Waterless dyeing device and dyeing method thereof by utilizing activated dye for cotton cone yarns

A reactive dye, anhydrous dyeing technology, applied in the field of textile printing and dyeing, can solve the problems of low solvent flash point, high cost, toxicity, etc., and achieve the effect of high dry rubbing fastness, high wet rubbing fastness, and avoiding environmental pollution.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

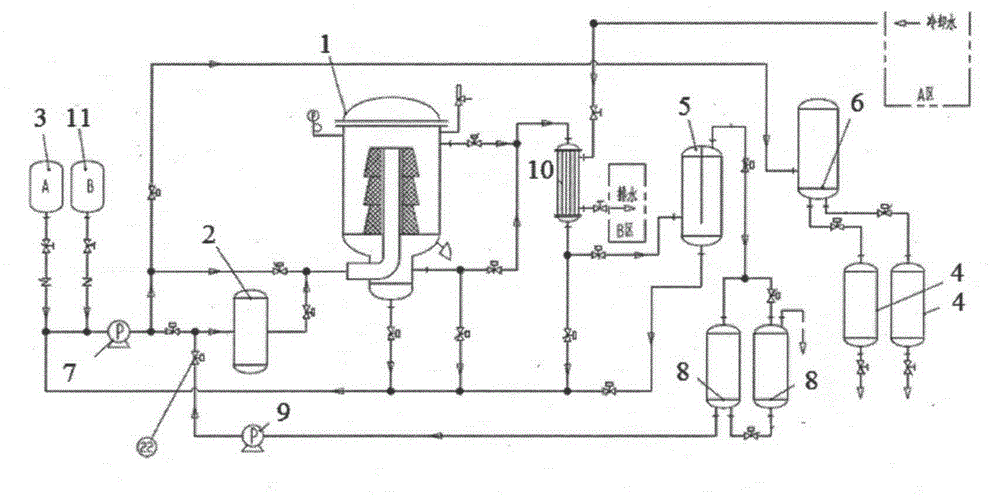

[0031] Such as figure 1 Shown is the diagram of the reactive dye anhydrous dyeing equipment for cotton cheese, the reactive dye anhydrous dyeing equipment for cotton cheese includes a main dyeing vat 1, and the main dyeing vat 1 is connected to an electric heating device 2 through a pipeline, and the electric heating device 2 is connected to the main dyeing vat 1. The heating device 2 is connected to the main pump 7 through the pipeline, and the main pump 7 is connected to the solvent storage device 3 and the dye solution dispensing device 11 through the pipeline, and the main dye vat 1 is connected to the condenser 10 through the pipeline, and the condenser 10 is connected through the pipeline The solvent storage device 3 and the dye liquor dispensing device 11, the main dye vat 1 is connected to the solvent separation device 6 through pipelines, and the solvent separation device 6 is connected to the solvent recovery device 4 through pipelines. The condenser 10 is connected ...

Embodiment 2

[0034] A kind of reactive dye anhydrous dyeing method of cotton cheese, adopts the reactive dye anhydrous dyeing equipment of cotton cheese described in embodiment 1, concrete steps are:

[0035] 500g pure cotton cheese (skimmed, bleached, 0.32g / cm 3 ) into the main dyeing vat 1, add 10L dimethyl sulfoxide, turn on the main pump 7, and heat up to 60° C. to swell for 2 hours. Discharge dimethyl sulfoxide to the solvent storage device 3, then add 15g of C.I. active red 24, 9g of tetramethylammonium hydroxide, 2L of dimethyl sulfoxide and 3L of dimethyl nylonate into the main dyeing vat 1 The formed dye liquor is heated to 90°C for cyclic dyeing for 2 hours, the flow rate of the dye liquor is 70L / kg·min, and the ratio of forward and reverse cycle time is: 1:1. After the dye liquor is cooled, it is separated by the gas-liquid separation device 5, The separated tetramethylammonium hydroxide, dimethyl sulfoxide and dimethyl nylon acid enter the gas storage device 8, and the separat...

Embodiment 3

[0037] A kind of reactive dye anhydrous dyeing method of cotton cheese, adopts the reactive dye anhydrous dyeing equipment of cotton cheese described in embodiment 1, concrete steps are:

[0038] 1kg pure cotton cheese (skimmed, bleached, 0.35g / cm 3) into the main dyeing vat 1, add 10L dimethyl sulfoxide, turn on the main pump 7, and heat up to 90° C. for 1 hour to swell. Discharge dimethyl sulfoxide to the solvent storage device 3, then add 30g C.I. reactive blue 19, 20g tetramethylammonium hydroxide, dimethyl sulfoxide 4L and diphenyl ether 4L to the main dye vat 1 The dyeing solution is heated to 90°C for cyclic dyeing for 3 hours, the flow rate of the dyeing solution is 80L / kg·min, and the ratio of forward and reverse cycle time is: 2:1. Tetramethylammonium hydroxide, dimethyl sulfoxide and dimethyl nylon acid enter the gas storage device 8, and the separated liquid is discharged into the dye liquor batching device 11, and dimethyl sulfoxide is added in the main dye vat 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com