Patents

Literature

42 results about "Titanium gold" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

In metallurgy, titanium gold (Ti-Au or Au-Ti) refers to an alloy consisting of titanium and gold. Such alloys are used in dentistry, ceramics and jewelry. Like many other alloys, titanium gold alloys have a higher yield strength, tensile strength, hardness, and magnetism than either of its constituent metals.

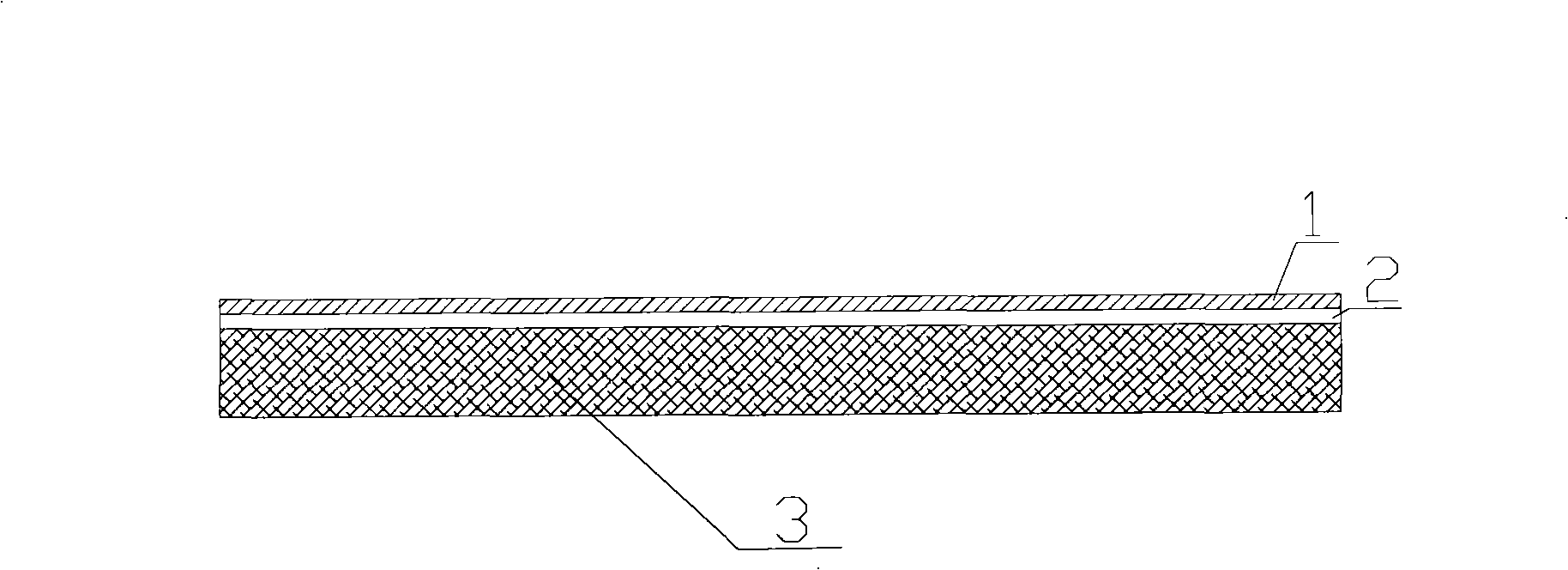

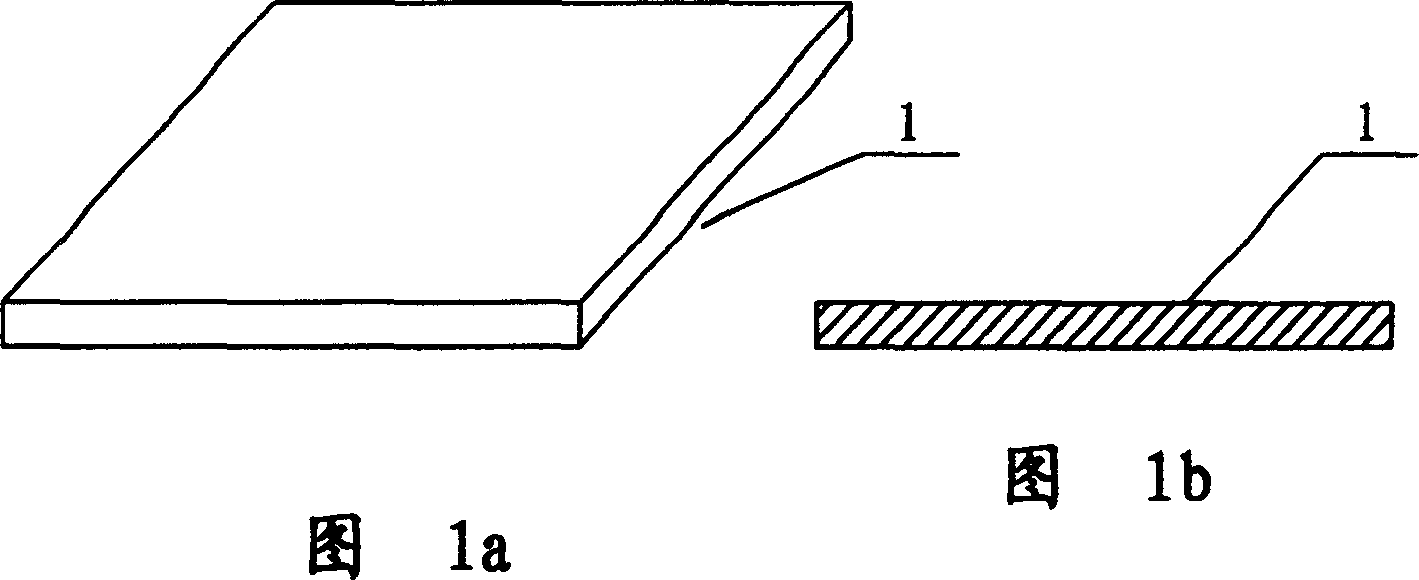

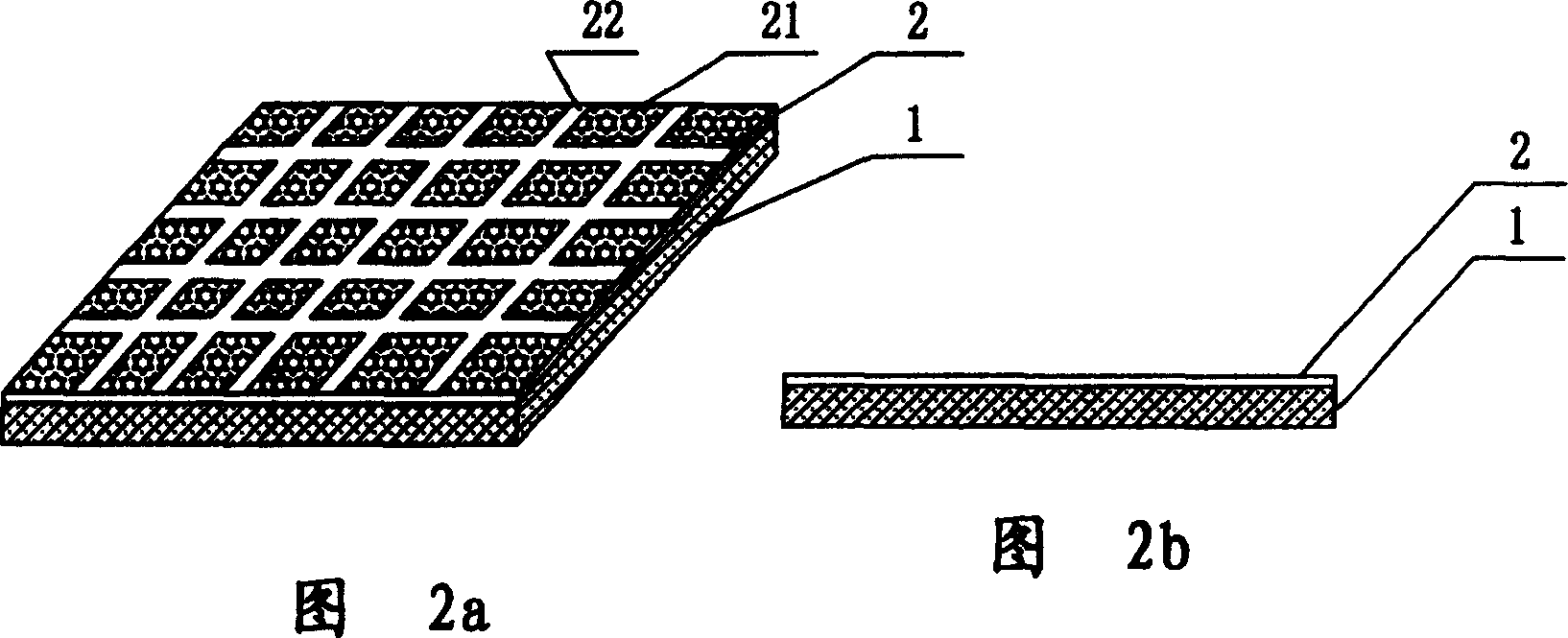

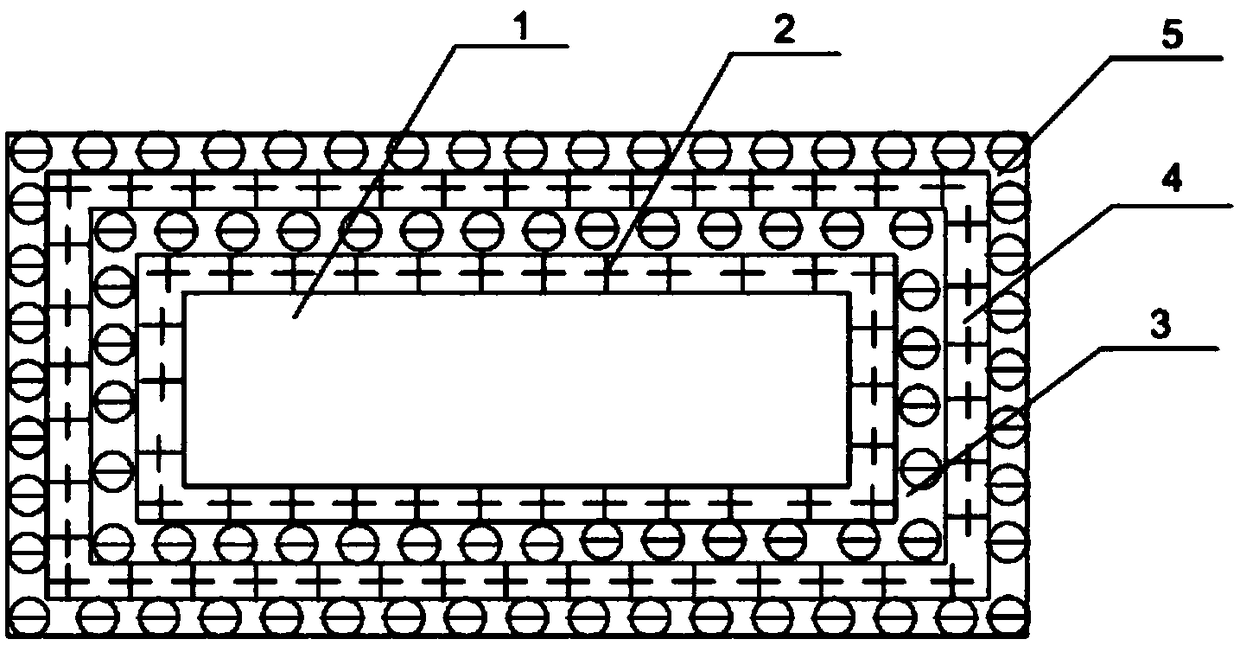

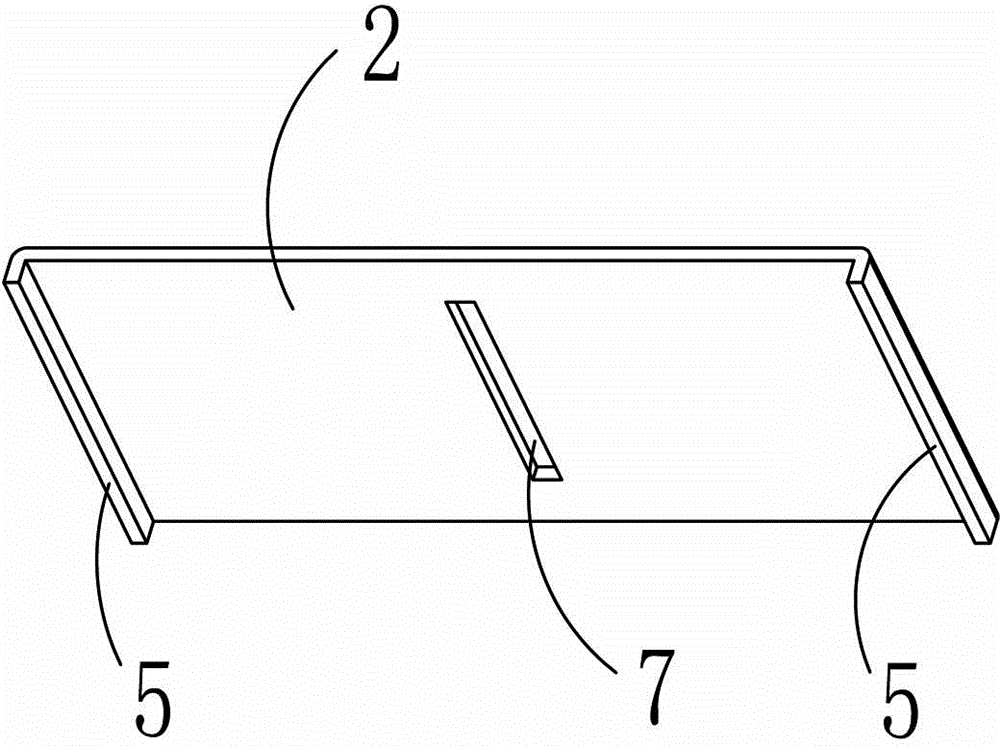

Double-sided metal clad plate and manufacturing method thereof

InactiveCN101513785ALuxurious decorative effectHigh-grade decorative effectLamination ancillary operationsSpecial ornamental structuresNonferrous metalFlexural strength

The invention discloses a double-sided metal clad plate and a manufacturing method thereof. The double-sided metal clad plate is jointly formed by a panel, a substrate and high polymer material in an intermediate layer. The panel chooses a nonferrous metal foil with the thickness of 0.05-1.5mm or a plate as a plane material, the material of which can be red copper, brass, titanium or stainless steel. The substate chooses a common metal plate with the thickness of 0.1mm-3mm as a base material, the material of which can be galvanized steel or antirust aluminum. The high polymer material can be used as an alite paste. A thin nonferrous metal and a thick common metal plate, the middle of which is lined with the higher polymer material, are made into the double-sided metal clad plate by the lamination technique. The metal clad plate has enough shearing strength and bending strength and is a new material which can be further processed by the cold-bending molding technique. The invention has simple manufacturing process and novel structure, is in line with the processing requirement and uses different materials for synthesizing advanced composite material to replace former precious nonferrous metals, thus greatly reducing the cost.

Owner:上海鑫型金属复合材料有限公司

High-tech health-care titanium ceramic material

The invention discloses a high-tech health-care titanium ceramic material. The material consists of the following components in percentage by weight: 0.1 to 2 percent of titanium oxide, 84.572 to 87.605 percent of zirconium oxide, 4.622 to 4.758 percent of iridium oxide, 1.962 to 2.088 percent of aluminum oxide, 2.156 to 2.463 percent of silicon oxide, 1.716 to 2.364 percent of hafnium oxide, 0.132 to 0.206 percent of magnesium oxide and 1.435 to 1.811 percent of other oxides. Negative ions and far infrared rays produced by the material are far more than those of the ordinary zirconium oxide ceramic product and the metabolism and blood circulation of a human body are promoted.

Owner:CARIDAR CLOCKS WATCHES CO LTD

Titanium oxide-titanium carbide whisker toughened magnesium alloy biomedical material

The invention belongs to the field of biomedical materials and particularly relates to a titanium oxide-titanium carbide whisker toughened magnesium alloy biomedical material. The titanium oxide-titanium carbide whisker toughened magnesium alloy biomedical material is composed of magnesium alloy substrate material powder and titanium oxide-titanium carbide whisker powder; the magnesium alloy substrate material powder and the titanium oxide-titanium carbide whisker powder are uniformly mixed through a mechanical mixing method; the mixed powder is subjected to cold pressing, vacuum heating degassing and vacuum sintering; and a heat pressing ingot is subjected to equal channel deformation, so that the titanium oxide-titanium carbide whisker toughened magnesium alloy biomedical material is obtained. The toughness, the abrasion resistance and the strength of in-situ generated titanium oxide-titanium carbide whisker toughened magnesium alloy are remarkably improved, and the in-situ generated titanium oxide-titanium carbide whisker toughened magnesium alloy is especially suitable for the biomedical material and also can be applied to parts such as high-end sports car magnesium alloy hubs requiring for high strength and high abrasion resistance.

Owner:SHANDONG JIANZHU UNIV

Zirconium oxide and zirconium carbide composite reinforced titanium oxide-based multi-element nano-composite ceramic die

The invention discloses a zirconium oxide and zirconium carbide composite reinforced titanium oxide-based multi-element nano-composite ceramic die. The die comprises the following raw materials in parts by weight: 60-80 parts of titanium oxide, 10-20 parts of zirconium carbide, 15-25 parts of zirconium oxide, 2-6 parts of praseodymium oxide, 4-8 parts of dysprosium oxide, 2-4 parts of nickel, 1-3 parts of cobalt and 1-3 parts of magnesium oxide, wherein nanoscale powder of all the raw materials is adopted; the grain size of titanium oxide is 10-100 nanometers; the grain sizes of zirconium carbide and zirconium oxide are 1-10 nanometers; the grain sizes of the other raw materials are 1-100 nanometers. A preparation method is characterized by using titanium oxide as the matrix, adding zirconium carbide and zirconium oxide as reinforcing phases, praseodymium oxide and dysprosium oxide as stabilizing agents and nickel, cobalt and magnesium oxide as sintering aids and carrying out hot pressed sintering on the materials, thus preparing the die. The die has strong ageing and defect resistance, good comprehensive mechanical properties and excellent antifriction and wear resistance properties.

Owner:潮州市嘉裕陶瓷制作有限公司

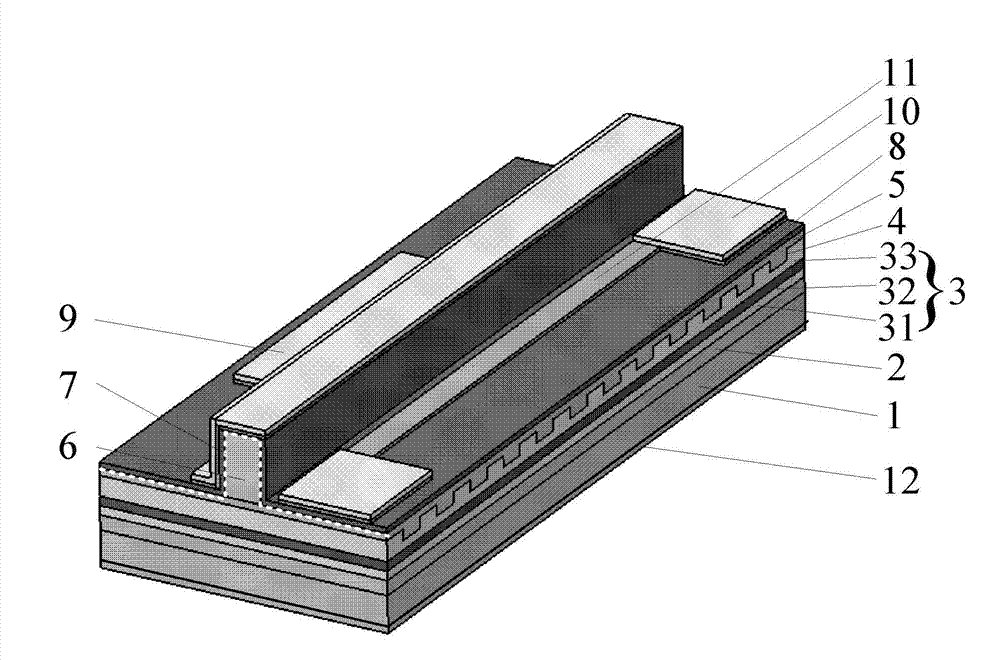

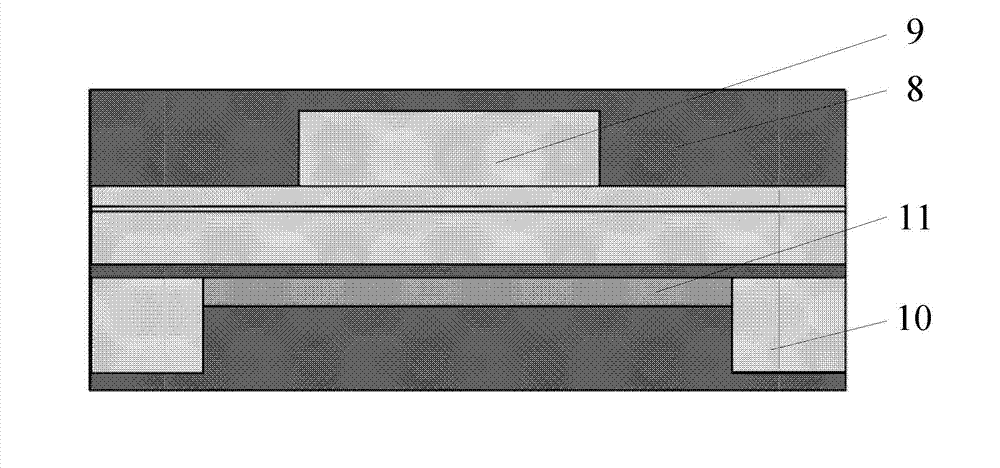

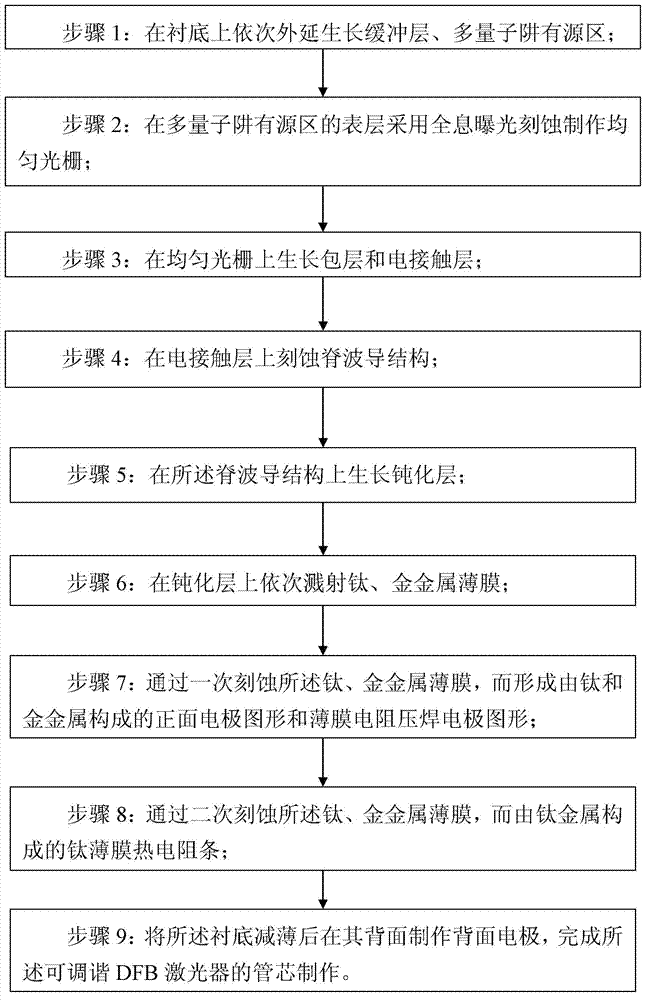

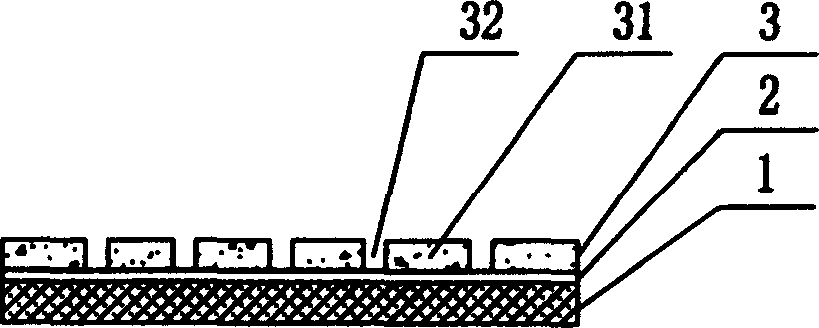

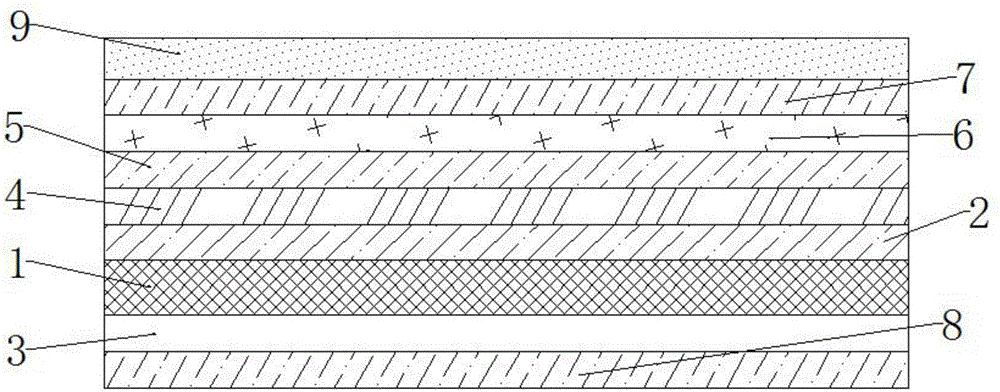

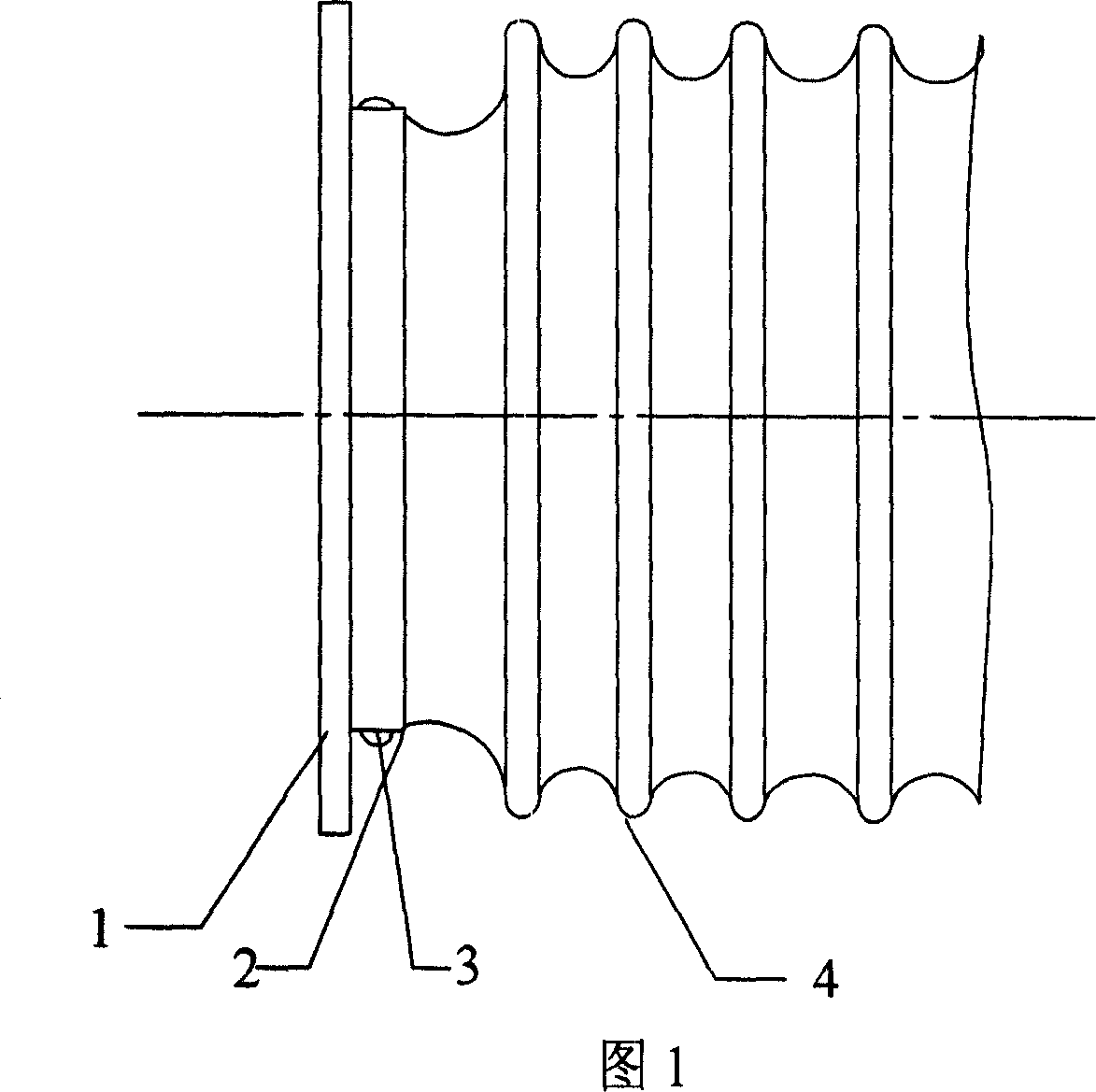

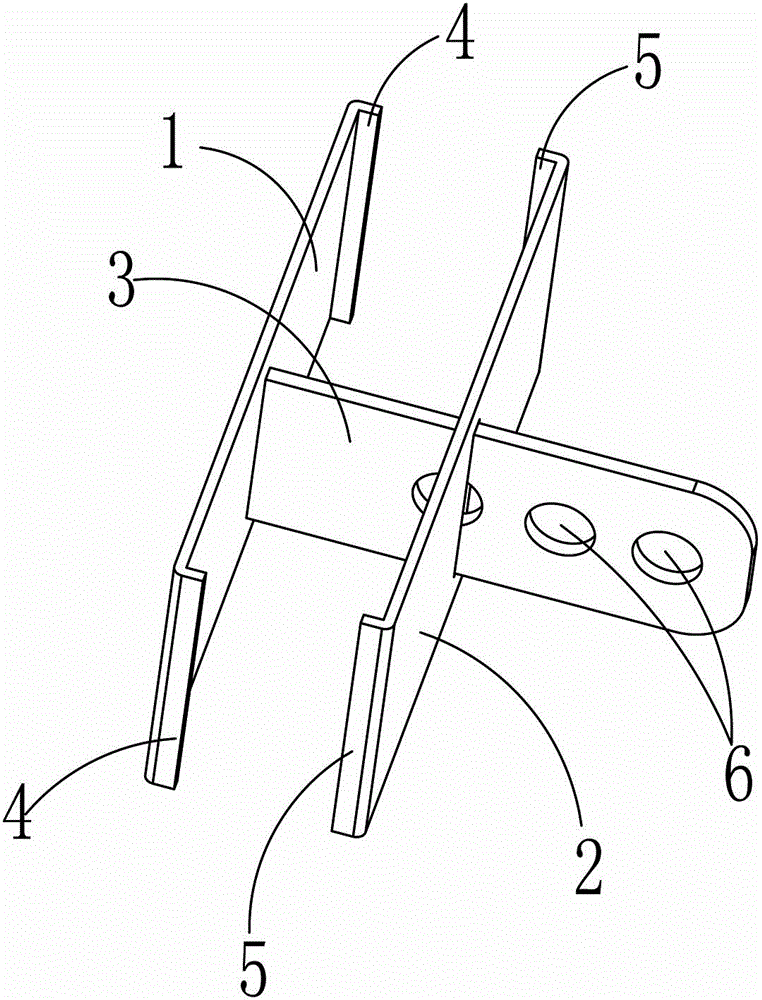

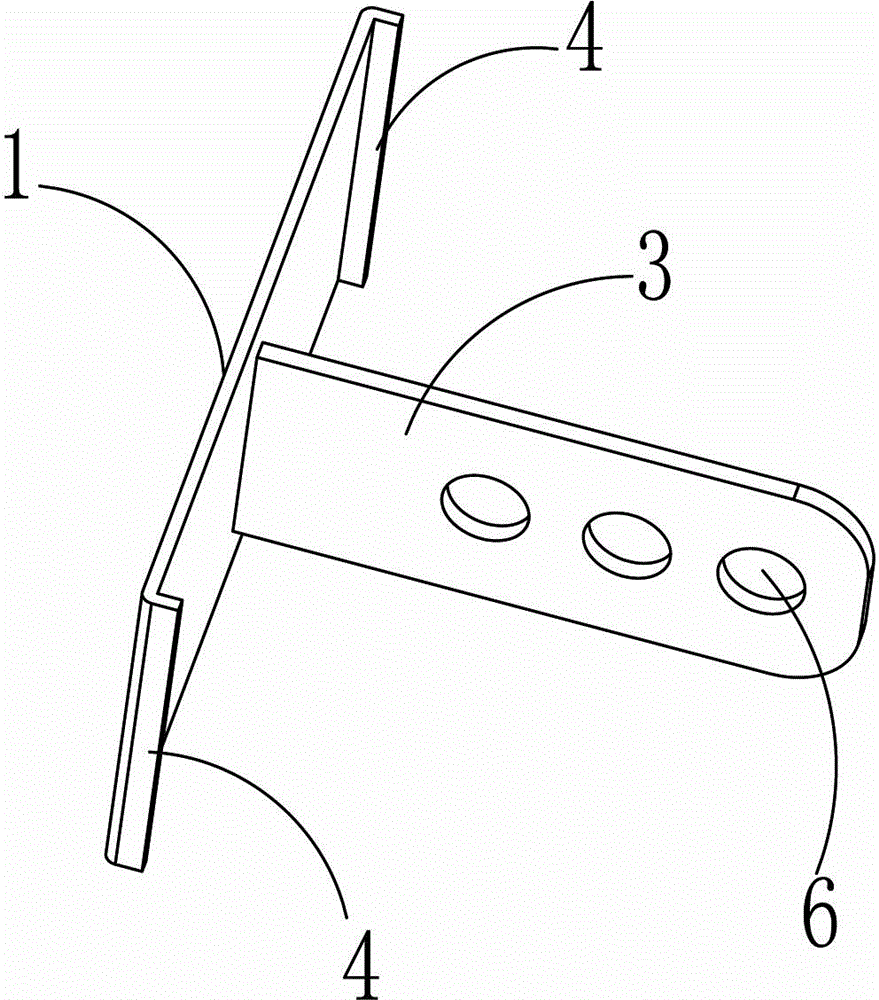

Manufacture method for monolithic integration titanium film thermal resistor tunable distributed feed back (DFB) laser

ActiveCN103094832AHigh resistivityHigh current tuning efficiencyLaser detailsLaser optical resonator constructionGratingWaveguide

The invention discloses a manufacture method for a monolithic integration titanium film thermal resistor tunable distributed feed back (DFB) laser. The manufacture method comprises the steps of selecting an indium phosphide substrate 1, sequentially and epitaxially growing a buffer layer 2 and a multiple quantum wells active area 3 on the substrate 1, manufacturing even gratings 4 on the surface layer of the multiple quantum wells active area 3 by adopting holographic exposure etching, growing a cladding 5 and an electric contact layer 6 on the even gratings 4, adopting a regular photoetching and etching process, manufacturing a ridge waveguide structure 7 on the electric contact layer 6, growing a passivation layer 8 on the manufactured ridge waveguide structure 7, sputtering titanium and gold metal film on the passivation layer 8 after a front face electrode window is opened by adopting regular photoetching, coating photoresist on the metal film, photoetching a front face electrode pattern 9, a film resistor pressure welding electrode pattern 10 and a film resistor area 11 for once, photoetching and selectively etching for twice to form a titanium film thermal resistor strip 11, manufacturing a back face electrode 12 on the back face of the substrate 1 after the indium phosphide substrate 1 is thinned, and achieving manufacturing of a tube core.

Owner:INST OF SEMICONDUCTORS - CHINESE ACAD OF SCI

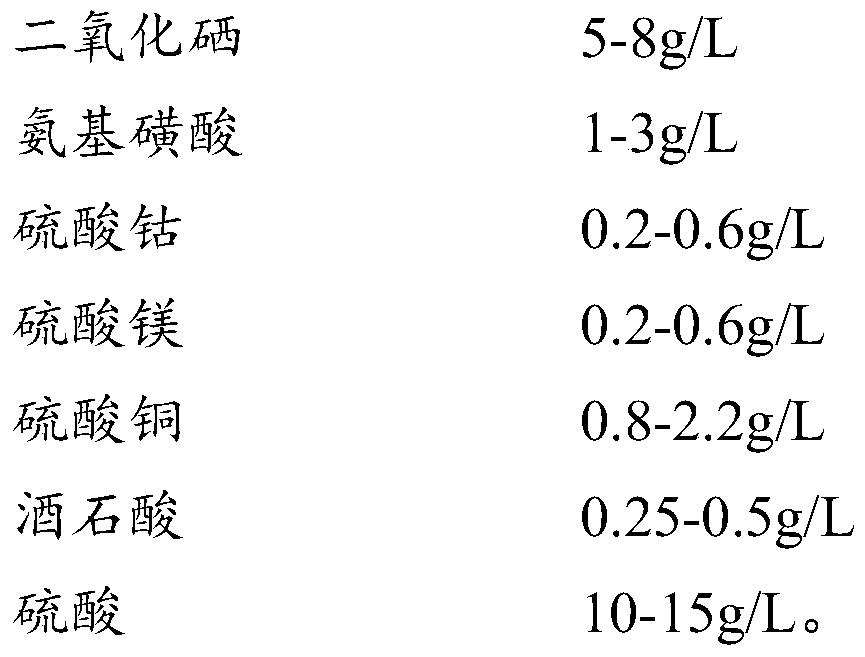

Aluminum profile anode oxide film titanium gold electrolytic coloring production process

InactiveCN109183120APrevent fadingExcellent coloring effectAnodisationElectrolysisWeather resistance

The invention discloses an aluminum profile anode oxide film titanium gold electrolytic coloring production process comprising the following processing steps of degreasing, water washing, water washing, alkali corrosion, anodic oxidation, water washing, water washing, activating treatment, electrolytic coloring, water washing, water washing, hole sealing and water washing. An electrolytic coloringagent in the electrolytic coloring step comprises, by weight, 10%-20% of selenium dioxide, 2%-8% of magnesium sulfate, 3%-7% of sulfuric acid, and the balance water. Trough solution in an electrolytic coloring trough comprises 40-50g / L of electrolytic colorant, 20-25g / L of free sulfuric acid, and the balance water. In the electrolytic coloring processing step, the trough solution in the electrolytic coloring trough is 40-50 DEG C, the voltage is 15-17 v, and coloring time is 0.5-8 min. A titanium gold aluminum profile prepared with the production process provided by the invention is bright incolor, a coloring film is uniform and stable in color and good in quality, no color fading problem exists in the use process, high weather resistance is achieved, and mass production can be formed.

Owner:FOSHAN HAIHUA SURFACE TREATMENT TECH CO LTD

Metal plated and polished ceramic products and their manufacture

Owner:佛山市贝丘文化陶瓷有限公司

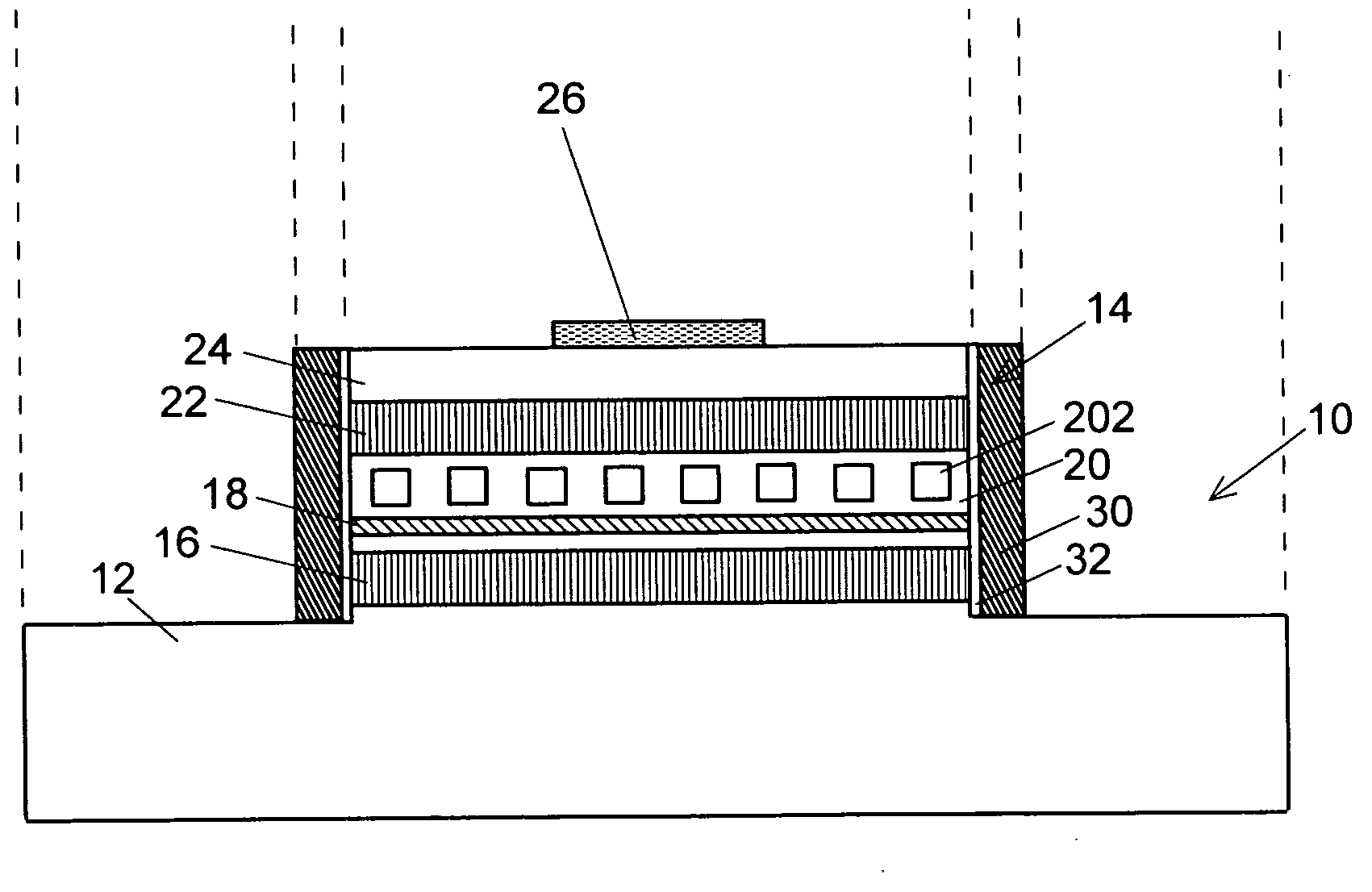

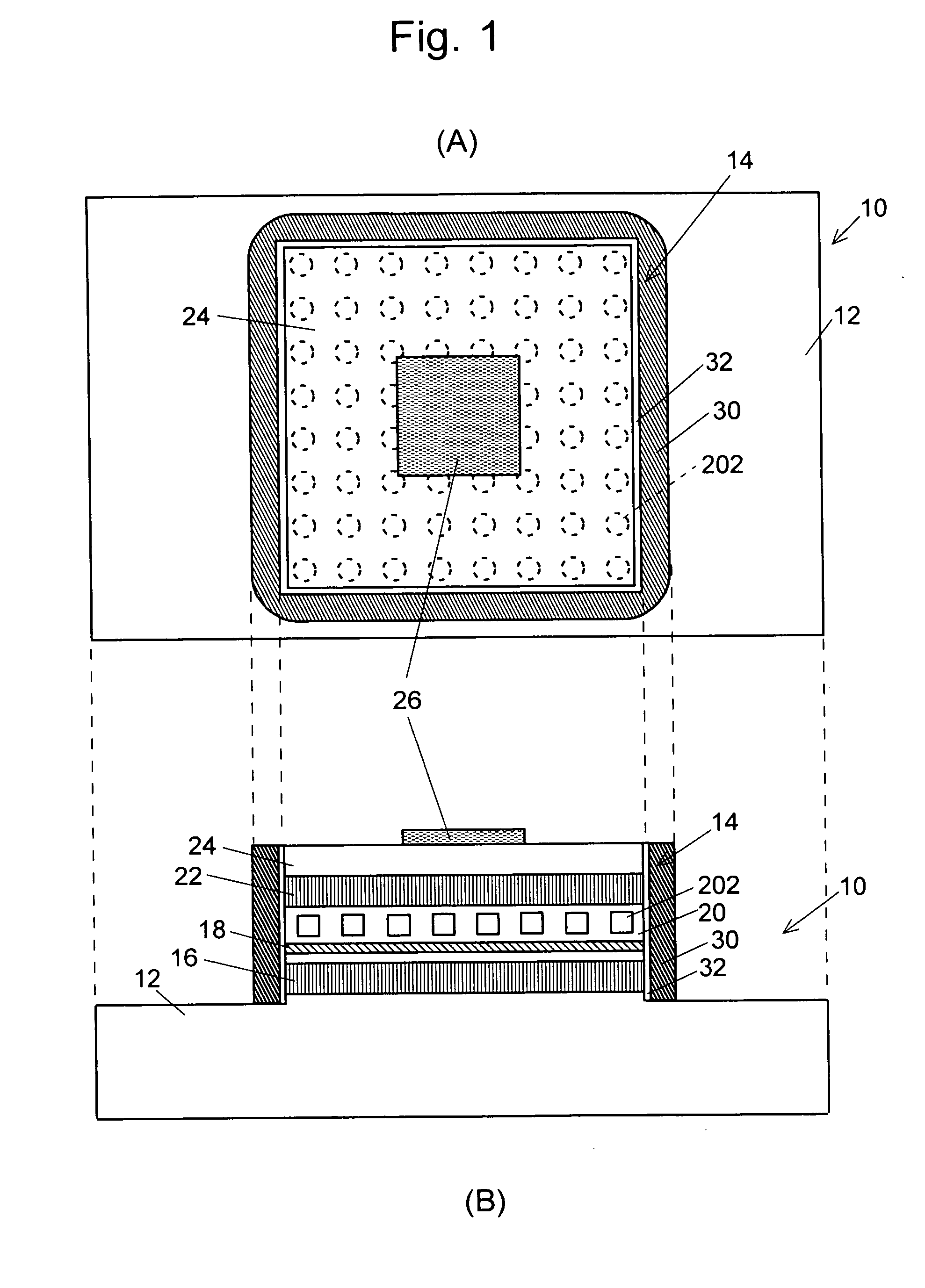

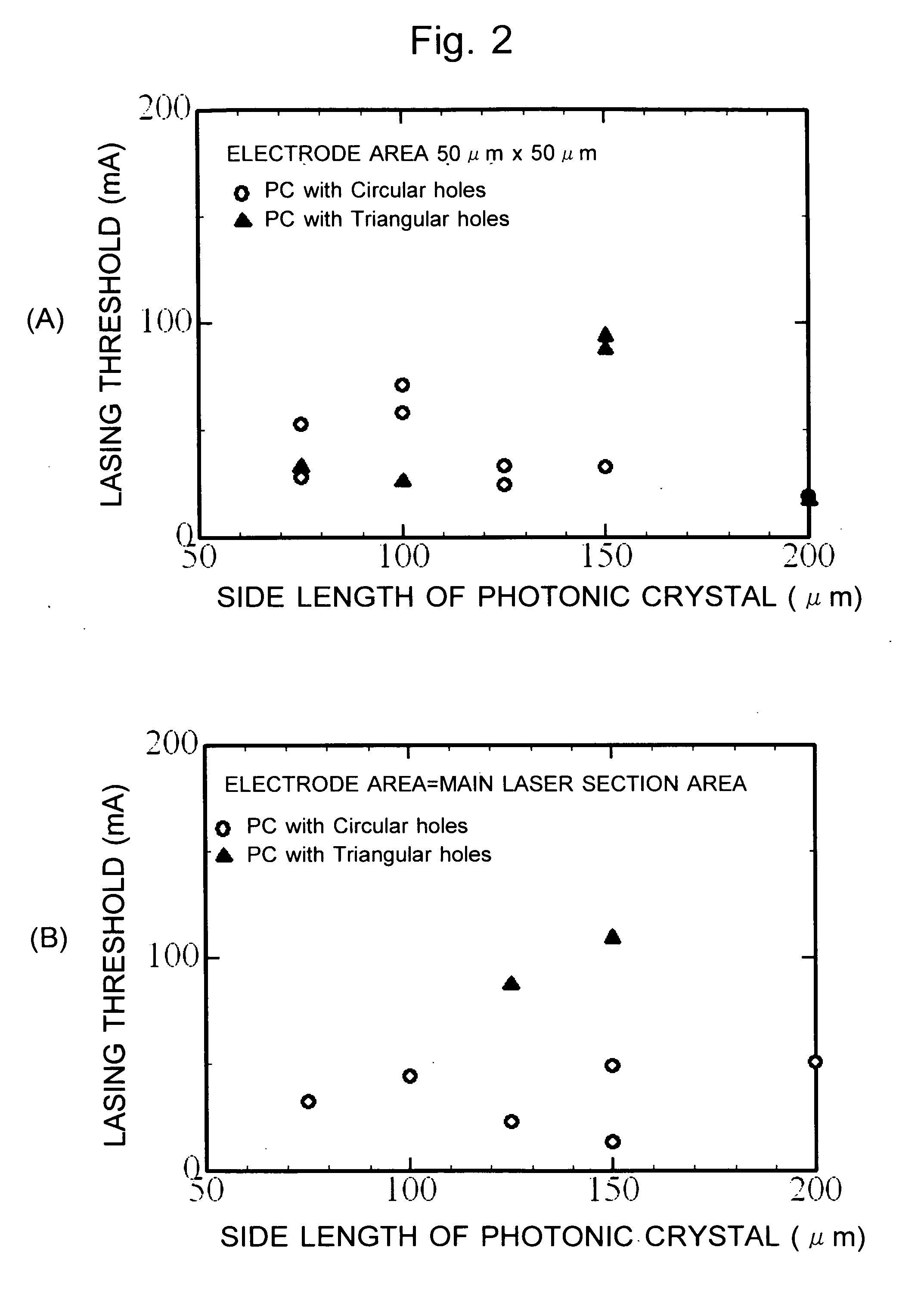

Two-dimensional photonic crystal surface-emitting laser

ActiveUS20080240193A1Improve the level ofEasy to produceOptical resonator shape and constructionNanoopticsPhotonic crystalContact layer

The two-dimensional photonic crystal surface emitting laser according to the present invention includes a semiconductor substrate, a main laser section and a reflection film. The main laser section includes a lower cladding layer, an active layer, a two-dimensional photonic crystal layer, an upper cladding layer and a contact layer, which are all deposited on the semiconductor substrate. The reflection film, which surrounds the entire side surfaces of the main laser section, is made of a thin titanium-gold film deposited by sputtering.

Owner:KYOTO UNIV +1

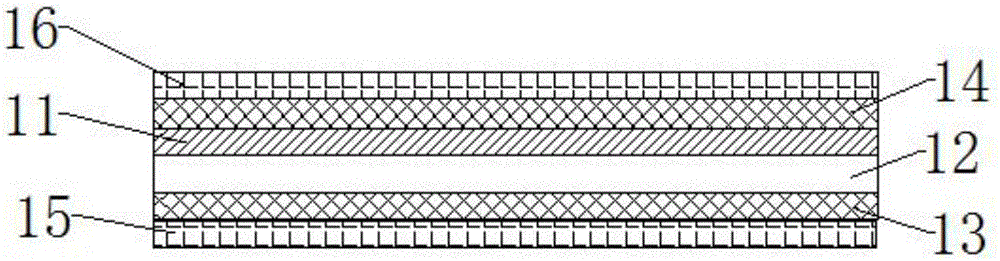

Method for preparing high-strength titanium and aluminum foil clad steel plate

InactiveCN106079774AReasonable structureNovel structureSynthetic resin layered productsLaminationChemical treatmentSheet steel

The invention provides a method for preparing a high-strength titanium and aluminum foil clad steel plate. The high-strength titanium and aluminum foil clad steel plate comprises a base plate, wherein a first chemical treatment layer is arranged on the upper side of the base plate, a second chemical treatment layer is arranged on the lower side of the base plate, and a back paint layer is arranged on the lower side of the second chemical treatment layer; a ground paint layer is arranged on the upper side of the first chemical treatment layer, a binder layer is arranged on the upper side of the ground paint layer, and an aluminum foil layer is arranged on the upper side of the binder layer; the upper side of the aluminum foil layer is covered with a PET film layer, and the upper side of the PET film layer is covered with a PE film; the base plate comprises a stainless steel plate, a titanium plate is arranged on the lower side of the stainless steel plate, a lower zinc coating is arranged on the lower side of the titanium plate, and an upper zinc coating is arranged on the upper side of the stainless steel plate; a lower aluminum foil cladding layer is arranged on the lower side of the lower zinc coating, and an upper aluminum foil cladding layer is arranged on the upper side of the upper zinc coating. The high-strength titanium and aluminum foil clad steel plate is reasonable and novel in structure, stable in quality and convenient to machine, and machining efficiency is use can be improved; furthermore, appearance is attractive, touch sense is good, and the high-strength titanium and aluminum foil clad steel plate can be widely applied to panels of various household appliances.

Owner:合肥禾盛新型材料有限公司

Fading proof process for aluminum alloy electrophoresis titanium gold

ActiveCN102817060AImprove heat resistanceImproves UV resistanceSurface reaction electrolytic coatingElectrophoresisGold colour

The invention discloses a fading proof process for aluminum alloy electrophoresis titanium gold. The process is characterized by comprising degreasing, alkaline etching, oxidation, electrolytic coloring for 7-12 min at 25-35 DEG C, moderate temperature sealing at 45-60 DEG C for 1-3 min, hot water washing, electrophoresis with voltage of 120-140 volt and curing. The electrophoresis titanium section produced by the invention does not show a color shallowing problem after electrophoresis baking or a fading problem in a usage process, and has good popularization value.

Owner:佛山金兰铝厂有限公司

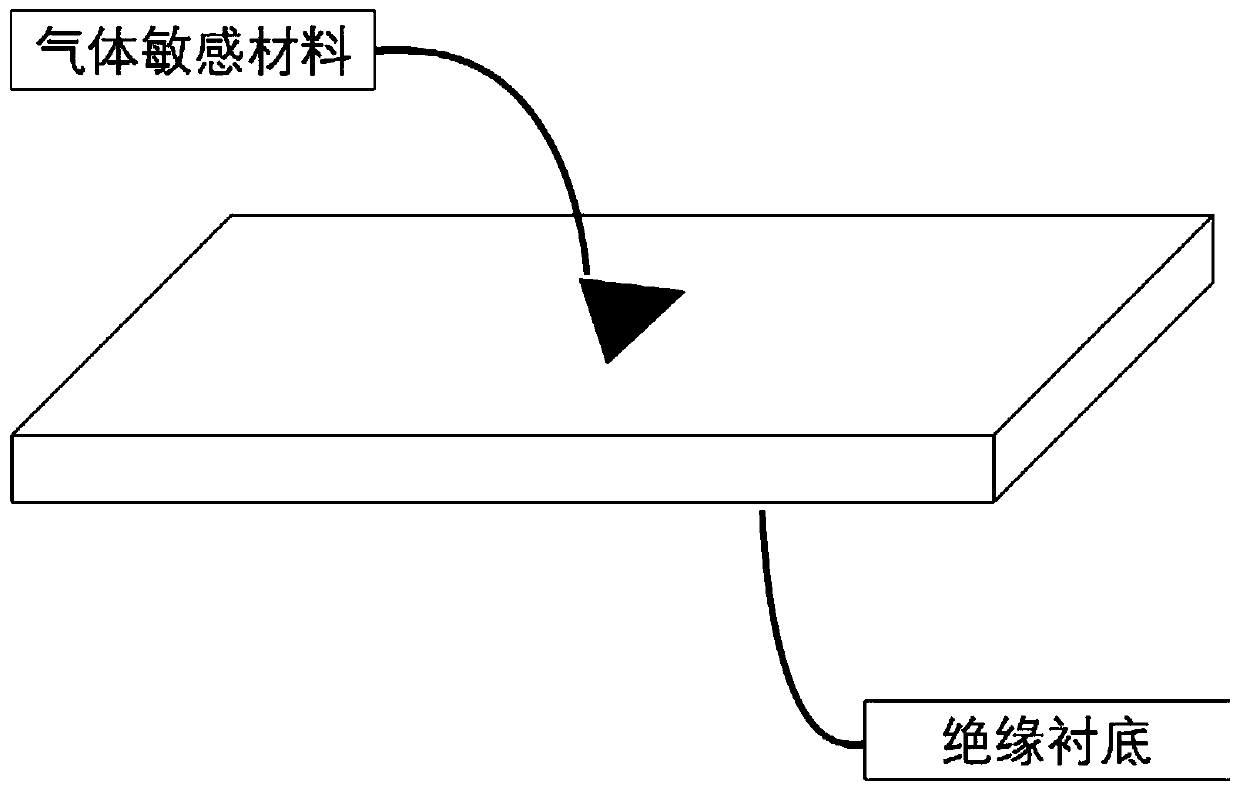

Method for improving sensitivity of gas sensor

InactiveCN110940709AHigh sensitivityVersatilityMaterial resistanceSolid-state physicsChemical physics

The invention relates to a method for improving the sensitivity of a gas sensor, and belongs to the field of gas sensors and the field of solid physics. Manganese or magnesium metal is adopted as an electrode material in contact with a gas sensitive material, and the characteristic that the manganese or magnesium metal has a lower work function than titanium, gold and other materials is utilized,so that the effect of improving the sensitivity of the gas sensor only by changing the material used by the contact electrode is achieved. According to the method for improving the sensitivity of thegas sensor, the metal with the large work function difference value with the gas sensitive material serves as the metal connected with the gas sensitive material, and the sensitivity of the gas sensorcan be improved. The method for improving the sensitivity is simple, and does not have strong requirements on environmental conditions in the use process.

Owner:BEIJING INSTITUTE OF TECHNOLOGYGY

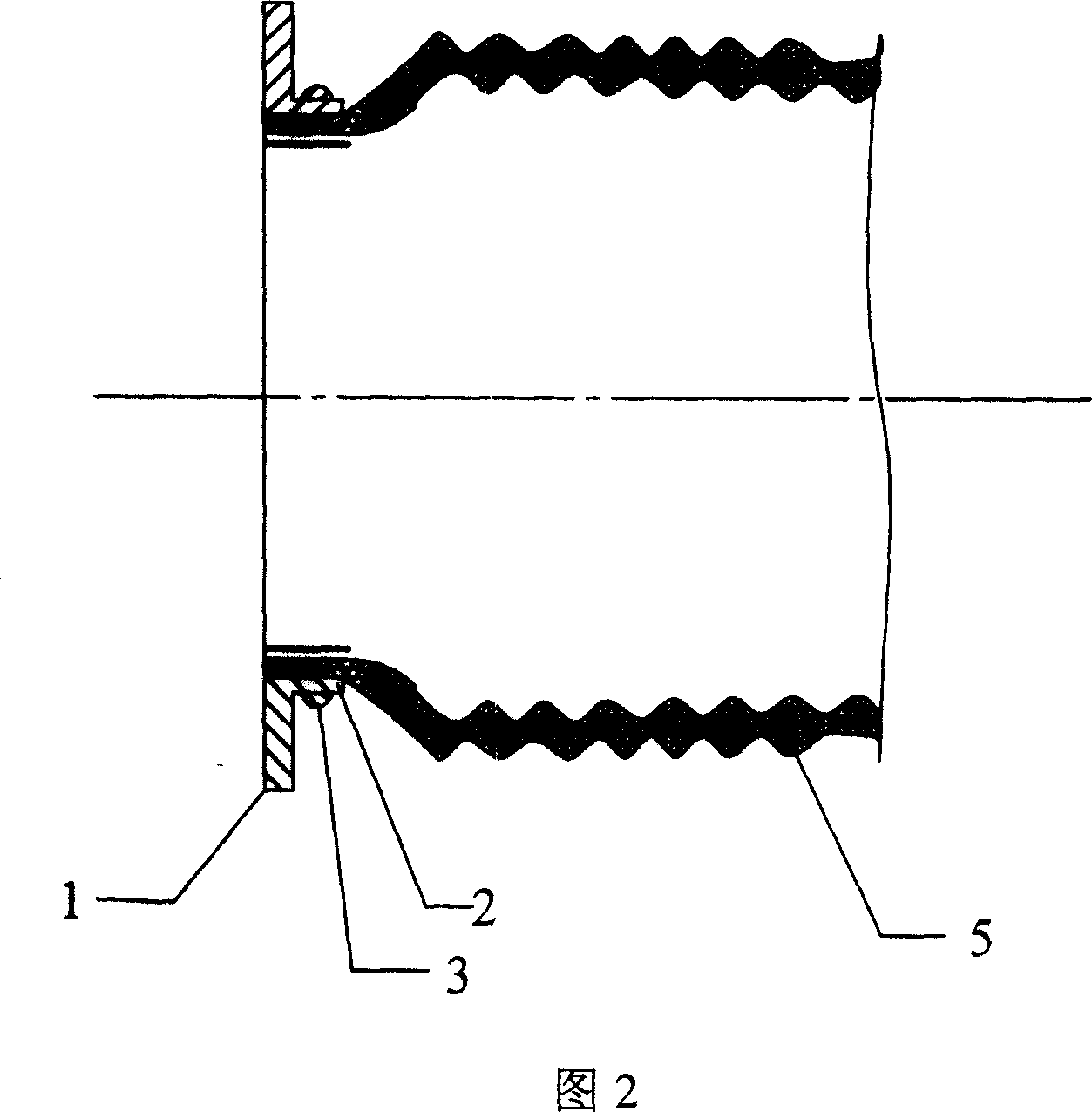

Silicon fiber Ti-gold no-burning flexible joint

InactiveCN101033814AOvercoming usage defectsImprove fire performanceFlexible pipesGlass fiberFire protection

The invention discloses a kind of silica fiber titanium gold non-ignitable soft joint which is made by silica fiber titanium gold non-ignitable material. The production technical process of this silica fiber titanium gold non-ignitable material is that: weave the base by using the glass fabric; make the glass fabric immersed the rubber; treat it by sub-salt, shoot off and curing; coat special siliceous rubber and siliceous titaniferous rubber; compose silica fiber titanium gold cloth. The silica fiber titanium gold non-ignitable soft joint of this invention makes the silica fiber titanium gold non-ignitable material instead of the aluminum foil glass thread and resolves the use flaw of the modern soft pipe thoroughly and improve the fire protection performance of it largely.

Owner:BEIJING FUWEIFENG BUILDING TECH CO LTD

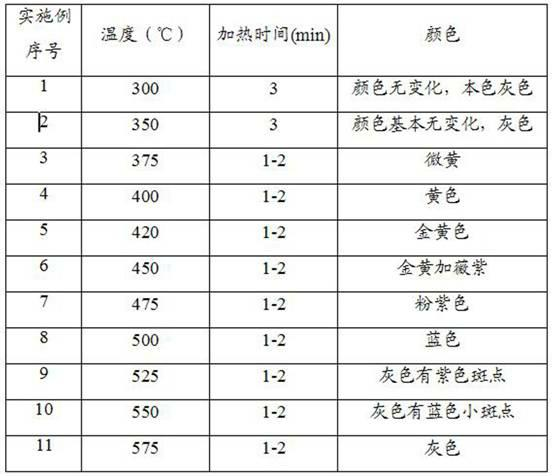

Titanium surface coloring process

InactiveCN102330050AColoring firmSave electricitySolid state diffusion coatingTitanium surfaceTitanium gold

The invention relates to the field of metal surface machining treatment, in particular to a titanium surface coloring process. According to the invention, the titanium surface coloring process comprises material selection, surface polishing treatment, constant temperature furnace heating coloring treatment and more. By using the titanium surface coloring process provided by the invention, no chemical reagent is needed in the whole process and pollution and potential safety hazard are effectively avoided; according to the invention, the titanium surface can be treated into different colors through adjusting the temperature of the constant temperature furnace and the constant temperature acting time; and the titanium surface coloring process provided by the invention has the advantages of simple process, short time, convenience in operation and the like.

Owner:SHENZHEN WOLFERS IND CO LTD

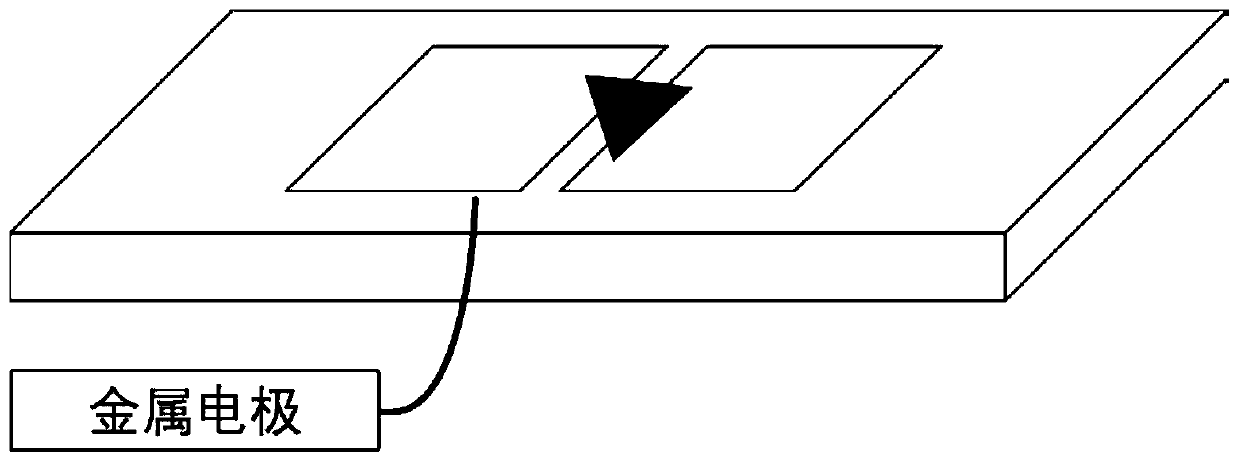

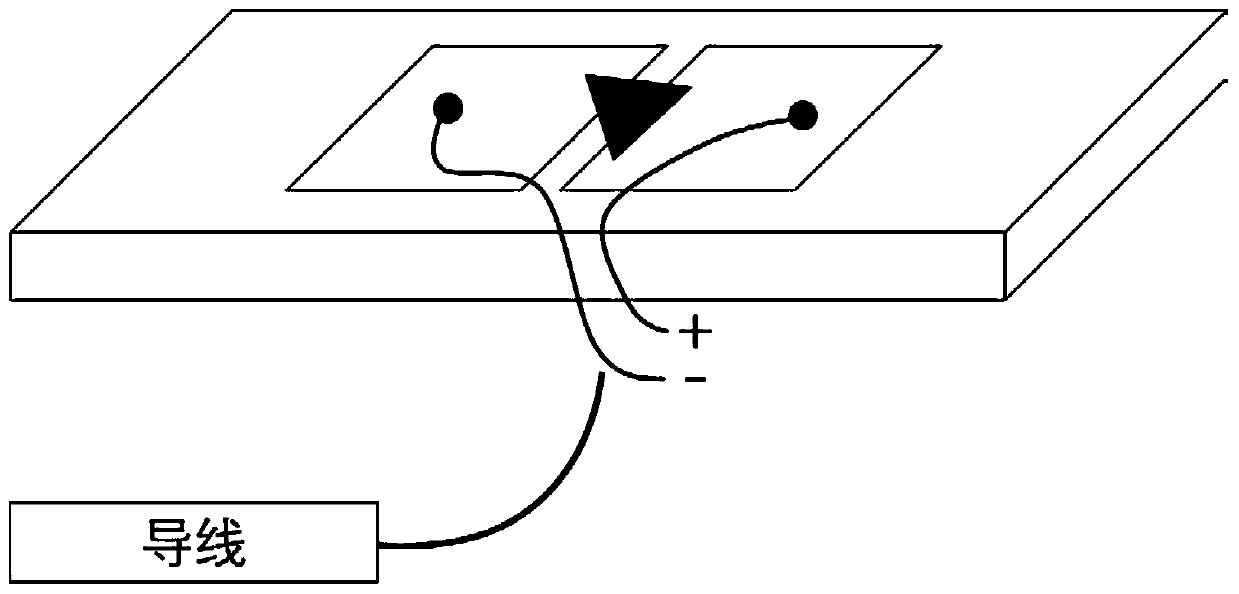

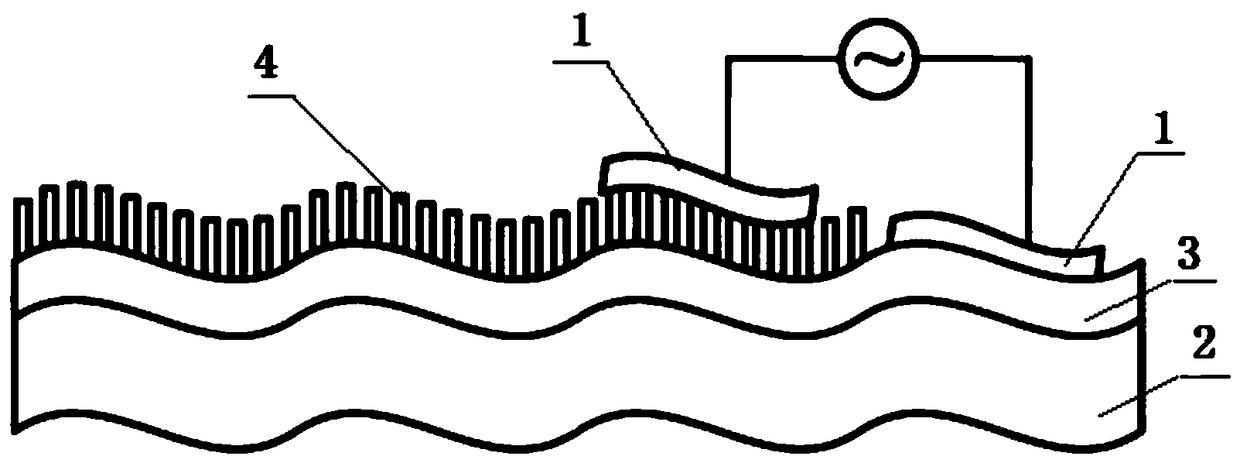

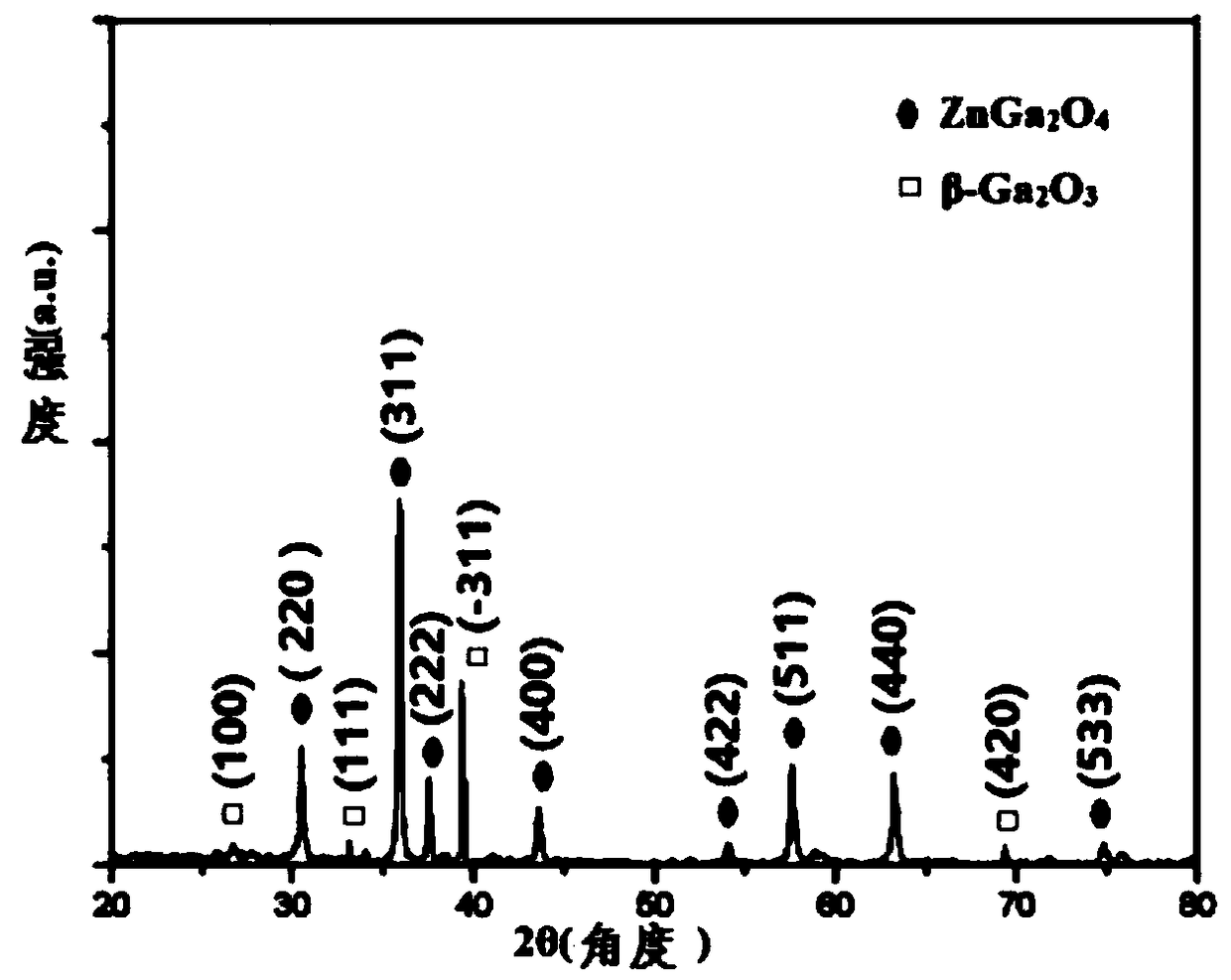

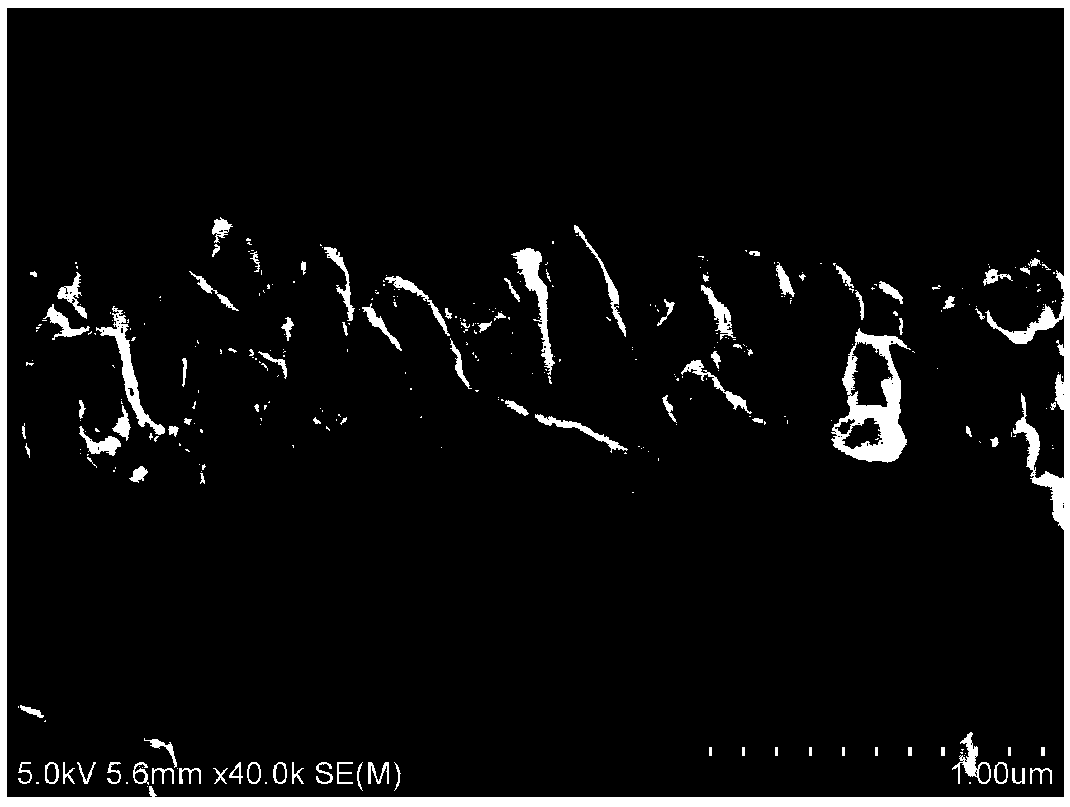

Flexible gas sensitive sensor based on gallium oxide/zinc gallate hetero-junction nano-array and preparation method thereof

ActiveCN108982600AImprove gas-sensing propertiesEasy to separateMaterial resistanceHeterojunctionGlass fiber

The invention relates to a flexible gas sensitive sensor based on a gallium oxide / zinc gallate hetero-junction nano-array and a preparation method thereof. The flexible gas sensitive sensor comprisestwo Ti / Au (Titanium Gold) electrodes, a flexible glass fiber cloth substrate, a ZnGa2O4 film located on the flexible glass fiber cloth substrate, and a beta-Ga2O3 nano-column array located on the ZnGa2O4 film; the two Ti / Au electrodes are respectively located above the ZnGa2O4 film and the beta-Ga2O3 nano-column array; the gallium oxide / zinc gallate hetero-junction nano-array is formed by the ZnGa2O4 film and the beta-Ga2O3 nano-column array. The sensor provided by the invention is an MSSM type hetero-junction flexible gas sensitive sensor in a Ti / Au / beta-Ga2O3 / ZnGa2O4 / Ti / Au structure, has a three-dimensional space hetero-junction interface structure, is stable in gas sensitive characteristics, flexible and bendable and low in working temperature and power consumption, can be used for detection of flexible wearable ethanol gas, and has great application prospects in fields such as production and monitoring of industrial alcohol and detection of drunk driving.

Owner:东营睿港招商服务有限责任公司

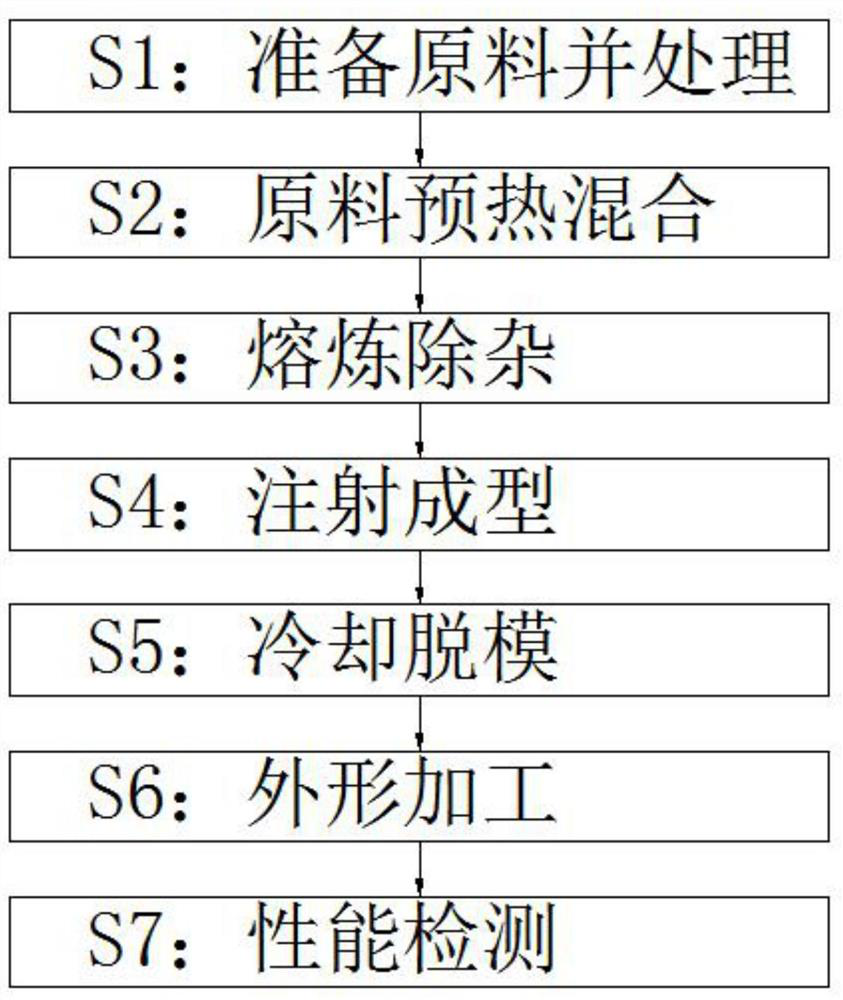

Preparation method for metal injection molding of titanium alloy composite material

The invention belongs to the technical field of titanium alloy composite metal preparation, particularly relates to a preparation method for metal injection molding of a titanium alloy composite material, and provides the following scheme now to solve the problems that traditional titanium alloy metal materials are mainly subjected to die casting, stirring casting and other methods, but the methods are generally complex in process equipment, high in cost and poor in preparation quality. The preparation method comprises the following preparation steps that S1, raw materials are prepared and treated; S2, the raw materials are preheated and mixed; S3, smelting and impurity removal are performed; S4, injection molding is performed; S5, cooling and demolding are performed; S6, shape machining is performed; and S7, performance detection is performed; the raw materials in S1 include titanium powder, a binder, boron carbide powder, aluminum powder, magnesium powder, copper powder, nickel powder, carbon fiber powder and a modifier. The preparation method is easy and convenient to operate, adopts an injection mode, can realize integral forming, and reduces the preparation difficulty; various metals and fibers are added during preparation, so that the strength and toughness of the composite material can be improved.

Owner:HAIAN YINGQIU POWDER METALLURGY CO LTD

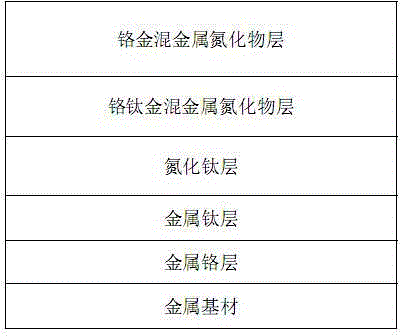

Composite film and film plating method thereof

ActiveCN102719789ALower resistanceDoes not affect conductivityVacuum evaporation coatingSputtering coatingFilm resistanceComposite film

The invention discloses a composite film and a film plating method thereof. The surface of a metal base material is plated with the composite film and the composite film comprises a metal chromium layer, a metal titanium layer, a titanium nitride layer, a chromium-titanium mixing metal nitride layer and a chromium mixing metal nitride layer successively from the metal base material to outside. The plating method thereof comprises the following steps: plasma treatment is performed on the metal base material to enhance the surface activity of the metal base material; the surface of the metal base material is plated with the metal chromium layer, the metal titanium layer, the titanium nitride layer, the chromium-titanium mixing metal nitride layer and the chromium mixing metal nitride layer successively; after the film plating, heating is stopped and the plated metal base material is taken out when the metal base material is cooled to below 100 DEG C. Modification treatment is performed on a simple-substance metal film to enhance the abrasive resistance and the corrosion resistance of the surface of the metal base material and keep long-term appearance beauty and value of the metal base material. The adhesive force and the mechanical resistance strength of the film are good. In addition, the film resistance is low, thus the conductivity performance of the metal surface is not affected.

Owner:GUANGDONG JANUS SMART GRP CO LTD

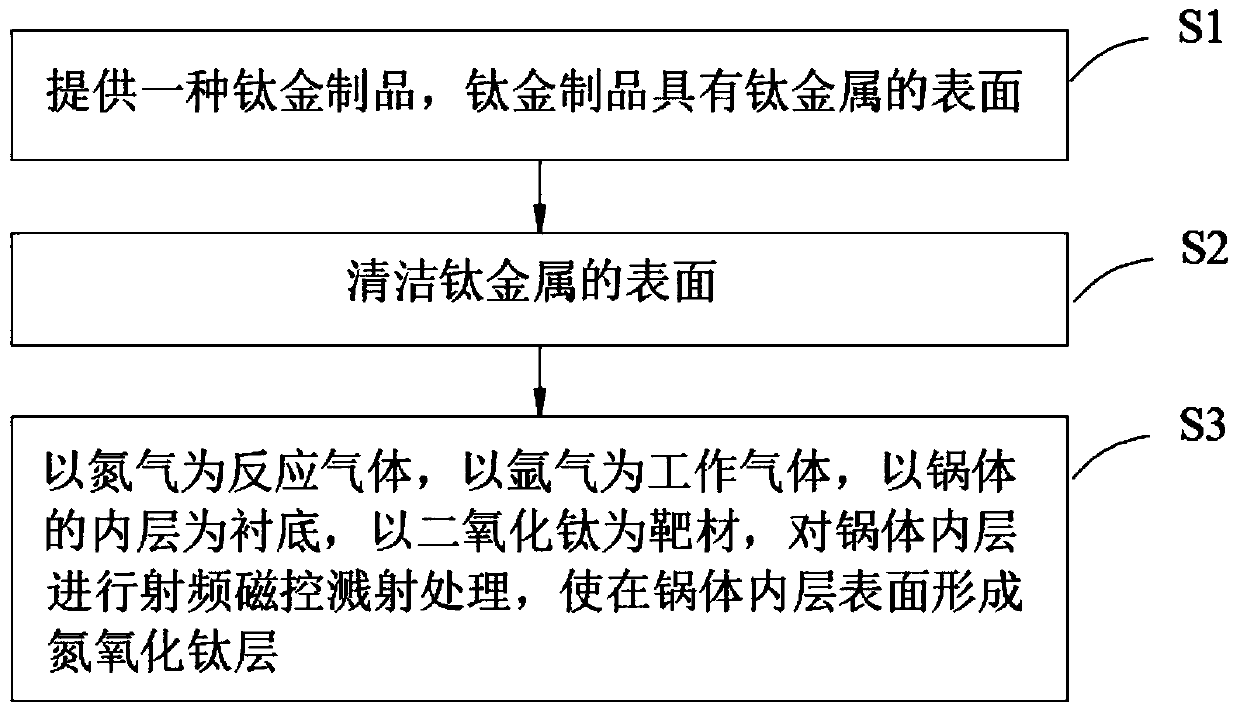

Preparation method of antibacterial titanium product

InactiveCN111424236AGood antibacterial effectHydrophilicVacuum evaporation coatingSputtering coatingRadio frequency magnetron sputteringTitanium metal

The invention provides a preparation method of an antibacterial titanium product. The preparation method comprises the following steps that S1, a titanium product is provided, wherein the titanium product is provided with a titanium metal surface; S2, the titanium metal surface is cleaned; and S3, nitrogen serves as reaction gas, argon serves as working gas, the titanium metal surface serves as asubstrate, titanium dioxide serves as a target material, radio frequency magnetron sputtering treatment is conducted on the titanium metal surface, and a titanium oxynitride film is formed on the titanium metal surface. According to the method, the titanium oxynitride film can be formed on the titanium metal surface of the titanium product, the nitrogen element is introduced into a crystal latticeor a crystal boundary of titanium dioxide, the impurity energy level and the defect energy level are introduced into a titanium dioxide forbidden band gap, the excitation energy borne by the titaniumdioxide forbidden band gap is reduced, the band gap of titanium dioxide is reduced, the light absorption range of titanium dioxide is widened, and the antibacterial effect of the titanium product isimproved.

Owner:JINYUN COUNTY TAI JI KE JI

High-brightness special titanium gold ink

The invention provides high-brightness special titanium gold ink, which meets the coloring requirement. In addition, the color does not change at high and low temperatures; meanwhile, the alcohol resistance is realized; eraser test requirements are met. The high-brightness special titanium gold ink is characterized by being prepared from the following ingredients including 5 to 7 percent of aluminum powder with the particle diameter being 20 mum, 5 to 7 percent of aluminum powder with the particle diameter being 5 mum, 58 to 62 percent of transparent ink, 3 to 5 percent of red color masterbatch, 8 to 12 percent of mirror surface gold, 2 to 2.5 percent of original yellow ink and the balance special ink curing agents through being metered in percentage by mass. The sum of the percentage of all substances is 100 percent.

Owner:SUZHOU ANJIE TECH

A titanium oxide-titanium carbide whisker toughened magnesium alloy biomedical material

ActiveCN106119742BImprove toughnessImprove corrosion resistanceProsthesisTitanium carbideTitanium oxide

The invention belongs to the field of biomedical materials and particularly relates to a titanium oxide-titanium carbide whisker toughened magnesium alloy biomedical material. The titanium oxide-titanium carbide whisker toughened magnesium alloy biomedical material is composed of magnesium alloy substrate material powder and titanium oxide-titanium carbide whisker powder; the magnesium alloy substrate material powder and the titanium oxide-titanium carbide whisker powder are uniformly mixed through a mechanical mixing method; the mixed powder is subjected to cold pressing, vacuum heating degassing and vacuum sintering; and a heat pressing ingot is subjected to equal channel deformation, so that the titanium oxide-titanium carbide whisker toughened magnesium alloy biomedical material is obtained. The toughness, the abrasion resistance and the strength of in-situ generated titanium oxide-titanium carbide whisker toughened magnesium alloy are remarkably improved, and the in-situ generated titanium oxide-titanium carbide whisker toughened magnesium alloy is especially suitable for the biomedical material and also can be applied to parts such as high-end sports car magnesium alloy hubs requiring for high strength and high abrasion resistance.

Owner:SHANDONG JIANZHU UNIV

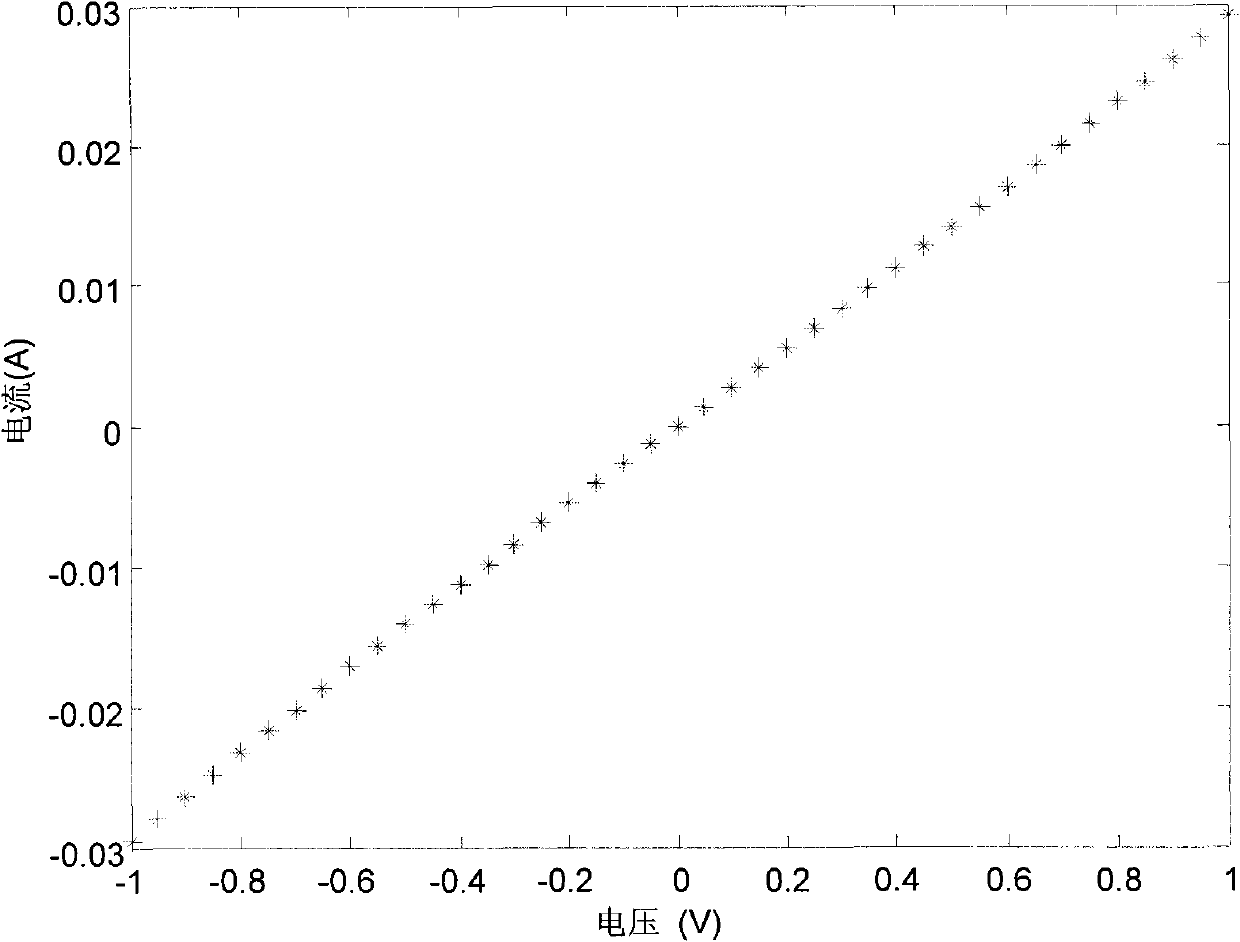

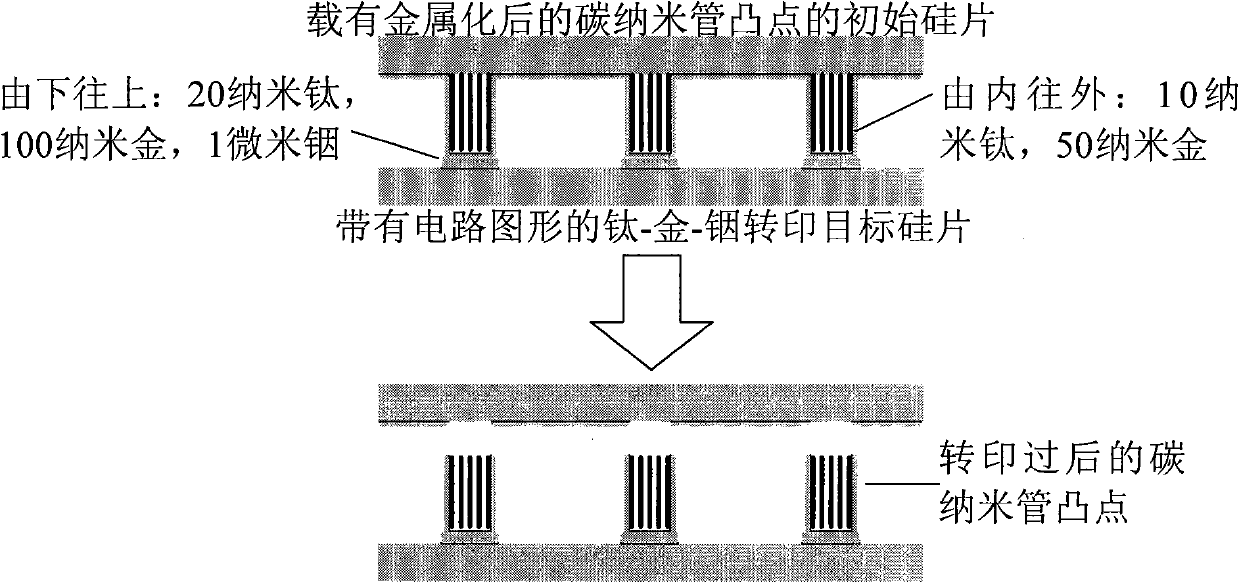

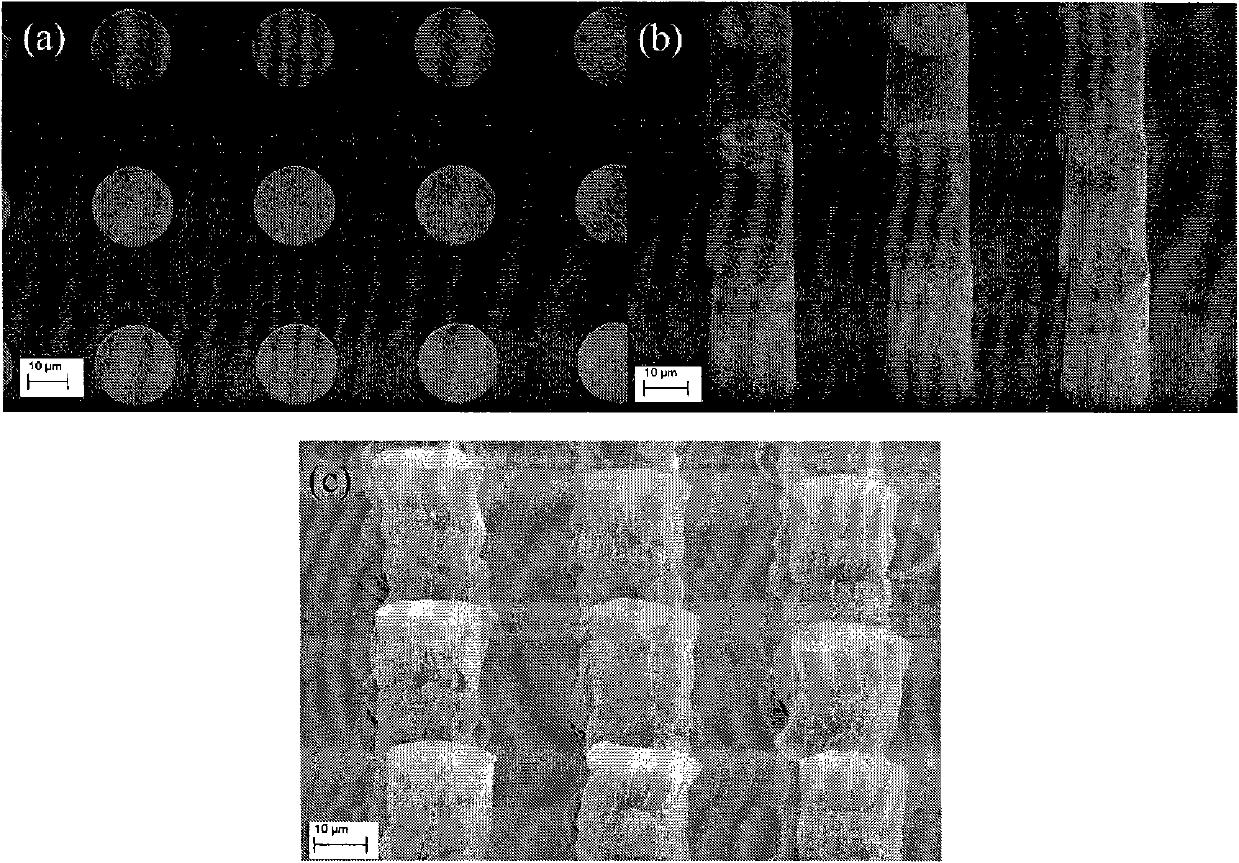

Low-temperature transfer printing method used for microelectronically packaged carbon nanotube bumps

InactiveCN101908494AFast transferIncrease the areaSolid-state devicesSemiconductor/solid-state device manufacturingIndiumMiniaturization

The invention relates to a low-temperature transfer printing method used for microelectronically packaged carbon nanotube bumps, and belongs to the technical field of microelectronic device manufacturing processes. The transfer printing method comprises the following steps of: aligning to extrude a metallized silicon wafer of which the surface is provided with the carbon nanotube bumps by using a titanium-gold-indium transfer-printing objective silicon wafer with a circuit pattern at the temperature of between 170 and 200 DEG C and under the pressure of 107 pascals, and transferring the carbon nanotube bumps to the transfer-printing objective silicon wafer with the circuit pattern. The method can rapidly perform transfer printing on the carbon nanotube bumps at small intervals at relatively low temperature in a large area and at a high success rate so as to meet the requirements on concentration and miniaturization of electronic components, reduce the production cost and improve the production efficiency.

Owner:SHANGHAI UNIV

Gold decoration process on precious stone

InactiveCN102774218ARealize the craftAchieve aestheticsDecorative surface effectsGold filmPrinting ink

The invention discloses a gold decoration process on a precious stone. The method comprises the steps of plating a titanium nitride TiN film layer on the surface of a the precious stone by vacuum ion plating, then plating a layer of a gold film on the surface of the precious stone through vacuum plating, printing preset grain decorations on the gold film of the precious stone by using printing ink, and drying the printing ink at the drying temperature of 150-300 DEG C; then eliminating the portion of the gold film, which is free from printing ink shielding by using gold eliminating liquid; eliminating the portion of a titanium metal film layer, which is free from printing ink shielding by using a titanium eliminating solution; and finally immersing the products of which the portions of titanium and gold, which are free from printing ink protection are eliminated, in acetone, and wiping out the protection printing ink on the surface by using the acetone. According to the process, the natural non-conducting precious stone with complex components, the titanium gold compound and gold are combined firmly, the overall appearance attractiveness and ornament of the precious stone are improved greatly, and the process effects and the process aesthetic perception of 'wire inlay' and 'slivering and gold plating' in traditional process and techniques can be achieved with low cost.

Owner:邓民

A manufacturing technology of a square silica-gel pad

InactiveCN103642243AWith wear-resistant functionWith acid and alkali resistanceInsolesManufacturing technologyHeating time

The invention discloses a manufacturing technology of a square silica-gel pad. The manufacturing method comprises a raw material preparation step and a mould pressing or injection moulding step. The raw material preparation step includes adding negative ion powder, titanium gold powder, a vulcanizing agent and a pigment into silica gel which is adopted as the main material, stirring uniformly, and expelling bubbles by reducing pressure to form the raw material. The mould pressing or injection moulding step includes putting or injecting the prepared raw material into a preset mould, heating to 206-220 DEG C and demoulding to obtain a blank, wherein the inner side surface of the mould is a square recessed surface, a circular arc type steel sheet is suspended in the mould, and the pressure heating time by a machine is 1550-1650 s. The technology overcomes disadvantages of the prior art, and has a simple design and a reasonable structure. A shoe pad manufactured by using the silica gel has wear resistance, acid resistance and alkali resistance and is durable.

Owner:ANHUI LVFENG RUBBER

Titanium plating technological process for aluminum section bar

InactiveCN107687009AHigh coating strengthImprove Surface ConsistencyChemical treatmentChemical reaction

The invention discloses a titanium plating technological process for an aluminum section bar. The titanium plating technological process is characterized by comprising the following steps of: chemically polishing; chemically removing oil; flushing with clear water; performing surface activation; putting a titanium aluminum section bar which is activated and is flushed with clear water into a liquid consisting of an edible salt, hydrochloric acid and water to perform normal-temperature chemical treatment for treatment time until the liquid generates fierce chemical reaction; putting a pre-plated product into a galvanic bath for plating titanium, and heating a plating solution to 55-60 DEG C, and stirring the electroplating solution, wherein the electroplating solution comprises nickel sulfate, nickel chloride, boric acid, lauryl sodium sulfate, saccharin and a brightening agent, the pH value is kept at 4.0-4.2, current density is 1.2-1.5 A / dm<2> and voltage is 17-19 V; cleaning after plating; drying; and finally packaging.

Owner:田静

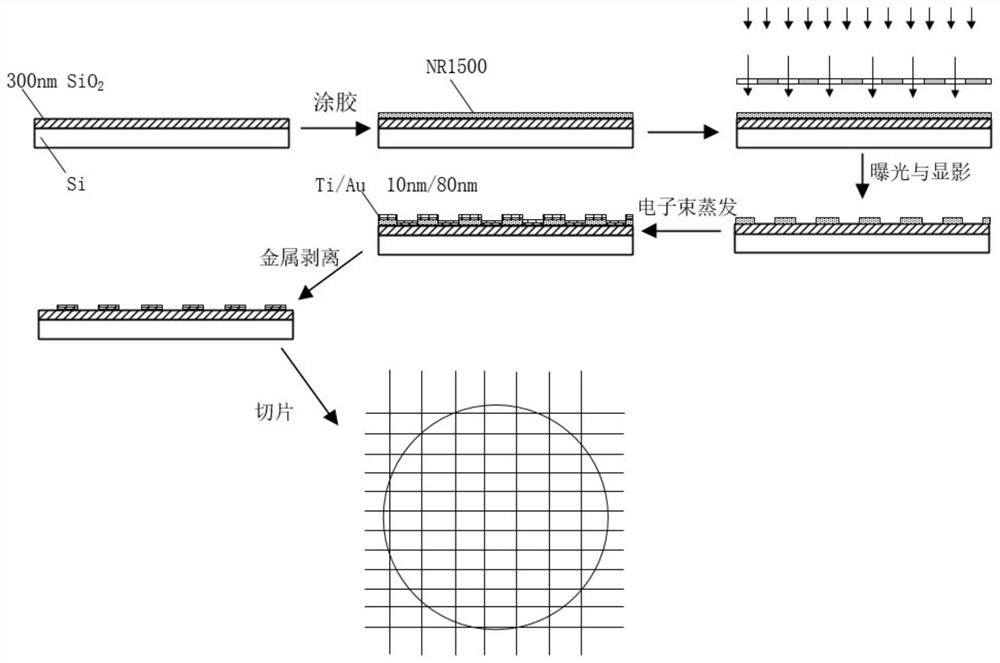

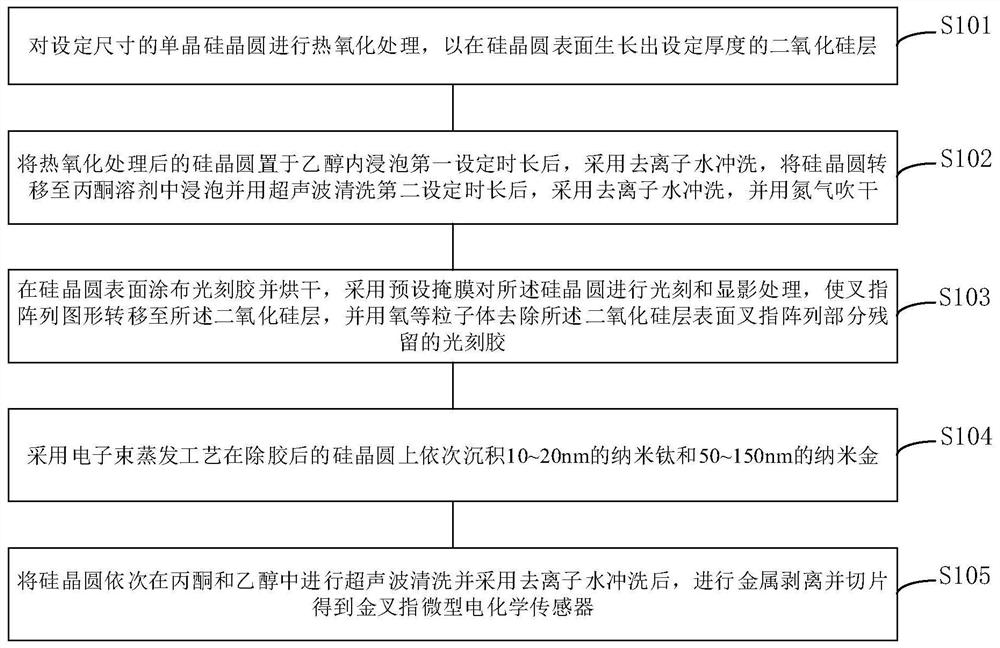

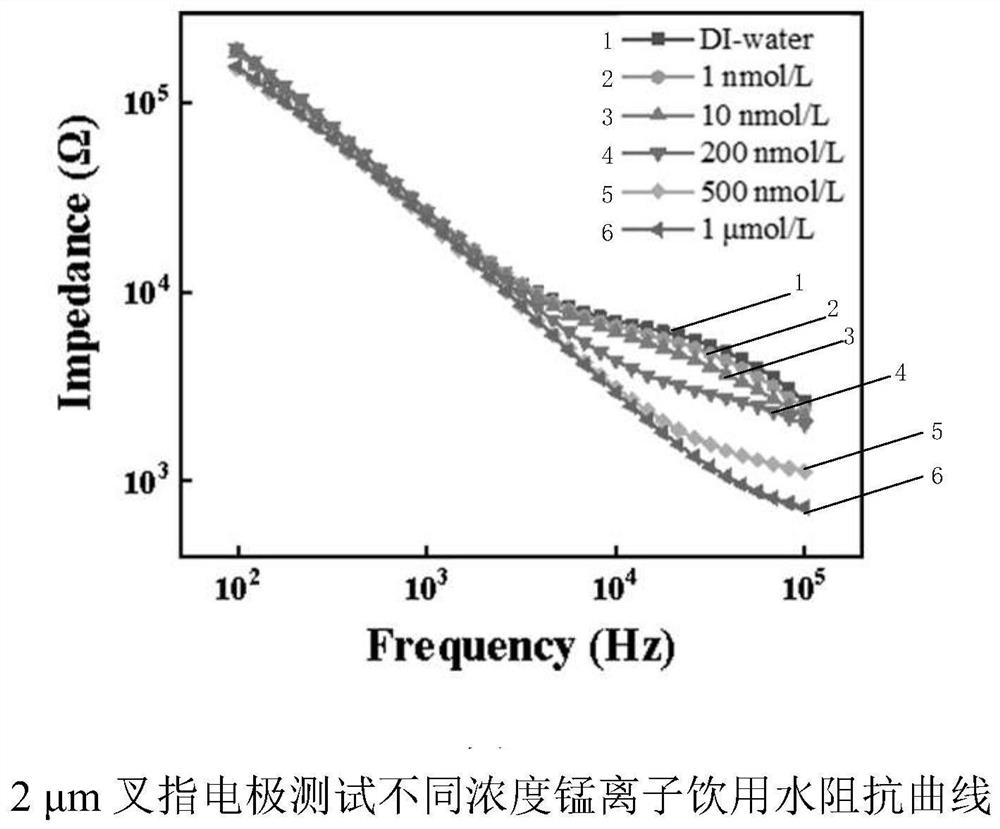

Gold interdigital micro electrochemical sensor and manufacturing method thereof

PendingCN112881487AThe preparation process is stableImprove machining accuracyNanosensorsMaterial electrochemical variablesEngineeringNano machining

The invention provides a gold interdigital micro electrochemical sensor and a manufacturing method thereof. The gold interdigital micro electrochemical sensor comprises a monocrystalline silicon substrate with a first set thickness, wherein a silicon dioxide layer with a second set thickness is arranged on the monocrystalline silicon substrate; and an interdigital electrode pair is arranged on the surface of the silicon dioxide layer, and the interdigital electrode pair comprises a nano titanium bonding layer of 10-20 nm and a nano gold sensing layer of 50-150 nm from inside to outside. According to the manufacturing method, a manufacturing method of integrated circuit micro-nano machining is adopted, silicon dioxide serves as an insulating substrate, titanium and gold serve as a bonding layer and a sensing layer respectively, and the sensor is prepared through electron beam evaporation and metal stripping processes. The gold interdigital micro electrochemical sensor which is complete in structure and morphology and sensitive in electrochemical property is obtained in batches under the treatment of multi-organic reagent washing and vacuum low-temperature drying process, and the gold interdigital micro electrochemical sensor is more stable in physicochemical property, sensitive in response and resistant to strong acid, strong alkali and a plurality of organic solutions.

Owner:NORTH CHINA UNIVERSITY OF TECHNOLOGY

Double-rod scale brushing type quick heating device and method

InactiveCN114383318AStable structureTargetedTelevision system detailsColor television detailsTitanium ionSewage outfall

The invention relates to a double-rod scale brushing type quick heating device and method, and the device comprises a customized quick heating framework which comprises a heating pipe body, a resistance magnesium rod, a titanium ion rod, a titanium enamel liner, a safety relief valve, a wire controller, a sewage draining exit, a water inlet and a water outlet, the heating pipe body is inserted from the right end of the titanium enamel liner and is arranged above the water inlet in parallel from right to left; and the horizontal driving mechanism is used for driving the heating pipe body to horizontally move from left to right until the heating pipe body does not receive the left-deviating detection signal when receiving the left-deviating detection signal. According to the double-rod scale brushing type quick heating device and method, the structure is reliable, and certain pertinence is achieved. A double-rod scale brushing mechanism can be introduced to effectively remove a large amount of scale in the quick heating process, and meanwhile, a self-adaptive control mechanism based on visual data is introduced to enable a heating pipe body of a quick heating device to be kept at the optimal heating position all the time, so that the intelligent level of the quick heating electric water heater is improved.

Owner:邓社进

A kind of electrolytic coloring titanium gold surface treatment method of aluminum material

ActiveCN110158136BEasy to operateGood resistance to impurity ionsAnodisationElectrolysisSand blasting

The invention discloses an electrolytic coloring treatment method for the titanium golden color surface of an aluminum material. The method comprises de-oiling, sand blasting, acid pickling, water washing, flushing, sprinkling and anodic oxidation, wherein a sprinkled aluminum alloy product is suspended on a suspending rack, the suspending rack is placed in an anodic oxidation solution, and anodicoxidation treatment is carried out under direct current electricity; water washing, flushing, sprinkling and secondary oxidation are sequentially carried out; the aluminum alloy product is placed ina coloring solution to expand holes, and then, secondary anodic oxidation is carried out under alternate current electricity; water washing is carried out after alternate current electrolytic coloring; the aluminum alloy product is put in hole sealing working fluid to seal the holes; and after water washing and drying are carried out on the aluminum alloy product, the aluminum alloy product with the titanium golden color surface is obtained. By improving the electrolytic coloring technology and agent, the coloring effect is more uniform and stable, and the coloring effect is optimal.

Owner:ZHEJIANG CANPHYS MEDICAL TECH CO LTD

Fading proof process for aluminum alloy electrophoresis titanium gold

InactiveCN102817060BImprove heat resistanceImproves UV resistanceSurface reaction electrolytic coatingElectrophoresesElectrolysis

Owner:佛山金兰铝厂有限公司

A kind of mica titanium gold pigment with blue effect and preparation method thereof

ActiveCN106380898BImprove visual effectsThe process is environmentally friendly and simplePigment treatment with macromolecular organic compoundsPigment preparationPrinting inkOrder structure

The invention relates to the field of pearlescent pigments, and discloses a mica-titanium gold pigment with a bluing effect. The mica-titanium gold pigment comprises a substrate, at least two cation layers and at least two pigment anion layers, the substrate is the innermost layer, the surface of the substrate is covered with the first cation layer, the surface of the first cation layer is covered with the first pigment anion layer, then the cation layers and the pigment anion layers alternately cover to construct to a multilayer ordered structure, and the outermost layer is the pigment anion layer. The invention also discloses a preparation method of the mica-titanium gold pigment with a bluing effect. The method allows the nanometer multilayer phthalocyanin pigment to be controllably constructed on the surface of the mica-titanium gold pigment in order to improve the bluing effect and the visual effect of the surface of the mica-titanium pearlescent pigment, and the pigment can be used in the fields of the automobile industry, anti-fake identification, ornaments and printing inks. The method has the advantages of controllable nanometer thickness, excellent bluing effect, simple process, environmental protection, good advanced property and wide application prospect.

Owner:杭州华大海天科技股份有限公司

Automatic glass sensing door locking apparatus

The present invention relates to an automatic glass sensing door locking apparatus, which comprises a first clamping plate, a second clamping plate and a tongue plate, wherein first snapping plates are fixedly arranged on the edges of both sides of the first clamping plate, the tongue plate is vertically and fixedly arranged in the middle of the first snapping plates, the tongue plate is provided with lock holes, second snapping plates are fixedly arranged on the edges of both sides of the second clamping plate, and a groove hole matched with the tongue plate is arranged in the middle of the second snapping plates. The automatic glass sensing door locking apparatus has the following characteristics that: the structure is simple, the use is easy, the production cost is low, the glass door can be easily locked in the case of no damage on the glass door titanium gold frame structure, the automatic glass sensing door locking apparatus is not limited by the power supply, and the safety is high.

Owner:STATE GRID CORP OF CHINA +1

A titanium tile emitting far infrared rays and a preparation process thereof

InactiveCN109970435AGood for healthImprove mechanical propertiesClaywaresTitanium metalHexagonal boron nitride

A titanium tile emitting far infrared rays and a preparation process thereof are provided. The ceramic tile can release far infrared rays beneficial to human health, and has the characteristics of high wear resistance, high strength, strong modern atmosphere, strong acid and alkali corrosion resistance, and appearance effects of the ceramic tile, such as color, pattern and texture, are slightly affected or not affected by deep-color far infrared ray emitting components in glaze layers or base glaze layers or the color of the ceramic tile body itself. Raw materials for a ceramic tile blank or aceramic tile body include 18-35% of kaolin, 15-20% of quartz, 15-30% of potassium feldspar, 15-30% of magnesia and 10-25% of bauxite. Raw materials of an overglaze layer and / or a base glaze layer include 10-30% of kaolin, 15-30% of quartz, 10-20% of alumina, 5-20% of tourmaline powder, 10-15% of hexagonal boron nitride and 10-25% of borax and / or calcium metaborate. The whole or a part of the surface layer is coated with a titanium metal coating, pattern or texture containing metal titanium and / or other compounds. The thickness of the ceramic tile body is 5-15 mm, the thickness of the overglaze layer and / or the base glaze layer is 0.5-1.0 mm, and the thickness of the titanium metal coating is 0.05-0.10 mm.

Owner:淄博锦昊陶瓷有限公司

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com