Dispersion adjusting device convenient to adjust and used for waterproof agent production

A technology of adjusting device and waterproofing agent, which is applied in the direction of dissolving, mixing machines, chemical instruments and methods, etc., can solve the problems of inconvenience and unfavorable material dispersion, and achieve the effect of simple and fast operation process, accelerated emulsification speed, and convenient installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

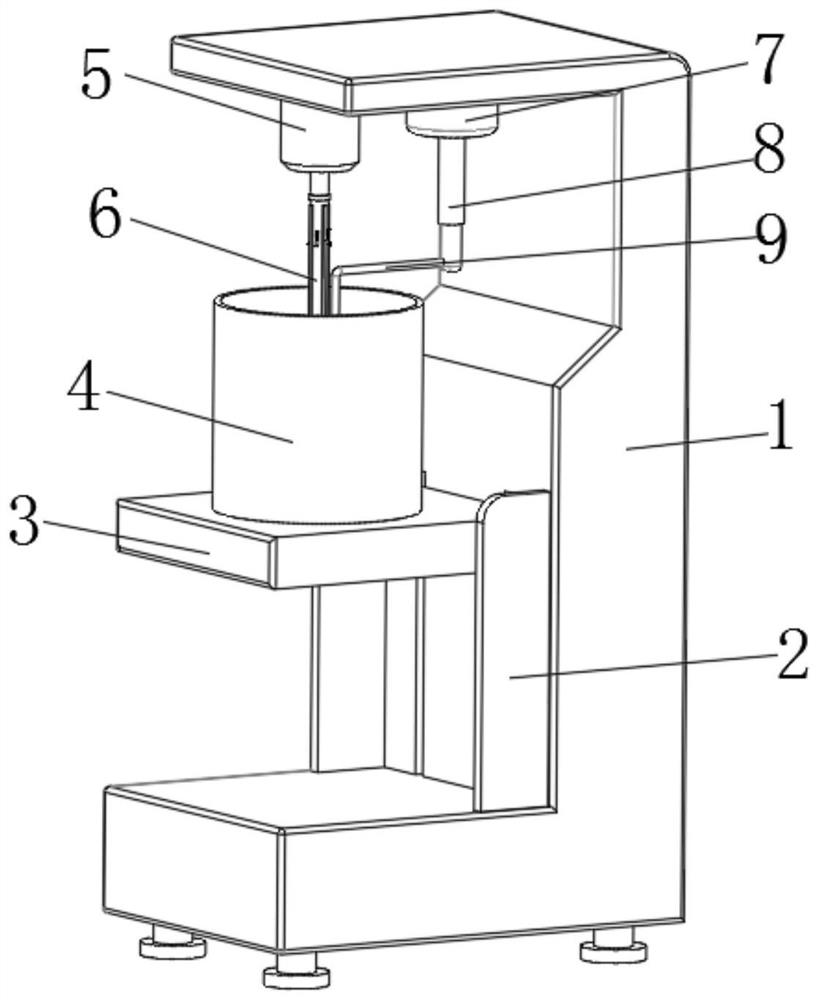

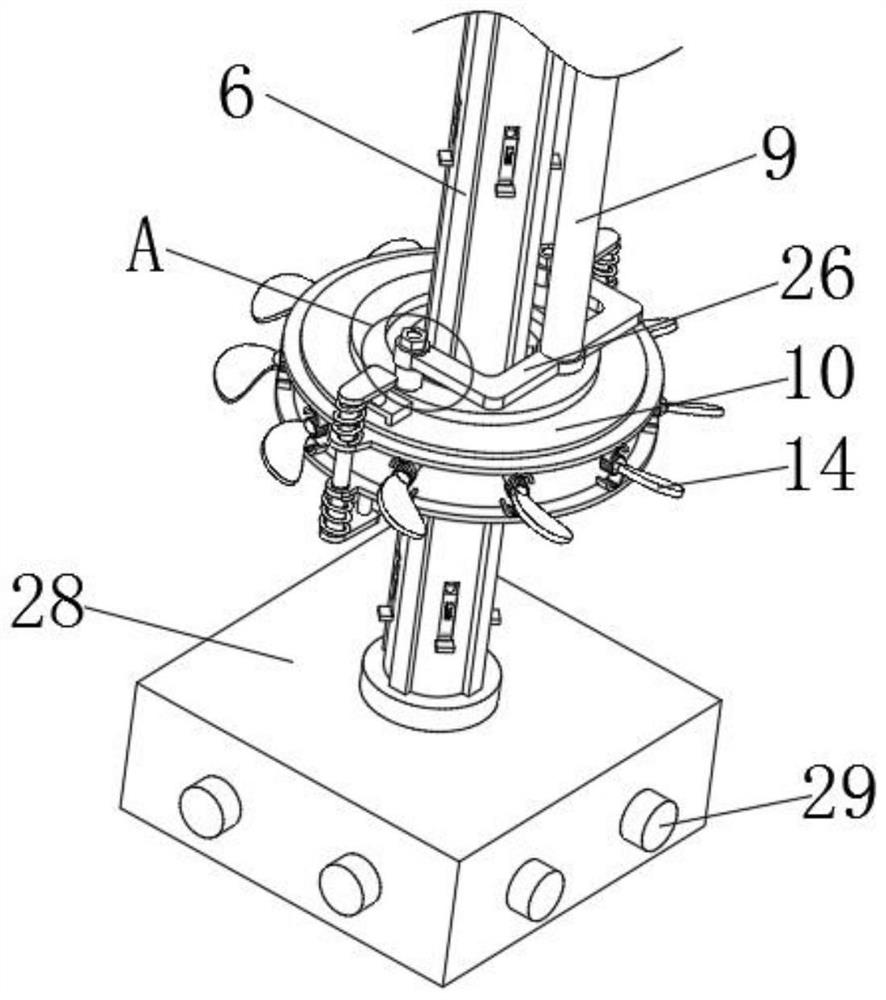

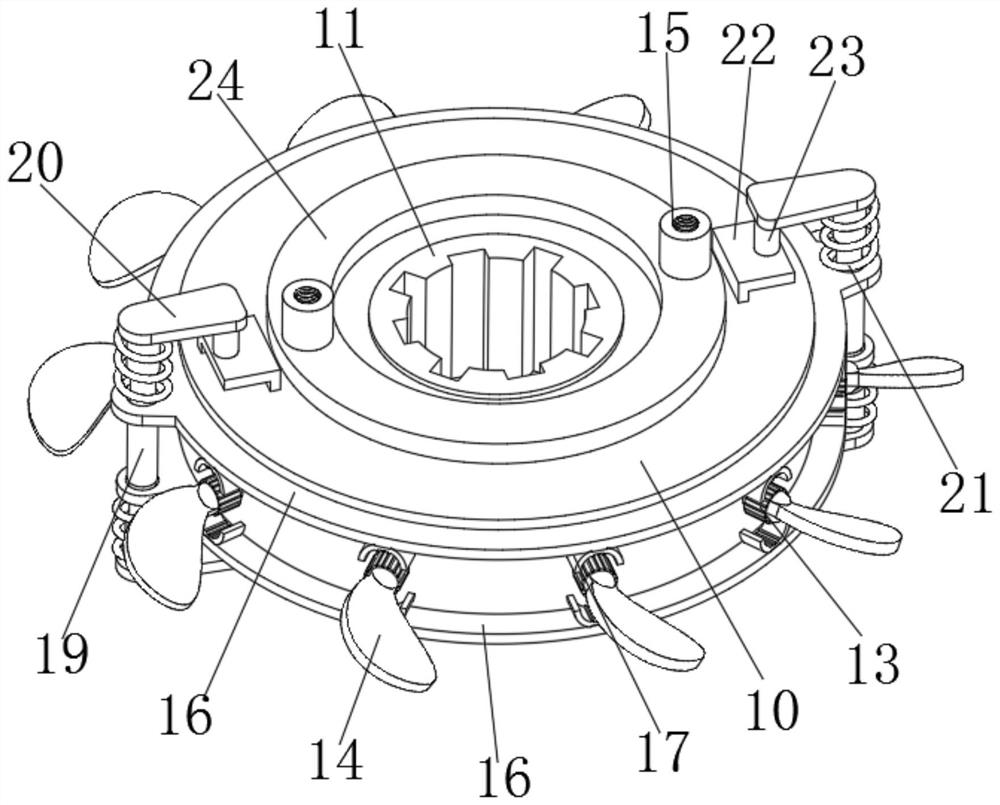

[0042] Example: Reference Figure 1-10 The dispersive adjustment device for the production of waterproofing agent that is easy to adjust, as shown, includes a frame 1, an electric guide rail 2 is installed on the frame 1, a supporting plate 3 is slidably connected in the electric guiding rail 2, and a material bucket 4 is placed on the top of the supporting plate 3 , the side wall of the frame 1 is fixedly connected with a transmission motor 5 and a lifting hydraulic cylinder 7, and the output end of the transmission motor 5 is drivingly connected with a spline shaft 6, and the transmission motor 5 can be any driving motor in the prior art, for example The drive motor model is 5IK120RGN. The spline shaft 6 can be connected to the output end of the drive motor 5 through a coupling. The spline shaft 6 is equipped with an adjustable dispersion part that can adjust the angle of the dispersion teeth 14. The lifting hydraulic pressure The output end of the cylinder 7 is driven and c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com