Patents

Literature

36results about How to "Fast emulsification" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Bio-enzyme bacteriostatic oil stain-emulsifying preparation

InactiveCN104498204AFast emulsificationEnhanced emulsification and decompositionInorganic/elemental detergent compounding agentsNon-ionic surface-active compoundsDecompositionStain

The invention discloses a bio-enzyme bacteriostatic oil stain-emulsifying preparation prepared from a surfactant, a chelating agent, a rust-proof preservative, triethanolamine, an environmental-protection organic solvent, a bactericide, D-limonene, bio-enzyme, an enzyme stabilizer and deionized water according to a certain weight ratio. The bio-enzyme bacteriostatic oil stain-emulsifying preparation allows the bio-enzyme stabilizer with the bio-enzyme, the surfactant and the bactericide to form a bio-enzyme complex system under a proper acidity and alkalinity condition, has the oil stain emulsification decomposition effect enhanced, has mild and no pungent smell, and provides anti-corrosion protection for light metals aluminum, zinc and the like.

Owner:JIANGSU XUE BAO DAILY CHEM CO

Ester emulsifying agent used for industrial emulsion explosive and preparation method thereof

ActiveCN101602634AFast emulsificationMatrix stabilizationNon-explosive/non-thermic compositionsAlkyl transferFiltration

The invention relates to an ester emulsifying agent used for an industrial emulsion explosive and a preparation method thereof. The ester emulsifying agent comprises an oily group component, a linking group component, a polar group component and a base oil component, the mol ratio proportion of the oily group component to the linking group component to the polar group component is 1:1-2:1-4, the oily group component, the linking group component and the polar group component react to generate polyolefine acid ester, then the polyolefine acid ester is diluted by using the base oil component, and the weight proportion of the polyolefine acid ester to the base oil component at the time of dilution is 1:0.8-1.2. The preparation method comprises the following steps that: in an alkylation process, the oily group component is put into a reactor and is heated, then the linking group component is put into the reactor, the temperature is kept, the mixture is stirred for 0.5-1 hour, the temperature is raised to 200-240 DEG C, and a reaction is carried out for 2-5 hours; and in an esterification process, the polar group component is added into polyolefine carboxylic acid or polyolefine carboxylic acid anhydride obtained by the reaction, the mixture is heated when being stirred, the reaction time lasts for 7-16 hours, the base oil component is added for dilution, and a product of the ester type emulsifying agent is obtained by filtration.

Owner:锦州康泰润滑油添加剂有限公司

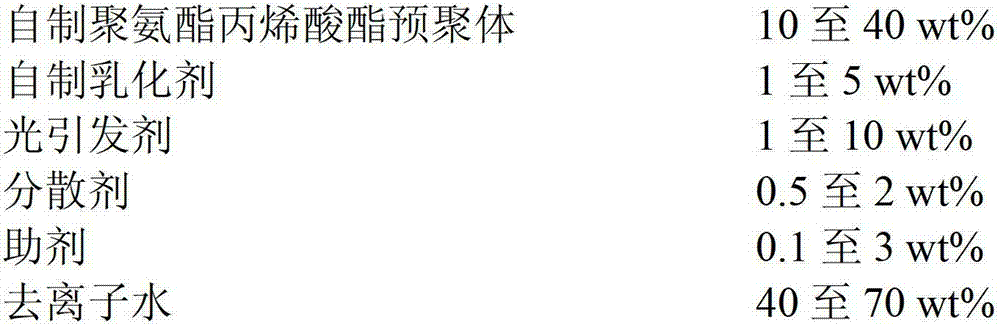

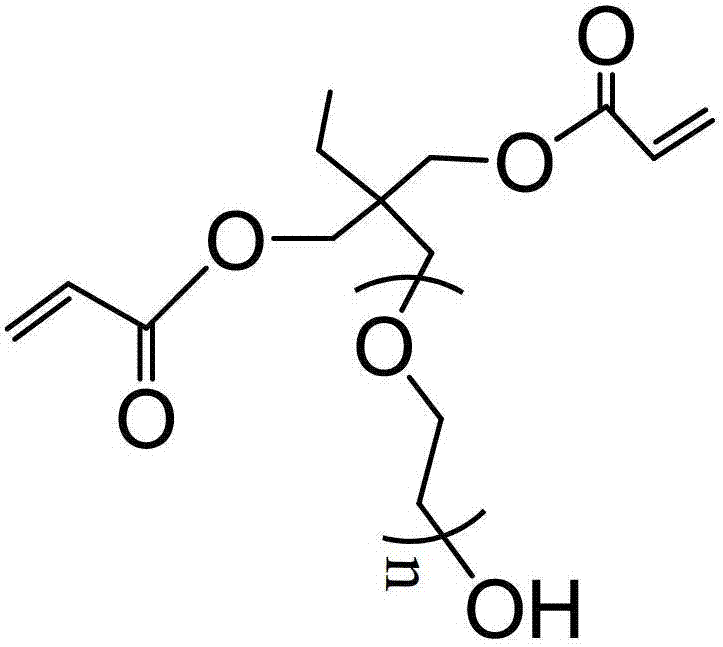

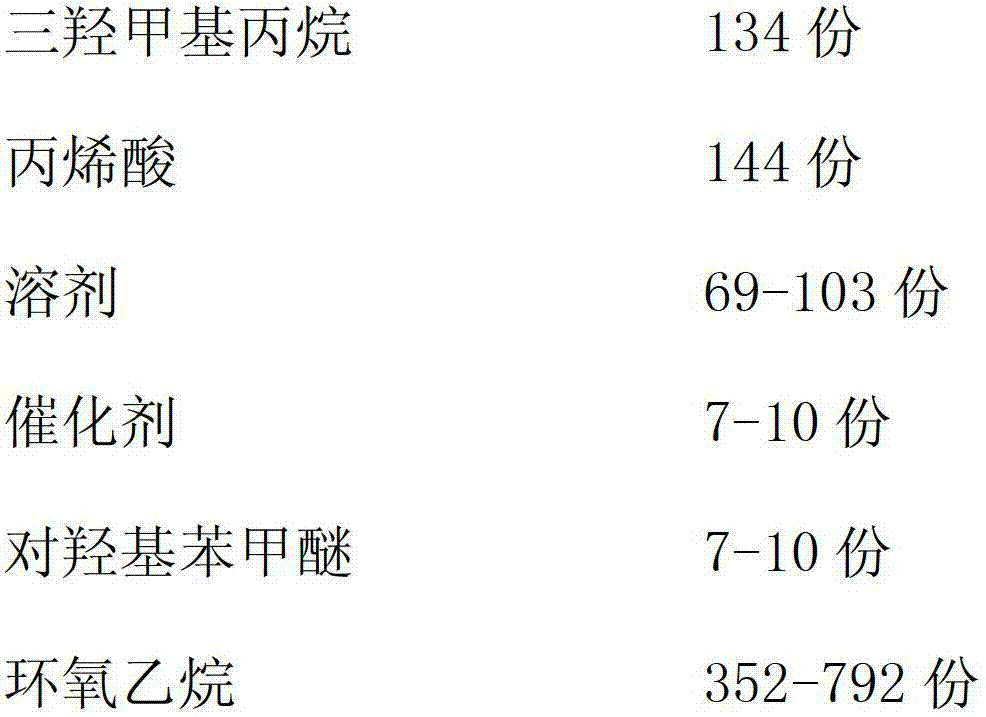

Environment-friendly water-based UV (ultraviolet) curable coating and production method

ActiveCN102876223AImprove stabilityGood mechanical properties of paint filmPolyurea/polyurethane coatingsWater basedUrethane acrylate

The invention discloses an environment-friendly water-based UV (ultraviolet) curable coating and a production method. The environment-friendly water-based UV curable coating comprises 10-40wt% of self-made polyurethane acrylate prepolymers, 1-5wt% of self-made emulsifier, 1-10wt% of photoinitiator, 0.5-2wt% of dispersing agents, 0.1-3wt% of auxiliaries and 40-70wt% of water. The production method of the coating includes steps of adding the self-made polyurethane acrylate prepolymers, the self-made emulsifier and partial defoamer into a dispersing cylinder in a reactor, heating the same to the temperature of 30-50 DEG C and uniformly mixing; cooling and adding the dispersing agents, wetting agents, partial defoamer, leveling agents, deionized water and the photoinitiator to sufficiently stir, and obtaining the ivory environment-friendly water-based UV curable coating after dedusting and filtering. The water-based UV curable coating has the advantages of environment-friendliness, good stability, good mechanical performances of film paining and the like, and the production method thereof is easy and feasible.

Owner:CHINA ACADEMY OF ENG PHYSICS FUNCTION MATERIAL RES INST

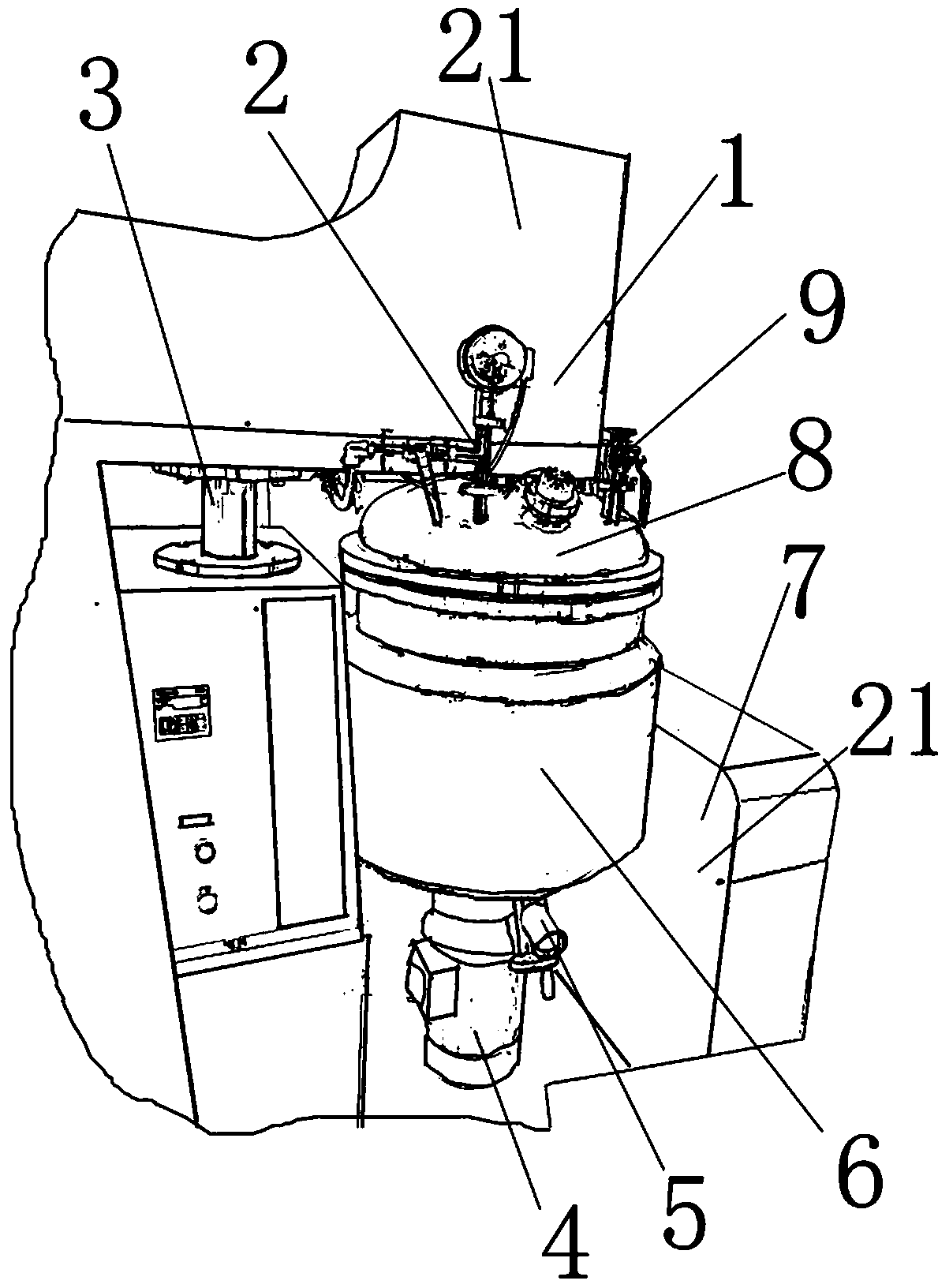

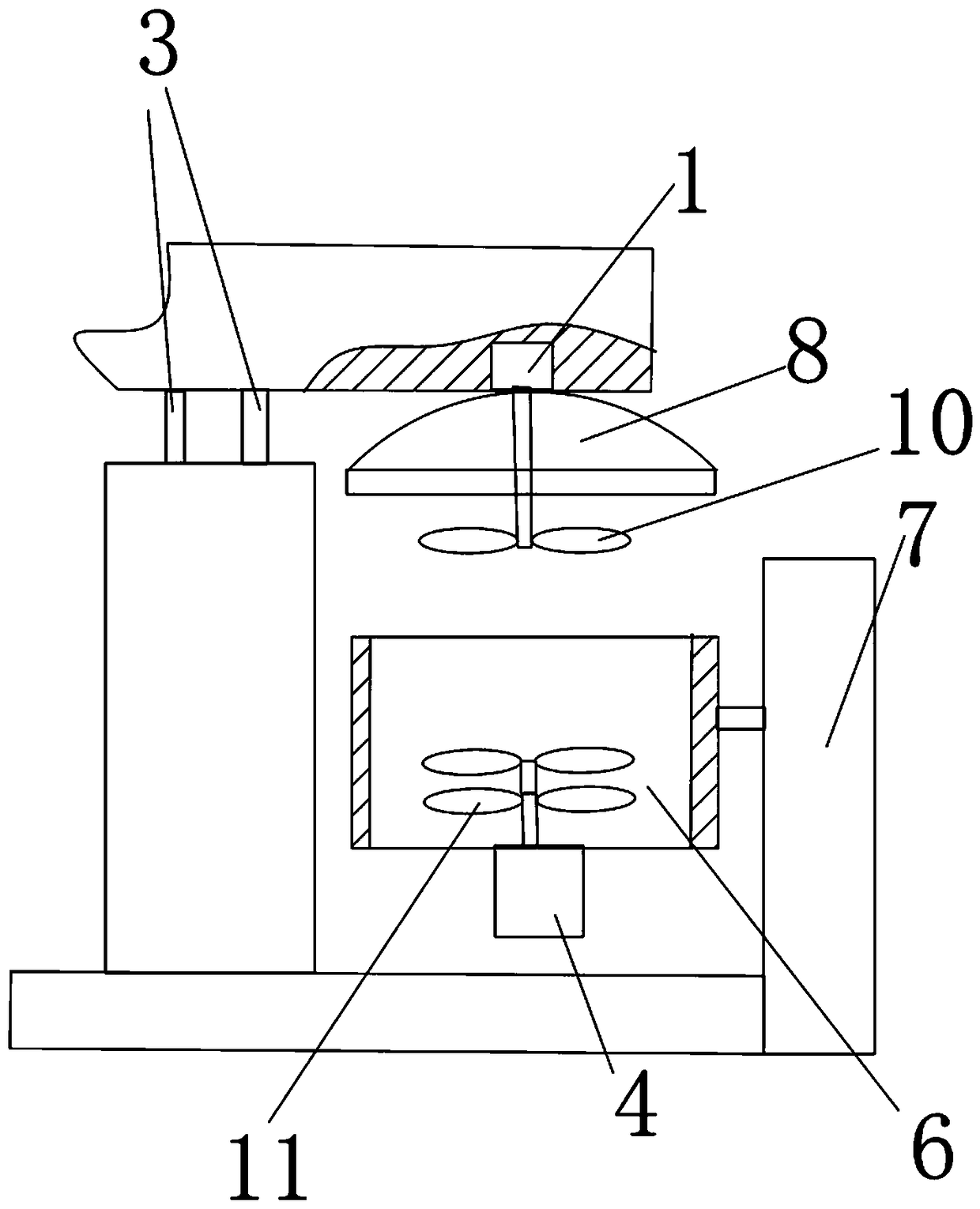

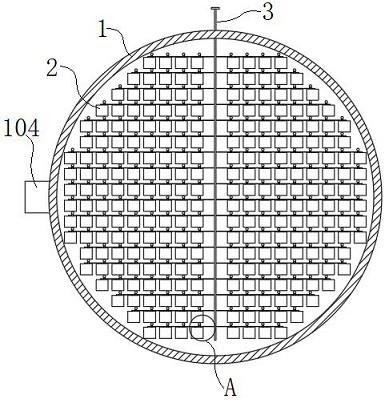

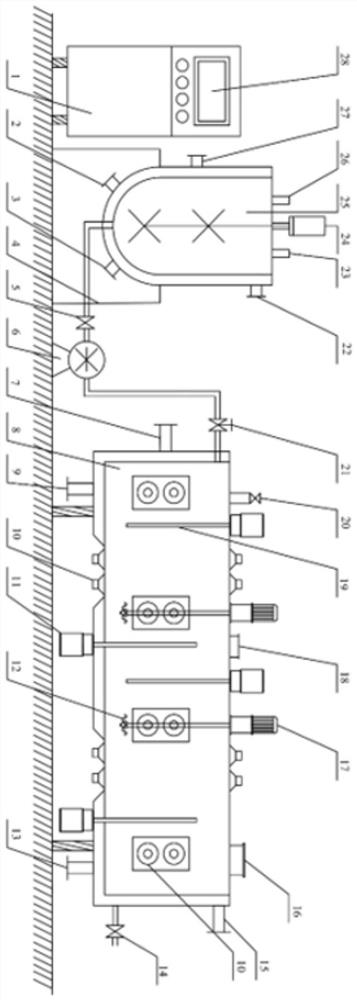

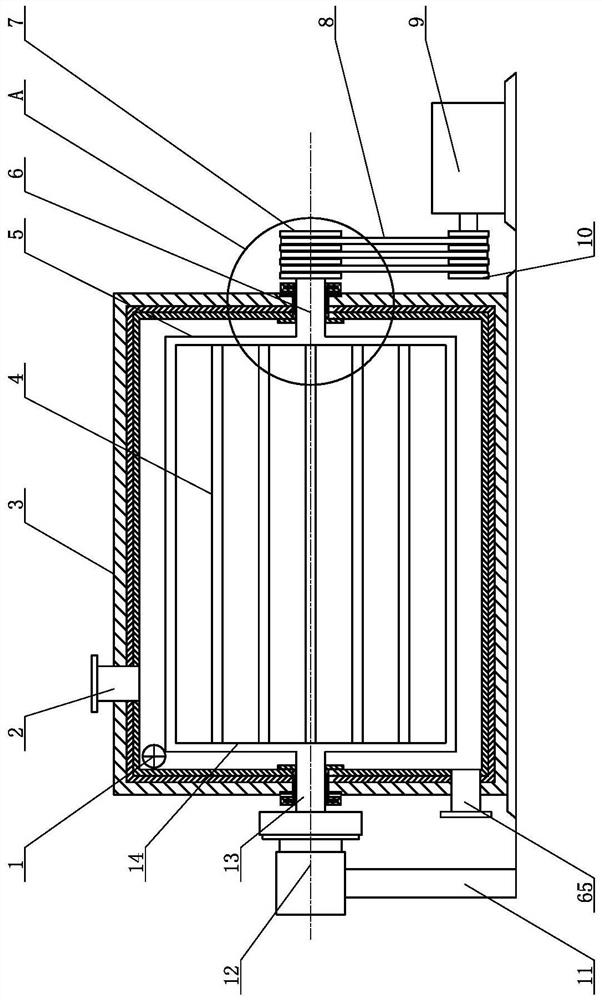

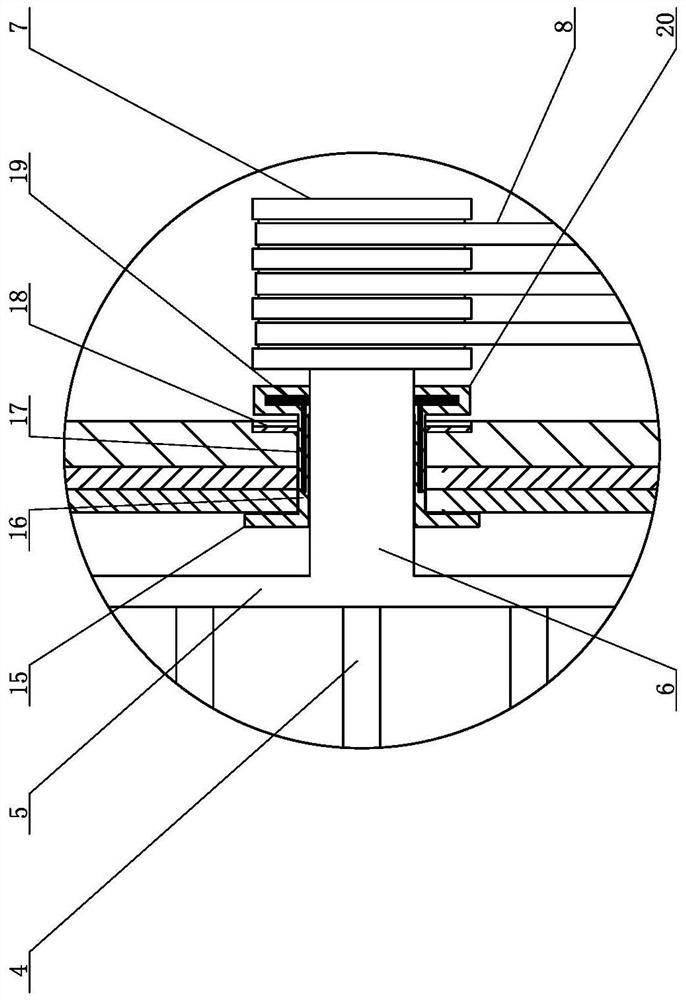

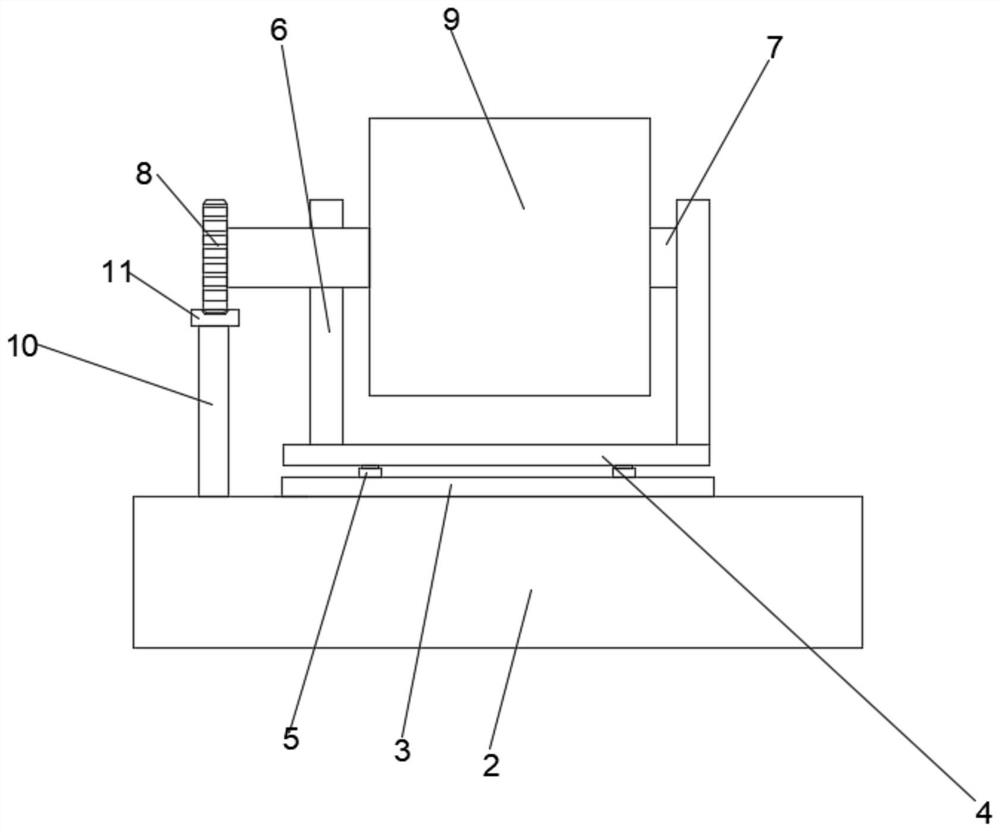

Homogeneous emulsification and filling integration device and application method thereof

PendingCN108295754ANot easy to affect the appearanceConvenient and quick escapeTransportation and packagingMixing methodsAir pumpPulp and paper industry

The invention provides a homogeneous emulsification and filling integration device and an application method thereof. The integration device comprises a homogeneous emulsification mechanism; the homogeneous emulsification mechanism comprises a control module, a vacuum tank and a machine table, a sucking pump and a first motor are connected to an upper cover of the vacuum tank, and the tank bottomof the vacuum tank is provided with a material outlet and a second motor which is connected with the vacuum tank into a whole; the first motor and the second motor are respectively connected with a stirring mechanism in the vacuum tank; the machine table is connected with the upper cover of the vacuum tank through a lifting mechanism, and is connected with a side wall of the vacuum tank through atank tilting mechanism; when the sucking pump is used for sucking air to form negative pressure, a material enters the tank through a pump-out slot of the vacuum tank; when a tank opening of the vacuum tank needs to be opened to operate, the machine table lifting mechanism is used for lifting the upper cover of the vacuum tank on the whole, and after the upper cover is separated from the tank bodyof the vacuum tank, the tank tilting mechanism is used for tilting the vacuum tank to an angle required. The homogeneous emulsification filling integration device can be conveniently used for carrying out homogeneous emulsification on a high-viscosity material, bubbles are difficult to generate in the processing process, and the device can further be cleaned and maintained conveniently.

Owner:福州法莫优科机械科技有限公司

Organic silicon defoaming agent and preparing method thereof

InactiveCN110064233AEasy to emulsifyImprove foam breaking abilityFoam dispersion/preventionDefoaming AgentsChemistry

The invention discloses an organic silicon defoaming agent and a preparing method thereof. The organic silicon defoaming agent is prepared from, by weight, 20-50 parts of polydimethylsiloxane, 1-10 parts of fumed silica, 2-15 parts of an emulsifying agent, 1-10 parts of a thickening agent and 30-80 parts of water; the fumed silica is surface-modified fumed silica, and the surface of the fumed silica is wrapped with a -Si-R3 group, wherein R is one or more of CH3, O-Si-(CH2)-OH, (Si(CH2))n-CH3. When the organic silicon defoaming agent is prepared, the fumed silica, parts of polydimethylsiloxaneand a silane coupling agent are mixed to prepare silicon paste with the viscosity of 500 cp to 200,000 cp; then the silicon paste, water, the emulsifying agent and the polydimethylsiloxane are mixed;finally, the thickening agent and the water are added, stirring is conducted, and the organic silicon defoaming agent is obtained. According to the organic silicon defoaming agent and the preparing method thereof, a silicon-paste midbody with the adjustable viscosity can be prepared, and a phenomenon that the silicon paste is over thin or over thick can be avoided; meanwhile, by introducing different pieces of hydrophobic fumed silica, and the defoaming performance and the foam inhibition performance of the defoaming agent can be effectively controlled; a preparing condition is mild, and operation is convenient.

Owner:HUBEI HUIFU NANOMATERIAL CO LTD

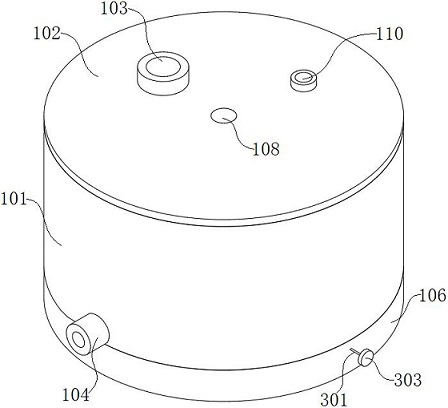

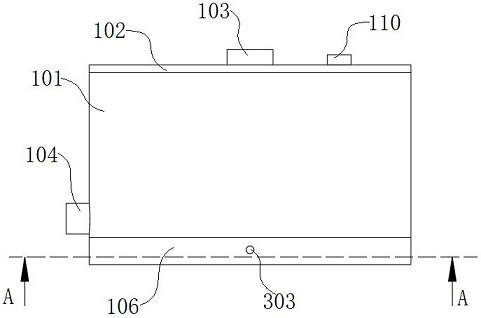

Emulsification accelerating device for mixed liquid

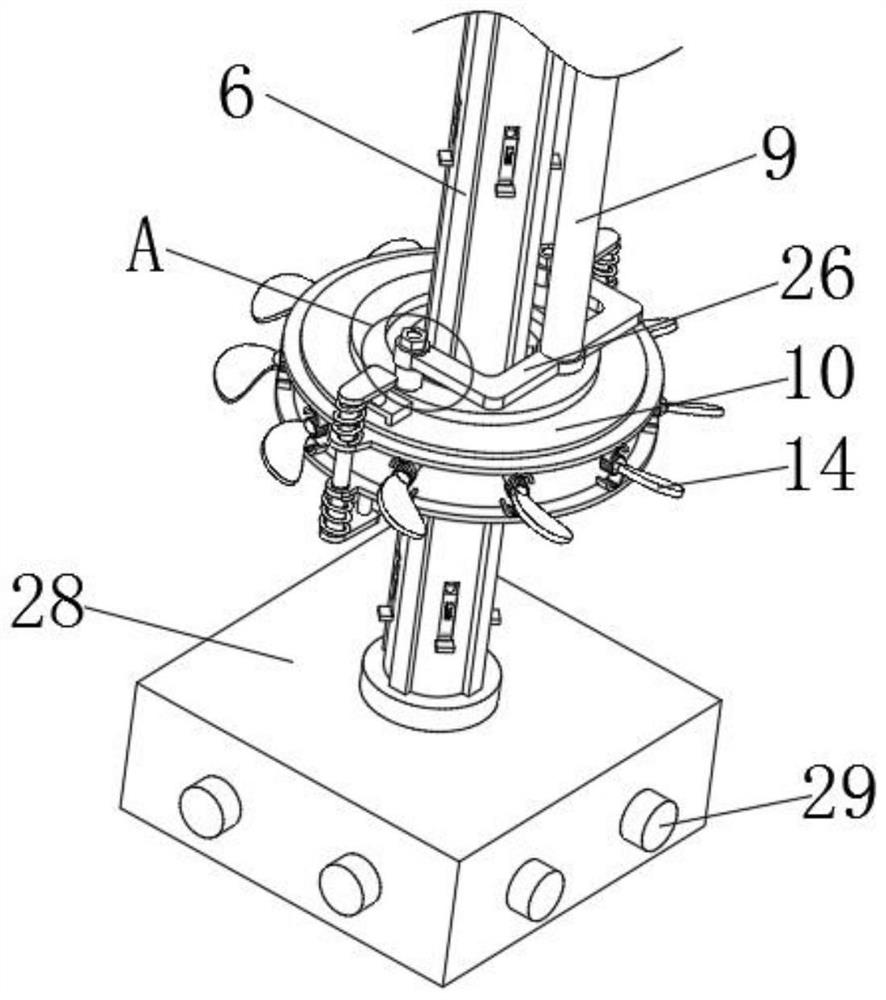

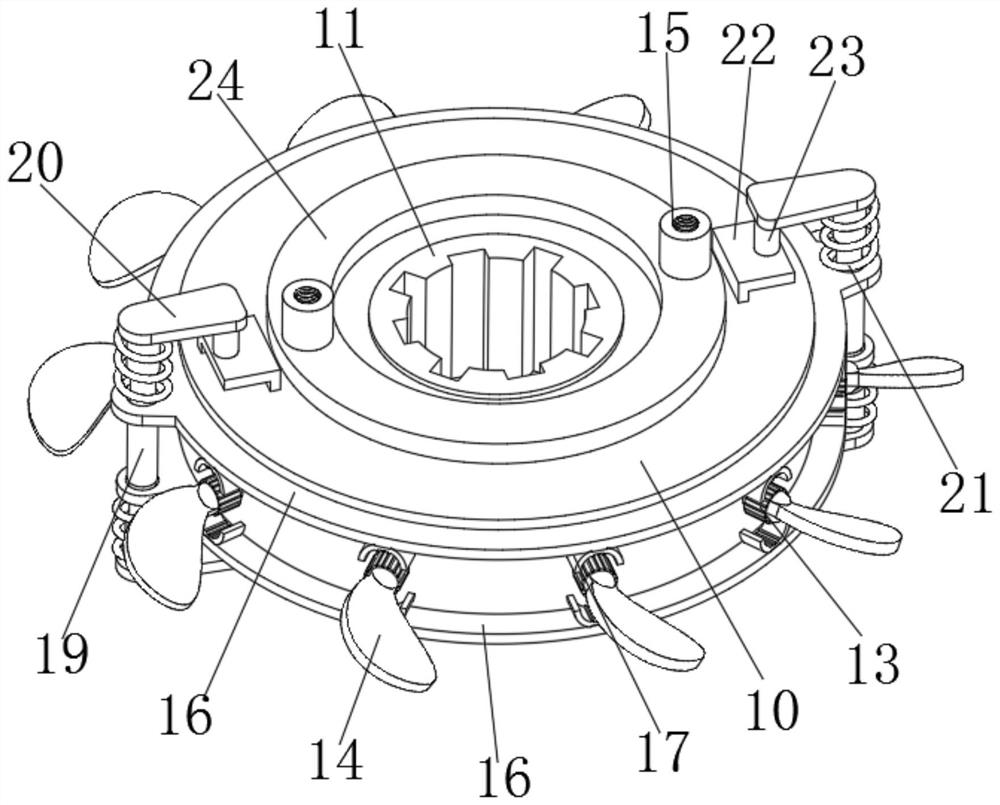

ActiveCN114011295AFast emulsificationDoes not affect fluid propertiesRotary stirring mixersTransportation and packagingElectric machineAir pump

The invention discloses an emulsification accelerating device for mixed liquid, and relates to the technical field of mixed liquid emulsification. The device comprises an emulsifying barrel, airflow control devices and a reset rod, the emulsifying barrel comprises a material barrel and a barrel seat, the barrel seat is mounted under the material barrel, the reset rod and the airflow control devices are mounted in the material barrel, the reset rod is matched with the airflow control devices, a rotating motor is mounted on the emulsifying barrel, and the airflow control devices are communicated with a pressurizing air pump through a barometer. Stirring blades and the airflow control device are arranged to exert positive and negative influences on mixed liquid in the emulsifying barrel, the emulsifying speed of the mixed liquid can be further increased under the condition that the fluid characteristics of target liquid are not affected, and the emulsifying efficiency of a product is improved.

Owner:烟台金能机械有限公司

Soothing and anti-inflammatory cleansing oil and preparation method thereof

PendingCN114588092AFast emulsificationStrong whiteningCosmetic preparationsMake-upAqueous solubilityDermatology

The invention relates to the technical field of cosmetics with the IPC classification number of A61K8 / 92, in particular to soothing and anti-inflammatory cleansing oil and a preparation method thereof. The cleansing oil is prepared from the following raw materials: 2wt%-10wt% of effective components and 90wt%-98wt% of main components, wherein the effective components comprise a water-containing emulsifier and a water-soluble active matter; the weight ratio of the water-containing emulsifier to the water-soluble active matter is 1: (0.5-5). According to the cleansing oil disclosed by the invention, water-soluble active substances can be added, and the addition amount of the water-soluble active substances is higher than that of the active substances in the prior art, so that the cleansing effect of the cleansing oil cannot be influenced when the higher active substances are added, the cleansing oil can be normally used, and after water is added for cleansing, the eye irritation is obviously improved.

Owner:ZHONGSHAN ZHONGYAN COSMETIC CO LTD

Washing-free kelp double-layer makeup removing lotion and preparing method thereof

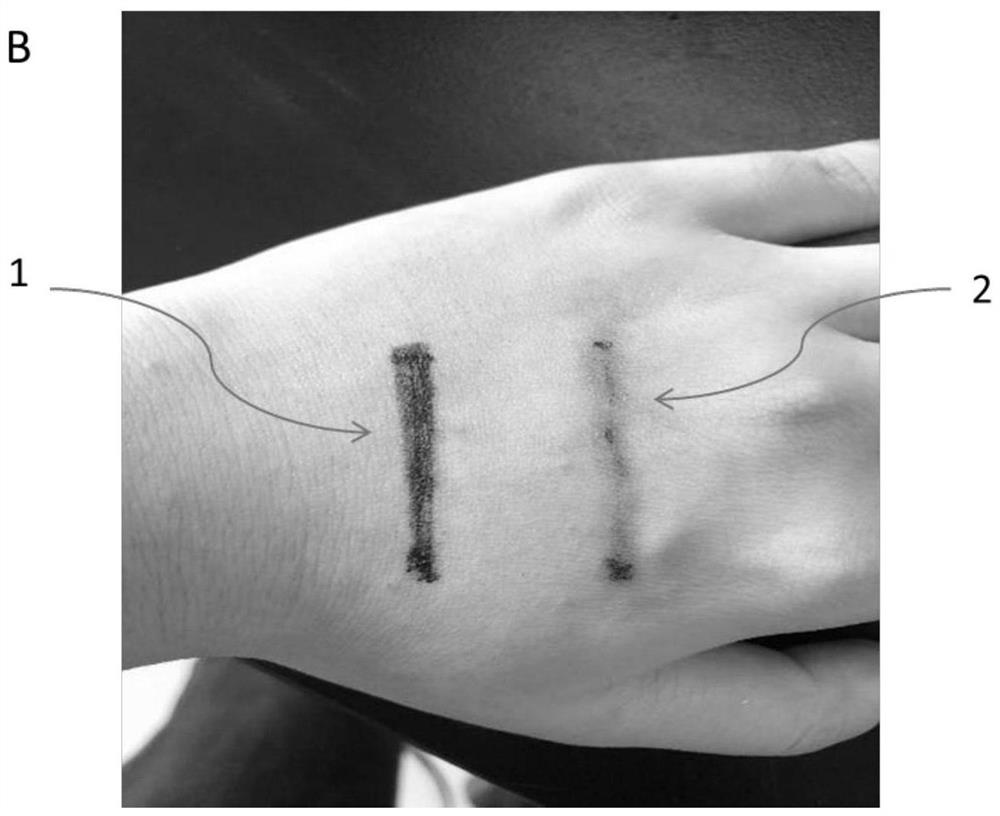

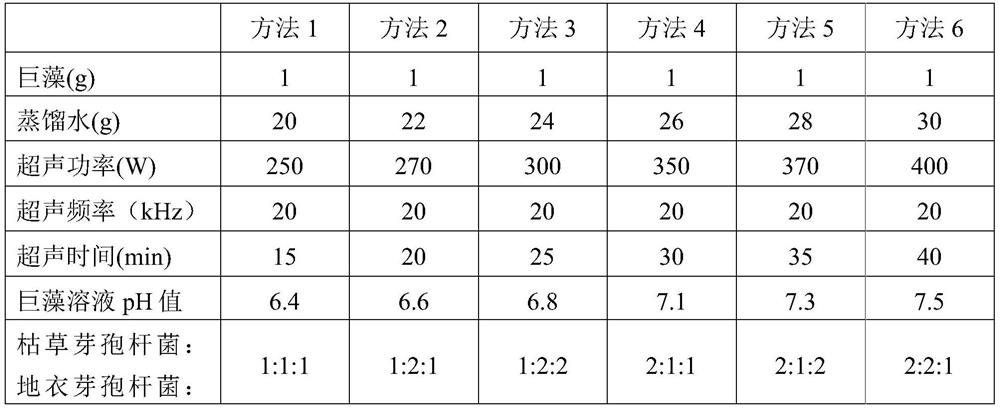

The invention relates to the field of cosmetics, in particular to washing-free kelp double-layer makeup removing lotion and a preparing method thereof. The makeup removing lotion contains compositioncomponents including algal oil, ferment, a polyglycerol emulgator and squalane; the ferment and algal oil are kelp extracts. The makeup removing lotion is high in emulsification speed, and is instantly emulsified during shaking and quickly layered after placement; the makeup removing lotion is mild in texture, washing is not needed, the makeup removing lotion can be scrubbed, the makeup removing effect is good, and the moisturizing and moistening functions are obvious.

Owner:GUANGZHOU KENENG COSMETICS RES CO LTD +1

Biomass degreasing agent and preparation method thereof

InactiveCN109181893AFast emulsificationEasy to cleanInorganic/elemental detergent compounding agentsOrganic detergent compounding agentsEnvironmental resistanceSolvent

The invention discloses a biomass degreasing agent and a preparation method thereof. The biomass degreasing agent is prepared from the following raw materials in parts by weight: 1-3 parts of stain emulsifier, 5-9 parts of amino acid cleaning factors, 1-3 parts of sodium carbonate, 1-3 parts of solubilizer, 3-5 parts of bio-enzyme, 3-7 parts of tail oil, 0.5-1 part of a defoaming agent, 1-3 partsof sodium citrate and 30-50 parts of solvent. The biomass degreasing agent can be used for easily removing various oil stains, has safe use, simple operation and remarkable effect, is environment-friendly and pollution free, and is harmless to base materials.

Owner:无锡德冠生物科技有限公司

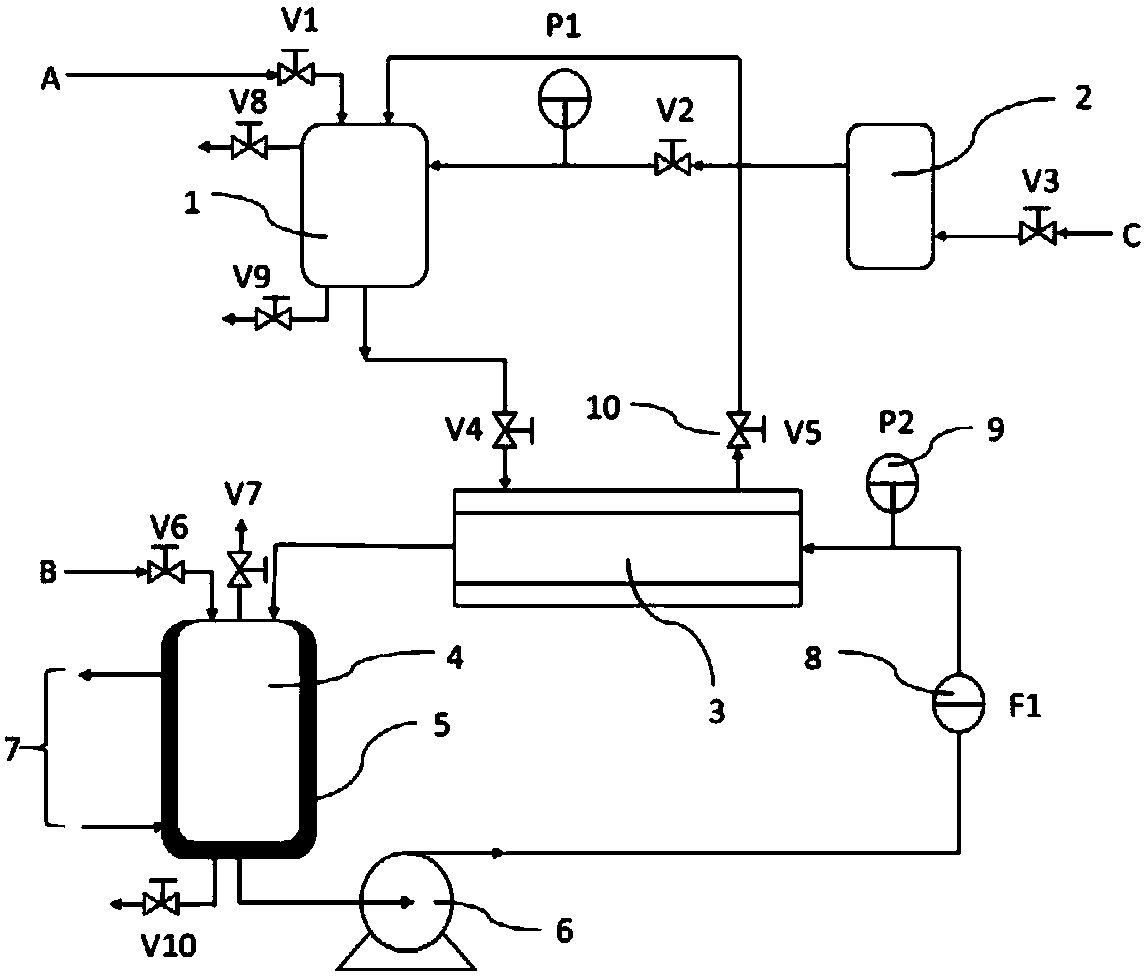

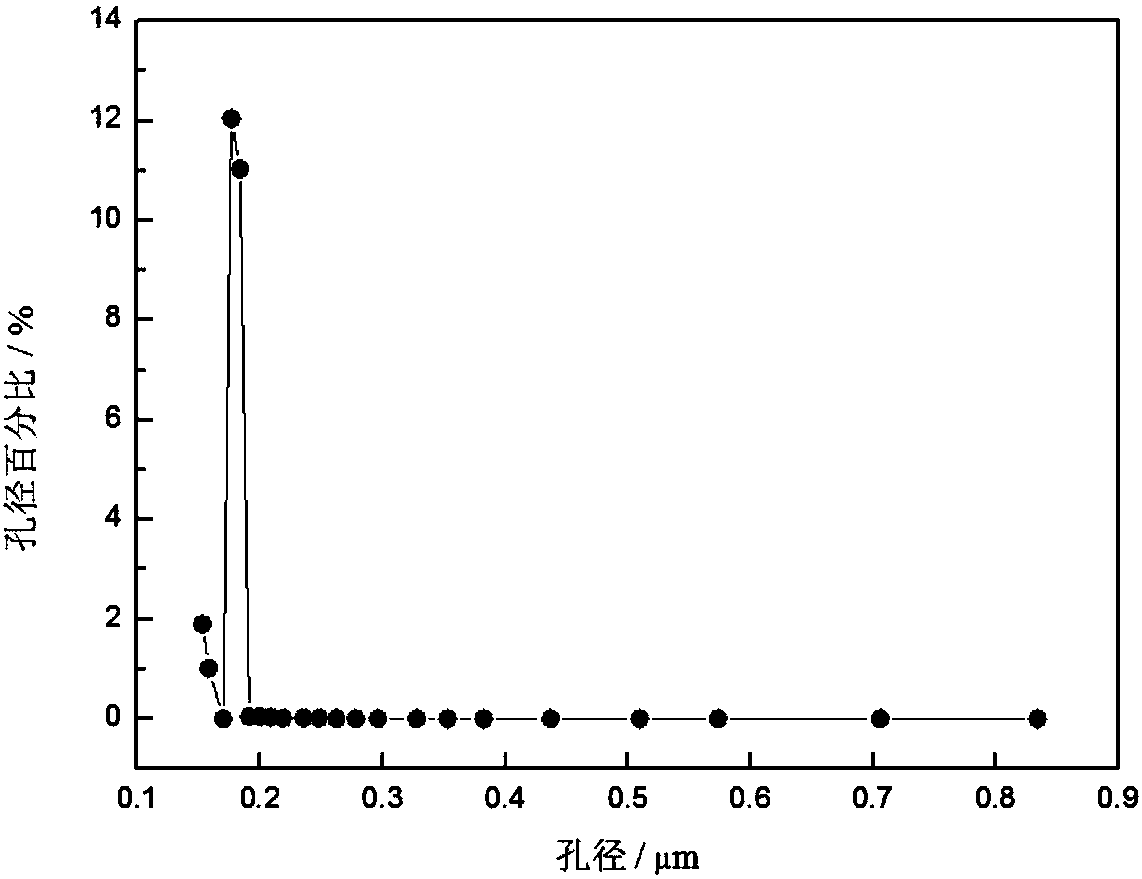

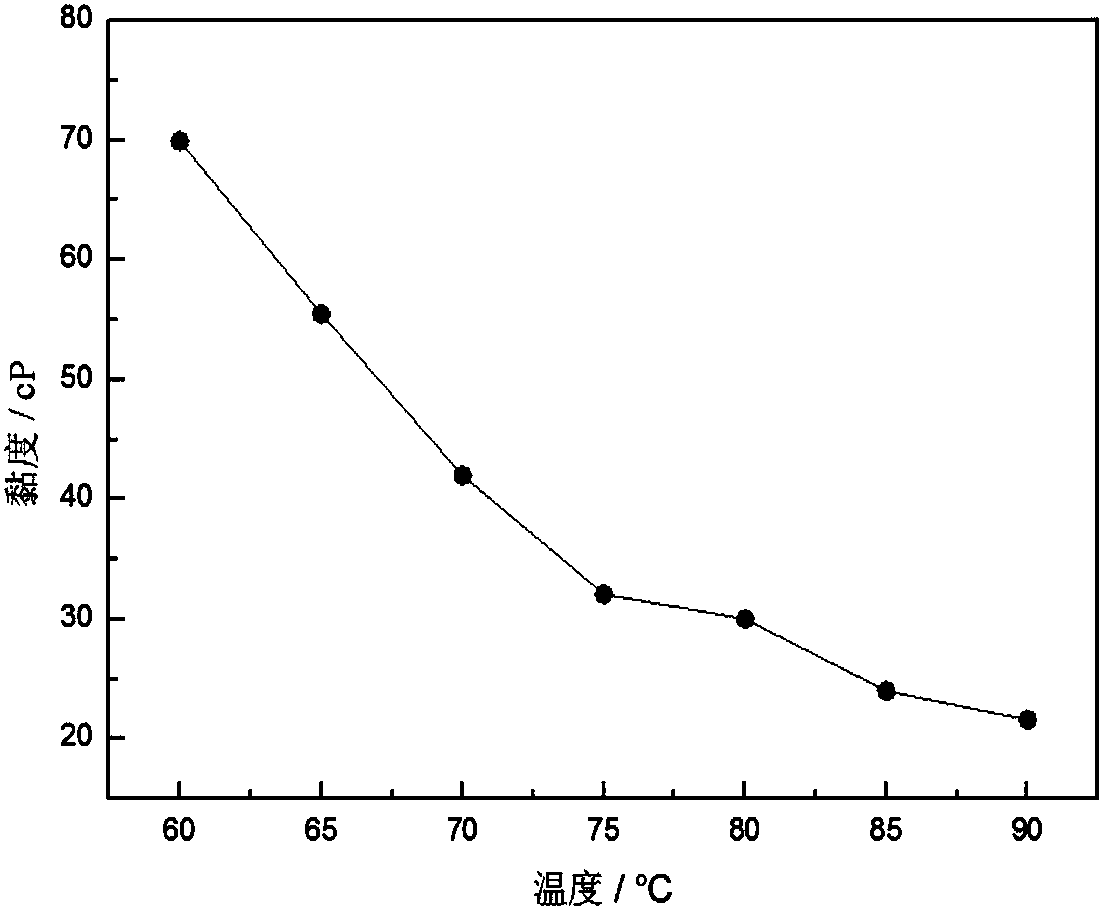

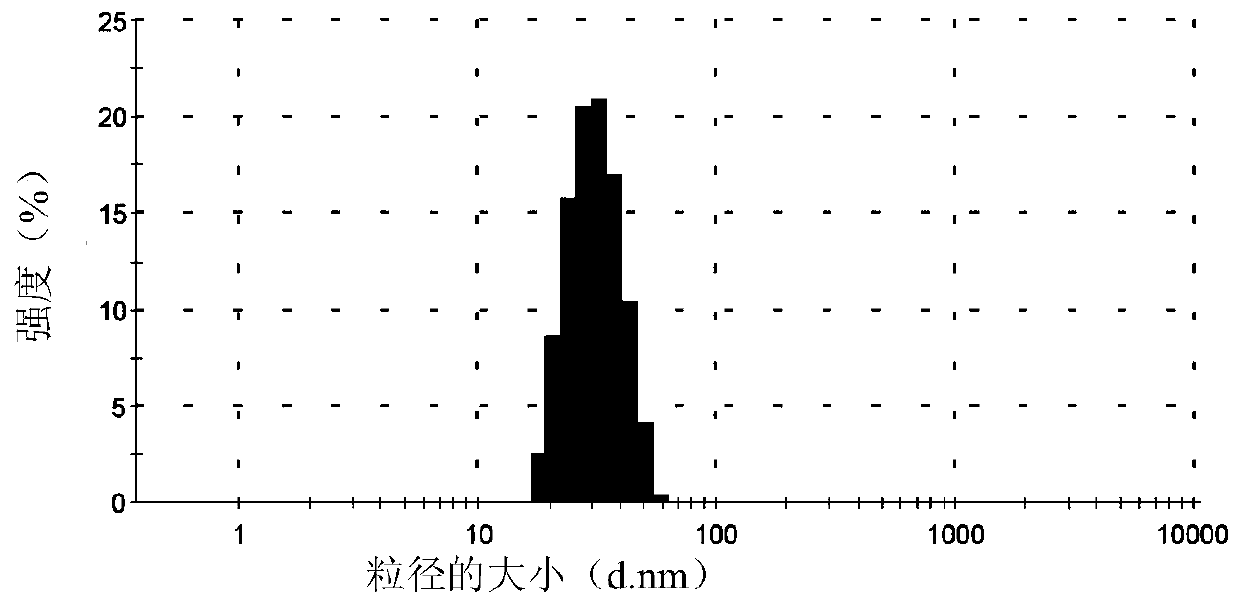

A kind of preparation method of emulsified heavy oil

ActiveCN106635131BReduce viscositySpeed up circulationRefining by dialysisHydrocarbon oils treatmentDispersityFuel oil

The invention provides a preparation method of emulsified heavy oil. The method is characterized by comprising the steps of taking a ceramic membrane as an emulsification medium, wetting the ceramic membrane in a disperse phase to reduce the surface energy of the ceramic membrane, dissolving an emulsifier into water as the disperse phase, wherein the heavy oil is a continuous phase; and pressing the disperse phase through the ceramic membrane to form a micro jet under a transmembrane pressure difference and forming water-in-oil type emulsified heavy oil under the action of continuous phase shear force, wherein the particle sizes of emulsion droplets in the prepared emulsified heavy oil are 1-20 microns. The method has the advantages of being simple in equipment, convenient to operate, high in membrane flux, narrow in emulsion size distribution, good in dispersity and the like, and can be used for raw material pretreatment in the catalytic cracking process of the heavy oil.

Owner:南京工大釜鼎能源技术有限公司

Packaging box printing process capable of preventing printing ink excessive emulsification and residues

InactiveCN112606581AAvoid over emulsificationStable temperature and humidityMeasurement devicesDuplicating/marking methodsEngineeringProcess engineering

The invention discloses a packaging box printing process capable of preventing printing ink excessive emulsification and residues. The packaging box printing process comprises the first step of workshop temperature and humidity control, the second step of paper pretreatment, the third step of preparation before printing, the fourth step of printing, the fifth step of shape fixing and the sixth step of hot pressing film covering. According to the packaging box printing process capable of preventing printing ink excessive emulsification and the residues, through the first step of workshop temperature and humidity control, the workshop temperature and humidity can be kept stable, and excessive emulsification of printing ink is avoided; through the second step of paper pretreatment, paper before printing is conveyed to a rotating rubber roller through a conveying belt, movement of the paper and a printing plate during printing is simulated, and paper hairs, paper powder and dirt which are likely to fall off from the paper can adhere to the rubber roller; and meanwhile, the rubber roller is cleaned through a dust collector located on the rear side of the rubber roller, and therefore clean printing paper is obtained, and the problems that in the printing process, due to printing ink excessive emulsification and the residues, the image-text hue on the surface of a printed product is slightly light, the color is not bright, screen dots are blurred and deformed seriously, and the printing plate cannot be inked are solved.

Owner:晋江市现代彩色印刷有限公司

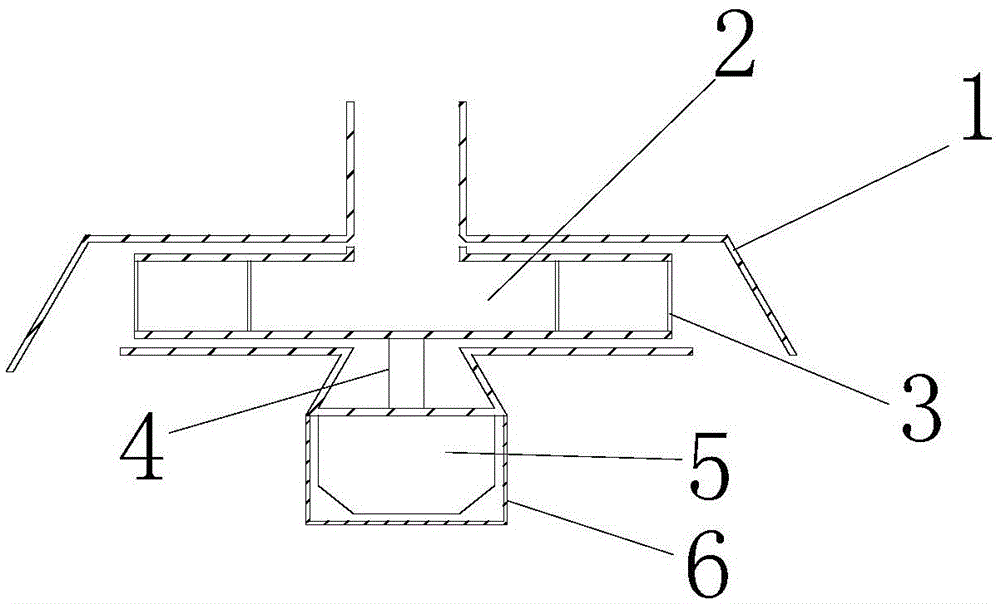

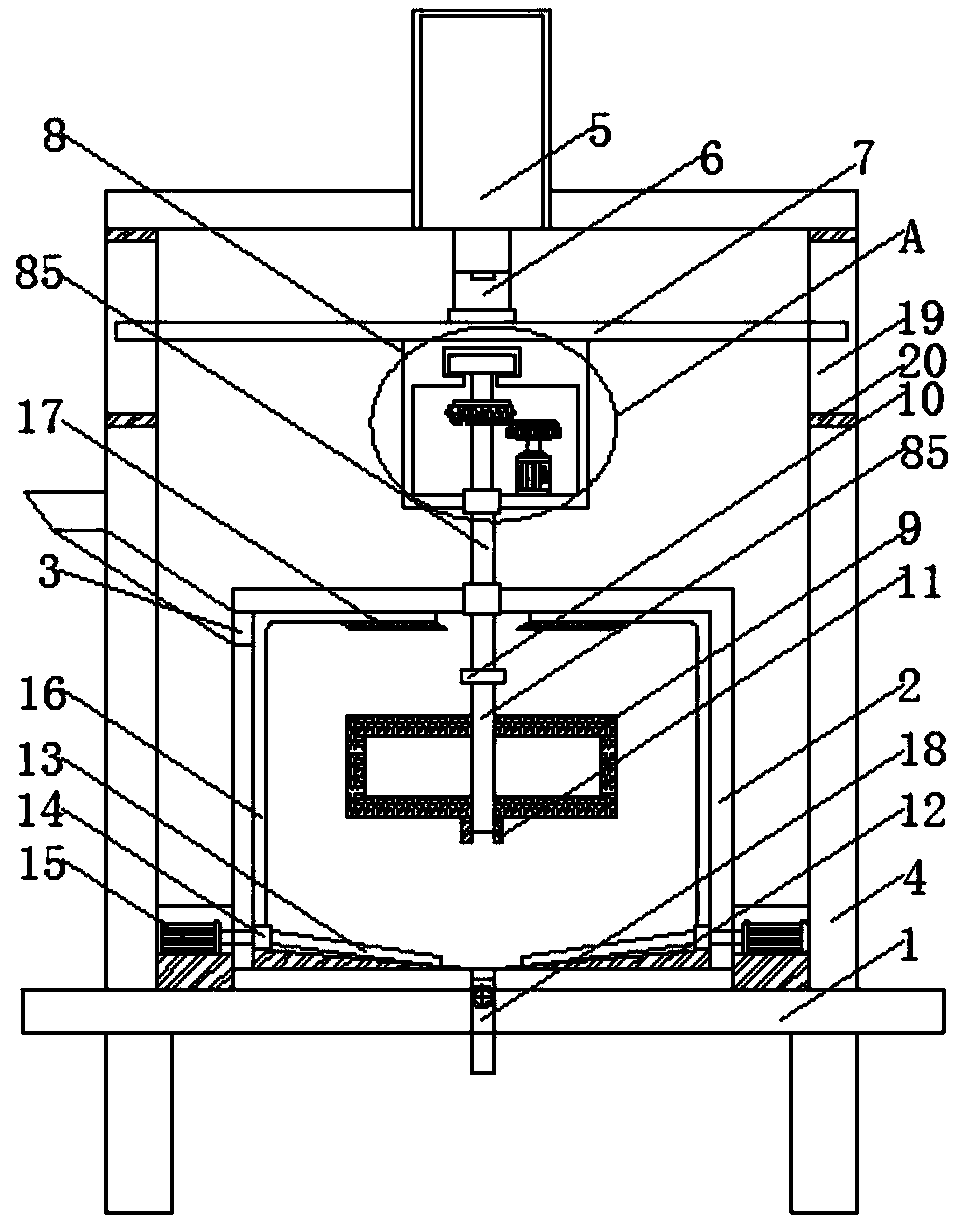

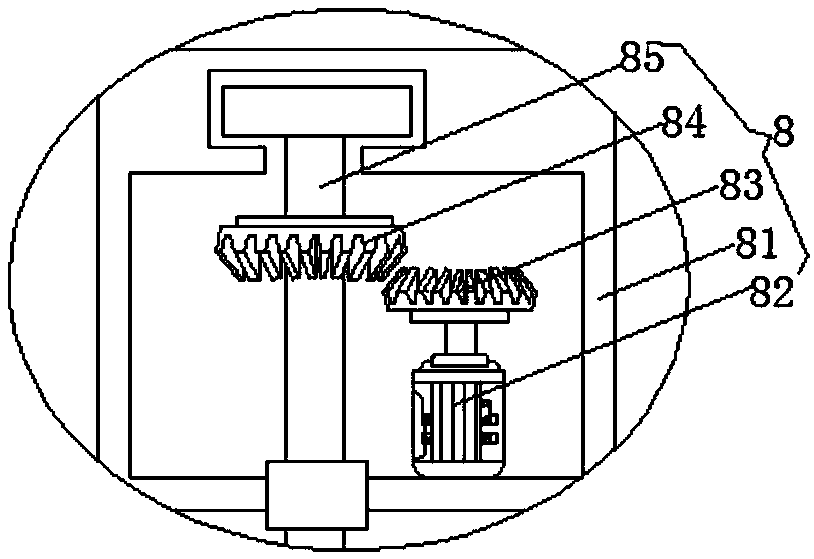

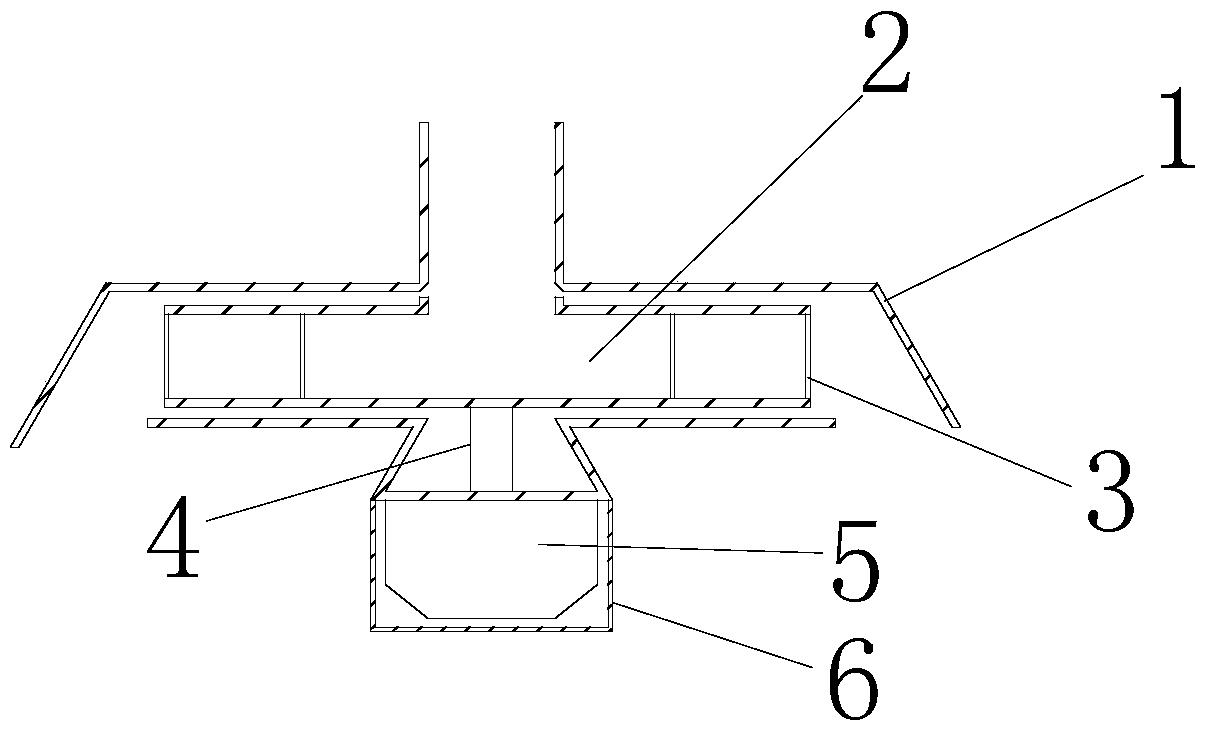

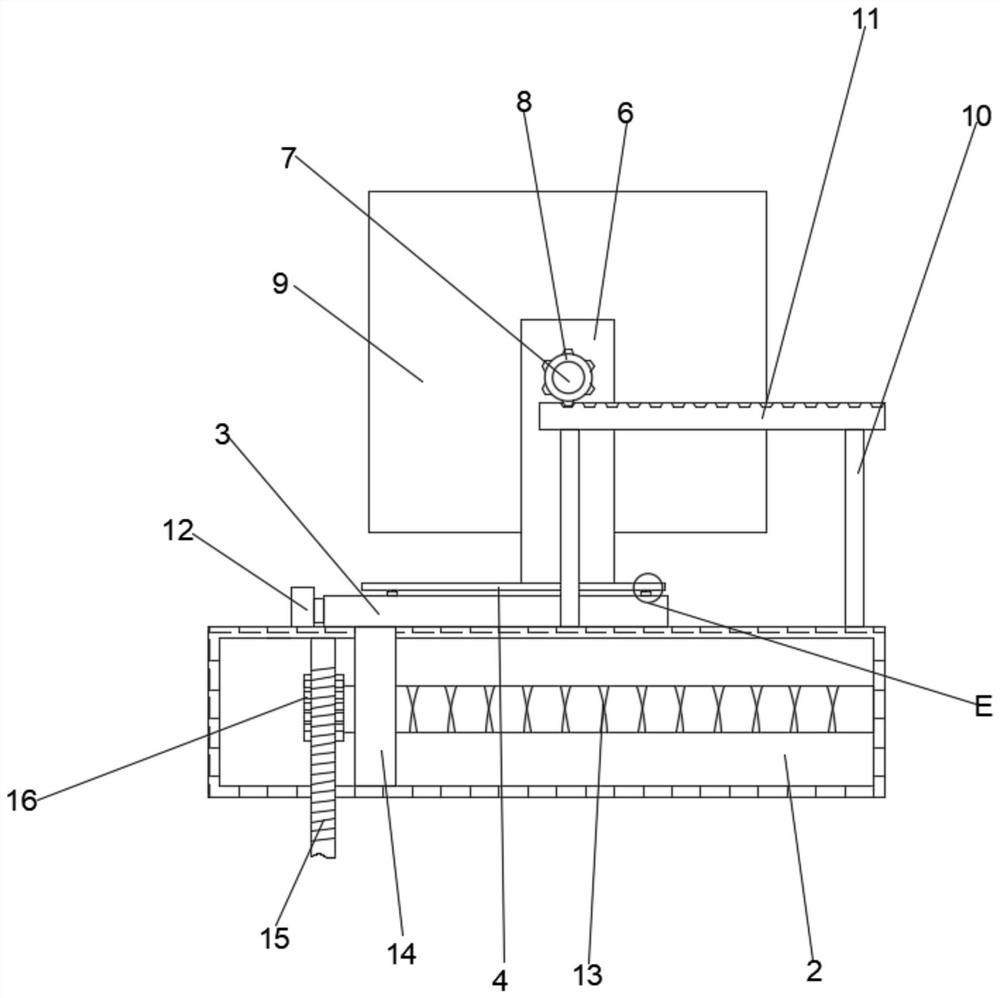

Application method of beating machine

InactiveCN103721597AEasy to useSimple structureMixing methodsRotary stirring mixersRotational axisMotor drive

The invention discloses an application method of a beating machine. The application method comprises the following steps: A, firstly, a block-shaped or pie-shaped organic bio-fertilizer after compost maturity and filter-press is cut into block-shaped materials with sizes about 10*10 cm, then the cut materials are added into a beating tank, and water or an emulsion in a certain proportion is poured in; B, a rotary motor is switched on, an output shaft of the rotary motor drives a rotary shaft to rotate, and then a rotary frame, external beating shaft columns and internal beating shaft columns are driven to rotate with the rotary shaft as a circle center; C, power supply of emulsification motors is further switched on, output shafts of emulsification motors drives gear shafts to rotate, then gear plates meshed with the gear shafts are driven to rotate and drive beating shaft to rotate, and beating teeth on two sides of each beating shaft perform beating and emulsifying operation on the mixed materials; and D, after the beating operation is finished, the organic bio-fertilizer after beating and emulsifying is sucked out of the beating tank by suction equipment. The invention has the advantages that the application method is simple; and a used product has simple structure, high strength, high emulsification speed, high production efficiency and uniform emulsification without caking.

Owner:刘成涛

Quick-hardening high-strength asphalt cold patch material and preparation method thereof

The invention discloses a quick-hardening high-strength asphalt cold patch material and a preparation method thereof, wherein the quick-hardening high-strength asphalt cold patch material is preparedby mixing aggregate, a filler, diesel oil, asphalt and a special cold patch agent, and the special cold patch agent is prepared by carrying out a chemical reaction on tall oil, concentrated sulfuric acid, turpentine, acetic acid and a resin according to a certain. Based on the problems of poor water stability and slow strength formation of the existing cold patch asphalt mixture, the invention provides an asphalt cold patch agent capable of increasing the strength formation speed of the asphalt cold patch material and improving the water stability of the asphalt cold patch material without theincrease of the viscosity of the cold patch asphalt.

Owner:武汉博盾工程科技有限公司

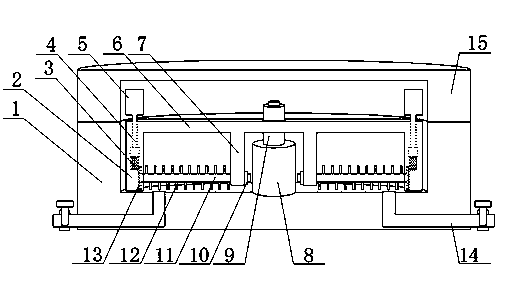

Continuous ultrasonic emulsification device for water-based resin and using method of continuous ultrasonic emulsification device

InactiveCN113181784AWell mixedSolving Mixing ProblemsShaking/oscillating/vibrating mixersTransportation and packagingUltrasonic emulsificationUltrasonic generator

The invention provides a water-based resin continuous ultrasonic emulsification device and a using method of the continuous ultrasonic emulsification device. The device comprises an emulsification cavity and a premixing cavity, wherein a first feeding port and a second feeding port are formed in the top of the premixing cavity, a material mixing and stirring device is arranged in the premixing cavity, a discharging port in the bottom of the premixing cavity is connected with a feeding port of the emulsification cavity through a feeding pump, energy-gathered ultrasonic generators are arranged at the top and the bottom of the emulsification cavity, ultrasonic probes of the energy-gathered ultrasonic generators extend into the emulsification cavity, a high-speed dispersion machine is arranged at the top of the emulsification cavity, a dispersion disc of the high-speed dispersion machine is arranged in the emulsification cavity, multiple sets of divergent ultrasonic generators are arranged on the outer wall of the emulsification cavity, and a discharge port valve is arranged at the discharge port of the emulsification cavity. According to the invention, a violent effect between particles is formed between two materials by utilizing a mechanical effect and a cavitation effect of ultrasonic waves, the emulsification process of the materials is completed in a very short time, the continuity of an ultrasonic emulsification device is improved, and the yield and the output efficiency of an emulsified product are improved.

Owner:SHAANXI UNIV OF SCI & TECH

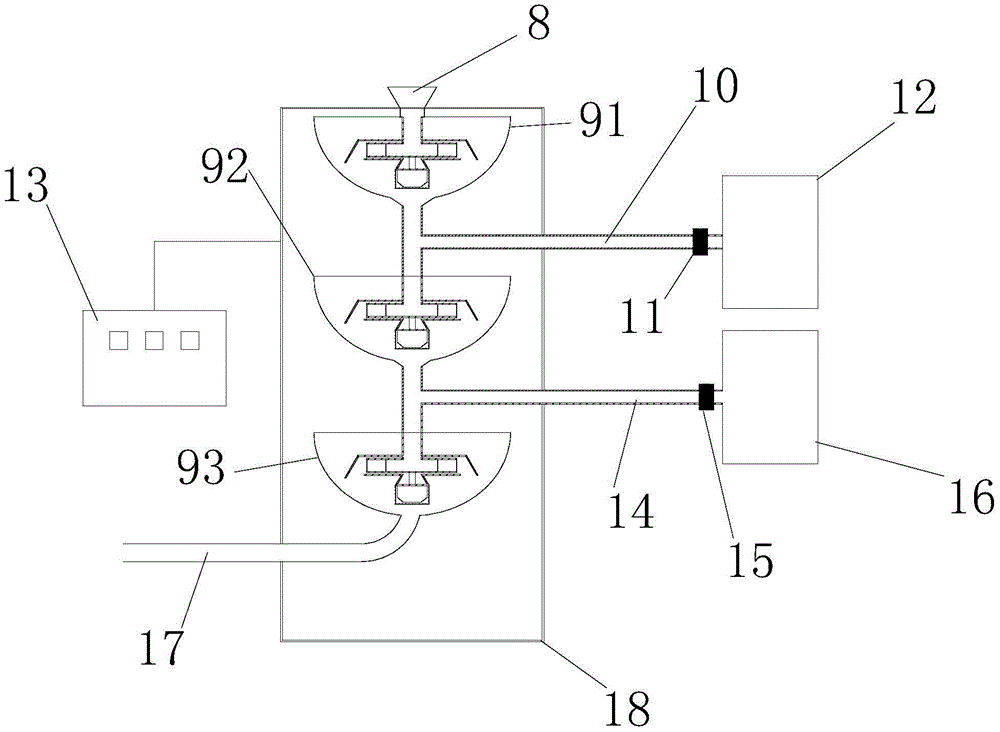

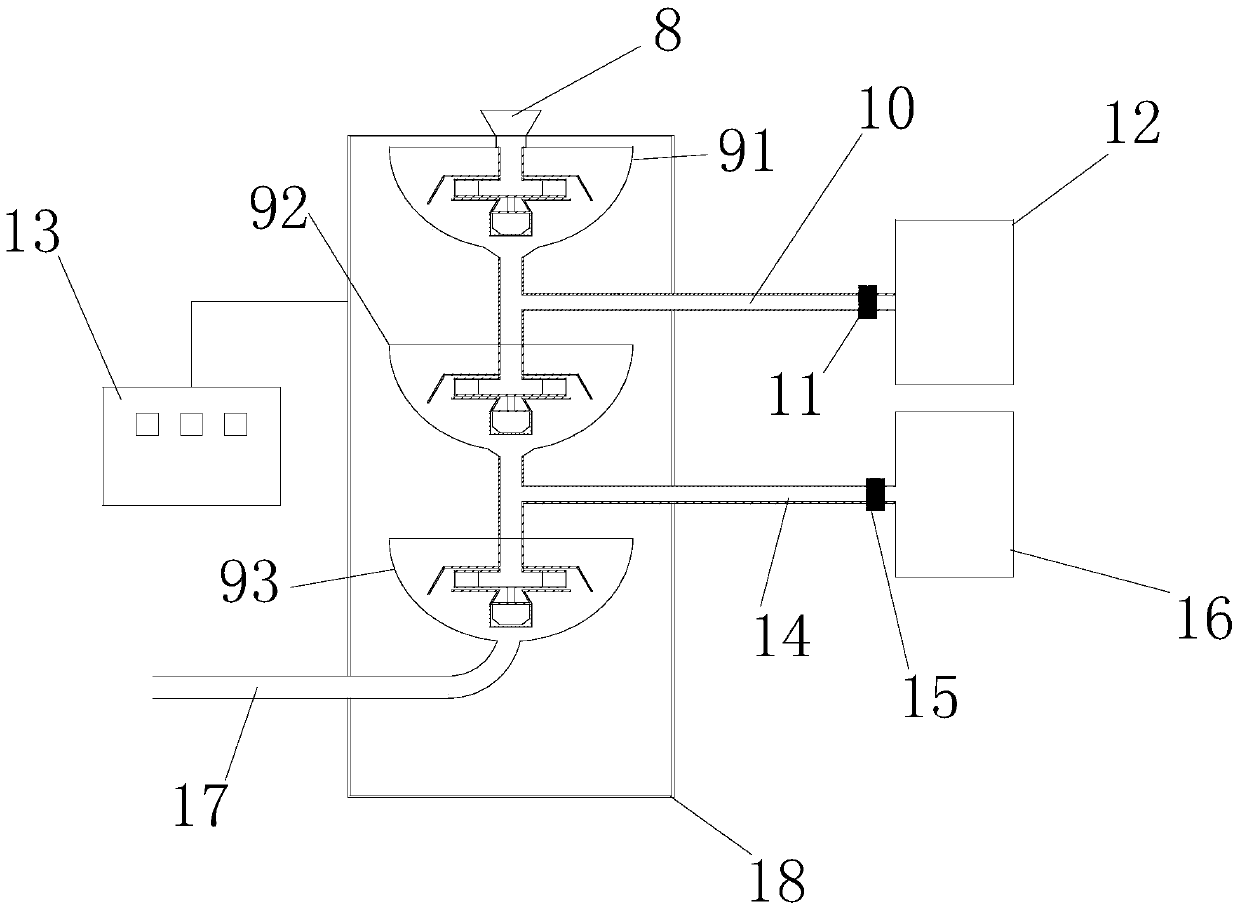

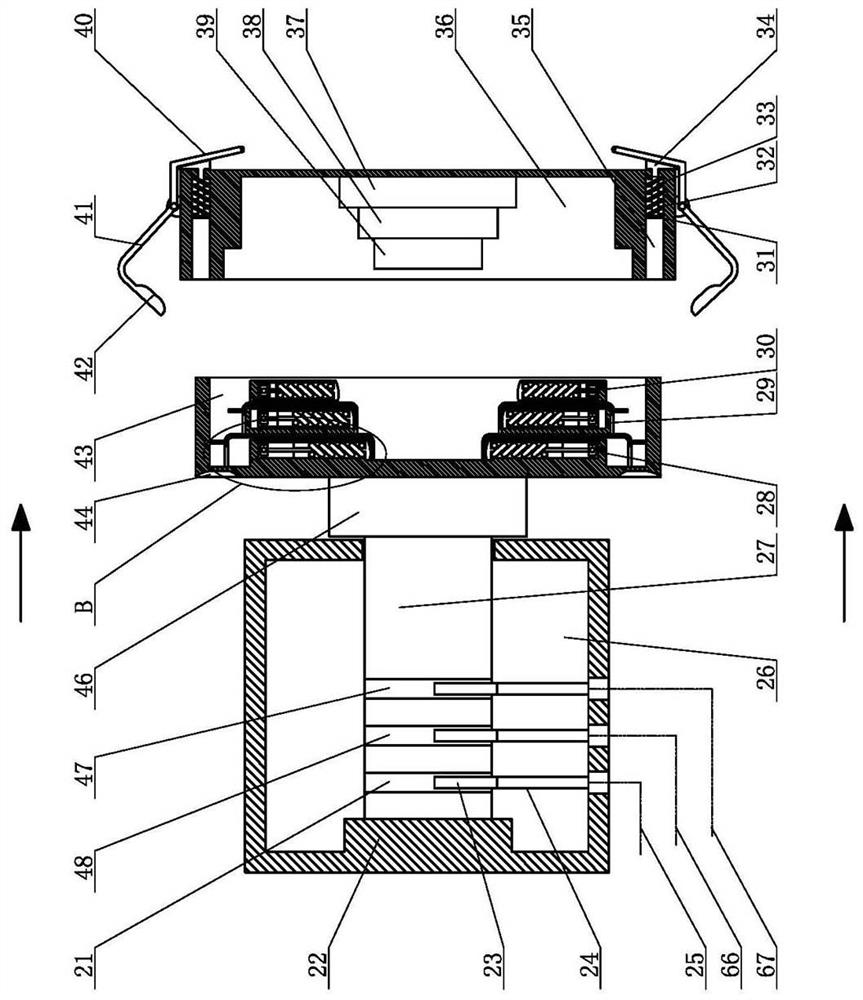

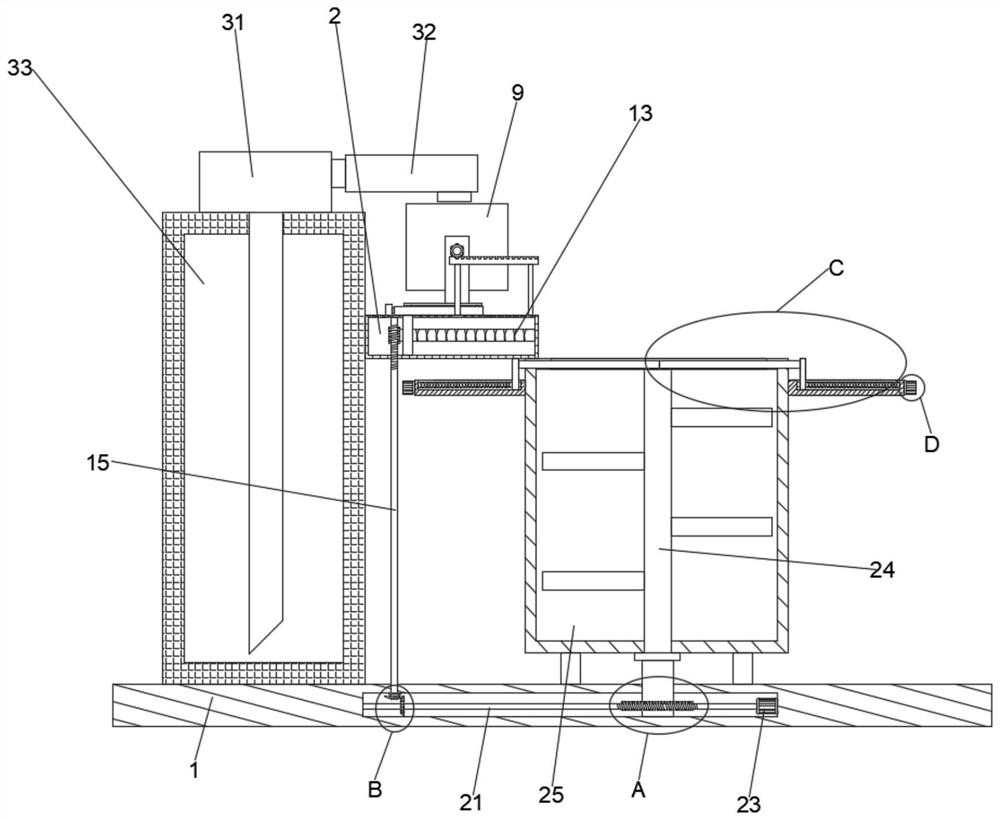

Centrifugal emulsified asphalt production device and production method thereof

ActiveCN105461937ASolve efficiency problemsFix stability issuesBuilding insulationsBitumen emulsionElectric machinery

The invention provides a centrifugal emulsified asphalt production device. A flow guiding mechanism is formed by connecting three layers of funnel-shaped flow guiding devices in series. The adjacent joints of the three layers of funnel-shaped flow guiding devices are connected with an upper flow guiding pipe and a lower flow guiding pipe respectively. The upper flow guiding pipe is connected with an upper liquid soap tank. The lower flow guiding pipe is connected with a lower liquid soap tank. An upper liquid soap pump and a lower liquid soap pump are installed on the upper flow guiding pipe and the lower flow guiding pipe respectively. The three layers of funnel-shaped flow guiding devices are each internally provided with a centrifuging device. The bottoms of the centrifuging devices are connected with motors through rotating shafts. Multiple layers of metal filter screens are installed in the centrifuging devices, and a centrifugal device housing is arranged on the top of each centrifuging device. Centrifugal force generated through rotation driven by the motors is adopted to achieve the emulsification purpose; due to emulsification of the three layers of centrifuging devices at different degrees, the emulsification efficiency is higher, emulsified asphalt particles are more uniform, emulsification quality is improved while emulsification efficiency is improved, emulsification speed is increased, and production cost is remarkably reduced.

Owner:甘肃昌恒公路养护技术有限责任公司

Emulsifying device for coating processing

InactiveCN108939999AFully emulsifiedGuaranteed stabilityShaking/oscillating/vibrating mixersFlow mixersEngineeringCirculating pump

The invention discloses an emulsifying device for coating processing. The emulsifying device comprises a base plate, wherein the upper end of the middle portion of the base plate is fixedly provided with an emulsification box, and one side of the upper end of the emulsification box is fixedly provided with a feeding port; the lower end of a hydraulic box is provided with a hydraulic rod, the lowerend of a fixing plate is fixedly provided with a stirring device, two sides of the bottom end in the emulsification box are fixedly provided with inclined plates, and the upper end of each inclined plate is fixedly provided with a first connecting pipe; a circulation pump is arranged at one side, far away from a connector, of each first connecting pipe and outside the emulsification box; and a material discharging refining mesh is fixedly arranged at one end, far away from one connector, of each second connecting pipe and at the top end in the emulsification box. The invention relates to thetechnical field of coating production equipment. The emulsifying device for coating processing is advantageous for accelerating the emulsification speed and fully emulsifying all materials, shortens the processing time, improves the production efficiency, has good emulsification effect and greatly improves the quality of products.

Owner:浙江安吉朝辉新材料有限公司

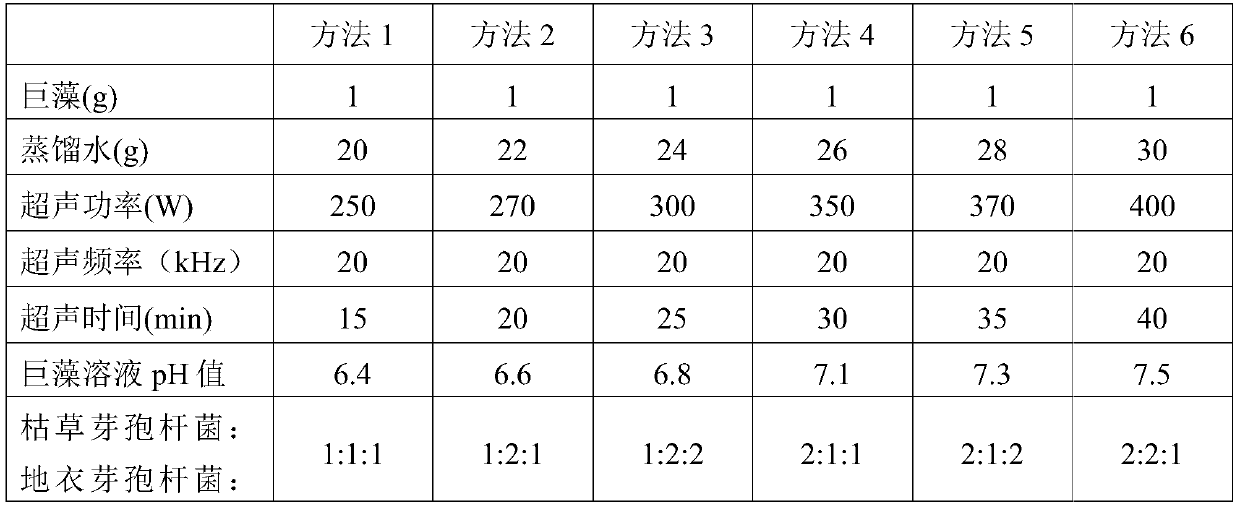

Self-emulsifying seaweed cleansing oil and preparation method thereof

The invention relates to a self-emulsifying seaweed cleansing oil and a preparation method thereof. Based on the total mass of the self-emulsifying seaweed cleansing oil, the self-emulsifying seaweed cleansing oil includes polyglycerol emulsifier: 15%-25%, squalane: 5%-25%, seaweed oil extract: 50% %‑68%, Seaweed Extract: 0.5%‑2%, Ethanol: 0%‑0.5%, Water: 0.5%‑1%. The self-emulsifying seaweed cleansing oil of the present invention. It is low in irritation, mild in nature, higher in safety, strong in makeup removal, fast in emulsification, easy to rinse, and has obvious moisturizing and emollient effect. Furthermore, the preparation method of the self-emulsifying seaweed cleansing oil of the present invention is simple to operate, the raw materials are easy to obtain, and can be produced in batches.

Owner:GUANGZHOU KENENG COSMETICS RES CO LTD +1

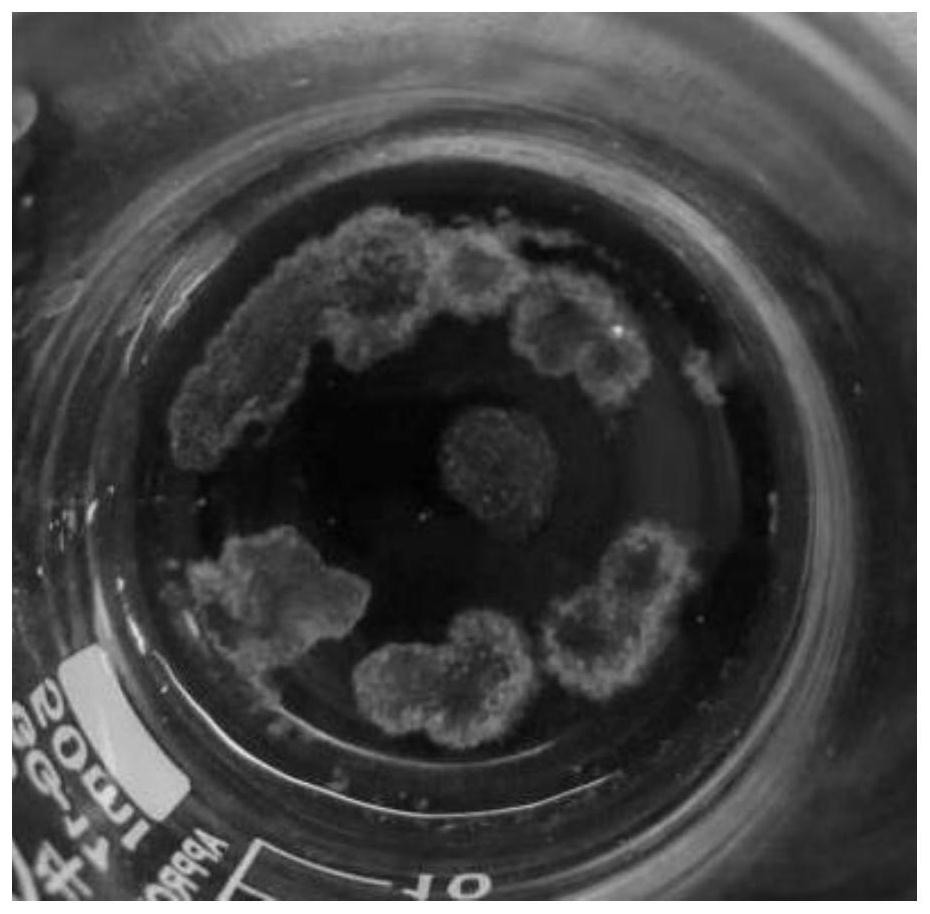

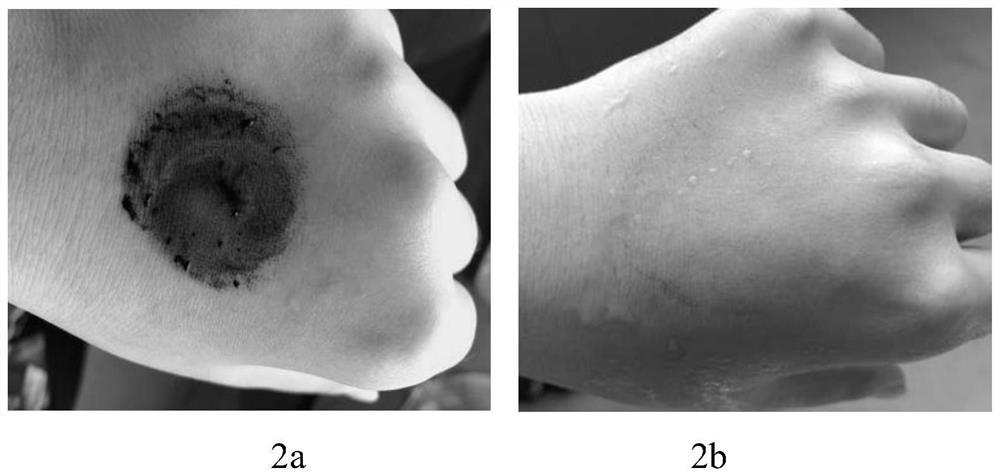

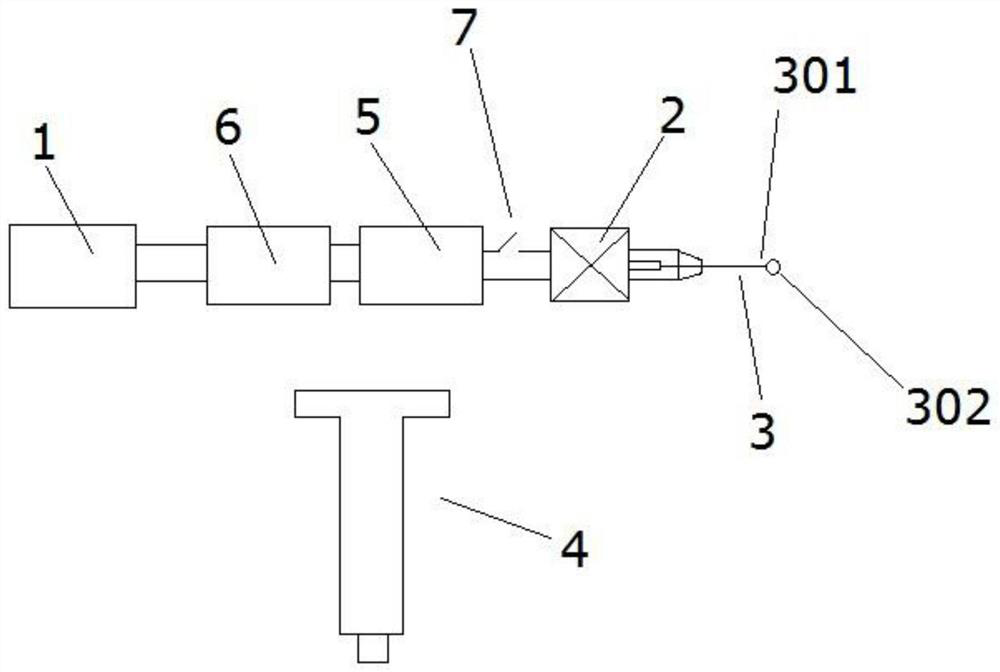

Antigen emulsifying device and use method thereof

PendingCN114307788AEliminate wasteSmall structureTransportation and packagingMixer accessoriesAntigenElectric machinery

The invention discloses an antigen emulsifying device and a using method thereof, the antigen emulsifying device comprises a power supply, a motor and a stirring needle, one end of the stirring needle is detachably inserted into an output shaft of the motor, and the other end of the stirring needle is a free stirring end; the needle tip part of the free stirring end is a circular ring; and the injector further comprises an injector needle cylinder. According to the antigen emulsifying device, the stirring needle can be replaced, the number of structural parts is small, electric operation is achieved, and labor is saved; the needle tip part of the free stirring end is a circular ring, and the circular ring structure is adopted, so that a vortex can be formed in a stirring system, the stirring is sufficient, the emulsifying time is controlled within 5-10 minutes, and the consumed time is short; in addition, a medical syringe needle cylinder is used for loading antigens, and stirring is carried out in the needle cylinder, so that the phenomenon of antigen waste is avoided.

Owner:NANJING LANSION BIOTECH CO LTD +1

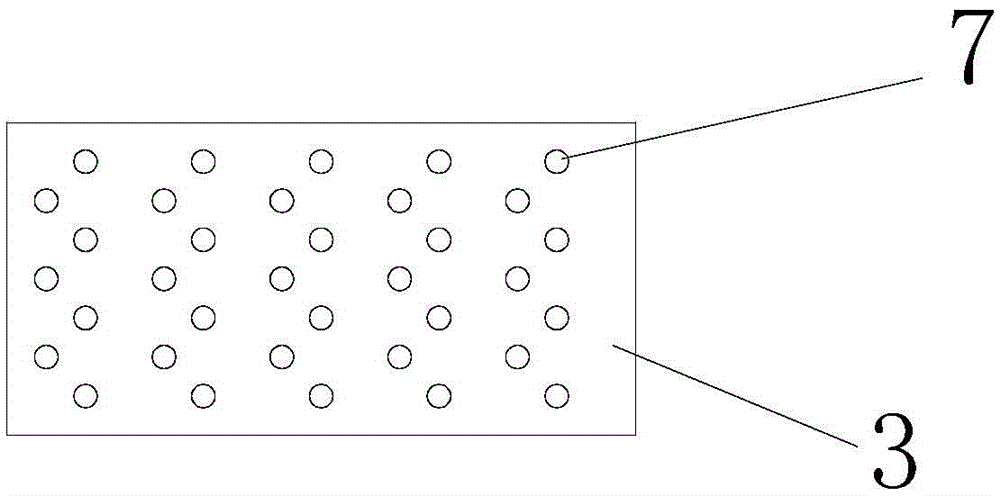

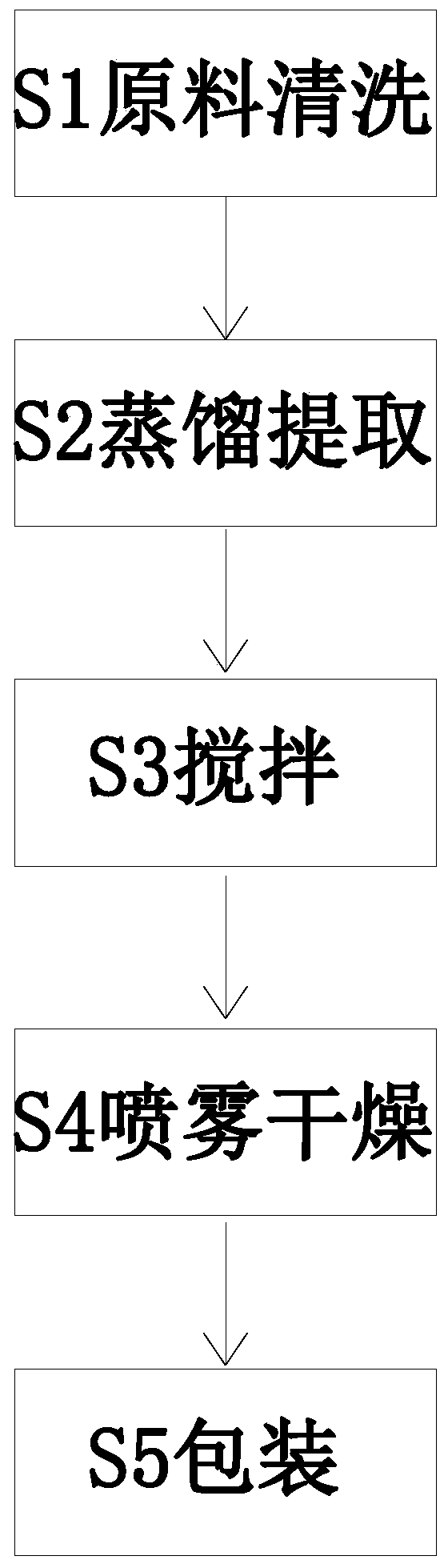

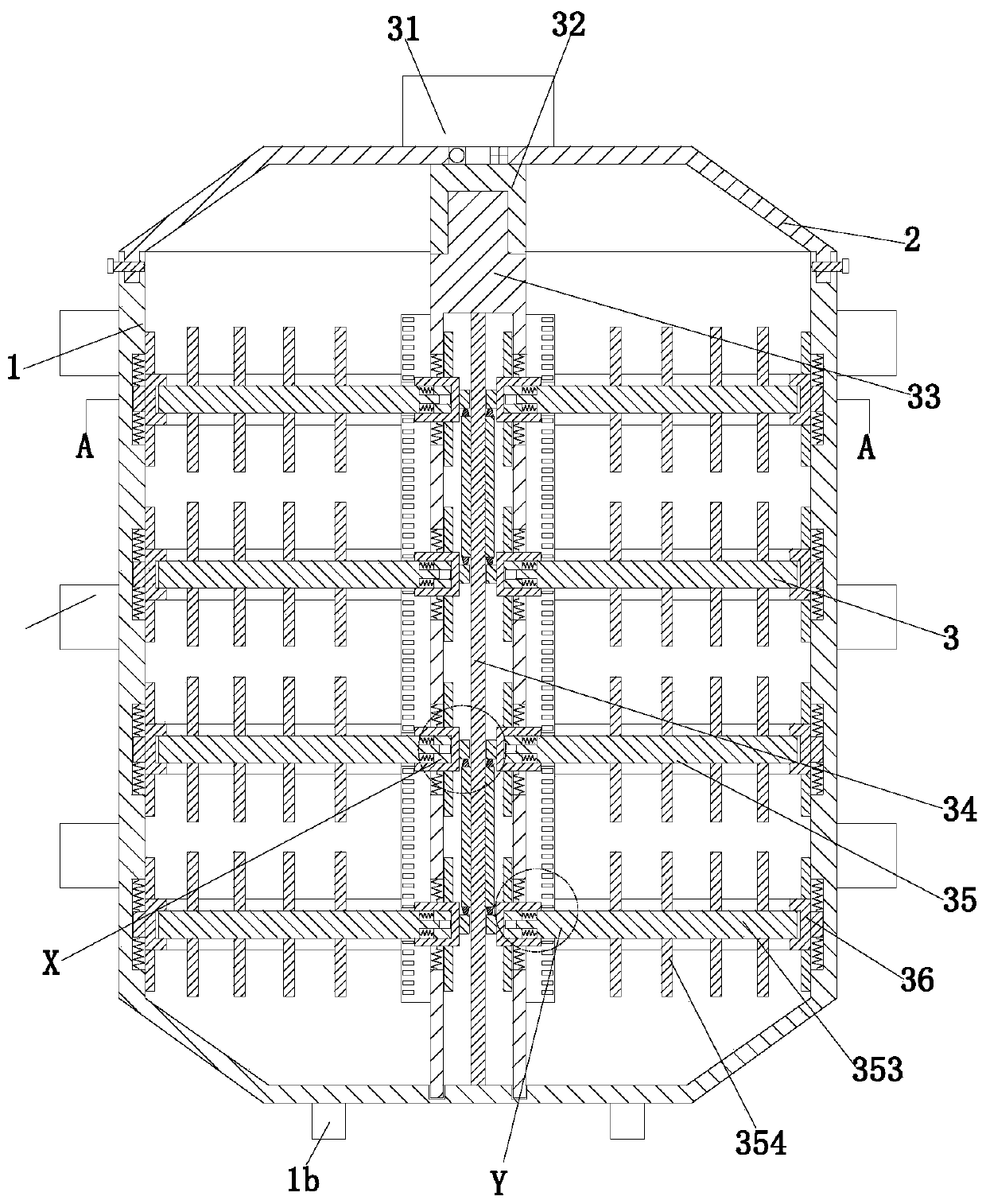

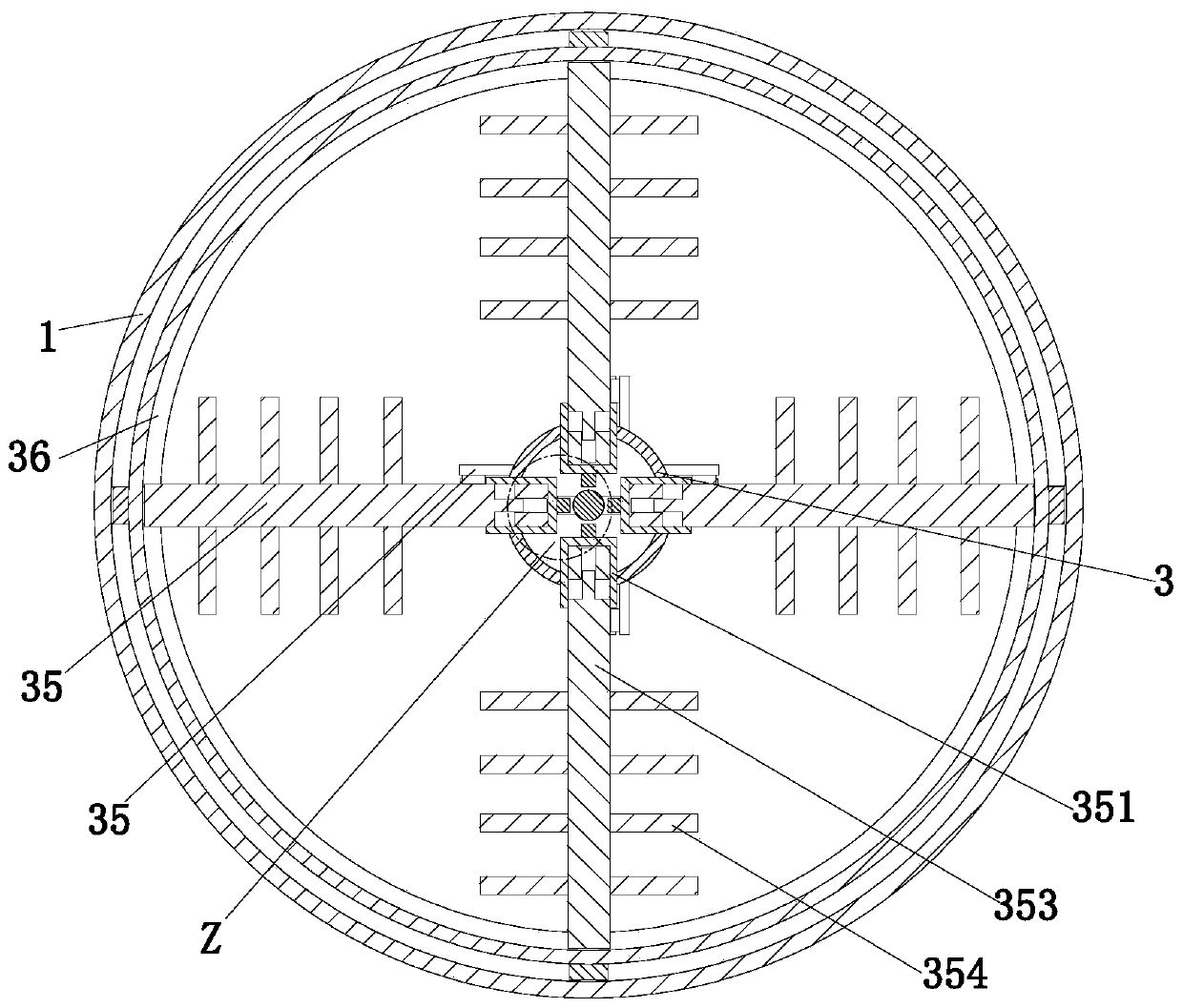

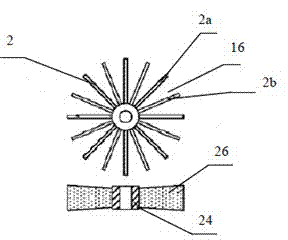

Preparation method of microcapsule plant essential oil

PendingCN111321035AExpand the mixing rangeFast emulsificationShaking/oscillating/vibrating mixersMixing methodsEmulsionProcess engineering

The invention relates to a preparation method of microcapsule plant essential oil, which uses dispersing and stirring equipment. The dispersing and stirring equipment comprises a stirring tank, a topcover and a dispersing device, the specific method for preparing the microcapsule plant essential oil by using the dispersing and stirring equipment comprises the following steps of: cleaning the rawmaterials, distilling, extracting, stirring, spray-drying and packaging. The top cover is installed at the top end of the stirring tank, a dispersing device is installed between the inner wall of thestirring tank and the lower end of the top cover, annular grooves are evenly formed in the inner wall of the stirring tank from top to bottom, the dispersing device comprises a rotating motor, a driving rod, a driven rod, a pushing rod, a stirring frame and a supporting sliding rail, and the stirring frame comprises an installation sleeve, protrusions, main stirring rods, auxiliary stirring rods and racks. The mixed liquid in the stirring tank is stirred in multiple directions through the dispersing device until an emulsion is formed, the stirring frame can reciprocate up and down in the stirring process, the stirring range is enlarged, and the emulsifying speed is increased.

Owner:谭宇航

Fuel pump

ActiveCN102900569BReduce volumeSimple structureNon-fuel substance addition to fuelMachines/enginesImpellerEmulsion

Owner:NANJING TECH UNIV

A kind of oral preparation containing polypeptide drug self-nanoemulsion and preparation method thereof

ActiveCN106334185BQuality controllableStable in naturePeptide/protein ingredientsMetabolism disorderPeptide drugActive agent

Owner:GUANGDONG GENERAL HOSPITAL

A kind of disposable macroalgae double layer makeup remover and preparation method thereof

ActiveCN109730937BFast emulsificationQuick layeringCosmetic preparationsMake-upBiotechnologyGlycerol

Owner:GUANGZHOU KENENG COSMETICS RES CO LTD +1

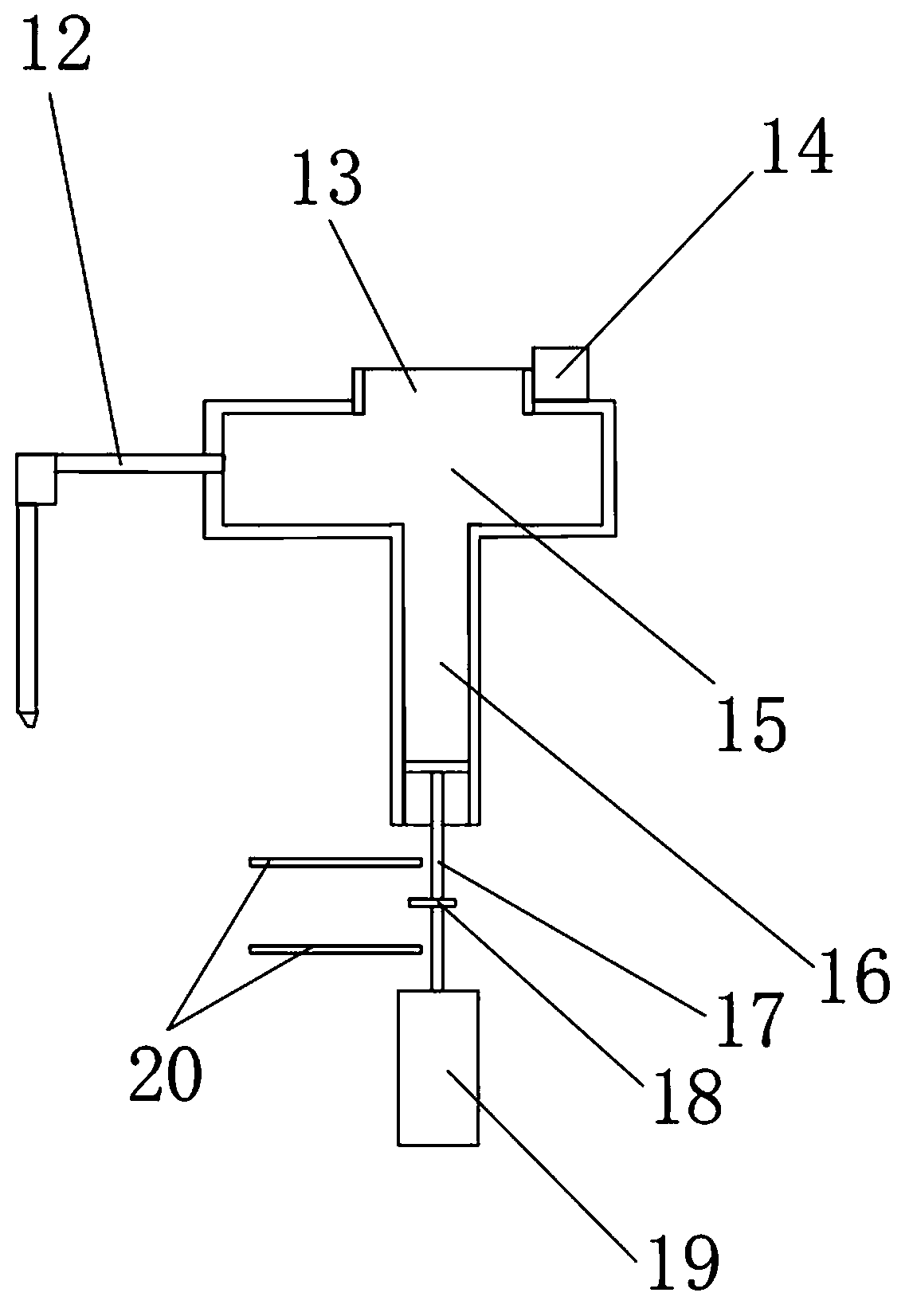

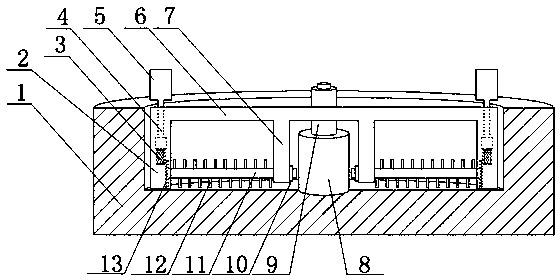

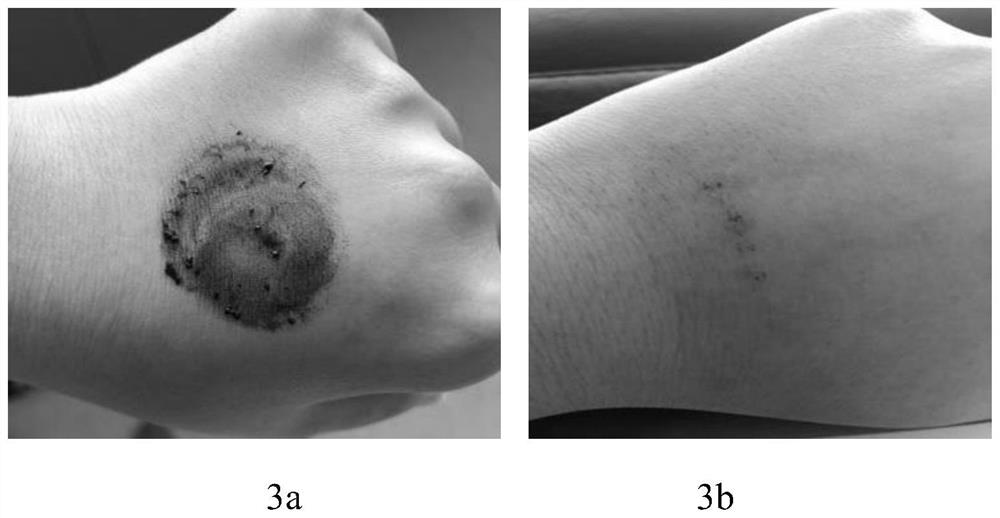

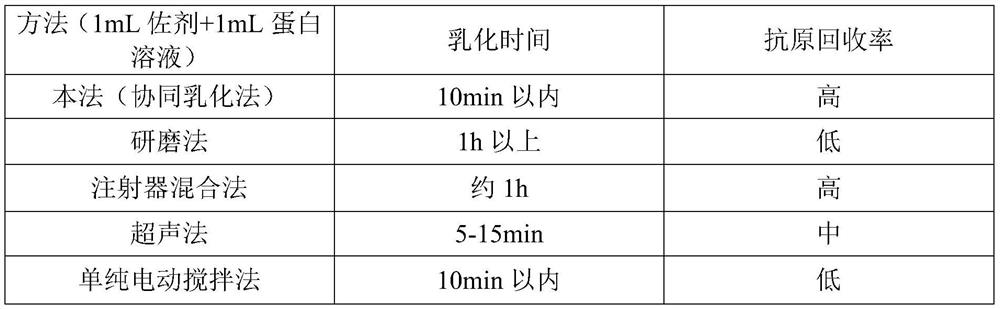

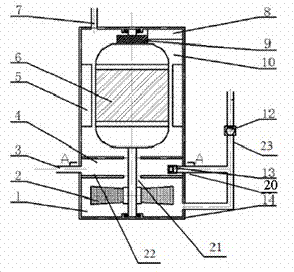

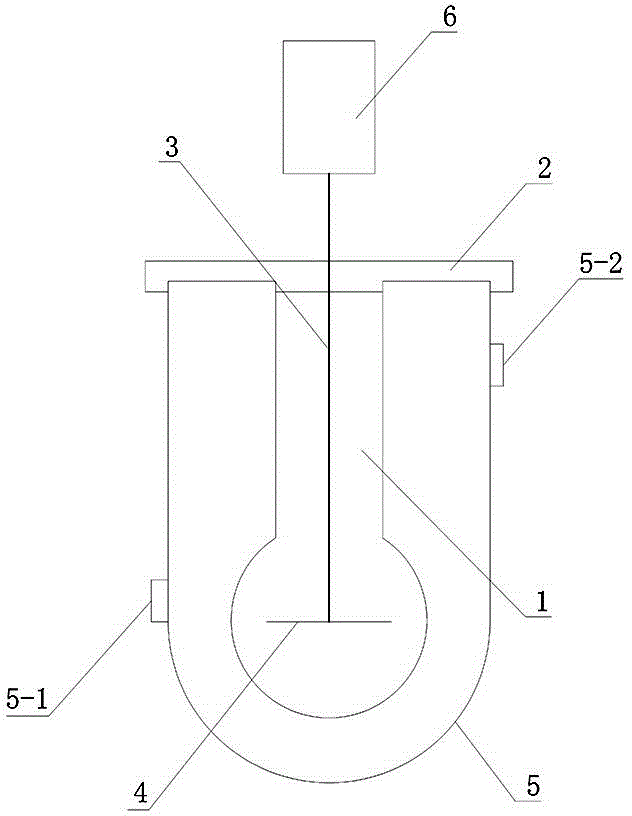

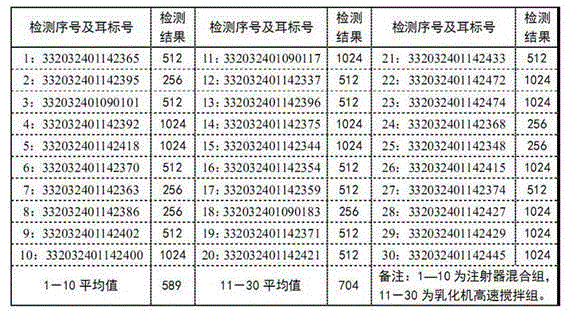

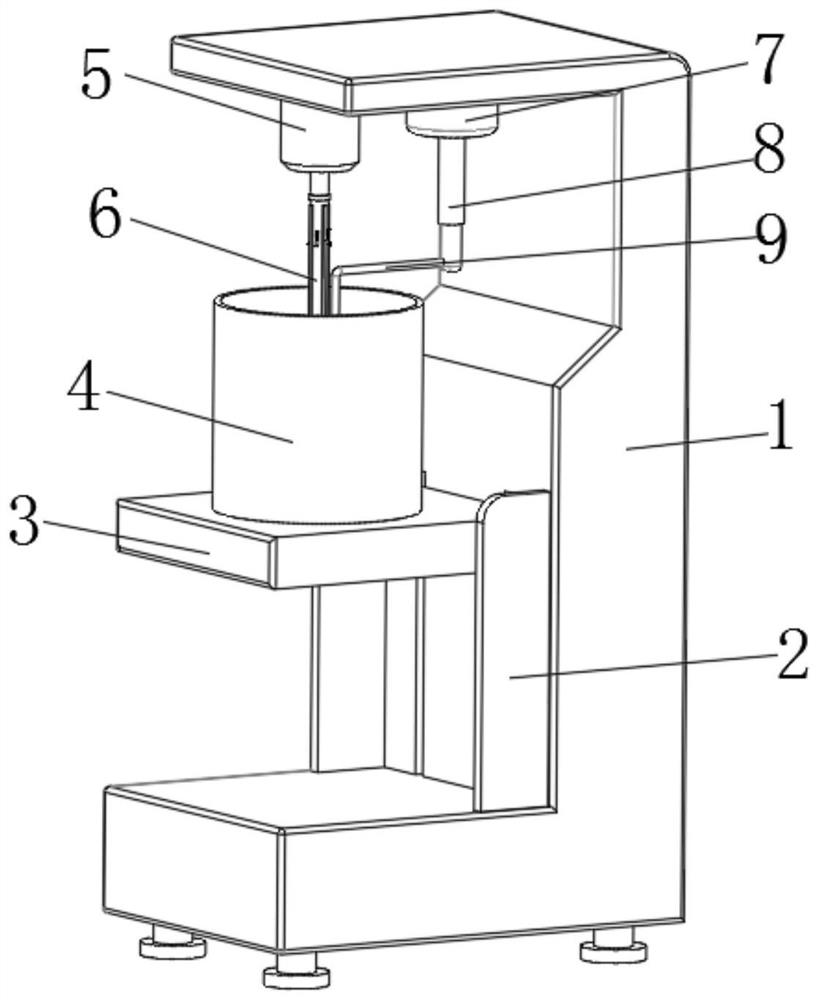

Antigen emulsification equipment and emulsification method

ActiveCN103446911BAvoid destructionFast emulsificationMixing methodsRotary stirring mixersAntigenEngineering

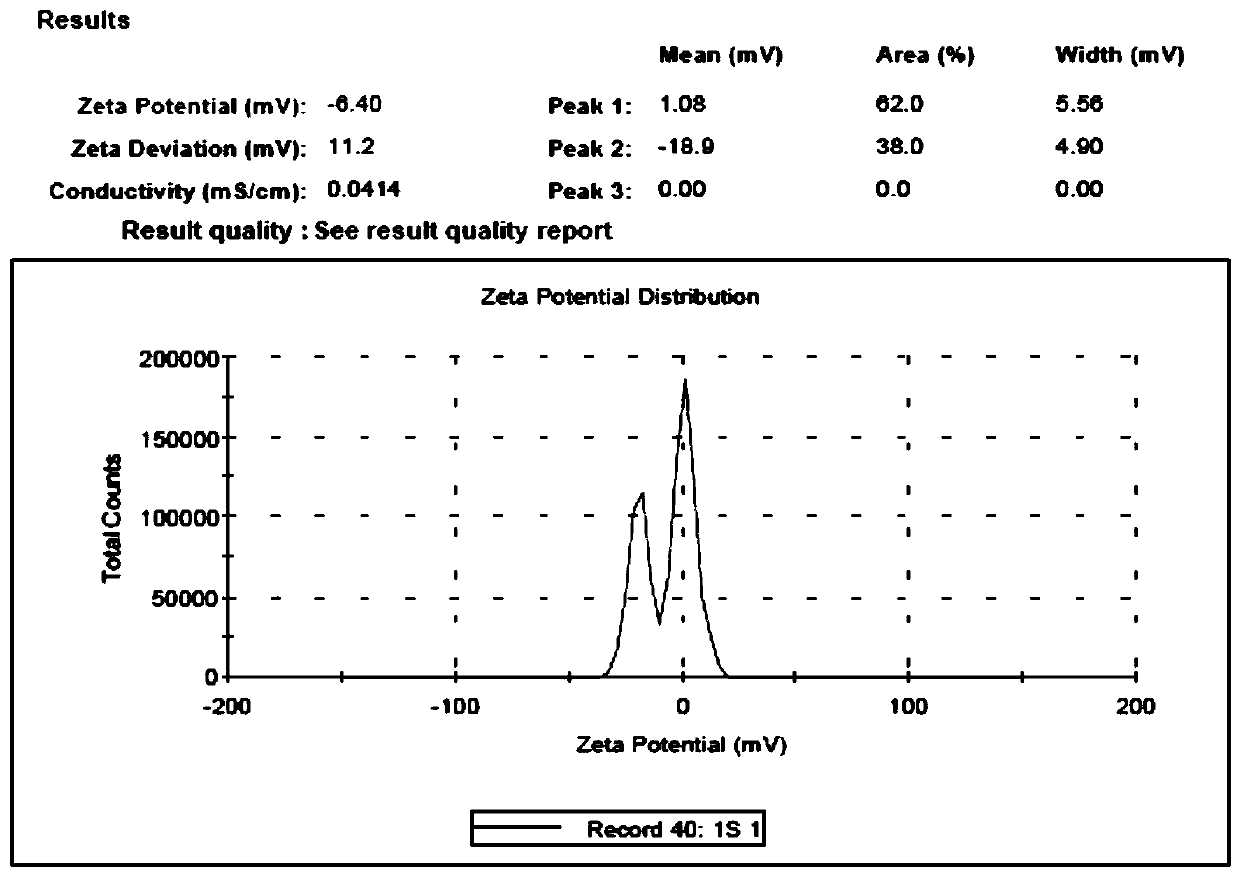

The invention relates to an antigen emulsification device and an emulsification method, wherein the antigen emulsification device comprises an emulsification container with a slender neck and a spherical bottom, a stirring rod extending into the emulsification container, installed at the bottom of the stirring rod and located at the emulsification The cutter head at the center of the bottom of the container, and the jacket installed outside the emulsification container, the tops of the emulsification container and the jacket are respectively sealed with the upper cover, and the top of the stirring rod passes through the upper cover. The emulsification method of the present invention includes the steps of installing the above equipment, feeding, stirring and the like. The invention has the advantages of small antigen loss, less damage, high emulsification speed and high degree.

Owner:ZHENJIANG AGRI SCI INST JIANGSU HILLY AREAS

A centrifugal emulsified asphalt production device and its production method

ActiveCN105461937BImprove emulsification efficiencyUniform particlesBuilding insulationsEngineeringCentrifugal force

The invention provides a centrifugal emulsified asphalt production device. A flow guiding mechanism is formed by connecting three layers of funnel-shaped flow guiding devices in series. The adjacent joints of the three layers of funnel-shaped flow guiding devices are connected with an upper flow guiding pipe and a lower flow guiding pipe respectively. The upper flow guiding pipe is connected with an upper liquid soap tank. The lower flow guiding pipe is connected with a lower liquid soap tank. An upper liquid soap pump and a lower liquid soap pump are installed on the upper flow guiding pipe and the lower flow guiding pipe respectively. The three layers of funnel-shaped flow guiding devices are each internally provided with a centrifuging device. The bottoms of the centrifuging devices are connected with motors through rotating shafts. Multiple layers of metal filter screens are installed in the centrifuging devices, and a centrifugal device housing is arranged on the top of each centrifuging device. Centrifugal force generated through rotation driven by the motors is adopted to achieve the emulsification purpose; due to emulsification of the three layers of centrifuging devices at different degrees, the emulsification efficiency is higher, emulsified asphalt particles are more uniform, emulsification quality is improved while emulsification efficiency is improved, emulsification speed is increased, and production cost is remarkably reduced.

Owner:甘肃昌恒公路养护技术有限责任公司

Blood fat reducing formula edible oil and preparation process thereof

PendingCN113647471AReduce hardening effectsActive preventionFatty-oils/fats refiningLipidic food ingredientsBiotechnologyAnimal science

The invention discloses blood fat reducing formula edible oil and a preparation process thereof, and belongs to the field of functional edible oil and processing processes and production equipment thereof. The blood fat reducing formula edible oil is characterized by comprising the following components in parts by mass: 68-82 parts of corn oil; 12-30 parts of linseed oil; and 6-12 parts of safflower seed oil. The nutrition and quality of the edible oil can be adjusted through the formula, the corn oil, the flaxseed oil and the safflower seed oil are organically blended into a whole, and various medical health-care effects of reducing blood fat and the like can be achieved. The deacidification equipment in the oil preparation process is scientifically and reasonably designed, the grease emulsification speed in the deacidification step is increased, and the discharge rate of fatty acid and other impurities in grease is increased, so that the flavor and quality of the prepared oil are improved, and the quality guarantee period is prolonged.

Owner:青岛葆福德生物医药科技有限公司

A feeding emulsification device and working method for defoamer preparation

ActiveCN113083048BFast emulsificationEasy feedingTransportation and packagingMixing methodsGear wheelProcess engineering

Owner:潮州市顺冠生物科技有限公司

Manufacturing method for fertilizer pulping machine

InactiveCN104190302ASimple structureEasy to useMixing methodsRotary stirring mixersRotational axisGear wheel

The invention discloses a manufacturing method for a fertilizer pulping machine. The manufacturing method comprises the following steps: the upper part of a rotary frame takes a rotary shaft as a circle center and two horizontal edges of the rotary frame extend until stretching into the inner side wall of a pulping tank; pulping shaft outer columns are respectively welded and fixed at positions, close to the inner wall of the pulping tank, of the two ends of the rotary frame; the inner part of each pulping shaft outer column is of a cavity structure and is vertical to the ground of the pulping tank; the length of each pulping shaft outer column is 60cm-80cm; an emulsifying motor is fixedly connected with the upper part of each pulping shaft outer column and an output shaft of each emulsifying motor vertically stretches into each pulping shaft outer column; a gear shaft is fixed at the end position of the output shaft of each emulsifying motor in a sleeving manner; pulping shaft inner columns are welded and fixed at positions, close to the two sides of a rotary motor, of the lower part of the rotary frame and are vertical to the ground of the pulping tank, and the length of each pulping shaft inner column is 60cm-80cm; and pulping shafts are horizontally arranged at the lower ends of the pulping shaft outer columns and the pulping shaft inner columns. The manufacturing method has the advantages that the manufacturing method is simple and a prepared product is simple in structure, high in strength, rapid in emulsifying speed and high in production efficiency, uniform emulsification is realized and a caking phenomenon does not exist.

Owner:QINGDAO TIANRUI ECOLOGICAL TECH

Dispersion adjusting device convenient to adjust and used for waterproof agent production

ActiveCN113522072AChange angleFlexible adjustmentShaking/oscillating/vibrating mixersMixing methodsHydraulic cylinderElectric machinery

The invention discloses a dispersion adjusting device convenient to adjust and used for waterproof agent production, and relates to the technical field of dispersers. The dispersion adjusting device comprises a rack, an electric guide rail is mounted on the rack, a supporting plate is slidably connected in the electric guide rail, a material barrel is placed at the top of the supporting plate, a transmission motor and a lifting hydraulic cylinder are fixedly connected to the side wall of the rack, the output end of the transmission motor is in driving connection with a spline shaft, and the spline shaft is provided with an adjustable dispersing part capable of adjusting the angle of the dispersing teeth. According to the device, the transmission motor drives dispersing teeth to rotate at a high speed to stir and disperse materials, one of the dispersing teeth can be rotated, and the other dispersing teeth are driven to rotate together through the linkage bevel gear and the adjusting bevel gear which are meshed with each other, so that the angles of all the dispersing teeth are changed at the same time, and the angles of the dispersing teeth can be flexibly and conveniently adjusted; the rotational flow direction can be changed, different materials can be matched, the emulsifying speed is increased, and the dispersing effect is improved.

Owner:江苏泓科钧工程科技有限公司

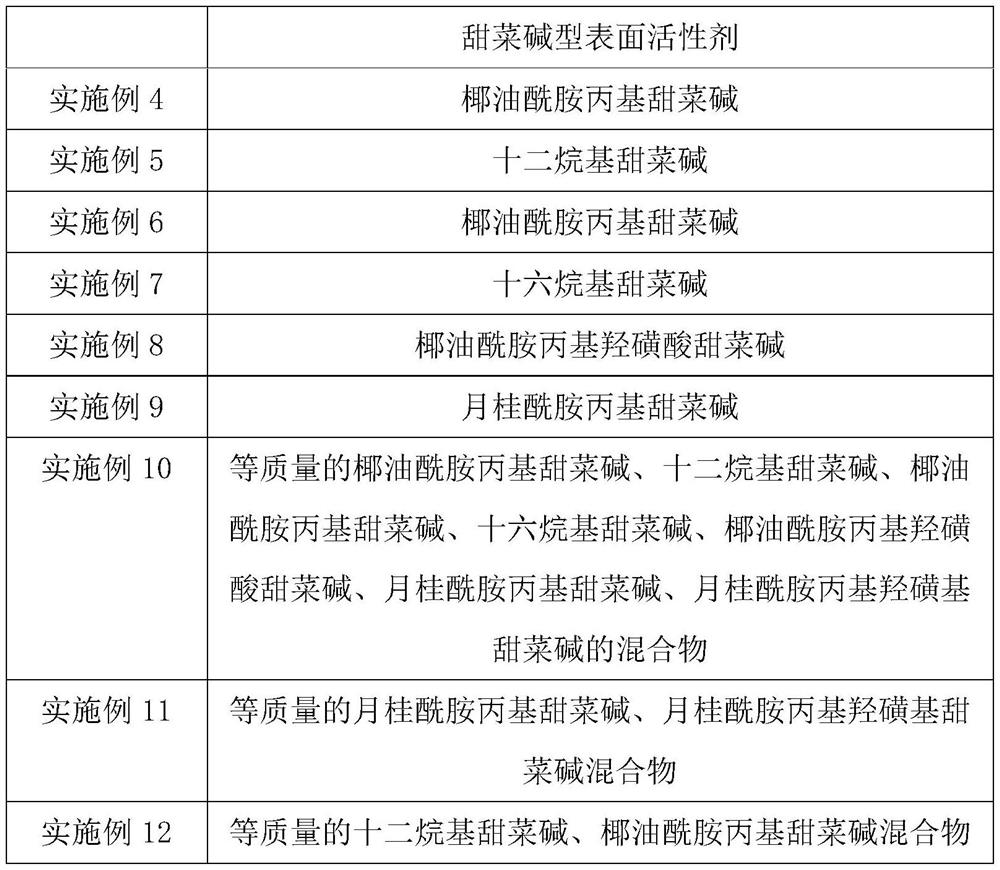

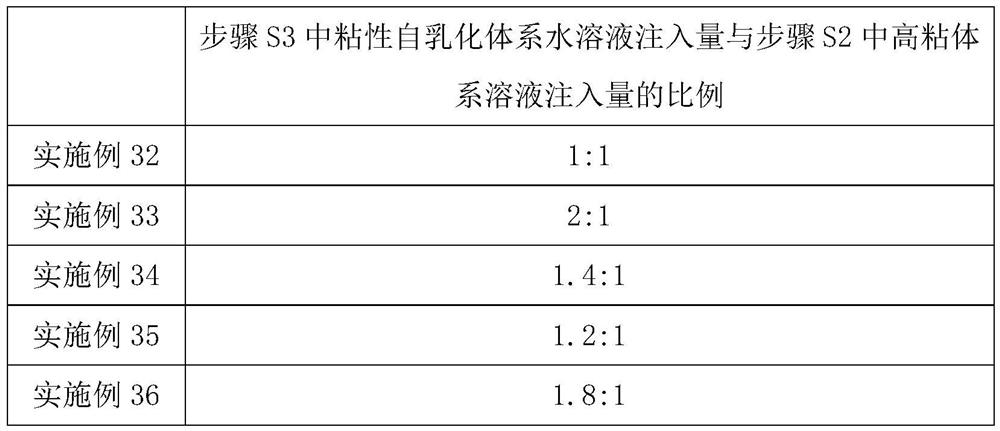

Viscous self-emulsifying system as well as preparation method and application thereof

PendingCN114456789AGood solubilityFast emulsificationFluid removalDrilling compositionChemistryActive agent

The invention discloses a viscous self-emulsifying system which comprises a betaine type surfactant and an auxiliary agent, and the mass ratio of the betaine type surfactant to the auxiliary agent is 1: (0: (01-0.8)). The invention also discloses a preparation method of the viscous self-emulsifying system, which comprises the following steps: (1) taking the betaine type surfactant according to the formula ratio, heating and stirring; and (2) adding the auxiliary agent according to the formula ratio, uniformly stirring, and cooling to room temperature to obtain the viscous self-emulsifying system. The viscous self-emulsifying system is used as a viscous oil field viscosity reducer. The invention has the following beneficial effects: 1, the preparation method is simple; 2, the viscous self-emulsifying system is good in dissolving property, high in thick oil emulsifying speed and not prominent in oil selectivity; and 3, the aqueous solution of the viscous self-emulsifying system has viscosity and activity, and can reduce the viscosity of crude oil, improve the oil washing efficiency and improve the recovery efficiency of a heavy oil field while changing the microscopic balance of oil and water in a stratum, emulsifying the crude oil and stripping the crude oil.

Owner:CHINA PETROLEUM & CHEM CORP +1

A kind of preparation method of cold supplement for asphalt cold supplement

ActiveCN110564166BImprove early strengthImprove compactionBuilding insulationsAcetic acidThermodynamics

The invention discloses a cold patching agent for asphalt cold patching material and a preparation method thereof, which is prepared by chemically reacting tall oil, concentrated sulfuric acid, turpentine, acetic acid, and resin in a certain proportion. Aiming at the problems of poor water stability and slow strength formation of cold-patch asphalt mixture at present, the present invention develops an asphalt that increases the strength formation speed of asphalt cold-patch material and improves its water stability without increasing the viscosity of cold-patch asphalt Cold tonic.

Owner:WUHAN MUNICIPAL CONSTR GROUP +1

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com