Patents

Literature

32results about How to "Simple coloring process" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

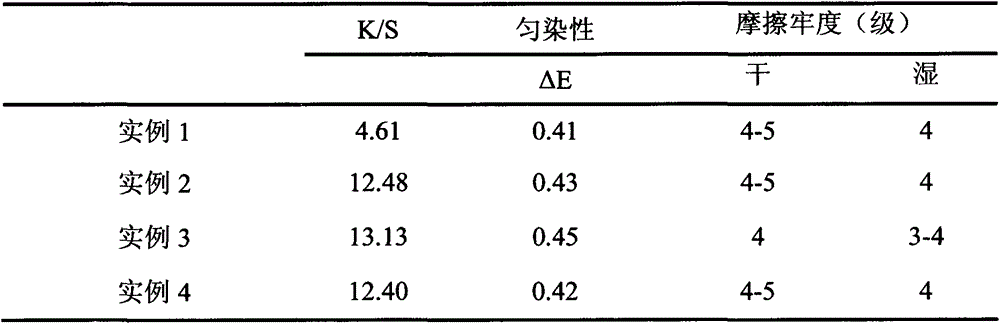

Method for coloring alginate fiber stoste by adopting lake colors

ActiveCN104264280AIncrease profitHigh color fastnessAlginate artificial filamentsDye addition to spinning solutionSolventFine chemical

The invention discloses a method for coloring alginate fiber stoste by adopting lake colors, and belongs to the field of fine chemical engineering and material science. The method comprises the following steps: adding sodium alginate into deionized water, and stirring so as to dissolve sodium alginate fully to prepare alginate fiber spinning stoste; then adding lake colors into the alginate fiber spinning stoste, stirring and mixing uniformly, filtering and defoaming to obtain the lake color colored alginate fiber stoste, and preparing further to obtain lake color colored alginate fibers. The method overcomes the problem of damage of traditional dye dying on fibers; the prepared colored alginate fibers have the advantages of bright colors, high color fastness, good solvent mobility resistance and the like.

Owner:JIANGNAN UNIV

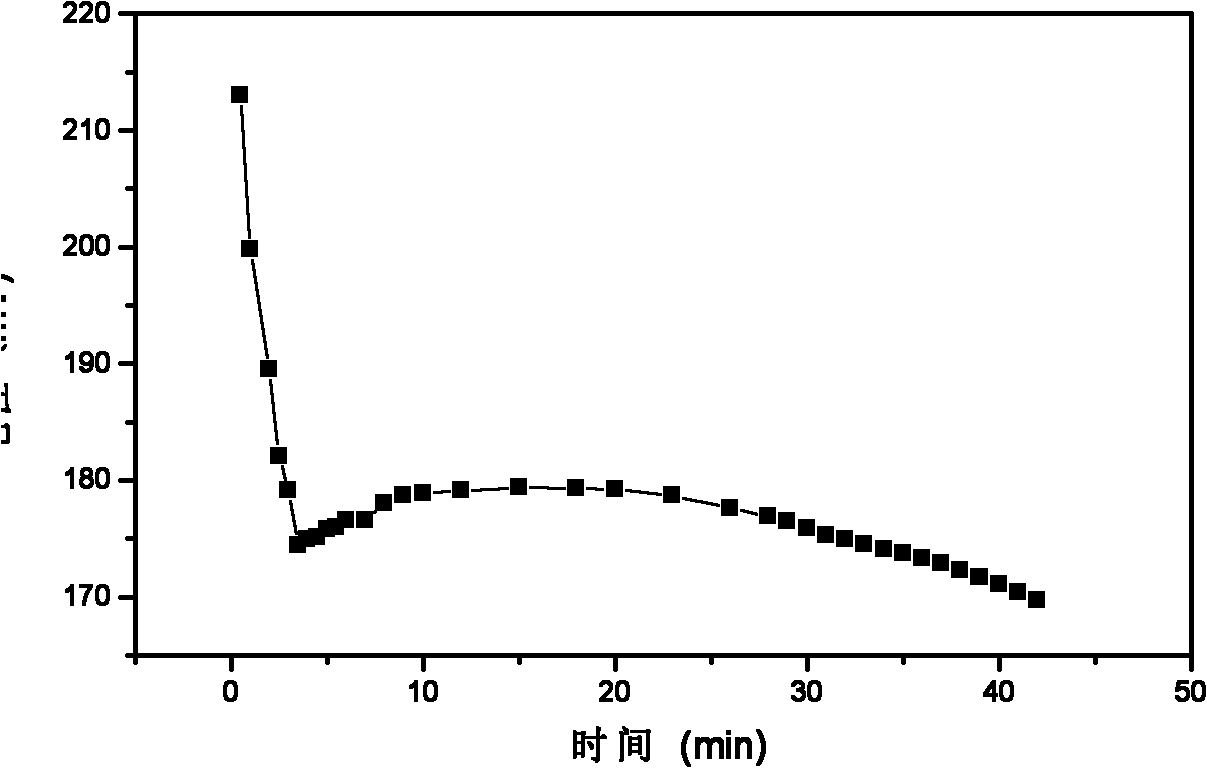

Coloring liquid and coloring method for chemically coloring stainless steel surface into black

InactiveCN102061500ASolve for uniformitySolve the problem of difficult reproducibilitySurface reaction electrolytic coatingMetallic material coating processesElectrolysisSulfate

The invention discloses a coloring liquid and a coloring method for chemically coloring a 304 stainless steel surface into black, belonging to the technical field of stainless steel surface treatment, aiming to coat a back film layer on the 304 stainless steel surface, mainly solving the problem that a colored film has poor uniformity and repeatability, and being used for improving the decorative performance, wear resistance and corrosion resistance of stainless steel. The invention mainly includes the prescription of the coloring liquid and the coloring method for coloring the 304 stainless steel surface into black, wherein the coloring liquid mainly comprises main film-forming agents (chromic anhydride and chromium sulfate), an assistant filming-forming agent (sulfuric acid), additives (ferric sulfate, manganese sulfate and cerous sulfate) and water; and the coloring method mainly comprises the steps of electrolysis pretreatment, chemical coloring and hole sealing post-treatment, wherein potential control is adopted in the coloring process. A black stainless steel film obtained by using the coloring liquid and the coloring method has the advantages of uniform colored film, no obvious color difference, bright color, excellent wear resistance and corrosion resistance, good film adhesion, simple and practical coloring method, easily controlled coloring process, good color repeatability and the like.

Owner:CENT SOUTH UNIV

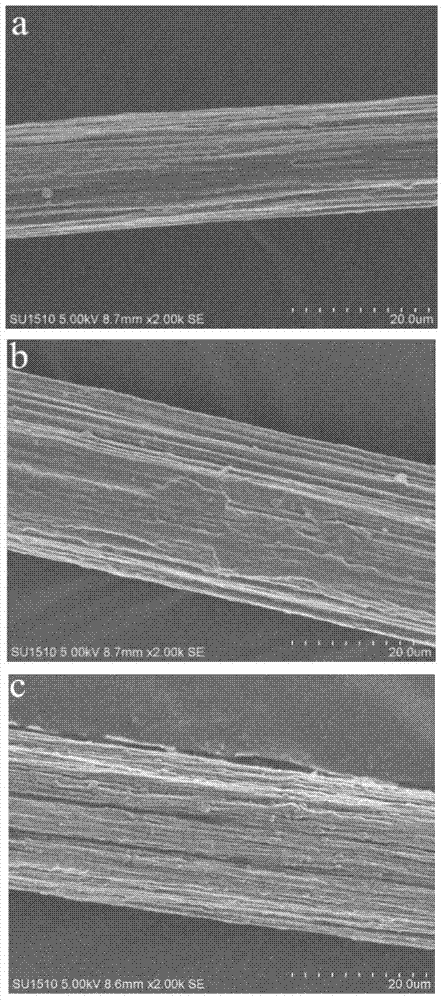

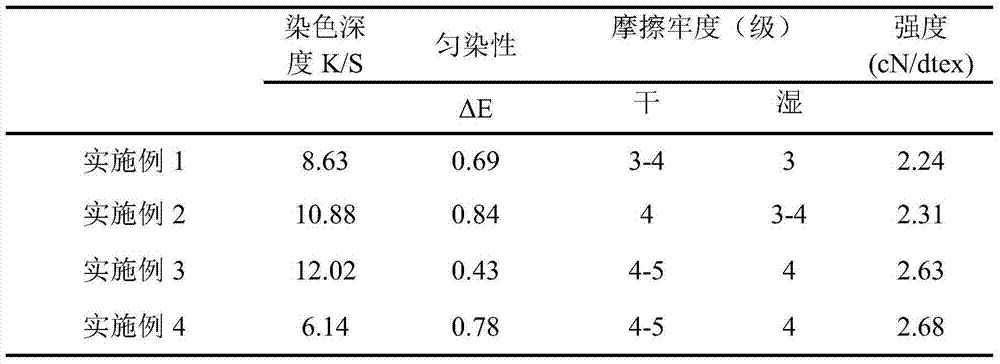

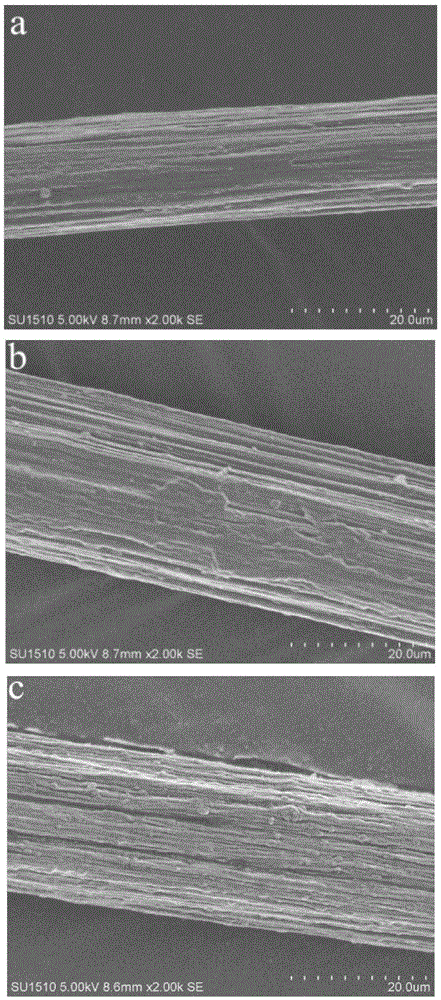

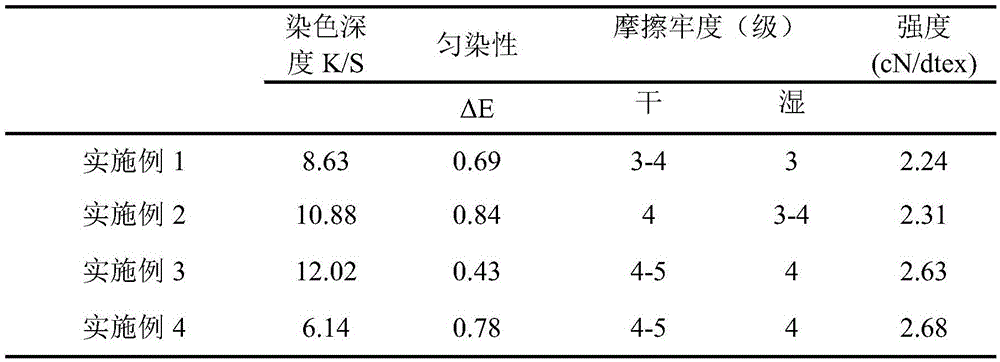

Method for coloring alginate fibers by nano pigment

ActiveCN103556301AIncrease profitAddressing Defects in StainingAlginate artificial filamentsPigment addition to spinning solutionWater resourcesRoom temperature

The invention discloses a method for coloring alginate fibers by a nano pigment. The method comprises the following steps: adding a certain quantity of superfine aqueous nano pigment into an alginate fiber spinning solution; agitating for uniformly dispersing pigment grains; filtering and defoaming; and carrying out wet-method spinning at room temperature to prepare colored alginate fibers, wherein the draw ratio of the fibers is 100%-300%. The alginate fibers prepared by the method are uniformly colored, is washable and has high sunlight fastness; water resources and energy consumption are saved and clean production is realized; the method for coloring the alginate fibers by the nano pigment has good application prospects in the fields of clothes and environmental protection.

Owner:吴江山湖颜料有限公司

Stainless steel chemical pigmenting liquid and chemical pigmenting method

InactiveCN101058882AAvoid color changesGood reproducibilitySuperimposed coating processElectrolysisWear resistance

The invention discloses a chemical coloring liquid of stainless steel and chemical coloring method, which comprises the following parts: chromic anhydride, sulfuric acid, water, accelerant, stabilizer, brightener and homogeneous agent. The coloring method comprises the following steps: predisposing the stainless steel surface; coloring; hardening film through little current; sealing; drying.

Owner:TAIYUAN UNIV OF TECH +1

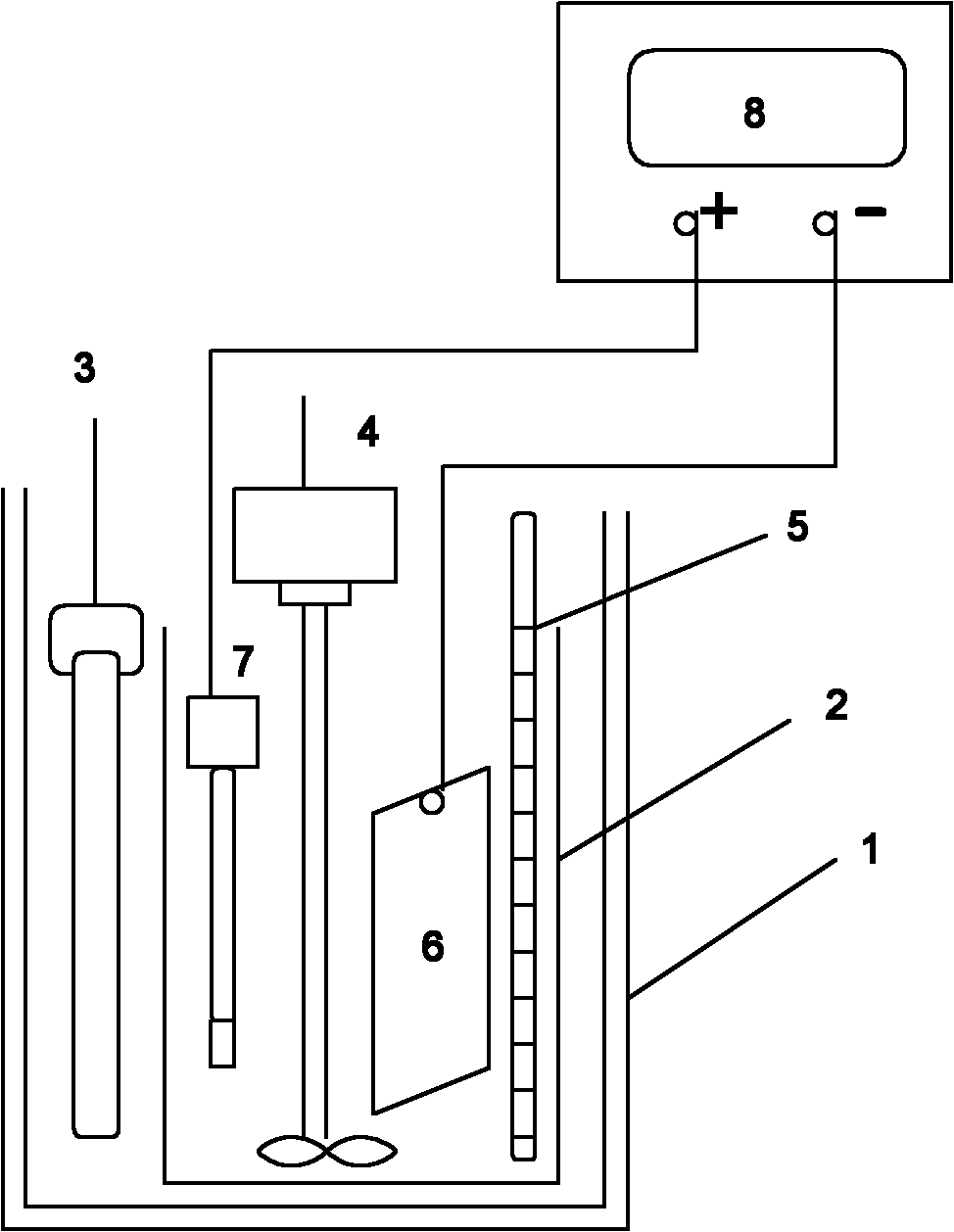

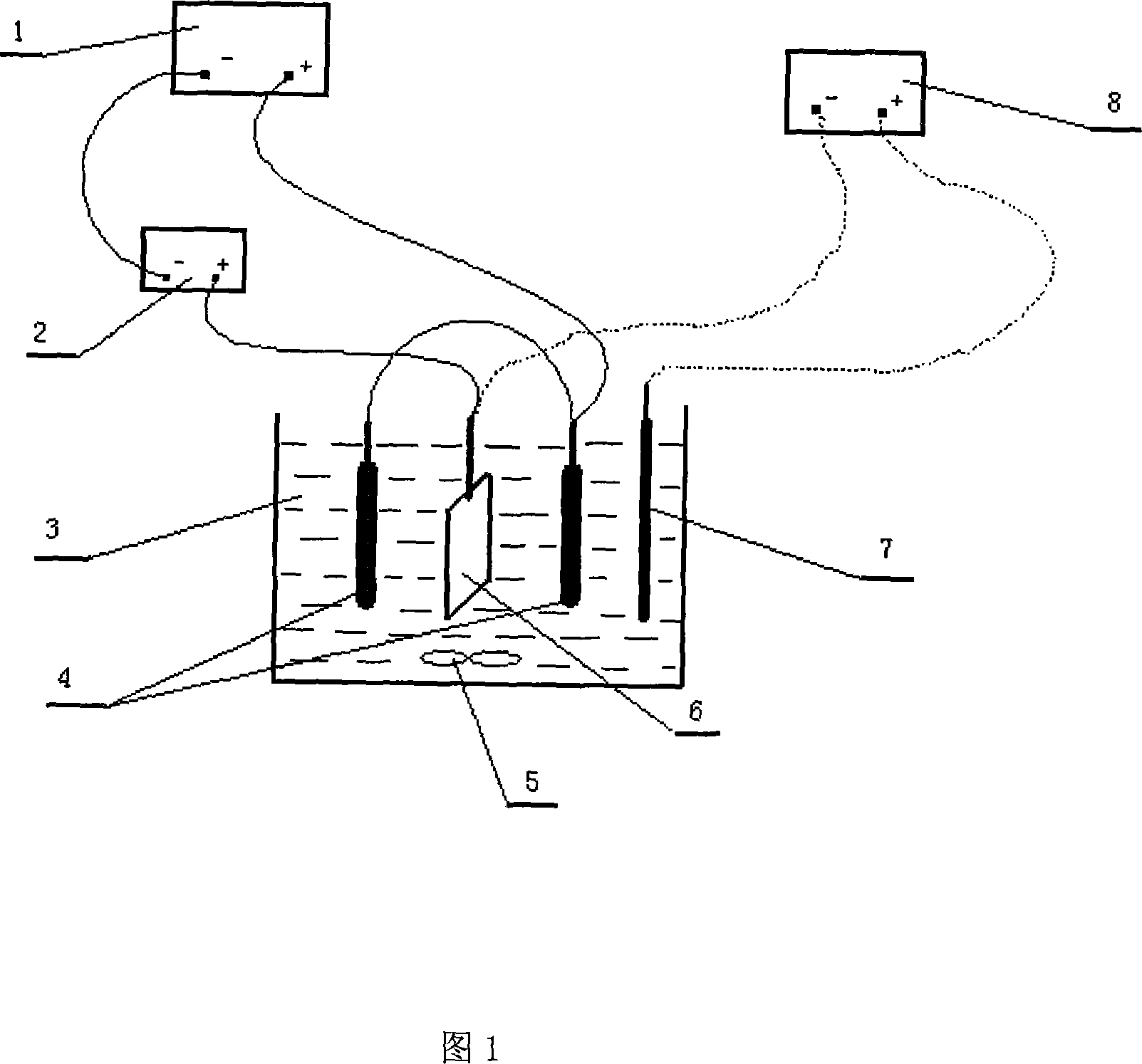

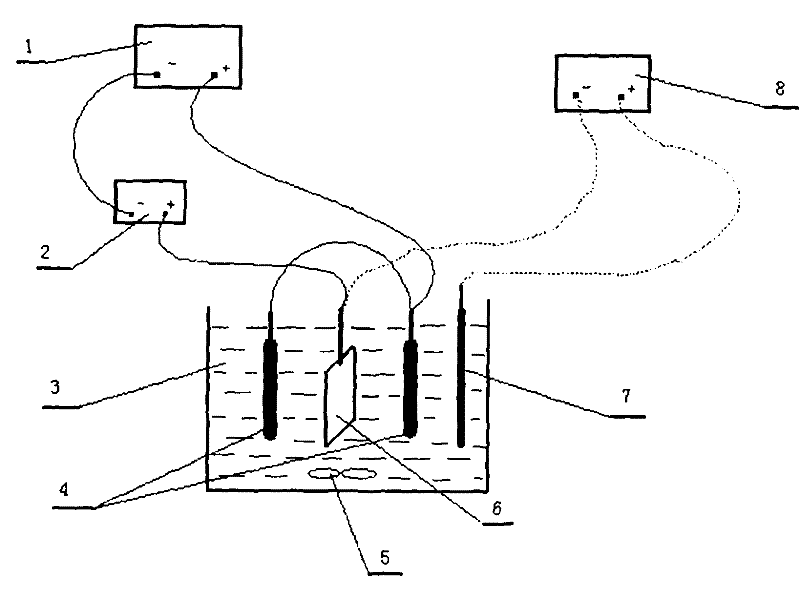

Colouring solution used for stainless steel electrochemical colouring and stainless steel electrochemical colouring method

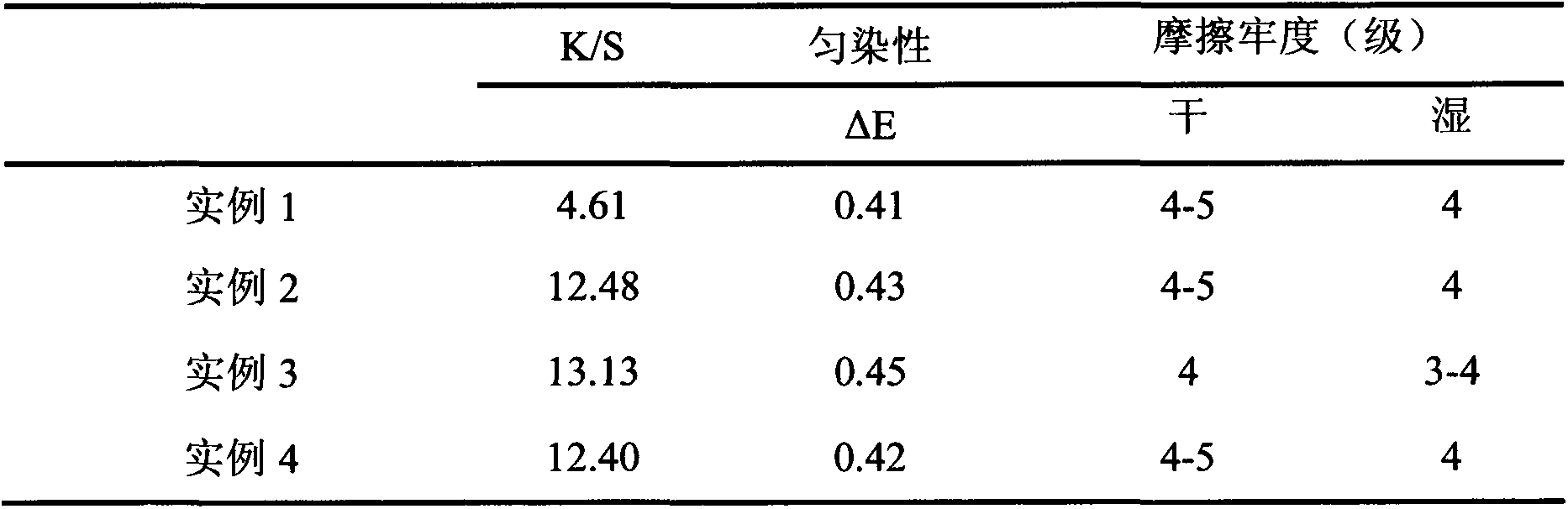

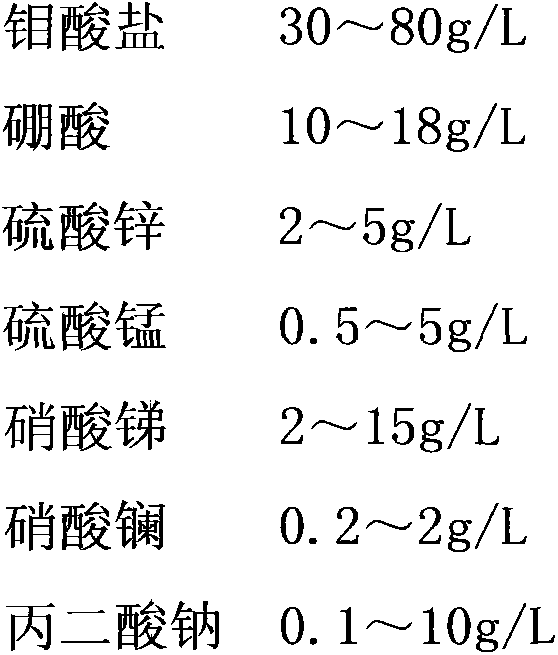

ActiveCN103114320AChange the polarization processImprove performanceAnodisationToxic materialMalonate

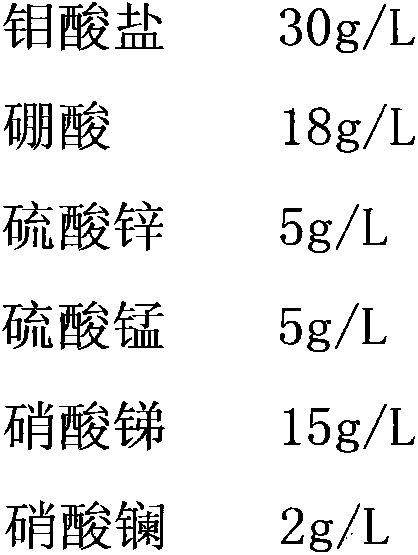

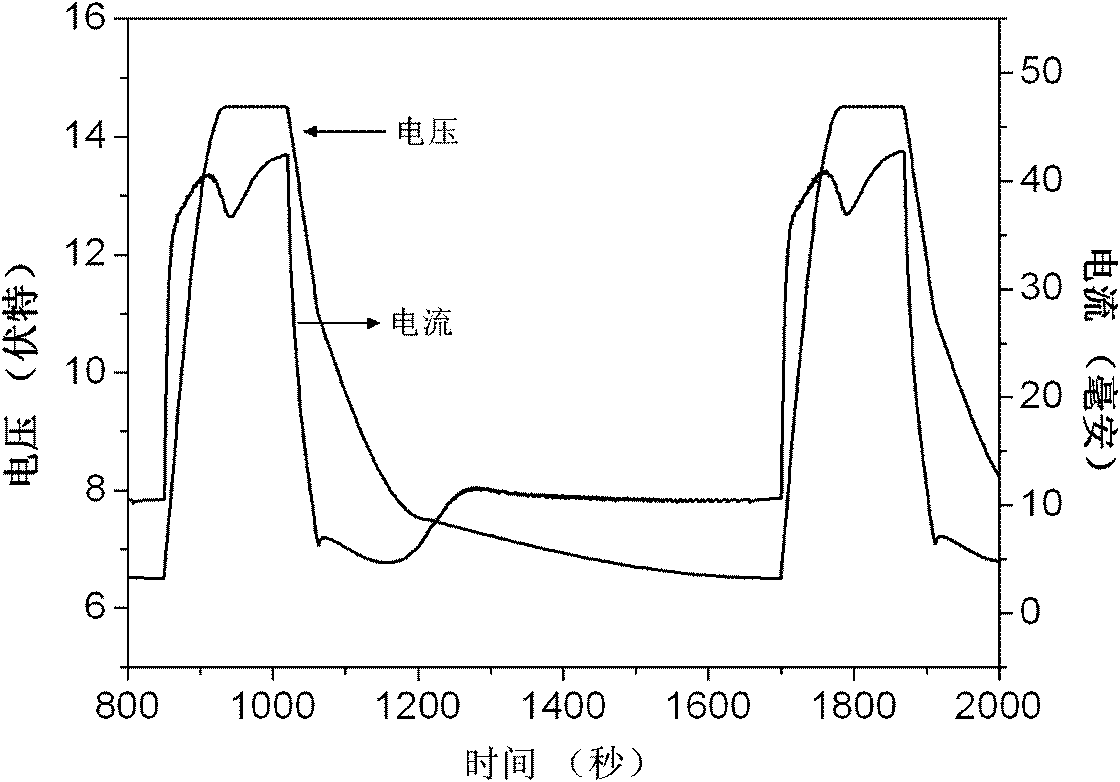

The invention relates to a stainless steel surface treatment reagent, in particular to a stainless steel surface colouring method. According to the invention, with water as a solvent, each litre of solution contains 30-80g of molybdate, 10-18g of boric acid, 2-5g of zinc sulphate, 0.5-5g of manganese sulphate, 2-15g of antimony nitrite, 0.2-2g of lanthanum nitrite and 0.1-10g of sodium malonate. The stainless steel surface colouring method comprises the following basic flow: oil removing, electrolytic polishing, cleaning, colouring, cleaning and drying and obtaining the finished product, wherein an anode is a workpiece to be coloured, a cathode is a lead plate, a colouring current is controlled to be 0.1-5A / dm<2>, voltage is 1.5-2.5V, a colouring temperature is room temperature, colouring time is 0.1-30 minutes, cleaning and drying are carried out after colouring, and the surface of the obtained sample is uniform and bright. The stainless steel electrochemical colouring process provided by the invention needs simple equipment, is easy to operate, contains no toxic substance and is beneficial to environmental protection; and colouring is stable, and a high-quality colour stainless steel product can be produced by adopting the stainless steel electrochemical colouring process.

Owner:湖南中皖骏环保科技有限公司

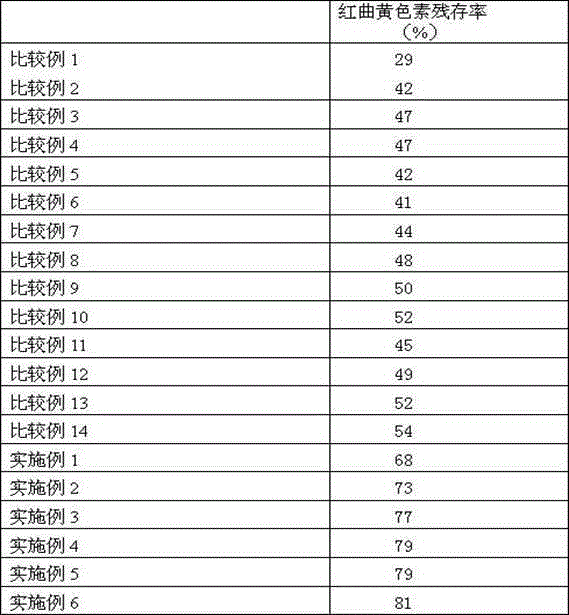

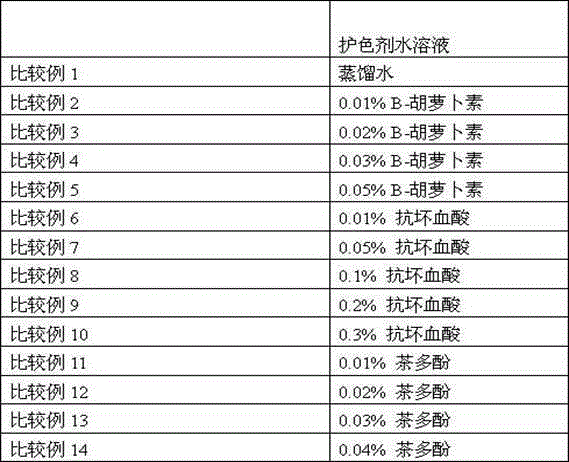

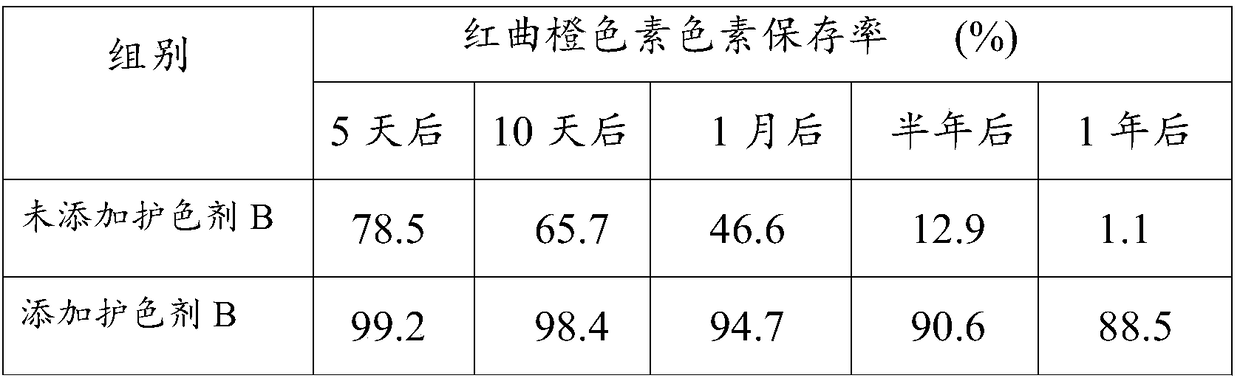

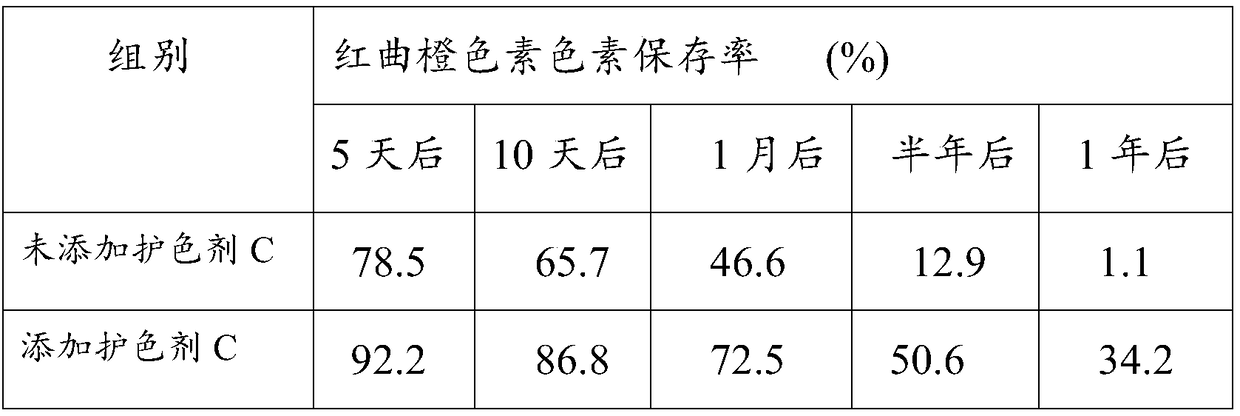

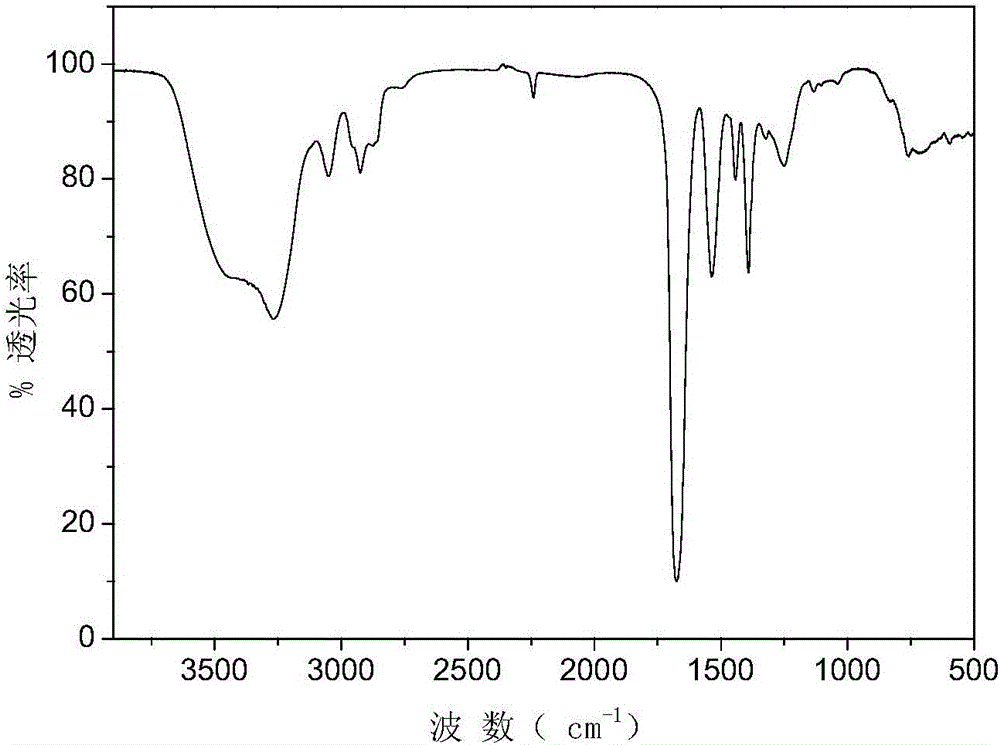

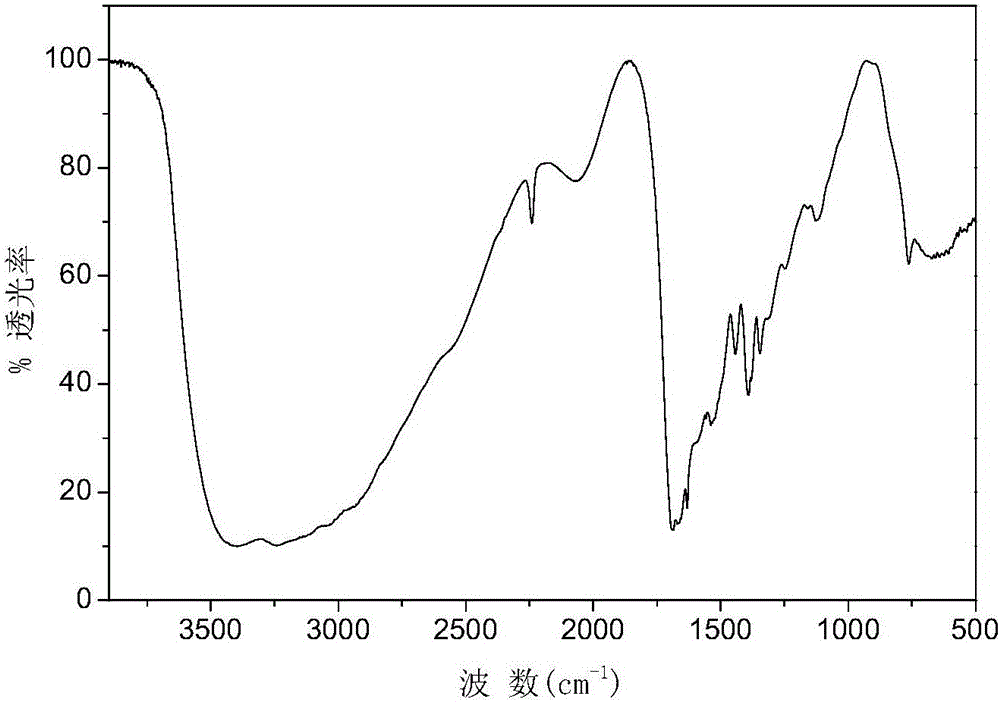

Method for enhancing light stability of monascus yellow pigment

InactiveCN105062134AGood coloring effectStore for a long timeCosmetic preparationsToilet preparationsBiotechnologyPhenolic content in tea

The invention discloses a method for enhancing the light stability of monascus yellow pigment. The method comprises the followings steps: a, weighing a certain amount of distilled water, and adding 0.02-0.04% of B-carotene, 0.2-0.4% ascorbic acid, 0.03-0.05% of polyphenol and 0.1-0.2% of citric acid in percentage by weight to prepare a mixed color fixative water solution; b, weighing a certain amount of monascus yellow pigment, and adding the mixed color fixative water solution according to the ratio of monascus yellow pigment to the mixed color fixative water solution of 1:(50-120) to prepare a monascus yellow pigment and mixed color fixative water solution preparation. The monascus yellow pigment and mixed color fixative water solution preparation prepared by the invention is high in light stability, and can be used for coloring of foods, cosmetics and medicines.

Owner:INST OF AGRI PROD QUALITY SAFETY & STANDARD JIANGXI ACAD OF AGRI SCI

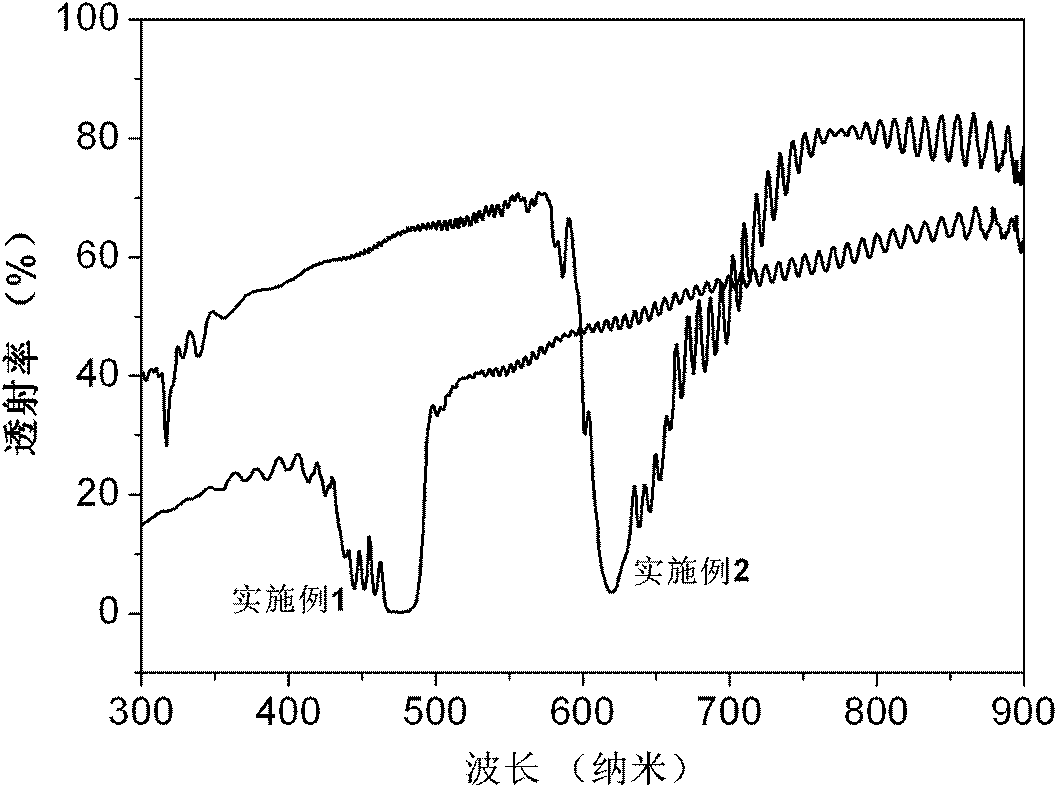

Method for coloring aluminum and alloy surface thereof

InactiveCN102181902ASimple processWide color adjustment rangeSurface reaction electrolytic coatingElectrolyteLamellar structure

The invention discloses a method for coloring aluminum and an alloy surface thereof, which comprises the following steps of: at first, cleaning and polishing the aluminum or the aluminum alloy surface; carrying out constant-pressure anode preoxidization for 20 minutes to 3 hours under the preoxidization voltage of 10 to 20 volts by using sulfuric acid electrolyte with the concentration of 0.1 to 3mol / liter under the conditions that the well-processed aluminum or aluminum alloy is used as an anode and graphite is used as a cathode; and then oxidizing the aluminum or the aluminum alloy by utilizing a voltage which varies periodically based on time to obtain a structurally laminar alumina photonic crystal, and coloring the aluminum or the aluminum alloy surface by the structural color of an optical forbidden band of the alumina photonic crystal, so that different colors can be adjusted within a scope of visible lights by maintaining constant time and changing the voltage only or maintaining constant voltage and changing time only. The coloration method of the invention has the advantages of no need of depositing metal ions, simple process and low cost, wide adjustment scope of colorsand less pollution.

Owner:SOUTH CHINA UNIV OF TECH

Electrochemical coloring solution for stainless steel and coloring method

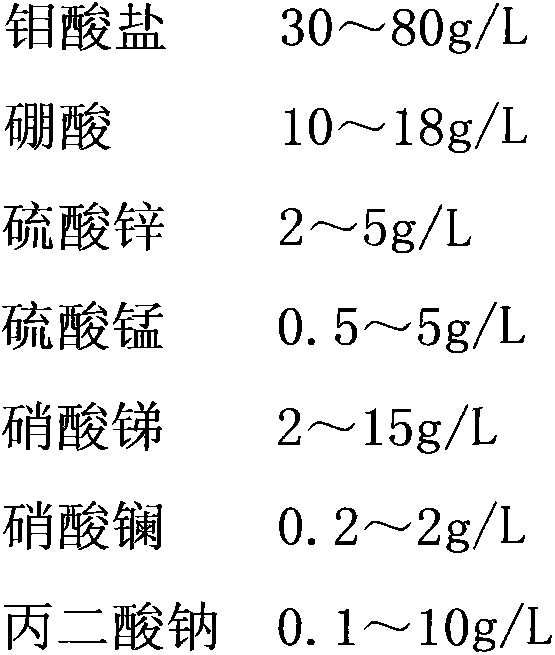

The present invention relates to an electrochemical coloring solution for stainless steel and coloring method, which is characterized in that the electrochemical coloring solution for stainless steel comprises the following components of 30-80g / L of molybdate, 10-18g / L sulfuric acid,2-5g / L of zinc sulfate, 0.5-5g / L of manganese sulfate, 10-20g / L of sodium nitrate, 0.1-10g / L of sodium malonate and solvent being water. The coloring method comprises (1) removing greasy dirt on the surface of the stainless steel by metal detergent, and then cleaning with hot water; (2) mechanically or electrolytically polishing stainless steel workpieces; (3) then cleaning with hot water; (4) coloring: placing stainless steel workpieces in the electrolytic bath filled with coloring solution, wherein stainless steel workpieces and lead plate are respectively taken as an anode and a cathode, the coloring voltage is 1.5-2.5V, the coloring current is 0.1-20A / dm<2> and the coloring time is 1-15 minutes; (5) washing and drying to obtain the finished product. The coloring solution and coloring method according to the invention can be used for producing high-quality stainless steel products which can meet the performance requirements and consistent color tones.

Owner:WUXI BAOSHUN STAINLESS STEEL

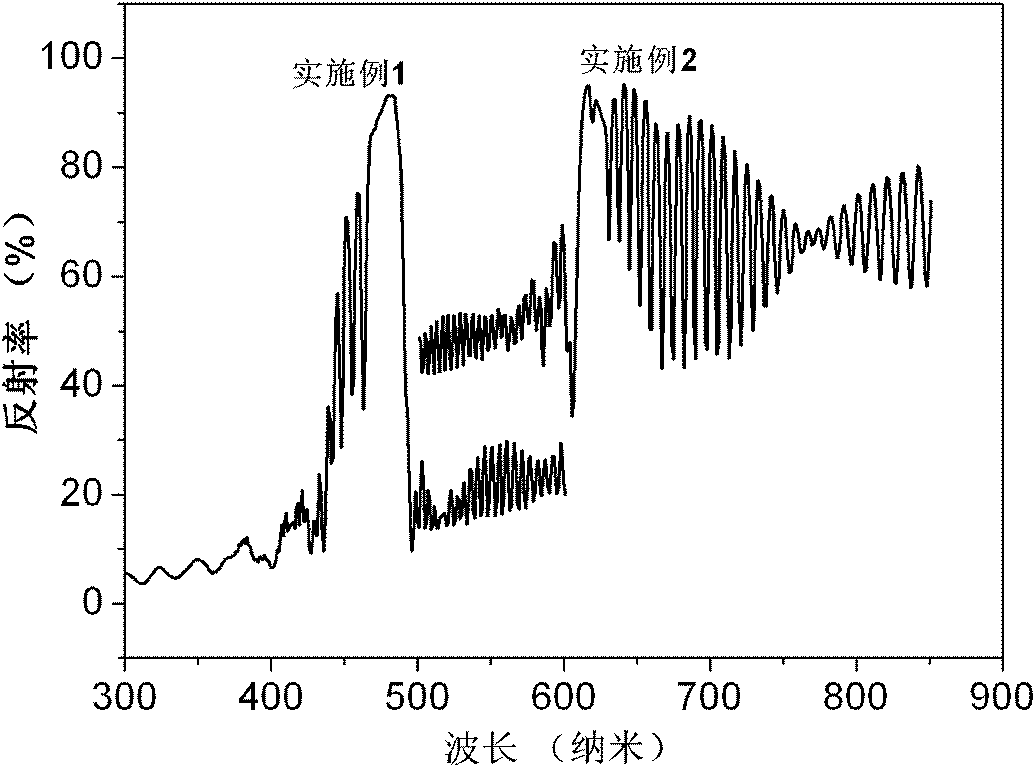

Coloration process of brass zipper

InactiveCN109112522AImprove bindingHigh fastnessMetallic material coating processesBiological activationProcess conditions

The invention provides a coloration process of a brass zipper. The coloration process comprises the following steps of a) chemical deoiling treatment; b) chemical polishing treatment; c) activation treatment; d) chemical coloration treatment; and e) post treatment. The invention discloses the coloration process of the brass zipper; the coloration process is simple, feasible, low in energy consumption and low in cost; through optimizing the constitution of a coloration solution and a process condition, not only is the higher bonding force of a colored film ensured, but also the better color fastness to washing and the corrosion resistance of the colored film are ensured; and the coloration process has higher popularization and application value.

Owner:道晟拉链科技(太仓)有限公司

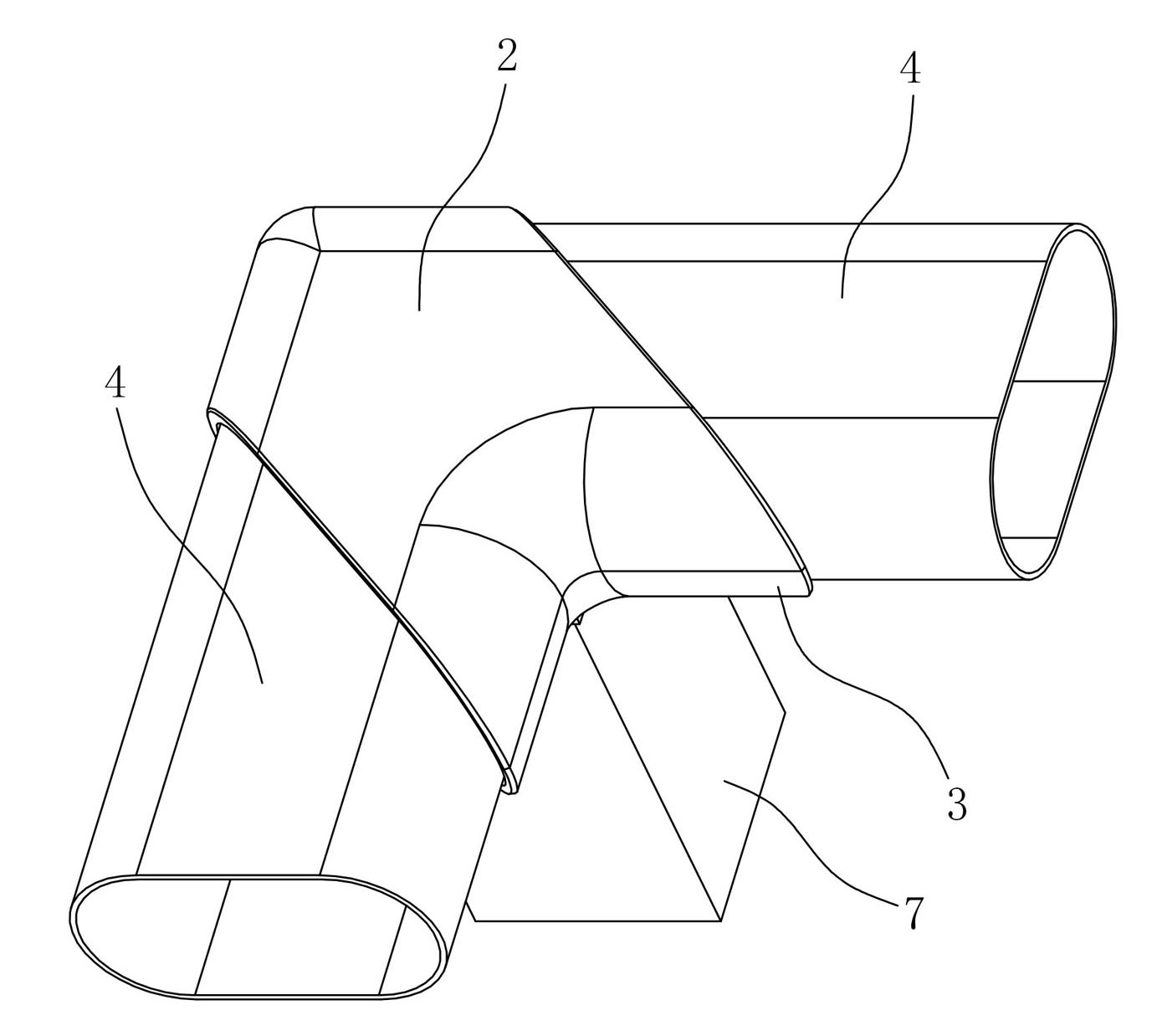

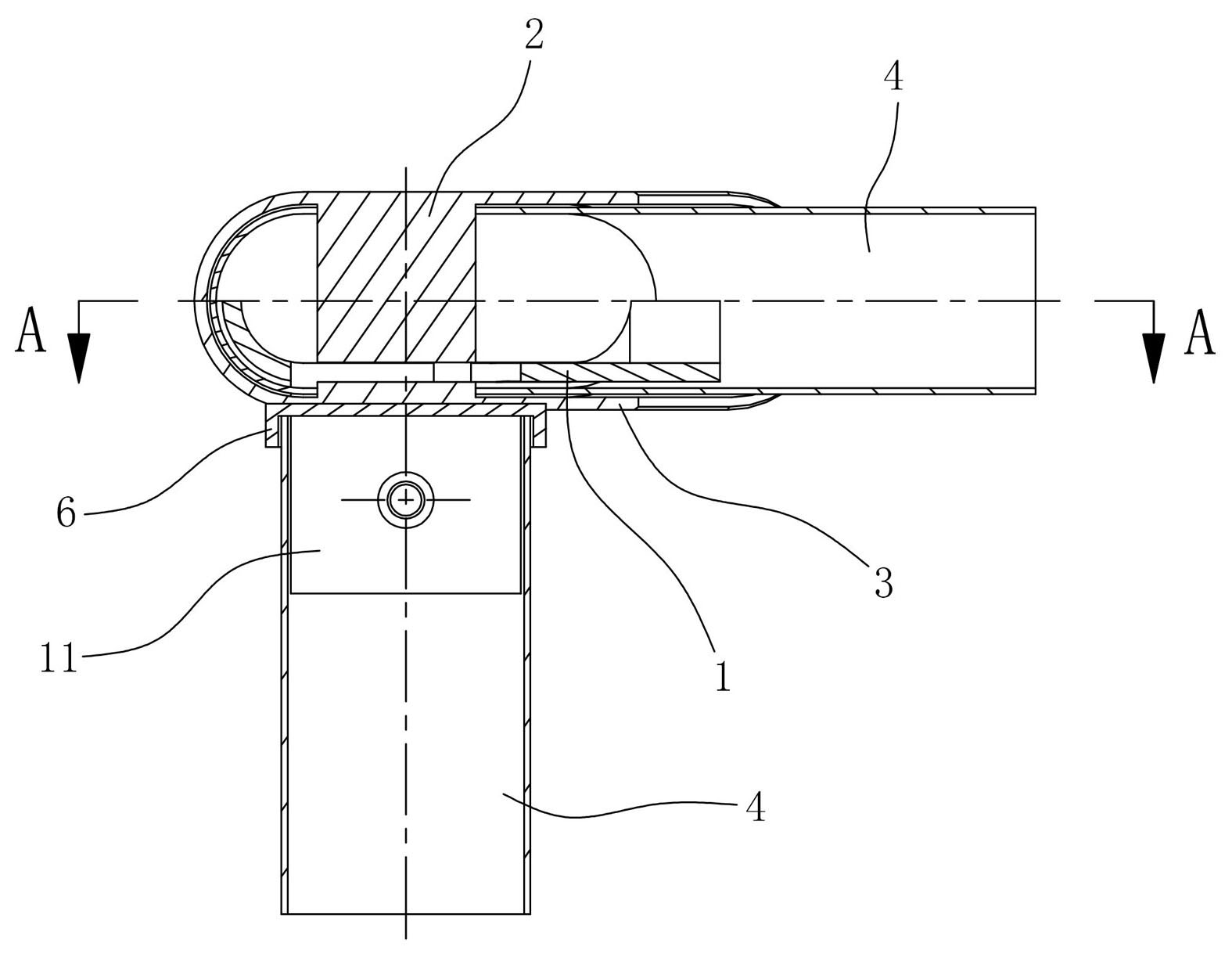

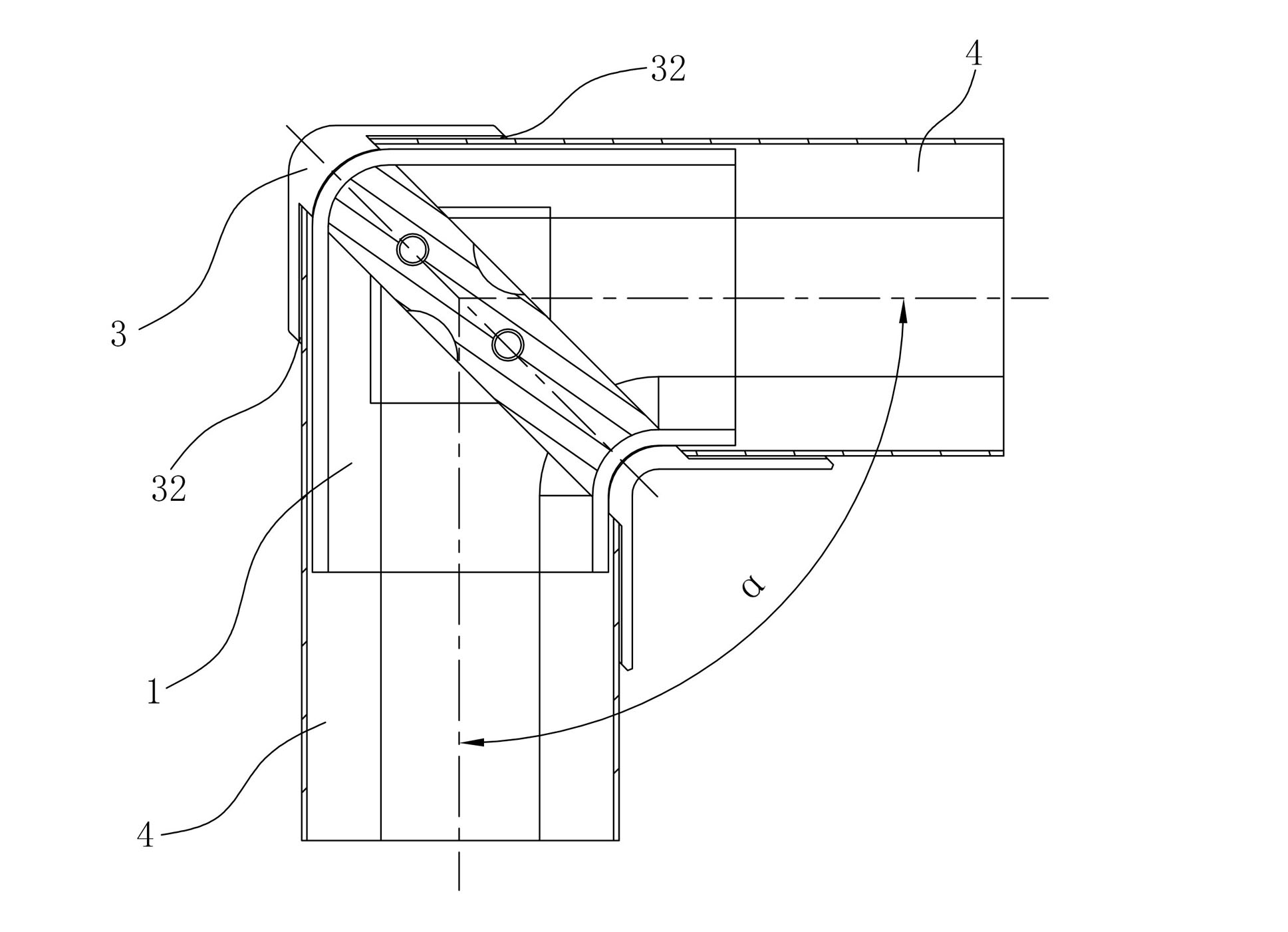

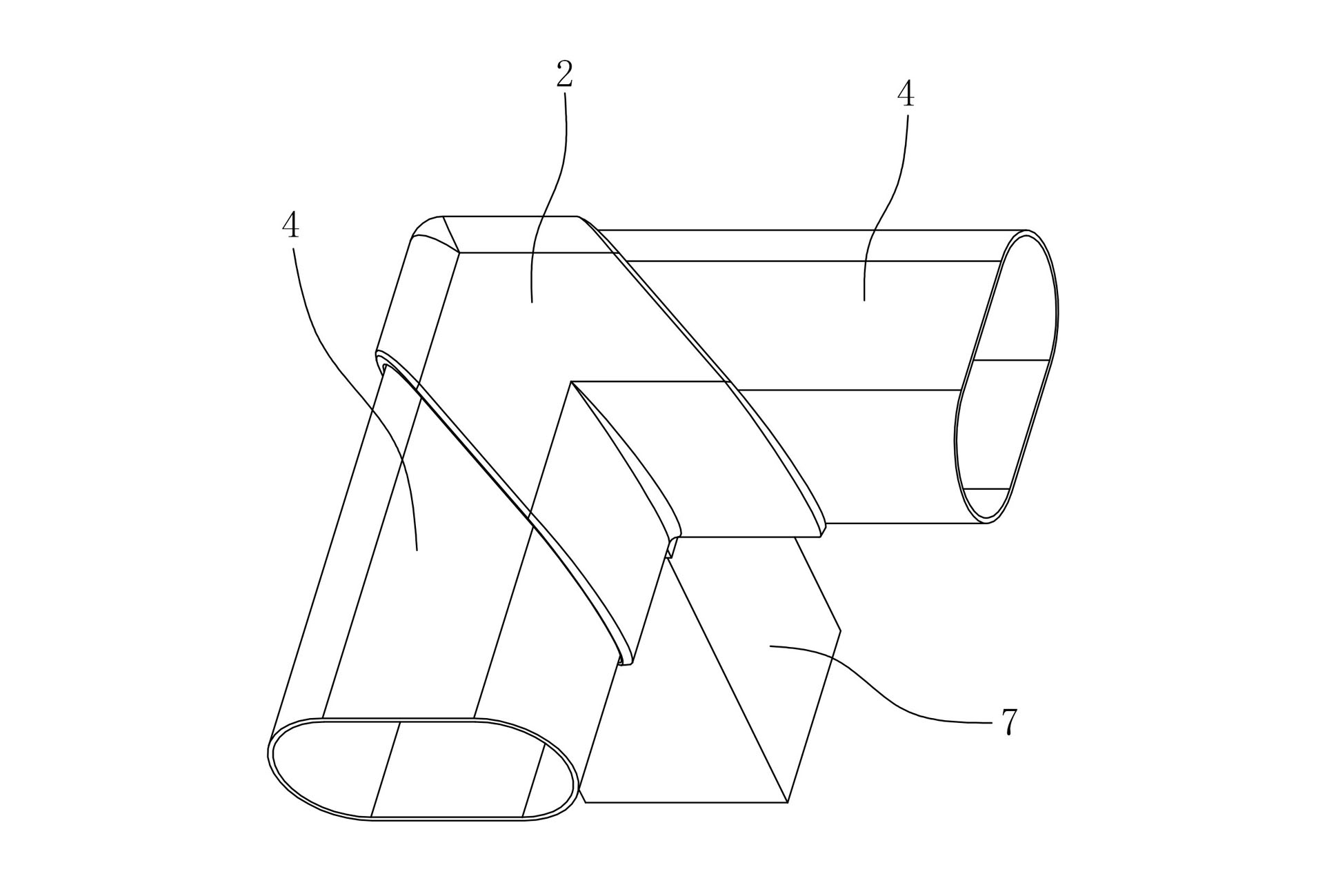

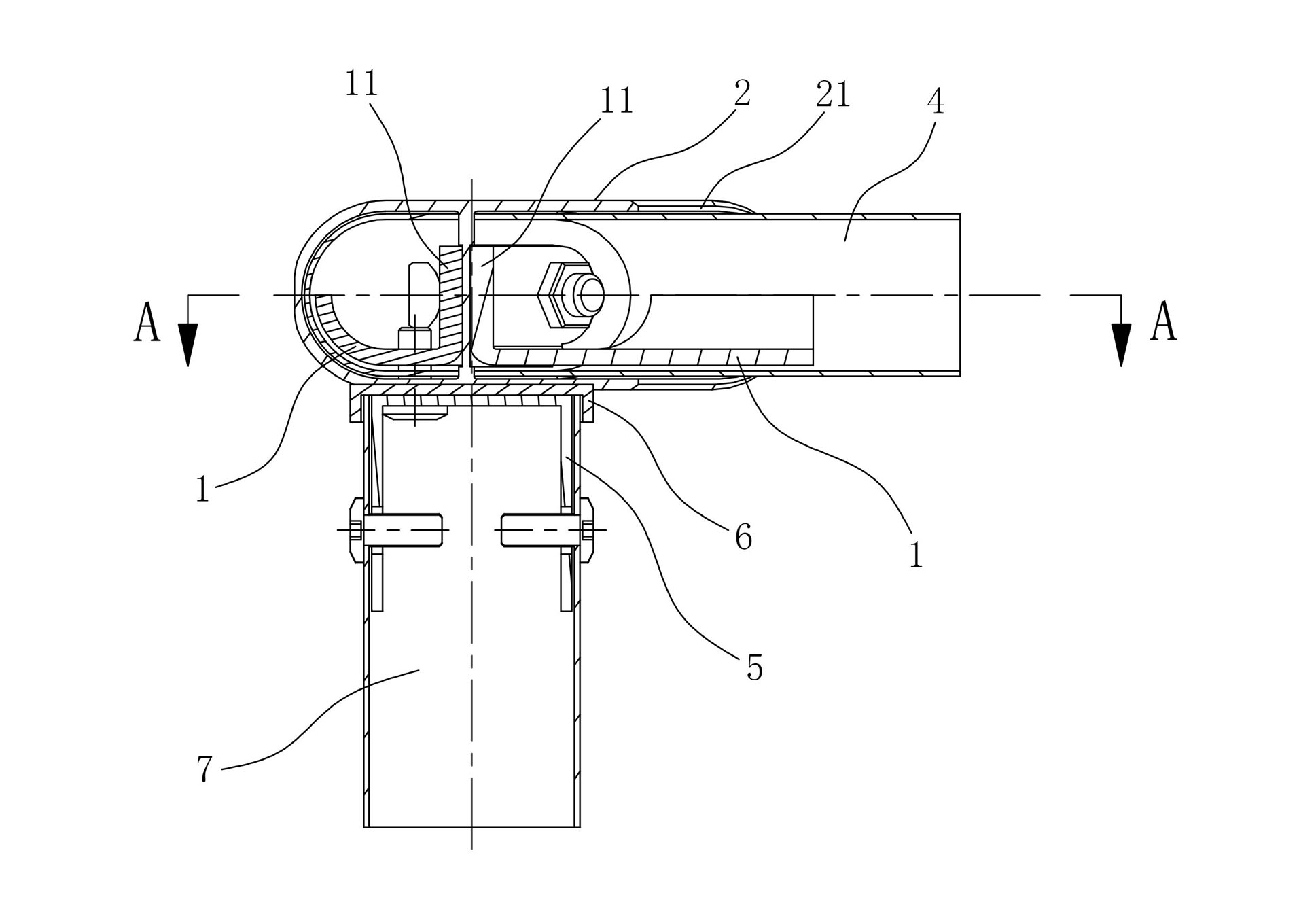

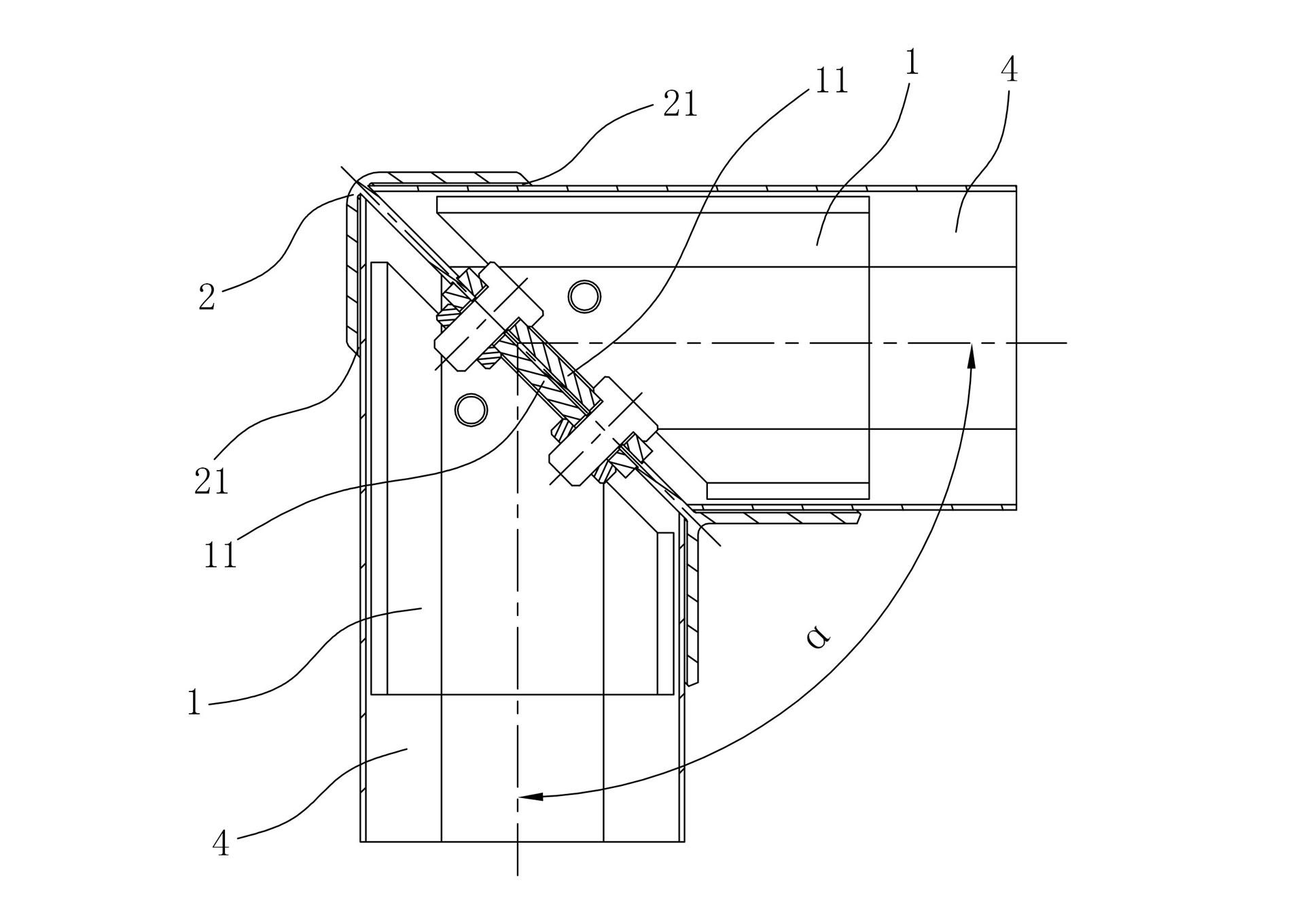

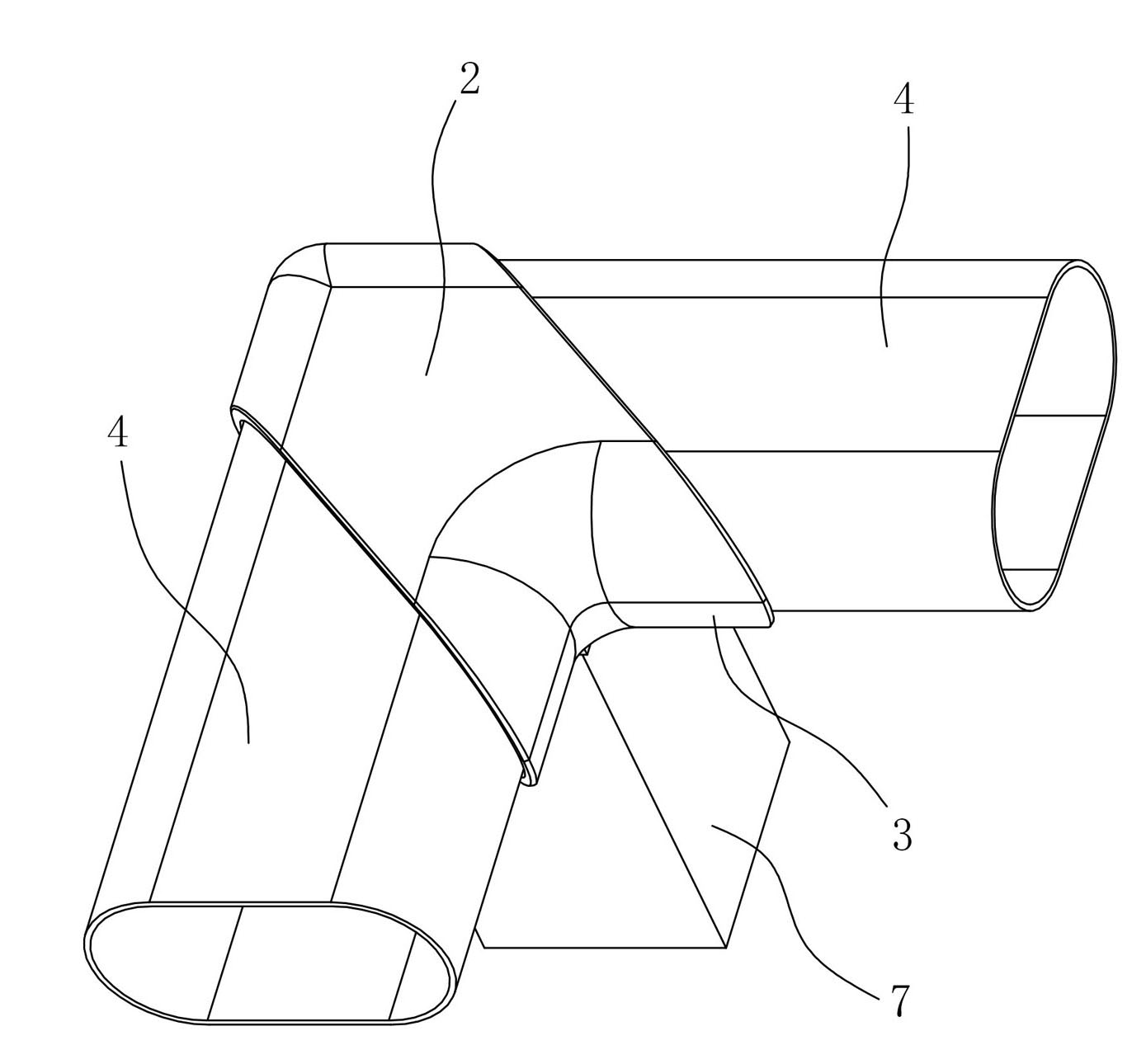

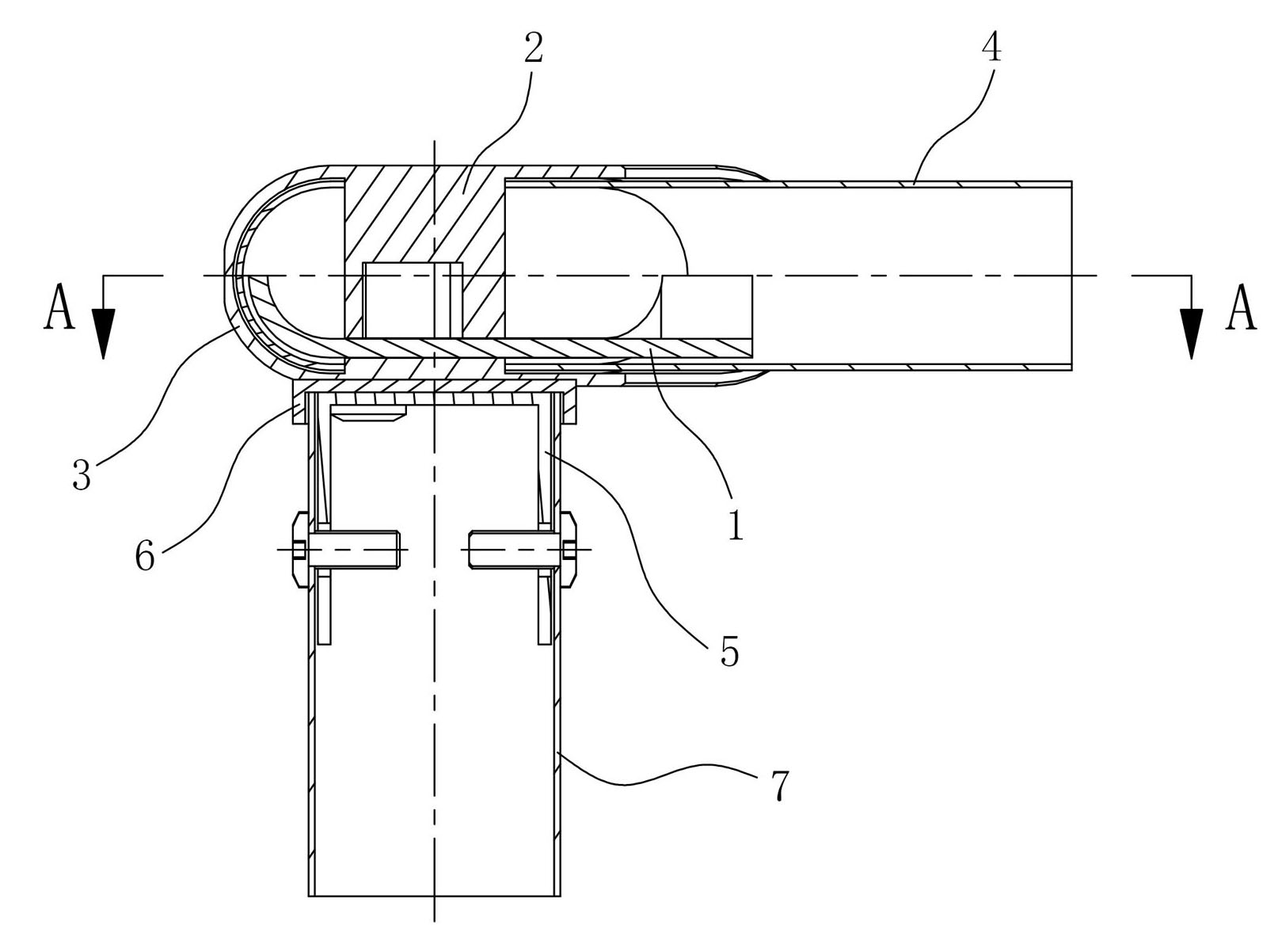

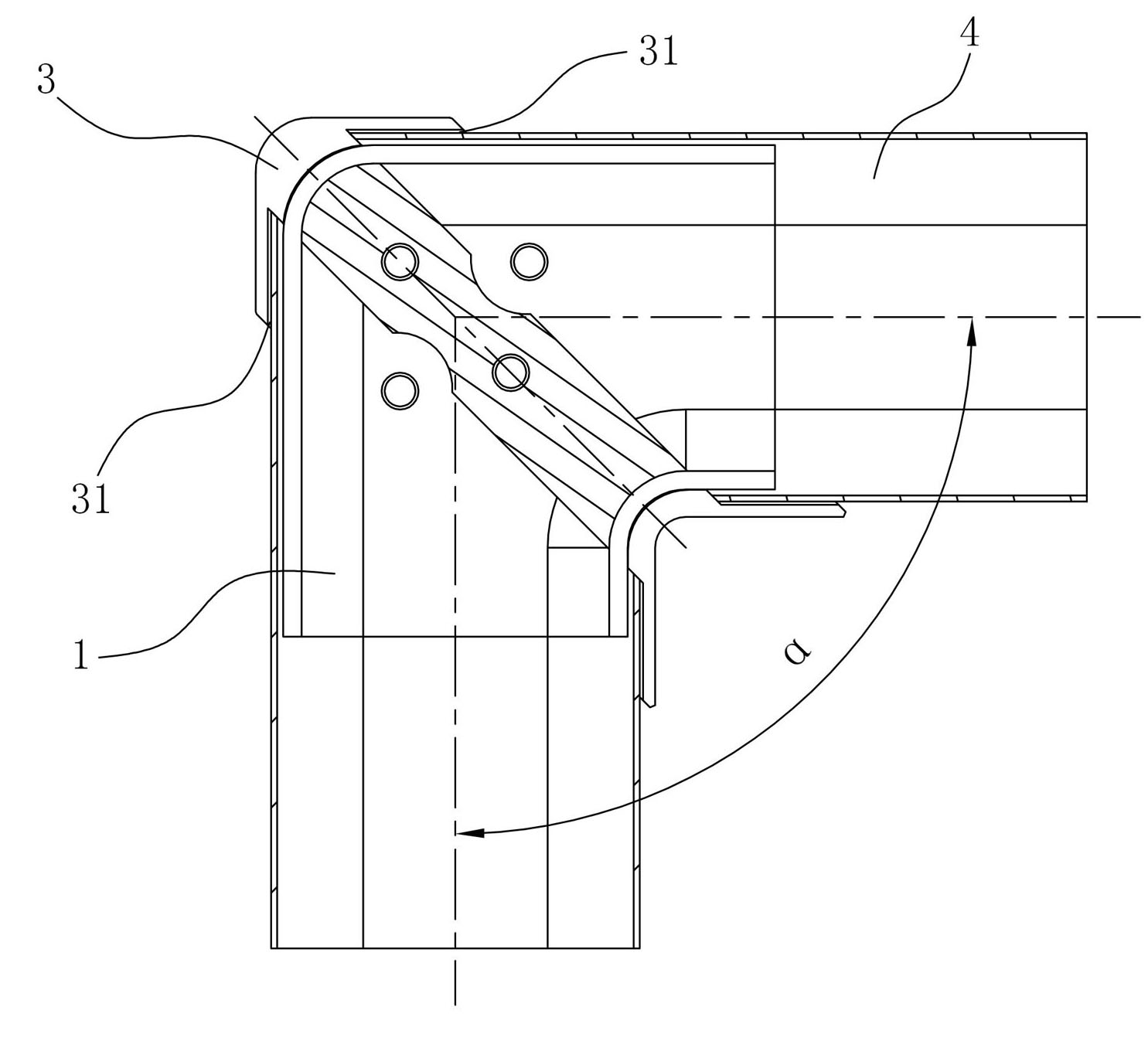

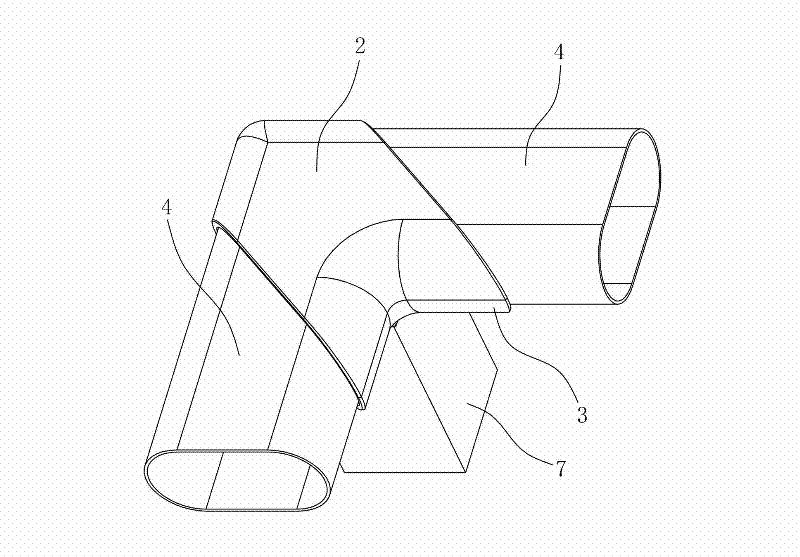

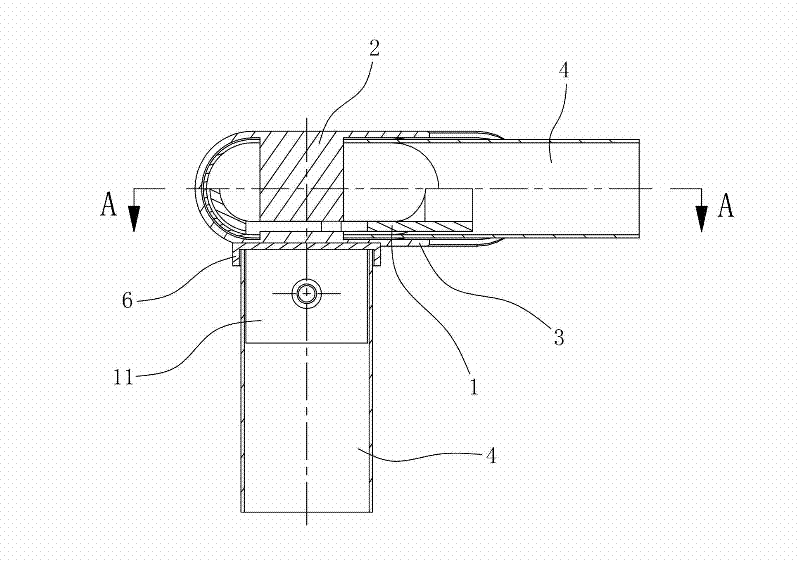

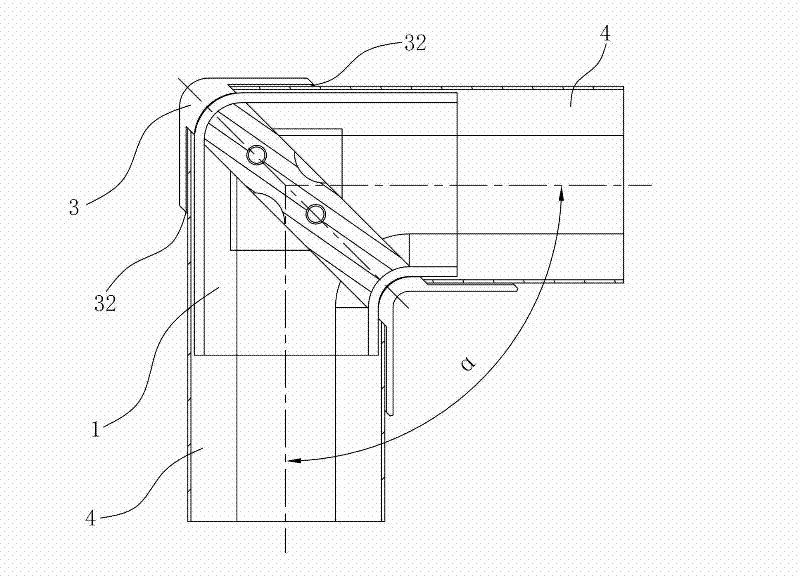

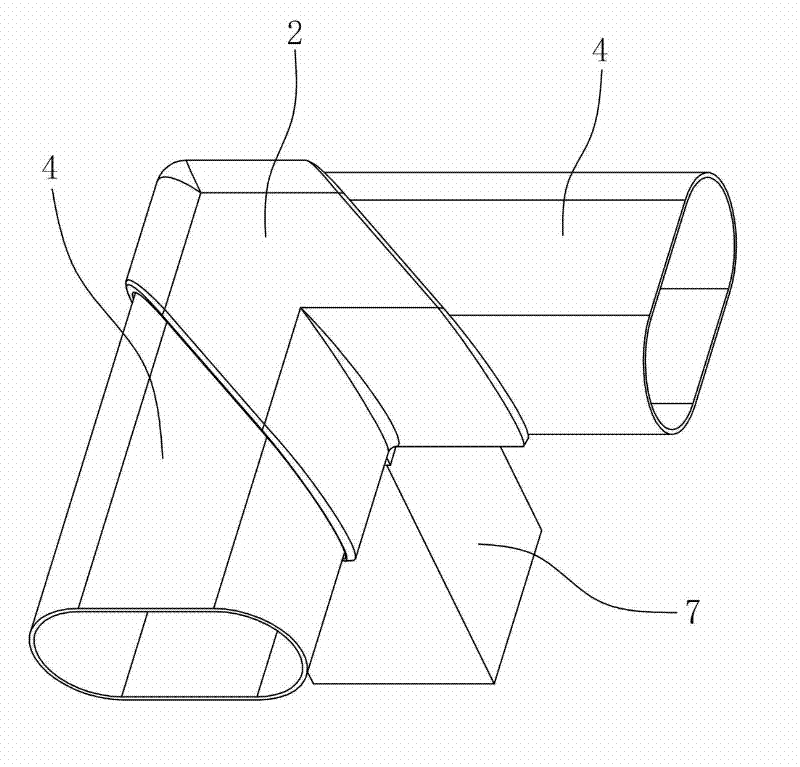

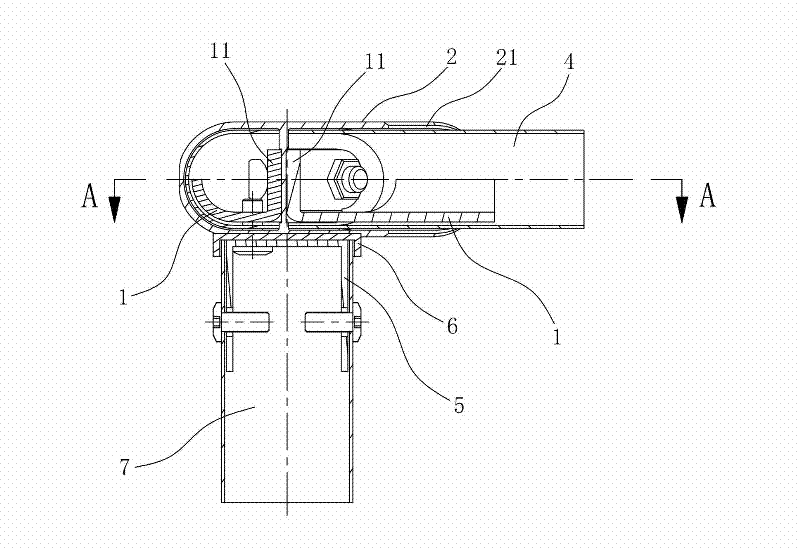

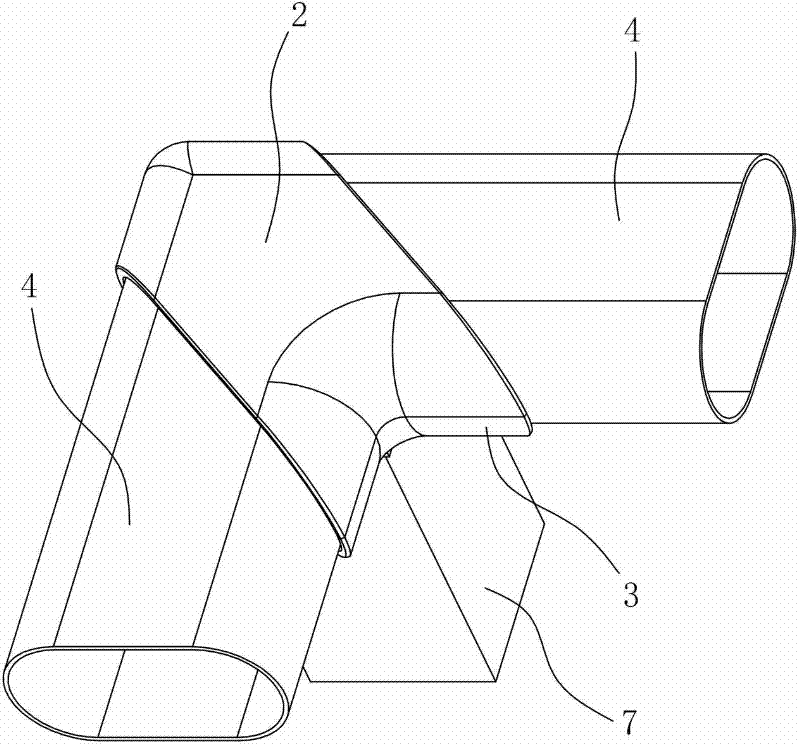

Three-way connecting fitting of face pipe

ActiveCN102072230AEasy to locate and installAccurate installation and positioningRod connectionsPlastic materialsEngineering

The invention discloses a three-way connecting fitting of a face pipe, which comprises a rigid plate, a clamping sleeve of an upper plastic material and a clamping sleeve of a lower plastic material, wherein the clamping sleeve of the upper plastic material and the clamping sleeve of the lower plastic material are mutually buckled and form a sealing component of the face pipe, the rigid plate is arranged in the clamping sleeve of the upper plastic material and the clamping sleeve of the lower plastic material, which are mutually buckled, and forms a connecting component for connecting the face pipe, and a connecting part of an upright post, which penetrates through the clamping sleeve of the lower plastic material, is arranged on the rigid plate. The three-way connecting fitting of the face pipe has the advantages of simple structure, high joint strength, good toughness, good sealing property and low cost.

Owner:HUNAN GOLDWELL NEW MATERIALS TECH CO LTD

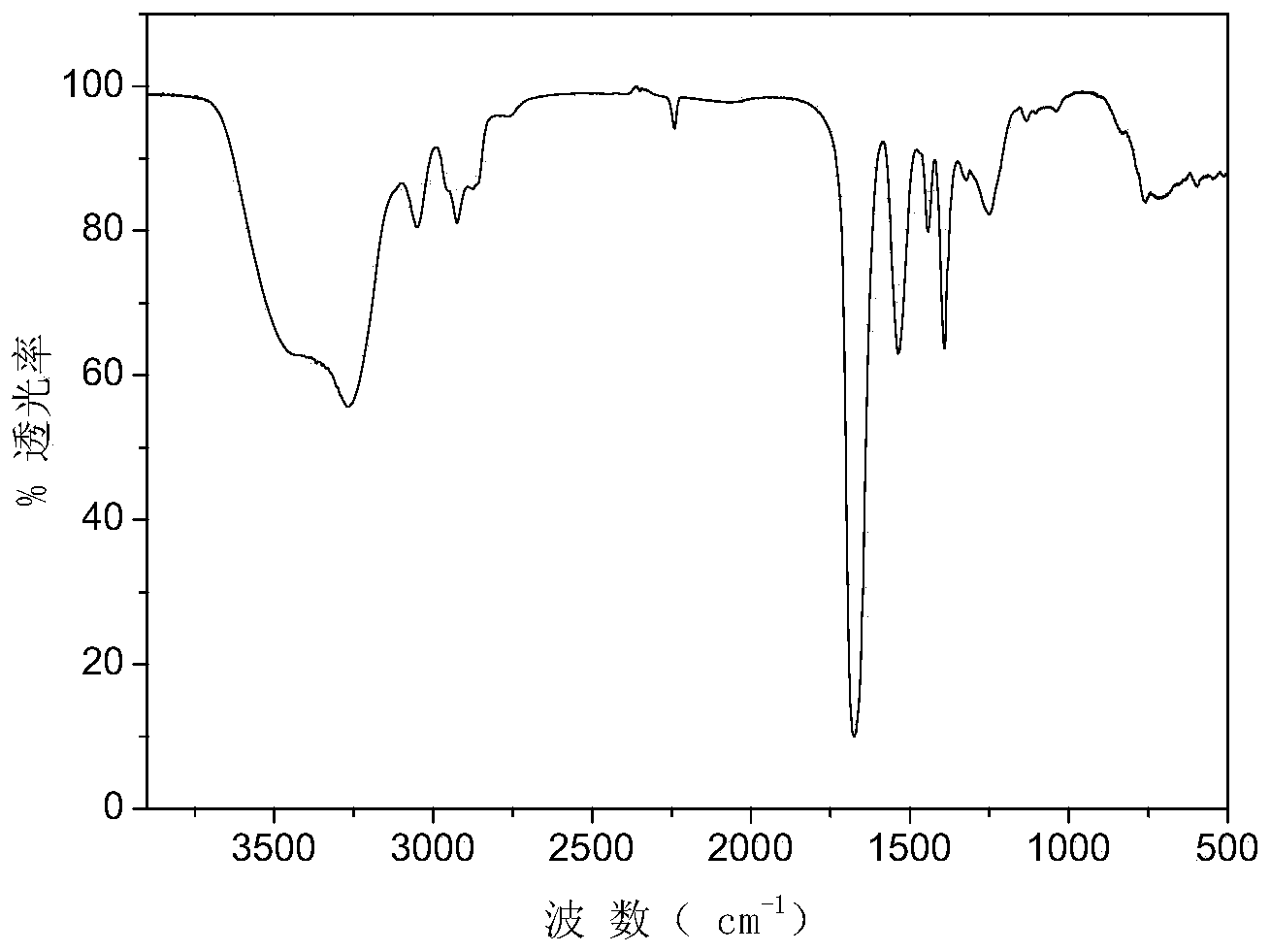

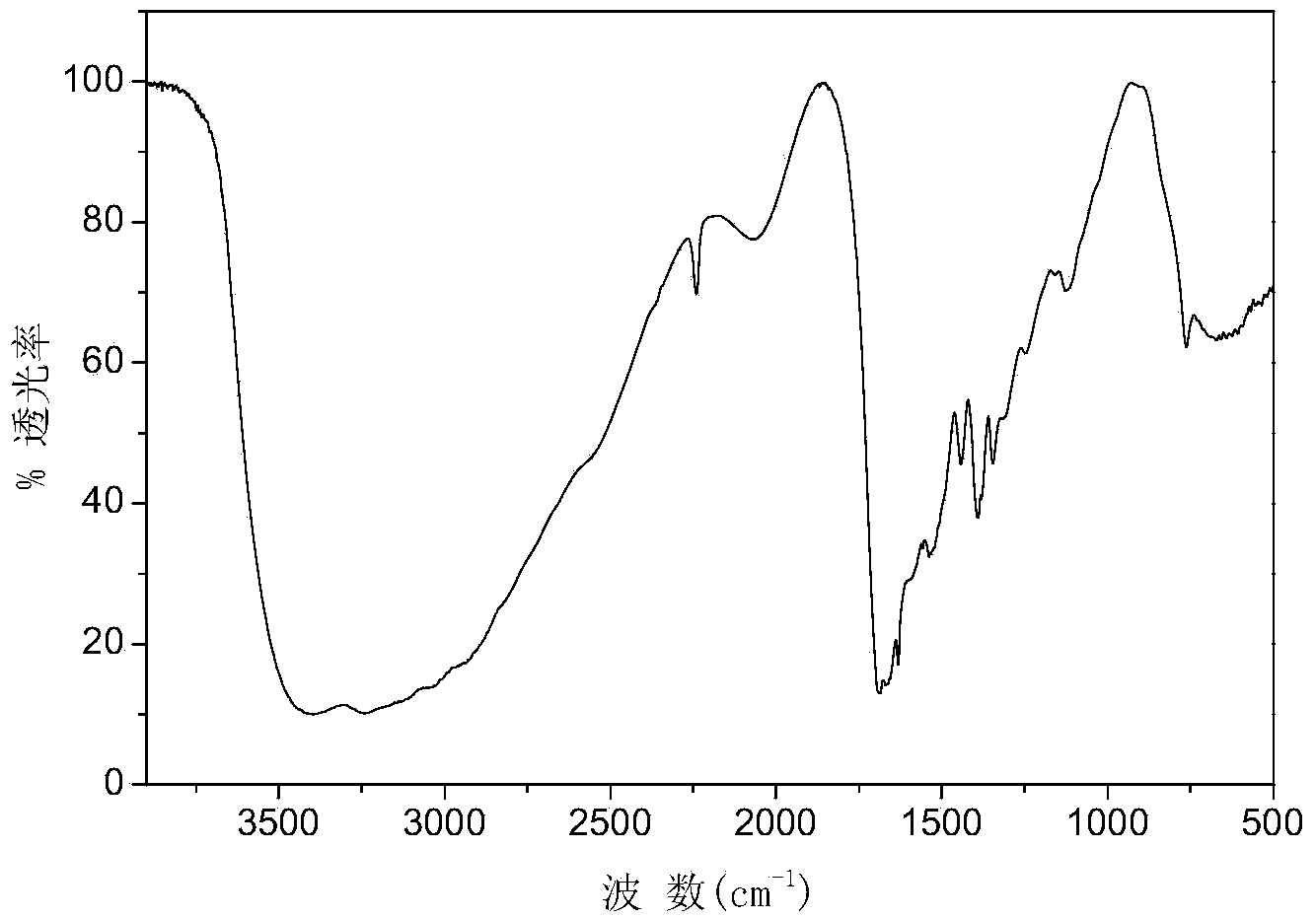

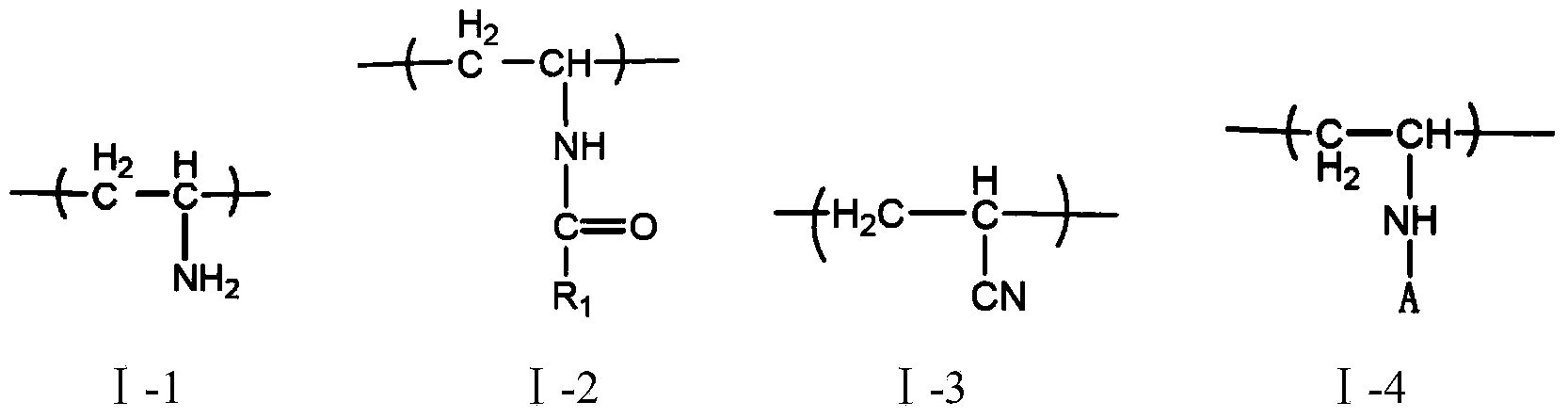

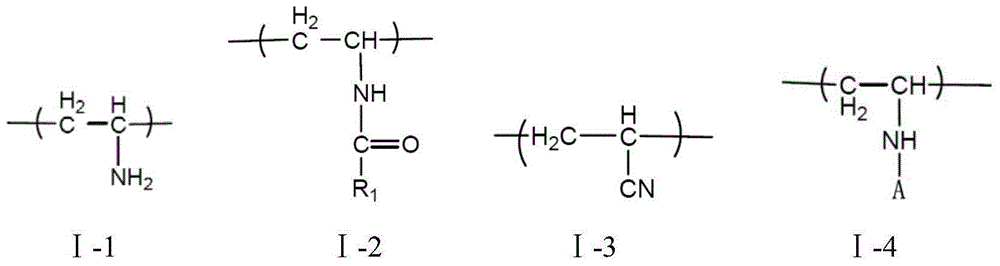

Polyvinylamine-co-acrylonitrile self-crosslinking dye as well as preparation method and application thereof

ActiveCN103665934AHigh color fixing rateGood light fastnessOrganic dyesDyeing processImideAcrylonitrile

The invention provides a polyvinylamine-co-acrylonitrile self-crosslinking dye as well as a preparation method and application thereof and particularly provides a preparation method of a macromolecular self-crosslinking dye formed by partially introducing dichloro-s-triazine micromolecular chromogens to an amino group of an aminoethenyl and acrylonitrile copolymer as a main chain. A macromolecular side chain of the dye contains amino, imide, cyano and dichloro-s-triazine micromolecular chromogens, and the dye has a self-crosslinking characteristic after dyeing fiber. The developed dye is suitable for dyeing cellulosic fiber, free of a crosslinking agent in a dyeing process and capable of reducing the production cost, simplifying the dyeing process and improving the light fastness of the dyed fiber.

Owner:DALIAN UNIV OF TECH

Method for coloring aluminum and alloy surface thereof

InactiveCN102181902BAddress controllabilityLow costSurface reaction electrolytic coatingPollutionElectrolyte

The invention discloses a method for coloring aluminum and an alloy surface thereof, which comprises the following steps of: at first, cleaning and polishing the aluminum or the aluminum alloy surface; carrying out constant-pressure anode preoxidization for 20 minutes to 3 hours under the preoxidization voltage of 10 to 20 volts by using sulfuric acid electrolyte with the concentration of 0.1 to 3mol / liter under the conditions that the well-processed aluminum or aluminum alloy is used as an anode and graphite is used as a cathode; and then oxidizing the aluminum or the aluminum alloy by utilizing a voltage which varies periodically based on time to obtain a structurally laminar alumina photonic crystal, and coloring the aluminum or the aluminum alloy surface by the structural color of an optical forbidden band of the alumina photonic crystal, so that different colors can be adjusted within a scope of visible lights by maintaining constant time and changing the voltage only or maintaining constant voltage and changing time only. The coloration method of the invention has the advantages of no need of depositing metal ions, simple process and low cost, wide adjustment scope of colorsand less pollution.

Owner:SOUTH CHINA UNIV OF TECH

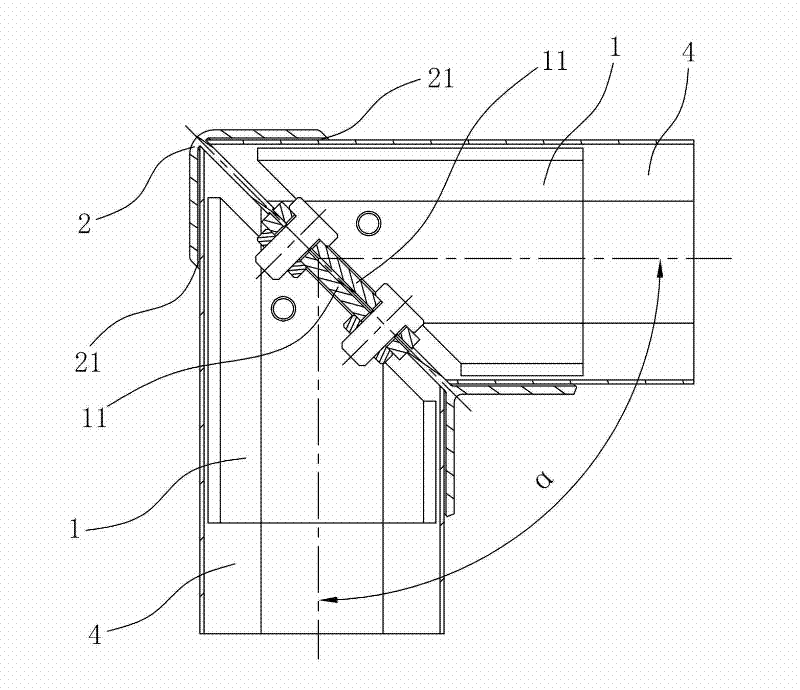

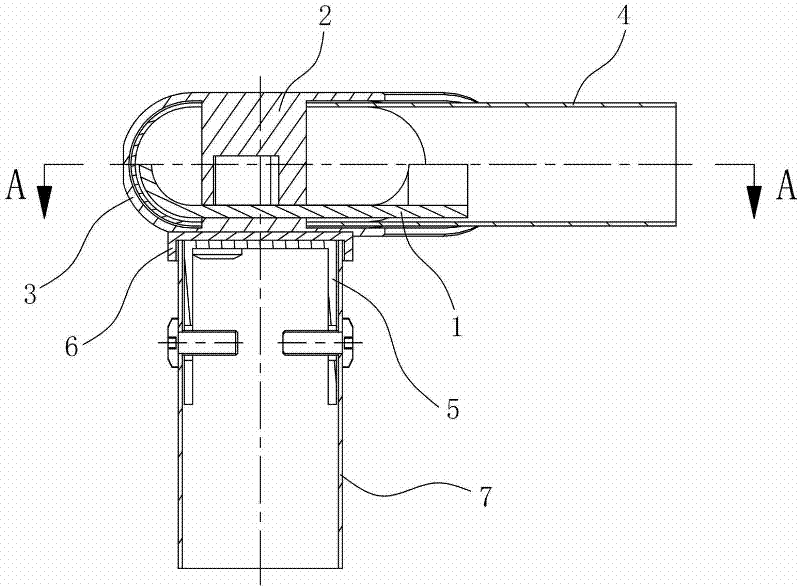

Connection fitting for face pipes

ActiveCN102032251AAccurate installation and positioningPrevent rustRod connectionsPlastic materialsEngineering

The invention discloses a connection fitting for face pipes. The connection fitting for the face pipes comprises a plastic material clamping sleeve and two rigid plates, wherein the plastic material clamping sleeve is used for sealing end openings of the face pipes and is provided with two face pipe sealing end openings; the two rigid plates are used for connecting the face pipes and are arranged into the sealing end openings of the face pipes respectively; and the two rigid plates are fixedly connected with each other. The connection fitting for the face pipes has the advantages of simple structure, high connection strength, high toughness, high sealing property and low cost.

Owner:HUNAN GOLDWELL NEW MATERIALS TECH CO LTD

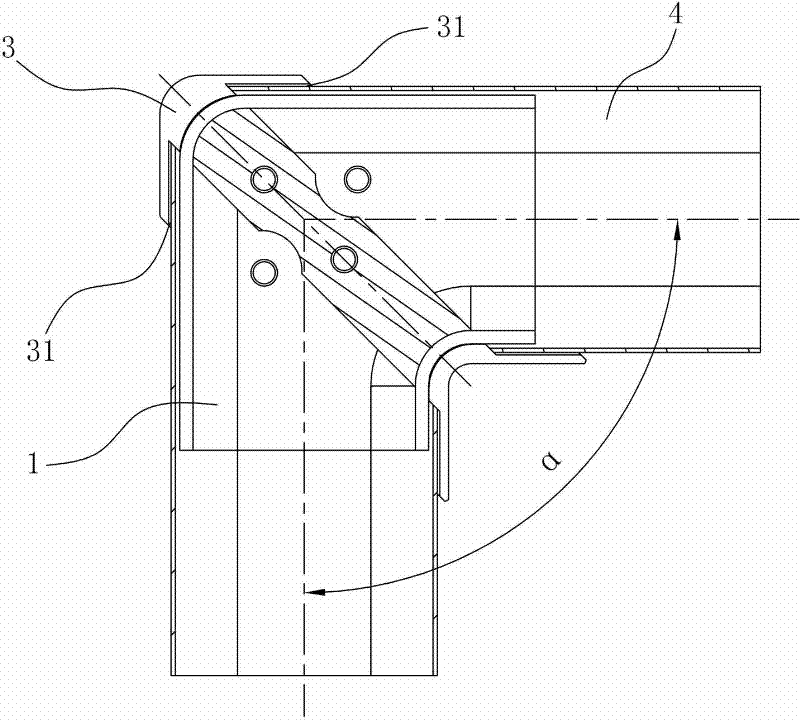

Face pipe connecting component

ActiveCN102072229AImprove connection strengthAccurate installation and positioningRod connectionsPlastic materialsUltimate tensile strength

The invention discloses a face pipe connecting component. The connecting component comprises a rigid plate, an upper plastic material sleeve chuck and a lower plastic material sleeve chuck, wherein the upper plastic material sleeve chuck and the lower plastic material sleeve chuck are mutually buckled and form a sealing component of a face pipe; and the rigid plate is arranged in the upper plastic material sleeve chuck and the lower plastic material sleeve chuck and forms the connecting component used for connecting the face pipe. The face pipe connecting component has the advantages of simple structure, high connecting strength, high toughness, high tightness, low cost and the like.

Owner:HUNAN GOLDWELL NEW MATERIALS TECH CO LTD

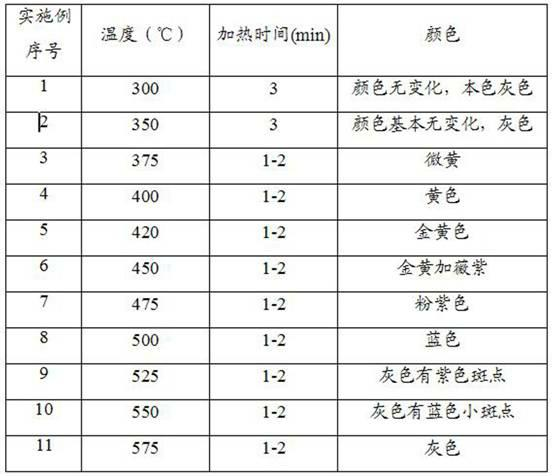

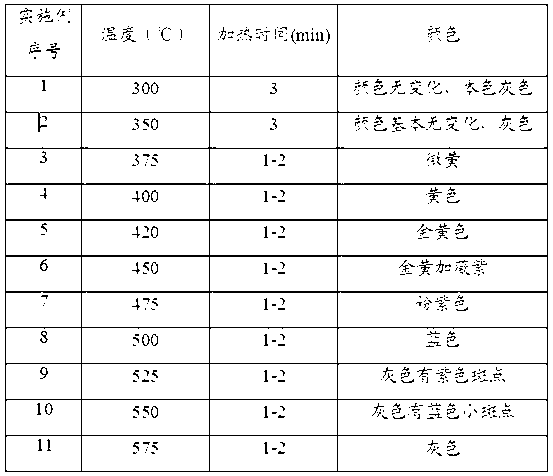

Titanium surface coloring process

InactiveCN102330050AColoring firmSave electricitySolid state diffusion coatingTitanium surfaceTitanium gold

The invention relates to the field of metal surface machining treatment, in particular to a titanium surface coloring process. According to the invention, the titanium surface coloring process comprises material selection, surface polishing treatment, constant temperature furnace heating coloring treatment and more. By using the titanium surface coloring process provided by the invention, no chemical reagent is needed in the whole process and pollution and potential safety hazard are effectively avoided; according to the invention, the titanium surface can be treated into different colors through adjusting the temperature of the constant temperature furnace and the constant temperature acting time; and the titanium surface coloring process provided by the invention has the advantages of simple process, short time, convenience in operation and the like.

Owner:SHENZHEN WOLFERS IND CO LTD

Printing and dyeing process for fire-fighting safety fabrics

InactiveCN108930174AReduce manufacturing costSimple coloring processDyeing processPhthalocyanine dyeAntioxidant

The invention discloses a printing and dyeing process for fire-fighting safety fabrics, wherein the printing and dyeing process comprises the raw material components in parts by weight: 35-85 parts ofpolyamide resin, 25-65 parts of a phthalocyanine dye, 12-60 parts of a wetting dispersant, 12-36 parts of a light stabilizer and 5-15 parts of an antioxidant. The phthalocyanine dye is one or more oftetrasulfonated metal phthalocyanine dyes, sulfonated phthalocyanine dyes and zinc phthalocyanine dyes. Through the way, the printing and dyeing process of the fire-fighting safety fabrics has low production cost, good stability after coloring, and simple coloring process, is mainly used for cotton spinning coloring, has good visual effect after dyeing and rich color types, and can be used for printing and dyeing of various fire-fighting safety fabrics.

Owner:贾留娜

Stainless steel chemical pigmenting liquid and chemical pigmenting method

InactiveCN101058882BAvoid color changesGood reproducibilitySuperimposed coating processElectrolysisWear resistance

The invention discloses a chemical coloring liquid of stainless steel and chemical coloring method, which comprises the following parts: chromic anhydride, sulfuric acid, water, accelerant, stabilizer, brightener and homogeneous agent. The coloring method comprises the following steps: predisposing the stainless steel surface; coloring; hardening film through little current; sealing; drying.

Owner:TAIYUAN UNIV OF TECH +1

Novel night-luminescent textile dye

InactiveCN107326695AReduce manufacturing costSimple coloring processDyeing processFire safetyPhthalocyanine dye

The invention discloses a novel night-time luminescent textile dye. The raw material components include: 35-85 parts of polyamide resin, 25-65 parts of phthalocyanine dye, 12-60 parts of wetting and dispersing agent, 12-36 parts of stabilizer and 5-15 parts of antioxidant, the phthalocyanine dye is one or more of tetrasulfometal phthalocyanine dye, sulfonated phthalocyanine dye and zinc phthalocyanine dye. Through the above-mentioned method, the production cost of the novel night-time luminescent textile dye of the present invention is low, and after coloring, it has better stability and a simple coloring process. It is mainly used for textile coloring of cotton, and the visual effect after dyeing is good. Used for printing and dyeing of various fire safety fabrics.

Owner:秦昌元

Novel fluorescent textile dye

InactiveCN109235074AReduce manufacturing costImprove stabilityOrganic dyesDyeing processPhthalocyanine dyeFluorescence

The invention discloses novel fluorescent textile dye. The novel fluorescent textile dye is prepared from the following raw materials in parts by weight: 35-85 parts of polyamide resin, 25-65 parts ofphthalocyanine dye, 12-60 parts of a wetting dispersant, 12-36 parts of a light stabilizer and 5-15 parts of an antioxidant, wherein the phthalocyanine dye is one or more of tetrasulfonyl metal phthalocyanine dye, sulfonated phthalocyanine dye and zinc phthalocyanine dye. Thus, the novel fluorescent textile dye has low production cost and good stability after coloring, the coloring process is simple, the dye is mainly used for coloring cotton textiles, has good visual effect and rich color types after dyeing and can be used for printing and dyeing various fire-fighting safety fabrics.

Owner:秦昌元

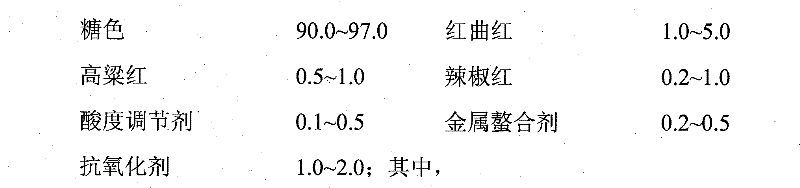

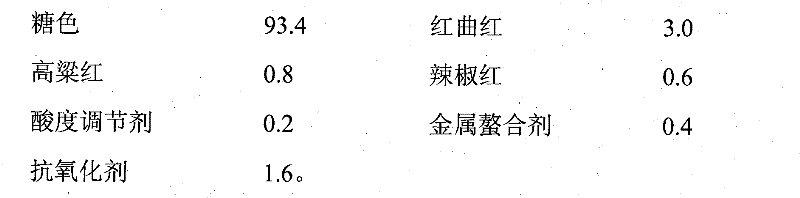

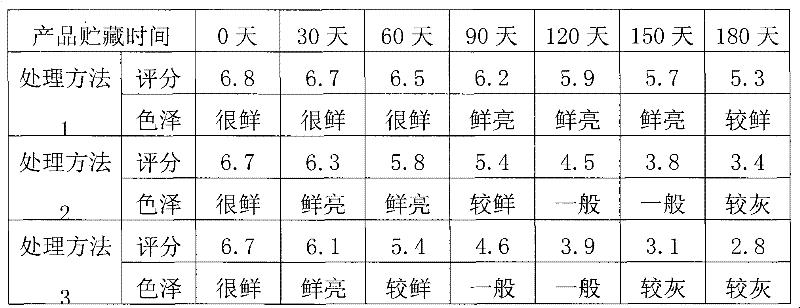

Compound coloring agent for pot-stewed meat products and method for using same

The invention discloses a compound coloring agent for pot-stewed meat products and a method for using same, belonging to the technical field of meat product processing. The coloring agent comprises the following components by the weight percentage: 90.0wt% to 97.0wt% of fried sugar, 1.0wt% to 5.0wt% of monascus red, 0.5wt% to 1.0wt% of sorghum red, 0.2wt% to 1.0wt% of capsicum red, 0.1wt% to 0.5%of acidity regulator, 0.2wt% to 0.5wt% of metal chelating agent and 1.0wt% to 2.0wt% of antioxidant. The method comprises the following steps in the concrete application to the preparation process ofthe pot-stewed meat: preparing raw meat; preparing liquid condiments; preparing the coloring agent; stewing and coloring; baking; vacuum-packaging; high-temperature sterilizing; and the like. The invention has the characteristics of good coloring effect, convenient use, high safety, high efficiency, stable, bright and red color and fading resistance and the like, and solves the problems that the conventional pot-stewed meat is unstable in appearance and color and prone to fade. The invention can be popularized and applied to food-processing enterprises, restaurants and families.

Owner:ZHEJIANG ACADEMY OF AGRICULTURE SCIENCES

Titanium surface coloring process

InactiveCN102330050BColoring firmSave electricitySolid state diffusion coatingTitanium surfaceCompound (substance)

The invention relates to the field of metal surface machining treatment, in particular to a titanium surface coloring process. According to the invention, the titanium surface coloring process comprises material selection, surface polishing treatment, constant temperature furnace heating coloring treatment and more. By using the titanium surface coloring process provided by the invention, no chemical reagent is needed in the whole process and pollution and potential safety hazard are effectively avoided; according to the invention, the titanium surface can be treated into different colors through adjusting the temperature of the constant temperature furnace and the constant temperature acting time; and the titanium surface coloring process provided by the invention has the advantages of simple process, short time, convenience in operation and the like.

Owner:SHENZHEN WOLFERS IND CO LTD

Three-way connecting fitting of face pipe

ActiveCN102072230BEasy to locate and installAccurate installation and positioningRod connectionsPlastic materialsEngineering

The invention discloses a three-way connecting fitting of a face pipe, which comprises a rigid plate, a clamping sleeve of an upper plastic material and a clamping sleeve of a lower plastic material, wherein the clamping sleeve of the upper plastic material and the clamping sleeve of the lower plastic material are mutually buckled and form a sealing component of the face pipe, the rigid plate is arranged in the clamping sleeve of the upper plastic material and the clamping sleeve of the lower plastic material, which are mutually buckled, and forms a connecting component for connecting the face pipe, and a connecting part of an upright post, which penetrates through the clamping sleeve of the lower plastic material, is arranged on the rigid plate. The three-way connecting fitting of the face pipe has the advantages of simple structure, high joint strength, good toughness, good sealing property and low cost.

Owner:HUNAN GOLDWELL NEW MATERIALS TECH CO LTD

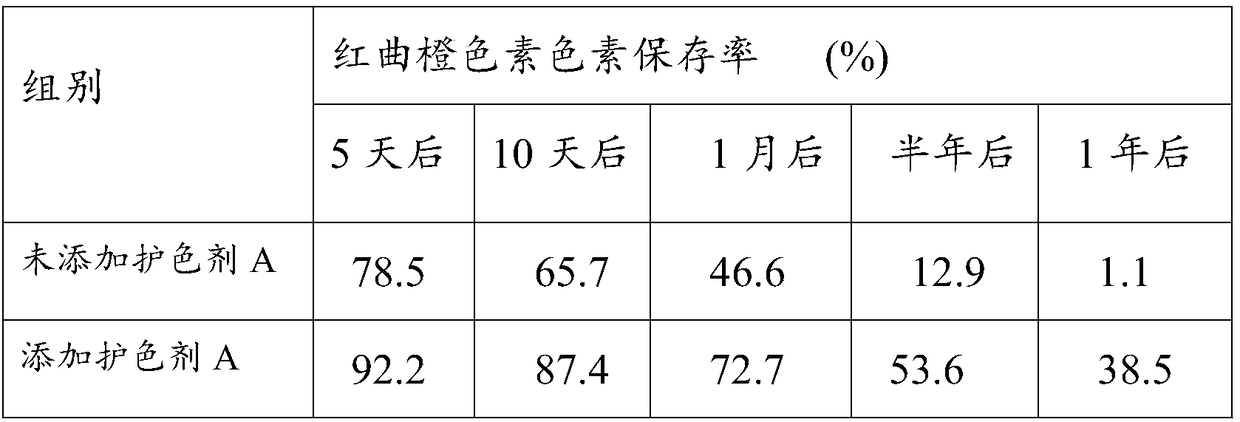

A kind of Monascus orange pigment photostability enhancement and determination method

The invention discloses methods for enhancing and measuring photostability of Monascus orange pigment; the method comprises: adding a mixture color protectant into Monascus orange pigment at a certain ratio to obtain Monascus orange pigment-mixture color protectant preparation; a method for measuring photostability of Monascus orange pigment is also provided. The Monascus orange pigment-mixture color protectant preparation prepared herein has good photostability; food and articles stained with the preparation have good light fastness.

Owner:INST OF AGRI PROD QUALITY SAFETY & STANDARD JIANGXI ACAD OF AGRI SCI

A kind of polyvinylamine-co-acrylonitrile type self-crosslinking dye, its preparation method and application

ActiveCN103665934BHigh color fixing rateGood light fastnessOrganic dyesDyeing processImideAcrylonitrile

The invention provides a polyvinylamine-co-acrylonitrile self-crosslinking dye as well as a preparation method and application thereof and particularly provides a preparation method of a macromolecular self-crosslinking dye formed by partially introducing dichloro-s-triazine micromolecular chromogens to an amino group of an aminoethenyl and acrylonitrile copolymer as a main chain. A macromolecular side chain of the dye contains amino, imide, cyano and dichloro-s-triazine micromolecular chromogens, and the dye has a self-crosslinking characteristic after dyeing fiber. The developed dye is suitable for dyeing cellulosic fiber, free of a crosslinking agent in a dyeing process and capable of reducing the production cost, simplifying the dyeing process and improving the light fastness of the dyed fiber.

Owner:DALIAN UNIV OF TECH

Connection fitting for face pipes

ActiveCN102032251BAccurate installation and positioningPrevent rustRod connectionsPlastic materialsEngineering

The invention discloses a connection fitting for face pipes. The connection fitting for the face pipes comprises a plastic material clamping sleeve and two rigid plates, wherein the plastic material clamping sleeve is used for sealing end openings of the face pipes and is provided with two face pipe sealing end openings; the two rigid plates are used for connecting the face pipes and are arrangedinto the sealing end openings of the face pipes respectively; and the two rigid plates are fixedly connected with each other. The connection fitting for the face pipes has the advantages of simple structure, high connection strength, high toughness, high sealing property and low cost.

Owner:HUNAN GOLDWELL NEW MATERIALS TECH CO LTD

A kind of method adopting lake dyestuff to color the seaweed fiber stock solution

ActiveCN104264280BIncrease profitHigh color fastnessAlginate artificial filamentsDye addition to spinning solutionSolventStock solution

The invention discloses a method for coloring seaweed fiber stock solution by using lake dye, and belongs to the fields of fine chemical industry and material science. In the present invention, sodium alginate is added into deionized water, stirred to make it fully dissolved, and seaweed fiber spinning stock solution is prepared, and then lake dye is added to the seaweed fiber spinning stock solution, stirred and mixed evenly, and then filtered and defoamed to produce The lake dye colored seaweed fiber spinning solution is obtained, and the seaweed fiber colored by the lake dye is further prepared. The method of the invention overcomes the problem of fiber damage caused by traditional dye dyeing, and the prepared colored seaweed fiber has the advantages of bright color, high color fastness, good solvent migration resistance and the like.

Owner:JIANGNAN UNIV

A method for coloring seaweed fibers with nano pigments

ActiveCN103556301BIncrease profitAddressing Defects in StainingAlginate artificial filamentsPigment addition to spinning solutionRoom temperatureNanometre

The invention discloses a method for coloring seaweed fibers with nano pigments. The method comprises the following steps: taking a certain amount of ultrafine water-based nano pigments and adding them to seaweed fiber spinning stock solution, stirring to disperse the pigment particles evenly, filtering and defoaming Afterwards, wet spinning is carried out at room temperature to prepare colored seaweed fibers, and the draft ratio of the fibers is 100-300%. The seaweed fiber prepared by the invention has uniform coloring, high washing and sunlight fastness, saves water resources and energy consumption, realizes clean production, and has good application prospects in the fields of clothing and environmental protection.

Owner:吴江山湖颜料有限公司

Colour simulation artistic moulding electric equipment switch socket and its production method

InactiveCN1461080AMeet individual wishesSimple coloring processContact member cases/bases manufactureCouplings bases/casesSurface plateSpray coating

The present invention relates to a kind of colour simulation artistic moulding electric equipment switch socket and its production method. It includes electric equipment switch panel, power socket panel, moulding process of combined socket panel and colouring process. Said colouring process ues Multimix high-performance paint as colouring material, and can adopt the various operation methods of spray-coating, brush-coating and hand-painting.

Owner:林天民

Magnesium alloy surface chemical coloring method

InactiveCN108385091AImprove corrosion resistanceColor adjustableMetallic material coating processesThermal waterSurface chemical

The invention discloses a magnesium alloy surface chemical coloring method. The magnesium alloy surface chemical coloring method comprises the steps that firstly, Zn(H2PO4)2 and Mn(H2PO4)2 are weighedand fetched, the Zn(H2PO4)2 and Mn(H2PO4)2 are added to water and stirred, the Zn(H2PO4)2 and the Mn(H2PO4)2 are completely dissolved, and it is guaranteed that the total mass concentration of the Zn(H2PO4)2 and the Mn(H2PO4)2 is 4%-6%; then, Na2ZrF6 is added, stirring continues, and the mass concentration of the Na2ZrF6 is 0.05-0.15%; after the Na2ZrF6 is completely dissolved, KMnO4 is added, the mass concentration of the KMnO4 is 0.5%-1.5%, and the solution is purple at the moment and stands for use; surface rust and oil removal and alkali washing-water washing are conducted on a magnesiumalloy, the magnesium alloy obtained after surface rust and oil removal is placed in the solution prepared in the beginning and is dipped, then the magnesium alloy is taken out and placed in hot waterfor washing, and then the colored magnesium alloy is obtained. The magnesium alloy surface chemical coloring method solves the problem that in the prior art, the color of the colored surface of the magnesium alloy is uneven and poor in durability.

Owner:XIAN UNIV OF TECH

Face pipe connecting component

ActiveCN102072229BImprove connection strengthAccurate installation and positioningRod connectionsPlastic materialsUltimate tensile strength

The invention discloses a face pipe connecting component. The connecting component comprises a rigid plate, an upper plastic material sleeve chuck and a lower plastic material sleeve chuck, wherein the upper plastic material sleeve chuck and the lower plastic material sleeve chuck are mutually buckled and form a sealing component of a face pipe; and the rigid plate is arranged in the upper plastic material sleeve chuck and the lower plastic material sleeve chuck and forms the connecting component used for connecting the face pipe. The face pipe connecting component has the advantages of simple structure, high connecting strength, high toughness, high tightness, low cost and the like.

Owner:HUNAN GOLDWELL NEW MATERIALS TECH CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com