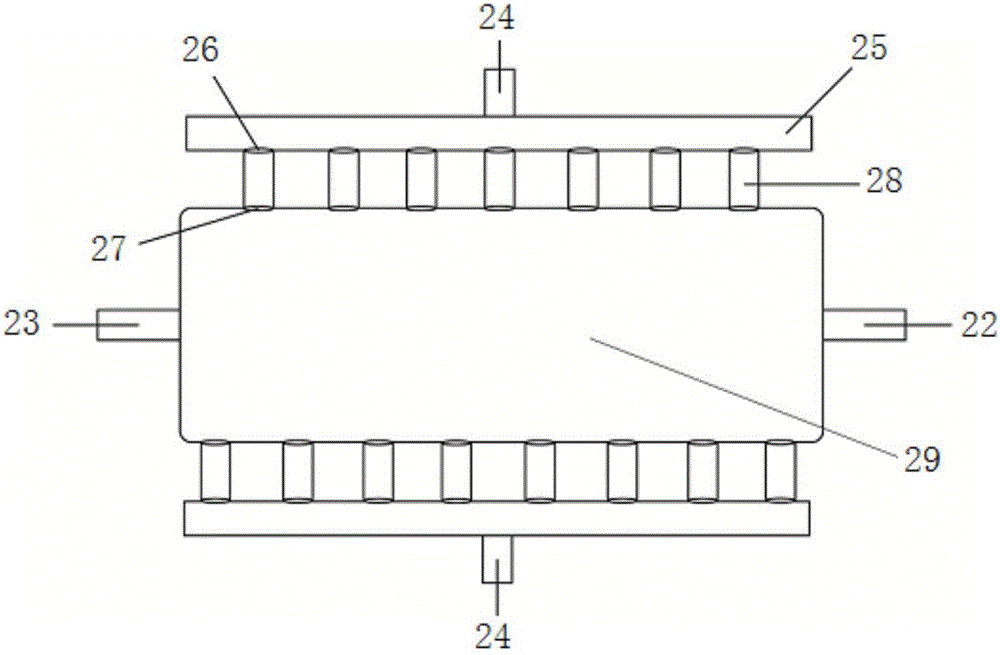

Finishing kettle and supercritical carbon dioxide anhydrous modification device and method for aramid fibers

ActiveCN106801309ANo damageQuality improvementTextile treatment containersSolvent treatment with solvent recoveryImpellerVapor–liquid separator

The invention discloses a finishing kettle and a supercritical carbon dioxide anhydrous modification device and method for aramid fibers. An finishing unit inside the finishing kettle is cylindrical, and comprises a top seal cover, a bottom seal cover I and a bottom seal cover II in sequence from top to bottom, and the center of the top seal cover and the center of the bottom seal cover I are connected with a porous center tube; the bottom seal cover I and the bottom seal cover II form a mixing chamber, a carbon dioxide fluid inlet tube penetrates through the bottom seal cover I, enters the mixing chamber and is provided with a impeller stirrer at the tail end inside the mixing chamber, and an atomizer is arranged inside the impeller stirrer; a finishing agent inlet tube is connected to the carbon dioxide fluid inlet tube; an atomizing sprayer is arranged inside the finishing agent inlet tube. With the device, surface modification can be achieved for the aramid fibers; an atomizing finishing agent and supercritical carbon dioxide fluid are evenly mixed, so that functional modification processing is completed for the aramid fibers; meanwhile, with a gas-liquid separator, the liquefied finishing agent can be condensed and recovered, and finally anhydrous clean modification is achieved for the aramid fibers.

Owner:泰和新材集团股份有限公司

Supercritical carbon dioxide dyeing device and its process

InactiveCN100359091CReduce pollutionImprove dye uptakeSolvent treatment with solvent recoveryTextile/flexible product manufactureProcess engineeringEnvironmental engineering

The invention discloses a supercritical carbon dioxide dyeing device, which comprises mainly a CO2 storage tank (H01), a dye kettle (H06), and a dyeing kettle (H07). Wherein, the dyeing technique comprises: cooling the CO2 from HO1 into liquid to send into preheater (HO5) connected to HO6 with carbon-dioxide high-pressure pump (HO4); sending supercritical carbon dioxide to HO7 by HO6; driving the dyed carbon dioxide to pass separator (HO8) and second condenser (HO9) and return to said storage tank (HO1). This invention can recycle 100% residual dye and carbon dioxide as dyeing medium, saves water and dye resource, and reduces pollution.

Owner:DALIAN POLYTECHNIC UNIVERSITY

Flax roving supercritical CO2 biological enzyme bleaching device and bleaching method thereof

ActiveCN106835559AReduce usageReflect the concept of modern lifeSolvent treatment with solvent recoveryTextile/flexible product manufactureBleachSingle fiber

The invention discloses a flax roving supercritical CO2 biological enzyme bleaching device and a bleaching method thereof. The bleaching method comprises the steps that flax roving is bleached for 30-120 minutes in supercritical CO2 fluid with dissolved bio-enzyme bleach, at a temperature of 25-65 DEG C, a pressure of 15-25 MPa, and CO2 fluid flow of 10-50 g / min. The enzyme bleaching agent contains 0.2-3% (o. w. f) xylanase and 0.2-5% (o. w. f) glucose oxidase. By the adoption of the bleaching method, the whiteness of the flax roving can reach 45-70%, the weight loss rate is 7-12%, the adhesive residue is 9-15%, a single fiber breaking tenacity is 6.5-13.5 cN / dtex, and the elongation at the breaking is 5-8.5%. By the flax roving supercritical CO2 biological enzyme bleaching device and the bleaching method, a clean bleaching production of flax roving is achieved using CO2 instead of aqueous medium, the use of a large amount of chemical reagents such as hydrogen peroxide and sodium hypochlorite is avoided; the whole bleaching process is free of filth and zero in emission, and the modern living concept of fashion and green for flax is expressed.

Owner:YIXING SUNSHINE LINEN TEXTILE CO LTD

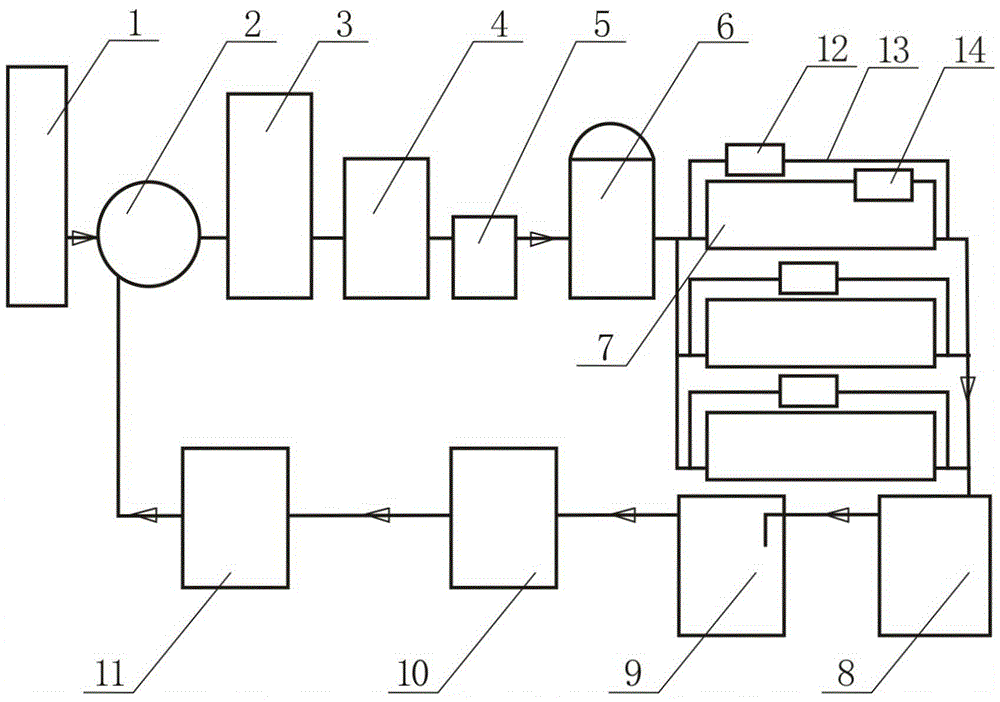

Separation, recycling and self-cleaning system of supercritical fluid dyeing machine

ActiveUS20180119324A1Easy to separateIncrease productionTextile treatment containersDispersed particle filtrationEngineeringHigh pressure

The invention relates to a separation, recycling and self-cleaning system of a supercritical fluid dyeing machine. The system includes a supercritical fluid medium reservoir, one or more parallel dyeing units, a high-pressure pump, a primary separator, a secondary separator and a membrane separator sequentially connected. A dyeing medium and residual dye in dyeing units can be efficiently separated and recycled simultaneously, and when the separation and recycling is finished, each dyeing unit can be directly opened so that the dyeing units and products can be cleaned after dyeing, thereby improving the production and processing efficiency of supercritical fluid waterless dyeing and achieving simple operations, complete separation, stability and reliability and a blowback self-cleaning. The invention has a broad application prospect and practical significance in fundamentally addressing generation and emission of pollutants in the textile printing and dyeing industry and realizing energy conservation, consumption reduction, emission reduction and clean production.

Owner:NANTONG TEXTILE & SILK IND TECH RES INST +1

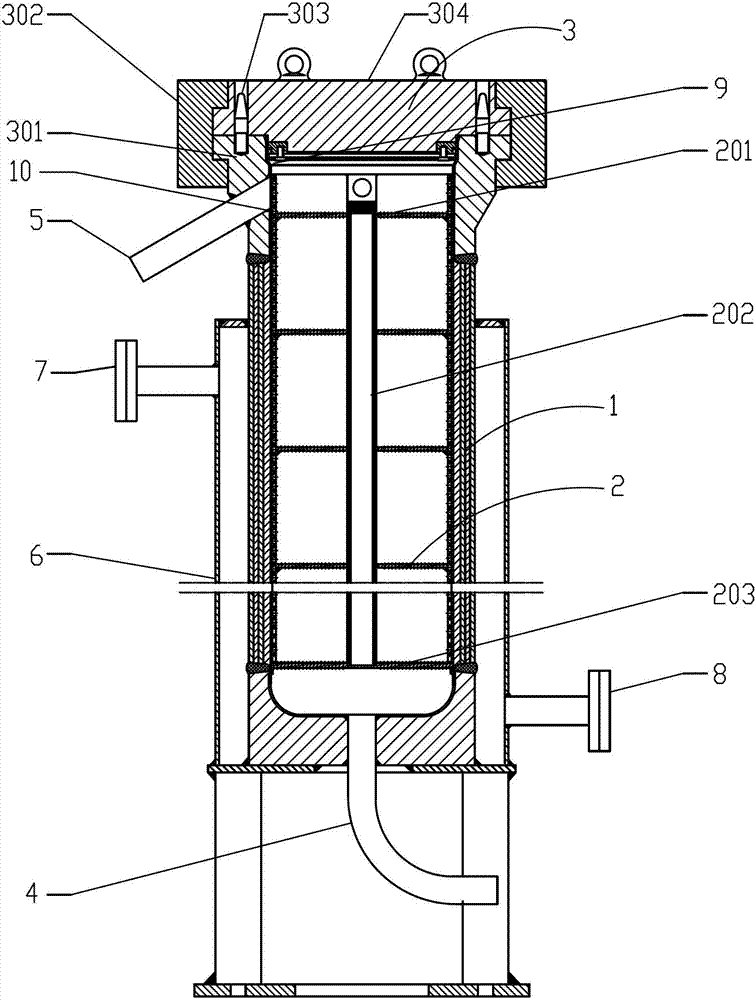

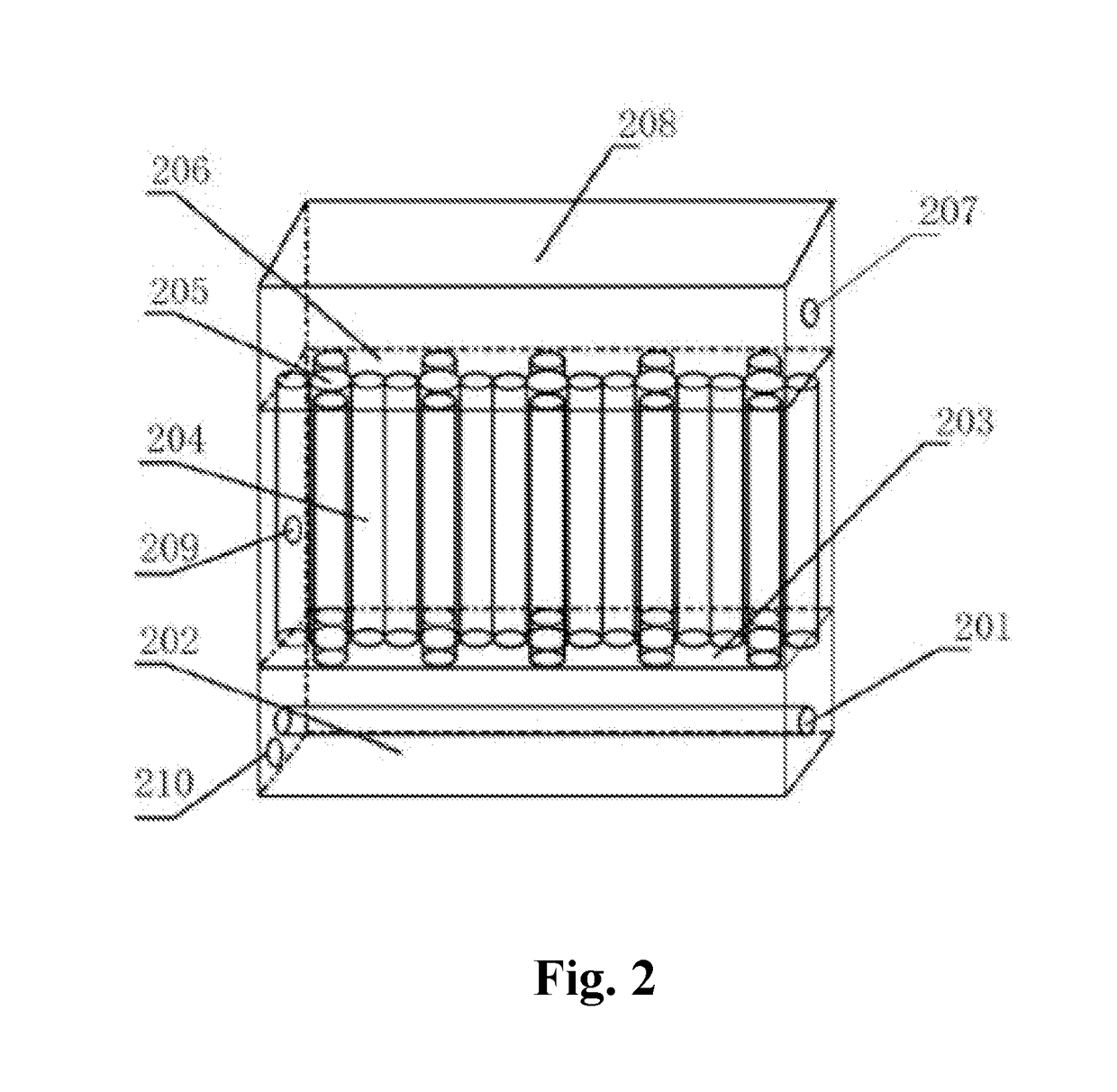

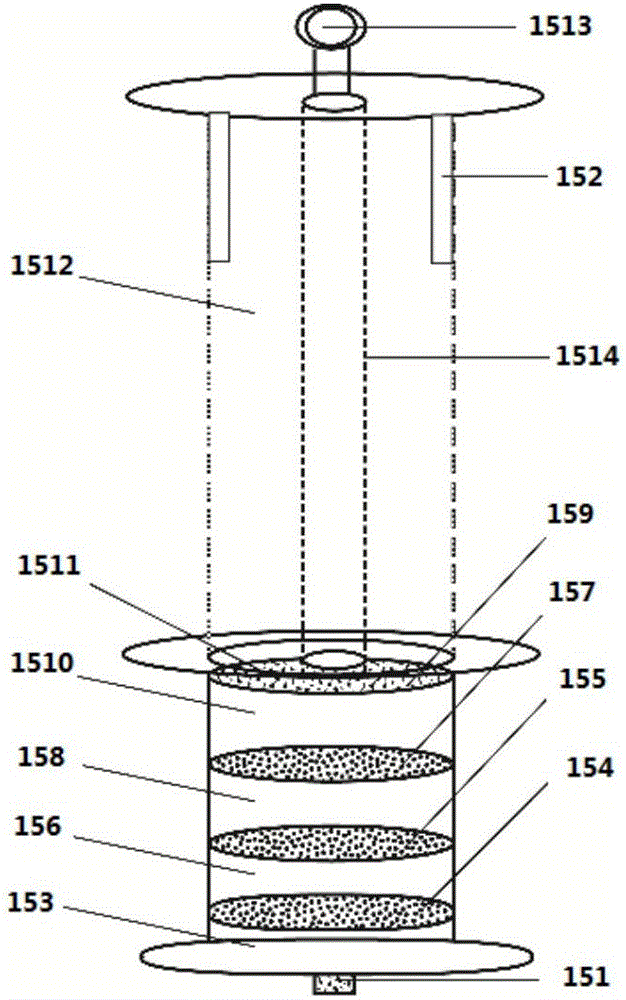

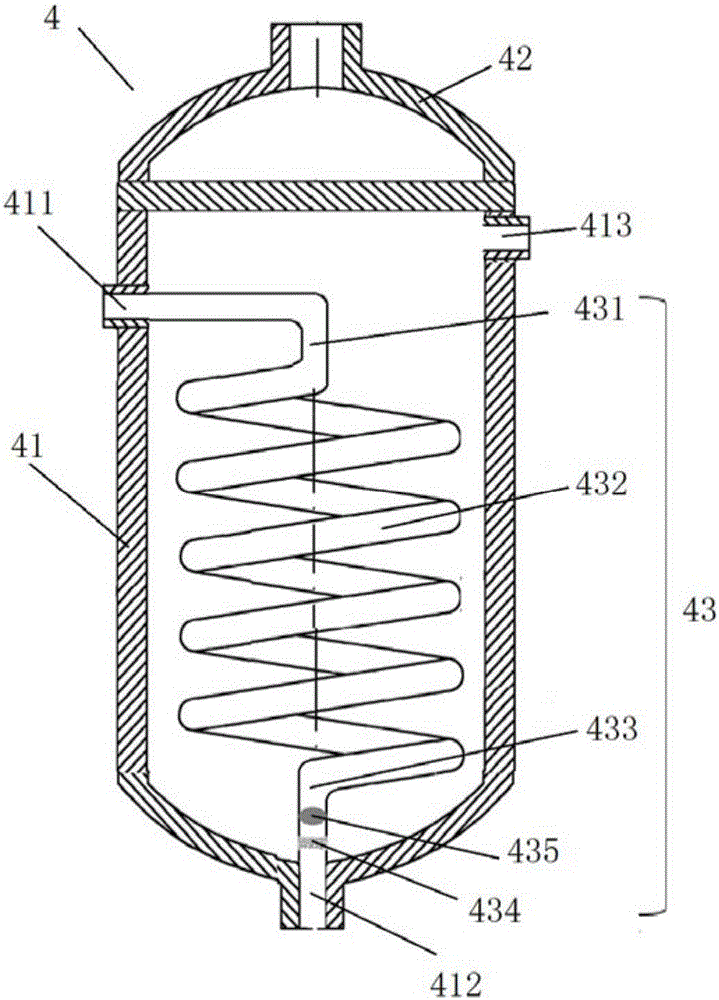

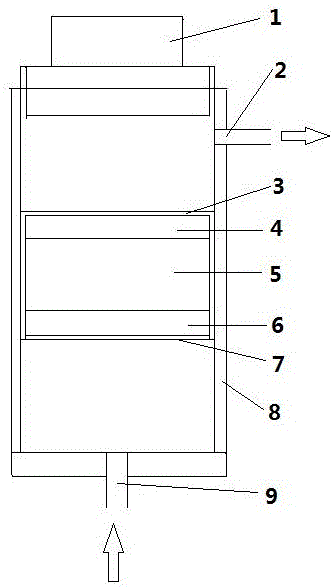

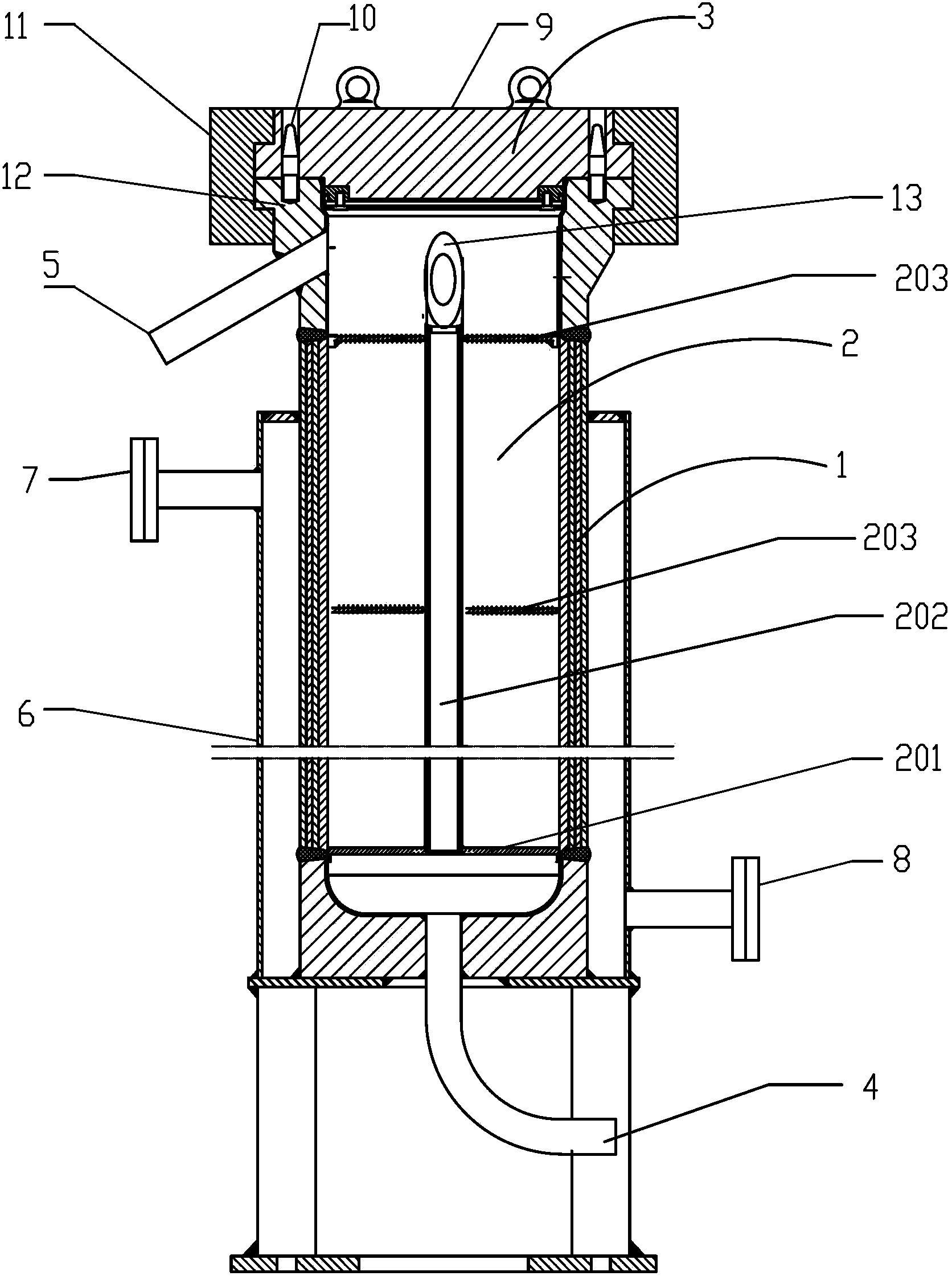

Recovery and separation kettle for supercritical CO2 dyeing gas-solid separation and recovery and separation method

ActiveCN105862292AQuick filter cleaningHigh-efficiency filter cleaningDispersed particle separationSolvent treatment with solvent recoveryMolecular sieveGas solid

The invention provides a recovery and separation kettle for supercritical CO2 dyeing gas-solid separation and a recovery and separation method. The recovery and separation kettle is characterized in that a tank body of the recovery and separation kettle comprises a cylindrical casing, a top cover, a base plate and an inner separation cylinder, wherein the top cover is mounted at the upper end of the cylindrical casing; the inner separation cylinder is arranged in the cylindrical casing; the base plate is mounted at the lower end of the cylindrical casing; a lower sponge layer, a molecular sieve and an upper sponge layer are sequentially arranged in the inner separation cylinder from bottom to top; a pipe being introduced into a tank cavity is arranged in the center of the base plate; a pipe communicated with a condensing unit is arranged at the upper part of the cylindrical casing. According to the recovery and separation kettle and the recovery and separation method, gas mixed with a large quantity of dyes, impurities and water after supercritical CO2 waterless dyeing is guided into the recovery and separation kettle for purification and recovery, and the purity degree and the drying degree of recovered CO2 can be increased in a molecular sieve purification manner; besides, the molecular sieve can be recycled after treatment.

Owner:QINGDAO JIFA GROUP

Chemical formulations and methods utilizing NPB(n-propyl bromide) as non-aqueous carrier mediums to apply fluorocarbons and other organic chemicals to substrates

InactiveUS20040006827A1No ozone pollution propertiesGood choicePhysical treatmentSolvent treatment with solvent recoveryWater basedPropyl bromide

The present invention relates to methods and chemical formulations utilizing NPB(n-propyl bromide) also called 1-bromopropane or propyl bromide or 1-BP or N-Bromopropane as non-aqueous carrier mediums to apply fluorocarbons and other chemicals to substrates, whereby the NPB is evaporated away leaving the remaining chemicals on the substrate. The present invention offers formula and method for applying organic chemicals to substrates that perform superior to current water based technology. Additional, the invention offers a more economical and environmental friendly alternative to current chlorinated hydrocarbons carriers that are being phased out by mandate of the Environmental Protection Agency (EPA).

Owner:RISING LARRY ERVIN

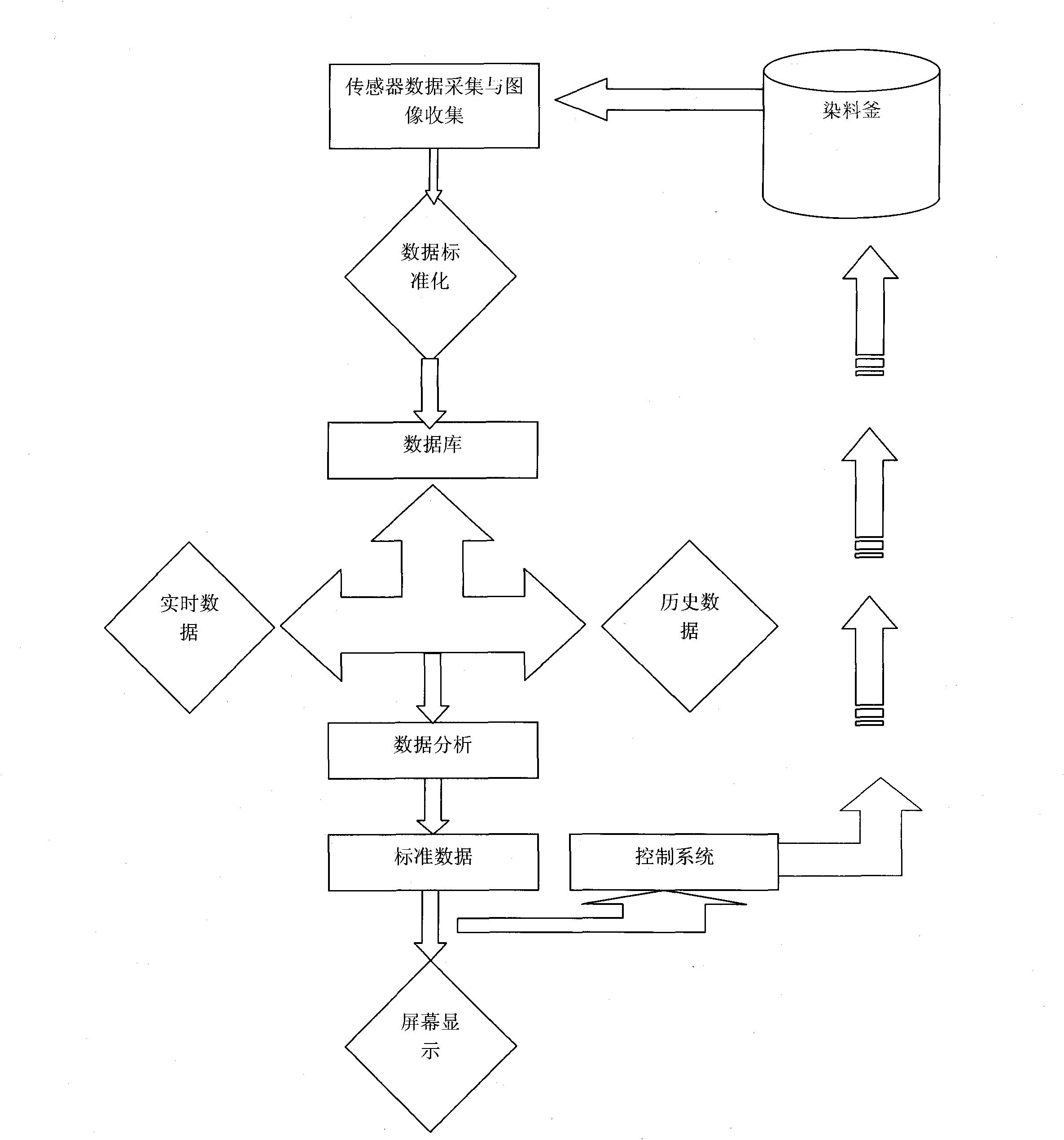

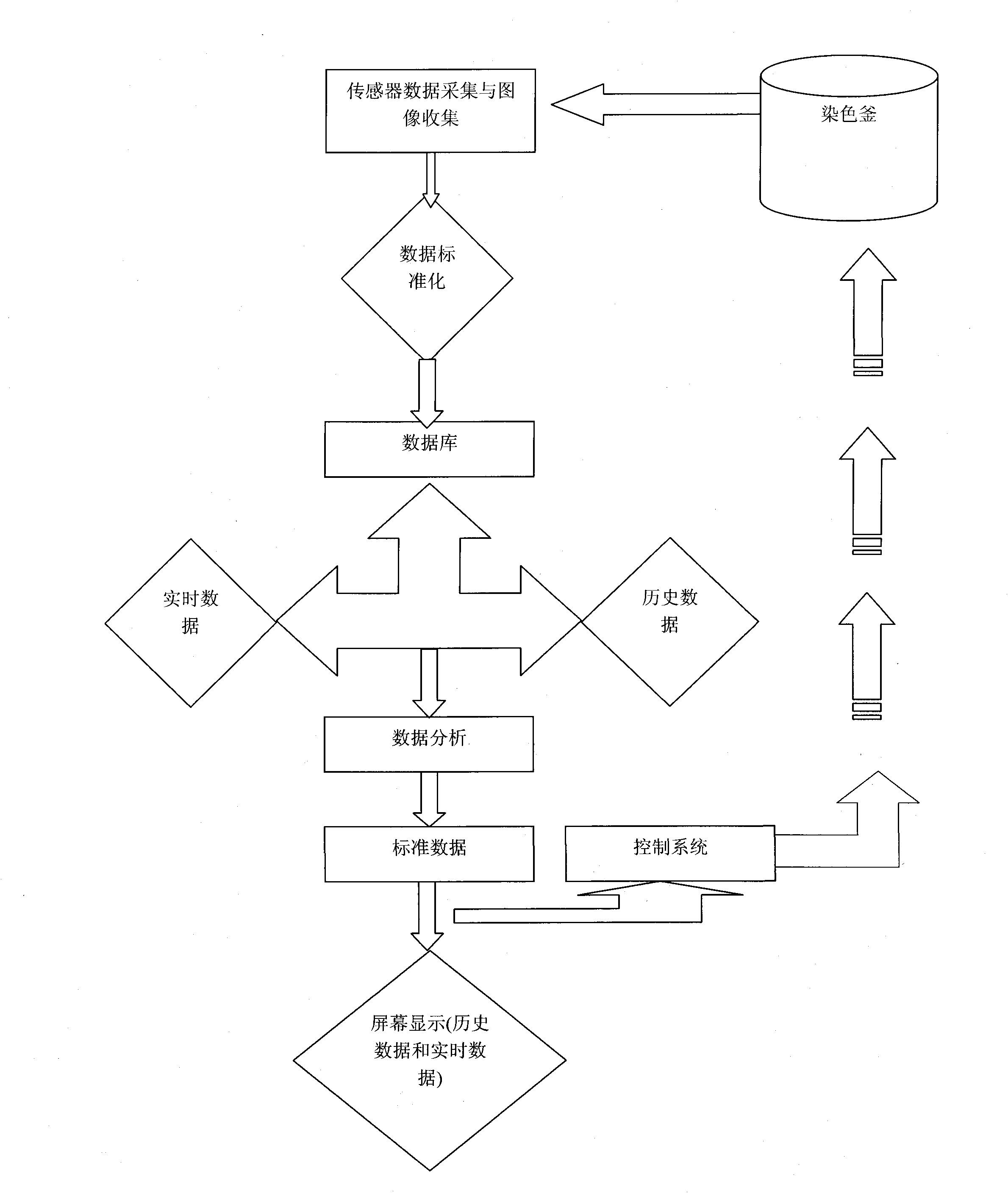

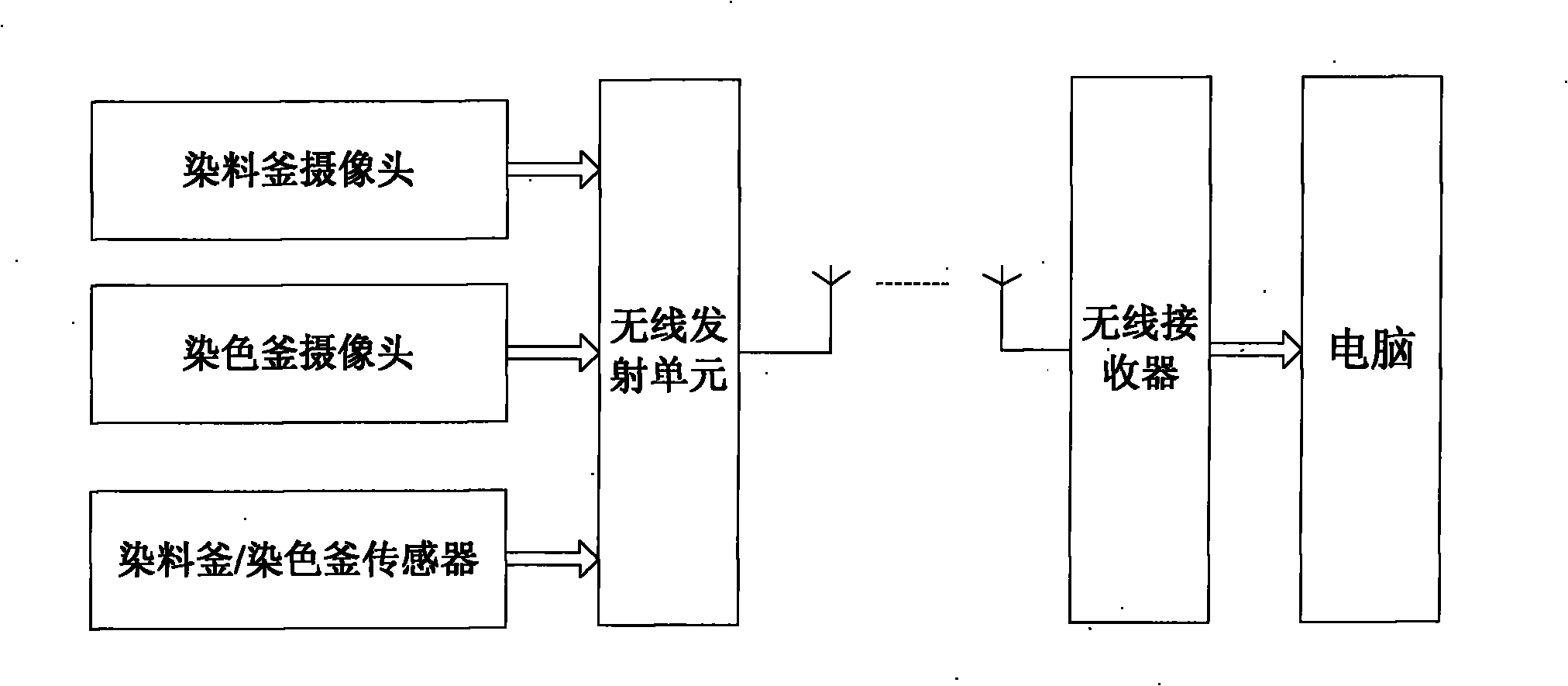

Visualization system in supercritical carbon dioxide dyeing device

ActiveCN101845732ASimple structureUniform dyeingTextile treatment machine partsSolvent treatment with solvent recoveryReal time displayComputer science

The invention discloses a visualization system in a supercritical carbon dioxide dyeing device, which comprises the following working principles of: obtaining the concentration, speed, temperature, pressure and image information of carbon dioxide in a dye kettle and a dying kettle by a sensor and a camera; introducing data into a database and displaying the image information by a display screen in real time; processing the data in the database and displaying the data by the display screen in real time; observing whether the surfaces of fabrics are covered with partial dye in the dying kettle by the display screen, if so, introducing carbon dioxide into the system to sufficiently dissolve the dye, in addition, when the dying temperature and the pressure reach standard, discovering no dye residues in the dying kettle by the display screenand observing whether the dye is attached to the fabrics in the dying kettle or not at the same time, if no, stopping running the whole supercritical dying system in advance. The visualization system has simple structure, is convenient to produce and install and is suitable for being widely popularized in the supercritical carbon-dioxide dying system.

Owner:晋江国盛新材料科技有限公司

Supercritical fluid spray-dyeing device

InactiveCN101798735BSimple structureOperational securityTextile treatment machine partsSolvent treatment with solvent recoveryDying processesSpray nozzle

The invention relates to the field of textile dyeing equipment, in particular to a supercritical fluid spray-dyeing device which comprises spray nozzle groups, used fluid collectors, winding rollers and a tensioning component. A driving winding roller and a driven winding roller are respectively installed at two ends of an operation orbit determined by a dyeing process flow in the device and usedfor winding, supporting and driving objects to be dyed; the spray nozzle groups and the used fluid collectors are respectively installed at two sides of the dying process flow operation orbit according to the order of dying processes and are respectively connected with mechanisms of supercritical fluid generation, dying material dissolution and supercritical fluid medium recycling separation and storage; guide rollers are arranged at the intervals of the all spray nozzle groups or the spray opening surfaces of the all spray nozzle groups are used for supporting and tensioning the object to bedyed; and the spray nozzle groups comprise extracting spray nozzle groups, dyeing spray nozzle groups and cleaning spray nozzle groups. The invention has the advantages of simple structure, convenient and safe operation, low investment, reasonable and advanced flow, good dyeing uniformity and continuity as well as high dyeing quality and productivity.

Owner:SHANDONG UNIV

Supercritical carbon dioxide skein dyeing kettle and waterless dyeing method thereof

ActiveCN102776739BGood level dyeingHigh fastnessTextile treatment containersSolvent treatment with solvent recoveryDistributorSupercritical carbon dioxide

Owner:晋江国盛新材料科技有限公司

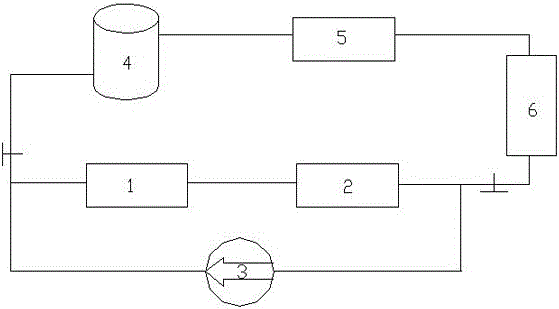

Dyeing system

InactiveCN103046270AImprove permeabilityGood level dyeingSolvent treatment with solvent recoveryTextile treatment machine arrangementsOrganic solventProcess engineering

The invention relates to a dyeing system and belongs to printing and dyeing textile equipment. The dyeing system is composed of a dyeing machine, a vacuumizer and a distillation recovery device, wherein the vacuumizer and the distillation recovery device are arranged at the tail end of the dyeing machine, an air guide port is arranged on a channel cover of the dyeing machine and connected to an air inlet of the vacuumizer through a pipeline, an air outlet of the vacuumizer is connected to a distillation still of the distillation recovery device through the pipeline, a liquid discharge port is arranged on an organic solvent storage of the distillation recovery device and connected to a material feed pipe arranged on the dyeing machine through the pipeline, and an organic solvent circulating pump is arranged at the liquid discharge port. The dyeing system is reasonable in design, concise in structure, capable of meeting dyeing process requirements of dye liquid in which organic solvents and a little water are mutually soluble for objects to be dyed under a vacuum state and recycling the organic solvents, suitable for to-be-dyed objects made of different textile materials, safe, reliable and stable in dyeing processes, good in dyeing effect and environment-friendly.

Owner:WUHAN TEXTILE UNIV

Popular searches

Detergent dyes Drying gas arrangements Detergent solvents Organic/inorganic per-compounds compounding agents Detergent bleaching agents Cation exchangers Alkali metal oxides/hydroxides Non-miscible liquid separation Water/sewage treatment by ion-exchange Organic non-surface-active detergent compositions

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com