Method for coloring aluminum and alloy surface thereof

An aluminum alloy surface and aluminum alloy technology, applied in the field of coloring the surface of aluminum and its alloys, can solve the problems of high equipment cost, inability to develop color, and no application, etc., and achieve simple equipment, convenient adjustment means, and beautiful color Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] This embodiment is implemented under the following technical requirement conditions:

[0034] (1) Cut a high-purity aluminum sheet with a thickness of 0.3mm and a purity of 99.999% into 6cm×7.5cm, and perform electropolishing in a solution mixed with ethanol and perchloric acid at a volume ratio of 4:1. The polishing time is 3 minutes, and the voltage is 21V.

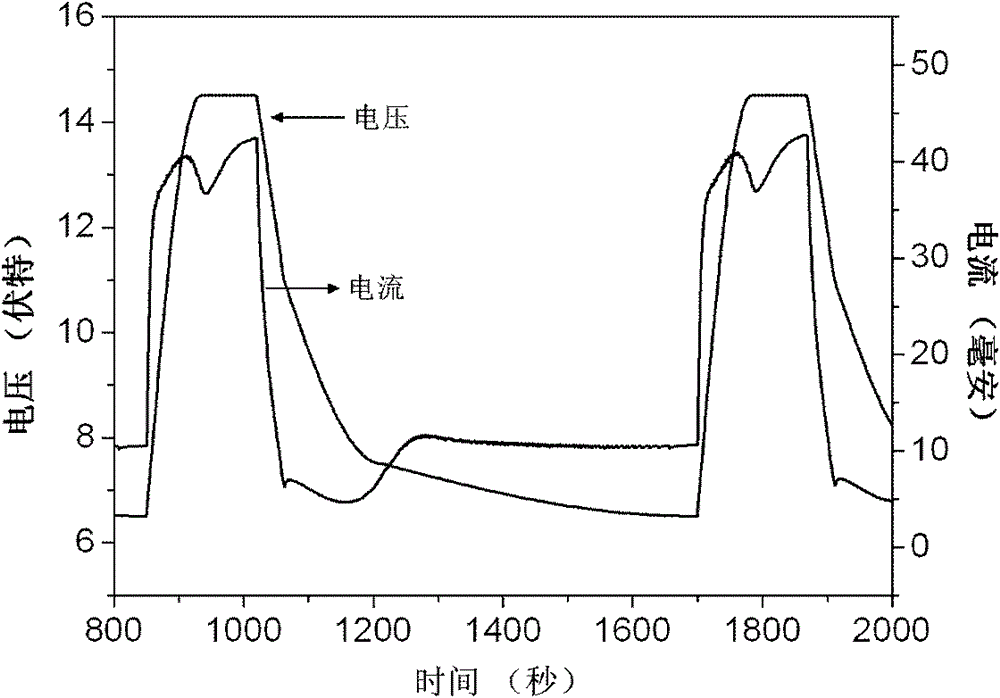

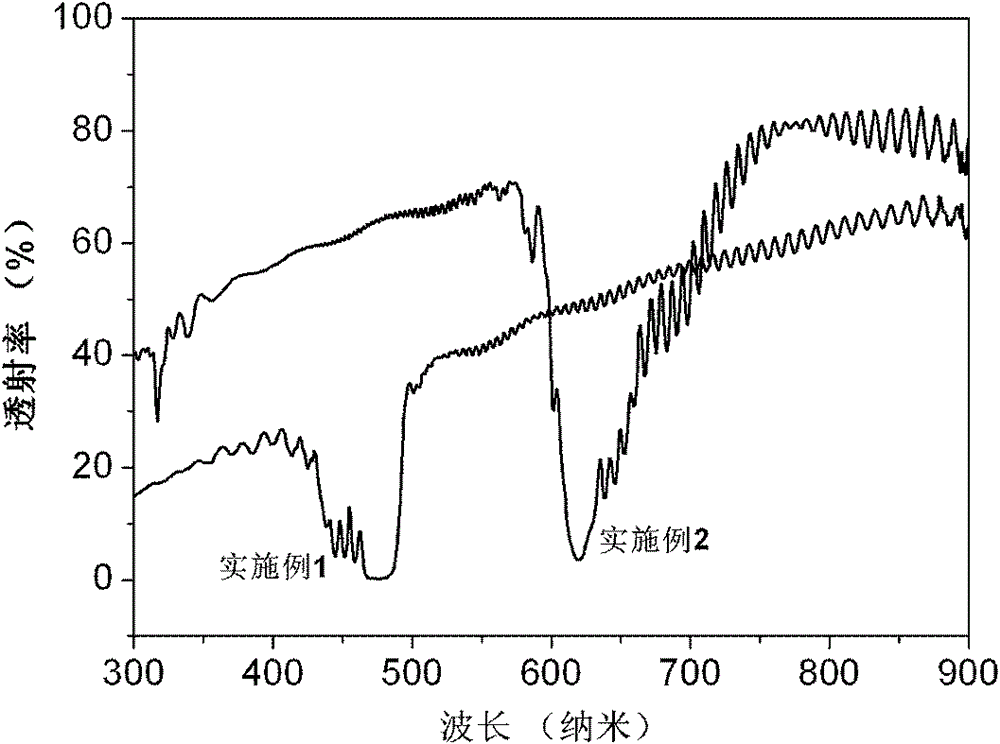

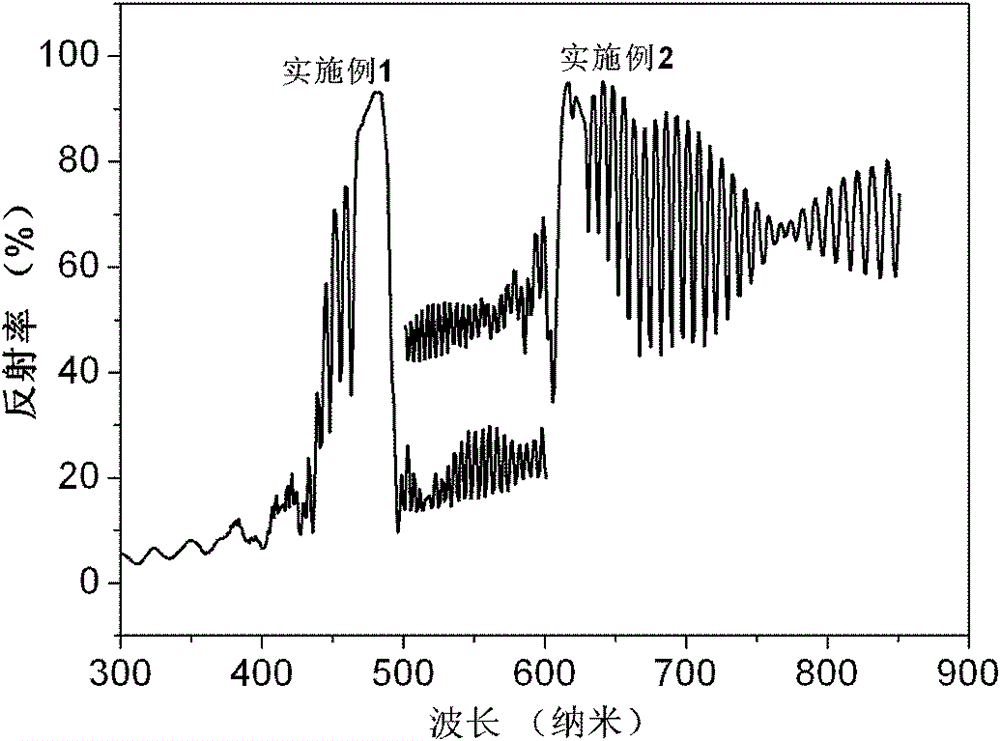

[0035](2) At 0° C., use a sulfuric acid solution with a concentration of 1.1 mol / liter as the electrolyte, aluminum as the anode, and graphite as the cathode for anodic oxidation. The oxidation area is a rectangle of 5 cm×6.5 cm. The specific oxidation process is as follows: first, 14V constant voltage pre-oxidation for 1 hour, and then use periodic voltage for oxidation. The periodic voltage waveform of one cycle is as follows: a sinusoidal rise from 6.5V to 14.5V within 85 seconds, and maintain for 85 seconds, then a linear drop from 14.5V to 11V within 42.5 seconds, and then a sinusoidal drop from 11V to 7.5...

Embodiment 2

[0038] This embodiment is implemented under the following technical requirement conditions:

[0039] At 1°C, other conditions are the same as in Example 1, and the periodic oxidation voltage waveform becomes: a sinusoidal rise from 6.5V to 14.5V within 120 seconds, and maintain for 120 seconds, and then drop linearly from 14.5V to 11V, followed by a sine drop from 11V to 7.5V in 220 seconds, and finally a sine drop from 7.5V to 6.5V in 680 seconds. The periodic voltage is repeated 105 times.

[0040] Carrying out the above steps can obtain brightly colored and evenly colored red colored film. like figure 2 As shown, the band gap of the visible light transmission spectrum of the colored film is 620nm, and the intensity is 3.5%. The reflection peak of colored aluminum is located at 656nm, and the intensity reaches 92.3%, such as image 3 shown.

Embodiment 3

[0042] This embodiment is implemented under the following technical requirement conditions:

[0043] At 2°C, other conditions are the same as in Example 1, and the periodic oxidation voltage waveform becomes: a sinusoidal rise from 6.5V to 13.5V within 120 seconds, and maintain for 120 seconds, and then drop linearly from 13.5V to 10.5V, followed by a sine drop from 10.5V to 7.5V in 220 seconds, and finally a sine drop from 7.5V to 6.5V in 680 seconds. The periodic voltage is repeated 105 times.

[0044] By implementing the above method, a blue colored film with uniform color and beautiful appearance can be obtained.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com