Dyeing system

A dyeing system and dyeing machine technology, applied in the field of textile printing and dyeing equipment, can solve the problems of inability to meet the requirements of dye liquor recovery and recycling, no recovery system configuration, water consumption, etc., achieve good dyeing effect, simple structure, and save consumption Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] specific implementation plan

[0014] The present invention will be described in further detail below in conjunction with accompanying drawing

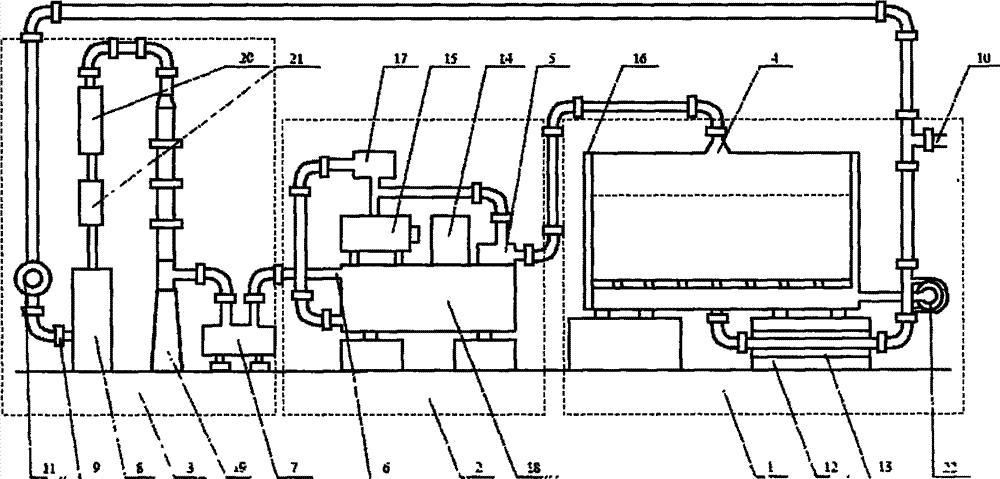

[0015] like figure 1 As shown, the dyeing system consists of a dyeing machine 1, a vacuum machine 2 and a distillation recovery device 3. At the tail end of the dyeing machine 1, a vacuum machine 2 and a distillation recovery device 3 are arranged in sequence. The dyeing machine can use one of the existing top dyeing machines or loose fiber dyeing machines or yarn dyeing machines or fabric dyeing machines according to the requirements of the dyed objects to dye the dyed objects; the vacuum pump 2 can be used in Wenzhou Bluestar automatic vacuum pump model LC-XD-020 produced by Bluestar Electromechanical Equipment Co., Ltd. is used to vacuumize the gas in the dyeing machine 1; the distillation recovery device 3 can use the JH pump produced by Wuxi Taihu Petrochemical Equipment Factory A series of recovery towers are used for ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com