A preparation method and preparation device of emulsion explosive containing calcium salt

A technology for emulsified explosive and preparation device, which is applied in explosive processing equipment, explosives, explosive composite components, etc., to achieve the effects of saving time and cost, alleviating operating pressure, and improving emulsification speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

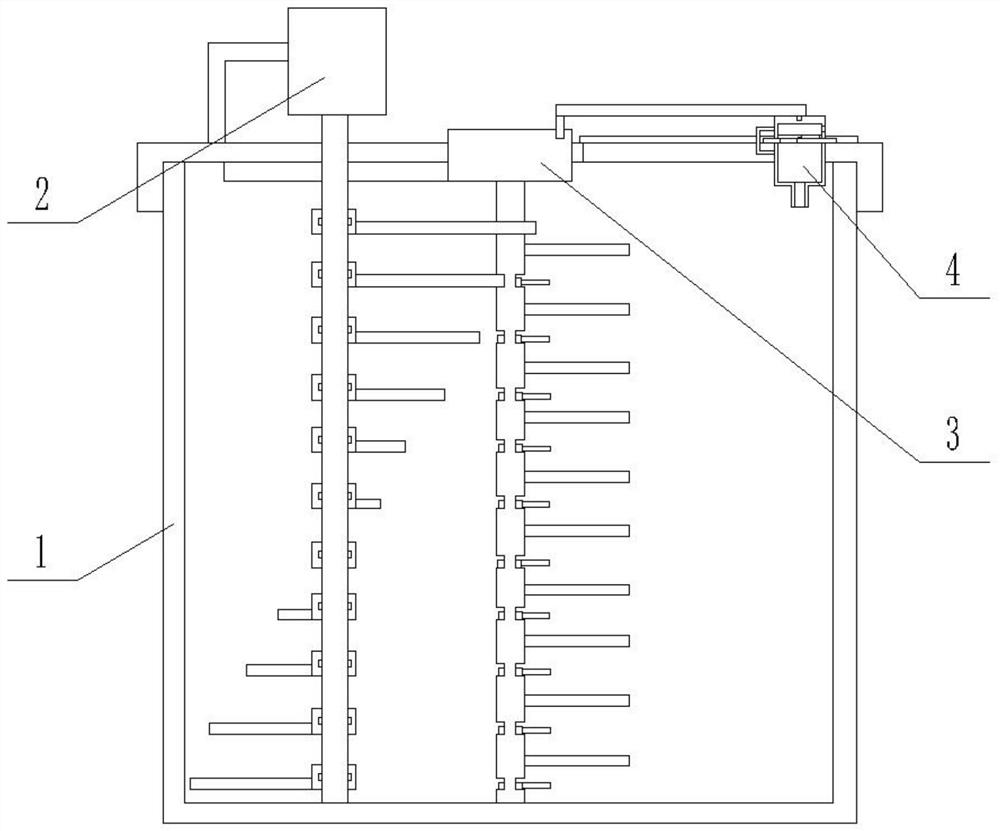

[0021] Specific implementation mode one: as Figure 1-7 As shown, this embodiment describes a preparation device for emulsion explosives containing calcium salts, including a storage tank 1, a stirring device I2, a stirring device II3 and an intermittent feeding device 4; the center of the storage tank 1 is provided with a stirring device II3 , the eccentric position of the storage tank 1 is provided with a stirring device I2, and the stirring device I2 and the stirring device II3 cooperate with each other; the intermittent feeding device 4 is arranged on the upper end of the storage tank 1, and the intermittent feeding device 4 and the stirring device Ⅱ3 connection.

specific Embodiment approach 2

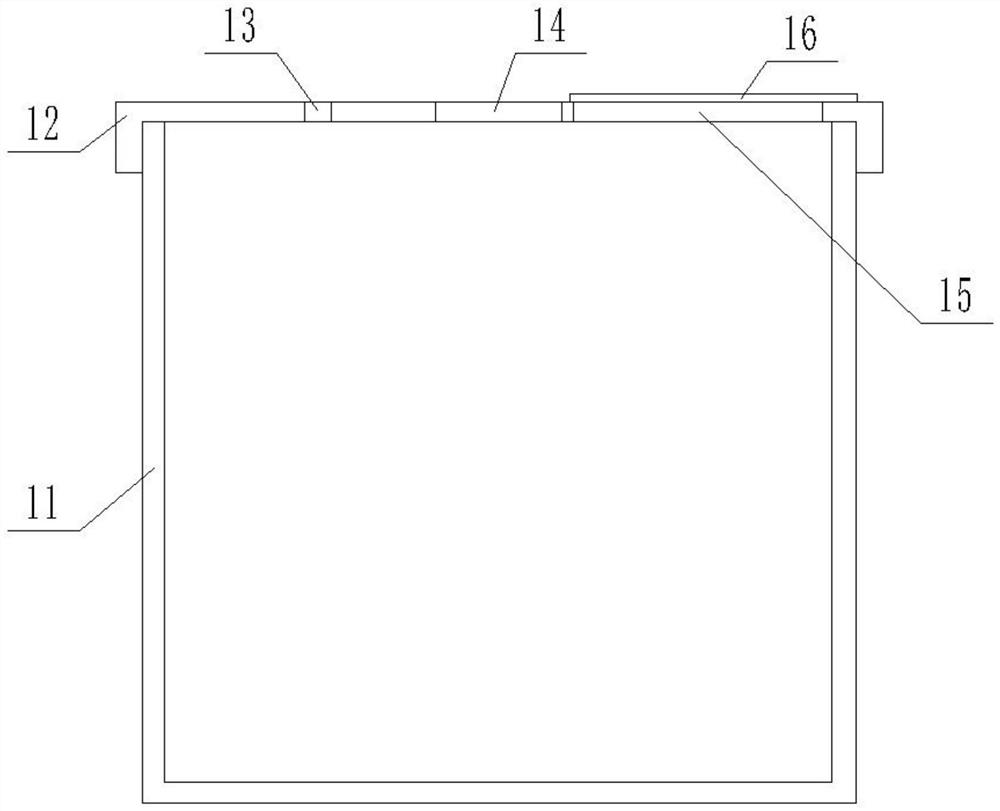

[0022] Specific implementation mode two: as Figure 1-7 As shown, this embodiment is a further description of specific embodiment one. The storage tank 1 includes a tank body 11, a cover 12 and a rack 16; the cover 12 is screwed to the upper end of the tank body 11, and the cover 12 A round hole I14 is provided at the center of the top of the top, and round holes II13 and chute 15 are respectively provided on both sides of the round hole I14;

specific Embodiment approach 3

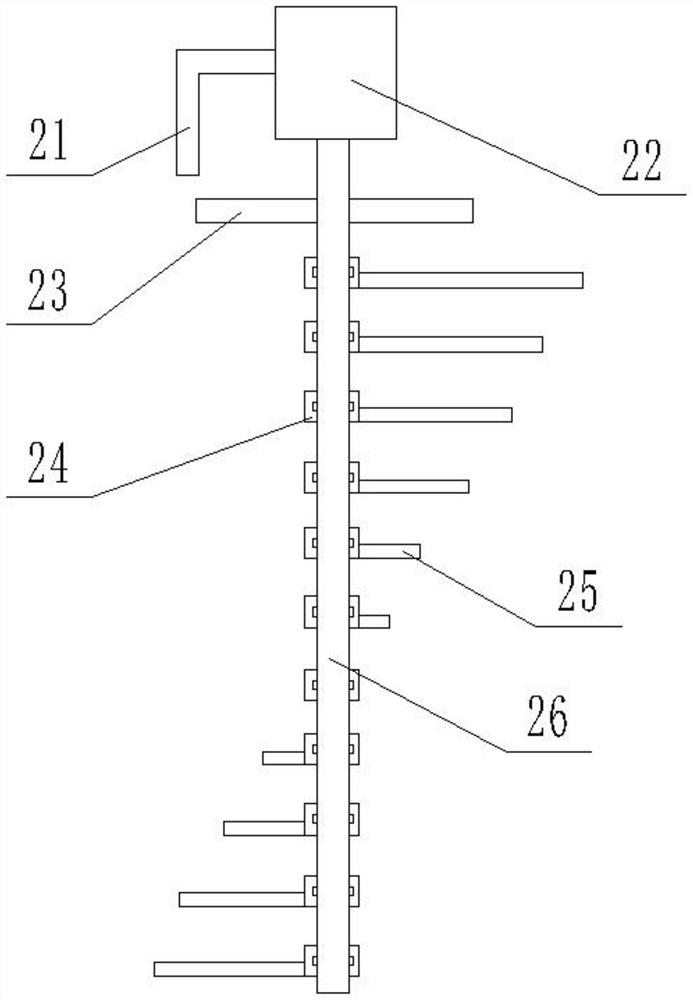

[0023] Specific implementation mode three: as Figure 1-7 As shown, this embodiment is a further description of specific embodiment one. The stirring device I2 includes a motor bracket 21, a motor 22, a gear I23, a connecting ring 24, a plurality of stirring rods I25 and a fixed rod 26; the motor 22 is fixedly connected to the cover 12 through the motor bracket 21, the output shaft of the motor 22 passes through the round hole II13 and is fixedly connected with a fixed rod 26; the fixed rod 26 is fixedly connected with a gear I23 and the fixed rod 26 is uniform from top to bottom A plurality of connecting rings 24 are arranged; each connecting ring 24 is fixedly connected with a corresponding stirring rod I25; the side of each stirring rod I25 is provided with a slot.

[0024] Specific implementation mode four: as Figure 1-7 As shown, this embodiment is a further description of Embodiment 1. Each connecting ring 24 includes a ring 241, a stopper I 243 and a spring 244; the f...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com