Visualization system in supercritical carbon dioxide dyeing device

A carbon dioxide and supercritical technology, applied in the field of visualization systems, can solve the problems of insufficient dyeing of fabrics, waste of dyes and fabrics, waste of time, etc., and achieve the effect of improving dyeing rate, high dyeing rate and saving dyeing time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

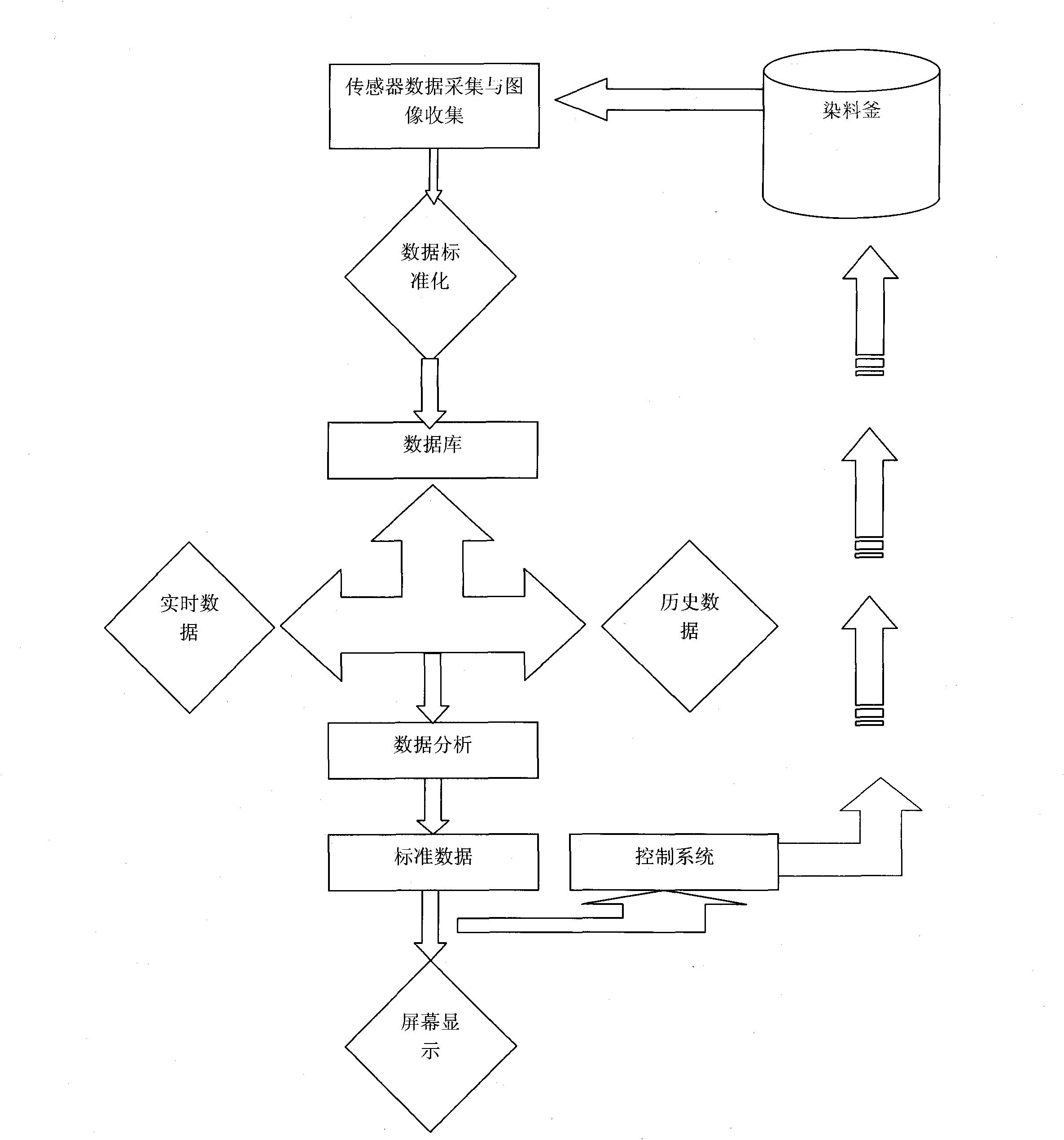

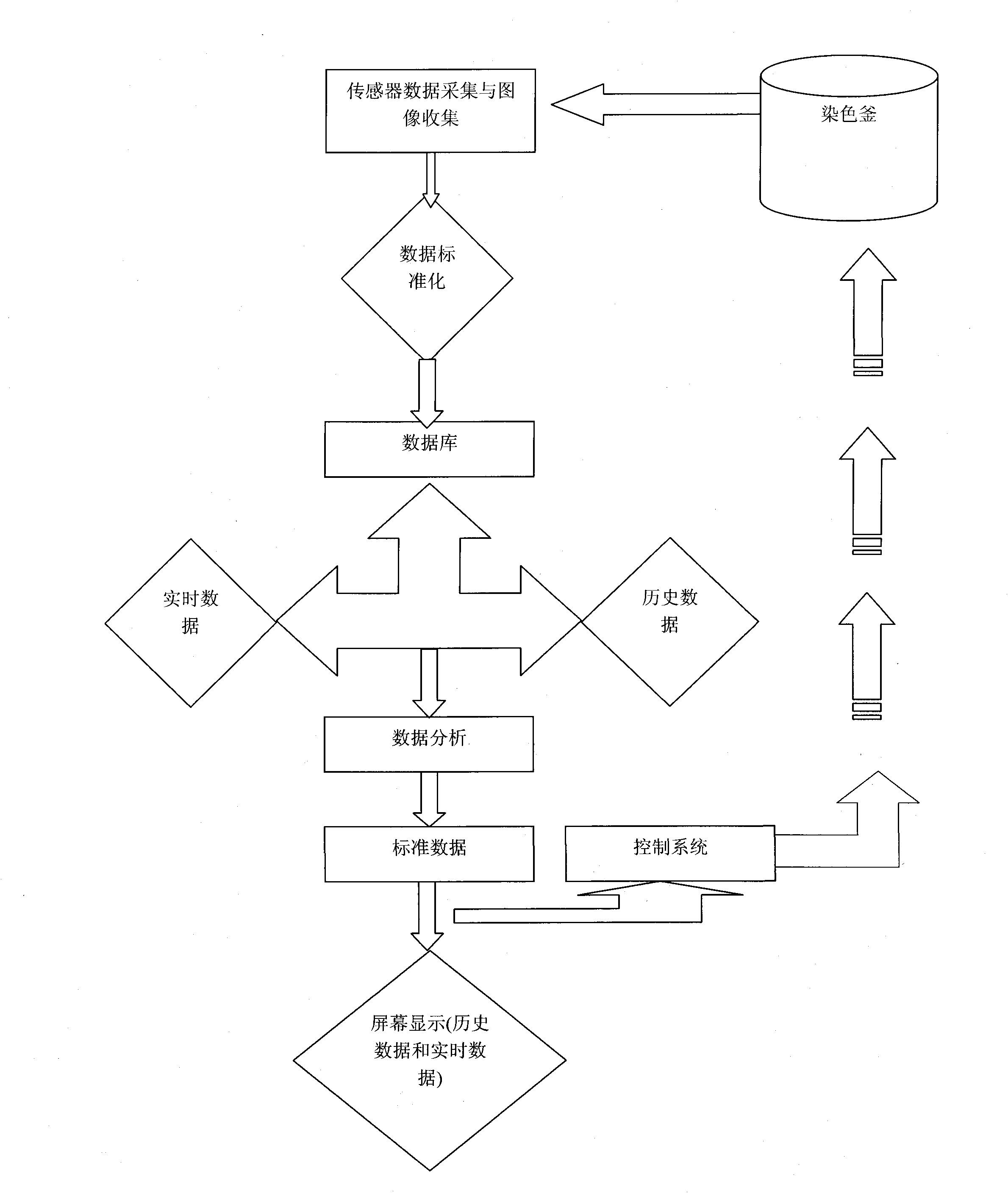

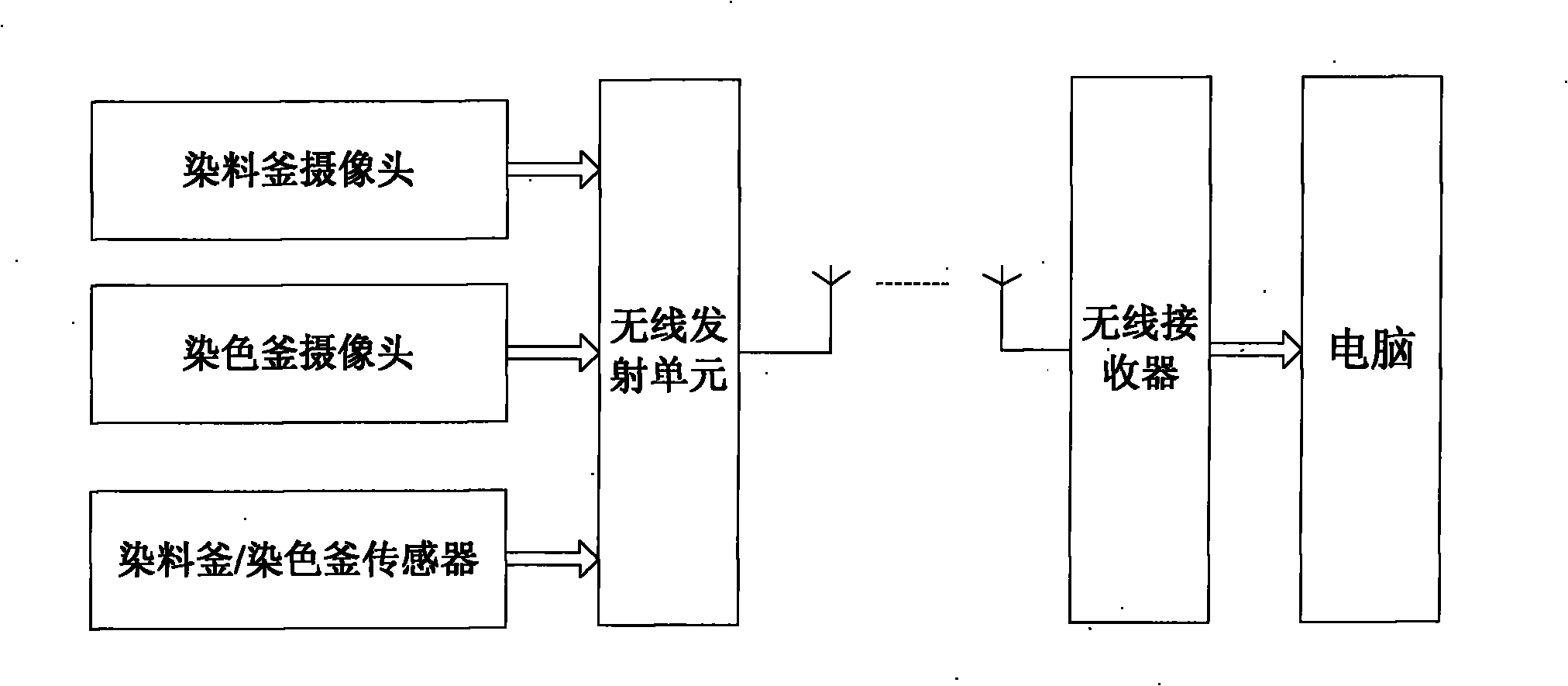

Method used

Image

Examples

specific example

[0087] The specific example is as follows: put 20g of polyester-cotton blended fabric in the dyeing kettle, and when there are 2g of dye in the dyeing kettle, the temperature set by the control system is 110°C, the pressure is 25MPa, the flow rate is greater than 200ml / min, and the dyeing time is 2 hours. The temperature and pressure in the system are gradually increased by heating in the oil bath and pressurized by the booster pump, and the real-time data of the system are transmitted to the computer through the dyeing kettle, the sensor and the camera in the dyeing kettle. Through the picture presented on the monitor, we observe the amount of dye attached to the surface of the fabric in the dyeing kettle. If the amount of attachment is too large to cover the surface of the fabric and affect the dyeing of the fabric, then we will continue to pressurize. If the pressure is greater than the initial setting of our system If the pressure is fixed, the booster pump will automatical...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com