Supercritical CO2 waterless dyeing system and cloth dyeing method thereof

An anhydrous dyeing and supercritical technology, applied in textile/flexible product manufacturing, textile material container processing, textile material processing equipment configuration, etc., can solve environmental pollution problems, achieve strong solubility, reduce costs, and dye fast Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

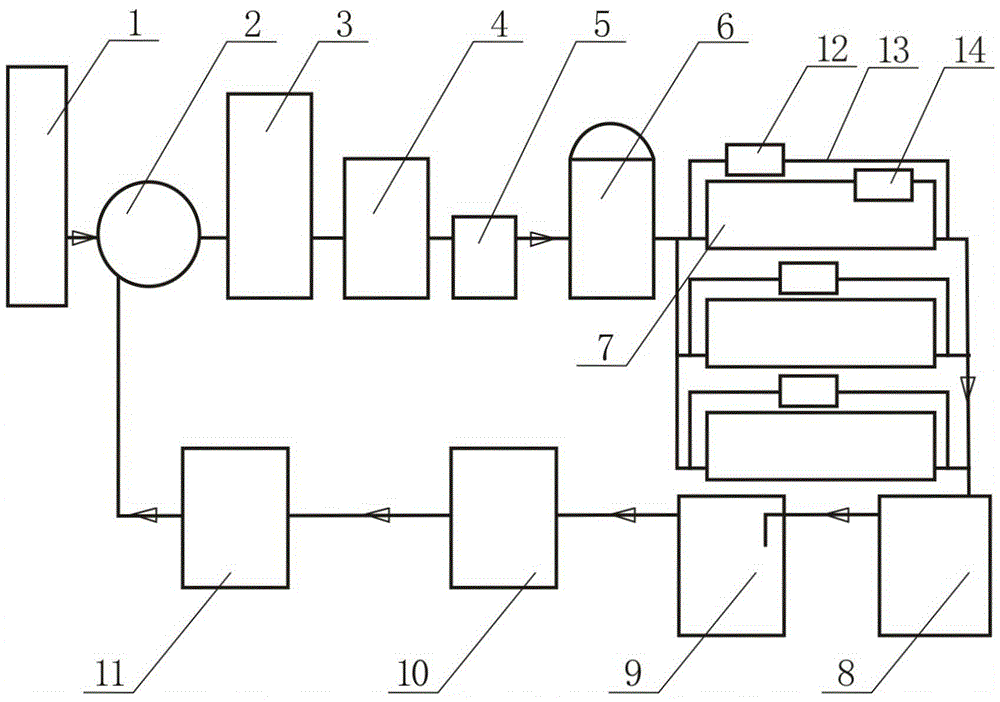

Image

Examples

Embodiment 1

[0031] Utilize supercritical CO2 The method for dyeing cloth of anhydrous dyeing system, comprises the following steps:

[0032] A. Preparation and storage of CO2: send the CO2 gas generated by the CO2 generation device into the storage tank by using the delivery plunger pump;

[0033] B. Cooling: The CO2 gas in the storage tank is cooled by the cooling device in turn. The pressure of the CO2 gas before and after cooling is 6MPA, and the temperature is 0°C;

[0034] C. Pressurization: Use a pressurized plunger pump to pressurize the CO2 gas, and the pressure of the CO2 gas after pressurization is 28MPA;

[0035] D. Heating: Use a heating device to form CO2 into a supercritical fluid, and heat the supercritical fluid to 120°C;

[0036] E. Dyeing: The circulation pump drives the mixture of supercritical fluid and dye to circulate in the circulation channel to dye the cloth in the autoclave; the pressure in the autoclave is 28MPA, the temperature is 120°C, and the circulation ti...

Embodiment 2

[0039] Utilize supercritical CO2 The method for dyeing cloth of anhydrous dyeing system, comprises the following steps:

[0040] A. Preparation and storage of CO2: send the CO2 gas generated by the CO2 generation device into the storage tank by using the delivery plunger pump;

[0041] B. Cooling: The CO2 gas in the storage tank is cooled by the cooling device in turn. The pressure of the CO2 gas before and after cooling is 10MPA, and the temperature is 4°C;

[0042] C. Pressurization: Use a pressurized plunger pump to pressurize the CO2 gas, and the pressure of the CO2 gas after pressurization is 30MPA;

[0043] D. Heating: Use a heating device to form CO2 into a supercritical fluid, and heat the supercritical fluid to 150°C;

[0044] E. Dyeing: The circulation pump drives the mixture of supercritical fluid and dye to circulate in the circulation channel to dye the cloth in the autoclave; the pressure in the autoclave is 30MPA, the temperature is 150°C, and the circulation t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com