Multi-element dyeing and finishing kettle and industrial supercritical CO2 fluid anhydrous dyeing and finishing equipment with scale of 1000L or more

A dyeing and finishing kettle, CO2 technology, applied in the processing of textile material equipment configuration, liquid/gas/steam textile material processing, solvent dyeing, etc., can solve the problems of difficult color change, single color, etc. The effect of water dyeing engineering production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

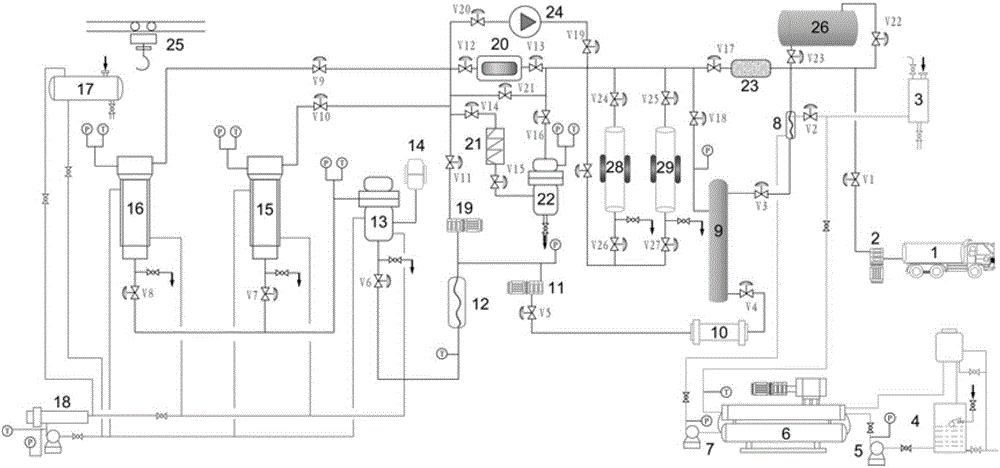

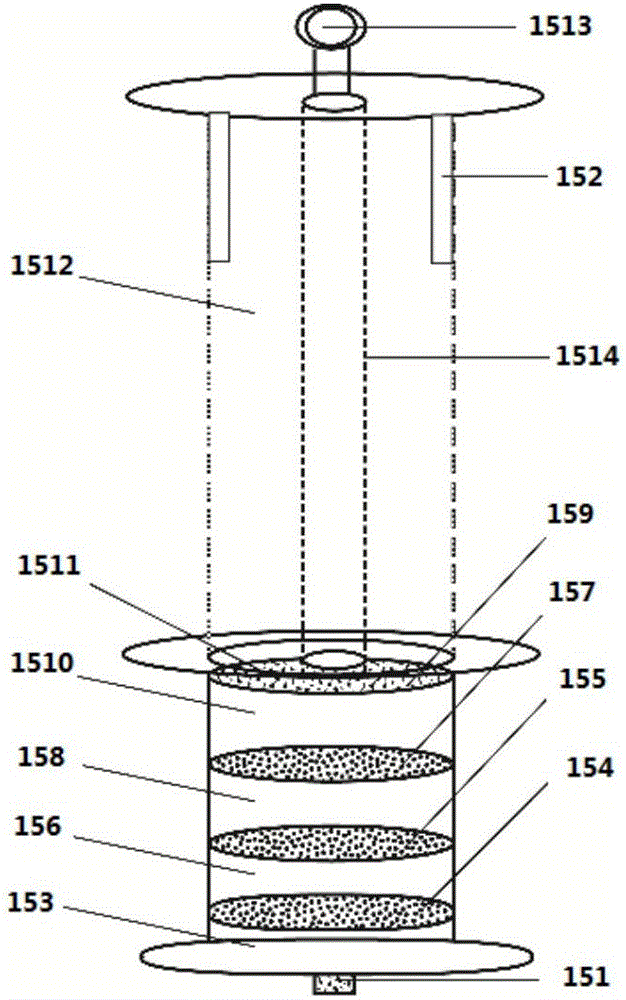

[0042] Such as figure 1 As shown, CO 2 Liquid CO in Transporter 1 2 Inflow of CO via cryogenic transfer pump 2 2 In the cryogenic storage tank 26, CO 2 Inflating process, when CO 2 When the liquid level rises to 2 / 3, stop inflating for use in dyeing and finishing production. Disperse Red 153 is placed in the dye unit in multi-component dyeing and finishing kettle I15, and disperse blue 148 is placed in the dye unit in multi-component dyeing and finishing kettle II16, and the dye consumption is 2% of the fabric weight. 100kg of polyester fabric is respectively wound on the fluid distribution pipe 1514 of the textile dyeing and finishing unit, and the integrated dyeing and finishing system is loaded into the multi-component dyeing and finishing kettle I15 and the multi-component dyeing and finishing kettle II16 by using the electric hoist 25 . Turn on the automatic control system of the dyeing device, close the multi-component dyeing and finishing kettle Ⅰ15 and multi-compo...

Embodiment 2

[0046] Such as figure 1 As shown, CO 2 Liquid CO in a transport vehicle 2 Inflow of CO via a cryogenic transfer pump 2 In cryogenic storage tanks, CO 2 Inflating process, when CO 2 When the liquid level rises to 2 / 3, stop inflating for use in dyeing and finishing production. Disperse Orange 30 is placed in the dye kettle, and the dye consumption is 1% of the fabric weight. 50kg of polyester cheese packages are placed on the fluid distribution pipe 1514 of the textile dyeing and finishing unit, and the integrated dyeing and finishing system is loaded into the multi-component dyeing and finishing kettle I15 and the multi-component dyeing and finishing kettle II16 by using an electric hoist. Turn on the automatic control system of the dyeing device, close the multi-component dyeing and finishing kettle Ⅰ15 and multi-component dyeing and finishing kettle Ⅱ16, and start the system self-inspection program to ensure that the kettle body and the solenoid valve are in the correct ...

Embodiment 3

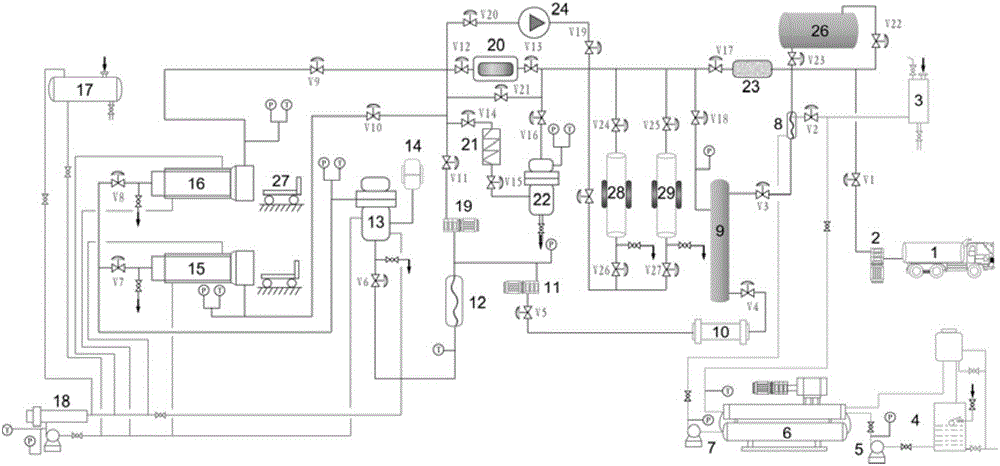

[0049] Such as figure 2 As shown, Disperse Orange 30 is placed in the dye kettle, and the dye consumption is 0.5% of the fabric weight. 100kg of acrylic fabrics are respectively wound on the textile dyeing and finishing unit, and the integrated dyeing and finishing system is loaded into the dyeing and finishing kettle by a support truck. Turn on the automatic control system of the dyeing device, close the multi-component dyeing and finishing kettle Ⅰ15 and multi-component dyeing and finishing kettle Ⅱ16, and start the system self-inspection program to ensure that the kettle body and the solenoid valve are in the correct switching state. After the self-test of the system is normal, turn on the cooling tower, water pump, and glycol pump in sequence, and then turn on the refrigeration unit and heating system. CO 2 The CO2 in the supply tank flows through the precooler to condense, and the CO2 2 The booster pump is injected into the dyeing and finishing equipment to complete t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com