Pure-blonde pearlescent pigment prepared from solid wastes produced in mica powder purification process

A pearlescent pigment and mica powder technology, applied in the field of pearlescent pigments, can solve the problems of high production cost of pearlescent pigments, increased environmental processing pressure, etc., and achieve the effects of reducing the cost of raw materials for production, excellent pigment brightness and simple structure.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

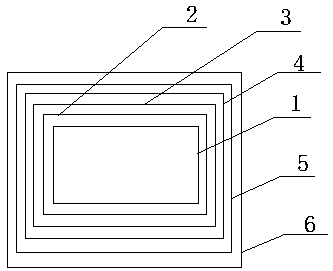

[0012] like figure 1 As shown, the present invention discloses a pure golden pearlescent pigment produced by using the solid waste produced in the process of purifying mica powder, including making the solid waste produced in the process of purifying mica powder into a mica powder base and coating the mica powder The composite layer on the base surface, the thickness of the mica powder base is 0.6-2 microns, the particle size range is 5-70 microns, D50=25±2 microns, the first layer of the composite layer is tin oxide, and the second layer is Titanium oxide, the third layer is iron oxide, the fourth layer is aluminum oxide, and the fifth layer is titanium oxide. The coating rate of the first layer of the composite layer is 0.5-2.5%, and the coating rate of the second layer of the composite layer is 30-40%, the coverage rate of the third layer of the composite layer is 1-4%, the coverage rate of the fourth layer of the composite layer is 0.5-2.5%, and the coverage rate of the fi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com