System for color-changeable engineered supercritical carbon dioxide fluid anhydrous dyeing and finishing and method thereof

A carbon dioxide and supercritical technology, applied in the field of dyeing and finishing, can solve the problems of single color and difficult color change, and achieve the effect of solving single color, excellent abrasion resistance and corrosion resistance, and improving stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

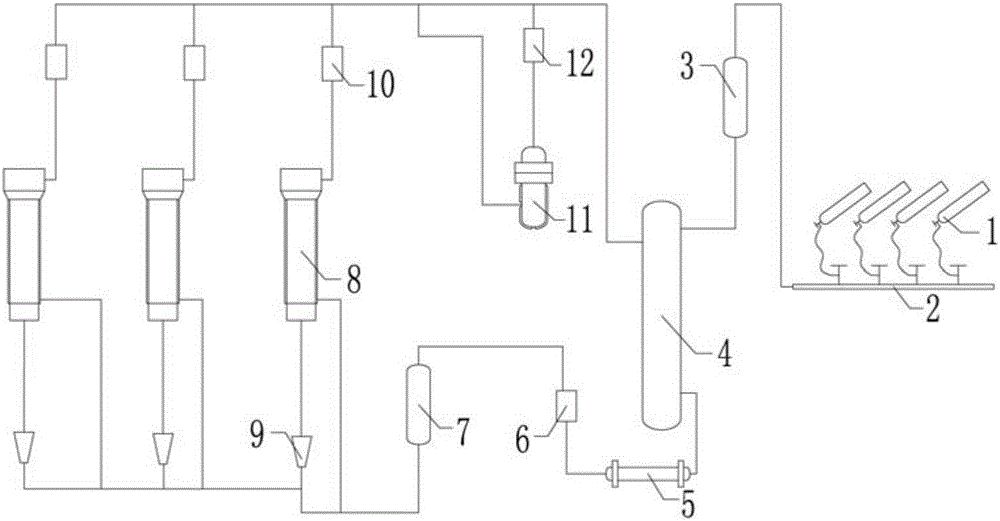

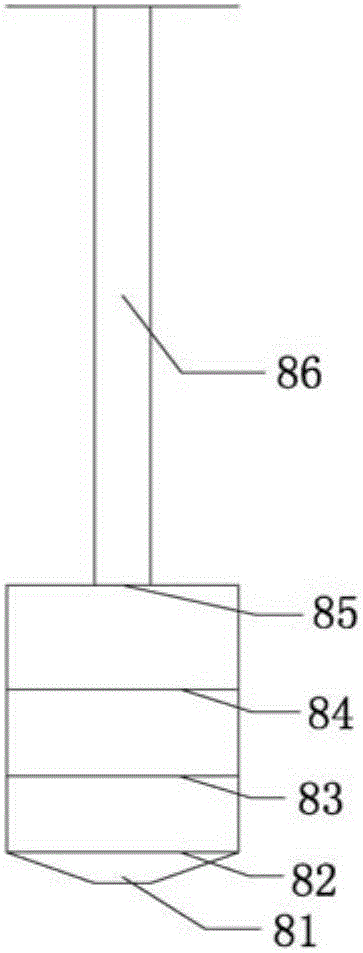

[0026] A color-changing engineered supercritical carbon dioxide fluid anhydrous dyeing and finishing system, the system includes a carbon dioxide gas source 1, and the carbon dioxide gas source 1 is connected to the inlet I of the carbon dioxide circulation tank 4 through a heater 2 and a condenser 3 in sequence , the outlet of the carbon dioxide circulation tank 4 is connected to each group of magnetic circulation pumps 9 through the precooler 5, the high pressure pump 6, and the preheater 7 successively, and the magnetic circulation pump 9 is connected to the inlet I of the dyeing and finishing kettle 8 respectively. connected, the outlet I of the dyeing and finishing kettle 8 returns to its inlet I through the respective magnetic circulation pump 9, the outlet II of the dyeing and finishing kettle 8 is connected with the separation kettle 11 through the respective adsorption kettle 10, and the outlet of the separation kettle 11 is The particle online detector 12 is connected...

Embodiment 2

[0029] A dyeing and finishing method utilizing the system described in Example 1, said method is: place Disperse Blue 60, Disperse Red 153, and Disperse Yellow 114 in different dyeing chambers respectively, and the consumption is 0.5w / w%. Super-imitation cotton fiber, polyester fabric, and wool cheese are respectively placed on different textile dyeing and finishing racks 86;

[0030] The carbon dioxide is heated and then cooled to a liquid state and stored in the carbon dioxide circulation tank 4. During dyeing and finishing, the carbon dioxide in the carbon dioxide circulation tank 4 is condensed, boosted, and heated to a supercritical state, and the supercritical carbon dioxide fluid enters the dyeing and finishing tank 8 of each group Finally, dissolve the dye first, then dye the textiles, circulate the dyeing under the action of the magnetic circulation pump 9, and dye for 60 minutes under the conditions of 120°C and 24MPa. Initial separation, the adsorption temperature i...

Embodiment 3

[0033] A kind of dyeing and finishing method utilizing the system described in embodiment 1, the difference with embodiment 2 is:

[0034] Disperse Red 153 was placed in different dye chambers, and the dosage was 1w / w%;

[0035] Dyeing at 100°C and 24MPa for 60min.

[0036] After testing, the K / S values of dyed super-imitation cotton fiber, polyester fabric, and wool cheese are 11.4, 10.6, and 5.2 respectively, and the standard deviation of the dyed K / S value is lower than 0.25%. , The color fastness to rubbing is above grade 4, and the color fastness to sunlight is above grade 6, meeting the requirements of commercial production.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Afterburn time | aaaaa | aaaaa |

| Damage length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com