Patents

Literature

57 results about "Gold colour" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

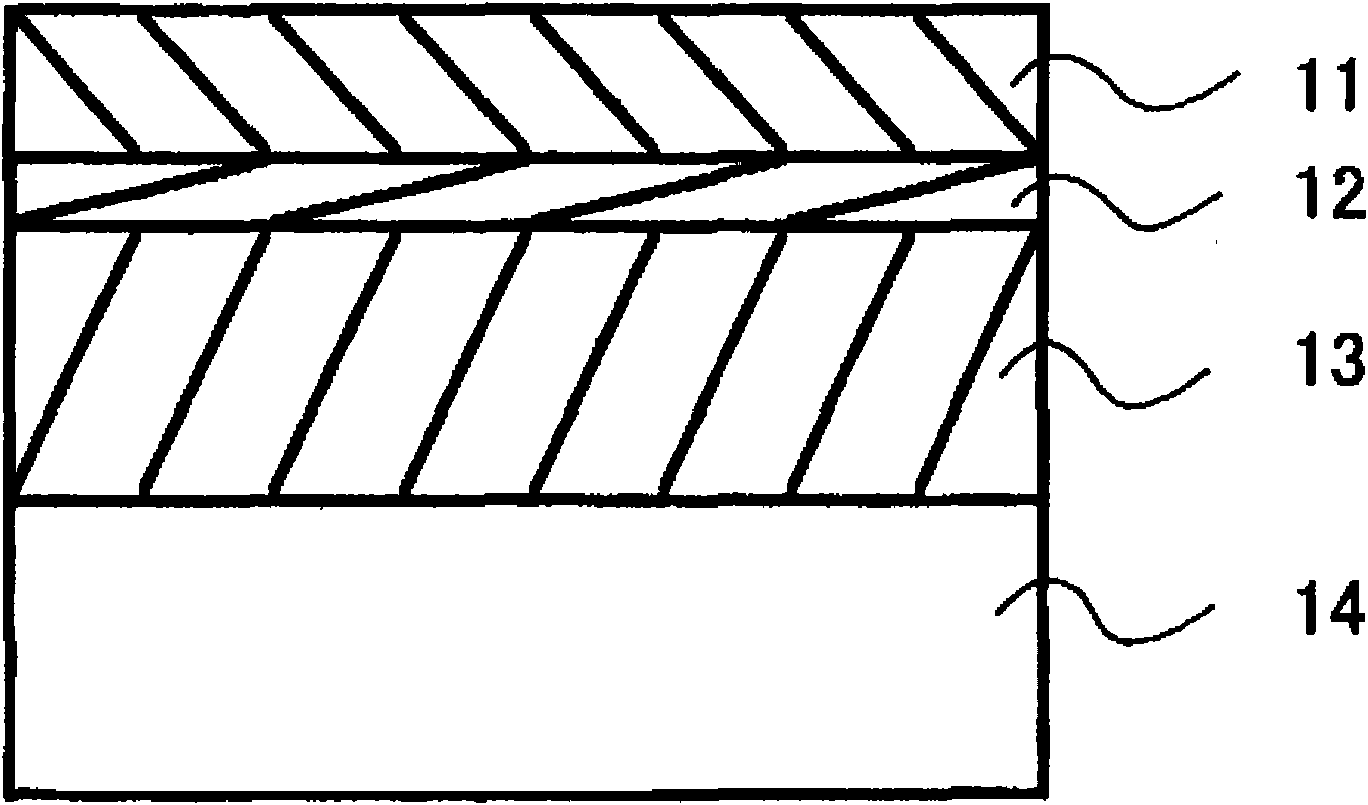

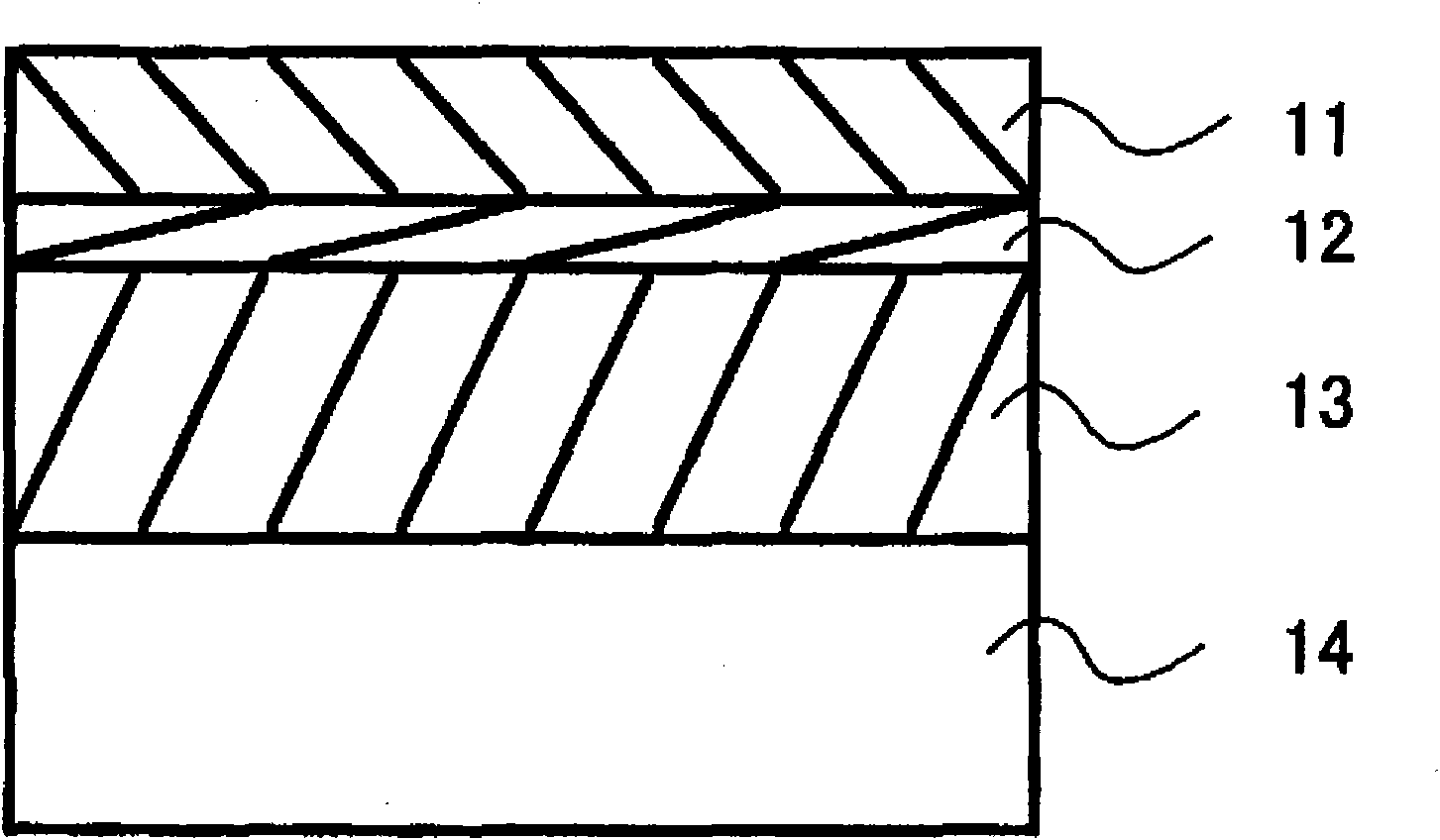

Preparation of a toner for reproducing a metallic hue and the toner

InactiveUS7326507B2Synthetic resin layered productsCellulosic plastic layered productsGold colourOrganic layer

The present invention relates to a toner and process for preparing a toner for reproduction of a metallic, preferably golden or silvery, hue by a printing process, especially for electrophotography. A congeneric process and / or a congeneric toner is preserved with regard to its metallic hue and at the same time not to impair the essential properties of the toner for the printing process in which it is to be used. At least one metallic pigment is provided with a coating of silicate and subsequently with an organic layer and combining the thus obtained particle with toner material.

Owner:EASTMAN KODAK CO

Preparation of a toner for reproducing a metallic hue and the toner

InactiveUS20050214666A1Synthetic resin layered productsCellulosic plastic layered productsGold colourOrganic layer

The present invention relates to a toner and process for preparing a toner for reproduction of a metallic, preferably golden or silvery, hue by a printing process, especially for electrophotography. A congeneric process and / or a congeneric toner is preserved with regard to its metallic hue and at the same time not to impair the essential properties of the toner for the printing process in which it is to be used. At least one metallic pigment is provided with a coating of silicate and subsequently with an organic layer and combining the thus obtained particle with toner material.

Owner:EASTMAN KODAK CO

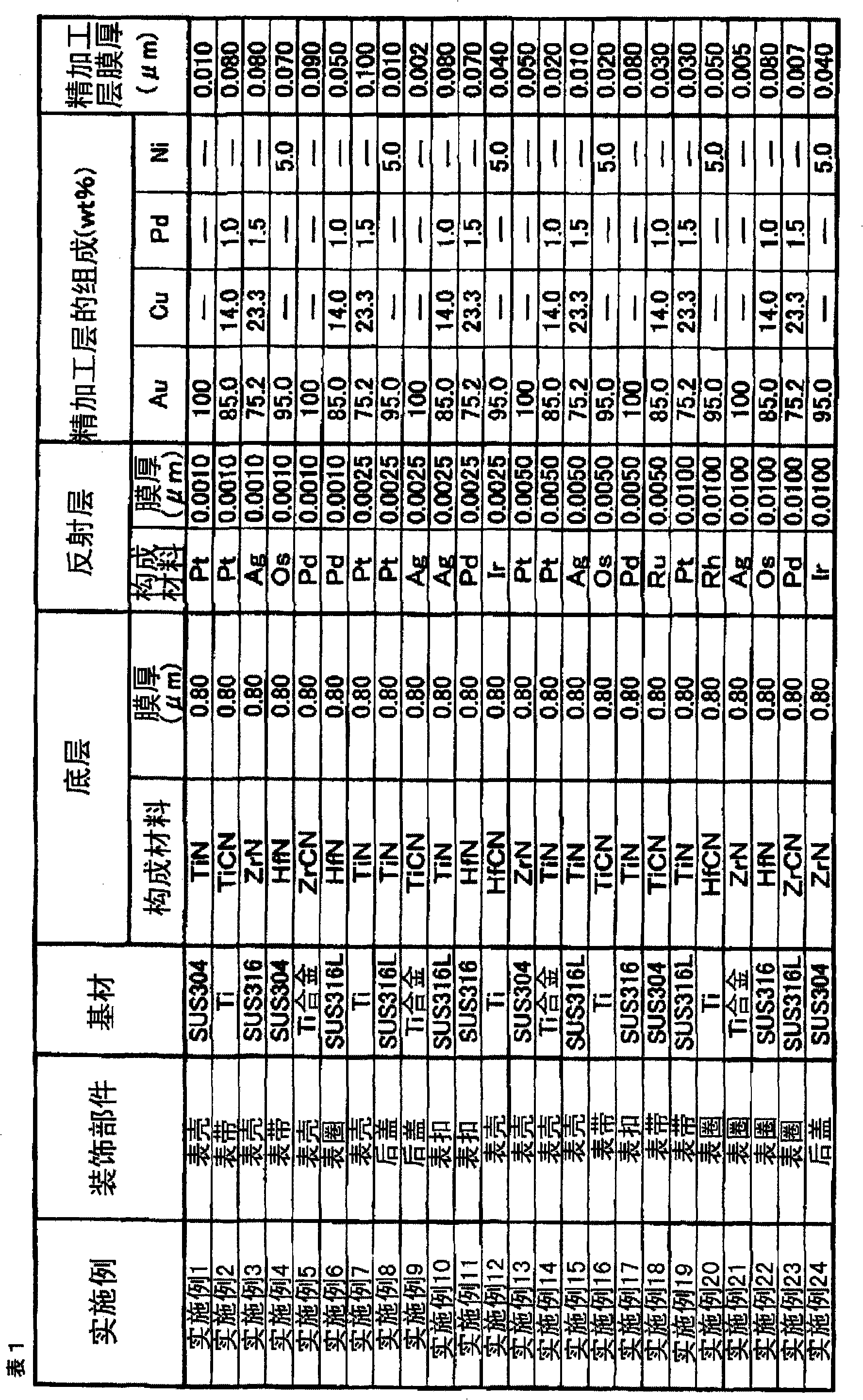

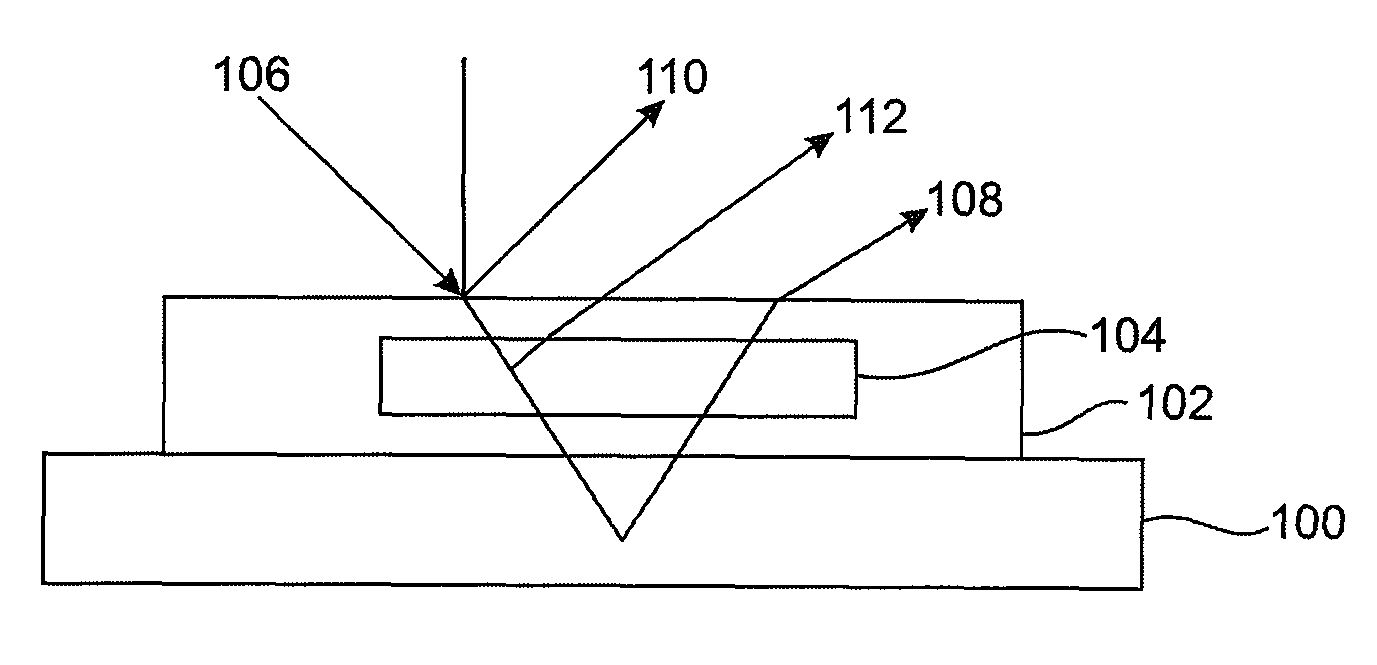

Decorative part

InactiveUS20100255338A1Improvement in finishing color toneIncrease brightnessVacuum evaporation coatingSputtering coatingGold colourCarbide

[Subject] To provide a decorative part having a hardening layer containing Au on the surface, particularly a gold colored decorative part having gloss and color tone inherent in gold, high brightness and high quality.[Means for Problem the Subject] The decorative part of the present invention comprises a substrate and, superimposed on the substrate, a hardening layer wherein the hardening layer comprises a primary layer comprising a nitride, a carbide or a carbonitride of one or two or more metals selected from Ti, Zr and Hf, a finishing layer comprising Au or an Au alloy having an arbitrary composition such as an Au—Ni alloy, an Au—Cu—Pd alloy etc. and, disposed between the primary layer and the finishing layer, a reflecting layer comprising a metal having a higher reflectance than one constituting the finishing layer, such as Ru, Pd, Rh, Ag, Os, Ir pr Pt.Thus, the gold colored decorative part having gloss and color tone inherent in gold, high brightness and high quality can be efficiently prepared.

Owner:CITIZEN WATCH CO LTD

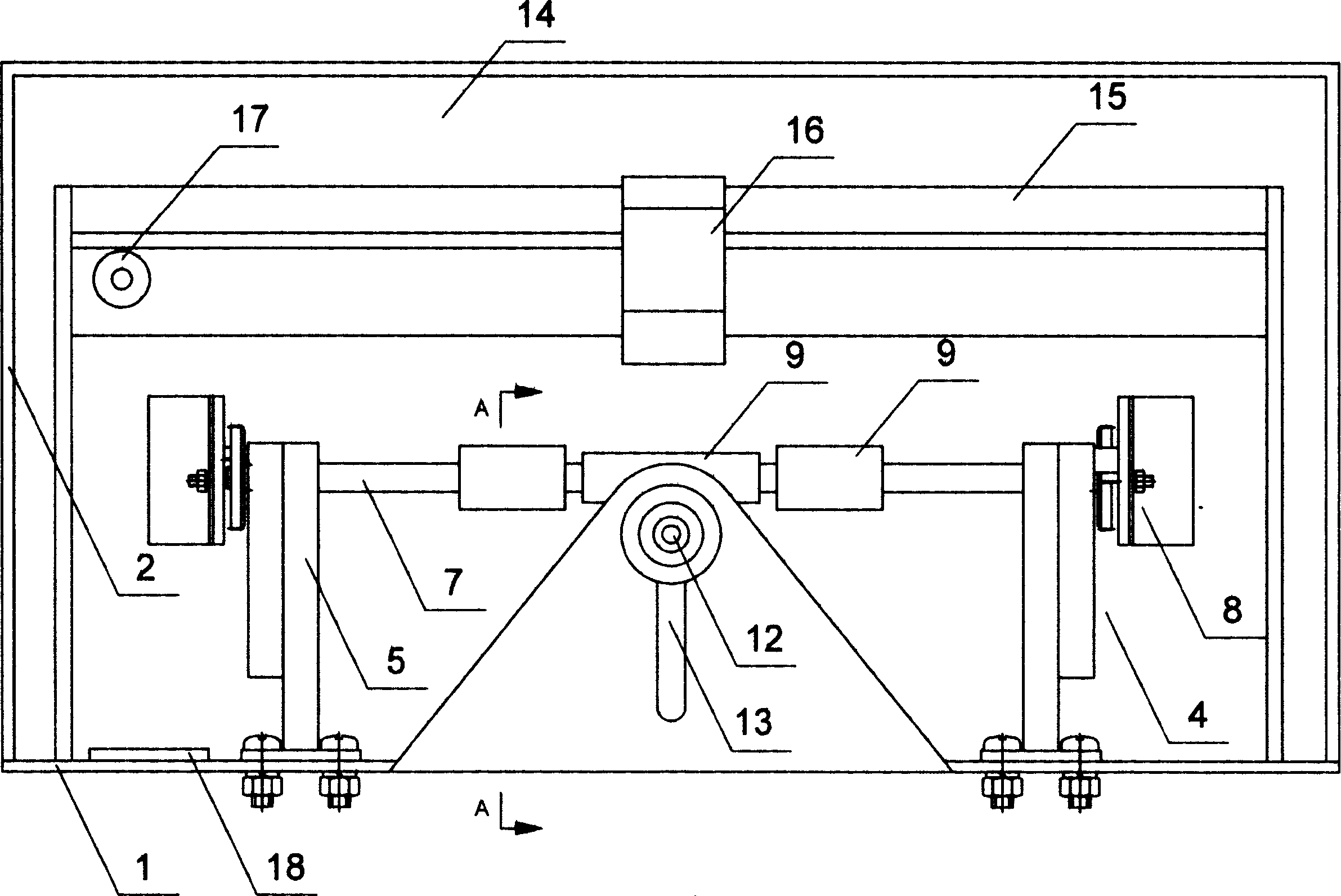

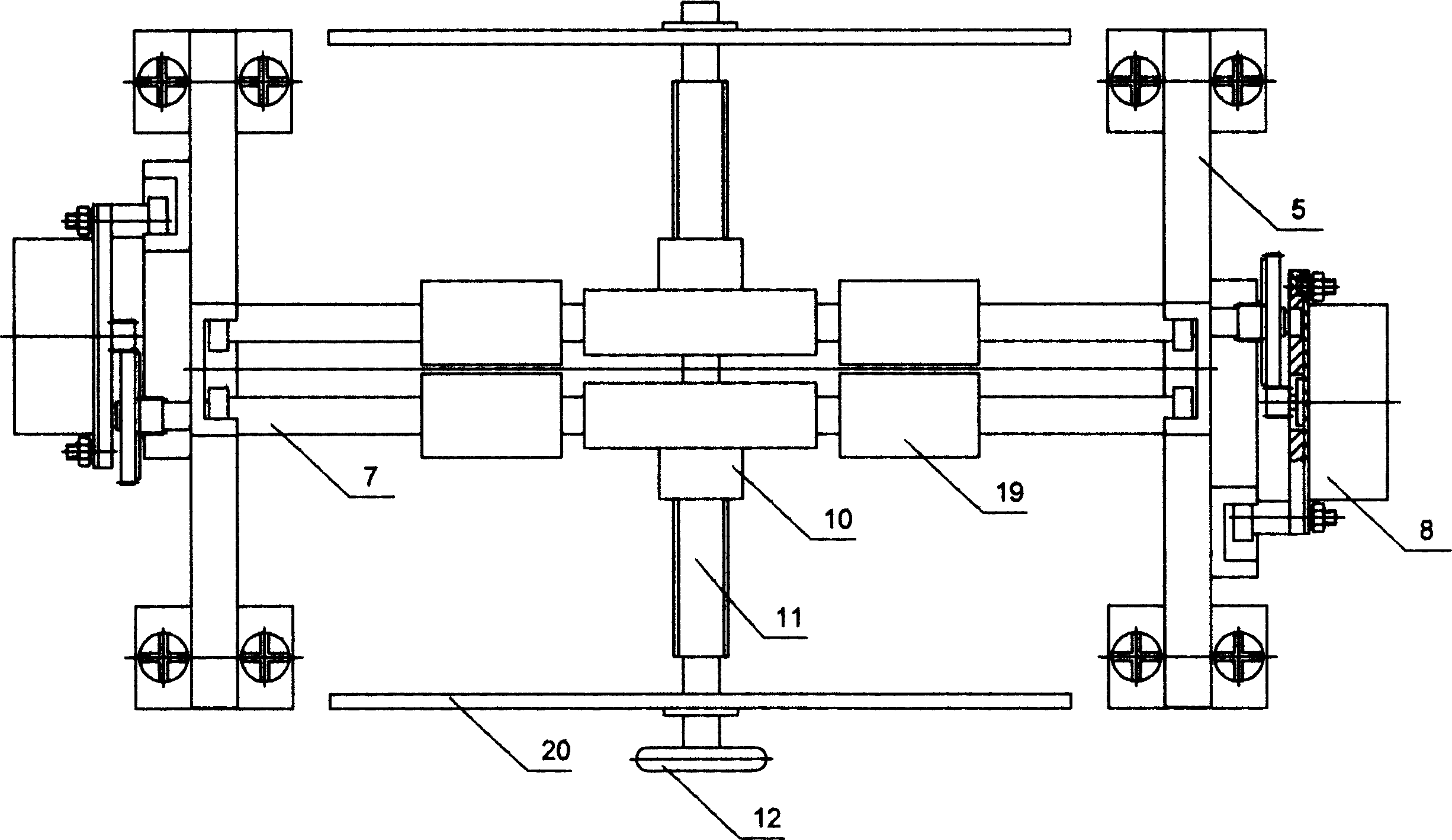

Device for printing picture-word on candle surface

InactiveCN1775540AHeight adjustableSimple structureTypewritersPower drive mechanismsReciprocating motionGold colour

The present invention relates to an equipment capable of printing gold colour, silver colour, white and chromatic pattern and characters on the surface of candle. Said equipment includes ink-jet printing unit, said ink-jet printing unit includes printing supporting frame, on the printing supporting frame a printing head is set, said printing head can make linear reciprocating movement relatively to said supporting frame, under the ink-jet printing unit two mutual parallel rotating shafts are set, at least one rotating shaft is coupled with drive device, and the drive device is coupled with ink-jet printing unit and circuit board.

Owner:王红

Hair colouring compositions

InactiveUS20060117494A1Improve hair damage profileCosmetic preparationsHair cosmeticsFiberGold colour

The present invention relates to an oxidative hair colouring and bleaching composition comprising an oxidizing agent, a source of carbonate ions, an alkalising agent, and specific dyes, as defined herein below, utilised at pH 9.5 and below which improved colour delivery and intensity whereby different colours / shades and chromophores are provided, are compatible with current dyes and dye precursor systems and result in improved lift and lightening for blonde shades, excellent dye deposition and colour and improved grey coverage. Moreover, the compositions of the present invention also exhibit low odour and deliver a high level of lift and lightening equal to the currently utilised ammonia / peroxide systems, whilst reducing the concentration of peroxide and reducing the hair fibre damage.

Owner:THE PROCTER & GAMBLE COMPANY

Living rose gold-plating production technique flow

The invention discloses an in vivo rose gold-plated production process flow which comprises the following steps: in vivo rose dry, impregnating resin, flushing and shearing, spraying resin and coloring, molding, petal assembling into flower, coating silver oil, and plating gold. The in vivo rose which is made by the process can never wilt and die, is refined and fresh, and has gorgeous color, flashing water, clearly visible petal skeleton, golden branches, as well as beautiful green branches and leaves; the crystal vase is warm and romantic, glittering and translucent carving, thus reflectingthe elegance of the gold-plated rose, and being full of spiritual vitality and infinite vigor.

Owner:深圳粤通国际珠宝股份有限公司

Security element and method for production thereof

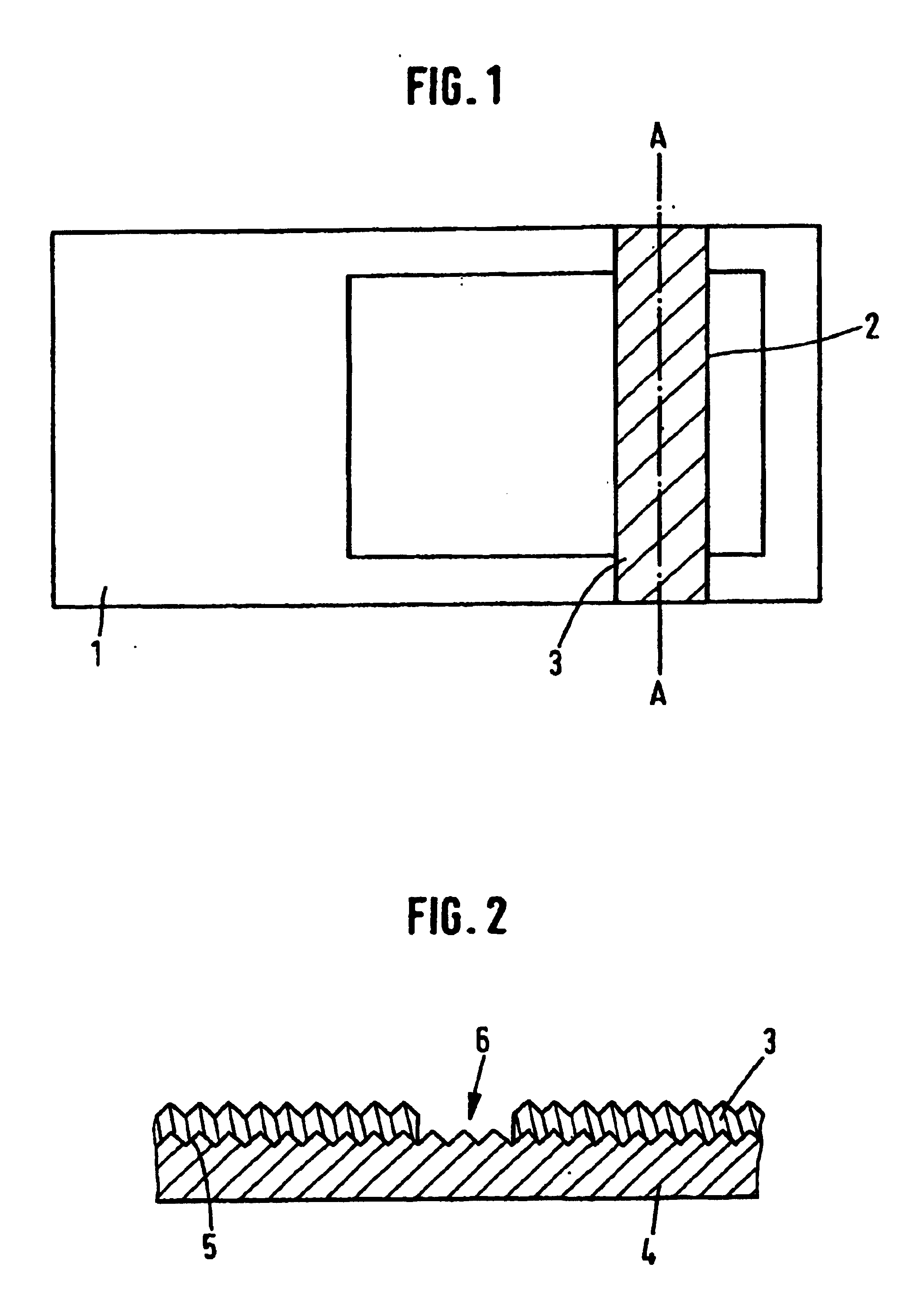

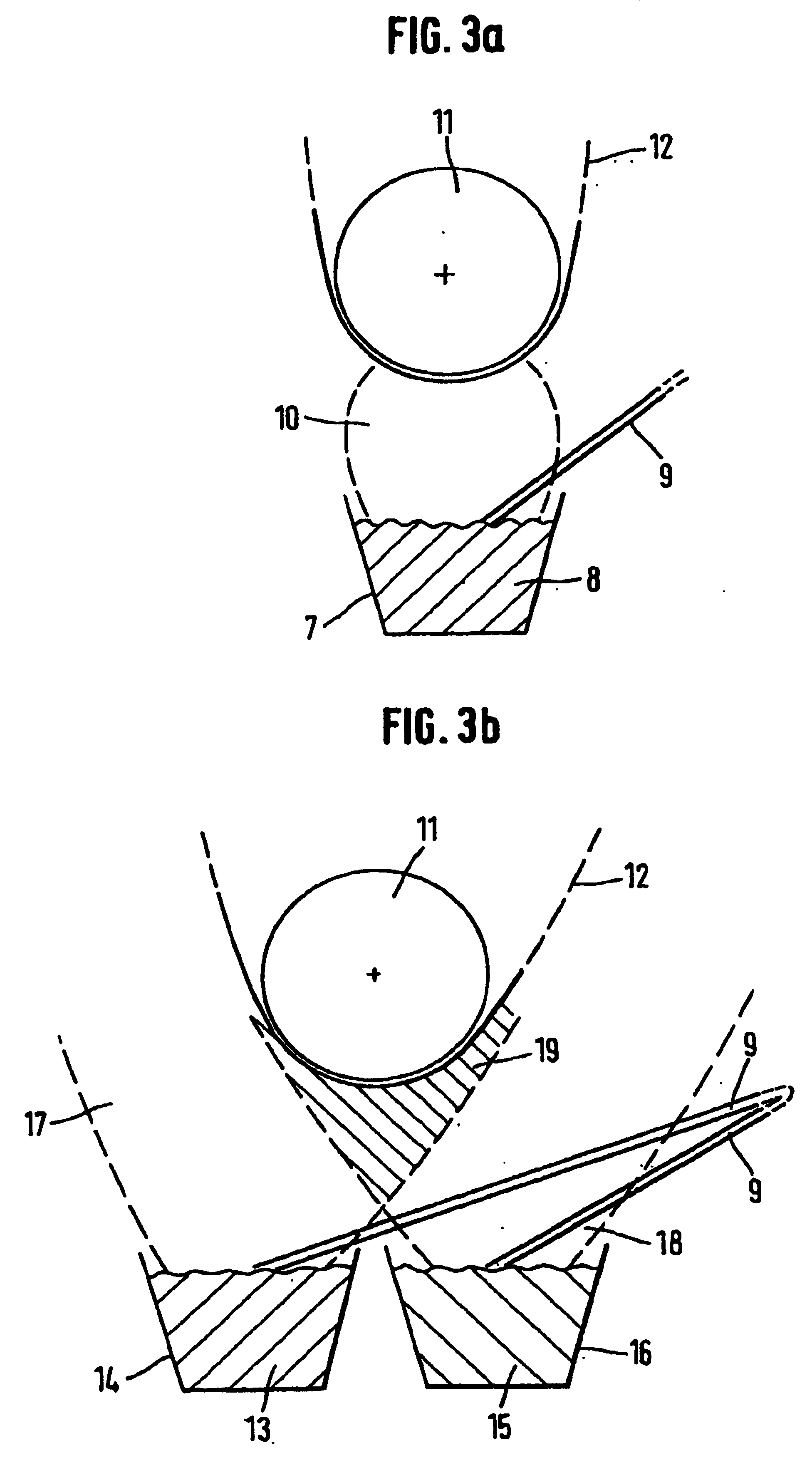

InactiveUS20050179254A1Improve anti-counterfeiting performancePigmenting treatmentNon-fibrous pulp additionEngineeringPaper sheet

The invention relates to an object, in particular a security element for security papers, bank notes, identity card or the like, as well as a security paper and a document of value with such a security element. Furthermore, the invention relates to a method for producing the object, in particular the security element or the security paper and the document of value with such a security element. The method in particular serves for manufacturing a precious-metal-coloured, preferably gold-coloured coating on a substrate.

Owner:GIESECKE & DEVRIENT GMBH

Environment-friendly electron beam cured gold surface coating used for aluminized paperboard and preparation method thereof

InactiveCN103343482APromote safe productionImprove efficiencyPaper coatingPaper/cardboardPhysical chemistryPaperboard

The invention relates to an environment-friendly electron beam cured gold surface coating used for an aluminized paperboard and a preparation method thereof. The painting is composed of the following components by mass part: 50-80 of a liquid coating composition being capable of being cured by the electron beam, 5-30 of yellow pigment slurry, 1-10 of red pigment slurry, and 0.5-3.0 of an auxiliary agent. The preparation method comprises preparing the red pigment slurry and the yellow pigment slurry through mixing, dispersing, grinding, etc., adding the red pigment slurry and the yellow pigment slurry into the liquid coating composition being capable of being cured by the electron beam in a certain proportion, uniformly stirring, adding the auxiliary agent, dispersing in a high speed for 1-2 hours, and filtering the mixture under a temperature of 40-60 DEG C to obtain the electron beam cured gold surface coating used for the aluminized paperboard. The method provided by the invention is safe during a production process, high in efficiency, low in energy consumption, and free of emission and pollution; and the coating is high in transparency and fullness, and compared with traditional coating materials, is superior in adhesion fastness, spalling resistance, solvent resistance, heat resistance, scratch resistance and printability.

Owner:YANTAI BOYUAN TECH MATERIALS +1

Golden condom

The invention discloses a golden yellow condom which shines golden yellow gloss and process for preparation, and the process comprises preparing golden yellow nacreous pigment powder into golden yellow pigment dispersion, then preparing golden yellow rubber latex by the golden yellow pigment dispersion and presulfurization rubber latex, and finally making into the golden yellow condom through adopting current conventional technology for making condom. The condom with golden yellow has bright color, which enables the product to have noble quality.

Owner:GUILIN ZIZHU LATEX PROD

Color Cosmetic

ActiveUS20100209464A1Eliminate riskImprove adaptabilityCosmetic preparationsOrganic active ingredientsSkin complexionMedicine

A foundation having a shade which covers a wide spectrum of different skin tones and undertones, comprises red and gold interference pigments, which provide a formula that is adaptable to both red and yellow skin undertones. The composition virtually eliminates the risk of application of the wrong foundation color, and provides enhanced color and textural effects, and superior optical performance.

Owner:GUTHY-RENKER +1

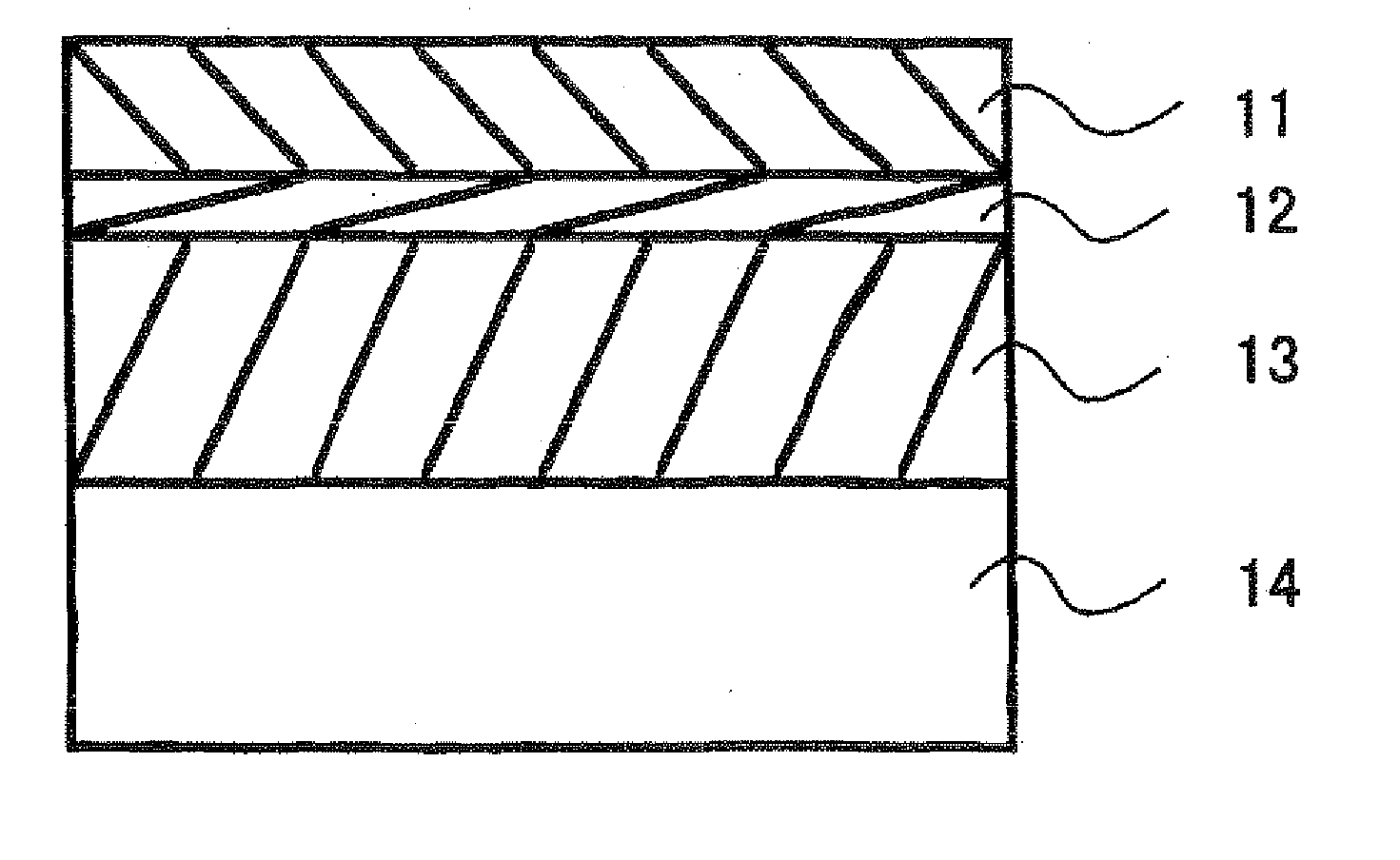

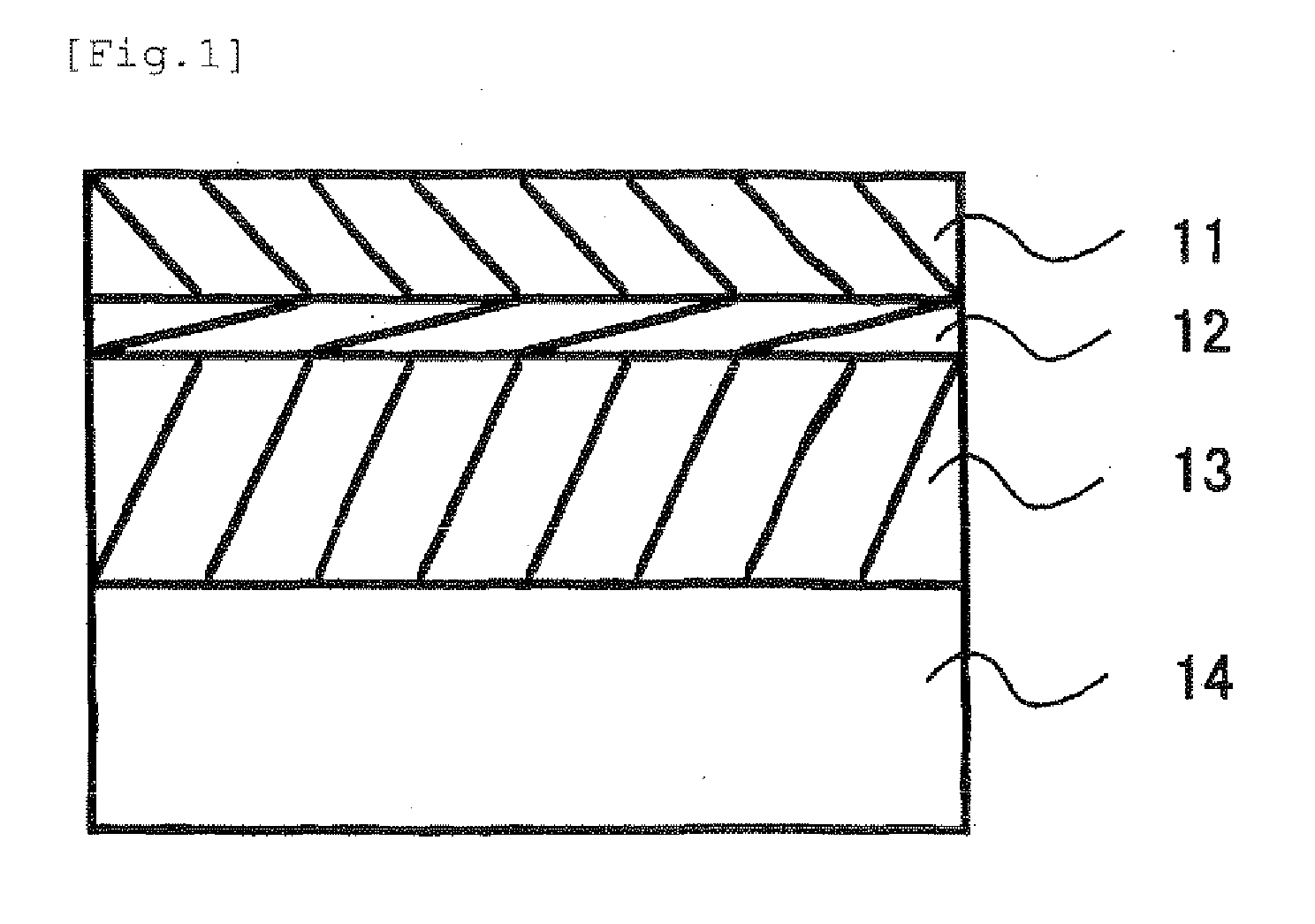

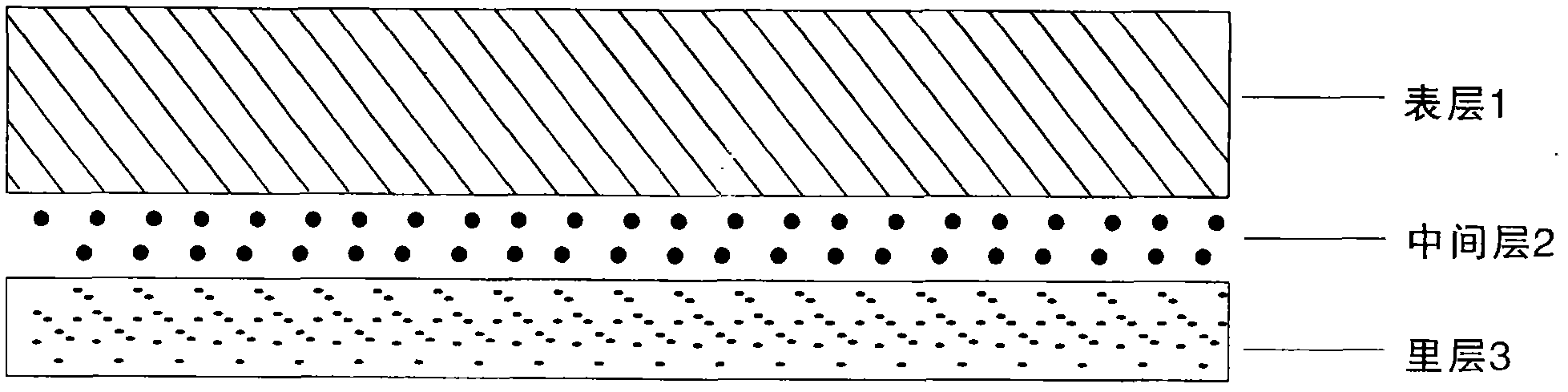

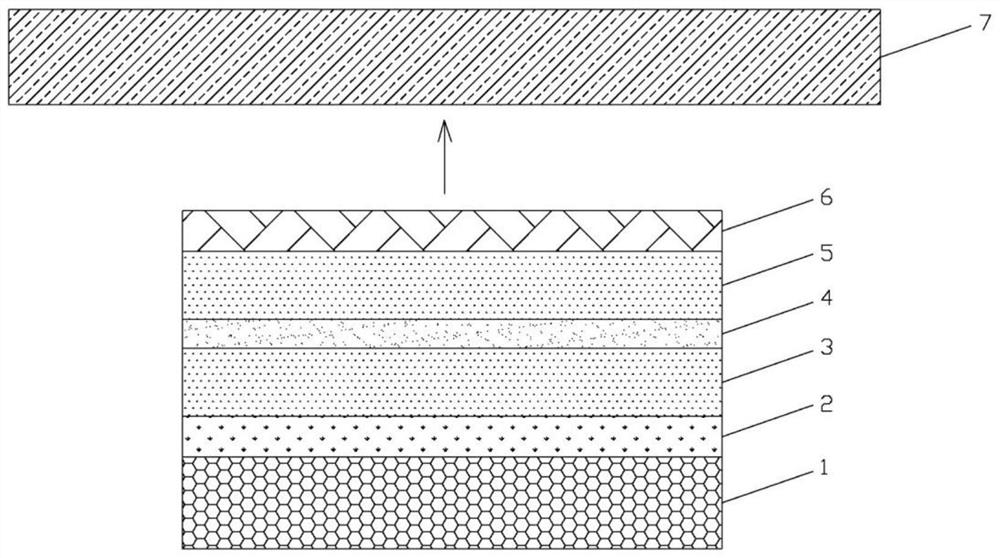

Large-jacquard seamless functional wall cloth

InactiveCN102535800AImprove breathabilityImprove mildew resistanceCovering/liningsSynthetic resin layered productsFiberPolyester

The invention relates to large-jacquard seamless functional wall cloth. The large-jacquard seamless functional wall cloth comprises a surface layer (1), a middle layer (2) and an inner layer (3) and is formed by compounding the three layers. A polyester fiber large-jacquard fabric selected according to the wall cloth has a golden uneven three-dimensional large-jacquard decorative pattern, high air permeability and extremely high mildew resistance, has water resistance, dirt resistance, oil resistance, fire resistance and flame retardance after being processed correspondingly, has high color fastness and abundant colors, is adhered in a seamless mode, is not required to be spliced and is easy to maintain; wood pulp backing paper is made of natural wood, does not generate poisonous and harmful gas, and does not inflame after flame-retardant anti-corrosion treatment; and simultaneously, an organic silicon adhesive has high-temperature resistance, is difficult to age and does not have peculiar smell. According to the large-jacquard seamless functional wall cloth, various colors can be dyed, decorative patterns of various styles can be woven, individual requirements can be met, and the aesthetic perception of indoor decoration can be improved.

Owner:SHAOXING SHULILE TEXTILE PROD

Construction technology of nitro wrinkle golden phantom antique effect in decoration

ActiveCN101559697ATo achieve the texture effectWipe evenlyPretreated surfacesArtistic surface treatmentWater basedWrinkle skin

The invention discloses a construction technology of a nitro wrinkle golden phantom antique effect in decoration, which is characterized by comprising the following steps: (1) sanding a material; (2) scraping water-base modeling paint; (3) sanding; (4) coating a nitro primer; (5) coating a nitro golden primer; (6) coating the nitro primer; (7) coating nitro black glaze; (8) coating the nitro primer; (9) coating nitro gray glaze; (10) coating the nitro primer; (11) coating nitro black and gray glaze; (12) coating the nitro primer; (13) sanding; and (14) coating nitro fully matte finishing coat. The construction technology has the advantage that the wrinkle golden phantom antique effect can be generated on the surface of furniture so as to meet the requirements of people on individuation, variety and coloration of the furniture.

Owner:上海展辰涂料有限公司 +1

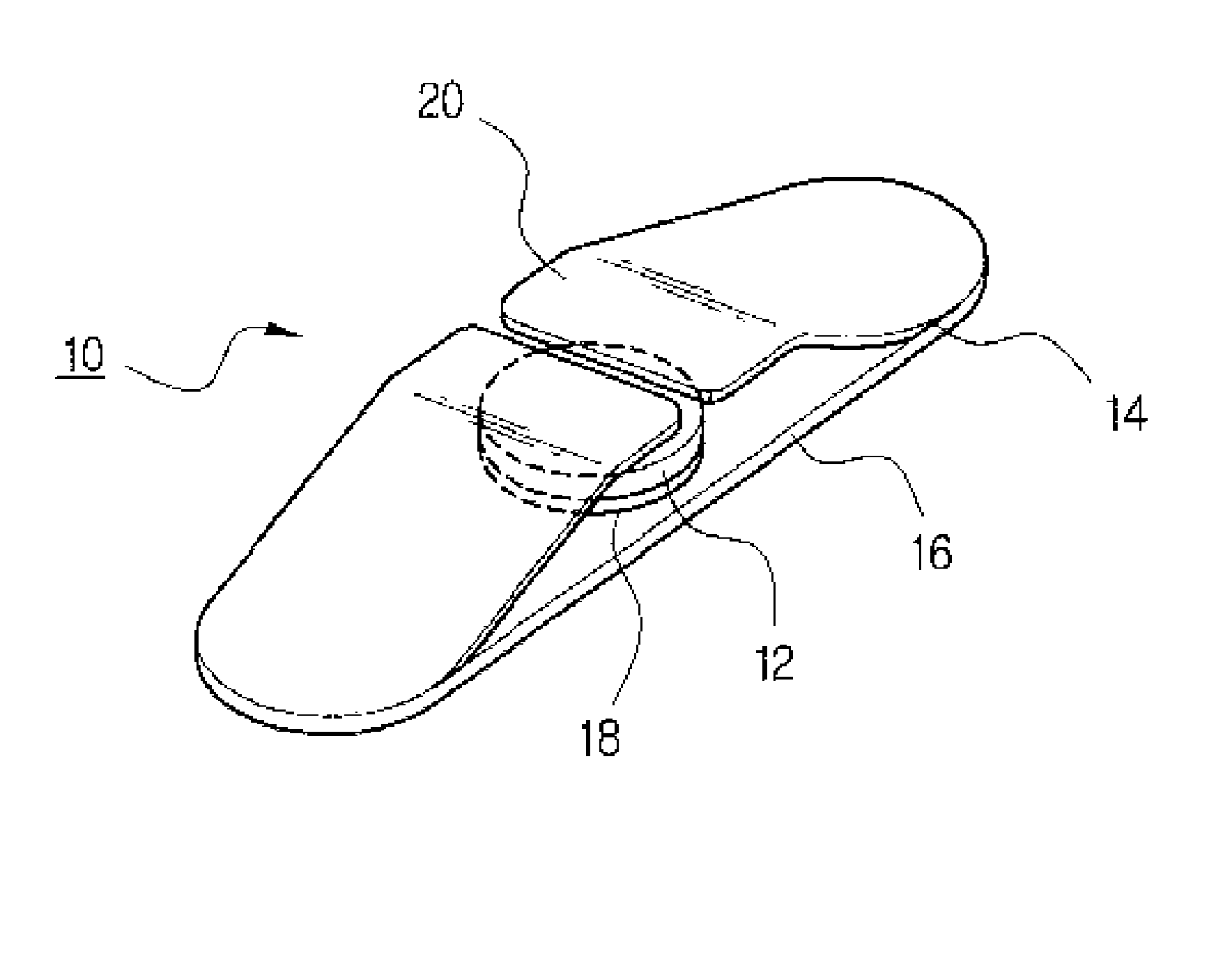

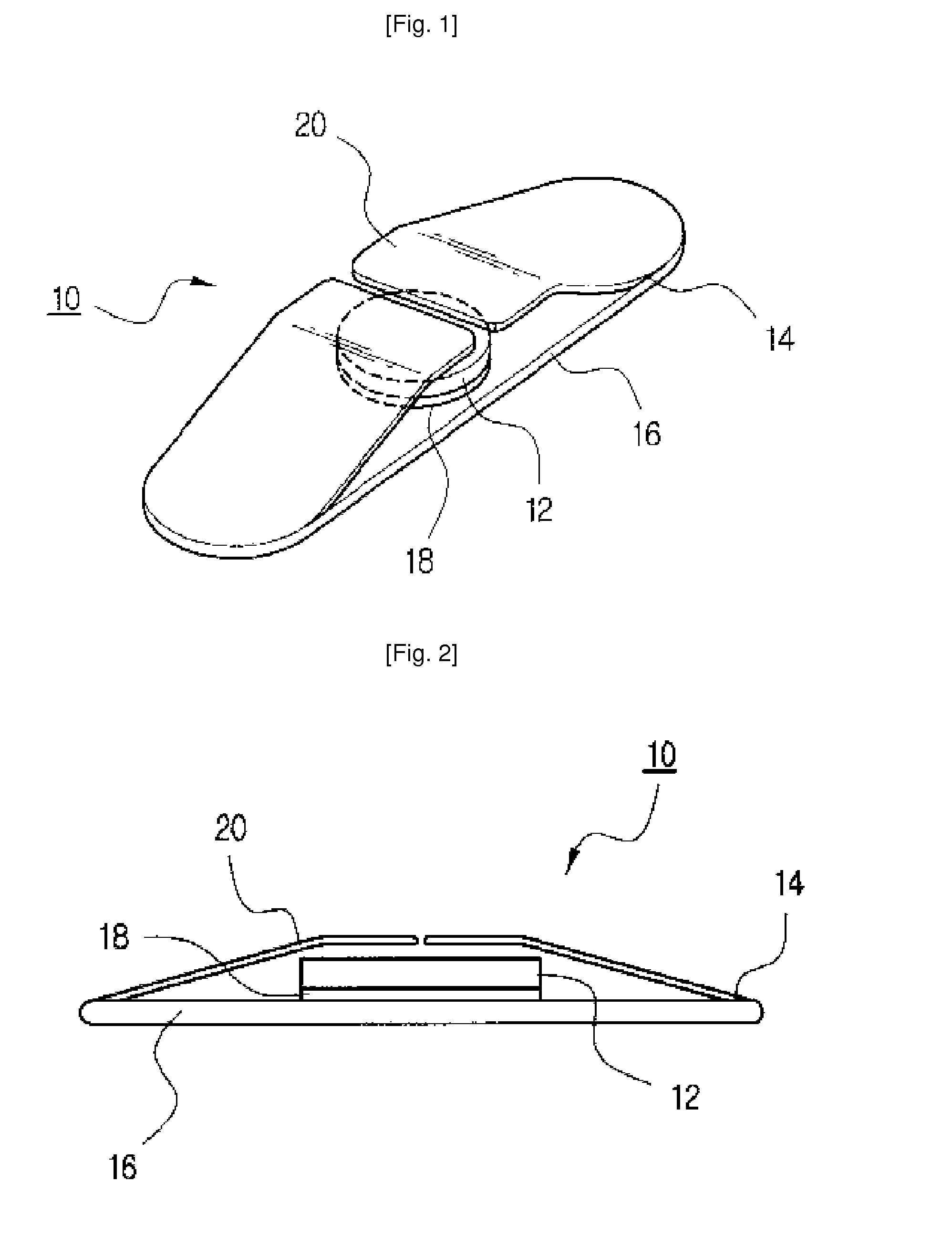

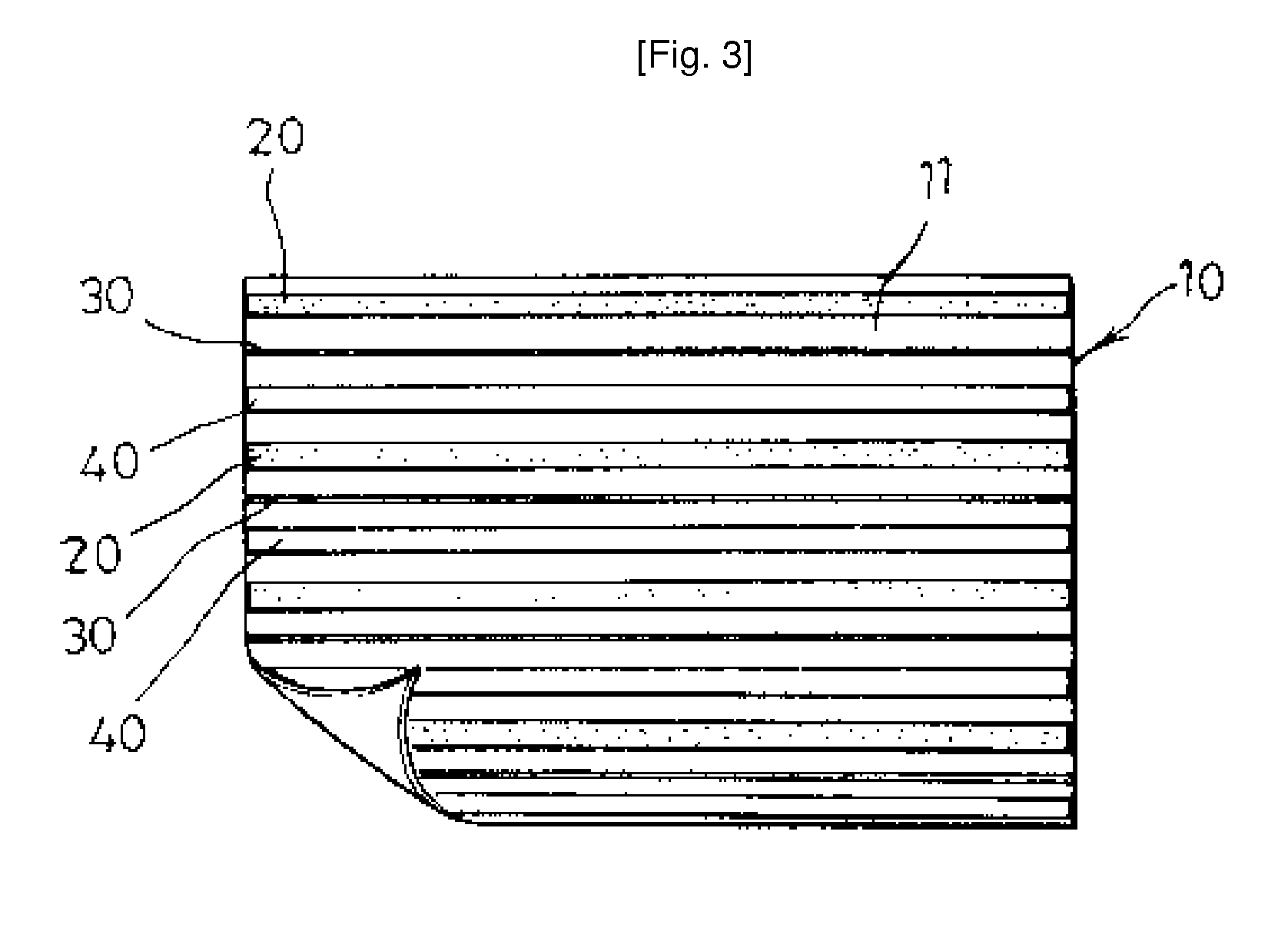

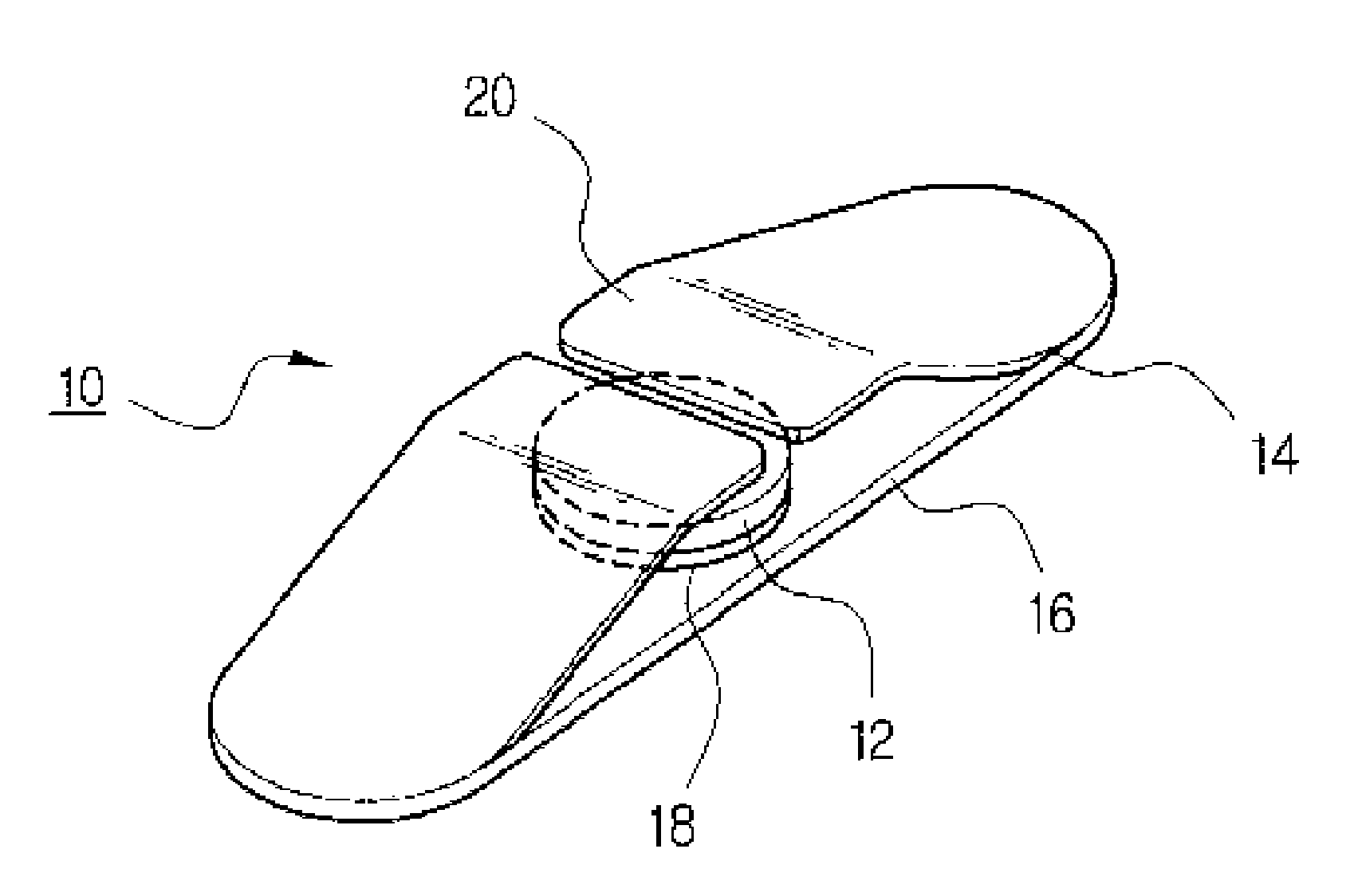

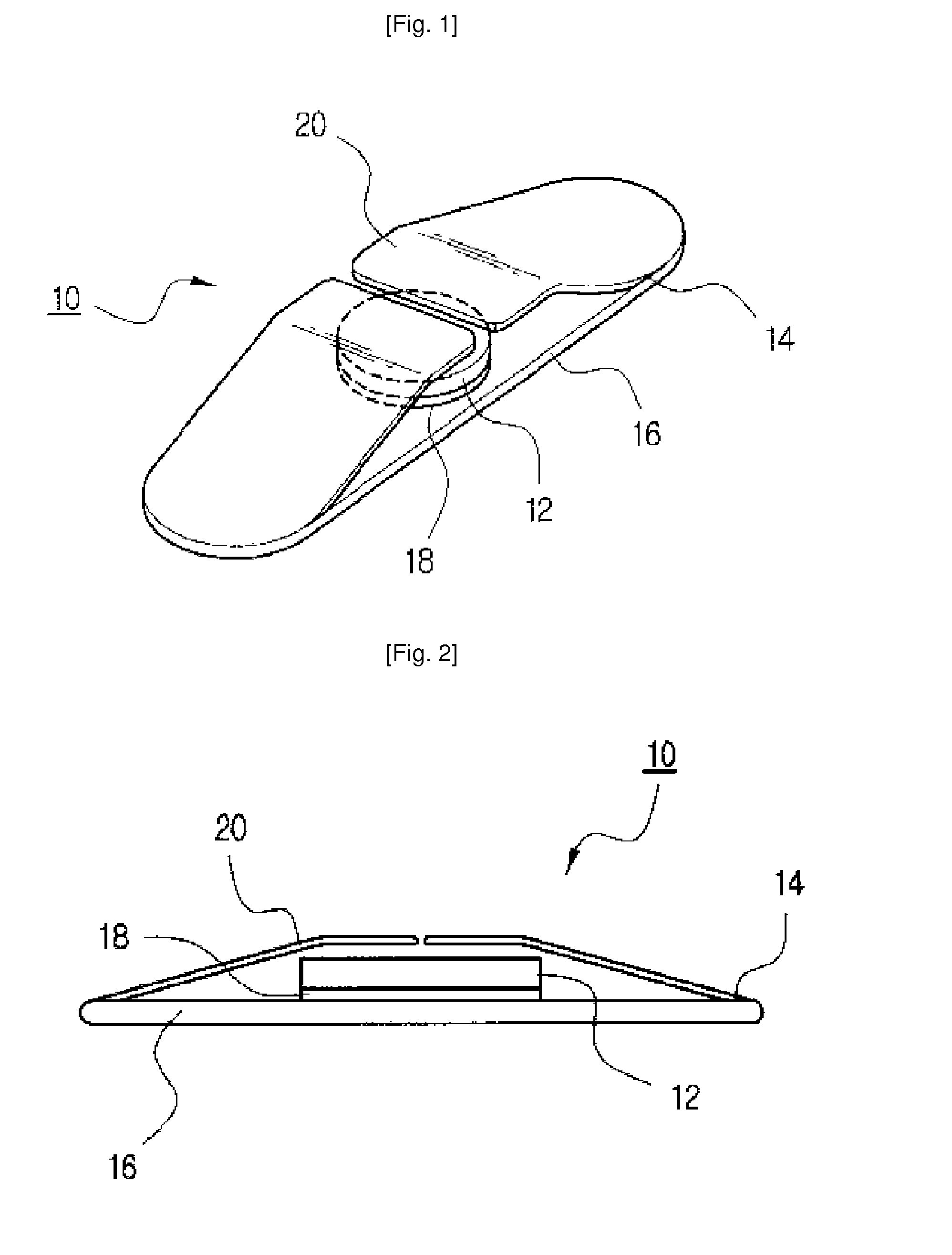

Functional metallicity ion band

ActiveUS7904173B2Rapid and safe and continuous treatmentLow costElectrotherapySurgeryAdhesivePhysical chemistry

Owner:KIM KYOUNG WON

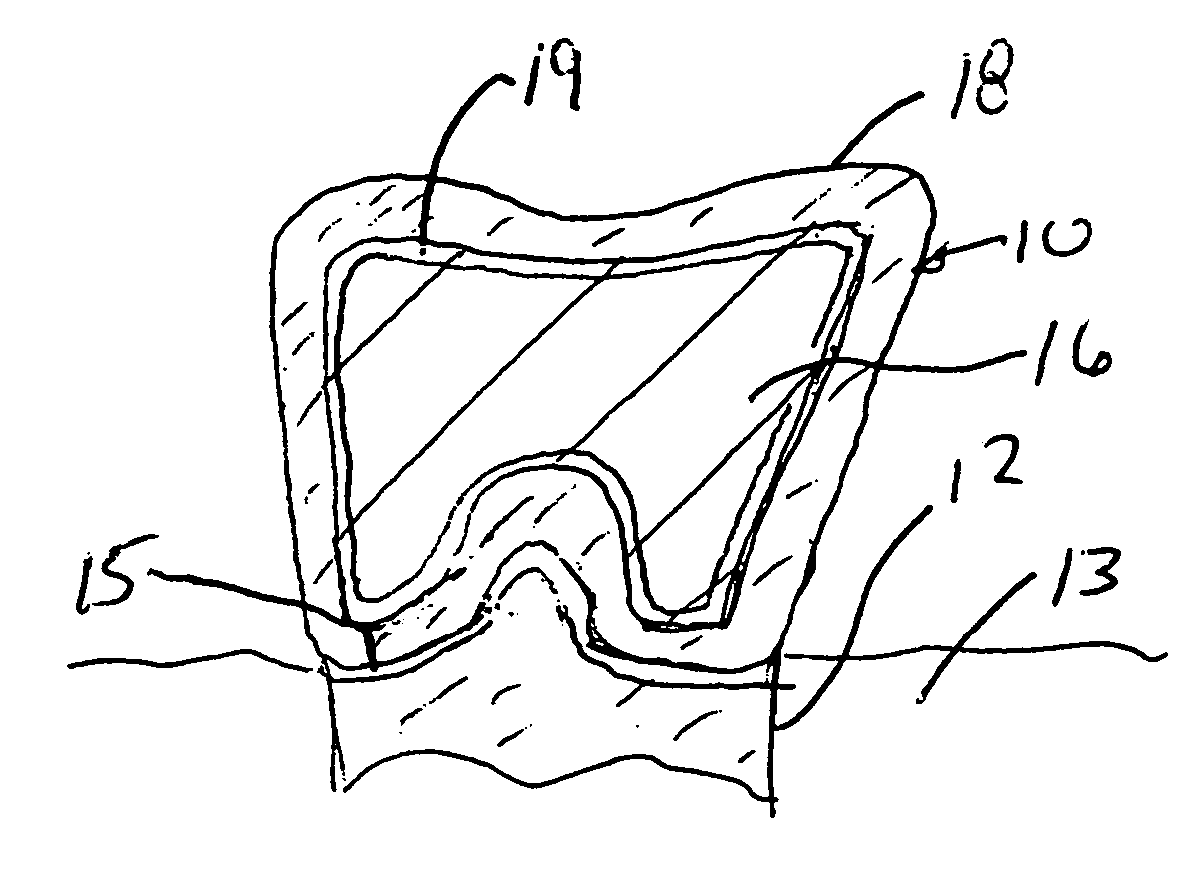

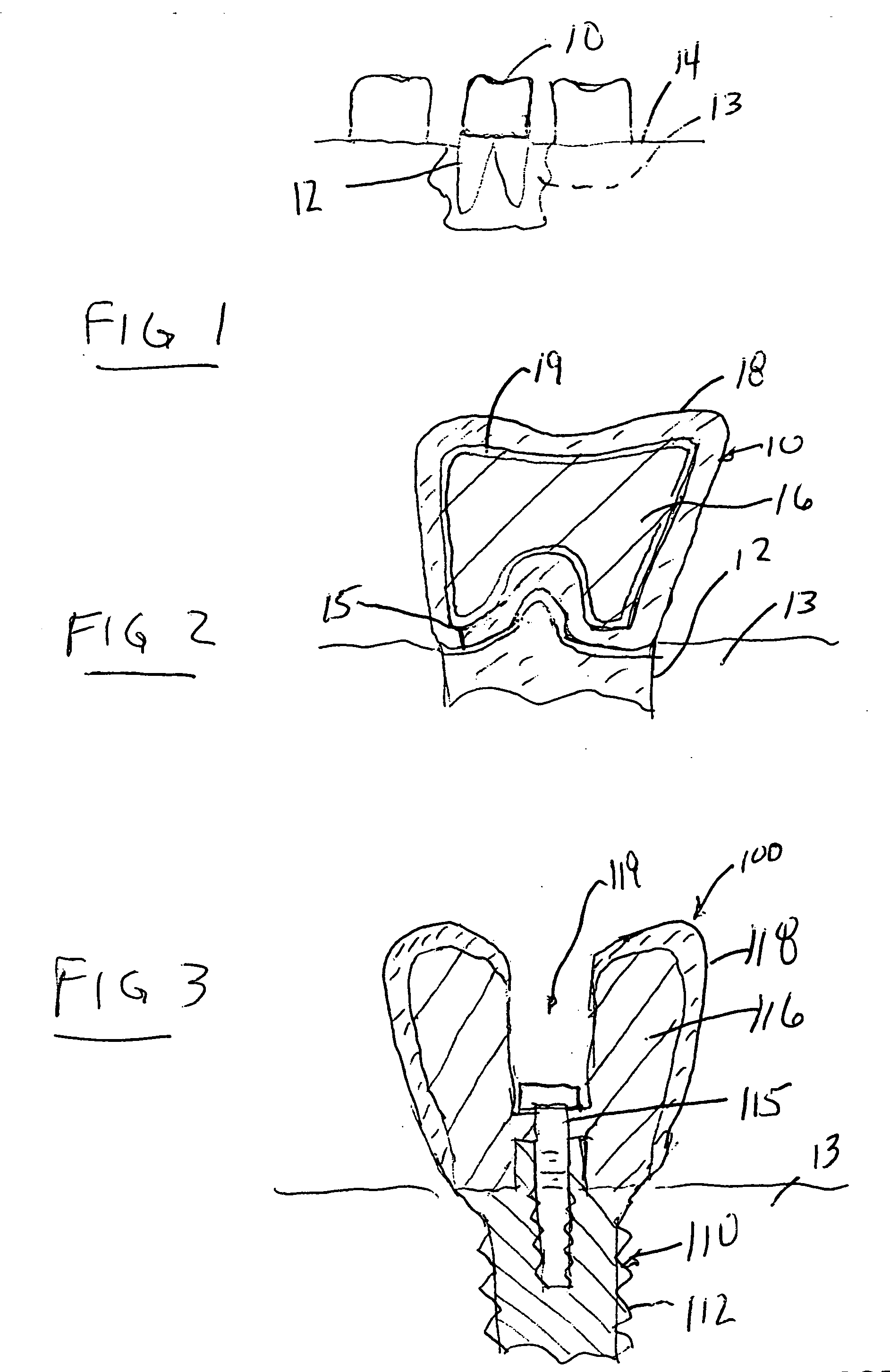

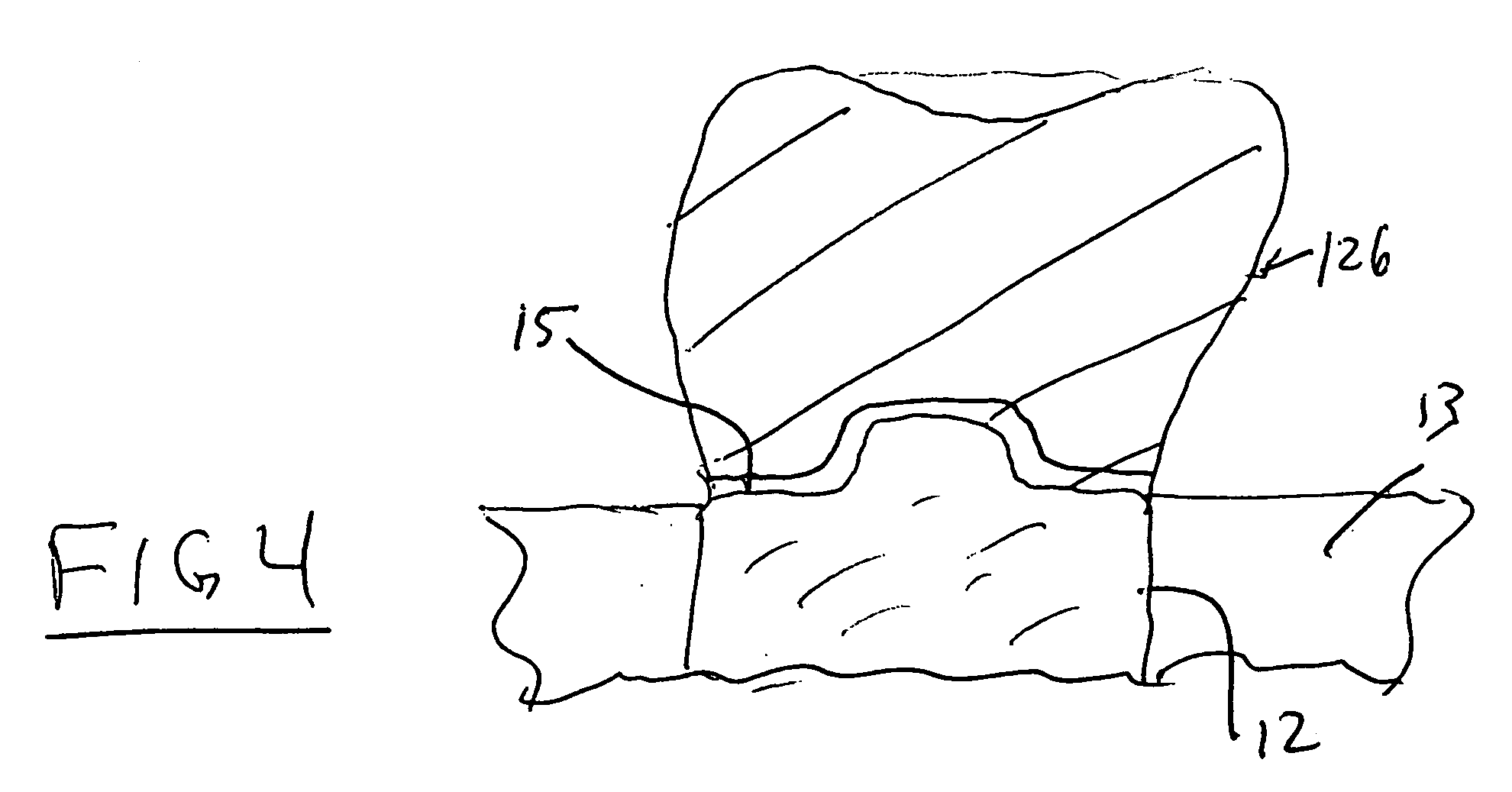

Dental crown composed of anodized titanium

InactiveUS20070003908A1Cost effectiveReadily apparentDental implantsTooth crownsNatural toothAnodizing

A dental crown includes a formed crown body simulating the contours of a natural tooth, composed of anodized titanium and permanently secured onto an abutment that is fixed into the patient's mouth. The crown body can include a ceramic layer, such as porcelain, adhered to, and overlaid on, the body. The body is preferably anodized to the extent that it displays a gold color, although other colors and varying shades are possible and effectively selectable by controlled use of the anodizing process.

Owner:SEQUOIA DENTAL STUDIO

Preparation method of orthodontic color coating tooth arch wire

InactiveCN102430511AUniform thicknessNo pollution in the processPretreated surfacesCoatingsArch wiresGold colour

A preparation method of an orthodontic color coating tooth arch wire is disclosed, and comprises the steps of: (1), performing surface pretreatment for a metal tooth arch wire; (2) straightening and fixing the pretreated metal tooth arch wire; and (3) standing the coated metal tooth arch wire at clean room temperature for 15min, curing for 10-30min at the curing temperature of 150-180 DEG C to obtain the color coating tooth arch wire. The preparation method provided by the invention is simple, and not affected by the shape of the tooth arch wire, causes no environmental pollution and can form a color coating (such as imitative golden, red, black, yellow, blue, green, pink and army green and the like) on the surface of the metal tooth arch wire so as to beautify the tooth arch wire. And the coating prevents the base metal from being directly contacted with oral saliva so as to effectively inhibit the base metal ions from releasing to human body and improve the using safety.

Owner:NANCHANG HANGKONG UNIVERSITY +1

Ornament parts

InactiveCN101802250AImprove reflectivityIncrease brightnessVacuum evaporation coatingSputtering coatingCarbideGold colour

To provide a golden ornament part having an Au-containing hard film on the surface which is characterized by exhibiting both gloss and color tone inherent in gold and having high lightness and high quality. A golden ornament part provided with a hardened layer which is composed of a primary layer constituted of nitride, carbide or carbonitride of one or more metals selected from among Ti, Zr and Hf, a finish layer made of Au or an Au alloy of arbitrary composition such as Au-Ni alloy or Au-Cu-Pd alloy, and a reflective layer that is made of a metal having a reflectance higher than that of the finish layer, namely, Ru, Pd, Rh, Ag, Os, Ir, Pt or the like and that is formed between the primary layer and the finish layer. Thus, the invention brings about high-lightness and high-quality golden ornament parts which effectively exhibit both gloss and color tone inherent in gold.

Owner:CITIZEN WATCH CO LTD

Color cosmetic

ActiveUS8252298B2Eliminate riskImprove adaptabilityCosmetic preparationsOrganic active ingredientsSkin complexionMedicine

A foundation having a shade which covers a wide spectrum of different skin tones and undertones, comprises red and gold interference pigments, which provide a formula that is adaptable to both red and yellow skin undertones. The composition virtually eliminates the risk of application of the wrong foundation color, and provides enhanced color and textural effects, and superior optical performance.

Manufacture method of antique copper imitation artware

The invention discloses a manufacture method of antique copper imitation artware, which causes artware newly produced to represent antique copper appearance. The manufacture method is realized by the following technical schemes: putting a trimmed white body on a paint spray rack; evenly spraying diluted nitro black paint on the white body; evenly blending gold varnish with bronze powder at the ratio of 1:1 to form gold ink; dipping little gold ink with a pig hair brush; rubbing a small piece of glass; then, sweeping the white body sprayed with black paint with the brush, wherein the extrude part becomes golden because of contacting the gold ink on the brush, and the concave part is still black because the concave part can not contact the gold ink; thus, quickly sweeping the whole surface; placing for certain time; and after the swept gold ink is dry, spraying one layer of varnish to obtain the artware. The product is bright and vivid and can be stored for a long term.

Owner:刘声兵

Novel medical lavender with good combustion performance and without powder pulling-off

InactiveCN101143227ARegular shapeImprove combustion performanceGaseous substancesFlavorProduction rate

The invention discloses a novel perfume, which is provided with good combustibility, and the powder is not fallen. The novel perfume is made by uniformly mixing wood powder or carbon powder, flavor powder and a bond to be processed by mould pressing, or the novel perfume is made by uniformly mixing the wood powder, the carbon powder, the flavor powder and the bond to be processed by mould pressing as the strip column shape or the shape of a disk body or the shape of the prior perfume. Coloring matter can be added into the prescription and can be not added; the surface of the perfume body can be coated with a silver decorative layer or a golden decorative and can be not coated. The perfume is provided with the good combustibility; the powder is not fallen; the perfume is not easily broken off or crashed; the commodity value of the perfume with structured appearance, the coloring matter and the decorative layer can be increased greatly. In addition, the perfume is pressed by the mould, which is convenient for the mechanized production and improves the productivity greatly.

Owner:莫永发

Fading proof process for aluminum alloy electrophoresis titanium gold

ActiveCN102817060AImprove heat resistanceImproves UV resistanceSurface reaction electrolytic coatingElectrophoresisGold colour

The invention discloses a fading proof process for aluminum alloy electrophoresis titanium gold. The process is characterized by comprising degreasing, alkaline etching, oxidation, electrolytic coloring for 7-12 min at 25-35 DEG C, moderate temperature sealing at 45-60 DEG C for 1-3 min, hot water washing, electrophoresis with voltage of 120-140 volt and curing. The electrophoresis titanium section produced by the invention does not show a color shallowing problem after electrophoresis baking or a fading problem in a usage process, and has good popularization value.

Owner:佛山金兰铝厂有限公司

Gold tattoo

An article of adornment in the form of a temporary gold tattoo comprises a gold leaf applied to a synthetic medical skin using Japan Gold Size, and die-cut to the desired shape. The synthetic medical skin is sterile, hypoallergenic and allows skin to which the adornment is adhered to breathe. Thus, the resulting temporary gold tattoo is thin and comfortable to wear and yet stays firmly in place, even withstanding normal bathing for a few days.

Owner:DAVANZO SARAH

Color correction methods for golden aluminum film

InactiveCN101178331AQuickly determine hueReduce consumptionColor measuring devicesTest sampleGold colour

Owner:广东东南薄膜科技股份有限公司

Gold-imitation coated glass and preparation technology thereof

ActiveCN104441841AStrong imitation gold decorationStrong color repeatabilityLayered product treatmentVehicle componentsAcid corrosionTitanium nitride

The invention belongs to the technical field of vacuum coating products, and particularly relates to gold-imitation coated glass and a preparation technology thereof. The gold-imitation coated glass comprises a glass substrate, and a hydrophilic ionized layer, a pure titanium film layer, a pure titanium and titanium nitride mixed film layer and a nitrogen-rich heat treatment layer which are sequentially arranged on the surface of the glass substrate. The gold-imitation coated glass has the relatively good surface glossiness, and a gold-imitation film layer is high in adhesive force, so that a relatively rich color selection effect can be provided, and the color repeatability is high; the gold-imitation coated glass has relatively high film layer binding force, a relatively compact surface effect, relatively high film layer wear resistance, acid corrosion resistance and the like, thus being widely applied to window glass such as a mobile phone panel and a computer touch screen.

Owner:GUANGDONG ZHENHUA TECH CO LTD

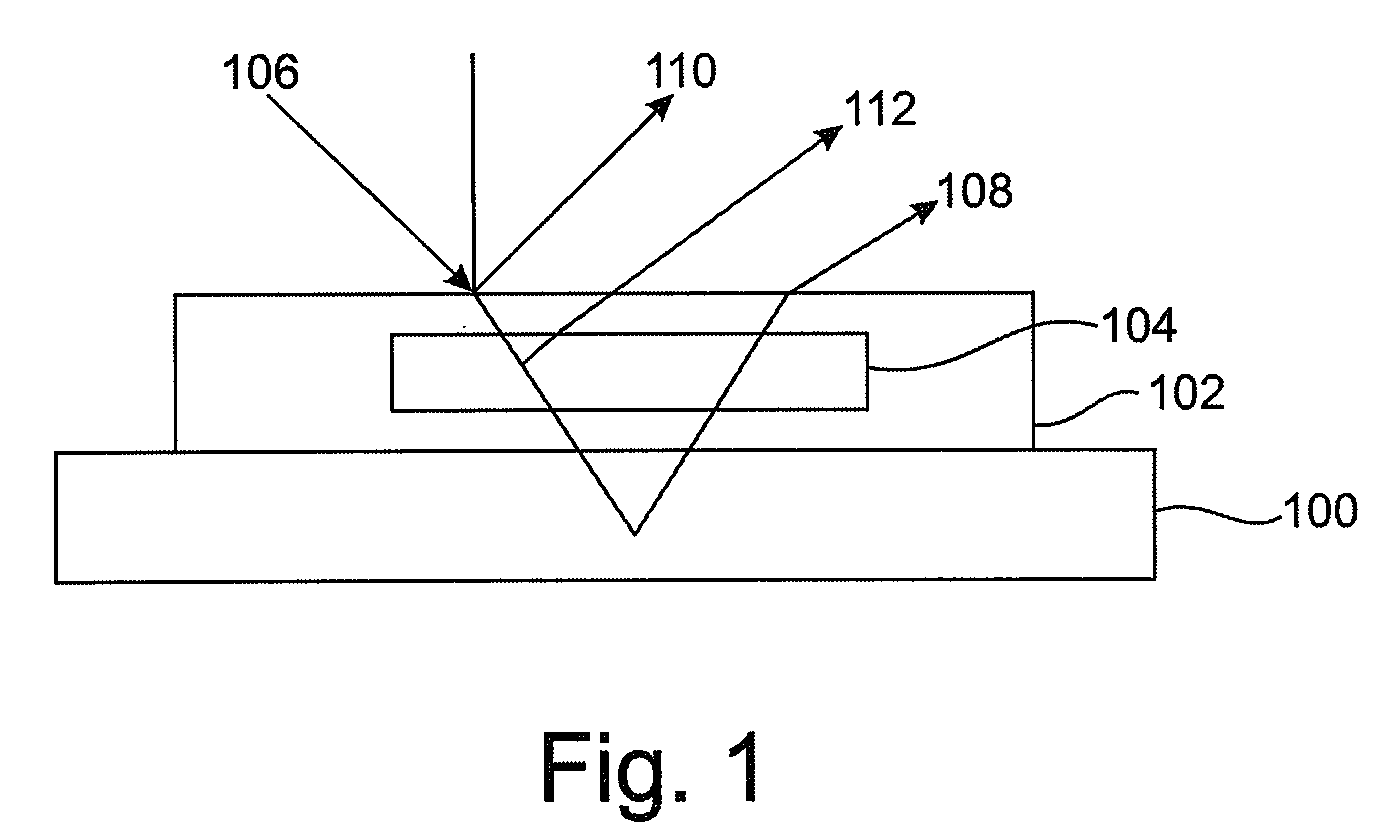

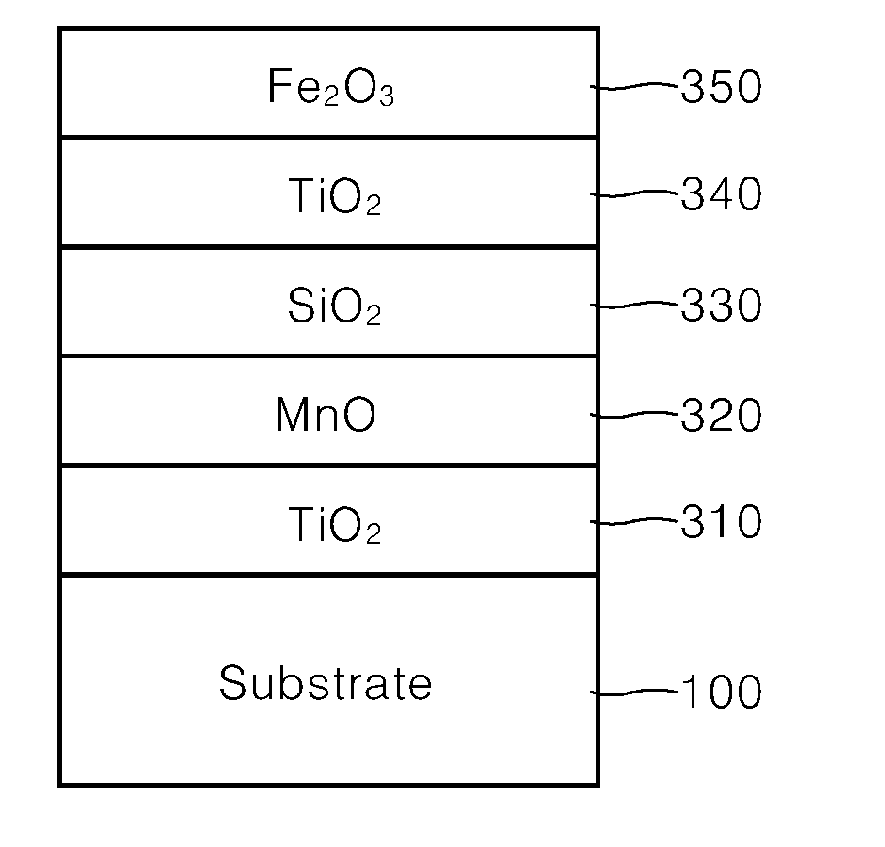

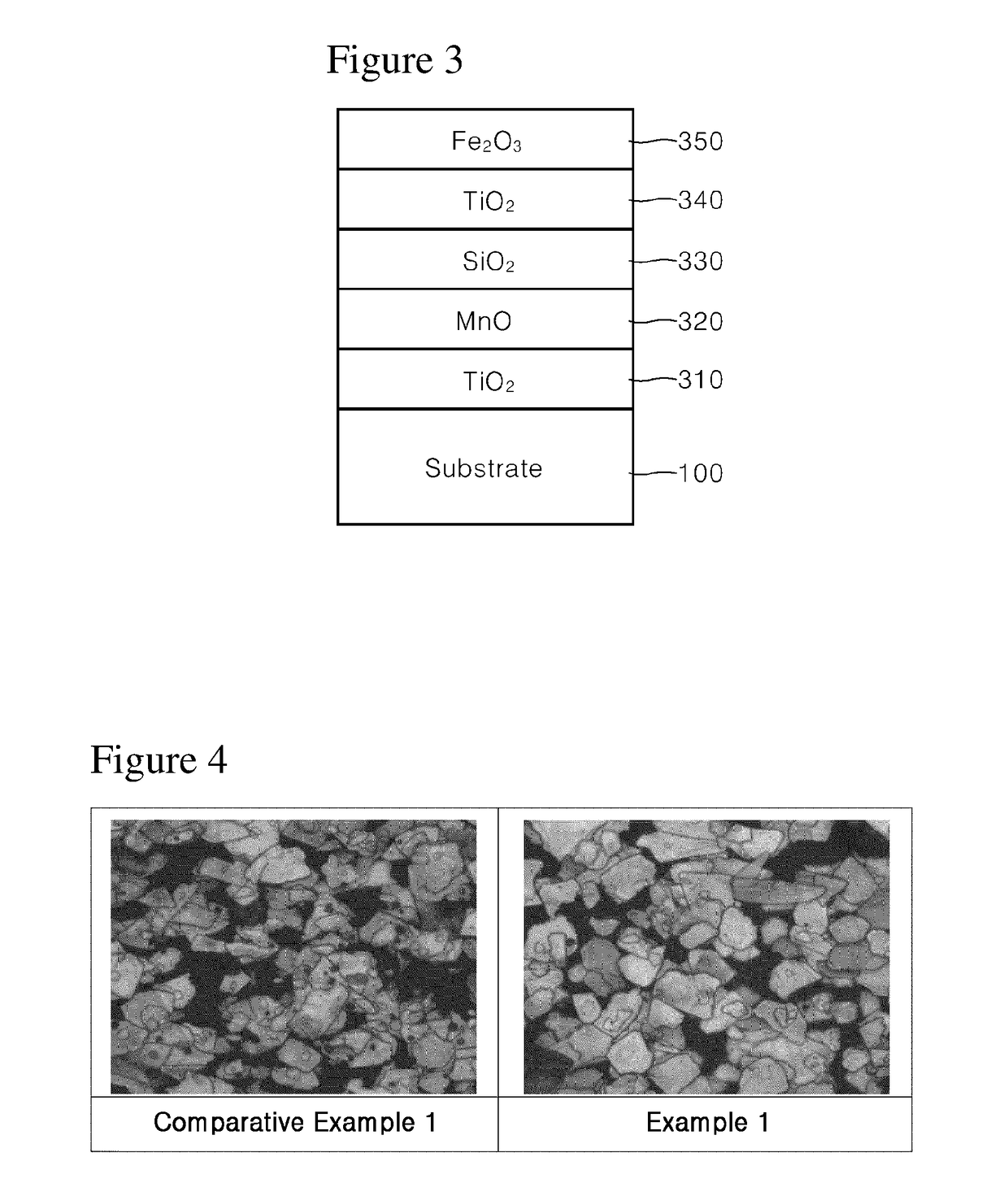

Gold pigment with high color strength

A gold pigment is disclosed. The gold pigment according to the present disclosure includes a substrate; a first coating layer formed on a surface of the substrate and including a metal oxide having a refractive index of more than 1.8; a second coating layer formed on the first coating layer and including an oxide containing manganese; a third coating layer formed on the second coating layer and including a colorless metal oxide having a refractive index of 1.8 or less; a fourth coating layer formed on the third coating layer and including a metal oxide having a refractive index of more than 1.8; and a fifth coating layer formed on the fourth coating layer and including Fe2O3.

Owner:CQV

High-brightness special titanium gold ink

The invention provides high-brightness special titanium gold ink, which meets the coloring requirement. In addition, the color does not change at high and low temperatures; meanwhile, the alcohol resistance is realized; eraser test requirements are met. The high-brightness special titanium gold ink is characterized by being prepared from the following ingredients including 5 to 7 percent of aluminum powder with the particle diameter being 20 mum, 5 to 7 percent of aluminum powder with the particle diameter being 5 mum, 58 to 62 percent of transparent ink, 3 to 5 percent of red color masterbatch, 8 to 12 percent of mirror surface gold, 2 to 2.5 percent of original yellow ink and the balance special ink curing agents through being metered in percentage by mass. The sum of the percentage of all substances is 100 percent.

Owner:SUZHOU ANJIE TECH

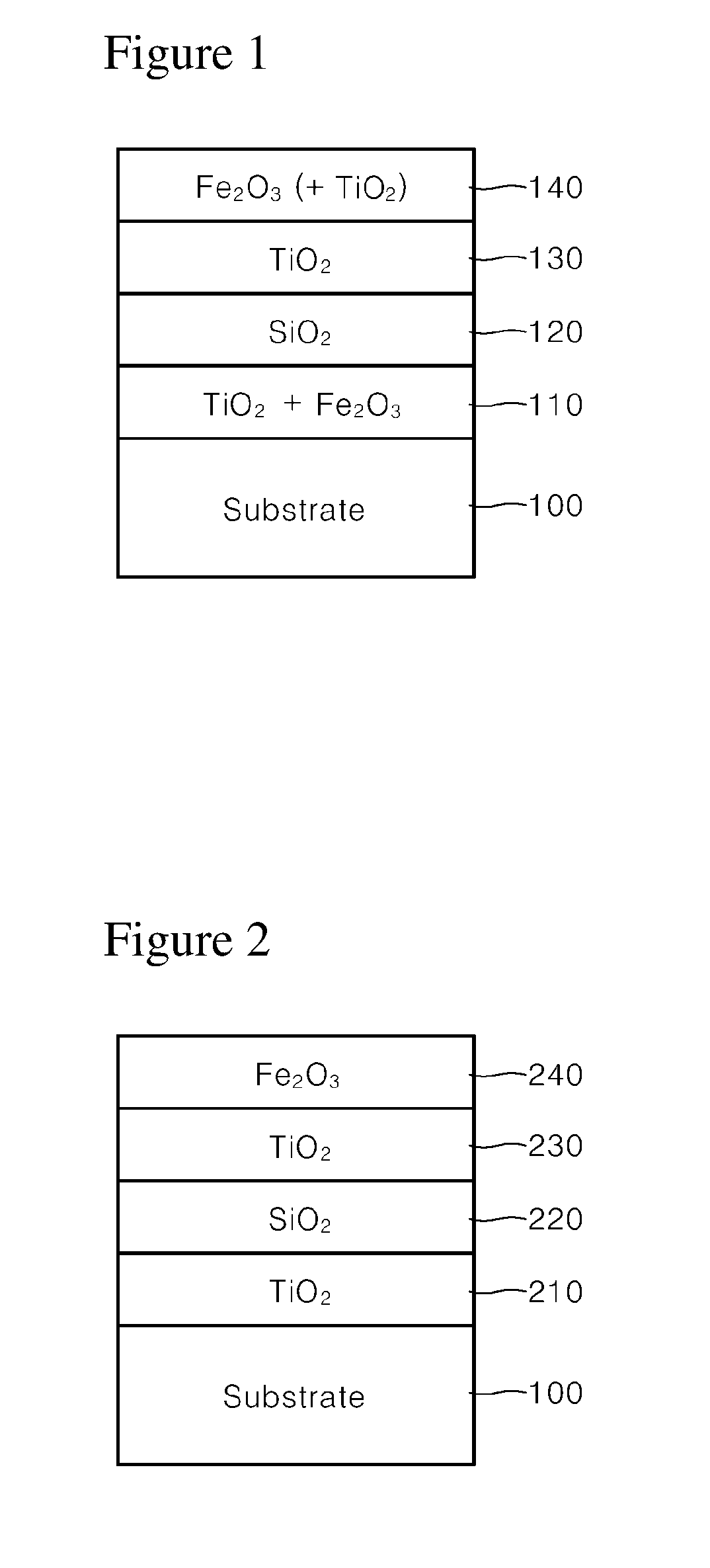

Pure-blonde pearlescent pigment prepared from solid wastes produced in mica powder purification process

InactiveCN108329722AReduce the cost of raw materials for productionRelieve pressureInorganic pigment treatmentDispersityWeather resistance

The invention discloses pure-blonde pearlescent pigment prepared from solid wastes produced in a mica powder purification process. The pure-blonde pearlescent pigment comprises a mica powder substrateprepared from solid wastes produced in the mica powder purification process and a composite layer covering the surface of the mica powder substrate, and the pure-blonde pearlescent pigment is characterized in that the thickness of the mica powder substrate is 0.6 to 2 micrometers, the particle size range is 5 to 70 micrometers, D50 is equal to 25 plus or minus 2 micrometers, a first layer of thecomposite layer is tin oxide, a second layer is titanium oxide, a third layer is ferric oxide, a fourth layer is aluminum oxide, and a fifth layer is titanium oxide. The pure-blonde pearlescent pigment is simple in structure and convenient in operation. The solid wastes produced in the mica powder purification process are used for preparing the pure-blonde pearlescent pigment, so that the production raw material cost of the pure-blonde pearlescent pigment is reduced, the pressure for processing tailings used as the solid wastes can be alleviated, the product is relatively good in blonde purity, high in blonde saturation, excellent in brightness, and good in dispersity, weather resistance and chemical stability when in use.

Owner:JIANGSU BEILIDE NOVEL MATERIALS

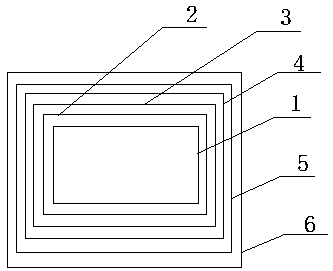

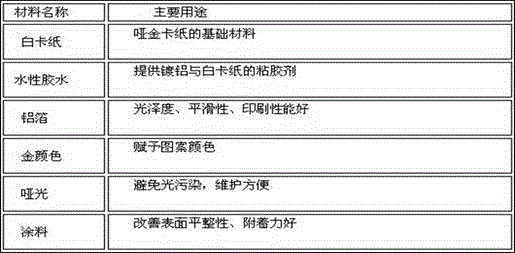

Matted gold cardboard and intaglio printing process thereof

InactiveCN106337319AReduce processingCompound transfer is convenientFlexible coversCoatings with pigmentsCardboardWaste treatment

The invention relates to a matted gold cardboard and an intaglio printing process thereof. The matted gold cardboard comprises a white cardboard, and a glue layer, an aluminum coated layer, a color coating layer, a matte layer and a painting layer; the color of color coating layer is gold, the C value of gold is 5-7, the M value of gold is 13-17, the Y value of gold is 12-16, and the K value of gold is 0-0.5; the tension of the aluminum coated layer is larger than or equal to 36 Dyn, and the thickness of the aluminum coated layer is 0.015-0.04 mm. According to the printing process, an original production process with transferring of the matted gold cardboard is changed, combined transferring is more convenient, production procedures are reduced, the sequence of steps is changed, meanwhile, the effect of transferring the matted gold cardboard can be achieved, and therefore production cost is greatly lowered; the printing process controls color difference easily, achieves even coating, and is simple and practicable; resource conservation, environmental protection and reduction of waste treatment are easily achieved.

Owner:JIANGSU SHUNTAI PACKAGING & PRINTING SCI TECH

Functional Metallicity Ion Band

ActiveUS20090306705A1Rapid and safe and continuous treatmentLow costElectrotherapySurgeryThin metalAdhesive

A pair of functional metal ion bands are provided. The pair of functional metal ion bands are attached to meridians and acupoints of the human body in a simple manner to induce a smooth flow of current in the body, thereby rapidly changing a disease condition to a normal state. The pair of functional metal ion bands comprise a gold-colored thin metal plate as a positive electrode and a silver-colored thin metal plate as a negative electrode wherein the gold-colored thin metal plate is composed of Cu and a metal selected from Ag, Au and Pt and the silver-colored thin metal plate is made of an alloy of Al, Si, Fe, Cu, Mn, Mg and Zn. The pair of functional metal ion bands are manufactured by processing each of the thin metal plates to have a thickness of 1 μm to 1 cm and a diameter of 1 mm to 50 cm, and attaching the processed metal plate to one side of a soft adhesive fabric using an adhesive.

Owner:KIM KYOUNG WON

Imitation golden decoration film capable of replacing gold foil and preparation method

InactiveCN111605350AGolden color brightImprove antioxidant capacityDecorative surface effectsVacuum evaporation coatingParaffin waxAntioxidant capacity

The invention discloses an imitation golden decoration film capable of replacing gold foil and a preparation method of the imitation gold decoration film. The imitation golden decoration film comprises a base film, and a mold release agent layer, a first coating layer, an aluminum coating layer, a second coating layer and a gelatinous layer which are sequentially arranged on the base film, whereinthe first coating layer and the second layer are formed by mixing and coating of golden paints and an antioxidant. The imitation golden decoration film disclosed by the invention can replace gold foils, the color and luster are the same as those of the gold foils, and are golden bright, so that the same effect can be achieved; graphene oxide is added to the paint, so that the antioxidant abilityof the imitation golden decoration film is improved, and blackening phenomenon cannot generate after the imitation golden decoration film is used for a long time, and the imitation golden decoration film has favourable anticorrosion performance and waterproof performance; paraffine emulsion is adopted as a material of the mold release layer, the wax capacity coated onto the base film is uniform, the film forming is uniform, and the stripping effect is good; the preparation method is simple and convenient, environmentally-friendly and economic; the material costs are greatly reduced; the usingmethod is convenient; and the imitation golden decoration film is applied to decoration construction of all kinds of occasions.

Owner:JIANGSU KINGHENG PACKAGE MATERIAL CO LTD

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com