Finishing kettle and supercritical carbon dioxide anhydrous modification device and method for aramid fibers

A carbon dioxide and aramid fiber technology, which is applied in the processing of textile material equipment configuration, textile material processing, and textile material container processing, can solve the problems of poor wetting performance and dyeing performance of aramid fiber, and achieve uniform modification Effect of finishing and improving wetting performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

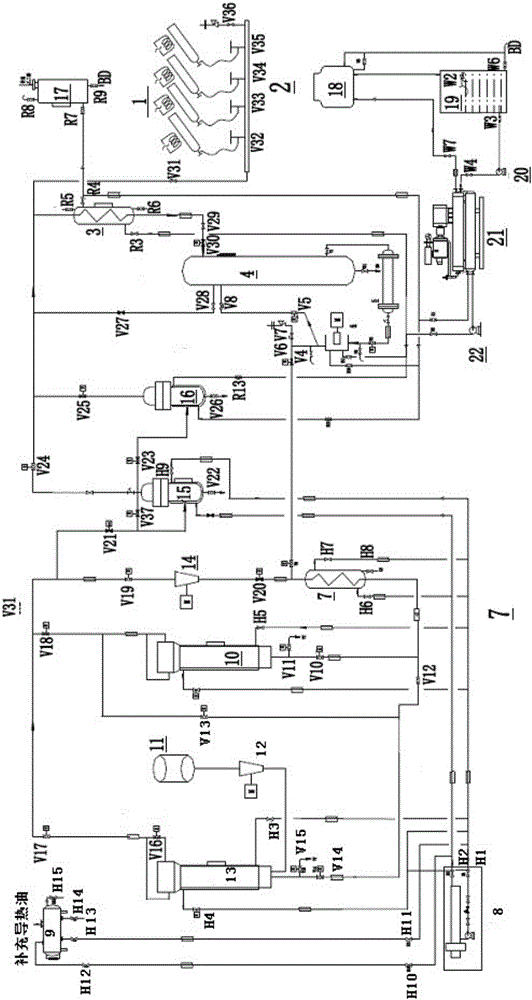

[0024] Under the action of the carbon dioxide heater 2, the carbon dioxide in the gas cylinder flows through the busbar, and is cooled by the condenser 3 to become a liquid carbon dioxide fluid, which is stored in the carbon dioxide storage tank 4 for use in the modification and finishing process. The carbon dioxide in the carbon dioxide storage tank 4 first flows through the precooler 5 to condense, and is injected into the system through the carbon dioxide booster pump 6 to complete the boosting process; then the heat exchanger is used to heat the carbon dioxide fluid to make it enter a supercritical state;

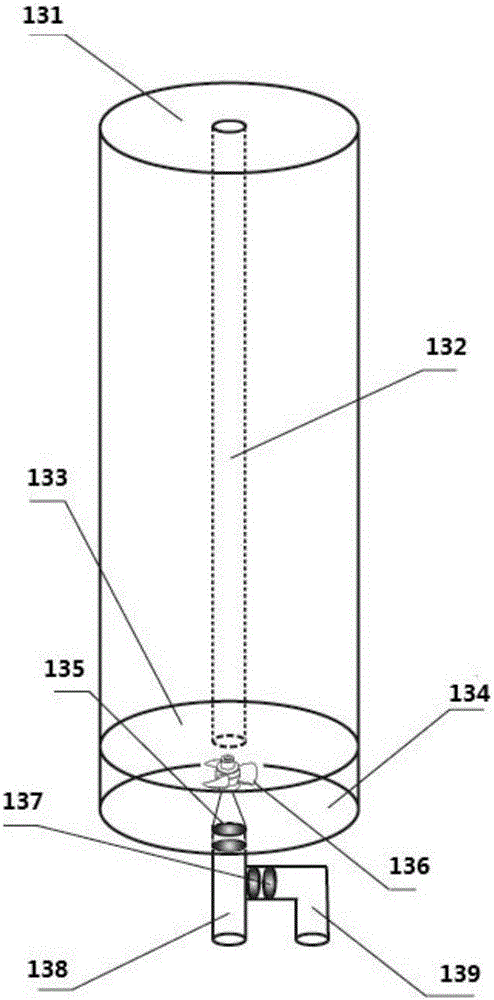

[0025] 500 kg of aramid 1313 fabric is wound on the perforated central tube 132 of the finishing unit. During the modification, the supercritical carbon dioxide fluid enters the carbon dioxide fluid inlet pipe 138 at the bottom of the finishing tank 13 and enters the finishing unit, and passes through the porous central pipe 132 to modify the aramid 1313 fabric. The sup...

Embodiment 2

[0029]Under the action of the carbon dioxide heater 2, the carbon dioxide in the gas cylinder flows through the busbar, and is cooled by the condenser 3 to become a liquid carbon dioxide fluid, which is stored in the carbon dioxide storage tank 4 for use in the modification and finishing process. The carbon dioxide in the carbon dioxide storage tank 4 first flows through the precooler 5 to condense, and is injected into the system through the carbon dioxide booster pump 6 to complete the boosting process; then the heat exchanger is used to heat the carbon dioxide fluid to make it enter a supercritical state;

[0030] Triazine type anti-ultraviolet finishing agent is placed in the finishing agent still 10, and its consumption is 3% of fabric weight. 500 kg of aramid 1313 fabric is wound on the perforated central tube 132 of the finishing unit. The finish pump 12 is switched off. Before the finishing process, first open the No. V15 valve at the bottom of the finishing kettle 13...

Embodiment 3

[0034] Under the action of the carbon dioxide heater 2, the carbon dioxide in the gas cylinder flows through the busbar, and is cooled by the condenser 3 to become a liquid carbon dioxide fluid, which is stored in the carbon dioxide storage tank 4 for use in the modification and finishing process. The carbon dioxide in the carbon dioxide storage tank 4 first flows through the precooler 5 to condense, and is injected into the system through the carbon dioxide booster pump 6 to complete the boosting process; then the heat exchanger is used to heat the carbon dioxide fluid to make it enter a supercritical state;

[0035] The non-ionic antistatic agent SN is placed in the liquid finishing agent tank 11, and its consumption is 2% of the weight of the fabric. 1000kg of aramid 1414 fabric is wound on the perforated central tube 132 of the finishing unit. Before sorting, first open the No. V15 valve at the bottom of the sorting kettle 13 to empty the air in the kettle body and pipelin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Water contact angle | aaaaa | aaaaa |

| Breaking strength | aaaaa | aaaaa |

| Tensile strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com