Consecutive production plant for supercritical carbon dioxide dyeing, and consecutive dyeing method

A carbon dioxide, production device technology, applied in the field of devices in the dyeing and finishing industry, can solve problems such as low efficiency, high dyeing operation cost, and large resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

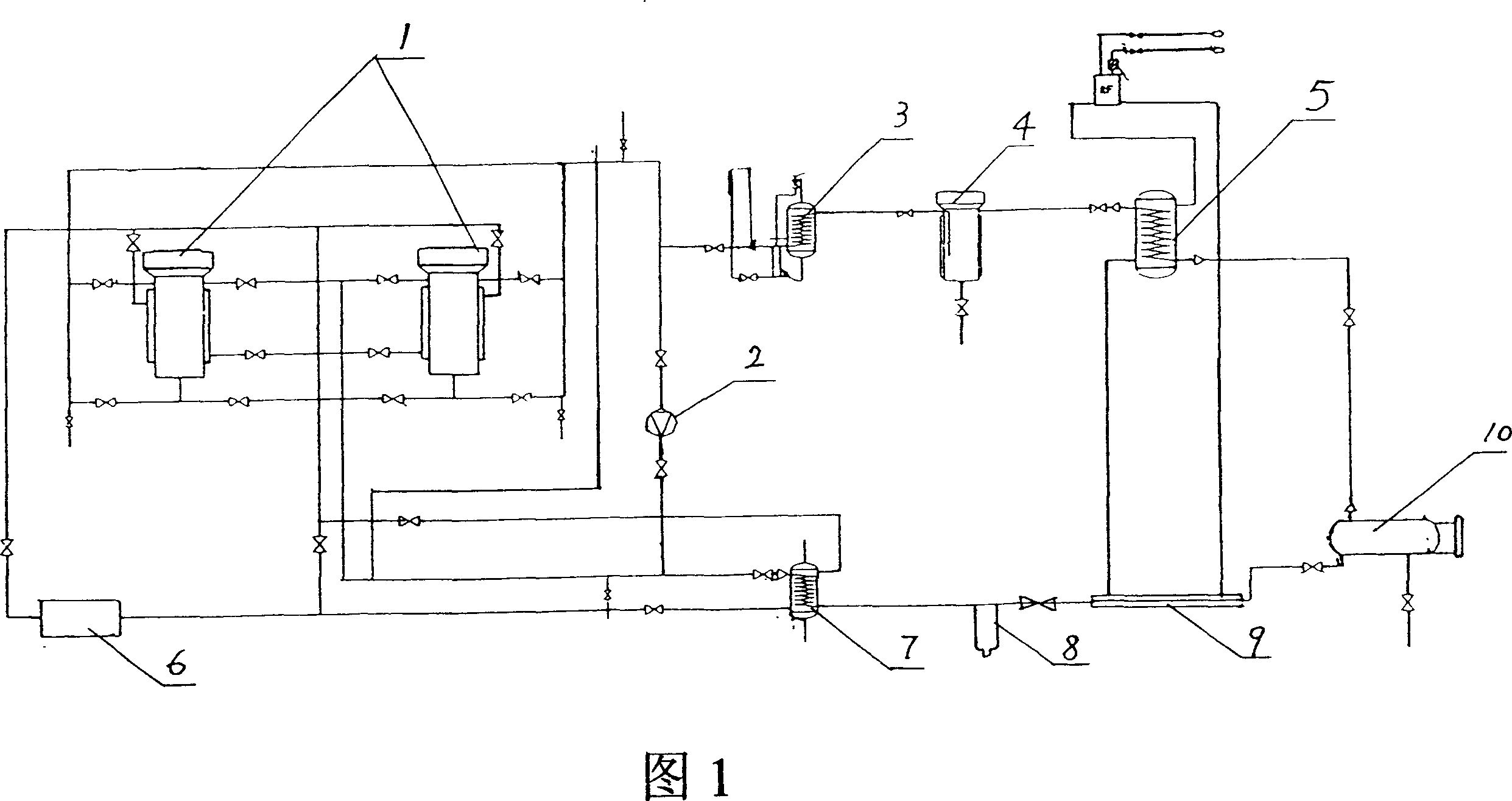

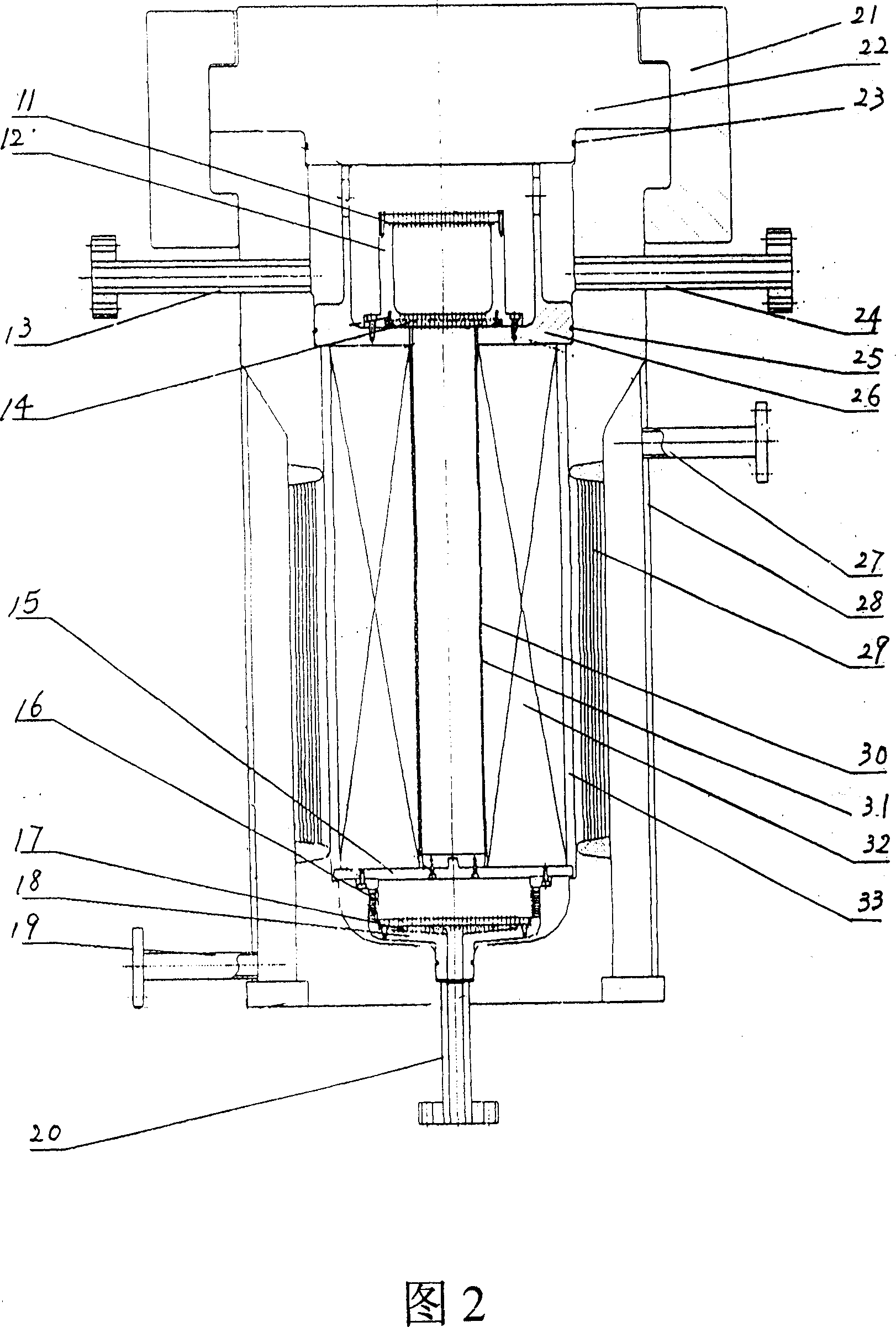

[0025] According to Fig. 1, shown in 2, the present invention is in the carbon dioxide storage tank 10 of existing large circulation system device, subcooler 9, main high-pressure pump 8, preheater 7, thermal oil stove 6, heater 3, dye separation tank 4. On the basis of condenser 5, control valve, pressure gauge and temperature gauge, the present invention connects an independently operated dyeing circulation system device that can be cut off by a valve through a pipeline after the preheater 7, and the independently operated dyeing circulation system is through Pipeline valves form cut-off communication with the large circulation system device; in the independent dyeing circulation system device, at least two independent dyeing and dyeing integrated kettles 1 are arranged side by side, and a high-pressure circulation pump 2 is arranged on the pipeline, as shown in Figure 2 The dyestuff and dyeing integrated kettle 1 has a kettle body 33, a kettle cover 22, a jacket 28, a hot oi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com