Liquid waterless staining technique

A fluid and dyeing system technology, applied in dyeing, textiles and papermaking, sustainable manufacturing/processing, etc., to achieve the effects of short dyeing process, uniform dyeing, energy consumption and production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

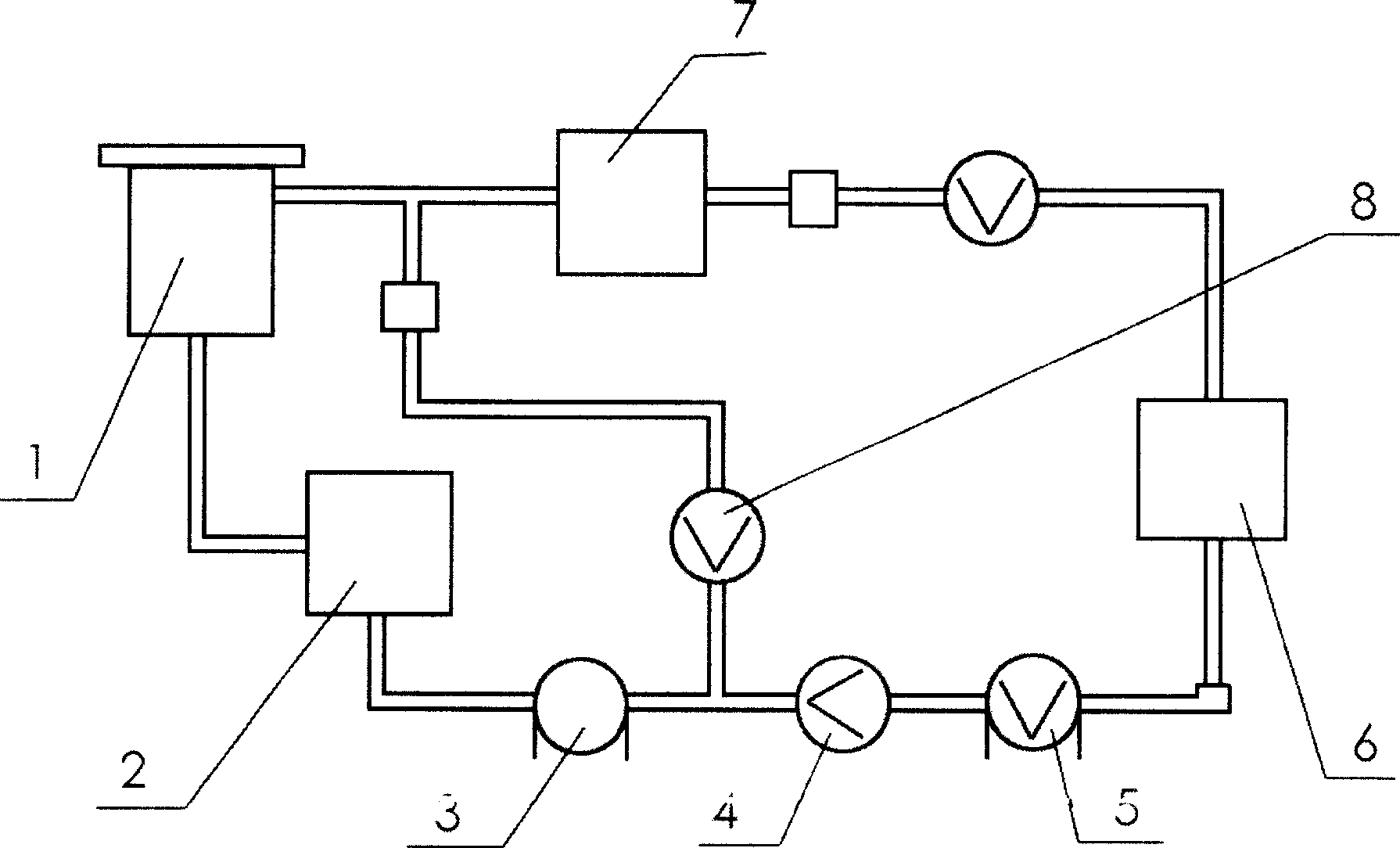

[0015] Technical scheme of the present invention comprises supercritical CO 2 Fluid dyeing process and supercritical CO 2 Fluid dyeing device.

[0016] 1. Supercritical CO 2 Fluid Dyeing Process

[0017] The core technology of the present invention is to use CO in a supercritical state 2 As a dye carrier for dyeing fabrics. liquid CO 2 Inject CO 2 in memory. The fabric is put into the dyeing kettle, and the solid dye is put into the dye kettle. Then start the booster pump to pump the liquid CO 2 from CO 2 Memory is injected into the dyeing system. CO of test dyeing unit 2 The design volume of the storage is 100 liters, liquid CO 2 Consumption is 150 kilograms. The staining requirement is deep staining. For 100 kilograms of dyed fabrics, the amount of solid dye is 7.5 kilograms. Then heat and pressurize the dyeing system to the dyeing temperature and pressure. The test temperature is 110°C and the pressure is 24Mpa. Then start the circulating pump to make the s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com